Page 1

QB-180/300

Oil Burners — Series 2

For Weil-McLain GO, 66 & 68 Boilers

Burner Manual

Patent 5,961-316

Read all instructions before installing

This manual must only be used by a qualified heating installer/service

technician. Failure to comply could result in severe personal injury, death or

substantial property damage.

Installer Leave all documentation with burner for future reference.

User Burner must be installed and annually serviced by a qualified installer/service

technician.

Part number 644-500-065/0200

Page 2

QB-180/300 Oil Burners Series 2 — Burner Manual

! ! !

IMPORTANT! Read this page first

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of

various risk levels or to important information concerning the life of the product.

Indicates presence of hazards that will

cause severe personal injury, death or

substantial property damage.

Indicates presence of hazards that can

cause severe personal injury, death or

substantial property damage.

Read and follow instructions below to install or service the burner to reduce risk of severe personal

injury, death or substantial property damage.

• Appliance must be connected to a flue with

sufficient draft at all times to assure proper

operation.

• Do not use crankcase drainings or any oil

containing gasoline as it is more combustible than No. 1 or No. 2 fuel oil.

• Do not attempt to start burner when excess

oil has accumulated in combustion chamber, when boiler is full of vapor, or when

combustion chamber is very hot.

• Always keep manual fuel supply valve shut

• Do not start burner unless flue collector

• Never burn garbage or paper in the appli-

• Never leave combustible material around

Indicates presence of hazards that will

or can cause minor personal injury or

property damage.

Indicates special instructions on

installation, operation or maintenance

that are important but not related to

personal injury or property damage.

off if burner is shut down for an extended

period of time.

hood, jacket cap, flue cap and burner

mounting door are secured in place.

ance.

appliance.

Part number 644-500-065/02002

Page 3

QB-180/300 Oil Burners Series 2 — Burner Manual

Contents

Hazard definitions .................................................................................... 2

Table of contents ...................................................................................... 3

Pre-installation considerations ................................................................ 4

1

Burner installation ................................................................................... 5

2

Fuel pumps and oil lines .......................................................................... 8

3

Wiring, operation and service ................................................................ 11

4

Troubleshooting ..................................................................................... 12

5

Parts list ................................................................................................. 14

6

Weil-McLain Limited Warranty .................................................. Back cover

Part number 644-500-065/0200 3

Page 4

QB-180/300 Oil Burners Series 2 — Burner Manual

1

Pre-installation considerations

Codes and standards

• Install burner in accordance with NFPA 31, Standard for Oil-Burning Equipment and all local codes

and regulations of authorities having jurisdiction.

In Canada, refer to CSA B139, Installation Code for

Oil-Burning Equipment. Regulations of these authorities take precedence over instructions in this

manual.

• All wiring must comply with National Electrical

Code and local ordinances; in Canada, CSA C22.1

Canadian Electrical Code Part One and any local

codes. Refer to wiring diagram in

supplied with burner.

ment

• Underwriters Laboratories has certified this burner

to comply with ANSI Standard 296.6 and has listed

it for use with No. 1 or No. 2 fuel oil as specified in

ASTM D396.

Control Supple-

Chimney or vent

Inspect existing chimney or vent

before installing new burner. Failure to

do the following will cause severe

personal injury or death.

• Clean chimney, including removal

of blockage.

• Repair or replace damaged pipe or

liner.

• Repair mortar and joints.

Set the over-fire draft to the appliance manufacturer’s

recommended setting if available, or to -0.01" to -0.02"

water column. Install barometric control in breeching,

per control manufacturer’s instructions, when excess

draft needs to be relieved or to comply with applicable

codes and regulations. Use draft gauge to adjust proper

opening.

Combustion and ventilation

air openings

See appliance manual and

Burning Equipment

practice in Canada, refer to

Adequate combustion and ventilation

air must be provided to assure proper

combustion and reduce risk of flue gas

leakage and carbon monoxide

emissions, leading to severe personal

injury or death.

When the boiler is installed in a confined space (volume of space less than 50 cubic feet per 1,000 Btuh

input of all appliances in space), two permanent openings must be provided:

• One near the top of the enclosure

• One near the bottom.

