Welbilt Delfield CV5E, Delfield CV10E, Delfield T40, Delfield CV15E-2, Delfield CV15E Original Instructions Manual

Page 1

Fresh Solutions, Fit for You

Blast Chillers

CV5E, CV10E, CV15E, CV15E-2 and T40

Original Instructions

Installation, Operation and Maintenance Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

Part Number: 9294045 07/19

Page 2

1 WARNINGS AND IMPORTANT ADVICE

2 TECHNICAL DATA

2.1 - Plate data

2.1 - Refridgerant

2.3 - Measurements

2.4 - Maximum loads

2.4.1 - Max load for internal structure capacity

2.4.2 - Max tray capaity

3 INSTALLATION

3.1 - Transportaion and handling

3.2 - Unpacking and disposal

3.3 - Positioning

3.4 - Ambient temperature and air exchange

3.5 - Hydraulic connection for water cooled units

3.6 - Electrical connection

3.7 - Remote group refrigerator connection

3.8 - Condensate drainage connection

3.9 - Notes for the installer

3.10 - Commissioning

3.11 - Safety and control systems

3.12 - Stop modes

3.13 - Signaling/reports of malfunction

3.14 - Appliance disposal

4 COMMAND INTERFACE SYMBOLS

5 MACHINE ON/OFF

5.1 - Compressor preheating management

6 DATE AND TIME SETTINGS

7 BLAST CHILLING CYCLES

7.1 - General chilling principles

7.1.1 - Chilling time

7.1.2 - Temperature chilling

7.1.3 - Chilling and storage status symbols

7.2 - Chilling phases

7.3 - Selecting and starting the pos. chill cycle

7.4 - Selecting and starting the neg. chill cycle

7.5 - Storage phases

8 DEFROST MODE

9 DRYING WITH MACHINE AT STANDSTILL

10 DOOR OPENING

11 OZONATOR

12 ICECREAM CYCLE

13 THAWING CYCLE

14 CHILLING PROGRAM STORAGE

15 CHILLING PROGRAM EXECUTION

16 ALARMS

10

10

10

10

10

11

12

12

12

12

12

12

12

12

13

13

13

14

14

14

14

15

15

15

16

16

16

2

5

5

5

6

7

7

7

8

8

8

8

9

9

9

9

9

9

16.1 - Evaporator probe alarm

16.2 - Product probe alarm

16.3 - Cell probe alarm

16.4 - Door micro-switch alarm

16.5 - Alarm - Diff. Thermal Breaker - Oil Pressure

16.6 - Auto reset minimum pressure swtich alarm

16.7 - Auto reset Kriwan Alarm

16.8 - Input alarm HT 1 - Fusable

16.9 - Overtemperature

16.10 - Black-Out Alarm

16.11 - Compressor preventative maint. alarm

16.12 - Temperature not reached in time alarm

16.13 - Power keypad-card connection alarm

16.14 - Maximum pressure switch alarm

17 HACCP ALARM MEMORIES RESET

18 HACCP DATA READING

19 HACCP DATA EXPORT WITH USB

19.1 - Extracted data format

19.2 - Data downloading with USB

20 ORDINARY MAINTENANCE

20.1 - Operations by the user that do not require

assistance of a qualified technician

20.1.1 - Cell cleaning

20.1.2 - Outer case cleaning

20.1.3 - Defrost water drainage

20.2 - Operation only for authorised installer

20.2.1 - Condenser cleaning

20.2.2 - Condenser filter cleaning

20.2.3 - Evaporator cleaning

20.2.4 - Ozonator maintenance

21 TIPS FOR SMOOTH OPERATION

21.1 - Operating instructions

21.2 - Pre-cooling

21.3 - Maximum load capacity for chilling/freezing

cycles

21.4 - How to load the machine

T40 information

1 UNIT INFORMATION

1.1 - Freezer Remote condensing unit details

1.2 - Remote water cooled condensing unit

1.3 - T5/T14D Refrigeration system schematic

1.4 - Wiring diagram

2 T40 INSTALLATION AND ASSEMBLY

2.1 - Supplied Equipment list

2.2 - Install and assembly instructions

3 - Controller buttons

4 -Controller functions

5 - Programming instructions

5.1 - Starting up the appliance

16

16

16

17

17

17

17

17

17

18

18

18

18

18

18

18

19

19

19

20

20

20

20

20

20

20

20

20

20

20

20

20

21

21

22

23

23

24

25

26

27

27

28

31

32

33

33

2 Part Number: 9294045 07/19

Page 3

Table of Contents

5.2 - Soft blast chilling by temperature

5.3 - Soft timed blast chilling

5.4 - Hard blast chilling by temperature

5.5 - Hard timed blast chilling

5.6 - Blast freezing by temperature

5.7 - Timed blast feezing

6 APPLIANCE FUNCTIONS

6.1 - Date and time settings

6.2 - Ice cream surface hardening

6.3 - Muting the beeper and alarm

6.4 - Program storage

6.5 - Displaying the three latest HACCP alarms

6.6 - printing out stored data

6.7 - Forced ventilation function

6.8 - Manual defrosting

6.9 - Automatic defrost cycles

6.10 - Printer operation

7. ALARM MANAGEMENT

7.1 - Storage of data/errors

7.2 - Software controls

33

34

34

35

35

36

37

37

37

37

37

37

37

38

38

38

38

39

39

39

Part Number: 9294045 07/19 3

Page 4

Safety Notices

Warning

n

Read this manual thoroughly before operating, installing

or performing maintenance on the equipment. Failure

to follow instructions in this manual can cause property

damage, injury or death.

DANGER

Do not install or operate equipment that has been

misused, abused, neglected, damaged, or altered/

modified from that of original manufactured

specifications.

DANGER

Keep power cord AWAY from HEATED surfaces. DO NOT

immerse power cord or plug in water. DO NOT let power

cord hang over edge of table or counter.

DANGER

All utility connections and fixtures must be maintained

in accordance with Local and national codes.

Warning

n

Authorized Service Representatives are obligated to

follow industry standard safety procedures, including,

but not limited to, local/national regulations for

disconnection / lock out / tag out procedures for all

utilities including electric, gas, water and steam.

Warning

n

Do not store or use gasoline or other flammable vapors

or liquids within or in the vicinity of this or any other

appliance. Never use flammable oil soaked cloths or

combustible cleaning solutions, for cleaning.

Warning

n

Do not use electrical appliances inside the food storage

compartments of the appliance, unless they are of the

type recommended by the manufacturer.

Warning

n

Use caution when handling metal surface edges of all

equipment.

Warning

n

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

concerning use of the appliance by a person responsible

for their safety. Do not allow children to play with this

appliance.

Caution

,

Use caution handling, moving and use of the R290

refrigerators to avoid either damaging the refrigerant

tubing or increasing the risk of a leak. Components

shall be replaced with like components. Servicing shall

be done by a factory authorized service personnel to

minimize the risk of possible ignition due to incorrect

parts or improper service.

Notice

Proper installation, care and maintenance are

essential for maximum performance and trouble-free

operation of your equipment. Visit our website www.

wbtkitchencare.com for manual updates, translations,

or contact information for service agents in your area.

Warning

n

This product contains chemicals known to the State

of California to cause cancer and/or birth defects or

other reproductive harm. Operation, installation, and

servicing of this product could expose you to airborne

particles of glasswool or ceramic fibers, crystalline

silica, and/or carbon monoxide. Inhalation of airborne

particles of glasswool or ceramic fibers is known to the

State of California to cause cancer. Inhalation of carbon

monoxide is known to the State of California to cause

birth defects or other reproductive harm.

Page 5

Section 2 Technical Information

2 TECHNICAL DATA

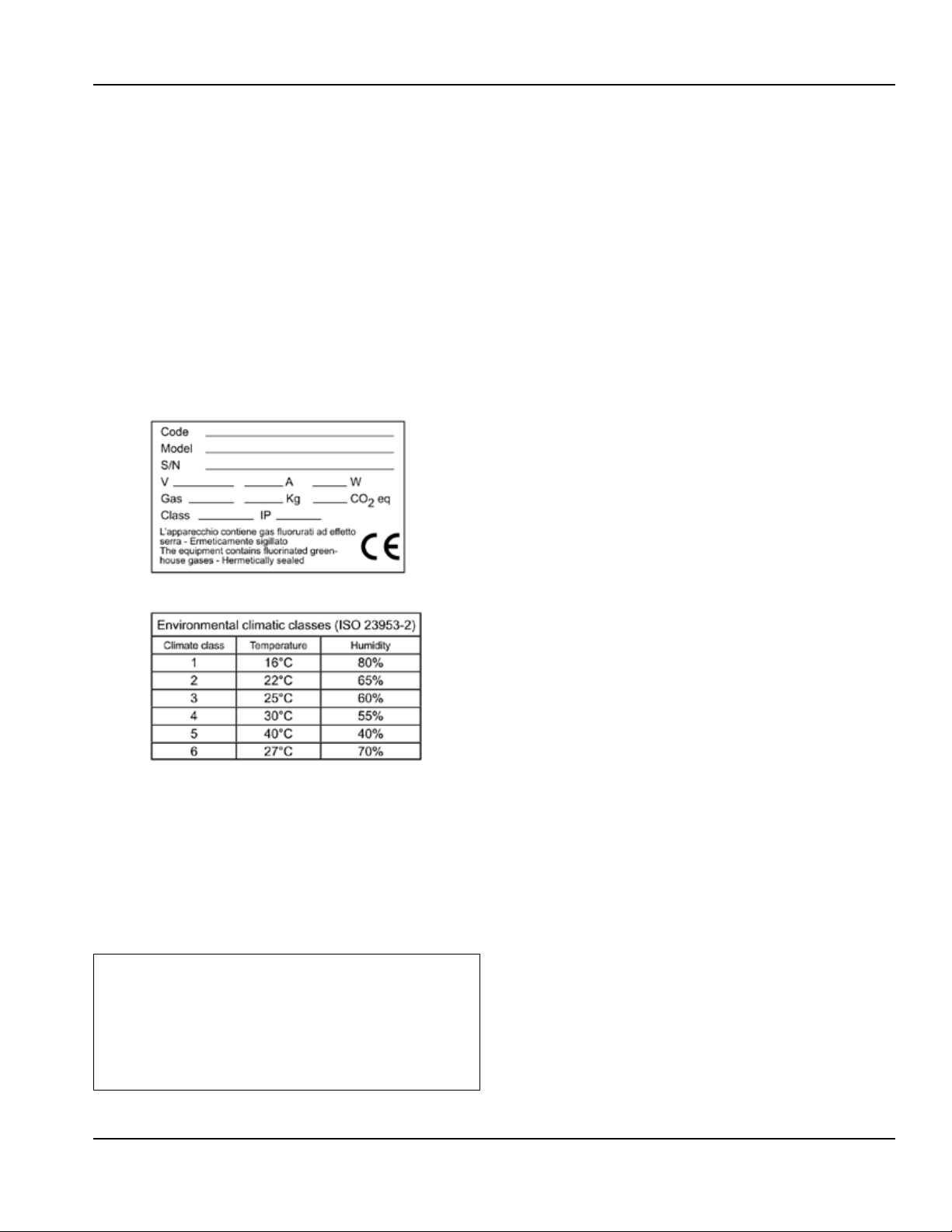

2.1 - Plate data

The plate bearing the equipment specifications should

be applied on the outside rear part of the machine and/

or on the electrical panels. Any preparation of machines

only for relocation of the condensing units must follow

the regulations enforced in the country of installation

regarding fire safety (refer to the command of the local

fire department for the relevent indications). It should

also be considered that the possible intervention of safety

valves or fusible plugs, located in the refrigerant circuit,

entail the immediate discharge of all the refrigerant into

the environment.

