Page 1

STAR HOLDINGS INTERNATIONAL INC.

IL3110

10 Sunnen Dr., St. Louis, MO 63143

telephone: 314-678-6303

OWNERS MANUAL

15lb COUNTERTOP

ELECTRIC FRYER

F15

MODEL

Includes

INSTALLATION

USE & CARE

EXPLODED VIEW

PARTS LIST

WIRING DIAGRAM

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your dealer if you have any questions

concerning installation, operation or maintenance of this equipment.

p/n 2M-Z21031 Rev. - 160120

Page 2

LIMITED WARRANTY STATEMENT

Unless otherwise specied, all commercial cooking

equipment manufactured by Wells Manufacturing is

warranted against defects in materials and workmanship

for a period of one year from the date of original installation

or 18 months from the date of shipment from our factory,

whichever comes rst, and is for the benet of the original

purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW

OR IN FACT, INCLUDING BUT NOT LIMITED TO,

WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE, AND/OR FOR

DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES

IN CONNECTION WITH WELLS MANUFACTURING

PRODUCTS. This warranty is void if it is determined

that, upon inspection by an authorized service agency,

the equipment has been modied, misused, misapplied,

improperly installed, or damaged in transit or by re, ood or

act of God. It also does not apply if the serial nameplate has

been removed, or if service is performed by unauthorized

personnel. The prices charged by Wells Manufacturing for

its products are based upon the limitations in this warranty.

Seller’s obligation under this warranty is limited to the

repair of defects without charge by a Wells Manufacturing

factory authorized service agency or one of its sub-service

agencies. This service will be provided on customer’s

premises for non-portable models. Portable models (a

device with a cord and plug) must be taken or shipped

to the closest authorized service agency, transportation

charges prepaid, for service. In addition to restrictions

contained in this warranty, specic limitations are shown

in the Service Policy and Procedure Guide. Wells

Manufacturing authorized service agencies are located in

principal cities. This warranty is valid in the United States

and Canada and void elsewhere. Please consult your

classied telephone directory, your foodservice equipment

dealer or contact:

Wells Manufacturing

10 Sunnen Dr., St. Louis MO 63143 USA

phone (314) 678-6314 or fax (314) 781-2714

SERVICE POLICY AND PROCEDURE GUIDE and ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specied on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

cleaning schedules, are customer responsibility.

Those miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted

for ninety (90) days from date of purchase on non-

warranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment

in this shipment was carefully inspected and packaged

by skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and le

“CONCEALED DAMAGE” claim with them. This

should be done within fteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Manufacturing cannot assume liability for damage or

loss incurred in transit. We will, however, at your request,

supply you with the necessary documents to support your

claim.

xi

Page 3

TABLE OF CONTENTS

WARRANTY xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

INSTALLATION 4

OPERATION 5, 6

CAUTIONS FOR ALL DEEP FAT FRYERS 7

CARE OF FAT 8

HANDY FRYING CHART 9

EXPLODED VIEW & PARTS LIST 10 12

WIRING DIAGRAM 13

INTRODUCTION

Proper installation, professional operation and consistent maintenance of this appliance will ensure that

it gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install this appliance, and to use and care for

the appliance in a manner which will ensure its optimum performance.

