Page 1

LGB

Gas–fired boiler

Control Supplement

Flame Guardian WMBC-1A

RM7895C Controller Electronic Pilot System

IRI

Contents

I. Installation ..................... 2

II. Gas piping ...................... 5

III. Wiring ............................. 5

IV.Startup ......................... 10

V. Sequence of operation 11

VI.Parts list ....................... 12

Indicates presence of hazards that can cause severe personal injury, death or

substantial property damage.

Indicates special instructions on installation, operation or maintenance that

are important but not related to personal injury or property damage.

This Control Supplement must only be used by a qualified installer/service

technician. Read these instructions completely before beginning the

installation. Failure to follow these instructions can cause severe personal

injury, death or substantial property damage.

Part Number 550-141-807/0298

Page 2

LGB

(Series 2) — Control Supplement

I Installation

1. For use with LGB-6 through 12 boilers.

2. LOCAL INSPECTOR MUST CERTIFY BOILER FOR IRI COMPLIANCE.

3. Assemble pilot burner and flame sensor to main burners with pilot brackets. See Figures 2

and 3. Install ground wiring as shown in Figures 2 and 3.

4. Reinstall burner assemblies. See Table 1 for pilot burner and flame sensor locations.

5. Assemble control panel to boiler. See Figure 1.

6. Install gas controls as shown in Figure 4, page 4.

7. IRI installations require manual reset controls. Weil-McLain recommends installing manual

controls in addition to standard as required by local inspector. Refer to the LGB Boiler

Manual, “Boiler Controls” sect ion.

a. Steam boilers require a manual reset Low Water Cutoff and manual reset Pressure Limit

Control.

b. Water boilers require a manual reset Low Water Cutoff and manual reset Temperature

Limit Control.