The appliance’s climate class is stated on the serial plate

2.2 - Refrigerant

The appliance contains flourinated greenhouose gases

covered by the Kyoto Protocol in the quantities indecated

on the serial plate. The type of refrigerant gas present in

the refrigerant circuit of the appliance is shown on the

serial plate. The GWP (global warming protential) of the

HFC R134a gas is 1430 and the HFCR404A gas is at 3922.

The CO2 equivalent data is shown on the serial plate.

,

According to regulation (EC) 1272/2008,

,

R134a and R404A gases are non-flammable

and non-toxic. in high concentrations they

cause burns and frostbite. in the system the

gas is pressurised; it may explode if heated.

Part Number: 9294045 07/19 5

Page 6

Technical Information Section 2

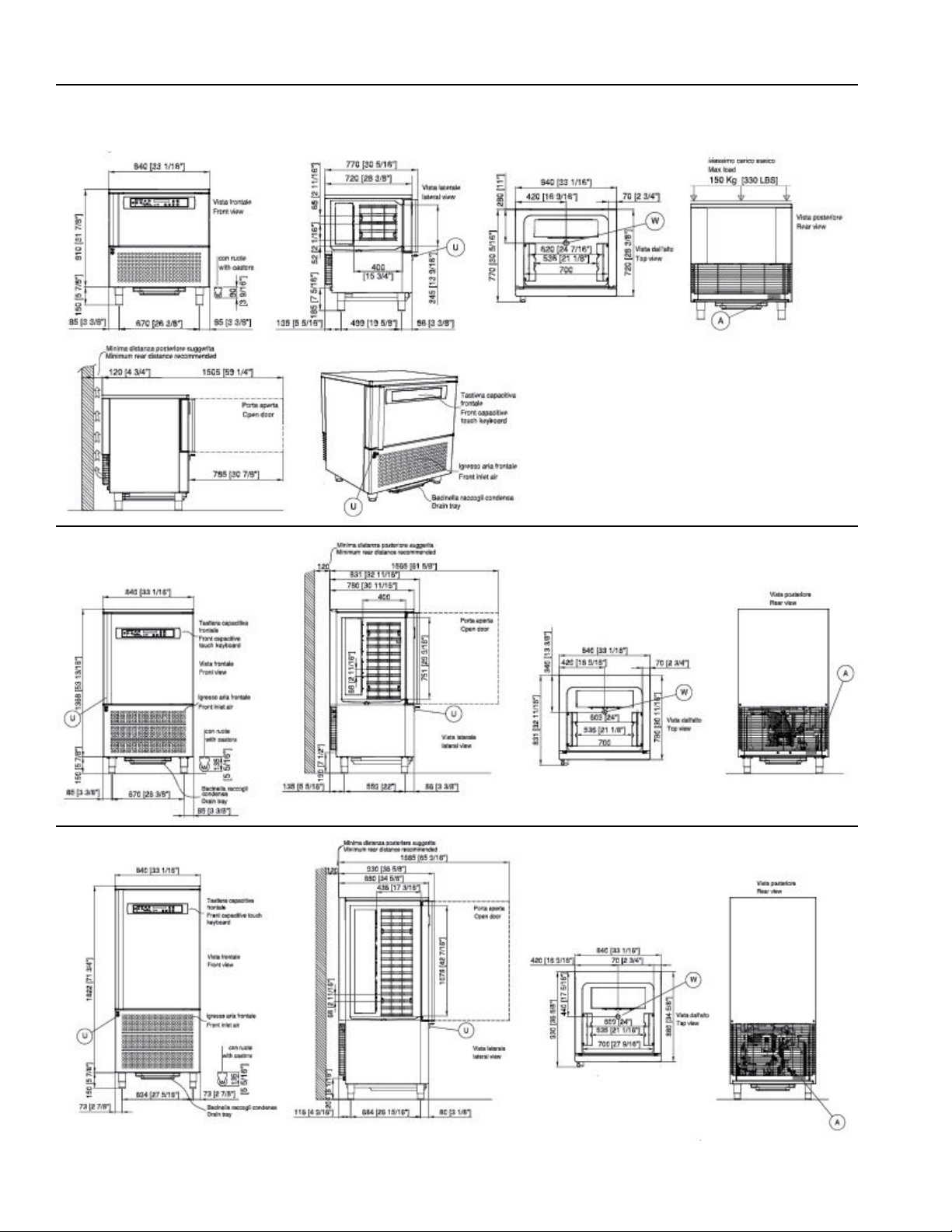

2.3 - Measurements

CV5E - 5 trays

CV10E - 10 trays

CV15E - 15 trays

6 Part Number: 9294045 07/19

Page 7

Section 2 Technical Information

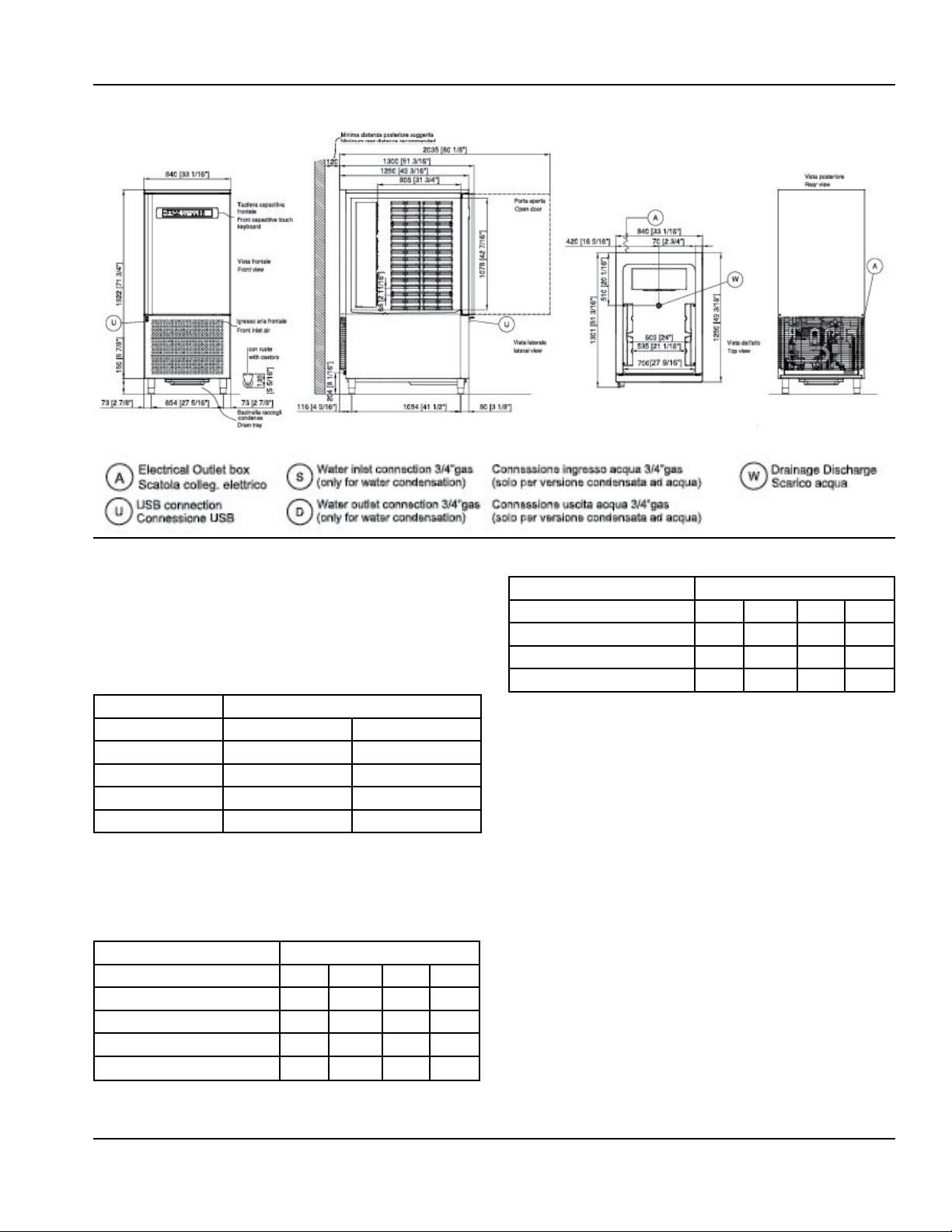

CV15E-2 - 30 trays

2.4 - Maximum load

,

Operators are strongly suggested to follow

enclosed instructions

2.4.1 - Maximum load for internal structure capacity

Maimum Capacity

Model Internal structure load per shelf

5T 1000oz (30kg) 700oz (20kg)

10T 1600oz (45kg) 700oz (20kg)

15T 2800oz (80kg) 700oz (20kg)

30T 3000oz (85kg) 700oz (20kg)

2.4.2 - Maximum trays capacity

(trays not supplied with the appliance)

Standard internal support structure

Model

Size Trays 5t 10T 15T 30T

15¾” x 23⁄” (600x400mm) 5 10 15 30

12¾” x 20¾” (530x325mm) 5 10 15 30

23⁄” x31½” (600x800mm) n/a n/a n/a 15

12¾” x 41½” (530x650mm) n/a n/a n/a 15

Optional internal support structure

Model

Size Trays 5t 10T 15T 30T

18” x 26” (655x453mm) n/a n/a n/a 15

12¾” x 20¾” (530x325mm) n/a n/a n/a 28

12¾” x41½” (530x650mm) n/a n/a n/a 14

Part Number: 9294045 07/19 7

Page 8

Technical Information Section 2

3 INSTALLATION

,

All stages of installation must be carried out in

,

compliance with the national standards in force

according to the manufacturer’s instructions and

by professionally qualified personnel.

Installation of the appliance and of the refrigerating

unit must only be carried out by technicians of the

manufacturer or by skilled personnel.

If the machine was supplied with a remote condesing

unit, it is the installer’s responsibilty to check all the

connections in accordance with the instructions provided

for the installation of the systems and machinery.

The installer is advised to use the appropriate personal

protective equipment necessary for processing and in

compliance with the regulations in force.

