Page 1

UNITY & UNITY

OPERATION MANUAL

+

UNITY_OM_EN_EU

Part No.: 1964161_01

Page 2

CONTENTS

UNITY & UNITY+

CONTENTS ...................................................................................................................................................... 2

MANUAL REVISIONS ................................................................................................................................. 4

GENERAL INFORMATION ..................................................................................................................... 5

Hazard intensity levels .............................................................................................................................5

Warnings .....................................................................................................................................................5

Introduction ...............................................................................................................................................6

Precautions .................................................................................................................................................9

Intended use ...............................................................................................................................................9

User groups ................................................................................................................................................9

Possible types of misuse ........................................................................................................................10

Installation notes .....................................................................................................................................10

Electrical connection notes ..................................................................................................................10

Warm connection requirements .........................................................................................................11

Refrigeration system information .......................................................................................................12

Safe milk handling reminders ................................................................................................................13

Disassembly and disposal ......................................................................................................................14

Disposal and scrapping ..........................................................................................................................14

Compliance code calculator .................................................................................................................15

Dispenser specifications ........................................................................................................................17

COMPONENT OVERVIEW ..................................................................................................................18

ES14/18_BTB_FMU_IN .........................................................................................................................18

Dimensions ...............................................................................................................................................18

Front View ................................................................................................................................................19

Front View, doors open .........................................................................................................................19

ES14/18_BTB_IN ....................................................................................................................................20

Dimensions ...............................................................................................................................................20

Front View ................................................................................................................................................21

Front View, doors open .........................................................................................................................21

INSTALLATION .............................................................................................................................................22

Initial set up and installation .................................................................................................................22

-2-

Page 3

CONTENTS

UNITY & UNITY+

OPERATION ...................................................................................................................................................25

Adjust slider .............................................................................................................................................25

Make a drink.............................................................................................................................................25

Fill coffee ...................................................................................................................................................26

Fill ingredients ..........................................................................................................................................26

Fill FMU .....................................................................................................................................................27

DAILY CLEANING AND CARE ..........................................................................................................29

Empty drip tray ........................................................................................................................................29

Empty waste bin ......................................................................................................................................30

Run rinsing cycle .....................................................................................................................................31

FMU cleaning............................................................................................................................................32

WEEKLY CLEANING AND CARE ....................................................................................................36

Clean brewers with tablet ....................................................................................................................36

ON SCREEN MESSAGES AND ALERTS .......................................................................................38

Dispenser error messages ....................................................................................................................38

Dispenser error messages ....................................................................................................................39

Dispenser error messages ....................................................................................................................40

FMU error messages ..............................................................................................................................41

