Page 1

WWDD22MM // WWDD22000000M

M

OOppeerraattiinngg IInnssttrruuccttiioonns

s

Page 2

TTaabbllee ooff ccoonntteenntts

s

PPaagge

e

1. WD2M Detailed View 1

2. Cautions / Warnings 2

3. Description 2

4. Technical data / LCD Display 3

5. Placing into Operation 4

6. Channel Selection 4

7. Special Functions 5

8. USB Interface 9

9. Operating Guidelines 9

10. Accessories 9

11. Packing List 9

12. WMRP Soldering Iron 10

13. RT Style Tips 12-13

14. WMRT Tweezers 14

15. WMRT Tips 16

16. WD2M Circuit Diagram 18

17. WD2M Exploded View 19

Page 3

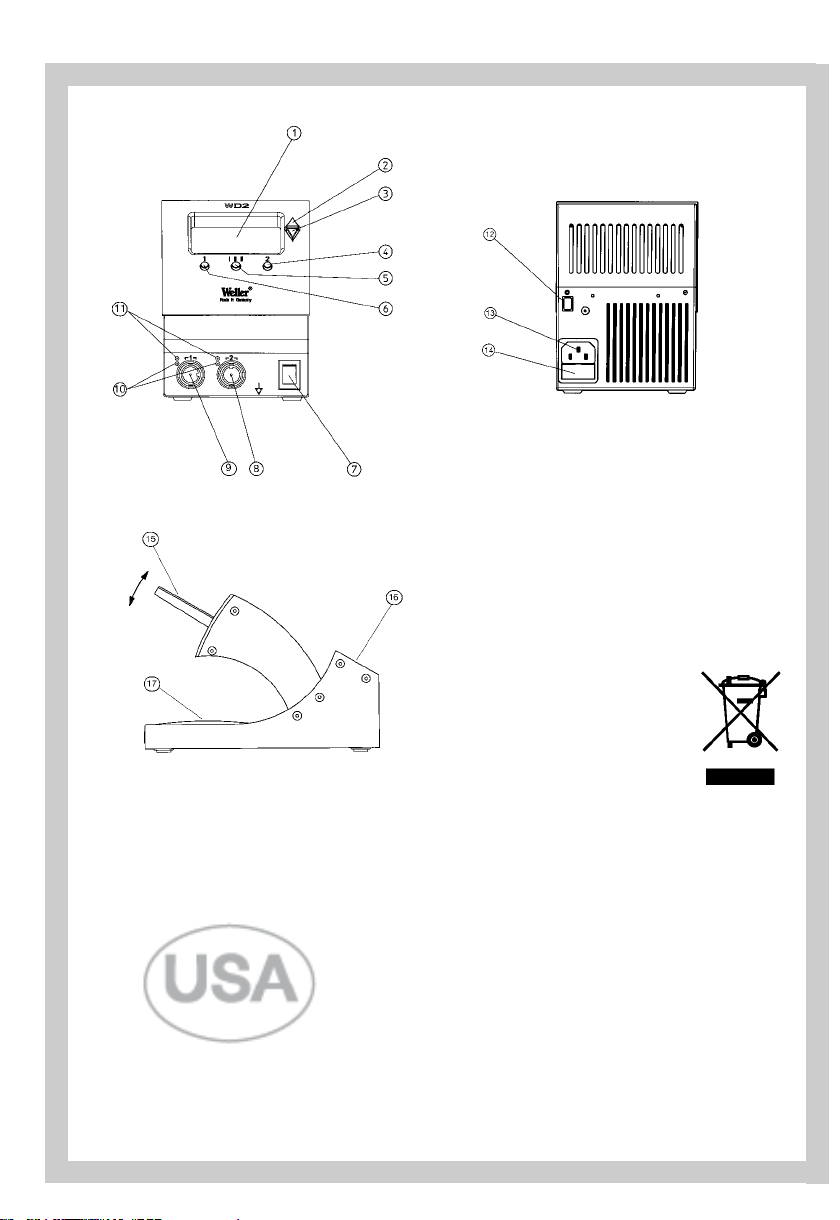

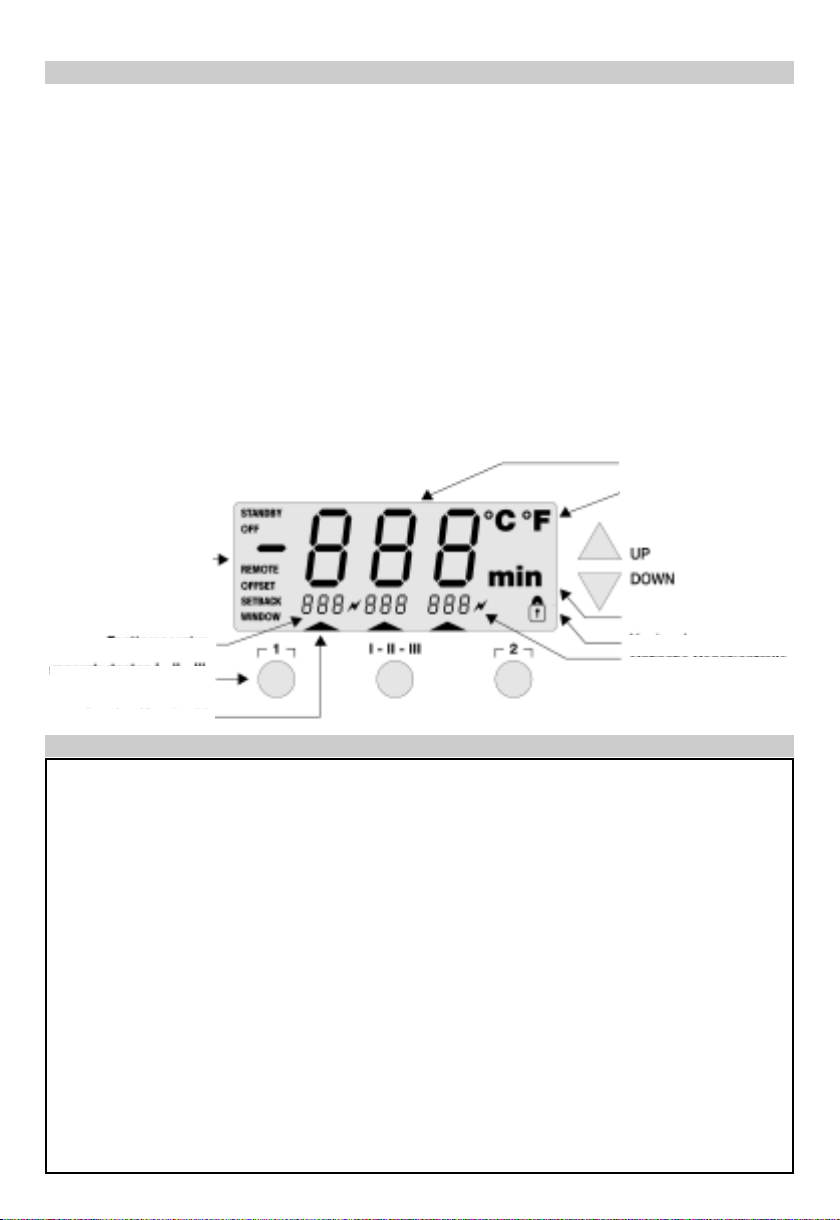

1. LCD Display

2. UP Scroll Key

3. DOWN Scroll Key

4. Radio Button / Channel 2 Selector

5. Radio button ( I - II - III ) Selector

6. Radio Button / Channel 1 Selector

7. Power Switch

8. Soldering Iron Receptacle Channel 2

9. Soldering Iron Receptacle Channel 1

10. LED Channel Selection Indicator

11. LED Heat Indicator

12. USB Port

13. Power Unit Receptacle

14. Primary Fuse

15. Soldering Tool Holder

16. Soldering Stand (Tip Storage)

17. Tray / Sponge

1. WD2M Detailed View

1

1

Page 4

2

2

Thank you for placing your trust in our company by

purchasing the Weller WD2M / WD2000M. This product

meets or exceeds the requirements established by

Weller for superior performance, versatility and quality.

22.. CCaauuttiioonnss!! // WWaarrnniinnggss!

!

Please read these Operating Instructions and the

attached Safety Information carefully prior to initial

operation. Failure to observe the safety warnings may

result in accident, injury, or risk to health.

The manufacturer shall not be liable for damage resulting from misuse or unauthorized alterations of the

equipment.

Warning: This product when used for soldering and

similar applications, produces chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

SSaaffeettyy IInnffoorrmmaattiioonn:

:

● Always place the soldering iron in its original

holder

● Remove all inflammable objects from the proximity of the hot soldering tool.

● Use suitable protective clothing to prevent the risk

of burns associated with molten solder.

● Never leave a hot soldering iron unattended.

● Never work on electrically live circuits or com-

ponents.

● Always wear eye protection when working with

soldering and desoldering applications.

The Weller microprocessor-controlled soldering station

WD2M / WD2000M corresponds to the EC Declaration

of Conformity in accordance with the basic safety

requirements of Directives 89/336/EEC and 73/23EEC.

33.. DDeessccrriippttiioon

n

33..11 CCoonnttrrooll uunniit

t

The microprocessor-controlled 2-channel soldering

station WD2M is part of a generation of devices developed for industrial electronic production, including

repair and laboratory applications. Digital electronic

controls, a precision sensor and heat transfer technology in the soldering tool provides precise temperature

control of the soldering tip.

Fast and precise sensor sampling in the closed loop

control provides tip temperature accuracy and maximum temperature control under load. The soldering

tools are recognized automatically by the WD2M and

the appropriate control parameters are set.

A Factory Control Check function, an Offset value input

option, programmable temperature decrease (Setback )

along with Standby and Lock functions enhance the

functionality of this unit.

The desired temperature can be set in the range

150 °F – 850 °F (50 °C – 450 °C). “Set” and “Read”

(actual tip temperature) values are displayed digitally.

Three Radio Buttons (4) (5) (6) are used for selection of