Table 1

Pilot burner and flame sensor

locations

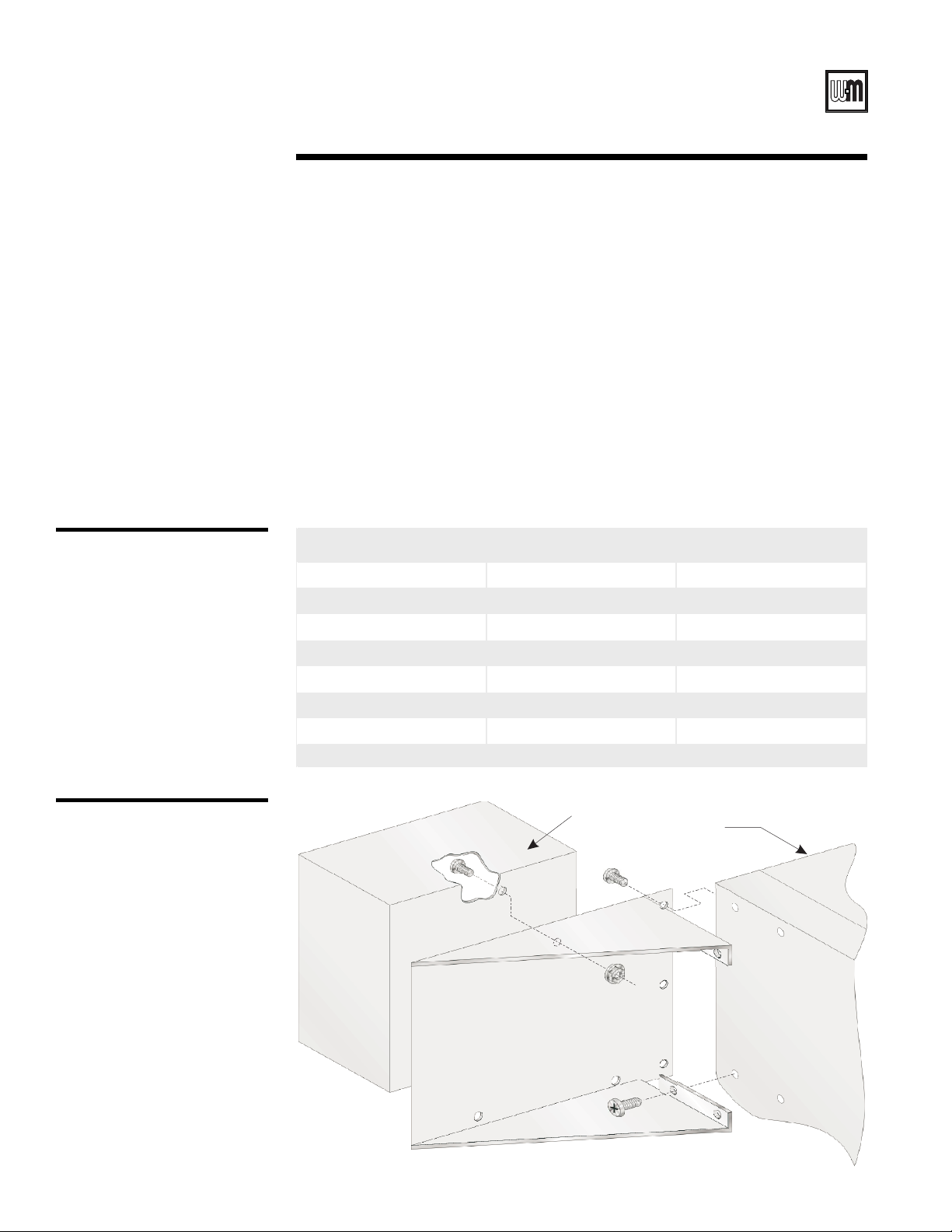

Figure 1

Mount control panel to jacket

as shown

Boiler Model Flame Sensor * Pilot Burner *

LGB-6 29

LGB-7 211

LGB-8 213

LGB-9 215

LGB-10 216

LGB-11 216

LGB-12 216

* From left burner.

