Page 1

NOTICE:

Series 1/Series 2 identification

Read the boiler rating plate to

determine the series number. The

rating plate is located on the right

side of the boiler.

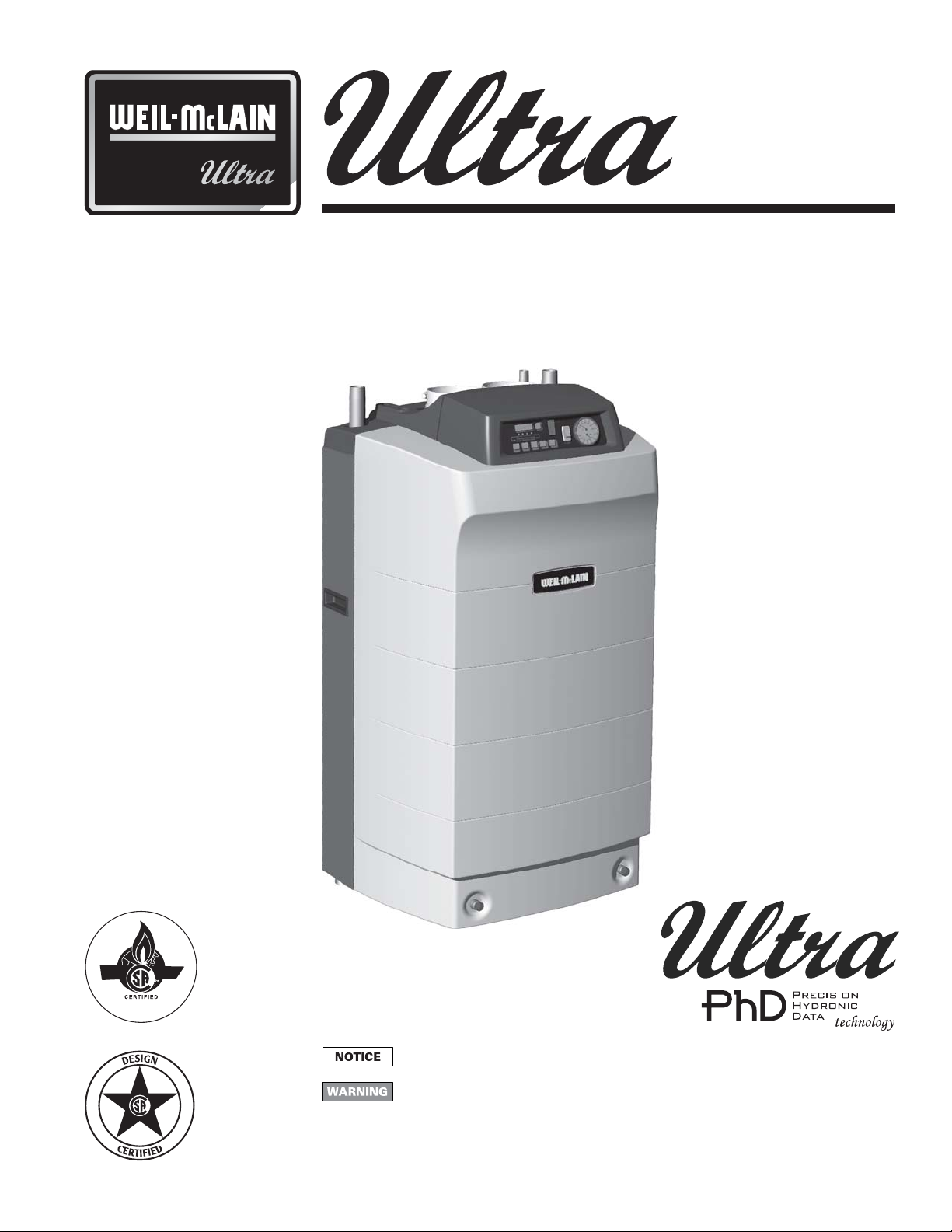

Gas-fired

Water boiler

Series 2

Control Supplement

Ultra-80, -105, -155, -230 & -310

• Wiring

• Operation

• Troubleshooting

with

Instructions in this supplement are based on factory default parameter settings.

This document is a supplement to the Ultra Boiler Manual, and must only be used

by a qualified heating installer/service technician. Read all instructions, including

the Ultra Boiler Manual, before installing, starting or servicing the boiler. Perform

all steps in the order given. Failure to comply could result in severe personal injury,

death or substantial property damage.

Part number 550-100-029/0404

Page 2

Contents

Please read before proceeding ............................................................. 3

Hazard definitions ................................................................................. 3

1 Field wiring ........................................................................................ 4

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

2 Startup

(

Note 1

) ................................................................................... 6

3 Operating information ...................................................................... 9

4 Troubleshooting .............................................................................. 21

Note 1:

See Ultra Boiler Manual for installation procedures and

additional startup and operating information, and

replacement parts.

2

Part number 550-100-029/0404

Page 3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Please read before proceeding

Installer— Read all instructions, including

this manual, Ultra Boiler Manual, and the

Ultra Vent Supplement, before installing.

Perform steps in the order given.

User — This manual is for use only by a

qualified heating installer/service

technician. Refer to User’s Information

Manual for your reference.

User — Have this boiler serviced/

inspected by a qualified service technician,

at least annually.

Failure to comply with the above could

result in severe personal injury, death or

substantial property damage.

When calling or writing about the boiler—

Please have the boiler model number from

the boiler rating label and the CP number

from the boiler jacket. You may list the CP

number in the space provided on the

Installation and service certificate found on

page 27 of the Ultra Boiler Manual.

Consider piping and installation when

determining boiler location.

Any claims for damage or shortage in

shipment must be filed immediately

against the transportation company by the

consignee.

When servicing boiler —

• To avoid electric shock, disconnect electrical supply before performing

maintenance.

• To avoid severe burns, allow boiler to cool before performing

maintenance.

Commonwealth of Massachusetts

When the boiler is installed within the Commonwealth of Massachusetts:

• This product must be installed by a licensed plumber or gas fitter.

