Page 1

Gas-fired

water boiler

PFG

• Installation

• Service

Series 7

• Operation

• Parts

For additional information,

refer to . . .

Control Supplement

Read all instructions before installing

This manual must only be used by a qualified heating installer/service technician.

Read all instructions before installing. Perform steps in the order given. Failure

to comply could result in severe personal injury, death or substantial property

damage.

Installer Leave all instructions with boiler for future reference.

Any claims for damage or shortage in shipment must be filed immediately against

the transportation company by the consignee.

Owner Installation and service must be performed by qualified contractor.

Part No. 550-110-641/0605

Page 2

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Contents

Section I: Installation 2-14

Codes ................................................................. 2

Combustion air and ventilation openings............ 3

Select the boiler location .................................... 3

Installation clearances ........................................ 3

Chimney or vent requirements ........................... 4

When removing boiler from common vent .......... 4

Boiler foundation ................................................ 5

Placing the boiler ................................................ 5

Residential garage installation ........................... 5

Hydrostatic pressure test .................................... 5

Boiler piping connections . . ............................... 6

Recommended piping ........................................ 6

Multiple zoning ................................................... 7

Filling the system ................................................ 7

Bypass piping ..................................................... 8

External heat exchangers ................................... 9

Freeze protection ................................................ 9

Using with refrigeration system .......................... 9

Size and install gas piping ........................... 10-11

Draft hood installation ....................................... 12

Spill switch installation ...................................... 12

Damper installation ........................................... 12

Breeching erection ........................................... 12

Wiring ............................................................... 12

Install room thermostat ..................................... 12

Wiring multiple zones ....................................... 13

Canadian installations – chain and s-hook ....... 13

Checkout procedure ......................................... 14

Section II: Service 15-19

Section III: Replacement Parts 20-21

Section IV: Ratings, Dimensions 22-23

Hazard definitions

The following defined terms are used throughout this manual to bring

attention to the presence of hazards of various risk levels, or to important

information concerning the life of the product.

Indicates presence of hazards that will cause severe personal

injury, death or substantial property damage.

Indicates presence of hazards that can cause severe personal

injury, death or substantial property damage.

Indicates presence of hazards that will or can cause minor

personal injury or property damage.

Indicates special instructions on installation, operation or

maintenance that are important but not related to personal

injury or property damage.

Read before proceeding

The boiler contains ceramic fiber and fiberglass materials.

Use care when handling these materials per instructions on

page 15 of this manual. Failure to comply could result in severe

personal injury.

Do not use petroleum-based cleaning or sealing compounds

in boiler system. Severe damage to system components can

result, causing substantial property damage.

Read all instructions before installing. Failure to follow all

instructions in proper order can cause severe personal injury,

death or substantial property damage.

When calling or writing about the boiler—

Please have the boiler model number from

the boiler rating label and the CP number

from the boiler jacket. You may list the

CP number in the space provided on the

Installation and service certificate

found on page 14.

Codes

Installation must comply with all local codes, laws,

regulations and ordinances. Also United States National

Fuel Gas Code ANSI Z223.1-latest edition. When required, the installation must conform to Standard for

Controls and Safety Devices for Automatically Fired

Boilers, ANSI/ASME CSD-1. Safe lighting and other

performance criteria were met with the gas manifold

and control assembly provided on the boiler when the

boiler underwent tests specified in ANSI Z21.13-latest

edition.

Canadian installations must comply with CAN/CSA

B149.1 or .2 Installation Codes. The equipment shall be

installed in accordance with those installation regulations in force in the local area where the installation is

to be made. These shall be carefully followed in all cases.

Authorities having jurisdiction shall be consulted before

installations are made.

2

Part Number 550-110-641/0605

Page 3

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Section I: Installation

Combustion air and ventilation openings

Combustion air and ventilation openings must comply with Section 5.3, Air for Combustion and Ventilation, of National Fuel

Gas Code ANSI Z223.1-latest edition, or applicable local building codes. Canadian installations must comply with CAN/CSA

B149.1 or .2 Installation Codes.

Provide adequate combustion and ventilation air to:

• Ensure proper combustion

• Reduce risk or severe personal injury or

death from flue gas spillage and carbon

monoxide emissions.

Do not install an exhaust fan in the boiler room.

Boiler installation must ensure sufficient openings in building

and boiler room to provide adequate combustion air and ventilation. Consider construction tightness of building when deciding

whether additional outside openings may be needed.

Older buildings with single-pane windows, minimal weatherstripping and no vapor barrier often provide enough natural

infiltration and ventilation without dedicated openings.

New construction or remodeled buildings are most often built

tighter. Windows and doors are weather stripped, vapor barriers

are used and openings in walls are caulked. As a result, such tight

construction is unlikely to allow proper natural air infiltration

and ventilation.

Select the boiler location

• Consider all connections to boiler before selecting a location.

• Boiler must be installed so gas control system components are pro

tected from dripping or spraying water or rain during operation or

service.

• Non-combustible floor ONLY. See “Boiler foundation”, Page 5.

To avoid personal injury, death or property damage,

keep boiler area clear and free from combustible

materials, gasoline and other flammable vapors

and liquids.

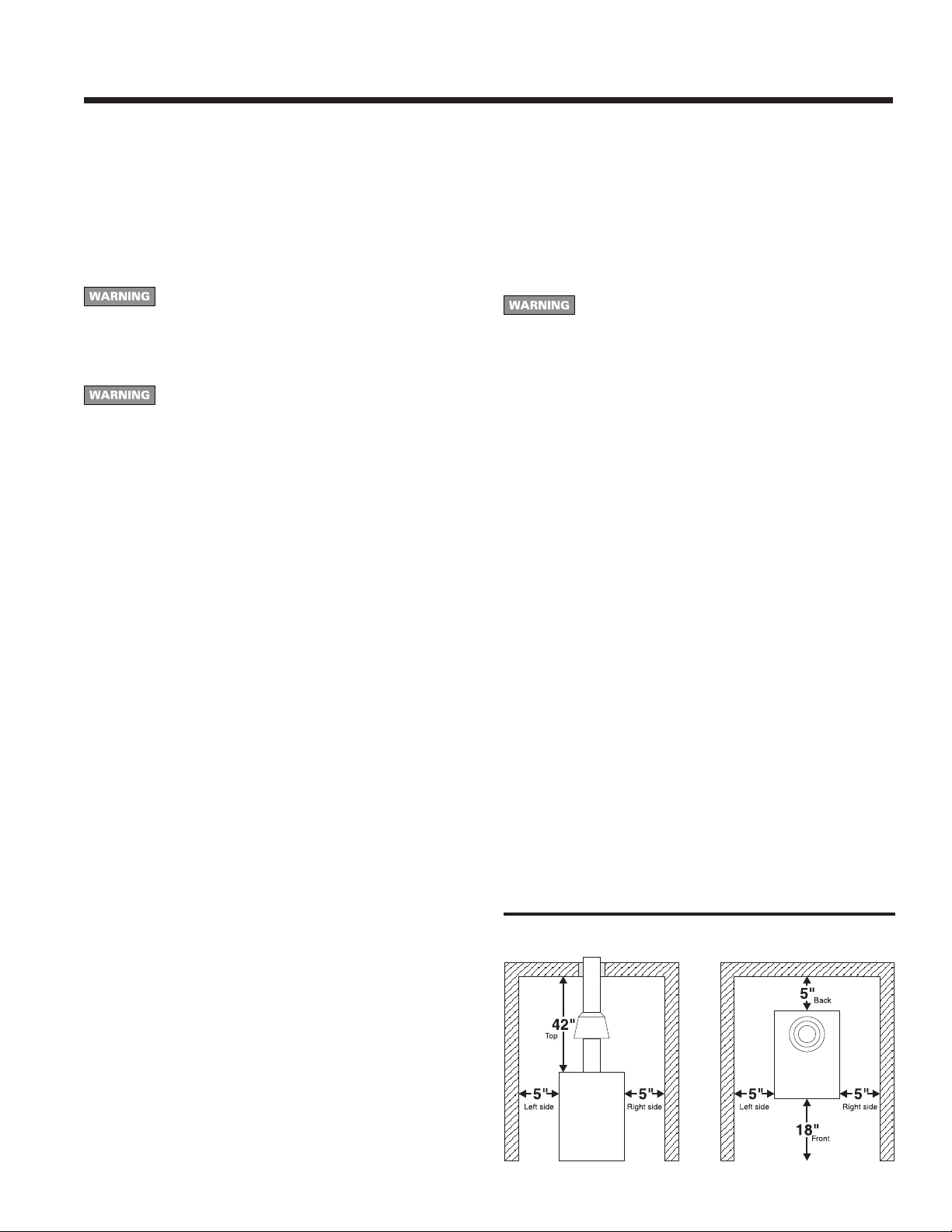

Installation clearances

Suggested minimum clearances for servicing

• 24 inches for cleaning and servicing, left side.

