Page 1

IMPORTANT:

WELLS MFG. PROPRIETARY INFORMATION

TECHNICAL CONTENT OF THIS MANUAL IS DESIGNED FOR

WELLS MANUFACTURING COMPANY

2 ERIK CIRCLE, P. O. Box 280

Verdi, NV 89439

Customer Service (775) 345-0444 Ext.502

fax: (775) 345-0569

www.wellsbloomfield.com

SERVICE

INSTRUCTIONS

BELGIAN

211

for

WAFFLE

BAKERS

Model

BWB-1S

USE BY QUALIFIED PROFESSIONAL TECHNICIANS ONLY

Part No. 502972 Rev. A S211 111000 cps

Page 2

GENERAL SAFETY PROCEDURES

Knowledge of proper procedures is essential to the safe operation of electrically energized

equipment. In accordance with generally accepted product safety labeling guidelines for

potential hazards, the following signal words and symbols are used throughout this manual.

DANGER - Danger is used to indicate the presence of a hazard which will

DANGER

WARNING - Warning is used to indicate the presence of a hazard which can cause

personal injury and possibly death, or major property damage, in the event the statement is ignored.

CAUTION - Caution is used to indicate the presence of a hazard which will or can

cause minor personal injury, or property damage in the event the statement is ignored.

CAUTION - Used to indicate the presence of an electrical hazard which will or can

cause personal injury, or property damage in the event the statement is ignored.

cause severe personal injury, death, or substantial property damage in the

event the statement is ignored.

NOTE - Note is used to notify personnel of installation, operation or maintenance informa-

tion which is important, but not hazard related.

WAFFLE BAKER PRECAUTIONS

AND GENERAL INFORMATION

1. This waffle baker is intended for use to bake food products for human consumption. No other use is

recommended or authorized by the manufacturer or its agents.

2. Service technicians must be familiar with the appliance use, limitations and associated hazards.

Operating instructions and warnings must be read and understood by all service personnel.

3. This piece of equipment is made in the USA and has American sizes on hardware.

4. This manual supplements the Installation, Operation and Maintenance (IOM) manual p/n 45257 for

this equipment. Refer to the IOM for normal operational procedures. Any trouble shooting guides,

component views, wiring diagrams or parts lists included in this manual are intended for use by

qualified technical personnel only.

xi

Page 3

TABLE OF CONTENTS

General Safety Procedures Inside Cover

Specifications 1

Features and Operating Controls 2

Servicing Precautions for This Equipment 3

Troubleshooting 4

Servicing Instructions 6

Wiring Diagrams 11

Parts Breakdown 12

DIMENSIONS

Wide 10-1/8”

Deep 14”

High 10-9/16”