• If antifreeze is used, a reduced pressure back-flow preventer device

shall be used.

Failure to adhere to the guidelines on this page can

result in severe personal injury, death or substantial

property damage.

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various

risk levels or to important information concerning the life of the product.

Indicates presence of hazards that will cause severe personal injury, death or substantial property

damage.

Indicates presence of hazards that can cause severe personal injury, death or substantial property

damage.

Indicates presence of hazards that will or can cause minor personal injury or property damage.

Indicates special instructions on installation, operation or maintenance that are important but not

related to personal injury or property damage.

Part number 550-100-029/0404

3

Page 4

1

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Field wiring

ELECTRICAL SHOCK HAZARD —

For your safety, turn off electrical power

supply at service entrance panel before

making any electrical connections to avoid

possible electric shock hazard. Failure to

do so can cause severe personal injury or

death.

Wiring must be N.E.C. Class 1. If original

wiring as supplied with boiler must be

replaced, use only type 105 °C wire or

equivalent. Boiler must be electrically

grounded as required by National Electrical

Code ANSI/NFPA 70 – latest edition.

Install field wiring before venting to allow

easier access to terminal strips.

Installation must comply with:

1. National Electrical Code and any other national, state,

provincial or local codes or regulations.

2. In Canada, CSA C22.1 Canadian Electrical Code Part 1,

and any local codes.