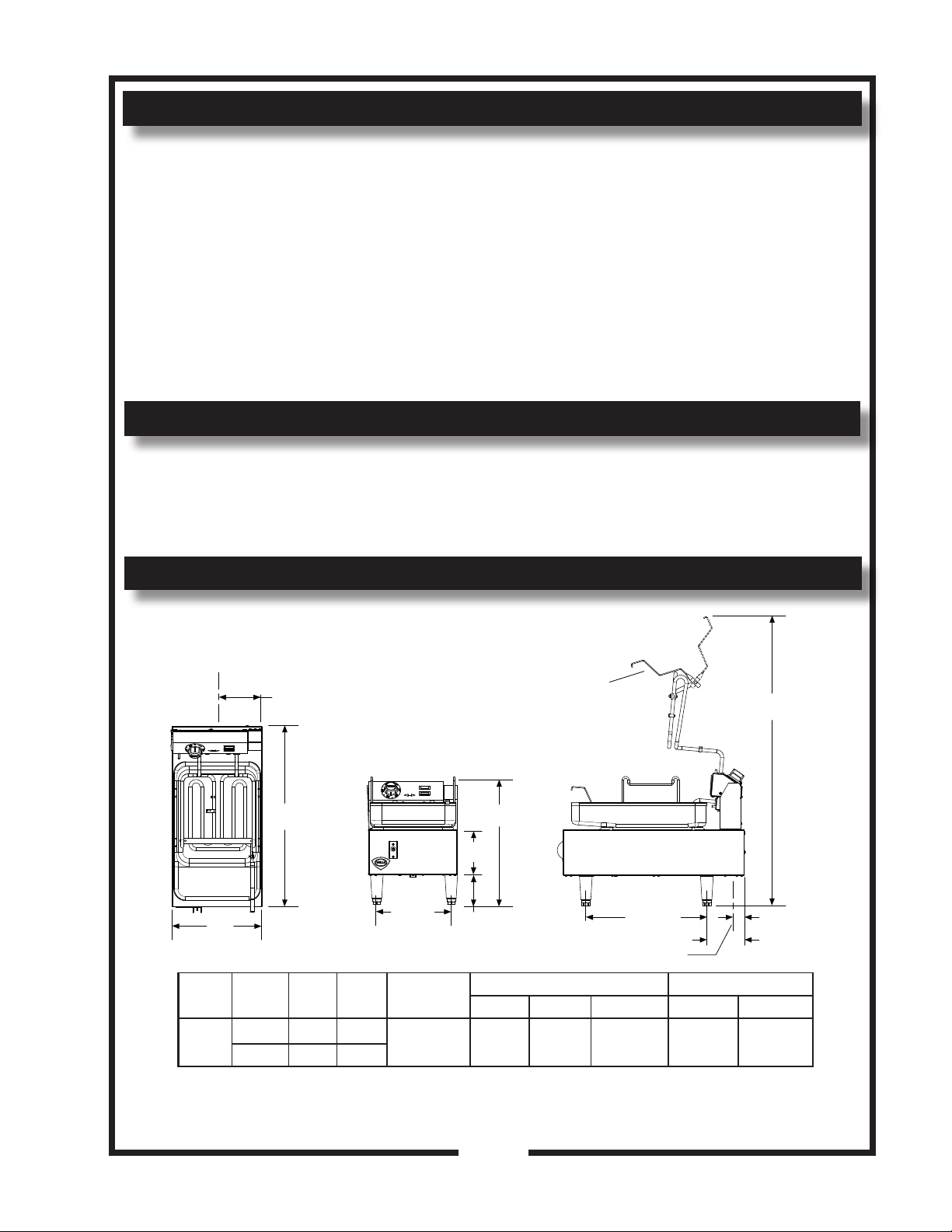

CENTERLINE OF

CONDUIT CONNECTION

6” (15.2 CM)

24”

(60.9 CM)

12”

(30.5 CM)

Model Voltage Watts Amps

2M-Z21031 Owners Manual for Countertop 15LB Electronic Fryer

F15

208V 4.3 20.8

(24.7 CM)

Power Suppy

NEMA 6-30P

240V 5.8 24.0

SPECIFICATIONS

ELEMENT HANDEL

SWINGS DOWN FOR

EXTRA CLEARANCE

16 3/4”

(42.5 CM)

6”

(15.2 CM)

9 3/4”

Cord

4”

(10.1 CM)

Width Depth Height Installed Shipped

12”

(30.5 cm)

36 11/32”

(97.3 CM) ref.

