Page 1

Gas-fired

water boiler

Ultra-80, -105, -155, -230 & -310

• Installation

• Startup

• Maintenance

• Parts

with

This manual must only be used by a qualified heating installer/service technician.

Read all instructions, including this manual, the Ultra Control Supplement and the

Ultra Vent Supplement, before installing. P erfo rm steps in the order give n. Failur e

to comply could result in severe personal injury, death or substantial propert y

damage.

Part number 550-101-233/0903

Page 2

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

PhPh

THE BOILER, WITH

PhDPhD

PhD technology

PhDPhD

PhD Technology, Precision hydronic Data, is an intelligent system that

delivers Precision hydronic heating and hot water needs while maximizing

efficiency by measuring the Data parameters of your heating system.

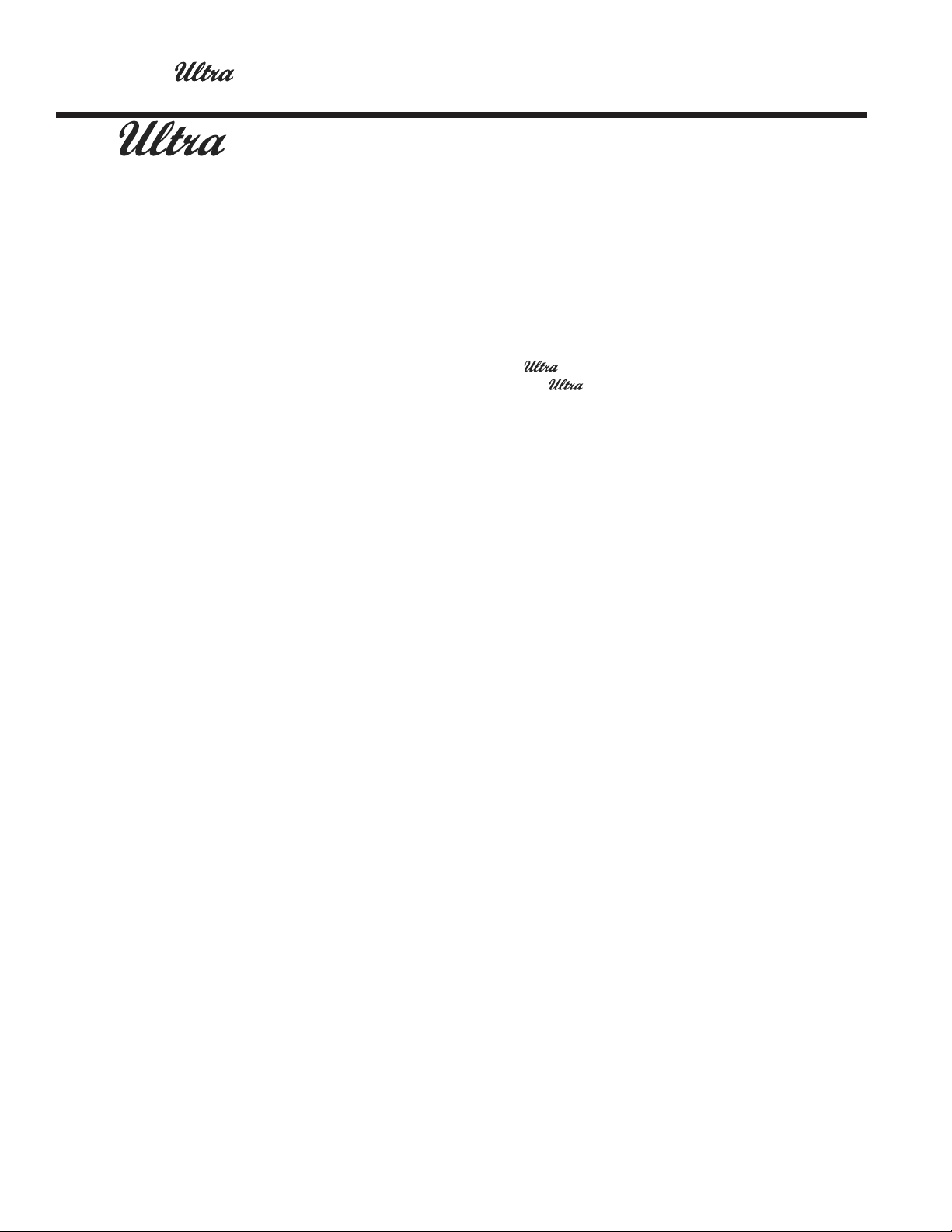

1. Cast aluminum heat exchanger

Ph

PhPh

DD

D

TECHNOLOGY – HOW IT WORKS . . .

DD

12. Burner

Made with high-grade stainless steel construction, the burner

uses pre-mixed air and gas and provides a wide range of firing

rates.

13. Water outlet pipe (system supply)

2. Heat exchanger access cover

3. Blower

The advanced blower design and air inlet silencer (5a) on Ultra boilers

result in very quiet operation.

80 & 105 — Air enters the boiler enclosure through the air intake adapter

(18), flows through the enclosure, enters the air inlet silencer (5a), then

enters the blower . The blower pulls air through the silencer and pushes it

into the venturi (5), where it mixes with gas before ente ring the burner.

155, 230 & 310 — Air enters the boiler enclosure through the air intake

adapter (18), flows through the enclosure, enters the air inlet silencer

(5a), then enters the venturi (5). The blower pulls air and gas through the

venturi and pushes the mixture into the burner .

4. Gas valve

The gas valve senses the vacuum in the venturi caused by flowing air , and

allows gas to flow when power is applied. The manual gas valve (4a) allows

shutting off the gas supply for servicing or shutdown. Models 80 and 105

use a sensing line (4b) from the gas valve to the blower outlet so the gas

valve references the same pressure as the venturi inlet.

5. Venturi

When air flows through the venturi, it creates a vacuum. This vacuum

pulls gas from the gas valve. So gas will only flow if air is flowing. On 80

and 105 models, the gas air mixture enters the burner after the venturi.

On 155, 230 and 310 models, the gas/air mixture enters the blower

before passing on to the burner .

6. Flue gas sensor

This sensor monitors the flue gas exit temperature. The control module

will shut down the boiler if flue gas temperature gets too hot. This protects

the flue pipe and the heat exchanger from overheating.

7. Outlet water temperature sensor

This sensor monitors boiler outlet water temperature (system supply).

The control module adjusts boiler firing rate so the outlet temperature is

correct.

8. Return water temperature sensor

This sensor monitors return water temperature (system return). The

control module reduces or increases boiler input, depending on how

close the return water temperature is to the outlet water temperature.

9. Temperature and pressure gauge

10. Electronic display & buttons

The 4-digit electronic display is used to:

• Set space heating temperature.

• Show outlet water temperature (normal) or other operating conditions

(in Information mode).

• Show boiler status and shutdown or lockout codes for easy

troubleshooting.

The buttons allow changing display mode and reset after lockout. The

on/off Power switch (10a) turns power to the boiler controls on or off.

11. Flue pipe adapter

14. Water return pipe (system return)

15. Gas connection pipe

16.

17. Transformer

18. Air intake adapter

19. Electrical entrance cover plate

20. Boiler drain valve

21. Line voltage receptacle

22. P/T gauge temperature sensor well

23. Flue gas condensate drain connection

24. Front door

25. Ignition electrode

26. Flame inspection window

Control Module

The

thermostat, supply water sensor, return water sensor, flue gas

sensor and (if used): domestic hot water aquastat, outdoor

temperature sensor, and summer/w inter switch. The control

module automatically adjusts blower speed (and gas flow rate)

to match boiler output to space heating and/or DHW heating

demand. The control module is accessed by removing top front

cover (16a).

The transformer reduces line voltage from 120 vac to 24 vac,

providing 24 vac to the control module for the gas valve and

blower signal .

Remove the electrical cover plate to access the line voltage

terminal strip (19b) and the low voltage terminal strip (19a).

Attach line voltage conduits to the three holes at the left of the

line voltage terminal strip for power, CH pump and DHW

pump. Route low voltage wires through the opening to the right

of the low voltage terminal strip.

Use this connection to plug in line voltage meters or tools while

working on boiler. Do not exceed 10-amp load.

The remote sensor for the panel-mounted pressure/temperature

gauge inserts into the outlet water pipe here.

Connect condensate drain line to ½" PVC te e here. The

condensate trap (23a) and PVC fittings are field-installed.

The front door is sealed to the boiler assembly around its entire

perimeter. Two knurled-head screws (24a) secure the door in

place.

The burner flame is ignited by applying a high voltage to the

ignition electrode. This causes a spark (from electrode to ground).

The quartz glass window provides a view of the burner surface

and flame.

Control Module responds to signals from the room

2

Part number 550-101-233/0903

Page 3

GAS-FIRED WATER BOILER — Boiler Manual

THE GAS-FIRED WATER BOILER, WITH

PhPh

Ph

PhPh

DD

D

TECHNOLOGY

DD

Part number 550-101-233/0903

3

Page 4

Contents

How it works.................................................................................... 2–3

Hazard definitions .............................................................................. 4

Please read before proceeding ........................................................ 5

1 Prepare boiler location .................................................................. 6

2 Prepare boiler ................................................................................. 9

3 Install water piping....................................................................... 12

4 Venting, combustion air & condensate line .............................. 19

5 Gas piping ..................................................................................... 21

6 Startup

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

(

Note 1

) ................................................................................. 23

7 Check-out/startup verification .................................................... 26

8 Annual startup and general maintenance ................................ 28

9 Replacement parts....................................................................... 35

10 Dimensions................................................................................. 4 3

11 Ratings ........................................................................................ 44

Note 1:

See Ultra Control Supplement for wiring and additional

startup and operating information.

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various

risk levels or to important information concerning the life of the product.

Indicates presence of hazards that will cause severe personal injury, death or substantial property

damage.

Indicates presence of hazards that can cause severe personal injury, death or substantial property

damage.

Indicates presence of hazards that will or can cause minor personal injury or property damage.

Indicates special instructions on installation, operation or maintenance that are important but not

related to personal injury or property damage.

4

Part number 550-101-233/0903

Page 5

GAS-FIRED WATER BOILER — Boiler Manual

Please read before proceeding

Installer— Read all instructions, including

this manual, the Ultra Control Supplement

and Ultra Vent Supplement, before

installing. Perfo rm steps in the order given.

User — This manual is for use only by a

qualified heating installer/service

technician. Refer to User’s Information

Manual for your reference.

User — Have this boiler serviced/

inspected by a qualified service technician,

at least annually .

Failure to comply with the above could

result in severe personal injur y, death or

substantial property damage.

The boiler contains ceramic fiber materials.

Use care when handling these materials per

instructions on page 29 of this manual.

Failure to comply could result in severe

personal injury.

When servicing boiler —

• T o avoid electric shock, disc onnect electrical supply before performing

maintenance.

• To avoid severe burns, allow boiler to cool before performing

maintenance.

Boiler operation —

• Do not block flow of combustion or ventilation air to boiler .

• Should overheating occur or gas supply fail to shut off, do not turn

off or disconnect electrical supply to circulator . I nstead, shut off the

gas supply at a location external to the appliance.

• Do not use this boiler if any part has been under water. Immediately

call a qualified service technician to inspect the boiler and to replace

any part of the control system and any gas control that has been

under water.