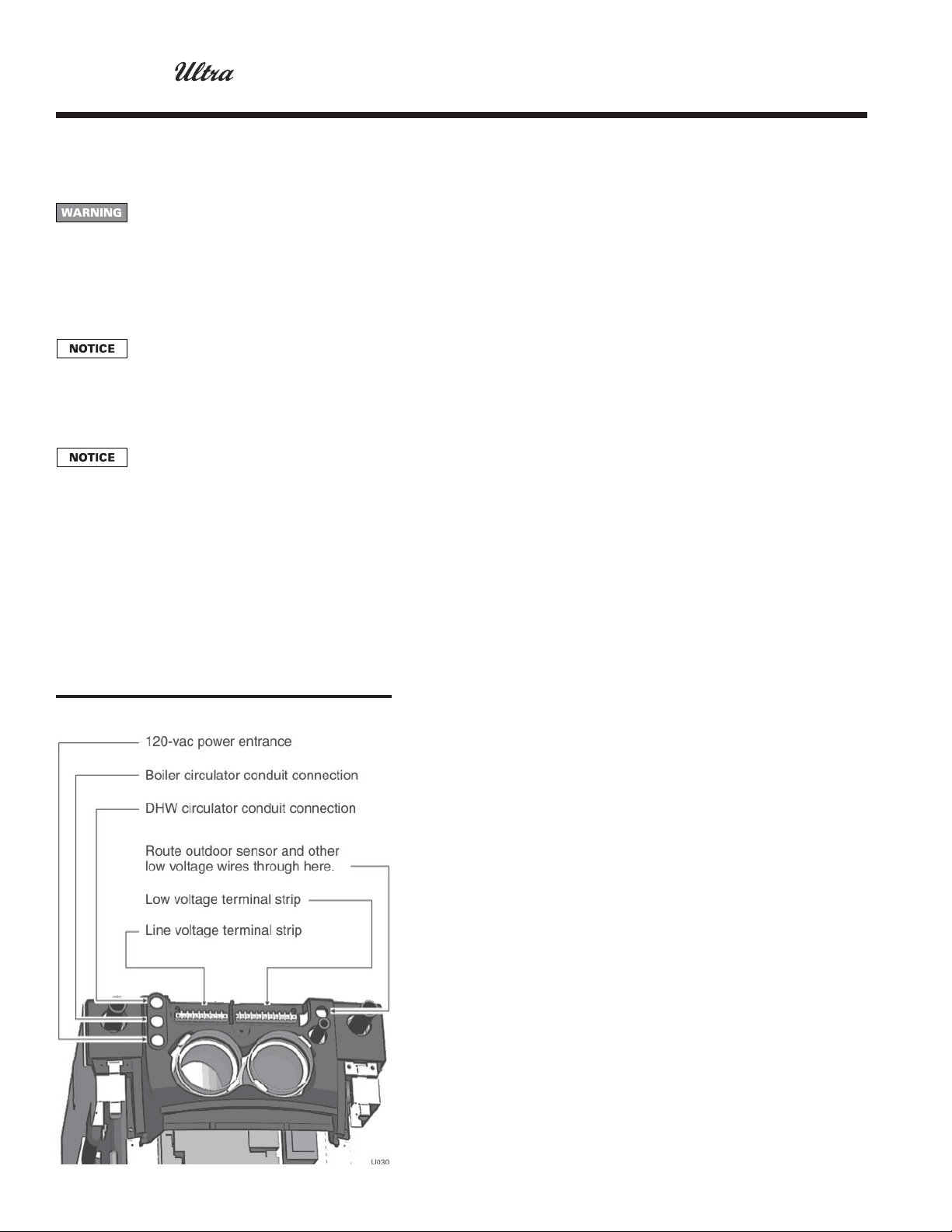

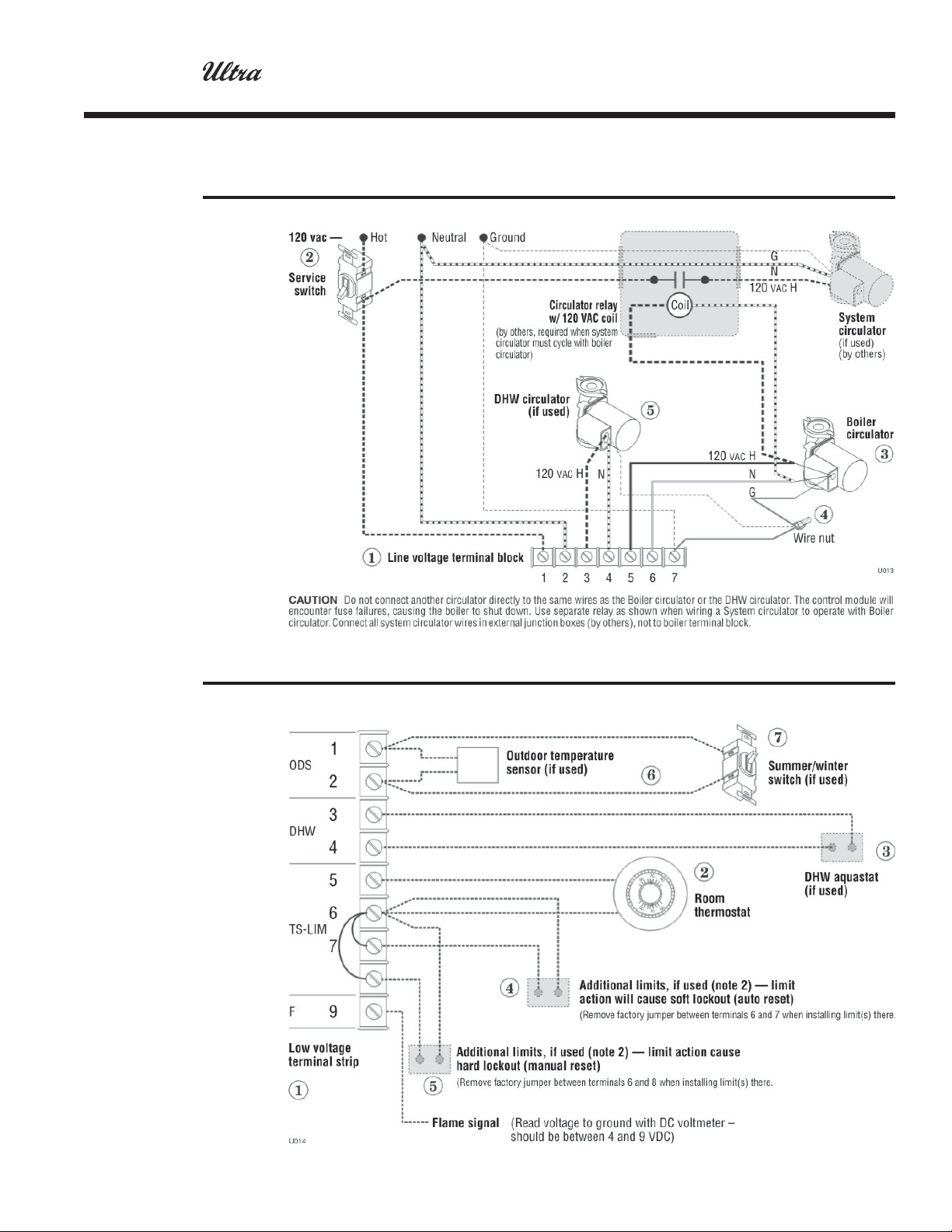

Line voltage connections

1. Connect 120 VAC power wiring to line voltage terminal

strip in left compartment of electrical entrance, as shown

in Figure 2, page 5, item 1.

Figure 1 Routing field wiring

2. Provide and install a fused disconnect or service switch (15 amp. recommended)

as required by the code. (See Figure 2, item 2)

3. Boiler circulator is shipped loose. Wire Boiler circulator as shown for Figure 2,

item 3.

4. When connecting a DHW circulator, connect wiring to line voltage terminal

strip as shown for Figure 2, item 5.

5. Route all wires and conduits to the jacket openings specified in Figure 1.

Wiring a system circulator

1. To activate a system circulator when the Boiler circulator operates, add a circulator

relay and wire as shown in Figure 2.

2. You must install a relay as shown. DO NOT wire in parallel with the Boiler

circulator. See CAUTION in Figure 2.