-3-

Page 4

MANUAL REVISIONS

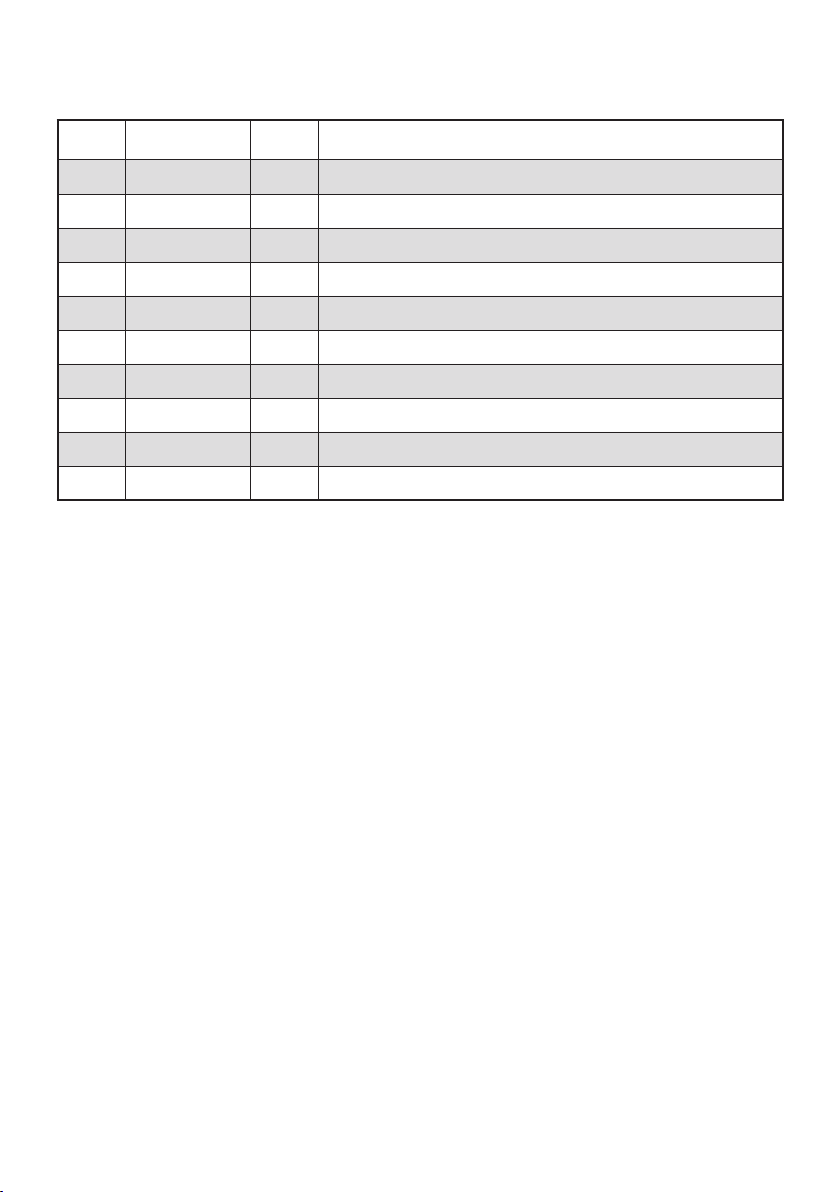

Rev. # Date TSB# Description

01

April 15, 2019 None First draft released for initial review by Crem Technical Dept.

02

03

04

05

06

07

08

09

10

Page 5

GENERAL INFORMATION

Hazard intensity levels

There are two different levels of notification intensity within this manual, as identified by the

signal words WARNING and Note. Always observe these warnings to ensure safety and

prevent potential injury or equipment damage.

UNITY & UNITY+

CAUTION:

Indicates a potentially hazardous situation which, if ignored, could result in serious

injury or even death.

-Risk of fire and electric shock.

-Replace only with manufacturer’s original cord set.

-Disconnect from power supply before servicing.

DANGER:

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, WILL RESULT IN SERIOUS INJURY OR EVEN DEATH.

Note:

i

Provides additional information which may be helpful during the operation, routine

maintenance, and cleaning.

Important:

Alerts against unsafe practices. Observe Important notifications to ensure food safety,

prevent possible minor personal injury, or damage to the machine.

Warnings

▪ Read the operating manual carefully before using the dispenser.

▪ It is essential to disconnect the dispenser from the power supply before carrying out

any repair work.

▪ Please observe the maintenance advice and intervals.

▪ Any maintenance, cleaning and repair tasks that the end customer is not specifically

authorised to perform may only be carried out by trained service personnel.

▪ For your own safety, and to ensure that your dispenser enjoys a long service life, you

should only use original equipment manufacturer (OEM) spare parts.

▪ The dispenser may only be used to prepare the products specified in the section on

intended use.

▪ Never submerge the dispenser or the power cable in water.

-5-

Page 6

GENERAL INFORMATION

Introduction

UNITY & UNITY+

CAUTION:

Before the installation and use of the appliance, carefully read the supplied instructions.

The manufacturer is not responsible if an incorrect installation and use causes injuries

and damages. Always keep the instructions with the appliance for future reference.

▪ Please read the operating manual carefully before using the dispenser.

▪ To ensure the safe operation of the dispenser, regional regulations (e.g. accident prevention

regulations) must be adhered to in addition to following the instructions in this manual.

▪ The operating company is responsible for providing the details of these additional regulations.

▪ This guide contains important instructions for proper and safe use of the appliance.

▪ Always keep this guide close at hand for future reference.

▪ This appliance dispenses fresh brewed coffee, coffee-based drinks, and filtered water. To keep

the appliance and base cabinet clean and hygienic, and all beverages tasting fresh, follow all steps

listed in the OPERATION and CLEANING sections of this manual.

▪ Access to the service area (appliance and base cabinet interior areas) is restricted to

persons having knowledge and practical experience of the appliance; in particular regarding safe handling and operation and performing cleaning tasks and maintaining adequate

hygiene. Only persons who have been adequately trained should access the service area, if

you require training contact your distributor for applicability or other options.

▪ To prevent dry ingredient spoilage, all dry ingredients (coffee beans, ground coffee, sugar,

ingredient powders, etc.) should be used up and refilled within one month, or disposed of

and replaced if older than one month.

▪ Never immerse the appliance, plug or mains cable in water. There is a danger of electric shock.

▪ This appliance can be used by children aged from 8 years and above and persons with re-

duced physical, sensory or mental capabilities or lack of experience and knowledge if they

have been given supervision or instruction concerning use of the appliance in a safe way

and understand the hazards involved.

▪ This appliance is not intended for use by persons (including children) with reduced physi-

cal, sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

▪ Children shall not play with the appliance.

▪ Children should be supervised to ensure that they do not play with the appliance.

▪ Cleaning and user maintenance shall not be made by children without supervision.

▪ The appliance is only to be installed in locations where it can be overseen by trained personnel.

▪ Do not use the appliance if the mains cable, plug is damaged or the appliance has fallen over.

