Page 1

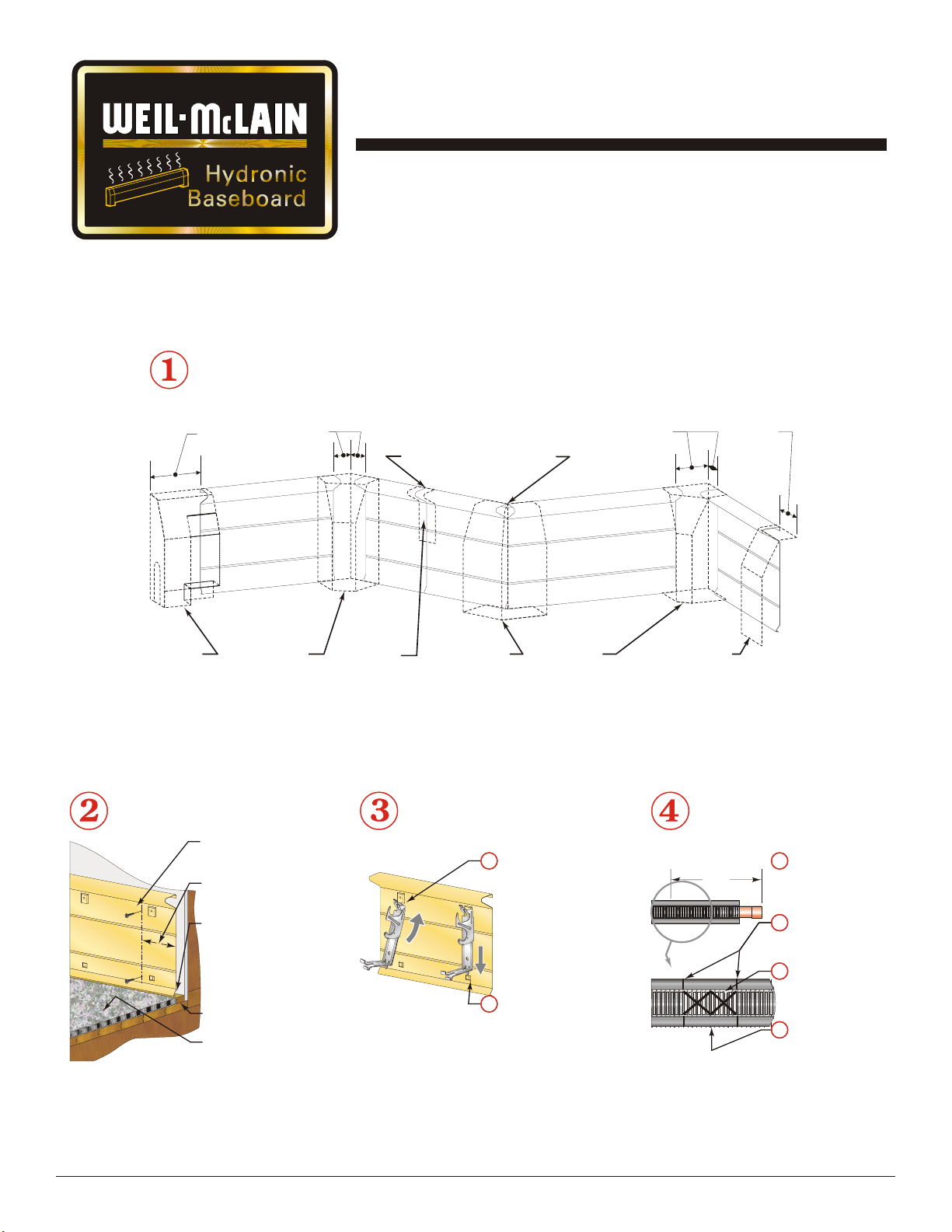

THERMA TRIM

MODEL TT HYDRONIC BASEBOARD

ASSEMBLY INSTRUCTIONS

Position back panels

Back panels must be positioned correctly to accommodate accessories, as shown below.

