Page 1

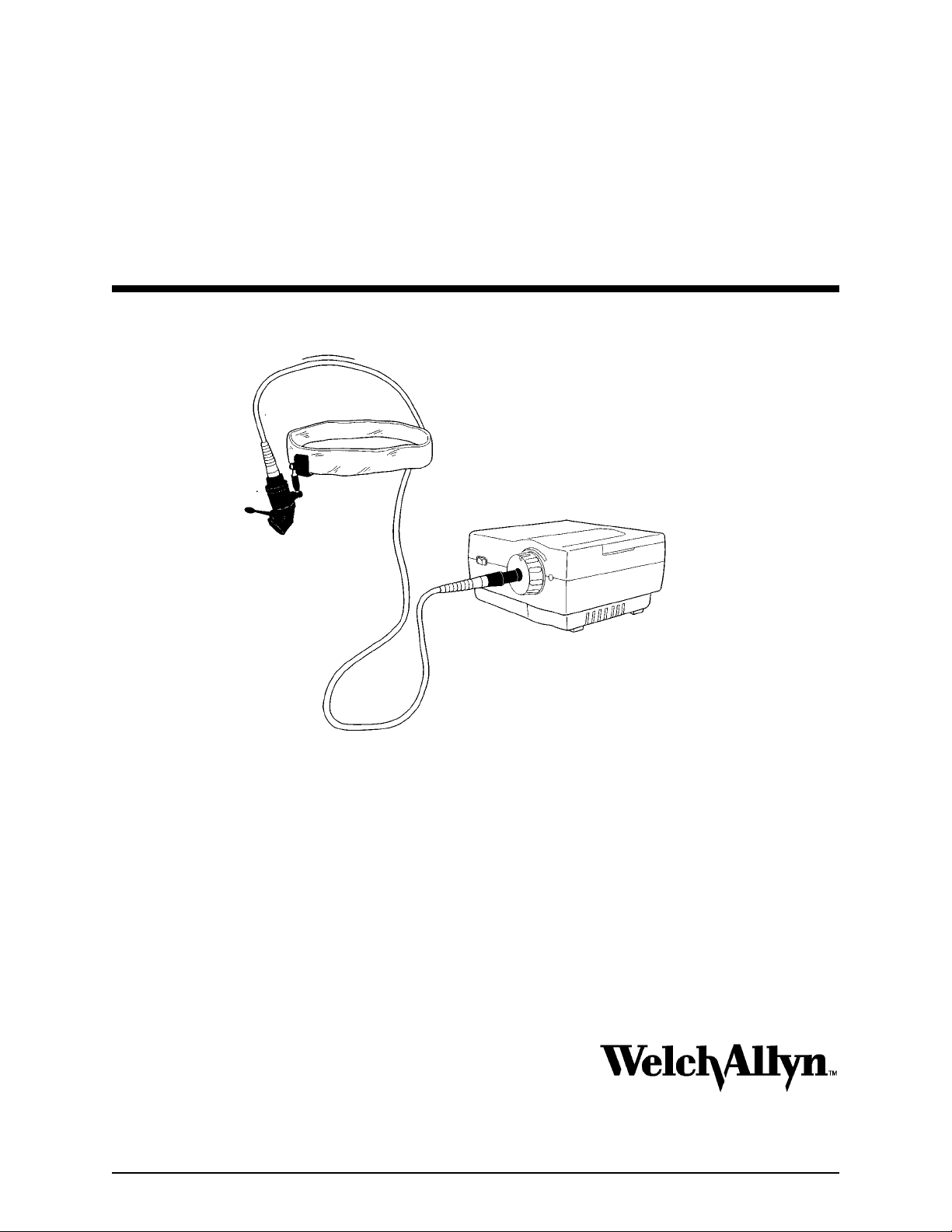

Welch Allyn Single Fiber

Headlights

Operation Manual

Illumination Headlight

System

Service Manual

Copyright 1997

Welch Allyn Inc.

4341 State Street Road

P.O Box 220

Skaneateles Falls, NY 13153-0220

P/N 496144 Rev A.

Models: 49600,49602,49604,49606,

47100,47102,47104,47106

Page 2

Revision (History) Page

Rev. Description of Change ECN # Date Initial

A New Release 5-34455 1/14/97 JJ/MD

SFI Light Source/Luminaire Service Manual Page 2

Page 3

Introduction

To Service Personnel:

The information in this manual is subject to change without notice and should

not be construed as a commitment by Welch Allyn, Inc.