▪ If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard.

▪ Only plug the appliance into a properly installed earth-grounded safety socket with line

voltage matching the technical data for the appliance.

▪ In case of emergency, (e.g., the machine catches fire or becomes unusually hot or noisy),

disconnect the power immediately and turn off the water supply.

-6-

Page 7

GENERAL INFORMATION

Introduction

UNITY & UNITY+

▪ If the machine is likely to be exposed to temperatures below 0ºC during handling and

transport, make sure that service personnel empties the boiler and water system. (The

machine’s boiler and water system is empty when delivered from the factory.)

▪ Do not install or use the appliance outdoors or anywhere it can be exposed to severe

weather (rain, snow, frost). It will cause material damage to the appliance.

▪ Prevent the appliance from freezing. If the water in the hydraulic system does freeze, do not

use the appliance. Unplug it an contact a technician to inspect it an perform necessary repairs.

▪ The A-weighted sound pressure level is below 70 dB.

▪ Keep ventilation openings, in the appliance enclosure or in the built-in

▪ Operation, filling and cleaning of the Appliance is restricted to authorized and trained persons.

Take care that new staff reads the operator manual carefully before operating the Appliance,

and understands the safety and hygiene aspects involved. For quick reference a cleaning instruction sticker is included inside the Appliance’s door.

▪ You may only use the appliance according to the instructions in this operator manual for

the delivery of drinks. The manufacturer is not liable for any damage or injury resulting from

improper use of the appliance or from non-compliance with the procedures described in this

operator manual.

▪ The appliance can be used by children aged 8 years and above and persons with reduced physi-

cal, sensory or mental capabilities, or lack of experience and knowledge, if they have been given

supervision or instruction concerning use of the appliance in a safe way and understand the

hazards involved.

▪ Children should be supervised to ensure they do not play with the appliance.

▪ Do not let children play with the packaging included with the appliance.

▪ Cleaning and user maintenance shall not be made by children.

▪ Installation, relocation (water and electrical mains connections), service and programming of

the appliance is restricted to authorized service technicians. The service area is restricted to

persons having knowledge and practical experience of the appliance; in particular as far as

safety and hygiene are concerned.

▪ This appliance is not suitable for installation where a pressure washer may be used.

▪ This appliance must not be cleaned by a pressure washer, sprayer or steam cleaner.

▪ Clean the appliance with a moist soft cloth and mild detergents as needed. Do not use abrasive

products, abrasive cleaning pads, solvents or metal objects - these can damage the finishes.

▪ This appliance is not suitable for outdoor use.

▪ The appliance is intended to be used in household and similar applications such as:

-Farm houses; staff kitchen areas in shops, offices and other working environments.

-By clients in hotels, motels, bed and breakfast and other residential type environments.

▪ Use the appliance for storage and dispensing of milk only.

▪ Do not store explosive substances such as aerosol cans with a flammable propellant in the

Appliance.

▪ Protect the appliance against running water, splashes, spray or steam, heat and heavy dust.

▪ The liquids delivered by the appliance and/or the paired coffee dispenser are hot!

-7-

Page 8

GENERAL INFORMATION

Introduction

UNITY & UNITY+

▪ Avoid scalding! Keep hands and other body parts away from the paired coffee dispenser while

drinks are being dispensed and during the rinsing program.

▪ Do not place cups, pots, or containers filled with hot liquids on top of the appliance.

▪ There is a risk of being scalded if the cups/pots/containers fall over, take care when handling them.

▪ Keep sufficient space around the appliance to get away easily in case of hot liquid splashes.

▪ When positioning the appliance, ensure the supply cord is not trapped or damaged.

▪ Never touch the power supply or power supply plug when your hands and/or the power cord

or plug are wet.

▪ If the power cord of the appliance is damaged, unplug the power cord from the electrical mains

and contact your system supplier for replacement.

▪ If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified person in order to avoid a hazard.

▪ The appliance is designed for indoor installation on a stable flat surface such as a table or a

counter. Shield the appliance from direct sunlight, frost and rain.

▪ Make sure that there is sufficient space around the appliance for ventilation, and the front/back/

sides are accessible for service.

▪ Keep ventilation openings, in the appliance enclosure or in the built-in structure, clear of

obstruction.

▪ In case of frost build-up inside the refrigerator box or cooling unit do not use mechanical

devices or other means to accelerate the defrosting process, other than those recommended

by the refrigerator’s manufacturer.

▪ Do not use electrical appliances inside the food storage compartments of the appliance, unless

they are of the type recommended by the manufacturer.

▪ Do not let hot items touch the plastic parts of the appliance.

▪ Only use water hoses and connections in compliance with local regulations.

▪ Connect the appliance to the drinking water line in compliance with local regulations.

