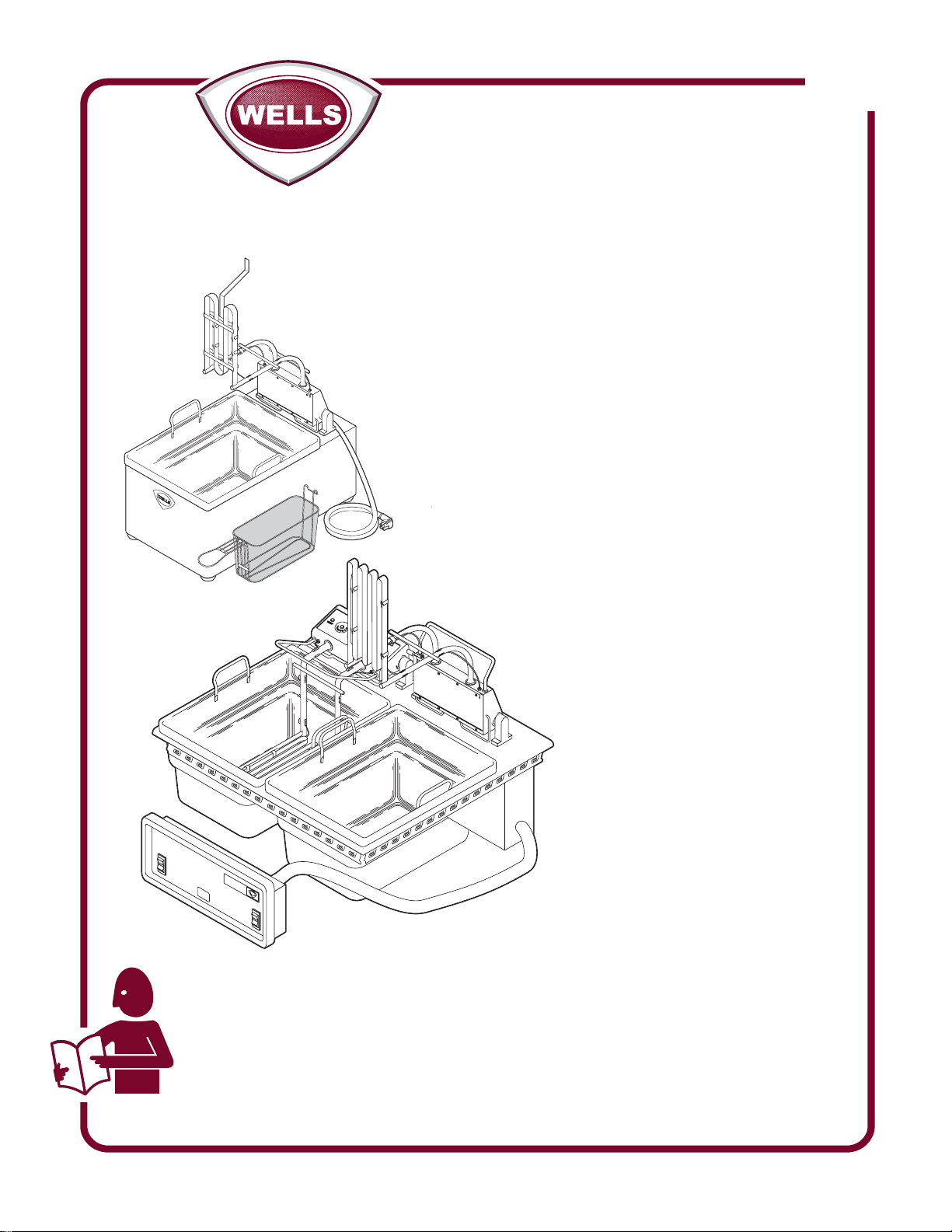

Page 1

WELLS BLOOMFIELD, LLC

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

telephone: 775-689-5703

fax: 775-689-5976

www.wellsbloomfield.com

SUPPLEMENTAL

SERVICE

INSTRUCTIONS

for

STANDARD

FRYERS

Models

301

F-14 (LLF-14)

F-49

F-55, F-556

F-67, F-676

F-85, F-856

IMPORTANT: WELLS BLOOMFIELD PROPRIETARY INFORMATION.

DISSEMINATION OF THIS INFORMATION TO ANYONE OTHER THAN

WELLS AUTHORIZED SERVICE AGENTS IS STRICTLY PROHIBITED.

TECHNICAL CONTENT OF THIS MANUAL IS DESIGNED FOR

USE BY QUALIFIED PROFESSIONAL TECHNICIANS ONLY.

PRINTED IN UNITED STATES OF AMERICA

SV301 (new) Rev. (-) S301 080326 cps

Page 2

GENERAL

PRECAUTIONS AND GENERAL INFORMATION

WARNING:

RISK OF

Installation procedures must

be performed by a qualified

technician with full knowledge

of all applicable electrical and

plumbing codes. Failure can

result in personal injury and

property damage.

PERSONAL INJURY

WARNING:

ELECTRIC

All servicing requiring

access to non-insulated

electrical components must

be performed by a qualified

technician.

Only qualified technicians are

authorized to open any

access panel which requires

the use of tools. Failure to

follow this warning can result

in severe electrical shock.

SHOCK HAZARD

WARNING:

SEVERE BURN

HAZARD

Cooking oil is very hot and

can cause severe injury.

Avoid contact with hot oil.

Avoid spilling or splashing or

splattering hot oil.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or

energize this appliance until

all installation instructions are

read and followed. Damage

to the appliance will result if

these instructions are not

followed.

This manual is considered to be Wells Bloomfield, LLC proprietary

information. Dissemination of this information to anyone other than

Wells Bloomfield authorized service agents is strictly prohibited.

Technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualified professional technicians

only.

This appliance is intended for use in commercial establishments

only.

This appliance is intended

No other use is

agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

DO NOT submerge this appliance in water. Do not splash or pour

water on, in or over any controls, control panel or wiring.

Never use a wire brush or metal scraper on aluminum components.

Use bristle or fiber brush to clean pivots and other cast components.

Any procedure which requires the use of tools must be performed by a

qualified technician.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware. Any conversion to

metric measurements are approximate and may vary.

Information in this manual reflects current production models as of

January 1, 2008. Specifications, model numbers, product numbers

and data subject to change without notice.

recommended or authorized by the manufacturer or its

to prepare food for human consumption.

SV301 Service Manual Standard Fryers

xi

Page 3

TABLE OF CONTENTS

Precautions & General Information …………………………… xi

General Information

Frypot Boil-Out ................................................................. 2

Disposing of Used Oil ....................................................... 3

Replacing Heating Elements ............................................ 4

Replacing Thermostats .................................................... 5

Replacing Fryhead Support Rod Spring .......................... 6

ID Chart - Thermostats & Knobs ..................................... 7

F-14 ....................................................................................... 8

F-49 ....................................................................................... 12

F-55, F-556 ........................................................................... 14

F-67, F-676 ............................................................................ 18

F-85, F-856 ............................................................................ 22

GENERAL

INTRODUCTION

This manual contains information needed to properly service and repair Wells standard fryers.