• Each opening must have a free area of not less than

one (1) square inch per 1,000 Btuh (140 square inch

per gph), of the total input rating of all the appliances in the space.

When building is of unusually tight construction, has

a kitchen ventilating system, exhaust fans, clothes dryer

or vented fireplaces, it may be necessary to duct outside air directly to the burner in order to support clean

combustion. Weil-McLain QB-A1 Outside Air Kit, part

number 644-500-056, provides outside air directly to

the burner.

• If QB-180 or QB-300 Oil Burner is

received separately for field installation,

proceed to page 5,

• If QB-180 or QB-300 Oil Burner is

received installed on the boiler, proceed

directly to page 8,

Lines

NFPA 31, Standard for Oil-

for details. For recommended

CSA Standard B139

Burner Installation

Fuel Pumps and Oil

.

.

.

Part number 644-500-065/02004

Page 5

QB-180/300 Oil Burners Series 2 — Burner Manual

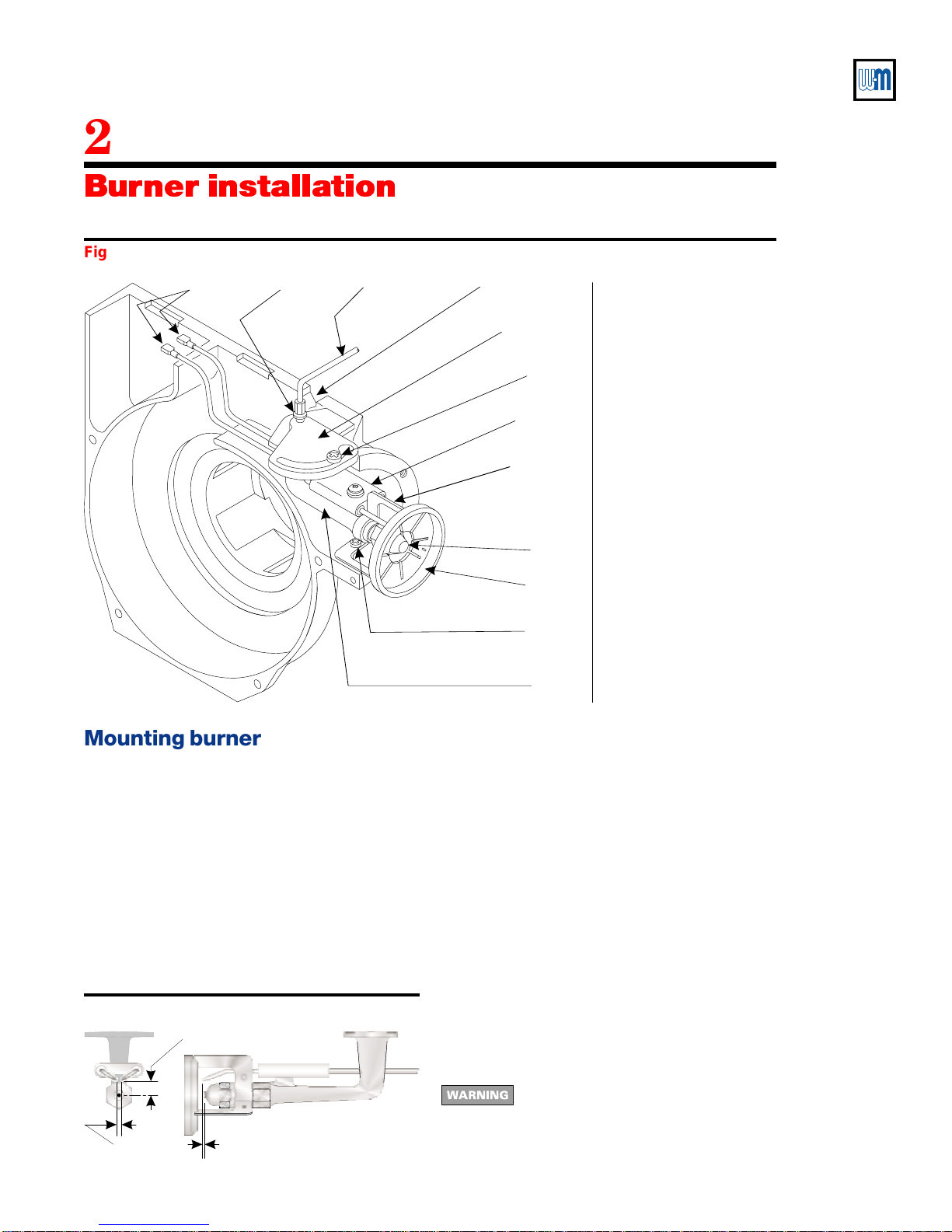

2

Burner installation

Figure 1 Burner components

Ignition

Wires

“E” Clip

3/16“ Oil Line

Nozzle Adapter

Wrench

Adjustment

Cam

Captive

Screw

Electrode

Assembly

Top Leg of

Spinner

Centered

Vertically

Between

Electrodes

Nozzle

Spinner

Assembly

Spinner

Clamping

Screw

Nozzle

Adapter

GUN ASSEMBLY Includes:

Adjustment Cam

Electrode Assembly

Spinner Assembly

Nozzle

Nozzle Adapter

Oil Line

Ignition Wires

06502

Mounting burner

1. Remove burner from packing box.

2. Detach and save plastic bag with instructions and

bypass plug from fuel pump.

3. Install or verify correct nozzle as applicable:

a. Loosen, but do not remove, screw holding hous-

ing cover plate in place. Pull ignitor back and up

to swing open cover plate.

b. Disconnect oil line from solenoid valve.

c. Disconnect ignition wires from ignitor. Loosen,

but do not remove, captive screw securing ad-

justment cam in place. Turn adjustment cam so

Figure 2 Electrode settings

from tip of electrode

5/16“

to centerline of nozzle

1/8“

between electrode tips from tip of nozzle to tip of electrode

1/16“

06501

that the larger end of the slot aligns with the captive screw. Pull gun assembly back and up to remove.

d. Loosen clamping screw on spinner assembly and

slide assembly off nozzle adapter.

e. See

Table 1

on page 6 for proper nozzle size. Make

sure nozzle is tight in adapter (110 in-lbs nominal). Nozzle adapter wrench in burner housing

can hold nozzle adapter while you tighten nozzle.

f. Check electrode settings per

Figure 2

.

g. Replace spinner assembly on nozzle adapter. Top

leg of spinner must align vertically between electrodes. Make sure clamp is back against the

shoulder on adapter. Tighten clamping screw.

Fuel pump is factory set at 140 psig

(QB-300) or 150 psig (QB-180). Use of

a nozzle selected for 100 psig pressure

could result in severe personal injury,

death or substantial property damage.

Part number 644-500-065/0200 5

Page 6

QB-180/300 Oil Burners Series 2 — Burner Manual

2

Burner installation

continued

Table 1 Burner nozzle selection Use only the nozzles specified.

Boiler

model

GO-2

GO-3

GO-4

GO-5

GO-6

268 *

368

468

568

668

266 *

366

466

566

666

* Install baffle clip per instructions packed with kit.