Welch Allyn assumes no responsibility for any errors that may appear in this

manual. If the product and/or its operation varies significantly from any

description herein, please contact the Welch Ally n Product Service Department

at 4341 State Street Road, Skaneateles Falls, New York 13153-0220, 1 800 6699771, (315) 685-4445

This product has been designed to provide a high degree of safety and

reliability. However, we can not guarantee against the deterioration of

components due to aging and normal wear.

All service and repairs must be pe rf o r med b y authorized Welc h Ally n p er sonnel

or agents, u si n g Welc h Allyn replacement p a rts. Failure to d o so will invalidate

the product warranty.

Authorized service centers should refer to repair specification for proper test

and device history record requirements.

Please refer to the product warranty for specific coverage.

Welch Allyn, Inc.

Medical Products

4341 State Street Road

Skaneateles Falls, New York 13153-0220

USA

1 800 669-9771

(315) 685-4445

SFI Light Source/Luminaire Service Manual Page 3

Page 4

Introduction

g

g

g

g

Table of Contents

SECTION 1: General Information

Basic System Description .............6

Specifications ......................7

SECTION 2: Service

Intent of Manual ....................8

Required Tools .....................8

Words of Caution ...................9

Performance Check .................9

Calibration .......................10

SECTION 3: Problem Solving

Troubleshootin

SECTION 4: Disassembly and Repair

SECTION 5: Maintenance

Preventative Maintenance ............22

Cleanin

Checkin

Measurin

Fuse or Lamp Replacement ..........25

SECTION 6: Theory of Operations

Introduction .......................26

Start Up Routine ...................26

Power Supply .....................27

Ballast Board......................27

...................11

.........................23

Ground Impedance ........23

Leakage Current ..........23

SFI Light Source/Luminaire Service Manual Page 4

Page 5

Introduction

Table of Drawings (Appendix A)

N/A ........................................ Parts List/Recommended Inventory

A03569 (Reference Only) .......................Electrical Safety Test Specification

496141 (Reference Only) .................................... SFI Exploded View

496045 (Reference Only) ..................................Interconnect Diagram

Note that the drawings contained within this manual are for reference only. Consult

factory for specific drawing and revision level.

SFI Light Source/Luminaire Service Manual Page 5

Page 6

General Information

Introduction

Basic System Description

Model # 49601 is a medical light source which is used in conjunction with the Welch Allyn SFI

Headlight Luminaire model 49610. The headlight is a lightweight fiber optic system that

provides a bright white light through the use of Arc Lamp technology.

49600....Welch Allyn Light Source

100-240 VAC

50/60 Hz

U.S.A. Plug Type

49602...Welch Allyn Light Source

100-240 VAC

50/60 Hz

European Plug Type

49604...Welch Allyn Light Source

100-240 VAC

50/60 Hz

U.K. Plug Type

49606...Welch Allyn Light Source

100-240 VAC

50/60 Hz

Australian Plug Type

SFI Light Source/Luminaire Service Manual Page 6

Page 7

Section 1 General Information

Specifications

Power Supply

100-240 VAC, 50-60 Hz, Universal input

Power Consumption 40 Watts Max.

Leakage Current: Less than 100 microamps

Light Source Dimensions

WxLxH = 4.5in (11.43cm) x 6.5in (16.5cm) x 2.5in (6.35cm)

Light Source Weight

Under 5 pounds (2.25 Kilograms)

Illumination System

Proprietary Arc Lamp

Color temperature: 5500K

Lamp: 60 Volts, 24 Watts

Lamp Life: 200 hours minimum when employed in a 45 minutes on / 15 minutes off

duty cycle. Average lamp life decreases when shorter duty times are employed.