• 18 inches for access to controls and components, front.

• 48 inches from top for cleaning flueways.

• 6 inches on remaining sides.

PFG-5 through PFG-7: Required minimum clearances

to combustible surface in alcove installations (see

below)

PFG 5 thru 7: Top 42” R. Side 5” Front: Alcove 18”

Rear 5” L. Side 5”

-

Air from inside building (boiler in interior room):

• Tightly constructed buildings must be provided with openings to

outside for combustion and ventilation air. These openings must be

sized to handle all fuel burning appliances, exhaust and ventilation

fans and fireplaces.

• When openings to boiler room are taken to interior spaces, provide

two permanent openings: a combustion air opening within 12 inches

of floor and a ventilation opening within 12 inches of ceiling. Each

opening must provide a minimum free area of one square inch per

1,000 Btuh input of all appliances in room plus requirements for

any exhaust fans in room. The interior space supplying combustion

and ventilation air must have adequate infiltration from outside.

Air directly from outside to boiler room:

• Tightly constructed buildings must be provided with combustion

air and ventilation openings to boiler room which are adequate to

handle the boiler needs plus the needs of all other fuel-burning appliances, fireplaces and exhaust or ventilation fans.

• Combustion and ventilation openings connecting directly or by

ducting to outside, or to attic or crawl spaces that freely connect

with outside, must be sized as follows:

1. Outside wall or vertical ducting - one square inch per 4,000

Btuh input of all appliances in room plus requirements for any

exhaust fans or other appliances in room.

2. Horizontal ducting - one square inch per 2,000 Btuh of all appli

ances in room plus requirements for any exhaust fans or other

appliances in room.

3. All ducting must be same size as permanent openings. Minimum

size of ducting must be no less than 9 square inches.

4. Other size ducting must comply with local codes.

PFG-8: Required minimum clearances to combustible

surfacel in alcove installations

PFG 8: Provide minimum 24” between jacket and any com

bustible wall(s). Provide minimum 48” between jacket top and

combustible ceiling or surface above the boiler.

Install in a space large in comparison to size of boiler.

Clearances from piping materials to combustible surfaces

• Single wall vent pipe must be at least 6 inches from combustible

surface.

• Type “B” double wall metal vent pipe - refer to vent manufacturer’s

recommendation for clearances to combustible surface.

• Hot water pipes must be at least ½” from combustible surface.

Note Minimum clearances from combustible

surfaces for models PFG-5 through PFG-7

-

-

Part Number 550-110-641/0605

3

Page 4

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Chimney or vent requirements

(also refer to Breaching erection, Page 12)

Venting must be installed according to Part 7, Venting of

Equipment, of National Fuel Gas Code, ANSI Z223.1latest edition and applicable building codes. Canadian

installations must comply with CAN/CSA B149.1 or .2

Installation Codes.

Minimum chimney or vent sizes are on page 22. A chimney or vent without a listed cap should extend at least

3 feet above the highest point where it passes through

a roof of a building and at least 2 feet higher than any

portion of a building within a horizontal distance of 10

feet. A chimney or vent must not extend less than those

distances stated above.

A lined chimney is preferred and must be used when

required by federal, provincial, territorial, state or local

building codes. Vitreous tile linings with joints which

prevent the retention of moisture and linings made

of corrosion-resistant materials are best. Advice for

flue connections and chimney linings can usually be

obtained from the local gas utility. Type “B” double

wall metal vent pipe or single wall vent pipe may be

used as a liner.

Cold masonry chimneys, also known as outside chimneys, typically have one or more walls exposed to

outside air.

When any atmospheric gas-fired boiler with automatic

vent damper is vented through this type of chimney, the

potential exists for condensation to occur. Condensation

can damage a masonry chimney.

Weil-McLain recommends the following to prevent

possible damage:

1. Line chimney with corrosion-resistant metal liner such as

AL29-4C® single wall stainless steel or B-vent. Size liner

per National Fuel Code ANSI Z223.1-latest edition.

2. Provide drain trap to remove any condensate.

Inspect existing chimney or vent before

installing boiler. Failure to clean or replace

perforated pipe or tile lining will cause

severe injury or death.

Do not alter boiler draft hood or place

any obstruction or non-approved damper

in the breeching of vent system. CSA

certification becomes void. Flue gas

spillage and carbon monoxide emissions

will occur causing severe personal injury

or death.

Where two or more gas appliances vent into a common

chimney or vent, equivalent area should be at least equal

to the area of the vent outlet on the largest appliance

plus 50 percent of the area of the vent outlet on the additional appliance(s).

When removing boiler from

common venting system

Failure to follow all instructions listed

below can cause flue gas spillage and

carbon monoxide emissions, resulting in

severe personal injury, death or substantial

property damage.

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in operation, while the other appliances remaining connected

to the common venting system are not in operation.

a. Seal any unused openings in the common venting sys-

tem.

b. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

c. Insofar as is practical, close all building doors and windows

and all doors between the space in which the appliances

remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes

dryers and any appliance not connected to the common

venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at

maximum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

d. Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

e. Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the flame of

a match or candle, or smoke from a cigarette, cigar or

pipe.

f. After it has been determined that each appliance remain

ing connected to the common venting system properly

vents when tested as outlined above, return doors, windows, exhaust fans, fireplace dampers, and any other gasburning appliance to their previous conditions of use.

g. Any improper operation of the common venting system

should be corrected so the installation conforms with the

National Fuel Gas Code, ANSI Z223.1-latest edition. When

resizing any portion of the common venting system, the

common venting system should be resized to approach

the minimum size as determined using the appropriate

tables in Part 11 in the National Fuel Gas Code, ANSI

Z223.1-latest edition.

Canadian installations must comply with CAN/CSA

B149.1 or B149.2 Installation Code.