1. Nozzle: Tighten to 110 in/lbs.

2. Nozzle types: A, AH, H = hollow;

QB-180 burner nozzle size (Pump pressure is 150 psig) Pump

Preferred Alternates

Delavan Hago Danfoss Steinen

0.65 70˚ A 0.65 70˚ B 0.65 70˚ AS

0.85 70˚ A 0.85 70˚ B 0.85 70˚ AS

1.00 70˚ B 1.00 70˚ B 1.00 70˚ AS

1.25 60˚ B 1.25 45˚ B 1.25 60˚ AS

1.50 45˚ B 1.50 45˚ B -

0.65 70˚ A 0.65 70˚ H -

0.85 70˚ A - 0.85 70˚ AH

1.10 70˚ A 1.10 70˚ ES 1.10 70˚ AS

1.25 60˚ B 1.25 70˚ B 1.25 60˚ AS

1.50 45˚ B 1.50 60˚ B or 1.50 45˚ ES 1.50 60˚ AS

0.65 70˚ A 0.65 70˚ H -

0.85 70˚ A 0.85 70˚ B 0.85 70˚ AS

1.10 70˚ A 1.10 60˚ H 1.10 70˚ AH

1.25 60˚ B 1.25 70˚ B 1.25 60˚ AS

1.50 45˚ B 1.50 60˚ B or 1.50 45˚ ES 1.50 60˚ AS

SS = semi-solid

B, ES, R, S, AS = solid

3. Suggested settings are for set-up with listed nozzle sizes only. Final

adjustments must be made with combustion test equipment and

should provide zero smoke with proper CO

4. For I=B=R boiler capacity, refer to individual boiler manual.

0.65 70˚ S 150 0.70/0.95 3.25

0.85 70˚ S 150 0.70/0.95 5.25

1.00 70˚ S 150 1.20 5.50

1.25 70˚ S 150 1.45 6.25

1.50 45˚ S 150 1.75 6.75

0.65 70˚ H 150 0.70/0.95 3.00

- 150 0.70/0.95 5.00

1.10 80˚ S 150 1.20 5.25

- 150 1.45 6.00

1.50 60˚ S 150 1.75 6.50

0.65 70˚ H 150 0.70/0.95 3.00

- 150 0.70/0.95 5.00

1.10 70˚ H 150 1.20 5.25

- 150 1.45 6.00

1.50 60˚ S 150 1.75 6.50

pressure

(psig)

setting

.

2

Cam

Air band

setting

Boiler

model

QB-300 burner nozzle size (Pump pressure is 140 psig) Pump

Preferred Alternates

Hago Delavan Steinen

GO-6

GO-7

GO-8

GO-9

668

768

868

968

666

766

866

966

1. Suggested settings are for set-up with listed nozzle sizes only. Final adjust-

2. For I=B=R boiler capacity, refer to individual boiler manual.

1.50 60˚ B or 1.50 45˚ B 1.50 45˚ B 1.50 60˚ S 140 1.75 2.25

1.75 60˚ B or 1.75 45˚ B 1.75 60˚ B 1.75 70˚ S 140 2.00 3.75

2.00 60˚ P or 2.00 45˚ P 2.00 70˚ B 2.00 70˚ S 140 2.30 5.75

2.25 60˚ P or 2.25 45˚ P 2.25 60˚ B or 2.25 45˚ B 2.25 60˚ S 140 2.55 5.25

1.50 60˚ B or 1.50 45˚ B 1.50 45˚ B 1.50 60˚ S 140 1.75 2.25

1.75 60˚ B or 1.75 45˚ B 1.75 60˚ B 1.75 70˚ S 140 2.00 3.75

2.00 45˚ P 2.00 70˚ B 2.00 70˚ S 140 2.30 5.75

2.25 60˚ P 2.25 60˚ B 2.25 60˚ S 140 2.55 5.25

1.50 60˚ B or 1.50 45˚ B 1.50 45˚ B 1.50 60˚ S 140 1.75 2.25

1.75 60˚ B or 1.75 45˚ B 1.75 60˚ B 1.75 70˚ S 140 2.00 3.75

2.00 45˚ P 2.00 70˚ B 2.00 70˚ S 140 2.30 5.75

2.25 60˚ P 2.25 60˚ B 2.25 60˚ S 140 2.55 5.25

ments must be made with combustion test equipment and should provide zero

smoke with proper CO

.

2

pressure

(psig)

3. Nozzle types:

B, ES, P, S = solid

4. Nozzle: Tighten to 110 in/lbs.

Part number 644-500-065/02006

Cam

setting

Air band

setting

Page 7

QB-180/300 Oil Burners Series 2 — Burner Manual

Burner settings

4. Reinstall gun assembly:

a. Insert gun assembly into burner – do not force

it. The gun assembly must be lifted and guided

into air cone at end of air tube.

b. Turn adjustment cam so that the larger end of

the slot drops over the captive screw.

c. Position gun assembly by rotating adjustment

d. Connect oil line to solenoid valve.

e. Connect ignition wires to ignitor.

f. Swing cover plate closed and push forward to

g. Tighten screw holding housing cover plate in

5. Mount burner to boiler with gasket supplied.

6. Verify attenuating air band setting. See

page 6, and

cam (

Figure 3

) to correct setting. See

Table 1

page 6, for correct adjustment cam setting.