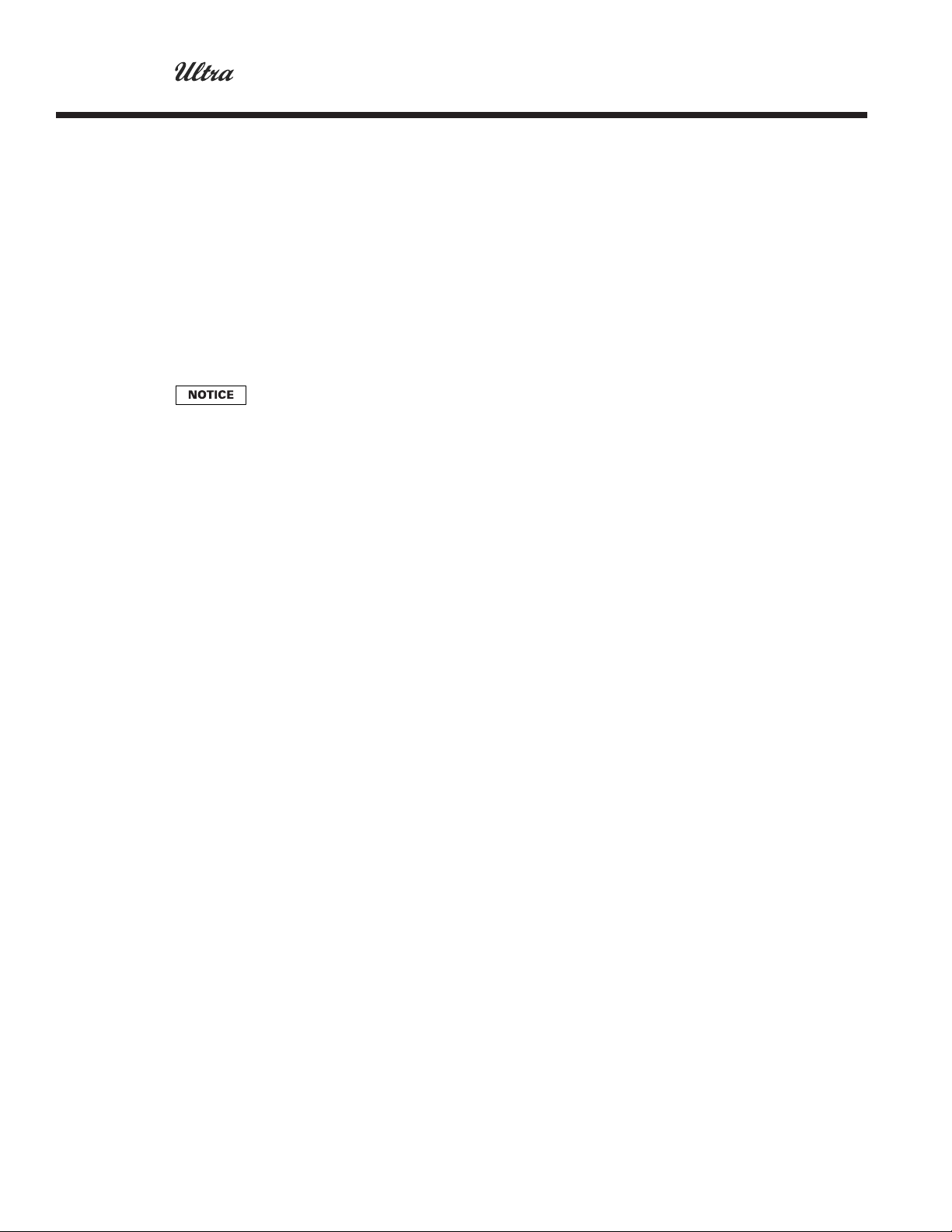

Low voltage connections

1. Connect low voltage wiring to low voltage terminal strip (Figure 3, page 5,

item 1) as shown in Figure 3 and the boiler wiring diagram.

2. Route all low voltage wires through grommeted jacket opening to right of low

voltage terminal strip, as shown in Figure 1.

Thermostat

1. Connect Figure 3, item 2, room thermostat or end switch (isolated contact

only) between terminals 5 and 6.

2. Install thermostat on inside wall away from influences of drafts, hot or cold

water pipes, lighting fixtures, television, sunrays, or fireplaces.

3. Thermostat anticipator (if applicable):

a. If connected directly to boiler, set for 0.1 amps.

b. If connected to relays or other devices, set to match total electrical power

requirements of connected devices. See device manufacturers’ specifications

and thermostat instructions for details.

Outdoor temperature sensor

1. Connect outdoor temperature sensor (Figure 3, item 6) between terminals 1

and 2 to enable outdoor reset operation of the Ultra boiler. If fixed-temperature

operation is required, do not install outdoor sensor.

2. Mount sensor on exterior wall, shielded from direct sunlight or flow of heat or

cooling from other sources.

3. If desired, install a summer/winter switch (Figure 3, item 7) across terminals 1

and 2. When the switch is closed, the boiler (space heating) circulator is disabled.

4. Route sensor wires through the hole at the right of the electrical entrance (see

Figure 1).

DHW aquastat

1. Connect storage indirect water heater (DHW) aquastat (Figure 3, item 3) between

terminals 3 and 4.

Additional limits

1. Connect additional limit controls and interlocks between the terminals shown

in Figure 3.

2. Controls connected between terminals 6 and 7 (see Figure 3, item 4) will cause

a soft lockout (automatic reset). When limit(s) closes, boiler will resume normal

operation.

3. Controls connected between terminals 6 and 8 (see Figure 3, item 5) will cause

a hard lockout (manual reset). The boiler will only restart after the Ultra display

panel RESET switch is pressed.

4

Part number 550-100-029/0404

Page 5

1

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Field wiring

Figure 2 Line voltage field wiring connections (service switch provided by installer)

(continued)

Figure 3 Low voltage field wiring connections

Part number 550-100-029/0404

5

Page 6

2

Startup

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Startup

1. Start the boiler only after completing all instructions

in the Ultra Boiler Manual.

2. To start the boiler, follow the procedure given in

Figure 4, page 7.

3. Once the boiler has started and is operating, continue

the startup procedure by performing all of the

following steps to set and verify operation of the Ultra

controls.

(continued from Ultra Boiler Manual)

Instructions in this supplement are based

on factory default parameter settings.

Set space heating operation

Verify space heating mode

1. Press the “Mode” button until the display shows

“Para.” This is the parameter mode.

2. Press the “Step” button until the display first digit

shows “3.”

3. The last digit must show “1.” If any other number

displays, press the “+” button until “1” shows in the

right-hand digit. Press the “Store” button to save this

setting.

4. See page 18 for further information.

Set space heating target temperature

1. Press the Ultra control panel “Step” button until the

display first digit shows “4.” The right 3 digits show

the outlet water temperature setting.

2. Press the “+” or “-” button to change the setting to

the desired outlet water temperature. (The factory

default setting is 190 °F.)

a. Outdoor sensor installed — Setting is the target

temperature for outdoor temperature at or below

(factory setting) 32 °F. At higher outside temperatures,

the Ultra PhD control module calculates the target

temperature. (See pages 9 and 10 for detailed discussion

of outdoor reset.)

When a summer/winter switch is used, closing the switch

will disable the boiler (space heating) circulator during

summer operation.

b. Outdoor sensor not installed — Setting is the target

temperature at all times.

3. Press the “Store” button to save the setting.

Check DHW operation setup

1. Go to step 2 if the control is in Parameter mode

already. Press the “Mode” button until the display

shows “Para” (parameter mode).

2. Press the “Step” button until the display first digit

shows “2.”

3. The last digit must show “1.” If any other number

displays, press the “+” button until “1” shows in the

right-hand digit. Press the “Store” button to save this

setting.

4. The Ultra PhD control module turns on the DHW

circulator when the indirect water heater operating

control closes. The control module shuts off the boiler

circulator (stops space heating) during calls for DHW

heating.

Verify operation — space heating

NOTE: “[ _ _ _ _ ]” in the following indicates the characters

that should show on the Ultra display panel. “180” in the

right 3 places means the display shows the measured

boiler water temperature. The number shown will not

necessarily be 180.

1. Turn down DHW aquastat on DHW tank (if used).

If necessary, turn off power and remove one of the

DHW aquastat wires to ensure boiler will not receive

a DHW heat call.

