Page 1

© 1987 McDonald's Corporation Printed in November Printed in All Rights Reserved

DUAL ACCESS BISCUIT CABINET

WELLS MODELS DABC-1PS

and DABC-1TL

This equipment chapter is to be placed in the Holding Cabinets Section of the Equipment Manual.

MANUFACTURED EXCLUSIVELY FOR

McDONALD'S

BY

WELLS MANUFACTURING

2 ERIK CIRCLE VERDI, NEVADA 89439

PHONE: 1 (702) 345-0444

TOLL FREE: 1 (800) 777-0450

FAX #: 1 (702) 345-0569

TABLE OF CONTENTS

WARRANTY......................................................................................................................... Page 2

INTRODUCTION.................................................................................................................. Page 2

SAFETY................................................................................................................................ Page 2

PARTS IDENTIFICATION/FUNCTION/PHOTOS..............................................................Page 3

HARDWARE IDENTIFICATION........................................................................................Page 19

EQUIPMENT SET UP AND CLOSE PROCEDURES .....................................................Page 20

TROUBLESHOOTING....................................................................................................... Page 22

PARTS ORDERING/SERVICE INFORMATION.............................................................. Page 24

NON-SCHEDULED MAINTENANCE.................................................. ...........................Page 24

WIRING PICTORIAL ..........................................................................................................Page 36

WIRING DIAGRAM............................................................................................................Page 38

This manual is for the exclusive use of licensees and employees of McDonald's Systems, Inc.

Reprinted in April, 1989 The United States of America

Page 2

DUAL ACCESS BISCUIT CABINET

Models DABC-1PSP and DABC-1TL

PRODUCT FEATURES

• Fully adjustable water and air temperatures.

• Front and rear doors allow loading and unloading from either end for

efficient workflow.

• Adjustable solid-state electronic thermostat senses and displays

accurate temperature.

• Built-in three channel timer displays that can be operated from both

front and back of unit.

• Signal light located on both front and rear to indicate that opposite

door is open.

• Audible and visual low water indicator.

• Heat ON indicator lights for both air and water.

• LED digital temperature display (F or C) for air or water - select by

switch.

• Easy to clean water pan with one multi-function probe for low water

level and temperature.

• All stainless steel construction.

• Cabinet designed for floor installation. Shipped with casters.

DIMENSIONS

INSTALLED SHIPPING

MODELS

DABC1PSP

DABC1TL

DIMENSIONS DIMENSIONS

W D H

20 1/4" 29" 33" 175 27 3/8" 33 3/4" 36 1/8” 204

WEIGHT

W D H

WEIGHT

ELECTRICAL INFORMATION

Model DABC-1PSP:

Voltage: 208V, three phase, four wire. Power: 1. 1 KW, for amperage

refer to table on reverse side. Cabinet is provided with a 10-foot cord

with pin-and-sleeve connector for power, and a 2-foot cord with pinand-sleeve auxiliary receptacle for 15 amp, 120V unit only.

Model DABC-1TL: (Replacement only)

Voltage: 120V, single phase.

Power: 1. 1 KW, for amperage refer to table on reverse side. Cabinet

is provided with a 10-foot cord with a NEMA L5-20P twist-lock for

power and NO auxiliary appliance connection.

PRODUCT FINISH

Stainless steel top. front, sides and back.

PRODUCT WARRANTY

The DABC-1PSP and DABC-1TL Dual Access Biscuit Cabinets

manufactured by Wells are warranted to be free from defects in

materials and workmanship for a period of one year from the date of

original installation and is for the benefit of the original purchaser only.

This warranty does not apply to damage resulting from fire, water,

burglary, accident, abuse, misuse, acts of God, faulty installation

including improper electrical supply.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, THERE BEING NO OTHER

WARRANTIES, EXPRESSED OR IMPLIED IN LAW OR

IN FACT, INCLUDING BUT NOT LIMITED TO,

WARRANTIES OF MERCHANT-ABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE, AND/OR FOR

DIRECT, INDIRECT. OR INCONSEQUENTIAL

DAMAGES IN CONNECTION WITH WELLS'

PRODUCTS.

Wells' obligation under this warranty is limited to the repair of defects

or replacement without charge by a WELLS factory authorized service

agency or one of its sub-service agencies. This service will be

provided on customer's premises.

Page 3

DUAL ACCESS BISCUIT CABINET

Models DABC-1PSP and DABC-1TL

ELECTRICAL SPECIFICATIONS

AMPS PER LINE THREE PHASE MODEL VOLTS KW

LI L2 L3 N

DABC-1PSP 208 1. 1 10 15 - 25 -

DABC-1TL 120 1. 1 - - - - 8. 8

NOTE: 4 WIRE 3 PHASE L3 NOT USED

AMPS

SINGLE

PHASE

Wells Manufacturing Company

2 Erik Circle, P. O. Box 280 • Verdi, NV 89439

(702) 345-0444 • FAX: 702-345-0569 TOLL-FREE

FAX: 800-356-5142, for orders only

1994 Wells Manufacturing Company Printed in U. S. A. Item No. 43958 B

Page 4

WARRANTY STATEMENT

The Dual Access Biscuit Cabinet manufactured by

Wells is warranted to be free from defects in materials

and workmanship for a period of one year from the date

of original installation and is for the benefit of the

original purchaser only, BUT NOT AGAINST DAMAGE

CAUSED BY ABUSE, FAULTY INSTALLATION,

INCLUDING IMPROPER ELECTRICAL CURRENT.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, THERE BEING NO OTHER WARRANTIES, EXPRESSED OR IMPLIED IN LAW OR IN

FACT, INCLUDING BUT NOT LIMITED TO,

WARRANTIES OF MERCHANT ABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE, AND/OR FOR

DIRECT, INDIRECT OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH WELLS

PRODUCTS.

Wells' obligation under this warranty is limited to the

repair of defects or replacement without charge by a

WELLS factory authorized service agency or one of its

sub-service agencies. This service will be provided on

customer's request.

Please contact the Service Department: Wells

Manufacturing Company, P. O. Box 280, Verdi, Nevada

89439; to arrange service or for additional information

and other details concerning the product and/or this

warranty.

INTRODUCTION

The commercial Dual Access Biscuit Cabinet is

designed to hold food at a desired serving temperature

and moistness plus allow access to the food product

from either the front or the rear of the cabinet. Both

models have built-in 3 channel product timers that can

be activated from either the front or the rear of the

cabinet.

The Model DABC-1 PS is configured with an IEC 309

Pin & Sleeve plug and connector for the main power

and auxiliary device connection.

WARNING: The DABC-1 PS operates on 120 VAC.

The power connection has been designed for 208 VAC,

3-Phase-Y, 5-wire, 120/208 split, such that two

independent 120 VAC inputs are supplied to the unit.

The auxiliary connection is 120 VAC at 15 amp

maximum for other appliances, i. e. Marinator Model

MDMW-3.

The Model DABC-1TL is configured with a NEMA L520P twist-lock for the power supply connection and NO

auxiliary appliance connection is provided.

SAFETY

Knowledge of proper installation, operation and

maintenance procedures is essential to ensure safe

operation of any equipment. The instructions contained

herein are meant as guidelines; major considerations to

be kept in mind are:

1. Always have dry hands prior to turning the power

switch ON or OFF.

2. Turn OFF the power switch anytime the cabinet is

not in use.

3. If an electric shock is felt when touching the

cabinet, disconnect the power immediately and

call Wells Service Department for assistance and

service.

4. Have the electrical power installed by a licensed

electrician. Make sure that the equipment is

properly grounded.

5. If you find that the electrical cord is frayed, DO

NOT PLUG IT INTO THE ELECTRICAL POWER

RECEPTACLE. IF IT IS ALREADY PLUGGED

IN, DISCONNECT THE PLUG AFTER

SHUTTING OFF THE CIRCUIT BREAKER.

6. DISCONNECT THE POWER CORD BEFORE

ATTEMPTING ANY REPAIRS AND/OR

CLEANING THE UNIT WITH WATER.

7. Allow the unit to cool before cleaning.

8. DON'T EVER SPLASH WATER WITH A HOSE

OR OTHERWISE ONTO THE UNIT. WET

ELECTRICAL COMPONENTS AND WIRING

PRESENT A HIGH SHOCK HAZARD.

9. Follow the cleaning procedures described on the

Biscuit Cabinet (Wells) Planned Maintenance

System Card #64.

CAUTION: DO NOT OPERATE THE UNIT UNLESS

ALL FOUR CASTERS ARE INSTALLED. THE UNIT IS

SHIPPED WITH THE CASTERS IN PLACE AND

THEY SHOULD NOT BE REMOVED. PERSONAL

INJURY AND DAMAGE TO THE UNIT MAY RESULT.

2

Page 5

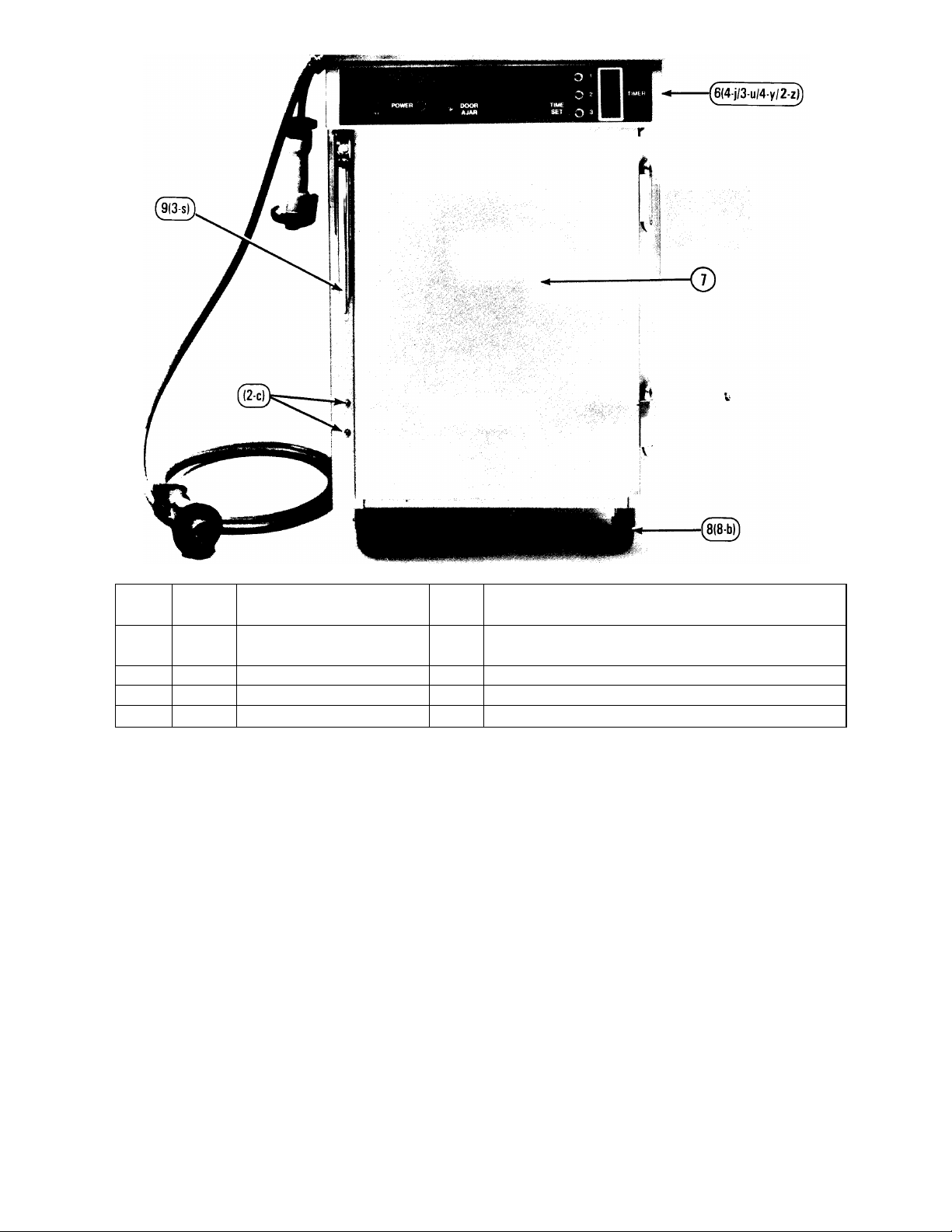

PARTS IDENTIFICATION/FUNCTION/PHOTOS

(DABC-1PS Shown, DABC-1TL Same except as noted)

ITEM

PART

NO.

