Page 1

Place this chapter in the OVEN section of the equipment manual.

WELLS BLOOMFIELD, LLC

10 Sunnen Drive P.O.Box 430195

St. Louis, MO 63143 USA

telephone: 314-781-2777

fax: 314-781-2714

www.wellsbloomfield.com

CONVECTION OVEN

903

OWNERS MANUAL

VENTED

MODEL

M4200 Convection Oven

This instruction is for the exclusive use of licensees

and employees of McDonalds Systems, Inc.

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

PRINTED IN UNITED STATES OF AMERICA

M4200-3S

M4200-3SEU

Includes

Installation

Use & Care

Programming

Exploded View

Parts List

Wiring Diagram

p/n 2M-307323 Rev. F M903 090429 rms

Page 2

INTRODUCTION

IMPORTANT: Use only factory

authorized service parts.

For factory authorized service,

or to order factory authorized

replacement parts, contact your

Wells authorized service agency,

or call:

Wells Bloomfield, LLC

10 Sunnen Dr., P.O.Box 430129

St. Louis MO 63143 USA

Service Dept.

phone: (314) 781-2777

fax: (314) 781-2714

Thank You for purchasing this Wells Bloomfield appliance.

Proper installation, professional operation and consistent

maintenance of this appliance will ensure that it gives you the very

best performance and a long, economical service life.

This manual contains the information needed to properly install this

appliance, and to use and care for the appliance in a manner that

will ensure its optimum performance.

xi

M903 2M-307323 Owners Manual M4200/M4200EU

Page 3

TABLE OF CONTENTS

GENERAL

OPERATION

PROGRAMMING

MAINTENANCE

SERVICE

AGENCY LISTING INFORMATION 1

WARRANTY 2

PRECAUTIONS & GENERAL INFORMATION 3

SPECIFICATIONS 4

INSTALLATION 5

FEATURES & OPERATING CONTROLS

OVEN FEATURES 8

SMART CONTROLLER 10

OPERATION

QUICK-GLANCE OPERATING GUIDE 12

DAILY SET-UP 13

COOK CYCLE OPERATION 14

PROGRAMMING

IMPORTANT:

Programming to be performed by Qualified Personnel ONLY!

ENTER PROGRAMMING MODE 15

CHANGE PROGRAMMED SETTINGS 16

ENABLING SCRATCH BISCUIT BUTTON (#6) 18

INSTRUCTIONS TO CHANGE COOKIE SETTINGS 19

INSTALL OPERATING SYSTEMS SOFTWARE 20

TRANSFER MENUS FROM CARD TO OVEN 21

TRANSFER MENUS FROM OVEN TO CARD 21

DEFAULT SETTINGS 22

CLEANING INSTRUCTIONS 23

TROUBLESHOOTING SUGGESTIONS 25

PREVENTATIVE MAINTENANCE 26

TEMPERATURE CALIBRATION 27

HINGE ADJUSTMENT

EXPLODED VIEW and PARTS LIST 28

WIRING DIAGRAM M4200-3S 208V 32

M4200-3S 240V 33

M4200-3SEU 34

PARTS & SERVICE 37

CUSTOMER SERVICE DATA FORM 37

This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions and

maintained according to the instructions in this manual.

M4200-3S (domestic) ovens are and listed under UL File

E6070 for 208V and 240V.

M903 2M-307323 Owners Manual M4200/M4200EU

M4200-3SEU (European) ovens comply with standards

for 380-415V 3NAC

1

AGENCY LISTING INFORMATION

STD 4

E6070

E6070

Page 4

LIMITED WARRANTY STATEMENT

The following equipment manufactured by WELLS BLOOMFIELD,

LLC for

sale to McDonald's, Inc. is warranted against defects

in materials and workmanship for a period of two years from

the date of installation (

on the equipment

as indicated by the installation punch-tag

), and is for the benefit of the original purchaser:

a. M4200-3 Convection Oven (208V and 240V models

only)

b. 1016BVM Coffee Brewer

All other equipment manufactured by WELLS BLOOMFIELD, LLC for sale to McDonald's, Inc. is warranted against

defects in materials and workmanship for a period of one

year from the date of installation (

punch-tag on the equipment

purchaser:

as indicated by the installation

),

and is for the benefit of the original

THE FOREGOING OBLIGATION IS EXPRESSLY GIVEN

IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY

OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, WHICH ARE HEREBY EXCLUDED.

WELLS BLOOMFIELD, LLC SHALL NOT BE LIABLE FOR

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

OR LOSSES FROM ANY CAUSE WHATSOEVER.

This warranty is void if it is determined that upon inspection

by an Authorized Service Agency that the equipment has

been modified, misused, misapplied, improperly installed, or

damaged in transit or by fire, flood or act of God.

It also does not apply if the serial nameplate has been

removed or unauthorized service personnel perform service.

The prices charged by Bloomfield Industries for its products

are based upon the limitations in this warranty. Seller’s

obligation under this warranty is limited to the repair of defects without charge by a Wells Bloomfield Authorized Service Agency or one of its sub-agencies. This service will be

provided on customer’s premises for non-portable models.

Portable models (a device with a cord and plug) must be

taken or shipped to the closest Authorized Service Agency,

transportation charges prepaid, for services.

In addition to restrictions contained in this warranty, specific

limitations are shown below (Additional Warranty Exclusions). Bloomfield Industries Authorized Service Agencies

are located in principal cities.

This warranty is valid in the United States and void elsewhere. Please consult your classified telephone directory or

your food service equipment dealer; or, for information and

other details concerning warranty, write to:

Wells Bloomfield, LLC

10 Sunnen Dr., P.O.Box 430129 St. Louis MO 63143 USA

phone (314) 781-2777 or fax (314) 781-2714

for information and other details concerning warranty.

SERVICE POLICY AND PROCEDURE GUIDE and ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specified on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted for

ninety (90) days from date of purchase on nonwarranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

M903 2M-307323 Owners Manual M4200/M4200EU

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by

skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

should be done within fifteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Bloomfield cannot assume liability for damage or loss

incurred in transit. We will, however, at your request, supply

you with the necessary documents to support your claim.

2

Page 5

PRECAUTIONS AND GENERAL INFORMATION

This appliance is intended for use in commercial establishments

only.

This appliance is intended

No other use is

agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

DO NOT submerge this appliance in water. This appliance is not jet

stream approved. Do not direct water jet or steam jet at this appliance,

or at any control panel or wiring. Do not splash or pour water on, in or

over any controls, control panel or wiring. Do not wash floor around

this appliance with water or steam jet.

Exposed surfaces of this appliance can be hot to the touch and may

cause burns.

Do not operate this appliance if the control panel is damaged. Do not

operate this appliance if the keypad section of the control panel is torn

or broken. Call your Authorized Wells Service Agent for service.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualified technical personnel.

Any procedure which requires the use of tools must be performed by a

qualified technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

recommended or authorized by the manufacturer or its

to prepare food for human consumption.

WARNING:

SHOCK HAZARD

All servicing requiring

access to non-insulated

electrical components

must be performed by a

factory authorized

technician.

DO NOT open any access

panel which requires the

use of tools. Failure to

follow this warning can

result in severe electrical

shock.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or

energize this appliance

until all installation

instructions are read and

followed. Damage to the

appliance will result if

these instructions are not

followed.

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

M903 2M-307323 Owners Manual M4200/M4200EU

3

Page 6

SPECIFICATIONS

DIMENSIONS APPLIANCE OVEN CAVITY

Wide 30-1/8” (765mm) 14-3/8” (365mm)

Deep 25-1/4” (641mm) oven only 21” (533mm)

27-7/8” (682mm) incl. handle

High 25-1/8” (638mm) oven only 20” (508mm)

34” (863mm) incl. prep-top\

and casters

Door Swing 20" (508mm )radius

ELECTRICAL

M4200-3S 208 VAC 3ø 60Hz 8750 kW total 21 Amps per leg

M4200-3S 240 VAC 3ø 60Hz 8750 kW total 21 Amps per leg

M4200-3SEU 380-415V 3NAC 5-/60Hz L1 11.7 Amps

8750 kW total L2 11.7 Amps

L3 11.7 Amps

N 1.0 Amps

Note: Shipped from the factory 3 phase with pin-and-sleeve electrical plug.

Unit is NOT approved for conversion to single phase.

4

M903 2M-307323 Owners Manual M4200/M4200EU

Page 7

INSTALLATION

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all

protective plastic film, packing materials and accessories from the

Appliance before connecting electrical power or otherwise performing

any installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read and understand all labels and diagrams attached to the

appliance.

Carefully account for all components and accessories before

discarding packing materials. Store all accessories in a convenient

place for later use.

COMPONENTS

3 ea. OVEN RACKS

2 ea. RACK SUPPORTS

1 ea. FAN BAFFLE

ACCESSORIES

1 ea. LITERATURE PACKAGE

OPTIONAL ACCESSORIES

22882 Stacking and Venting Kit

505504 Venting Duct Assembly Kit (single oven)

SERVICE TECHNICIAN INSTALLATION NOTES

1. Installation and start up should be performed by an authorized

installation company. Installer must record installation particulars

on the CUSTOMER SERVICE DATA form on page 33 of this

manual.

2. Verify that this equipment installation is in compliance with the

specifications listed in this manual and with local code

requirements.

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING:

RISK OF

INJURY

Installation procedures must

be performed by a qualified

technician with full knowledge

of all applicable electrical and

plumbing codes. Failure can

result in personal injury and

property damage.

IMPORTANT:

It is the RESPONSIBILITY

OF THE INSTALLER to

check with the AUTHORITY

HAVING JURISDICTION, in

order to verify compliance

with local codes and

ordinances for THIS

SPECIFIC EQUIPMENT

INSTALLATION.

