Page 1

Service Manual

Atlas Monitor

Atlas Patient Monitor

Welch Allyn

8500 SW Creekside Pl

Beaverton, Oregon 97008

6200-43E Revision D Copyright 2007

Page 2

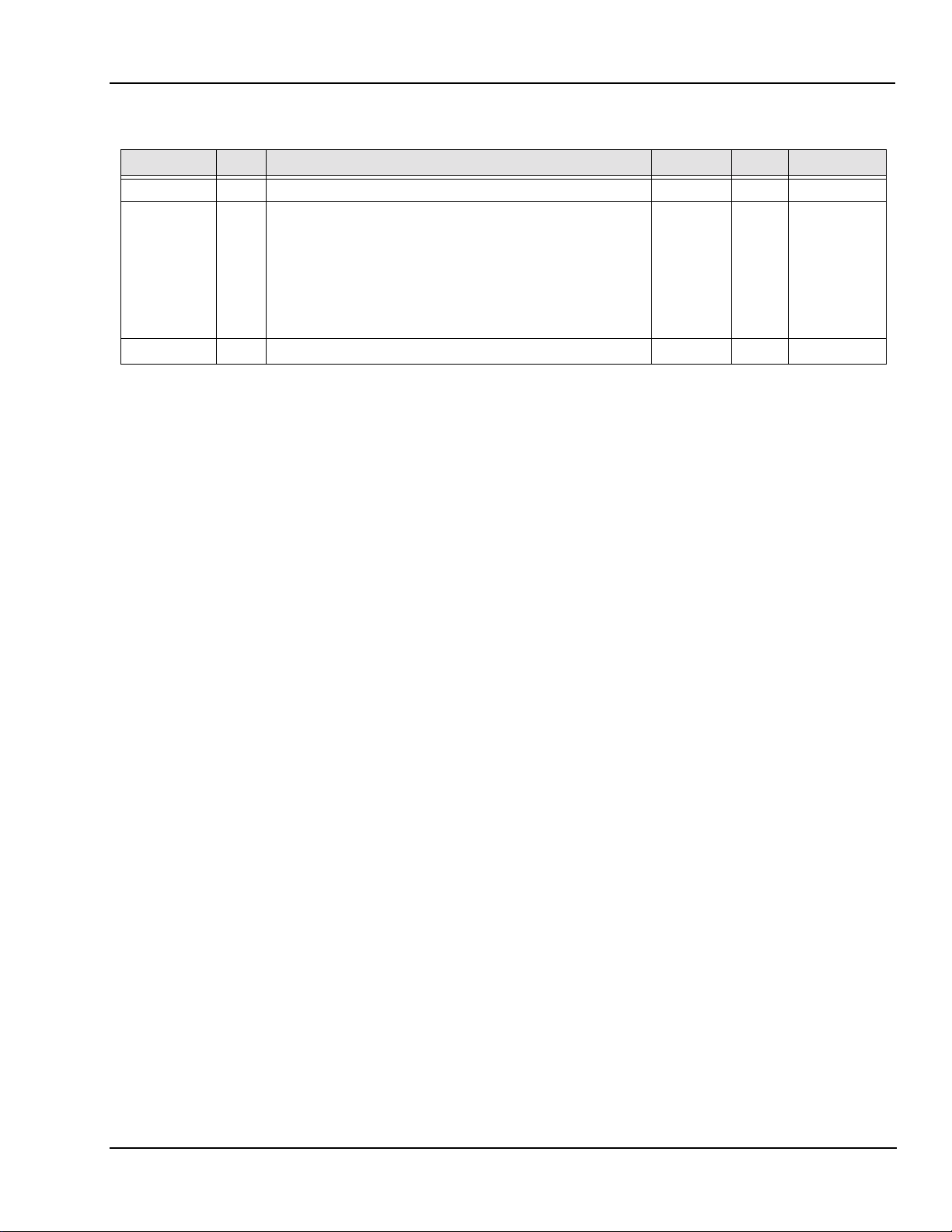

Part No. Rev. Description ECN# Date Approved

6200-43E A New release of Atlas Service Manual 5-40429 10/99 RS/LP

6200-43E B Updated calibration procedures

Updated performance verification procedures

Updated drawing 620150 Rev B to Rev C

Updated drawing 620201 Rev A to Rev B

Updated drawing 620524 Rev A to Rev B

Added complete repair parts lists.

Added calibration date table

6200-43E C Updated to reflect changes in hardware and software 5-45730 03/03 DK

5-44782 07/02 DK

Drawings and/or illustrations and/or part numbers contained in this

document are for reference purposes only. For current revisions call the

Welch Allyn Customer Service phone number listed in Section 1 page 2.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor i

Page 3

CONTENTS

List of Figures ...................................................................................................................vi

List of Tables .....................................................................................................................ix

Section 1: General Information

About the Atlas Monitor........................................................................................................1

Help Information ...................................................................................................................2

Agency Approvals .................................................................................................................3

Warning, Cautions and Notes................................................................................................3

Product Model Number Structure.........................................................................................5

623xP Main Menu Architecture............................................................................................6

622xP Main Menu Architecture............................................................................................7

621xP Main Menu Architecture............................................................................................8

Atlas System Block Diagram .................................................................................................9

Section 2: Service

Incoming Inspection............................................................................................................ 11

Calibration and Maintenance Schedule..............................................................................12

Setting Date and Time .........................................................................................................14

Pangea Communication Protocol........................................................................................ 14

BP Calibration...................................................................................................................... 14

50mmHg Calibration............................................................................................................17

250mmHg Calibration..........................................................................................................17

Reset (623xx Models Only)..........................................................................................18

CO

2

ET CO

No-Load Battery Voltage Calibration ..................................................................................20

Battery Voltage Calibration..................................................................................................21

Printer Print Adjustment..................................................................................................... 22

Temperature Calibration...................................................................................................... 23

Calibration Date Set............................................................................................................. 24

Explanation of an Atlas Service Screen..............................................................................25

Calibration ..............................................................................................................19

2

Software Upgrade Procedure...............................................................................................27

Down Loading NVRAM Files..............................................................................................28

ii Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 4

Section 3: Functional tests and Trouble Shooting

Power on Self Test ...............................................................................................................37

Menu Functional Test..........................................................................................................38

BP Test..................................................................................................................................40

Static Manometer Accuracy Test.........................................................................................41

BP Leak Test ........................................................................................................................42

Over 15 mmHg Test .............................................................................................................42

BP Dump Verification Test ..................................................................................................43

Hardware Fail Safe Tests .....................................................................................................43

ECG/Respiration Test...........................................................................................................44

SpO2 Test..............................................................................................................................45

Temperature Test .................................................................................................................45

CO2 Functional Test.............................................................................................................45

Battery Functional Test........................................................................................................46

Printer Functional Test ........................................................................................................47

Print on Alarm Test..............................................................................................................47

Software/Firmware ..............................................................................................................47

ECG Alarms Test ..................................................................................................................48

Respiration Alarms Test ......................................................................................................50

SpO2 Alarm Test ..................................................................................................................51

Silence Alarm Test...............................................................................................................52

CO2/RESP Test .....................................................................................................................52

Blood Pressure Alarm Test ..................................................................................................53

Trouble Shooting..................................................................................................................56

Section 4: Disassembly and Repair

About Section 4 ...................................................................................................................63

Battery Door Removal..........................................................................................................64

Battery Removal...................................................................................................................64

Rear Housing Removal ........................................................................................................65

Printer Cable and Display Cable Removal ..........................................................................66

Power Supply Ground Wire Removal.................................................................................66

Tie Wrap Removal................................................................................................................67

CPU Removal .......................................................................................................................67

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor iii

Page 5

Main PCB Removal.............................................................................................................. 67

Main PCB Side Connector Removal....................................................................................68

Main PCB Hose and Wire Removal..................................................................................... 68

Pump Removal.....................................................................................................................68

Exhaust Removal..........................................................................................................69

CO

2

Pryon PCB Removal.............................................................................................................69

E-Pac Foam Removal (Top). ................................................................................................69

Power Supply Removal. ......................................................................................................70

Power Supply Fuse Location ..............................................................................................70

Fan Removal ........................................................................................................................70

E-Pac Removal (Lower)........................................................................................................71

Deflection PCB Removal...................................................................................................... 71

CRT Removal .......................................................................................................................71

Display PCB Removal.......................................................................................................... 72

Printer Door Button Removal.............................................................................................. 73

Printer Assembly Locking Tab Release. .............................................................................. 73

Printer Positioning Slot Removal........................................................................................74

Printer Assembly Removal.................................................................................................. 74

Printer Lip Assembly. ..........................................................................................................74

Printer Cable Routing. .........................................................................................................75

Appendix A: Theory of Operation

Power Supply Circuits.........................................................................................................77

Model 622 and Model 623...................................................................................................80

On/Off Circuits ....................................................................................................................81

Battery Charger ....................................................................................................................84

NIBP Circuits ......................................................................................................................87

CRT Deflection Board.......................................................................................................... 92

Vertical Amplifier: ...............................................................................................................92

Recorder Electronics............................................................................................................96

Power Supply – 24 Switcher...............................................................................................96

Motor Driver:........................................................................................................................97

Patient Isolated Circuits ......................................................................................................98

Linear Regulators and Filtering – Model 621 .....................................................................99

iv Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 6

Linear Regulators and Filtering – Model 622 and 623.....................................................100

A/D Circuits .......................................................................................................................101

A/D Multiplexer.................................................................................................................102

Serial Communication.......................................................................................................103

Signal Isolation ..................................................................................................................104

ECG Circuits.......................................................................................................................104

Impedance Respiration (Model 622/623 only) .................................................................109

SpO2 Circuits .....................................................................................................................110

Appendix B: Repair Parts Lists

621N0 .................................................................................................................................113

621NP .................................................................................................................................116

621S0..................................................................................................................................119

621SP..................................................................................................................................121

622N0 .................................................................................................................................124

622NP .................................................................................................................................127

622S0..................................................................................................................................130

622SP..................................................................................................................................133

623NP .................................................................................................................................136

623SP..................................................................................................................................142

Appendix C: Interconnect Diagram

Interconnect diagram 620396 Rev A.................................................................................145

Appendix D: Atlas Drawings and Electrical Schematics

See List of Figures on page v for individual drawings.....................................................146

Appendix E: Calibration Date Table

Calibration Date Index Table. ............................................................................................187

Appendix F: Serial Number Cut in History. ...............................................211

Appendix G: Atlas Calibration and Functional Test Form........................ 213

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor v

Page 7

List of Figures

Figure 1-1. 623xP Main Menu Architecture. ........................................................................6

Figure 1-2. 622xP Main Menu Architecture. ........................................................................7

Figure 1-3. 621xP Main Menu Architecture. ........................................................................8

Figure 1-4. Atlas System Block Diagram ..............................................................................9