1 62385 Outer Cabinet Top 1 Covers and protects the controls, wiring and components.

2 63045 Front Door Handle 1 Provides access to the unit and secures the door when

3 62391 Front Door Wrap 1 Provides an exterior cover for the cavity door assembly.

4 63042 Swivel Wheel with Brake 2 Allows the unit to be moved about and secures it in place

5 63425 Front Control Panel Sub-

DESCRIPTION QTY. FUNCTION

closed.

when stationary.

1 Used to mount electrical control components.

Assembly

3

Page 6

ITEM

PART

NO.

10 62405 Cord Strain Relief

11 62378 Electric Conversion Panel 1 Attaches plug/connector assemblies to the unit.

12 56307 Cord 14/3 STO (DABC-1PS

13 62404 Female Connector (DABC-1PS

14 62384 Side Panel 2 Side cover of the unit. (1 per left and right side)

15 56313 Cord 14/4 STO (DABC-1PS

56307 Cord 14/3 STO (DABC-1TL

16 62412 Plug 4-Wire P&S (DABC-1PS

60649 Plug L5-20P (DABC-1TL ONLY) 1

DESCRIPTION QTY. FUNCTION

2 1 Attaches cord to the conversion panel.

DABC-1PS DABC-1TL

2 ft. Transfers electric power to secondary equipment,

ONLY)

1 Connects power to 120 VAC, 15 amp maximum secondary

ONLY)

11 ft. Transfers electric power to the unit.

ONLY)

11 ft.

ONLY)

ONLY)

equipment.

1 Connects the unit to the electrical power.

Page 7

ITEM

PART

NO.

6 63426 Rear Control Panel Sub-

7 62370 Rear Door Wrap 1 Provides an exterior cover for the cavity door assembly.

8 63041 Ridged Wheel 2 Allows the unit to be moved about.

9 62389 Rear Door Handle 1 Provides access to the unit and secures the door closed.

DESCRIPTION QTY. FUNCTION

1 Used to mount electrical control components.

Assembly

4

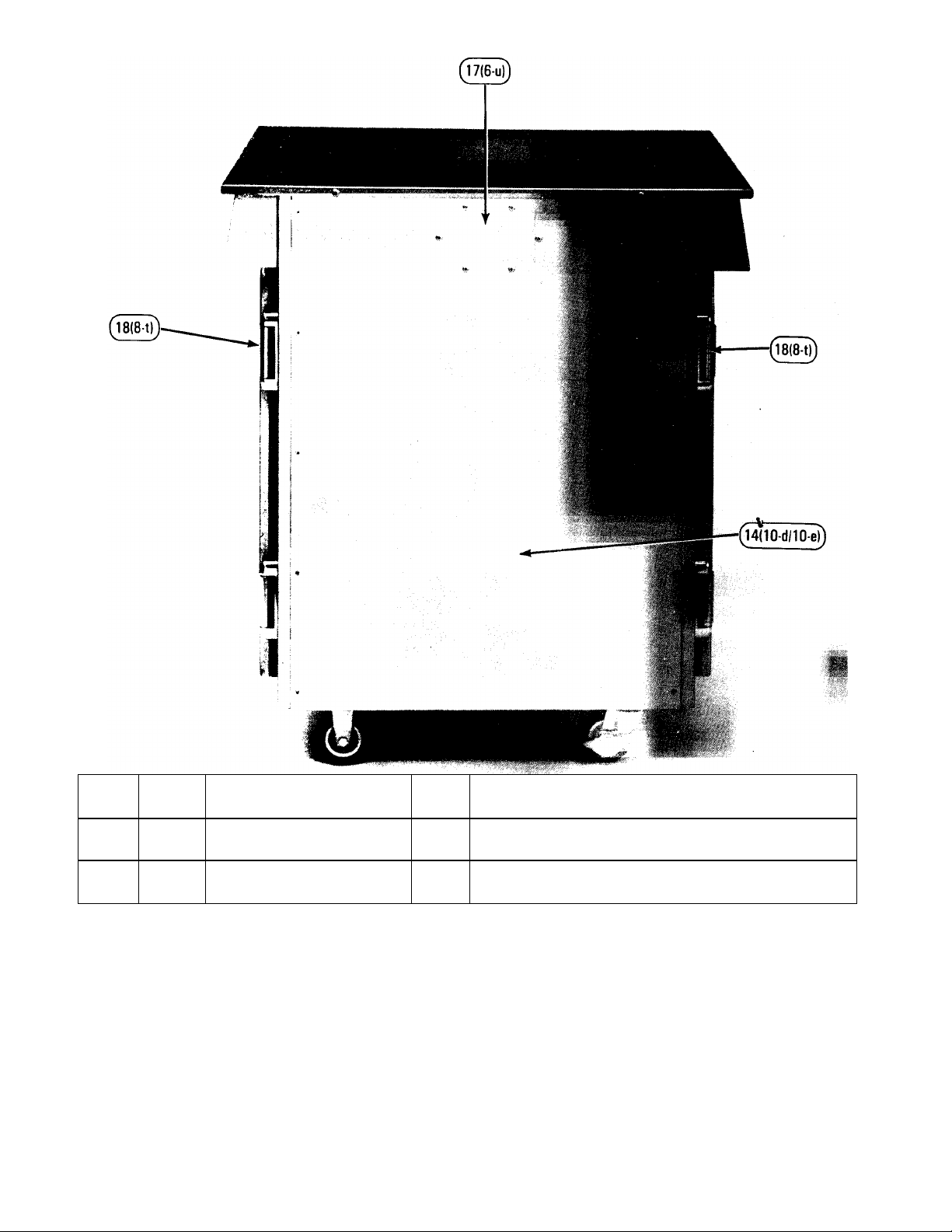

Page 8

ITEM

PART

NO.

17 62376 Blank Electrical Conversion

18 60787 Door Hinge 4 Mounts the doors to the cabinet and allows the doors to open

DESCRIPTION QTY. FUNCTION

1 Opposite side cover for power conversion.

Panel

and close. (2 per front and rear door)

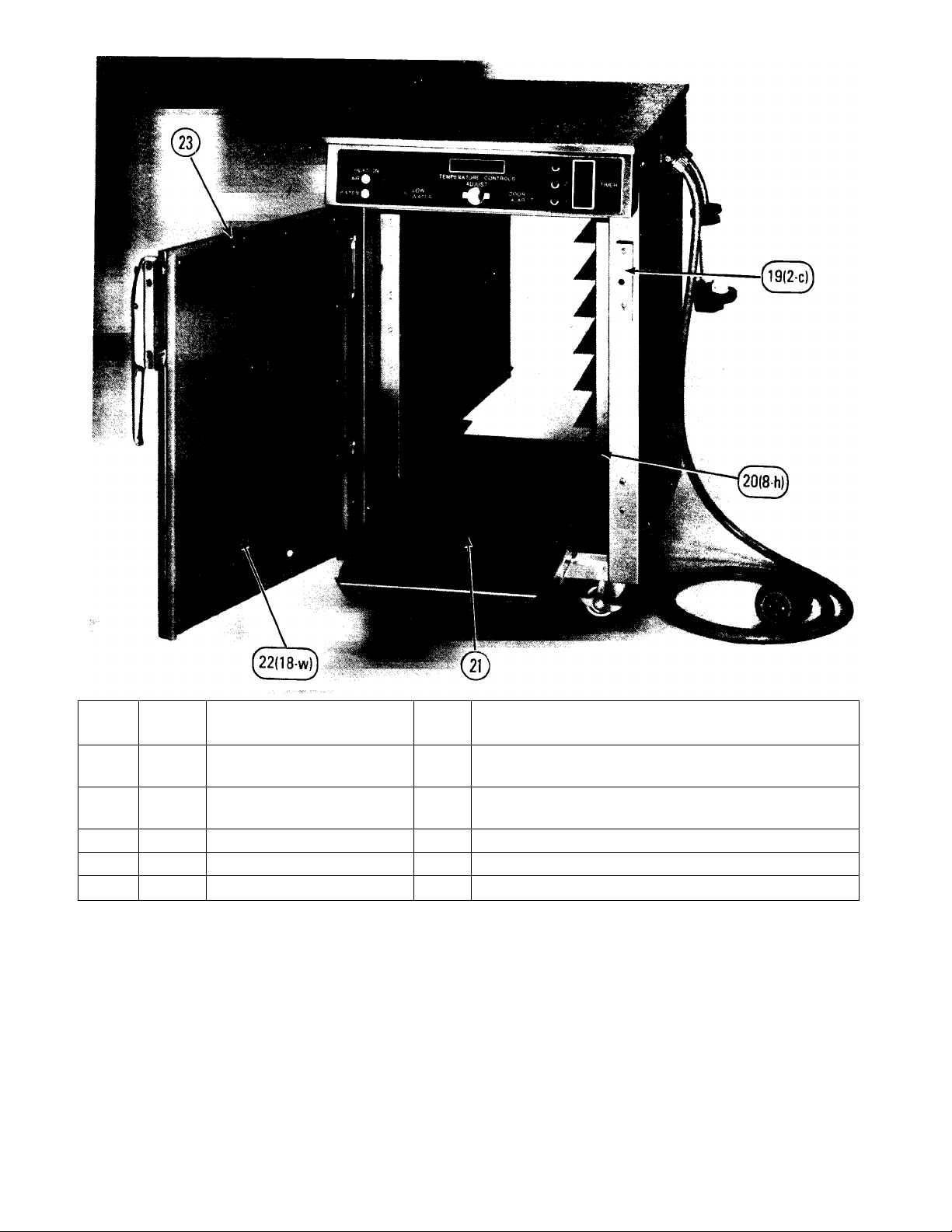

Page 9

ITEM

PART

NO.

19 63045 Front Door Striker Plate 1 Latches door to cabinet and houses the door ajar sensor.

20 63212 Tray Rack 2 Holds biscuit tray. (1 for the left and 1 for the right sides of the

21 60794 Crumb Shield 1 Prevents crumbs from falling into the water.

22 62373 Front Door Interior Panel 1 Secures the door gasket and protects the insulation.

23 60820 Front Door Gasket 1 Seal to retain the interior environment.

DESCRIPTION QTY. FUNCTION

cavity)

7

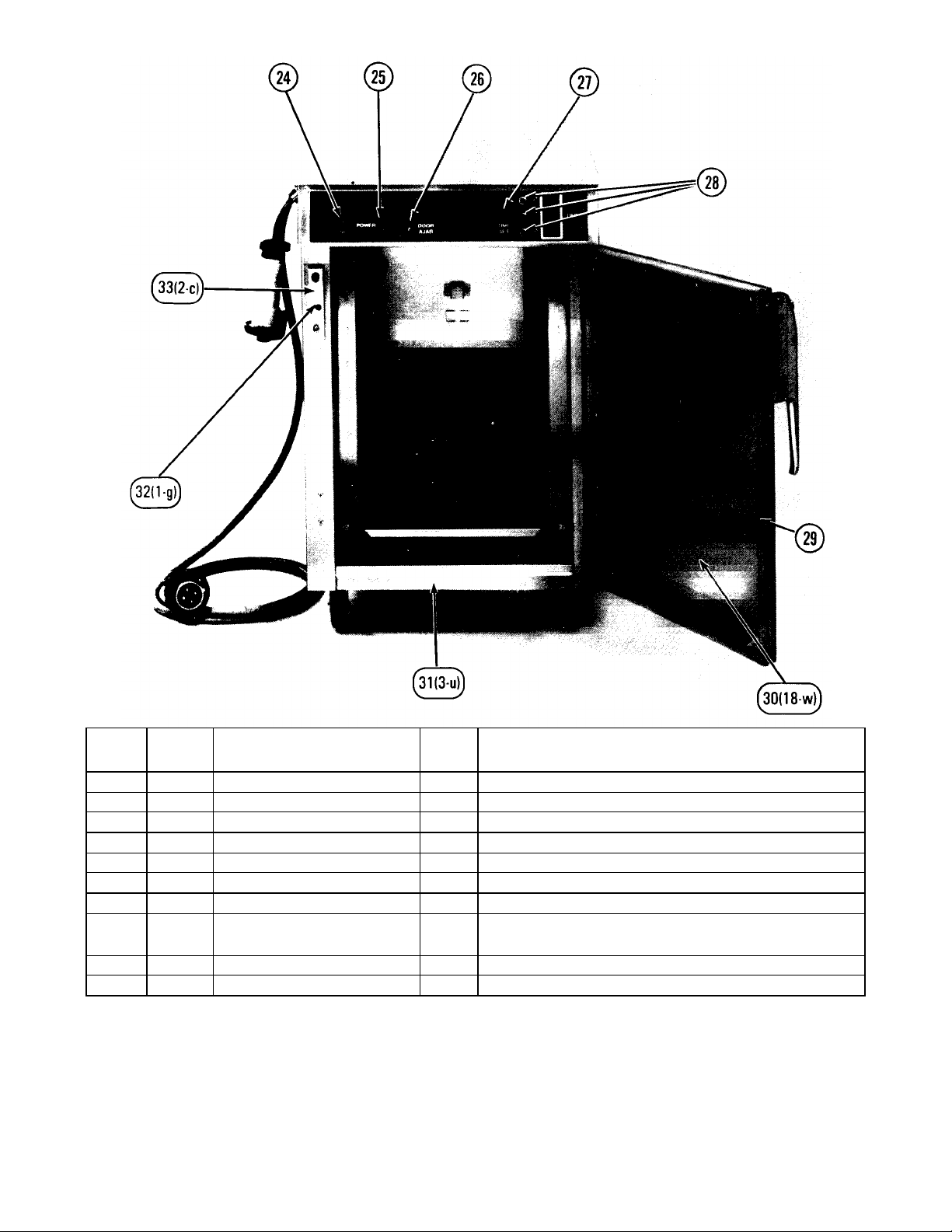

Page 10

ITEM

PART

NO.