▪ When connected to a wall outlet power supply, use a grounded safety plug socket in compli-

ance with local regulations. Ensure that the electric circuit is protected by means of a ground

fault current safety switch and that the power supply plug remains accessible after installation.

-8-

Page 9

GENERAL INFORMATION

Precautions

UNITY & UNITY+

▪ Do not try to open the appliance or repair it in any way.

▪ Only have the appliance repaired in a technical workshop, service centre or by a qualified person.

▪ Remove the mains cable from the socket when the appliance is not in use for longer periods.

▪ To do this, pull the plug not the cable.

▪ This appliance must be placed in a horizontal surface resistant to any water that may leak.

▪ Place the appliance out of the reach of children.

▪ Position the mains cable so that people cannot trip over it.

▪ Keep it away from sharp edges and heat sources.

▪ The new hose-sets supplied with this appliance are to be used, old hose-sets must not be re-used.

▪ This appliance is not suitable for installation in an area where a water jet could be used.

▪ This appliance must not be cleaned by a water jet.

▪ Do not store explosive substances such as aerosol cans with a flammable propellant in

the appliance or refrigerator.

Intended use

This appliance is intended to be used indoors only, for applications such as:

▪ Staff kitchen areas in shops.

▪ Offices and other commercial working environments, break rooms.

▪ On agricultural estates.

▪ By clients in hotels, motels and other residential type environments.

▪ Bed and breakfast type environments.

User groups

User: Customer/consumer/front line operator (FLO). Uses the dispenser to consume

drinks in accordance with the conditions defined by the operating company. Does not have

access to internal parts of the dispenser or its programming without adequate training as

provided by the manufacturer, operating company or distributor.

Service personnel: Personnel trained by the manufacturer, operating company or

distributor who know how to fill and clean the dispenser.

Service technician: Expert trained by the manufacturer, operating company or distributor

who is aware of the hazards posed by the dispenser and is familiar with the dispenser’s

technical equipment. Service technicians are trained and capable of installing, maintaining and

repairing the dispenser.

Operating company: Responsible for setting up and operating the dispenser correctly.

CAUTION:

No one is permitted to carry out service, maintenance or repair work on the

dispenser unless they have been properly trained and instructed by the operating

company or the manufacturer.

-9-

Page 10

GENERAL INFORMATION

Possible types of misuse

UNITY & UNITY+

▪ Danger caused by incorrect installation.

▪ Relying on personnel to care for the appliance that have not been properly instructed

and are not fully qualified.

▪ Using products or ingredients that are out of date or are close to their best-before date.

▪ Using products that have not been approved by the manufacturer.

▪ Using spare parts that have not been approved by the manufacturer.

▪ Technical changes and modifications to the dispenser that have not been authorised by

the manufacturer.

▪ Operating the dispenser outside of the specifications defined in this manual.

Installation notes

CAUTION:

Appliance may only be installed by qualified personnel who has been trained by the

manufacturer or their distributor.

▪ Remove all the packaging and dispose of it in the appropriate recycling bin.

▪ Do not install or use a damaged appliance.

▪ Do not install the appliance close to radiators or cookers, ovens or hobs/ranges.

▪ Do not install the appliance where it is exposed to direct sunlight.

▪ Make sure the power cable is not pinched or trapped when installing the appliance

Electrical connection notes

CAUTION:

Risk of fire and electrical shock!

▪ The appliance must only be connected to an earth grounded power outlet.

▪ All electrical connections should be made by a qualified personnel.

▪ Make sure that the electrical information on the rating plate agrees with the mains power

supply for the installation location.

▪ Always use a correctly installed shockproof socket.

▪ Do not use multi-plug adapters or extension cables to provide power to the appliance.

▪ Before maintenance, turn off the appliance and disconnect the mains power plug from the

mains socket.

-10-

Page 11

GENERAL INFORMATION

Warm connection requirements

UNITY & UNITY+

▪ When connecting the appliance and/or refrigerator unit to the mains power supply make

sure that the power rating shown in the “FACTS & WEIGHT” section matches the supply

voltage for the installation location.

▪ When installing the appliance unobstructed-dimensions are:

- Behind: 10cm minimum (for hose and power connection and ventilation)

- Above: 20cm minimum (for access and ingredient refilling)

- In front: 45cm minimum (for door opening and interior access)

▪ For the optimal performance of the appliance these hydraulic (domestic water

connection) parameters shall not be exceeded:

- Maximum inlet water pressure : 500KPa (5Bar)

- Minimum inlet water pressure: 200KPa (2Bar)

- Maximum ambient working temperature: 40ºC

- Minimum ambient working temperature: 10ºC

▪ The dispenser is designed exclusively for use with drinking water that has a hardness of

6-8°dH. If the hardness is higher, a suitable filter must be used.

▪ New hose-sets supplied with the appliance are to be used. Old hose-sets should not be

reused.