Failure to adhere to the guidelines on this page can result in

severe personal injury, death or substantial propert y

damage.

When calling or writing about the boiler—

Please have the boiler model number from

the boiler rating label and the CP number

from the boiler jack et. You may list the CP

number in the space provided on the

Installation and service certificate found on

page 27.

Consider piping and installation when

determining boiler location.

Any claims for damage or shortage in

shipment must be filed immediately

against the transportation company by the

consignee.

Commonwealth of Massachusetts

When the boiler is installed within the Commonwealth

of Massachusetts:

• This product must be installed by a licensed

plumber or gas fitter .

• If antifreeze is used, a reduced pressure back-flow

preventer device shall be used.

Boiler water —

• The Ultra heat exchanger is made of aluminum, and requires that

system pH always be between 7.0 and 8.5 and water chemistry be

checked. Chemical treatment ma y be necessary. See page 24 for details.

• Thoroughly flush the system (without boiler connected) to remove

sediment. The high-efficiency heat exchanger can be damaged by

build-up or corrosion due to sediment.

• Do not use petroleum-based cleaning or sealing compounds in boiler

system. Gaskets and seals in the system may be damaged. This can

result in substantial property damage.

• Do not use “home made cures” or “boiler patent medicines.” Serious

damage to boiler, personnel and/or pr operty may result.

• Continual fresh make-up water will reduce boiler life. Mineral buildup

in heat exchanger reduces heat tr ansfer, overheats the aluminum

heat exchanger , and causes failu re. Addition of oxygen carried in by

make-up water can cause internal corrosion. Leaks in boiler or piping

must be repaired at once to prev ent make-up water.

• Do not add cold water to hot boiler. Thermal shock can cause heat

exchanger to crack.

Freeze protection fluids —

NEVER use automotive or standard glycol antifreeze, even glycol made

for hydronic systems. Use only freeze-protection fluids recommended in

the Ultra Boiler Freeze Protection Supplement.

Follow all guidelines in the Ultra Boiler Freeze Protection Supplement.

Thoroughly clean and flush any replacement boiler system that has used

glycol before installing the new Ultra boiler .

Part number 550-101-233/0903

5

Page 6

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

1

Prepare boiler location

Installations must comply with:Installations must comply with:

Installations must comply with:

Installations must comply with:Installations must comply with:

• Local, state, provincial, and national codes, laws,

regulations and ordinances.

• National Fuel Gas Code, ANSI Z223.1 – latest edition.

• Standard for Controls and Safety Devices for

Automatically Fired Boilers, ANSI/ASME CSD-1,

when required.

• National Electrical Code.

• For Canada only: B149.1 or B149.2 Installation Code,

CSA C22.1 Canadian Electrical Code Part 1 and any

local codes.

The Ultra boiler gas manifold and controls

met safe lighting and other performance

criteria when boiler underwent tests

specified in ANSI Z21.13 — latest edition.

Before locating the boiler, check:

1. Check for nearby connection to:

• System water piping

• Venting connections

• Gas supply piping

• Electrical power

2. Check area around boiler . Remov e any combustible

materials, gasoline and other flammable liquids.

Failure to keep boiler area clear and free of

combustible materials, gasoline and other

flammable liquids and vapors can result in

severe personal injury , death o r substantial

property damage.

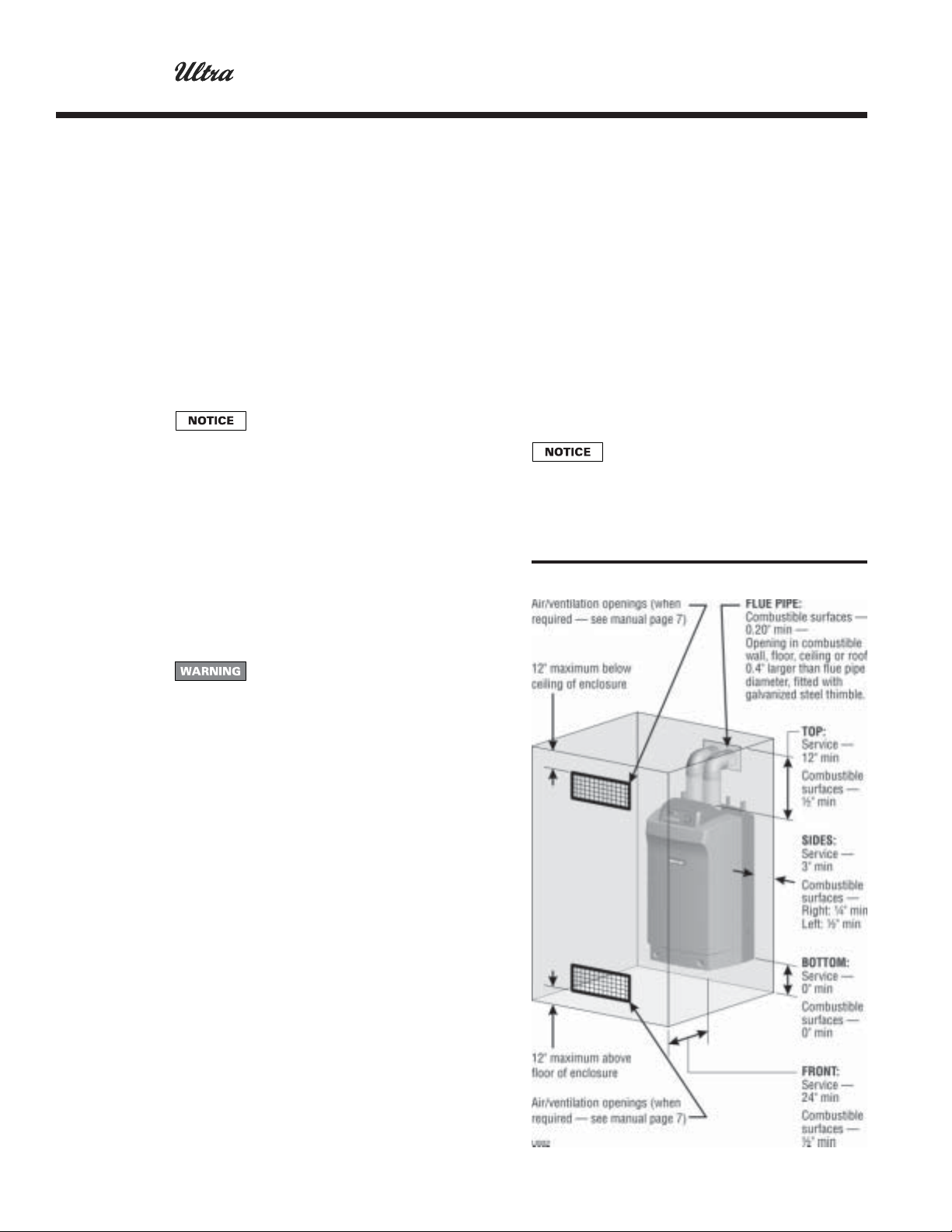

Provide clearances:

Clearances from combustible materials

1. Hot water pipes — at least ½" from combustible

materials.

2. Vent pipe — at least 0.20" from combustible

materials.

3. See Figure 1 for other clearance minimums.

Clearances for service access

1. See Figure 1 for recommended service clearances. If

you do not provide minimum clearances shown, it

might not be possible to service the boiler without

removing it from the space.

Ultra boilers, except the Ultra-310, may be

wall mounted (using special wall mount

kit) or floor mounted. No clearance is

required at the rear of the unit, either for

service or for clearance to combustible

surfaces.

Figure 1 Clearances required

3. The Ultra boiler must be installed so that gas control

system components are protected from dripping or

spraying water or rain during operation or service.

4. If new boiler will replace existing boiler, check for and

correct system problems, such as:

• System leaks causing oxygen corrosion or heat

exchanger cracks from hard water deposits.

• Incorrectly-sized expansion tank.

• Lack of freeze protection in boiler water causing system

and boiler to freeze and leak.

6

Part number 550-101-233/0903

Page 7

1

GAS-FIRED WATER BOILER — Boiler Manual

Prepare boiler location

Flooring and foundation

Flooring

The Ultra boiler is approved for installation on

combustible flooring, but must never be installed on

carpeting.

Do not install boiler on carpeting even if

foundation is used. Fire can result, causing

severe personal injury , death or s ubstantial

property damage.

Foundation

Provide a solid foundation pad, at least 2 inches above

the floor, if any of the following is true:

• floor can become flooded.

• the floor is dirt, sand, gravel or other loose material.

• the boiler mounting area is severely uneven or sloped.

The minimum foundation size is:

• Ultra-80 to -230: 24 inches wide x 20 inches deep.

• Ultra-310: 24 inches wide x 23 inches deep

24 inches x 20 inches.Foundation may be of wood, brick

or concrete (minimum 2 inches thick) construction.

If flooding is possible, elevate boiler sufficiently to prevent

water from reaching boi ler .

(continued)

Ultra boiler in same space with other gas or

oil-fired appliances

1. Follow the National Fuel Gas Code (U. S.) or CSA

B149.1 and B149.2 (Canada) to size/verify size of the

combustion/ventilation air openings into the space.

The space must be provided with

combustion/ventilation air openings

correctly sized for all other appliances

located in the same space as the Ultra boiler .

Replace boiler jacket front door after

servicing. The boiler front door must be

securely fastened to the boiler to prevent

boiler from drawing air from inside the

boiler room. This is particularly important

if the boiler is located in the same room as

other appliances.

Failure to comply with the above warnings

could result in severe personal injury , death

or substantial property damage.

2. Size openings only on the basis of the other appliances

in the space. No additional air opening free area is

needed for the Ultra boiler because it takes its

combustion air from outside (direct vent installation).

Residential garage installation

Precautions

Take the following special precautions when installing

the boiler in a residential garage. If the boiler is located in

a residential garage, per ANSI Z223.1, paragraph 5.1.9:

• Mount the boiler with a minimum of 18 inches above

the floor of the garage to the bottom of the boiler to

ensure the burner and ignition devices will be no less

than 18 inches above the floor .

• Locate or protect the boiler so it cannot be damaged

by a moving vehicle.

Provide air openings to room:

Ultra boiler alone in boiler room

1. No air ventilation openings into boiler room are

needed when clearances around Ultra boiler are at

least equal to the SERVICE clearances shown in

Figure 1. For spaces that do NOT supply this

clearance, provide two openings as shown in Figure 1.

Each opening must provide 1 square inch free area

per 1,000 Btuh of boiler input.

Vent and air piping

The Ultra boiler requires a special vent system, designed

for pressurized venting. Ultra boilers are rated ANSI

Z21.13 Category IV (pressurized vent, likely to condense

in the vent).

Y ou must also install air piping from outside t o the boiler

air intake adapter . The resultant installation is categorized

as direct vent (sealed combustion). Note prevention of

combustion air contamination on page 8 when

considering vent/air termination.

V ent and air must t erminate near one another and may

be vented vertically through the roof or out a side wall.

Y ou ma y use any of the vent/air piping methods cov ered

in the Ultra Boiler Vent Supplement, included in the

envelope assembly. Do not attempt to install the Ultra

boiler using any other means.

Be sure to locate the boiler such that the vent and air

piping can be routed through the building and properly

terminated. The vent/air piping lengths, routing and

Part number 550-101-233/0903

7

Page 8

1

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

Prepare boiler location

Prevent combustion air

contamination

Install air inlet piping for the Ultra boiler as described in

the Ultra Boiler Vent Supplement. Do not terminate vent/

air in locations that can allow contamination of

combustion air. Refer to Table 1 for products and areas

which may cause contaminat ed combustion air .