24 61776 Power On Switch 1 Turns the electrical power on or off to the unit.

25 60758 Power Telite (Red) 1 Indicates that the power is on to the unit.

26 60825 Rear Door Ajar Telite (L.E.D.) 1 Indicates when the front door is ajar.

27 62417 Timer Program Switch 1 Programs the desired time into the internal product timer.

28 62418 Timer Operate Switch 3 Starts and stops the internal product timer.

29 62411 Rear Door Gasket 1 Seal to retain the interior environment.

30 63206 Rear Door Interior Panel 1 Secures the door gasket and protects the insulation.

31 62364 Bottom Panel 2

32 62397 Rear Door Ajar Sensor 1 Detects when the rear door is closed or open.

33 62389 Rear Door Striker Plate 1 Latches door to cabinet and houses the door ajar sensor.

DESCRIPTION QTY. FUNCTION

Covers the front and rear lower frame members. (1 in the

front and 1 in the rear of the unit)

8

Page 11

ITEM

*Not shown

PART

NO.

34* 60819 Front Door Insulation

35* 60819 Rear Door Insulation

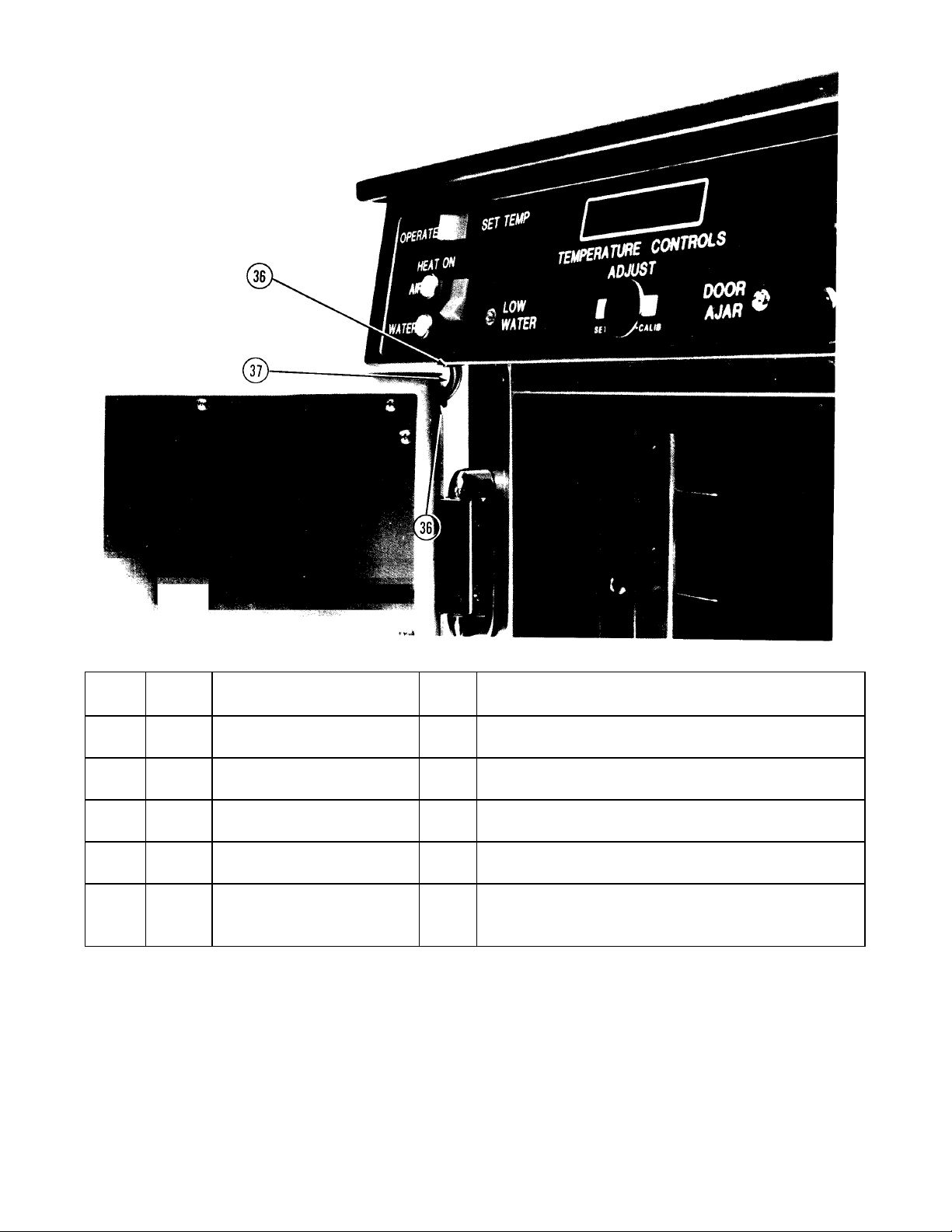

36 62392 Conduit Bushing 4 Guide for the front and rear thermocouple conduit. (2 each

37 62393 Thermocouple Conduit 2 Conduit for the front and rear air thermocouple wires. (1

38* 56315 Thermocouple Conduit

DESCRIPTION QTY. FUNCTION

1 Thermal seal for the front door.

(not shown)

1 Thermal seal for the rear door.

(not shown)

door)

each, front and rear door)

2 Abrasion barrier between the air sensor thermocouple wires

Insulation Tubing (not shown)

and the thermocouple conduit for the front and rear doors. (1

each front and rear door)

Page 12

ITEM

PART

NO.

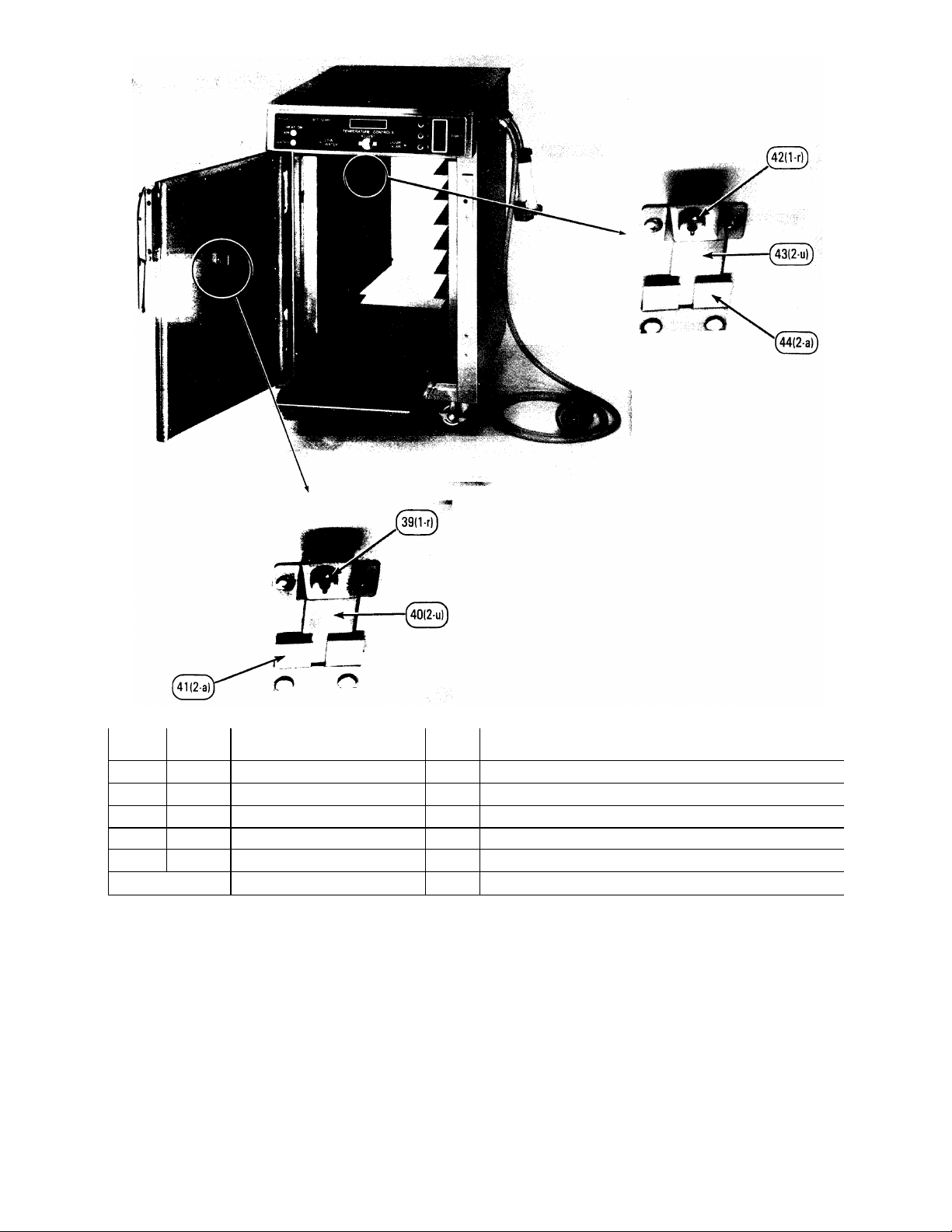

39 62367 Front Door Air Sensor 1 Senses the air temperature inside the unit.

40 60789 Front Thermo Bracket 1 Protective guard for the air sensor.

41 62379 Front Air Probe Bracket 1 To hold biscuit oven probe.

42 62413 Rear Door Air Sensor 1 Senses the air temperature inside the unit.

43 60789 Rear Thermo Bracket 1 Protective guard for the air sensor.

44 62379 Rear Air Probe Bracket 1 To hold biscuit oven probe.

DESCRIPTION QTY. FUNCTION

10

Page 13

ITEM

*Not shown

PART

NO.