Tighten captive screw to lock adjustment cam

in place.

engage locking pins.

place.

Table 1

Figure 4

Starting settings in

.

Table 1

are for setup

only. Final adjustments must be made

with combustion test equipment and

should provide zero smoke with

proper CO2. See

Final adjustments

page 11.

Adjust the air band setting first. If

adjustments of the air band do not

result in clean combustion, then adjust

the cam setting. Increase the setting to

increase air. Decrease the setting to

reduce air. Cam adjustments should be

minor only.

Figure 3 Adjustment cam setting

,

2.00

2.25

1.75

2.50

H

P

G

QB-300

cam

GPH

QB 180

,

Figure 4 Attenuating air band setting

on

Screw

indicates

setting

1.75

.45

1

1.20

0.95

0.70

QB-180

cam shown

06503

Y

LL

PEN

9

OPEN

TOTA

O

8

7

6

5

4

CLO

3

SE

2

1

0

TOTALLY

CLOSED

06504

Part number 644-500-065/0200 7

Page 8

QB-180/300 Oil Burners Series 2 — Burner Manual

3

Fuel pumps and oil lines

General

All installations must comply with national or local

codes and ordinances.

Oil line must be piped properly to

avoid risk of serious personal injury,

death or substantial property damage.

Follow these recommendations:

• When installing oil lines, use

continuous runs of heavy-wall

copper tubing.

• Be sure all connections are airtight.

Flared fittings are recommended.

Do not use compression fittings.

Do not use Teflon tape.

• Use an oil filter of adequate size for

all installations. Install filter inside

building between tank shutoff valve

and burner. For easy servicing,

locate shutoff valve and filter near

burner.

• Long or oversized inlet lines may

require the pump to operate dry

during initial bleeding period. In

such cases, assist priming by

injecting fuel oil into pump gearset.

• Never exceed 3 psi pressure to inlet

side of pump. Pressure over 3 psi

may damage shaft seal and allow it

to leak oil.

port. Do not use easy flow air bleed valve. It contains

higher pressure than operating pressure.

Setting pump pressure with gauge in easy flow air bleed

valve will result in wrong operating pressure.

Average cutoff pressure is 120 psig. Check cutoff

pressure by installing pressure gauge in nozzle port of

fuel pump. Run burner for short time. Shut off burner.

Gauge shows cutoff pressure.

Figure 5 Fuel pump — Typical

Solenoid valve

Solenoid valve supplied in nozzle line is a non-delay

valve and provides instant oil supply shutoff to nozzle.

Vacuum gauge

Vacuum gauge may be installed in either of the ¼" inlet

ports. Vacuum is total of all pressure drops in system

from tank to pump inlet.

Oil pump pressure

To check operating pressure, use gauge port or nozzle

Inlet ¼" npt (2 locations)

Return ¼" npt

Solenoid valve

Easy flow air bleed valve

Nozzle port 1/8" npt (read operating pressure)

Pressure gauge port 1/8" npt (read operating pressure)

Regulating pressure (behind inlet)

1/16" bypass plug — insert for

(use 5/32" allen wrench)

two-pipe systems ONLY

Part number 644-500-065/02008

06505

Page 9

QB-180/300 Oil Burners Series 2 — Burner Manual

One-pipe oil systems (Figure 6)

Use one-pipe oil piping only when:

• the fuel is gravity fed — or —

• the fuel must be lifted

. (If the fuel lift is greater than 8 feet use two-

ure 6

pipe fuel piping —

• fuel suction line vacuum is less than 6" Hg for ei-

ther a single-stage or two-stage burner fuel pump.

Burner fuel pump bypass plug must not be used with

one-pipe installations.

One-pipe installations must be absolutely air tight to

prevent leaks or loss of prime

pump completely. Bleed for 15 seconds after last air

bubble is seen from easy flow air bleed valve to be certain lines are air free. When bleeding oil pumps on

burners equipped with lockout-type controls, you may

have to cycle the burner several times to complete purging.

no more than 8 feet. See

Figure 7

on page 10.)