fixed/preset temperatures. The Heater Control

Indicator flashes (“

~” symbol in the display) when

the “Set” temperature is reached.

33..22 UUSSBBPPoorrt

t

The WD2M has a USB port for remotely controlling the

soldering station and temperatures can be read and

printed using a standard PC and PC software.

33..33 TTooooll SSttaannd

d

When not in use, the soldering iron should always be

placed in the Tool Stand.

The Tool Holder (14) for the soldering iron has four different settings, (30-80°) and can be moved to an operator’s preferred position without the use of tools. Areas

have been provided on the rear (15) of the Tool Stand

for placing the soldering tip when not in use. The base

of the Tool Stand contains a sponge (16) for cleaning

the soldering tips. (Note: LT tips require tip retainer for

storage in Tool Stand.)

33..44.. SSoollddeerriinngg iirroonns

s

WWMMRRP

P

An extremely powerful 40 W fine soldering iron with

the heating system integrated into the soldering tip.

Thanks to a plug-in system, the soldering tip can be

changed without tools. The soldering tip temperature is

reached rapidly and controlled precisely. Thanks to a

sensor installed in the handle, the soldering iron is

shut off automatically when it is placed in the WMRH

holder. Note: Minimun Tool Temperature 200 °F 100 °C.

WWMMRRT

T

The Weller WMRT Tweezers are designed for rework

and repair of precision SMT electronic devices. The

desoldering tip set can be quickly and easily changed

without the use of tools.

The tips are pre-aligned and

additional alignment is not required. The integrated (2

X 40 W) heating elements ensure that the desoldering

tip temperature is reached ver

y quickly and controlled

precisely. The desoldering tweezers are switched off

automatically when placed in the WMRTH tool holder.

Note: Minimun

T

ool

T

emperature 200

°F 100 °C.

E

nglish

Page 5

3

3

English

Active Channel Indicator

Dimensions: 5.27” L x 4.27” W x 5.77” H; (134mm L x 108mm W x 147mm H)

Primary voltage: 120 VAC / 50/60 Hz

Power Input: 85 Watts

Power Output: 24VAC

Fuse (10): T1.0A (120 VAC) (5 x 20mm)

Temperature Control: 150 °F – 850 °F (50 °C – 450 °C); WSP150 : 999 °F ( 550 °C )

WMRP and WMRT Tools - 200 °F – 850 °F (100 °C – 450 °C)

Temperature Accuracy: ±17 °F (±9°C)

Temperature Stability: ±9 °F (±5°C)

Meets or Exceeds: IPC / EIA J-STD-001C (Appendix A ) Commercial Soldering Standard

( Specific to WMRP / WMRT Soldering and Desoldering Tools )

Tip to Ground Resistance < 2 Ω ( Specific to the WSP80 / WP80 / WMP / WTA50 Soldering / Desold-

ering Tools )

Tip to Ground Millivolt Potential < 2 mV ( Specific to the WSP80 /

WP80 /

WMP / WTA50 Soldering / Desold-

ering Tools )

Temperature display

Temperature Symbol

Time Functions Indicator

Station Lock Indicator

Heater Control Indicator

Special Functions

“Menu 1”

3 Pre-Selected Temperatures

3 Radio Buttons

Scroll Key

Scroll Key

LCD Display

4. Technical Data

WWPP8800 ((OOppttiioonnaall)):

:

The WP80 Soldering iron is characterized by fast heatup and precise control of the soldering tip. Due to its

slim design, 80W heater output and short reach (tip to

grip), this tool can be used for a variety of applications,

from extremely fine soldering tasks to those requiring

high temperatures.

WWMMPP ((OOppttiioonnaall)):

:

The WMP Micro Soldering Iron’s very fast heat-up time

and short reach (tip to grip), makes it ideal for precision SMT electronics. The short distance between the

grip and soldering tip makes precise handling of the

65W soldering iron possible while performing very fine

soldering tasks.