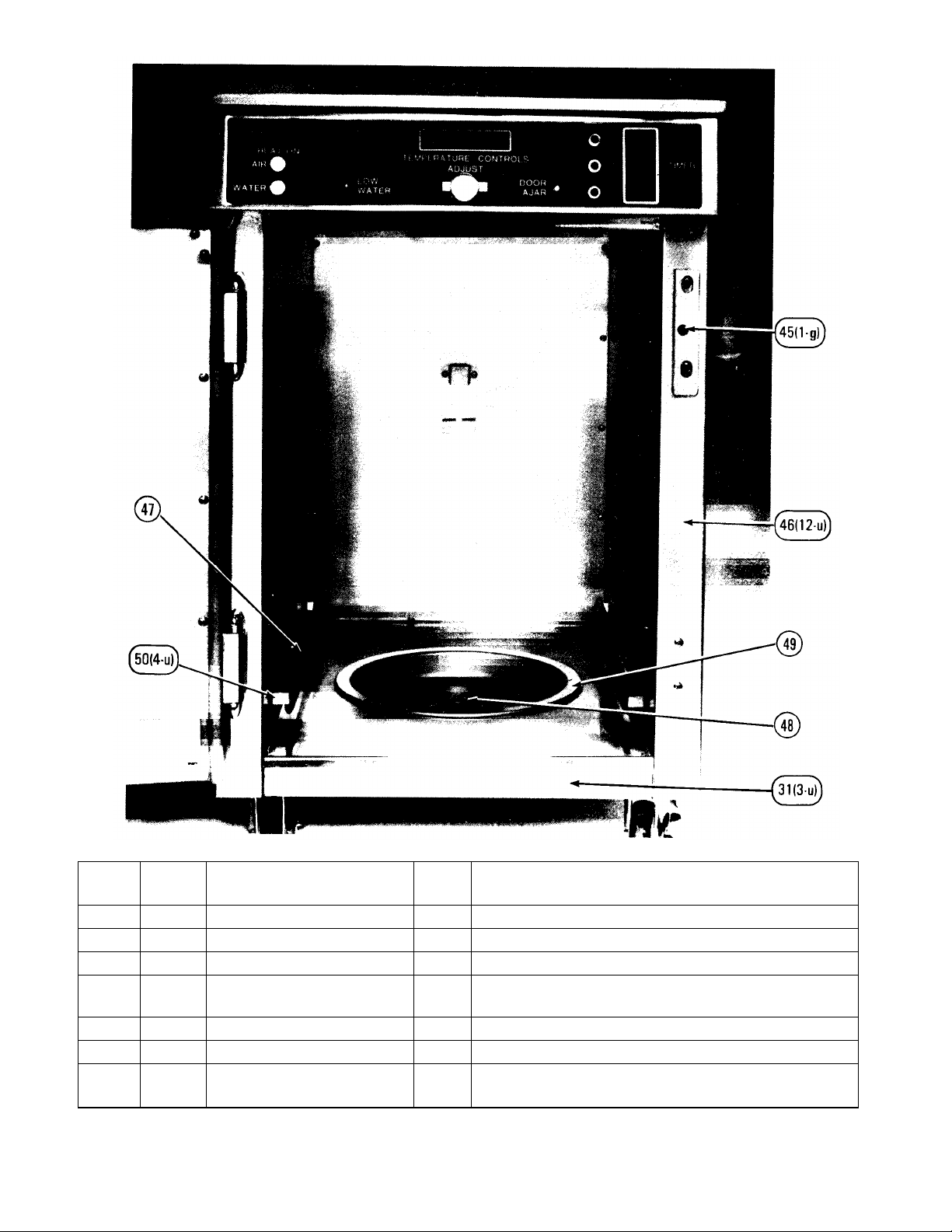

45 62388 Front Door Ajar Sensor 1 Detects when the front door is closed or open.

46 63204 Cavity Assembly 1 Provides the interior surface of the unit.

47 62375 Air Heating Element 2 Heats the air within the cabinet. (1 each side)

48 60815 Thermal/Low Water Sensor

49 60807 Water Pan 1 Holds water for humidity.

50 60752 Element Clip 4 Holds the element in place. (2 clips per element)

51* 60799 Side Insulation (not shown) 2 Thermal barrier for both sides of the cabinet, 1 piece per for

DESCRIPTION QTY. FUNCTION

1 Senses temperature and water level within the water pan.

Assembly

each side.

11

Page 14

ITEM

PART

NO.

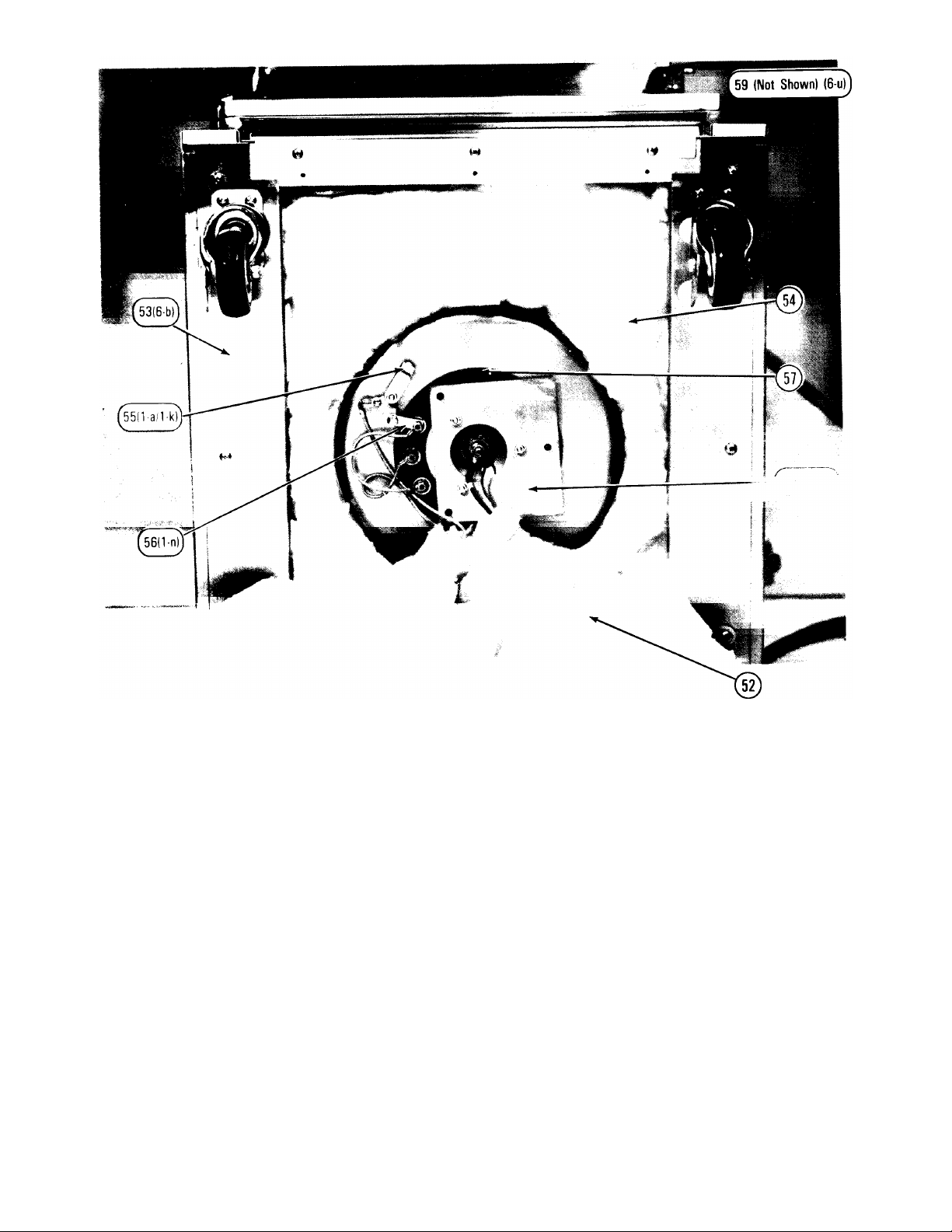

52 60782 Outer Bottom Insulation 1 Thermal seal around the water pan.

53 62368 Base Rail 2 Base for the wheels to attach to. (1 per each side of the unit)

54 60751 Inner Bottom Insulation 1 Thermal seal around the water pan.

55 60527 High-Limit Water Thermostat 1 Safety device which prevents excessive water pan

56 50002 Electrical Jumper 1 Connects the water heating element to the high limit

57 60768 Water Heating Element 1 Heats the water in the pan.

58 60810 Water Heater Element Retainer 1 Holds the water heating element in place.

59* 63044 Base Cover Assembly (not

*Not shown

DESCRIPTION QTY. FUNCTION

temperature.

thermostat.

1 Covers the water heating element and associated wiring.

shown)

12

Page 15

ITEM

PART

NO.

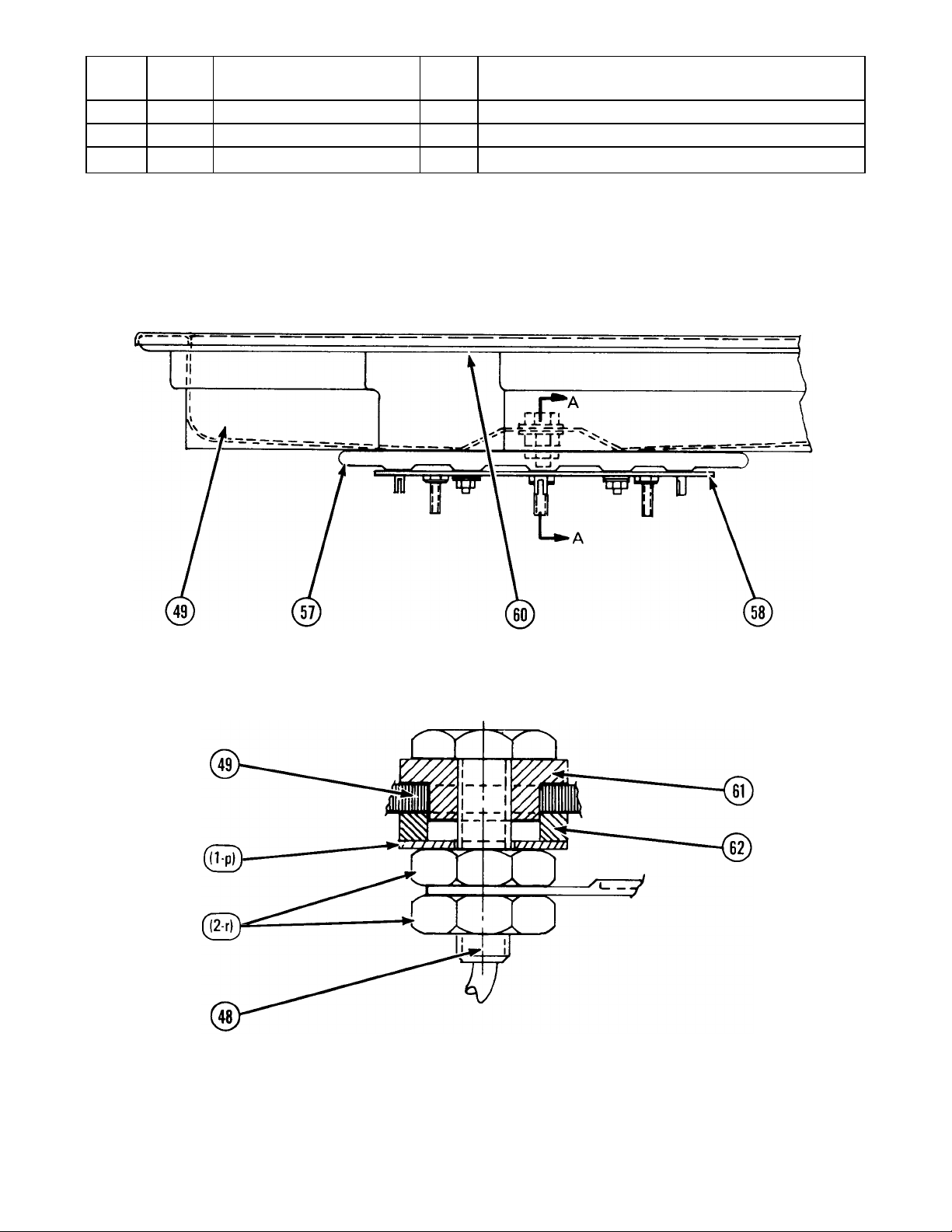

60 61056 Water Pan Gasket 1 Seals the water pan to the bottom of the cavity.

61 61030 Shoulder Washer 1 Water seal and upper sensor insulator.

62 61031 Washer 1 Water seal and lower sensor insulator.

DESCRIPTION QTY. FUNCTION

SIDE VIEW

(BOTTOM OF CABINET)

CROSS SECTION A-A

13

Page 16

ITEM

*Not shown

PART

NO.

63* 62392 Wiring Bushing (not shown) 2 Protects the wiring from the sharp edges of the cavity sides.

64 51040 Insulation Grommet 2 Protects the wiring from the sharp edges of both sides.

65 62360 Frame Assembly 1 Substructure of the entire cabinet.

66 62418 Timer Operate Switch 3 Starts and stops the internal product timer timing.

67 60825 Front Door Ajar Telite (L.E.D.) 1 Indicates when the rear door is open or closed.

68 63203 Hole Plug 1 Covers the temperature set and calibrate controls.

69 60825 Low Water Telite (L.E.D.) 1 Indicates when water is required.

70 60763 Air/Water Mode Rocker Switch 1 Used to select temperature readout on the display to air or

71 60890 Red Rocker Cover for the

72 60563 Thermostat Telite (White) 2 Indicates when a heater is on.

73 60890 Red Rocker Cover for

74 60763 Operate/Set Temp. Mode

DESCRIPTION QTY. FUNCTION

(1 each, left and right side)

water.

