Welbilt Delfield CV5E, Delfield CV10E, Delfield T40, Delfield CV15E-2, Delfield CV15E Original Instructions Manual

Fresh Solutions, Fit for You

Blast Chillers

CV5E, CV10E, CV15E, CV15E-2 and T40

Original Instructions

Installation, Operation and Maintenance Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

Part Number: 9294045 07/19

1 WARNINGS AND IMPORTANT ADVICE

2 TECHNICAL DATA

2.1 - Plate data

2.1 - Refridgerant

2.3 - Measurements

2.4 - Maximum loads

2.4.1 - Max load for internal structure capacity

2.4.2 - Max tray capaity

3 INSTALLATION

3.1 - Transportaion and handling

3.2 - Unpacking and disposal

3.3 - Positioning

3.4 - Ambient temperature and air exchange

3.5 - Hydraulic connection for water cooled units

3.6 - Electrical connection

3.7 - Remote group refrigerator connection

3.8 - Condensate drainage connection

3.9 - Notes for the installer

3.10 - Commissioning

3.11 - Safety and control systems

3.12 - Stop modes

3.13 - Signaling/reports of malfunction

3.14 - Appliance disposal

4 COMMAND INTERFACE SYMBOLS

5 MACHINE ON/OFF

5.1 - Compressor preheating management

6 DATE AND TIME SETTINGS

7 BLAST CHILLING CYCLES

7.1 - General chilling principles

7.1.1 - Chilling time

7.1.2 - Temperature chilling

7.1.3 - Chilling and storage status symbols

7.2 - Chilling phases

7.3 - Selecting and starting the pos. chill cycle

7.4 - Selecting and starting the neg. chill cycle

7.5 - Storage phases

8 DEFROST MODE

9 DRYING WITH MACHINE AT STANDSTILL

10 DOOR OPENING

11 OZONATOR

12 ICECREAM CYCLE

13 THAWING CYCLE

14 CHILLING PROGRAM STORAGE

15 CHILLING PROGRAM EXECUTION

16 ALARMS

10

10

10

10

10

11

12

12

12

12

12

12

12

12

13

13

13

14

14

14

14

15

15

15

16

16

16

2

5

5

5

6

7

7

7

8

8

8

8

9

9

9

9

9

9

16.1 - Evaporator probe alarm

16.2 - Product probe alarm

16.3 - Cell probe alarm

16.4 - Door micro-switch alarm

16.5 - Alarm - Diff. Thermal Breaker - Oil Pressure

16.6 - Auto reset minimum pressure swtich alarm

16.7 - Auto reset Kriwan Alarm

16.8 - Input alarm HT 1 - Fusable

16.9 - Overtemperature

16.10 - Black-Out Alarm

16.11 - Compressor preventative maint. alarm

16.12 - Temperature not reached in time alarm

16.13 - Power keypad-card connection alarm

16.14 - Maximum pressure switch alarm

17 HACCP ALARM MEMORIES RESET

18 HACCP DATA READING

19 HACCP DATA EXPORT WITH USB

19.1 - Extracted data format

19.2 - Data downloading with USB

20 ORDINARY MAINTENANCE

20.1 - Operations by the user that do not require

assistance of a qualified technician

20.1.1 - Cell cleaning

20.1.2 - Outer case cleaning

20.1.3 - Defrost water drainage

20.2 - Operation only for authorised installer

20.2.1 - Condenser cleaning

20.2.2 - Condenser filter cleaning

20.2.3 - Evaporator cleaning

20.2.4 - Ozonator maintenance

21 TIPS FOR SMOOTH OPERATION

21.1 - Operating instructions

21.2 - Pre-cooling

21.3 - Maximum load capacity for chilling/freezing

cycles

21.4 - How to load the machine

T40 information

1 UNIT INFORMATION

1.1 - Freezer Remote condensing unit details

1.2 - Remote water cooled condensing unit

1.3 - T5/T14D Refrigeration system schematic

1.4 - Wiring diagram

2 T40 INSTALLATION AND ASSEMBLY

2.1 - Supplied Equipment list

2.2 - Install and assembly instructions

3 - Controller buttons

4 -Controller functions

5 - Programming instructions

5.1 - Starting up the appliance

16

16

16

17

17

17

17

17

17

18

18

18

18

18

18

18

19

19

19

20

20

20

20

20

20

20

20

20

20

20

20

20

21

21

22

23

23

24

25

26

27

27

28

31

32

33

33

2 Part Number: 9294045 07/19

Table of Contents

5.2 - Soft blast chilling by temperature

5.3 - Soft timed blast chilling

5.4 - Hard blast chilling by temperature

5.5 - Hard timed blast chilling

5.6 - Blast freezing by temperature

5.7 - Timed blast feezing

6 APPLIANCE FUNCTIONS

6.1 - Date and time settings

6.2 - Ice cream surface hardening

6.3 - Muting the beeper and alarm

6.4 - Program storage

6.5 - Displaying the three latest HACCP alarms

6.6 - printing out stored data

6.7 - Forced ventilation function

6.8 - Manual defrosting

6.9 - Automatic defrost cycles

6.10 - Printer operation

7. ALARM MANAGEMENT

7.1 - Storage of data/errors

7.2 - Software controls

33

34

34

35

35

36

37

37

37

37

37

37

37

38

38

38

38

39

39

39

Part Number: 9294045 07/19 3

Safety Notices

Warning

n

Read this manual thoroughly before operating, installing

or performing maintenance on the equipment. Failure

to follow instructions in this manual can cause property

damage, injury or death.

DANGER

Do not install or operate equipment that has been

misused, abused, neglected, damaged, or altered/

modified from that of original manufactured

specifications.

DANGER

Keep power cord AWAY from HEATED surfaces. DO NOT

immerse power cord or plug in water. DO NOT let power

cord hang over edge of table or counter.

DANGER

All utility connections and fixtures must be maintained

in accordance with Local and national codes.

Warning

n

Authorized Service Representatives are obligated to

follow industry standard safety procedures, including,

but not limited to, local/national regulations for

disconnection / lock out / tag out procedures for all

utilities including electric, gas, water and steam.

Warning

n

Do not store or use gasoline or other flammable vapors

or liquids within or in the vicinity of this or any other

appliance. Never use flammable oil soaked cloths or

combustible cleaning solutions, for cleaning.

Warning

n

Do not use electrical appliances inside the food storage

compartments of the appliance, unless they are of the

type recommended by the manufacturer.

Warning

n

Use caution when handling metal surface edges of all

equipment.

Warning

n

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

concerning use of the appliance by a person responsible

for their safety. Do not allow children to play with this

appliance.

Caution

,

Use caution handling, moving and use of the R290

refrigerators to avoid either damaging the refrigerant

tubing or increasing the risk of a leak. Components

shall be replaced with like components. Servicing shall

be done by a factory authorized service personnel to

minimize the risk of possible ignition due to incorrect

parts or improper service.