Panel

Front of

Boiler

Drill (3) Holes in Front

Drill (7) 1/8“

Drill (7) 1/8“

Holes In Jacket

Holes In Jacket

to Mount

to Mount

Bracket

Bracket

Drill (4) Holes in SideDrill (4) Holes in Side

Part Number 550-141-807/02982

55BGL

Page 3

Flame Guardian WMBC-1A Electronic Pilot System – IRI

I Installation – continued

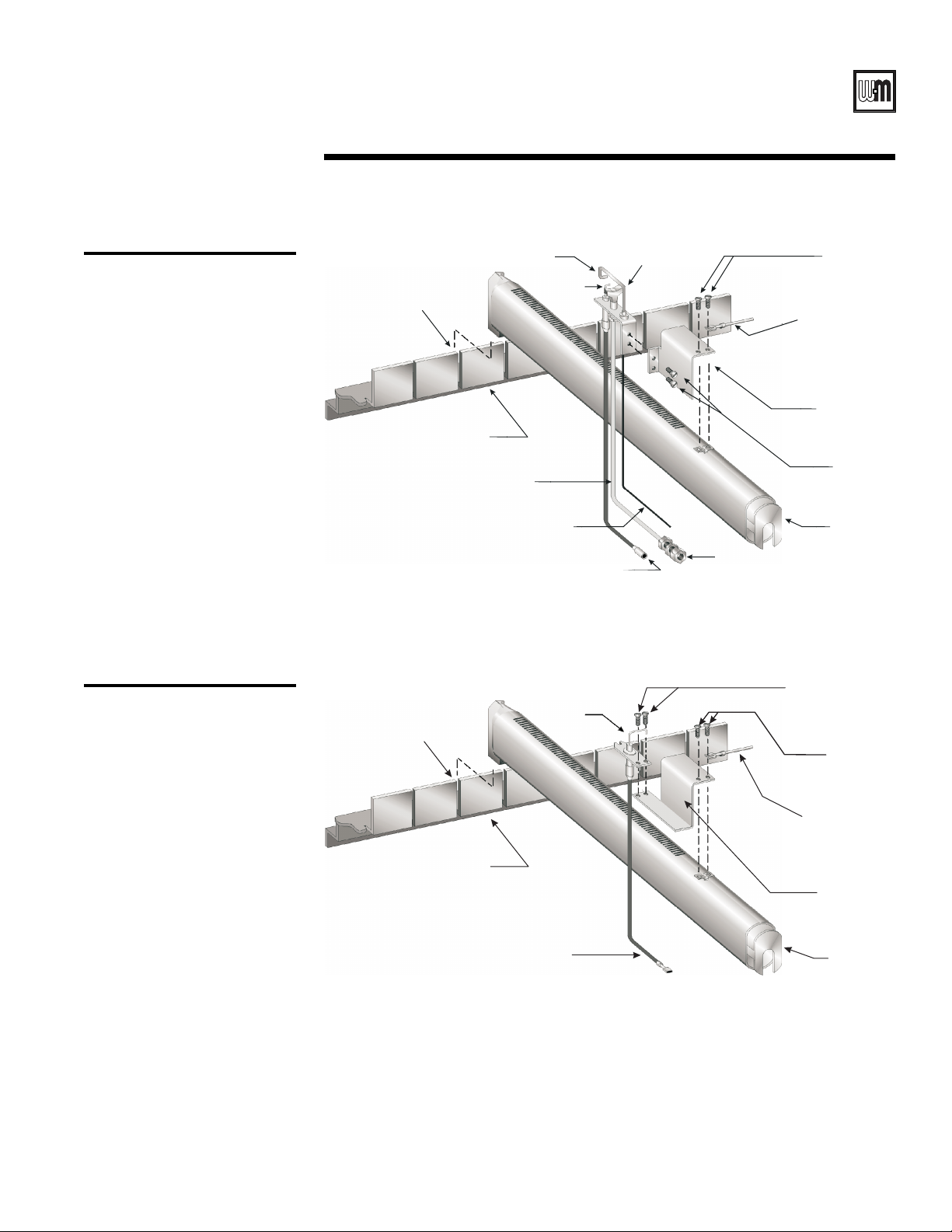

Figure 2

Q179 pilot burner assembly

Figure 3

Main flame sensor assembly

LGB-A56

Locating Slot

Burner Support Bar

Pilot Line Tubing

Locating Slot

Sensor

Igniter

Sensor Lead

Flame

Sensor

Igniter Lead

Q179 Pilot

Burner

Compression

Union

10-32 x 5/16“

Machine Screws(2)

Ground Leadwire:

Connect to WMBC

Panel Terminal G2

(Ground Terminal)

Pilot Mounting

Bracket

10-32 x 1/4“

Machine Screws (2)

Main Burner

(with Pilot

Mounting

Bracket)

6-32 x 5/16“ Type ”F”

Self Tapping Screws(2)

10-32 x 5/16“

Machine Screws(2)

Ground Leadwire:

Connect to Main Flame

Proving Module

24 V (GND) terminal

Burner Support Bar

Flame Sensor

Mounting Bracket

Sensor Lead

LGB-A85

Main Burner

(with Pilot

Mounting

Bracket)