1 External cover for the rocker switch and provides means to

Air/Water Switch

Operate/Set Temp. Switch

Rocker Switch

operate switch.

1 External cover for the rocker switch and provides means to

operate switch.

1 Used to select temperature set and operate functions and

changes the display accordingly on the temperature

controller.

14

Page 17

Term. Power SW.

ITEM

PART

NO.

75 62415 PC Board Support 4 Provides the required spacing of the time display board to the

76 63039 Front Time Display PC Board 1 Displays the product hold time.

77 63040 Timer Control PC Board 1 Logic controller for the time display boards.

78 62409 L.E.D. Telite Lens 1 Protects the telite.

79 62410 L.E.D. Telite Base 1 Mounts the L.E.D. telite to the front control panel.

80 63049 Transformer 1 Provides low voltage power to the electronic controls.

81 60310 Power Terminal Block 1 Connection block for the main power supply to the unit.

82A 60305 Temperature Controller with

DESCRIPTION QTY. FUNCTION

front control panel and attaches it to the panel.

1 Solid state controller for the air and water temperature.

Std./Aux. WO/side pots & 12

82B 69064 Temperature Controller with

1 Solid state controller for the air and water temperature.

Wet/Dry SW. W/side pots and 4

83 63201 Spacer 4 Provides the required spacing of the temperature controller

from the front control panel.

15

Page 18

ITEM

PART

NO.

84 62409 L.E.D. Telite Lens 1 Protects the telite.

85 62410 L.E.D. Telite Base 1 Mounts the L.E.D. telite to the front control panel.

86 63201 Spacer 4 Provides proper spacing of the door sensor controller to the

87 62398 Door Sensor Control PC Board 1 Solid state device that determines and indicates whether a

88 60964 Water Relay 1 Turns the water heater on and off.

89 60870 Air Relay 1 Turns the air heaters on and off.

90 62399 Electronic Component Bracket 1 Used to mount electrical control components.

DESCRIPTION QTY. FUNCTION

component bracket.

door is open or closed.

16

Page 19

ITEM

PART

NO.

91 63039 Rear Time Display Board 1 Displays the product hold time.

92 62415 PC Board Support 4 Provides the required spacing of the time display board to the

93 63038 Timer Speaker 1 Produces audible 3-tone sound, indicating the end of a time

94 57260 Speaker Bracket 1 Holds the speaker in place.

95 62409 L.E.D. Telite Lens 2 Protects the telite.

96 62410 L.E.D. Telite Base 2 Mounts the L.E.D. telite to the front control panel.

DESCRIPTION QTY. FUNCTION

rear control panel and attaches it to the panel.

cycle from the internal timer.

17

Page 20

ITEM PART

NO.

97 61102 Thermostat Strap 1 Holds the air high-limit thermostat in place.

98 60824 Top Insulation 1 Thermal seal for the top of the unit.

99 61183 Air High-Limit Thermostat 1 Safety device which prevents excessive internal cabinet

DESCRIPTION QTY. FUNCTION

temperatures.

18

Page 21

HARDWARE IDENTIFICATION

ITEM PART NO. DESCRIPTION TOTAL QUANTITY

a 51053 Nut, Hex 8-32, Kep 25

b 53890 Screw, Pan Hd. Phil. 12-24 x 3/4 22

c 53983 Screw, Rd. Hd. Sltd. 10-32 x 1/2 8

d 54285 Screw, Flt. Hd. Phil. 8-32 x 3/8 20

e 55137 Speednut 8-32 Long 20

f 55736 Nut, Hex 8-32 Green Kep 2

9 58625 Retainer, Circ Push-On 5/16 ID. 2

h 60670 Screw, Trs. Hd. Sltd. 1/4-20 x 3/8 8

j 60680 Nut, Hex 10-32 Kep 8

k 51333 Screw, Rd. Hd. Sltd. 6-32 x 3/8 1

1 52176 Nut, Hex 8-32 w/Stems 3

m 52242 Washer, Brass Lrg. Pat. #10 3

n 57457 Screw, Binding Hd. 10-32 x 3/8 1

p 61035 Washer, Flt. 5/16 SS. 1

r 61036 Nut, Hex 5/16-18 Unc SS. 4

s 60821 Screw, Flt. Hd. 10-32 x 1-1/2 6

t 60822 Screw, Flt. Hd. 10-32 x 1/2 16

u 61620 Screw, Truss Hd. Phil. 8-32 x 1/2 46

v 62067 Screw, Truss Hd. Phil. 10-32 x 3/8 12

w 55487 Screw, Truss Hd. Phil. 8-32 x 5/16 36

y 53961 Nut, Hex 6-32 Kep 14

z 51708 Nut, Hex 8-32 2

aa 62432

Nut. Hex 1/2 NPT DABC-1PS

DABC-1TL

2

1

19

Page 22

EQUIPMENT SET-UP AND CLOSE

PROCEDURES

Set-up — Complete the following:

1. Ensure that the power cord is plugged into the

appropriate power source.

2. Ensure that the water pan has melted ice in it and

is approximately two-thirds full.

3. Turn the power switch to the ON position.

4. Ensure that the temperature setting for both the air

and water (flashing digital display) are set

correctly. (See PMS Card #64)

5. Ensure that both doors are closed (check the

DOOR AJAR lights).

6. Allow the unit to warm up for forty-five (45) minutes

before placing product inside.

7. Ensure that the timers are set for the correct time.

CAUTION: On model DABC-1PS the yellow plug is

for 120V, 15amp auxiliary power to other

appliances, ie. Marinator (Model MDMW-3).

Close — Complete the following:

1. Turn the power switch to the OFF position.

2. Unplug the power cord from the power source and

allow the unit to cool down.

CAUTION: THE EQUIPMENT AND THE WATER

CONTENTS ARE HOT! THE HEATING ELEMENTS WILL

BURN YOU!! ALLOW THE CABINET TO COOL DOWN FOR

APPROXIMATELY 30 MINUTES WITH BOTH DOORS

OPEN.

3. Remove the crumb tray and side racks.

4. Sponge out the remaining water in the water pan.

5. Using a clean, damp cloth, wipe out the water pan and

the interior of the cabinet.

6. Wipe down the exterior of the cabinet.

7. Replace the side racks.

8. Fill the water pan with ice or melted ice.

9. Replace the crumb tray.

PROCEDURE TO ATTACH OVEN

PROBE TO CABINET

1. Open the front door of the biscuit cabinet (the

door associated with the temperature digital

display).

2. Hold the Biscuit Oven Probe with the sloped

angle toward the inner rear door and with the

alligator clip at the bottom on the right side.

3. Move the Biscuit Oven Probe up above the air

probe bracket and move it back near the rear

inner door of the cavity.

4. Move the Biscuit Oven Probe down onto the air

probe bracket so that the narrow section of the

tapered angle (cobraneck) of the Biscuit Oven

Probe fits into the slot in the air probe bracket.

5. Push the Biscuit Oven Probe down onto the air

probe bracket until it stops.

20

Page 23

PROCEDURE FOR CABINET STORAGE

1. Turn the power switch to the OFF position.

2. Unplug the power cord from the power source

and allow the unit to cool down.

CAUTION: THE EQUIPMENT AND THE WATER

CONTENTS ARE HOT! THE HEATING ELEMENTS

WILL BURN YOU!! ALLOW APPROXIMATELY 30

MINUTES WITH BOTH DOORS OPEN FOR THE UNIT

TO COOL DOWN.

3. Remove the crumb tray and the side racks.

4. Sponge out the remaining water in the water

pan.

5. Using a clean, damp cloth, wipe out the water

pan and the interior of the cabinet.

6. Wipe down the exterior of the cabinet.

7. Replace the side racks and the crumb tray.

8. Wrap the power cord and plug around the

cabinet and secure as shown.

9. Move the cabinet to its storage location.

2. Remove the top cover from the cabinet by

removing the four (4) screws.

3. Remove only the four (4) screws from the top and

bottom of the blank conversion panel (Item 17) and

one (1) of the side screws. This will allow the panel

to pivot on the remaining screw to a position where

you can hold onto it with your fingers. Holding the

panel (so that it will not drop down between the

side panel and the side insulation), remove the

remaining side screw and remove the blank

conversion panel from the side of the unit.

4. Remove all six (6) screws from the electrical

conversion panel (the one with the cords attached

— Item 11) and allow the assembly to hang freely.

5. Pass the electrical conversion panel through the

passageway at the top of the cabinet, pulling the

two cords and plugs with it. Be careful not to snag

and pull any of the internal wiring with the electrical

conversion panel or plugs as you pass them

through the unit.

6. Pass the plugs and cords through the left-hand

passageway, pulling the electrical conversion

panel with them.

7. Secure both conversion panels to the cabinet sides

using the six (6) screws previously removed and

#222 loctite.

8. Replace the top cover to the cabinet and secure

with the four (4) screws.

TIMER OPERATION

Introduction

The Dual Access Biscuit Cabinet models have the

product timer as an integral part of the unit. The timer

within the cabinet consists of three independent

product timers that can be activated from the front or

rear control panels with the timer program switch

located on the rear control panel.

Set-Up

1. Make sure that the power cord is plugged into the

appropriate power source.

2. Turn the power switch to the ON position.

3. Verify that the time being displayed is correct; if

not, correct the time using the following

instructions:

To Program Times

1. Wait for the channel selected to time out or cancel

the time manually.

PROCEDURE TO CHANGE CORD FROM RIGHTHAND SIDE TO LEFT-HAND SIDE

1. Unplug the cord from the power source.

21

Page 24

2. Press and hold the PROGRAM switch (Item #27) to

the left to change tens of minutes and to the right to

change minutes.

3. Press the OPERATE switch (Item #28) of the channel

display to be changed. The display will turn to

maximum brightness.

NOTE: Holding the OPERATE switch in will cause the

display to rotate automatically from "0" through "9".

5. After the timer has counted down to zero time, a threetone audible signal will be heard and the timer display

will read "00" and flash. To stop the audible signal,

press the operate switch (Item 28 or 66) adjacent to

the blinking time display. This will stop the audible

signal and return the timer to its original setting and

the display will be dim and constant.

TROUBLESHOOTING

NOTE: Both displays (front and rear control panels) will

read the same.

Operation

1. Make sure that the power cord is plugged into the

appropriate power source.

2. Turn the power switch to the ON position.

3. Verify that the time being displayed is correct. If it is not

correct, set the time as explained in TO PROGRAM

TIMES section.

4. To activate the timer, press the timer operate switch

(Item 28 or 66) next to the corresponding time display

(on either side of the cabinet). The display will

become brighter and a timer indicator dot will appear

in the lower right hand corner.

TROUBLESHOOTING GUIDE

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Unit fails to operate. (No

power or telite indications.)

Faulty power switch. Replace power switch. (See page 25.)

Unit fails to operate. (Power

telite is all that works.)

Faulty air high limit thermostat. Replace air high limit thermostat. (See page

Holding temp. too high. Air temp. set too high. Check air temp. setting. (See PMS Card #64.)

Power switch off. No power to unit. Turn power switch on. Verify plug connection,

Air temp. set too high. Check air temp. setting, allow unit to cool

In servicing the equipment which has malfunctioned, it is

very important to:

1. DEFINE the problem and accurately determine

what is the malfunction.

2. Determine the BASIC CAUSE.

3. ELIMINATE the cause and repair the malfunction. If

the cause is not properly identified and eliminated, the

malfunction may recur.

It is usually relatively easy to define the malfunction, but

sometimes very difficult to spot the cause.

If the problem remains after following the suggestions

listed, contact Wells Manufacturing Company Service

Department at (702) 345-0444.

check circuit breaker, check voltage supply to

unit.

down. (See PMS Card #64.)

25.)

Unit out of calibration. Recalibrate the unit. (See PMS Card #64.)

Holding temp. too low. Air temp. set too low. Check air temp. setting. (See PMS Card #64.)

Unit out of calibration. Recalibrate the unit. (See PMS Card #64.)

Door(s) ajar. Close the door(s).

22

Page 25

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

never

recovers.

Finished product too dry. Air temp. set too high. Check air temp. setting. (See PMS Card #64.)

Water temp. set too low.

Low water level.

Check water temp. setting. (See PMS Card

#64.)

1. Check low water telite; should be on and

sounding. 2. Refill water pan.

Door(s) ajar. Check door ajar telite(s); if on, close door(s).

Door gasket leak. Adjust door. (See page 25.)

Finished product too moist. Air temp. set too low. Check air temp. setting. (See PMS Card #64.)