WWTTAA5500 (( OOppttiioonnaall )) :

:

The WTA50 Desoldering Tweezers were designed

specifically for desoldering SMT components. Two heating elements (2 x 25W), each with its own temperature

sensor, maintain the same temperature on both tweezer

tips.

WWSSPP115500 (( OOppttiioonnaall )) :

:

The WSP150 Soldering iron is an especially powerful

tool for soldering tasks with extremely highheat

requirements. ( Note: Only one channel is active when

this Soldering iron is used. )

See Accessories for a list of other soldering tools that

can be connected.

Page 6

4

4

English

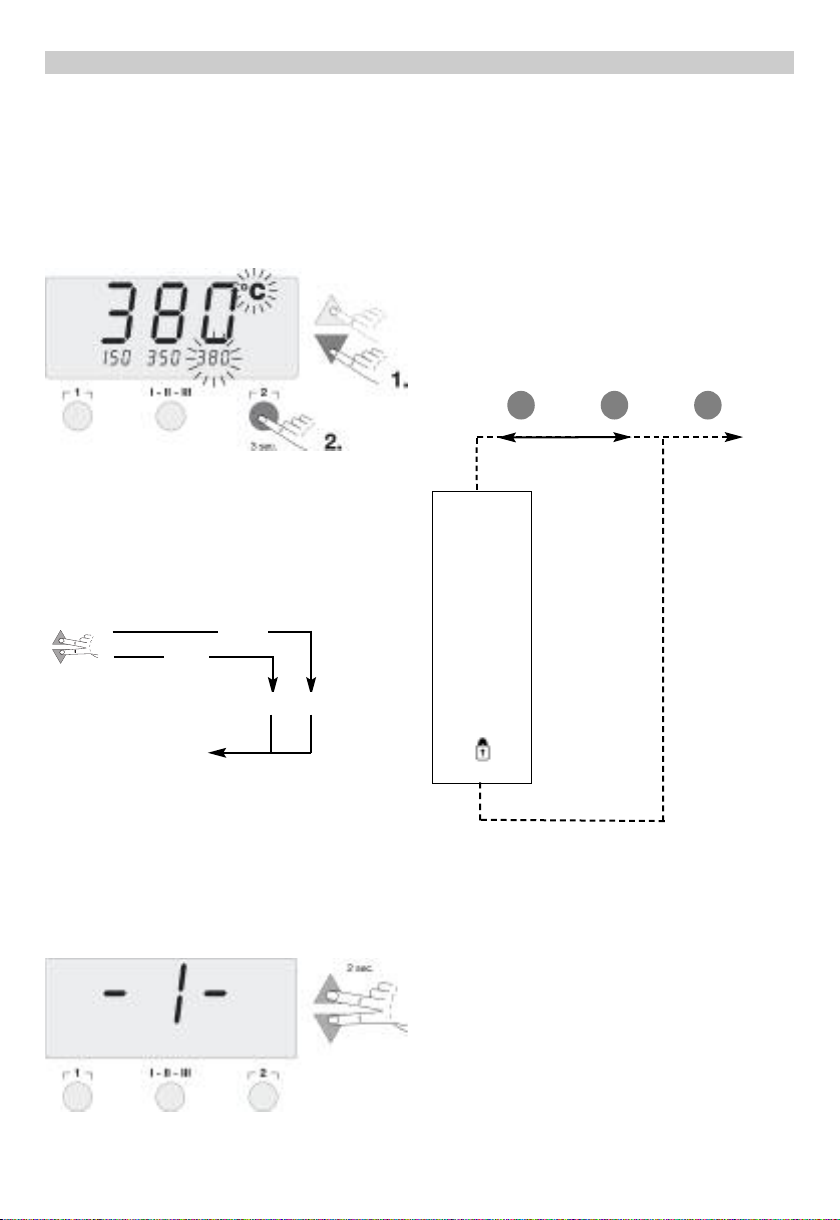

55.. PPllaacciinngg iinnttoo OOppeerraattiioon

n

Take care when unpacking the unit and accessories.

Place the soldering tools in the safety rest. Insert the

soldering iron plug into the connection socket (8) and

(9) of the control unit and lock by turning slightly to the

right. Verify the supply voltage matches the specification on the Base Unit Label and that the Power Switch

(7) is Off. Connect the control unit to the receptacle (12)

on the rear of the control unit and plug into a properly

grounded receptacle. Switch On the unit at the Power

Switch (7). The unit performs a self-test when it is

switched “On”, whereby all LCD Icons are briefly displayed (1).

Following this, the “Set” temperature of the active

channel is displayed for a brief period. The electronic

system then switches automatically to the “Read”

value. The "

~" symbol appears and the three fixed

temperatures of Radio Buttons

11 ,II--IIII--IIIIII,

,

and

2

2

are dis-

played. The "

~" symbol serves as a Heater Control

Indicator. The “Set” temperatures for channel 1 and 2

appear in small form in the display. The “Active” channel is labeled with an arrow underneath it. In addition

to this, the displayed channel is indicated by a red LED

next to the connection socket. The "

~" symbol and the

green LED on the connection socket are used as a visual control check. Flashing indicates the “Set” temperature has been reached and the tool has stabilized.

66.. CChhaannnneell SSeelleeccttiioon

n

When the channel selection Radio Button

11

or

2

2

is

depressed, the display shows the “Set” value of the

selected channel. The active channel in the display is

indicated with an arrow underneath it. In addition to

this, the displayed channel is indicated by a red LED

over the connection socket.

The displayed channel can be switched off by simultaneously pressing the

UUP

P

and

DDOOWWN

N

buttons (2) (3). This

is confirmed in the display with

OOFFF

F

.

To activate a deactivated channel, select it using the

channel selection button, if necessary, and simultaneously press the

UUP

P

and

DDOOWWN

N

buttons (2) (3) to switch

it on. The actual value appears in the display.

66..11 TTeemmppeerraattuurree sseettttiinng

g

66..11..11 SSeettttiinngg TTeemmppeerraattuurree wwiitthh UUpp//DDoowwnn SSccrroollll KKeeyys

s

As a rule, the main display (1) shows the tip temperature (“Read”) value. By depressing the

UUP

P

or

DDOOWWN

N

Scroll Keys (2 & 3), the display switches to the currently

“Set” value. The temperature symbol flashes

°°F

F

(or

°°CC)).

.

The “Set” value can now be changed by tapping or

holding in the

UUP

P

or

DDOOWWN

N

Scroll Key (2) (3). If the

Scroll Key is held depressed, the “Set” value changes

rapidly. Approximately 2 seconds after the Scroll Key is

released, the display switches automatically back to the

“Read” value.

66..11..22SSeettttiinngg TTeemmppeerraattuurree wwiitthh tthhee RRaaddiioo BBuuttttoonnss 11,

,

II--IIII--IIIIII,, 2

2

The “Set” value for the temperature can be changed via

the three Radio Buttons 1, I-II-III, 2 .