. Bleed line and fuel

Fig-

Figure 6 One-pipe oil system, typical

Air vent

Fuel pump

Fill pipe

Shutoff

valve

06506

Maximum one-pipe

system lift = 8 feet

Oil

tank

Filter

Inlet

Part number 644-500-065/0200 9

Page 10

QB-180/300 Oil Burners Series 2 — Burner Manual

3

Fuel pumps and oil lines

Two-pipe oil systems (Figure 7)

Use two-pipe installations when fuel must be lifted

greater than 8 feet.

Burner fuel pump — A single-stage pump is limited

to a fuel lift height of no more than 10 feet. For greater

lifts install a two-stage pump on the burner.

Fuel suction line vacuum must not exceed 12" Hg

for a single-stage pump or 17" for a two-stage pump.

Bypass plug must be used with two-pipe installations.

Remove plug from plastic bag attached to fuel pump.

Remove ¼" plug from return port. Insert bypass plug.

Attach return and inlet lines.

Always terminate return line as shown in

To determine two-pipe maximum line lengths, use

Table 2,

page 10.

Figure 7

Figure 7 Two-pipe oil system, typical

L

(lift)

.

06507

continued

Fuel pump

Filter

Return line

Oil

tank

Return line terminates

Fill

pipe

Inlet line

Air vent

Return line

inches above inlet line3 to 4

Inlet line

Table 2 Two pipe oil system maximum oil line lengths (feet)

Lift

“L”

0 84 100 93 100

2 73 100 85 100

4 63 100 77 100

6 52 100 69 100

8 42 100 60 100

10 31 100 52 100

12

14 36 100

16 27 93

18 -- 65

Note: Line lengths include total of vertical and horizontal lengths.

Single-stage oil pump Two-stage oil pump

3/8" O.D. 1/2" O.D. 3/8" O.D. 1/2" O.D.

Not recommended

— use two-stage pump

44 100

Part number 644-500-065/020010

Page 11

QB-180/300 Oil Burners Series 2 — Burner Manual

4

Wiring, operation and service

Wiring

Wire the burner (and boiler) following instructions in

the burner

Control Supplement

and the

Boiler Manual

Start-up

Read the sequence of operation and start-up procedures in the burner

Control Supplement

.

Final Adjustments

You must use test instruments to

properly start, check and adjust burner.

Failure to do so could result in severe

personal injury, death or substantial

property damage.

1. Make sure combustion and ventilation air supply

is sufficient for normal appliance operation. Close

windows and doors in appliance area to simulate

normal job condition. Start boiler and allow for a

10-minute warm up.

2. Check for -.01" to -.02" W.C. draft in combustion

chamber. Adjust barometric damper as necessary.

3. Check for 0 smoke.

4. Check for CO2 between 11% and 12 ½%.

• To increase CO2, close attenuating air band set-

ting.

• To decrease CO2, open attenuating air band set-

ting.

5. Check CO2, smoke and draft levels again.

6. Start and stop unit several times.

7. Check operation of limits, thermostats and timing

of combustion control.

8. Check for oil leaks.

9. Recheck all installations after one to two weeks of

operation.

Service

.

Boiler Service/Maintenance Guide

1. See

of annual service call, including cleaning boiler

flueways.

2. Oil blower motor (if required). Refer to motor

name plate/specifications label for any instructions.

3. Replace oil filter cartridge once a year to prevent

fuel oil contamination from plugging fuel pump

and nozzle.

4. Replace nozzle once a year before start up of heating season. Always use proper nozzle. See

on page 6.

5. Check electrode settings once a year. See page 5.

6. Clean fan and blower housing regularly to keep free

of dirt and lint.

7. Check and adjust burner according to

cedures in

ing.

8. Contact your Weil-McLain distributor for all

burner parts that need replacement.

When servicing a NO HEAT call:

Check each item below, making sure to complete

each check before going to the next one.

❏ Thermostat(s).

❏ Main fuse and power supply.

❏ Service switch on boiler.

❏ Oil level in oil tank.

❏ Oil valves.

❏ Limit control.

❏ Primary control.

❏ Motor.

Electrical shock hazard. Failure to shut

off electrical supply before servicing can

cause severe personal injury, death or

substantial property damage.

for details

Start-up

Control Supplement

after each servic-

Table 1

pro-

Part number 644-500-065/0200 11

When all of the above checks are made, then refer to

Troubleshooting on pages 12 and 13.

