Page 1

WRK - Operating Instructions 1-9

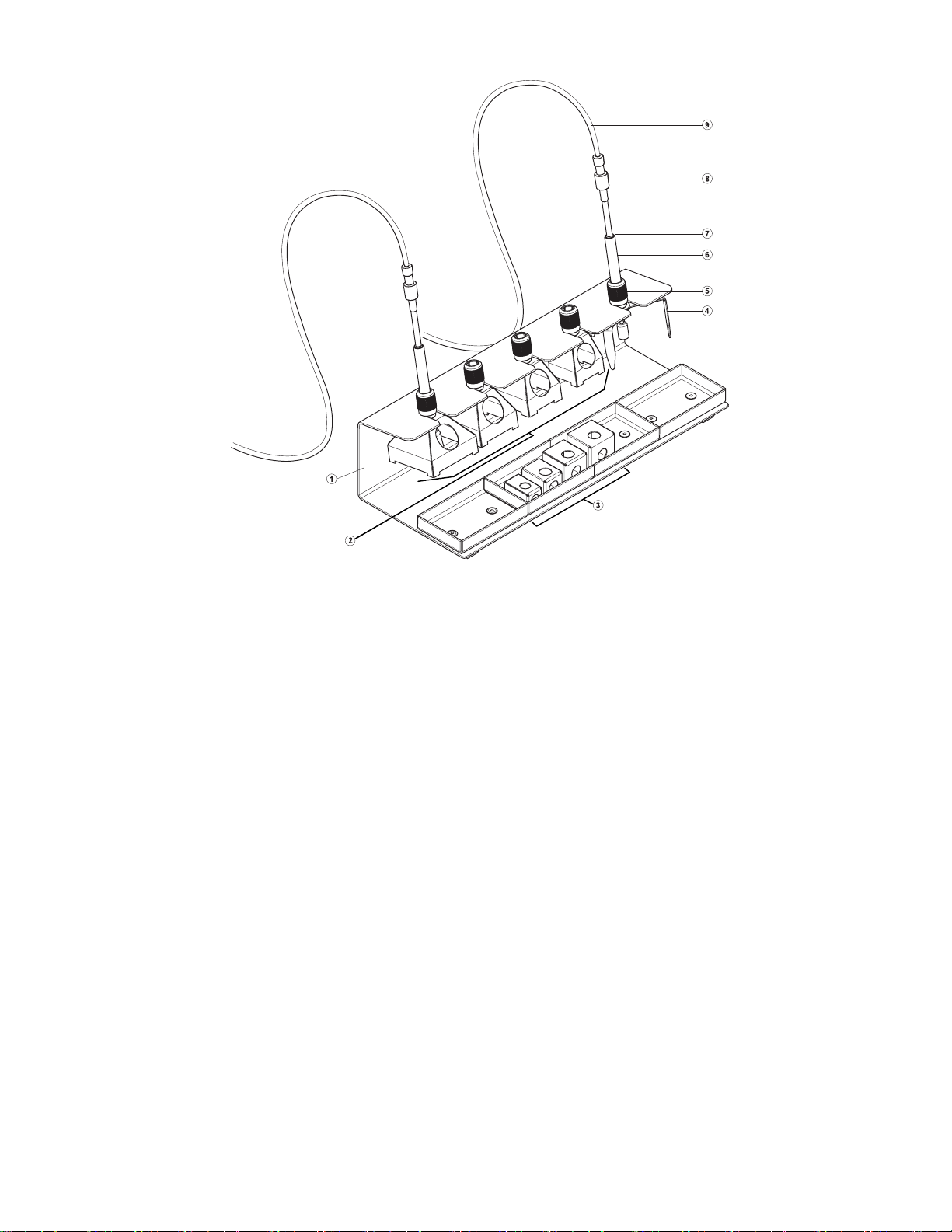

Device Overview

1 WRK Stand / Tool Holder

2 Reflow nozzle, large

3 Reflow nozzle, small

4 Tripod / Stand-Off

5 Clamping sleeve

6 Vacuum pick-up tool

7 Marker ring (Indicates Component Height)

8 Vacuum tube connector

9 Vacuum tube

10 Vacuum Cup with Heat Shield

Page 2

2-9 WRK

Contents

1 Instructions ................................................................................2

2 Cautions and Warnings! ............................................................2

3 Description of the WRK .............................................................3

4 Initial Setup................................................................................3

5 Using the WRK..........................................................................5

6 Accessories ...............................................................................7

7 Packing List ...............................................................................7

8 Disposal.....................................................................................7

9 Warranty ....................................................................................8

1 Instructions

Thank you for placing your trust in our company by purchasing the

Weller WRK.