Part Number 550-141-807/0298 3

Page 4

LGB

(Series 2) — Control Supplement

I Installation – continued

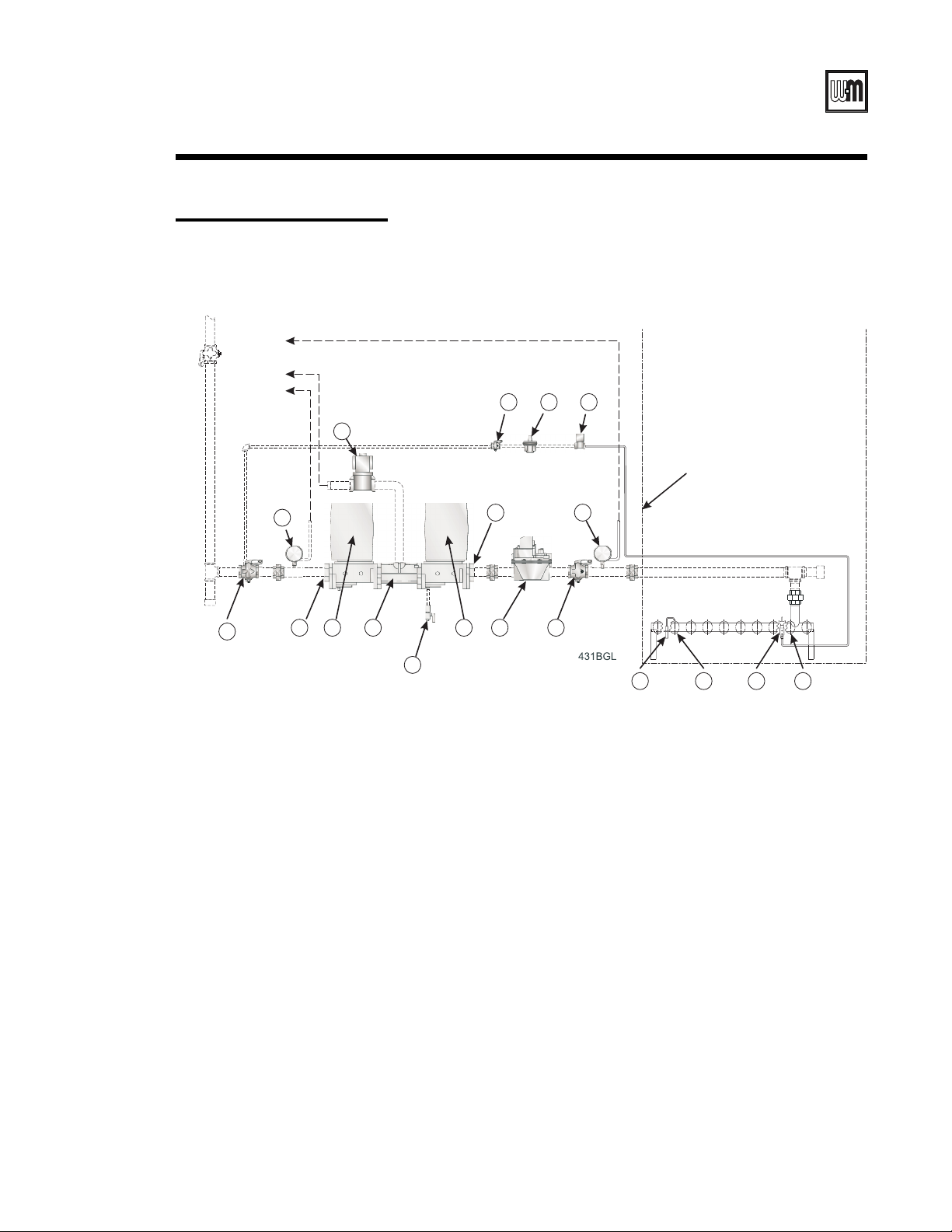

Figure 4

IRI gas train schematic

Atmosphere

Vent to Outside

6

5

3

7

Boiler Jacket

2

Drip Leg Service Valve

1718

1

4

8

GAS PIPING DIAGRAM - LGB (Series 2)

1

Manual main shut-off gas valve

2

Low gas pressure switch

3

Pilot manual shut-off valve

4

Motorized gas valve w/ on/off actuator

5

Pilot gas pressure regulator

6

Normally open solenoid vent valve

7

Pilot solenoid gas valve

8

Test cock

Second motorized gas valve w/ on/off actuator

9

18

11

9

IRI Gas Train

10

Manual leak checking gas valve

11

Regulating diaphragm gas valve (two stage)

12

High gas pressure switch

13

Main flame sensor

14

Main burner with main flame sensor bracket

15

Pilot burner

16

Main burner with pilot burner bracket

Adapter, for N. O. vent valve

17

18

Pipe flanges

10

12

14

1613 15

Part Number 550-141-807/02984

Page 5

Flame Guardian WMBC-1A Electronic Pilot System – IRI

’20’30’40’50’75’

’

’

II Gas piping

1. Size gas piping considering:

a. Diameter and length of gas supply piping.

b. Number of fittings.

c. Maximum gas consumption (including any possible future expansion).

d. Allowable pressure drop from gas meter outlet to boiler. For pressure drops, see ANSI-Z223.1 – latest

edition.

2. Size natural gas piping from table below. Size piping to provide proper inlet pressure to gas valve when operating

at rated input.

a. Inlet gas pressure to manual main shutoff gas valve minimum 7” W.C. standard (5½” on special order) –

maximum 13” W.C.

b. If pressure to gas valve exceeds 13” W.C., install positive dead-end lockup gas pressure regulator up stream of

hand valve.

c. To obtain approximate cubic feet per hour, divide input (BTU/HR) by 1000.

3. Remove gas supply knockout disc from jacket panel.

4. Follow good piping practices.

5. Pipe joint compound (pipe dope) must be resistant to corrosive action of liquefied petroleum gases. Apply

sparingly only to male threads of pipe joints.