2. Turn off power to boiler at service switch.

3. Wait a few seconds, then turn on power to boiler.

[A180] (self-check on power-up, for a few seconds)

[0180] (no call for heat)

4. Raise room thermostat to call for heat.

[5180] (blower/circulator on) The blower and boiler

circulator energize and the control checks for air flow.

[1180] (prepurge) Blower speed will increase to ignition

speed. The blower will run in prepurge for 10 seconds.

[2180] (ignition) After prepurge, the control module opens

the gas valve and starts ignition spark.

a. If burner flame proves within 4.5 seconds, burner

continues to fire. Burner will fire at startup rate

— 50% of maximum input — for about 10

seconds to allow flame to stabilize.

b. If burner flame does not prove within 4.5 seconds,

control module attempts ignition sequence again.

Flame must prove within 5 attempts or control

will lockout (display will show [E 02]).

c. Verify flame failure operation by closing boiler

manual gas cock to prevent gas flow. Open manual

gas valve after testing.

[3180] (burner on, space heating) Once flame is proven

and stable, the burner turns down to low fire for

approximately 2 minutes.

• After this low fire period, the burner is allowed to

modulate. Firing rate depends on actual outlet water

temperature versus target temperature.

6

Part number 550-100-029/0404

Page 7

2

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Startup

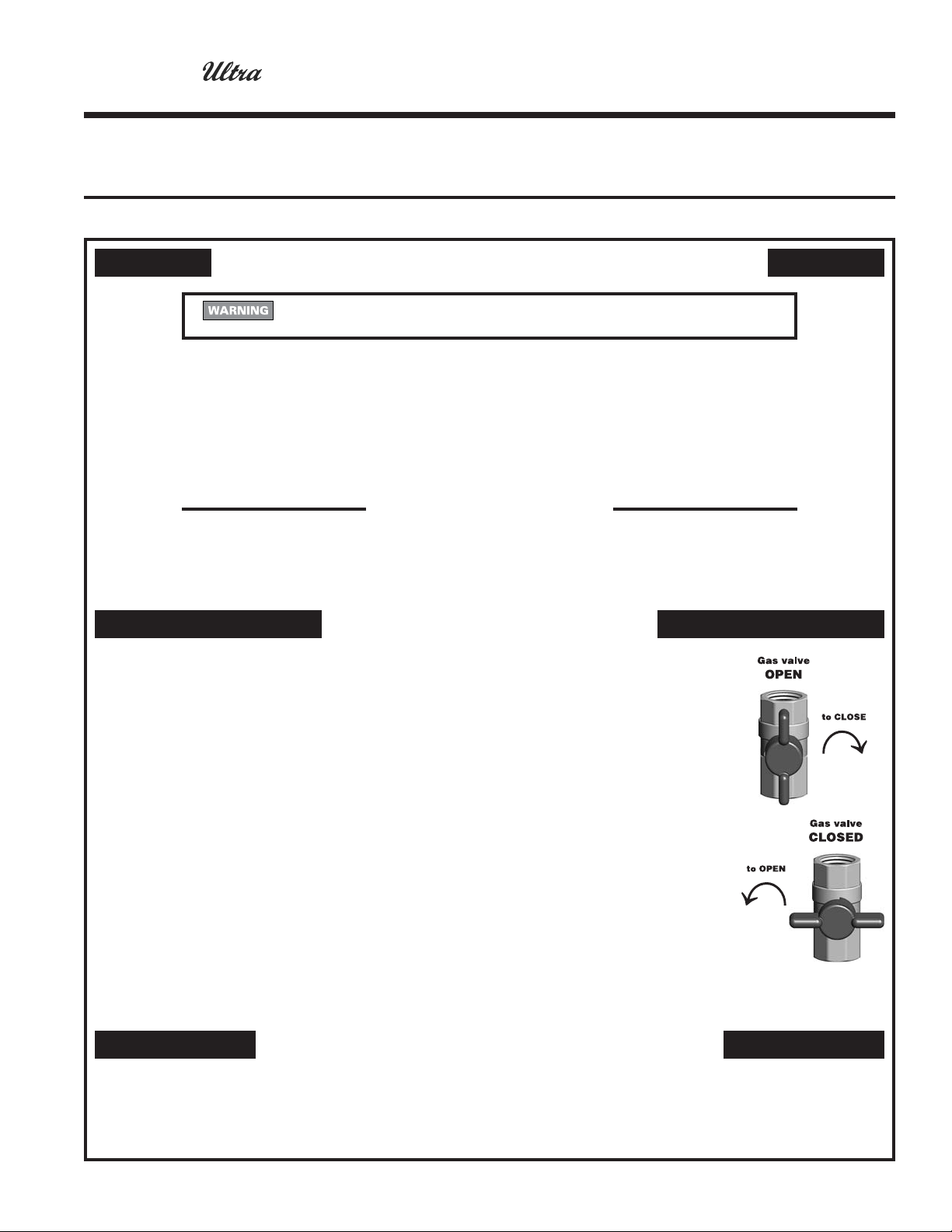

Figure 4 Operating Instructions

(continued)

(Read page 7 and the Ultra Boiler Manual before proceeding.)

FOR YOUR SAFETY READ BEFORE OPERATING

If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

A. This appliance does not have a pilot. It is equipped with an

ignition device which automatically lights the burner. Do

not try to light the burner by hand.

B. Before OPERATING, smell all around the appliance area

for gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor. See below.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in

your building.

C. Use only your hand to turn the gas control knob. Never use

tools. If the knob will not turn by hand, don't try to repair it;

call a qualified service technician. Force or attempted repair

may result in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control, which has been under water.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

OPERATING INSTRUCTIONS

1. Stop! Read the safety information above. This

appliance is equipped with an ignition device

which automatically lights the burner. Do not

try to light the burner by hand.

2. Set room thermostat(s) to lowest setting.

Verify external manual gas valve is open (valve

handle parallel to gas piping).

3. Turn OFF POWER switch on the Ultra control

panel.

4. Rotate two thumb screws at bottom of access

door counterclockwise to release door.

5. Remove boiler access door.

6. Turn boiler manual gas valve knob

counterclockwise to open gas supply.