Notice

Proper installation, care and maintenance are

essential for maximum performance and trouble-free

operation of your equipment. Visit our website www.

wbtkitchencare.com for manual updates, translations,

or contact information for service agents in your area.

Warning

n

This product contains chemicals known to the State

of California to cause cancer and/or birth defects or

other reproductive harm. Operation, installation, and

servicing of this product could expose you to airborne

particles of glasswool or ceramic fibers, crystalline

silica, and/or carbon monoxide. Inhalation of airborne

particles of glasswool or ceramic fibers is known to the

State of California to cause cancer. Inhalation of carbon

monoxide is known to the State of California to cause

birth defects or other reproductive harm.

Section 2 Technical Information

2 TECHNICAL DATA

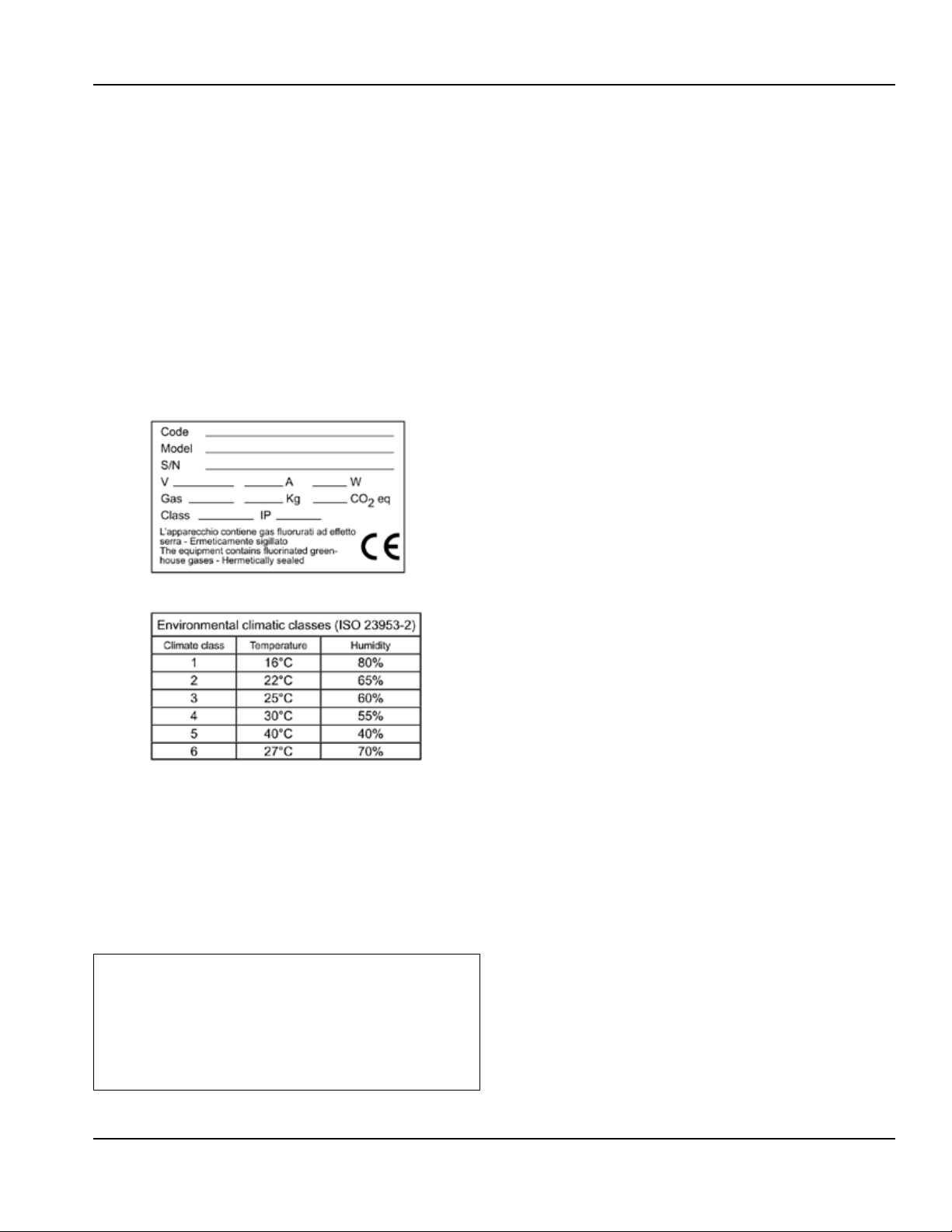

2.1 - Plate data

The plate bearing the equipment specifications should

be applied on the outside rear part of the machine and/

or on the electrical panels. Any preparation of machines

only for relocation of the condensing units must follow

the regulations enforced in the country of installation

regarding fire safety (refer to the command of the local

fire department for the relevent indications). It should

also be considered that the possible intervention of safety

valves or fusible plugs, located in the refrigerant circuit,

entail the immediate discharge of all the refrigerant into

the environment.

The appliance’s climate class is stated on the serial plate

2.2 - Refrigerant

The appliance contains flourinated greenhouose gases

covered by the Kyoto Protocol in the quantities indecated

on the serial plate. The type of refrigerant gas present in

the refrigerant circuit of the appliance is shown on the

serial plate. The GWP (global warming protential) of the

HFC R134a gas is 1430 and the HFCR404A gas is at 3922.

The CO2 equivalent data is shown on the serial plate.

,

According to regulation (EC) 1272/2008,

,

R134a and R404A gases are non-flammable

and non-toxic. in high concentrations they

cause burns and frostbite. in the system the

gas is pressurised; it may explode if heated.

