Weil-McLain PER 550-141-396-0801 User Manual

PER Series 3

Electric-Hydronic Boilers

Installation Instructions

Installer

Read all instructions before

installing. Follow all instructions in

proper order to prevent personal

injury or death.

• Consider piping and installation when determining

boiler location.

• Any claims for damage or shortage in shipment

must be filed immediately against the

transportation company by the consignee.

These Instructions must be used only by a qualified installer/service

technician. R ead these instructions completely before beginning. Fail ure to

follow these instructions can cause severe personal injury, death or

substantial property damage.

When calling or writing about the boiler— Please have the boiler model

number from the boiler rating label and the CP number from the boiler

jacket. You may list the CP number in the space pro vided on the Installation

and service certificate found on page 9.

User

• This manual is for use only by

your qualified heating installer/

service technician.

• W e rec ommend regular service

by a qualified service

technician, at least annually.

Part number 550-141-396/0801

PER Series 3 Electric-Hydronic Boilers Installation Instructions

Please read before proceeding

Hazard Definitions

The following defined terms are used throughout these Instructions to b ring attention t o the prese nc e of hazards

of various risk levels, or to important information concerning the life of the product.

Indicates presence of hazards that will cause severe personal injury , death or substantial property

damage.

Indicates presence of hazards that can cause severe personal injury , death or substantial property

damage.

Indicates presence of hazards that will or can cause minor personal injury or property damage.

Indicates special instructions on installation, operation or maintenance that are important bu t

not related to personal injury or property damage.

Failure to adhere to the guid elines on this pag e can res ult in sev er e pers onal inj ury, death

or substantial property damage.

When servicing boiler —

• To avoid electric shock, disconnect electrical supply before performing maintenance.

• To avoid severe burns, allow boiler to cool before performing maintenance.

• The boiler contains fiberglass materials. Use care when handling these materials per instructions on page

11 of this manual.

Boiler operation —

• Do not block flow of ventilation air to boiler. Will cause components to overheat.

• Should overheating occur , do not disc onnect electrical supply to circulator . Instead, sh ut off the electrical

supply at a location external to the appliance.

• Do not use this boiler if any part has been under water. Immediatel y call a qualified service technician to

inspect the boiler and to replace any part of the control system that has been under water.

Boiler water —

• Do not use petroleum-based cleaning or sealing compounds in boiler system. This can result in substantial

property damage.

• Do not use "homemade cures" or "boiler patent medicines". Serious damage to boile r, personnel and/or

property may result.

• Continual fresh makeup water will reduce boiler life. Mineral buildup in section reduces heat transfer,

overheats cast iron, and causes section failure. Addition of oxygen and other gases can cause internal

corrosion. Leaks in boiler or piping must be repaired at once to prevent makeup water.

• Do not add cold water to hot boiler. Thermal shock can cause sections to crack.

Glycol — potential fire hazard —

All glycol is flammable when exposed to high temperatures. If glycol is allowed to accumulate in or around

the boiler or any other potential ignition source, a fire can develop. In order to prevent potential severe

personal injury, death or substantial property damage from fire and/or structural damage:

• Never store glycol of any kind near the boiler or any potential ignition source.

• Monitor and inspect the system and boiler regularly for leakage. R epair any leaks immediately t o prevent

possible accumulation of glycol.

• Never use automoti ve antifreeze or ethylene glyc ol in the system. U sing these glycols can lead to hazardous

leakage of glycol in the boiler system.

2

Part number 550-141-396/0801

PER Series 3 Electric-Hydronic Boilers Installation Instructions

Pre-installation

General instructions

The Weil-McLain Model PER electric-hydronic boilers

are assembled units designed for use in forc ed hot water

heating systems. The suggested design temperature rise

through the boiler is 20°F. The PER boiler is a complete

package including the circulator and expansion tank.

Low flow rates through the boiler at elevated

temperatures should be avoided. The structure to be

heated should be insulated in the conv entional manner

used in your area for electrically heated buildings. Boiler

must be installed in accordance with these instructions

so as not to void our warranty.

Open the boiler crate and check the contents. In the

event of shortage or damage, notify the transportation

company immediately.

Locating the boiler

The compact construction of the electric-hydronic

boiler permits installation in an alcove, storeroom or

other small area. The location chosen should have

convenient electrical service.

Allow sufficient clearance above and below the boiler

cabinet to permit installation of supply and return

piping. A minimum of 6 inches is required at the top o f

the boiler for installation and accessories. A clearance

of 10 inches is required on the right hand side for

removal of the elements.