-

4

Part Number 550-110-641/0605

Page 5

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

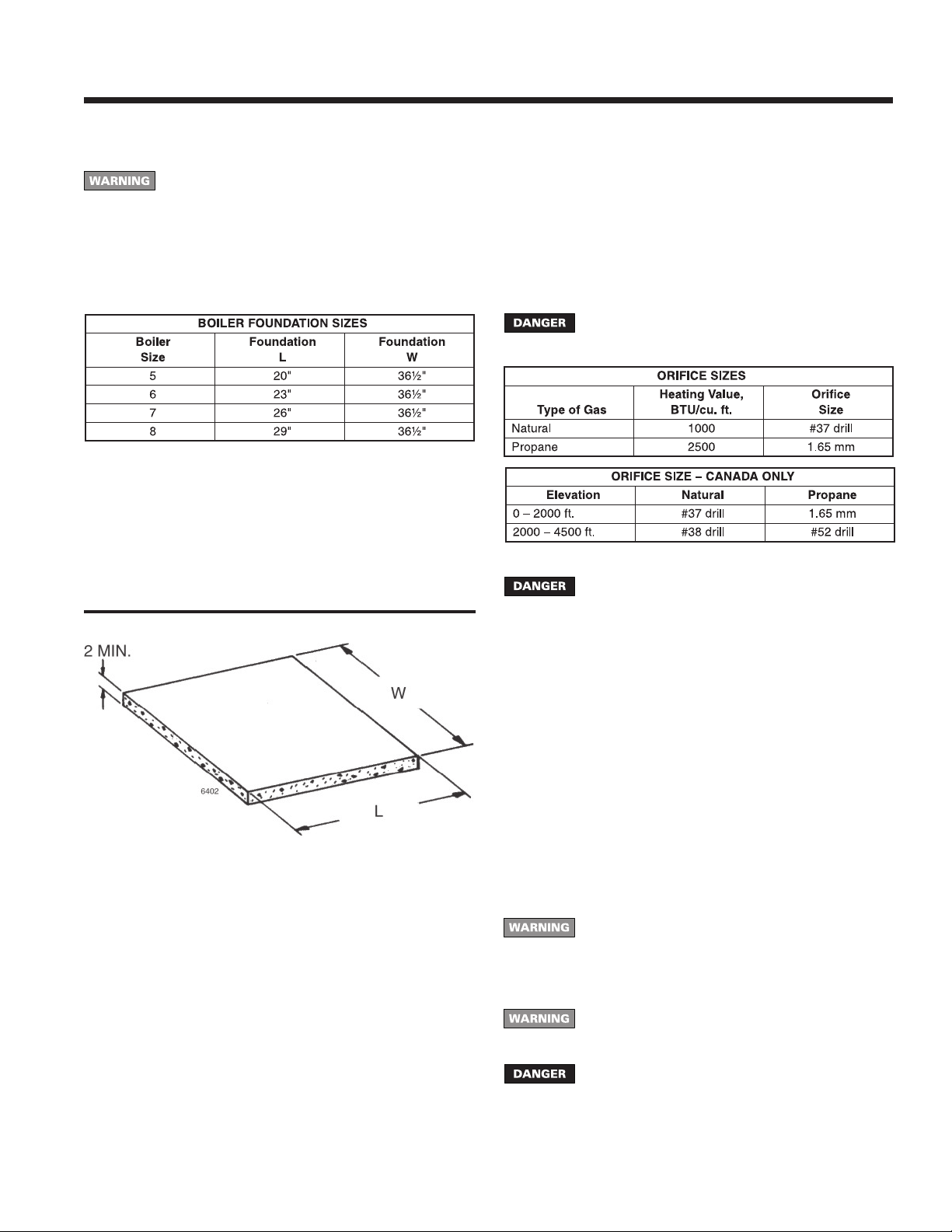

Boiler foundation

Never install boiler on combustible flooring or

carpeting, even if a concrete or aerated foundation

is used. Severe personal injury, death or substantial

property damage can result.

1. See Figure 1. A level concrete or solid brick pad is required if:

a) There is a possibility of the floor becoming flooded.

b) Non-level conditions exist.

2. An aerated boiler foundation is recommended if any of the following

conditions exist:

a) Electrical wiring or telephone cables buried in the concrete floor

of the boiler room.

b) Concrete floor is “green.”

c) There is a history of the floor becoming flooded.

d) Water is channeled under the concrete.

Figure 1 Boiler foundation

Placing the boiler

1. Remove boiler from shipping pallet. Do not drop boiler or bump

jacket on floor or pallet.

2. Level boiler so that the built-in air separation will work correctly.

Shim legs if necessary. Do not alter legs.

3. Remove front jacket door and burner access panel. Unscrew access

panel screws, remove and discard shipping washers, and reinstall

screws.

4. Check for proper orifice sizing from charts below.

Proper orifices must be used. Failure to do so will

cause severe personal injury, death or substantial

property damage.

5. Level and straighten the burners.

Burners must be seated properly in locating slots

with their openings facing up. Gas orifices must

inject down the center of the burner. Failure to

properly seat burners will result in severe personal

injury, death or substantial property damage.

6. Reinstall access panel.

Residential garage installation

Install boiler so burners are at least 18 inches above the floor.

Hydrostatic pressure test

Pressure test before attaching gas piping or electrical supply.

1. Plug any necessary boiler tappings or openings.

2. Connect water supply. Fill boiler and purge all air. Test at 45 psi for

more than 10 minutes.

Do not leave boiler unattended. A cold water

fill could expand and cause excessive pressure,

resulting in severe personal injury, death or

substantial property damage.

3. Check for maintained gauge pressure and leaks. Repair if found.

Leaks must be repaired at once. Failure to do so

can cause boiler damage, resulting in substantial

property damage.

Do not use petroleum-based sealing compounds in

boiler system. Severe damage to boiler will result,

causing substantial property damage.

4. Drain boiler and remove testing plugs.

Part Number 550-110-641/0605

5

Page 6

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Boiler piping connections to the heating

system (refer to piping diagrams, Page 7)

Failure to properly pipe the boiler may result in

improper operation and damage to the boiler or

building.

These boilers are provided with built-in air elimination systems.

1. Install relief valve vertically in top ¾” tapping in right end section.

See WARNING following.

To avoid water damage or scalding due to relief

valve operation:

• Discharge line must be connected to relief valve

outlet and run to a safe place of disposal. Terminate

the discharge line to eliminate possibility of severe

burns should the valve discharge.

• Discharge line must be as short as possible and be

the same size as the valve discharge connection

throughout its entire length.

• Discharge line must pitch downward from the valve

and terminate at least 6” above the floor drain where

any discharge will be clearly visible.

• The discharge line shall terminate plain, not threaded, with a material serviceable for temperatures of

375 °F or greater.

• Do not pipe the discharge to any place where freezing could occur.

• No shutoff valve shall be installed between the

relief valve and boiler, or in the discharge line. Do

not plug or place any obstruction in the discharge

line.

• Failure to comply with the above guidelines could

result in failure of the relief valve to operate, resulting in possibility of severe personal injury, death or

substantial property damage.

• Test the operation of the valve after filling and pressurizing system by lifting the lever. Make sure the

valve discharges freely. If the valve fails to operate

correctly, replace it with a new relief valve.

2. Install pressure-temperature gauge in tapping provided in left end

section.

3. This boiler is for forced hot water circulation only. The circulator and

expansion tank must be selected and sized according to the design

requirements of the system.

a) Size and install circulator. Can be installed on supply or return

piping

b) Size expansion tank to handle the volume of water in the sys

tem.