This product meets or exceeds the requirements established by

Weller for superior performance, versatility and quality.

These instructions contain information to help you operate and

service the WRK safely and correctly.

Z Read these instructions in their entirety before working with the

WRK.

Z Keep these instructions in a place that is accessible to all users.

1.1 Additional Documents

− Please read the Operating Instructions of your Control Unit and

Safety Information booklet

2 Cautions and Warnings!

Please read the WRK Operating Instructions and the attached Safety

Information carefully prior to initial operation. Failure to observe the

safety warnings may result in accident, injury, or risk to health.

The manufacturer shall not be liable for damage resulting from

misuse of this product or unauthorized alterations.

Warning: This product when used for soldering and similar

applications, produces chemicals known to the State of California to

cause cancer and birth defects or other reproductive harm.

Page 3

WRK 3-9

2.1 Safety Information

Always place the Reflow Nozzles in the original holder

Remove all inflammable objects from the proximity of the hot

soldering tool.

Use suitable protective clothing to prevent the risk of burns

associated with molten solder.

Never work on electrically live circuits or components.

Always wear eye protection when working with soldering and

desoldering applications.

3 Description of the WRK

The Weller WRK Removal Kit optimizes the rework process and

enables SMT components to be removed precisely and without being

damaged.

The removal procedure can be optimized for each component size

between .120" and 1.181", (3 mm and 30 mm) with the aid of the

different reflow nozzles.

The reflow nozzles are suitable for the use of the HAP 1 and

HAP 200 Hot Air tools.