Y ou must pipe c ombustion air to the boiler

air intake. Ensure that the combustion air

will not contain any of the contaminants

below . Contaminat ed combustion air will

damage the boiler, resulting in possible

severe personal injury , death o r substantial

property damage. Do not pipe combustion

air near a swimming pool, for example.

Also avoid areas subject to exhaust fumes

from laundry facilities. These areas will

always contain contaminants.

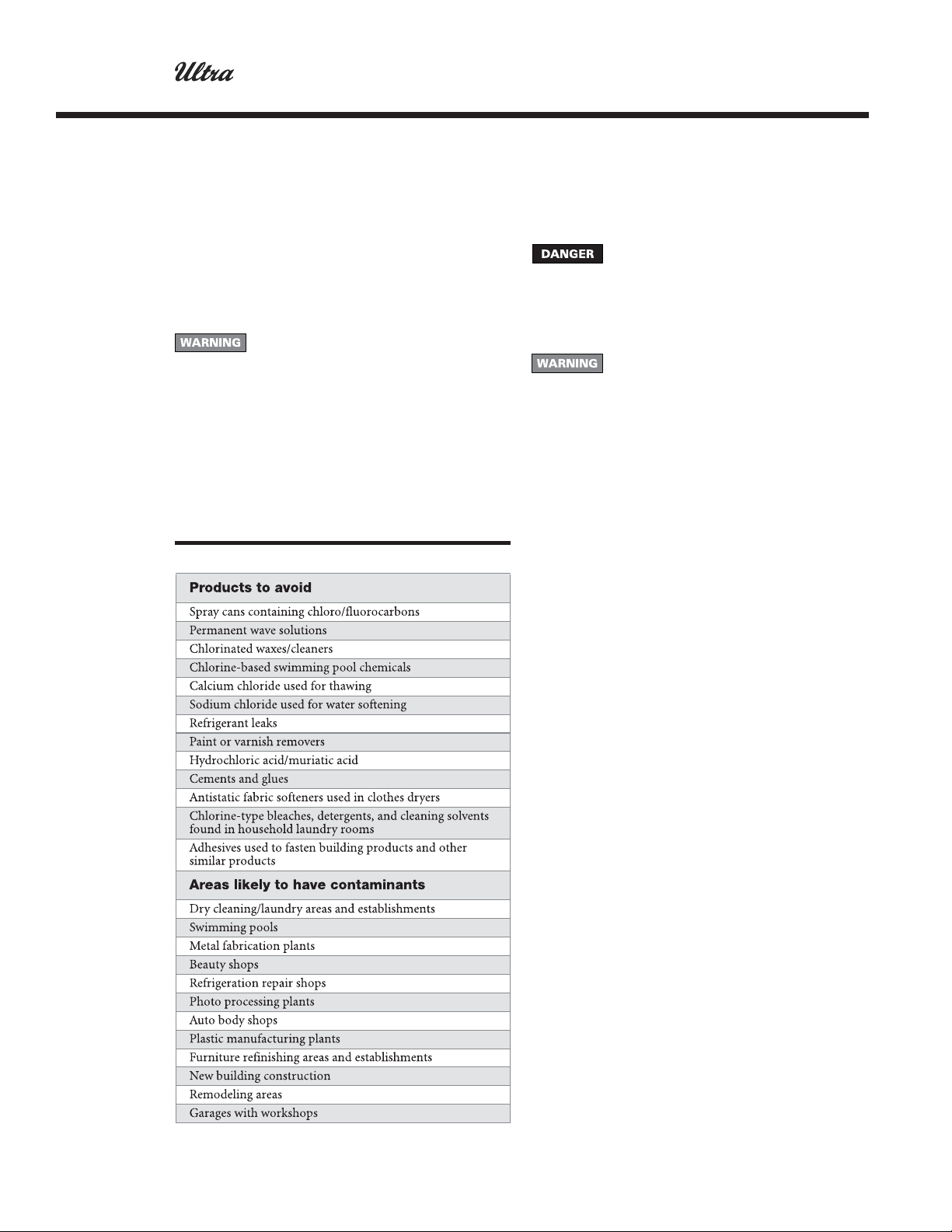

Table 1 Corrosive contaminants and sources

(continued)

When removing a boiler from

existing common vent system:

Do not install the Ultra boiler into a

common vent with any other appliance.

This will cause flue gas spillage or appliance

malfunction, resulting in possible severe

personal injury, death or substantial

property damage.

Failure to follow all instructions can result

in flue gas spillage and carbon monoxide

emissions, causing severe personal injury

or death.

At the time of removal of an existing boiler, the fo llowing

steps shall be followed with each appliance remaining

connected to the common venting system placed in

operation, while the other appliances remaining connected

to the common venting system are not in operation.

a. Seal any unused openings in the common venting

system.

b. Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion or other

deficiencies which could cause an unsafe condition.

c. Test vent system — Insofar as is practical, close all

building doors and windows and all doors between

the space in which the appliances remaining

connected to the common venting system are located

and other spaces of the building. Turn on clothes

dryers and any appliance not connected to the

common venting system. Turn on any exhaust fans,

such as range hoods and bathroom exhausts, so they

will operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

d. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat

so appliance will operate continuously.

e. Test for spillage at draft hood relief opening after 5

minutes of main burner operation. Use the flame of

a match or candle, or smok e fro m a cigarette, cigar,

or pipe.

f. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined herein, return

doors, windows, exhaust fans, fireplace dampers, and

any other gas-burning appliance to their previous

conditions of use.

Any improper operation of common venting system

should be corrected so the installation conforms with

the National Fuel Gas Code, ANSI Z223.1 — latest edition.

Correct by resizing to approach the minimum size as

determined using the appropriate tables in Part 11 of

that code. Canadian installations must comply with

B149.1 or B149.2 Installation Code.

8

Part number 550-101-233/0903

Page 9

2

GAS-FIRED WATER BOILER — Boiler Manual

Prepare boiler

Remove boiler from crate

Cold weather handling — If boiler has been

stored in a very cold location (below 0°F) before

installation, handle with care until the plastic

components come to room temperature.

1. The Ultra boiler is generally easier to handle and maneuver

after removing from crate.

2. After removing outer shipping carton from boiler,

REMOVE jacket front door by loosening two knurledhead screws at lower front. Removing the door will prevent

possible damage to the door during handling.

3. To remov e boiler from pallet (after remo ving jacket front

door):

a. Remove the four lag screws securing shipping brackets.

b. Unscrew the two rear boiler legs and remove the

shipping brackets.

c. Replace legs.

d. Discard the cardboard protector insert on the rear of

the boiler.

Do not drop boiler or bump jacket on floor or

pallet. Damage to boiler can result.

Prepare for propane if operating

on propane — Ultra-80 & -105

Ultra-80: DO NOT apply the following

instructions to conversion of Ultra-80 boilers.

Follow the instructions provided with the

optional propane conversion kit. The propane

conversion kit is NOT included as standard

equipment for the Ultra-80.

Do not apply the following to conversion of a

boiler already installed and connected to gas

supply. For a boiler alr eady installed, you must

turn off gas supply, turn off power and allow

boiler to cool before proceeding. You must also

completely test the boiler after conversion to

verify performance as described under “Startup, ”

Section 6 of this manual. See separate natural

to propane conversion instructions for

conversion of an existing boiler.

Y ou m ust install the propane o rifice to fire the

Ultra boiler on propane. Verify when installing

that the orifice size marking matches boiler

size. Failure to comply could result in severe

personal injury, death or substantial property

damage.

Ultra-80-LP boilers are factory-equipped

to operate on propane gas.