2” (5.1 CM)16” (40.6 CM)

CENTERLINE OF

CONDUIT CONNECTION

5” (12.7 CM)

Dimensions Approximate Weight

24”

(61 cm)

16.75”

(42.5 cm)

38 lbs

(21.3 kg)

47 lbs

(20.9 kg)

IL3105

1

Page 4

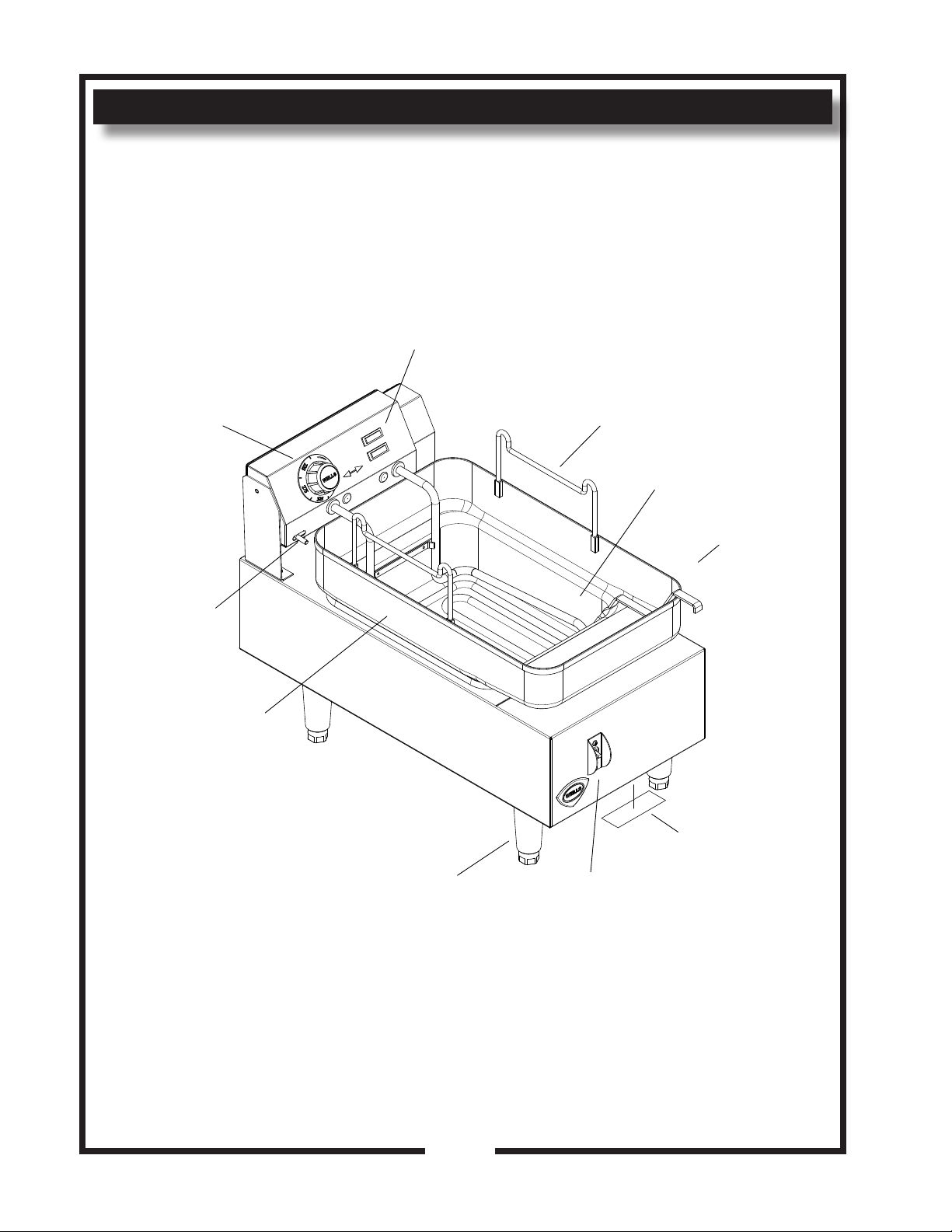

FEATURES & OPERATING CONTROLS

(not shown, on back)