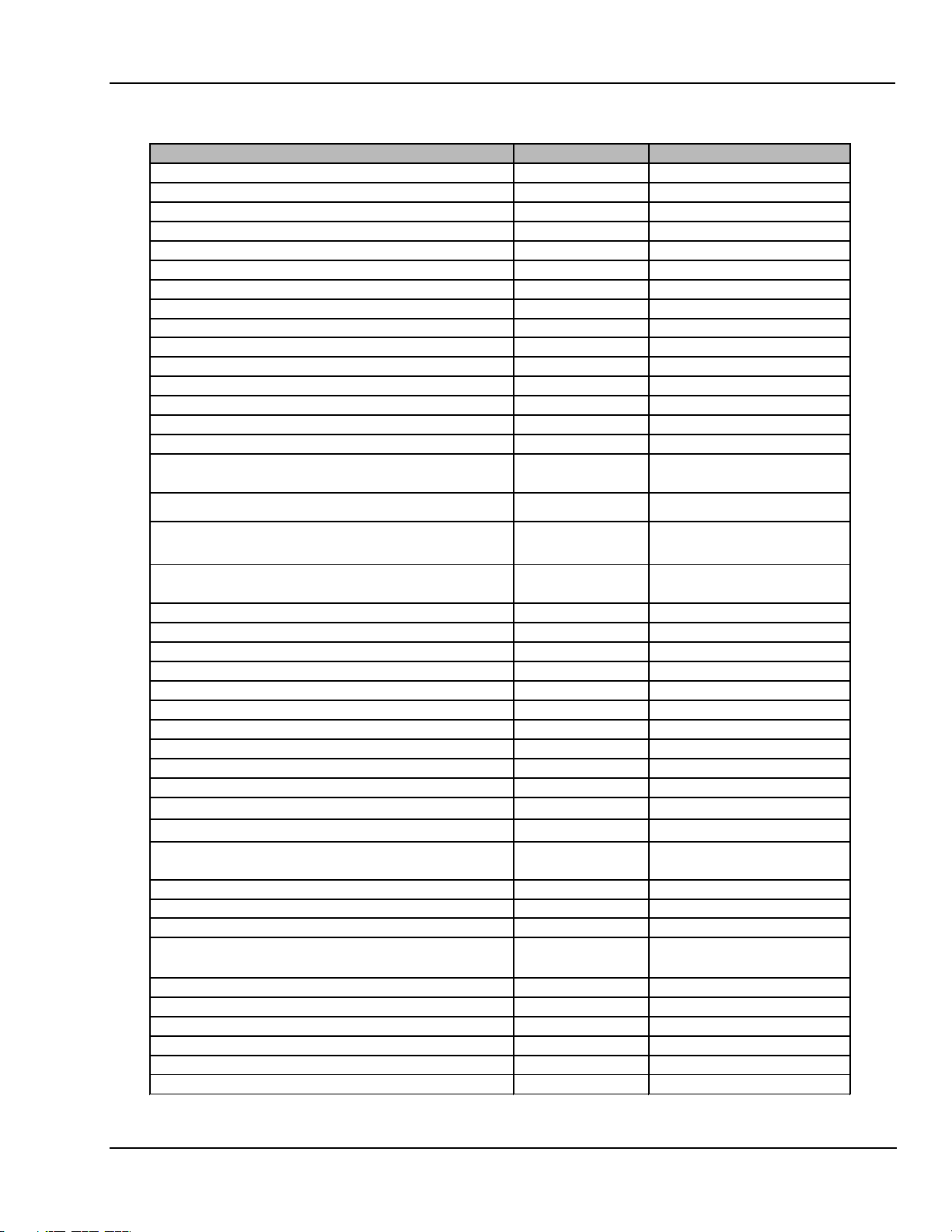

Figure 2-1. Example of a new HyperTerminal connection. ...............................................15

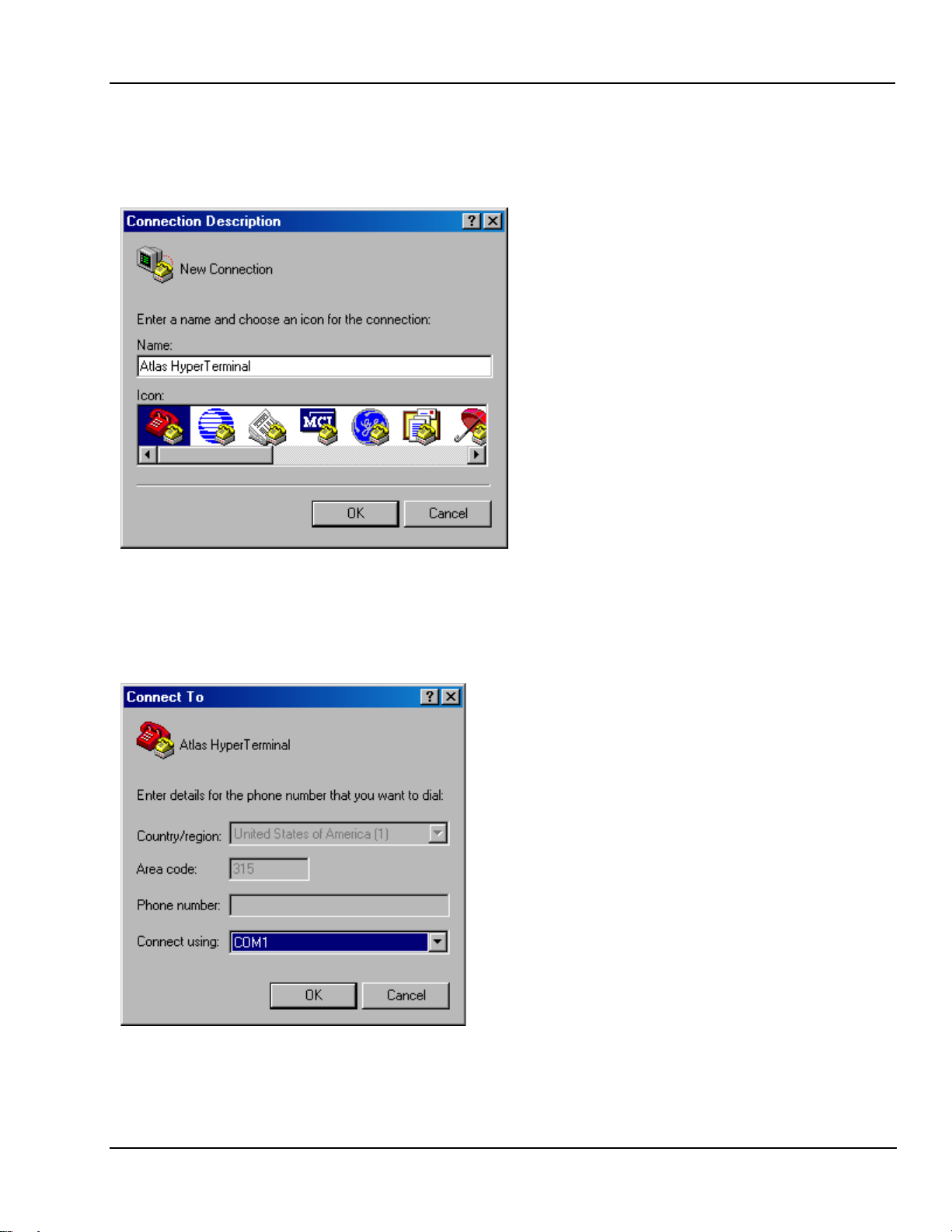

Figure 2-2. Choosing COM1 in HyperTerminal..................................................................15

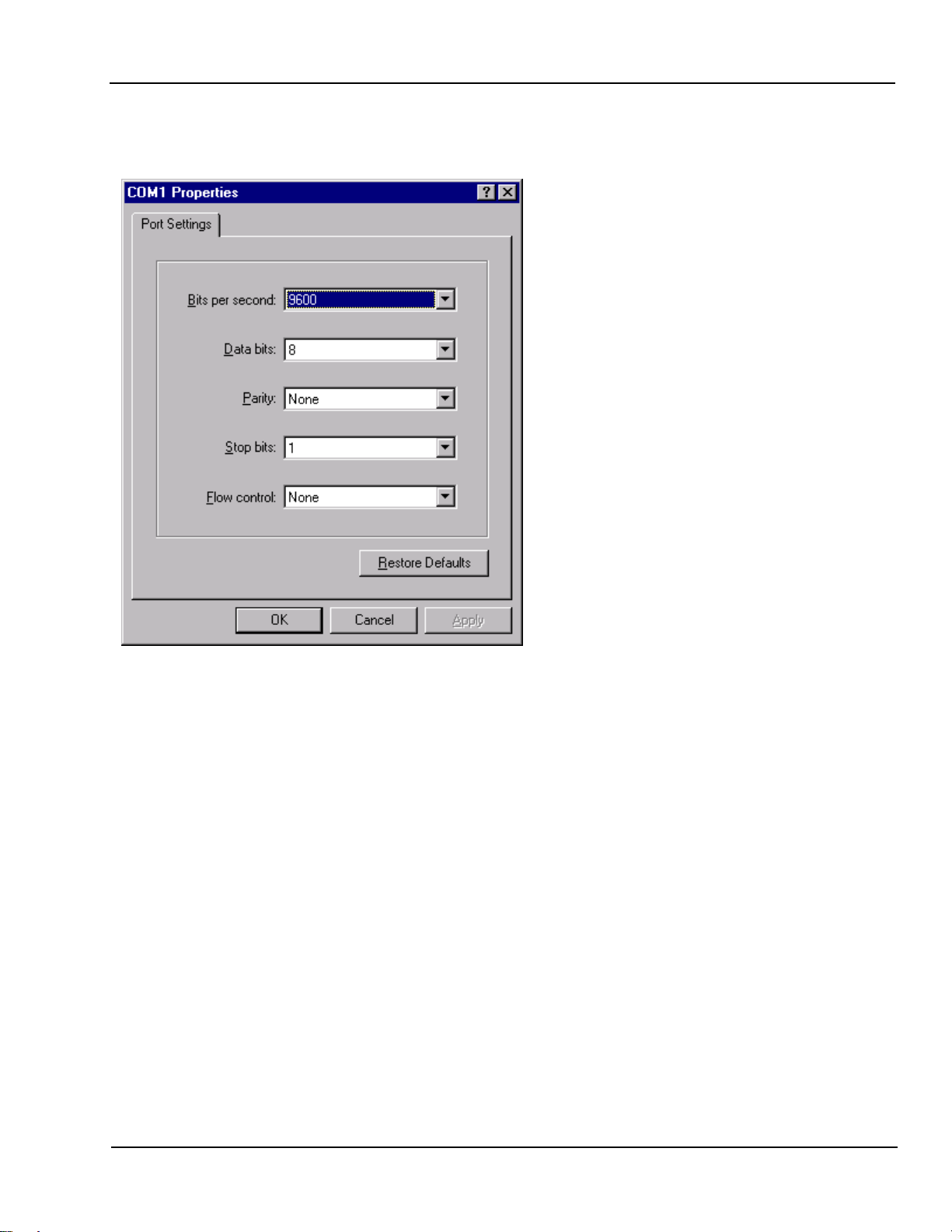

Figure 2-3. HyperTerminal Port Settings. ...........................................................................16

Figure 2-4. Photo of Atlas BP calibration setup. ................................................................17

Figure 2-5. Example of CO2 calibration setup.................................................................... 21

Figure 2-6. Example and Explanation of an Atlas Service Screen ....................................25

Figure 2-7. Pangea prompt in HyperTerminal ....................................................................29

Figure 2-8. Choosing “Send Text File” in HyperTerminal.................................................29

Figure 2-9. Choosing directory where NVRAM files are stored. ....................................... 30