M903 2M-307323 Owners Manual M4200/M4200EU

5

Page 8

INSTALLATION (continued)

WARNING:

SHOCK HAZARD

All servicing requiring

access to non-insulated electrical components must be

performed by a factory authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

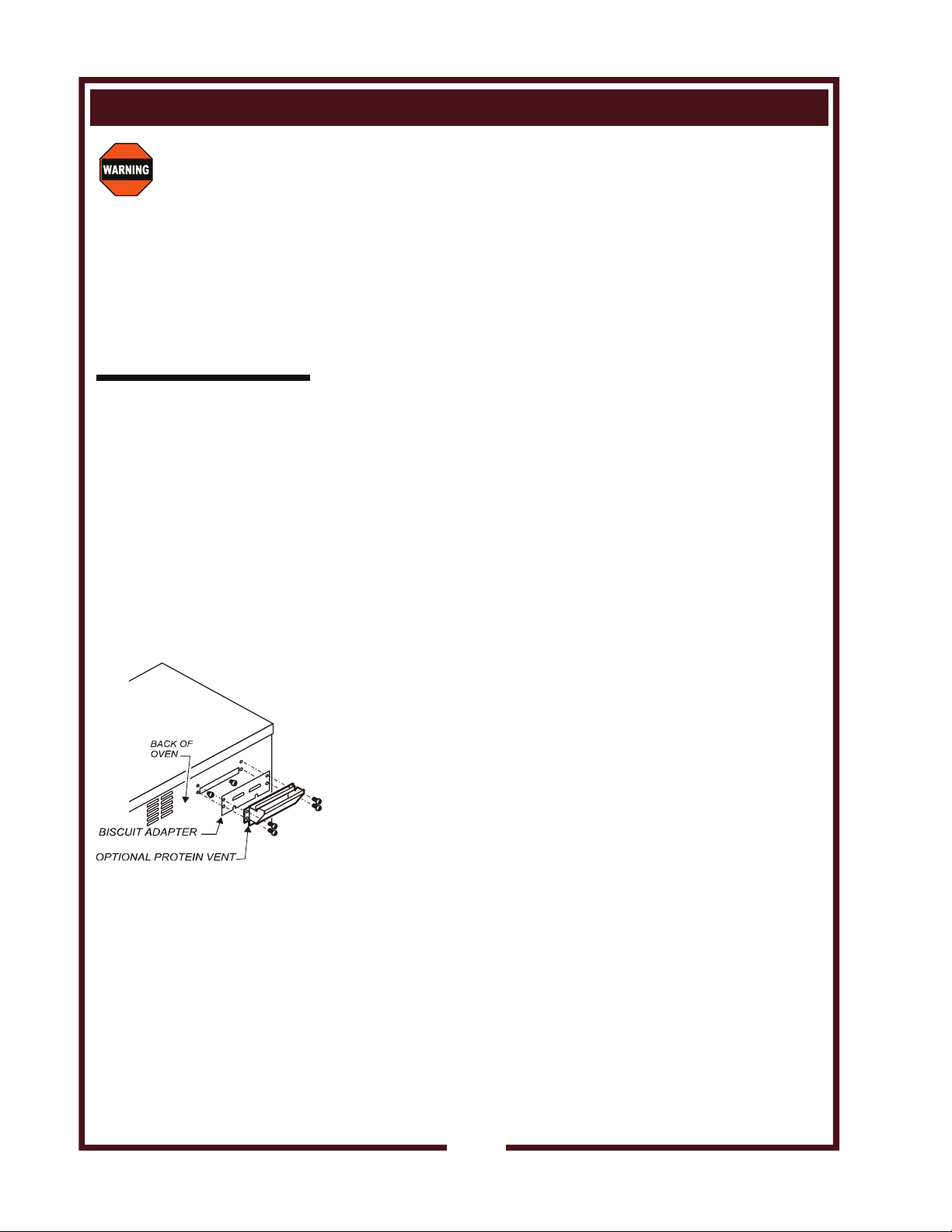

NOTE: Oven is shipped with

biscuit baking adapter plate

attached to rear panel.

If oven is used exclusively for

bread products (bread, pies,

etc.), DO NOT remove adapter.

If oven is used for proteins,

install optional external vent

kit #505504. Protein requires

additional venting to decrease

release of cooking vapors when

opening the door.

Vent Duct Installation

EQUIPMENT SET-UP

1. IF CONVECTION OVEN IS TO BE USED FOR PROTEINS,

INSTALL EXTERNAL DUCT

a. Remove two screws at each end of adapter plate on back of

oven.

b. Loosen two screws at bottom of adapter plate. Remove

adapter plate.

c. Slide bottom flange of vent duct over the two loosened screws.

D. Install four and tighten screws at ends of vent duct, then

tighten bottom screws.

2. CURB or COUNTER MOUNTING

a. Setup the appliance only on a firm, level, non-combustible

surface. Verify local codes for requirements. Concrete, tile,

terrazzo or metal surfaces are recommended. Metal over

combustible material may not meet code for non-combustible

surfaces.

b. Appliance is approved for installation with zero clearance at

bottom.

c. Recommend at least 3” clearance on sides and ba ck to allow

adequate air flow.

3. INSTALLING OPTIONAL CASTERS (NOTE: casters are not

provided and must be purchased separately: kits 21372 & 21373.)

a. Install casters, one on each corner of the appliance, in the

holes provided. Locking casters must be installed on the

FRONT of the appliance.

b. Set up the appliance only on a firm, level, non-combustible

surface. Verify local codes for requirements. Concrete, tile,

terrazzo or metal surfaces are recommended. Metal over

combustible material may not meet code for non-combustible

surfaces.

c. LEVELING: Verify that the appliance sits firmly on all four

casters when in its normal operational position. With a spirit

level, check that the appliance is level front-to-back and

side-to-side.

4. INSTALLING OPTIONAL LEGS (NOTE: Legs are not provided

and must be purchased separately: (kit 22226.)

a. Install adjustable legs, one on each corner of the appliance, in

he holes provided.

b. Set up the appliance only on a firm, level, non-combustible

surface. Verify local codes for requirements. Concrete, tile,

terrazzo or metal surfaces are recommended. Metal over

combustible material may not meet code for non-combustible

surfaces.

c. LEVELING: Verify that the appliance sits firmly ON ALL FOUR

LEGS. With a spirit level, check that the appliance is level

front-to-back and side-to-side.

5. OTHER OPTIONAL KITS

a. Kit 21445 Prep Top allows the top of the M4200 to be used

as an NSF 4-compliant work surface.

b. Kit 21342 Oven Stacking Kit allows M4200 units to be

stacked 2-high. The kit provides extended ducting for the

vent system.

c. Kit 505504 - Convert to protein oven.

M903 2M-307323 Owners Manual M4200/M4200EU

6

Page 9

INSTALLATION (continued)

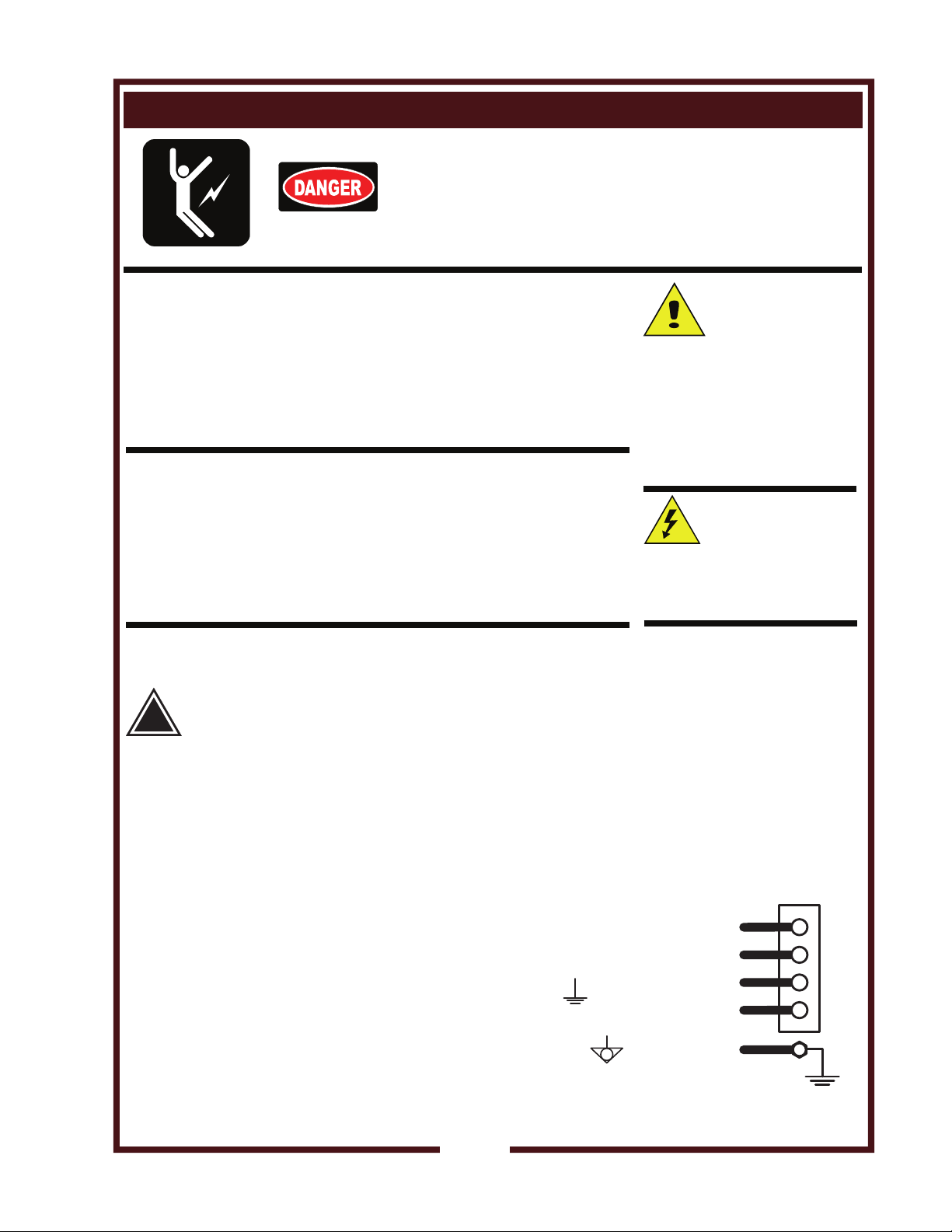

!