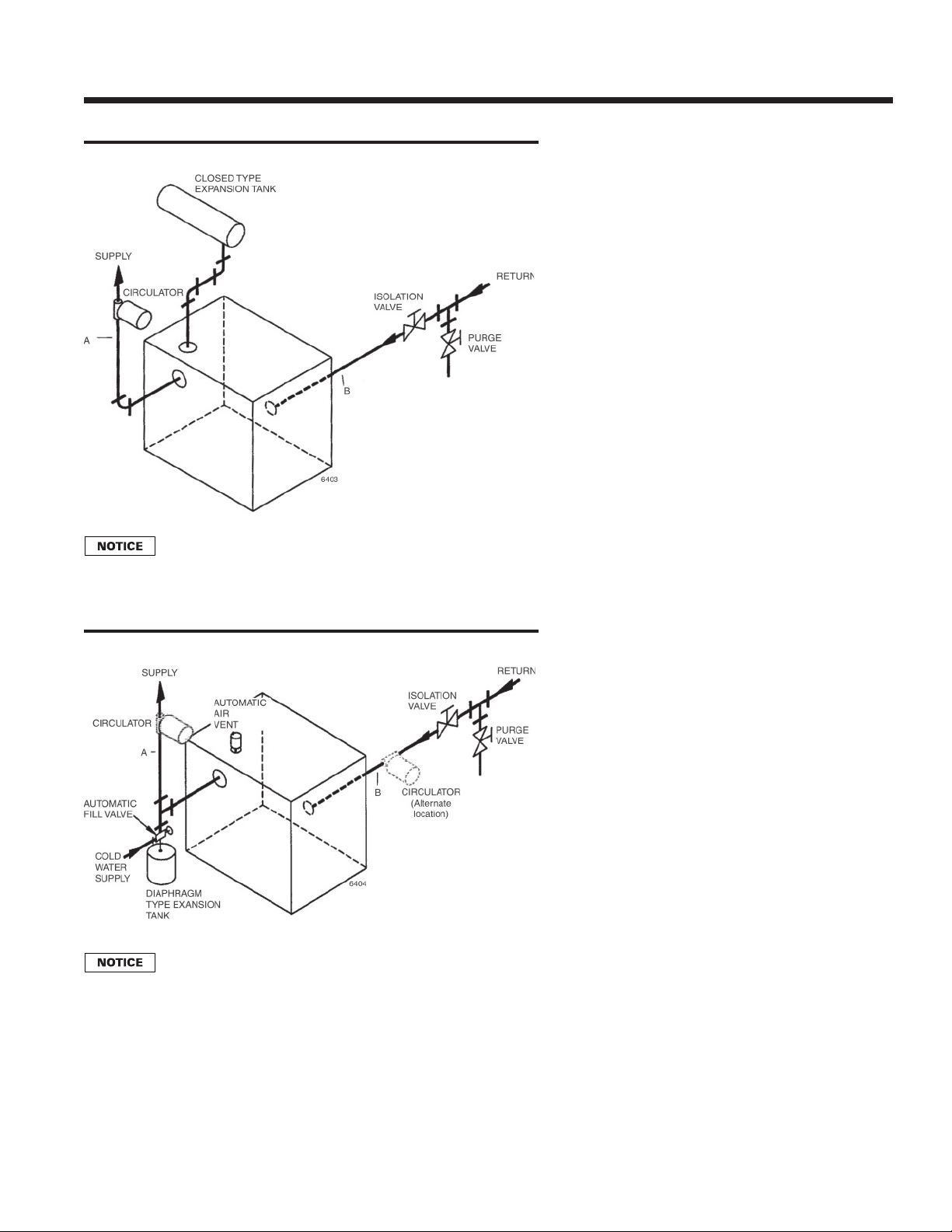

4. Expansion tank installations.

a) Closed type expansion tanks - connect from the ¾” N.P.T.

expansion tank tapping on the left end section (located just

behind the supply outlet tapping) to the expansion tank using

¾” N.P.T. piping. Any horizontal expansion tank piping must

pitch upward toward the tank at least 1 inch for each 5 feet of

piping.

b) Diaphragm type expansion tank - may be located anywhere in

the system, preferably near the boiler.

A manual or automatic type air vent must be

installed in the ¾” N.P.T. tapping when a diaphragm

type tank is used.

The most common cause of lime deposits in boilers is inadequate

expansion tank volume. If the expansion tank is too small, system

water is lost from the relief valve and make-up water is added

through the fill valve. Eventual section failure will result.

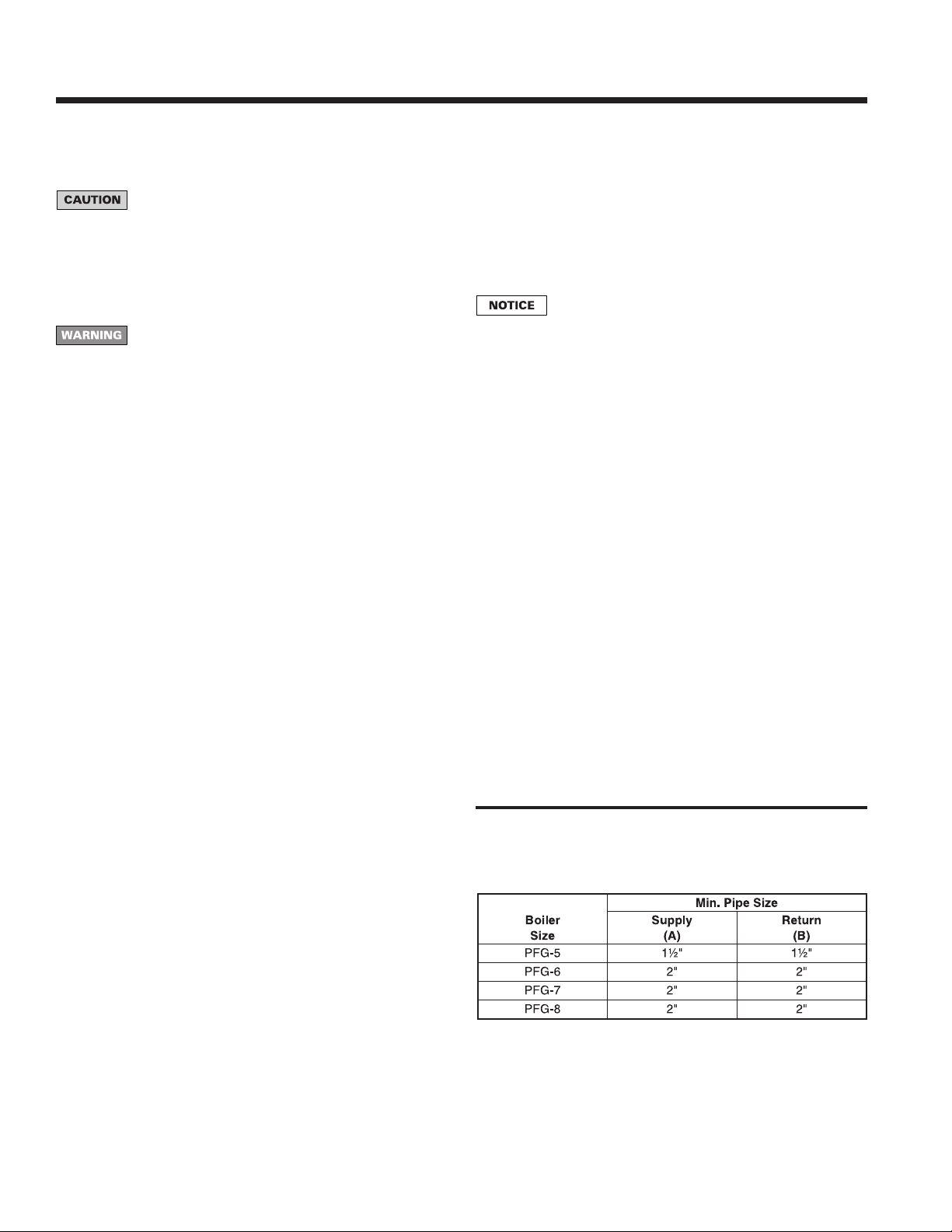

5. Connect the system supply piping to the supply outlet tapping on

the left end of the boiler. See Figure 2a for minimum pipe size.

6. Connect the system return piping to the return tapping on the right

end of the boiler. See Figure 2a for minimum pipe size.

7. Install drain valve provided with boiler on left side. The installer

must provide a drain cock to drain the right (return) side of the

boiler and its connecting piping. The drain cock on the left side of

the boiler will not fully drain the right side.

8. Low water cut off:

a) Must be installed on any PFG boiler if the boiler is located above

radiation level.

b) Must be installed on all PFG-8 boilers to meet ASME specifica

tions (low water cut-off not supplied by Weil-McLain).

c) May be required by certain state, local or territorial codes or

insurance companies.

If a low water cut-off is required, use a control designed especially

for water installations. An electrode probe type low water cut-off

may be located in a tee in the supply line above the boiler.

9. If the system is to be ASME inspected and approved, an additional

high temperature limit is needed. Purchase and install the control

in the supply outlet piping to the boiler.

Figure 2a Minimum recommended pipe sizes

(Supply and return sizes refer to minimum size of

pipe connected to the boiler for 20°F temperature

drop between supply and return.)

-

-

6

Part Number 550-110-641/0605

Page 7

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Figure 2b Piping – Closed type expansion tank

Use circulators or zone valves in each circuit for multiple

circuit applications.

Figure 2c Piping – Closed diaphragm type expansion tank

Use circulators or zone valves in each circuit for multiple

circuit applications.

Multiple zoning

1. Zone valves:

a) Refer to zone valve manufacturer’s literature for wiring

and application. A separate transformer is required to

power zone valves.

b) Provide balancing valves to adjust the flow so it is

about the same in each zone.

2. Circulators:

a) Zoning with circulators requires a relay for each cir

cuit.

b) Install flow control valves to prevent gravity circula

tion.

c) Provide balancing valves to adjust the flow so it is

about the same in each zone.

d) Size common return and supply piping for total flow

of all circulators.

Filling the system

1. Close manual air vents, drain cock, and automatic air vent,

if used.

2. Fill to correct system pressure. Correct pressure will vary

with each application. Residential systems are often designed for 12 pounds cold fill pressure.

3. Open automatic air vent one turn, if used.

4. Air must be vented for the system. Air in the system can

interfere with water circulation and cause improper heat

distribution.

a) Open manual water feed valve.

b) Starting on the lowest floor, open the air vents one at

a time until water squirts out. Close vent.

c) Repeat with remaining vents.

d) Close manual water feed valve when correct boiler

pressure is reached.