Hi- Limit

Temperature

Adjustment

Fryer Head

Latch

15lb Kettle

Power & Heating

Indicators

Basket

Hanging Brackets

Element

Fryer Head

Lifting Handle

4” Adjustable Legs

On / Off

Switch

Fig. 1 Countertop Electric Fryer (shown with the fryer head in the down position)

2

Nameplate

IL3113

2M-Z21031 Owners Manual for Countertop 15LB Electronic Fryer

Page 5

PRECAUTIONS AND GENERAL INFORMATION

DANGER: BURN HAZARD

Contact with cooking grid surface will cause severe burns. Use the handle to lift the

grid. Avoid contact with grid surfaces.

WARNING: ELECTRIC SHOCK HAZARD

All servicing requiring access to non-insulated components must be performed by

qualied service personnel. DO NOT open any access panel that requires the use

of tools. Failure to heed this warning may result in severe electric shock.

This equipment is designed and sold for commercial use only by personnel

trained and experienced in its operation and is not sold for consumer use

in and around the home nor for use directly by the general public in food

service locations.

Before using your new equipment, read and understand all the instructions

& labels associated with the unit prior to putting it into operation. Make

sure all people associated with its use understand the units operation &

safety before they use the unit.

All shipping containers should be checked for freight damage both visible

and concealed. This unit has been tested and carefully packaged to

insure delivery of your unit in perfect condition. If equipment is received in

damaged condition, either apparent or concealed, a claim must be made

with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after

equipment is unpacked, a request for inspection of concealed damage

must be made with carrier within 15 days. Be certain to retain all contents

plus external and internal packaging materials for inspection. The carrier

will make an inspection and will supply necessary claim forms.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the safety

of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

DO NOT submerge this appliance in water. This appliance is not jet

stream approved. DO NOT direct water jet or steam jet at this appliance,

or at any control panel or wiring. DO NOT splash or pour water on, in or

over any controls, control panel or wiring.

Exposed surfaces of this appliance can be hot to the touch and may cause

burns.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment procedures,

is intended for use by qualied technical personnel. Any procedure which

requires the use of tools must be performed by a qualied technician.

This manual is considered to be a permanent part of the appliance.

2M-Z21031 Owners Manual for Countertop 15LB Electronic Fryer

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the appliance

if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance will result if

these instructions are not

followed.

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

3

Page 6

INSTALLATION

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance will result

if these instructions are not

followed.

WARNING:

Improper installation,

adjustment, alteration, service

or maintenance can cause

property damage, injury or

death. Read the installation,

operating and maintenance

instructions thoroughly before

installing or servicing the

equipment.

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all protective

plastic lm, packing materials and accessories from the appliance before

connecting performing any installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read and understand all labels and diagrams attached to the appliance.

Carefully account for all components and accessories before discarding

packing materials. Store all accessories in a convenient place for later

use.

ELECTRICAL INSTALLATION

This fryer is equipped for the voltage and wattage indicated on the

nameplate mounted on the bottom of the unit, just left of the power

switch. It is designed for use on alternating current (AC) only. It is

intended for use by properly trained personnel only.

DO NOT CONNECT TO DIRECT CURRENT (DC)

The installation of the appliance should conform to the:

NATIONAL ELECTRIC CODE AND ALL LOCAL ELECTRIC

CODES AND ORDINANCES AND THE LOCAL ELECTRIC

COMPANY RULES AND REGULATIONS

For your protection we recommend that a qualied electrician install

this appliance. He should be familiar with electrical installations and all

electrical codes. Proper connections and power supply are essential

for efcient performance. The external wiring should be in conduit or

an approved type of exible cable suitable for operation at 194°F (90°C)

and of a proper size to carry the load. The supply circuit should be

properly fused and equipped with a means of disconnection, as required

by local electrical code. THE BODY OF THE APPLIANCE SHOULD

BE GROUNDED - DO NOT GROUND TO A GAS SUPPLY LINE. Four

legs are provided and should be installed for ease of cleaning. DO NOT

INSTALL WITHOUT FEET PROVIDED. Level unit by adjusting the (4)

feet which have an adjustment of 1-3/8" (34.92 mm) for accurate leveling

and perfect line-up

with other units.