Page 12

QB-180/300 Oil Burners Series 2 — Burner Manual

5

Troubleshooting

If burner

does not start

If burner starts, but

there is no flame

The relay in the primary control may not be pulling in — Check for:

❏

Broken wires

❏ Dirty thermostat contacts

The motor is out on thermal overload — Check for:

Seized motor bearing

❏

❏ Fan locked against housing

❏ Defective starter switch

Primary control may have pre-purge — Check Control Supplement.

There may be insufficient oil flow — Check for:

❏ Defective fuel pump

❏ Pump strainer clogged

❏ Defective solenoid valve

❏ Loose coupling

❏ Defective thermostat

❏ Defective primary control

❏ Seized fuel pump

❏ Start winding burned out

❏ Defective wiring

❏ Air leaks in suction line

❏ Clogged or dirty nozzle

❏ Clogged fuel filter

If burner starts

and has flame,

but flame goes out

There is no ignition spark — Check for:

Defective/loose wiring connec-

❏

tions at primary control or electrode assembly

❏ Incorrect electrode settings

There is oil and spark, but no flame — Check for:

❏

Loose, dirty or defective nozzle

❏ Low pump pressure

❏ Excess air/high draft

❏ Incorrect electrode settings

Primary control will shut off flame — Check for:

❏

Dirty cad cell

❏ View of fire obstructed, so that

cad cell cannot see flame

❏ Defective cad cell

❏ Defective porcelain insulator on

electrode assembly

❏ Defective ignitor

❏ Improper oil conditions

❏ Improper spinner position. To

verify position, see page 5,

step 3g.

