Page 1

WELLS MANUFACTURING COMPANY

2 ERIK CIRCLE, P. O. Box 280

Verdi, NV 89439

Customer Service (775) 345-0444 Ext.502

fax: (775) 345-0569

www.wellsbloomfield.com

OPERATION

MANUAL

BELGIAN

WAFFLE

BAKER

211

for

Model

BWB-1S

includes:

INSTALLATION,

OPERATION

and

PREVENTATIVE

MAINTENANCE

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the BELGIAN WAFFLE BAKER

and is to be given to the OWNER or MANAGER of the restaurant, or to

the person responsible for TRAINING OPERATORS of this WAFFLE

BAKER. Additional manuals are available from your Wells Dealer.

P/N 45257 Rev. D M211 111500 cps

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS

USING OR INSTALLING THIS BELGIAN WAFFLE BAKER.

Contact your Wells Dealer if you have any questions concerning

installation, operation or maintenance of this appliance.

Page 2

LIMITED WARRANTY STATEMENT

All commercial cooking equipment manufactured by

WELLS MFG. CO. is warranted against defects in

materials and workmanship for a period of one year

from the date of original installation or 18 months

from the date of shipment from our factory, whichever comes first, and is for the benefit of the original purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW

OR IN FACT, INCLUDING BUT NOT LIMITED TO,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, AND/

OR FOR DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH WELLS

MFG. CO. PRODUCTS. This warranty is void if it is

determined that, upon inspection by an authorized

service agency, the equipment has been modified,

misused, misapplied, improperly installed, or damaged in transit or by fire, flood or act of God. It also

does not apply if the serial nameplate has been removed, or if service is performed by unauthorized

personnel.

The prices charged by Wells Mfg. Co.for its products are based upon the limitations in this warranty.

Seller’s obligation under this warranty is limited to

the repair of defects without charge by a Wells Mfg.

Co. factory authorized service agency or one of its

sub-service agencies. This service will be provided

on customer’s premises for non-portable models.

Portable models (a device with a cord and plug) must

be taken or shipped to the closest authorized service agency, transportation charges prepaid, for service. In addition to restrictions contained in this warranty, specific limitations are shown in the Service

Policy and Procedure Guide. Wells Mfg. Co. authorized service agencies are located in principal cities.

This warranty is valid in the United States and

Canada and void elsewhere. Please consult your

classified telephone directory, your food service

equipment dealer, or write the Factory Service Department, Wells Manufacturing Company, P.O. Box

280, Verdi, Nevada 89439, phone (775) 345-0444

or (888) 492-2782, for information and other details

concerning warranty.

SERVICE POLICY AND PROCEDURE GUIDE

ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, overload protectors, and/or fuse replacements are not covered by this warranty unless

warranted conditions are the cause.

2. All problems due to operation at voltages or phase other than specified on equipment nameplates are not covered by this warranty.

Conversion to correct voltage and/or phase must be the customers responsibility.

3. All problems due to electrical connections not made in accordance with electrical code requirements and wiring diagrams

supplied with the equipment are not covered by this warranty.

4. Calibration of heat controls after the first sixty (60) days on original equipment; replacement of items subject to normal wear, to include

such items as knobs, light bulbs; and, normal maintenance functions including adjustments of thermostats, adjustment of micro switches

and replacement of fuses and indicating lights are not covered by warranty.

5. All welding of components in the field is not covered by warranty.

6. Deterioration of aluminum components due to the insertion of metal implements or use of abrasive cleaners is not covered by warranty.

7. Full use, care, and maintenance instructions are supplied with each machine. Noted maintenance and preventative maintenance items,

such as servicing and cleaning schedules, are customer responsibility. Those miscellaneous adjustments noted are customer

responsibility. Proper attention to preventatve maintenance and scheduled maintenance procedures will prolong the life of the machine.