7. Smell for gas in the boiler enclosure. If you

smell gas, STOP! Follow "B" in the safety

information above. If you don't smell gas, go

to the next step.

TO TURN OFF GAS TO THE APPLIANCE

8. Turn ON POWER switch on the Ultra

control panel.

9. Set thermostat(s) to desired setting.

10. The Ultra control panel display left digit will

show a sequence of numbers (0, 1, 2, etc.)

that indicate boiler control sequence. Digit 3

or 4 indicates boiler is firing. Digit 0 means

there is no call for heat (all room

thermostats and domestic water heater

satisfied).

11. If the appliance will not operate when there

is a call for heat and piping is not hot, follow

the instructions "To Turn Off Gas To

Appliance" below and call your service

technician or gas supplier.

12. Replace jacket front panel. Make sure panel

is seated firmly in place and all joints are

visually sealed. Then tighten the two thumb

screws at bottom of access door firmly.

Boiler manual

gas valve

1. Set room thermostats to lowest setting.

2. Turn off all electric power to the boiler if service is to be

performed. Turn OFF POWER switch on the Ultra control

panel.

Part number 550-100-029/0404

3. Close external manual gas cock (valve handle perpendicular

to gas piping). Remove boiler access door. Turn boiler manual

gas valve knob clockwise to close gas supply.

4. Replace boiler access door.

7

Page 8

2

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Startup

(continued)

Verify operation — space heating

(continued from previous page)

5. Allow boiler to bring water temperature to target

temperature.

[6180] (target temperature reached) The burner will shut

down. The blower will run in postpurge (see below),

then turn off. The boiler circulator continues to run as

long as there is a call for heat.

6. Lower room thermostat to stop call for heat.

[1180] (postpurge) When the room thermostat is satisfied

(call for heat ended), the burner turns off. The blower

will continue for a 15-second postpurge, then turn off.

(If another call for heat occurs, the boiler will remain

off for one minute before starting again, and the display

will show [6180].)

[0180] (no call for heat) Boiler is now in standby mode

(waiting for heat call).

7. Repeat above steps several times to verify operation.

8. Return the room thermostat to normal setting.

Verify operation — DHW

1. Reconnect DHW aquastat wiring to boiler if

necessary.

2. Turn off power to boiler at service switch.

3. Wait a few seconds, then turn on power to boiler.

[A180] (self-check on power-up, for a few seconds)

[0180] (no call for heat)

4. Raise DHW aquastat above tank temperature, to call

for heat.

[5180] (blower/circulator on) The blower and DHW

circulator energize and the control checks for air flow.

[1180] (prepurge) Blower speed will increase to ignition

speed. The blower will run in prepurge for 10 seconds.

[2180] (ignition) After prepurge, the control module opens

the gas valve and starts ignition spark.

a. If burner flame proves within 4.5 seconds, burner

continues to fire. Burner will fire at startup rate

— 50% of maximum input — for about 10

seconds to allow flame to stabilize.

b. If burner flame does not prove within 4.5 seconds,

control module attempts ignition sequence again.

Flame must prove within 5 attempts or control

will lockout (display will show [E 02]).

c. Verify flame failure operation by closing boiler

manual gas valve to prevent gas flow. Open gas

cock after testing.

[4180] (burner on, DHW) Once flame is proven and stable,

the burner is allowed to modulate. Firing rate depends

on actual outlet water temperature versus target

temperature.

5. Allow boiler to bring water temperature to target

temperature.

[6180] (target temperature reached) The burner will shut

down. The blower will run in postpurge (see below),

then turn off. The DHW circulator continues to run as

long as there is a call for DHW heating.

6. Lower DHW aquastat to stop call for heat.

[1180] (postpurge) When the room thermostat is satisfied

(call for heat ended), the burner turns off. The blower

will continue for a 15-second postpurge, then turn off.

(If another DHW call for heat occurs, the boiler will

begin the heating cycle immediately.)

[8180] (DHW circulator run-on) The DHW circulator

continues to run for 30 seconds.

[0180] (no call for heat) Boiler is now in standby mode

(waiting for heat call).

7. Repeat above steps several times to verify operation.

8. Return the DHW aquastat to normal setting.

Operating information

1. To check operating conditions (actual and target

temperatures, for example), see page 15 for an

explanation of the Ultra control module Information

mode.

2. During normal operation (no shutdown or lockout),

the right 3 display digits show actual boiler outlet

water temperature.

Perform Check-out procedures

1. Perform all steps of the Check-out/startup verification

listed in the Ultra Boiler Manual.

Replace boiler jacket front door

Replace boiler jacket front door after

servicing. The boiler front door must be

securely fastened to the boiler to prevent

boiler from drawing air from inside the

boiler room. This is particularly important

if the boiler is located in the same room as

other appliances. Failure to keep the door

securely fastened could result in severe

personal injury or death.

8

Part number 550-100-029/0404

Page 9

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

Ultra Control Module

The Ultra boiler is controlled by a microprocessor

electronic control — the Ultra

The module senses outlet water temperature, return water

temperature, flue temperature and outdoor temperature

(when outdoor sensor is installed). It uses this

information (plus input from external limit and operating

controls) to regulate boiler on/off operation and can

modulate boiler firing rate to more closely match output

to demand.

Control Module.

Electrical specifications

Ultra boilers require 120 VA C /60 HZ power supply and are

not polarity sensitive.

Control module specifications

• Supply voltage 120 vac / 60 hz

• Electrical demand 10 va

• Prepurge timing 10 seconds

• Postpurge timing 15 seconds

• Min. off time, space heating 1 minute

• Pump run on after space htg. 10 seconds

• Min. off time, DHW 0 seconds

• Pump run on after DHW 30 seconds

• Line voltage fuse, F1 5 amp fast-blow

• Low voltage fuse, F3 4 amp slow-blow

Boiler temperature regulation

Additional Thermal Overrun Protection

High limit operation shuts down the burner when the

outlet water temperature exceeds the target temperature.