Figure 2-10. Choosing the nvram_cal_init.txt file. ............................................................. 30

Figure 2-11. Pangea screen after opening the nvram_cal_init.txt file. ..............................31

Figure 2-12. Pangea screen after opening the nvram_common.txt file. ............................31

Figure 2-13. Pangea prompt after opening the model# file................................................ 32

Figure 2-14. Pangea screen after loading a language file. ..................................................33

Figure 2-15. Pangea screen after downloading the nvram_printer.txt file. .......................34

Figure 2-16. Pangea screen nvram set serial command. .................................................... 35

Figure A-1. Model 621 DC/DC circuit block diagram. .......................................................77

Figure A-2. On/Off Control Circuits. ..................................................................................78

Figure A-3. Model 621 Buck converter...............................................................................79

Figure A-4. Model 621 linear regulation. ...........................................................................80

Figure A-5. DC/DC circuit diagram.....................................................................................81

Figure A-6. Boost converter and off/on switch. .................................................................82

Figure A-7. Boost converter.................................................................................................83

Figure A-8. Battery charging. ..............................................................................................85

Figure A-9. Linear regulator. ...............................................................................................86

Figure A-10. NIBP PWM A/D converter. ............................................................................86

Figure A-11. PWM timing. ..................................................................................................87

Figure A-12. Primary transducer amplifier.........................................................................89

Figure A-13. Safety transducer amplifier............................................................................90

vi Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 8

Figure A-14. Over pressure fault circuit. ............................................................................91

Figure A-15. Pump relay circuit..........................................................................................91

Figure A-16. Ramp generator circuit...................................................................................92

Figure A-17. Vertical amplifier circuit................................................................................93

Figure A-18. Horizontal amplifier grid voltage circuit. .....................................................95

Figure A-19. Video amplifier circuit...................................................................................96

Figure A-20. Recorder power supply circuit. .....................................................................97

Figure A-22. Print head temperature circuit. .....................................................................98

Figure A-23. Patient isolation circuit..................................................................................99

Figure A-24. Model 621 line regulation and filtering. .......................................................99

Figure A-25. Model 622/623 line regulation and filtering...............................................100

Figure A-26. A/D converter circuit. ..................................................................................101

Figure A-27. A/D multiplexer circuit. ..............................................................................102

Figure A-28. Serial communication circuit. .....................................................................104

Figure A-29. Defib protect and RFI filtering circuit. ........................................................105

Figure A-30. Input buffer circuit.......................................................................................105

Figure A-31. Lead select circuit. .......................................................................................106

Figure A-32. Differential amp/slew rate amp circuit. ......................................................107

Figure A-33. Right leg drive circuit. .................................................................................107

Figure A-34. High pass and gain stage circuit. .................................................................108

Figure A-35. Temperature amplifier circuit......................................................................108

Figure A-36. Respiration drive circuit. .............................................................................109

Figure A-37. Respiration diff amp circuit......................................................................... 110

Figure A-38. Gain and filter circuit...................................................................................110

Figure C-1. Atlas Interconnect Diagram............................................................................145

Figure D-1. Atlas model 200 main board..........................................................................147

Figure D-2. Atlas model 200 NIBP electronics. ................................................................148

Figure D-3. Atlas model 200 power supply......................................................................149

Figure D-4. Atlas Power isolation /SpO2 interface........................................................... 150

Figure D-5. Atlas model 200 ECG amp. ............................................................................151

Figure D-6. Atlas ECG A/D interface.................................................................................152

Figure D-7. Atlas CPU subsystem. ....................................................................................153

Figure D-8. Atlas FPGA. ....................................................................................................154

Figure D-9. Atlas 200/210/220 I/O filters. ........................................................................155

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor vii

Page 9

Figure D-10. Flash, SDRAM HRESET config word. .........................................................156

Figure D-11. Power PC MP C823 CPU. .............................................................................157

Figure D-12. Power distribution........................................................................................ 158

Figure D-13. Front panel display. .....................................................................................159

Figure D-14. Key board scanner. .......................................................................................160

Figure D-15. Temp/pulse LED drivers. .............................................................................161

Figure D-16. NIBP LED drivers. ........................................................................................162

Figure D-17. SpO2 LED drivers. ........................................................................................163

Figure D-18. CRT deflection board. ..................................................................................164

Figure D-19. Printer electronics. .......................................................................................165

Figure D-20. Model 220 main board. ................................................................................166

Figure D-21. 210/220 NIBP electronics.............................................................................167

Figure D-22. DC/DC power supply....................................................................................168

Figure D-23. Power isolation/SpO2 interface. ..................................................................169

Figure D-24. 210/220 ECG amp.........................................................................................170

Figure D-25. 210/220 ECG A/D interface..........................................................................171

Figure D-26. 210/220 Respiration circuit. ........................................................................172

Figure D-27. 210/220 serial communication. ...................................................................173

Figure D-28. 200/210/220 transformer isolation. .............................................................174

Figure D-29. 200/210/220 ECG patient cable. ..................................................................175

Figure D-30. 200/210/220 power supply sub assy. ..........................................................176

Figure D-31. 220 ETCO2 PCB assembly. ...........................................................................177

Figure D-32. 200/210/220 Power supply. .........................................................................178

Figure D-33. Nonin SpO

Board........................................................................................179

2

Figure D-34. Motor Stepper...............................................................................................180

Figure D-35. Pump Pneumatic. .........................................................................................181

Figure D-36. 200/210/220 ECG cable assembly. ...............................................................182

Figure D-37. CO2 cable assembly. .....................................................................................183

Figure D-38. Nellcor sensor cable assy. ............................................................................ 184

Figure D-39. 200/210/220 Pneumatic sub assy.................................................................185

Figure D-40. 220 CO

cable assy. ......................................................................................186

2

viii Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 10

List of Tables

Table 1-1. Operator manual part numbers. ...........................................................................1

Table 2-1. Atlas Packing List. ..............................................................................................11

Table 2-2. Tools Required for Service. ................................................................................13

Table 2-3. Software Revision Table .....................................................................................26

Table 2-4. Files needed to download language(s)...............................................................33

Table 3-1. Transducer pressure table...................................................................................41

Table 3-2 Resistor and temperature reference. ...................................................................45

Table 3-3. Atlas failure trouble shooting.............................................................................56

Table 3-4. Atlas failure trouble shooting.............................................................................57

Table 3-5. Atlas failure trouble shooting.............................................................................58

Table 3-6. Atlas failure trouble shooting.............................................................................59

Table 3-7. Atlas failure trouble shooting.............................................................................60

Table 3-8. Atlas failure trouble shooting.............................................................................61

Table A-1. Temperature coefficient.....................................................................................84

Table B-1. Atlas 621N0 repair parts ..................................................................................113

Table B-2. Atlas 621NP repair parts. .................................................................................116

Table B-3. Atlas 621S0 repair parts...................................................................................119

Table B-4. Atlas 621SP repair parts...................................................................................121

Table B-5. Atlas 622N0 repair parts. .................................................................................124

Table B-6. Atlas 622NP repair parts. .................................................................................127

Table B-7. Atlas 622S0 repair parts...................................................................................130

Table B-8. Atlas 622SP repair parts...................................................................................133

Table B-9. Atlas 622NP repair parts. .................................................................................136

Table B-10. Atlas 623SP repair parts................................................................................. 139

Table B-11. Atlas 623NP repair parts. ...............................................................................142

Table D-1. Atlas drawings revision page...........................................................................146

Table F-1. Changed to a new BP Valve..............................................................................211

Table F-2. Changed E-Pac and Changed to class B power supply. ..................................211

Table F-3. Upgraded printer cable to a cable with foam tape. .........................................211

Table F-4. Upgraded Revision level of CPU from 501 to 502...........................................211

Table F-5. Upgraded Revision level of Nellcor SpO

to 506............................................212

2

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor ix

Page 11

x Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 12

Page 13

General Information Section 1

About the Atlas Monitor

The Atlas Monitor combines in one unit all the necessary measurements for patients under

anesthesia, for surgical recovery, or bed side monitoring. See Section 1, page 5 for a complete

listing of product models and options.

According to the standards of care for Nurse Anesthetists and Anesthesiologists, all patients

receiving conscious sedation are to be continuously monitored throughout the procedure and

recovery phase by ECG, SpO2, and NIBP. CO2 monitoring is a requirement during gas

anesthesia (when patient is ventilated).

The Atlas combines a CRT to display ECG, CO2, SpO2, and respiration waveforms. It utilizes

LEDs for the other numeric values to maximize visibility and viewing angle. Although not

designed to be a transport product, the monitor has an integral handle and it is small and

light enough at 13 lbs. to be easily moved.

A battery was added to enable the monitor to be used if there is a power outage or to be

unplugged momentarily when moved with the patient from the surgery room to the recovery

room. The battery was not designed to make the Atlas into a transport monitor. The Atlas

monitor should be plugged into AC as much as possible to give you the maximum battery

backup time when there is a power outage. It will maintain unit operation for up to an hour

when power is interrupted if the battery is fully charged.

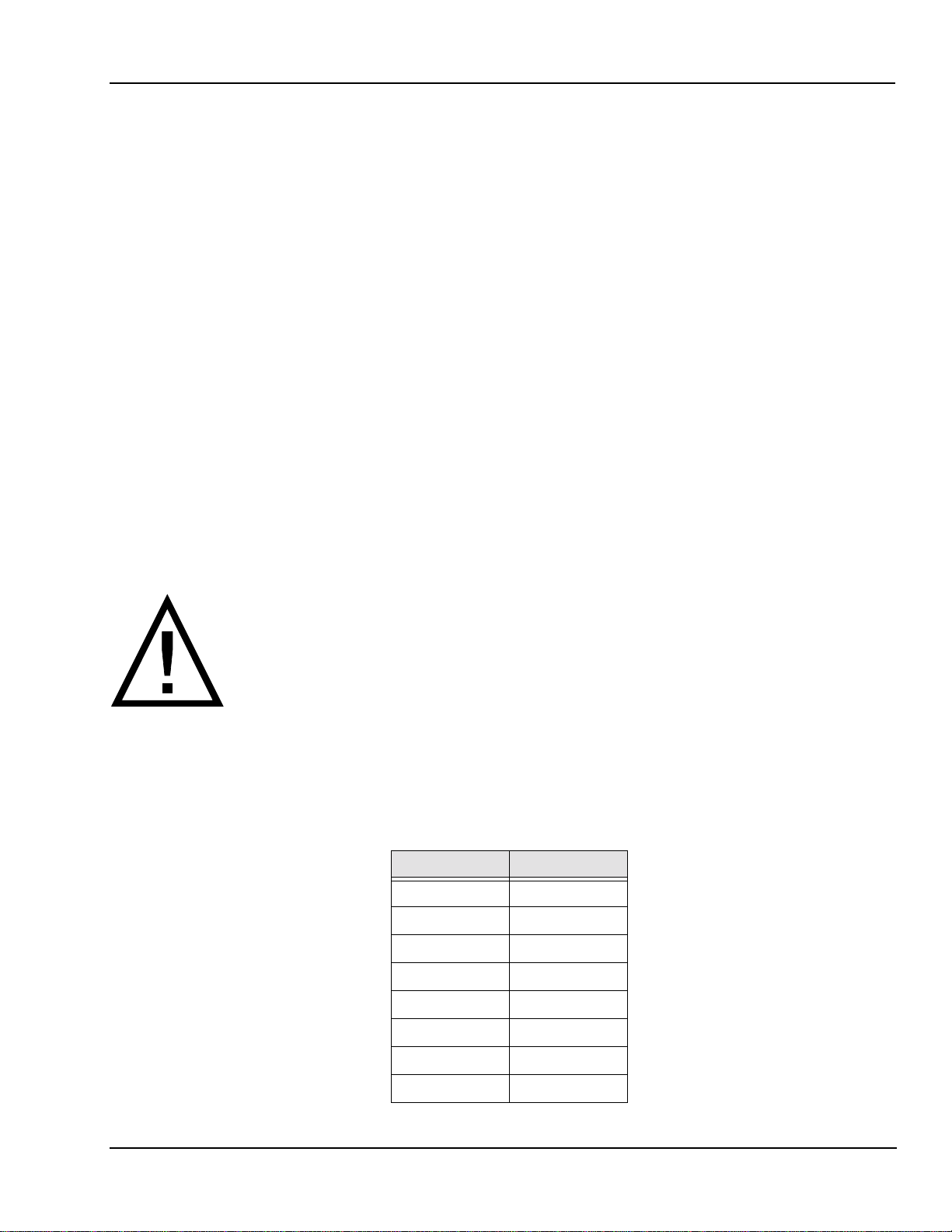

WARNING: Discharging the battery frequently will shorten the battery

life and will shorten the battery backup time.