POWER SUPPLY

These models are wired at the factory for operation on a single phase

power supply. For specic wiring, check the wiring diagram.

2M-Z21031 Owners Manual for Countertop 15LB Electronic Fryer

4

Page 7

OPERATION

OPERATING INSTRUCTIONS

PLACE THE LAMINATED WARNING SIGN SUPPLIED

WITH THE FRYER IN AN AREA VISIBLE TO THE

FRYER OPERATOR.

CLEAN KETTLE BEFORE USING

Take out baskets, push and hold element catch, lift up on element lift

handle until elements lock in a vertical position, and remove kettle. The

kettle can be cleaned in a sink.

DO NOT use soap when cleaning the kettle, it will discolor the kettle.

ADDING FAT

Replace kettle and swing the element down, making fryer ready for use.

Add fat. The kettle has a 15 lb. fat capacity. A fat level line on the rear

of the kettle will guide you in determining the minimum cold fat level. A

higher fat level can be used when frying bulky foods, such as chicken or

sh cakes. The fat level should be chosen carefully so that the foaming

action of the fat does not spill out of the kettle. If solid shortening is used,

pack carefully around the elements.

CONTROLS

1. ON/OFF TWO-POLE SWITCH - Located on the front panel is a twopole switch which turns power on or off. An indicator light

(Power On) is located on the control housing.

2. THERMOSTAT CONTROL - Located on the Control Housing, this

control allows you to select the desired frying temperature. A signal

light "Heating" indicates when the element is on. When the light goes

off, the desired temperature has been reached.

3. HI-LIMIT THERMOSTAT - Should fat temperatures reach 450° F

(230° C), this control will shut off the power to the heating elements.

The unit will still have power. The fat temperature must cool to

400° F (202.4° C) and the manual reset button located on the back

panel of the control housing must be pressed to restore operation.

Should the hi-limit control activate twice in succession, the primary

thermostat should be checked for malfunction by a qualied service

technician.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance will result if

these instructions are not

followed.

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

2M-Z21031 Owners Manual for Countertop 15LB Electronic Fryer

5

Page 8

OPERATION continued

CAUTION:

HOT SURFACE

DO NOT ATTEMPT TO

REMOVE THE KETTLE

FILLED WITH HOT OIL.

CONTACTING HOT OIL

CAN RESULT IN SEVERE

INJURIES OR DEATH

FRYING

After fat has been added, turn the switch on and set the thermostat at

200°F (92.4° C). After the fat has melted, turn the thermostat to the

desired setting. Included in this instruction booklet is a frying chart

and some helpful hints on fat use. After the selected fat temperature

has been reached, slowly lower half lled baskets into the fat. Do not

overload baskets as this causes foods to be improperly fried.

NOTE: Baskets should be allowed to drain after frying cycle.

The kettle handles serve as basket hangers.

IDLING

During idle periods turn thermostat control to approximately

200° F (92.4° C). The fast recovery fryers can be brought up to frying

temperature in a matter of minutes. Lowering the temperature during

idle periods saves energy costs and prolongs fat life.

DRAINING KETTLE

Turn switch to "OFF". Raise element to the rst stop and allow to drain.

Raise the element to the vertical position and siphon the oil out of the

kettle. Once drained, the kettle can be washed out with warm water and

wiped dry before returning it to the unit..

DO NOT use soap when cleaning the kettle, it will discolor the kettle.

If kettle needs further cleaning, contact your dealer for product specic

to cleaning fryer kettles. Follow the directions provided with that specic

cleaner.

CAUTION

DO NOT ATTEMPT TO REMOVE THE KETTLE FILLED

WITH HOT OIL. CONTACTING HOT OIL CAN RESULT IN

SEVERE INJURIES OR DEATH.

If you do not have a siphon, order one from your dealer or dip the oil

out and strain into a container. After oil has been removed, remove the

kettle and clean.