However, adverse conditions could cause the water

temperature to rise too quickly, overshooting this

temperature. The Ultra control module’s technology

provides advanced protection in the event of thermal

overrun. Using its electronics, the Ultra control module

provides two additional levels of overrun protection:

Level 1 Indication would occur if supply or return

water temperature reached 203°F. The Ultra

control module would display a soft lockout

code (“b” followed by “18” if on the supply, or

“19” if on the return). The module would not

operate the burner again until the water

temperature dropped 9°F below target

temperature.

Level 2 Lockout would occur if supply or return water

temperature reached 210°F. The Ultra module

would enter hard lockout and display an error

code (“E” followed by “18” if on the supply or

“19” if on the return). NOTE: Hard lockout

requires manually pressing the Ultra display

panel reset button to restart operation. Service

technician must troubleshoot the cause of the

problem and correct it before placing the boiler

back in operation.

Operating temperature (target)

The Ultra control module senses outlet water temperature

and regulates boiler firing rate to achieve a target

temperature, set by installer, by setting Parameter 4.

Temperature can be set between 70°F and 190°F. See

page 18 for procedure.

• Space heating — Target temperature is fixed (equal

to Parameter 4) when outdoor reset is not installed.

• Space heating — Target temperature is calculated as

described under “Outdoor reset operation” when

outdoor sensor is connected. Exception: See

explanation of “Supply temperature boost.”

• DHW heating — Target temperature is 50°F +

Parameter 1. Do not change parameter 1 from the

factory default setting of 140°F unless the application

is specially engineered for other temperature.

High limit operation

If outlet water temperature exceeds target temperature

(or 190°F, whichever is lower), high limit action occurs.

The control module shuts the burner off.

DHW operation (if used)

The boiler is factory set to immediately change target

outlet water temperature to 190°F on a call for heat from

the DHW aquastat.

Low water protection

1. The control module uses temperatures sensed at

both supply and return areas of the heat exchanger.

If the flow rate is too low (temperature difference too

high) or either temperature is too high, the control

module shuts the boiler down. This ensures boiler

shutdown in the event of low water or low flow

conditions.

2. Some codes and jurisdiction may accept these integral

features of the control in lieu of requiring an

additional limit control or low water cutoff. Consult

local jurisdiction to determine.

Outdoor reset operation, if used

Target temperature with outdoor reset

All Ultra boilers are shipped with an outdoor temperature

sensor. When this sensor is installed (low voltage terminal

strip terminals 1 and 2), the control module regulates

target outlet water temperature based on outside

temperature.

Set the temperature curve by setting Parameter 4 to:

• ODT (outdoor design temperature for the area).

• For ODT of 32°F or lower:

• Set Parameter 4 to the desired supply temperature at

the ODT.

Part number 550-100-029/0404

9

Page 10

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

Figure 5 Outdoor reset target temperature

• For ODT above 32°F:

• Set Parameter 4 to the desired system temperature when

outdoor temperature is 32°F.

Reset curve

Figure 5 shows how the Ultra control module calculates

target temperature.

• For outdoor temperature at or below 32°F, the target

temperature equals Parameter 4 and never higher.

• For outdoor temperature above 32°F, the target

temperature is reduced on a curve that would result

in 70°F supply temperature at 70°F outdoor

temperature.

Summer/winter switch option

Install a summer/winter switch, if desired, to disable the

boiler (space heating) circulator during non-heating

months. Connect switch across the outdoor sensor

terminals. When switch closes, the boiler circulator is

disabled and the boiler operates only on call for DHW

heating.

Supply temperature boost

In outdoor reset operation (outdoor sensor connected),

the Ultra control module automatically increases the

target outlet water temperature if a call for heat exceeds

10 minutes. At each 10 minutes of a continuous call for

heat, the control module increases the target temperature

by 18°F. The module will continue increasing target

temperature until it reaches the value set in parameter 4.

When the call for heat ends while target temperature is

“boosted,” the target temperature drops about 2°F for

each minute the thermostat is open.

Purpose of boost — If the target temperature happens to

be too low, the control “boosts” the target temperature

until the supply water meets the system’s needs.

(continued)

DHW operation, if used

The PhD Control Module allows connection of a

DHW aquastat to low voltage terminal strip terminals 3

and 4. When the DHW aquastat calls for heat, the module

shuts down the boiler circulator, activates the DHW

circulator and immediately sets target outlet water

temperature to 190°F. This provides automatic priority

heat allocation to the indirect water heater for maximum

response and recovery. The DHW circulator continues

for 30 seconds after the heating cycle to deliver the most

possible heat.

Boiler circulator

Each Ultra boiler is shipped with a circulator. The

circulator has sufficient head to handle boiler pressure

drop plus reasonable pressure drop in the connecting

piping. See Ultra Boiler Manual for piping and flow rate

information. The control module internal relay contact

is suitable for handling only the boiler circulator provided.

Do not wire additional pumps in parallel with the boiler

circulator. To operate a system circulator when the boiler

circulator operates, see pages 4 and 5 for wiring required.

Freeze protection

DO NOT install the boiler in a room likely to freeze.

The following integral feature of the Ultra control module

provides some protection for the boiler only — not for

the system.

• The Ultra control module provides freeze-up

protection as follows when the boiler water

temperature drops below 45 °F:

• Below 45 °F, the boiler circulator operates constantly.

• Below 37 °F, the boiler turns on at low fire.

• Boiler and circulator turn off if boiler water temperature

rises above 50 °F.

This feature of the Ultra control module

does not eliminate the possibility of freezing.

The installation must still use recognized

design, installation and maintenance

practice to prevent freeze potential for the

boiler and system.

External controls (interlocks) (if used)

External limit controls wired between low voltage

terminal strip terminals 6 and 7 will cause the boiler to

shut down in soft lockout when they open. Remove the

factory jumper between these terminals when using.

External limit control wired between low voltage terminal

strip terminals 6 and 8 will cause the boiler to hard lockout

(requiring manual reset of the electronic display RESET

button). Remove the factory jumper between these

terminals when using.