IMPORTANT: For a complete description on the function and use of the Atlas, as well as user

safety warnings, cautions, and warranty information, read and understand the Atlas

Operator’s Manual. See the Table 1-1 below for correct Operator’s Manual part #.

Table 1-1. Operator manual part numbers.

Language Part#

English 6200-42E

French 6200-42F

German 6200-42G

Italian 6200-42I

Spanish 6200-42S

Portuguese 6200-42P

Japanese 6200-42J

Chinese 6200-42C

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 1

Page 14

Section 1 General Information

J

J

Help Information

To assure correct operation and performance all service and repairs must be performed by

fully trained and properly equipped personnel, using genuine replacement parts and correct

procedures. Failure to do so will also invalidate the product warranty.

Welch Allyn Inc.

State Street Plant /Corporate Headquarters

4341 State Street Road

Skaneateles Falls, NY 13153-0220, USA

tel: 1-800-535-6663

315-685-4100

fax: 315-685-3361

www.welchallyn.com/medical/support/tech

Welch Allyn GMBH

Zollerstrasse 2-4

72417 Jungingen, Germany

tel: (011) 49-7477-927186

fax: (011) 49-7477-927193

Welch Allyn UK Ltd

St. Georges House

Vernon Gate, Derby

England DE1 1UQ

tel: (011) 44-01332-206208

fax: (011) 44-01332-206209

mob: (011) 44-0467-301814

MD International

11300 N.W. 41st Street

Miami, FL 33178 USA

tel: 305-669-9003

fax: 305-669-1971

Welch Allyn France SARL

814 rue Charles de Gaulle

77100 Mareuil les Meaux

France

tel: ( 011) 33 1.6009.3366

Fax: (011) 33 1 .6009.6797

Welch Allyn Australia Pty

The Metro Centre Unit 5

38-46 South Street

Rydalmere NSW 2116, Australia

Postal address:

PO Box 132

Rydalmere NSW 1701, Australia

tel: (011) 612 9638-3000

fax: (011) 612 9638-3500

Welch Allyn Singapore Ltd

300 Beach Road, #25-08

The Concourse

Singapore 199589, Singapore

tel: (011)

fax: (011)

Welch Allyn Japan K.K.

Bon Marusan 8F, 3-5-1 Kanda

inbo-Cho, Chiyoda-Ku

Tokyo 101-0051

apan

tel: (011) 813-5212-7391

fax: (011) 813-3261-7372

65-291-0882

65-291-5780

China Service Center

Room 708 Central Plaza

No. 277 Huang Pi Bei Rd.

Huang Pi District

Shanghai 200003

China

tel: (011) 86-21-63279631

fax: (011) 86-21-63279632

2 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 15

General Information Section 1

Agency Approvals

ETL Listed

UL2601-1,

CSA C22.2 No. 601.1

IEC 60601-1, AS 3200.1

IEC 60601-1-2

US

The CE mark on this product indicates that it

has been tested to and conforms with the

provisions noted

within the 89/336/ECC

Electromagnetic Compatibility Directive.

Australia EMC Framework Compliance

C

L

D

I

S

E

T

742 27

N344

Warning, Cautions and Notes

All operating and service personnel should be familiar with the general safety information

in this summary. Specific warnings and cautions will also be found throughout the operators manual. Such specific warnings and cautions may not appear here in the summary.

Electrical Shock Hazard

CAUTION

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 3

Page 16

Section 1 General Information

ATTENTION. Consult accompanying document

Handle With Care

Storage Humidity. Refer to technical specifications in operator's

95%

MAX

for more details.

Storage temperature. Refer to technical specifications in operator's

manual for more details.

Lead Acid Battery. For disposal see maintenance

section in opertor's manual

PB

4 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 17

General Information Section 1

Product Model Number Structure

621S0-E1 ECG, Nonin SpO2, NIBP

621SP-E1 ECG, Nonin SpO2, NIBP, Printer

621N0-E1 ECG,Nellcor SpO2,NIBP

621NP-E1 ECG,Nellcor SpO2,NIBP, Printer

622S0-E1 ECG, Nonin SpO2, NIBP, Temp, Respiration, Battery, RS232

622SP-E1 ECG, Nonin SpO2, NIBP, Temp, Respiration, Battery, RS232, Printer

622N0-E1 ECG, Nellcor SpO

, NIBP, Temp, Respiration, Battery, RS232

2

622NP-E1 ECG, Nellcor SpO2, NIBP, Temp, Respiration, Battery, RS232, Printer

623SP-E1 ECG, Nonin SpO2, NIBP, ETCO2, Temp, Respiration, Battery, RS232, Printer

623NP-E1 ECG, Nellcor SpO2, NIBP, ETCO2, Temp, Respiration, Battery, RS232, Printer

Product Structure Meaning:

The first three digits in the product structure sequence designates the model number. The

fourth character in the sequence designates the SpO2. The fifth character in the sequence

designates if it has a printer or not. The first suffix designates the country language when

shipped. The second suffix designates the power cord shipped with the Atlas.

First Three Characters:

Fourth Character: N=Nellcor SpO2, S=Nonin SpO

Model number, 621, 622, 623

2

Fifth Character: P=Printer, 0=No Printer

First Suffix:

E = English, F= French, G= German, I= Italian, S= Spanish, P= Portuguese C =

Chinese,

J= Japanese

Second Suffix:

1 = US, Canada, Japan

2 = European

4 = United Kingdom

6 = Australian

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 5

Page 18

Section 1 General Information

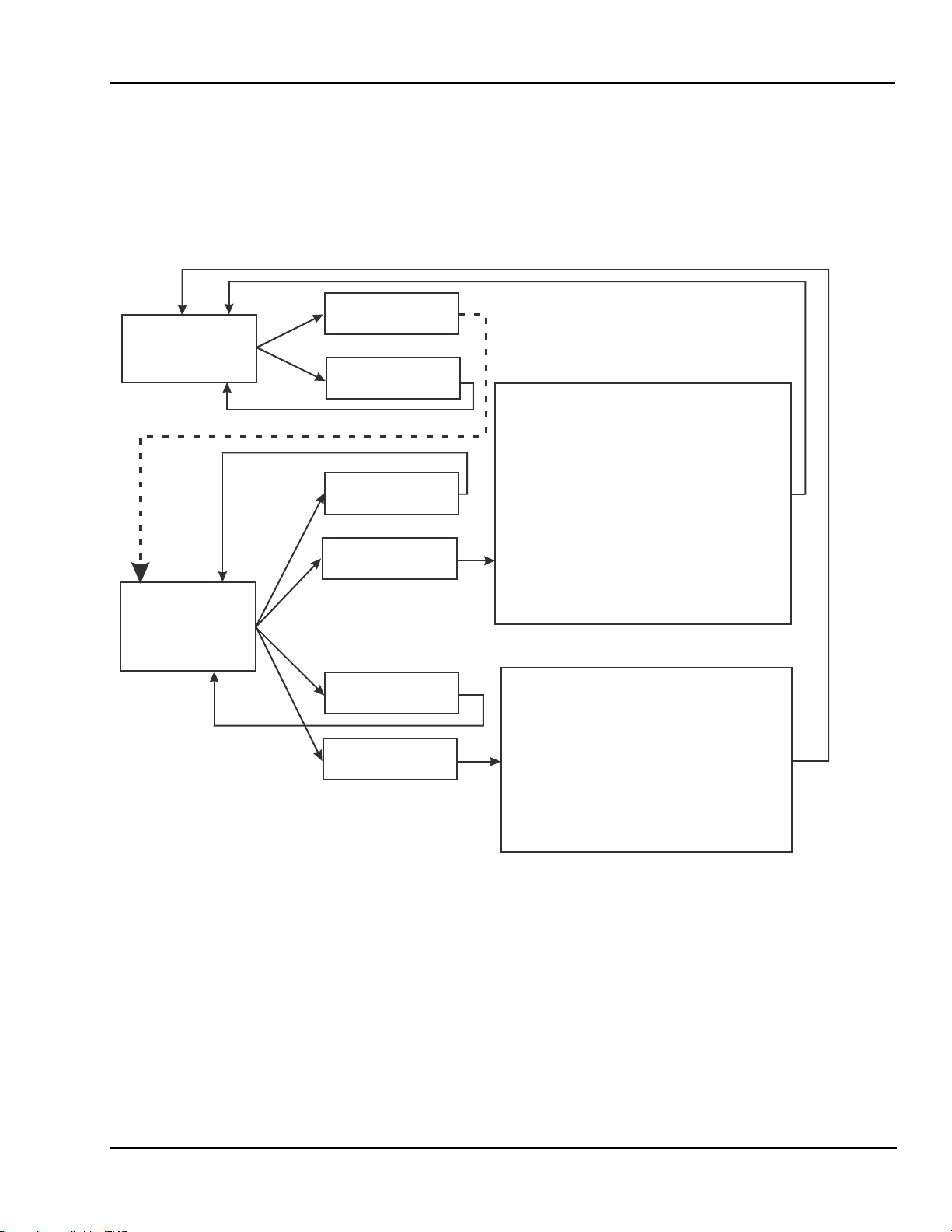

623xP Main Menu Architecture

Figure 1-1. 623xP Main Menu Architecture.

623xP

Date/Time

Wavef orm

screen

Date/Time

Screen

Screen

Trend

Screen

Set date & time

Advanced

Configuration

Co

2

Reset

Save

Settings

Service Mode

Screen

Advanced Configuration Screen

Language

Silence duration

ECG gain

ECG lead set

ECG speed

ECG bandwidth

Initial pressure

MAP

Second trace selection

Temperature units

Respiration speed

units

CO

2

Print on alarm

(only with software Rev.

BB.2.2000 or higher)

Service Mode Screen

Verify manometer

Reset to factory defaults

Battery test

Calibrate Co

CRT test pattern

Printer test pattern (Models 621SPand

LED test

Button test

Display A/D channels *

2

621NP only)

NOTE: The Print on alarm function in Advanced configuration mode screen is only

available with software version BB.2.2000 and higher.