DANGER: SHOCK HAZARD

ELECTRICAL CONNECTIONS MUST BE MADE BY A

LICENSED ELECTRICIAN

Electrical shock will cause death or serious injury.

Refer to the nameplate on the front of the appliance.

• Verify the ELECTRICAL SERVICE POWER.

• Voltage and ph ase must match the nameplate specifications, and electrical

service amps must meet or exceed the specifications listed on page 1.

IMPORTANT:

The appliance is shipped from the factory wired for 3-phase (3ø) electrical

service. This appliance is not approved for 1ø operation. Conversion of this

appliance to single-phase operation will void the warranty.

M4200-3S (domestic) field wiring must be no less than 10 AWG 4 conductor

solid copper wire, rated for at least 90ºC.

NOTE: Wire gauge, insulation type and temperature rating , as well as type,

size and construction of conduit, must meet or exceed applicable specifications

of local codes and of the National Electrical Code.

This appliance is equipped with a Hubbell™ L430P9 plug, which must be

plugged into a matching Hubbell™ L430R9 receptacle. The ground lug of the

receptacle must be connected to a suitable building ground.

M4200-3SEU (European) field wiring must have a minimum cross-sectional

area of 1.5mm2.

NOTE: Strain relief supplied loose is for metal conduit connection. For flexible

power cords an approved strain relief fitting must be supplied by others.

EU INSTALLATION INSTRUCTIONS:

1. Using a screwdriver, remove terminal access panel located behind front

door marked: NOTICE - REMOVE THIS PANEL FOR TERMINAL BLOCK

2. Knock out the appropriate hole plug located on enclosure panel and

3. Thread supply leads through strain relief

M903 2M-307323 Owners Manual M4200/M4200EU

4. Secure all connections and reinstall terminal access cover.

5. “Equal Potential” grounding screw is located at rear of frame, marked

Remove screw and secure an appropriate grounding wire with

terminal.

IMPORTANT: An approved all pole power disconnect switch,

With at least 3 mm contact gap, must be supplied and installed in the

fixed wiring in an accessible location (close proximity to the appliance)

by a licensed electrician.

connect conduit strain relief.

• Connect supply power lines to terminals marked: L1, L2, L3

• Connect the neutral li ne terminal marked: N

• Connect green-with-yellow-stripe lead to ground lug marked

CAUTION:

RISK OF

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance will result if

these instructions are not

followed.

DAMAGE

CAUTION:

SHOCK HAZARD

The ground lug of this

appliance must be connected

to a suitable building ground.

IMPORTANT:

Contact a licensed electrician to

install and connect electrical

power to the appliance.

IMPORTANT:

Damage due to being connected

to the wrong voltage or phase is

NOT covered by warranty.

IMPORTANT

PROGRAMMING NOTE:

This oven is pre-programmed

from the factory and normally

does not require programming

adjustments.

EU Connections

SUPPLYLINE 3

SUPPLYLINE 2

SUPPLYLINE 1

NEUTRAL

GROUND

L3

L2

L1

N

7

Page 10

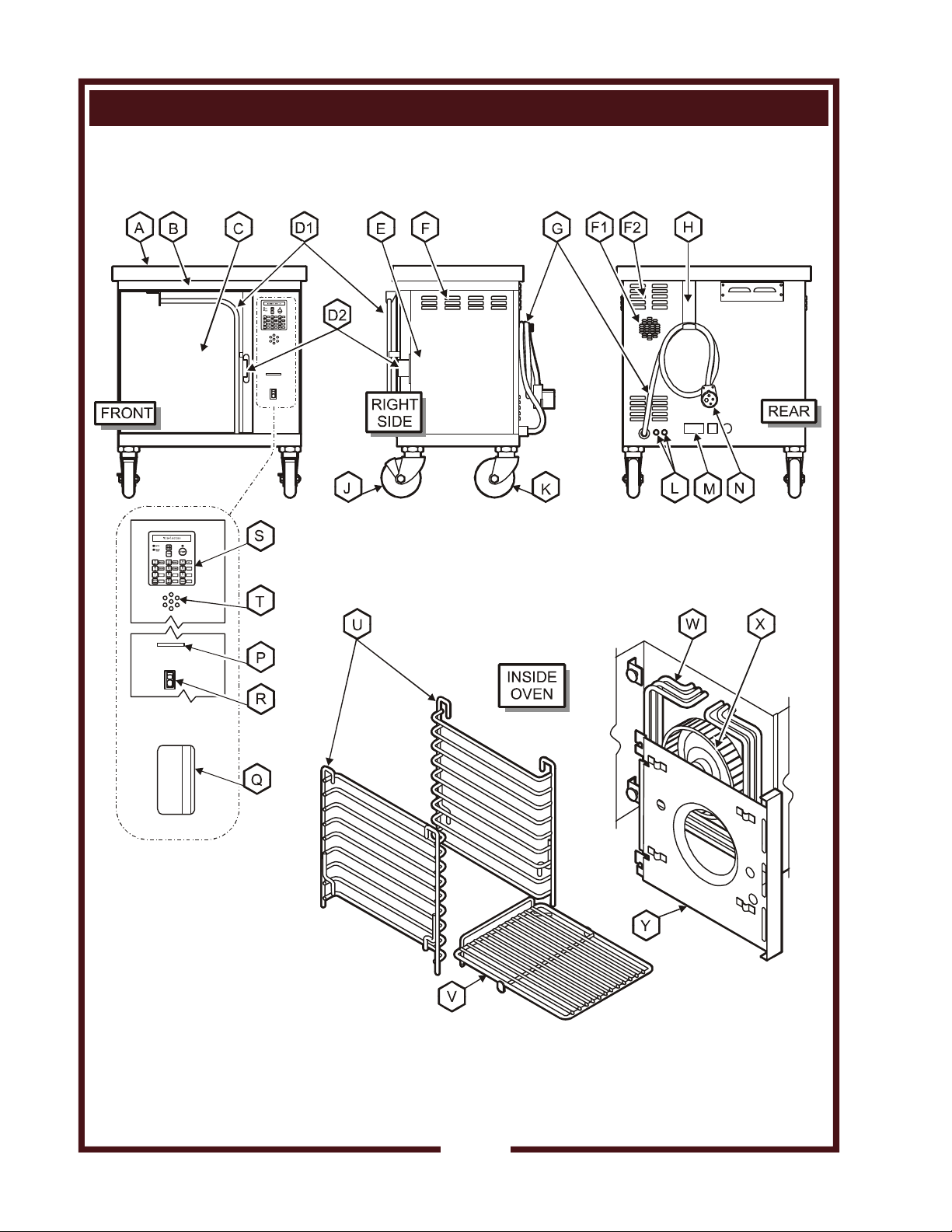

FEATURES & OPERATING CONTROLS

M4200 CONVECTION OVEN FEATURES

8

M903 2M-307323 Owners Manual M4200/M4200EU

Page 11

FEATURES & OPERATING CONTROLS (continued)

ITEM DESCRIPTION FUNCTION

A. OPTIONAL PREP TOP Allows top of oven to be used as a work surface

B. OVEN TOP Covers and protects top insulation

C. OVEN DOOR Covers and provides access to oven cavity

D1. DOOR HANDLE Safe hand hold to open or close oven.

D2. DOOR STRIKER & LATCH Striker and door- mounted latch hold oven door closed

E. ACCESS PANEL Covers and provides access to fan motor and electric

connections and controls

F1. COOLING FAN INLET Provides air circulation for cooling. DO NOT spray or pour

F2. COOLING LOUVERS water into cooling fan inlet or louvers

G. POWER CORD

(not provided on EU models) Supplies power from receptacle to oven

H. CORD HANGER Provides storage for cord when moving oven

I. EXTERNAL CAVITY VENT Cooking fumes are vented here

J. OPTIONAL FRONT CASTERS Allow oven to be easily moved; locking to stabilize oven

when in position

K. OPTIONAL REAR CASTERS Allow oven to be easily moved.

L. POWER FUSES Protect electrical circuits from overload

M. DATA PLATE Provides manufacturer, model and serial number information.

Also, provides electrical specifications and requirements

N. POWER PLUG

(not provided on EU models) Plugs into power receptacle

P. CARD READER Reads menu card

Q. MENU CARD Contains default information; used to reprogram smart

controller with default settings in the event of program errors

R. ON/OFF SWITCH Energizes appliance

S. SMART CONTROLLER Controls cooking times and temperatures; selectable

pre-programmed settings.