This manual applies to the following Wells Bloomfield models manufactured after Jan. 1, 2008:

F-14

F-49

F-55, F-556

F-67, F-676

F-85, F-856

SV301 Service Manual Standard Fryers

For units built after Jan. 1, 2008:

For installation, operation and maintenance instructions of countertop fryers, refer to Operation Manual

p/n 307588.

For, installation, operation and maintenance instructions of built-in fryers, refer to Operation Manual

p/n 307589.

For units built prior to Jan. 1, 2008:

For installation, operation and maintenance instructions of countertop fryers F-49, F-55ST D an d F-67,

refer to Operation Manual p/n 304355.

For installation, operation and maintenance instructions of countertop fryer LLF-14, refer to Operation

Manual p/n 45779.

For installation, operation and maintenance instructions of countertop fryers with safety test system,

F-55STS,and F-85 (including obsolete model F-101) refer to Operation Manual p/n 304356

For installation, operation and maintenance instructions of built-in fryers F-55STD and F-676, refer to

Operation Manual p/n 304359.

For installation, operation and maintenance instructions of built-in fryers with safety test system,

F-556STS, F-856, (including model F-1016) refer to Operation Manual p/n 304360.

1

Page 4

PERIODIC CLEANING

GENERAL

CAUTION:

BURN HAZARD

Be sure frypot and

elements are dry before

returning unit to service.

Water left in the frypot will

boil off when heating,

splattering hot oil.

CAUTION:

BURN HAZARD

Before cleaning, ALWAYS:

• Unplug the fryer and

allow to cool.

• Drain the oil and wipe

out the frypot.

Periodic cleaning is

necessary to remove

carbonization from the

elements and frypot.

Frypot may be cleaned by

the method described at

right, or with a commercial

frypot cleaner. Be sure to

follow the manufacturer's

directions.

PERIODIC CLEANING

Add 1/2 cup of granulated dishwasher detergent to frypot. Fill with water

to the MAX OIL line.

Lower the element into the frypot and set the control knob to 225ºF

Boil the mixture for five minutes. Turn the control knob to OFF. Allow the

mixture to set in the frypot overnight.

After the soak period, raise the elements and remove any remaining

carbonization with a stiff bristle brush. Be careful that the capillary tubes

of the thermobulbs are not moved or damaged during cleaning.

Drain the frypot and wash with warm water and mild detergent.

Reinstall the frypot in the fryer. Add 1 quart of vinegar, then fill to the MAX

OIL line with cold water.

Lower the elements into the vinegar solution. Allow to set for 15 minutes.

Drain the frypot and rinse with clean water. Dry the frypot and elements

thoroughly before returning the fryer to operation.

IMPORTANT:

Nickel plated frypot must be dried completely in order to prevent rusting,

and to eliminate water contamination of the cooking oil.

2

SV301 Service Manual Standard Fryers

Page 5

DISPOSAL OF USED OIL

DANGER: BURN HAZARD

Contact with hot oil will cause severe burns. Allow the fryer to cool before cleaning.

Always wear protective clothing and heat resistant gloves when handling hot oil.

PREPARATION Turn temperature control to OFF

Allow fryer to cool completely before draining

FREQUENCY Daily, or as needed

TOOLS Container for disposal of used oil.

OIL DISPOSAL

1. Turn temperature control to OFF.

2. Allow the oil to cool to a safe temperature (120ºF or 50ºC).

3. Raise the element head and lift the frypot out of the fryer by the

frypot handles.

4. Dispose of the used oil in an approved oil disposal receptacle, or

filter the oil for reuse.

5. Wipe the frypot and reinstall in the fryer.

Procedure is complete.

CAUTION:

BURN HAZARD

Allow fryer to cool completely

before draining.

CAUTION:

SLIP AND FALL

HAZARD

Clean up oil spills

immediately. Slipping in oil

can cause injury.

CAUTION:

HEALTH

Clean up oil spills

immediately. Oil provides an

environment for the growth of

bacteria, which presents a

health hazard.

HAZARD

GENERAL

SV301 Service Manual Standard Fryers

3

Page 6

REPLACE HEATING ELEMENT (all exc. F-14)

GENERAL

CAUTION:

BURN HAZARD

Allow fryer to cool before

performing this service.

CAUTION:

SHOCK HAZARD

Unplug fryer from electric

power before servicing.

IMPORTANT:

DO NOT damage the

capillary tubes. If the tubes

are pinched or kinked, they

are not repairable.