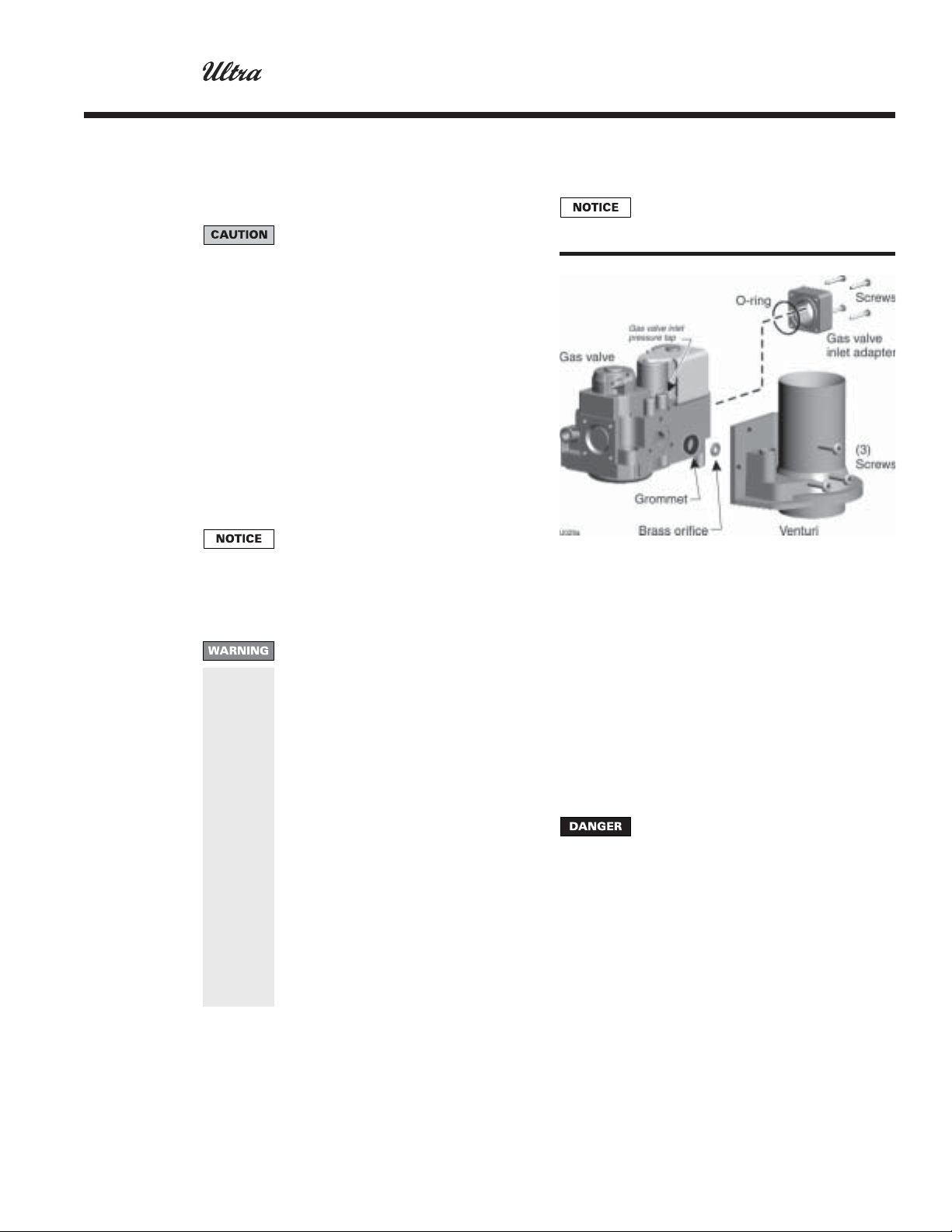

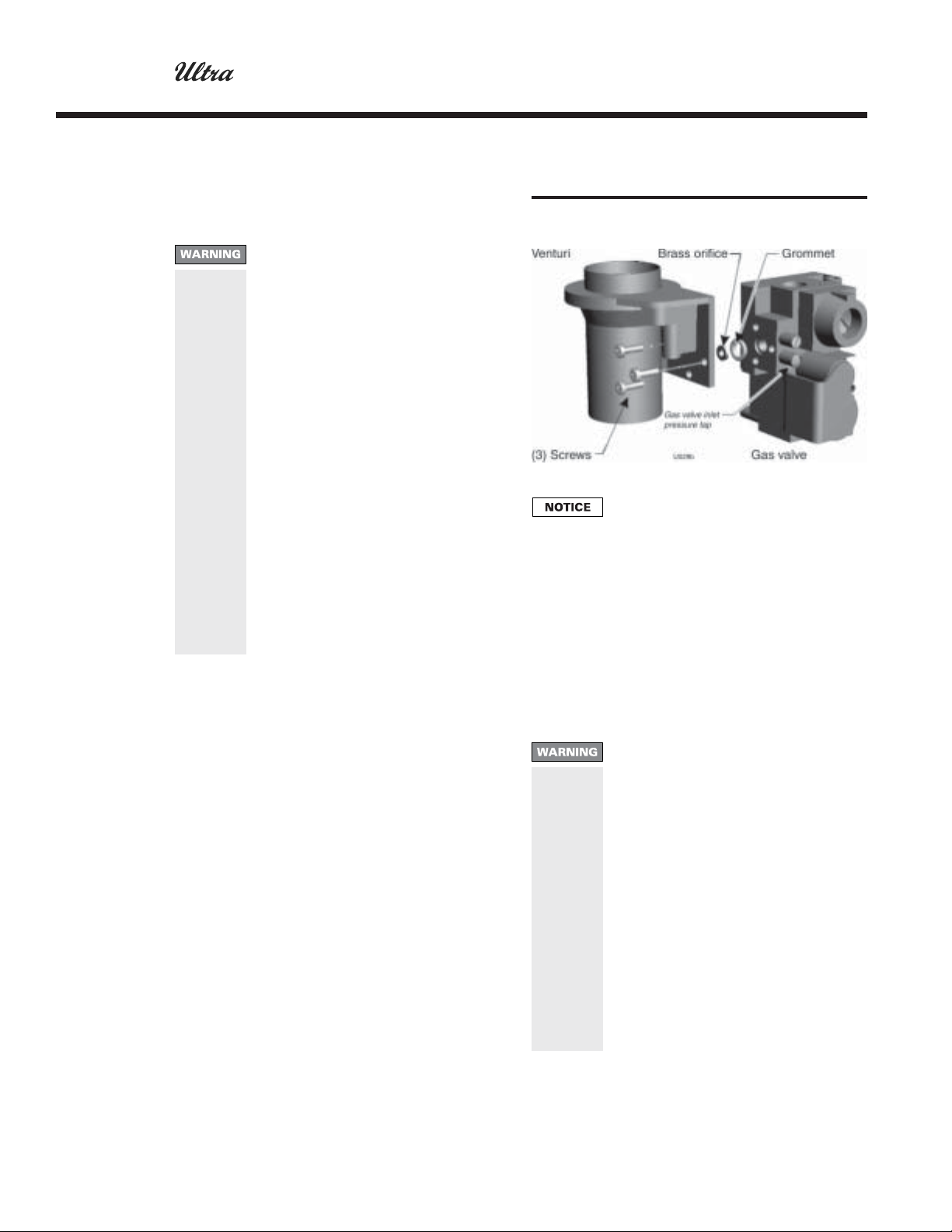

Figure 2 Installing propane orifice (Ultra-105)

1. With boiler on its back, remove jacket front door by

removing two knurled head screws at lower front. Then

lift door away fro m boiler.

2. Disconnect the gas valve electrical plug.

3. Remove the 4 screws securing gas valve inlet adapter to

valve.

4. Remove (3) TORX screws securing gas valve to venturi

(Figure 2).

5. Locate propane orifice disc from co nversion kit bag. Verify

that the stamping on the orifice disk matches the boiler

size. Place orifice in the black rubber grommet in the side

of the gas valve and secure in valve (Figure 2).

6. Reposition gas valve against venturi and replace (3) TORX

screws securing valve to venturi. Secure gas valve inlet

adapter to gas valve with 4 screws. Make sure the plastic

hose is connected from gas valve to inlet elbow.

Inspect the O-ring between the gas valve and

gas valve inlet adapter block whenever they are

disassembled. The O-ring must be in good

condition and must be installed. Failure to

comply will cause a gas leak, resulting in severe

personal injury or death.

7. DO NOT attempt to adjust gas valve outlet pressure.

8. Connect gas valve electrical plug to valve terminals.

9. After installation is complete, attach the propane

conversion label (in conversion kit bag) next to the boiler

rating plate.

10. Replace jacket front panel.

Part number 550-101-233/0903

9

Page 10

2

GAS-FIRED WATER BOILER — Boiler Manual

Prepare boiler

Prepare for propane if operating

on propane — Ultra-155 to -230

Ultra-80: DO NOT apply the following

instructions to conversion of Ultra-80

boilers. Follow the instructions provided

with the optional propane conversion kit.

The propane conversion kit is NOT

included as standard equipment for the

Ultra-80.

Do not apply the following to conversion

of a boiler already installed and connected

to gas supply . For a boiler already installed,

you must turn off gas supply, tur n off

power and allow boiler to cool before

proceeding. You must also co mpletely test

the boiler after conversion to verify

performance as described under “Startup , ”

Section 6 of this manual. See separate

natural to propane conversion instructions

for conversion of an existing boiler .

Y ou must install the pr opane orifice to fire

the Ultra boiler on propane. Verify when

installing that the orifice size marking

matches boiler size. Failure to comply could

result in severe personal injury, death or

substantial property damage.

1. With boiler on its back, remove jacket front door by

removing two knurled head screws at lower front.

Then lift door away fr om boiler.

2. Disconnect the gas valve electrical plug.

3. Disconnect the gas line union below the gas valve.

4. Remove (3) TORX screws securing gas valve to venturi

(Figure 2a).

5. Locate propane orifice disc from conversion kit bag.

V erify that the stamping on the orifice disk mat ches

the boiler size. Place orifice in the black rubber

grommet in the side of the gas valve and secure in

valve (Figure 2).

6. Reposition gas valve against venturi and replace (3)

TORX screws securing valve to venturi. Reconnect

gas line union.

7. DO NOT attempt to adjust gas valve outlet pressure.

8. Connect gas valve electrical plug to valve terminals.

9. After installation is complete, attach the propane

conversion label (in conversion kit bag) next to the

boiler rating plate.

10. Replace jacket front panel.

(continued)

Figure 2a Installing propane orifice (Ultra-155

and Ultra-230)

Ultra-310 boilers cannot be equipped for

propane firing as of October, 2003.

Propane capability should be available in

2004.

Placing floor-mounted boilers

1. Set boiler in place and check level.

a. Adjust legs, if necessary to level boiler.

Placing wall-mounted boilers

1. Ultra-80, -105, -155 and -230 boilers can be wall

mounted. Use only the separately available Ultra

boiler wall mounting kit and instructions. See

W ARNING below .

The wall must be vertically plumb and

capable of carrying the weight o f the boiler.

The operating weights are:

Ultra-80: 139 pounds.

Ultra-105: 145 pounds.

Ultra-155: 181 pounds.

Ultra-230: 192 pounds.

Model Ultra-310 boilers are NOT designed

for wall mounting.

W all mount Ultra boilers only using W eilMcLain Ultra boiler wall-mounting kit and

accompanying instructions. This kit is not

supplied as standard equipment with the

boiler, and must be purchased separately .

Failure to comply with above could result

in severe personal injury, death or

substantial property damage.

10

Part number 550-101-233/0903

Page 11

2

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

Prepare boiler

Perform hydrostatic pressure test

Pressure test boiler before permanently attaching water

or gas piping or electrical supply .

Prepare boiler for test

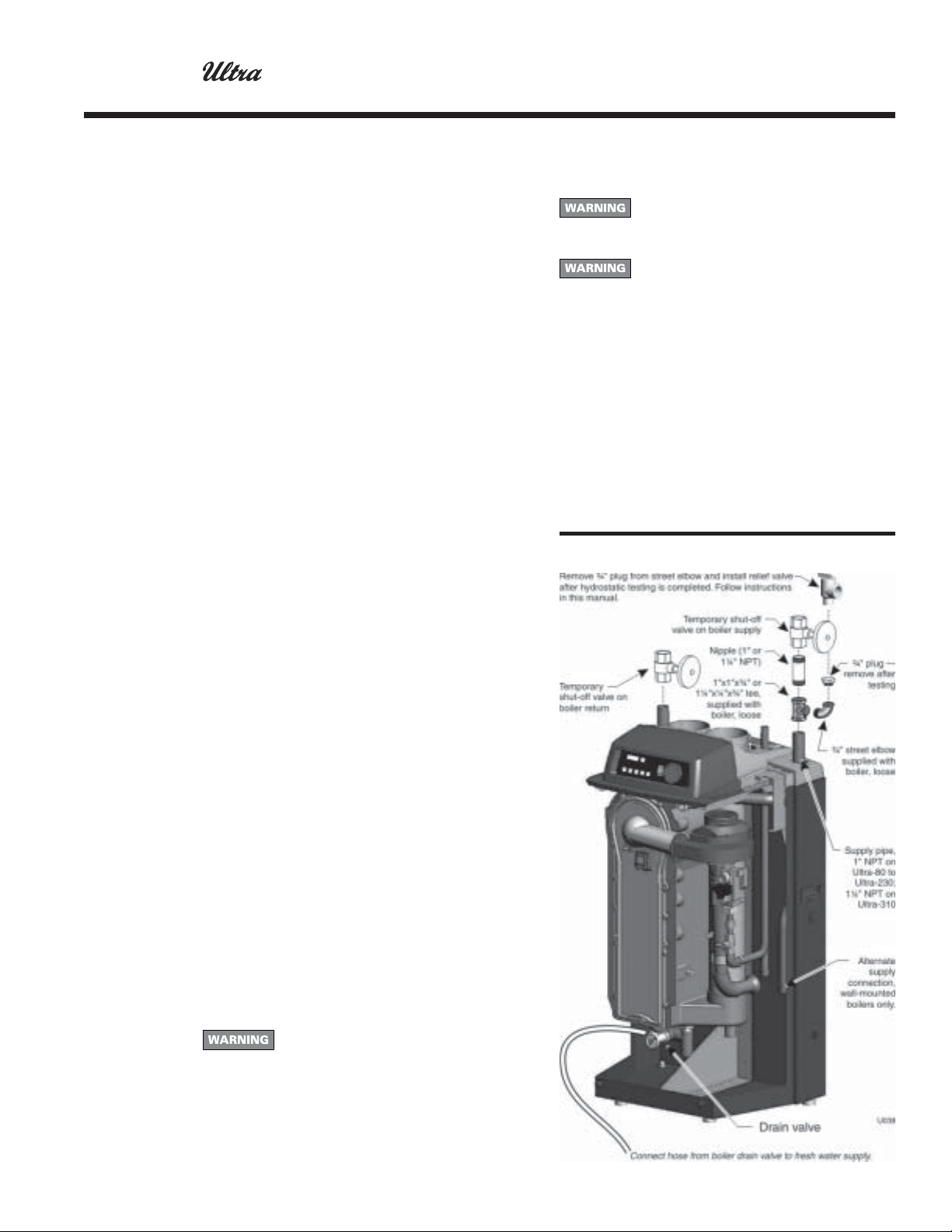

1. See Figure 3 for reference in following steps.

2. Remove supply line tee* and ¾” street elbow from

accessory bag. Pipe to boiler supply connection as

shown. Use pipe dop e sparing ly. (*1" x 1" x ¾" tee

with Ultra-80 to -230 or 1¼" x 1¼" x ¾" tee with

Ultra-310)

3. Temporarily plug the ¾" relief valve tapping in the

street elbow with a ¾" NPT pipe plug.