▪ The dispenser is to be installed with adequate backflow protection to comply with

applicable Federal, state, and local codes.

-11-

Page 12

GENERAL INFORMATION

Refrigeration system information

UNITY & UNITY+

▪ Do not use mechanical devices or other means to accelerate the defrosting process, other

than those recommended by the manufacturer.

▪ Do not damage the refrigerant circuit.

▪ Do not use electrical appliances inside the food storage compartments of the

appliance, unless they are of the type recommended by the manufacturer.

▪ Do not store explosive substances such as aerosol cans with a flammable propellant in

this appliance.

▪ The appliance contains hydrocarbons in the cooling unit. Only qualified personnel may

perform maintenance or recharging of the refrigerant circuit.

▪ Do not damage the refrigerant circuit.

▪ Do not put flammable products or items that are wet with flammable products inside

the appliance. Do not store flammable gas and liquid in the appliance.

▪ Do not touch the compressor or the condenser, THEY GET HOT!

▪ If damage occurs to the refrigerant circuit, make sure there are no flames or other

sources of ignition in the room. Ventilate the room to prevent fire.

CAUTION:

Risk of Fire or Explosion due to Flammable Refrigerant Used. Follow Handling

Instructions Carefully in Compliance with U.S. Government Regulations.

DANGER:

Be careful not to cause damage to the refrigerant circuit. It contains isobutane (r600a), a

natural gas with a high level of environmental compatibility. This gas is flammable.

-12-

Page 13

GENERAL INFORMATION

Safe milk handling reminders

UNITY & UNITY+

CAUTION:

Risk of machine damage! Improper handling of the appliance can result in

damage!

Under no circumstance may the appliance be used to heat or dispense any liquid

other than the intended milk products (UHT / Pasteurized milk / Almond milk /

Wheat milk / Soy milk).

Improper handling of milk can cause health problems.

Always adhere to the following points:

▪ Never use unpasteurized or raw milk.

▪ Follow daily cleaning procedures precisely as described in this manual.

▪ Only use pre-chilled milk stored at a temperature between 2–5ºC.

▪ Only add milk directly from the original packaging into the milk container.

▪ Clean the milk container and appliance daily according to the cleaning program in the user

manual.

▪ Always reclose the milk container lid and cooling unit (internal/external) immediately after filling.

▪ Store milk in accord with the manufacturer’s specifications.

▪ Store milk separately away from cleaning products.

▪ Always use the oldest products first (“first in, first out” principle).

▪ Use milk before the expiry date. If the expiry date has passed, the milk cannot be consumed

and must be disposed of.

▪ Always reseal packages after opening to ensure that the contents remain fresh and are

protected from contamination.

▪ When the appliance is to be switched off, first clean it with a tablet according to the

cleaning program in the user manual. Then clean the milk container and leave it empty.

-13-

Page 14

GENERAL INFORMATION

Disassembly and disposal

UNITY & UNITY+

▪ Dispose of the dispenser in accordance with appliance regional disposal regulations.

▪ This appliance is subject to the Waste Electrical and Electronic Equipment Directive

(WEEE/EU directive) and must not be disposed of together with normal domestic waste.

▪ The packaging is made from various recyclable materials. After installing the appliance,

please contact the waste disposal department of your local authority to check what options

are available for recycling the packaging material or disposing of it in an environmentally

friendly way.

Disposal and scrapping

If the appliance ever needs to be scrapped and disposed of, be sure to:

▪ Disconnect the appliance from the mains power supply.

▪ Disconnect the mains cable and dispose of it in the appropriate recycling bin.

▪ The insulation material is ozone friendly, but contact your local municipal authority for

information on how to discard the appliance in accord with local laws.

▪ Do not release the compressed refrigerant into the atmosphere without authorization,

reclamation by an authorized person may be required. If refrigerator gas reclamation is

required, this must be done by a licensed, qualified individual.

-14-

Page 15

GENERAL INFORMATION

UNITY & UNITY+

Compliance code calculator

The UNITY and UNITY+ coffee dispensing platform is designed to be modular and highly exible so as to adapt

to a nearly unlimited array of serving environments. Additionally, the platform is easily customizable due to easy

part and system interchangeability. As a result, the number of possible combinations is vast. Form regulatory

certication purposes, each unique conguration can be identied and labelled using a standardized 12-digit

compliance code. To make understanding the assigned compliance code for each unique version easier the

compliance code calculator tool, and an explanatory chart, are provided below:

Pos. 1 - 4:

Pos. 5:

Pos. 6:

Pos. 7:

Pos. 8:

Pos. 9:

Pos. 10:

Pos. 11:

Sample code: A I E F - G # # # - # # B #

POSITION #: CODE I.D.: EXPLANATION:

1

2

3

4

5

6

7

Continued on next page...