Dimming System

Manual Shutter: 20% to 100% full output

Fiber Optic Cable Interface

Welch Allyn proprietary connector

Approvals

UL 2601-1 IEC 801-2,3,4,5

CSA C22.2 no. 601.1-M90 EN 55011

IEC 601-1 IEC 601-1-2

Australia AS3200

Light Spot Diameter at 16in (40cm) Distance

Minimum: .75in (20mm)

Maximum: 3.0in (75mm)

Environment

Operating: 60F to 85F

Storage: -13F to 140F

Equipment Classification

Light Source: Type B

Luminaire: Type BF

Fuses

T1.0A L250V (1.0Amp., 250V, time lag (Slow-Blow), Low breaking capacity)

SFI Light Source/Luminaire Service Manual Page 7

Page 8

Service

Intent of Manual

The purpose of this manual is to provide Welch Allyn Inc. authorized servi ce representativ es wi th

systematic guidelines for preventative maintenance, problem identification, and service of the

Welch Allyn Single Fiber Headlight System. We have included the theory of operation schematic

diagrams, simplified drawings, service tips and procedures to assist a trained service

represen tative with board-level repairs. Should you encounter problems that are beyond the

scope of this manual, please contact the Technical Service Depar tment of Welch Allyn's Medical

Products for assistance.

Required Tools for Service

1. 3/8" Nut Driver

2. Screwdriver(s): Phillips #1, Phillips #2

3. Screwdriver: Flat Blade #4

4. Long Nose Pliers

5. Wire Cutters Xcelite 54CG

Required Equipment:

1. Digital Volt/Ohm Meter with Leads (True RMS). Beckman model 310 or equivalent.

2. Soldering Iron

3. Solder Sucker or Desoldering Wick

4. Kepco Model MSK 10-10M Power Supply. Capable of 10 amps at 10VDC.

5. Hy-Pot Tester- Associated Research Inc. Model 35400D or Equivalent.

SFI Light Source/Luminaire Service Manual Page 8

Page 9

Section 2 Service

Words of Caution:

High Voltage

Use caution when servicing. When servicing the unit, potentially

dangerous high voltage levels are exposed. Disconnect the

power cord whenever possible to avoid electric shock.

Static Electricity (ESD)

Adhere to standard ESD practices at all times when servicing this

equipment. Many of the electronic devices in this equipment are

static sensitive, and may suffer catastrophic or latent failure if

handled improperly.

Heat

Lamps, power supplies, and heat sinks may emit extreme

amounts of heat during and after operation. Approach and

handle these and other potentially hot components with caution.

Finished Parts

Handle all finished parts with care. The finish can be easily scratched or damaged

from poor or improper handling.

Performance Checks

The following performance checks will help you (1) determine whether or not the system

is operating properly, and (2) isolates a problem, if there is one.

SFI Light Source/Luminaire Service Manual Page 9

Page 10

Section 2 Service

System Set Up

Make sure the system is connected as follows:

1. Be sure that power is being provided by the wall outlet.

2. Be sure that the Lamp is installed properly.

3. Be sure that the cooling fan is turning when the unit is turned on.

4. The light source should produce a bright continuous white light with no

flickering after a warm-up period of 5-15 seconds.

If any of these conditions do not occur, see the troubleshooting section.

Calibrations

Not Applicable

SFI Light Source/Luminaire Service Manual Page 10

Page 11

g

g

g

g

g

g

g

g

Problem Solvin

Troubleshooting

Experience shows that many service calls are due to improper operator technique and

poor connections. Before taking apart the light source, make sure that setup errors are

not caus ing the problem.

signal through the harness wires, connectors, and on the circuit board.

Symptom Possible Cause Procedure

When checking voltages or signals, be sure to verify the

Lamp does not illuminate, but

the fan is runnin

.

Lamp connector is out of place.

Lamp is blown.

Defective ballast

Defective Power supply. No

+15VDC present.

Remove lamp cover and reseat

the connector.

Verify unit functions with a

known

functions with a known

unit.

Verify Volta

of the Ballast board. Refer to

wirin

1KV to 2KV present at the

output during startup.

Check output of power supply

per wirin

Replace supply if no volta

present.

ood lamp or lamp

e input and output

diagram.

Note: There is

diagram.

ood

e is

SFI Light Source/Luminaire Service Manual Page 11

Page 12

Section 3 Problem Solving

g

g

gag

g

g

g

g

g

g

g

g

g

g

g

g

g

Symptom Possible Cause Procedure

Lamp not illuminated, fan does

not function (No power is

apparent).

ht Source overheatin

Li

Power line is damaged or

disconnected.

Power is not turned "ON"

Lamp Door Interlock switch is

disen

AC line fuses F1 and/or F2 are

open.

Open circuit connection.

Power supply circuit defective.

Other circuits loadin

power supply.

Fan Not workin

ed.

down

properly

Connect, repair, or replace as

necessary.

Turn power on.