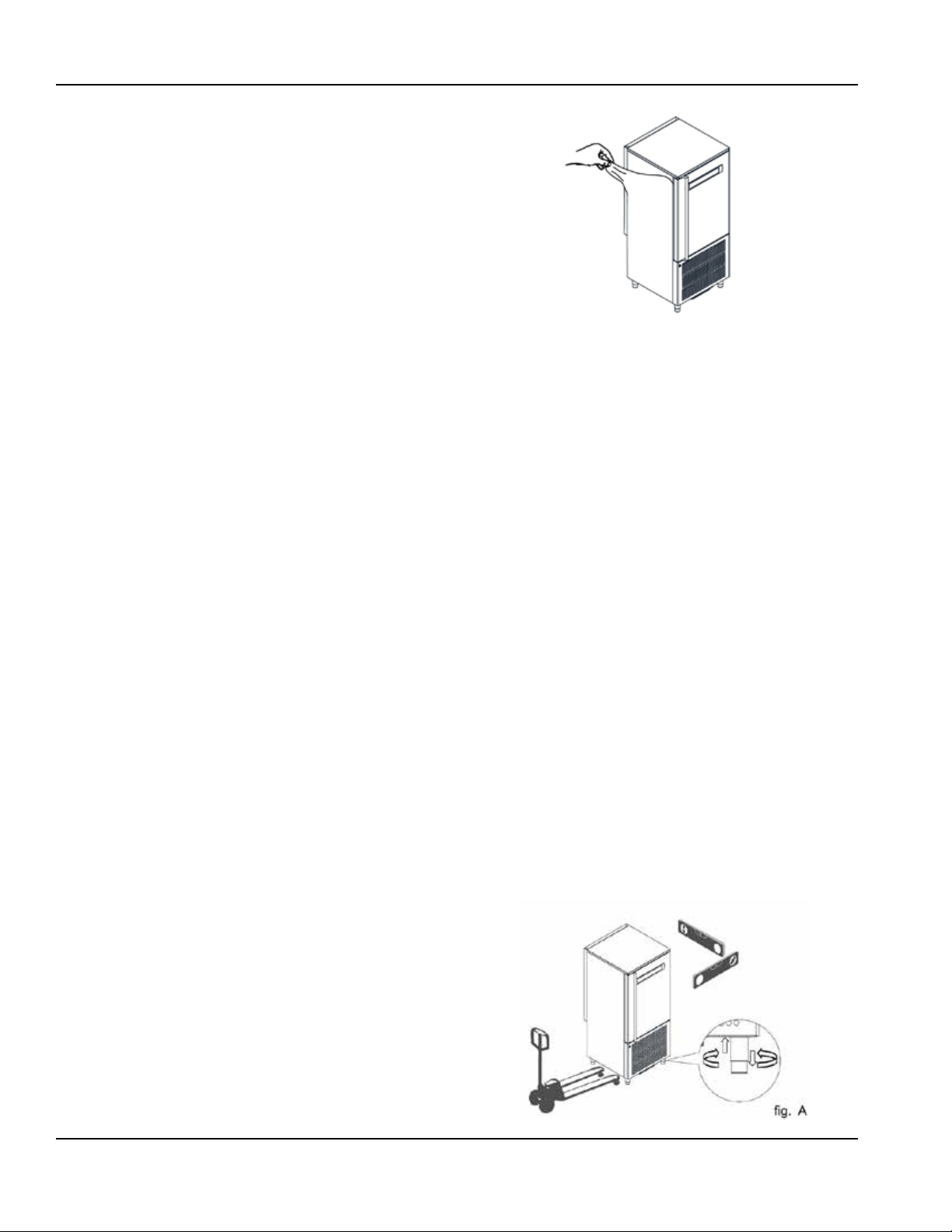

3.1 - Transportation and handling

The net and gross weight of this appliance can be found

on the external packaging.

Loading and unloading of the appliance and/or of the subsystems from the means of transport can be performed

using a forklift truck or fork pallet truck, the length of

which is more than half that of the unit or using cranes

where the apppliance/sub-system is fitted with eyebolts.

The lifting equipment must be chosen according to the

size of the packaged machine/components and with

sufficient capacity. For handling of the appliance/subsystems, every precaution must be taken not to damage

them, respecting the indications on the packaging.

3.2 - Unpackaging and disposal

Remove all cardboard or the wooden crate from the base

on which the machine is placed. Then lift the machine/

sub-assemblies with a suitable means (forklift truck);

remove the wooden base and position the machine/subassemblies in the place provided.

After removing the packaging, verify the integrity of the

machine/sub-assemblies in case of uncertainty do not use

it and contact the distributor.

Remove the protective PVC film on the stainless steel

panels from all sides both internally and externally.

NOTE: All the various components of the packaging must

be disposed of according to the regulations in force in the

country where the appliance is being used. In any case

nothing must be disposed of into the environment.

3.3 - Positioning

The appliance:

• must be installed in places where it can be checked by

qualified personnel

• it must not be installed outdoors.

• it must not be installed in dusty environments.

• it must not be placed in locations with the presence of

water jets.

• it must not be washed with water jets.

• it must be installed and tested in full compliance with

safety laws, traditional systems and with the regulations

in force.

• it must be positioned at a minimum distance of 120mm

from the rear wall.

The installer must verify any requirements for fire safety

(refer to the command of the local fire department for the

relevant indications.)

Level the appliance through adjustment of the feet. For

the setting up of heavier machines, use dedicated hoists

(fig. A - chap. 3.1).

If the appliances are not levelled their functioning and the

flow of condensates could be impaired.

8 Part Number: 9294045 07/19

Page 9

Section 2 Technical Information

,

Avoid:

• direct exposure to sunlight;

• closed sites with high tempuratures and poor air

circulation;

• indoor environments at high temperatures and poor air

circulation, and avoid installing the machine near any

heat sources

3.4 - Ambient temperature and air exchange

For air cooled liquid chillers, the ambient operating

temperature must not exceed 90°F (32°C). Above this

temperature the declared performance is not guaranteed.

The machine can operate safely up to a temperature that is

referref to by the climate class indicated on the serial plate.

Remote condensing units must be instaled in special rooms

or, if outdoors, in a place protected from direct sunlight,

from adverse weather conditions and from heavy wind

(above 5m/sec). Where circumstances so require, it is the

responsibility of the installer to evaluate the use of a cover

or canopy (costs to be borne by the purchaser). In any case

sufficient air circulation must be guaranteed.

3.5 - Hydraulic connection for water cooled condensing

units

It is advisable to install a valve between the mains and

the appliance’s inlet hose in order to be able to stop the

passage of water if necessary.

For appliances with water cooled units the water supply

temperature must be between 50°F (10°C) and 86°F (30°C)

and the operating pressure must be between 0.1 MPa (1 bar

- 14psi) and 0.5 MPa (5 bar - 72 psi).

regulations in the country of installation.

The electric connecting cables must be dimensioned

in accordance with the rules in force in the country of

installation. In cases wwhere the power cord of the

appliance is damaged, it must be replaced with another

with characteristics that comply with the rules in force in

the country of installation and performed by a qualified

personnel in order to prevent any risk to persons.

The earthing conductor must be correctly connected to

an efficient earthing system.

The manufacturer declines any responsibility and any

warranty obligation in the event of damage to the

equipment, to persons and property caused by incorrect

installation and/or failure to respect the applicable laws.

3.7 - Remote group refrigerator connection

The diameters of the supply lines of the equipment

are sized for distances of up to 10 meters. Contact the

manufacturer for longer distances.

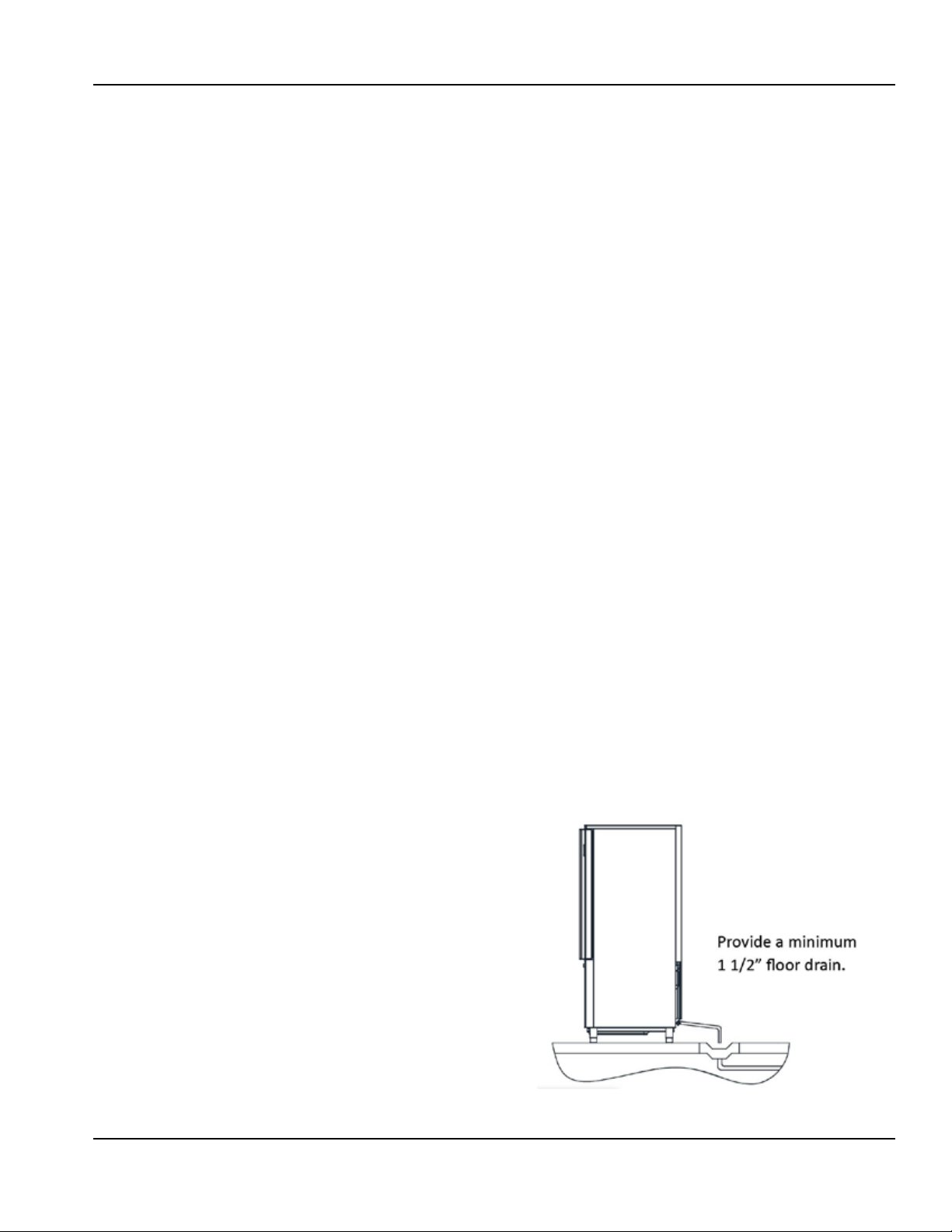

3.8 - Condensate drainage connection (if applicable)

It is necessary to provide a drainage pipe for the

condensation and washing water of a minimum diameter

of 1”. It is advisable to dispose of the condensate through an

open drain at ground level and fitter with a siphon with a

minimum diameter of 1/2”.

3.9 - Notes for the installer

• Verify the correct installation and system testing before

starting up the machine (test report).

• Check for any gas leaks from the welds or joints made

during the installaition phase.

3.6 - Electrical connection

No responsibility is accepted for damage to

,

persons, animals or property cause by failure

to earth the appliance and the creating of an

electrical installation that does not comply with

current standards.

The mains connection must be made according to existing

national rules and by experienced, qualified personnel.

Before connecting the appliance to the mains make

sure that the mains voltage corresponds to the voltage

indicated on the data plate.