Min 3 ¾"

Hinged

end cap

Max 4 ½"

Max 1>|zn"

Inside

bay corner

Attach back panel to wall

Screw or nail into wall

studs at top and bottom.

No closer than 3 inches

from end of panel.

Min 1Z\v"

Butt back panels together.

Splice

Outside

corner

Install brackets

Position brackets evenly along length of

panel, approximately every 2 feet.

a

Insert top bracket tab

into top slot in back

panel.

Inside

corner

Min 3"

Max 3Z\v"

Plain end cap

Min 0"

Max 2 Z|x "

or wall end

Cut element

When a shorter length is needed

New

length

a

Measure from the

female end for the

required length.

Bottom of panel must

never be lower than the

surface of the finished

floor or carpet.

Add shim as shown if

necessary.

Shim (if needed)

Finished floor surface

or carpeting.

Press bracket flat

b

against back panel

and slide down so

bottom tab enters

bottom slot in back

panel.

New

length

Cut glide rails with

b

tin snips.

c

Remove 6 fins on

each side of the

location to be cut.

Cut copper using

d

tube cutter and

ream to remove

burrs.

550-110-762/0400

Page 2

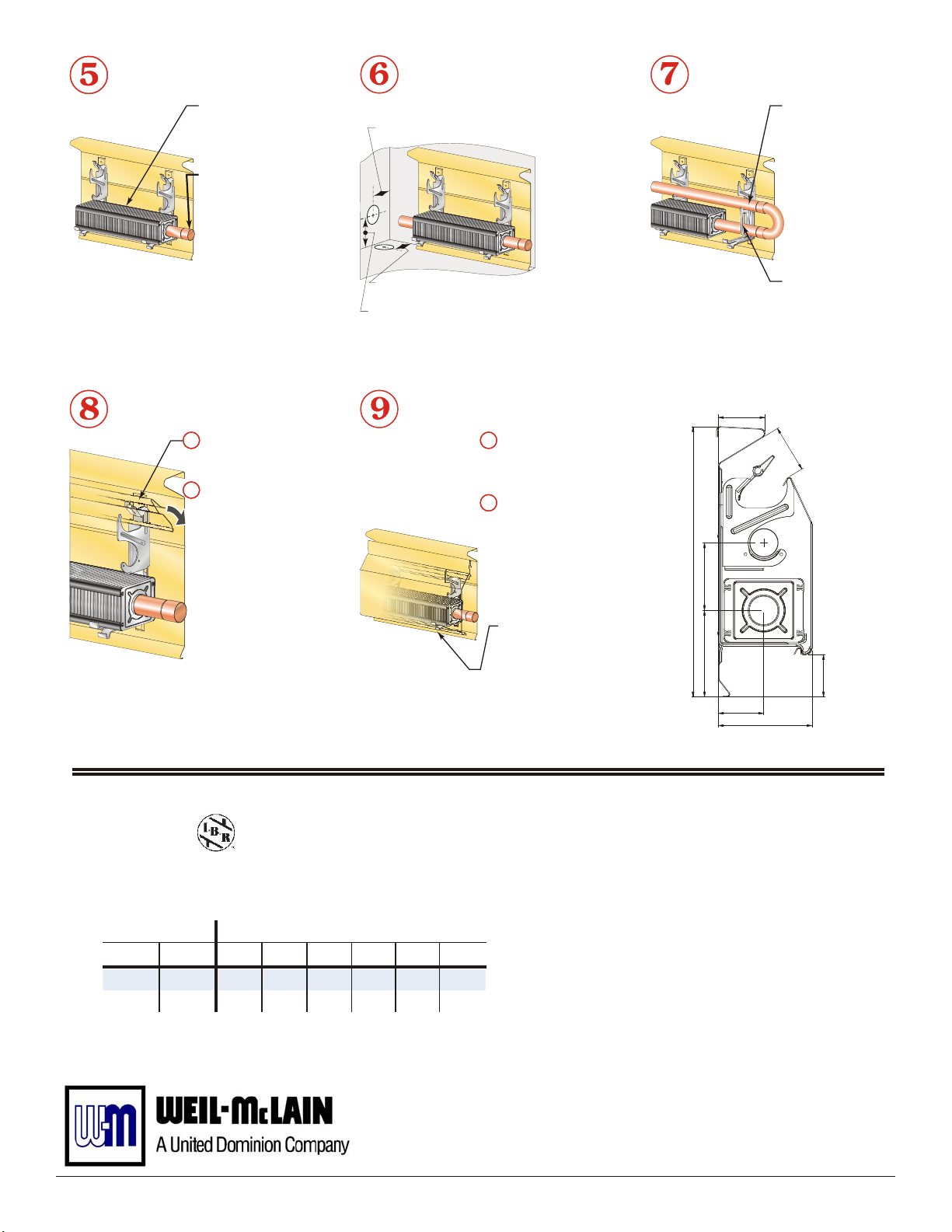

Install element

Place element on

brackets as shown.

Assemble multiple

elements by soldering

the male end on one

element into the female

end of another.

Holes for risers & connectors

Drill 1½" holes for risers or connectors

Solder elements to risers

1C\," from wall

and to any additional

tubing that may be

required.

Support bare tubing

Place return pipe in

cradle provided by

bracket, as shown.

Install damper

a

b

For horizontal runs of

more than 30 feet,

install expansion

joints.

Place open end of

damper onto bracket

half rounds.

Press down and inward

to snap onto bracket.

1C\," from wall

2 >\zn" above

finished floor

Install front cover

When attaching radiant tubing,

solder connectors and let cool

before attaching tubing. Follow all

tubing manufacturer's instructions.