Default settings:

1

1

300 °F ( 150 °C)

II--IIII--IIIII

I

662 °F ( 350 °C)

2

2

716 °F ( 380 °C).

By depressing a Radio Button, the pre-selected value

for that button now becomes the “Set” temperature.

The new value appears for Approximately 2 seconds in

the display and the temperature symbol flashes

°°FF (

(

or

°°CC)

)

. The display then switches back automatically to the

“Read” value.

66..11..33 CChhaannggiinngg PPrreesseett VVaalluueess ooff RRaaddiioo BBuuttttoonnss 11,, II--IIII--IIIIII,

,

22

The 3 Radio Buttons

11,, II--IIII--IIIIII,, 2

2

can be preset with tem

-

perature values as desired.

Depress the

UUP

P

or

DDOOWWN

N

Scroll Key to set a desired

temperature (see 6.1.1) in the large display. The

°°F

F

(or

Page 7

5

5

English

°°CC))

temperature symbol flashes

.

.

Next, depress and hold the desired Radio Button

11,, II--IIII-

-

IIIII

I

or

2

2

. While the button is depressed, the small display

assigned to the Radio Button also flashes and, after 3

seconds, accepts the value of the large display.

Release the Radio Button.

Setting a Radio Button to a low temperature gives you

the option of manually and quickly decreasing temper-

ature when the soldering iron is not being used.

77.. SSppeecciiaall ffuunnccttiioonnss

The special function are split in two menu sections.

Special functions menu 1: often used functions like

STANDBY, OFFSET, SETBACK, ...

Special functions menu 2: Calibration function, Remote

Id

77..11 SSppeecciiaall ffuunnccttiioonnss mmeennuu 1

1

Select the desired channel (CH1 or CH2) for inputting

the special functions. If the

UUP

P

and

DDOOWWN

N

buttons are

pressed simultaneously, after approx. 2 seconds the

menu selection for the special functions is activated

and -

I

I

- appears in the display, release buttons.

The following set-

tings are possible:

OFFSET, STANDBY, WINDOW (temperature settings);

SETBACK, OFF (time settings); Lock function (On/Off);

Temperature scale ( °F /°C ).

Radio Buttons

1

1

and I-II-I

III

I

are used for menu item

selection.

Radio Button

2

2

is used to exit the menu.

RReesseettttiinngg tthhee SSttaattiioonn ttoo FFaaccttoorryy SSeettttiinnggss:

:

Depress and hold Radio Button

2

2

. Then depress the

UUP

P

and

DDOOWWN

N

Scroll Keys at the same time. "

FFSSE

E

",

“Factory Setting Enabled” appears in the display. The

soldering station is now reset to its factory default settings.

77..11..11 SSttaannddbbyy TTeemmppeerraattuurre

e

When the Setback time has elapsed, the “Set” temperature is decreased automatically to the Standby value.

The “Read” temperature is displayed (flashing) and

"

SSTTAANNDDBBY

Y

" appears in the display. The Standby temperature can be set in the range ( 200 - 600°F/100 300°C ).

Adjust the standby temperature with the

UUP

P

or

DDOOWWN

N

Scroll Keys.

Switch to the previous menu item with Radio Button

1

1

.

Switch to the next menu item with Radio Button I-II-I

III

I

.

SSTTAANNDDBBY

Y

OOFFF

F

OOFFFFSSEET

T

SSEETTBBAACCK

K

WWIINNDDOOW

W

°°CC//°°F

F

11 II--IIII--IIIIII 22EEXXIIT

T

-1- -2-

2 (EXIT)

4 sec.

2 sec.

Menu Selection Exit

Page 8

6

6

E

nglish

77..11..22 AAuuttoo OOffff TTiimmee ((““OOFFFF””)

)

When the soldering tool is not in use, it is automatically

switched off after the “OFF” time has elapsed. The Auto

Off time can be set from 0 – 999 minutes. With a setting

of "0 min", the Auto Off function is disabled. Auto Off is

carried out independently of the Setback function. The

“Read” temperature is displayed (flashing) and may be

monitored as a decreasing heat indicator; "

OOFFF

F

"

appears in the display. Below 122°F ( 50°C ), a flashing

dash appears in the center of the display.

Change the “OFF” time with the

UUP

P

or

DDOOWWN

N

Scroll Keys.

Switch to previous menu item with Radio Button

1

1

.

Switch to next menu item with Radio Button

II--IIII--IIIIII

.

77..11..33 TTeemmppeerraattuurree OOffffsseet

t

The actual soldering tip temperature can be changed

±72°F/±40°C by the input of a temperature offset. The

Offset function is used to match the station display to

the tip temperature when measured with an external

instrument.

Change the “Offset” value with the

UUP

P

or

DDOOWWN

N

Scroll

Key.

Switch to previous menu item with Radio Button

1

1

.

Switch to next menu item with Radio Button

II--IIII--IIIIII

.

77..11..44 SSeettbbaacckk TTiimme

e

If the soldering tool is not being used, the temperature

is decreased automatically to Standby temperature (see

7.1.1) after the specified Setback time has elapsed. The

Setback time, after which the soldering unit switches to

Standby mode, can be set from 0 – 99 minutes. With a

setting of "0 min", the Setback function is switched Off.

The Setback status is indicated by a flashing “Read”

temperature and "

SSTTAANNDDBBY

Y

" appears in the display.

Depress the

UUP

P

or

DDOOWWN

N

Scroll Key to end “Setback”

and return the station to the “Set” temperature.

Change the “Setback” time with the

UUP

P

or

DDOOWWN

N

Scroll

Key.

Switch to previous menu item with Radio Button

1

1

.

Switch to next menu item with Radio Button

II--IIII--IIIIII

.

77..11..55 WWiinnddooww FFuunnccttiioon

n

The Window Function allows the temperature to be

adjusted within a range (max. ±180 °F. (±99 °C )), above

and below the Locked temperature (see 7.1.7). The

Locked temperature thus represents the middle of the

settable temperature range.

Note: To utilize the window function, the station has to

first be placed into Lock mode.

Use the

UUP

P

/

DDOOWWN

N

Scroll Keys to change the range of

temperatures allowed within the operating “window”.

Switch to previous menu item with Radio Button

11.

.

Page 9

7

7

English

Switch to next menu item with Radio Button I-II-I

III

I

.

77..22 SSppeecciiaall FFuunnccttiioonnss MMeennuu 2

2

Select the desired channel (CH1 or CH2) for inputting

the special functions. If the

UUP

P

and

DDOOWWN

N

Scroll Keys

are pressed simultaneously, after approximately 4 seconds, the menu selection for the Special Functions is

activated and

-- 22 -

-

appears in the display. Release the

Scroll Keys.

Radio Buttons

1

1

and I-II-III are used for menu selection.