5. To purge air from system, install isolation valve in return

piping.

a) Connect a garden hose to the purge valve located

above the isolation valve.

b) Close isolation valve. Open purge valve.

c) Open hand water feed valve and allow system to purge

all air. If system has more than one circuit, purge each

circuit separately by opening each balancing valve one

at a time.

d) Close purge valve.

e) Open isolation valve.

f) Fill the system to the correct pressure.

6. Keep the system filled by occasionally opening the air

vents as in Step 4 above. Add water to make up system

pressure.

-

-

Part Number 550-110-641/0605

7

Page 8

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

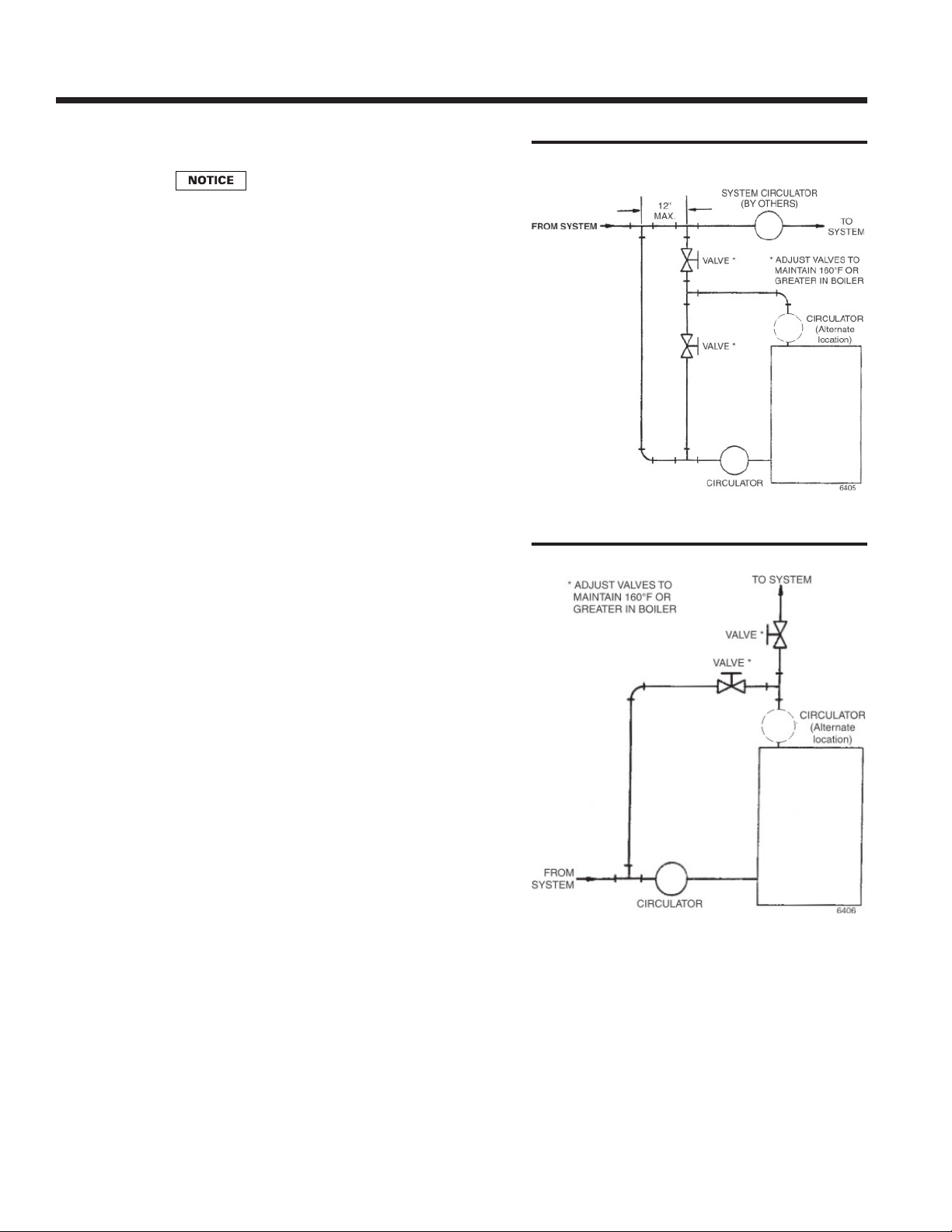

Bypass piping

Bypass piping is not normally required on

any baseboard system.

Bypass piping should be used for the following installations. (Bypass, supply, and return piping should be

same size.)

1. Use the piping shown in Figure 3 to protect:

• radiant panels, plaster, etc. from high temperature

water supplied from boiler, or

• boiler from condensation caused by low temperature

water returned from system.

2. Use the piping shown in Figure 4 to protect boiler from

condensation formed by low water temperature returned

from large water content converted gravity systems, etc.

Figure 3

Figure 4

8

Part Number 550-110-641/0605

Page 9

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

External heat exchangers

The PFG boiler can be used with a storage tank/heat exchanger unit for

domestic hot water. The boiler/tank combination should be installed and

wired in accordance with the tank manufacturer’s instructions, which will

also show any additional components required. A zone valve or separate

circulator must be installed to regulate the production of hot water.

Freeze protection

Use antifreeze especially made for hydronic systems. Inhibited propylene

glycol is recommended.

Do not use automotive, ethylene glycol or undiluted antifreeze.

Severe personal injury, death or substantial property damage

can result.

50% solution provides protection to about -30°F

Local codes may require a back-flow preventer or actual disconnect from

city water supply.

Determine quantity according to system water content. Boiler water content

is listed on page 23.

Follow antifreeze manufacturer’s instructions.

Using with refrigeration system

The boiler must be installed so that chilled medium is piped in parallel with

the heating boiler with appropriate valves to prevent the chilled medium

from entering the boiler. Consult I=B=R Installation and Piping Guides.

If boiler is connected to heating coils located in air handling units where they

can be exposed to refrigerated air, gravity circulation during the cooling cycle

must be prevented with flow control valves or other automatic means.

Part Number 550-110-641/0605

9

Page 10

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Size and install gas piping

In sizing the gas piping, the following factors should

be considered.

a) Diameter and length of the gas supply piping.

b) Number of fittings.

c) Maximum gas consumption (including any pos

sible future expansion).

d) Allowable loss in gas pressure from gas meter out

let to boiler. For pressure drops, see ANSI Z223-1

latest edition. Canadian installations must comply

with CAN/CSA B149.1 or .2 Installation Codes.

1. Size natural gas piping from the following table. Piping

must be sized to provide proper inlet gas pressure to the

gas valve when boiler is operating at rated input. For

natural gas, inlet gas pressure to gas valve should be a

minimum of 5 inches water column and a maximum of 13

inches water column. If inlet natural gas pressure exceeds

13 inches water column, a 100 percent lock-up type gas

pressure regulator of adequate size must be installed in gas

supply piping and adjusted to prevent pressure in excess

of 13 inches water column.

To obtain cubic feet per hour, divide the input (Btu per

hour) by the heating value (Btu per cubic foot).

Pipe delivery schedule

2. PFG 6 thru 8 only (and no damper on PI boilers) - for

propane gas, inlet gas pressure to gas valve should be

11 to 13 inches water column. The gas pressure regulator (furnished by the gas supplier) must be adjusted

to provide lock-up pressures not exceeding 13 inches

water column. Select the pipe size, tanks and regulators

as required.

If boiler is to be propane fired, a conversion

kit must be used. Failure to use kit or to

properly install kit will result in severe

personal injury, death or substantial

property damage.

3. Remove jacket door and connect from gas valve to

-

-

gas meter. Use a street elbow or an elbow and close

nipple at the inlet connection of the gas valve to run

gas piping through opening in jacket side panel.

4. Follow good piping practices.

5. Pipe joint compound (pipe dope) must be resistant

to corrosive action of liquefied petroleum gases and

applied sparingly only to male threads of pipe joints.

6. A drip leg must be installed at inlet of gas connection to

boiler. Where local utility requires drip leg be extended

to the floor, use an appropriate length of pipe between

the cap and tee.

7. A ground joint union must be installed in the piping

to provide for servicing (see Figure 5).