A preassigned, not changeable

I preassigned, not changeable

E preassigned, not changeable

F preassigned, not changeable

G preassigned, not changeable

3 indicates version with 10” touchscreen

8 indicates version with 7” touchscreen

1 indicates version with Grinder + Mono brewer

2 indicates version with Grinder + Mono brewer and Instant

3 indicates version with Grinder + Espresso brewer and Instant

4 indicates version with Mono Brewer

6 indicates version with Mono Brewer and Instant (1 Brewer)

7 indicates version with Grinder + Espresso brewer, Mono Brewer and Instant

8 indicates version with Grinder + Mono Brewer, Mono Brewer and Instant

9

A indicates version with Mono Brewer and Instant (2 Brewer)

B indicates version with Grinder + Espresso brewer

C indicates version with Grinder + Mono Brewer and Grinder + Espresso

indicates version with Grinder + Espresso brewer, Grinder + Mono Brewer

and Instant

Pos. 12:

-15-

Page 16

GENERAL INFORMATION

Compliance code calculator

...continued from previous page.

Pos. 1 - 4:

Sample code: A I E F - G # # # - # # B #

POSITION #: CODE I.D.: EXPLANATION:

A indicates Standard version

B indicates CVS door cover version

I indicates FMU module version

8

9

10

11

12

J indicates 3G module version

K indicates FMU module + CVS door cover version

L indicates FMU module + 3G module version

M indicates CVS door cover + 3G module version

N indicates FMU module + CVS door cover + 3G module version

1 indicates no grinder

2 indicates one grinder

3 indicates two grinders

1 indicates no canister version

2 indicates one canister version

3 indicates two canister version

4 indicates three canister version

5 indicates four canister version

6 indicates five canister version

B preassigned, not changeable

M indicates non-water tank version

N indicates water tank version

Pos. 5:

Pos. 6:

Pos. 7:

Pos. 8:

Pos. 9:

Pos. 10:

Pos. 11:

UNITY & UNITY+

Pos. 12:

-16-

Page 17

GENERAL INFORMATION

Dispenser specifications

SPECIFICATIONS ES14/18_BTB_FMU_IN ES14/18_BTB_IN

UNITY & UNITY+

Built-in grinder

Compliance code

Drink options

Ingredient canister

Fresh milk unit

Bean hopper

Waste bin volume

Drip tray volume

Electronic temperature control

Adjustable spout

Adjustable cup height

Energy saving mode

Height, Width, Depth

Boiler volume

Water hardness requirement

Water tank

2

AIEF-G39I-33BM AIEF-G39B-33BM

10 standard (220 possible)

2

Yes No

2

2kg used coffee waste (dry weight)

1L

Ye s

Ye s

Ye s

Ye s

660, 605, 580mm 660, 410, 580mm

0.7L

20-32 ppm calcium

Optional

Power supply

Water connection

Weight

220-240V, 50-60Hz, 2300-2700W

Speed fitting 8mm with Teflon tube

75KG 60KG

-17-

Page 18

COMPONENT OVERVIEW

ES14/18_BTB_FMU_IN

Dimensions

B

C

D

E

A F

Side view, right Front view

UNITY & UNITY+

G

H

J

K

I

Side view, doors open

Position A B C D E F G H I J K

Dimension(mm) 580 575 355 240 60

-18-

605 660 750 780 680 270

Page 19

COMPONENT OVERVIEW

Front View

UNITY & UNITY+

Coffee Canisters

Main Module

FMU

Hot Water Tap

FMU Compressor

Drip Tray

Front View, doors open

Instant Canisters

Touchscreen

Instant Module

Adjustable Spout

Waste Bin

Water Tank (Optional)

Milk Tank

Espresso Brewer

Mixers

BTB Brewer

-19-

Page 20

COMPONENT OVERVIEW

ES14/18_BTB_IN

Dimensions

B

C

D

E

A

Side view, right Back view

UNITY & UNITY+

G

F

H

J

K

I

Side view, doors open

Position A B C D E F G H I J K

Dimension(mm) 580 575 355 240 60

-20-

410 660 750 780 680 270

Page 21

COMPONENT OVERVIEW

Front View

UNITY & UNITY+

Coffee Canisters

Main Module

Hot Water Tap

Drip Tray

Front View, doors open

Instant Canisters

Touchscreen

Instant Module

Adjustable Spout

Waste Bin

Water Tank (Optional)

Espresso Brewer

Mixers

BTB Brewer

-21-

Page 22

INSTALLATION

UNITY & UNITY+

Important:

The appliance is intended to be installed by a trained technician only. If you are unsure about any of the

installation steps listed below, do not attempt installation. Contact your distributor for a technician to

perform the installation for you. Incorrect installation may cause damage to the appliance and will result

in voiding of warranty.

Initial set up and installation

01

03

A B

02

Confirm Unity is placed on a waterproof and level

surface prior to use, check for level and plumb (A),

adjust feet up or down as necessary (B).