77..22..11 F

F

actory

CCoonnttrrooll C

C

heck

FFuunnccttiioonn (( FFCCCC )

)

This function checks temperature accuracy of the soldering station and allows modifications if necessary. To

perform the “FCC” function, the soldering tip temperature must be measured using an external temperature

measuring instrument.

Switch to next menu item with Radio Button

II--IIII--IIIIII

.

77..11..66 SSwwiittcchhiinngg TTeemmppeerraattuurree SSccaalleess °°FF//°°CC

Use the UP or DOWN Scroll Key to switch between

°°F

F

and

°°CC

and vice versa.

Switch to previous menu item with Radio Button

1

1

.

Switch to next menu item with Radio Button I-II-I

III

I

.

77..11..77 LLoocckk FFuunnccttiioonn ““”

”

The Lock Function locks the soldering station control

so that no setting changes are possible. Radio Buttons

11,, II--IIII--IIIIII,, aanndd 2

2

remain operational in the lock mode.

When the lock function is selected in the Special

Functions menu, “

OOFFF

F

” and the flashing “ ” symbol

appears in the menu display. If Radio Buttons

11 orII--IIII-

-

IIIIII

are depressed while “

OOFFF

F

” appears in the display,

no code is saved.

The

UUP

P

or

DDOOWWN

N

Scroll Keys can be used to enter a 1, 2

or 3-digit Lock code. Confirm the code by depressing

Radio Button

2

2

for 5 seconds. The station is now

Locked and the “ ” symbol appears in the main display.

To unlock, activate the Lock Function in Special

Functions menu 1. “

OON

N

” appears in the display. Enter

the code and confirm by depressing Radio Button

2

2

.

The station is now unlocked.

Switch to previous menu item with Radio Button

1

1

.

5 sec.

Menu 2 Menu selection Exit

FFaaccttoorry

y

CCoonnttrrooll CChheecck

k

RREEMMOOTTEE IId

d

1 I-II-III 2 EXIT

FFCCCC 221122°°FF//110000°°C

C

+ 1

- 1

II--IIII--IIIII

I

Confirmation

FFCCCC 884422°°FF//445500°°C

C

+ 1

- 1

II--IIII--IIIII

I

Confirmation

EXIT

EXIT

Page 10

English

8

8

Select the “FCC” High or Low Set point with the

UUP

P

or

DDOOWWN

N

Scroll Key. After the “FCC” function is complete

at both “Set” points, Radio Button

22

is used to exit the

menu.

UUP

P

Scroll Key: High “Set” point 842°F/450°C

DDOOWWN

N

Scroll Key: Low “Set” point 212°F/100°C

RReesseettttiinngg tthhee SSppeecciiaall FFuunnccttiioonnss ttoo FFaaccttoorryy SSeettttiinnggs

s

Press and hold the

22

Radio Button. Then press the

UUP

P

and

DDOOWWN

N

Scroll Keys at the same time. "

FFSSE

E

",

“Factory Setting Enabled” appears in the display. The

station is now reset to its factory default settings.

IImmppoorrttaanntt:

:

TThhee ssoollddeerriinngg ttooooll bbeeccoommeess hhoott dduurriinngg tthhee FFaaccttoorry

y

CCoonnttrrooll CChheecckk.. NNeevveerr lleeaavvee ccoommbbuussttiibbllee mmaatteerriiaallss nneeaar

r

tthhee hhoott ssoollddeerriinngg iirroonn.

.

77..22..22 AAddjjuussttiinngg FFaaccttoorryy CCoonnttrrooll CChheecckk SSeettttiinnggss ((FFCCCC)

)

CCoonnttrrooll CChheecckk aatt 221122°°FF//110000°°C

C

DDeepprreessss tthhee DDOOWWNN SSccrroollll KKeeyy

The station sets the temperature of the soldering tip to

212°F/100°C. Once the temperature becomes stable (at

which point the indicator flashes), the soldering tip

temperature reading on the external device is compared

to that shown on the station display. If the temperature

readings differ, the

UUPP//DDOOWWN

N

Scroll Keys can be used

to make adjustments. The temperature Offset is indicated in the display. A maximum temperature adjustment

of ±72°F/±40°C is possible. After the measured temperature matches that shown on the station display,

depress the Radio Button

II--IIII--IIIII

I

to confirm. The temperature Offset is reset to “0”. This concludes the Factory

Control Check adjustments at 212°F/100°C.

Press Radio Button 2 to exit the menu without saving

any changes.

CCoonnttrrooll CChheecckk aatt 884422°°FF//445500°°C

C

DDeepprreessss tthhee UUPP SSccrroollll KKeey

y

The station sets the temperature of the soldering tip to

842°F/450°C. Once the temperature becomes stable (at

which point the indicator flashes), the soldering tip

temperature reading on the external device is compared

to that shown on the station display. If the temperature

readings differ, the

UUPP//DDOOWWN

N

Scroll Keys can be used

to make adjustments. The temperature offset is indicated in the display. A maximum temperature adjustment

of ±72°F/±40°C is possible. After the measured temperature matches that shown on the display, depress the

Radio Button

II--IIII--IIIII

I

to confirm. The temperature offset

is reset to 0. This concludes the Factory Control Check

adjustment at 842°F/450°C.

Press Radio Button

22

to exit the menu without saving

any changes.

After both control points, 212°F(100°C) and 842°F

(450°C), have been set and confirmed, the Factory

Control Check process is complete.

77..22..33 SSttaattiioonn CCooddee ((IIDD nnuummbbeerr)

)

When using multiple WD stations, you can assign a

number from 0 - 999 to each soldering station for identification purposes.

Use the

UUPP // DDOOWWN

N

Scroll Keys to change the ID number.

Switch to previous menu item with Radio Button

1

1

.

Switch to next menu item with Radio Button

II--IIII--IIIII

I

.

Radio Button

22

is used to exit Special Functions Menu

842°F /450°C

212°F /100°C

Temperature

Deviation

Page 11

9

9

2.

88.. UUSSBBIInntteerrffaacce

e

The WD2M Soldering Station is equipped with a mini

USB interface. Weller standard software ( CD included )

has been provided to use the USB port. This software

contains a firmware updater and monitor software.

The firmware updater is used to provide a software

update, whereby the Soldering Station can be supplied

with the most up-to-date software.

The monitor software can be used for remote control of

the unit. Temperature curves can be displayed, printed

out and saved.

99.. OOppeerraattiinngg GGuuiiddeelliinnees

s

During initial heat-up, tin the soldering tip with solder

to remove oxidation and contamination on the soldering

tip. Before placing tool in holder, be sure the soldering

tip is well tinned. Use of an aggressive flux will shorten

tip life.

The contact surfaces between the heating element/sensor and the soldering tip must not be obstructed. Dirt or

foreign materials could cause damage and could affect

tip temperature accuracy.

HHaannddlliinngg tthhee SSoollddeerriinngg TTiipps

s

●

Select the lowest working temperature possible.