8. Install manual shut-off valve outside boiler jacket as

shown in Figure 5 when required by local codes.

9. Piping must be supported by hangers, not by the boiler

or its accessories.

10. In Canada only - when manual main shut off valve is

used, it must be identified by installer.

11. Purge all air from the supply piping.

Before starting the boiler, and during

initial operation, smell near the floor and

around the boiler for gas odorant or any

unusual odor. Remove boiler front door

and smell interior of boiler enclosure. Do

not proceed with startup if there is any

indication of a gas leak. Repair any leak

at once.

12. Before placing boiler in operation, check boiler and its

gas connection for leaks.

a) If test pressure is less than

then close manual main shut-off valve.

b) If test pressure is greater than

then boiler and gas valve must be disconnected from

gas supply piping.

13.0 inches water column

13.0 inches water column

Do not check for gas leaks with an open

flame - use bubble test. Failure to do so

can cause severe personal injury, death or

substantial property damage.

PFG-8, as required by ANSI Z21.13/CSA 4.9, is equipped

with a manual test valve as shown in Figure 5a. Close

this valve to test boiler gas valve without supplying gas

to the manifold.

10

Part Number 550-110-641/0605

Page 11

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Figure 5 Gas supply piping

Figure 5a Leak test valve (model PFG-8 ONLY)

Part Number 550-110-641/0605

11

Page 12

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Draft hood installation

Secure the draft hood to the outlet at the top of the boiler

with sheet metal screws. The bottom of the draft hood

or “skirt” must have the clearance dimension above the

jacket top panel as indicated on the draft hood.

Do not alter draft hood. CSA design

certification becomes void. If draft hood

is altered, severe personal injury or death

will occur, resulting from flue gas spillage

or carbon monoxide emissions.

Spill switch installation (PFG-5 ONLY)

Fasten spill switch to draft hood as shown on page 21.

Connect wires as shown on wiring diagram label located

inside boiler door.

Damper installation

If damper will be installed, see Control Supplement for

information.

Breeching erection

(Also refer to chimney or vent requirements, Page 4)

Connect from draft hood or damper outlet to chimney

or vent with same size as breeching. Where possible,

vertical venting to the outside from the draft hood or

damper outlet will offer best performance. Where horizontal breeching is used, slope upward at least ¼ inch

per lineal foot toward the chimney or vent and support

with hangers to prevent sagging.

A minimum vertical height of 3 feet of

breeching before any elbow or horizontal

breeching is recommended to reduce

chances of flue gas spillage at the draft

ho o d . Lo ng horizon t a l bre e c hings,

excessive numbers of elbows or tees, or

other obstructions that restrict the flow

of combustion gas should be avoided.

Breeching must not be connected to any portion of a

mechanical draft system that can operate under positive pressure.

Wiring

For your safety, turn off the electrical

power supply at the service entrance panel

before making any electrical connections

to avoid possible electrical shock hazard.

All wiring must be installed in accordance with requirements of the National Electrical Code and any

additional national, state or local code requirements

having jurisdiction. All wiring must be N.E.C. Class 1.

The boiler must be electrically grounded in accordance

with the National Electrical Code, ANSI/NFPA No. 70latest edition.

In Canada, all wiring must be done in accordance with

the CSA C22.1 Canadian Electrical Code Part 1.

If original rollout thermal fuse element wire as supplied with

PFG-5 boiler must be replaced, type 200°C wire or

equivalent must be used. If other original wire as supplied with any PFG boiler must be replaced, type 105°C

wire or equivalent must be used.

The boiler is shipped with control components completely wired except for spill switch and damper (if

provided).

A separate electrical circuit should be used for the

boiler with a fused disconnect switch (15 amp. recommended).

Refer to wiring diagram label affixed to the inside of

the jacket door. Bring electrical supply through proper

opening in the jacket left end panel and into the electrical junction box. Wire electrical supply, circulator and

thermostat as shown on the wiring diagram.

For boilers equipped with control systems other than

constant burner pilot, refer to separate instructions for

application data.

Install room thermostat

Install room thermostat on an inside wall. Never install

where it will be influenced by drafts, hot or cold water

pipes, lighting fixtures, television, rays of the sun or

near a fireplace.

Heat anticipator in thermostat must be set to match the

power requirements of the primary control to which it

is connected. Refer to wiring diagram on jacket door for

recommended heat anticipator setting with standard

equipment. Wire the thermostat as shown.

12

Part Number 550-110-641/0605

Page 13

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Figure 6 Typical wiring – zoning with zone valves

Wiring multiple zones

Refer to zone valve manufacturer’s literature for wiring

and application. A separate transformer is required to

power zone valves. Zoning with circulators requires a

relay for each zone circulator.

Canadian installations – Chain &

s-hook

See illustration below.

The chain and s-hook should be installed

according to this instruction by a qualified

installer/service technician prior to boiler

installation. Please follow steps outlined

below for the installation of the chain and

s-hook.

1. Crimp one side of each s-hook to each end of the chain.

2. Remove the two screws that attach the transformer plate

to the junction box.

3. Remove the transformer relay assembly and drill a 1/8”

hole through the plate as shown below. Do not allow

drill shavings to fall into the boiler jacket or onto any

control.

4. Crimp the s-hook to the 1/8” hole in the transformer

plate. Crimp the other side of the chain to the junction

box lower flange as shown below.

5. Replace the transformer relay assembly on the junction

box and secure with the two screws removed in step 2.

Figure 6 Chain and s-hook installation – Canadian installations only

Part Number 550-110-641/0605

13

Page 14

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Check-out procedure

Check off steps as completed.

Check to make sure base insulation is secure. See "To inspect base

❏

insulation," page 17.

Boiler and heat distribution units filled with water?

❏

Automatic air vent, if used, open one turn?

❏

Air purged from system?

❏

Air purged from gas piping? Piping checked for leaks per page 10?

❏

Follow operating/lighting instruction label on boiler for proper

❏

start-up. Also refer to “To place in operation,” page 17.

Are proper orifices installed? See page 5 for proper orifice size.

❏

Proper orifices must be used. Failure to do so will cause

severe personal injury, death or substantial property

damage.

Proper burner flame? Refer to "Check main burner

❏

flames" and "Check pilot burner flame," page 17.

Test limit control: While burners are operating, move the indicator

❏

of the high limit control below actual boiler water temperature.

The burners should go off while the circulator continues to operate.

Raise the limit control above the boiler water temperature and the

burners should reignite.

Test any additional field-installed controls: If boiler has low water

❏

cut-off, additional high limit or other controls, test for operation as

outlined by manufacturer. Burners should be operating and should

go off when controls are tested. When controls are restored, burners

should reignite.

To test ignition system shut-off device:

❏

a. For PI systems: Connect a manometer to outlet side of gas

valve. Start boiler, allowing for normal start-up cycle to occur

and main burners to ignite. With main burners on, manually

shut off gas supply at manual main shut-off gas valve. Burners

should go off. Open manual main shut-off gas valve. The manometer should confirm there is no gas flow. Pilot will relight,

flame sensing element will sense pilot flame and the main burners reignite.

b. For standing pilot systems: Turn gas knob to PILOT position

and extinguish pilot flame - Pilot gas flow should stop in less

than 3 minutes. Put system back into operation. See page 17.

High limit control set to design temperature requirements of the

❏

system? Maximum high limit setting - 240 °F.

For multiple zones, flow adjusted so it is about the same in each

❏

zone?

Thermostat heat anticipator is set properly? Refer to "Install room

❏

thermostat," page 12, and wiring diagram on jacket door.

Boiler cycled with the thermostat? Raise to highest setting. Boiler

❏

should go through normal start-up cycle. Lower to lowest setting.

Boiler should go off.

Measure gas input (natural gas only):

❏

a. Operate boiler 10 minutes.

b. Turn off all other appliances served by the gas meter, including

gas stove, pilot lights and gas yard lights.

c. At natural gas meter measure time (in seconds) required to use

on cubic foot of gas.

d. Calculate gas input:

e. Btuh calculated should approximate input rating on rating

label.

Check manifold gas pressure by connecting manometer to down-

❏

stream test tapping on main gas valve. Manifold gas pressure for

natural gas should be 3 1/2 inches water column and for propane

gas should be 10 inches water column.