DO NOT spray or pour water into controller

T. BEEPER Audible indicator for alarms, end-of-cycle, etc.

U. RACK SUPPORTS Hold cooking racks

V. PRODUCT RACK Holds product to be cooked

M903 2M-307323 Owners Manual M4200/M4200EU

W. HEATING ELEMENTS Provide cooking heat when energized

X. FAN Circulates heated air during cooking

Y. FAN BAFFLE Covers fan, also provides mounting for right rack support

9

Page 12

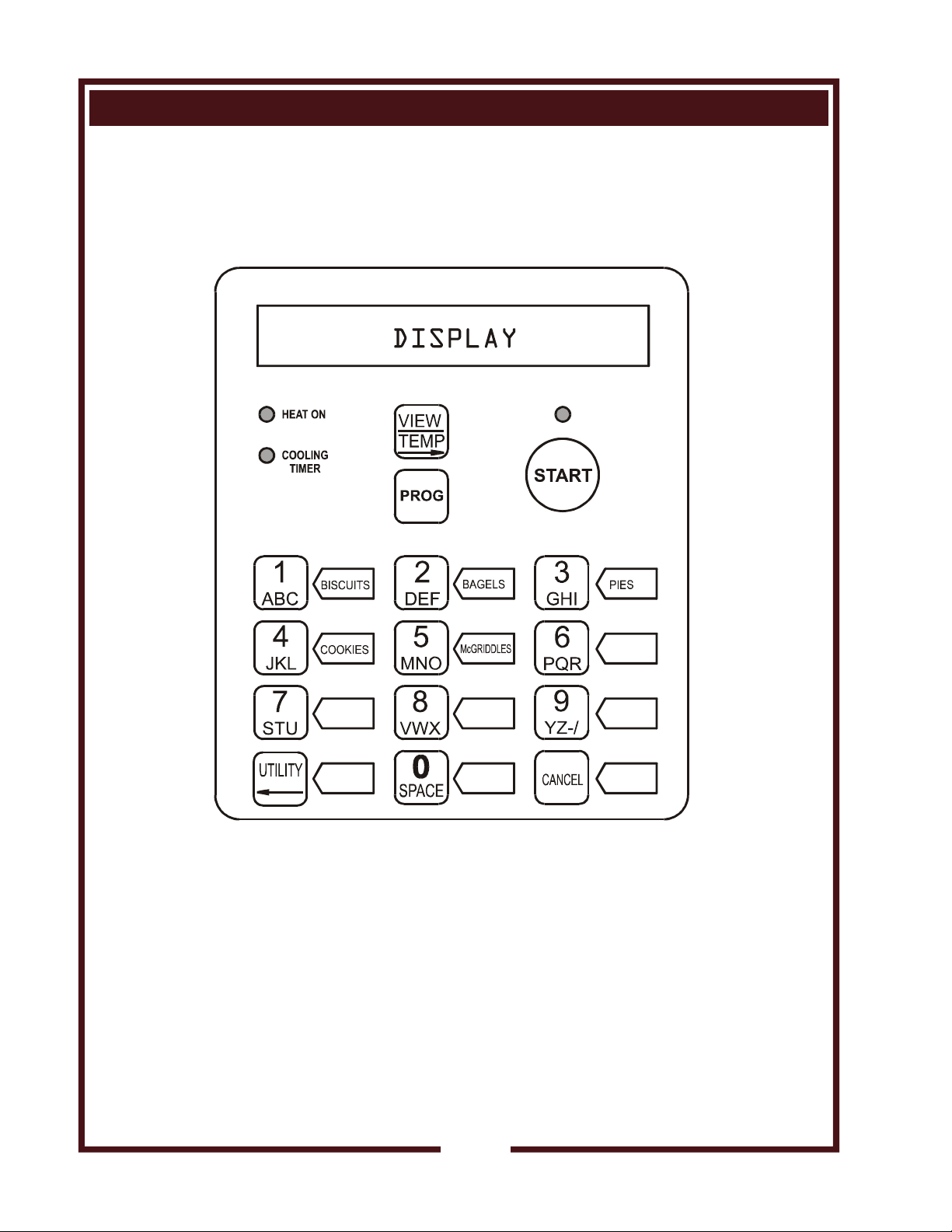

FEATURES & OPERATING CONTROLS (continued)

SMART CONTROLLER

10

M903 2M-307323 Owners Manual M4200/M4200EU

Page 13

FEATURES & OPERATING CONTROLS (continued)

BUTTON DESCRIPTION / FUNCTION

VIEW View current temperature & setpoint temperature by pressing and holding 3 seconds.

TEMP When baking multiple products can view time remaining. In program mode arrow

indicates cursor will move to the right when entering data.

PROG Press and hold for 5 seconds to enter into program mode. After entry and pressing

PROG button can access the following areas. When asked for password, enter 9793.

1) Temp Cal - - Not password protected. Used for calibrating temperature

2) View menu - - Not password protected. In this mode can view each product setting by

pressing the appropriate button. Cannot edit or change settings in this mode.

3) Edit menu - - Password protected (Authorized Personnel Only). In this mode can

view and change settings, names, alarms, etc. in buttons 1 – 0

4) Service menu - - Password protected (A uthorized Personnel Only).

Contains the following information

a) Unit ID # f) Rise Time 10:00

b) Scale ºF g) Detect Current YES

c) Temp Comp YES h) Time (clock, real time)

d) Energy Saver NO

e) Default Menu

5) Transfer menu - - Password protected (Authorized Personnel Only ).

Contains the following functions;

a) Read Menu Card Controller will read information from the card

b) Write Menu Card Controller will transfer information to the card

c) Restore Menu Restores default menu settings (Use Menu Card)

d) Restore Systems Restore default operating systems settings (Use System

Card)

6) Systems info - - Not password protected. Contains the following information used to

determine system versions and updates.

a) Model #

b) Bios Version

c) O/S Version (operating systems)

d) Default Menu

NOTE: Program button is used as the enter key for accepting data and / or moving to the next function.

START Actuates the timing cycle for baking. In programming mode used to exit and save

Buttons 0 – 9 Used to select stored menu items. In programming mode also used to enter alpha

sequences to change or enter product names.

Buttons 2 & 8 Select menu items. Also used in the programming mode for scrolling up or down

numerically for temperature calibration, and changing no to yes or vice versa.

UTILITY 1) Contains cool down function.

2) Used to switch between dayparts by holding UTILITY button for 3 seconds then

pressing PROG.

3) In program mode arrow function is used to move cursor to the left

CANCEL 1) Used to cancel alarms.

2) In program mode used to exit out without saving.

M903 2M-307323 Owners Manual M4200/M4200EU

3) Used to cancel a bake cycle. Press VIEW to display desired bake cycle, then press

CANCEL to cancel that bake cycle.

IMPORTANT PROGRAMMING NOTE: This oven is pre-programmed from the factory and does not

require programming adjustments under normal circumstances.

11

Page 14

QUICK-GLANCE OPERATING GUIDE

WELLS CONVECTION OVEN OPERATING INSTRUCTIONS

(SEE OPERATION SECTION OF OWNERS MANUAL FOR MORE INFORMATION)

START-UP AND NORMAL OPERATION

ACTION DISPLAY WILL READ

1. Verify the oven is plugged into proper outlet.

2. Turn power switch to “ON” position. WELLS BLOOMFIELD <for 3 seconds>

3. Oven will begin to heat up to a pre-set

temperature of 375ºF. TOO COOL

NOTE: Controller display will read “TOO COOL” until oven reaches pre-set temperature of 375ºF.

During initial heat up, oven will not operate until “OVEN READY” is displayed.

When “OVEN READY” is displayed, have product ready to put into oven.

4. Open door, position product on proper shelf

and close door. OVEN READY

5. Press correct product button

Press “START” button. EXAMPLE: BISCUITS 3:00

6. At end of a cook cycle audible alarm will sound.

Alarm will automatically shut off when door is opened BISCUITS REMOVE

or CANCEL button is pushed.

7. Remove product and close door OVEN READY

8. Repeat numbers 4, 5, 6 and 7 for additional cook cycles.

Be sure correct menu option is selected and displayed.

Always push “START” button to begin cook cycle.

SHUT-DOWN PROCEDURE

ACTION DISPLAY WILL READ

1. When last product is done for the day

open door of oven and let it remain open.

2. Press “UTILITY” button. FAST COOL MODE

3. Press “START” button. Fan will start COOL DOWN

4. Allow cool-down process for a minimum

time of 3 – 5 minutes.

5. Press power switch to “OFF” position.

Interior of oven can then be safely cleaned.

M903 2M-307323 Owners Manual M4200/M4200EU

12

Page 15

OPERATION

DAILY SET-UP PROCEDURES

1. Make sure the power cord is plugged into the appropriate

power supply receptacle.

2. Place the ON/OFF switch in the ON position. A double "beep" will

sound, display will read WELLS BLOOMFIELD for 3 seconds,

then display oven status:

a. Display will read TOO COOL and the heat light will glow during

warm-up.

b. Display will read OVEN READY and the heat light will go out

when oven temperature reaches the setpoint.

c. Heat light will cycle as heating elements cycle to maintain

desired temperature.

3. To view actual and setpoint temperature, press and hold TEMP key

for 5 seconds (example: TEMP 340F SET 375F).

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

Oven door will be hot to the

touch during operation. Use

the provided handle to open

and close oven door.

NOTE: A "beep" will sound

each time a key is pressed.

M903 2M-307323 Owners Manual M4200/M4200EU

13

Page 16

OPERATION (continued)

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

Oven door will be hot to the

touch during operation. Use

the provided handle to open

and close oven door.

Product and trays will be hot

after baking. Use appropriate

oven mitt to remove product

or trays.

CAUTION:

CUT HAZARD

Fan will be running during

cool-down. Avoid reaching

into the oven while oven is in

cool-down mode.

Fan blades are sharp and can

cause lacerations.

NOTE: Convection fan will

be running at all times the

power switch is ON and the

oven door is closed.

NOTE: Menu items are

subject to change at the

discretion of McDonalds

Management.

COOK CYCLE OPERATION

1. Slide racks of product into oven as appropriate. Shelf positions

required for quality baked products are:

NO. OF PANS RACK POSITION

OF PRODUCT UTILIZED

1 5

2 2 & 8

3 2, 5 & 8

2. Press the appropriate menu key.

Press button ONCE for any full tray of

product (1, 2, 3).

Press button TWICE for any partial tray of

product (1/2, 1/4, …).

Display will show selected menu item and

associated time (example: BISCUITS 03:00). Within 5 seconds,

press START key to begin cooking. Start indicator light will glow

and display time will begin cook timer.

a. If START is not pressed within 5 seconds, controller returns

to OVEN READY.

b. Display shows product and time remaining on cook timer.