Verify that the lamp cover is

firmly and properly in place and

that interlock switch is

functionin

continuity to be sure that the

switch is w orkin

Verify and replace as

necessary.

Verify AC input throu

the Switchin

Verify DC output at J2 of

Switchin

If the fuse is blown, disconnect

the plu

Switchin

Replace the blown fuse, and

reapply power. Verify DC

output at J2. If no volta

present or fuse is a

replace Switchin

supply.

Verify correct volta

input and output of the power

supply

496045).

within specification, then

replace motor/secondary wire

harness assembly.

properly. Verify

properly.

h unit to

Power Supply.

Power Supply.

from J2 (Output of the

Power Supply).

e is

ain blown,

Power

es at the

(See wiring diagram

If all voltages are

SFI Light Source/Luminaire Service Manual Page 12

Page 13

Section 3 Problem Solving

g

g

g

g

gg

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

Symptom Possible Cause Procedure

Light Source over Heatin

Continued..

No li

ht at Luminaire, but light at

ht source.

li

Low li

ht output at Luminaire.

Covered or clo

No +12VDC output from power

supply to operate the fan.

Broken fiber optic cable.

Dirt on fiber optic li

Dirt on li

Solarc li

ht reflector inside the

ht source.

ed air vent.

ht carrier.

Check to see if anythin

coverin

filter is extremely dirty. Replace

filter as described in section 4 if

necessary.

Check volta

Replace power supply if no

volta

Replace fiber optic cable with a

know

Remove the fiber optic cable from

the li

and clean both ends with alcohol

and a cotton swab.

Clean the reflector of any debris

usin

rade methyl alcohol.

Isopropyl alcohol or cotton

swabs.

scratched or pitted the entire lens

platform assembly will need to be

replaced.

the air vents, or if the air

e per wiring diagram.

e is present.

ood cable.

ht source and the Luminaire,

lens paper and an optical

If the reflector becomes

is

Do not use

The shutter assy. in the li

source is misali

workin

.

ned or not

ht

n the shutter gear as shown on

Ali

view "L" below.

SFI Light Source/Luminaire Service Manual Page 13

Page 14

Disassembl

y

p

About This Section:

This section describes how to remove and replace major sub assemblies of the

49601 SFI Light Source.

and Re

air

Note:

reference on the Parts List to determine the correct part number.

Refer to the "Bubble Number" on each drawing and the cross

Part Number Description Bubble # Start Up Qty

496024-501 PLATFORM PKGD 40 1

106124-25 #8 X 1.00 PLASTITE SCREW 41 10

106100-11 PHPS 4-40 X.312 43 10

SFI Light Source/Luminaire Service Manual Page 14

Page 15

Section 4 Disassembly and Repair

Top Housing Assy Disassembly

1. Fan guard:

___

Remove

2. Remove the Top Housing:

___

Remove

housing assembly upwards.

Ballast Board Replacement

1.. Top Housing:

___

Remove

2. Fan Air Baffle:

___

Remove

3. Wire Connectors:

___

Unplug

the top two screws (Phillips) that hold the fan guard in place.

the five screws (Phillips) on the bottom of the unit and lift the top

the top housing.

the two Phillips head screws holding the baffle inplace.

the two connectors located on the ballast board.

4. Lamp Wires:

___

Lift

board, and

5. Reassembly:

___

Reassemble

under the ballast board. The black and white wire from the lamp connector

should be routed through the insulator then resoldered into the proper holes in

the ballast board (refer to wiring diagram).

screws, for they are only screwed into plastic.

the ballast board up, so that it is resting on top of the power supply

Desolder

the black and white wires from the ballast board.

in reverse order. Be sure to reinstall the insulating material

Take care not to over tighten the

SFI Light Source/Luminaire Service Manual Page 15

Page 16

Section 4 Disassembly and Repair

Power Supply Replacement

1. Top Housing:

___

Remove

2. Power Switch:

___

Unplug

supply, by

3. Secondary Output:

___

Unplug

connector with a pair of needle-nose pliers.

4. Grounding Wire:

___

Unplug

5. Wire Tie:

___

Cut

chassis using a small pair of side cutters.

the top housing as instructed in "Top Housing Removal" section.

the connector (J1) with the brown and blue wires from the power

Pulling

the secondary output plug (J2), by

the green and yellow ground wire that attaches to the power supply.

the wire tie that holds the thermal cutout wires to the power supply

straight up on the connector with a pair of needle-nose pliers

Pulling

straight up on the

6. Power Supply Board:

___

Unscrew

board and lift the power supply out of the bottom housing.