Water temp. set too high.

Check water temp. setting. (See PMS Card

#64.)

Unit out of calibration. Recalibrate the unit. (See PMS Card #64.)

Air or water temp. is above

set temp. but telite indicates

Defective temp. control board or relay.

power to heaters.

Air or water temp. is below set

temp. but telite does not indicate

power to heaters.

Unit out of calibration. Recalibrate the unit. (See PMS Card #64.)

Defective temp. control board or relay.

Replace temp. control board. (See page 26.)

Replace air relay. (See page 27.)

Replace temp. control board. (See page 26.)

Replace temp. relay. (See page 27.)

Both doors ajar. Close the doors.

Air or water temp. is constantly

below the set temp. and the unit

Defective heating element.

Replace air heater. (See page 27.) Replace

water heater. (See page 28.)

Water over temp. thermostat defective (for

water only).

Replace water over temp. thermostat. (See

page 29.)

Air thermocouple shorted (for air only). Replace air thermocouple. (See page 26.)

Door(s) ajar (for air). Close door(s).

Low water indicator is on but

water tray is full.

Soft or distilled water used. Add a pinch of salt to the water.

Defective temp. control board.

Replace temp. control board. (See page 26.)

Defective low water sensor. Replace water sensor. (See page 29.)

Low water indicator does not

go on when water tray is

empty.

Short circuit from low water sensor to water

tray.

Defective temp. control board.

Repair water sensor. (See page 29.)

Replace temp. control board. (See page 26.)

23

Page 26

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Air or water temperature

readout is 0 to 2 degrees

and will not change.

Both doors ajar. Check door ajar telite, should be on, close

Defective door control board. Replace door control board. (See page 30.)

Air or water temperature

readout is at room temp. and

will not change.

Door ajar telite will not turn

Defective door sensor. Replace door sensor. (See page 31.)

Door control board requires adjustment or is

Time display readout does

not work correctly.

Loose connection. Check wire connections.

Time program cannot be

changed.

Defective time control board. Replace time control board. (See page 33.)

Poor connection of thermocouple wires to

control boards or defective thermocouple.

Thermocouple shorted or defective. Check Thermocouples Air: (See page 26.)

Door not closed. Check doors and close.

defective.

Defective display or control board. Replace the display or control board. (Display

Defective program switch. Replace program switch. (See page 33.)

Check thermocouples Air: (See page 26.)

Water: (See page 29.)

door.

Water: (See page 29.)

Adjust controller or replace door control board.

(See page 30.)

see page 33.) (Control see page 33.)

Loose connection. Check wire connections.

Timer does not start when

activate switch is pushed.

Defective activate switch. Replace operate switch. (See page 34.)

Loose connection. Check wire connections.

Defective time control board. Replace time control board. (See page 33.)

PARTS ORDERING/SERVICE INFORMATION

If service parts or technical information is required, please

contact the Factory Service Department. To help speed up

your inquiry the following information is required.

1. Model Number:_______________________

2. Serial Number: __________________________ (fill in

for your records.)

3. Voltage: ________________________________

4. Item Part Number: ____________________

5. Quantity Required: _____________________

6. Nature of Service problem and symptoms.

7. Any other information that may be helpful in solving your

service problem.

NON-SCHEDULED MAINTENANCE

Under normal conditions, with proper use and cleaning,

very little non-scheduled maintenance (NSM) will be

required for this unit. However, this

section provides procedures for checking and

replacement of various parts and components used

within the Dual Access Biscuit Cabinet in the event that it

becomes necessary. Before replacement of any parts,

refer to the Troubleshooting Guide for assistance in

determining the cause of any malfunction and remember,

if in doubt, call the Service Department: Wells

Manufacturing Company, P.O. Box 280, Verdi, Nevada

89439, (702) 345-0444.

WARNING: SOME OF THE PROCEDURES

CONTAINED IN THIS SECTION INVOLVE ACCESSING

BARE ELECTRICAL TERMINALS AND EXPOSURE TO

VOLTAGES CAPABLE OF PRODUCING A FATAL

SHOCK; THEREFORE, THEY MUST BE USED BY

PROPERLY TRAINED PERSONNEL AND STANDARD

SAFETY RULES FOR ELECTRICAL EQUIPMENT

MUST BE ADHERED TO.

Note: Loctite #222 should be applied to all threaded

hardware parts before reassembly (except electrical wire

connection terminals).

24

Page 27

Note: The wiring diagram is located on the

underside of the top of the cabinet. In order to

use it, the top must be removed but only after

the unit has been unplugged from the

overhead electrical power.

Procedure: Replacement of the Power

Switch

Tools: Needle Nose Pliers, Phillips Head

Screwdriver

Parts: Power ON Switch (Item 24)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. Remove the wires from the switch using needle

nose pliers.

4. Push the power switch through the control panel

by depressing the securing clips on the back

side of the switch body.

5. Follow the reverse procedure and the wiring

diagram to install the new power switch.

Procedure: Replacement of the Air High-Limit (OT)

Thermostat

Tools: 11/32 Nutdriver, Phillips Head Screwdriver, 5/16

Nutdriver

Parts: Air High-Limit Thermostat (Item 99)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet and move the

insulation covering the thermostat located in the

center of the cavity top.

3. Disconnect the two wires from the thermostat.

4. Remove the two hex nuts from the thermostat

strap (Item 97) that holds the thermostat in

place and remove the strap.

5. Remove the thermostat and replace it with the new

Air High-Limit Thermostat.

25

6. Follow the reverse procedure to install the

new thermostat.

CAUTION: MAKE SURE THAT THE INSULATION

HAS BEEN REDRESSED ON THE TOP OF THE

UNIT. FAILURE TO DO SO MAY CAUSE OVERHEATING AND SUBSEQUENT FAILURE OF THE

ELECTRONICS WITHIN THE UNIT.

Procedure: Adjustment of the Door

Tools: Phillips Head Screwdriver, 1/8 Slotted

Head Screwdriver

Parts: None

1. ADJUSTMENT OF THE HANDLE SIDE

OF THE DOOR: Loosen the three (3)

screws that hold the door handle in

position.

2. If the door seal is not tight enough, move

the handle away from the striker plate

one notch at a time, tighten the three (3)

screws and check for a tight seal.

Continue until a tight seal is obtained

along the door gasket.

3. If the door seal is too tight, move the

handle towards the striker plate one

notch at a time, tighten the three (3)

screws and check for a tight seal.

Continue until a tight seal is obtained

along the door gasket.

4. Check the seal on the hinge side of the

door after adjustment is complete for

possible need of adjustment.

5. ADJUSTMENT OF THE HINGE SIDE OF THE

DOOR: Pry off the decorative covers on both

the top and bottom hinges.

6. If the door seal is not tight enough, loosen

the four (4) screws that hold the door to

the hinge and move the door towards the

cavity one notch at a time; tighten the

four (4) screws and check for a tight seal;

continue until a tight seal is obtained.

7. If the door seal is too tight, loosen the four (4)

screws that hold the door to the hinges and

move the door away from the cavity one notch

at a time; tighten the four (4) screws

Page 28

and check for a tight seal; continue until a tight seal

Procedure: Inspection/Replacement of the Air

26

is obtained.

8. Check the seal on the handle side of the door

after the adjustment is complete for possible

need of adjustment.

STEP 1

CAUTION: MAKE SURE THAT THE CORK INSULATOR

IS STILL IN PLACE AFTER NEW CONTROL BOARD IS

INSTALLED. FAILURE TO DO SO MAY RESULT IN

CONTROL BOARD FAILURE.

5. Follow the reverse procedure and the wiring

diagram to install the new Temperature Control

Board. Make sure that a spacer is on each of

the four (4) corners and that the retaining wire

for the hole plug (Item 68) is secure on the stud.

STEP 5

Procedure: Replacement of the Temperature

Control Board

Tools: Phillips Head Screwdriver, 1/16 Slotted Head

Screwdriver, 11/32 Open or Box-end Wrench,

Needle Nose Pliers

Parts: Temperature Control Printed Circuit

Board (Item 82)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. Remove the wires from the control board using

needle nose pliers.

Note: Do not remove the wires connected to the

ORANGE TERMINAL BLOCK. To remove their

connection from the PC Board, just lightly pull the

ORANGE TERMINAL block from the PC Board.

4. Remove the four (4) mounting nuts located in the

corners of the control board and remove the control

board from the mounting studs.

CAUTION: DO NOT LOSE THE SPACERS THAT

POSITION THE CONTROL BOARD TO THE FRONT

PANEL BECAUSE THEY MUST BE REUSED.

Sensor Thermocouple

Tools: Phillips Head Screwdriver, 1/8 Slotted Head

Screwdriver, 1/2-inch Open or Box-end Wrench

(2 required)

Parts: Air Temperature Sensor, Thermocouple (Item

39 for front door; Item 42 for rear door)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. FOR INSPECTION OF WIRES ONLY: Check

the connections of the thermocouple wires from

the Air Temperature Sensors to the Door

Sensor Control Board and the same

connections to the Temperature Control Board

(yellow and red wires from the Door Sensor

Control Board to the Temperature Control

Board).

Note: It may be necessary to remove the wires and

reinstall them in order to verify whether they are

secure.

Page 29

4. FOR REPLACEMENT OF WIRES ONLY:

Disconnect the corresponding thermocouple

wires from the Door Sensor Control Board.

5. Open the corresponding door and remove the

thermoguard from the interior of the door.

6. Remove the inner door panel and gasket from the

door.

7. Hold the air temperature sensor on the front of the

inner door panel with a 1/2-inch wrench and remove

the nut from the rear of the inner door panel with the

second 1 /2-inch wrench.

8. Pull the air temperature sensor and thermocouple

wire through the conduit and door panel to remove

it.

2. Remove the top from the cabinet.

3. Disconnect the wiring from the relay using needle

nose pliers.

4. Remove the nut from the mounting stud and

remove the relay.

Note: Pay attention to the position of the relay

terminals with respect to the front and rear of the

cabinet. The new relay must be installed in the same

orientation or the wire lengths will not be correct for

reconnection to the new relay.

5. Place a small amount of silicone heat transfer

agent (white paste) onto the bottom (metal plate)

of the new relay and install it over the stud in the

same orientation as the one removed (use this

procedure picture for the correct relay orientation).

6. Follow the reverse procedure and the wiring

diagram to install the new relay.

CAUTION: DO NOT LOSE THE INSULATION TUBING

PROTECTING THE UPPER END OF THE CONDUIT

BECAUSE IT MUST BE REUSED.

9. Follow the reverse procedure and the wiring diagram

to install the new Air Temperature Sensor.

Note: Loctite #222 must be reused on all threaded

hardware in the reassembly of the inner door panel.

Procedure: Replacement of the Air or Water Relays

Tools: Phillips Head Screwdriver, 11/32 Nut-driver,

Needle Nose Pliers

Parts: Water Relay and/or Air Relay (Item 88 for

Water; Item 89 for Air)

1. Unplug the cabinet from the power source.

Procedure: Replacement of the Air Heating Element

Tools: Phillips Head Screwdriver, 1/8 Slotted

Head Screwdriver, Pliers

Parts: Air Heating Element (Item 47)

1. Unplug the cabinet from the power source.

2. Open both doors and remove the rack assemblies

and crumb tray from the interior of the unit.

3. Remove the corresponding outer side panel.

4. Remove the side insulation and remove the wires

from the element terminals. Use pliers to hold the

terminal so that it will not turn.

27

Page 30

5. Remove the element clips from the interior of the

cabinet, remove the element from the cabinet

and remove the clips from the element by

sliding them around the element sheath and

over the terminal ends.

6. Follow the reverse order to install the new element.

CAUTION: MAKE SURE THAT THE INSULATION IS

REINSTALLED INTO THE SIDE OF THE UNIT FOR

PROPER UNIT OPERATION.

5. Remove the water temperature thermocouple and

the low water sensor wires from the Temperature

Control Board using needle nose pliers and the flat

head screwdriver. Pull the wires through the two

openings in the cavity side to free them from the

unit.

6. Remove the three nuts from the wire terminals of

the heating element and remove the wires.

7. Remove the three nuts from the element retaining plate

and remove the element.

8. Follow the reverse procedure and the wiring

diagram to install the new Water Heating Element.

Procedure: Replacement of the Water Heating

Element

Tools: Phillips Head Screwdriver, 11/32 and 5/16

Nutdrivers, Needle Nose Pliers, 1/8 Slotted

Head Screwdriver

Parts: Water Heating Element (Item 57)

1. Unplug the cabinet from the power source.

2. Remove the excess water, racks, and crumb tray

from the unit.