Part Number: 9294045 07/19 5

Technical Information Section 2

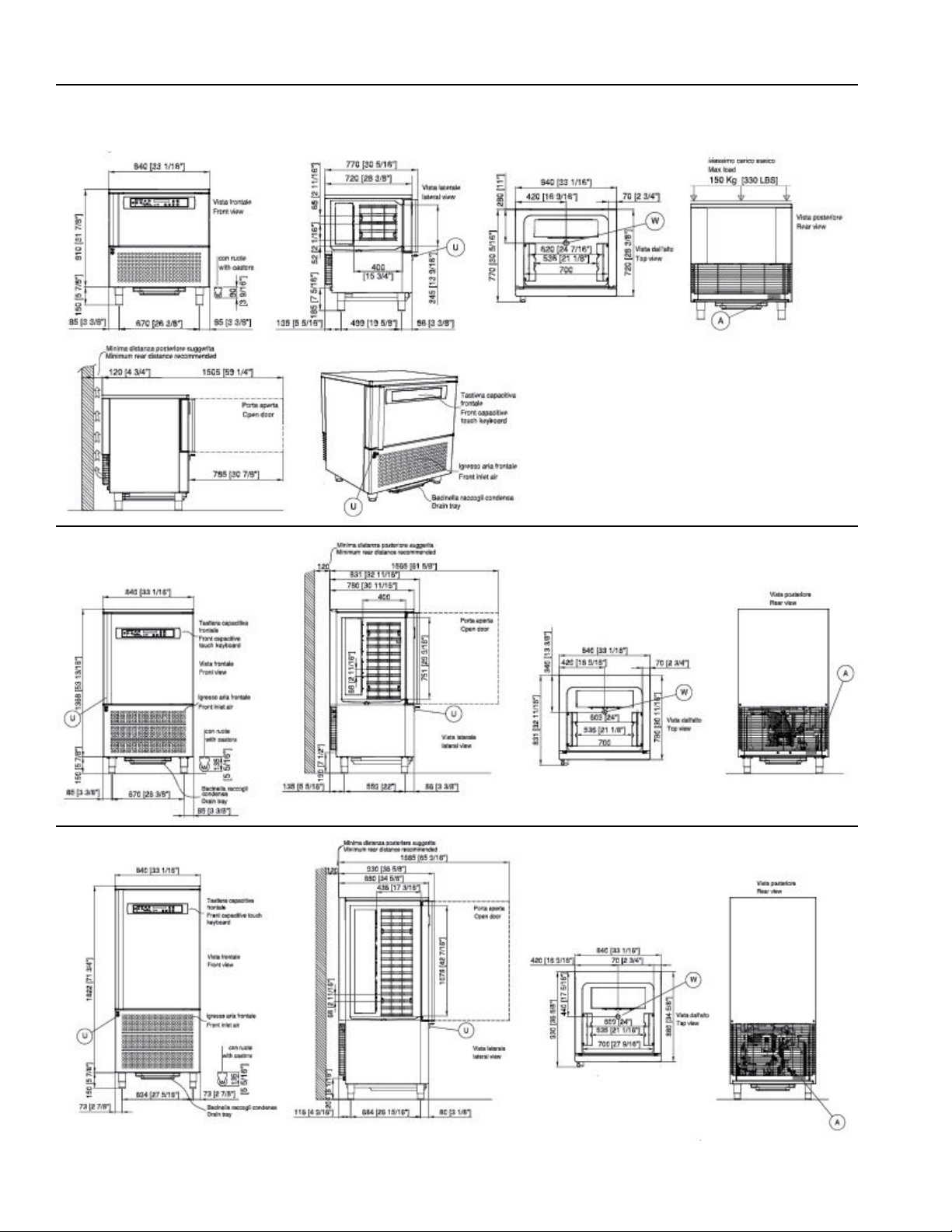

2.3 - Measurements

CV5E - 5 trays

CV10E - 10 trays

CV15E - 15 trays

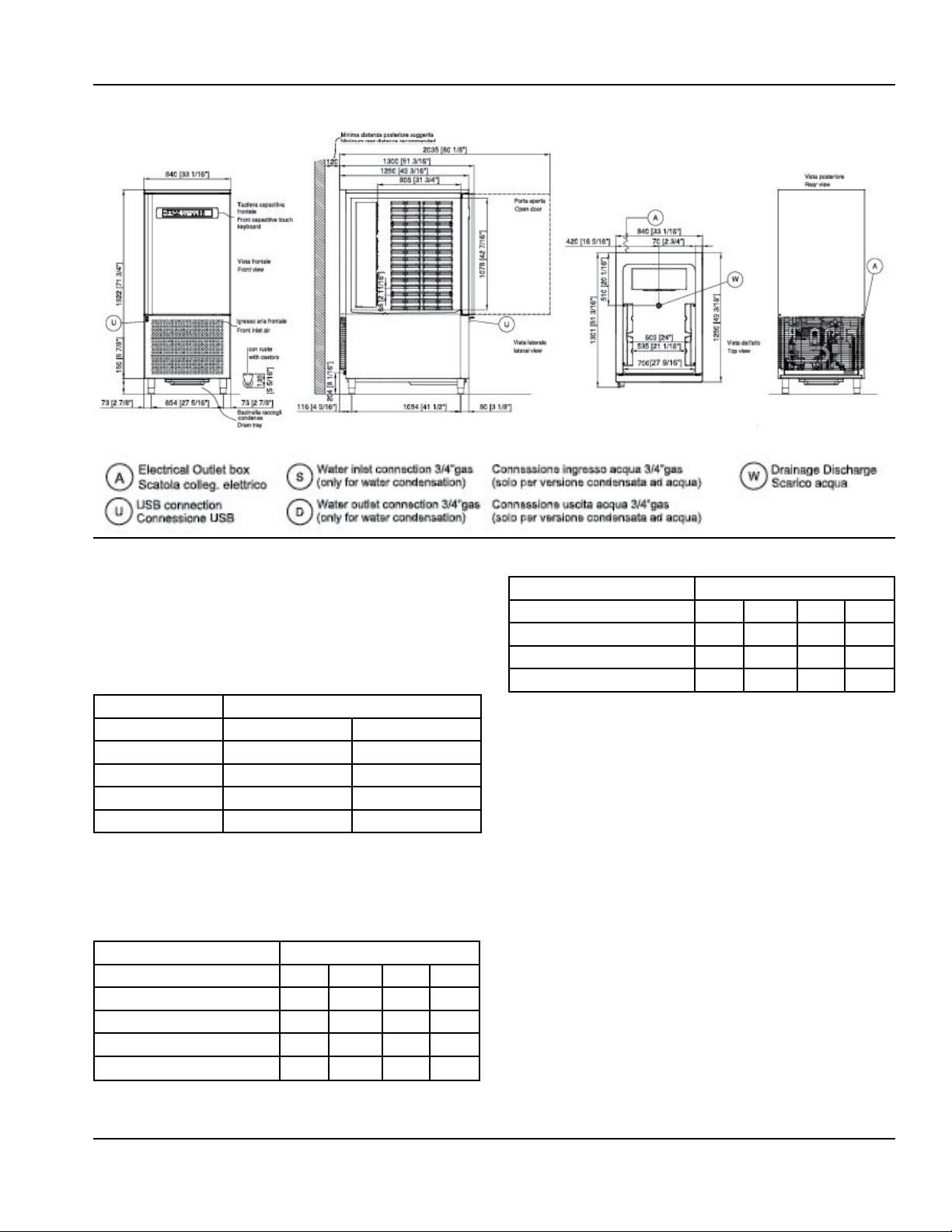

6 Part Number: 9294045 07/19

Section 2 Technical Information

CV15E-2 - 30 trays

2.4 - Maximum load

,

Operators are strongly suggested to follow

enclosed instructions

2.4.1 - Maximum load for internal structure capacity

Maimum Capacity

Model Internal structure load per shelf

5T 1000oz (30kg) 700oz (20kg)

10T 1600oz (45kg) 700oz (20kg)

15T 2800oz (80kg) 700oz (20kg)

30T 3000oz (85kg) 700oz (20kg)

2.4.2 - Maximum trays capacity

(trays not supplied with the appliance)

Standard internal support structure

Model

Size Trays 5t 10T 15T 30T

15¾” x 23⁄” (600x400mm) 5 10 15 30

12¾” x 20¾” (530x325mm) 5 10 15 30

23⁄” x31½” (600x800mm) n/a n/a n/a 15

12¾” x 41½” (530x650mm) n/a n/a n/a 15

Optional internal support structure

Model

Size Trays 5t 10T 15T 30T

18” x 26” (655x453mm) n/a n/a n/a 15

12¾” x 20¾” (530x325mm) n/a n/a n/a 28

12¾” x41½” (530x650mm) n/a n/a n/a 14

Part Number: 9294045 07/19 7

Technical Information Section 2

3 INSTALLATION

,

All stages of installation must be carried out in

,

compliance with the national standards in force

according to the manufacturer’s instructions and

by professionally qualified personnel.

