Page 1

Material No. 460134 Rev. D

Solid State Procedure Headlight System

REF 49020, 49022, 49024, 49026

Symbol Descriptions

Attention: Consult user’s Manual for additional information

Double Insulation

INTENSE LIGHT

when in use. May be harmful to eyes.

Lamp On

: Lamp is bright. Do not stare at the lamp

Lamp Off

Warnings & Cautions

ATTENTION: Read Operating Manual for Warnings,

Cautions, and Instructions for Use.

IPXØ: Not protected against the ingress of water.

WARNING: Solid State Procedure Headlight is not suitable

for use in the presence of a flammable anesthetic mixture

with air or oxygen or nitrous oxide. An explosion may

result.

INTENSE LIGHT

when in use. May be harmful to eyes.

USE ONLY: Solid State Procedure Headlight Power Source/

Battery Charger and rechargeable battery pack supplied by

Welch Allyn.

There are no user-serviceable parts inside the device

except the rechargeable batteries and headband. Contact

the Authorized Service Center listed on page 15 for further

assistance.

: Lamp is bright. Do not stare at the lamp

Guidelines for the safe use of the Solid State

Portable Headlight

General practices to minimize risk of harm to the skin

from optical radiation hazards include: minimizing

illumination intensity at the tissue examination site,

minimizing exposure times, and taking additional

precautions when skin sensitivity has been altered

through tissue trauma or the use of anesthesia.

General good practices to minimize risk of harm to the

eyes from optical radiation hazards include: Avoiding

looking at bright light sources and their reflections, and

protect eyes where normal pupil sizes and aversion

responses are not present.

Introduction

Thank you for purchasing the Solid State Procedure Headlight by Welch

Allyn, the worldwide leader in illuminated medical diagnostic

instrumentation. By following the use and care guidelines supplied in this

Owner’s Manual, you will enjoy years of dependable, trouble-free service

from your new headlight.

This headlight is designed to meet the various needs of the physician’s

office, hospital environment, and specialist’s office.