Verify that the electrical installation is adequate to the

maximum power of the appliance, as indicated on the

plate. Upstream of each device it is mandatory to install

a differential thermal breaker according to current

Part Number: 9294045 07/19 9

Page 10

Technical Information Section 2

• Check the efficient insulation of the connecting pipes

between the condenser and the remote condensing

unit.

• Check the electrical connection

• Check the electrical input

• Verify the standard pressures of the refrigerating system

• Check the water connections with adjustment of the

pressure valve during operation and good circulation of

the condensation water (water cooled groups).

3.10 - Commissioning

Commissioning must be carried out by

,

authorised and qualified personnel.

Perform at least one complete cycle of rapid storage

freezing (to reach the SET temperature), and a manual

defrost cycle. If the equipment or the remote condensing

units were delivered in an upright position (e.g. on their

back) or were overturned during installation, do not turn

on immediately but wait at least 4 hours before use.

Inform the customer of the exact use of the equipment

with specific reference to the use and to customer

requirements.

3.13 - Signalling/reports of malfunctioning

In cases of malfuntion of the machine and for report

signalling concerning the blast chillers supplied.

Assembled

You are requested to communicate to the retailer/service

center the machine model, code and the serial number

shown on the registration plate located on the rear of the

machine and inside the door.

Dismantled (with condesnsing units/remote

condensors)

You are requested to communicate to the retailer/service

center the machine model and the code shown on the

registration plate located above the control panel.

3.14 - Appliance disposal

After the useful life of the appliance has been realized be

sure to demolish and dispose of the machine in compliance

with the regulations applied in the country of installation,

particularly in regards to refrigerant gas and compressor

lubricant oil.

3.11 - Safety and control systems

• Door microswitch: this locks operation of the fans in the

cell when the door is opened.

• General protection fuses: they protect the entire power

circuit against short circuits and possible overloads.

• Compressor thermal relay: this intervenes in case of

overloads or malfunction.

• Safety pressure switch: this operates in the case of

excess pressure in the refrigerant circuit.

• Fusible plug: this intervenes in the case of overpressure

and failure of the afore-mentioned safety pressure

switch.

• Chamber temperature control: this is operated by the

electronic card via the probe positioned inside the cell.

• Defrost termination temperature control: this is

managed by the electronic card via the probe located

on the evaporator.

3.12 - Stop modes

In an emergency, to stop the machine remove power from

the main panel using the earthing switch or by removing

the plug from the socket making sure hands are not wet or

damp.

10 Part Number: 9294045 07/19

Page 11

Section 2 Technical Information

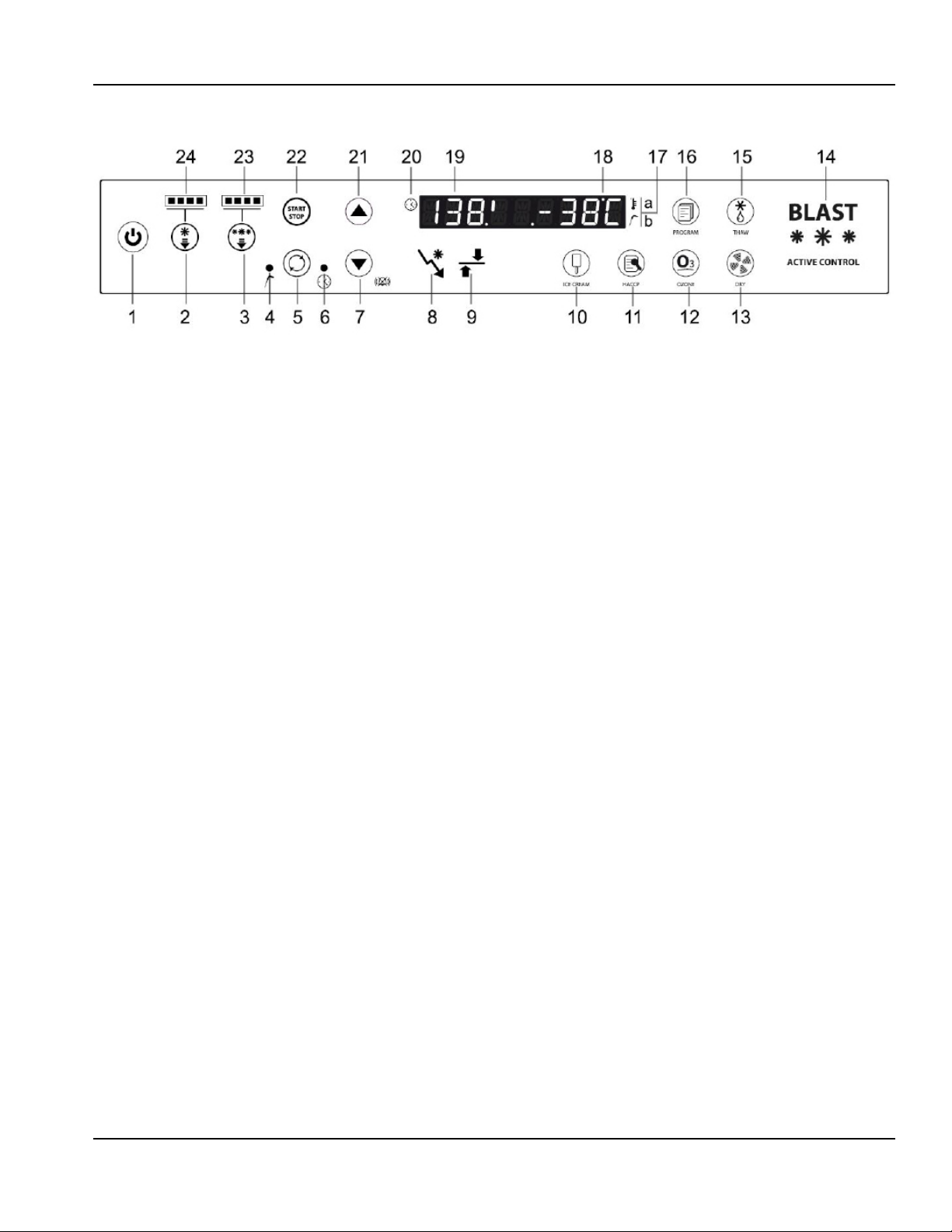

4 COMMAND INTERFACE SYMBOLS

1 - Stand-by button - Standby button, if pressed for more

than 3 seconds it takes the card into standby or switches

it on again.

2 - Positive chilling button - Used to select the mode of

positive chilling.

3 - Negative chilling button - Used to select the mode of

negative chilling.

4 - Chill. LED Temperature - LED on means that the chilling

is via tempurature mode (insert probe)

5 - Chilling mode button - A button that selects the mode

of chilling with Time or Temperature (insert prode use);

the selected mode is represented by ignition of one of the

two LEDs located on the right and left of the button and

the are marked with the temperature or time symbol.

6 - Chill. LED Time - LED on means that the chilling is via

Time mode

7 - Decrease button - Parameter or setting value decrease

buttons (the “-” button allows silencing of the beeper if

active.)

8 - Chilling phase LED - Symbol representing the chilling

phase (it flashes when at that phase.)

9 - Storage phase LED - Symbol representing the chilling

phase (it flashes when at that phase.)

10 - Ice-cream button - The ice-cream button which starts

the ice-cream cycle. (see section 12).

11- HACCP button - The HACCP button which starts the

data reversal cycle onto USB.

12 - Ozone button - Button that starts the ozone sanitising

cycle (if any).

13 - Defrost button - Button that when pressed once starts

drying with door oper (see section 9), while if pressed for

at least 3 seconds it starts the hot gas defrost cycle.

14 - Status LED - RGB on mark lettering. The lettering

assumes the following colors depending on the following

relative connected states:

BLUE - Phase of chilling, deep-freezing or storage

ORANGE - Thawing

GREEN/BLUE - Machine on stand by

WHITE - Machine at standstill

RED FLASHING - Serious alarm

FLASHING YELLOW - Non-serious alarm (door opening -

maintenance)

15 - Thawing button - Button that when pressed starts the

defrost cycle

16 - Program button - Programs recall or storage button

17 - Temperature symbol - The symbol lights up when a

cycle is active and the cell temperature (time chilling) or

product temperature (temperature chilling) is detected.

In the second case the product probe is shown with the

highest value. With the cycle in progress press the button

(12) to display in sequence the values of the insert probe

1 and 2 and the evaporator sensor probe in flashing mode

and the display (19) will show the letters in sequence SP1+

“probe value”, SP2+”probe value” and SE+”value”.

18 - Display temperature - Second part of the alphanumeric

desplay (last 4 digits) for representation of the T° cell or T°

product and evaporater value.

19 - Display time - First part of the alphanumeric display

(first 4 digits) for representation of the time value

remaining of chilling.

20 - Time symbol - The symbol lights up when the cycle

is running; the time remaining will be displayed. If the

button (5) is pressed the elapsed time will flash for 5

seconds (both for Time and Temperature chilling).

21 - Increase button - Parameter or setting value increase

buttons.

22 - Cycles start/stop button - start/stop the chilling cycle

set; with a cycle started, the button remains lit.

23 - Negative chilling LED - The number of LEDs lit indicates

the intensity of the negative chilling.

24 - Positive chilling LED - The number of LEDs lit indicates

the intensity of the positive chilling.

Part Number: 9294045 07/19 11

Page 12

Technical Information Section 2

5 MACHINE ON/OFF

When the equipment is powered, it will appear in

STANDBY conditions (scrolling text on the display). To start

the machine press the button (1) for at least 3”. Similar to

machine without cycles in progress, to switch it off simply

press the button (1) for at least 3”.

Where a cycle was in progress, and the situation is returning

from a blackout the appliance, once reconnected, will

resume from the interrupted cycle.

5.1 - Compressor preheating management

Upon ignition of the equipment a compressor preheating

time of 120 minutes must be respected where the blast

chiller is not available.

The scrolling text will appear “Compressor HeatingRiscaldamento Compressore” and then the fixed lettering

“XXX min” to represent the time remaining. These two

messages will alternate until the end of heating. This phase

can be bypassed by pressing the “HACCP” (11) button for

approximately 5 seconds.

6 DATE AND TIME SETTING

Upon initial ignition, it is advisable to check the date and

time set; their accuracy is beneficial in relation to HACCP

management.

To access the clock setting, press for more than 5 seconds

the Temperature/Time button (5) with the machine in

Stop mode. The laels shown below will appear on the left

display; the right display will show the 2-digit numeric

value to be set:

Hour(Ora) / Minute(Minuti) / Day(Giorno) / Month(Mese) /

Year(Anno)

The Temperature/Time button (5) can be used to scroll

through the labels, while with the +/- buttons (21/7) it is

possible to change the values.

After the year value the change will be automatically

saved.

7 BLAST CHILLING CYCLES

7.1 - General operating principles

Pre-cooling of the machine should always be performed

upon initial running of a blast chilling or deep freezing

operation. This optimises the subsequent work cycle,

reducing the time.