7. Reassembly:

___

Reassemble

original position.

screwed into plastic.

the four screws located on the four corners of the powersupply

in reverse order. Be sure to put the insulator back into its

Take care not to over tighten the screws, for they are only

SFI Light Source/Luminaire Service Manual Page 16

Page 17

Section 4 Disassembly and Repair

Fan / Thermal Cutout Replacement

The fan and the thermal cutout come as part of the fan harness assembly; therefore, the

*

entire secondary wire harness assembly must be replaced.

1. Top Housing:

___

Remove

2. Air Baffle:

___

Remove

3. Wire Ties:

___

Cut

4. Fan/Fan Guard:

___

Unscrew

Taking care to remember how the ground wire is connected and routed.

5. Thermal Cut Off Sensor:

___

Remove

sensor switch bracket assembly, and remove the sensor.

the top housing as outlined in top housing removal section.

the two screws that hold the baffle in place, and

the two wire ties that hold the wiring harness to the internal chassis.

the remaining two screws that hold the fan to the bottom housing.

the screw and plastic washer holding the temperature sensor to the

the baffle out.

lift

6. Connectors:

___

Unplug

connector (P2) from the ballast board.

7. Harness:

___

Remove

8. Reassembly:

___

Reassemble

(M11047) needs to be

new thermal switch will be installed.

the 5 pin connector (J2) from the Condor power supply and the 2 pin

the Secondary Wiring Harness assembly.

in reverse order.

applied to

the switch bracket, where the flat side of the

(Note)

A small amount of

thermal compound

SFI Light Source/Luminaire Service Manual Page 17

Page 18

Section 4 Disassembly and Repair

Lamp Cover Safety Interlock Switch:

1. Top Housing:

___

Remove

2. Lamp Cover:

___

Remove

be removed.

3. Safety Switch Assy:

___

Unscrew

bottom housing. Keep the outside insulators.

4. Primary Wires:

___

Disconnect

5. Reassembly:

___

Reassemble

were removed in step #1. Refer to wiring diagram 496045 for additional help.

the top housing as outlined in top housing removal section.

the lamp cover door. The ground wire on the door does not need to

the two Phillips head screws that hold the switch assembly to the

the primary wires from the switch, and remove the switch.

in reverse order. Make sure to reinstall the two insulators that

SFI Light Source/Luminaire Service Manual Page 18

Page 19

Section 4 Disassembly and Repair

Power Switch Replacement

1. Top Housing:

___

Remove

section.

2. Power Switch removal:

___

Unplug

defective switch.

3. Power Switch replacement:

___

Reassemble

quick connect terminals. The switch should

be set into the bottom housing with the "1"

closest to the light attenuator control.

Replacement of the IEC Power Filter

the top housing assembly as described in top housing disassembly

the four quick connect terminals from the switch and

the switch to the four

remove

1. Top Housing:

___

Remove

described on the top housing removal

nstructions.

2. IEC Line Filter:

___

Loosen

screws holding the IEC line filter to

the bottom housing.

3. Primary Wires:

___

Unplug

leading to the interlock switch from the line filter.

4. Ground Wire:

___

Unplug

5. Jumper Wires:

___

Unplug

line filter. Replace these wires if they appear to be damaged.

force is required to push the new wires on to the spade connectors, so use

caution that the spade connector does not get bent.

the Top housing as

the two Phillips head

the brown and blue wires

the Green and yellow ground wire from the IEC line filter.

the brown and blue jumper wires and install them onto the new IEC

A fair amount of

6. Reassembly :

___

Reassemble

assembly drawing 496000 for proper wire connections.

SFI Light Source/Luminaire Service Manual Page 19

in reverse order. Refer to wiring diagram 496045 and

Page 20

Section 4 Disassembly and Repair

Attenuator Control:

1. Reflector platform assembly:

___Remove

section.

2. Gear (Plastic)

___

Push

place by putting a flat blade screwdriver under the closed side of the clip and

prying

3. Knob:

___

Pull

the knob shaft. Remove the bearing and reuse it if a new knob is being installed.

4. Reassembly:

a. ___

Replace

the reflector platform assembly as described in the Reflector Assy.

in on the black plastic gear and remove the "C-clip" that holds it in

upwards.

the knob out of the bottom housing. The bearing will probably stay on

any defective or worn components.

b. ___

housing aligns with the mating part on the bushing.

c. ___

and black gear onto the knob shaft.

d. ___

together, then inserting the c-clip into the grove on the knob shaft.