4. Connect a hose to boiler drain valve, the other end

connected to a fresh water supply. Make sure hose

can also be used to drain boiler after test.

5. Connect a nipple and shutoff valve to system supply

connection on the supply tee. This valve will be used

to bleed air during the fill. (V alv e and nipple are not

included with boiler .)

6. Connect a shutoff valve to system return connection.

(V alve is not includ ed with boiler.)

7. To avoid getting water on boiler, you may want to

pipe street elbows on top of shutoff valves and attach

catch-buckets beneath.

8. If convenient, install the boiler circulator and any

other piping compatible with Figure 3 that would

still allow bleeding air from shutoff valves. Follow

guidelines in this manual for piping components,

locations and sizing.

(continued)

Leaks must be repaired at once. Failure to

do so can damage boiler, resulting in

substantial property damage.

Do not use petroleum-based cleaning or

sealing compounds in boiler system.

Gaskets and seals in the system may be

damaged. This can result in substantial

property damage.

Drain and remove fittings

1. Disconnect fill water hose from water source.

2. Drain boiler through drain valve. Remove hose after

draining.

3. Remove nipples and valves unless they will remain

for use in the system piping.

4. Remove plug from relief valve street elbow. See

section 3 (page 12) to install relief valve.

Figure 3 Hydrostatic test piping connections

Fill and pressure test

1. Open the shutoff valves you installed on supply and

return connections.

2. Slowly open boiler drain valve and fresh water supply

to fill boiler with water. The boiler will fill quickly

because of its low water content.

3. When water reaches shutoff valves, close boiler drain

valve.

4. Close shutoff valves.

5. Slowly reopen boiler drain valve until test pressure

on the pressure/temperature gauge reaches at least

45 psig, but no higher than 55 psig.

6. Hold at test pressure for 10 minutes.

7. Make sure constant gauge pressure has been

maintained throughout test. Check for leaks. Repair

if found.

Part number 550-101-233/0903

Do not leave boiler unattended. A cold

water fill could expand and cause excessive

pressure, resulting in severe personal injury ,

death or substantial property damage.

11

Page 12

3

GAS-FIRED WATER BOILER — Boiler Manual

Install water piping

Install relief valve

1. Install relief valve in ¾" street elbow piped from boiler

supply piping tee (Figure 3, page 11). Pipe the relief

valve only as shown, in the location shown.

2. Connect discharge piping to safe disposal location,

following guidelines in the W ARNING below .

To avoid water damage or scalding due t o

relief valve operation:

• Discharge line must be connected to relief

valve outlet and run to a safe place of

disposal. Terminate the discharge line in a

manner that will prevent possibility of

severe burns or property damage should

the valve discharge.

• Discharge line must be as short as possible

and be the same size as the valve discharge

connection throughout its entire length.

• Discharge line must pitch downward from

the valve and terminate at least 6" above

the floor drain where any discharge will be

clearly visible.

• The discharge line shall terminate plain, not

threaded, with a material serviceable for

temperatures of 375 °F or greater.

• Do not pipe the discharge to any place

where freezing could occur.

• No shutoff valve shall be installed between

the relief valve and boiler , or in the discharge

line. Do not plug or place any obstruction

in the discharge line.

• Test the o peration of the valve after filling

and pressurizing system by lifting the lev er.

Make sure the valv e discharges freely . If the

valve fails to operate correctly, replace it

with a new relief valve.

• Failure to comply with the above guidelines

could result in failure of the relief valve to

operate, resulting in possibility of severe

personal injury, death or substantial

property damage.

Use two wrenches when tightening water

piping at boiler, using one wrench to

prevent the boiler return line or supply line

from turning. Failure to support the boiler

piping connections to prevent them from

turning could cause damage to boiler

components.

General piping information

Additional controls, when required

The Ultra control module uses

temperature sensors to provide both high

limit protection and modulating

temperature control. The control module

also provides low water protection by

sensing the temperature of the heat

exchanger . Some codes/jurisdictions may

require additional external controls for

high limit and/or low water cutoff

protection.

Additional limit control:

Following standard industry practices, if installation is

to comply with ASME or Canadian requirements, an

additional high temperature limit is needed. Consult local

requirements for other codes/standards to determine if

needed.

1. Install additional high temperature limit constructed

to prevent a temperature setting above 200°F in system

supply piping between boiler and isolation valve.

(Note that the Ultra control module operating limit

function shuts the boiler down at 190°F or Parameter

4, whichever is lower .)

2. See Ultra Control Supplement for wiring.

a. If limit control is to cause a boiler hard lockout (requiring

manual reset of Ultra control module), connect isolated

contact to field control wiring terminals 6 and 8 as

shown in wiring diagram.

b. Otherwise, connect isolated contact between

terminals 6 and 7 for a soft lockout (automatic reset).

c. If using a manual reset limit control or wiring in the

manual reset circuit, Parameter 4 should be no closer

than 20°F to the limit control setting (i.e., no higher

than 180°F for a 200°F limit setting, for example).

Separate low water cutoff:

A low water cutoff device is required when boiler is

installed above piping level or by certain state or local

codes or insurance companies. Consult local

requirements to determine.

1. If required, use a low water cutoff designed for water

installations. Electrode probe-type is recommended.

2. Purchase low water cutoff and install in tee in supply

piping above boiler .

3. See Ultra Control Supplement for wiring.

a. If limit control is to cause a boiler hard lockout (requiring

manual reset of Ultra control module), connect isolated

contact to field control wiring terminals 6 and 8 as

shown in wiring diagram.

b. Otherwise, connect isolated contact between

terminals 6 and 7 for a soft lockout (automatic reset).

Backflow preventer:

Use backflow check valve in cold water supply as required

by local codes.

12

Part number 550-101-233/0903

Page 13

3

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

Install water piping

System water piping methods

All piping methods shown in this manual

use primary/secondary connection to the

boiler loop. These designs ensure proper

flow through the Ultra boiler , fo r the most

efficient and reliable operation of the boiler

and the heating system. For other piping

methods, consult your local Weil-McLain

representative or refer to separate Ultra

boiler piping guides.

Wall-mounted boilers — Piping can exit

bottom of boiler enclosure. See separate

wall-mounting instructions for details.

Expansion tank and make-up water

1. Ensure expansion tank size will handle boiler and

system water volume and temperature. Allow 3

gallons for boiler and its piping.

Undersized expansio n tanks cause system

water to be lost from relief valve and makeup water to be added through fill valve.

Eventual boiler failure can result due to

excessive make-up water addition.

(continued)

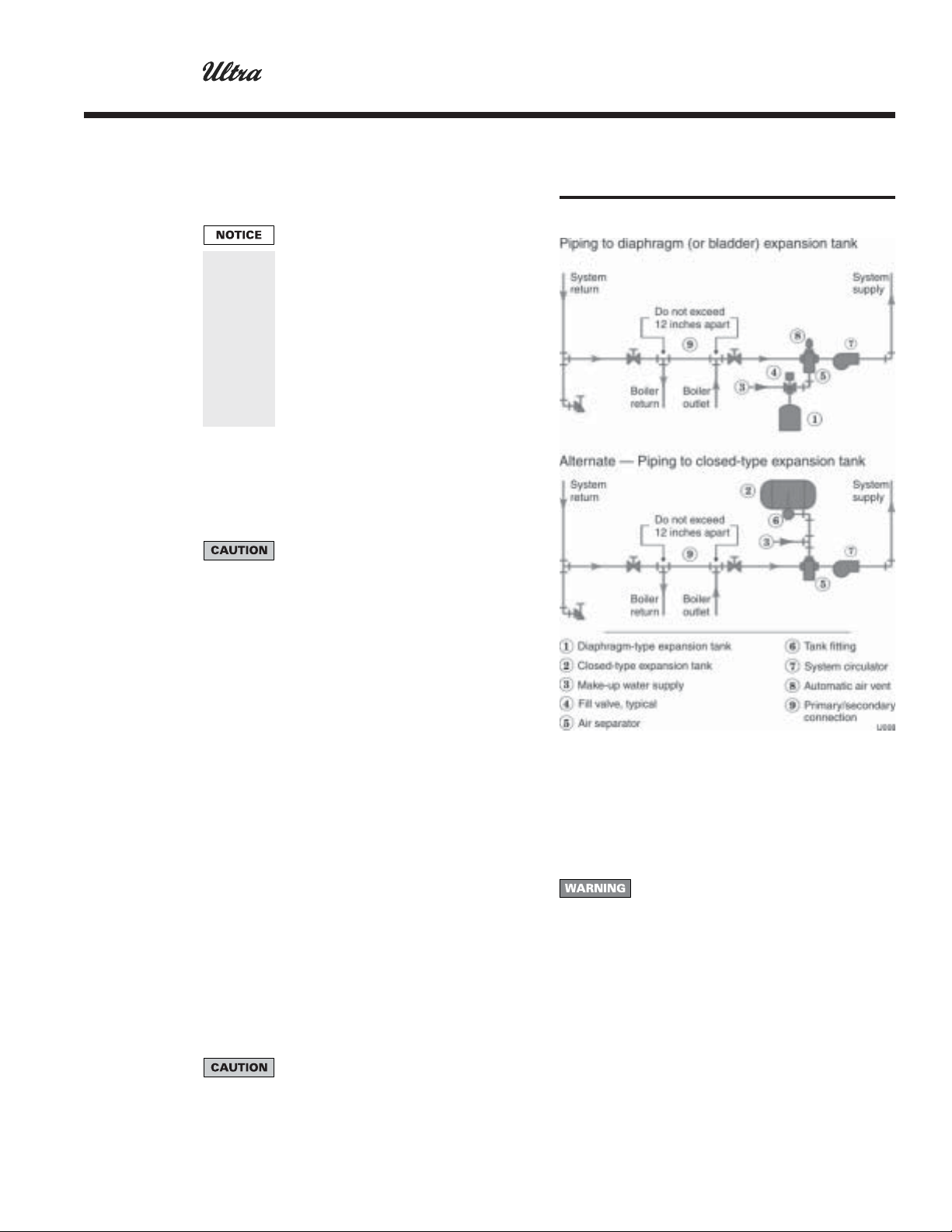

Figure 4 Expansion tank piping

2. Tank must be located as shown in this manual, or

following recognized design methods. See tank

manufacturer’ s instructions for details.

3. Connect the expansion tank to the air separator only

if the separator is on the suction side of the circulator.