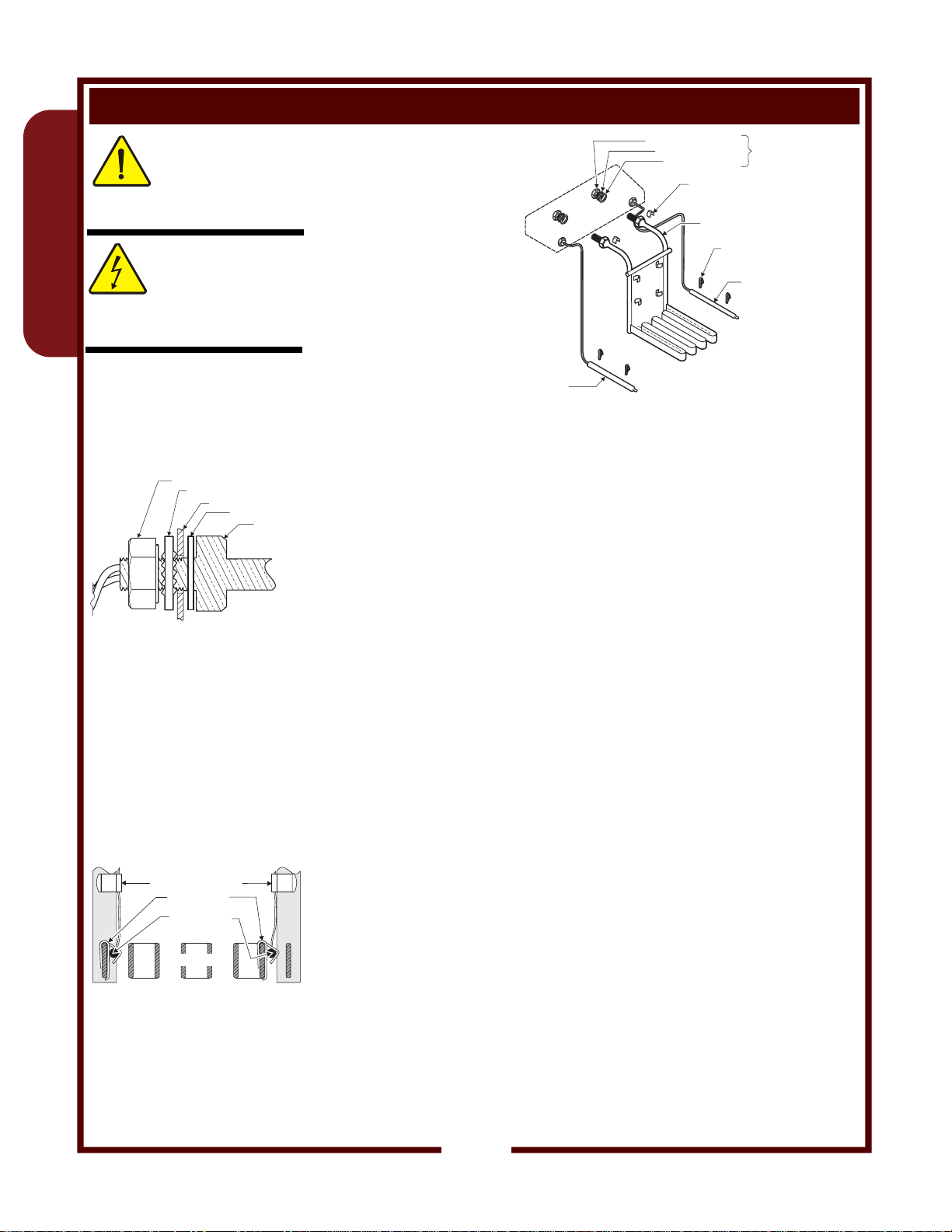

5/8-18 NUT

Element Attachment

IMPORTANT:

Be sure thermobulbs are

correctly seated in bulb clips.

These clips hold the bulbs

away from the element

surface. Failure to properly

position the clips will result in

the immediate failure of the

thermostat due to thermobulb

damage.

CAPILLARY CLIP

BULB CLIP

BULBS (ref)

ELEMENT

Cross-Section View of

Element and Thermobulbs

LOCK WASHER

CONTROL BOX

FIBER WASHER

ELEMENT

Element Assembly

5/8-18 NUT

LOCK WASHER

FIBER WASHER

CAPILLARY CLIP

6 places

ELEMENT

2 places

BULB CLIP

4 places

HI-LIMIT

BULB (ref)

TEMP

CONTROL

BULB (ref)

IMPORTANT: Unplug fryer and allow to cool before servicing.

A. REMOVE ELEMENT HEAD FROM FRYER

1. Remove two screws holding either element head pivot.

Remove pivot.

2. Lift element head assembly from fryer.

3. Remove bottom cover from control box.

B. DISCONNECT ELEMENT

1. Disconnect the wiring from the element terminals.

2. Note position of each thermobulb and the routing of the capillary

tubes. Remove bulbs from element by removing two bulb clips and

three capillary clips from each bulb.

3. Undo both holding nuts from terminal end of the element.

4. Withdraw the element from the control box.

C. INSTALL NEW ELEMENT

1. Wipe area around element openings in control box to remove any

grease or other cooking debris.

2. Slide one fiber washer over each end of the new element.

3. Insert element into the control box. Slide a lock washer over each

element, then thread on the holding nuts. Make sure the element

is square with the control box. Tighten holding nuts.

4. Reconnect wiring to the element terminals.

5. Reinstall the thermobulbs. Be sure a bulb clip is in place at each

end of the thermobulb.

NOTE: Control and HI-Limit thermobulbs may require different

bulb clips. Refer to parts list for proper component.

Snap a bulb clip over the element to secure the bulb. Carefully

route the capillary tube and secure with three capillary clips.

Repeat for both bulbs.

D. REINSTALL ELEMENT HEAD ON FRYER

1. For F-49, be sure the pivot washer is in place on the pivot brackets.

While holding the support rod in the forward position, slide the

element head assembly onto the fixed pivot. Reinstall the pivot

removed In step A.

Test fryer for proper operation and return to service.

SV301 Service Manual Standard Fryers

4

Page 7

REPLACE CONTROL OR HI-LIMIT THERMOSTAT (all exc. F-14)