ELECTRICAL

Voltage 120 VAC 1Ø

Amperage 7.5 Amp

Wattage 900 W

Cord NEMA 5-15P

GENERAL SPECIFICATIONS

1

Page 4

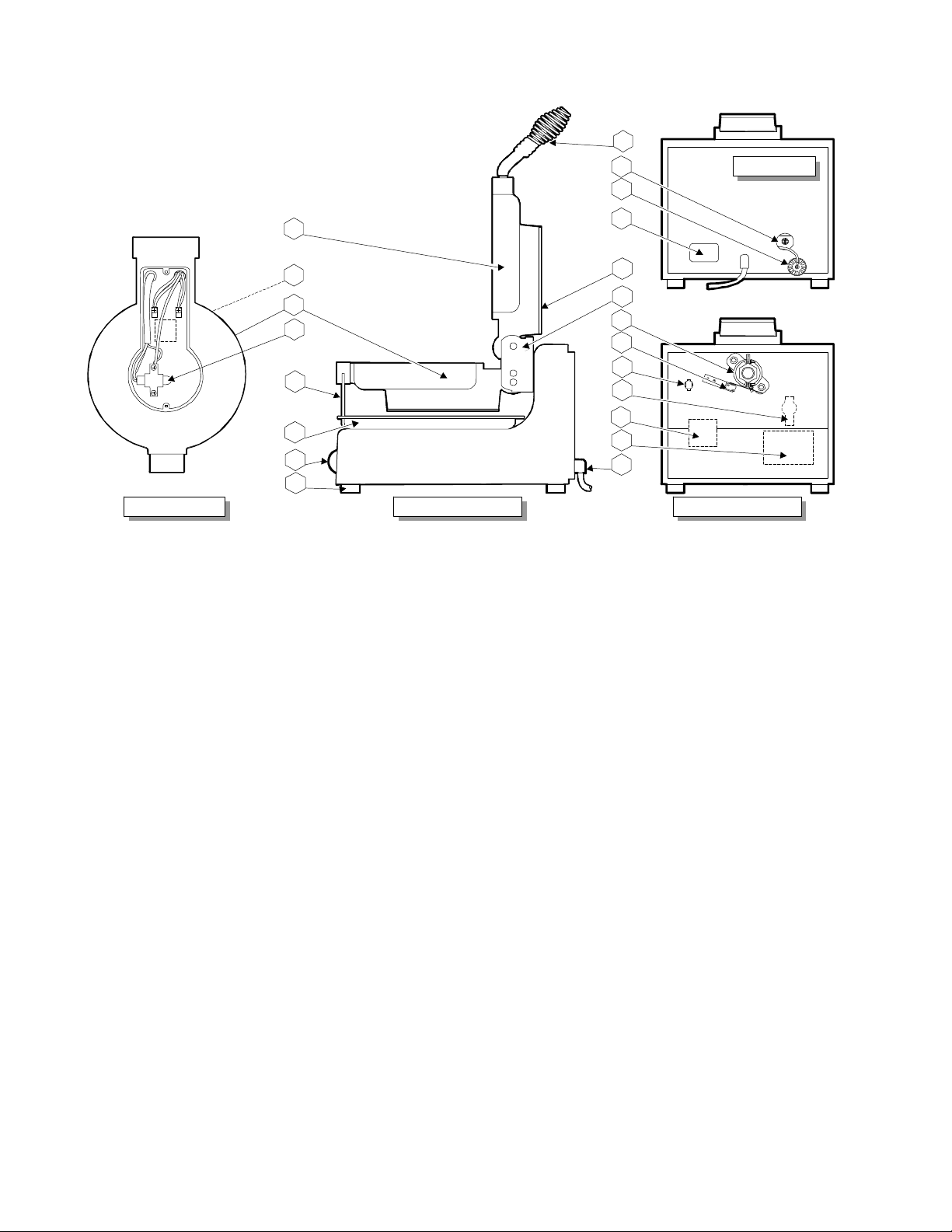

FEATURES AND OPERATING CONTROLS

.1

9

2847827481039

17

48

19

BACK VIEW

43

73

42

16

18

75

66

41

BOTTOM GRID

wiring cover removed shown in “open” position

RIGHT SIDE VIEW

20

40

8. POWER CORD 115VAC NEMA 5-15P

9. DATA PLATE Specifies power requirements

10. MICRO SWITCH Initiates timer

16. TEMPERATURE PROBE Thermistor temperature sensor

2

1

INTERIOR VIEW

back panel removed

3

4

5

6

17. HANDLE ASSY Used to raise / lower / rotate grids

18. SUPPORT BRACKET Supports front of grids

19. HOLE PLUG Allows access to timer adjustment

20. WIRING COVER Protect wiring in grids

27. TEMP. CONTROLLER In concert with thermistor, controls temperature of grids

28. INDICATOR LIGHT Lit during timed cook cycle

39. BEARING ASSY Supports back of grids; allows grids to rotate

40. PIVOT ASSY Holds grids in alignment; allows grids to rotate

41. RUBBER FEET Provide necessary non-slip support for waffle baker

42. BOTTOM GRID Cooking element; holds temperature probe

43. TOP GRID Cooking element

47. BUZZER Sounds momentarily at end of cook cycle

48. TIMER Audio alarm - warns operator of end of cook cycle

66. POWER SWITCH Energizes the Waffle Baker

(73.) (HI-LIMIT THERMOSTAT) Eliminated on later models. See page 11.

75. DRIP TRAY Catches excess waffle batter for easier clean-up

2

Page 5

PRECAUTIONS FOR SERVICING THIS EQUIPMENT

GROUND

Disconnect electrical power to equipment prior to performing cleaning or other service.

In order to avoid electrical shock, injury and/or equipment damage, use appropriate

precautions whenever electrical power must be restored for adjusting, calibrating or

taking voltage measurements.

Ensure that input power matches the nameplate data for voltage and phase.

Input power circuit must meet or exceed the nameplate power requirements.

Equipment is equipped with the proper electrical plug for the specific power

requirements of the unit. DO NOT alter the power cord or plug. Never cut off a ground

prong, or twist a prong, to allow the plug to fit an existing receptacle.