* NOTE: The Display A/D channels function in the Service Mode Screen only allows

you to view system information by pressing the SET button. It does not allow

you to change system settings.

6 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 19

General Information Section 1

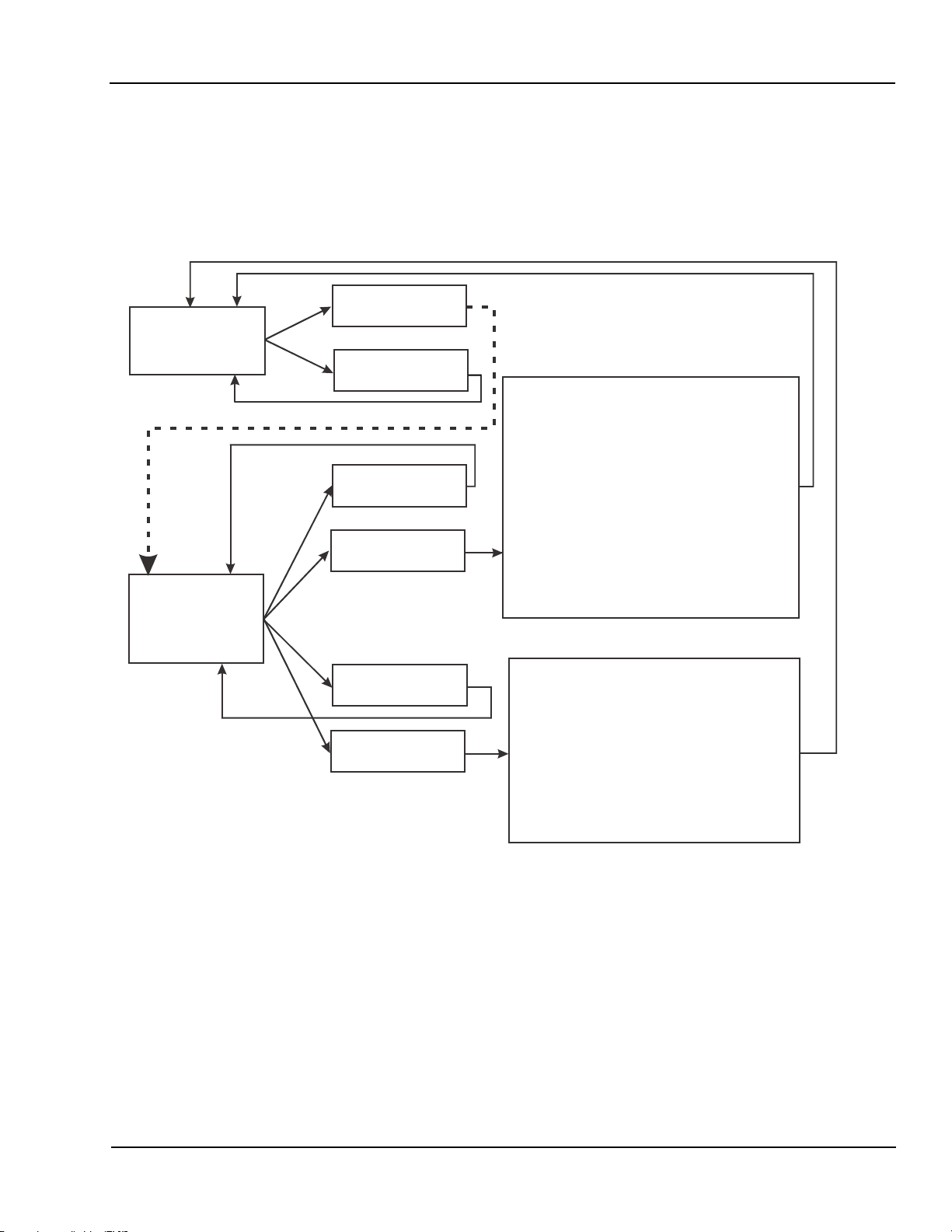

622xP Main Menu Architecture

Figure 1-2. 622xP Main Menu Architecture.

622xP

Date/Time

Waveform

screen

Date/Time

Screen

Screen

Trend

Screen

Set date & time

Advanced

Configuration

Advanced Configuration Screen

Language

Silence duration

ECG gain

ECG lead set

ECG speed

ECG bandwidth

Initial pressure

MAP

Second trace selection

Temperature units

Respiration speed

Print on Alarm

(Only with software Rev.

BB.2.2000 and higher.)

Service Mode Screen

Save

Settings

Service Mode

Screen

Verify manometer

Reset to factory defaults

Battery test

CRT test pattern

Printer test pattern

LED test

Button test

Display A/D channels

(Models 622SP and

622NP only)

*

NOTE: The Print on alarm function in Advanced Configuration Screen is only

available with software version BB.2.2000 and higher.

NOTE: On models 622S0 and 622N0 delete the Print test pattern function in the

Service Mode Screen. Model 622S0 and 622N0 do not come with printers.

* NOTE: The Display A/D channels function in the Service Mode Screen only allows

you to view system information by pressing the SET button. It does not allow

you to change system settings.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 7

Page 20

Section 1 General Information

621xP Main Menu Architecture

Figure 1-3. 621xP Main Menu Architecture.

621xP

Date/Time

Waveform

screen

Screen

Trend

Screen

Set date & time

Advanced

Configuration

Advanced Configuration Screen

Language

Silence duration

ECG gain

ECG lead set

ECG speed

ECG bandwidth

Initial pressure

MAP

Second trace selection

Print on Alarm

(Only with software Rev.

BB.2.2000 and higher.)

Date/Time

Screen

Service Mode Screen

Save

Settings

Service Mode

Screen

Verify manometer

Reset to factory defaults

CRT test pattern

Printer test pattern

LED test

Button test

Display A/D channels

(Models 621SP and

621NP only)

*

NOTE: The Print on alarm function in Advanced configuration mode screen is only

available with software version BB.2.2000 and higher.

NOTE: On models 621S0 and 621N0 delete the Print test pattern function in the

Service Mode Screen. Model 622S0 and 622N0 do not come with printers.

* NOTE: The Display A/D channels function in the Service Mode Screen only allows

you to view system information by pressing the SET button. It does not allow

you to change system settings.