Installation of the appliance and of the refrigerating

unit must only be carried out by technicians of the

manufacturer or by skilled personnel.

If the machine was supplied with a remote condesing

unit, it is the installer’s responsibilty to check all the

connections in accordance with the instructions provided

for the installation of the systems and machinery.

The installer is advised to use the appropriate personal

protective equipment necessary for processing and in

compliance with the regulations in force.

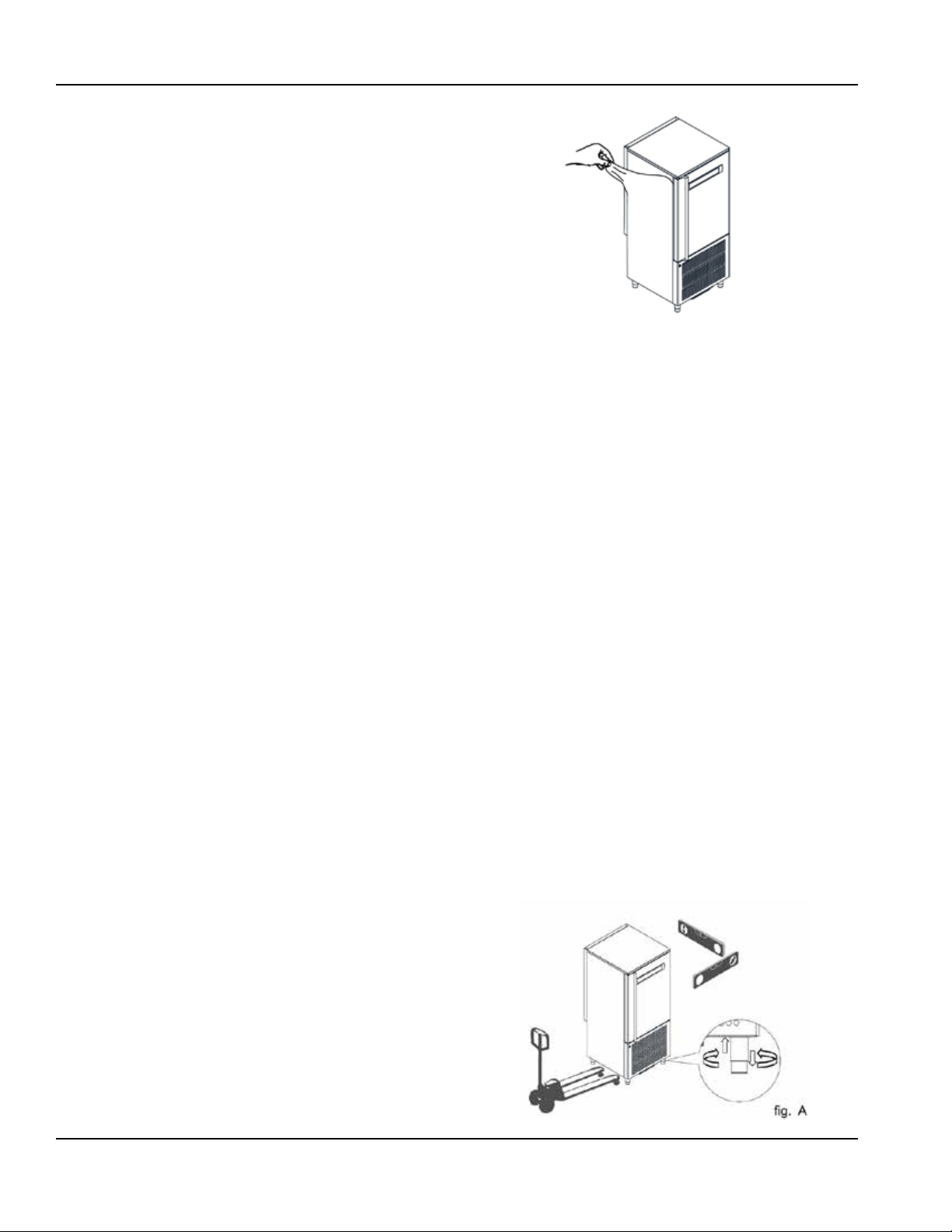

3.1 - Transportation and handling

The net and gross weight of this appliance can be found

on the external packaging.

Loading and unloading of the appliance and/or of the subsystems from the means of transport can be performed

using a forklift truck or fork pallet truck, the length of

which is more than half that of the unit or using cranes

where the apppliance/sub-system is fitted with eyebolts.

The lifting equipment must be chosen according to the

size of the packaged machine/components and with

sufficient capacity. For handling of the appliance/subsystems, every precaution must be taken not to damage

them, respecting the indications on the packaging.

3.2 - Unpackaging and disposal

Remove all cardboard or the wooden crate from the base

on which the machine is placed. Then lift the machine/

sub-assemblies with a suitable means (forklift truck);

remove the wooden base and position the machine/subassemblies in the place provided.

After removing the packaging, verify the integrity of the

machine/sub-assemblies in case of uncertainty do not use

it and contact the distributor.

Remove the protective PVC film on the stainless steel

panels from all sides both internally and externally.

NOTE: All the various components of the packaging must

be disposed of according to the regulations in force in the

country where the appliance is being used. In any case

nothing must be disposed of into the environment.

3.3 - Positioning

The appliance:

• must be installed in places where it can be checked by

qualified personnel

• it must not be installed outdoors.

• it must not be installed in dusty environments.

• it must not be placed in locations with the presence of

water jets.

• it must not be washed with water jets.

• it must be installed and tested in full compliance with

safety laws, traditional systems and with the regulations

in force.

• it must be positioned at a minimum distance of 120mm

from the rear wall.

The installer must verify any requirements for fire safety

(refer to the command of the local fire department for the

relevant indications.)

Level the appliance through adjustment of the feet. For

the setting up of heavier machines, use dedicated hoists

(fig. A - chap. 3.1).

If the appliances are not levelled their functioning and the

flow of condensates could be impaired.