Several operating cycles observed for proper operation? If damper

❏

is provided, see Control Supplement for check-out procedure.

Room thermostat set to desired temperature?

❏

Installation and Service Certificate on this page completed?

❏

All instructions shipped with this boiler reviewed with owner or

❏

maintenance person, returned to envelope and given to owner or

displayed near boiler?

Installation and Service Certificate

Boiler model __________________ Series __________ CP number ___________ Date installed _______________

o Installation instructions have been followed.

Measured Btuh input ____________

Installer ________________________ ________________________________ ______________________________

(company) (address) (phone)

_____________________________________

(installer’s signature)

14

o Check-out sequence has been performed.

o Above information is certified to be correct.

o Information received and left with owner/maintenance person.

Part Number 550-110-641/0605

Page 15

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Section II: Service

Also Refer to Additional Instructions Shipped With The Boiler For

Specific Control Operation and Troubleshooting.

Verify Proper Operation After Servicing.

Your boiler should be inspected, cleaned

and, if necessary, adjusted once a year.

A qualified service agency should be

called.

To av o id pe rs o na l i nju r y, be for e

servicing:

1. Disconnect electrical supply.

2. Shut-off gas supply.

3. Allow boiler to cool.

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Handling ceramic fiber and fiberglass materials

This product contains fiberglass jacket insulation and

ceramic fiber materials in combustion chamber lining

or base panels in gas fired products. Airborne fibers

from these materials have been listed by the State

of California as a possible cause of cancer through

inhalation. The combustion chamber lining or base

insulation panels in this product contain ceramic

fiber materials. Ceramic fibers can be converted to

cristobalite in very high temperature applications. The

International Agency for Research on Cancer (IARC)

has concluded, “Crystalline silica inhaled in the form

of quartz or cristobalite from occupational sources is

carcinogenic to humans (Group 1).”:

Suppliers of fiberglass wool products recommend the

following precautions be taken when handling these

materials:

Precautionary measures

• Avoid breathing fiberglass dust and contact with skin or

eyes.

• Use NIOSH certified dust respirator (N95). This type of

respirator is based on the OSHA requirements for fiberglass

wool at the time this document was written. Other types of

• Wear long-sleeved, loose fitting clothing, gloves, and eye

• Apply enough water to the combustion chamber lining or base

• Remove combustion chamber lining or base insulation from

• Operations such as sawing, blowing, tear out and spraying

• Wash potentially contaminated clothes separately from other

NIOSH stated First Aid.

• Eye: Irrigate immediately

• Breathing: Fresh air.

To avoid personal injury, death or property

damage, keep the boiler area clear and free

from combustible materials, gasoline and

other flammable vapors and liquids.

Do not block flow of air to boiler.

Incomplete combustion and carbon

monoxide emissions can cause severe

personal injury, death or substantial

property damage.

Do not store sources of hydrocarbons (i.e.,

bleaches, cleaners, chemicals, sprays, paint

removers, fabric softeners, etc.) in boiler

area. This can contribute to shortened

boiler/vent system life.

respirators may be needed depending on the job site conditions. Current NIOSH recommendations can be found on

the NIOSH web site at http://www.cdc.gov/niosh/homepage.

html. NIOSH approved respirators, manufacturers, and phone

numbers are also listed on this web site.

protection.

insulation to prevent airborne dust.

the boiler and place it in a plastic bag for disposal.

may generate airborne fiber concentration requiring ad

ditional protection. Bag for disposal.

clothing. Rinse clothes washer thoroughly.

-

Part Number 550-110-641/0605

15

Page 16

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Suggested Minimum Service Schedule

for Qualified Service Technician Only

Beginning of each heating season:

1. Annual service call by a qualified service agency.

2. Check burners and flueways and clean if necessary. Reference “To clean boiler heating surfaces” and “To clean main

burners,” page 18.

3. Visually inspect base insulation. Reference “To inspect base insulation,” page 17.

4. Follow procedure “To place in operation,” page 17.

5. Visually inspect main burner flames. Refer to “Check main burner flames,” page 17.

6. Check pilot burner flame. Refer to page 17.

7. Visually inspect venting system for blockage, deterioration or leakage. Reference “Inspect venting system,”

page 18.

8. Check operation of low water cut-off, if used, and additional safety devices. Refer to manufacturer’s instruc

tions.

9. Check that boiler area is free from combustible materials, gasoline and other flammable vapors and liquids.

10. Check for and remove any obstruction to the flow of combustion or ventilation air to the boiler.

11. Follow instructions on circulator to oil, if oil lubricated. Over oiling will damage the circulator. Water lubricated

circulators do not need oiling.

-

Daily during heating season:

1. Check that boiler area is free from combustible materials, gasoline and other flammable vapors and liquids.

2. Check for and remove any obstruction to the flow of combustion or ventilation air to the boiler.

Periodically during heating season:

1. Check relief valve. Reference manufacturer’s instructions on relief valve tag.

2. Test low water cut-off, if used. Blowdown if low water cut-off is float type. Reference manufacturer’s instruc

tions.

Monthly during heating season:

1. Check for leaks in the boiler and piping. If found, repair at once.

Leaks must be repaired at once. Failure to do so can cause boiler damage, resulting in substantial

property damage.

Do not use petroleum-based sealing compounds in boiler system. Severe damage to boiler will result,

causing substantial property damage.

2. Visually inspect main burner flames. Reference “Check Main Burner Flames.”

3. Check pilot burner flame. Refer to page 17.

4. Visually inspect venting system for blockage, deterioration or leakage. Reference “Inspect venting system,”

page 18.

5. Check automatic air vent for leakage. If leaking, remove vent cap and push valve core in to wash off sediment that

may have accumulated on the valve seat. Release valve, replace cap, and open one turn.

-

16

End of each heating season:

1. Follow “Annual shut-down procedure,” page 18.

Part Number 550-110-641/0605

Page 17

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

To inspect base insulation:

The boiler contains ceramic fiber and fiberglass materials.

Use care when handling these materials. See WARNING

above. Failure to comply could result in severe personal

injury.

Make sure base insulation is secure against base front and back panels. If

base insulation is damaged or displaced, do not operate boiler. Replace

or reposition insulation.

Failure to replace damaged insulation or reposition

insulation can result in a fire hazard, causing severe

personal injury, death or substantial property damage.

To place in operation:

1. Make sure boiler is filled with water.

2. Follow lighting/operating instructions on boiler.

PROPANE BOILERS ONLY – Your propane

supplier mixes an odorant with the propane to

make its presence detectable. In some instances, the

odorant can fade, and the gas may no longer have

an odor.

Propane gas can accumulate at floor level. Smell

near the floor for the gas odorant or any unusual

odor. If you suspect a leak, do not attempt to light

the pilot.

• Use caution when attempting to light a propane

pilot. This should be done by a qualified service

technician, particularly if pilot outages are

common.

• Periodically check the odorant level of your gas.

• Inspect boiler and system at least yearly to make

sure all gas piping is leak-tight.

• Consult your propane supplier regarding installation

of a gas leak detector. There are some products on

the market intended for this purpose. Your supplier

may be able to suggest an appropriate device.

3. If boiler starts, go to Step 5. If boiler fails to start, go to Step 4.

4. If boiler fails to start, check for following conditions:

a) Loose connection or blown fuse?

b) High limit setting below boiler water temperature?

c) Thermostat setting below room temperature?

d) Gas not turned on at meter?

e) Gas not turned on at boiler?

f) If above fails to eliminate the trouble, refer to Control Supple

ment.

5. Make sure boiler goes through several normal operating cycles.

6. Turn thermostat or operating control to desired setting.

Check pilot burner flame:

1. Proper pilot flame

a) Blue flame.

b) Inner cone engulfing pilot flame sensor.

c) Pilot flame sensor glows cherry red.

2. Improper pilot flame

a) Overfired - flames large and lifting or blowing past pilot flame

sensor.

b) Underfired - flame small; pilot flame sensor not engulfed by

inner cone.

c) Lack of primary air - flame tip yellow.

d) Pilot flame sensor not heated properly.

Figure 7 Typical pilot burner flame

Check main burner flames:

1. Proper burner flame - Yellow-orange streaks may appear - caused

by dust.