8 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 21

General Information Section 1

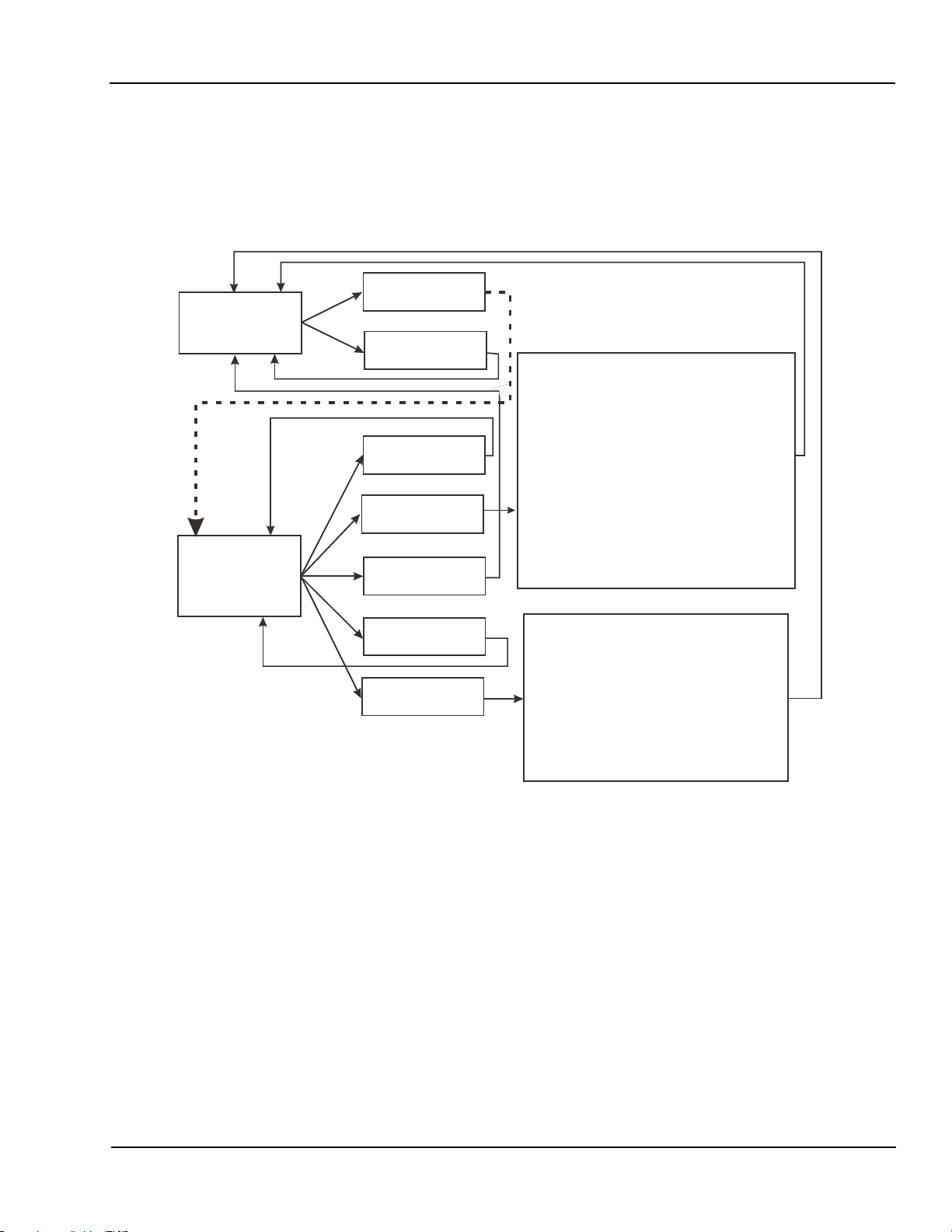

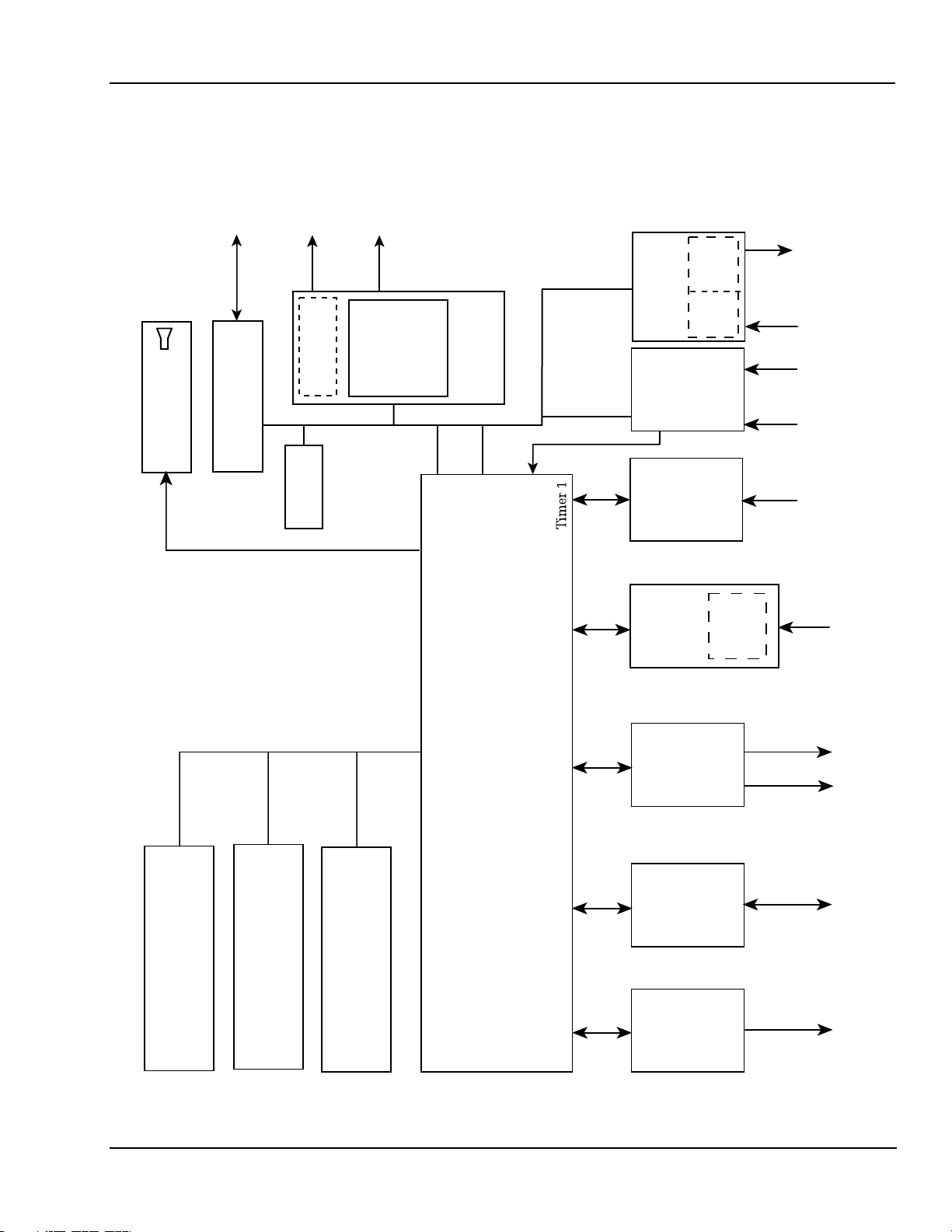

Atlas System Block Diagram

Figure 1-4. Atlas System Block Diagram

15X7

31 LEDs

24

Keys

EKG

X5

Temp

Primary

Sensor

CO2 Sensor

CRT SubSystem

CO2 SubSystem

Motor

Driver Motor

Configuration

EEPROM

Print Head

Clock, Load

AT90A4414

8 bit

Controller

Strobe

SPI

Printer

Subsystem

GPIO

3-wire SPI + nine

chip select

Timer 2

LED

Drivers

Front Panel

Front End

P

W

EKG +

Key

Temp

(Isolated)

Board

PW

NIBP

Front End

5 Volt Video Signals:

H-Sync, V Sync, Video

4M X 16

SDRAM

Local System Bus

Address,Data,Control

512 X 16 Flash

Bus Config.

Register

Motorola CPU

MPC823Z3

GPIO

GPIO

UART-2

UART-1

ON,OFF

ACON,

SYNC

2

TTL

RS-232

Power

Supply

NIBP

Pnuematic

Control

SPO2

Sub-System

(Isolated)

RS-232

Drivers

(Isolated)

Battery

Drivers

Valv e

PumpSPO2

Sensor

Rs-232

Test

AC

Port

Line

TTL

RS-232

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 9

Page 22

Page 23

Service Section 2

Incoming Inspection

NOTE: Use the following guidelines when unpacking the monitor from its shipping carton.

1. Before opening the monitor shipping carton, check for damage.

2. If damage is apparent, stop unpacking the carton and contract the shipping company for

further instructions. If the carton is intact, unpack the monitor.

3. With the monitor out of its carton, check to see that all the items listed on the packing

slip are in the shipping carton. See table 2-1 below.

Table 2-1. Atlas Packing List.

Qty. Description

1 Warranty card

1 Adult Durable 1pc. Cuff

1 Large Adult Durable 1pc. Cuff

1 5ft. Stra ight Hose

1 ECG Patient Cable (Three Lead)

3 ECG Lead Wires

1SpO

1ETCO

1ETCO

1 Nasal Canula 623 only

1Atlas Monitor

1 Detachable Power Cord

1 Printer Paper Roll

1 Operation Manual

1 Skin Tem perature Probe 622/623 only

Sensor/ Finger Clip

2

Water Trap 623 only

2

Scrubber 623 only

2

4. If an item is missing, first check the carton, then check with your receiving department. If necessary

contact Welch Allyn at the address and phone number shown on Section 1.

5. Clean and disinfect by following the instructions printed in the Operator Manual.

NOTE: Perform all functional tests as listed in Section 3 before and after servicing.

Operate the Atlas to verify the customer complaint before making any changes to the unit.

Call the customer if the complaint is unclear.

If the unit has caused or is suspected of having caused an injury of any type: DO NOT

DISASSEMBLE OR REPAIR THE UNIT IN ANY WAY. Contact Welch Allyn Customer

Service immediately.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 11

Page 24

Section 2 Service

Calibration and Maintenance Schedule

The Atlas Monitor must be serviced by authorized Welch Allyn personnel or agents at 6

month intervals. Maintenance requirements are specified for 6 month and 12 month service

intervals. The monthly CO2 Reset operation can be performed by the user.

Service Interval Maintenance Requirements

Every 6 months: CO2 Calibration

Every 12 months: BP calibration, CO2 reset, battery voltage calibration,

printer adjustment,and temperature calibration.

Complete functional test

12 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 25

Service Section 2

Table 2-2. Tools Required for Service.

Description Part# Company

100cc Test Volume T-112189 Welch All

500cc Test Volume T-112854 Welch All

T-10 TORX screwdriver XTD-10 Xcelite brand

7/16" dee

S

queeze Bulb and Valve 5088-01 Welch Allyn

Calibrated Manometer (0-10PSIG) Di

Bio-Tek (NIBP TESTER) BP Pum

Pneumatic Tubin

Pneumatic Tubin

"Y" Fittin

"T" Fittin

Nonin Patient Simulator 8000S Nonin

Nonin Cable 5200-52 Nonin

Calibrated Thermome ter for 90F to 115F ran

LG, Adult Cuff/Ba

Nellcor Patient Simulator For atlas with "MP

204/205 S

Nellcor Patient Simulator "MP 506 PCB ONLY " SRC-MAX Nellcor

Nellcor Sensor Cable "Purple Connectors" will work

on all Atlas units with 204/205/506 S

Nellcor Sensor Cable "Gray Connectors" "For Atlas

units with MP 204/205 S

ECG Simulator with Im

ECG Patient Cable (5 lead AHA) 6200-02 Welch All

ECG Patient Cable (5 lead IEC) 6200-04 Welch All

ECG leads, 5 Lead (IEC) 6200-08 Welch All

ECG leads, 5 Lead AHA 6200-06 Welch All

Certified Gas "10% CO2,10% O2, balance N2"

ETCO2 Water Tra

ETCO2 Scrubber 6200-21 Welch All

ETCO2 Adult Nasal Sam

Surface Sensor, Tem

Atlas Re

Printer Pa

Digital Multimeter with 10mV accuracy on a 10V

scale; 10A Ran

Ad

Battery cable assembly 620174-1 Welch Allyn

Atlas interface cable to PC 6200-60 Welch All

PC with Windows 95 and above and with

HyperTerminal serial port software

1/4" Mono Phono Jack

1000 Ohm

1200 Ohm

1350 Ohm

1540 Ohm

1870 Ohm

p socket for Temperature Port nut Generic 1/4" drive

gimano 1000 Netech

p Bio-Tek

g 5200-19 Welch Allyn

g (coiled) 5200-19M Welch Allyn

g "Optional" 9586TPK4 Welch Allyn

g (3) 9858TPK4 Welch Allyn

ge 1002-3FC ERTCO

g 5200-02 Welch Allyn

pO2 PCB ONLY " SRC-2 Nellcor

pO2 PCB DEC-8 Nellcor

pO2 PCB only"EC-8 Nellcor

pedance Respiration 214B DNI Nevada

0304724SRBD Scott Medical Products

p (package of 5) 6200-20 Welch Allyn

ple Line 6200-22 Welch Allyn

perature 6200-15 Welch Allyn

pair and Calibration Software 620538 Welch Allyn

per - Case 6200-40 Welch Allyn

ge

justable DC power supply 5A @ 7V

Part of Windows 95 &

above

precision resistor 1%

precision resistor 1%

precision resistor 1%

precision resistor 1%

precision resistor 1%

yn

yn

yn

yn

yn

yn

yn

yn

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 13

Page 26

Section 2 Service

Setting Date and Time

NOTE: Check date and time before doing any calibration. Set date and time if incorrect. Set

time and date as follows;

1. Turn Atlas on.

2. Press CLOCK button next to power on button to check date and time. Use the far right

SELECT button to scroll. Highlight the date or time that needs changed.

3. Press the SET button to adjust date and time.

4. Press CLOCK button to exit.

Pangea Communication Protocol

The Pangea Communication Protocol allows interaction of the Atlas with the computer

through the serial interface port. A prompt is emitted at the computer screen when the

instrument powers up and is ready to accept commands. The prompt is Pangea>. A prompt

is emitted after the completion of each pangea command. Pangea commands are case sensitive. They are in English only.

BP Calibration

Required material.

1. 500cc vessel 4. Calibrated digital manometer

2. Squeeze bulb with one-way valve 5. Tubing and T fittings

3. PC with HyperTerminal 6. Serial cable

NOTE: To start HyperTerminal you must have Windows7 95 or higher installed on your

computer.

1. From the Windows main screen follow the following sequence:

Start !Programs ! Accessories ! Communication ! HyperTerminal

2. HyperTerminal setting are:

9600 baud rate, 8 bit word, 1 stop bit

no parity, no flow control

ANSI character set

14 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 27

Service Section 2

3. When you open HyperTerminal you will see a screen similar to the example in Figure

2-1. You will be prompted for a connection description. Choose any name. After you

type in a name click OK.

Figure 2-1. Example of a new HyperTerminal connection.

4. The next window you will see will be the window as shown in Figure 2-2. Click on

Connect using then click on COM1.

Figure 2-2. Choosing COM1 in HyperTerminal.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 15

Page 28

Section 2 Service

5. Set the port settings as shown in the example in Figure 2-3. Now click OK.

Figure 2-3. HyperTerminal Port Settings.

6. Connect the pressure meter, bulb, and 500cc vessel to BP port with “T” connectors as

shown in photograph Figure 2-4.

7. Connect the Atlas to PC with serial cable.

8. Turn the Atlas on. Start HyperTerminal on PC. Press the <Enter> key and you should see

a Pangea> prompt.

NOTE: Take no more than 3 minutes for the 50mmHg calibration nor more than 3 minutes

for the 250mmHg calibration as the Atlas will automatically, as a safety feature, open the

blood pressure valve. If this happens you will have to turn the Atlas off then back on again

and restart the calibration again.