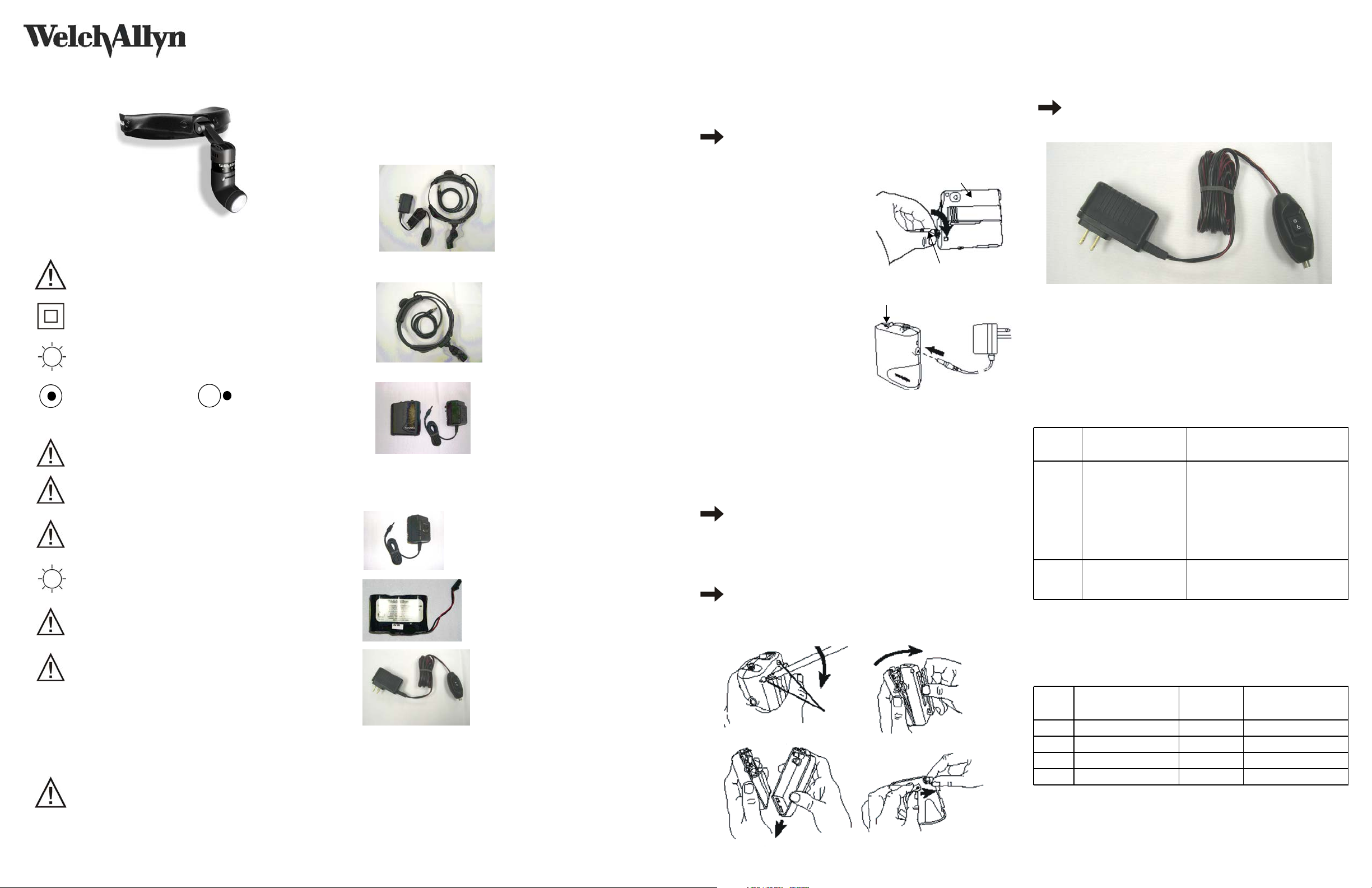

Components

Standard Parts List

Solid State Procedure Headlight with Direct Power Supply

Model 49020 (Domestic)

Model 49022 (European)

Model 49024 (U.K.)

Model 49026 (Australia)

Accessory Parts List

Model 49000 Procedure Headlight

Model 49099 Carrying Case

Model 72250 Rechargeable Battery

Model 75260 Battery Pack with Charger

(Domestic)

Model 75262 Battery Pack with Charger

(European)

Model 75264 Battery Pack with Charger

(U.K.)

Model 75266 Battery Pack with Charger

(Australia)

Replacement Parts List

When ordering replacement parts for your Solid State Procedure Headlight,

please use the following numbers

Model 74180 Charger (Domestic)

Model 74182 Charger (European)

Model 74184 Charger (U.K.)

Model 74286 Charger (Australia)

Model 72250 Replacement Battery

Model 75270 Direct Power Supply

(Domestic)

Model 75272 Direct Power Supply

(European)

Model 75274 Direct Power Supply (U.K.)

Model 75276 Direct Power Supply

(Australia)

Set-up and Operation

Instructions for Use

The Solid State Procedure Headlight (REF 49020), consisting of Procedure

Headlight (REF 49000) with Direct Power Source (REF 75270), and

Accessory Portable Power Source/Charger (REF 75260). The Solid State

Procedure Headlight is designed to operate off the direct or the portable

power source. To operate the headlight using the direct power source,

follow the instructions and illustrations in the section labeled Direct Plug-In

Transformer. Simply turn on the on/off switch located on the Direct Plug to

operate the headlight. To operate the headlight using the portable power

source, follow the instructions and illustrations under the section labeled

“Connecting Headlight to Portable Power source”.

To recharge the portable power source, follow the instructions and

illustrations in the “Recharging the Portable Power source” section. To

adjust the light spot size, turn the knob on the front section of the luminaire.