To display multiple cook cycles, press VIEW button repeatedly.

Partial tray readout is <BISCUITS PAR>

c. Typical menu items

for full trays for partial trays

1. BISCUITS BISCUITS PAR

2. BAGELS BAGELS PAR

3. PIES PIES PAR

4. COOKIES COOKIES PAR

5. McGRIDDLES McGRIDDLES PAR

6. SCR BISCUITS

3. If necessary to interrupt cook cycle:

a. Timer pauses if door is opened during cook cycle. Timer will

resume countdown when door is closed.

NOTE: Opening oven door during baking is not recommended.

b. Press and hold CANCEL key for 5 seconds to cancel countdown

and return to OVEN READY.

4. At end of cook cycle, a continuous tone will sound and display will

advise to remove product (example: BISCUITS REMOVE).

IMPORTANT: Use oven mitt to remove product. Open oven door

or press CANCEL to silence tone. When door is closed, oven will

return to OVEN READY.

5. Cooling Timer is currently enabled for baking pies, and set to

10 minutes.

IMPORTANT: Product and trays will be hot after baking.

Wear appropriate oven mitt to handle hot product or trays.

a. At end of baking cycle cooling indicator light will glow.

Remove trays. Products are to remain on trays.

b. Close oven door. Oven timer will automatically sound after

time expires. Display will read <PIES COOL>.

c. Do not box product until cooling time has expired.

M903 2M-307323 Owners Manual M4200/M4200EU

14

Page 17

PROGRAMMING INSTRUCTIONS

IMPORTANT: This oven is pre-programmed from the factory and does not require

programming adjustments under normal circumstances. Any programming

changes must be performed by qualified persons only.

ENTER PROGRAM MODE

NOTE: Oven must be turned ON. No cooling timer or bake cycle can be active.

Special Button Functions:

Scroll through the options by pressing the PROG button:

# 2 and #8 allows scrolling up or down; and, changes from yes or no

ACTION DISPLAY WILL READ

1) To enter programmin g mod e, press and hold

PROG button for 5 seconds TEMP CAL NO

This option allows temperature calibration

2) Press PROG button VIEW MENU ITEM NO

This option allows viewing programmed values of menu items

3) Press PROG button EDIT MENU NO

This option allows changing programmed values of menu items

4) Press PROG button SERVICE MENU NO

This option allows changes to temperature scale and to set real-time clock

5) Press PROG button TRANSFER MENU NO

This option allows history upload, read menu card, write menu card and restore defaults

6) Press PROG button SYSTEM INFO NO

This option allows viewing of controller model number, BIOS program number and version,

operating system (O/S) number and version, and default menus

To EXIT PROGRAM MODE:

Press CANCEL button two (2) times.

Controller will revert to RUN mode OVEN READY

Button Designation:

# 1 BISCUITS

# 2 BAGELS

# 3 PIES

# 4 COOKIES

# 5 McGRIDDLES

M903 2M-307323 Owners Manual M4200/M4200EU

# 6 SCRATCH BISCUITS (disabled where ready to bake biscuits are used)

# 7 Disabled for future menu options

# 8 Disabled for future menu options

# 9 Disabled for future menu options

# 0 Disabled for future menu options

15

Page 18

Page 19

PROGRAMMING INSTRUCTIONS (continued)

IMPORTANT: This oven is pre-programmed from the factory and does not require

programming adjustments under normal circumstances. Any programming

changes must be performed by qualified persons only.

ACTION DISPLAY WILL READ

IMPORTANT: DO NOT CHANGE FACTOR VALUES OR TIME VALUES FOR EXISTING MENU ITMES

13) Press PROG button. Display will read FACTOR 1 VALUE 00000

FACTOR 1 TIME 00000

14) Press PROG button repeatedly to cycle through

factor values and factor times (1 - 5).

Display will read <COOLING TIMER> COOLING TIMER NO

15) Press button #2 or #8 to enable or disable

cooling timer. COOLING TIMER YES

16) Press PROG button COOLING TIME

17) Set desired cooling time (0 - 60 minutes)

Press button #2 to increase time

or button #8 to decrease time 10:00

18) Press PROG button. Beep will sound to

indicate new information is saved. UPDATING MENU ITEM

(This is the end of this programming

cycle. If no other menu items are to be

programmed, go on to # 19. If other menu

items are to be programmed, press PROG

to return to # 6.) SELECT DAYPART # 1

19) Press START button EDIT MENU ITEM NO

20) Press START button OVEN READY

Programming the controller is now complete.

NOTE: ENTER PROGRAMMING and VIEW PROGRAMMING are disabled during coo k cycle and while

cooling timer is activated.

M903 2M-307323 Owners Manual M4200/M4200EU

17

Page 20

PROGRAMMING INSTRUCTIONS (continued)

IMPORTANT: This oven is pre-programmed from the factory and does not require

programming adjustments under normal circumstances. Any programming

changes must be performed by qualified persons only.

ENABLING SCRATCH BISCUIT BUTTON (#6)

ACTION DISPLAY WILL READ

1. Enter programming mode, press and

hold PROG button for 5 seconds CAL TEMP NO

2. Press PROG button until EDIT MENU is

reached EDIT MENU ITEM NO

3. Press #2 or #8 button for YES EDIT MENU ITEM YES

4. Press PROG button PASSWORD 0000

See page 22 for password and recommended oven settings

5. Press PROG button to select daypart. SELECT DAYPART # 1

NOTE: Only daypart #1 is activated

6. Press PROG button SEL>

7. Press # 6 button to select SCRATCH BISCUITS SCRATCH BISCUITS

8. Press PROG button to enable any name change S

9. Press PROG button ENABLE NO

10. Press #2 button to enable SCRATCH BISCUIT

Button ENABLE YES

11. Press PROG button CANCEL A/M MANUAL

(Should always be Manual)

12. Continue pressing PROG button until beep

sounds, indicating new information was saved UPDATING MENU ITEM

13. Press START button OVEN READY

Enabling Scratch Biscuit button (#6) is now complete.

IMPORTANT: DO NOT CHAN GE FACTOR VALUES OR FACTOR TIMES FOR EXISTING MENU

ITEMS

NOTE: Cannot go into edit or view program mode when cooling timer is activated or when in

a bake cycle.

CRATCH BISCUITS

M903 2M-307323 Owners Manual M4200/M4200EU

18

Page 21

IMPORTANT: Programming changes to be performed by qualified persons only.

INSTRUCTIONS FOR CHANGING COOKIE SETTINGS

The Wells Convection Oven comes pre-programmed from the factory for cookies baked at 6:00 minutes at

a temperature of 375 F. Following is the procedure to change the settings only in the event your location

uses a different cookie or manufacturer.

NOTE: Oven must be in turned ON. No cooling timer or bake cycle can be active.

ACTION DISPLAY WILL READ

1. To enter programming mode, press and hold

PROG button for 5 seconds, display will read TEMP CAL NO

2. Press PROG button until display reads EDIT MENU NO

3. Press #2 or #8 button to select YES. EDIT MENU YES

4. Press PROG button and enter the PASSWORD 0000

5. Press PROG button SELECT DAYPART # 1

6. Press PROG button SEL->

7. Press button #4 to select COOKIES COOKIES

8. Press PROG button to cycle through C

9. Enter desired cook time. COOK TIME 06:00

10. Press PROG button and enter desired COOK TEMP 375

11. Press PROG button repeatedly to cycle FACTOR 1 VALUE 00000

IMPORTANT: Do not change FACTOR VALUES or TIMES for existing menu items.

12. If cooling timer is desired, COOLING TIMER YES

13. Press PROG button and enter the COOLING TIME 20:00

desired cooling time.

14. Press PROG button. UPDATING MENU ITEM

This indicates the end of this programming cycle.

If no other menu items need programming, continue with Step 15.

M903 2M-307323 Owners Manual M4200/M4200EU

If other menu items need programming, go to Step 6.

15. Press PROG button SELECT DAYPART # 1

16. Press START button until displays OVEN READY

Shows OVEN READY

Changing the cookie settings is now complete.

<EDIT MENU NO>

following coded password 9793

the following settings until display ENABLE YES

reads COOK TIME CANCEL A/M MANUAL

COOK TIME 06:00

temperature

through factor values and factor times (1-5) FACTOR 1 TIME 00000

until display reads COOLING TIMER. COOLING TIMER NO

press button #2 or #8 to select YES.

If not continue to Step 15.

PROGRAMMING INSTRUCTIONS (continued)

OOKIES

19

Page 22

PROGRAMMING INSTRUCTIONS (continued)

IMPORTANT: This oven is pre-programmed from the factory and does not require

programming adjustments under normal circumstances. Any programming

changes must be performed by qualified persons only.

PROCEDURE TO INSTALL O/S SYSTEM INTO CONTROLLER

ACTION DISPLAY WILL READ APPROX. TIME

1. Oven switch must be in the “OFF” position

2. Insert menu Runware Card into card reader slot

with chip facing down. Push in until resistance is

met, then another 1/8”

3. Press “UTILITY” and “CANCEL” button at the

same time. Hold these buttons.

4. Turn oven switch to “ON” position

5. Release “UTILITY” and “CANCEL” button

at the same time.

6. Display will read the following for

approximate time: LOADING O/S 1 second

Rotating Bar indicates controller TESTING CARD 28 seconds

is accepting information LOADING O/S 56 seconds

LOADING DEFAULT MENU 1 second

WELLS BLOOMFIELD 1 second

Oven Will Start INCORRECT CARD (BEEP)

Remove card

7. Audible alarm will sound and oven will start.

Remove card from slot and return to protective

packaging.

8. Oven will say “TOO COOL”, and start to heat up.

Install operating system is now complete

M903 2M-307323 Owners Manual M4200/M4200EU

20

Page 23

PROGRAMMING INSTRUCTIONS (continued)

IMPORTANT: Programming changes to be performed by qualified persons only.