16 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 29

Service Section 2

T112854

Pressure

Meter

Figure 2-4. Photo of Atlas BP calibration setup.

T Fittings

Squeeze Bulb

Calibrated 500cc Volume

50mmHg Calibration

1. Enter the following commands at the Pangea prompt.

Pangea> bp valve close <ENTER>

Pangea> bp safety off <ENTER>

Pangea> bp cal 5000 Do not press <ENTER> yet!

2. Raise the pressure with bulb to as close to 50.00mmHg as possible. Now press <ENTER>.

3. Release the pressure.

250mmHg Calibration

1. Enter the following command

Pangea> bp cal 25000 Do not press <ENTER> yet!

2. Raise the pressure with bulb as close to 250.00 mmHg as possible. Now press < ENTER >

3. Enter the following command to save the calibration in the Atlas.

Pangea> nvram write <ENTER>

4. Release the pressure.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 17

Page 30

Section 2 Service

CO2 Reset (623xx Models Only)

Required material. 1. Watertrap

2. Scrubber

NOTE: The Scrubber looks similar to a watertrap, but it is filled with white granules. The

scrubber is included with the 623XX models only.

NOTE: Make sure date and time are correct before performing the CO2 reset.

1. Turn Atlas on. Make sure the watertrap and scrubber are NOT attached to the Atlas.

2. Press the DATE/TIME button on the lower right of the monitor. The Set Date and Time

and Other Options menu will be displayed.

3. Press the CO2/RESP ALARMS Off button. The CO2 Reset screen will appear.

4. You will see the following messages on the CRT.

“CO2 Reset”

“Install CO2 scrubber”

“Press Trend to abort”

5. Install the watertrap to the Atlas. Install the scrubber to the watertrap.

6. You will see the following instructions on the screen.

“Warming up” will be flashing on CRT.

“May take up to five minutes” on CRT.

“Press Trend to abort” on CRT.

7. After about 5 minutes you will see on the CRT.

“CO2 Reset”

“Reset complete”

“Remove CO2 scrubber”

“Press the trend button to exit”

8. Remove the CO

watertrap and scrubber.

2

9. Press TREND button to return to idle screen.

Replace watertrap after every six hours of use. Treat watertrap and used CO2

sample lines as bio hazard material!

18 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 31

Service Section 2

ET CO2 Calibration

Required material:

1. Tank of approximately 10% CO2, balance N2 (certified) Blood Gas Mixture.

2. Tubing and T connectors.

3. Watertrap and scrubber.

1. Make sure the watertrap and scrubber are not attached to the Atlas. Turn the Atlas on.

2. Place the instrument into the Service Mode by pressing the DATE/TIME button. Make

sure date and time are correct. Press the LEAD SELECT button.

3. Press SELECT button and scroll down to Calibrate CO2.

The message “Install CO2 Scrubber” will appear on the right side of screen.

4. Attach the scrubber to the water trap.

5. Insert the scrubber/water trap assembly into water trap socket. The message

“Enter span gas value using Set button 10%” will appear.

6. Press the SET button to change the value of span gas being used. The factory default

value is 10%. Calibrate with a 8% to 12% certified CO2 concentration known to be

±0.01%).

7. The message press “BP Start/Cancel” will appear at the bottom right of CRT. Press the

BP/Start/Cancel button.

8. If you receive a “Calibration Failed” message at this point, check the date. If date is

2022 or above it will fail CO2 calibration.

9. Next you will see a message “Warming up”. After the Atlas warms up you will see a

message “Attach CO2 gas”. Remove the scrubber from the CO2 water trap. Do not

remove water trap.

10.Attach the certified source of CO

gas to the CO2 side-stream sampling tube as per

2

Figure 2-5 below.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 19

Page 32

Section 2 Service

Adjust Regulator to

Approximately 2 psi

Water

Trap

Vent

2

CO

Figure 2-5. Example of CO2 calibration setup.

CAUTION: IMPROPER USE,STORAGE OR HANDLING OF COMPRESSED

GAS VESSELS CAN CAUSE DEATH OR INJURY. FOLLOW GAS MANUFACTURES SAFETY PROCEDURES!

11.Adjust the CO2 regulator just enough to allow a small amount of gas to flow out of the

vent (approximately 2 psi).

12.Press the BP START/CANCEL button. The message: “Sampling” will appear on CRT.

“CO2 calibration successful” or “CO2 calibration failed” will appear on the CRT

display.

13.Press the TREND button to exit.

No-Load Battery Voltage Calibration

NOTE: No-Load Battery Voltage Calibration procedure is for models 622 and 623 only. If

you disconnect the battery you must reset time and date after you reconnect the battery.

Specifications: No load battery charge 6.85 VDC

Required materials: DVM

1. Remove the battery and disconnect the battery leads from the Atlas. Use the DVM to

measure across the connectors, red+ and black-.

2. Adjust the voltage to 6.85 VDC by turning potentiometer R338, located behind the right

battery jack. Turning clockwise will increase the no-load voltage and counter clockwise

will decrease the no-load voltage.

20 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 33

Service Section 2

Battery Voltage Calibration

Required materials.

1. DC power supply rated: 7 VDC at 5A

2. DMM / DVM with 10mV resolution on a 10 DC volt scale.

3. PC with HyperTerminal

4. Serial interface cable

1. Connect the serial cable to the PC and Atlas.

2. Hyper Terminal Settings are:

9600 Baud, 8 bit word, 1 stop bit

no parity, no flow control

ANSI character set

Find HyperTerminal in Windows 95 or higher

Start !Programs!Accessories ! Communication! HyperTerminal

NOTE: Make sure the Atlas IS NOT plugged into AC for this calibration procedure.

3. Remove and disconnect the battery from Atlas.

4. Set the power supply to 6.8VDC " 200mV and connect the power supply to the battery

connector on the Atlas.

5. Turn Atlas on..

6. Reduce the power supply to 6.0VDC and measure the voltage at the battery connector

(at the Atlas) to the nearest 10mV.

NOTE: Do not measure at the power supply, since cable resistance will introduce error.

7. At the HyperTerminal prompt type:

Pangea> power cal XXXX <ENTER>

NOTE: XXXX represents the measured voltage in millivolts no decimal point. For

example, if you measured 6.010VDC at the battery connector, use the command “power cal

6010 <ENTER>”.

8. The Atlas will respond: raw = ZZZZ mV true = 6010 mV OK

NOTE: ZZZZ is the raw uncalibrated reading that the instrument made.

9. Reduce the power supply to 5.6 VDC. You should soon hear the “low battery” alarm.

10.Measure the voltage at the battery connector to the nearest 10mV.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 21

Page 34

Section 2 Service

11.At the HyperTerminal prompt type:

Pangea> power cal XXXX <ENTER>

NOTE: XXXX represents the measured voltage in millivolts with no decimal point. For

example if you measured 5.590 volts at the battery connector, then you would enter the

command “power cal 5590” <ENTER>.

12.The Atlas will respond:

raw = ZZZZmV true = 5590 OK

NOTE: ZZZZ is the raw uncalibrated reading that the instrument made.

13.Finish the calibration by typing:

Pangea> hw reset <ENTER>

NOTE: This will re-boot the Atlas.

14.Turn the Atlas off and reinstall the battery.

15. Reset time and date.

Printer Print Adjustment

1. Install new paper.

2. Turn Atlas on.

3. Attach an ECG simulator to Atlas and set simulator for a heart rate of 60 bpm, normal

sinus rhythm.

4. Press PRINT button. Evaluate the darkness of waveform and text printout.

5. If either need to be changed press DATE/TIME button then press LEAD SELECT button

to access Advanced Configuration menu.

6. Press SELECT button and scroll down to Printer Test Pattern. Then Press

HR ALARMS OFF button

7. Two lines will be displayed:

1. Waveform+128

2. Text+ 78

NOTE: These two numbers are the factory defaults and are a good starting point if the system is printing poorly or not at all.

22 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 35

Service Section 2

8. The left SET button controls the waveform darkness and the right SET button controls

the text darkness.

NOTE: Pressing the SET button up will increase the number and darken the waveform

while pressing the SET button down will decrease the number and will lighten the waveform.

9. Make changes to the printout as needed.

10.Press Trend button to return to waveform screen.

Temperature Calibration

Required Material:

1. PC with Windows7 95 or higher 4. 1/4O mono phono jack

2. Atlas serial cable 5. Soldering iron and solder

3. 1k Ohm, 1/2 watt precision resistor 6. Ohm Meter

1. Solder the 1 K Ohm resistor to 1/4” mono phono jack.

2. Measure the resistance at the tip of the phono jack. Record that resistance reading, to two

decimal points.

3. Plug the phono jack into the Atlas.

NOTE: The Atlas will show a temperature reading in the temperature display.

4. Start HyperTerminal on PC.

5. Hyper Terminal Settings are:

9600 Baud, 8 bit word, 1 stop bit

no parity, no flow control

ANSI character set

Find HyperTerminal in Windows7 95 or higher

Start !Programs ! Accessories ! Communication ! HyperTerminal

6. At the Pangea prompt Type: PANGEA> temp cal XXXXXX <ENTER>

NOTE: XXXXXX is the resistance reading you measured and recorded in milliohms at the

tip of the mono phono jack.

Example: If you measure 1000.40 ohms at the tip of the phono jack then you would type

temp cal 100040 <Enter>.

7. Wait four seconds then type: PANGEA> temp state <ENTER>. You will see a value

returned at the Pangea prompt.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 23

Page 36

Section 2 Service

8. Verify that the resistance given by the above command returns a value " 0.5 ohms.

9. Verify temperature accuracy as outlined in Chapter 3, Table 3-2.

Calibration Date Set

NOTE: After calibrating the Atlas you must reset the calibration date. The calibration date

is the date you performed the calibration. The calibration date appears in the Service Mode

menu. See Figure 2-6 for an explanation of the Service screen.

1. At the Pangea prompt type.

Pangea> nvram set cal_date XXXX <ENTER>

NOTE: XXXX is the number of days from January 1, 1998 until the present date. See

APPENDIX E for that number or calculate manually.

24 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 37

Service Section 2

Explanation of an Atlas Service Screen

Service Mode

Select a test

Verifyff manomete

Reset to factory default

Battery test

Calibrate CO2

CRT test pattern

Printer test pattern

LED test

Button test

Display A/D channels

0.00

A

B

C

D

Model 220 with printer Cal:27 Nov 2002

Sn: 62304064 Sw: BB.025000 Boot: AA.01.0000

SpO2: NELLCOR MP506 V1.8.0 6/21/02

CO2 1.0 V3 .00 #2542 Cal: 27 Nov 2002 14 Nov 200 2

Press the Trend button to exit

Figure 2-6. Example and Explanation of an Atlas Service Screen

Line A Indicates that the Atlas is a model 220 and that the Atlas has a printer. If the Atlas

did not have a printer then the text “with printer” would be absent. The date field following

indicates the date the Atlas was last calibrated.

Line B starts with a numeric sequence. The first three digits are the model number of the

Atlas. The next five numbers are the Atlas serial number. The next sequence,alphanumeric,

indicates what software version is currently loaded into the Atlas. The third sequence,

alphanumeric, indicates what version boot software is currently loaded into the Atlas.