●

Select the largest possible soldering tip for the application. Rule of thumb: approximately as large as the

soldering pad.

●

Maximize heat transfer between soldering tip and

solder joint by tinning the soldering tip.

●

To extend tip life, switch the soldering system off, or

use the Weller Standby/Setback function to decrease

temperature before work breaks or extended periods

of non-use.

●

Tin the tip before placing the soldering iron in the Tool

Holder.

●

When making a connection, solder should be applied

to the solder joint and not to the tip.

●

Where necessary, use the appropriate tool to change

the soldering tips.

●

Never apply mechanical force to the soldering tip.

1100.. AAcccceessssoorriiees

s

0052918099 Soldering Pencil, WP80 / 80W,

Short Grip

0058744845 Short Grip Tip Retainer, WP80

0058744846 Long Grip Tip Retainer, WP80

WMP WMP Soldering Pencil, WMP

Micro 65W

0053313399 Desoldering Tweezer Set WTA50

0053315199 FE75 / Fume Extraction Pencil,

80W Set

0053313599 Soldering Iron Set WSP150

0051512299 WDH20 Soldering Iron Holder for

WMP

0051512199 WDH10 Soldering Iron Holder for

WP80/WSP80

0051504299 AK51 Tweezer Stand for WTA50

0052241999 Sponge

0052609899 10’ Extension Cordset for WP80

( Made to Order ) Not Shown

1111.. PPaacckkiinngg LLiisst

t

WD2M

Control Unit

120 VAC Power Cord

USB Cable

CD / Operating Instruction / Software for PC Connection

Operating Instructions

Safety Information Booklet

WD2000M

WD2M Control Unit

120 VAC Power Cord

WMRP Soldering Iron

WMRH Soldering Iron Holder for WMRP

WMRT Desoldering Tweezers

WMRTH Tweezer Stand

USB Cable

CD / Operating Instruction / Software for PC Connection

Operating Instructions

Safety Information Booklet

Subject to technical change without notice.

Page 12

110

0

TTeecchhnniiccaall SSppeecciiffiiccaattiioonns

s

TTeecchhnniiccaall DDaatta

a

Supply Voltage: 24 VAC

Power Rating: 40 W

Heat Up Time: 3 sec. from ambient to 750ºF (399ºC)

Max. Temp.: 850ºF (450ºC)

Min. Temp.: 200ºF (100ºC)

Tool Cord: Silicone rubber, burn resistant

Connector: Polarized, 5 pin locking

Tool Weight: Less than 1/2 ounce

Sensor Type: Integrated sensor / heater tip cartridge

Tip Type: RT series

1. Tool holder

2. Ball joint clamping screw

3. Ball joint for setting the tool holder angle

4. Sponge

5. Hand piece connector / plug

6. Soldering iron handle

7. Soldering tip

WWMMRRPPIIrroonn aanndd SSttaannd

d

Page 13

111

1

E

nglish

Thank you for placing your trust in our company by

purchasing the Weller WMRP Micro-Soldering Pencil.

The ergonomic anti-static design, the quick-change

plug-in micro-soldering tips, extremely fast tool heat

up, and an auto-off feature when placed in the tool

holder, provide the superior performance, versatility,

and quality established by Weller.

11.. CCaauuttiioonnss aanndd WWaarrnniinnggss!

!

Please read these Operating Instructions and the

attached Safety Information carefully prior to initial

operation. Failure to observe the safety warnings may

result in accident, injury, or risk to health.

The manufacturer shall not be liable for damage resulting from misuse or unauthorized alterations of the

equipment.

Warning: This product, when used for soldering and

similar applications, produces chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

SSaaffeettyy IInnffoorrmmaattiioon

n

● Always place the soldering iron in the original holder

● Remove all inflammable objects from the proximity

of the hot soldering tool.

● Use suitable protective clothing. There is a risk of

burns from molten solder.

● Never leave the hot soldering iron unattended.

● Never work on electrically live circuits or compo-

nents.

● Always wear eye protection when working with soldering and desoldering applications.

22.. DDeessccrriippttiioon

n

An extremely powerful 40 W fine soldering iron with the

heating system integrated into the soldering tip. Thanks

to a plug-in system, the soldering tip can be changed

without tools. The soldering tip temperature is reached

rapidly and controlled precisely. Thanks to a sensor

installed in the handle, the soldering iron is shut off

automatically when it is placed in the WMRH holder.

33.. PPllaacciinngg iinnttoo OOppeerraattiioon

n

Place the soldering iron in the WMRH tool stand and

ensure that the soldering iron grip is correctly seated

against the tool holder ( 1 ). Move all combustible

objects away from the soldering iron and the work

area. Insert the connector plug ( 5 ) in the power

supply receptacle and lock it by turning clockwise. Turn

the station’s power switch “On” and set the desired

temperature. When the tool reaches the set temperature, tin the soldering tip with solder.

44.. OOppeerraattiinngg IInnffoorrmmaattiioon

n

CChhaannggiinngg tthhee ssoollddeerriinngg ttiip

p

Caution, risk of burns!

Soldering tips must only be changed when cool. The tip

change does not require tools. The soldering tip is

removed by simply grasping the soft grip of the soldering tip and pulling from the tool. A tip is inserted by

pushing the plug end of the tip into the front end receptacle of the hand piece.

IImmppoorrttaanntt:

:

Always ensure that the soldering tip is properly seated.

When installing a new soldering tip, ensure that the soldering tip is inserted completely up to the stop in a single motion. Operation with a soldering tip that is not

completely inserted can cause the tip to malfunction.

During initial heat-up, tin the soldering tip with solder.

This removes oxide layers and contamination on the

soldering tip. Before placing the tool in the holder,

always ensure the soldering tip is well tinned. The use

of an aggressive flux may shorten tip life.

Always keep the cleaning sponge ( 4 ) damp. Use only

distilled or de-ionized water.

In addition to the informaton included in this manual,

please see the safety manual and the instructions for

the applicable power unit.

SSuubbjjeecctt ttoo tteecchhnniiccaall cchhaannggee wwiitthhoouutt nnoottiiccee!

!