8. Travel mileage is limited to sixty (60) miles from an Authorized Service Agency or one of its sub-service agencies.

9. All labor shall be performed during regular working hours. Overtime premium will be charged to the buyer.

10. All genuine Wells replacement parts are warranted for ninety (90) days from date of purchase on non-warranty equipment. This parts

warranty is limited only to replacement of the defective part(s). Any use of non-genuine Wells parts completely voids any warranty.

11. Installation, labor, and job check-outs are not considered warranty and are thus not covered by this warranty.

12. Charges incurred by delays, waiting time or operating restrictions that hinder the service technician’s ability to perform service are not

covered by warranty. This includes institutional and correctional facilities.

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in this shipment was carefully inspected and packaged by skilled personnel before

leaving the factory. Upon acceptance of this shipment, the transportation company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any visible loss or damage is noted on the freight bill or express receipt, and that

the note of loss or damage is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY: Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is unnoticed until the merchandise is unpacked, notify the transportation company

or carrier immediately, and file “CONCEALED DAMAGE” claim with them. This should be done within fifteen(15) days from the

Wells Manufacturing cannot assume liability for damage or loss incurred in transit. We will, however, at your request, supply you with the

necessary documents to support your claim.

date the delivery was made to you. Be sure to retain the container for inspection.

xi

Page 3

TABLE OF CONTENTS

Warranty Inside Cover

Specifications 1

Features and Operating Controls 2

Safety Procedures 3

Installation Instructions 4

Operating Instructions 6

Preventative Maintenance Procedures

Timer Adjustment 7

Daily Cleaning 7

Removing Excess Carbon Build-Up 8

Troubleshooting 9

Parts and Service 10

DIMENSIONS

Wide 10-1/8”

Deep 14”

High 10-9/16”