REPLACE SPRING FOR FRYHEAD SUPPORT ROD

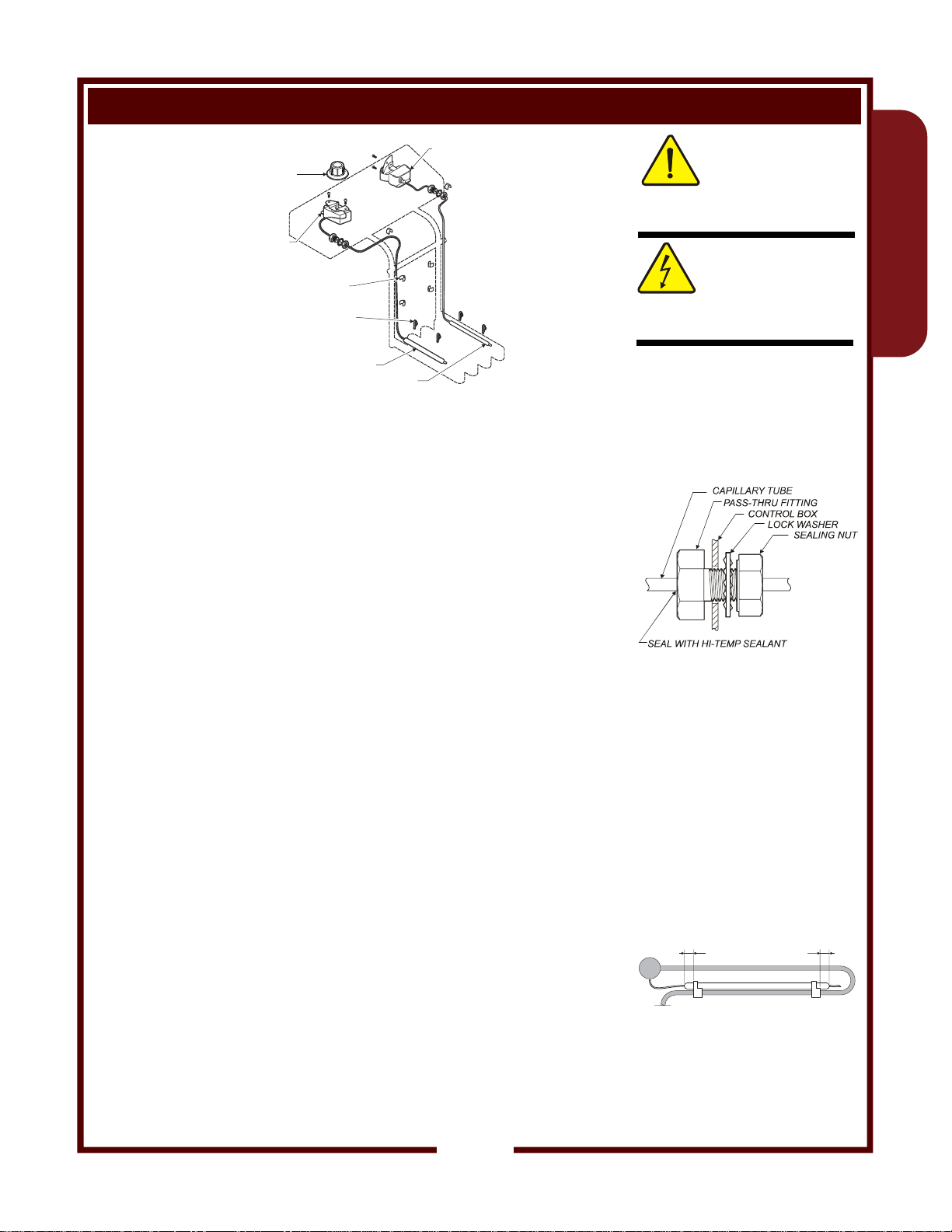

CONTROL

KNOB

HI-LIMIT

THERMOSTAT

Thermostat

Installation

TEMP

CONTROL

THERMOSTAT

CAPILLARY CLIP

6 places

TEMP CONTROL

THERMOSTAT BULB

BULB CLIP

4 places

HI-LIMIT THERMOBULB

Unplug fryer and allow to cool before servicing.

A. REMOVE ELEMENT HEAD FROM FRYER

Note: Some operations can be performed without removing the

fryhead. However, doing so will ease access to components and

fasteners.

1. Remove two screws holding either element head pivot.

Remove pivot.

2. Lift element head assembly from fryer.

3. Remove bottom cover from control box.

B. DISCONNECT THERMOSTAT

1. Remove the control knob if replacing the temperature control

thermostat.

2. Remove the two screws holding the thermostat to the control box.

3. Note the position of the wiring. Disconnect the wiring from the

thermostat terminals.

4. Note position of the thermobulb and the routing of the capillary

tube. Remove the bulb from the element by removing two bulb

clips and three capillary clips.

5. Undo the pass-thru fitting and withdraw the thermostat from the

control box.

SV301 Service Manual Standard Fryers

C. INSTALL NEW THERMOSTAT

1. Wipe area around pass-thru openings in control box to remove any

grease or other cooking debris.

2. Undo nut and lock washer from pass-thru fitting of the new

element. Insert the bulb from the inside of the control box.

3. Reconnect wiring to the thermostat terminals. Connect wiring then

attach the thermostat to the control box

4. Reinstall the thermobulbs. Slide two bulb clips over the bulb,

spacing the clips 3/8" from each end of the bulb. Snap the bulb

clips over the element, centering the bulb between element bends.

Carefully route the capillary tube and secure with three

capillary clips.

5. Carefully route capillary tube away from electrical terminals

inside of the control box. Tighten the pass-thru fitting then seal the

inside of the pass-thru fitting with hi-temp sealant.

D. REINSTALL ELEMENT HEAD ON FRYER (see page 4)

Test fryer for proper operation and return to service.

CAUTION:

BURN HAZARD

Allow fryer to cool before

performing this service.

CAUTION:

SHOCK HAZARD

Unplug fryer from electric

power before servicing.

IMPORTANT:

DO NOT damage the

capillary tubes. If the tubes

are pinched or kinked, they

are not repairable.

Capillary Tube Pass-Thru

Fitting

IMPORTANT:

Be sure bulb clips are

properly positioned on bulb,

and are clipped to element to

maintain the gap between

bulb and element. Failure to

properly position the rings will

result in the immediate failure

of the thermostat due to

thermobulb damage.

3/8"

Bulb Clip Spacing

3/8"

GENERAL

5

Page 8

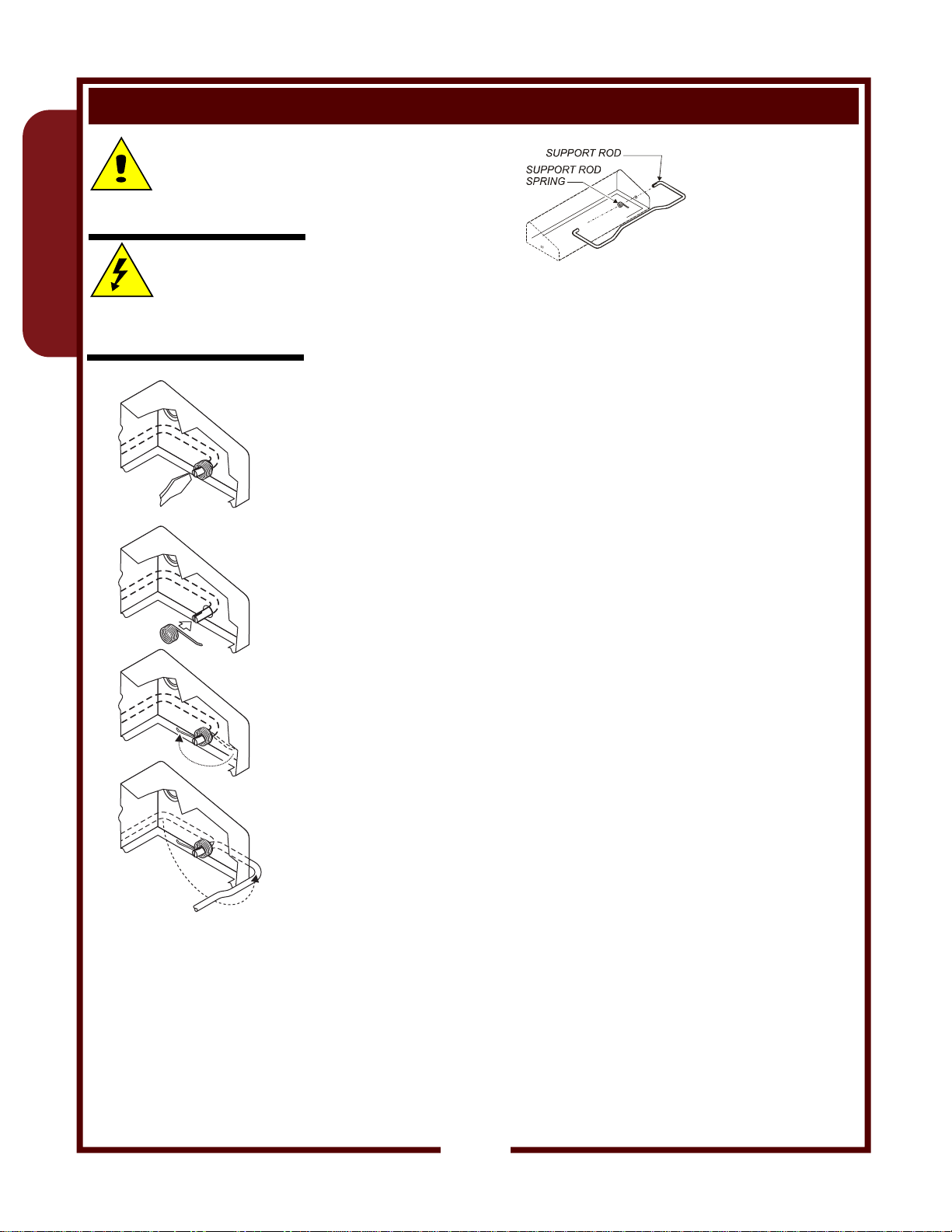

REPLACE SPRING FOR FRYHEAD SUPPORT ROD

GENERAL

Allow fryer to cool before

performing this service.