CAUTION: This Wells Waffle Baker is equipped with a three-

prong electrical plug. The three-prong plug is part of a system

that will protect you in the event of an electrical wiring failure.

Be sure the three-prong plug is plugged into a matching and

properly grounded three-prong receptacle. DO NOT cut or

break off the ground prong of this plug.

OPERATING AN APPLIANCE WITHOUT PROPER GROUNDING

CAN RESULT IN SERIOUS PERSONAL INJUR Y

PRONG

CAUTION: Test electrical receptacle for proper polarity. For the safety of personnel,

it is important that electrical ground and electrical neutral are maintained as designed

by the factory.

CAUTION: DO NOT plug in or energize this appliance until Installation

Instructions are read and followed. Injury to the operator and damage to the Waffle

Baker may occur if these instructions are not followed.

CAUTION: Never submerge electrical equipment in water.

Avoid contaminating electrical components with water when cleaning cooking surfaces

or cabinet.

IMPORTANT: Never use a wire brush or metal scraper on aluminum components. Use a soft

bristle, fiber brush to clean grids.

Data sheets and text in this manual are representative of current production models as of

November, 2000. Specifications, Model Numbers, Product Numbers and data are subject to

change at any time without notice.

Whenever servicing is required to correct electrical or temperature complaints, always refer service

to a Wells Factory Authorized Service Agency.

Refer to Wells Form #37000 for a complete listing of factory authorized service agency locations.

3

Page 6

TROUBLE SHOOTING

test points are terminals

CAUTION: ELECTRIC SHOCK HAZARD

Live electrical circuits are exposed

during troubleshooting procedures

CAUTION: BURN HAZARD

Equipment surfaces will be hot

during troubleshooting procedures

B. TEMPERATURE CHECKS

1. Desired baking temperature is 390ºF ±5ºF (200ºC ±3ºC).

2. Turn the power switch ON and allow the Waffle Baker to heat for

a minimum of 30 minutes. Insert a pyrometer of known accuracy

betwen the grids and allow the readings to stabilize.

3. Temperature may be adjusted by removing the back panel,

and turning the dial on the temp controller:

CW to decrease temperature; CCW to increase temperature.

NOTE: Manufacturer’s calibration point (390ºF) is indicated by a black dot on the face of the dial.

A. ELECTRICAL TEST POINTS

390ºF

CALIBRATION

POINT

TP1

TP3

ELEMENT / GRID

bottom shown - top similar

TP2

TP4

TEMPERATURE CONTROLLER

test points are terminals

TIMER MODULE

B. AMPERAGE AND RESISTANCE CHECKS

1. Amperage may be checked with an inductive amperage tester (Amprobe™ or similar) by encircling

wire #4 at temperature controller terminal 2. Total amperage is 7.5 Amps with the waffle baker in

the pre-heat mode.

2. The heating element is integral with the Grid casting.

Disconnect wire #7 to #8 from temperature controller to check resistance of both grids at once.

Resistance from # 7 to #8 is 16Ω (cold) ± 1Ω. A reading of 32.0Ω indicates one defective element

or a broken element jumper wire.

Data for one element: 450 Watts, 3.8 Amps

Resistance of one element TP1 to TP2, (wires disconnected) is 32.0Ω (cold) ± 1Ω.

4

Page 7

D. VOLTAGE CHECKS

NOTE: Resistance of the temperature probe is typically 5 megohm at room temperature, with

resistance decreasing as temperature rises. A shorted temperature probe will cause a runaway

condition, and an open probe will cause a continuous OFF condition.

1. Voltage between temperature controller terminals 2 & 3 will be 120V any time the power switch

(item 66) is turned ON. Absence of 120V indicates power switch OFF or defective, or a wiring or

connector problem.

2. Voltage between TP1 and TP2 will be 120V when the unit is calling for heat. Absence of 120V,

when heating is required, indicates:

a.) Power switch defective or OFF; or,

b.) Temperature controller defective or open temperature probe; or,

c.) Wiring or connector problem

3. Voltage between TP1 and TP2 will be 120V when the unit is calling for heat. Failure to heat

when 120V is present indicates that the element being tested is defective.

4. Voltage between temperature controller terminals 1 & 3 will be 120V when the thermostat is

calling for heat. Absence of 120V, when heating is required, indicates:

a.) Power switch defective or OFF; or,

b.) Temperature controller defective, or

c.) Shorted temperature probe or probe wiring shorted (check between terminals 4 & 5); or,

d.) Wiring or connector problem

5. TP3 and TP4 are found only on waffle bakers equipped with a hi-limit thermostat. The hi-limit

thermostat should be removed and bypassed to increase the reliability of the waffle baker.