Reflector Platform Assembly

1. Lamp:

___

2. Lamp Wires:

___

Unscrew

the reflector platform.

3. Top Housing:

___

the bearing into the bottom housing, so that the notch on the bottom

Slide

Slide

Reinstall

Remove

Remove

the knob through the bearing and place the flat washer, spring washer,

the C-clip, by pressing the black gear and the control knob

the lamp socket assembly.

the two screws holding the black and white wire retainers to the bottom of

the top housing as described in the top housing removal section.

4. Thermal Cut Out:

___

bracket.

lift it up and out of the way.

5. IEC Line Filter:

SFI Light Source/Luminaire Service Manual Page 20

the wire ties that hold the thermal cut out wires to the sensor switch

Cut

Unscrew

the Phillips screw that holds the thermal sensor in place, and

Page 21

Section 4 Disassembly and Repair

___

Remove

6. Platform Air Baffle:

___

Unscrew

the baffle straight up.

7. Platform Ground:

___

Unscrew

8. Platform Reflector Assembly:

___

Unscrew

bottom housing.

9. Reassembly:

___

Reassemble

the light attenuator knob fully

Turn

counterclockwise,

knob gear tooth into the 3rd notch

on the flag gear.

the IEC power filter as described in IEC Power filter section.

the two screws holing the baffle to the platform assembly and

the screw holding the ground wire to the platform assembly.

the two remaining screws holding the platform assembly to the

Tilt

in reverse order.

align

lift

the platform assembly and lift it out.

the first

SFI Light Source/Luminaire Service Manual Page 21

Page 22

Maintenance

Preventative Maintenance

The purpose of preventative maintenance is to pro-actively reduce or eliminate future problems.

Keeping the Light Source in good operating condition ensures that it will perform reliably and

safely. Every six to twelve months, you should:

* Check power cable for wear.

* Ensure that, during use, the light source receives adequate ventilation.

* Ensure that the ball detent is still functioning properly.

Visual Inspection

Check for anything out of the ordinary. For instance:

- Does the light source make too much noise?

- Are there any loose parts inside the box?

- Is the power switch working properly?

- Do all components connect/disconnect easily?

SFI Light Source/Luminaire Service Manual Page 22

Page 23

Section 5 Maintenance

CLEANING

Refer to Operating Manual, Welch Allyn Part Number 496027 or 496130.

Check Ground Continuity

1. Disconnect the power cord from the SFI Light Source.

2. Verify the impedance between the ground pin of the IEC detachable ground cord and the

thumb screw meets the requirements as outlined on drawing A03387( see Apnd. A).

Measuring Leakage Current

To check the Chassis Leakage Current:

1. Connect the light source to a leakage tester (refer to figure 5-1), and measure leakage

current on leakage meter. Ensure that leakage is less than 100 microamperes.

2. Open ground line, and ensure leakage current is less than 100 microamperes.

3. Reverse line polarity, and ensure that leakage current is less than 100 microamperes.

4. With reversed polarity, open ground line and ensure leakage is less than 100

microamperes.

CAUTION: The meter must be suitably insulated and

capable of withstanding the power line voltage.

SFI Light Source/Luminaire Service Manual Page 23

Page 24

Section 5 Maintenance

LEAKAGE CURRENT TE ST SET-UP

When the light source is used in conjunction with other accessories, it may be necessary to

measure the leakage current level of the entire set-up. A typical system setup is shown in Figure

5-1. Using a standard leakage tester, this set-up will allow the overall system leakage current to

be measured. If this value exceeds 100 microamps (or whatever the maximu m requirements are

for a particular region), an isolation transformer should be used.

Figure 5-1: Typical Current Leakage Test Set-Up

SFI Light Source/Luminaire Service Manual Page 24

Page 25

Section 5 Maintenance

FUSE REPLACEMENT

1. Turn the power switch OFF and disconnect the power cord from the light source.

2. Open fuse drawer located as part of the power cord receptacle.

3. Remove fuse by pulling it out firmly.

4. Check fuse condition. Replace if blown. Replacement

fuse: 250V, 1.0 Amps. 5 x 20mm , Slow-Blow.

fuse only! An unqualified fuse may fail prematurely.