CAUTION:

BURN HAZARD

CAUTION:

SHOCK HAZARD

Disconnect fryer from electric

power before servicing.

Installation Sequence

Support Rod

Spring Installation

Unplug fryer and allow to cool before servicing.

A. REMOVE ELEMENT HEAD FROM FRYER

Note: Some operations can be performed without removing the

fryhead. However, doing so will ease access to components and

fasteners.

1. Remove two screws holding either element head pivot.

Remove pivot.

2. Lift element head assembly from fryer.

3. Remove bottom cover from control box.

B. REMOVE BROKEN SPRING

1. Using a flat blade screwdriver or other suitable tool, pry the split

end of the support rod to open the slot.

2. Remove and discard the broken spring parts.

C. INSTALL NEW SPRING

1. Position the support rod toward the back (power cord) side of

the control box, then slide the new spring over the split end of

the support rod.

Note orientation: Long leg of spring at the top and pointing

toward the front; short leg of spring in the slot.

2. Using pliers, squeeze the split end of the support rod to capture

the spring.

3. Tension the spring by swinging the long leg clockwise, and

allowing it to rest against the lip of the control box.

D. REINSTALL ELEMENT HEAD ON FRYER

1. For F-14 and F-49, be sure the pivot washer is in place on the pivot

brackets. While holding the support rod in the forward position,

slide the element head assembly onto the fixed pivot. Reinstall the

pivot removed In step A

Test fryer for proper operation and return to service.

6

SV301 Service Manual Standard Fryers

Page 9

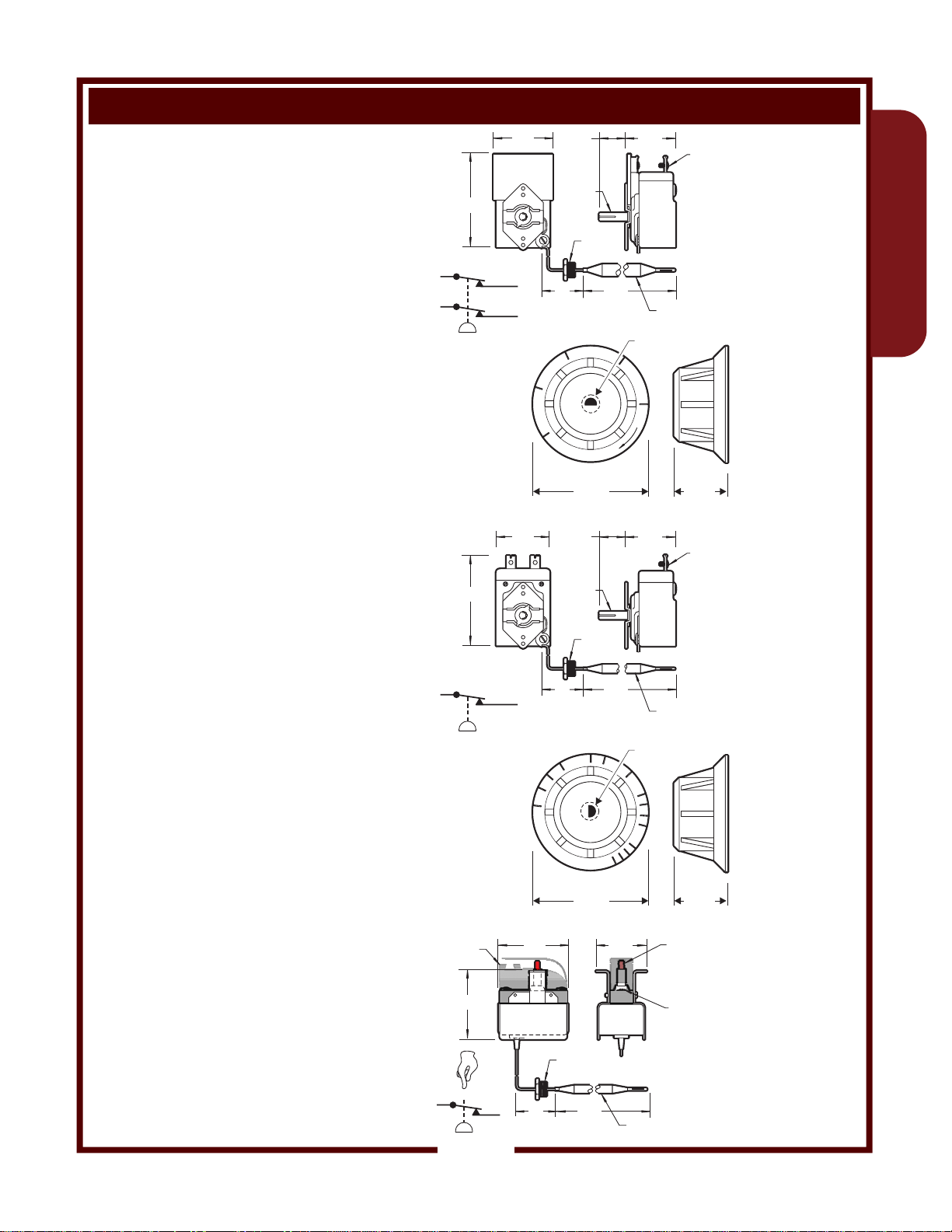

IDENTIFICATION CHART - THERMOSTATS AND CONTROL KNOBS

50133

THERMOSTATIC SWITCH

DPST - OPEN ON RISE

30AMP 240V

2.88

CAPILLARY & BULB

TEMP CONTROL

OFF - 200ºF TO 375ºF

F-14(LLF-14), F-49, F-55, F-67

COM1

COM2

T

54066

KNOB, TEMPERATURE CONTROL

THERMOSTAT

OFF (Bottom): 225ºF - 375ºF

Gray Plastic Knob / SS Skirt / Black Markings

Brushed Aluminum Center Insert

Fryer F-14( F-49, F-67LLF-14),

(WELLS)