NOTE: Newer waffle bakers do not use a hi-limit thermostat. Existing hi-limit thermostats may

be safely removed and bypassed without affecting the UL approval. See page 11.

6. Voltage between timer terminals 2 & 3 is 120V any time the power switch is ON. Absence of 120V

indicates:

a.) power switch defective or OFF; or,

b.) a wiring or connector problem

7. Voltage between timer terminals 5 & 6 is 0V when the microswitch (item 10) is activated. Any

voltage other than 0V indicates a defective microswitch, or a wiring or connector problem.

8. Voltage between timer terminals 1 & 2 is 120V during the cook cycle. Absence of 120V indicates

a defective timer module.

9. An indicator light NOT lit when reading a voltage between timer terminals 1 & 2 is 120V indicates:

a.) loose or defective wiring to the indicator light; or,

b.) defective indicator light

10. Voltage between timer terminals 2 & 4 is momentarily 120V at the end of the cook cycle.

Absence of 120V indicates a defective timer module.

5

Page 8

SWITCH

SEAL

BOTTOM

SERVICING INSTRUCTIONS

CABINET

SUPPORT BRACKET

TRADEMARK PLATE

RETAINER

A. CABINET ASSEMBLY

SEAL

INDICATOR

GUARD

ON/OFF PLATE

PANEL

RUBBER FOOT

1. Insert the trademark plate from the front. From the rear of the cabinet, slide retainers over the

trademark plate pins. Using a deep socket, tap the retainers down until they are flush with the

cabinet surface.

2. Attach wires 1, 2, 3 & 4 to the switch. Thread one nut onto the switch shaft approximately 1/2”, then

slide the switch seal over the switch shaft. Insert the switch from the rear of the cabinet. Slide the

guard, then the on/off plate over the switch shaft. Thread on and tighten the second nut.

3. Work the seal over the body of the indicator light, then press the indicator into the cabinet until it

pops securely into place.

4. Install the support bracket.

5. Screw four rubber feet into the bottom panel, then install the bottom panel onto the cabinet.

6

Page 9

HOLE PLUG

TEMPERATURE

ALL GROUND

ADJUSTMENT

WIRES

CONNECT TO

THIS STUD

BUZZER

TIMER

TIMER BRACKET

PC BOARD STANDOFF

ASSEMBLY

POWER

CORD

STRAIN

RELIEF

THERMAL

MASTIC

HEAT SINK

BACK

PANEL

FOAM

TAPE

CONTROLLER

MODULE

B. BACK PANEL ASSEMBLY

1. Apply foam tape to the back panel flange - inside surfaces for the right, left and bottom; outside

surface for the top.

2. Insert the power cord into the strain relief, then install the strain relief from the outside of the back

panel.

3. From the outside, thread the ground wire of the hole plug assembly thru the large hole in the back

panel. Tap the hole plug into place.

4. Press the adjustment module onto pin 6 of the temperature controller and secure it with a dab of

silicone sealant. Press the wire lead of the adjustment module onto pin 2. Coat both faces of the

heat sink with thermal mastic (heat transfer compound). Slide the heat sink, then the

temperature controller over the stud closest to the data plate embossing. The adjustment module

should be oriented down and toward the outside.

5. Insert four printed circuit board standoffs into the timer bracket. Push them until the button head is

flush against the inside surface. Slide the bracket over the stud closest to the large hole, then

secure with two screws from the bottom.

6. Slide the buzzer over the same stud as the timer bracket.

7. Lightly thread the nut onto the stud to retain the buzzer. Upon wiring the unit, after all ground wires

have been attached to this stud, tighten the nut securely to ensure a positive chassis ground

connection.

7

Page 10

C. TOP GRID

687

TEMP

PROBE

PROBE

RETAINER

GRID

1. Prepare grid casting by applying a small amount of

anti-sieze paste to all threaded holes.

2. Feed wires 5, 6 & 20 thru the right feed-thru hole.

Attach wires 5 & 6 to the element terminals. Attach

wire 20 to the center-most boss at the front of the

casting.

3. Pull the wires back until they have only a small

amount of slack. Seal both sides of both feed-thru

holes with hi-temperature silicone sealant.