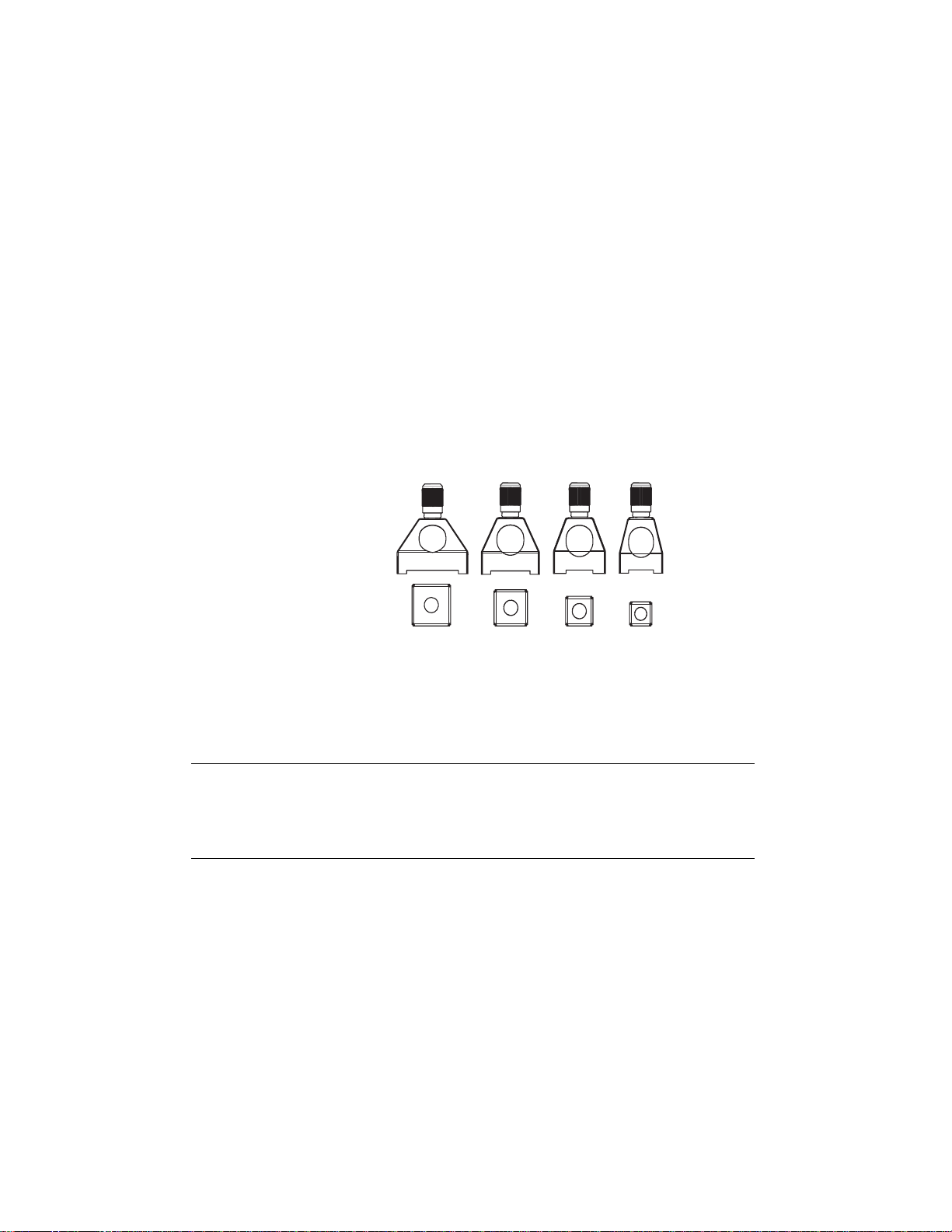

Suitable reflow nozzles for HAP 1 and HAP 200

ENFRITESPTNLSVDKFIGRTRCZPLHUSKSLEELVLT

WARNING!

•

Large

Reflow

nozzles

Small

Reflow

Nozzles

4 Initial Setup

Risk of injury due to incorrectly connected vacuum

hose.

Z Never connect the vacuum hose to the "Air“ port!

Page 4

4-9 WRK

Also read and observe the Operating Instructions of your control

Note

unit.

1. Carefully unpack the WRK.

2. Assemble reflow nozzles (2, 3), tripod (4) and pick-up tool (6) in

holder (1).

3. Switch off the control unit.

4. Connect the hot-air pencil (HAP) with air hose to the "Air“ outlet of

the control unit and insert with the attachment plug in the correct

connection socket of the repair station. Lock by turning clockwise

slightly (connect HAP 1 with adapter only).

5. Connect vacuum pick-up (6) with vacuum hose to the vacuum

pick-up ports of the control unit.

6. Attach a suitable reflow nozzle or tripod to the vacuum pick-up

(see Sections 5.1 and 5.2).

It is possible to use large reflow nozzles, small reflow nozzles with

tripod or the tripod on its own to lift off small components with the

vacuum pick-up tool.

4.1 Mounting the Reflow Nozzle

1. Check the .400 ", (10 mm) diameter vacuum pick-up tool to ensure

the components (clamping sleeve (5), marker ring (7) and vacuum

cup with heat shield (10)) are correctly installed.

2. Assemble nozzles directly to vacuum pick-up tool (6) using the

clamping sleeve (5).

Note The reflow nozzles are not assembled directly to the .180 ", (4.5

mm) vacuum pick-up tool. Ensure the tripod and the.180 ", (4.5 mm)

diameter vacuum pick-up tool are correctly positioned in the nozzle

and on the component.

4.2 Mounting the tripod

1. Check the .180 ", (4.5 mm) diameter vacuum pick-up tool to

ensure the components (clamping sleeve (5), marker ring (7) and

vacuum cup with heat shield (10)) are correctly assembled.

2. Screw tripod (4) to the vacuum pick-up tool (6) using the clamping

sleeve (5).

You can use the .180 ", (4.5 mm) diameter vacuum pick-up tool

mounted in this way with a Large reflow nozzle (A1) or with Small a

reflow nozzle (B1). When working without a reflow nozzle, you can

also use a .400 " (10 mm) diameter vacuum pick-up tool.

Page 5

WRK 5-9

5 Using the WRK

WRK operation during the component removal procedure is divided

into 3 steps:

1. Positioning the Vacuum Pick-up tool

2. Preparing for Component Pick-up

3. Reflow and Removal of the component

5.1 Positioning the Pick-up

A 1 B 1

ENFRITESPTNLSVDKFIGRTRCZPLHUSKSLEELVLT

The component to be reworked must be at least .08 " , (2 mm)

smaller than the diameter of the reflow nozzle used, otherwise the

component may be damaged.

Z Carefully position the large reflow nozzle (A1) or tripod with small

reflow nozzle (B1) with the vacuum pick-up tool over the

component and center the component within the nozzle.

Page 6

6-9 WRK

5.2 Preparing for Component Pick-up

1

2

A 2

B 2

Note Pictures are for illustration use only. Vacuum hose must be

connected and activated for the vacuum pick-up tool to operate.

1. Carefully position the vacuum pick-up tool with mounted reflow

nozzle, (A2) or with the tripod, (B2) over the component.

2. Carefully press the vacuum pick-up tool down .120- .400 ", (3-5

mm) over the component (1) without damaging the component.