To adjust the headband, simply rotate the adjustment knob located on the

back of the headband.

Use the Solid State Procedure Headlight to provide illumination while

performing a number of activities in the physician’s office, hospital, or

emergency environment such as minor surgery, general exam, foreign body

removal, OB/GYN applications/procedures, dermatology examinations or

any procedure which requires a small, homogenous, and well-defined spot.

Follow the assembly instructions listed below and the

corresponding illustration.

Connecting Headlight to Portable Power Source

1. Plug the instrument power cord into

the power cord connector port on

the top of the power source.

2. Push in until it is firmly in place.

3. Gently screw the external

connector sleeve clockwise to

secure.Recharging the Portable

Power Source

Portable Power Source

Instrument

Power Cord

Recharging the Portable Power Source

1. Turn the portable power source off.

2. Disconnect instrument from power

source.

3. Plug charging transformer into

portable power source.

4. Plug charging transformer into wall

socket. LED light indicates unit is

charging.

5. Disconnect charging transformer

from power source when fully

charged, approximately 10 - 12

hours.

On/Off Switch

Maintenance

Each month examine cords and connections. The user can perform battery

and/or headband replacement on an as needed basis. Return the unit to an

authorized Welch Allyn Technical Service Department or distributor for

additional servicing. See “Service and Warranty Information” section.

Cleaning (Recommonded Monthly)

Excess solution entering the luminaire assembly could damage

internal components. Use caution to ensure cloth is not

saturated with solution.

1. Unplug the unit prior to cleaning.

2. Wipe down the entire luminaire with a cloth slightly dampened with a

mild solution of detergent.

3. Do not operate the light until the light is thoroughly dry.

Do not sterilize the unit.

CAUTION: Do not immerse in cleaning solutions.

Battery Replacement

Screws

Step 1 Step 2

Step 3 Step 4

1. Verify power is off.

2. Remove both screws from back of p ower source with Phillips head

screwdriver (figure 1).

3. Grasp the belt clip, gently pull back and down on the housing (figure 2

and 3).

4. Lift battery out and unplug from unit.

5. Replace with new battery and reverse above steps.

Securely tighten the power source housing screws in order to

properly hold electrical components in place.

Direct Plug-In Transformer

1. Plug Power cord from the Solid State Procedure Headlight into the

Direct Plug-In Power cord.

2. Push until firmly in place.

3. Gently screw the external connector sleeve clockwise to secure.

4. The instrument is now ready for use.

5. Plug direct power source into a nearby receptacle.

Troubleshooting

Trouble

Area

No Light

Output

Low

Light

Output

Possible Cause Corrective Action

Verify that the unit operates on

direct power source. If yes, insure

that the battery is connected

Dead battery or

battery not connected

properly

Low charge on battery

properly; refer to the battery

replacement section for instructions

on connecting the battery. If the

battery is connected properly,

recharge or replace battery

Verify that the unit operates on

direct power source. If yes,

recharge or replace battery

Specifications

Electrical

Ref

Model

49020 120VAC ± 50/60 Hz 5 volts vdc <10 uA

49022 230VAC ± 50/60 Hz 5 volts vdc <10 uA

49024 230VAC ± 50/60 Hz 5 volts vdc <10 uA

49026 240VAC ± 50/60 Hz 5 volts vdc <10 uA

Input Voltage

Output

Voltage

Leakage Current

Page 2

Emissions and Immunity Information

Guidance and Manufacturer’s Declaration - Emissions

The REF 49000 is intended for use in the electromagnetic environment

specified below. The customer or user of the REF 49000 should ensure that

it is used insuch an environment.

Emissions

Test

RF Emissions

CISPR11 Group 1

RF Emissions

CISPR11 Class B

Harmonics

IEC 61000-3-2 Class A

Flicker

IEC 61000-3-3 Complies

Radiated and Conducted Emissions were tested on the FRIWO 15.1504

power supply. It complies with the EN55022 Class B limits; same limits

as EN55011 Group 1, Class B. Harmonics and Flicker testing were

performed on a REF 46000 with a 230 VAC FRIWO 15.1504 power

supply.