INAPPROPRIATE USE DUE TO A LACK OF COMMON

SENSE MAY RESULT IN PRODUCT DAMAGE OR

PERSONAL INJURY.

CLEANING THE EXTERIOR

The exterior surfaces can be cleaned by regularly wiping with a soft

cloth. Any discoloration can be removed with a non-abrasive cleaner.

2M-Z21031 Owners Manual for Countertop 15LB Electronic Fryer

6

Page 9

CAUTIONS FOR ALL DEEP FAT FRYERS

• Have your equipment checked regularly to

NEVER LEAVE AN OPERATING FRYER UNATTENDED

REMEMBER HOT OIL IS DANGEROUS –

WARNING – INSTALLATION

• Locate your fryer in a protected place so

that it cannot be tipped over or knocked

off its support. A mechanical restraint

should be installed to prohibit the fryer

from tipping or moving. Consult your local

codes for allowable methods of restraint.

• Install an automatic re extinguisher over

the fryer and in the exhaust duct.

• Be sure your power supply is installed

properly and in accordance with the local

and national codes.

• Install a shut-off switch or gas valve close

to the fryer. It must turn off the fryer

immediately.

• Failure to add a mechanical restraint can

result in oil splashing out and contacting

the skin, leading to serious injury or death!

WARNING – HOT OIL

• Hot oil is dangerous – Severe burns can

result when hot oil contacts the skin.

• Hot oil is ammable – Keep open ames

away from hot oil and its vapors.

RESPECT IT!

WARNING – MAINTENANCE

insure its safe and properly functioning.

• If your fryer starts to smoke or boil

abnormally, cut off the power supply

immediately and determine the reason for

the smoking or boiling before attempting

to use it again.

WARNING – TRAINING

• Train all personnel to understand the

hazards of hot oil. Instruct them on the

proper action to take if something does

not seem to be acting properly.

• Instruct your personnel on what to do if

there is an oil re. Do not use water on

an oil re! Use only re extinguishers of

the approved type and never direct such

extinguishers so as to blow the oil out of

the oil container.

• Inappropriate use due to a lack of

common sense may result in product

damage or personal injury.

• Never allow water or ice to get in hot oil.

IT CAN EXPLODE!

WARNING - ENVIRONMENT

• Keep your oors clean and free of grease

and all other substances so no one slips

accidentally and contacts the hot fryer.

2M-Z21031 Owners Manual for Countertop 15LB Electronic Fryer

• Keep areas and lters clean above your

fryers – Oil soiled lint or dust can ignite

easily and ames will spread rapidly.

7

Page 10

CARE OF FAT

In three to six months you may spend as much for fat

as you paid for your kettle. So fat is an item you want

to know all about; how to select it; how to manage it.

The more production you can get from each pound of

fat, the more protable your frying operation will be.

To get a high rate of production per pound of fat you

have to avoid two things. One is early breakdown and

spoilage of the compound so that you have to throw

it away before it does enough work to "earn its keep."

The other is excessive sponging up of fat by the food

being fried.

10 POINT PROGRAM TO PRESERVE

FAT AND PRODUCE THE FINEST FRIED

FOODS

1. Choose a fat that does not break down quickly.

Hydrogenated shortening, corn, and peanut

oils are less likely to break down under high

temperatures.

2. Do not fry foods at temperatures above those

recommended. The higher the fat temperature,

the more rapid the rate of fat deterioration.

Above 400°F fats quickly deteriorate.

The main cause of fat breakdown is excessive heat.

On the other hand abnormal absorption is caused by

frying too long at too low temperatures. One answer

to both problems is exact control of heat — so that fat

neither smokes up nor soaks up.

Of course, no fat "keeps" forever. Not only heat,

but air and moisture, salt particles and crumbs of

food work to break it down. But you can slow up fat

deterioration by maintaining proper temperatures and

by draining your kettle, ltering or straining the fat

once or twice a day and by keeping the kettle itself

absolutely clean.