Always install the system fill connection at the same

point as the expansion tank connection to the system.

4. Most piping drawings in this manual show

diaphragm expansion tanks. See Figure 4 for piping

from air separator to expansion tank and make-up

water line using a closed-type expansion tank.

5. Most chilled water systems are piped using a closedtype tank, as shown in Figure 10, page 18.

Diaphragm (or bladder) expansion tank

1. (Figure 4) Always install an automatic air vent on

top of the air separator to remove residual air from

the system.

Closed-type expansion tank

1. See Figure 4, Alternate, for piping connections when

using a closed-type expansion tank.

2. Pitch any horizontal piping up towards tank 1 inch

per 5 feet of piping. Connect to tank with at least ¾"

piping to allow room for air to rise.

DO NOT install automatic air vents on

closed-type expansion tank systems. Air

must remain in the system and return to

the tank to provide its air cushion. An

automatic air vent would cause air to leave

system, resulting in water-logging the

expansion tank.

Circulators

The boiler circulator (Taco 007 for Ultra-80 and -105;

T aco 0011 for Ul tra-155, -230, and -310) is shipped loose.

Locate it either in the return or supply piping, as shown

in the appropriate piping diagram in this manual.

DO NOT use the boiler circulator in any

location other than the ones shown in this

manual. The boiler circulator is selected to

ensure adequate flow through the Ultra

boiler. Failure to comply could result in

unreliable performance and nuisance

shutdowns from insufficient flo w.

Sizing space heat system piping

1. See Figures 7 through 10, pages 15 – 18, for

recommended piping. In all diagrams, the space

heating system is isolated from the boiler loop by the

primary/secondary connection.

2. Size the piping and components in the space heating

system using recognized design methods.

Part number 550-101-233/0903

13

Page 14

3

GAS-FIRED WATER BOILER — Boiler Manual

Install water piping

Sizing DHW system piping

When using the boiler for dedicated DHW

applications, use the circulator supplied with

the boiler (007 for Ultra-80/105; 0011 for

Ultra-155/230/310) to circulate to the water

heater except where higher flow rates may be

required for the heater used. Use the following

method to select a circulator for the water

heater on combined space heating/DHW

systems.

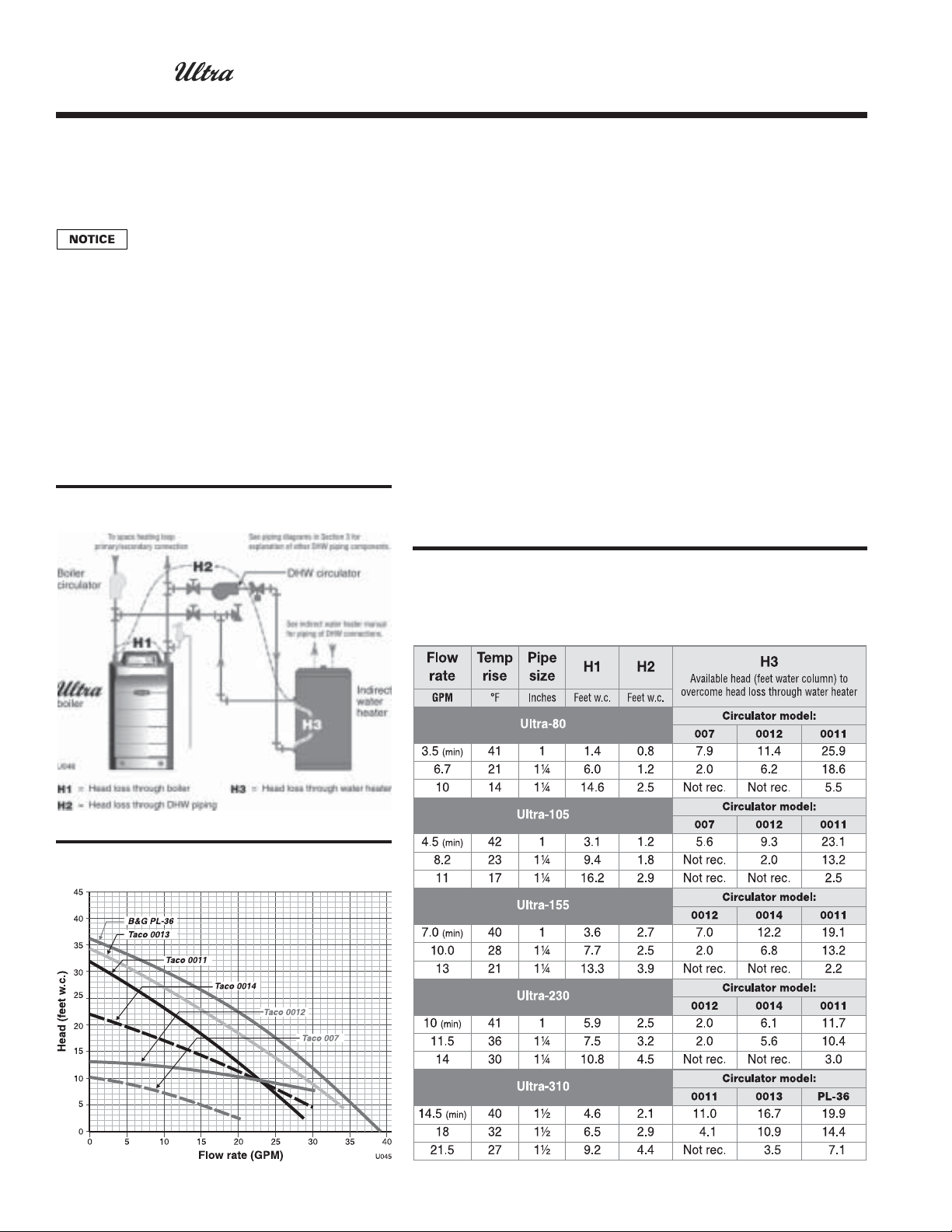

1. Figure 5 shows recommended DHW piping, as shown in

Figures 7 through 10, pages 15 – 18. All show direct

connection of the DHW piping to the boiler because the

boiler circulator shuts down during DHW operation.

2. Figure 6 shows the pump curves for suggested DHW

Figure 5 DHW piping (see Table 2 f or approxi-

mate head losses)

(continued)

circulators (Taco 007, 0011, 0012, 0013, 0014, B&G PL-36 or equivalent). Use

these curves along with boiler pressure drop data fro m T able 2 to size the DHW

piping and circulator . Or you can use T able 2 for a quick-selection method.

3. Table 2 uses the available head from the circulat ors list ed to help you select the

right circulator.

a. See Figure 5.

b. H1 is the head loss across the boiler.

c. H2 is the head loss across the DHW piping.

d. H3: Table 2 subtracts H1 and H2 from the available head of the circulator. This

gives the maximum value for H3, head loss across the water heater.

4. Procedure to select a circulator using Table 2:

Step 1: From the water heater manufacturer’s data, find:

• Required boiler water flow rate, GPM, at 180°F.

• Pressure drop across the water heater at this flow rate, in feet water column.

Step 2: Find your boiler model in Table 2. Select a flow rate in column 1 just

larger than the required flow rate from step 1.

Step 3: The value in column H3 must be larger than the water heater pressure

drop from step 1.

Table 2 Pipe sizing and head losses for DHW applications

(H1=boiler head loss; H2=piping head loss; H3=maximum

allowable head loss through water heater based on available head

of circulator chosen; i.e., Taco 007, 0011, 0012, 0013 or 0014, Bell

or Gossett PL-36)

Figure 6 Pump curves for typical circulators

suggested for DHW loop

14

Part number 550-101-233/0903

Page 15

3

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

Install water piping

Zoning with zone valves

1. Connect boiler to system as shown in Figure 7 when

zone valve zoning. The primary/secondary piping

shown ensures the boiler loop will have sufficient

flow. It also avoids applying the high head of the

boiler circulator to the zone valves.

2. When using a closed-type expansion tank, connect

the expansion tank and make-up water piping as

shown in Figure 4, page 13.

3. Connect DHW (domestic hot water) piping to indirect

storage water heater as shown.

The PhD Control Module turns off

space heating during DHW heating. The

boiler circulator will turn off, preventing

hot water from circulating to the system.

The flow/check valve shown on the boiler

outlet piping prevents gravity circulation

in the boiler loop during DHW heating.

4. Controlling the system circulator

a. To cycle the system circulator from the Ultra PhD

control module, add a circulator relay wired to the

boiler circulator terminals as shown in the Ultra Control

Supplement.

(continued)

Figure 7 Zone valve zoning plus optional

DHW piping

NOTE 1: To ensure adequate flow rate through the

boiler, use the following pipe size on all boiler

loop piping (connecting boiler to and from

the primary/secondary connection, item 21):

Ultra-80 or Ultra-105 – 1" or larger .

Ultra-155 or -230 – 1¼" or larger .

Ultra-310 – 1½" or larger.

Use at least the minimum piping size above

and pipe the boiler using only primary/

secondary piping as shown. Failure to

follow these guidelines could result in

system problems.

Legend Figure 7

1 Ultra boiler

2 Indirect water heater (DHW), if used

3 Boiler relief valve (see page 12 for piping details)

4 Relief valve discharge piping (see page 12 for details)

5 DHW circulator (see page 14 for suggested sizing)

6 Isolation valves

7 System circulator

8 Diaphragm (or bladder) type expansion tank (see page 12

for piping of closed-type expansion tank, if used)

9 Air separator [with automatic air vent only on systems

using diaphragm (or bladder) type expansion tank]

10 Flow/check valves (with weighted seats to prevent gravity

circulation)

11 Purge/drain valves

12 Boiler circulator

13 Zone valves, typical

20 Make-up water supply

21 Primary/secondary connection

Part number 550-101-233/0903

15

Page 16

3

GAS-FIRED WATER BOILER — Boiler Manual

Install water piping

Zoning with circulators

1. Connect boiler to system as shown in Figure 8 when

circulator zoning. The boiler circulator cannot be used

for a zone. It must supply only the boiler loop.

2. Install a separate circulator for each zone.

3. When using a closed-type expansion tank, connect

the expansion tank and make-up water piping as

shown in Figure 4, page 13.

4. Connect DHW (domestic hot water) piping to indirect

storage water heater as shown.

The PhD Control Module turns off

space heating during DHW heating. The

boiler circulator will turn off, preventing

hot water from circulating to the system.

The flow/check valve shown on the boiler

outlet piping prevents gravity circulation

in the boiler loop during DHW heating.

NOTE 1: To ensure adequate flow rate through the

boiler , use the follo wing pipe size on all boiler

loop piping (connecting boiler to and from

the primary/secondary connection, item 21):

Ultra-80 or Ultra-105 – 1" or larger .

Ultra-155 or -230 – 1¼" or larger .

Ultra-310 – 1½" or larger.

Use at least the minimum piping size above

and pipe the boiler using only primary/

secondary piping as shown. Failure to

follow these guidelines could result in

system problems.