Guidance and Manufacturer’s Declaration - Immunity

The REF 49000 is intended for use in the electromagnetic environment

specified below. The customer or user of the REF 49000 should ensure that

it is used in such an environment.

Immunity Test

ESD

IEC 61000-4-2

EFT

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage Dips/

Dropout

IEC 61000-4-11

Power Frequency

Compliance

IEC 60601

Test Level

± 6kV Contact

± 8kV Air

±2kV Mains

±1kV I/Os

±1kV Differential

±2kV Common

>95% Dip for 0.5

Cycle

60% Dip for 5

Cycles

30% Dip for 25

Cycles

>95% Dip for 5

Seconds

3 A/m 3 A/m

50/60Hz

Magnetic Field

IEC 61000-4-8

Electromagnetic Environment -

Guideance

The REF 49000 uses RF energy only for

its internal function. Therefore, its RF

emissions are very low and are not likely

to cause any interference in nearby

electronic equipment.

The REF 49000 is suitable for use in all

establishments, including domestic, and

those directly connected to the public

low-voltage power supply network that

supplies buidlings used for domestic

purposes.

Compliance

Level

± 8kV Contact

± 15kV Air

±2kV

±2kV

±2kV

±2kV

>95% Dip for

0.5 Cycle

60% Dip for 5

Cycles

30% Dip for 25

Cycles

>95% Dip for 5

Seconds

Electromagnetic

Environment -

Guidance

Floors should be

wood, concrete,

or ceramic tile. If

floors are

synthetic, the r/h

should be at least

30%.

Mains power

quality should be

that of a typical

commercial or

hospital

environment.

Mains power

quality should be

that of a typical

commerical or

hospital

environment.

Mains power

quality should be

that of a typical

commerical or

hospital

environment.

Power frequency

magnetic fields

should be that of

a typical

commerical or

hospital

environment.

Guidance and Manufacturer’s Declaration - Immunity

The REF 49000 is intended for use in the electromagnetic environment

specified below. The customer or user of the REF 49000 should ensure that

it is used in such an environment.

Immunity Test

IEC 60601

Test Level

Compliance

Level

Electromagnetic

Environment - Guidance

Portable and mobile

communications

equipment should be

separated from the

REF 49000 by no less

than the distances

calculated/listed

below:

D=0.35 (Sqrt P)

D=1.2 (Sqrt P)

D=0.35 (Sqrt P)

80 to 800 MHz

Where P is the max

power in watts and D is

the recommended

separation distance in

meters.

Field strengths from

Conducted

RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

(Ouside ISM)

10Vrms (In

ISM Bands)

150 kHz to

80MHz

10 V/m

80 MHz to 2.5

GHz

10 Vrms

10 Vrms

10 V/m

fixed transmitters, as

determined by an

electromagnetic site

survey, should be less

than 10Vrms or 10V/m.

Interference may occur

in the vicinity of

equipment containing

a transmitter.

Conducted RFI and Radiated RFI testing was performed on a FRIWO

15.1504 power supply, monitoring the output for drops in voltage; none

were detected.

Recommended Separations Distances between portable and mobile RF

Communications equipment and the REF 49000

The REF 49000 is intended for use in the electromagnetic environment in

which radiated disturbances are controlled. The customer or user of the

REF 49000 can help prevent electromagnetic interference by maintaining a

minimum distance between portable and mobile RF Communications

Equipment and the REF 49000 as recommended below, according to the

maximum output power of the communications equipment.