TRANSFER MENUS FROM MENU CARD TO CONTROLLER

Loading new settings to Controller from Menu Card to Oven using Smart Card Reader

NOTE: Oven must be in turned ON. No cooling timer or bake cycle can be active.

ACTION DISPLAY WILL READ

1. Insert menu card into card reader slot

Insert menu card with chip facing down.

Push in until resistance is met, then another 1/8” TESTING CARD (approx. 30 sec.)

PASSWORD 0000

2. Refer to page 22 for password READ MENU CARD NO

3. Press #2 button. READ MENU CARD YES

4. Press PROG button. TESTING CARD (approx. 30 sec.)

READING CARD

A rotating bar indicates the controller is

reading and downloading the information from

the menu card. When finished, audible alarm

will sound.

5. Remove card from slot and return to protective packaging.

6. Press START button. TOO COOL

TRANSFERRING MENUS FROM CONTROLLER TO MENU CARD

Saving new menu settings from Oven to Menu Card using Smart Card Reader

NOTE: Oven must be in turned ON. No cooling timer or bake cycle can be active.

ACTION DISPLAY WILL READ

1. Insert menu card into card reader slot

Insert menu card with chip facing down.

Push in until resistance is met, then another 1/8” TESTING CARD (approx. 30 sec.)

PASSWORD 0000

2. Enter password # 9793 READ MENU CARD NO

3. Press PROG button. WRITE MENU CARD NO

4. Press # 2 button. WRITE MENU CARD YES

5. Press PROG button. WRITING CARD

A rotating bar indicates the controller is

writing the information from the oven to

the menu card, and the information is being

accepted. When finished, audible alarm

M903 2M-307323 Owners Manual M4200/M4200EU

will sound.

6. Remove card from slot and return to protective packaging.

7. Press START button. TOO COOL

21

Page 24

PROGRAMMING INSTRUCTIONS (continued)

RECOMMENDED OVEN SETTINGS AS OF JAN. 1, 2004

IMPORTANT: Programming changes to be performed by qualified persons only.

SCALE FACTORS*

1 105 120

2 0 120

3 0 120

4 0 120

5 0 120

1 56 60

2 0 60

3 0 60

4 0 60

5 0 60

1 90 120

2 0 120

3 0 120

4 0 120

5 0 120

1 0 0

2 0 0

3 0 0

4 0 0

5 0 0

1 89 60

2 0 60

3 0 60

4 0 60

5 0 60

1 50 60

2 30 120

3 0 120

N/A

4 0 120

5 0 120

MENU ITEM DEFAULT SETTINGS

McDONALD’S PRODUCT FACTORY DEFAULT SETTINGS

NAME"

PRODUCT

"BISCUIT" ENABLE CANCEL COOK TIME COOK TEMP COOLING TIMER COOLING TIME FACTOR VALUE TIME

"DISPLAYED

3:00 375 NO N/A

A/M

MANUAL

YES

minutes

Base Time 3

A/M

"BAGELS" ENABLE CANCEL COOK TIME COOK TEMP COOLING TIMER COOLING TIME FACTOR VALUE TIME

Base Time 3

3:00 375 NO N/A

MANUAL

YES

minutes

A/M

"PIES" ENABLE CANCEL COOK TIME COOK TEMP COOLING TIMER COOLING TIME FACTOR VALUE TIME

Base Time 10

10:00 375 YES 10:00

MANUAL

YES

minutes

A/M

"COOKIES" ENABLE CANCEL COOK TIME COOK TEMP COOLING TIMER COOLING TIME FACTOR VALUE TIME

BAMA Base

6:00 375 NO N/A

MANUAL

YES

Time 6 minutes

A/M

Base Time 6

"McGRIDDLES" ENABLE CANCEL COOK TIME COOK TEMP COOLING TIMER COOLING TIME FACTOR VALUE TIME

6:00 375 NO N/A

MANUAL

YES

minutes

ENABLE CANCEL COOK TIME COOK TEMP COOLING TIMER COOLING TIME FACTOR VALUE TIME

"SCRATCH

BISCUITS"

12:00 375 NO

A/M

MANUAL

NO

minutes

Base Time 12

M903 2M-307323 Owners Manual M4200/M4200EU

BUTTON #

BUTTON #1

BUTTON #2

BUTTON #3

BUTTON #4

BUTTON #5

BUTTON #6

* Scale Factors - FACTOR VALUES 1 - 5 and FACTOR TIMES 1 - 5 should not be changed for existing menu items PASSWORD for oven settings : 9793

22

Page 25

CLEANING INSTRUCTIONS

PREPARATION Allow oven to cool to 150ºF or less

FREQUENCY Daily

TOOLS Clean Towels

DAILY CLEANING

1. With power switch ON, open oven door. Press UTILITY key.

Display will read FAST COOL MODE. Press START key. Display

will read COOL DOWN and fan will start. When oven has cooled,

press power switch OFF.

2. Wipe down interior of oven and inside surface of door with a clean

towel dampened with water.

3. Dry by wiping with a clean dry towel.

4. Wipe control panel with a clean dry towel to remove any build-up of

grease or food particles.

PROCEDURE IS COMPLETE

CAUTION:

SHOCK HAZARD

Disconnect appliance from

electric power

before cleaning.

CAUTION:

BURN HAZARD

Allow appliance to cool to

150ºF or less before cleaning.

Do not attempt to clean the

oven until it has cooled to

150ºF or less. It can burn

you. Hand protection is

required.

IMPORTANT:

DO NOT use steel wool

or abrasive cleansers for

cleaning this appliance.

Always wipe or rub in the

direction of the polish lines

or grain of the metal.

IMPORTANT:

DO NOT spill or pour water

into control panel or wiring.

NOTE:

Damage to internal

components from water

damage is not covered by

warranty.

M903 2M-307323 Owners Manual M4200/M4200EU

23

Page 26

CLEANING INSTRUCTIONS (continued)

PREPARATION Allow oven to cool to 150ºF or less

CAUTION:

SHOCK HAZARD

Disconnect appliance from

electric power

before cleaning.

CAUTION:

BURN HAZARD

Allow appliance to cool to

150ºF or less before cleaning.

Do not attempt to clean the

oven until it has cooled to

150ºF or less. It can burn

you. Hand protection is

required.

CAUTION:

CUT HAZARD

Fan will be running during

cool-down. Avoid reaching

into the oven while oven is in

cool-down mode.

FAN BLADES ARE SHARP.

Use due care when cleaning

and/or wiping.

IMPORTANT:

DO NOT use steel wool

or abrasive cleansers for

cleaning this appliance.

Always wipe or rub in the

direction of the polish lines

or grain of the metal.

IMPORTANT:

DO NOT spill or pour water

into control panel or wiring.

Damage to internal

components from water

damage is not covered by

warranty.

IMPORTANT:

Take care to avoid damage to

fan blades when reinstalling

fan baffle.

FREQUENCY Monthly

TOOLS Fiber Brush, Plastic Scouring Pad, Plastic Scraper

Mild Detergent, McD Sanitizer,

APC All Purpose Cleaner, Clean Towel

MONTHLY CLEANING

1. With power switch ON, open oven door. Press UTILITY key.

Display will read FAST COOL MODE. Press START key. Display

will read COOL DOWN and fan will start. When oven has cooled,

press power switch OFF.

2. Remove racks and rack supports. Remove fan baffle.

3. Brush the fan wheel and wipe it with a moist cloth. Sponge out all

loose particles.

4. Scrub entire interior of convection oven with a plastic scouring pad

and APC cleaner.

5. For baked on food spills, apply APC cleaner. Close the oven door

and let stand for 10 minutes with the power OFF. Wipe food spill

with a plastic scouring pad as needed. Rinse area by wiping with a

clean sanitized towel.

6. Wipe down the entire interior using a clean cloth or moistened with

water and a mild detergent. Rinse by wiping with a clean towel

moistened with sanitizer.

7. Clean oven racks and rack supports in a sink or dishwasher.

8. Reinstall the fan baffle, paying

particular attention that the lip on

the right side of the fan baffle is

fully seated in the slot in the edge

of the oven cavity. Reinstall rack

supports and racks.

9. Press power switch ON, press

UTILITY key then START key.

Verify that fan runs smoothly and

does not contact fan baffle.

Press power switch OFF.

Reposition fan baffle if necessary.

10. Wipe down exterior of the oven

using a clean cloth moistened with

water and a mild detergent.

11. Repl ace oven rack supports.

PROCEDURE IS COMPLETE

M903 2M-307323 Owners Manual M4200/M4200EU

24

Page 27

CAUTION: SHOCK HAZARD

Removal of any cabinet panel will result in exposed electrical circuits.

Any procedure requiring the removal of any cabinet panel must be performed by a qualified

technician only

CAUTION: SHOCK HAZARD

Fuse replacement may expose dangerous voltages.

Fuse replacement must be performed by a qualified technician.

TROUBLESHOOTING SUGGESTIONS

.

SYMPTOM

No power to appliance

Oven will not heat

Blower fan will not run

Door pops open during

cook cycle

Product not baking

properly (too light / too

dark)

On startup controller

Displays <HTR ERROR>

On startup controller

M903 2M-307323 Owners Manual M4200/M4200EU

Displays <MTR ERROR>

POSSIBLE CAUSE

Circuit breaker off or tripped

Power cord unplugged or damaged

Fuse blown or loose

Power switch turned OFF

Oven door not closed

Hi-limit control tripped on excessive

oven temperature

Damaged controller

Oven door not closed

Damage to internal components

Latch out of adjustment

Temperature out of calibration

Proper programming not set for menu

Item

Heating element is not working

properly

Fan motor is not working properly

SUGGESTED REMEDY

Reset circuit breaker

Check power cord

Plug in or repair as required

Check power fuses. If blown,

correct problem and replace

fuses

Turn power switch ON

Be sure door is closed and

latched

Allow oven to cool

Hi-limit will reset

Contact Authorized Wells

Service Agency for repairs

Be sure door is closed and

latched

Contact Authorized Wells

Service Agency for repairs

Adjust latch

Follow procedures to calibrate

temperature. See Preventative

Maintenance pg. 26

Check menu item programming.

