Page 1

MACH 6 Quick Reference Guide

Daily Requirements Powder Canister Level and moisture

Monthly Requirements Filters and Moisture

Handpiece/s Handpiece Hose/s and Nozzles

Pinch Tube (check)

Quarterly Requirements Pinch Tube (replace)

BI-Annual Requirements Pinch Valve Assembly (l ubricate)

Inspect Canister components

Annual Requirements Air In and Out In-Line Filters (replace)

Internal Tubing (re -tube)

Powder Canister (replace components)

Maintenance Checks

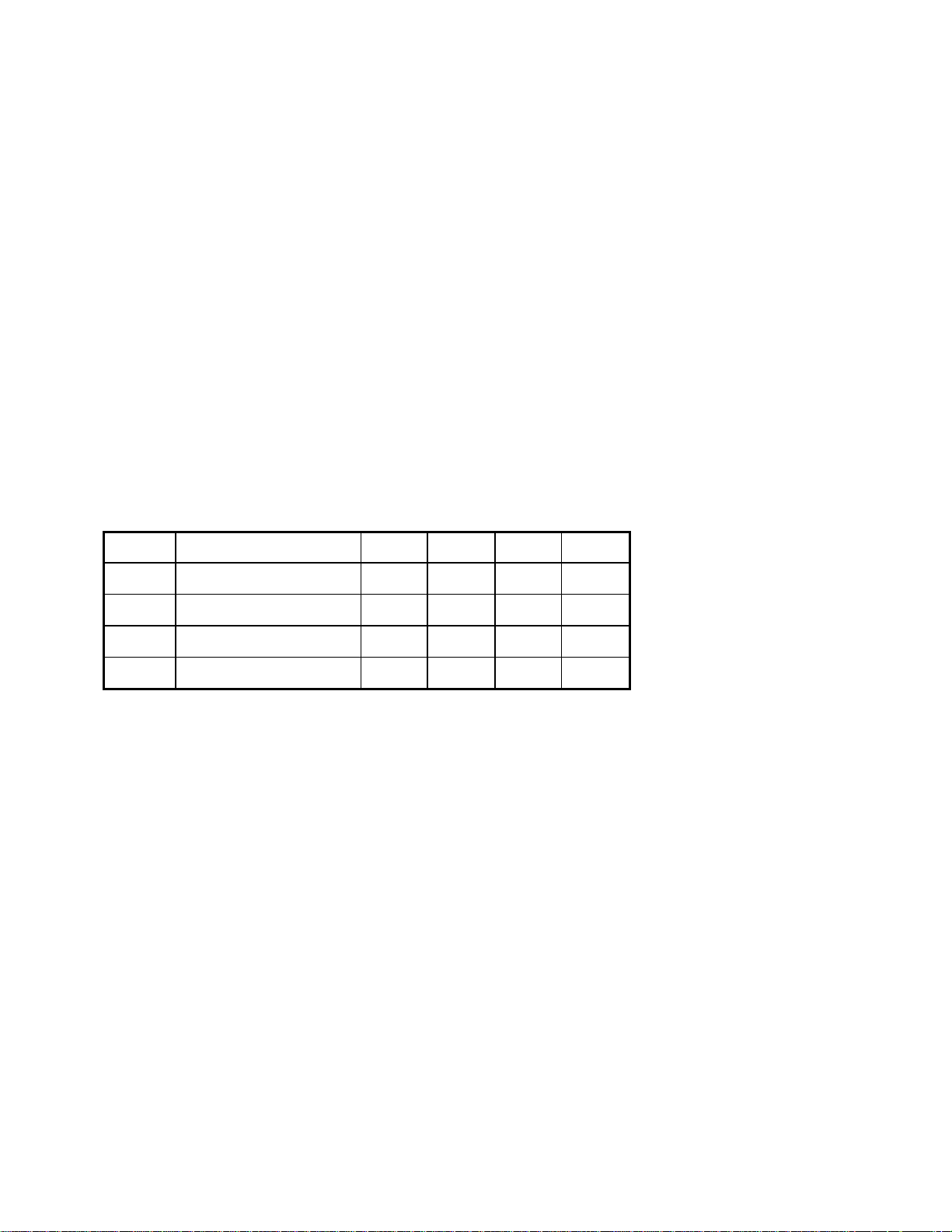

No. Maintenance item 6 mo. 12 mo. 18 mo. 24 mo.

PM 1 Maintain Pinch Valve XX XX XX XX

PM 2 Replace Filters & Tubing XX XX

PM 3 Maintain Powder Canister XX XX

PM 4 Calibrate system XX XX XX XX

PM 1. Maintain pinch valve block 6/12 Months) : .50 hour

One Year Maintenance Kit K150034

PM 2. Replace the Filters and tubing (12 months): 1.0 hour

One Year Maintenance Kit K150034

PM 3. Check Powder Canister (6/12 months): 0.5 hour

One Year Maintenance Kit K150034

Check Canister Gasket and lid

Clear powder ports and back flush canister

Clean Gasket and Canister lid

Clear and measure Orifice Plate holes

Replace powder and verify system operation

Maintain Powder Canister (12 month) 1.0 hour

One Year Maintenance Kit K150034

PM 4. Calibrate system (6 months): 1.0 hour

Verify and calibr ate using procedure

K990291 Rev. C

Page 2

MACH 6 Quick Reference Guide

Troubleshooting Guide

PROBLEM

No powder or air from the

handpiece nozzle.

Air from the handpiece but no

powder flow.

Air and powder from the

handpiece flow for only a few

seconds then stop.

Air and powder flow

continuously from handpiece

even when in the Standby

mode.

Powder inside the unit

chassis.

Unit Plugged into Water Contact Welch Allyn Service center for unit Repair

SOLUTION

?? The handpiece is clogged. Use an orthowire to clear the nozzle. Disconnect

the handpiece from the handpiece hose and blow air through it.

?? No Powder

?? Blown Pinch Tube

?? Clogged orifice plate. Empty the powder from the canister. With an ortho

wire, gently move the wire back and forth in the small holes in the bottom of the

Powder Canister.

?? Pinch Valve Piston stuck

?? A pinch tube is sticking. Replace the pinch tube.

?? Pinch Valve Piston stuck

?? Change pinch tube.

?? Shoe block cover has become scarred. Replace the shoe block cover.

?? Blown Pinch Tube

?? Hole in Powder tubing

?? Shoe block cover has become scarred. Replace the shoe block cover.

K990291 Rev. C

Loading...

Loading...