(continued)

Figure 8 Circulator zoning plus optional

DHW piping

16

Legend Figure 8

1 Ultra boiler

2 Indirect water heater (DHW), if used

3 Boiler relief valve (see page 12 for piping details)

4 Relief valve discharge piping (see page 12 for details)

5 DHW circulator (see page 14 for suggested sizing)

6 Isolation valves

7 System circulator

8 Diaphragm (or bladder) type expansion tank (see page 12

for piping of closed-type expansion tank, if used)

9 Air separator [with automatic air vent only on systems

using diaphragm (or bladder) type expansion tank]

10 Flow/check valves (with weighted seats to prevent gravity

circulation)

11 Purge/drain valves

12 Boiler circulator

14 Zone circulators, typical

20 Make-up water supply

21 Primary/secondary connection

Part number 550-101-233/0903

Page 17

3

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

Install water piping

(continued)

Radiant heating applications

1. The Ultra boiler is ideal for use in radiant heating. The Ultra boiler’s

unique heat exchanger design allows it to work well even in condensing

mode. So there is no need to regulate boiler return water temperature in

radiant heating applications.

2. Connect boiler to system as shown in Figure 9 for typical radiant heating

applications. The primary/secondary piping shown ensures the boiler

loop will have sufficient flow. Size the system piping and circulator to

provide the flow and pressure drop needed for the radiant system.

3. Add the high limit control (Figure 9, item 22) to ensure supply water

temperature will not exceed the maximum allowable for the radiant

system. Wire this limit control between low voltage terminal strip terminals

6 and 7.

4. When using a closed-type expansion tank, connect the expansion tank

and make-up water piping as shown in Figure 4, page 13.

5. Connect DHW (domestic hot water) piping to indirect storage water

heater as shown.

The PhD Control Module turns off space heating during

DHW heating. The boiler circulator will turn off, preventing

hot water from circulating to the system. The flow/check valve

shown on the boiler outlet piping prevents gravity circulation

in the boiler loop during DHW heating.

Figure 9 Typical radiant heating system

piping plus optional DHW

6. Controlling the system circulator

a. To cycle the system circulator from the Ultra PhD control module, add a

circulator relay wired to the boiler circulator terminals as shown in the Ultra

Control Supplement

7. Setting boiler outlet water target temperature.

a. Follow procedure in Ultra Control Supplement to set space heating target

temperature to the desired supply temperature for the system. For outdoor

reset operation, install and connect the outdoor temperature sensor supplied

with the boiler.

NOTE 1: T o ens ure adequate flow rate thr ough the boiler , use the foll owing

pipe size on all boiler loop piping (connecting boiler to and from

the primary/secondary connection, item 21):

Ultra-80 or Ultra-105 – 1" or larger .

Ultra-155 or -230 – 1¼" or larger .

Ultra-310 – 1½" or larger.

Legend Figure 9

1 Ultra boiler

2 Indirect water heater (DHW), if used

3 Boiler relief valve (see page 12 for piping details)

4 Relief valve discharge piping (see page 12 for details)

5 DHW circulator (see page 14 for suggested sizing)

6 Isolation valves

7 System circulator

8 Diaphragm (or bladder) type expansion tank (see page 12 for piping of closed-

type expansion tank, if used)

9 Air separator [with automatic air vent only on systems using diaphragm (or

bladder) type expansion tank]

Use at least the minimum piping size at left

and pipe the boiler using only primary/

secondary piping as shown. Failure to

follow these guidelines could result in

system problems.

10 Flow/check valves (with weighted seats to prevent gravity

circulation)

11 Purge/drain valves

12 Boiler circulator

13 Zone valves, when used (zoning may also be done using

manifold-mounted valve actuators)

20 Make-up water supply

21 Primary/secondary connection

22 High limit temperature control, set to protect radiant tubing

Part number 550-101-233/0903

17

Page 18

3

GAS-FIRED WATER BOILER — Boiler Manual

Install water piping

(continued)

Chilled water systems

1. Install boiler so that chilled medium is piped in parallel with the heating

boiler. U se appropriat e valves to pr event chilled medium from entering

boiler. See Figure 10 for typical installation of balancing valve and check

valve.

2. The space heating system may be zoned with circulators if a separate

circulator is supplied for the chilled water loop.

3. If boiler is connected to heating coils located in air handling units where

they can be exposed to refrigerated air, use flo w control valv es or other

automatic means to prevent gravity circulation during cooling cycle.

Follow these piping guidelines below to ensure chilled water

does not enter the boiler loop.

Chilled medium, if used, is piped in parallel with heating boiler

as shown in Figure 10. Use appropriate valves to prevent chilled

medium from entering boiler .

If boiler is connected to heating coils located in air handling

units where they can be exposed to refrigerated air, use flow

control valves or other automatic means to prevent gravity

circulation during cooling cycle.

NOTE 1: T o ens ure adequate flow rate thr ough the boiler , use the follo wing

pipe size on all boiler loop piping (connecting boiler to and from

the primary/secondary connection, item 21):

Ultra-80 or Ultra-105 – 1" or larger .

Ultra-155 or -230 – 1¼" or larger .

Ultra-310 – 1½" or larger.

Use at least the minimum piping size above and pipe the boiler

using only primary/secondary piping as shown. Failure to

follow these guidelines could result in system problems.

Figure 10 Chilled water system plus optional

DHW piping

Legend Figure 10

1 Ultra boiler

2 Indirect water heater (DHW), if used

3 Boiler relief valve (see page 12 for piping details)

4 Relief valve discharge piping (see page 12 for details)

5 DHW circulator (see page 14 for suggested sizing)

6 Isolation valves

7 System circulator

9 Air separator (DO NOT use automatic air vents on systems fitted with closed-

type tanks)

10 Flow/check valves (with weighted seats to prevent gravity circulation)

11 Purge/drain valves

18

12 Boiler circulator

13 Zone valves, typical

15 Closed-type expansion tank

16 Water chiller

17 Check valve

18 Strainer

19 Balancing valve

20 Make-up water supply

21 Primary/secondary connection

Part number 550-101-233/0903

Page 19

4

GAS-FIRED WATER BOILER — Boiler Manual

Venting, combustion air & condensate line

Install vent and combustion air

piping

Ultra Boiler must be vented and supplied

with combustion and ventilation air as

described in Weil-McLain Ultra Boiler V ent

Supplement (included in envelope

assembly). Ensure the vent and air piping

and the combustion air supply comply

with these instructions regarding vent

system, air system and combustion air

quality. See also Section 1 of this manual.

Inspect finished vent and air piping

thoroughly to ensure all are airtight and

comply with the instructions provided and

with all requirements of applicable codes.

Failure to provide a properly-installed vent

and air system will cause severe personal

injury or death.

Prepare condensate fittings

1. Remove PV C fittings and gasket from the acc essories

bag.

2. Deburr and chamfer outside and inside of ½" x 1¼"

PVC nipple t o ensure even cement distribution when

joining.

3. Clean nipple ends and all fittings. Dry thoroughly.

4. For each joint in the condensate line, apply the

following. Assemble parts ONL Y in the o rder given.

a. Apply primer liberally to both joint surfaces — pipe

end and fitting socket.

b. While primer is still damp, lightly apply approved cement

to both surfaces in a uniform coating.

Figure 11 Condensate trap assembly

c. Apply a second coat of cement to both surfaces. A v oid

using too much cement on sockets to prevent cement

buildup inside.

d. With cement still wet, insert pipe into fitting, twisting

¼ turn. Make sure pipe is fully inserted.

e. Wipe excess cement from joint. Check joint to be sure

a smooth bead of cement shows around the entire

joint.

5. See Figure 11.

6. Assemble the ½" PVC nipple to the PVC reducing

elbow as shown.

7. Allow joint to dry completely . Then slide gasket ove r

nipple as shown.

8. Slide nipple through jacket condensate line hole to

position as shown in Figure 13, page 20.

9. Cement the ½" tee to the protruding ½" nipple. Be

sure both nipple and reducing elbow finish upright.

IMPORT ANT : Firmly press the reducing elbo w and

the tee together while the cement sets to ensure the

gasket is securely compressed. The gasket ensures the

jacket enclosure is airtight at this location.

Part number 550-101-233/0903

19

Page 20

4

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

Venting, combustion air & condensate line

Connect condensate drain

1. Remove condensate trap line from bag. Prepare and

install per page 19. Secure to jacket by attaching PV C

tee as shown in Figure 13.

2. Slide trap line onto flue outlet condensate connection

and PVC reducing e lbo w as shown in Figure 12, 13

or 14. Secure with hose clamps.

3. Connect condensat e drain tubing to the ½" PVC tee

and run to floor drain or condensate pump. Use ½"

PVC or CPV C pipe; o r 5/8" I.D . tubing.

Use materials approved by the authority

having jurisdiction. In the absence of other

authority, PVC and CPVC pipe must

comply with ASTM D1785, F441 or D2665.

Cement and primer must comply with

ASTM D2564 or F493. For Canada, use

CSA or ULC certified PV C or CPVC pipe,

fittings and cement.

4. Leave the top of the ½" tee OPEN. This is needed as a

vacuum break.

5. When installing a condensate pump, select one

approved for use with condensing boilers and

furnaces. The pump should have an overflow switch

to prevent property damage from condensate spillage.

6. Condensate from the Ultra boiler will be slightly acidic

(typically with a pH from 3.2 to 4.5). Install a

neutralizing filter if required by local codes.

Figure 12 Condensate drain — Ultra-80 & -105

Figure 13 Condensate drain — Ultra-155 & -230

(PVC tee installation shown applies

to all models))

(continued)

The condensate line must remain

unobstructed, allowing free flow of

condensate. If condensate is allowed to

freeze in the line or if the line is obstructed

in any other manor, condensate can exit

from the boiler tee, resulting in potential

water damage to pro perty .

Figure 14 Condensate drain — Ultra-310

20

Part number 550-101-233/0903

Page 21

5

Gas piping

GAS-FIRED WATER BOILER — Boiler Manual

Connecting gas supply piping

1. Remove jacket front panel and refer to Figure 15 to

pipe gas to boiler.

a. Install ground joint union for servicing, when required.

b. Install manual shutoff valve in gas supply piping outside

boiler jacket when required by local codes or utility

requirements.

c. In Canada — When using manual main shutoff valve,

it must be identified by the installer.

2. W all-mounted boilers

a. Refer to separate Ultra Boiler Wall-mounting

instructions.

b. Gas connection may enter from the bottom of boiler

as explained in the Wall-mounting instructions.

3. Support piping with hangers, not by boiler or its

accessories.

Figure 15 Connect gas supply piping

4. Purge all air from gas supply piping.

5. Before placing boiler in operation, check boiler and

its gas connection for leaks.

a. Close manual main shutoff valve during any pressure

testing at less than 13" w.c.

b. Disconnect boiler and gas valve from gas supply piping

during any pressure testing greater than 13" w.c.

Do not check for gas leaks with an open

flame — use bubble test. Failure to use

bubble test or check for gas leaks can cause

severe personal injury , death or substantial

property damage.

6. Use pipe dope compatible with propane gases. Apply

sparingly only to male threads of pipe joints so that

pipe dope does not block gas flow.

Failure to apply pipe dope as detailed above

can result in severe personal injury , d eath

or substantial property damage.

DO NOT adjust or attempt to measure

gas valve outlet pressure. The gas valve is

factory-set for the correct outlet pressure.

This setting is suitable for natural gas and

propane, requiring no field adjustment.

Attempting to alter or measure the gas valve

outlet pressure could result in damage to

the valve, causing potential severe personal

injury, death or substantial property

damage.