ELECTRICAL

Voltage 120 VAC 1Ø

Amperage 7.5 Amp

Wattage 900 W

Electrical Plug Configuration NEMA 5-15P

GENERAL SPECIFICATIONS

1

Page 4

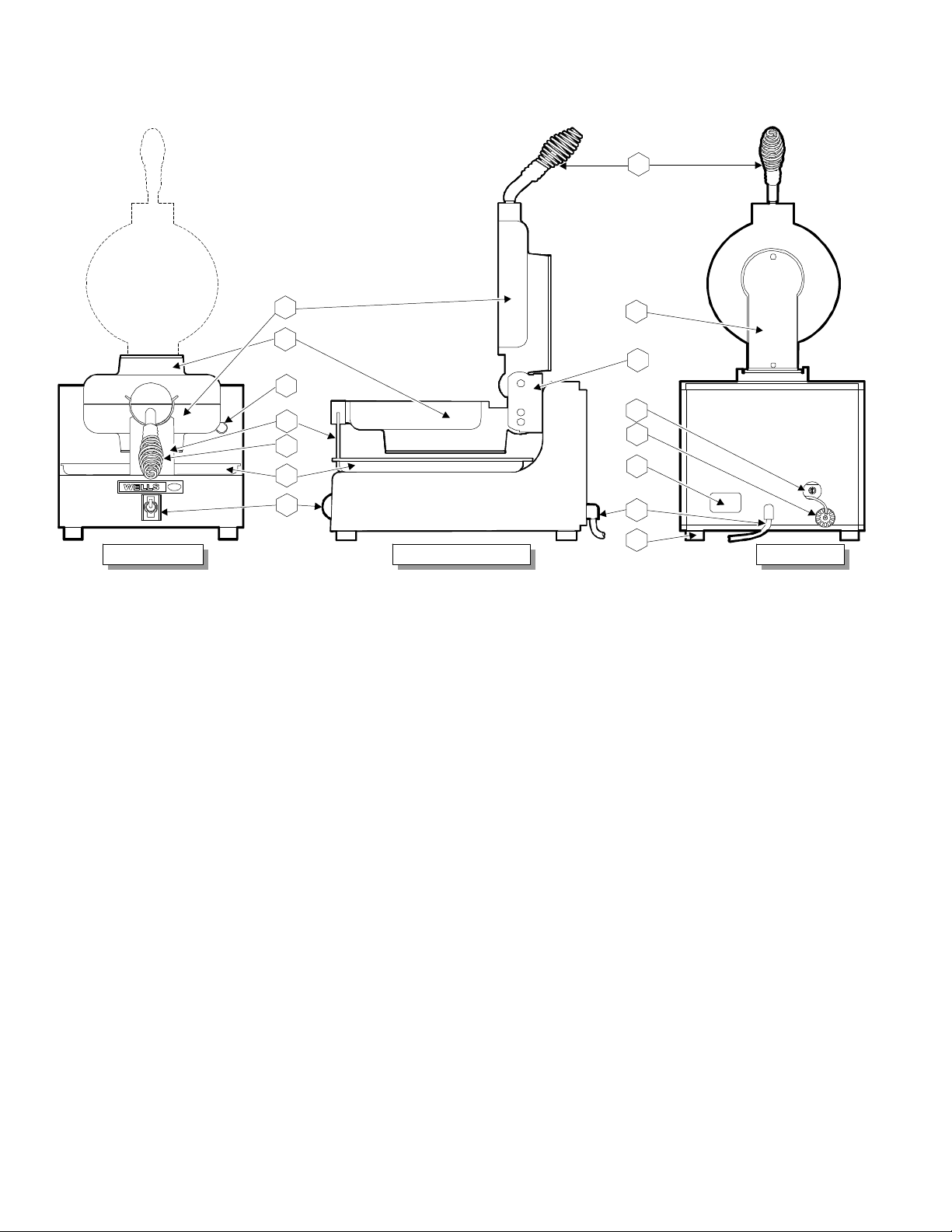

FEATURES & OPERATING CONTROLS

.1

8919

482040

41

RIGHT SIDE VIEW

shown in “open” position

17

43

42

28

18

17

75

3

2

4

1

5

6

66

FRONT VIEW

BACK VIEW

shown in “cook” position

8. POWER CORD 115VAC. NEMA 5-15P Plug

9. DATA PLATE Identifies Manufacturer, Model & Serial numbers;

gives voltage rating.