8 Part Number: 9294045 07/19

Section 2 Technical Information

,

Avoid:

• direct exposure to sunlight;

• closed sites with high tempuratures and poor air

circulation;

• indoor environments at high temperatures and poor air

circulation, and avoid installing the machine near any

heat sources

3.4 - Ambient temperature and air exchange

For air cooled liquid chillers, the ambient operating

temperature must not exceed 90°F (32°C). Above this

temperature the declared performance is not guaranteed.

The machine can operate safely up to a temperature that is

referref to by the climate class indicated on the serial plate.

Remote condensing units must be instaled in special rooms

or, if outdoors, in a place protected from direct sunlight,

from adverse weather conditions and from heavy wind

(above 5m/sec). Where circumstances so require, it is the

responsibility of the installer to evaluate the use of a cover

or canopy (costs to be borne by the purchaser). In any case

sufficient air circulation must be guaranteed.

3.5 - Hydraulic connection for water cooled condensing

units

It is advisable to install a valve between the mains and

the appliance’s inlet hose in order to be able to stop the

passage of water if necessary.

For appliances with water cooled units the water supply

temperature must be between 50°F (10°C) and 86°F (30°C)

and the operating pressure must be between 0.1 MPa (1 bar

- 14psi) and 0.5 MPa (5 bar - 72 psi).

regulations in the country of installation.

The electric connecting cables must be dimensioned

in accordance with the rules in force in the country of

installation. In cases wwhere the power cord of the

appliance is damaged, it must be replaced with another

with characteristics that comply with the rules in force in

the country of installation and performed by a qualified

personnel in order to prevent any risk to persons.

The earthing conductor must be correctly connected to

an efficient earthing system.

The manufacturer declines any responsibility and any

warranty obligation in the event of damage to the

equipment, to persons and property caused by incorrect

installation and/or failure to respect the applicable laws.

3.7 - Remote group refrigerator connection

The diameters of the supply lines of the equipment

are sized for distances of up to 10 meters. Contact the

manufacturer for longer distances.

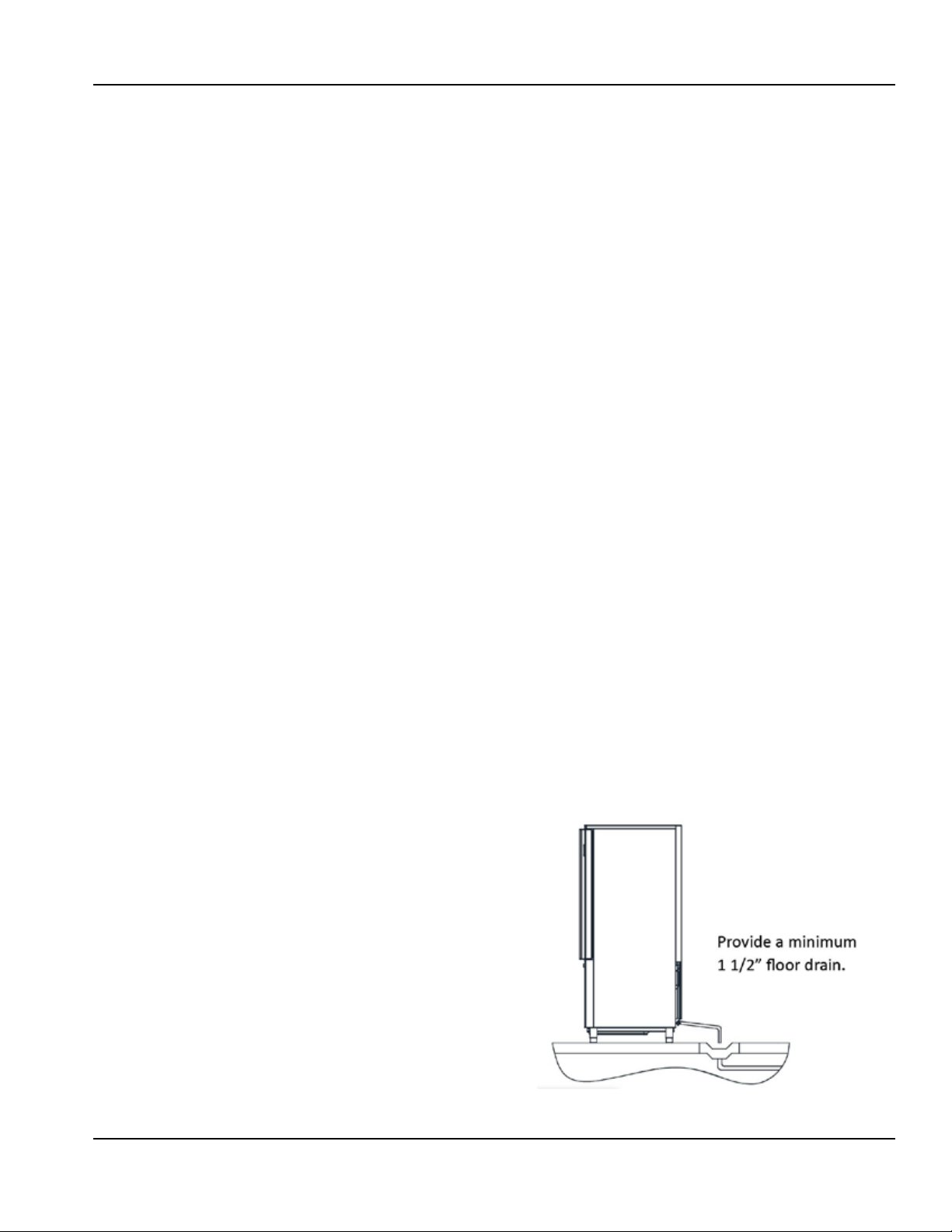

3.8 - Condensate drainage connection (if applicable)

It is necessary to provide a drainage pipe for the

condensation and washing water of a minimum diameter

of 1”. It is advisable to dispose of the condensate through an

open drain at ground level and fitter with a siphon with a

minimum diameter of 1/2”.

3.9 - Notes for the installer

• Verify the correct installation and system testing before

starting up the machine (test report).

• Check for any gas leaks from the welds or joints made

during the installaition phase.

3.6 - Electrical connection

No responsibility is accepted for damage to

,

persons, animals or property cause by failure

to earth the appliance and the creating of an

electrical installation that does not comply with

current standards.

The mains connection must be made according to existing

national rules and by experienced, qualified personnel.

Before connecting the appliance to the mains make

sure that the mains voltage corresponds to the voltage

indicated on the data plate.

Verify that the electrical installation is adequate to the

maximum power of the appliance, as indicated on the

plate. Upstream of each device it is mandatory to install

a differential thermal breaker according to current

Part Number: 9294045 07/19 9

Technical Information Section 2

• Check the efficient insulation of the connecting pipes

between the condenser and the remote condensing

unit.