+/-1°

A

B

+/-1°

-22-

Page 23

INSTALLATION

Initial set up and installation

04 05 06

B

A

07

A B

UNITY & UNITY+

-23-

Page 24

INSTALLATION

Initial set up and installation

08 09 10

UNITY & UNITY+

-24-

Page 25

OPERATION

Adjust slider

01 02

Make a drink

UNITY & UNITY+

± 20mm

01

04

02

-25-

03

Page 26

OPERATION

Fill coffee

01 02

Fill ingredients

01 02

UNITY & UNITY+

-26-

Page 27

OPERATION

Fill FMU

01 02

03 04

UNITY & UNITY+

05 06

-27-

Page 28

OPERATION

Fill FMU

07 08

09

UNITY & UNITY+

-28-

Page 29

DAILY CLEANING AND CARE

Empty drip tray

01 02

03 04

UNITY & UNITY+

-29-

Page 30

DAILY CLEANING AND CARE

Empty waste bin

01 02

03 04

UNITY & UNITY+

05

-30-

Page 31

DAILY CLEANING AND CARE

UNITY & UNITY+

Run rinsing cycle

01 02

Press the top right corner to access Service Menu. Input the Service Menu password. (Password is

available from the distributor.)

03 04

Press the Cleaning icon to access the cleaning

options.

05

Press Start, follow on screen instructions.

Press the Rinsing icon.

CAUTION:

Cleaning water is very hot!

-31-

Page 32

DAILY CLEANING AND CARE

FMU cleaning

UNITY & UNITY+

01

Unlock the door. Open the door.

03 04

Remove the milk container.

02

Dispose of any remaining milk.

05

A B

Wash the milk container either by hand (A), or in a dishwasher (B) that does not exceed 69ºC.

-32-

Page 33

DAILY CLEANING AND CARE

FMU cleaning

06

BA

Place the milk contianer on the door (A) and insert the dip tube into the cleaning vessel (B).

UNITY & UNITY+

07

X1

Add one cleaning tablet to the cleaning vessel.

09 10

Press the Cleaning icon to access the cleaning

options.

08

Replace the milk container fully into the fridge.

Press the Cleaning FMU icon.

-33-

Page 34

DAILY CLEANING AND CARE

FMU cleaning

UNITY & UNITY+

11

Place an empty 1L container under the outlet.

13

To save time during FMU cleaning, wipe exterior

surfaces and interior of FMU.

15

12

Press Start, follow on screen instructions.

14

After cleaning is nished, remove the dip tube from

the cleaning vessel.

16

Fill the milk contanier with fresh milk.

Replace the dip tube into the milk container.

CAUTION:

Cleaning water is very hot!

-34-

Page 35

DAILY CLEANING AND CARE

FMU cleaning

UNITY & UNITY+

17

Replace the milk container fully into the fridge.

19

18

Close the door.

Lock the door.

-35-

Page 36

WEEKLY CLEANING AND CARE

Clean brewers with tablet

01 02

UNITY & UNITY+

Adjust the spout to the top position.

03 04

Unlock the door.

05 06

Open the door lock access cover.

Raise the door to the highest position.

Press top right corner to access Service Menu.

Input the Service Menu password. (Password is

available from the distributor.)

-36-

Page 37

WEEKLY CLEANING AND CARE

Clean brewers with tablet

UNITY & UNITY+

07

Press Program to access the short-cut cleaning

menu.

09

Press the Purication icon.

12

08

X1

X1

i

Add one cleaning tablet to each brewer.

09

Close the door. Place an empty 1L container under

the outlet.

Press Start, follow on screen instructions.

CAUTION:

Cleaning water is very hot!

-37-

Caza E-22

cleaning tablets

(Art. #: 10037458)

Note:

i

The FMU has been designed and tested to be

cleaned ONLY with the detergent tablet listed.

Use of any other cleaning tablet is not advised

as it may result damage to the brewing system

or cause residue to presist in the brewer after

cleaning and rinsing if nished.

Page 38

ON SCREEN MESSAGES AND ALERTS

UNITY & UNITY+

Dispenser error messages

The following error messages may be displayed as a result of a fault in the coffee or instant

ingredient systems.

Error Code: Error Explanation: Required Action:

EC_1 General system fault

EC_2 No machine connected

EC_3 Machine not ready

EC_5 Internal error

ECM Program memory error

ECD_01

ECD_02

ECD_5

ECE_2

EC1G_2

EFG Boiler is not completely filled

EGN Driptray full Empty drip tray.

EGM Driptray not present Replace drip tray.

EFZ_6 Sensor-reading out-of-range Contact technician for repair.

EFC_8 No flow detected

EFZ_9 Element not detected (STB!)