A number of commercial devices and materials are

available to aid in eliminating fat impurities. There are

several excellent models of pressure lters as well

as strainer-type lters, which, if used regularly, will

prolong life of fat.

However, no purication device will renew broken

down or rancid fat or put new life into it. Once you

have allowed fat to break down it becomes unsuitable

for frying — in fact browning is impossible.

3. During short intervals between frying, turn

the heat down. Do not keep heat on for long

periods between batches.

4. Keep fat clean. Strain or lter daily or at end of

each shift. Add at least 15% fresh fat to your

kettle daily.

5. At least once a day, cool a small amount of fat

and taste it to see if it has picked up foreign

avors.

6. Discard fat that tends to bubble excessively

before food is added.

7. Do not overload baskets-pieces should not

touch when frying. Shake baskets to prevent

food from sticking together. Fry similar sizes

together.

8. Never salt foods directly over fat, salt in fat

reduces its life.

In addition to ltration, you can prolong the usefulness

of fat by sweetening it with fresh compound every day

- replacing about 15% of the bulk you started with. If

you do enough frying so that normal absorption of fat

in food amounts to 15% to 20% of the capacity of your

kettle every day - then you can call that your turn-over

food. It means you can add the recommended 15% of

fresh fat without discarding any of the old.

8

9. Raw, wet foods, such as potatoes and oysters,

should be drained or wiped dry before frying to

extend the life of the frying fat. Have foods to

be fried at room temperature.

10. Keep fat temperatures below smoking point to

minimize frying odors.

2M-Z21031 Owners Manual for Countertop 15LB Electronic Fryer

Page 11

HANDY FRYING CHART

FOOD COATING PROCEDURE TEMP MINUTES

POTATOES

Standard French Fries Cut in uniform pieces 1/2” 350° 5-7

Blanch Only square the long way 350° 3-1/2

Brown Only 350° 3-1/2

Long Branch Cut in uniform pieces 3/4” square the long way 350° 7-10

Julienne (shoe string) Cut in uniform pieces 1/8” to 1/4” square the long way 350° 3-6

Chips Soak in cold running water until water does not run milky 350° 2-3

CHICKEN

Large Pieces Batter or Some prefer rolling in 325° 9-1l

Small Pieces Breading seasoned our, dipping in egg 340° 7-10

Pre-cooked wash, and frying 350° 3-4

FISH

Fillets (Large) Breading Select llets of uniform 350° 4

Fillets (Small) or Batter size, skin out and dry. 350° 3

Oysters

Clams Batter 350° 1

Scallops Breading 350° 4

Shrimp Batter Some prefer soaking 1/2 hour in cold seasoned milk 350° 3

Smelts Breading Cut spinal cord several 350° 4

Chicken Fried Steak Breading

Cutlets Breading 350° 3-4

Chops Breading 340° 3-4

Meat Balls

Brains Breading 340° 3-5

Asparagus Batter or crumbs Pre-cook in salted water 350° 3

Cauliower Batter or crumbs Pre-cook and separate owers 350° 3

Egg Plant Crumb Breading Peel, cut cross-wise into 1/4” slices 350° 3

Onions Light batter Slice thin, soak in milk for two hours 350° 3

Fruit (bananas, pineapples,

apricots, berries)

Corn Batter Serve with syrup or jelly 350° 3-5

Vegetable (peas, green

beans)

Croquettes Breading 360° 3

Chinese Noodles 375° 1-2

French Toast 375° 1

2M-Z21031 Owners Manual for Countertop 15LB Electronic Fryer

Cake 375° 1-1/2 - 2

Yeast, raised 375° 1

Breading Use Oyster liquor in batter 350° 5

or Batter or breading 350° 5

MEATS

Sever all connecting membranes at one inch intervals to

prevent curling

Breading or rolled

in our

360° 3-4

340° 4-6

VEGETABLES

FRITTERS

Serve with fruit juice 350° 3-5

Serve with tomato cheese sauce 350° 5-8

MISCELLANEOUS

DOUGHNUTS

9

Page 12

Loading...

Loading...