• Check the electrical connection

• Check the electrical input

• Verify the standard pressures of the refrigerating system

• Check the water connections with adjustment of the

pressure valve during operation and good circulation of

the condensation water (water cooled groups).

3.10 - Commissioning

Commissioning must be carried out by

,

authorised and qualified personnel.

Perform at least one complete cycle of rapid storage

freezing (to reach the SET temperature), and a manual

defrost cycle. If the equipment or the remote condensing

units were delivered in an upright position (e.g. on their

back) or were overturned during installation, do not turn

on immediately but wait at least 4 hours before use.

Inform the customer of the exact use of the equipment

with specific reference to the use and to customer

requirements.

3.13 - Signalling/reports of malfunctioning

In cases of malfuntion of the machine and for report

signalling concerning the blast chillers supplied.

Assembled

You are requested to communicate to the retailer/service

center the machine model, code and the serial number

shown on the registration plate located on the rear of the

machine and inside the door.

Dismantled (with condesnsing units/remote

condensors)

You are requested to communicate to the retailer/service

center the machine model and the code shown on the

registration plate located above the control panel.

3.14 - Appliance disposal

After the useful life of the appliance has been realized be

sure to demolish and dispose of the machine in compliance

with the regulations applied in the country of installation,

particularly in regards to refrigerant gas and compressor

lubricant oil.

3.11 - Safety and control systems

• Door microswitch: this locks operation of the fans in the

cell when the door is opened.

• General protection fuses: they protect the entire power

circuit against short circuits and possible overloads.

• Compressor thermal relay: this intervenes in case of

overloads or malfunction.

• Safety pressure switch: this operates in the case of

excess pressure in the refrigerant circuit.

• Fusible plug: this intervenes in the case of overpressure

and failure of the afore-mentioned safety pressure

switch.

• Chamber temperature control: this is operated by the

electronic card via the probe positioned inside the cell.

• Defrost termination temperature control: this is

managed by the electronic card via the probe located

on the evaporator.

3.12 - Stop modes

In an emergency, to stop the machine remove power from

the main panel using the earthing switch or by removing

the plug from the socket making sure hands are not wet or

damp.

10 Part Number: 9294045 07/19

Section 2 Technical Information

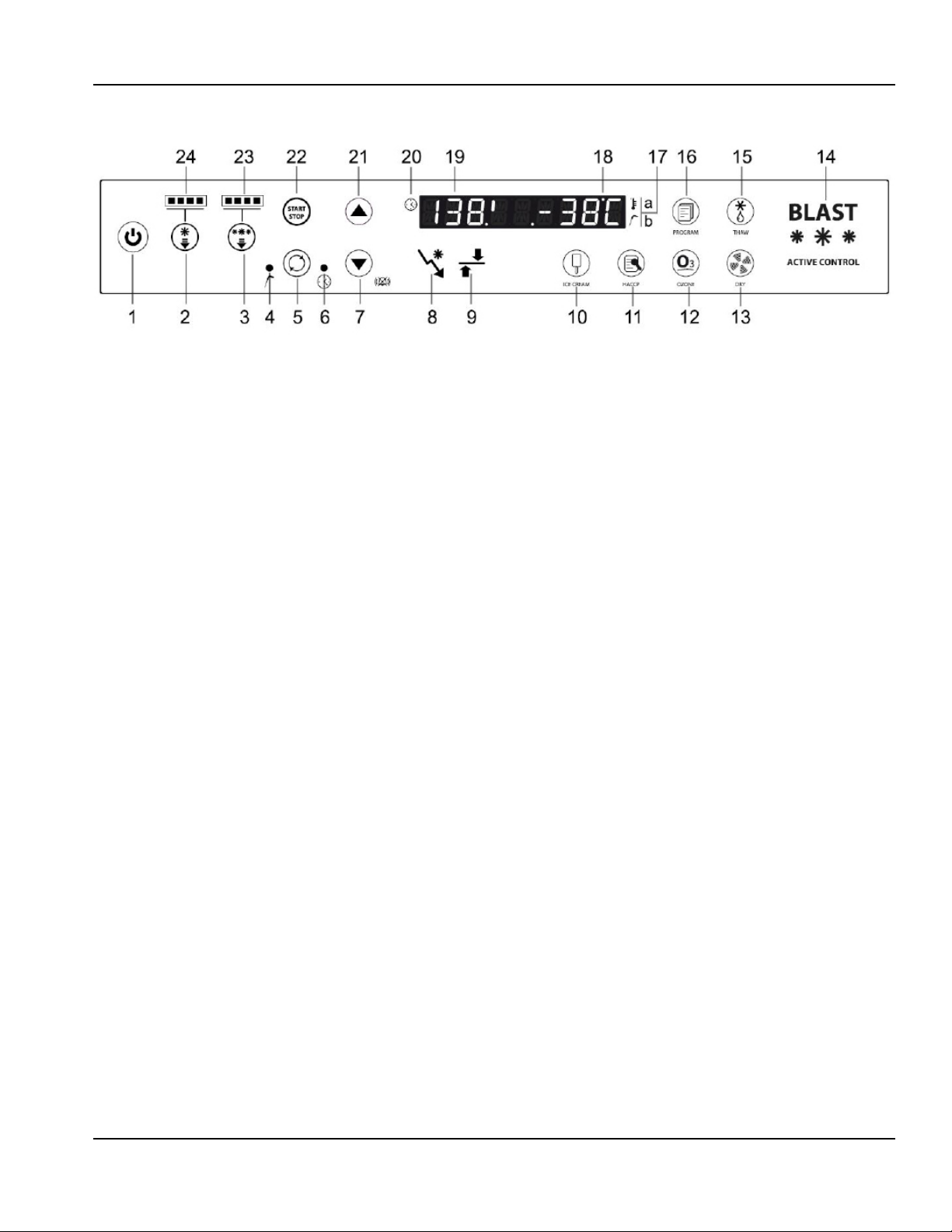

4 COMMAND INTERFACE SYMBOLS

1 - Stand-by button - Standby button, if pressed for more

than 3 seconds it takes the card into standby or switches

it on again.

2 - Positive chilling button - Used to select the mode of

positive chilling.

3 - Negative chilling button - Used to select the mode of

negative chilling.

4 - Chill. LED Temperature - LED on means that the chilling

is via tempurature mode (insert probe)

5 - Chilling mode button - A button that selects the mode

of chilling with Time or Temperature (insert prode use);

the selected mode is represented by ignition of one of the

two LEDs located on the right and left of the button and

the are marked with the temperature or time symbol.

6 - Chill. LED Time - LED on means that the chilling is via

Time mode

7 - Decrease button - Parameter or setting value decrease

buttons (the “-” button allows silencing of the beeper if

active.)

8 - Chilling phase LED - Symbol representing the chilling

phase (it flashes when at that phase.)

9 - Storage phase LED - Symbol representing the chilling

phase (it flashes when at that phase.)