55510

THERMOSTATIC SWITCH

SPST - OPEN ON RISE

30AMP 240V

CAPILLARY & BULB

TEMP CONTROL

OFF - 300ºF TO 375ºF

2.88

1.83

NC1

NC2

1.66

375

.25 DIA

SHAFT

20

325

WELLS

.25 DIA

SHAFT

.81

7/16-28

FERRULE

OFF

2.38”

.81

7/16-28

FERRULE

5.75

275

1.55

.38 DIA

BULB

8-32

SCREW

TERMINAL

(4 PLACES)

Æ.25” x .19”

225

1.13”

1.55

8-32

SCREW

TERMINAL

(2 PLACES)

GENERAL

F-55, F-85

COM1

T

SV301 Service Manual Standard Fryers

55511

KNOB, TEMPERATURE CONTROL

(WELLS)

THERMOSTAT

NC1

36

375

350

WELLS

8.50

.25 DIA

BULB

Æ.25” x .19”

325

OFF (Bottom): 300ºF - 375ºF

1.44

300

.25 DIA

BULB

1.13”

PUSH-BUTTON

RESET (RED)

8-32

SCREW

TERMINAL

(2 PLACES)

Gray Plastic Knob / SS Skirt / Black Markings

Brushed Aluminum Center Insert

Fryer F-55, F-85

FISH PAPER

58656

INSULATOR

THERMOSTATIC SWITCH

SPST - OPEN ON RISE

440ºF ±15ºF 30AMP 240V

2.13

CAPILLARY & BULB

HI-LIMIT SAFETY w/

MANUAL RESET

F-14(LLF-14), F-49, F-55,

F-67, F-85

RESET

COM1

T

NC1

2.16

24

OFF

2.38”

7/16-28

FERRULE

5.0

7

Page 10

COUNTERTOP FRYER F-14

Allow fryer to cool before

performing this service.

F-14

Unplug fryer from electric

power before servicing.

IMPORTANT:

DO NOT damage the

capillary tubes. If the tubes

are pinched or kinked, they

are not repairable.

F-14 Element Attachment

IMPORTANT (F-14):

Be sure wire rings are in

place on thermobulbs. Rings

must be positioned between

the bulb clips. Failure to

properly position the rings will

result in the immediate failure

of the thermostat due to

thermobulb damage.

Cross-Section View of F-14

Elements

CAUTION:

BURN HAZARD

CAUTION:

SHOCK HAZARD

REPLACE ELEMENT (F-14)

Element Assembly

(F-14)

IMPORTANT: Unplug fryer and allow to cool before servicing.

A. REMOVE ELEMENT HEAD FROM FRYER

1. Remove two screws holding either element head pivot.

Remove pivot.

2. Lift element head assembly from fryer.

3. Remove bottom cover from control box.

B. DISCONNECT ELEMENT

1. Remove the handle and clamps from the element.

2. Disconnect the wiring from the element terminals.

3. Note position of each thermobulb and the routing of the capillary

tubes. Remove bulbs from element by removing two bulb clips and

three capillary clips from each bulb.

4. Undo both holding nuts from terminal end of the element.

5. Withdraw the element from the control box.

C. INSTALL NEW ELEMENT

1. Wipe area around element openings in control box to remove any

grease or other cooking debris.

2. Slide one fiber washer over each end of the new element.

3. Insert element into the control box. Slide a lock washer over each

element , then thread on the holding nuts. Make sure the element

is square with the control box. Tighten holding nuts.

4. Reconnect wiring to the element terminals.

5. Reinstall the thermobulbs. Be sure the wire ring is intact and in

place at each end of the thermobulb. Snap a bulb clip over the

element and over each end of bulb to secure the bulb to the

element. The wire rings must be between the bulb clips. Carefully

route the capillary tube and secure with three capillary clips.

Repeat for both bulbs.

6. Reinstall handle and clamps.

D. REINSTALL ELEMENT HEAD ON FRYER

1. Be sure the pivot washer is in place on the pivot brackets.

While holding the support rod in the forward position, slide the

element head assembly onto the pivot. Reinstall the pivot

removed In step A.

Test fryer for proper operation and return to service.

SV301 Service Manual Standard Fryers

8

Page 11

COUNTERTOP FRYER F-14

REPLACE CONTROL OR HI-LIMIT THERMOSTAT (F-14)

Thermostat

Installation

Unplug fryer and allow to cool before servicing.

A. REMOVE ELEMENT HEAD FROM FRYER

1. Remove two screws holding either element head pivot.

Remove pivot.

2. Lift element head assembly from fryer.

3. Remove bottom cover from control box.

B. DISCONNECT THERMOSTAT

1. Remove the control knob if replacing the temperature control

thermostat.

2. Remove the two screws holding the thermostat to the control box.

3. Note the position of the wiring. Disconnect the wiring from the

thermostat terminals.

4. Note position of the thermobulb and the routing of the capillary

tube. Remove the bulb from the element by removing two bulb

clips and three capillary clips.

5. Undo the pass-thru fitting and withdraw the thermostat from the

control box.

C. INSTALL NEW THERMOSTAT

1. Wipe area around pass-thru openings in control box to remove any

SV301 Service Manual Standard Fryers

grease or other cooking debris.

2. Undo nut and lock washer from pass-thru fitting of the new

element. Insert the bulb from the inside of the control box.

3. Reconnect wiring to the thermostat terminals. Connect wiring then

attach the thermostat to the control box

4. Reinstall the thermobulbs. Be sure the wire spacing rings are

intact and in place at each end of the thermobulb. Snap a bulb clip

over the element and over each end of bulb to secure the bulb to

the element. The wire spacing rings must be between the bulb

clips. Carefully route the capillary tube and secure with three

capillary clips.

5. Carefully route capillary tube away from electrical terminals

inside of the control box. Tighten the pass-thru fitting then seal the

inside of the pass-thru fitting with hi-temp sealant.

D. REINSTALL ELEMENT HEAD ON FRYER (see page 8)

Test fryer for proper operation and return to service.

Allow fryer to cool before

performing this service.

CAUTION:

BURN HAZARD

CAUTION:

SHOCK HAZARD

Unplug fryer from electric

power before servicing.

IMPORTANT:

DO NOT damage the

capillary tubes. If the tubes

are pinched or kinked, they

are not repairable.

Capillary Tube Pass-Thru

Fitting

IMPORTANT:

Be sure wire rings are in

place on thermobulbs. Rings

must be positioned between

the bulb clips. Failure to

properly position the rings will

result in the immediate failure

of the thermostat due to

thermobulb damage.