Part number 550-101-233/0903

Ultra boilers are shipped ready to fire

natural gas ONLY. (Exception: Ultra-80LP

is propane-ready.) You must install the

propane orifice if the boiler will be

connected to propane. See page 9. Failure

to comply could result in severe personal

injury, death or substantial property

damage.

Use two wrenches when tightening gas piping at boiler , using one wrench to prevent the boiler gas line

connection from turning. Failure to support the boiler gas connection pipe to prevent it from turning

could damage gas line components.

21

Page 22

5

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

Gas piping

Natural Gas:

Pipe sizing for natural gas

1. Refer to T a ble 4 for pipe length and diameter . Base on

rated boiler input (divide by 1,000 to obtain cubic

feet per hour).

a. Tab le 4 is only for natural gas with specific gravity 0.60,

with a pressure drop through the gas piping of 0.30"

w.c.

b. For additional gas pipe sizing information, refer to

ANSI Z223.1 (or B149.1 or B149.2 for Canadian

installations).

Natural gas supply pressure requirements

1. Pressure required at gas valve inlet pressure port:

• Maximum: 13" w.c. with no flow (lockup) or w ith

boiler on

• Minimum: 5" w.c. with gas flowing (verify during boiler

startup, while boiler is at high fire)

2. Install 100% lockup gas pressure regulator in supply

line if inlet pressure can exceed 13" w .c. at any time.

Adjust lockup regulator f or 13" w.c. maximum.

(continued)

Propane Gas:

Ultra boilers are shipped ready to fire

natural gas ONLY (ex ception: Ultra-80-LP

is propane-ready). You must install the

propane orifice if the boiler will be

connected to propane. See page 9. Failure

to comply could result in severe personal

injury, death or substantial property

damage.

Pipe sizing for natural gas

1. Contact gas supplier to size pipes, tanks and 100%

lockup gas pressure regulator .

Propane supply pressure requirements

1. Adjust propane supply regulator provided by gas

supplier for 13" w .c. maxim um pressure.

2. Pressure required at gas valve inlet pressure port:

• Maximum: 13" w.c. with no flow (lockup) or w ith

boiler on

• Minimum: 4" w.c. with gas flowing (verify during boiler

startup, while boiler is at high fire)

Table 4 Pipe capacity for 0.60 specific gravity natural gas

Gas pipe

length

(feet)

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 860

40 63 130 245 500 760

50 56 115 215 440 670

75 45 93 175 360 545

100 38 79 150 305 460

150 31 64 120 250 380

½" ¾" 1" 1¼" 1½"

Capacity of pipe for pipe size of:

(Capacity in cubic feet gas per hour)

22

Part number 550-101-233/0903

Page 23

6

Startup

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

Check/control water chemistry

Do not use petroleum-based cleaning or sealing

compounds in boiler system. Damage to elastomer

seals and gaskets in system could occur , resulting in

substantial property damage.

Before filling the boiler and system with water, verify

the following. Failure to comply could result in boiler

failure or unreliable operation.

Water pH between 7.0 and 8.5

1. Maintain boiler water pH between 7.0 and 8.5. Check with

litmus paper or have chemically analyzed by water treatment

company.

2. If pH differs from above, consult local water treatment

company for treatment needed.

Hardness less than 7 grains

1. Consult local water treatment companies for unusually hard

water areas (above 7 grains hardness).

Chlorine concentration less than 200 ppm

1. Filling with chlorinated fresh water should be acceptable since

drinking water chlorine levels are typically less than 5 ppm.

2. Do not use the boiler to directly heat swimming pool or spa

water .

3. Do not fill boiler or operate with water containing chlorine in

excess of 200 ppm.

Clean system to remove sediment

1. You must thoroughly flush the system (without boiler

connected) to remove sediment. The high-efficiency heat

exchanger can be damaged by buildup or corrosion due to

sediment.

2. For zoned systems, flush each zone separately through a purge

valve. (If purge valves and isolation valves are not already

installed, install them to properly clean the system.)

3. Flush system until water runs clean and you are sure piping is

free of sediment.

Test/replace freeze protection fluid

1. For systems using freeze protection fluids, follow guidelines in

Ultra Boiler Freeze Protection Supplement.

Freeze protection (when used)

NEVER use automotive or standard glycol antifreeze,

even glycol made for hydronic systems. Use only

freeze-protection fluids recommended in the Ultra

Boiler Freeze Protection Supplement. Follow all

guidelines in the Freeze Protection Supplement, and

thoroughly clean and flush any replacement boiler

system that has used glycol before installing the new

Ultra boiler.

1. Determine freeze protection fluid quantity using total system

water content, following fluid manufacturers’s instructions.

Boiler water content is listed on page 43. Remember to include

expansion tank water content.

2. Local codes may require back flow preventer or actual

disconnect from city water supply .

3. When using freeze protection fluid with automatic fill, install a

water meter to monitor water make-up. Freeze protection fluid

may leak before the water begins to leak, causing concentration

to drop, reducing the freeze protection level.

Fill and test water system

1. Fill system only after ensuring the water meets the requirements

of this manual.

2. Close manual and automatic air vents and boiler drain valve.

3. Fill to correct system pressure. Correct pressure will vary with

each application.

a. Ty pical cold water fill pressure for a residential system is 12 psi.

b. Pressure will rise when boiler is turned on and system water

temperature increases. Operating pressure must never exceed 25 psig.

4. At initial fill and during boiler startup and testing, check system

thoroughly for any leaks. Repair all leaks before proceeding

further.

Eliminate all system leaks. Continual fresh make-up

water will reduce boiler life. Minerals can build up in

sections, reducing heat transfer, overheating heat

exchanger , and causing heat ex changer failure.

5. The system may have residual substances that could affect

water chemistry . After the sy stem has been filled and leak tested,

verify water pH and chlorine concentrations are acceptable.

Purge air from water system

1. Purge air from system:

a. Connect a hose to the purge valve (see purge/drain valves, item 11,

in piping diagrams on pages 15 through 18. Route hose to an area

where water can drain and be seen.

b. Close the boiler or system isolation valve between the purge valve

and fill connection to the system.

c. Close zone isolation valves.

d. Open quick-fill valve on cold water make-up line.

e. Open purge valve.

f. One zone at a time, open the isolation valves. Allow water to run

through the zone, pushing out the air. Run until no noticeable air

flow is present. Close the zone isolation valves and proceed with the

next zone. Follow this procedure until all zones are purged.

g. Close the quick-fill water valve and purge valve and remove the

hose. Open all isolation valves. Watch that system pressure rises to

correct cold-fill pressure.

h. After the system has operated for a while, eliminate any residual air

by using the manual air vents located throughout the system.

i. If purge valves are not installed in system, open manual air vents in

system one at a time, beginning with lowest floor. Close vent when

water squirts out. Repeat with remaining vents.

2. Open automatic air vent (diaphragm-type or bladder-type

expansion tank systems only) one turn.

3. Open other vents:

a. Starting on the lowest floor, open air vents one at a time until water

squirts out.

b. Repeat with remaining vents.

4. Refill to correct pressure.

Part number 550-101-233/0903

23

Page 24

6

GAS-FIRED WATER BOILER — Boiler Manual

Startup

(continued)

Check for gas leaks

Before starting the boiler, and during initial operation, smell

near the floor and around the boiler for gas odorant or any

unusual odor. Re move boiler fr ont door and smell interior of

boiler enclosure. Do not proceed with startup if there is any

indication of a gas leak. Repair any leak at once.

DO NOT adjust or attempt to measure gas valve outlet pressure.

The gas valve is factory-set for the correct outlet pressure. This

setting is suitable for natural gas and propane, requiring no

field adjustment. Attempting to alter or measure the gas valve

outlet pressure could result in damage to the valve, causing

potential severe perso nal injury, death or substantial pro perty

damage.

Propane boilers only — Your propane supplier mixes an

odorant with the propane to make its presence detectable. In

some instances, the odorant can fade, and the gas may no

longer have an odor. Before startup (and periodically

thereafter), have the propane supplier verify the correct odorant

level in the gas.

Check thermostat circuit(s)

1. Disconnect the two external wires connected to the boiler thermostat

terminals (low voltage terminal strip terminals 5 and 6).

2. Connect a voltmeter across these two incoming wires. Close each

thermostat, zone valve and relay in the external circuit one at a time and

check the voltmeter reading across the incoming wires.

3. There should NEVER be a voltage reading.

4. If a voltage does occur under any condition, check and correct the external

wiring. (This is a common problem when using 3-wire zone valves.)

5. Once the external thermostat circuit wiring is checked and corrected if

necessary, r econnect the ext ernal thermostat circuit wires to bo iler low

voltage terminal strip terminals 5 and 6. Allow the boiler to cycle.

Inspect/fill condensate system

Inspect/check condensate lines and fittings

1. Inspect the condensate drain line, condensate PVC fittings and condensate

trap. (See page 20 for component locations.)

2. Pour water int o the top of the boiler’s ½" PV C c ondensate t ee and check

for any leaks in the condensate drain line or fittings. Repair any leaks.

Fill condensate trap with water

1. Loosen the hose clamp securing the right end of the condensate trap to

the PVC r educing elbow (see page 20).

2. Slide the trap hose end off of the elbow.

3. Fill the trap with fresh water to within a inch of the end of the hose.

4. Replace trap hose on PV C reducing elbo w and tighten the hose clamp.

The condensate trap (page 3, item 23a) must be filled with water

during all times of boiler operation to avoid flue gas emission

from the condensate drain line. Failure to fill the trap could

result in severe personal injury or death.

Final checks before starting boiler

Read the Ultra Control Supplement to familiarize

❏

yourself with Ultra PhD control module operation.

Read Operating Instructions in Control Supplement

for proper steps to start boiler.

V erify the boiler and system are full of water and all

❏

system components are correctly set for operation.

Verify the preparation procedures of se ction 6,

❏

pages 23 and 24 have been completed.

Fill vent condensate trap with water (by removing

❏

hose clamp and hose at PVC reducing elbow).

Replace hose on PV C r educing elbow and tighten

clamp.

V erify electrical connections are correct and securely

❏

attached.

Inspect vent piping and air piping for signs of

❏

deterioration from corrosion, physical damage or

sagging. Verify air piping and vent piping are intact

and correctly installed per Ultra Boiler Vent

Supplement.

To start the boiler

1. T urn OFF Po wer switch on Ultra display panel. T urn

on power to boiler .

2. Read and follow the Operating Instructions in the

Ultra Control Supplement.

If boiler does not start correctly

1. Check for loose connections, blown fuse or service

switch off?

2. Is external limit control (if used) open? Is boiler water

temperature above 200 °F?

3. Is thermostat set below room temperature?

4. Is gas turned on at meter or boiler?

5. Is incoming gas pressure less than 4" w .c. for natural

gas or 5” w.c. for propane?

6. Are parameters set correctly as instructed in the Ultra

Control Supplement?

If none of the above corrects the problem, refer to

T roubleshooting in the U ltra Control Supplement.

24

Part number 550-101-233/0903

Page 25

6

3600 x 1000

number of seconds from step c

= Btuh

GAS-FIRED WATER BOILER — Boiler Manual

GAS-FIRED WATER BOILER — Boiler Manual

Startup

(continued)

❏ Check system and boiler

❏❏

❏ Check water piping

❏❏

1. Check system piping for leaks. If found, shut down

boiler and repair immediately . (See WARNINGS on

page 23 regarding failure to repair leaks.)

2. Vent any remaining air from system using manual