4. Install the grid cover.

D. BOTTOM GRID

1. Prepare grid casting by applying a small amount of

anti-sieze paste to all threaded holes.

2. Set the grids waffle-side down, and with the rear

portions touching. This positions the grids properly

for later assembly.

3. Feed the temperature probe leads and wire 10 thru

the hi-temp tubing, then thru the left feed-thru hole.

4. Feed wires 5, 6, & 20 (from top grid) and wires

7 & 8 thru the right feed-thru hole. Attach wires

5 & 8 to one element terminal, and wires 6 & 7

to the other element terminal.

5. Set the temperature probe between the two screw

bosseswith its round nose pointing to the right.

Slide the retainer over the probe. Install the screws

with wires 10 & 20 attached to the center-most screw

boss.

6. Route wires as shown. Pull the wires and hi-temp

tubing back until they have only a small amount of

slack. Seal both sides of both feed-thru holes with

hi-temperaturesilicone sealant.

7. Install the grid cover.

HI-

TEMP

TUBING

see page 11

5

20

10

8

Page 11

E. GRID ASSEMBLY

BOTTOM GRID HINGE

TEFLON DRIP GUIDE

HANDLE

ASSEMBLY

1. Turn and position the grids so that the waffle-sides are facing each other. Thread the hi-temp tubing

thru the shaft of the pivot housing. Attach the pivot housing to the bottom grid with screws (bottom

hole) and screws with washers (middle hole). Use anti-sieze paste on the screw threads, but do

not tighten the screws yet.

2. Insert the pivot shaft thru the pivot housing and top

grid, making sure wires 5, 6 & 20 are routed between

the pivot shaft and the body of the top grid casting.

Secure the pivot shaft with “C” clips on each end.

3. Verify that the top and bottom grids match at the

mating surfaces, then tighten the screws securing

the pivot housing to the bottom grid.

4. Thread the brass bushing over hi-temp tubing and the

shaft of the pivot housing. Press the bushing all the

way against the face of the pivot housing.

5. Install the handle asembly in the top grid. Use

Loctite on the screw threads

6. Install the top grid wiring cover, then the teflon drip

guide and bottom grid wiring cover. Use anti-sieze

paste on the screw threads.

7. The top grid should pivot smoothly. Gently bend the

upper lip of the bottom grid wiring cover until the gap

between wiring covers is maintained thru the entire

swing of the top grid, and the top grid closes

completely on the bottom grid.

TOP GRID HINGE

WIRING COVER

WIRING COVER

9

Page 12

F. PIVOT BEARING ASSEMBLY

1.

2. Looking into the back panel, turn the bearing until the set screws are at the 10:00 and 2:00 position.

3. Thread the wires of the grid assembly thru the pivot bearing from the outside, then insert the pivot

4. If not already present, assemble the support

4. Rotate the grid assembly to the COOK position.

5. Using Loctite on the threads, assemble the

The pivot bearing may be out of alignment as it comes from the box. Tap the collar of the bearing

with a plastic hammer until the axis of the bearing is perpendicular to the base. Attach the pivot

bearing to the inside of the cabinet. The zerk fitting points downward. Use Loctite on the threads.

Assemble the actuator to the pivot bearing. The set screws will protrude thru the holes on the

actuator halves. The long arm of the actuator should point down, with the screws pointing left.

housing shaft into the pivot bearing. Thread the actuator nut on the pivot housing shaft using

Loctite on the threads. Tighten the pivot nut until the grid assembly rotates freely, but latches

securely into the detent.

bracket to the cabinet. Make sure the front of

the grid assembly rides smoothly in the support.

Make sure the long arm of the actuator points

straight down, then tighten the set screws.

microswitch to the switch saddle. Install the

switch assembly into the cabinet. Adjust the

position of the microswitch until a single CLICK is

heard from the microswitch as the long arm of the actuator contacts the microswitch arm and the

grid assembly rotates into the cook position detent.

10

Page 13

G. BYPASS HI-LIMIT THERMOSTAT

1

2

3

45N.C.

N.O.

CONNECTOR (2)

TEMPERATURE

437812

TEMP.

SENSOR

LOWER

HEATING

ELEMENT

HEATING

ELEMENT

5

MICRO

SWITCH

719CERAMIC

WIRE NUT

1. The hi-limit thermostat in this Belgian Waffle Baker has been found to be unnecessary. Wells

BWB-1S has been tested and approved by UL for use without the hi-limit thermosat.