F-14 Thermobulb Installation

F-14

9

Page 12

COUNTERTOP FRYER F-14

F-14

temp control

51157

red

54066

50516

amber

50133

65725

(120V)

shown

65729

(240V)

similar

65777

50792

65774

55747

53436

(pk 2)

58667

58656

hi-limit

58667

55736

(pk 10)

KEPS green

18-302

52428

52427

65777

55637

65061 (120V )

20141 (240V )

5-15P

6-30P

65788 (120V)

50789 (240V)

65783

kit: handle &

front clamp assy

65784

kit: rear clamp assy

21056

65767

55566

(pk 100)

65765

51053

(pk 100)

65728

(pk 4)

55028

53890

(pk 10)

20169

53848

SV301 Service Manual Standard Fryers

10

Page 13

POWER CORD

COUNTERTOP FRYER F-14

THERMOSTAT

HI-LIMIT

THERMO

SIGNAL

LITE

CONTROL

HEATING

ELEMENT

WIRE NUT

(50/60 HZ)

TEMP

LITE

VOLTS

120

208

240

RELAY

HI-LIMIT

THERMO

COIL

NO

C

FRYER F-14

AMPS

1 PHASE

15.0

16.3

18.8

WIRE NUT

F-14

L1

SV301 Service Manual Standard Fryers

HI-LIMIT

THERMO

T

CONTACT SET 1

TEMP CONTROL

WIRE NUT

LITE

TEMP

RELAY

HI-LIMIT

L2

CONTACT SET 2

TEMP CONTROL

TT

C

LITE

SIGNAL

HEATING

ELEMENT

WIRE NUT

WIRING DIAGRAM F-14 (LLF-14) p/n 307306

11

Page 14

COUNTERTOP FRYER F-49

50516

51157

58656

F-49

amber

red

hi-limit

62504

(pk 4)

54452

50176

50177

(pk 10) lock washer

50172

fiber washer

nut

50157

RESET

50157

52482

54066

50133

temp control

62891 (208V)

62892 (240V)

53436

53435

53890

(pk 10)

HEAD ASSY COMPLETE, F-49

62899 (208V)

62900 (240V)

63665

(pk 10)

20161

1/2 size

20162

full size

55566

(pk 100)

54323 51206

54206

20314 plastic

20563 metal

(pk 4)

55736

(pk 10)

KEPS green

52427

51208

51207

(pk 4)

20169

53848

SV301 Service Manual Standard Fryers

22728

50789

12

Page 15

POWER CORD

CONTROL

THERMOSTAT

COUNTERTOP FRYER F-49

RELAY

HI-LIMIT

THERMO

WIRE NUT

HI-LIMIT

THERMO

SIGNAL

L1

LITE

WIRE NUT

HEATING

ELEMENT

TEMP

LITE

FRYER F-49

VOLTS

(50/60 HZ)

208/240

208

COIL

C

208

240

NO

WIRE NUT

F-49

AMPS

1 PHASE

16.6

19.1

22.1

L2

SV301 Service Manual Standard Fryers

LITE

SIGNAL

RELAY

HI-LIMIT

LITE

TEMP

C

CONTACT SET 1

TEMP CONTROL

WIRE NUT

T

HI-LIMIT

THERMO

WIRE NUT

HEATING

ELEMENT

WIRE NUT

CONTACT SET 2

TEMP CONTROL

TT

WIRING DIAGRAM F-49 p/n 307298

13

Page 16

COUNTERTOP FRYER F-55

50516

51157

58656

hi-limit

62504

54452

F-55(6)

50176

amber

red

53068

(pk 4)

50177

(pk 10) lock washer

50172

50464

fiber washer

nut

50157

RESET

50157

52428

52427

55511

55510

temp control

62504

(pk 4)

62842 (208V)

62866 (240V)

53890

(pk 10)

52806

51717

(pk 40)

HEAD ASSY COMPLETE, F-55

62903 (208V)

62904 (240V)

20161

1/2 size

20162

full size

20169

50183

55028

55566

(pk 100)

20314 plastic

20563 metal

(pk 4)

22728

50789

51206

OPTIONAL

51208

51207

(pk 4)

51053

(pk 100)

53068

54005

55736

(pk 10)

KEPS green

50131

61974

53848

(pk 10)

SV301 Service Manual Standard Fryers

14

Page 17

BUILT-IN FRYER F-556

50516

amber

51157

red

58656

hi-limit safety

53068

50464

50176

54452

50177

lock washer

50172

fiber washer

(pk 10)

nut

62504

(pk 4)

RESET

50157

52428

52427

55511

55510

temp control

62842 (208V)

62866 (240V)

53890

62504

(pk 4)

(pk 10)

51717

52806

HEAD ASSY, COMPLETE, F-556

62903 (208V)

62904 (240V)

20161

20162

(pk 40)

1/2 size

full size

20169

F-55(6)

51208

51207

(pk 4)

50183

SV301 Service Manual Standard Fryers

55028

55566

(pk 100)

51206

55736

(pk 10)

green KEPS

53068

54005

50131

61974

(pk 10)

51053

(pk 100)

15

Page 18

COUNTERTOP FRYER F-55 and BUILT-IN FRYER F-556

F-55(6)

TERMINAL BLOCK

L2

L1

CONTROL

THERMOSTAT

HI-LIMIT

THERMO

SIGNAL

LITE

WIRE NUT

TERMINAL BLOCK

FLAME SENSOR

REMOVE JUMPER WHEN

EXTERNAL CONTROL USED

IMPORTANT:

DO NOT CONNECT ANY POWER TO

FLAME SENSOR TERMINAL BLOCK

RELAY

HI-LIMIT

THERMO

COIL

NO

C

WIRE NUT

TEMP

LITE

HEATING

ELEMENT

FRYER F-55 and F-556

VOLTS

(50/60 HZ)

208

240

WIRING DIAGRAM F-55 and F-556 p/n 307309

16

AMPS

1 PHASE

27.6

24.0

SV301 Service Manual Standard Fryers

Page 19

COUNTERTOP FRYER F-55 and BUILT-IN FRYER F-556

L1

LITE

TEMP

RELAY

HI-LIMIT

C

LITE

SIGNAL

L2

T

FLAME SENSOR JUMPER

OR EXTERNAL CONTROL

HI-LIMIT

THERMO

HEATING

CONTACT SET 2

TEMP CONTROL

TT

WIRE NUT

SV301 Service Manual Standard Fryers

ELEMENT

WIRE NUT

WIRING SCHEMATIC F-55 and F-556

CONTACT SET 1

TEMP CONTROL

F-55(6)

17

Page 20

COUNTERTOP FRYER F-67 and BUILT-IN FRYER F-676

HEAD ASSY COMPLETE

F-67(6)

NOTE: Unit has two identical

fryer heads. Only one is shown

50516

51157

50177

50176

amber

red

fibre washer

(pk 10 ) lock washer

50172

nut

62916 (240V)

54066

(208V)62915

50133

temp control

F-67(6)

58656

54452

hi-limit

62504

(pk 4)

50157

RESET

50157

62891 (208V)

62892 (240V)

52428

52427

51208

51207

(pk 4)