10

Part number 550-100-029/0404

Page 11

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

Figure 6 Schematic wiring diagram — Ultra-80 through Ultra-230

Part number 550-100-029/0404

11

Page 12

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

Figure 7 Ladder wiring diagram — Ultra-80 through Ultra-230

(continued)

12

Part number 550-100-029/0404

Page 13

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

Figure 8 Schematic wiring diagram — Ultra-310

(continued)

Part number 550-100-029/0404

13

Page 14

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

Figure 9 Ladder wiring diagram — Ultra-310

(continued)

14

Part number 550-100-029/0404

Page 15

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

The data port is for use only when connecting a PC to the control, using the optional Advance

Parameter Kit. Do not connect to this port for any other purpose.

(continued)

Part number 550-100-029/0404

15

Page 16

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

Where two keys are shown pressed at the same time, you must press the keys together. A slight delay in pressing one

of the keys may cause a different result.

(continued)

Instructions in this supplement are based

on factory default parameter settings.

16

Part number 550-100-029/0404

Page 17

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

(continued)

Instructions in this supplement are based

on factory default parameter settings.

Part number 550-100-029/0404

17

Page 18

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

(continued)

Instructions in this supplement are based

on factory default parameter settings.

18

Part number 550-100-029/0404

Page 19

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

(continued)

Instructions in this supplement are based

on factory default parameter settings.

Part number 550-100-029/0404

19

Page 20

3

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Operating information

(continued)

Instructions in this supplement are based

on factory default parameter settings.

20

Part number 550-100-029/0404

Page 21

4

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Troubleshooting

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Always disconnect power to boiler before

servicing. Failure to comply could result in

severe personal injury, death or substantial

property damage.

Never jumper (bypass) any device except

for momentary testing as outlined in

Troubleshooting Charts. Severe personal

injury, death or substantial property

damage can result.

Before troubleshooting:

1. Have the following items:

a. Voltmeter that can check 120 VAC , 24 VAC and 12

VDC.

b. Continuity checker.

c. Contact thermometer.

2. Check for 120 VAC (minimum 102 VAC to maximum

132 VAC) to boiler.

3. Make sure thermostat is calling for heat and contacts

(including appropriate zone controls) are closed.

Check for 24 VAC between thermostat wire nuts and

ground.

4. Make sure all external limit controls are either installed

(and closed) or temporarily jumpered for testing.

Always check control module fuses

ALWAYS check control module fuses before

replacing control module or any major

components (blower, etc.). If one of these

fuses is blown, it can prevent control

module or other components from

operating.

1 . Turn OFF power to boiler at external line switch.

2. Remove jacket top front panel (Ultra Boiler Manual,

page 37, item 8).

3. Remove control module cover.

4. Inspect fuses F1 and F3 (located as shown below).

Check the following:

1 . Wire connectors to control module are securely

plugged in at module and originating control.

2. Gas pressures:

• Maximum: 13" w.c. with no flow (lockup) or with

boiler on

• Minimum: 5" w.c. with gas flowing (verify during boiler

startup with boiler at high fire)

Replace boiler jacket front door

Replace boiler jacket front door after servicing. The boiler front door must be securely fastened to the

boiler to prevent boiler from drawing air from inside the boiler room. This is particularly important if

the boiler is located in the same room as other appliances. Failure to keep the door securely fastened

could result in severe personal injury or death.

VERIFY PROPER OPERATION AFTER SERVICING.

(see Ultra Boiler Manual for procedures)

5. The boiler is shipped with two spare fuses attached

to the control module cover.

6. If necessary, replace open fuse (F1 is 5-amp fast-blow;

F3 is 4-amp slow-blow).

Do not jumper fuse or replace with any

fuse except as specified. Failure to comply

could result in severe personal injury, death

or substantial property damage.

7. Install control module cover and jacket top front

cover after fuse inspection.

8. Restore power to boiler at external line switch and

verify boiler operation (Ultra Boiler Manual, pages 23

through 26) after completing boiler service.

Part number 550-100-029/0404

21

Page 22

4

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Troubleshooting

(continued)

Instructions in this supplement are based

on factory default parameter settings.

Checking temperature sensors

1. The boiler temperature sensors (flue, outdoor, return water and supply

water) are all resistance-type devices.

2. The table at right shows the correct value for the sensor at various

temperatures.

3. Use the resistance values at 32°F, 60°F, 70°F and 212°F to measure the

sensor resistance at known temperatures (ice point, room temperature

and sea level boiling point). For ice point and boiling point, insert the

sensor in water at that temperature. Use an ohmmeter to read resistance

value.

4. To check whether the control module is correctly sensing temperature,

you can use a resistance decade box. Connect the decade box temporarily

in place of a sensor and use the control module Information mode (see

page 19 for details) to read the temperature. The temperature should be

close to the value corresponding to the input resistance.

22

Sensor resistance values

Te mp

(°F)

32 34265 37871 130 3698 4088

40 27834 30764 140 3043 3364

50 21630 23907 150 2517 2782

60 16944 18727 160 2091 2311

70 13372 14780 170 1744 1928

80 10629 11747 180 1461 1615

90 8504 9399 190 1229 1359

100 6847 7568 200 1038 1147

110 5545 6129 210 880 972

120 4517 4992 212 851 941

Sensor ohms

Min Max Min Max

Te mp

(°F)

Part number 550-100-029/0404

Sensor ohms

Page 23

4

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Troubleshooting

(continued)

Instructions in this supplement are based

on factory default parameter settings.

Part number 550-100-029/0404

23

Page 24

4

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Troubleshooting

(continued)

Instructions in this supplement are based

on factory default parameter settings.

24

Part number 550-100-029/0404

Page 25

4

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Troubleshooting

(continued)

Instructions in this supplement are based

on factory default parameter settings.

Part number 550-100-029/0404

25

Page 26

4

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Troubleshooting

(continued)

Instructions in this supplement are based

on factory default parameter settings.

26

Part number 550-100-029/0404

Page 27

4

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

Troubleshooting

(continued)

Instructions in this supplement are based

on factory default parameter settings.

Part number 550-100-029/0404

27

Page 28

GAS-FIRED WATER BOILER SERIES 2 — Control Supplement

28

Part number 550-100-029/0404

Loading...

Loading...