Use WA

5. This system has two fuses. Be certain to check the

condition of both fuses.

LAMP REPLACEMENT

Refer to users manual 496027 or 496130 for full detail.

1. Turn the power switch OFF and disconnect the power cord from the light source.

2. Wait a minimum of 5 minutes to allow the lamp to cool.

3. Remove the lamp cover on the bottom of the Light Source by unscrew ing the thumb screw

on the bottom of the light source.

NOTE:

Removing the cover will automatically cut off p ower to the Light Source.

4. Loosen the thumb screw that holds the metal bracket in place over the Lamp Assy.

5. With the metal bracket up out of the way, remove the lamp assembly by pulling straight up.

6. Acquire new replacement lamp assembly.

7. Reseat the new lamp assembly. It will make a "click" sound when fully seated.

8. Slide the black connector on to lamp, and secure the metal bracket that holds the lamp

assembly in place.

Note:

Route wires to the sides of the metal bracket, not under it. See the picture on the

inside of the lamp cover.

9. Secure the lamp cover, reconnect the system, and verify lamp operation.

SFI Light Source/Luminaire Service Manual Page 25

Page 26

Introduction

Theory of Operation

SFI Light Source

Model # 49601 is a

:

medical light source

which is used in conjunction with the Welch Allyn

single fiber Luminaire. The light source is comprised of a power supply, a ballast, and an ArcLamp. The light generated by the Arc-Lamp is focused into a sm all single point by using two

reflectors. The re fl e c t ors a nd t h e lamp are optically aligned at the factory; therefore, there is

no repair to these subassemblies.

SFI Luminaire:

Model # 49610 Cogent Luminaire, designed and assembled by Cogent Light Technologies, is

designed to work with the SFI light source and single fiber optic cable. The Luminaire utilizes a

series of adjustable lenses to focus the light into a spot of diameter of 25mm-77mm at a distance

of 16in.. The joystick assembly is the only replaceable part on the Luminaire.

Single Fiber Cable:

The Welc h Allyn Single Fiber Optic Cable is a lightweight quartz glass fiber within a Teflon and

silicone jacket. The fiber-optic cable has approximately 11 feet of useable length from the light

source to the Luminaire. There are no repairable parts on this component of the SFI system.

Start up Routine (Lamp Ignition)

Upon turning the power switch to the "ON" position, the lamp ballast will ignite the lamp s for an

approximate warm-up phase of 15 seconds. Once this warm-up phase is complete, the the

lamps will be warmed up, and the system will be ready for use.

Note: The fiber bundle must be in place to stabilize light output. Do not toggle the power

switch ON and OFF. Doing so will dramatically shorten lamp life.

SFI Light Source/Luminaire Service Manual Page 26

Page 27

Section 6 Theory of Operation

Power Supply

UNIVERSAL INPUT, SWITCHING AC TO DC MEDICAL GRADE POWE R SUPPLY

The power supply accepts an input v ol tag e of 100-240 VAC, 50- 60 H z, single phase. The primary

circuit provides adequate control of leakage current, which is limited to 35 microamperes

maximum. The pri mar y side of the power s upply recti fi es t h e AC voltage and converts it to a high

voltage DC level. This DC voltage is connected to the isolation transformer through a switching

device, typically a mosfet. The mosfet is triggered by a high frequency clock circuit, typically at a

30-50 KHz rate. The secondary side of this transformer provides isolation between primary and

secondary circuits. The secondary voltage is rectified and filtered to provide a +15 VDC output

voltage at 5.3 amps. The output voltage is regulated to 2%, with peak-to-peak noise of 150mV.

The output is fully protected against short circuit and output overload. Short circuit protection is a

cycling type power limit with automatic recovery after fault.

Ballast Board

The ballast board is a power supply used to operate the 24 watt Welch Allyn miniature arc lamp.

The nature of arc lamps require a ballast which limits the current, and therefore the power, in the

lamp. There are three states of the operation of the ballast: ignition, warm-up, and steady state.

In ignition the ballast provides the lamp with a train of ignition pulses between 6 and 7 kV. Once

the lam p is ignited the ballast conducts current at a very low impedance, which constitutes the

warm-up phase. Once it warms up, the impedance changes to a higher steady state value. The

ballast board also controls the Bulb Replacement indicator located directly next to the attenuator

contro l. Th is lamp will light when the output voltage to the lamp exceeds 61.5VDC, which is an

indication that the Arc Lamp is going to or has failed.