3. Remove the top of the unit and gently lay the unit

on its left side.

4. Remove the right side panel, bottom cover, side

insulation and the bottom outer insulation from the

unit.

CAUTION: MAKE SURE THAT THE WATER

TEMPERATURE THERMOCOUPLE AND THE LOW

WATER SENSOR WIRES ARE ROUTED THROUGH THE

INSULATION SUCH THAT THE INSULATION LIES

BETWEEN THE WIRES AND THE WATER HEATING

ELEMENT. ALSO MAKE SURE THAT THE SIDE

INSULATION IS REINSTALLED FOR PROPER UNIT

OPERATION.

28

Page 31

Procedure: Replacement of Water High-Limit

4. FOR REPAIR ONLY:

Thermostat

Tools: 11/32 Nutdriver, Phillips Head Screwdriver, 1/8

Slotted Head Screwdriver

Parts: High-Limit Water Thermostat (Item 55)

1. Unplug the cabinet from the power source.

2. Remove the excess water, the racks and the crumb

tray from the unit and gently lay it on its side.

3. Remove the bottom cover from the cabinet and the

outer bottom insulation.

4. Remove the wire from the thermostat and

disconnect the thermostat arm from the brass

jumper.

5. Remove the nut holding the thermostat in place

and remove the thermostat.

6. Follow the reverse procedure to install the new

Water High-Limit Thermostat.

CAUTION: MAKE SURE THAT THE WATER

TEMPERATURE THERMOCOUPLE AND THE LOW

WATER SENSOR WIRES ARE ROUTED THROUGH THE

Procedure: Inspection/Repair/Replacement of the

Thermal/Low Water Sensor

Tools: Phillips Head Screwdriver, 1/8 Slotted Head

Screwdriver, 1/2-inch Open or Box-end Wrench

(2 required). Needle Nose Pliers

Parts: Thermal/Low Water Assembly (Item 48), Teflon

Washer/Spacer Set (Items 61 and 62)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. FOR INSPECTION OF WIRES ONLY: Check the

connections of the thermocouple wires from the

Water Temperature Sensor to the Temperature

Control Board.

Note: It may be necessary to remove the wires and

reinstall them in order to verify whether they are

secure.

INSULATION SUCH THAT THE INSULATION LIES

BETWEEN THE WIRES AND THE WATER HEATING

ELEMENT FOR PROPER UNIT OPERATION.

Gently lay the cabinet on its left side and remove the

side panel, bottom cover, side insulation and the

bottom outer insulation from the unit.

5. Remove the water temperature thermocouple wires

from the Temperature Control Board, using the flat

head screwdriver. Pull the wires through the two

openings in the cavity side to free them from the

unit.

29

Page 32

6. Hold the Sensor Assembly from the inside of the

water pan with a 1/2-inch wrench and remove the

nut from the bottom with the other 1/2-inch wrench.

Parts: Door Sensor Control Board (Item 87)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. REPLACEMENT ONLY:

Disconnect the wires from the Door Sensor Control

Board using needle nose pliers and the slotted head

screwdriver.

4. Remove the four (4) nuts holding the control

board in place and remove it from the unit.

CAUTION: DO NOT LOSE THE SPACERS THAT

POSITION THE CONTROL BOARD TO THE

MOUNTING BRACKET BECAUSE THEY MUST BE

REUSED.

7. Pull the Sensor Assembly through the water-pan

and remove it from the unit.

8. Replace the two-piece teflon washer/spacer

assembly (Items 61 & 62) on the Sensor Assembly

and follow the reverse procedure and the wiring

diagram to install the Sensor Assembly.

9. FOR REPLACEMENT ONLY: Replace the two-piece

teflon washer/spacer assembly (Items 61 & 62) and the

Thermal/Low Water Assembly (Item 48) and follow the

reverse procedure and the wiring diagram to install the

new Sensor Assembly.

CAUTION: MAKE SURE THAT THE WATER

TEMPERATURE THERMOCOUPLE AND THE LOW

WATER SENSOR WIRES ARE ROUTED THROUGH THE

INSULATION SUCH THAT THE INSULATION LIES

BETWEEN THE WIRES AND THE WATER HEATING

ELEMENT. ALSO MAKE SURE THAT THE SIDE

INSULATION HAS BEEN INSTALLED FOR PROPER UNIT

OPERATION.

Procedure: Replacement/Adjustment of the Door Sensor

Control Board

Tools: Phillips Head Screwdriver, 11/32 Nut-driver, 1/8

Slotted Head Screwdriver, Needle Nose Pliers,

Multimeter or Voltmeter with 200 millivolt DC range

and alligator clip leads

5. Follow the reverse procedure and the wiring

diagram to install the new Door Sensor Control

Board.

Note: The following adjustment procedure must be

performed each time the Door Sensor Control

Board or the individual door sensor(s) are replaced.

Please reference the diagram below for the

following procedures.

6. ADJUSTMENT PROCEDURE: Connect the

voltmeter to the control board in areas noted as

Front Door Sensor adjustment (see diagram).

Note polarity.

CAUTION: THE FOLLOWING STEPS ARE

PERFORMED WITH THE POWER CONNECTED TO

THE CABINET. USE APPROPRIATE SAFETY.

30

Page 33

7. Set the voltmeter to the 200mv range, plug the cabinet

into the power source and turn it ON.

8. FULLY OPEN the FRONT door and note the

reading of the voltmeter. Adjust PI so that the

voltmeter reads between +70 and +80 millivolts.

9. Close and open the door. Verify that the door ajar

telite is working and that the reading of the

voltmeter is a NEGATIVE voltage when the door

is closed.

10. Repeat steps 6 through 9 for the REAR DOOR

except connect the voltmeter to the control

board in areas noted as Rear Door Sensor

adjustment and adjust P2 instead of PI (see

diagram).

11. After adjustments have been made, reinstall the

top of the cabinet.

Procedure: Adjustment/Replacement of the Door Ajar

Sensor

Tools: Phillips Head Screwdriver, 1/2-inch Box-end

Wrench

Parts: 5/16 Retainer (Item g). Door Sensor (Item 32, Rear

Door; Item 45, Front Door), Clear RTV

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. Remove the RIGHT side of the cabinet and remove the

side insulation.

4. Remove the corresponding door Striker Plate from the

unit.

31

Page 34

5. Disconnect the sensor wires from the Door Sensor

Control Board and remove the sensor by pulling it

through the cabinet and frame (see diagram below).

6. Using the 1/2-inch box-end wrench, press the 5/16

retainer (Item g) onto the small tube end of the

sensor (Item 32 or 45) so that it is approximately 1

/4-inch past the end of the sensor.

7. Insert the wires through the cabinet and frame

and place the sensor in position.

8. Reinstall the door Striker Plate and verify that the

sensor is recessed a maximum of 1 /32-inch to flush

with the door striker plate. If not, adjust the sensor

position by moving the 5/16 retainer.

9. Seal the sensor end with the clear RTV.

10. Follow the reverse procedure to finish installing the

door sensor.

CAUTION: MAKE SURE THAT THE SIDE INSULATION

HAS BEEN REINSTALLED FOR PROPER UNIT

OPERATION.

11. ADJUSTMENT ONLY:

The Door Sensor Control Board must be adjusted to

the new door sensor whenever they are replaced.

Refer to Replacement/Adjustment of the Door

Sensor Control Board (page 30), steps 6 through 10

for the adjustment procedure.

32

Page 35

Procedure: Replacement of the Timer Display

Board

' Tools: Phillips Head Screwdriver, Needle Nose

Pliers

Parts: Time Display Board (Item 76, Front Display;

Item 91, Rear Display)

3. Disconnect the wires from the Timer Control Board using

the needle nose pliers.

CAUTION: DO NOT USE PLIERS TO REMOVE THE

RIBBON WIRES FROM THE CONTROL BOARD. TO

REMOVE, GENTLY PULL UP ON THE HOUSING USING

YOUR FINGERS.

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. Disconnect the activate and program switches

(as applicable) from the Time Display Board

and the ribbon wire from the timer control

board.

4. Using the needle nose pliers, squeeze the tips

of the board retainers and pull the board from

the retainers.

5. Push the new Time Display Board onto the

board retainers until they "pop" into position.

Reconnect the switches per the wiring

diagram.

6. Follow the reverse procedure to finish installing

the new Timer Display Board.

Procedure: Replacement of the Timer Control

Board

Tools: Phillips Head Screwdriver, 5/16 Nutdriver,

Needle Nose Pliers

Parts: Timer Control Board (Item 77)

4. Remove the four (4) nuts holding the control board

in place. Remove the control board from the unit.

5. Install the new Timer Control Board and verify that

the mode jumper is set for a 2x3 timer. If not,

remove the jumper and reconnect it in the 2x3

timer position.

6. Follow the reverse procedure and the wiring

diagram to install the new Timer Control Board.

Procedure: Replacement of the Timer

Program Switch

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

Tools: Phillips Head Screwdriver, Needle Nose

Pliers

Parts: Timer Program Switch (Item 27)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. Disconnect the switch wires from the Time Display

Board.

4. Push the switch from the rear control panel and remove

it from the unit using needle nose pliers, if required.

5. Follow the reverse procedure to install the new

Timer Program Switch.

33

Page 36

Note: Install the new switch with the red wire closest to

the time display board for proper switch operation.

Procedure: Replacement of a Telite (Red or White)

Tools: Phillips Head Screwdriver, Needle Nose

Pliers

Parts: Telite Red (Item 25) or White (Item 72)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. Remove the wires from the rear of the telite

using the needle nose pliers.

4. Using the needle nose pliers, squeeze the two ears

on the plastic body of the telite and push it out of the

control panel.

5. Follow the reverse procedure to install the new

Telite.

Procedure: Replacement of the Timer Operate

Switch

Tools: Phillips Head Screwdriver, Needle Nose

Pliers

Parts: Timer Activate Switch (Item 66, Front Control; Item 28,

Rear Control)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. Disconnect the wires from the time display board.

4. Using the needle nose pliers, remove the nut from

the back of the switch and remove the switch.

5. Follow the reverse procedure to install the new Timer

Activate Switch.

Procedure: Replacement of the Mode Rocker

Switches

Tools: Phillips Head Screwdriver, Needle Nose

Pliers

Parts: Rocker Switch (Item 70 or Item 74), Rocker

Cover (Item 71 or 73)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. Remove the wires from the switch using needle

nose pliers.

4. Push the rocker switch through the control panel by

depressing the securing clips on the back side of the

switch body.

5. Follow the reverse procedure and the wiring

diagram to install the new rocker switch.

34

Page 37

When installed, gently press the rocker cover into

the front of the switch until it snaps into place.

Procedure: Replacement of Door Ajar/Low Water

Telite(s), all or any part

Tools: Phillips Head Screwdriver, Slotted Head

Screwdriver

Note: If the telite does not work after installation,

reverse the LED electrical connection to the LED

light.

Procedure: Replacement of Low Voltage Power

Transformer

Tools: Phillips Head Screwdriver, Needle Nose

Pliers, 11/32 Nutdriver

Parts: Transformer (Item 80)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. Disconnect the wires from the transformer using

needle nose pliers.

4. Remove the two (2) hex nuts securing the

transformer to the component bracket and remove

the transformer.

5. Follow the reverse procedure to install the new low

voltage power transformer.

Parts: LED Light (Item 26 or 67 or 69) and/or Yellow

Lens (Item 78 or 84 or 95) and/or LED Base

(Item 79, 85, 96)

1. Unplug the cabinet from the power source.

2. Remove the top from the cabinet.

3. Remove the LED lens by gently prying it off from

the front of the control panel using the slotted head

screwdriver.

4. Disconnect the LED connector from the LED and

remove the LED base and light from the unit.

5. Replace the appropriate part and follow the reverse

procedure and the wiring diagram to install the

telite.

Note: If the telite does not work after installation,

reverse the LED electrical connection to the LED light.