Line C starts with the SpO2 OEM board used in the Atlas. There are two SpO2 OEM boards

used in the Atlas. One is Nellcor and the other is Nonin. The next sequence indicates the

model of the SpO2 board. The next sequence, that starts with a letter “V”, is the version software used with the current SpO2 board. The date following the SpO2 software is the date

the OEM loaded the software into the SpO

board. SpO2 OEM software can not be upgraded.

2

If the most current software is needed, you will need to replace the SpO2 board.

Line D is the CO

installed. If your Atlas does not have CO

information if your Atlas has CO

2

installed then line D will be absent. If your Atlas

2

installed. Only models 623 have CO2

2

has CO2 installed then line D will start with CO2 followed by a numeric number. That

numeric value is the software loaded into the CO

board. The next alphanumeric sequence,

2

starting with a “V”, is the version of that software. The next numeric sequence starting with

a “#” is the serial number of the CO2 board. The next sequence, a date, is the date the CO2

was last calibrated. The last sequence, a date, is the date the CO2 was reset. CO2 OEM software can not be upgraded. If the current software is needed, you will have to replace the

CO2 board.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 25

Page 38

Section 2 Service

Table 2-3. Software Revision Table.

Model Operating System Boot loader Nellcor Nonin Pryon

621S0 AA.01.4000, 9/8/99 AA.01.0000, 6/20/99 V7

621S0 BB.02.0000, 4/4/01 AA.01.0000, 6/20/99 V7

621S0 BB.02.2000, 6/4/02 AA.01.0000, 6/20/99 V7

621S0 BB.02.5000, 10/14/02 AA.01.0000, 6/20/99 V7

621N0 BB.02.5000, 10/14/02 AA.01.0000, 6/20/99 V1.8.1.0, 10/14/02

621SP AA.01.4000, 9/8/99 AA.01.0000, 6/20/99 V7

621SP BB.02.0000, 4/4/01 AA.01.0000, 6/20/99 V7

621SP BB.02.2000, 6/4/02 AA.01.0000, 6/20/99 V7

621SP BB.02.5000, 10/14/02 AA.01.0000, 6/20/99 V7

621NP BB.02.5000, 10/14/02 AA.01.0000, 6/20/02 V1.8.1.0, 10/14/02

622S0 AA.01.4000, 9/8/99 AA.01.0000, 6/20/99 V7

622S0 BB.02.0000, 4/4/01 AA.01.0000, 6/20/99 V7

622S0 BB.02.2000, 6/4/02 AA.01.0000, 6/20/99 V7

622S0 BB.02.2000, 6/4/02 AA.01.0000, 6/20/99 V7

622S0 BB.02.5000, 10/14/02 AA.01.0000, 6/20/99 V7

622SP AA.01.4000, 9/8/99 AA.01.0000, 6/20/99 V7

622SP BB.02.0000, 4/4/01 AA.01.0000, 6/20/99 V7

622SP BB.02.2000, 6/4/02 AA.01.0000, 6/20/99 V7

622SP BB.02.5000, 6/14/02 AA.01.0000, 6/20/99 V7

622N0 AA.01.4000, 9/8/99 AA.01.0000, 6/20/99 V 1.2.0.0 12/17/97

622N0 BB.02.0000, 4/4/01 AA.01.0000, 6/20/99 V 1.2.0.0 12/17/97

622No BB.02.2000, 6/4/02 AA.01.0000, 6/20/99 V 1.2.0.0 12/17/97

622N0 BB.02.5000, 10/14/02 AA.01.0000, 6/20/99 V 1.8.1.0 10/14/02

622NP AA.01.4000, 9/8/99 AA.01.0000, 6/20/99 V 1.2.0.0 12/17/97

622NP BB.02.0000, 4/4/01 AA.01.0000, 6/20/99 V 1.2.0.0 12/17/97

622NP BB.02.2000, 6/4/02 AA.01.0000, 6/20/99 V 1.2.0.0 10/14/02

622NP BB.02.5000, 10/14/02 AA.01.0000, 6/20/99 V 1.8.1.0 10/14/02

623SP AA.01.4000, 9/8/99 AA.01.0000, 6/20/99 V7 0.E V1.00

623SP BB.02.0000, 4/4/01 AA.01.0000, 6/20/99 V7 0.E V1.00

623SP BB.02.2000, 6/4/02 AA.01.0000, 6/20/99 V7

622SP BB.02.5000, 10/14/02 AA.01.0000, 6/20/99 V7

623NP AA.01.4000, 9/8/99 AA.01.0000, 6/20/99 V 1.2.0.0 12/17/97 0.E V1.00

623NP BB.02.0000, 4/4/01 AA.01.0000, 6/20/99 V 1.2.0.0 12/17/97 0.E V1.00

623NP BB.02.2000, 6/4/02 AA.01.0000, 6/20/99 V 1.2.0.0 12/17/97

623NP BB.02.5000, 10/14/02 AA.01.0000, 6/20/99 V 1.8.1.0 10/14/02

26 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 39

Service Section 2

Software Upgrade Procedure

NOTE: The following procedures are required to upgrade the software on a fully functioning Atlas or to reload software after replacing the CPU board. The download utility

“atlas_dl.exe” loads the following files automatically.

1. atlas.out.gz

2. nvram_common.txt

3. nvram_(model#).txt

4. nvram_(language).txt

“Atlas_dl.exe” will also query the Atlas to determine what model number the Atlas is and

what language to download.

Equipment or supplies required:

1. PC with Windows7 95 or higher

2. Atlas serial cable

3. File: atlas_dl.exe (Included in the Atlas Repair Software listed in Table2-2.)

NOTE: Make sure you have HyperTerminal turned off or the following utility download will

not work!

1. Run the program atlas_dl.exe from the CD or copy the file to your hard drive and run the

program from there.

2. Connect the serial cable between the Atlas and the PC s’“COM1 port”.

3. Turn your computer on and locate the “atlas_dl.exe” file.

4. Double left click on the “atlas_dl.exe” file.

5. When the file starts to download, the CRT will go blank on the Atlas.

NOTE: Do not use the computer while the program is downloading.

6. After down loading is complete, check all alarm settings and all user advanced

configuration settings since these are RESET by this utility software download

procedure.

NOTE: Stop here if you are just upgrading software on a fully functional Atlas monitor or if

you have replaced the CPU board.

NOTE: If you have replaced the MAIN BOARD then you MUST continue with the next

procedure (DOWNLOADING NVRAM FILES).

NOTE: Perform the following NVRAM downloading procedure if you have replaced the

MAIN BOARD. The NVRAM resides on Main Board.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 27

Page 40

Section 2 Service

Down Loading NVRAM Files

Required Materials.

1. Computer with Windows7 95 or higher.

2. The latest Atlas repair software. Call your local Welch Allyn

representative.

1. Once you have procured the latest Atlas Repair Software, you will be able

to run the programs straight from the CD or copy the files to your hard drive.

NOTE: Through HyperTerminal you will need to load the following files:

1. nvram_cal_init.txt

2. nvram_common.txt

3. model# of Atlas

3.1.You will load “nvram200.txt” if your Atlas is a model 621xx.

3.2.You will load “nvram210.txt” if your Atlas is a model 622xx.

3.3 You will load “nvram220.txt” if your Atlas is a model 623xx.

4. “language.txt”Any combination of or all of the following files

4.1 “nvram_english.txt” for the English language

4.2 “nvram_french.txt” for the French language

4.3 “nvram_german.txt” for the German language

4.4 “nvram_spanish.txt” for the Spanish language

4.5 “nvram_potuguese.txt” for the Portuguese language

4.6 “nvram_italian.txt” for the Italian language

4.7 “nvram_chinese.txt” for the Chinese language

4.8 “nvram_japanese.txt” for the Japanese language

5. printer.txt (if fitted with a printer), or no_printer.txt. (if not fitted with a printer)

NOTE: After loading the preceding files you, must then type the following commands at

the Pangea prompt.

1. “nvram set serial xxxxx” where xxxxx is the serial number of the Atlas monitor.

2. “nvram write” writes the information to memory.

3. “hw reset” performs a hardware reset.

2. Connect the serial cable between the Atlas and the PC COM1 port.

3. Open HyperTerminal program on PC.

Hyper Terminal Settings are:

9600 Baud, 8 bit word, 1 stop bit

no parity, no flow control

ANSI character set

Find HyperTerminal in Windows7 95 or higher

Start !Programs ! Accessories ! Communication ! HyperTerminal

28 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 41

Service Section 2

4. Turn Atlas on. You should see the Pangea prompt. See example in Figure 2-7.

Figure 2-7. Pangea prompt in HyperTerminal.

5. Scroll over to “Tran sf er ” and then scroll down and choose “Send Text File”.

See example in Figure 2-8.

Figure 2-8. Choosing “Send Text File” in HyperTerminal.

6. Another window will then appear and prompt you for the location of the files. Double

left click on that folder to open that directory. You can also run these programs from the

CD. See example in Figure 2-9.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 29

Page 42

Section 2 Service

Figure 2-9. Choosing directory where NVRAM files are stored.

7. Once the folder is open, open the file “nvram_cal_init.txt” file by double left clicking on

that file or by high lighting the file and then click on the Open button. See example in

Figure 2-10.

Remember that after you have download the files in this section and you must

complete this entire “Downloading NVRAM files” section, that you must perform

a complete calibration on the Atlas monitor.

Figure 2-10. Choosing the nvram_cal_init.txt file.

30 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 43

Service Section 2

NOTE: After the nvram_cal_init.txt has executed you should see a Pangea screen similar to

window as shown in Figure 2-11.

Figure 2-11. Pangea screen after opening the nvram_cal_init.txt file.

8. From your pangea window choose Transfer then choose Send Text File.

9. Open the directory where the file nvram_common.txt is located or open from the CD.

10.Double left click on nvram_comm.txt file or highlight the file and then choose Open.

NOTE: After opening the nvram_common.txt file you should see a screen similar to the

window shown in Figure 2-12.

Figure 2-12. Pangea screen after opening the nvram_common.txt file.

Service Manual 6200-43E Rev. D Welch Allyn Atlas Monitor 31

Page 44

Section 2 Service

NOTE: Next you will download the model# of the Atlas by choosing only one of the three

following files.

1. If you have an Atlas model 621 then you will only download the file nvram200.txt.

2. If you have an Atlas model 622 then you will only

3. If you have an Atlas model 623 then you will only

11.Open the directory where the model number files are located or open from CD.

12.Open the file by double left clicking on the file that represents the model number of the

Atlas you are working on or highlight that file then choosing Open.

NOTE: After opening the Atlas model# file you should see a Pangea screen similar to the

window as shown in Figure 2-13.

download the file nvram210.txt.

download the file nvram220.txt.

Figure 2-13. Pangea prompt after opening the model# file.

32 Welch Allyn Atlas Monitor Service Manual 6200-43E Rev. D

Page 45

Service Section 2

NOTE: Next you will download the language(s) that you want the Atlas to store in it’s

Advanced Configuration menu for languages. You can have one or all the languages loaded

in the Atlas. Listed in Table 2-4 are the language(s) choices and the files you will need to

download to have the language(s) loaded in the Atlas. Each language you want loaded in

the Atlas will require that the file associated with that language be loaded.

Table 2-4. Files needed to download language(s).

Language File needed to download

English nvram_english.txt

French nvram_french,txt