SFI Light Source/Luminaire Service Manual Page 27

Page 28

Appendix A

Part Number Description Bubble # Start up order

Qty

761076-0 POWER CORD,

DETACH.(DOM/JAPAN)

761076-2 POWER CORD,

DETACH. (EUROPE)

761076-4 POWER CORD,

DETACH. (U.K.)

761076-6 POWER CORD,

DETACH. (AUSTRALIA)

496017-1 LABEL NAMEPLATE - DOMESTIC

(USA)

496017-2 LABEL NAMEPLATE -

INTERNATIONAL

496028-501 CARTON ASSY, COG LT BOX NA 5

496002-1 BOTTOM, LIGHT BOX (COATED) 1 1

496071 AIR FILTER 2 5

496080 INTERLOCK SWITCH 3 1

496081-501 HARNESS ASSY (SWITCH) 5 5

495074 INSULATING PLATE 6 10

NA 2

NA 2

NA 2

NA 2

NA 5

NA 5

451534 SCREW PHP #4-40 X1.0 7 10

106124-1 PLASTITE PAN HEAD SCREW 9 10

455508 LABEL, PROTECTIVE EARTH

GROUND

106106-7 GROUND LOCK WASHER 11 10

106105-4 SPLIT RING WASHER 12 10

106109-9 NUT 13 10

495075 BALLAST SIDE CONN ASSY C12A003 16 5

496025 INSULATOR, BALLAST 17 5

495068 BALLAST 24W UNREGULATED 19 5

106124-34 #4 X.375 PLASTITE PHPS 21 10

496131-501 HARNESS ASSY (LED) 22 5

106132-3 4-40 X 1 23 10

10 5

SFI Light Source/Luminaire Service Manual Page 28

Page 29

Appendix A

Part Number Description Bubble # Start up order

Qty

106106-2 #4 INTRNL TOOTH LOCKWASHER 24 10

495067 FAN GUARD 25 0

496093 FAN MOUNTING RING 26 0

496062-504 HARNESS ASSY, FAN 27 5

496124 FAN NUT PLATE 28 0

106105-3 #4 LOCKWASHER,HEL 29 10

790043 4-40 X .250 HEX NUT 30 10

106132-5 4-40 X .750 PH TR MS SS 31 10

880031 POWER SUPPLY 40 WATT 32 5

496026 INSULATOR, POWER SUPPLY 33 10

106144-4 BEARING, NYLINER 34 2

496005 KNOB, COGENT LT BOX 35 2

496075 WASHER, ATTENUATOR KNOB 36 2

496068 BOWED WASHER 37 2

496023 GEAR,KNOB COGENT LT BOX 38 2

106101-18 RETAINING RING 39 2

496024-501 PLATFORM PKGD 40 1

106124-25 #8 X 1.00 PLASTITE SCREW 41 10

106100-11 PHPS 4-40 X.312 43 10

496076-501 SHAFT ASSY, GEAR/ATTENUATOR 48 1

106101-17 RETAINING RING 49 6

496077 ATTENUATOR FLAG ASSY 50 1

106103-38 WASHER, PIVOT 51 10

SFI Light Source/Luminaire Service Manual Page 29

Page 30

Appendix A

g

Part Number Description Bubble # Start up order

Qty

488308-4 Cable Clamp 53 20

M11047 Thermal Compound #120-5

713104 6-32 X .186 Phph

761077-1 Tie Wrap

106103-37 Pivot Washer

106100-46 10-32 X .25 Screw

106124-9 Screw

496123 IEC Power Filter

106100-42 4-40 X .25 Screw

236706-3117 Fuse

236733 Fuse Drawer

106120-4 6-32 X .750 Screw

496033 Lamp Access Door Knob

09600-501 Fixtured Lamp Packa

495083 Rubber Feet

M30373 Loctite 425

47143 Fiber Optic Cable (304.8cm)

49571 Joystick Assembly (Post on Luminaire.)

e

54

56

57

55

58

60

63

64

65

66

70

71

76

77

78

NA

NA

N/A

10

50

5

10

10

0

10

20

1

10

0

3

0

0

20

10

SFI Light Source/Luminaire Service Manual Page 30

Page 31

Appendix A

Reference Drawing #A03569

SFI Light Source/Luminaire Service Manual Page 31

Page 32

Page 33

Loading...

Loading...