35

Page 38

Page 39

Page 40

MODEL DABC-1PS 208V, 3

PHASE-Y, 5 WIRE REVISION C

Page 41

Page 42

ADDENDUM TO

EQUIPMENT MANUAL

#43215

The current version of the Dual Access Biscuit Cabinet has externally adjustable control knobs for air and water

temperature as well as a "dry' operation switch. Front and rear "Door Ajar" lights and sensors are no longer provided

on the cabinets

ITEM PART NO. DESCRIPTION QTY FUNCTION

2 60786 Door handle with Striker Plate 1 Provides access to unit and secures front and rear door

when closed

3 68453 Front door wrap 1 Provides an exterior cover for cabinet door assembly

5 69161 Front control panel sub-assembly 1 Used to mount electrical control components

6 69160 Rear control panel sub-assembly 1 Used to mount electrical control components

7 68134 Rear door wrap 1 Provides an exterior cover for cabinet door assembly

9 60786 Door handle with striker plate 1 Provides access to unit and secures front and rear door

when closed

17 69151 Temperature adjustment panel 1 Used to mount water and air temperature

potentiometers and wet/dry switch

17A 60763 Wet/Dry switch 1 Used lo set interior of cabinet for wet or dry operation

17B 69142 Temperature adjustment knob 2 Used to adjust air and water temperature potentiometers

19 60786 Striker plate with door handle 1 Latches Magnetic handle and secures door when closed

20 65073 Tray rack assembly 2 Supports up to 8 biscuit trays in cabinet cavity

22 68402 Front door interior panel 1 Secures door gasket and protects insulation

26 — Deleted — —

32 — Deleted — —

33 60786 Striker plate with door handle 1 Latches magnetic handle and secures door when closed

39.40.41 — Deleted — —

42 68394 Rear door air sensor 1 Senses air temperature inside cabinet

45 — Deleted — —

46 68412 Cavity assembly 1 Provides intenor surface of cabinet

48 66945 Thermal/low water sensor 1 Senses water temperature and level in water pan

53 65181 Base 1 Base for wheels to attach to

55 65478 High limit water thermostat 1 Safely device which prevents excessive water pan

temperature

59 65188 Base cover extension 1 Covers water heating element and associated wiring

61 65476 Shoulder washer 1 Water seal and upper insulator for sensor

62 65475 Washer 1 Water seal and lower insulator for sensor

65 68400 Frame assembly 1 Substructure of the entire cabinet

67 — Deleted — —

80 63049 Transformer 1 Provides low voltage power to electronic controls

82 69064 Temperature controller 1 Solid state controller for the air and water temperature

87 — Deleted — —

90 68411 Electronic component bracket 1 Used to mount electrical control components

95.96 — Deleted — —

1996

WELLS MANUFACTURING COMPANY

Page 43

OPERATING INSTRUCTIONS

for DABC-1 with AUXILIARY OPERATION CONVERSION-140

Standard Operation:

1. Ensure that the power cord is plugged in.

2. Ensure that the water pan is filled approximately

2/3rds full with ice or melted ice.

3. Push the power switch to the "STD" position (top).

4. Verify the air and water temperature settings.

5. Allow the unit to warm up for 45 minutes before

placing product inside.

USE THE STANDARD PMS CARD »#64 FOR CALIBRATION AND TEMPERATURE SET INSTRUCTIONS.

Auxiliary Operation;

1. Ensure that the power cord is plugged in.

2. Ensure that the water pan in EMPTY.

3. Push the power switch to the "AUX" position (bottom).

4. Verify that the air temperature setting is at 140° +/- 5°F. (this cannot be adjusted from

the front panel controls. If it is not correct, refer to the DABC-I Auxiliary Operation

Temperature Setting Instructions).

5. Allow the unit to warm up for I hour before placing product inside (or 15 minutes if you

are changing from the "STD" to the "AUX" mode).

NOTE: The auxiliary power switch position turns off the water heater and low water

indicator, plus it also automatically sets the air temperature to 140° +/- 5°F.

Auxiliary Temperature Setting:

CAUTION; THE FOLLOWING PROCEDURE IS PERFORMED WITH POWER

TO THE UNIT AND EXPOSED ELECTRICAL WIRING.

1. Remove the top from the cabinet and push the power

switch to the "AUX" position (bottom).

2. Place the operation switch on the front control panel to the "SET" position (display is

blinking when the switch is in the set position) and the mode switch to the "AIR"

position.

EPC06/29/892001-0I45263 P/N 45263 Rev. C

Page 44

DABC-I Instructions-14O page 42

3. Locate and adjust the pot that is mounted on a separate printed circuit board and secured

to the temperature control board behind the front control panel. This pot adjusts the

"AUX" air temperature only.

4. Calibration of the cabinet is accomplished in the "STD" power switch setting only. Refer

to PMS card #64 for instructions. (The "AUX" temperature is calibrated at the same time

as the "STD" temperature.)

5. Turn the power off and replace the top of the unit.

P/N 45263 Rev. C

Page 45

DUAL ACCESS BISCUIT CABINET

MODELS DABC-1PSP and DABC-1TL with adiustable controls

TO ADJUST TEMPERATURE:

1. Select SET TEMP on Operate / Set Temp Switch on the front panel.

2. Select AIR or WATER on the Air / Water Switch on the front panel to display AIR or WATER set temperature. Display

will blink.

3. Rotate AIR TEMP. ADJUST, or WATER TEMP. ADJUST knob on side of cabinet CLOCKWISE to INCREASE or

COUNTERCLOCKWISE to DECREASE air or water temperature setting.

4. Select WET on the Wet / Dry Switch on the side of the cabinet if a WATER SET TEMPERATURE is required ( Make sure

that the water pan has been filled with water. ).

5. Select DRY on the Wet / Dry Switch on the side of the cabinet if a WATER SET TEMPERATURE is NOT required ( Moke

sure that the water pan has been emptied. >. The LOW WATER ALARM and WATER HEAT will be disabled and will not

turn on.

1991 WELLS MANUFACTURING CO. INC.

PRINTED IN U.S.A

Item No 4922

REV (-)

Page 46

DABC-I PASTA CONVERSION INSTRUCTIONS

NOTE: If the power switch has an "Aux" position, omit Steps 2 - 6

1. Disconnect power supply cord (plug) from power receptacle, remove

top cover by removing the 4 screws that secure the top to the cabinet and

lift off top cover.

2. Remove original red On/Off rocker type double pole power switch from the rear

control panel by squeezing the 4 plastic retaining fingers at the top and bottom of

the switch housing and applying pressure to the rear of the switch. Disconnect all

the wires from the 4 push-on terminals.

3. Install a new "Aux/Std" combination trim plate and mounting bracket by inserting

through window in rear control panel* (The new <» pole rocker power switch mounts

on the rear of this bracket.)

4. Unplug the piggy-back terminals on pin <4 of the water relay. (Leave wires 26

and 34 connected together.) Tape the junction of these two wires with electrical

tape to prevent the terminals from short ing to other terminals or metal objects.

(See the wiring diagram supplied with the kit.)

5. Reconnect original cabinet wiring per the new wiring diagram (supplied with kit)

and connect new wiring leads to new power switch per wiring diagram. Connect new

wires 69 through 72 and connect the 5 in-line splice connectors supplied with the

kit to the other end of these <4 wires, and one end of wire 73. Connect the other

end of wire 73 to pin <» of the water relay. Install jumpers 7<» and 75 and wires

65 and 66 to the switch.

NOTES Make sure all push-on terminals are tight. If you can remove any of these

terminals by pulling on the wires, they are not tight enough and you will have to

pre-load the female terminal (with the connector unplugged) by lightly squeezing the

rolled edges of the connector terminal with long nose pliers to ensure a tight

connection between the male and female terminals.

6. Assemble the new <» pole power switch to the mounting plate installed in Step 3

by snapping the 4 metal tabs into the 4 front rectangular holes in the bracket.

EPC05/13/91@0002-CI46538 P/N 46338

Page 47

DABC-I Pasta Conversion Instructions

page 45

7. NOTE: Applies to cabinets with "Aux" power switch position only.

Remove wire 73 from the power switch and install I in-line splice connector supplied

with the kit to wire 73.

PRINTED CIRCUIT BOARD REMOVAL AND REPLACEMENT WITH AUXILIARY OPERATION PRINTED CIRCUIT BOARD

NOTE; Spacers between the rear of the printed circuit board and the from control

panel must be reused when installing the new auxiliary operation printed circuit

board.

Remove the original temperature control printed circuit board P/N 60816 (or 63305)

9.

from the front control panel by removing the 5 wires ((4, 18, 19, SO and 23) from the

original printed circuit board and the 4 mounting nuts from the mounting studs. Be

sure the spacers listed in the warning above are left in place on the studs.

NOTE: On printed circuit board P/N 63305, remove the red, violet,

black and orange wires from the in-line splices.

9. Remove the thermocouple leads from the 4 pin terminal block on the

upper left of the controller board.

10. Remove the water and air relay control wires (21 and 22) from the

controller board pins marked water and air .

Remove the orange 8 pin terminal block from the right side of the controller board by

inserting a small flat blade screwdriver under the terminal block and lifting it

straight up and off the pins on the board. (It is not necessary to remove the wires

from the terminal block to remove the block from the board.)

NOTE: There are 2 anti-static single color band resistors attached to the 4 screw

terminals on the terminal block on the left side of the printed circuit board. These

2 resistors MUST be removed from the new controller board and reinstalled on the old

controller board to protect it from static damage during shipment.

Install the new controller board P/N 66521 on the front control panel, reconnect

wires (4, 18, 19, 20, 21, 22 and 23 to the proper push-on terminals on the board,

reconnect the thermocouple leads removed in Step 8 above, make sure the red leads are

on top and the yellow lead are on the bottom (see wiring diagram for wiring

connections). Reinstall the orange terminal block removed in Step 10 above.

Page 48

DABC-1 Pasta Conversion Instructions page 46

13. Connect the orange wire from the printed circuit board to the new wire 69, the black

wire to the new wire 73, the red wire to the new wire 71, the violet wire to the new

wire 72.

NOTE: Make sure all push-on terminals are tight. If you can remove any of these terminals by

pulling on the wires, they are not tight enough and you will have to pre-load the female

terminal (with the connector unplugged) by' lightly squeezing the rolled edges of the

connector terminal with long nose pliers to ensure a tight connection between the male and

female terminals.

14. Inspect general layout of components altered during this conversion for lead dress and

mounting to avoid shorting of components or wiring

15. Fill the water pan, connect the power cord plug to the proper 120VAC supply. Place the

"Operate/Set" rocker switch to the "Set" position. Place the "Air/Mater" rocker switch

in the "Air" position. Turn the new "Power Switch" to the "Aux" position.

16. The digital display will be flashing. With a small flat blade screwdriver, adjust

the "Air Set" potentiometer on the REAR of the controller printed circuit board

(adjust only the one on the small auxiliary printed circuit board attached to the

rear of the printed circuit board) to show a flashing 165°F ((74degC)).

NOTE; If the display shows a "C" in the upper window just to the right of the temperature

display, the small toggle switch located in the upper left of the printed circuit board is

switched to the Celsius position.

17. Place the "Air/Mater" rocker switch in the "Water" position.

18. The digital display will be flashing. With a small flat blade screwdriver, adjust the

"Water Set" potentiometer on the REAR of the controller printed circuit board (adjust

only the one on the small auxiliary printed circuit board attached to the rear of the

controlle printed circuit board) to show a flashing 165°F ((74degC)) reading.

19. Roll up the new wiring diagram and place it at the right side of the unit on top of the

timer board cover between the ribbon cable and the sidewall. Install the top assembly

on the cabinet with the 4 screws removed at the start of the conversion.

Page 49

DABC-1 Pasta Conversion Instructions page 47

20. Set the new power switch to the "Std" position. Pry off the snap-in cover plate on

the front control panel. When looking into the hole where the snap-in cover was

just removed, you will see the adjustment potentiometers for setting the air and

water temperatures for standard operation. The upper left potentiometer is the

"Air" set. Set it for 145°F (63°C). The display will be flashing.

21. Position the "Air/Water" rocker switch to the "Water" position. The display will be

flashing. Adjust the lower left potentiometer to give a flashing 135°F (57°C)

reading. (The 2 potentiometers on the right are for calibrating the air and water.

(See Card No. 64 to adjust.)

This completes the "Pasta" conversion of the unit. A calibration check is now required'.

Use the Standard Maintenance Card No. 64 published for this unit to perform the normal

calibration of the air and water sensors.

WARNING: The water pan must have water in it for calibration.

NOTE: Instruct store management personnel on the operation of the unit in the "Aux"

operation mode. Be sure to advise them that a 15 minute period of stabilization of the

temperature inside is required before changing products after changing from "Aux/Std"

modes. Also advise them of the location of the auxiliary temperature "Set" potentiometer

and that the adjustment cannot be accessed through the front control panel. This

adjustment can only be accessed from inside the component area with the too removed.

Page 50

Loading...

Loading...