10 - Ice-cream button - The ice-cream button which starts

the ice-cream cycle. (see section 12).

11- HACCP button - The HACCP button which starts the

data reversal cycle onto USB.

12 - Ozone button - Button that starts the ozone sanitising

cycle (if any).

13 - Defrost button - Button that when pressed once starts

drying with door oper (see section 9), while if pressed for

at least 3 seconds it starts the hot gas defrost cycle.

14 - Status LED - RGB on mark lettering. The lettering

assumes the following colors depending on the following

relative connected states:

BLUE - Phase of chilling, deep-freezing or storage

ORANGE - Thawing

GREEN/BLUE - Machine on stand by

WHITE - Machine at standstill

RED FLASHING - Serious alarm

FLASHING YELLOW - Non-serious alarm (door opening -

maintenance)

15 - Thawing button - Button that when pressed starts the

defrost cycle

16 - Program button - Programs recall or storage button

17 - Temperature symbol - The symbol lights up when a

cycle is active and the cell temperature (time chilling) or

product temperature (temperature chilling) is detected.

In the second case the product probe is shown with the

highest value. With the cycle in progress press the button

(12) to display in sequence the values of the insert probe

1 and 2 and the evaporator sensor probe in flashing mode

and the display (19) will show the letters in sequence SP1+

“probe value”, SP2+”probe value” and SE+”value”.

18 - Display temperature - Second part of the alphanumeric

desplay (last 4 digits) for representation of the T° cell or T°

product and evaporater value.

19 - Display time - First part of the alphanumeric display

(first 4 digits) for representation of the time value

remaining of chilling.

20 - Time symbol - The symbol lights up when the cycle

is running; the time remaining will be displayed. If the

button (5) is pressed the elapsed time will flash for 5

seconds (both for Time and Temperature chilling).

21 - Increase button - Parameter or setting value increase

buttons.

22 - Cycles start/stop button - start/stop the chilling cycle

set; with a cycle started, the button remains lit.

23 - Negative chilling LED - The number of LEDs lit indicates

the intensity of the negative chilling.

24 - Positive chilling LED - The number of LEDs lit indicates

the intensity of the positive chilling.

Part Number: 9294045 07/19 11

Technical Information Section 2

5 MACHINE ON/OFF

When the equipment is powered, it will appear in

STANDBY conditions (scrolling text on the display). To start

the machine press the button (1) for at least 3”. Similar to

machine without cycles in progress, to switch it off simply

press the button (1) for at least 3”.

Where a cycle was in progress, and the situation is returning

from a blackout the appliance, once reconnected, will

resume from the interrupted cycle.

5.1 - Compressor preheating management

Upon ignition of the equipment a compressor preheating

time of 120 minutes must be respected where the blast

chiller is not available.

The scrolling text will appear “Compressor HeatingRiscaldamento Compressore” and then the fixed lettering

“XXX min” to represent the time remaining. These two

messages will alternate until the end of heating. This phase

can be bypassed by pressing the “HACCP” (11) button for

approximately 5 seconds.

6 DATE AND TIME SETTING

Upon initial ignition, it is advisable to check the date and

time set; their accuracy is beneficial in relation to HACCP

management.

To access the clock setting, press for more than 5 seconds

the Temperature/Time button (5) with the machine in

Stop mode. The laels shown below will appear on the left

display; the right display will show the 2-digit numeric

value to be set:

Hour(Ora) / Minute(Minuti) / Day(Giorno) / Month(Mese) /

Year(Anno)

The Temperature/Time button (5) can be used to scroll

through the labels, while with the +/- buttons (21/7) it is

possible to change the values.

After the year value the change will be automatically

saved.

7 BLAST CHILLING CYCLES

7.1 - General operating principles

Pre-cooling of the machine should always be performed

upon initial running of a blast chilling or deep freezing

operation. This optimises the subsequent work cycle,

reducing the time.

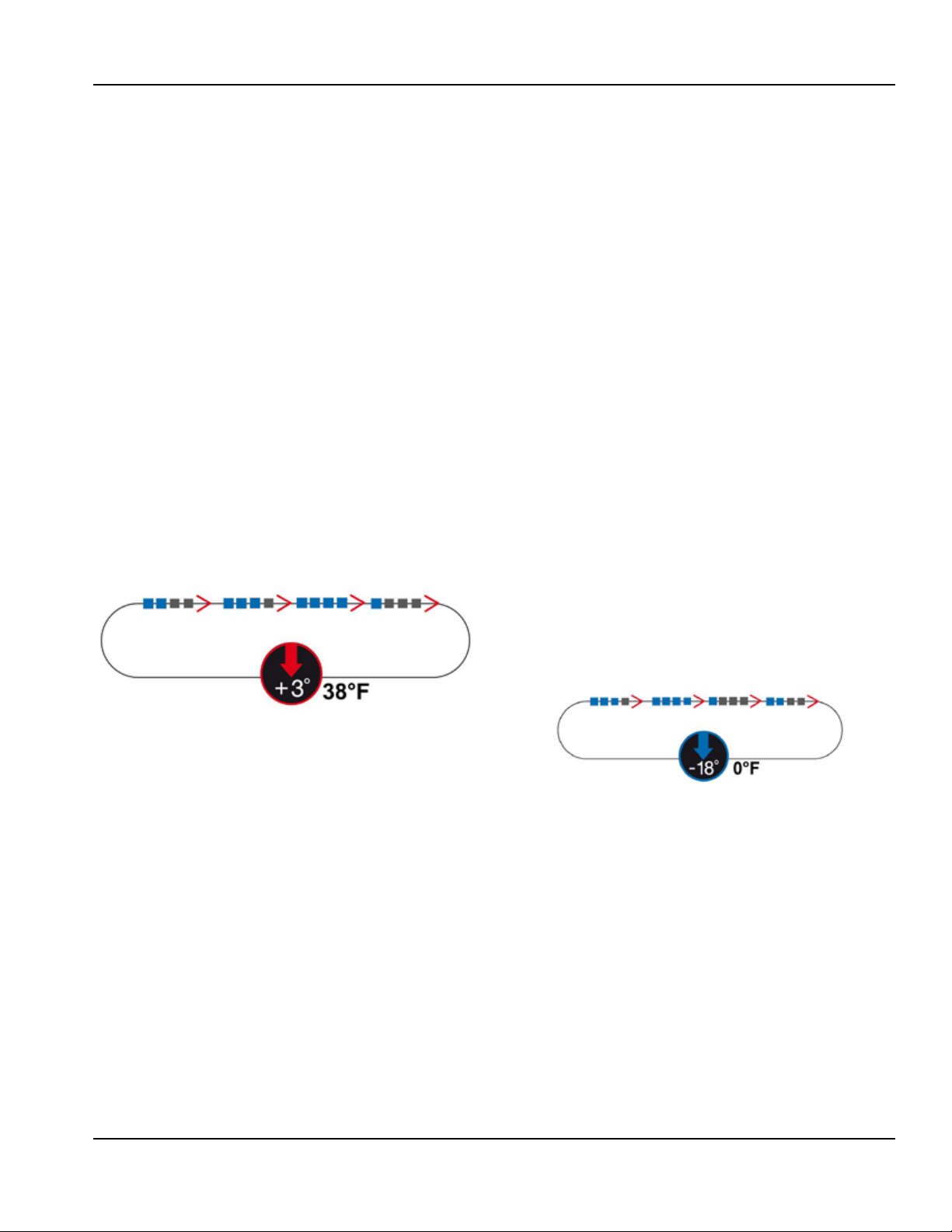

Blast chillers are refrigeration systems that work with a twophase cycle:

• Chilling phase (limited duration)

• Storage phase (unlimited period)

The chilling phase starts upon pressing of the “Start/Stop”

button (22) and continues until the end of the chilling

phase that is used to achieve the time set (Time chilling) or

for reaching of the product temperature set (Temperature

chilling); changing to the unlimited duration storage cycle

takes place automatically (except for the the HARD+HARD

negative chilling cycle). It is possible to stop the chilling

or storage at any time by pressing the “Start/Stop” button

(22).

Chilling time

During this type of chilling, the display (18) shows the cell

probe temperature while the other display (19) shows the

time remaining at the end of the chilling phase. The Time

chilling LED (6) is lit as is the time symbol (20).

Temperature chilling

If Temperature chilling is selected, at the start of a cycle a

check is performed of the correct insertion of the product

probe (if enabled). If the test provides a negative result

an alert appears on the display “SONDA NON INSERITA PROBE NOT INSERT” and the beeper sounds for 60 seconds

(parameter c9); that symbol disappears when the beeper

is silenced by pressing the button (7). If instead the button

is pressed again (5) switching to Temperature cycle, the

cycle continues based on the data read by the product

probe. If nothing is pressed, the temperature cycle

automatically switches into a Time cycle for the remaining

duration of the countdown.

During this type of chilling, a display (18) will show the

temperature of the probe (the highest value of the two)

and the other (19) will show a countdown. The countdown

only starts when the insert temperature is less than 149°F

(65°C). The temperature chilling LED (4) is on as is the

probe insert symbol (17).

Chilling and strorage status symbols

During chilling the LED that lights the sybol will be lit and

flashing. Upon completion of chilling, this LED flashes

alternately with the LED located beneath the storage

symbol (8) while the beeper sounds for 60 sec, and the

scrolling text appears “End Cycle - Fine Ciclo”. After this

time, the chilling LED (9) switches off, the storage one

starts flashing (8) and the scrolling text disappears (even

when the beeper silencer button (7) is pressed.

The LED (8) will flash when the compresser is on while if

the set value has been reached, they will only remain lit

until transition to storage. Similarly with storage, the LED

(9) will flash when the compressor is active and will remain

lit for the rest of the storage.

12 Part Number: 9294045 07/19

Section 2 Technical Information

7.2 - Chilling phases

Pressing the positive chilling button (2) or negative

chilling button (3) allows selection of a different chilling

mode. The number of LEDs lit (23) or (24) define the

“intensity” of chilling. The “Time” or “Temperature” chilling

mode will be set by pressing the button (5). Lighting up of

the corresponding LEDs on the sides will define the type

of chilling.

Each time the positive chilling button (2) is pressed the

display will show successively for 3 seconds one of the

following cycles:

LIGHT, SOFT, MEDIUM, FAST.

Each time the negative chilling button (3) is pressed the

display will show successively for 3 seconds one of the

following cycles:

LIGHT, SOFT, HARD, RUN.

7.3 - Selecting and starting the positive chilling cycle

When the button (2) is pressed for the first time, “SOFT”

mode will be selected, represented with lighting up of

two of the four LEDs (24); subsequent pressing takes to 3

and 4 LEDs lit and results in the “HARD” mode. Successive

pressing reduces from 4 to 1 the LEDs lit and so on.

cooling in the presence of products that are resistant and

very hot initially.

Once the MEDIUM or FAST cycles are started, to modify the

HARD phase duration simply press the button (2) that will

show on the display (19) the words “Hard” and will result

in flashing on the display (18) the value in minutes of the

HARD phase. With the +/- buttons it is possible to increase

or decrease the value and confirm with the button (2) or

wait 5 seconds (N.B. THE CHANGED VALUE ONLY APPLIES

TO THE CYCLE IN PROGRESS).

Once the cycle is selected, it is necessary to select the Time

or Temperature mode by pressing the button (5) until

coming on of the relevant LED.

At this point to start the cycle press the START/STOP

button (22).

In the even of Temperature chilling, it is possible to

change this chilling end value by pressing the button (2)

or (3) depending on the type of chilling in process. Having

pressed the button, the display (18) will appear the value

of the end chilling temperature set, which can be modified

within the envisaged range. Having pressed the button (2)

or (3) or after 5 seconds the changed value is saved.

7.4 - Selection and starting the Negative chilling cycle

“LIGHT” - 1 LED only on

In this condition, there will be a cell temperature set of

27F (-3C). This avoids the risk of ice formation during the

positive chilling phase and it will be used for loads which

can be damaged by excessively heavy treatment.

“SOFT” - 2 LEDs on (default)

In this condition, there will be a cell temperature set of 23F

(-5C). This set will allow quicker chilling for products that

in any case are fairly resistant to the freezing process.

“MEDIUM” - 3 LEDs on

In this condition, there will be an initial cell temperature

set of -4F (-20C); after the HARD time, this will be taked to

a cell temperature of 24F (-3C). This method accelerates

cooling in the presence of products that are resistant and

very hot initially.

“FAST” - 4 LEDs on

In this condition, there will be an initial cell temperature

set of -4F (-20C), after the HARD time, this will be taken to

a cell temperature of 23F (-5C). This method accelerates

Pressing the button (3) for the first time will select the

“HARD” mode, represented by coming on of three of the

four LEDs (23) present. Subsequent pressing will take to

4 the LEDs lit and will return into “RUN+HARD” mode.

Successive presses reduce from 4 to 1 the LEDs and so on.

“LIGHT” - 1 LED only on

In this condition, there will be a cell temperature set of

23F (-5C); after the SOFT time defined by the parameter

(ts) this will move to a temperature of -22F (-30C). This

mode is for use on large pieces where it is important to

homogenise the chilling cycle.

“SOFT” - 2 LEDs on

In this condition, there will be a cell temperature set of

-4F (-20C); after the SOFT time defined by the parameter

(ts) this will move to a temperature of -22F (-30C). This

mode is for use on large pieces where it is important to

homogenise the chilling cycle.

In the case of SOFT or LIGHT temperature chilling, the

set change will be decided by the product temperature

detected according to the parameter (C2).

Part Number: 9294045 07/19 13

Loading...

Loading...