Page 14

112

2

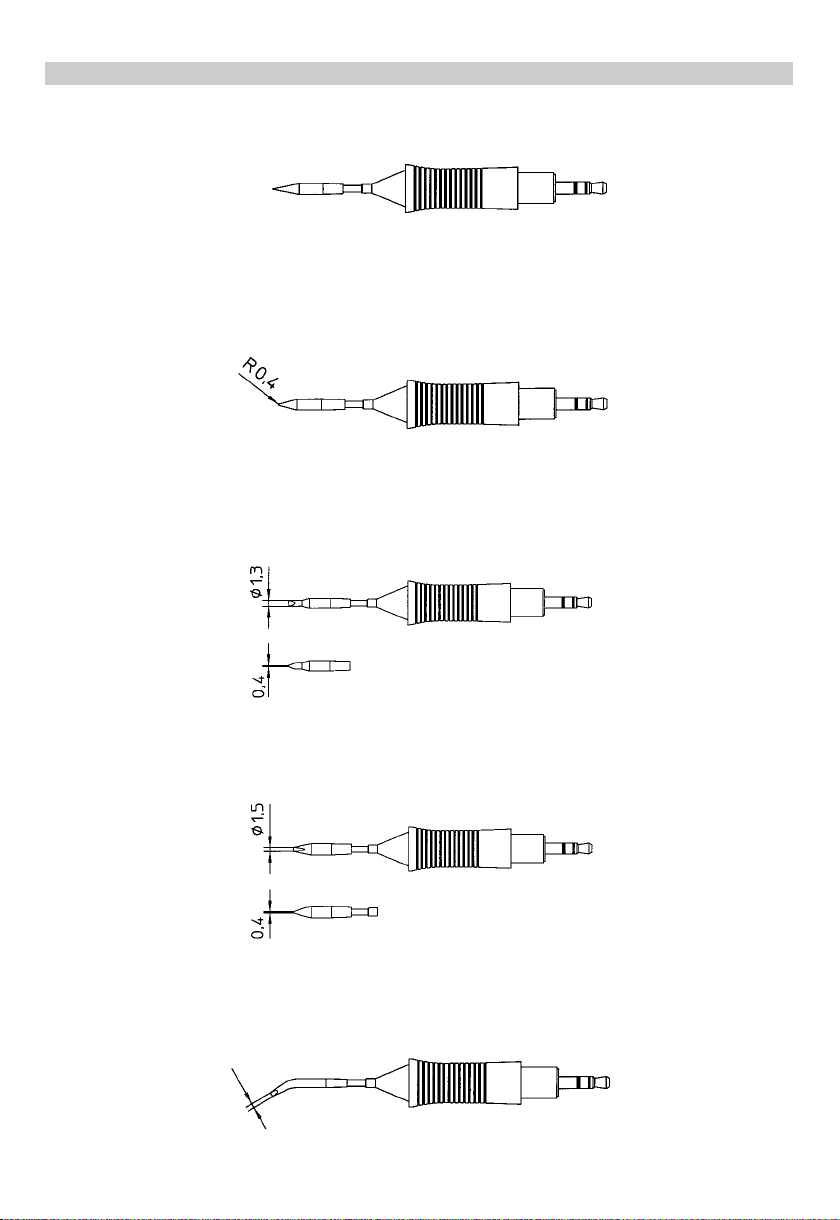

SSoollddeerriinngg TTiipps

s

0054460199 RT1 Needle Tip

0054460299 RT2 Fine Point Tip R 0.020” (0,4mm)

0054460399 RT3 Chisel Tip 0.050 x 0.020” (1,3mm x 0,4mm)

0054460599 RT5 Chisel Tip 30° bent 0.030” x 0.020” (0,8mm x 0,4mm)

0054460499 RT4 Chisel Tip 0.060” x 0.020” (1,5mm x 0,4mm)

Page 15

113

3

RReeppllaacceemmeenntt PPaarrttss aanndd AAcccceessssoorriieess

RReeppllaacceemmeenntt PPaarrttss aanndd AAcccceessssoorriiees

s

KKEEYY NNOO.. PPAARRTT NNOO.. DDEESSCCRRIIPPTTIIOON

N

Shown in diagram 0051514599 WMRH Tool Holder for WMRP Soldering Iron

5,6 0052917199 WMRP Pencil, No Tips

4 0052241999 Sponge

For RT series tips see pages 3,4.

SSoollddeerriinngg TTiipps

s

0054460699 RT6 Round Tip 0.050” x 45° (1,2mm x 45°)

0054460799 RT7 Knife Tip 0.090” x 45° (2,2mm x 45°)

Page 16

114

4

TTeecchhnniiccaall SSppeecciiffiiccaattiioonns

s

TTeecchhnniiccaall DDaatta

a

Supply Voltage: 24 VAC

Power Rating: 80 W (2 x 40 W)

Heat Up Time: 3 - 5 sec. (approx.) from ambient to 750ºF (399ºC)

Max. Temp.: 850ºF (450ºC)

Min. Temp.: 200ºF (100ºC)

Tool Cord: Silicone rubber, burn resistant

Connector: Polarized, 6 pin locking

Tip Type: RTW series

Tool Weight: 1.5 ounces without cord

1. Stand / Tool Holder

2. Tip Cleaning Sponge

3. Desoldering Tip Cartridge with Molded Grips

4. Hand Piece

5. Connector / Plug

WWMMRRTTTTwweeeezzeerrss aanndd SSttaannd

d

Page 17

115

5

Thank you for placing your trust in our company by

purchasing the Weller WMRT Micro Tweezer. The

ergonomic anti-static design, selection of desoldering

tweezer tips, and 80 watts of power, provide Weller

superior performance, versatility, and quality.

11.. CCaauuttiioonnss // WWaarrnniinnggss !

!

Please read these Operating Instructions and the

attached Safety Information carefully prior to initial

operation. Failure to observe the safety warnings may

result in accident, injury, or risk to health.

The manufacturer shall not be liable for damage resulting from misuse or unauthorized alterations of the

equipment.

Warning: This product, when used for soldering and

similar applications, produces chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

SSaaffeettyy IInnffoorrmmaattiioon

n

● Always place the WMRT tweezer in the original

holder.

● Remove all inflammable objects from the

proximity of the hot desoldering tool.

● Use suitable protective clothing. There is a risk of

burns associated with molten solder.

● Never leave the hot WMRT tweezer unattended.

● Never work on electrically live circuits or

components.

● Always wear eye protection when working with

soldering and desoldering applications.

22.. DDeessccrriippttiioon

n

The Weller WMRT Tweezers are designed for rework and

repair of precision SMT electronic devices. The desoldering tip set can be quickly and easily changed without the use of tools. The tips are pre-aligned and additional alignment is not required. The integrated (2 X 40

W) heating elements ensure that the desoldering tip

temperature is reached very quickly and controlled precisely. The desoldering tweezers are switched off automatically when placed in the WMRTH tool holder.

The Weller WMRT Tweezers may only be used with the

WD1M or WD2M series power units.

33.. PPllaacciinngg iinnttoo OOppeerraattiioon

n

Place the desoldering tweezers ( 4 ) in the tool holder

and ensure that the hand piece is correctly seated in

the stand ( 1 ). Move all combustible objects away

from the tweezers and the work area. Insert the connector ( 5 ) into the power supply receptacle and lock it

by turning clockwise. Turn the station’s power switch

“On” and set the desired temperature. When the tips

have reached the set temperature, tin both tweezer tips

with solder.

44.. OOppeerraattiinngg IInnffoorrmmaattiioon

n

CChhaannggiinngg tthhee DDeeoollddeerriinngg TTiipps

s

CCaauuttiioonn,, rriisskk ooff bbuurrnnss!

!