Separation (m)

Max

Output

Power

(Watts)

0.01 0.035 0.12 0.035 0.07

0.1 0.111 0.379 0.111 0.221

1 0.35 1.2 0.35 0.7

10 1.107 3.795 1.107 2.214

100 3.5 12.0 3.5 7.0

150kHz to

80MHz

Non-ISM

D=(3.5/V1)

(Sprt P)

Separation (m)

150kHz to

80MHz

ISM

D=(12/V2)

(Sprt P)

Separation (m)

80 to 800MHz

D=(3.5/E1)

(Sprt P)

Separation (m)

800MHz to

2.5GHz

D=(7/E1)

(Sprt P)

Dimensions

Headband Adjustment Range Small, Medium, Large

Illumination System

5 watt Solid State Lamp

Color Temperature 5500 Degree Kelvin

50 Lumens

LED life > 10,000 hours

Working distance 16 inches

Spot size range 1.5 to 6 inches at the working distance

Weight

6 ounces

Environment

Operating: 32°F - +104°F (0°C - +40°C)

75% RH Max continuous

500 hPa - 1060 Altitude

Storage/Transport: -4°F - +120°F (-20°C -+49°C)

95% RH Max continuous

500 hPa - 1060 Altitude

Equipment Classification

Class II, Continuous Operation

IPXØ: Not protected against the ingress of water

Category: Not AP/APG Equipment

This device complies with current required standards for electromagnetic

interference, and should not present problems to other equipment or be

affected by other devices. As a precaution, avoid using this device in close

proximity to other equipment.

Approvals

ETL Listed:

CERTIFIED TO: CAN/CSA STD C22.2 NO. 601.1

CONFORMS TO: IEC 60601-1,IEC 60601-1-2, UL STD

60601-1, AS/NZS 3200.1

The CE mark on this product indicates that it has been

tested to and conforms with the provisions noted within

the 93/42/EEC Medical Device Directive.

Regulatory Affairs Representative

Welch Allyn Limited

Navan Business Park

Dublin Road

Navan, County Meath, Republic of Ireland

Complies with EMC Framework of Australia

Power Sources

UL Recognized US/Canada

UL2601-1, CAN/CSA C22.2 No. 601.1

VDE Certified

IEC 60601-1, EN 60601-1, VDE 0750

Warranty

Instrumentation purchased new from Welch Allyn, Inc. (Welch Allyn) is

warranted to be free from original defects in material and workmanship

under normal use and service for a period of one year for the Solid State

Procedure Headlight from the date of first shipment from Welch Allyn. This

warranty shall be fulfilled by Welch Allyn or its authorized representative

repairing or replacing at Welch Allyn’s discretion, any such defect, free of

charge for parts and labor.

Welch Allyn should be notified via telephone of any defective product and

the item should be immediately returned, securely packaged and postage

prepaid to Welch Allyn. Loss or damage in shipment shall be at the

purchaser’s risk.

Welch Allyn will not be responsible for loss associated with the use of any

Welch Allyn product that (1) has had the serial number defaced, (2) has

been repaired by anyone other than an authorized Welch Allyn Service

Representative, (3) has been altered, or (4) has been used in a manner

other than in accordance with the instructions.

Service Information

For Technical Support or to obtain return instructions, please contact the

nearest Welch Allyn service center listed below:

USA Customers

Phone: +1 315 685 4560

or +1 800 535 6663

(North America Only)

INTERNATIONAL Customers

Welch Allyn Germany

Tel: +49 695 098 5132

Welch Allyn Ltd. Singapore

Tel: +65 6419 8100

Welch Allyn Latin America

Tel: +1 305 669 9003

4341 State Street Road

Skaneateles Falls, NY 13153

Tel: (800) 535-6663 or (315) 685-4560

www.welchallyn.com

Canada Customers

Phone: 905 890 0004

or +1 800 561 8797

(North America Only)

Welch Allyn Australia

Tel: +61 2 9638 3000

Welch Allyn UK Ltd.

Tel: +44 20 7365 6780

Welch Allyn China

Tel: +86 216 327 9631

Loading...

Loading...