17. HANDLE ASSEMBLY Used to raise/lower top lid and to rotate grids for cooking.

18. SUPPORT BRACKET Supports front of grids.

19. HOLE PLUG ASSEMBLY Covers and protects timer control.

20. GRID COVER Covers and protects electrical wiring in grid.

28. INDICATOR LIGHT When lit, indicates timer is in “cook” cycle.

40. PIVOT ASSEMBLY Supports back of grids, allows grids to rotate for cooking.

41. RUBBER FOOT Non-skid support for baker; allow adjustments for levelling.

42. LOWER GRID ASSEMBLY Cooking element (grid); contains temperature control sensor.

43. UPPER GRID ASSEMBLY Cooking element (grid).

48. TIMER Sounds audible alarm to warn operator at end of bake cycle.

66. POWER SWITCH Energizes/de-energizes the baker.

75. DRIP TRAY Catches batter drippings for easier clean-up.

2

Page 5

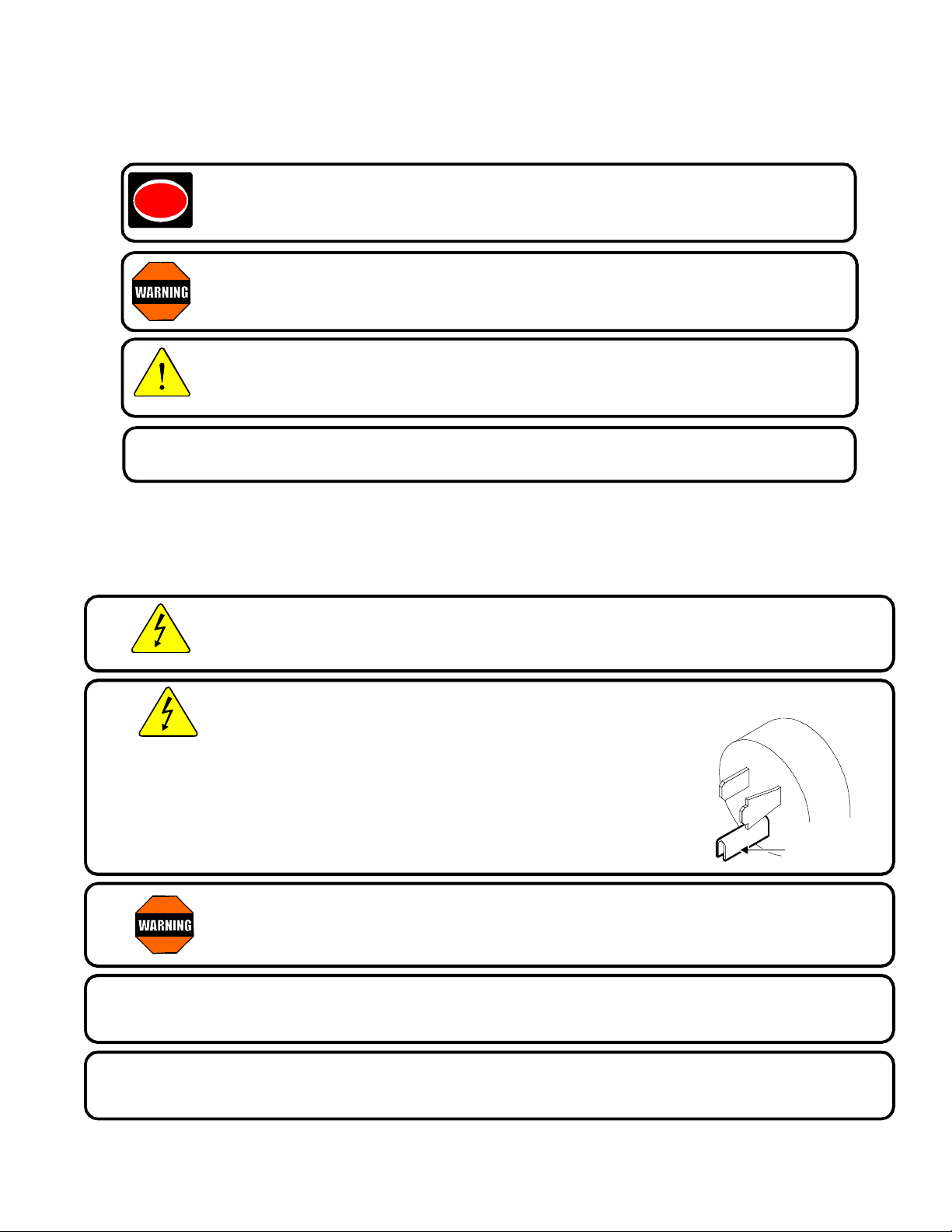

SAFETY PROCEDURES

GROUND

Knowledge of proper procedures is essential to the safe operation of electrically energized equipment. In

accordance with generally accepted product safety labeling guidelines for potential hazards, the following

signal words and symbols are used throughout this chapter.

DANGER - Danger is used to indicate the presence of a hazard which will cause

DANGER

severe personal injury, death, or substantial property damage in the event the state ment is ignored.

WARNING - Warning is used to indicate the presence of a hazard which can cause

personal injury, possible death or major property damage in the event the statement is

ignored.

CAUTION - Caution is used to indicate the presence of a hazard which will or can

cause minor personal injury, or property damage in the event the statement is

ignored.

NOTE - Note is used to notify personnel of installation, operation or maintenance information

which is important, but not hazard related.

WARNINGS AND GENERAL PRECAUTIONS

This appliance is intended for use in commercial establishments to cook food for human consumption.

No other use is recommended or authorized by the manufacturer or its agents.

CAUTION: DO NOT plug in or energize this appliance until Installation

Instructions are read and followed. Injury to the operator and damage to the Waffle

Baker may occur if these instructions are not followed.