51206

63665

(pk 10)

54323

55566

(pk 100)

50183

53245

18

53895

53890

51717

52806

(pk 10)

(pk 40)

SV301 Service Manual Standard Fryers

Page 21

COUNTERTOP FRYER F-67 and BUILT-IN FRYER F-676

53068

F-67 CABINET

COMMON

COMPONENTS

20314

20563

plastic

metal(pk 4)

54005

50131

61947

(pk 10)

55736 (pk 10)

green KEPS

51053

53848

(pk 100)

20169

SV301 Service Manual Standard Fryers

20161 1/2 size

20162 full size

55736

green KEPS

(pk 10)

19

F-67(6)

53068

54005

50131

61974

(pk 10)

F-676 CABINET

Page 22

COUNTERTOP FRYER F-67 and BUILT-IN FRYER F-676

TERMINAL BLOCK

TERMINAL BLOCK

(3 PHASE)

L1 L1

L2 L2

L3 L3

1 1

1 1

2

2

CONTROL

THERMOSTAT

CONTROL

THERMOSTAT

RELAY

HI-LIMIT

HI-LIMIT

THERMO

WIRE

NUT

THERMO

COIL COIL

NO NO

CC

WIRE

NUT

HI-LIMIT

THERMO

WIRE

NUT

(1 PHASE)

RELAY

HI-LIMIT

THERMO

2

2

WIRE

NUT

F-67(6)

FRYER F-67 and F-676

VOLTS

(50/60 HZ)

208/240V

VOLTS

(50/60 HZ)

208/

240V

208

SIGNAL

208

240

208

AMPS 3 PHASE

L1 L2 L3

208

28.8

240

33.2

38.3

LITE

AMPS

1 PHASE

33.2

38.3

44.2

16.6

19.2

22.1

16.6

19.2

22.1

TEMP

LITE

HEATING

ELEMENT

SIGNAL

LITE

TEMP

LITE

HEATING

ELEMENT

WIRING DIAGRAM F-67 and F-676 p/n 307302

SV301 Service Manual Standard Fryers

20

Page 23

COUNTERTOP FRYER F-67 and BUILT-IN FRYER F-676

L1 L2 L3

LITE

SIGNAL

T

HI-LIMIT

THERMO

CONTACT SET 1

TEMP CONTROL

T

CONTACT SET 2

TEMP CONTROL

T

LITE

TEMP

HEATING

ELEMENT

RELAY

HI-LIMIT

C

WIRE NUT

WIRE NUT

LITE

SIGNAL

LITE

TEMP

RELAY

HI-LIMIT

C

T

SV301 Service Manual Standard Fryers

HI-LIMIT

THERMO

HEATING

CONTACT SET 2

TEMP CONTROL

T

WIRE NUT

ELEMENT

WIRE NUT

WIRING SCHEMATIC F-67 and F-676

CONTACT SET 1

TEMP CONTROL

T

FOR SINGLE PHASE

CONNECT TOL2

F-67(6)

21

Page 24

COUNTERTOP FRYER F-85 and BUILT-IN FRYER F-856

HEAD ASSY COMPLETE, F-85

NOTE: Unit has two identical

fryer heads. Only one is shown

62903

62904 (240V)

(208V)

50516

51157

red

58656

54452

50176

amber

hi-limit

50177

fibre washer

(pk 10 ) lock washer

50172

nut

50157

62504

(pk 4)

RESET

55511

55510

50157

62891 (208V)

62892 (240V)

52428

52427

temp control

51208

51207

62504

(pk 4)

(pk 4)

F-85(6)

54323

55566

(pk 100)

(typical)

50183

53245

53895

22

53890

(pk 10)

51717

(pk 40)

52806

51206

SV301 Service Manual Standard Fryers

Page 25

COUNTERTOP FRYER F-85 and BUILT-IN FRYER F-856

F-85 CABINET

51053

(pk 100)

57779 (208V)

57780 (240V)

20314

20563

F-856 CABINET

plastic

metal

(pk 4)

53068

54005

50131

55736

green KEPS

(pk 10)

55127

61974

(pk 10)

53848

20161

1/2 size

20162

full size

COMMON

COMPONENTS

53068

54005

SV301 Service Manual Standard Fryers

50131

61974

(pk 10)

51053

(pk 100)

20169

F-85(6)

57779(208V)

57780(240V)

51881

sleeve (requires 3')

53848

55127

23

Page 26

COUNTERTOP FRYER F-85 and BUILT-IN FRYER F-856

LEFT

HEATING

ELEMENT

TEMP LIGHT

(AMBER)

CONTROL

THERMOSTAT

13

CONTACTOR

C

14

HI-LIMIT

T'STAT

15

9

TROUBLE

LIGHT (RED)

20

C

50

21

19

16

17

CONTACTOR

18

RIGHT

HEATING

ELEMENT

TEMP LIGHT

(AMBER)

CONTROL

THERMOSTAT

2222 2323

1

CONTACTOR

C

5251

2

HI-LIMIT

T'STAT

3

TROUBLE

LIGHT (RED)

212121

20

CONTACTOR

C

1010 77

50

*REMOVE JUMPER WHEN

EXTERNAL CONTROL IS

USED.

IMPORTANT:

DO NOT CONNECT ANY

POWER TO FLAME

SENSOR TERMINAL

BLOCK!

FLAME SENSOR

25

TERMINAL BLOCK*

19

TERMINAL

26

BLOCK

L1

L2

L3

6

4

5

GROUND

1212 9

1111 88

F-85(6)

VOLTS

50/60 HZ

WIRING DIAGRAM F-85 p/n 307495

208

240

POWER

SWITCH

WITH

LIGHT

25

27

3 PHASE AMPS PER LEG

L1 L2 L3

31.9

31.9 31.9

27.6 27.6 27.6

1 PHASE

AMPS

47.9

19

13

27

5

15

14

18

1

SINGLE PHASE

CONFIGURATION

2

4

16

19

3

6

17

26

TERMINAL

BLOCK

GROUND

L1

L2

SV301 Service Manual Standard Fryers

24

Page 27

COUNTERTOP FRYER F-85 and BUILT-IN FRYER F-856

L1 L2 L3

HEATING ELEMENT

TEMP LIGHT

T

HI-LIMIT T'STAT

T

TROUBLE LIGHT

SV301 Service Manual Standard Fryers

HI-LIMIT T'STAT

T

TROUBLE LIGHT

C

CONTACTOR

C

CONTACTOR

CONTROL T'STAT

HEATING ELEMENT

TEMP LIGHT

CONTROL T'STAT

T

C

CONTACTOR

C

CONTACTOR

POWER

SWITCH

JUMPER

OR

EXTERNAL

CONTROL

F-85(6)

WIRING SCHEMATIC F-85 and F-856 - 3 PHASE

25

Loading...

Loading...