3. Switch on the vacuum on the control unit and subject the

component to suction.

4. Slide the marker ring in this position downwards (2).

The marker ring indicates whether the component subjected to

suction is raised (rubber = at top) or not raised (rubber = at

bottom).

5.3 Reflow and Removal of the Component

A 3 B 3

A 4 B 4

Page 7

WRK 7-9

1. Position the vacuum pick-up tool over the componet (see 5.1) and

prepare desoldering (see 5.2).

2. Feed the hot-air tool from the side through the designated nozzle

opening up to the component and actuate the hot air tool until the

component is reflowed and raised by the vacuum pick-up tool (see

5.3).

The marker ring is now in the upper position.

3. Remove the hot-air tool and switch off.

4. Position the vacuum pick-up tool together with the nozzle and the

removed component on a heat resistant surface.

5. Carefully press the vacuum pick-up tool downwards and switch off

the vacuum. Wait several seconds for the component to release

before moving the tool

Note You can also work without a reflow nozzle, e.g. in the case of

components larger than 1.180 ", (30 mm).

6 Accessories

0051515499 WRK holder

0058761730 Nozzle set 33x33/24x24 with pick-up

0058761731 Nozzle set 27x27/20x20 with pick-up

0058761732 Nozzle set 18/15.5/12.5/10 with pick-up

7 Packing List

ENFRITESPTNLSVDKFIGRTRCZPLHUSKSLEELVLT

• WRK consisting of :

• Holder.

• 180 " (4.5 mm) diameter Pick-up

• .400 ", (10 mm) diameter Pick-up

• Tripod

• Reflow nozzles:

• Large (33x33 mm, 27x27 mm, 24x24 mm, 20x20 mm)

• Small (18x18 mm, 15.5x15.5 mm, 12.5x12.5 mm,

10x10 mm)

• 3 suction inserts each for .180 " (4.5 mm) diameter and .400 " (10

mm) diameter

• 2 vacuum hoses with connector

• Operating Instructions for WRK removal kit

8 Disposal

Dispose of replaced equipment parts, filters or old devices in

accordance with the rules and regulations applicable in your country.

Page 8

8-9 WRK

9 Warranty

Cooper Hand Tools warrants to the original purchaser and any

subsequent owner (“Buyer”) that Weller soldering and desoldering

products will be free from defects in material and workmanship for a

period of one year from date of purchase, provided that no warranty

is made with respect to products which have been altered, subjected

to abuse or improperly used, installed or repaired. Use of nonCooper Hand Tools components will void this warranty if a nonCooper Hand Tools component is defective (or is the source of the

defect). Cooper Hand Tools will repair or replace products found to

be defective not caused by a part, component or accessory

manufactured by another company, during the warranty period.

Contact Cooper Hand Tools with dated proof of purchase and return

to Cooper Hand Tools, 1000 Lufkin Road, Apex, NC 27539. All costs

of transportation and reinstallation shall be borne by Buyers.

IN NO EVENT SHALL COOPER HAND TOOLS BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. COOPER HAND

TOOLS LIABILITY FOR ANY CLAIMS ARISING OUT OF THIS

WARRANTY SHALL NOT EXCEED THE PURCHASE PRICE OF

THE PRODUCT.

THE PERIOD OF ALL IMPLIED WARRANTIES APPLICABLE TO

THIS PRODUCT INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS, OR FITNESS FOR A

PARTICULAR PURPOSE IS LIMITED TO 12 MONTHS FROM THE

DATE OF PURCHASE BY THE USER.

Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not

apply to you. Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not apply to you.

This warranty gives you specific legal rights, and you may also have

other rights, which vary, from state to state.

Page 9

WRK 9-9

www.Cooperhandtools.com

Weller is a registered Trademark and registered Design of Cooper

Industries, Inc.

U.S Mailing Address:

Cooper Hand Tools

P.O. Box 728

Apex, NC 27502-0728

U.S Shipping Address:

1000 Lufkin Road

Apex, N.C. 27539

Tel: (919) 387-0099

Fax: (919) 387-2379

For inquiries concerning Technical /

Customer Service please call:

(800) 476-3030 Ext. 1

Canada Shipping Address:

Cooper Tools

164 Innisfil Street

Barrie, Ontario

Canada L4N 3B7

Attn: Repairs

Fax: 1-800-403-TOOL (8665)

Phone: 705-728-5564 Ext. 2026

ENFRITESPTNLSVDKFIGRTRCZPLHUSKSLEELVLT

005 XX XXX XX / 03.07 © 2007 Cooper Industries

Loading...

Loading...