2. All units requiring service, whether in or out of warranty, should have the hi-limit thermostat

bypassed.

3. With the power cord unplugged, remove wires

7 & 19 from the hi-limit thermostat (located in the

bottom grid).

7

4. Cut the push-on terminals from wires 7 & 19, as

close to the terminals as possible.

5. Remove 1/2” of insulation from the ends of wires

7 & 19. Connect the wires together using a ceramic

wire nut of the appropriate size.

6. Plug the waffle baker in, and test for proper

operation.

HI-LIMIT

THERMOSTAT

19

white

black

green

POWER CORD

11

16

10

INDICATOR

LIGHT

1

14

WIRING DIAGRAM

POWER

SWITCH

17

TIMER

6

5

4

15

9

13

COM

1

2

2 3

BUZZER

L1

L2

CONTROLLER

20

6

UPPER

VOLTS AMPS 1Ø

120 7.5 50/60 Hz

11

p/n 44867 Rev.D

Page 14

PARTS BREAKDOWN

REF DESCRIPTION PART

# #

1 BOTTOM PANEL

2 BACK PANEL

3 WRAP, CABINET ASSEMBLY

5 SWITCH SADDLE

6 TRADEMARK PLATE

7 RETAINER, TRADEMARK (pk 10) 51038

8 CORD, 125v 15a NEMA 5-15p 55539

9 DATA PLATE

10 SWITCH MICRO 120V 15A 64887

12 STRAIN RELIEF 51217

15 RETAINER RING (pk 10) 50222

16 PROBE, THERMISTOR, BWB-1S 64872

17 HANDLE ASSY BWB-1S 62257

18 BRACKET, FRONT SUPPORT BWB-1S 62028

19 HOLE PLUG ASSY 61064

20 COVER, BWB-1S 62029

21 ACTUATOR

22 SPACER, BWB-1S 62035

23 PIN PIVOT UPPER HINGE, BWB-1S 62018

24 COVER, WIRING, UPPER BWB-1S 62023

25 COVER, WIRING, LOWER BWB-1S 62031

27 CONTROLLER,TEMPERATURE BWB-1S 64276

28 LIGHT, INDICATOR RED 60758

31 POP RIVET, 1/16 1/8

32 SLEEVING, HI-TEMP (8.5") 64201

39 BEARING, BWB-1S 62232

40 HOUSING ASSY, PIVOT 62006

41 RUBBER FEET, (pk 4) 21657

42 GRID & ELEMENT, LOWER BWB-1S 62007

43 GRID & ELEMENT, UPPER BWB-1S 62008

44 NUT, PIVOT HOUSING

45 TIMER BRACKET

46 STANDOFF, PC BOARD BWB-1S 63565

47 BUZZER 60529

48 TIMER, ELECTRONIC, BWB-1S 63179

50 LABEL, DO NOT IMMERSE

62 SEAL, O-RING, SIGNAL LIGHT 64890

64 ON-OFF PLATE 53192

65 SWITCH GUARD

66 SWITCH, TOGGLE W/SEAL 64904

67 HOLDER, PROBE BWB-1S 64885

75 DRIP TRAY, BWB-1S 21107

76 FOAM TAPE

77 HEAT TRANSFER COMPOUND (THERMAL MASTIC) 66160

78 HEAT SINK 502900

79 TEFLON DRIP GUIDE 503523

NOT SHOWN:

WIRING DIAGRAM BWB-1S 44876

WIRESET BWB-1S (OVER HEATED OR RUNAWAY TEMP DAMAGE) 64917

ELEMENT JUMPER WIRESET ONLY 502863

12

Page 15

20

66

274619

128319767778

67

16

42

79

25

BWB-1S BELGIAN WAFFLE BAKER

EXPLODED VIEW

21 44 5

32

39

22

10

65

64

24

40

43

17

20

18

2

76

23

50

15

3

7

6

47

45

48

62

28

41

1

75

13

Page 16

IMPORTANT:

TECHNICAL CONTENT OF THIS MANUAL IS DESIGNED FOR

USE BY QUALIFIED PROFESSIONAL TECHNICIANS ONLY

WELLS MFG. PROPRIETARY INFORMATION

WELLS MANUFACTURING COMPANY

2 ERIK CIRCLE, P. O. Box 280

Verdi, NV 89439

Service Parts Dept. (888) 492-2782

fax: (888) 492-2783

wservice@ellsbloomfield.com

Loading...

Loading...