See default settings pg. 15 - 19.

Contact Authorized Wells

Service Agency for repairs

Contact Authorized Wells

Service Agency for repairs

NOTE: There are no user serviceable components in the appliance. In all cases of damage or

component malfunction, contact your Authorized Wells Service Agency for repairs.

25

Page 28

PREVENTATIVE MAINTENANCE

TEMPERATURE CALIBRATION

THE FOLLOWING PROCEDURE IS TO BE PERFORMED BY QUALIFIED PERSONNEL ONLY

PRECAUTIONS: BURN HAZARD - Wear appropriate protective gloves

FREQUENCY: Monthly

TOOLS: Digital Thermometer with Oven Probe

TEMPERATURE CALIBRATION

1. Verify power cord is plugged into appropriate supply.

2. Use a digital thermometer with oven probe. Open the oven door and clamp the probe to the center

of the middle rack.

3. Route the probe wires between door gasket segments on the right corner of the oven. Close the

oven door. Plug the probe into the digital thermometer.

4. Press the POWER SWITCH to ON. Wait at least 30 minutes for temperatures to stabilize.

No cooling timer or bake cycle can be active.

ACTION DISPLAY WILL READ

a) To enter programming mode, press and hold

PROG button for 5 seconds TEMP CAL NO

b) Press #2 or #8 button TEMP CAL YES

c) Press PROG button to display oven temp CAL TEMP xxxF yyyC

in Fahrenheit and Celsius where xxxF is ºF and yyyC is ºC

d) Compare displayed temp with the digital thermometer reading. CAL TEMP should read within

±3ºF (±1ºC) of temperature on the digital thermometer. If temperatures are within 3ºF (1ºC) of

each other, proceed to Step f. If the difference between temperatures exceeds 3ºF (1ºC),

proceed with Step e.

e) Change the CAL TEMP to match the thermometer reading. Use the “2” button to increase

CAL TEMP and “8” button to decrease the CAL TEMP. Always increase or decrease CAL TEMP

in increments of 3 - 5 degrees, then wait about 1 minute for the oven to adjust. You may not see

an immediate change in CAL TEMP when “2” or *”8” is pressed. Repeat as necessary.

IMPORTANT: Pressing CANCEL at any time while in the TEMP CAL mode will cause any

changes to be ignored. These changes will neither be saved nor implemented.

f) Press PROG button to view the following defaults. Stop when you hear a beep and UPDATING

SYSTEM is flashed on the display. Any changes have been saved.

DEFAULT MENU

RISE TME 10:00

DETECT CURRENT NO

CAL CURRENT NO

TIME (Ex: 00:00:00)

UPDATING SYSTEM

TEMP CAL NO

g) Press the CANCEL button to exit programming mode OVEN READY

CAUTION:

BURN HAZARD from oven before use.

Oven and inner door surfaces

are hot. Wear appropriate

protective gloves.

Remove temperature probe

M903 2M-307323 Owners Manual M4200/M4200EU

26

Page 29

PREVENTATIVE MAINTENANCE (continued)

CAUTION:

BURN HAZARD

Allow appliance to cool

completely before adjusting.

Hinge Adjustment

M903 2M-307323 Owners Manual M4200/M4200EU

HINGE ADJUSTMENT

PRECAUTIONS: None

FREQUENCY: As Needed

TOOLS: Phillips (+) Screwdriver

7/16" Nut Driver

7/8" and 1-1/8" Wrenches

THE FOLLOWING PROCEDURE IS TO BE

PERFORMED BY QUALIFIED PERSONNEL ONLY

1. Remove bottom panel to access pivot.

2. Gap between top of door and frame , and between bottom

of door and frame must be approximately equal

Adjust height of door by loosening jamb nut, then turning

pivot on its screw mounting. Clockwise lowers the door

height. Counter-clockwise raises the door height.

Re-tighten jamb nut.

3. Gap between left side of door and frame must be the

same from top to bottom

Adjust door for plumb by loosening holding screws. Turn

adjusting bolt to increase or decrease gap at bottom.

Clockwise increases gap. Counter-clockwise decreases gap.

Re-tighten holding screws.

4. Gap between top of door and frame must be the same

from side to side

Adjust door for level by loosening holding screws, then

raising or lowering latch-end of door until it is level.

Re-tighten holding screws.

5. Reinstall bottom panel.

Procedure is complete

27

Page 30

EXPLODED VIEW and PARTS LIST

M4200 and M4200EU

Cabinet & Related Components

D

81

40

M903 2M-307323 Owners Manual M4200/M4200EU

28

Page 31

EXPLODED VIEW and PARTS LIST (continued)

ITEM DESCRIPTION M4200 (EU) QTY

1 ASSY, CAVITY 1

6 PANEL, CONTROL 1

10 BRACKET, MOTOR MOUNT 1

13 BRACKET, CAVITY SUPPORT 2

14 GROMMET, 7/8" O.D. 2K-31040 2

17 ASSY, BAFFLE SUPPORT 2

19 MOUNT, TEMP SENSORS 1

20 COVER, DOOR GASKET 4

21 CLIP, RACK SUPPORT F6-43889 8

22 HANDLE ASSEMBLY 1

24 BRACKET, HI-LIMIT THERMO 1

29 ASSY, DOOR COMPLETE F6-504444 1

30 GASKET, DOOR, SIDE F6-46313 2

35 GASKET, DOOR, TOP/BOT F6-46314 2

36 ASSY, OVEN TOP 1

38 HANGER, CORD 1

39 PANEL, EXTERIOR SIDE 2

40 INSULATION, MOTOR MOUNTING 1

42 ASSY, FRAME 1

44 SLEEVE, DOOR HINGE 2A-43900 1

47 GUARD, PROX. SWITCH F6-45647 1

50 DOOR STRIKER 2C-305616 1

51 DOOR LATCH 2C-305615 1

52 BUSHING, TOP DOOR HINGE 2K-305619 1

54 PIN, HINGE, DOOR TOP AND BOTTOM 2A-305610 2

55 ASSY, BOT DOOR HINGE F6-43896 1

56 PANEL, REAR 1

57 ASSY, VENT DUCT 1

58 TRIM, LOWER FRONT F6-43804 1

59 BRACKET, PROX SWITCH F6-43787 1

60 PLATE, DOOR PIVOT F6-43899 1

68 PLATE, DOOR HINGE PIN DD-43913 2

69 PLATE, DOOR PIVOT HOLE F6-43899 1

80 NUT, HEX 3/4-10 UNC 2C-44363 1

81 BISCUIT BAKING ADAPTER F6-305523 1

90 WIRE SET (not shown) 1

92 TIE, WIRE, STANDOFF (not shown) 2

101 BAFFLE, OVEN 1

102 RACK, PRODUCT WS-21376 3

103 SUPPORT, RACK (pk 2) WS-21375 2

cc CLIP, TINNERMAN 2C-37943 AR

OPTIONAL PARTS

A LEG 4" ADJUSTABLE (SET OF 4) DD-22226 1

B CASTER, LOCKING (FRONT) WS-21373 1 (SET OF 2)

CASTER, SWIVEL (REAR) WS-21372 1 (SET OF 2)

C PREP TOP WS-21445 1

CLIP, PREP TOP 4

D KIT, EXTERIOR VENT DUCT (SINGLE OVEN) WS-505504 1

M903 2M-307323 Owners Manual M4200/M4200EU

29

Page 32

EXPLODED VIEW and PARTS LIST (continued)

G

2 pc. 3pl.

61

24

M4200 & M4200EU

Internal Components

64

31

59

63

62

6

71

70

19

25

91

ref.

5

12

9

70

26

208V

240V

380-415V

15

11

18

2

4

28

7.1

13

72

3

10

40

7

8

34

81

43

89

30

23

ref.

M903 2M-307323 Owners Manual M4200/M4200EU

7.2

66

67

67.1

Page 33

EXPLODED VIEW and PARTS LIST (continued)