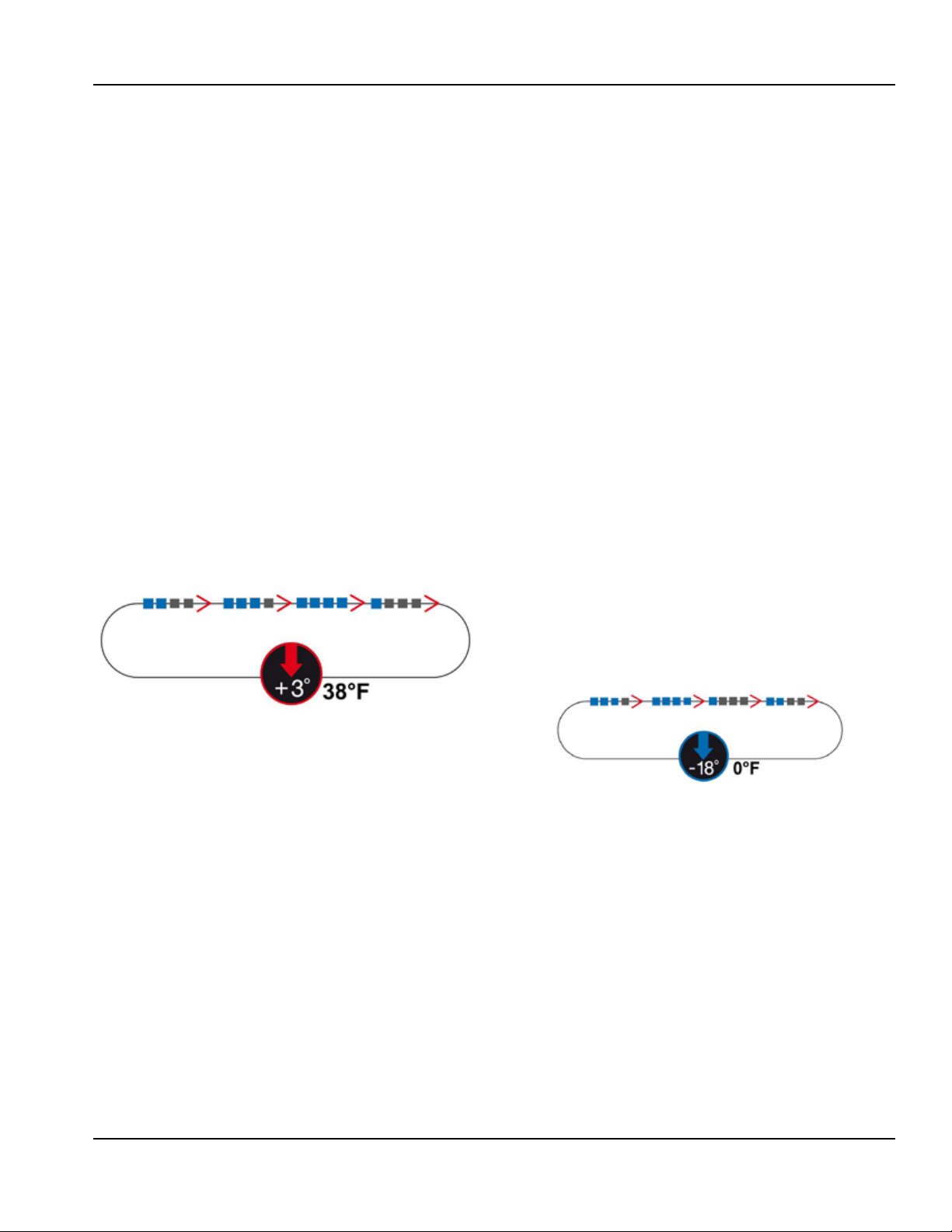

Blast chillers are refrigeration systems that work with a twophase cycle:

• Chilling phase (limited duration)

• Storage phase (unlimited period)

The chilling phase starts upon pressing of the “Start/Stop”

button (22) and continues until the end of the chilling

phase that is used to achieve the time set (Time chilling) or

for reaching of the product temperature set (Temperature

chilling); changing to the unlimited duration storage cycle

takes place automatically (except for the the HARD+HARD

negative chilling cycle). It is possible to stop the chilling

or storage at any time by pressing the “Start/Stop” button

(22).

Chilling time

During this type of chilling, the display (18) shows the cell

probe temperature while the other display (19) shows the

time remaining at the end of the chilling phase. The Time

chilling LED (6) is lit as is the time symbol (20).

Temperature chilling

If Temperature chilling is selected, at the start of a cycle a

check is performed of the correct insertion of the product

probe (if enabled). If the test provides a negative result

an alert appears on the display “SONDA NON INSERITA PROBE NOT INSERT” and the beeper sounds for 60 seconds

(parameter c9); that symbol disappears when the beeper

is silenced by pressing the button (7). If instead the button

is pressed again (5) switching to Temperature cycle, the

cycle continues based on the data read by the product

probe. If nothing is pressed, the temperature cycle

automatically switches into a Time cycle for the remaining

duration of the countdown.

During this type of chilling, a display (18) will show the

temperature of the probe (the highest value of the two)

and the other (19) will show a countdown. The countdown

only starts when the insert temperature is less than 149°F

(65°C). The temperature chilling LED (4) is on as is the

probe insert symbol (17).

Chilling and strorage status symbols

During chilling the LED that lights the sybol will be lit and

flashing. Upon completion of chilling, this LED flashes

alternately with the LED located beneath the storage

symbol (8) while the beeper sounds for 60 sec, and the

scrolling text appears “End Cycle - Fine Ciclo”. After this

time, the chilling LED (9) switches off, the storage one

starts flashing (8) and the scrolling text disappears (even

when the beeper silencer button (7) is pressed.

The LED (8) will flash when the compresser is on while if

the set value has been reached, they will only remain lit

until transition to storage. Similarly with storage, the LED

(9) will flash when the compressor is active and will remain

lit for the rest of the storage.

12 Part Number: 9294045 07/19

Page 13

Section 2 Technical Information

7.2 - Chilling phases

Pressing the positive chilling button (2) or negative

chilling button (3) allows selection of a different chilling

mode. The number of LEDs lit (23) or (24) define the

“intensity” of chilling. The “Time” or “Temperature” chilling

mode will be set by pressing the button (5). Lighting up of

the corresponding LEDs on the sides will define the type

of chilling.

Each time the positive chilling button (2) is pressed the

display will show successively for 3 seconds one of the

following cycles:

LIGHT, SOFT, MEDIUM, FAST.

Each time the negative chilling button (3) is pressed the

display will show successively for 3 seconds one of the

following cycles:

LIGHT, SOFT, HARD, RUN.

7.3 - Selecting and starting the positive chilling cycle

When the button (2) is pressed for the first time, “SOFT”

mode will be selected, represented with lighting up of

two of the four LEDs (24); subsequent pressing takes to 3

and 4 LEDs lit and results in the “HARD” mode. Successive

pressing reduces from 4 to 1 the LEDs lit and so on.

cooling in the presence of products that are resistant and

very hot initially.

Once the MEDIUM or FAST cycles are started, to modify the

HARD phase duration simply press the button (2) that will

show on the display (19) the words “Hard” and will result

in flashing on the display (18) the value in minutes of the

HARD phase. With the +/- buttons it is possible to increase

or decrease the value and confirm with the button (2) or

wait 5 seconds (N.B. THE CHANGED VALUE ONLY APPLIES

TO THE CYCLE IN PROGRESS).

Once the cycle is selected, it is necessary to select the Time

or Temperature mode by pressing the button (5) until

coming on of the relevant LED.

At this point to start the cycle press the START/STOP

button (22).

In the even of Temperature chilling, it is possible to

change this chilling end value by pressing the button (2)

or (3) depending on the type of chilling in process. Having

pressed the button, the display (18) will appear the value

of the end chilling temperature set, which can be modified

within the envisaged range. Having pressed the button (2)

or (3) or after 5 seconds the changed value is saved.

7.4 - Selection and starting the Negative chilling cycle

“LIGHT” - 1 LED only on

In this condition, there will be a cell temperature set of

27F (-3C). This avoids the risk of ice formation during the

positive chilling phase and it will be used for loads which

can be damaged by excessively heavy treatment.

“SOFT” - 2 LEDs on (default)

In this condition, there will be a cell temperature set of 23F

(-5C). This set will allow quicker chilling for products that

in any case are fairly resistant to the freezing process.

“MEDIUM” - 3 LEDs on

In this condition, there will be an initial cell temperature

set of -4F (-20C); after the HARD time, this will be taked to

a cell temperature of 24F (-3C). This method accelerates

cooling in the presence of products that are resistant and

very hot initially.

“FAST” - 4 LEDs on

In this condition, there will be an initial cell temperature

set of -4F (-20C), after the HARD time, this will be taken to

a cell temperature of 23F (-5C). This method accelerates

Pressing the button (3) for the first time will select the

“HARD” mode, represented by coming on of three of the

four LEDs (23) present. Subsequent pressing will take to

4 the LEDs lit and will return into “RUN+HARD” mode.

Successive presses reduce from 4 to 1 the LEDs and so on.

“LIGHT” - 1 LED only on

In this condition, there will be a cell temperature set of

23F (-5C); after the SOFT time defined by the parameter

(ts) this will move to a temperature of -22F (-30C). This

mode is for use on large pieces where it is important to

homogenise the chilling cycle.

“SOFT” - 2 LEDs on

In this condition, there will be a cell temperature set of

-4F (-20C); after the SOFT time defined by the parameter

(ts) this will move to a temperature of -22F (-30C). This

mode is for use on large pieces where it is important to

homogenise the chilling cycle.

In the case of SOFT or LIGHT temperature chilling, the

set change will be decided by the product temperature

detected according to the parameter (C2).

Part Number: 9294045 07/19 13

Page 14

Technical Information Section 2

Once the cycle to change the duration of the SOFT phase

is started (never greater than the parameter C4) simply

press the button (3) which will show on the display (19)

the wording “Soft” and on the display (18) the value in

minutes of the SOFT phase. With the +/- buttons, it is

possible to increase or decrease this value and confirm it

with the button (3) or wait 5 seconds (N.B. THE CHANGED

VALUE ONLY APPLIES TO THE CYCLE IN PROGRESS).

In the case of temperature chilling, the set changes will

be decided by the product temperature detected (see

paramerer cd).

“HARD” -3 LEDs on (Default)

In this condition and in the absence of adjustments 0.10V

of the compressor, there will be a set cell temperature of

-40°F (-40°C). This set accelerates the freezing process in

the presence of products that do not require particular

preperation.

“RUN” -4 LEDs on flashing

In this condition and in the absence of adjustments 0.10V

of the compressor, there will be a set cell temperature of

-40°F (-40°C). This set accelerates the freezing process in

the presence of products that do not require particular

preperation. In this case then the deep-freezing cycle will

be continuous without moving into storage. The move

to storage will be performed by pressing the button (3)

and reducing the LEDs from 4 to 3. That process should

be used in continous insertion and extraction condition

produced by the blast chiller.

During negative chilling, the compressor stops when the

air temperature reaches the planned set point. In this

cycle there will NOT BE automatic defrosting.

- Probes value reading

With the cycle in progress, pressing the button (12) will

chow in sequence, after the cell probe value, the values

of the insert probe 1 and 2 and the evaperator probe in

flashing mode on the display (18) while on the display (19)

will appear the wording in sequence of SP1, SP2 and SE

that represent the type of probe being displayed.