2. Improper flame

a) Overfired - Flames large.

b) Underfired - Flames small.

c) Lack of primary air - Yellow tipping on flames; sooting will oc

cur.

Figure 8 Typical main burner flame

-

-

Part Number 550-110-641/0605

17

Page 18

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Inspect venting system:

1. Check venting system at least once a month during heating season.

With boiler in operation (at least 5 minutes), hold a candle or match

below lower edge of draft hood “skirt.” If flame is undisturbed or

leans under skirt, vent system is functioning properly. If flame is

extinguished, flickers, or reduced while flame is pushed out side

skirt, the vent system must be checked for obstructions or other

causes of improper venting.

2. Inspect all parts of venting systems for deterioration from corrosion,

physical damage, sagging, etc. Correct all conditions found.

3. Verify damper, if used, is open when burner ignites. For additional

information, see Control Supplement.

To clean boiler heating surfaces

The boiler contains ceramic fiber and fiberglass materials.

Use care when handling these materials per instructions

on page 15 of this manual. Failure to comply could result

in severe personal injury.

1. Follow shut-down procedure.

2. Remove breeching, draft hood and damper (when used).

Remove jacket top panel. Turn back jacket insulation to expose col

lector hood.

3. Remove collector hood. Clean excess boiler cement from collector

hood and cast iron sections.

4. Remove radiation plates.

5. Remove burners from base of boiler. Follow “To clean main burners,”

page 18, to thoroughly clean burners.

6. Place newspaper in base of the boiler to collect soot that will fall.

7. With a wire flue brush, clean between the sections.

8. Remove newspaper and soot. Vacuum or brush base and surrounding

area to remove soot.

9. Reinstall radiation plates.

10. Reinstall collector hood. Seal with boiler cement.

11. Reinstall insulation and jacket panel.

12. Reinstall burners.

When reinstalling, burner tubes must be seated in their

locating slots with the openings facing up. Gas orifices

must inject down center of burner. Failure to properly

seat burner will result in severe personal injury, death or

substantial property damage.

13. Reinstall draft hood, damper (when used), and breeching.

14. Follow “To Place in Operation” procedure.

Excessive sooting indicates improper combustion of the

gas. Call a qualified service agency or your local gas utility

to check for proper combustion and make any necessary

adjustments.

Annual shut-down procedure:

1. Follow lighting/operating instructions label on boiler.

2. DO NOT drain the system unless exposure to freezing

temperatures will occur. If antifreeze is used with system,

do not drain.

3. If the complete boiler and piping system must be drained

to avoid freezing, then a means must be provided for

draining water from BOTH ends of the boiler at or below

the level of the return tapping. A boiler drain cock is provided by Weil-McLain on the left side of the boiler only.

To replace a boiler section

If replacing any section (see Figure 9):

• Approved RTV silicone sealant (Dow Corning 700 or

732 or G.E. 808 or 108) must be used to seal between

sections.

• Place ball bearings in the holes in the locator holes on

the sides of the sections to ensure section alignment and

reliable placement.

-

Figure 9 Section assembly

Failure to use PFG Series 7 intermediates

or to properly seal sections per Figure

9 can cause flue gas spillage or carbon

monoxide emissions, resulting in severe

personal injury, death or substantial

property damage.

To clean main burners:

1. Vacuum or brush burners to remove dust and lint.

When reinstalling, burner tubes must be seated in their

locating slots with the openings facing up. Gas orifices

must inject down center of burner. Failure to properly

seat burner will result in severe personal injury, death or

substantial property damage.

18

Part Number 550-110-641/0605

Page 19

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Common problems and possible solutions

Part Number 550-110-641/0605

19

Page 20

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Item Description Part Number

1 Draft hood: PFG-5 (7” x 7” dia x 24.45”)

PFG-6 (8” x 8” dia x 27.80”)

PFG-7 (9” x 9” dia x 31.05”)

PFG-8 (9” x 9” dia x 36.55”)

450-021-200

450-021-201

450-021-202

450-021-205

2 Collector hood: PFG-5

PFG-6

PFG-7

PFG-8

450-014-819

450-014-820

450-014-821

450-014-822

3 Right hand end section, 51113 312-804-405

4 Intermediate section, 51125 312-804-416

5 Left hand end section, 51113 312-804-405

NS Section replacement kit (one per joint; 4 seals, 4 ball bearings, and sealant) 386-700-856

6 Burner, main 512-200-022

NS Burner, main with pilot bracket 512-200-023

7 Right hand/left hand base rail 452-800-655

8 Base front panel: PFG-5

PFG-6

PFG-7

PFG-8

452-800-500

452-800-501

452-800-502

452-800-503

9 Front base insulation: PFG-5

PFG-6

PFG-7

PFG-8

591-222-020

591-222-021

591-222-022

591-222-025

10 Base access panel: PFG-5

PFG-6

PFG-7

PFG-8

452-800-540

452-800-541

452-800-542

452-800-543

11 Manifold: PFG-5

PFG-6

PFG-7

PFG-8

591-125-820

591-125-821

591-125-822

591-125-823

12 Base back panel: PFG-5

PFG-6

PFG-7

PFG-8

452-800-580

452-800-581

452-800-582

452-800-583

13 Back base insulation: PFG-5

PFG-6

PFG-7

PFG-8

591-222-030

591-222-031

591-222-032

591-222-033

14 Tie rod without nut (2 per boiler): PFG-5 ⁵⁄₈”-11

UNC

x 15”

PFG-6 ⁵⁄₈”-11

UNC

x 18”

PFG-7 ⁵⁄₈”-11

UNC

x 21”

PFG-8 ⁵⁄₈”-11

UNC

x 24”

560-134-506

560-134-507

560-134-508

560-134-509

15 Flue baffle: PFG-5

PFG-6

PFG-7

PFG-8

452-800-449

452-800-450

452-800-451

452-800-452

16 Flue baffle insulation: PFG-5

PFG-6

PFG-7

PFG-8

591-222-095

591-222-096

591-222-097

591-222-098

17 Spill switch, PFG-5 only 510-300-014

18 Rollout thermal fuse element, PFG-5 only 512-050-230

19 Radiation shield (2 per joint) 460-003-700

20 Section alignment ball bearings, 1/4” diameter (4 per joint)

Ball bearing kit (4 bearings)

562-930-250

386-700-856

NS Main burner orifice (natural gas) #37 drill 560-529-055

NS Main burner orifice (propane gas) 1.65 mm 560-529-056

Section III: Replacement Parts

The boiler contains ceramic fiber and fiberglass materials. Use care when handling these materials, per

instructions on page 15 of this manual. Failure to comply could result in severe personal injury.

To avoid personal injury, before replacing any parts on the boiler:

1. Turn off power.

2. Shut off gas supply.

3. Allow boiler to cool.

20

Part Number 550-110-641/0605

Page 21

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Part Number 550-110-641/0605

21

Page 22

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

Section IV: Ratings and dimensions

DOE

Standard equipment

Factory Fire Tested

•

Insulated Extended Jacket

•

Built-In Air Separator

•

Draft Hood (Shipped in separate carton)

•

Combination Gas Valve

•

Non-Linting Pilot Burner

•

Aluminized Steel Burners

•

Combination Relay Receptacle and 40 VA Trans-

•

former

Relay

•

High Limit Control

•

Spill Switch (PFG-5 only)

•

Rollout Thermal Fuse Element (PFG-5 only)

•

30 P.S.I. Relief Valve (shipped in separate carton)

•

(boiler sections tested for 50 P.S.I. water working

pressure)

22

Combination Pressure-Temperature Gauge

•

(shipped in separate carton)

Drain Valve (shipped in separate carton)

•

PIDN

Intermittent Electronic Ignition System

•

Automatic Vent Damper

•

PIN

Intermittent Electronic Ignition System

•

SPN

Constant Burning Thermally Supervised Pilot System

•

Thermocouple

•

Part Number 550-110-641/0605

Page 23

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

* Locate manual main Shut-Off Gas Valve (where required) according to local utility requirements.

Part Number 550-110-641/0605

23

Page 24

PFG SerieS 7 GaS-Fired Water Boiler — Boiler Manual

24

Part Number 550-110-641/0605

Loading...

Loading...