ITEM DESCRIPTION M4200 M4200EU QTY

1 ASSY, CAVITY 1

2 TERMINAL BLOCK WS-50131 2E-40310 1

3 SPACER, BLOWER MOTOR 4

4 LUG, SOLDERLESS 1

5 FAN, COOLING 2U-44687 2U-44687 1

6 PANEL, CONTROL 1

7 MOTOR, 1/4 HP WS-63932 WS-63932 1

7.1 START CAPACITOR 69823 69823 1

7.2 BRACKET, START CAPACITOR 2V-300933 2V-300933 1

8 SPACER, MOTOR MOUNT 4

9 BLOWER WHEEL 2U-43797 2U-47397 1

10 BRACKET, MOTOR MOUNT 1

11 SSR MODULE 2E-304615 2E-304615 1

12 RELAY, E-SAFE 2E-306967 2E-306967A 1

13 ASSY, CURRENT DETECTOR 2E-306976 2E-306976 1

14 GROMMET, 7/8" O.D. 2K-31040 2K-31040 2

15 CONTACTOR, HI-LIMIT 208V WS-57779 1

RELAY, HI-LIMIT 240V and 380-415V 2E-307328 2E-307328 1

18 TRANSFORMER 2E-305804 2E-303286 1

23 READER, MAGNETIC CARD 2E-306977 2E-306977 1

24 BRACKET, HI-LIMIT THERMO 1

25 THERMOSTAT, HI-LIMIT 2T-45180 2T-45180 1

26 THERMOCOUPLE 2J-304580 2J-304850 1

28 LABEL, GROUND SYMBOL 64584 64584 1

31 ASSY, PROXIMITY SWITCH F6-45239 F6-45239 1

34 FUSEHOLDER, 10A 240V (M4200-3SV) 2E-34769 2

FUSEHOLDER, 5A 240V (M4200EU) DD-73795 1

40 INSULATION, MOTOR MOUNTING 1

42 ASSY, FRAME F6-504609 F6-504609 1

43 FUSE, 10A 240V (M4200-3SV) 2E-34768 2

FUSE, 5A 240V (M4200EU) 2E-73794 1

59 BRACKET, PROX SWITCH F6-43787 F6-43787 1

62.1 INNER ELEMENT, 208V (4" GAP) 2N-43872UL 1

62.2 INNER ELEMENT, 240V (4" GAP) 2N-43783UL 2N-43783UL 1

63.1 MIDDLE ELEMENT, 208V (2.5" GAP) 2N-43866UL 1

63.2 MIDDLE ELEMENT, 240V (2.5" GAP) 2N-43800UL 2N-43800UL 1

64.1 OUTER ELEMENT, 208V (1" GAP) 2N-43873UL 1

64.2 OUTER ELEMENT, 240V (1" GAP) 2N-43949UL 2N-43949UL 1

66 ASSY, POWER CORD 1

67 STRAIN RELIEF 2K-48754 2K-48754 1

67.1 NUT (ONLY), STRAIN RELIEF WS-65504 WS-65504 1

70 GASKET, ELEMENT 2I-43834 2I-43834 1

71 COVER, ELEMENT GASKET INNER F6-43836 F6-43836 1

72 COVER, ELEMENT GASKET OUTER F6-43837 F6-43837 1

81 CONTROLLER, TIME & TEMPERATURE 2J-306966 2J-306966 1

89 SWITCH, ON/OFF 2E-305295 2E-306824 1

93 OP. MANUAL M4200 (not shown) 2M-307323 2M-307323 1

M903 2M-307323 Owners Manual M4200/M4200EU

31

Page 34

WIRING DIAGRAM M4200 208V

PICTORIAL WIRING DIAGRAM FOR

M4200 OVEN 208, 3 PHASE

(3 PCS)

AIR HEATER

THERMOCOUPLE

19

RED

YEL.

DETECT

CURRENT

HI-LIMIT

THERMOSTAT

26

18

55

54

52

50

ASSY

19

14

32

25

35

53

51

WIRE

10

7

4

1

NUT

11

89

56

23

E-SAFE

RELAY

1

2

12

32

24

42

43

FAN

COOLING

A1

A2

L1

T1

L2

T2

L3

T3

47

48

HI-LIMIT

CONTACTOR

(2PCS)

10AMPFUSE

11

10

5

WHITE

RED

GROUND

POWER

SUPPLY

P/N 307321 REV.A

CORD

41

44

BLACK

17

P2

P1

T3 T2 T1

L3 L2 L1

45

46

20

BLOCK

TERMINAL

LOOP

WIRE NO.22

49

FIVE TIMES

23-27

21

L3

4

18

6

HZ

50/60

AMPS 3 PHASE

21

L2

21

21

L1

21

21

22

TRANSFORMER

SSR

6

7

MOTOR

+-

17

42

CONFIGURED FOR 208V

240

208COM

2

240

208

VOLTS

1

43

3

9

WHITE

BLOWER

MOTOR

M

M903 2M-307323 Owners Manual M4200/M4200EU

GRD/YEL

DOOR

SENSOR

SW.

BLACK

36

34

MOTOR RUN

CAPACITOR

32

33

27

7

+

LIGHTED

ROCKER

SWITCH

3

5

33

11

35

CONTROLLER

NCC

TIME / TEMPERATURE

23-27

32

TERMINAL

BLOCK

1K OHM

RESISTOR

23-27

Page 35

WIRING DIAGRAM M4200 240V

M903 2M-307323 Owners Manual M4200/M4200EU

M4200 OVEN 240 VOLTS, 3 PHASE

PICTORIAL WIRING DIAGRAM FOR

(3 PCS)

AIR HEATER

THERMOCOUPLE

19

RED

YEL.

DETECT

CURRENT

HI-LIMIT

THERMOSTAT

26

18

55

54

52

50

ASSY

19

14

32

25

35

51

WIRE

42

43

E-SAFE

RELAY

FAN

COOLING

A1

A2

L1

53

T1

L2

T2

L3

T3

LOOP

FIVE TIMES

WIRE NO.22

47

48

HI-LIMIT

RELAY

17

49

6

3

9

5

2

8

B

A

7

4

1

(2PCS)

10AMPFUSE

11

10

5

WHITE

RED

GROUND

POWER

SUPPLY

P/N 307321 REV.(-)

CORD

41

44

BLACK

45

46

20

BLOCK

TERMINAL

23-27

21

L3

4

18

6

HZ

50/60

L2

L1

AMPS 3 PHASE

21

21

21

21

21

22

TRANSFORMER

SSR

6

7

MOTOR

+-

17

42

CONFIGURED FOR 240V

240

208COM

2

240

208

VOLTS

1

43

3

9

WHITE

BLOWER

MOTOR

NUT

M

GRD/YEL

DOOR

SENSOR

SW.

BLACK

36

34

MOTOR RUN

CAPACITOR

1

2

11

10

12

89

7

56

4

1

23

32

24

33

27

7

+

32

LIGHTED

ROCKER

SWITCH

3

5

33

11

35

CONTROLLER

NCC

TIME / TEMPERATURE

23-27

33

TERMINAL

BLOCK

1K OHM

RESISTOR

23-27

Page 36

WIRING DIAGRAM M4200EU

43

42

56

55

57

54

M4200EU OVEN 380-415 3NAC

PICTORIAL WIRING DIAGRAM FOR

(3PCS)

AIR HEATER

FIELD CONVERTIBLETO SINGLE PHASE

REFER TOWIRING ILLUSTRATION BELOW

THERMOCOUPLE

19

14

RED

YEL.

HI-LIMIT

AUTORESET

THERMOSTAT

18

52

50

WIRE #22LOOPED

26

25

FIVE (5)TIMES

19

32

35

53

51

WIRE

NUT

11 10

123

23

SENSOR

CURRENT

22

1

2

12

987

654

24

+

N

A1

A2

L1

T1

T2

L2

L3

T3

-+

SSR

MOTOR

6

BLOWER

MOTOR

33

27

7

COOLING

39

RELAY

E-SAFE

18

3

FAN

48

23-27

17

7

WHITE

M

BLACK

POWER SWITCH

FUSE

5 AMP

9

6

8

5

B

7

A

4

RELAY

HI-LIMIT

4

6

5

2

1

CAPACITOR

37

6

56

11

39

44

45

TRANSFORMER

12

11

8

7

34

BLOCK

TERMINAL

57

46

BLOCK

TERMINAL

1

38

2

DOOR

SENSOR

SW.

33

1K OHMS

RESISTOR

GROUND

36

56

P/N 307322REV.(-)

L3 L2 L1 N

1.0

N

11.7

L3

50/60HZ

L2

11.7

AMPS 3PHASE

L1

11.7

240

VOLTS

M903 2M-307323 Owners Manual M4200/M4200EU

27

GROUND

N

TERMINAL

BLOCK

L1

L2

L3

SINGLE PHASE

WIRING ILLUSTRATION

44

45

35

46

10

47

49

3

2

1

42

38

43

3

9

GRN/YEL

MOTOR RUN

32

11

CONTROLLER

NCC

TIME /TEMPERATURE

23-27

23-27

34

Page 37

NOTES

M903 2M-307323 Owners Manual M4200/M4200EU

35

Page 38

NOTES

36

M903 2M-307323 Owners Manual M4200/M4200EU

Page 39

PARTS & SERVICE

DESCRIPTION PART NO.

CASTER SET, OVEN (set of 4) WS-21330

OVEN STACKING & VENTING KIT WS-21342

CASTER, SWIVEL (set of 2) WS-21372

CASTER, LOCKING (set of 2) WS-21373

OVEN RACK, REPLACEMENT (ea.) WS-21376

PREP TOP WS-21445

WALL SPACER KIT DD-21717

LEG, OVEN, S/S (4 NEEDED) 2A-45598

VENTING KIT, SINGLE OVEN WS-505504

IMPORTANT: Use only

factory authorized service

parts and replacement

filters.

For factory authorized

service, or to order factory

authorized replacement parts,

contact your Wells authorized

service agency, or call:

Wells Bloomfield, LLC

2 Erik Circle

P. O. Box 280

Verdi, NV 89439

Service Parts Dept.

phone: (775) 689-5707

fax: (775) 689-5976

Service Parts Department can

supply you with the name and

telephone number of the

WELLS AUTHORIZED

SERVICE AGENCY

nearest you.

CUSTOMER SERVICE DATA

RESTAURANT _____________________________ LOCATION _____________

INSTALLATION DATE ________________________ TECHNICIAN ___________

SERVICE COMPANY ________________________________________________

ADDRESS ___________________________ STATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. _______________

EQUIPMENT SERIAL NO. _______________

M903 2M-307323 Owners Manual M4200/M4200EU

VOLTAGE: (check one) 208V 240V 380-415V 3NAC

please have this information available if calling for service

37

Page 40

Genuine Parts

Protect - YOU - All - Ways

SERVICE TRAINING - QUALITY SERVICE

CUSTOMER SATISFACTION

Commercial Food Equipment Service Association

Wells Bloomfield proudly supports CFESA

Commercial Food Equipment Service Association

SERVICE TRAINING - QUALITY SERVICE

CUSTOMER SATISFACTION

PREPARED FOR

BY

WELLS BLOOMFIELD, LLC

10 Sunnen Drive P.O.Box 430195

St. Louis, MO 63143 USA

telephone: 314-781-2777

fax: 314-781-2714

www.wellsbloomfield.com

PRINTED IN UNITED STATES OF AMERICA

Loading...

Loading...