6. Install drip leg at inlet of gas connection to boiler. Where local utility requires, extend drip leg to floor.

7. Install ground joint union when required for servicing.

8. Support piping by hangers, not by boiler or its accessories.

9. Purge all air from supply piping.

10. Check all connections for leaks.

Do not check for gas leaks with an open flame – BUBBLE TEST. Failure to use bubble test or test for leaks can cause

severe personal injury, death or substantial property damage.

a. Close manual main shutoff valve during any pressure testing at less than 14.0 inches water column.

b. Disconnect boiler and gas controls from gas supply piping during any pressure test greater than 14.0 inches

water column.

11. Set gas pressure switches as follows or to local inspector’s requirements:

a. Low – 3.0” W.C. b. High – 14.0” W.C

Table 2

Natural gas

supply pipe

sizing

PIPE

SIZE

1¼" 1,050 730 590 500 440 360 305 250

1½" 1,600 1,100 890 760 670 545 460 380

2½" 4,800 3,300 2,700 2,300 2,000 1,650 1,400 1,130

* Include measured length of gas supply piping and allowance in feet for number and size of fittings.

PIPE LENGTH, FEET (NATURAL GAS CAPACITIES, LISTED IN MBH)

(Specific Gravity 0.60 @ Pressure Loss of 0.30" w.c.)

2" 3,050 2,100 1,650 1,450 1,270 1,020 870 710

3" 8,500 5,900 4,700 4,100 3,600 2,900 2,500 2,000

4" 17,500 12,000 9,700 8,300 7,400 6,000 5,100 4,100

III Wiring

For your safety, turn off electrical power supply before making any electrical connections to avoid possible electrical

shock hazard.

1. All wiring must be installed in accordance with the requirements of the National Electrical Code and any additional

national, state or local code requirements having jurisdiction. All wiring must be N.E.C. Class 1.

2. The boiler must be electrically grounded in accordance with the National Electrical Code, ANSI/NFPA No. 70latest edition. Use 105 °C. thermoplastic wire, or equivalent, if any of the original wire must be replaced (except

for pilot spark, sense and ground wires).

3. Supply wiring to the boiler must be No. 14 gauge or heavier. Install in conduit.

4. A separate electrical circuit with a fused disconnect switch (15 amp. recommended) should be used for the boiler.

10

100

150

Part Number 550-141-807/0298 5

Page 6

LGB

Figure 5 — WMBC-1A panel wiring schematic

(Series 2) — Control Supplement

Flame Guardian WMBC-1A Electronic Pilot System – IRI

Part Number 550-141-807/02986

Part Number 550-141-807/0298 7

Page 7

LGB

(Series 2) — Control Supplement

Figure 6 — WMBC-1A panel wiring diagram – factory wiring

Part Number 550-141-807/02988

Page 8

Flame Guardian WMBC-1A Electronic Pilot System – IRI

Figure 7 — WMBC-1A field wiring diagram

Part Number 550-141-807/0298 9

Page 9

LGB

Low Fire Adjustment

(Series 2) — Control Supplement

IV Start-up

Turn off electrical power supply and gas supply to boiler before making the following connections

and adjustment. Failure to do so can cause severe personal injury, death or substantial property

damage.

1. Disable high fire by disconnecting the blue wire in the two-stage gas valve.

2. Connect manometer to gas manifold (manometer must be capable of measuring 0” to 14”

W.C.).

3. Turn on electrical power supply and gas supply to boiler.

4. Fire boiler, which will light off and remain on low fire.

5. While reading manometer, turn low fire adjustment screw clockwise (Figure 5) until pressure

reading is 1.2” W.C.

6. Turn off boiler.

Turn off electrical power supply and gas supply to boiler before the following steps. Failure to

do so can cause severe personal injury, death or substantial property damage.

7. Remove manometer from manifold and plug the tapping.

8. Reconnect the blue wire in the two-stage gas valve junction box.

9. Turn on electrical power supply and gas supply to boiler.

10. Follow operating instructions label on boiler to set boiler in operation.

Figure 8

Low fire adjustment

Part Number 550-141-807/029810

Page 10

Flame Guardian WMBC-1A Electronic Pilot System – IRI

V Sequence of operation

1. Operating control begins startup sequence:

a. Limit control contacts are closed.

b. Purge timer is energized.