7.5 - Storage phase

Storage always takes over and automatically after every

chilling event (apart from the negative RUN+HARD

exception) and keeps the product at the storage

temperature of 35.6°F (2°C) or -13°F (-25°C), depending on

the typre of chilling.

These values will be editable in all cases by pressing

the button (2) or (3). It is possible to change during the

storage phase the temperature set which appears flashing

on the display (18), while on the display (19) the wording

SET appears. To adjust the value (within 6 seconds) press

the buttons +/-.

8 DEFROST MODE

“Gas-hot” or “air” defrosting takes place:

- in automatic mode only during the storage phase and

with a default time of 8 hours that is editable - or -

- manually both with machine in storage and with machine

in STOP (not during chilling) by pressing the defrost

button (13). All defrosting in progress can be interupted

by pressing the defrost button.

Duration of the defrost cycle is given by reaching the

defrost end temp measured by the evaporator probe;

there is in any case a maximum length for defrost after

which defrosting ends automatically.

Whenever possible, namely during the cycles of chilling,

of ice-cream hardening, of storage, defrosting in storage

and defrosting at machine standstill, it is possible to view

the evaporator probe temperature by pressing the button

(12): the display will show fo r5 seconds the wording “S.EV

+ valore”.

Manual defrosts cannot be activated in the event that

the value of the evaporator probe is higher than a certain

temperature value, in which case a series of beeps will be

emitted to alert the user to the fact that it is not possible

to defrost and the wording “NoDefrost” will appear for 5

seconds.

9 DRYING WITH MACHINE AT STANDSTILL

When the machine is stopped by pressing the button (13)

for more than 3 seconds, ventilation will be activated for

a maximum time of 20 minutes (either with door open

or closed). During this function the LED flashes and the

display shows the scrolling text “Air Defrost”. To exit from

this function press (short press) the defrost button (13).

This mode is used when the machine is at a standstill for

air defrost or to dry the machine after cleaning.

10 DOOR OPENING

When the machine is running (chilling, storage, defrost),

the door is opened, the display shows the scrolling text

“DOOR OPEN” every 5 seconds, alternating with the value

read, and the beeper emits beeps.

When closing the door, the fan starts without delays.

If the machine is running the door remains open for

more than 5 minutes, the fan does NOT start again. The

compressor is also locked and the open door alarm is

given. Door reclosing, resetting of the audible alarm,

visual and alarm relay.

If the door is opened while the machine is in “stop” the

beeper does not sound but the appearance of the wording

DOOR OPEN continues.

14 Part Number: 9294045 07/19

Page 15

Section 2 Technical Information

11 OZONATOR

This function is only available when the machine is

stopped and is activated by pressing the ozonation

button (12) (the LED of the button comes on) . The ozone

is released for 120 minutes after which the release ends

(the LED goes off). At the same time as the Ozonator the

fan is also activated to facilitate movement.

During the sterilisation cycle the word “Ozone” will

flash on the display (18) and the display (19) will show

the countdown of the cycle time. If the door is opened

during the 120 minutes, the sterilisation cycle will stop

IMMEDIATELY; it will not even start upon closing of the

door, and the scrolling text “STOP Ozone Cycle” will appear

for 5 seconds. If the ozonator is not installed the scrolling

text “Ozone Not Present - Ozone non presente” will appear

on the display for 10 seconds.

12 ICECREAM CYCLE

This cycle enables the user to use the chiller in negative

chiller mode with a Timer that schedules the introduction

and extraction of ice-cream containers, allowing the

surfaces to harden, after leaving the ice-cream making

machine.

With the machine in stop mode, press the “ice-cream”

button (10); the beeper will emit a beep and the LED of

the button will start to flash. The negative chilling cycle

will start immediately (to cool the machine), the display

(19) of the time will show the flashing cycle time while

the display (18) will indecate the tempetature of the cell

probe.

The user has the option,n at this point, to modify the time

of the hardening cycle by pressing the “+” and “-”, and to

confirm the time by pressing the “ice-cream” button (10).

After this setting when the user opens the door (to

introduce the ice-cream) and then reclose it, a beep is

emitted as comfirmation and the countdown will start.

When the time reaches zero, the beeper will sound for

60 seconds, and the sliding text “carica gelato - charge

ice cream” will appear. Then whenever the door is closed,

any countdown in progress is interrupted and a new one

starts.

During the cycle the user may at any time change the time

and the temperature set as default as follows:

1) by pressing the “ice-cream” button (10), with the first

time press the time on the display (19) will flash and it can

be changed with the +/- buttons.

2) the next press of the button (10) will acquire the new

value.

3) now using the buttons +/- it is possible to chance the

flashing set represented on the display (18) with a value

that can range from the minimum value to a maximum

one (this theoretically allows setting of the long softening

cycles for ice-cream which, extracted from the storage

machine, must be placed on display.)

4) pressing the button (10) allows saving of the new value

followed by the return to the cycle.

The user can stop this cycle at ay time by pressing the

START/STOP button (22).

13 THAWING CYCLE

This function aims to safely thaw (below 50°F (10°C)

of temperature cell) previously frozen or deep-frozen

products. The process is based both on cell temperature

control, with a positive value between 38°F (3°C) and 50°F

(10°C) average, and on the action of forced ventilation.

When the machine is stopped, select the thawing cycle by

pressing the button (15); the cycle will start immediately

showing on the “display 19” the standard thawing time

and on “display 18” the measured cell temperature.

To change the values of time and temperature set, simply

press the button (15) until the display flashes which

will present the time value set. With the +/- buttons it is

possible to modify the thawing time. With the modification

completed with the +/- buttons it is possible to change

the SET which will be confirmed by pressing the button (5)

or by waiting 5 seconds.

The the temperature set value flashes on the display (8)

which can also be changed with the +/- buttons. With

the modification completed with the +/- buttons (6) it is

possible to change the SET by pressing the button (3) or

by waiting 5 seconds.

Then on the display, if VE2 is different from 100, the

wording “HARD FANS” will be represented (if fan

regulation is enabled). To confirm press the button (5),

while to change press the +/- buttons until appearance

of the second option “SOFT FANS” (reduced evaporator

fan speed); pressing the button (5) the value selected is

confirmed.

After this operation, the cycle in fuction is resumed which

when finished will activate the beeper and the scrolling

text “End Cycle - Fine Ciclo” will appear. At that time the

cycle will go into storage.

To see the value of the insert probe during thawing, simply

press the button (12) which will display the product probe

value for 5 seconds flashing on the display (18) and the

wording “SP1” and “SP2” is shown on the display (19) to

distinguish the probe reading.

Part Number: 9294045 07/19 15

Page 16

Technical Information Section 2

14 CHILLING PROGRAM STORAGE

The user has the button (16), which allows the saving or

recalling of 99 chilling cycles.

To store a chilling cycle the user must:

1) set a chilling type (button 1 - 2)

2) set the mode of chilling (by temperature or by time,

button (5))

3) set the total time or the final temperature +/- buttons.

4) press and hold (long press) the “PROGRAM” button

(16) until the beeper emits a beep; the LED of the button

starts to flash. On the basis of the first display it will flash

signifying waiting for setting of the first letter/number.

5) then using the keys +/- set the first letter/number and

confirm with the button (5). This will confirm the value,

passing on to the next one. Arriving at the ninth character

or even before, it is possible to press the START button for

start and storage (ATTENTION, if a program with the same

name already exists, it will be overwritten.)

6) press START/STP (22)

With Start the software stores the “type” and “mode” of the

chilling selected.

To discontinue saving of the program, press the storage

button again or wait for the TimeOut (approximately 10

seconds). If time chilling has been set, the duration set is

stored.

In the case of temperature chilling, it will store the

time in which the insert probe reaches the PRODUCT

TEMPERATURE SET, and will store this time as durtion of

chilling.

In addition, if the chilling is Positive Hard, it also saves the

time necessary to reach the core at 68°F (20°C) (Hard).

When saving a temperature (insert probe) chilling cycle,

the LED of the programming button flashes to indicate

that storage of the times is in progress. As soon as the

temperature chiling cycle ends, the LED stops flashing to

indicate that storage has been successful.

If storing a temperature cycle, this stops (due to alarms,

button stop, etc.), the cycle times are not saved. The initial

settings however remain saved.

15 CHILLING PROGRAM EXECUTION

To call up and run a memory-resident program, the user

must:

1) press the “PROG” button (short press), the LED lights up

and with the +/- buttons, select one of the saved programs.

2) press START

If the save button is pressed by accident, pressing it again

will exit that function.

While a program is running, by pressing the “PROG” button

the display shows the name of the program in progress.

16 ALARMS

Summerized here are the main alarms that can appear

and that will be represented by the scrolling text on the

display:

16.1 - Evaporator probe alarm

Cause: being outside the operation range (-58°F (-50°C) /

212°F (100°C)) for more than 30 seconds.

Effect: Interruption of any defrosting in progress. Inhibition

of all periodic defrosting. Inhibition of manual defrosting

(except forcing of fans with machine at standstill).

Beeper: The beeper sounds (3 seconds then pauses for 30

seconds) until the silencer button is pressed.

Display: The display shows the scrolling text “AL01 SONDA EVAPORATORE DIFETTOSA - FAULT EVAPORATOR

PROBE”. Flashing RED symbol (14).

Reset: It resets by itself if the value of the probe falls

(approximately 20 seconds), or if the probe is excluded

with parameter “/5”.

16.2 - Product probe alarm

Cause: being outside the operation range (-58°F (-50°C)

/ 212°F (100°C)) for more than 30 seconds with a

temperature chilling cycle in progress.

Effect: Interruption of the temperature chilling cycle in

progress resulting in automatic start of Time chilling.

Inhibition of all periodic defrosting. Inhibition of

temperature chilling button.

Beeper: The beeper sounds (3 seconds then pauses for 30

seconds) until the silencer button is pressed.

Display: The display shows the scrolling text “AL02 SONDA PRODOTTO 1(2) DIFETTOSA - FAULT PRODUCT

PROBE 1(2)”. Flashing RED symbol (14).

Reset: Press the alarm silencer button (with beeper off)

or exclede with parameter “/9” (temperature chilling

disabled).

16.3 - Cell probe alarm

Cause: being outside the operation range (-58°F (-50°C) /

212°F (100°C)) for more than 30 seconds.

Effect: If START is given to a positive chilling (both with Time

and Temperature) or if the latter is already in progress, it

immediately goes into pause-work positive storage mode

(C5 and C6 parameters0

If START is given to a negative chilling (both with Time

16 Part Number: 9294045 07/19

Page 17

Section 2 Technical Information

and Temperature) or if the latter is already in progress, it

continues (as it is not conditioned by the cell temperature

until passing into negative storage which will be in pausework mode (C5 and C7 parameters)). If the event takes

over during storage, this continues in pause-work mode.

Beeper: The beeper sounds (3 seconds then pauses for 30

seconds) until the silencer button is pressed.

Display: The display shows the scrolling text “AL03 SONDA CELLA DIFETTOSA - FAULT ROOM PROBE”. Flashing

RED symbol (14).

Reset: It resets by itself if the value of the probe is activated.

NOTE: With cell probe anomaly it is in any case possible

to perform RUN+HARD chilling (compressor goes into

continuous mode).