a

Hook bottom lip of

front cover under

lower bracket arm

as shown.

b

Lift the front cover

until top lip of cover

snaps over top prong

of bracket.

If cover does not fit

snugly, bend lower

bracket arm down

and reinstall front

cover.

Support bare supply

tubing from bracket

using wire hangers,

(not supplied).

DimensionsDimensions

1-3/8

8

2

2-9/16

1-11/32

2-25/32

1

-

1

3

/ 2

3

1-1/4

RatingsRatings

Therma Trim Model TT I=B=R Approved Water Ratings

Water Flow Rate

GPM

1

4

Capacities in BTU/Hr. per Linear Foot with 65 F Entering Air

0

Average Water Temperature ( F)

180 190

Lbs/Hr

500

2000

170

510

540

580

610

200 210 220

710

650

750

690

780

820

0

Notes: Notes:

850

900

I=B=R approved water ratings are based on the active (finned) length and

include the 15% addition for heating effect allowed by the I=B=R Testing

and Rating Code for Baseboard Type of Radiation. The active length is 3"

less than the enclosure length. Ratings apply to the assembly with the

damper installed and adjusted to the normally open position.

The heating elements are constructed of 3/4" nominal copper tubing

expanded into 1 7/8" x 2 11/32" aluminum fins, which are spaced 67 to the

foot; fin thickness is .008". Elements are unpainted.

Use of I=B=R ratings at the 4 gpm flow rate is limited to installations in

which the water flow rate through the baseboard unit is equal to or greater

than 4 gpm. Where the water flow rate is not known, the I=B=R ratings at

the standard flow rate of 1 gpm must be used. Flow rates exceeding 6

gpm should be avoided because of possible noise.

Pressure drop through Therma Trim Baseboard is 0.047" of water per

linear foot at the 1 gpm flow rate. At the 4 gpm flow rate, pressure drop is

0.525" of water per linear foot.

Weil-McLain

500 Blaine Street

Michigan City, IN 46360-2388

http://www.weil-mclain.com

550-110-762/0400

Loading...

Loading...