2. Flame safeguard control pilot circuit energizes after 2.0 seconds.

a. Pilot gas valve opens.

b. Ignition transformer energizes.

c. Yellow “pilot on” lamp lights.

d. Pilot ignition spark begins.

e. Pilot ignites.

f. Pilot flame proves.

3. Flame safeguard control energizes main flame circuit:

a. Blue “gas valve on” lamp lights.

b. Gas control train energizes.

c. Downstream gas valve opens to low-fire position.

d. Main burners ignite, operate at low fire.

4. Ignition transformer de-energizes after 10-second trial for ignition.

5. Pilot de-energizes after 10-second trial for main flame. Yellow “pilot on” lamp goes out.

6. Main flame sensor proves main burner operation at low fire.

7. Flame safeguard control energizes downstream gas valve to high-fire (through firing rate

control, when used):

a. Main burners operate at high fire.

b. Main burners operate at low fire when water temperature or pressure reaches setting of

firing rate control, when used.

8. Boiler shuts down when operating control satisfied.

9. Flame safeguard control lockout circuit energized if pilot is not proved during start-up or if

main flame is not proved during run sequence.

a. Flame safeguard control locks out on safety.

b. Red “alarm” lamp, alarm relay, and alarm bell energize. Silencing switch can shut off

alarm bell.

c. Alarm relay de-energizes purge timer.

d. Press reset button on flame safeguard control to permit normal start-up after correcting

lockout condition.

e. Normal start-up resumes after purge timer automatically resets (5 minute enforced

wait).

Part Number 550-141-807/0298 11

Page 11

LGB

p

(Series 2) — Control Supplement

VI Parts list – Table 3

Description Size Vendor/Part Number Weil-McLain Part Number

Primary Control Honeywell RM7895C1012 510-350-431

Prepurge Timing Card 2.0 Seconds Honeywell ST7800A1005 510-350-432

Flame Amplifier Honeywell R7847A1033 510-350-434

Electric Bulb 120V Sylv. 120MB/CHI Min. CM8-967 *

Fuse 6 Amp. Bussman MTH-6 *

Relay 120V DPDT Honeywell R4222D1013 510-311-012*

Control Timer SSAC EDRM427 510-350-430

Gas Cock, ¼ M x ¼ F Conbraco 53-300-01 *

Pilot Regulator, ¼ NPT Maxitrol RV20A *

Pilot Solenoid ¼" Honeywell V4046C

Johnson Controls H91ABA

Brass Union, 1/8 NPT x 1/4cc *

Low Gas Pressure Switch Honeywell C645A1030 511-624-550*

High Gas Pressure Switch Honeywell C645B1013 511-624-555*

Gauge Cock ¼" Conbraco 41-560-05 511-210-415*

Pilot Burner Honeywell Q179C1009 511-330-181*

Pilot Bracket Weil-McLain 460-005-624

Main Flame Sensor Honeywell 392956 511-724-274

Main Flame Sensor Bracket Weil-McLain 423-300-420

Main Burner with Bracket Weil-McLain 512-200-055

Ignition Transformer Honeywell Q624A1014 511-802-014*

1" Essex 500 *

Hand Valve

Valve Body

(small - u

Pipe Flanges (for Valve Body)

Actuator For Valve Body (On/Off) Honeywell V4055A 510-744-317

Solenoid Vent Valve

(Normally Open)

Adapter for small valve body

(for vent valve)

Gas Valve with Regulator

to 2" Pipe Flanges)

1 ¼" Essex 600 *

1 ½" Conbraco 50-603 *

2" Conbraco 50-703 *

Honeywell V5097A 510-744-315

1" Honeywell 32000109-002 511-044-170

1 ¼" Honeywell 32000109-003 511-044-171

1 ½" Honeywell 32000109-004 511-044-172

2" Honeywell 32000109-005 511-044-173

¾" Honeywell V4295S 511-046-340

1" Honeywell V4295S 511-046-342

Honeywell 32002513 511-044-176

1" Honeywell V4944N1011 511-048-503

1 ¼" Honeywell V4944N1029 511-048-502

1 ½" Honeywell V4944N1037 511-048-501

2" Honeywell V4944N1045 511-048-500

* Listed part can be purchased at local supply house

511-044-040*

Weil-McLain

500 Blaine Street

Michigan City, IN 46360-2388

http://www.weil-mclain.com

Part Number 550-141-807/029812

Loading...

Loading...