16.4 - Door micro-switch alarm

Cause: Active input for more that 5 minutes (uF parameter)

with maching in start.

Effect: The blast chiller behaves as described in the section

“7 Door Opening 7”.

Beeper: The beeper sounds (3 seconds and then pauses

for 30 seconds) until the silencer button is pressed.

Display: The display shows the scrolling text “PORTA

APERTA - DOOR OPEN”. The symbol (14) flashes YELLOW.

Reset: Press the alarm silencer button (with beeper off), or

it resets by itself if the input status is activated.

16.5 - Alarm - Differential Thermal Breaker - Oil Pressure

Cause: When the input alarm is activated for more than 5

seconds.

Effect: It places the machine in STOP. Inhibition of all

the buttons except that of silence/reset, entering the

parameter menu and ON/OFF

Beeper: The beeper sounds (3 seconds and then pauses

for 30 seconds) until the silencer button is pressed.

Display/LED: The display shows the scrolling text “AL06 MAGNETOTERMICO-PRESS. OLIO - BREAKER - OIL PRESS”.

Flashing RED symbol (14).

Reset: Pressing the off beeper alarm silencer button and

alarm cause disappearance.

16.6 - Automatic reset minimum pressure switch alarm

Cause: When the machine is in start the alarm input is

activated for more than 5 seconds (with machine in STOP it

is not activated). The alarm is inhibited for approximately 2

minutes with each compressor start. The alarm is inhibited

during “pump downs”.

Effect: It places the machine in STOP. Inhibition of the

Start/Stop and Defrost buttons.

Beeper: The beeper sounds (3 seconds and then pauses

for 30 seconds) until the silencer button is pressed.

Display/LED: The display shows the scrolling text “AL07

- PRESSIONE MINIMA - MIN. PRESSURE”. Flashing RED

symbol (14).

Reset: Pressing the off beeper alarm silencer button or

switching off and switching on the card again (stand-by).

16.7 - Automatic reset Kriwan Alarm

Cause: When the input is activated with machine in start

for more than 5 seconds, at least 3 times in the same cycle.

Effect: Each time only the compressor stops and starts up

again when the input is activated. Upon the third time the

machine is placed in STOP.

Beeper: The beeper sounds (3 seconds and then pauses

for 30 seconds) until the silencer button is pressed.

Display/LED: If the Kriwan alarm is activated, for the two

times only the word “Kriwan” appears, alternatinf with

the Temperature and Time values represented, without

locking the machine but only the compressor. Upon the

third time the scrolling text “AL08 - KRIWAN COMPRESSORE

- COMPRESSOR KRIWAN” will appear. Flashing RED symbol

(14).

Reset: Pressing the off beeper alarm silencer button or

switching off and switching on the card again (stand-by).

16.8 - Input alarm HT1 - fusable

Cause: When the alarm is activated for more than 5

seconds.

Effect: Electrical disconnection of certain components

downstream of the fuse.

Beeper: The beeper sounds (3 seconds and then pauses

for 30 seconds) until the silencer button is pressed.

Display/LED: The display shows the scrolling text “AL09 CAMBIA FUSIBLE - REPLACE FUSE”. Flashing RED symbol

(14).

Reset: It resets itself when the status of the input is

activated.

16.9 - Overtemperature alarm

Cause: The overtemperature alarm is activated (only

during the storage) when the cell probe detects a certain

temperature value time greater than the sum of the positive

or negative storage set with the relevant alarm delta

(parameter A2 or parameter A4). The overtemperature

alarm is in any case disabled for a certain length of time

(parameter 5) from the start of the storage phase and after

a defrost. This alarmis not activated/managed if the cell

probe is in alarm.

Effect: Storing of the alarm is the HACCP memory together

Part Number: 9294045 07/19 17

Page 18

Technical Information Section 2

with tthe date and time.

beeper: The beeper sounds (3 seconds and the pauses for

30 seconds) until the silencer button is pressed.

Display/LED: The display shows the scrolling text “AL11 SOVRATEMPERATURA - OVER TEMPERATURE”. The symbol

(14) flashes YELLOW.

Reset: Pressing the off beeper alarm silencer button or

switching off and switching on the card again (stand-by).

16.10 - Black-Out Alarm

Cause: It is activated when a cycle in progress is interrupted

by a blackout, and when the duration of the blackout is

greater than the time defined by the parameter “uL”.

Effect: Storing of the alarm in the HACCP memory together

with the date and time. The machine restarts the cycle set,

in the case of chilling time from the total time.

Beeper: The beeper sounds (3 seconds and then pauses

for 30 seconds) until the silencer button is pressed.

Display/LED: The display shows the scrolling text “AL12

- BLACKOUT DURATA 00h 00’ - DURATION BLACKOUT

00h00’“. The symbol (14) lights up flashing YELLOW (21).

Reset: Press the alarm silencer beeper off button.

16.11 - Compressor preventative maintenance alarm

Cause: When the operating hours of the compressor are

an interger multiple of the hours set (if alarm activated).

Effect: none

Beeper: The beeper sounds (3 seconds and then pauses

for 30 seconds) until the silencer button is pressed.

Display/LED: The display shows the scrolling text “SERVICE

+ TEL . 00000000000000” (see parameter TEL). Alternating

with the time and temperature values represented. The

symbol (14) flashes YELLOW.

Reset: Press the alarm silencer beeper oof button.

16.12 - Temperature not reached in the time set alarm

Cause: When temperature chilling lasts longer than the

times for Time out (parameter c1 or c4).

Effect: Signalling with flashing time or temperature

display and beeper sound; press the “-” button (7) to stop

the signals.

Beeper: The beeper sounds (3 seconds and then pauses

for 30 seconds) until the silencer button is pressed.

Reset: Press the alarm silencer beeper off button.

16.13 - Power keypad-card connection alarm

Cause: when there is no connection between the interface

and the power card.

Effect: All the buttons are disabled. All the relays are

deactivated. All the inputs are ignored. The LED comes on

correponding to the button that was pressed.

Beeper: the beeper sounds (3 seconds and then pauses for

30 seconds) indefinitely.

Display/LED: The display (with scrolling text “AL15 CONNESSIONE TASTIERA - KEYBOARD CONNECTION”.

Flashing RED symbol (14).

Reset: Removing and restoring the power supply to the

card.

NOTE: As long as this warning persists, the chiller is

unusable.

16.14 - Maximum pressure switch alarm

Cause: When the alarm is activated for more than 5

seconds. Or in the presence of maximum pressure gauge

if the maximum pressure value defined by the parameter

“uH” is exceeded.

Effect: The machine goes into STOP inhibition of all

the buttons except that of silence/reset, entering the

parameter menu and ON/OFF.

Beeper: The beeper sounds (3 seconds and then pauses

for 30 seconds) until the silencer button is pressed.

Display/LED: The display shows the scrolling text “AL 16 PRESS. MASSIMA - MAX PRESS.” Flashing RED symbol (14).

Reset: Press the alarm silencer button (7) in the condition

of the beeper off and alarm cause disappeared.

NOTE: In the case of multiple simultaneous alarms, all the

active alarms will be displayed alternately.

NOTE: When the beeper sounds the user can silence it

with the silencer button (7), by repressing the button (7).

If the conditions no loner persist, the alarm can be reset.

17 HACCP ALARM MEMORIES RESET

With the appliance in the standby mode press the HACCP

button (11) for at least 5 seconds; the display will show

the scrolling text “OFF RESET”. Use the +/- keys (6) to show

“ON RESET” and then confirm the alarms cancellation

by pressing the HACCP button (11). The card goes back

automatically to standby.

18 HACCP DATA READING

For HACCP management there will be three types of

alarms recorded:

- overtemperature alarm (only active in storage mode)

- black-out alarm

- the alarm of chilling/deep-freezing that is overly long

that will only be recorded in the cycles file that can be

downloaded using the USB key.

18 Part Number: 9294045 07/19

Page 19

Section 2 Technical Information

NOTE: Of these alarms the last 20 alarms are stored.

To view this history press (long press) the HACCP button

(11) with the machine in STOP. To scroll through the

alarms on the display, press the + and - buttons as if they

were the UP/DOWN buttons; to exit press the HACCP

button (11) again or the standby button (1).

Here is an example of what will appear in succession, by

pressing the down button (7):

1) the scrolling display “Alarm 1” + “Sovratemperatura Overtemperature” or “black-out”

2) scrolling “Data Inizio - Start Date” -- “1/02/15”

3) scrolling “Ora Inizio - Start Hours” -- “01:23”

4) scrolling “Data Fine - End Date” -- “2/02/15”

5) scrolling “Ora Fine - End Hours” -- “01:37”

19 HACCP DATA EXPORT WITH USB

There now follows a description on how to record data

and to extract in onto a USB stick.

19.1 - Extracted data format

The data that can be exported in txt format are the Alarms

and the Working cycles

Alarms:

Each individual alarm is recorded, with it’s number linked

to the type of alarm, in a dedicated file and marked with

the following nomenclature:

Date - Alarm start time - ALXX.txt

Defrost: THAW

Ice-Cream: GEL

Ozone Cycle: OZN

The cycle start and end conditions will typically be

recorded and any alarms that intervene in the cycle and

sampling of all the sensitive values will be provided.

19.2 - Data downloading with USB

To extract the data with the machine at standstill insert

the USB stick. The card will propose on the display (7)

the scrolling text “Download Giorno - Day”; with the

buttons (6) it will be possible to select the scrolling text

“SETTIMANA-WEEK” or “MESE - MONTH” or “TUTTO - ALL”,

which will select the time range for which to download

the files recorded on the USB stick.

Downloading will be performed as soon as the HACCP

button (16) is pressed. During downloading the segments

that will increase from 1 to 9 will appear on the display to

simulate the download. With downloading finished, for at

least 10 seconds (if no button is pressed), the scrolling text

“FINE DOWNLOAD - END DOWNLOAD” will appear on the

display (7).

Possible saturation of the memory will be resolved by

erasing older files and replacing them with new ones.

The information and instructions in this chapter are

intended for all staff who work on the machine: the user,

the maintainer and unskilled personnel. All cleaning

and maintenance operations must be performed after

disconnection the electricity supply from the system.

For example a high pressure alarm will have:

05_03_2014-12h24-AL16.txt

Inside the .txt file generated should be recorded all the

sizes of digital/analogue I/O; the alarm start and end data

will also be record.

Work Cycles:

Every single work cycle in progress will be recorded with

the following nomenclature:

Date - cycle start time - Cycle type .txt

In the event of positive SOFT chilling we will have:

05_04_2014-13h54-POS2.txt

By cycle type it is meant:

Positive chilling: POS2-POS1-POS3 (depending on the

LEDs lit).

Negative chilling: NEG1-NEG2-NEG3-NEG4 (depending

on the LEDs lit).

Chilling program: PROG no

Part Number: 9294045 07/19 19

Page 20

Maintenence Section3

20 - Ordinary Maintenance

20.1 Operations by the user that do not require the

assistance of a qualified technician

20.1.1 - Cell cleaning

In order to ensure hygiene and protection of the quality

of the food being processed, interal cleaning of the cell

must be performed frequently, depending on the type of

food stored.

Suggested frequency: weekly cleaning.