❏ Defective primary control

❏ Loss of oil prime

Part number 644-500-065/020012

Page 13

QB-180/300 Oil Burners Series 2 — Burner Manual

If burner starts and

has a smoky flame

If you hear

mechanical noise

from the burner

If you hear

combustion noise

Check for: ❏ Insufficient combustion air

❏ Improper mixing of oil and air

❏ Insufficient draft

Check for: ❏ Defective motor bearings

Check for: ❏ Insufficient draft in breeching

❏ Loose fan

❏ Air in oil line

❏ Defective pump gears

❏ Obstructed suction line

or overfire

❏ Flame impingement on target

wall or crown sheet of boiler

❏ Nozzle afterdrip due to faulty

solenoid or cutoff valve

❏ Pump and motor shaft mis-

aligned

❏ Defective ignitor

❏ Defective primary control

❏ Incorrect adjustment cam set-

ting

If there is puffback

from burner

If there is nozzle

drip

❏ Improper mixing of oil and air

❏ Incorrect attenuating air band

setting

Check for: ❏ Delayed ignition

❏ Nozzle afterdrip due to poor

cutoff

Check for: ❏ Air in supply line from oil tank

to fuel pump

❏ High vacuum

❏ Loose or dirty fan

❏ Excessive draft

❏ Incorrect attenuating air band

setting

❏ Hot nozzle or gun assembly due

to improper draft, misadjusted

burner or blocked flueways in

boiler

Part number 644-500-065/0200 13

Page 14

QB-180/300 Oil Burners Series 2 — Burner Manual

6

Parts list

Item

Number

1 Motor with flange, 120 V.A.C., 1/7 HP, 3450 RPM 643-900-050

2 Blower wheel 643-900-025

3 Burner coupling 3 1/4" Length 643-900-105

4 Air tube gasket 643-900-095

5 Air tube 644-200-042 644-200-046

5a Air cone 644-200-050 644-200-051

6 Flange gasket 643-900-100

7 Burner plug — GO boiler series only 643-900-020

8 Attenuating air band 643-900-030 643-900-305

9 Fuel pump — Suntec, A2VA-7116-7, single-stage 643-900-060

Not shown Fuel pump — Suntec, B2VA-8216, two-stage 643-900-315

10

Not shown Solenoid coil replacement kit 643-900-008

11 Spinner assembly, 12 vane 643-900-110 643-900-310

12 Nozzle adapter kit 643-900-005

13 Electrode assembly kit 643-900-010

14 Adjustment cam kit 643-900-325 643-900-326

15 Screw, captive, 8-32 x 3/8" (12 per bag) 643-900-085

16 Wire assembly, transformer to electrode assembly 643-900-080

17 Oil line 3/16" diameter with fittings 643-900-115

18

19 Cover plate kit 643-900-015

20 Cad cell 643-900-070

21 Primary control — R8184G, 1336 with T-T terminals 643-900-075

Not shown Primary control — 50200-02 with T-T and alarm contacts 643-900-319

Not shown

22 "E" clip, oil line to cam 3/8" shaft diameter (12 per bag) 643-700-218

23 Mounting flange 644-700-201

Not shown Baffle clip kit — 266 or 268 boiler sizes only 643-900-006 --

Not shown Burner head protector 643-900-007

Not shown Outside Air Kit QB-A1 643-900-056

Description Weil-McLain Part Number

QB-180 QB-300

Solenoid valve, Combu 50010 E7-LUS/115 volt, no delay

opening

Solid state ignitor kit, including adapter plate and hardware

Transformer PRI-120 V.A.C., secondary, 10,000 @ 23 ma.

Primary control — 60200-02 with T-T and alarm contacts, with

prepurge and postpurge

643-900-065

643-900-318

643-900-055

643-900-317

Part number 644-500-065/020014

Page 15

QB-180/300 Oil Burners Series 2 — Burner Manual

17

18

16

19

20

21

22

15

14

13

12

11

10

9

8

7

5a (QB300)

2

1

Part number 644-500-065/0200 15

4

3

5

5a

(QB180)

23

6

06510

Page 16

Weil-McLain Limited Warranty

for QB-180 and QB-300 Burners

RESIDENTIAL OIL-FIRED BURNERS

3-Year Limited Warranty

Weil-McLain warrants that its residential oil-fired burners are free from defects in material and workmanship

for three years from the date of installation. If any parts

are found to be defective in manufacture, Weil-McLain

will provide replacement of such defective parts with

the following exceptions:

• nozzles

• cad cell

The provisions of this warranty for the above parts

are limited to 12 months from the date of installation or 18 months from the date of manufacture,

whichever date occurs first.

This warranty does not cover:

1. Workmanship of any installer of Weil-McLain’s resi-

dential oil-fired burners. In addition, this warranty

does not assume any liability of any nature for unsatisfactory performance caused by improper installation.

2. Filters, strainers or any other routine maintenance

part as supplied through the contractor.

3. Any costs for labor for removal and reinstallation

of the alleged defective part, transportation to WeilMcLain, if necessary, and any other materials necessary to perform the exchange.

4. Unsatisfactory performance or damage caused by

improper burner adjustments, control settings, care

or maintenance.

5. Burners operated with combustion air contaminated externally by chemical vapors or with improper fuel additives.

This warranty extends only to the first retail purchaser

of the burner and only to a burner that has not been

moved from its original installation site.

THE WARRANTY DESCRIBED ABOVE IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE AND MERCHANTABILITY.

WEIL-McLAIN EXPRESSLY DISCLAIMS AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL,

INCIDENTAL, INDIRECT OR PUNITIVE DAMAGES

FOR BREACH OF ANY EXPRESS OR IMPLIED

WARRANTY.

For prompt warranty claims, notify the installer who,

in turn, will notify the Weil-McLain distributor from

whom he purchased the burner. If this action does not

result in warranty service, contact Weil-McLain Consumer Relations Department, 500 Blaine Street, Michigan City, Indiana 46360-2388, with details in support

of the warranty claim. Alleged defective part or parts

must be returned through trade channels in accordance

with the Weil-McLain procedure currently in force for

handling returned goods for the purpose of inspection to determine cause of failure. Weil-McLain will

furnish new part(s) to an authorized Weil-McLain distributor who, in turn, will furnish the new part(s) to

the heating contractor who installed the burner. If you

have any questions about the coverage of this warranty,

contact Weil-McLain at the address above.

Weil-McLain

500 Blaine Street

Michigan City, IN 46360-2388

http://www.weil-mclain.com

Part number 644-500-065/020016

Loading...

Loading...