CAUTION: This Wells Belgian Waffle Baker is equipped with

a three-prong electrical plug. The three-prong plug is part of a

system that will protect you in the event of an electrical wiring

failure. Be sure the three-prong plug is plugged into a matching and

properly grounded three-prong receptacle. DO NOT cut or break

off the ground prong of this plug.

OPERATING AN APPLIANCE WITHOUT PROPER GROUNDING

CAN RESUL T IN SERIOUS PERSONAL INJUR Y

WARNING: All servicing requiring access to non-insulated electrical components

must be performed by a qualified service technician. Do not open any access panels

which require the use of tools. Failure to follow these directions can result in electrical shock.

PRONG

IMPORTANT: Make sure that the incoming voltage is the same as the unit is rated for. See

the data plate on the back of the waffle baker for the specified voltage and wattage.

NOTE: This manual should be considered a permanant part of this appliance. This

manual must remain with the appliance if it is sold or moved to another location.

3

Page 6

INSTALLATION INSTRUCTIONS

A. UNPACKING AND INSPECTION

1. Carefully remove the Waffle Baker from the carton. Remove all protective plastic film, packaging

materials and accessories from the Waffle Baker before connecting electrical power or otherwise

performing any installation procedures.

NOTE: DO NOT discard the CARTON and other PACKAGING MATERIAL until you have

inspected the Belgian Waffle Baker for hidden damage and tested it for PROPER OPERA TION.

Refer to SHIPPING DAMAGE CLAIM PROCEDURE on the inside front cover of this manual.

2. Read all instructions in this manual carefully before starting installation of this Waffle Baker.

READ AND UNDERSTAND ALL LABELS AND DIAGRAMS ATTACHED TO THE

WAFFLE BAKER.

3. Carefully account for all components and accessories before discarding packing materials.

Store the accessories in a convenient place for later use:

C. EQUIPMENT SET-UP

1. Setup the Waffle Baker only on a firm, level surface. The area around the Waffle Baker must be

kept clear of combustible or flammable materials.

2. Verify that the four RUBBER FEET are in place on the bottom of the Waffle Baker legs.

WARNING: DO NOT ATTEMPT to operate this Belgian Waffle Maker without the

rubber feet installed. The rubber feet provide non-skid support to allow the Waffle

Baker to operate without shifting or “walking”. Operating the Waffle Baker without

the rubber feet may result in serious injury to the operator.

3. LEVELING: Verify that the Waffle Baker sits firmly ON ALL FOUR RUBBER FEET. With a spirit

level, check that the Waffle Baker is level front-to-back and side-to-side. Adjust the rubber feet as

necessary to level the Waffle Baker.

4. Verify the voltage of the receptacle matches the nameplate voltage before plugging in the power

cord.

IMPORTANT: Plugging the Waffle Baker into greater voltage than its rating may damage internal

components. Plugging the Waffle Baker into lesser voltage than its rating will cause a significant

decrease in performance.

5. Certain codes require specific ventilation and access requirements. It is the RESPONSIBILITY OF

THE INSTALLER to check with the AUTHORITY HAVING JURISDICTION, in order to ascertain

the applicability of these requirements to THIS SPECIFIC BELGIAN WAFFLE BAKER INSTALLATION.

4

Page 7

D. SEASONING THE GRIDS

1. Lightly spray commercial waffle baker spray on both grid surfaces.

2. Carefully close the upper grid. Turn the power switch to the ON position and allow the Waffle Baker

to pre-heat for at least twenty (20) minutes.

3. Using the handle, lift the upper grid and lightly re-coat both grid surfaces with commercial waffle

baker spray. Lower the upper grid.

4. The grids are now seasoned, and the Waffle Baker is ready to use.

5

Page 8

OPERATING INSTRUCTIONS

A. PRE-HEAT

1. Turn the power switch to the ON position.

2. With the upper lid closed, allow the Waffle Baker to pre-heat for twenty (20) minutes in order to

allow the grids to reach the proper baking temperature.