- The shape of the cell and of the internal components

allow its cleaning using a cloth or sponge.

- Clean with water and non-abrasive neutral detergents.

Rinsing is possible with a cloth or sponge soaked in water

or with a moderate water jet (not exceeding the system

pressure). Do not scrape the surfaces with sharp or

abrasive items.

20.1.2 - Outer casing cleaning

For cleaning of the casing simply use a cloth dampened

with a chlorine-free product, suitable for stainless steel.

20.1.3 - Defrost water drainage

The system was designed for automatic and manual

defrosting when needed.

Check for correct water drainage of the evaporator on

the drop tray (if supplied), avoiding the occurrence of

obstructions of the drainage pipe.

,

20.2 - Operations only for authorised installer

Below are listed the routine maintenance operations

that must only be performed by qualified installation

techinicians. The manufacturer declines all liability

for accidents caused by non-compliance with the

requirement.

Below is a list of operations useful to preserve the efficient

operation of the appliance with related recommended

frequencies.

Detailed maintenance operations are described in the

Service Manual kept by installers and qualified technicials.

20.2.1 - Condenser cleaning

(for air cooled models only)

For the correct and efficient operation of the condenser,

the air cooled condenser must be kept clean to allow the

circulation of air.

Recommended frequency: operation to be performed

every 30 days or in any case according to the working

condintions of the appliance (the presence of dust and

flour in the work environment of the appliance significantly

affects dirt accumulation of the condenser thus making it

less efficient).

20.2.2 - Condenser filter cleaning

(for air cooled models only)

Recommended frequency: operation to be performed

every 30 days or in any case according to the working

condintions of the appliance (the presence of dust and

flour in the work environment of the appliance significantly

affects dirt accumulation of the condenser thus making it

less efficient).

20.2.3 - Evaporator cleaning

For the correct and efficient operation of the appliance,

the evaporator battery must be kept clean to allow free

air circulation and especially to remove food residue and

grease the can be a source of bacteria harmful to human

health.

Suggested frequency: operation to be performed every 30

days or depending on the type of food being processed.

20.2.4 - Ozonator maintenance

Dirty and dusty environments reduce efficiency of the

ozonator: for longer lamp life and for greater efficiency,

the bulb of the ozonator should be cleaned periodically. To

ensure maximum fucntionality the bulb must be replaced

every 12 months.

For the correct maintenance and cleaning practices

comply with the instructions in the service manual.

Suggested frequency: clean the lamp of the ozonator at

least every 3 months.

Replacement of the lamp every 12 months (only genuine

spare parts).

21 TIPS FOR SMOOTH OPERATION

21.1 - Operating instructions

Before operating the machine it is necessary to perform

thorough cleaning inside the cell.

21.2 - Pre-cooling

Before using the machine for the first time or after a period

of disuse. pre-cool the cell by running the machine empty

until it reaches the working temperature set.

To obtain good performance of the machine and to aviod

food alterations, it is advisable to:

• stack the products in order to promote the

20 Part Number: 9294045 07/19

Page 21

Section 3 Maintenence

circulation of cold air in the entire cell;

• avoid prolonged and frequent door openings.

21.3 - Maximum Load capacity for chilling/freezing

cycles

Do not overload the machine beyond what is stated by

the manufacturer.

Blast chilling cycles

Type of Cycle Time of Cycle

Related to Light

Positive Cycle

Model

5T

10T

15T

30T

Light

Positive

700/20 700/20 700/20 700/20 110

1234/35 1234/35 1234/35 1234/35 110

2290/35 2290/35 2290/35 2290/65 125

2470/70 2470/70 2470/70 2470/70 125

Soft

Positive

oz/kg oz/kg oz/kg oz/kg minutes

Medium

Positive

Fast

Positive

Blast freezing cycles

B

C) Place the trays in the inner part of the door, making sure

that theu are as close as possible to the evaporator.

C

Type of Cycle

Time of Cycle

Model

5T

10T

15T

30T

Light

Negative

425/12 425/12 425/12 425/12 240

880/25 880/25 880/25 880/25 240

1760/50 1760/50 1760/50 1760/50 240

1940/55 1940/55 1940/55 1940/55 240

Soft

Negative

oz/kg oz/kg oz/kg oz/kg minutes

Hard

Negative

Run

Negative

21.4 - How to load the machine

A) In order to grant chilling/freezing time ensure that food

to be chilled/frozen in seperated pieces (max thinkness

2”/50mm).

B) Ensure a sufficient distance is maintained between the

trays to allow adequate air circulation.

If the machine is not completely loaded, distribute the

trays and the load over the entire useful height avoiding

concentrations.

A

D) The core probe must be positioned correctly in the

center of the product with the largest cut or piece, making

sure that the tip of the probe does not protrude out or

touch the tray. The probe must be cleaned and sanitised

before each new cycle (work) in order to avoid undesirable

contamination.

D

E) Do not cover the trays and/or container with lids or

insulating films: the more the food is insulated the greater

the time required for chilling and rapid freezing.

Packaging of the trays must be performed when the

product is already frozen, before it is put into storage.

E

Part Number: 9294045 07/19 21

Page 22

Troubleshooting Section 4

T40:

BLast Chiller/Shock

Freezer

22 Part Number: 9294045 07/19

Page 23

Section 4 Troubleshooting

T40: Blast Chiller / Shock Freezer Remote

Condesing Unit

Ambient Operating Limits: -20°F to 120°F

NOTE: The Delfield Blast Chiller/Shock Freezer is wired

independently of the remote condensing unit. No

interconnecting wiring is required between the blast

chiller and the condensing unit. All condensing units have

crankcase heaters. Condensing unit control systems are

provided wired from the factory. Field connection is made

by connection supply power to the compressor contactor.

Delfield Model #: T40CU

Refrigerant 404A

Compressor and Wiring Compressor and Capacity 6HP Compressor

Condensing Unit Wiring 208/230V/60Hz/3ph

Control System High Pressure Switch Set Point: 450 pisg, 380 psig re-set

Low Pressure Switch Set point: 25 psig, Range = 15in to 100psig

Outdoor condensing unit applications require the use

of an optional UL listed hood, Delfield P/N CUHOOD, for

protection from the elements. Water cooled units are not

recommended for outdoor installation. Interconnecting

piping, curbs or other mounting methods and refrigerant

are not included. Installation must be made by a qualified

refrigeration technician. Piping runs of greater than 100

feet require consultation with the factory.

24,150 BTUH @ -32F, 90 amb, 102.2 Cond:

46,730BTUH @ -5F, 90amb 110.3 Cond.

Max Fuse size: 60A

Max Circuit Ampacity: 42.3A

Oil Pressure Differential Switch Sensotronic Oil Pressure Switch

Compressor Reliability Crankcase Heater 65 watts

Flow Control Condensor Capacity control Head Pressure Control Set at 84F, 185psig

Reciever Capacity 55.4lbs @ 90% liquid refrigerant fill (37.5lbs

max refrigerant charge)

Accumulator 500 Cubic Inch capacity

Oil Separator Yes

Oil Filter Yes

Part Number: 9294045 07/19 23

Page 24

Troubleshooting Section 4

T40: Remote Water Cooled

Condesing Unit

Ambient Operating Limits: 50°F to 110°F

NOTE: The Delfield Blast Chiller/Shock Freezer is wired

independently of the remote condensing unit. No

interconnecting wiring is required between the blast

chiller and the condensing unit. All condensing units have

crankcase heaters. Condensing unit control systems are

provided wired from the factory. Field connection is made

by connection supply power to the compressor contactor.

Delfield Model #: T40CU

Refrigerant 404A

Compressor and Wiring Compressor and Capacity 6HP Compressor

Condensing Unit Wiring 208/230V/60Hz/3ph

Control System High Pressure Switch Set Point: 450 pisg, 380 psig re-set

Low Pressure Switch Set point: 25 psig, Range = 15in to 100psig

Oil Pressure Differential Switch Sensotronic Oil Pressure Switch

Outdoor condensing unit applications require the use

of an optional UL listed hood, Delfield P/N CUHOOD, for

protection from the elements. Water cooled units are not

recommended for outdoor installation. Interconnecting

piping, curbs or other mounting methods and refrigerant

are not included. Installation must be made by a qualified

refrigeration technician. Piping runs of greater than 100

feet require consultation with the factory.

24,950 BTUH 4.1 gpm waterflow @ -32F, 90

amb, 102.2 Cond: 18,090 BTUH @ -40F, 85F

inlet water, 105F Condensign.

Max Fuse size: 60A

Max Circuit Ampacity: 42.3A

Compressor Reliability Crankcase Heater 65 watts

Flow Control Condensor Capacity control Head Pressure Control Set at 84F, 185psig

Reciever Capacity 55.4lbs @ 90% liquid refrigerant fill (37.5lbs

max refrigerant charge)

Accumulator 500 Cubic Inch capacity

Oil Separator Yes

Oil Filter Yes

Shipping Weight Condensing Unit 600 Lbs.

Outdoor Hood 100 Lbs.

24 Part Number: 9294045 07/19

Page 25

Section 4 Troubleshooting

T5/T14D Refrigeration System Schematic

Part Number: 9294045 07/19 25

Page 26

Troubleshooting Section 4

T5/T14D Wiring Diagram

26 Part Number: 9294045 07/19

Page 27

Section 4 Troubleshooting

T40 Installation and Assembly

Supplied Equipment List

T40 Base

T40 Control Box

T40 LS Wall Panel

T40 Front Panel

With Door

T40 Back Panel

T40Top Panel

Alignment Blocks

T40RS Wall Panel

T40 Air Deflection

Sheilds

Cam Hole Covers

T40 Remore Condensing Unit

Part Number: 9294045 07/19 27

Cam Lock T-Handle

Page 28

Troubleshooting Section 4

T40 Installation and Assembly

NOTE: Do not break alignment block when placing panels

in place.

The first panel will be the left side of the unit you are

facing the door.

NOTE: Ensure all cam locks are in the open position before

placing any panels.

Make sure the skirt on the vertical panels

covers the outside of the mounting floor.

Lock botton locking cams on

the outside of the first panel.

1. Position cabinet floor on a flat, level serface with the

slotted end facing up

Insert T-Handle wrench

and twist clockwise until a

positive stop is acheived.

The panel will now stand on

its own.

NOTE: Do not lean or push on unsupported

panels.

- Ensure the entryway is facing forward (grey plastic

transition piece.)

- Insert one alignment block to the channel in between

each of the locking cams.

2. Raise the first panel (with the evaporator, fans and air

channel) onto the mounting floor with the fans facing

inside.

- Place bottom of the panel into the alignment channel

on the mounting floor for proper placement, using the

alignment block to align panel.

3. Attach the back panel to the

mounting floor in the same

manner as the first panel. The

back panel will wrap around

both sides.

NOTE: Ensure all cam locks are in

the open position before placing

any panels.

NOTE: Do not break alignment block when placing panels

in place.

Lock the side locking cams on the outside of the first

panel and the left side and bottom locking cams on the

inside of the back panel. Insert T-handle wrench and twist

until a positive stop is achieved.

- Attach deflector shields either side of

the first panel as shown. The deflector

shields with cover the corners on the first

panel and are attached with provided

screws.

28 Part Number: 9294045 07/19