Desoldering tips must only be changed when cool. The

tip change does not require tools. The desoldering tip

cartridge is inserted into the front of the hand piece ( 4

). The 5-pin mini-plug on the back of the tip cartridge is

polarized for correct alignment with the hand piece. The

top of the tip cartridge is printed with L (Left) and R

(Right) indicators for proper orientation. The indicators

align with L and R indicators printed on the hand piece.

The tip cartridge ( 3 ) can be removed from the hand

piece by grasping the molded grips and pulling outward

to release.

IImmppoorrttaanntt:

:

Always ensure that the desoldering tip is properly seated.

When installing a new desoldering tip cartridge, ensure

that the cartridge is inserted completely against the

stop in a single motion. Operation with a desoldering tip

that is not completely inserted can cause the tip cartridge to malfunction.

During initial heat up, tin the tips with solder. This

removes oxidation and contamination on the desoldering tips. Before placing the tool in the holder, always

ensure that the desoldering tips are well tinned. Use of

an aggressive flux will possibly shorten tip life.

Always keep the cleaning sponge ( 2 ) damp. Use only

distilled or de-ionized water.

In addition to the informaton included in this manual,

please see the safety manual and the instructions for

the applicable power unit.

SSuubbjjeecctt ttoo tteecchhnniiccaall cchhaannggee wwiitthhoouutt nnoottiiccee!

!

EEnngglliisshh

Page 18

116

6

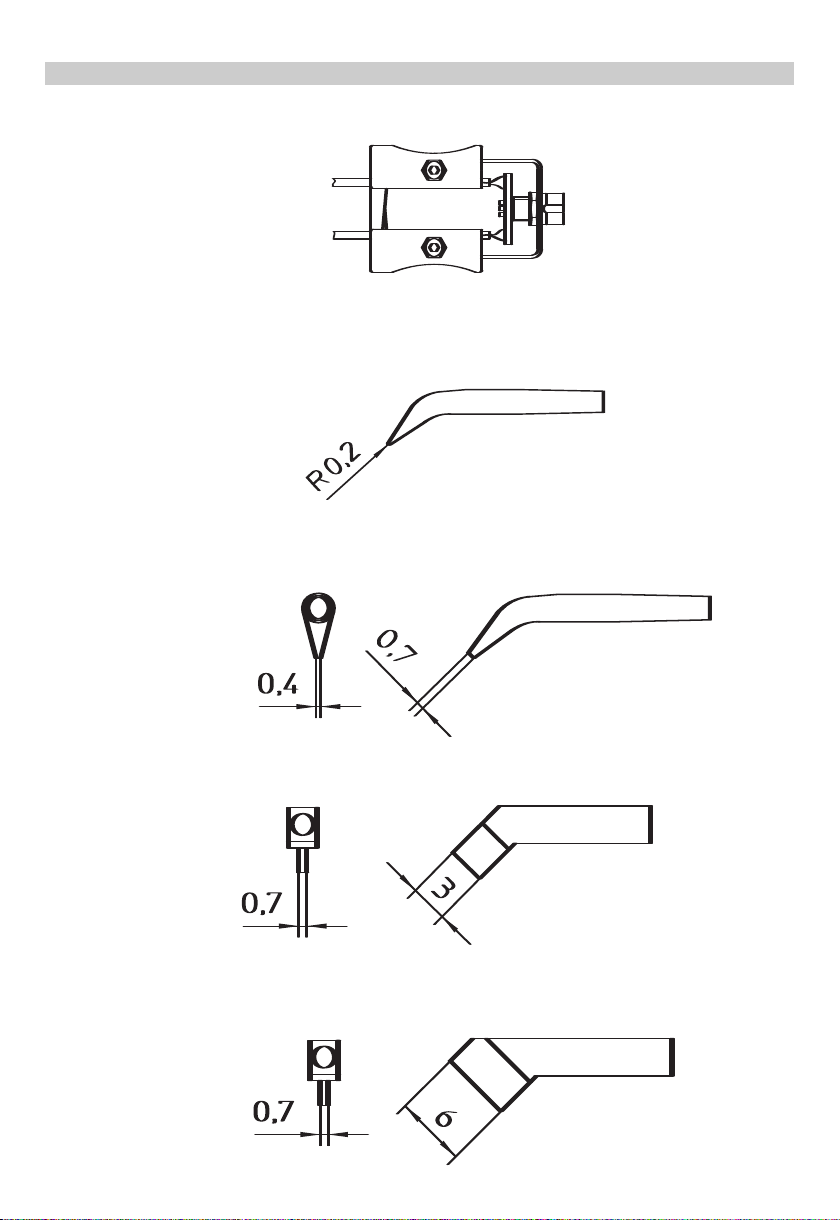

DDeessoollddeerriinngg TTiipps

s

WMRT Tip Cartridge

0054465199 RTW1 Tip Set 0,2 mm (.008”), 45°

0054465299 RTW2 Tip Set 0,7 x 0,4 mm (.028” x .016”), 45°

0054465399 RTW3 Tip Set 3 x 0,7 mm (.118” x .028”), 45°

0054465499 RTW4 Tip Set 6 x 0,7 mm (.236” x .028”), 45°

Page 19

117

7

RReeppllaacceemmeenntt PPaarrttss aanndd AAcccceessssoorriiees

s

KKEEYY NNOO.. PPAARRTT NNOO.. DDEESSCCRRIIPPTTIIOON

N

1,2 0051514699 WMRTH Tool Holder / Stand

2 0052241999 Sponge

3,4,5 0051317299 WMRT Micro Tweezers with RTW2 Tip Set

1,2,3,4,5 0051317399 WMRT Micro Tweezers with WMRTH Stand and RTW2 Tip Set

*For Desoldering Tip Cartridges see page 3.

RReeppllaacceemmeenntt PPaarrttss aanndd AAcccceessssoorriiees

s

Page 20

118

8

WD2M Circuit Diagram

E

nglish

Page 21

119

9

English

WD2M Exploded View

Page 22

wwwwww..ccooooppeerrhhaannddttoooollss..ccoom

m

005 XX XXX XX / 03.06 © 2006 Cooper Industries

Weller is a registered Trademark and registered Design of Cooper Industries, Inc.

UU..SS MMaaiilliinngg AAddddrreessss:

:

CCooooppeerr HHaanndd TToooolls

s

P.O. Box 728

Apex, NC 27502-0728

UU..SS SShhiippppiinngg AAddddrreessss:

:

1000 Lufkin Road

Apex, N.C. 27539

Tel: (919) 387-0099

Fax: (919) 387-2379

For inquiries concerning Technical /

Customer Service please call:

(800) 476-3030 Ext. 1

CCaannaaddaa SShhiippppiinngg AAddddrreessss:

:

CCooooppeerr TToooolls

s

164 Innisfil Street

Barrie, Ontario

Canada L4N 3B7

Attn: Repairs

Fax: 1-800-403-TOOL (8665)

Phone: 705-728-5564 Ext. 2026

Loading...

Loading...