Page 1

WS80 SOLDERING STATION

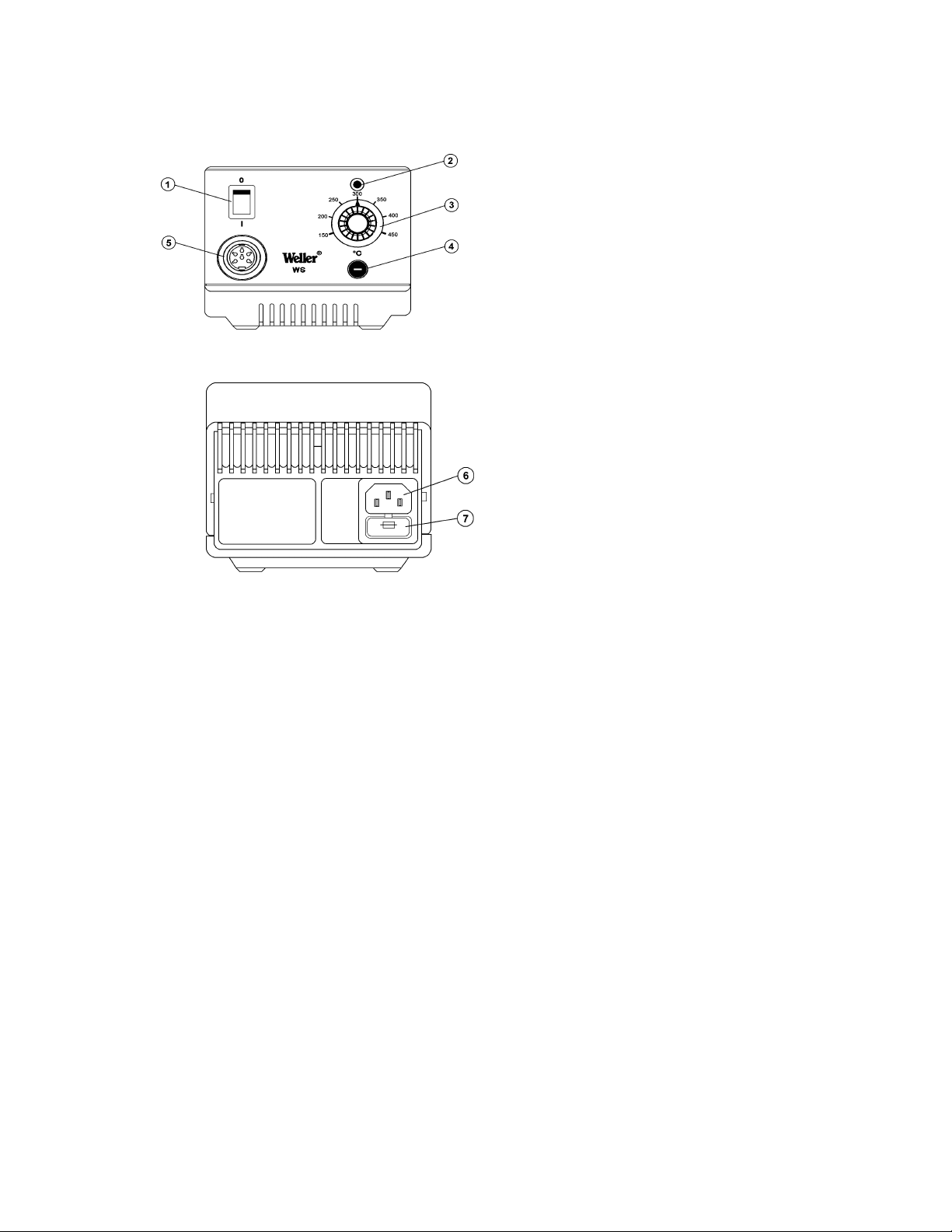

1. Power switch

2. Optical regulator (LED)

3. Rotary potentiometer for setting temperature

(300°F - 850°F)

4. Key switch

5. Connection receptacle for soldering iron

6. Power supply connector

7. Fuse/Holder

WARNING: This product, when used for soldering and

similar applications, produces chemicals

known to the State of California to cause

cancer and birth defects or other

reproductive harm.

DESCRIPTION

CONTROL UNIT

The soldering station WS80 is a part of the range of products, which were developed for industrial manufacturing as well

as for the repair and laboratory sector. The analog electronic control system guarantees the best possible control performance for various soldering tools. The high-powered 24 V heating elements make excellent dynamic performance

possible, so that the soldering tools can be used universally.

A grounded soldering iron tip, zero power switch and antistatic design of control unit and iron complete the high quality

standard. The desired temperature can be set by a rotary potentiometer in an infinitely variable range between 300°F850°F.

The set temperature can be locked by the key switch (4) integrated in the front plate. Temperature settings cannot be

changed when the unit is locked. A blinking red LED signals that the preset temperature has been reached - this serves

as an optical regulator. This station meets all applicable MIL-STDs and the J-STD-001B standards.

SOLDERING IRONS

WSP80: The soldering iron WSP80 is characterized by its capacity for reaching the soldering temperature quickly and

precisely. Its slim design and heating power of 80 watts makes universal usage possible - from extremely

fine applications to high-temperature soldering work. Work can be continued immediately after switching

soldering tips, since the temperature is reached again quickly.

See Accessories for additional tools.

CAUTION: (For Removing Tip) turn station OFF before removing tip/retainer. Hold iron tip down to remove

tip retainer and tip.

1

Page 2

TECHNICAL DATA

Dimensions in mm: 166 x 155 x 101 (lxwxh)

Supply voltage (7): 120 V

Power input: 50/60 Hz, 90 watts

Fuse (8): 1 A (5mm x 20mm in power supply receptacle)

Temp. control: 300°F - 850°F

Stability: ±10°F from target value

STARTING

Assemble soldering iron stand. Place the soldering iron in the stand. Insert the soldering iron plug into the receptacle (6) of

the control unit and lock by turning to the right. Check that the power supply corresponds to the specifications on the

nameplate and that the power switch (1) is in the OFF position. Connect the control unit to the power supply. Set the

temperature at the rotary potentiometer (3). Switch on unit at the supply switch (1). Red LED (2) will illuminate. This LED

functions as the optical regulator. Constant illumination means that the system is overheating. The blinking LED signals

that the operating temperature has been reached.

MAINTENANCE

The transition between the heating element/sensor and the tip of the soldering iron may not come in contact with dirt,

foreign particles or become damaged, since this affects the precision of the temperature control.

INSTRUCTIONS FOR USE

For initial heating, coat the selective tinnable tip with solder. This removes any oxidation or dirt on the tip, which may

have occurred during storage. During pauses between soldering and before storing the soldering iron, ensure that the tip

of the soldering iron is well coated. Do not use aggressive fluxing agents.

NOTE: Always ensure the proper position of the soldering iron tip. When removing the tip (HOLD TIP

DOWN)!

These soldering irons have been adjusted for an average-size tip. Temperature deviations can occur due to exchanging

of the tip style or using other tip designs.

SCOPE OF SUPPLY

Control unit

Solder iron WSP80

Power cable

Operating instructions

Soldering iron holder

Illustration: Exploded view, See Page 3

2

Page 3

WS80 EXPLODED VIEW

REPLACEMENT PARTS

WSP80 Soldering Iron Complete

WSP80AP Soldering Iron w/Stand

WS101 Heater/Sensor

WS102 Tip Retainer

WS103 Handle/Cord*

WS104 Power Supply Cord*

WS105 Control Board

WS107 Transformer*

*Special Order

S1096CH

Rev. 3/98

3

Loading...

Loading...