B. ADD BATTER

1. Using the handle, lift the upper lid.

2. Pour the desired amount of Belgian Waffle Batter on the lower grid.

C. COOK

1. Using the handle, carefully close the upper lid. Rotate the grid assembly 180º clockwise until the

detent is engaged. This rotation will automatically activate the solid state timer. The indicator light

will come on, and will stay on for the duration of the “cook” cycle.

Note: Factory set for 3 min, adjustable for .1 to 6 minutes. See page 7 for TIMER ADJUSTMENT

PROCEDURE.

2. Allow the waffle to cook IN THE INVERTED POSITION.

3. At the end of the time delay (pre-set at the factory for 3 minutes), the buzzer will sound for a short

interval. At the end of the interval, both the buzzer and indicator light will shut-off.

4. Using the handle, rotate the grid assembly counter-clockwise 180º until the detent is engaged.

Raise the upper lid and remove the waffle from the grid.

IMPORTANT: The timer is ONLY A WARNING DEVICE and DOES NOT TURN THE ELEMENT

ON or OFF. Remove the waffle promptly when the buzzer sounds.

D. OPERATING HINTS

1. Return the upper lid to the closed position between baking periods for optimum baking performance

and to minimize carbon deposit build-up.

2. Use a soft-bristle brush to lightly brush and clean the Waffle Baker whenever waffle residue is

present on the grids.

3. Waffle grids should be re-seasoned after every 3 to 4 waffles to guard against waffles sticking to the

grids. Follow steps 3 thru 4 in the SEASONING THE GRID section. Seasoning interval may be

extended by adding oil or butter to the waffle mix.

4. Always use fresh batter which contains sufficient shortening. Add shortening if required and do not

store batter over prolonged periods of time.

5. Frequent cleaning with a soft-bristle brush, and grid re-seasoning during operation will ensure a

perfect, great-tasting Belgian Waffle every time.

6. Every second or third waffle, lightly spray commercial waffle baker spray on the grids.

7. If the Waffle Baker is left on but idle for over an hour, lightly spray commercial waffle baker spray on

the grids prior to baking the next waffle.

8. NEVER apply beeswax, parafin, etc. to the grid surfaces.

9. NEVER use sharp implements (i.e. knives, forks, metal tongs) to remove waffles from the grid.

6

Page 9

PREVENTATIVE MAINTENANCE PROCEDURES

MINUTES

.1

BACK

VIEW

A. TIMER ADJUSTMENT

TOOLS REQUIRED: Flat Blade Screwdriver - 1/32” x 1/8”

NOTE: The necessity to increase baking time may be due to carbon build-up on the grids. Always clean

and de-carbonize the grids prior to adjusting the timer.

1. Remove the hole plug from the rear panel of the Waffle Baker. DO NOT remove the hole plug from

the attached grounding wire.

2. Using the screwdriver, rotate the adjusting knob:

clockwise to increase time, or

counter-clockwise to decrease time.

3

2

4

B. DAILY CLEANING PROCEDURE

CAUTION - ELECTRICAL SHOCK HAZARD

DO NOT SUBMERGE THE WAFFLE BAKER IN WATER.

If internal components become wet, the operator may suffer electrical shock,

and the Waffle Baker will be damaged.

1

.1

5

6

3

2

4

1

5

6

1. Allow the Waffle baker to cool to room temperature.

2. Clean grids by using a soft-bristle brush to remove all excess waffle residue.

3. Clean the outside of the Waffle Baker by wiping it with a soft, clean cloth, warm water and a mild

soap or detergent. NEVER USE AN ABRASIVE CLEANSER.

4. Always re-season the grids after cleaning.

7

Page 10

C. REMOVING EXCESS CARBONIZATION

Use this procedure to clean any black residue (carbonization) remaining on the grids

after the daily cleaning. Grids must be cleaned to remove the black residue, then re-seasoned, to

ensure maximum Belgian Waffle Baker performance.

CAUTION:

CHEMICAL BURN HAZARD

WAFFLE IRON CLEANER CAN CAUSE SERIOUS BURNS

ON CONTACT.