EFZ_12 Triac not de-activated

EFZ_13

No communication with

PCB75395

No communication with

PCB75623 (hydraulic board)

Slave I/O at address #2 does not

respond

Slave I/O at address #2 does not

completely support protocol

Purification program has not been

successful completed

Contact technician for repair.

Check that water is turned on at

the mains connection. If yes, then

contact technician for repair.

Check that water is turned on at

the mains connection. If yes, then

contact technician for repair.

Contact technician for repair.EFZ_11 Triac not activated

Purification program has not been

successful completed

EFB_3 Airbreak empty

EFB_5 Airbreak sensors swapped

-38-

Contact technician for repair.EFB_4 Airbreak valve defect

Page 39

ON SCREEN MESSAGES AND ALERTS

UNITY & UNITY+

Dispenser error messages

The following error messages may be displayed as a result of a fault in the coffee or instant

ingredient systems.

Error Code: Error Explanation: Required Action:

ELE_1 Grinder-1 has no beans left Add coffee.

ELE_2 Grinder-2 has no beans left Add coffee.

ELE_5 Grinder-1 blocked

ELE_6 Grinder-2 blocked

ECB_01

ECB_02

ECB_03

ECB_11

ECB_12

ECB_14

ECB_15

ECC_06

ECC_07 Too much current: Brewer-2 wiper

ECC_08

ECC_09

ECC_10

ECC_11

ECC_12

Too much current in circuit-1

(detected by software)

Too much current in circuit-2

(detected by software)

Too much current in circuit-3

(door board or STUMv06+ door

circuit)

Too much current in circuit-1

(detected by hardware)

Too much current in circuit-2

(detected by hardware)

Too much current in circuit-1

on Slave-IOboard (detected by

hardware)

Too much current in circuit-2

on Slave-IOboard (detected by

hardware)

Too much current: Brewer-2

motor

Too much current: Canister-1

motor

Too much current: Canister-2

motor

Too much current: Canister-3

motor

Too much current: Canister-4

motor

Too much current: Brewer-1

motor

Contact technician for repair.

-39-

Page 40

ON SCREEN MESSAGES AND ALERTS

UNITY & UNITY+

Dispenser error messages

The following error messages may be displayed as a result of a fault in the coffee or instant

ingredient systems.

Error Code: Error Explanation: Required Action:

ECC_13

ECC_14 Too much current: Brewer-1 wiper

ECC_15

ECC_17 Too much current: Fan

ECC_32 Too much current: inlet-valve

EJ_1 Protocol out of sequence

EOA Failed sensor or incorrect reading

EJB Error dispense motor

EJM

EJE

EJM

Too much current: Brewer-1/2

motor or Brewer-1/2 wiper

Too much current: ES brewer

valve

Contact technician for repair.

Cannot communicate with motor

pcba

The drum mechanism does not

turn correctly

An error has been detected in the

product delivery system

-40-

Page 41

ON SCREEN MESSAGES AND ALERTS

UNITY & UNITY+

FMU error messages

The following error messages may be displayed as a result of a fault in the FMU system.

Error Code: Error Explanation: Required Action:

0 Gear pump not connected.

2 Gear pump friction is too high.

10 Air valve not connected.

12 Water valve not connected.

14 Milk valve not connected.

16 Cleaning valve not connected.

18 Water flush valve not connected.

20 Water flow not detected.

24

25

27 Descaling was aborted.

35 FTH not heating.

36 FTH not connected.

37 EEPROM failure.

46 FTH temperature too high.

50

51 Cleaning calendar invalid.

52

53 Cleanshot error.

Temperature sensor mixing block

detects water too warm.

Temperature sensor mixing block

detects water too warm.

Cleaning aborted by MCB, no

tablet detected.

Clock timer invalid, FMU not

synced to Main module.

Contact technician for repair.

Check that water is turned on at

the mains connection. If yes, then

contact technician for repair.

Contact technician for repair.

Restart FMU cleaning program (be

sure to add tablet).

Contact technician for repair.

Restart FMU cleaning program (be

sure to add tablet).

Contact technician to reset

cleaning calendar in Service Menu.

Contact technician for repair.

Restart FMU at main switch. If

error persist, contact technician

for repair.

55 Cleaning overdue.

56 Cleanshot aborted.

-41-

Restart FMU cleaning program (be

sure to add tablet).

Page 42

Page 43

Page 44

For the warranty to be valid the conditions for maintenance must have been

followed according to the manufacturer’s instructions, proper precaution has been

made and warranty claim has been issued without delay.

The affected equipment may not be used while awaiting service if there is any risk

that the damage or defect could worsen.

The warranty will not cover consumable supplies such as cups or condiments,

normal maintenance such as cleaning of lters, contaminations in water, lime scale,

incorrect voltages, pressure or adjustment of water volumes.

The warranty will not cover damages or defects caused by incorrect handling and

operation of the appliance.

FOR SERVICE

Please contact your dealer:

www.creminternational.com

Loading...

Loading...