WEAR PROTECTIVE CLOTHING AND SAFETY GLASSES WHEN

USING WAFFLE IRON CLEANER.

Carefully read and follow directions and warnings on the label.

1. Allow the Belgian Waffle Baker to cool to room temperature.

2. Liberally apply a commercial carbon cleaning solution to the grids with a new 1” paint brush. Be

extremely careful when applying the carbon cleaning solution on the grid surfaces. DO NOT spill

any carbon cleaning solution or other caustic cleaning product on yourself or on the area in which

you are working.

IMPORTANT: Read and follow all manufacturer’s instructions when using commercial carbon

cleaners. Carbon cleaner can be hazardous. It is the operator’s responsibility to use the product

safely, in the manner directed by the carbon cleaner manufacturer.

3. Close the upper lid and allow the Waffle Baker to stand for several hours, or overnight, depending

upon the extent of the carbonization.

4. Thoroughly remove the carbon cleaning solution and black residue using a fiber brush. Wipe down

the grid surfaces carefully and thoroughly with water. It is important that all carbon cleaning solution

is removed.

IMPORTANT: Make certain water and cleaner are not allowed to get into internal parts. The Waffle

Baker will be damaged if internal components are allowed to get wet.

CAUTION - ELECTRICAL SHOCK HAZARD

DO NOT SUBMERGE THE WAFFLE BAKER IN WATER.

If internal components become wet, the operator may suffer electrical shock,

and the Waffle Baker will be damaged.

5. Clean the outside of the Waffle Baker by wiping it down with a clean cloth, warm water and a mild

detergent or soap. NEVER USE AN ABRASIVE CLEANSER.

6. Dry the Waffle Baker with a clean, dry cloth. Always re-season the grids after de-carbonizing.

8

Page 11

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE REMEDY

WILL NOT HEAT Power switch not ON Turn switch to ON position

Power cord not plugged in Plug power cord into an energized

120V receptacle

Circuit breaker tripped Reset circuit breaker

Hi-Limit tripped Contact an Authorized Wells Service

Agency for repairs

Internal component damage Contact an Authorized Wells Service

Agency for repairs

DOES NOT MAINTAIN

TEMPERATURE Internal component damage Contact an Authorized Wells Service

TRIPS CIRCUIT Too many appliances on circuit

BREAKER Have a licensed electrician

ALL OTHER Internal component damage Contact an Authorized Wells Service

PROBLEMS Agency for repairs

Excessive carbonization of grids Clean grids

Agency for repairs

Re-distribute appliances

install a dedicated 20 Amp circuit

Internal component damage Contact an Authorized Wells Service

Agency for repairs

9

Page 12

PARTS and SERVICE

NOTE: Accessory Parts, as well as factory authorized service, are available from your WELLS

AUTHORIZED SERVICE AGENCY.

Wells Manufacturing Co., Service Parts Department

2 Erik Circle, P.O.Box 280

Verdi, NV 89439

phone: (775) 345-0444 Ext 504 fax: (888) 492-2783

Service Parts Department can supply you with the name / telephone number of the WELLS

AUTHORIZED SERVICE AGENCY nearest you.

ACCESSORIES

DESCRIPTION PART #

DRIP TRAY, BWB-1S 21107

RUBBER FEET (pk 4) 21657

CUSTOMER SERVICE DATA

please have this information available if calling for service

RESTAURANT _____________________________ LOCA TION _______________

INSTALLATION DA TE ________________________ TECHNICIAN _____________

SERVICE COMP ANY __________________________________________________

ADDRESS ___________________________ ST ATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. ______________________________________________

EQUIPMENT SERIAL NO. ______________________________________________

VOLTAGE: (check one) 120V 208V 240V

10

Page 13

NOTES

11

Page 14

WELLS MANUFACTURING COMPANY

2 ERIK CIRCLE, P. O. Box 280

Verdi, NV 89439

Customer Service (775) 345-0444 Ext. 502

fax: (775) 345-0569

www.wellsbloomfield.com

Loading...

Loading...