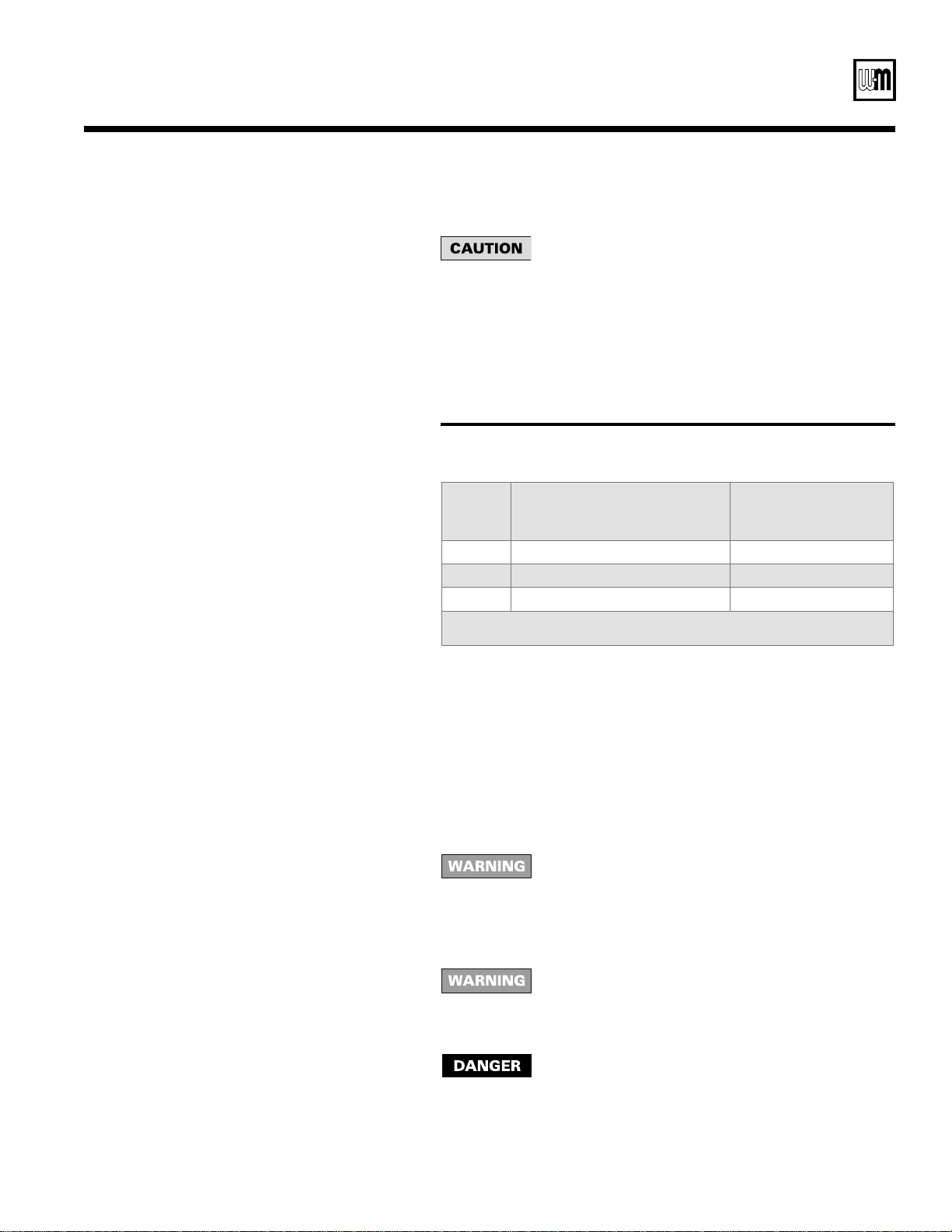

Expansion tank sizing

Undersized expansion tanks cause system water to be

lost from relief valve and mak eup wat er added through

fill valve. Eventual section failure can result.

If a Fill-Trol system is used, refer to Table 1 for proper sizing. If Fill-Trol

action is not desired, size the expansion tank ac cording to the wat er volume

of the system. If a standard closed expansion tank (without a diaphragm)

is used, the air vent tapping on the boile r casting makes a co nv enient point

of connection. The No. 109 Fill-Trol is furnished as standard equipment.

T ab le 1 Expansion tank sizing (Tank sizing based on 200 °F

average system temperature.)

Boiler

model

number

PER-15 No. 109 No. 15

PER-20 No. 109 No. 15

PER-25 No. 109 No. 15

Note: Gravity systems converted to a forced hot water system usually require

additional compression tank capacity.

Standard Fill-Trol tank

(for series loop or one-pipe system

with convector baseboard)

Additional Ex-Trol tank

(for cast-iron radiators or

cast-iron baseboard)

Mounting the boiler

Normally, the boiler will be installed against a frame or

masonry wall. If the wall surface is rough or uneven, it

may be necessary to mount plywood on the wall, then

mount the boiler on the plywood. Refer to

“Dimensions” on page 12 and “Ratings” on page 13, and

note the boiler weight. Be sure that the wall structure

will support the boiler and its piping.

The 9/16" top mounting holes and 5/16" lower mounting

holes are on 16-inch centers to permit installation on

studs in standard wall construction. The use of ¼" x

2½" lag screws is recommended for mounting the boiler .

The head diameters of the top two screws must not

exceed 9/16".

1. Locate the top mounting holes so that the boiler

will be level. Install the screws so that the heads

protrude ¾" from the wall.

2. Raise the boiler to mounting position by placing a

board across the bottom of the boiler or by grasping

the lower left and right inside corners. Do not

attempt to lift the boiler by grasping the bottom

jacket cross tie.

3. Place the top brackets o ver the lag scr ews and then

install screws through the lower mounting holes.

The top screws can now be tightened.

Hydrostatic pressure test

Pressure test boiler before attaching piping or electrical supply.

1. Install air vent in tapping on top of boiler .

2. Plug remaining tappings, including relief valve opening.

3. Connect water supply. Fill boiler and purge all air. For more than 10

minutes, pressure-test at 1½ times maximum working pressure.

Do not leave boiler unattended. Cold water fill could

expand and cause excess pressure, resulting in severe

personal injury, death or substantial property damage.

4. Check for maintained gauge pressure. V isually check for leaks if gauge

pressure drops.

5. Drain boiler and repair leaks if found.

Leaks must be repaired at once. Failure to do so can

damage boiler , resulting in substantial property damage.

6. Retest boiler after repairing leaks.

7. Remove testing plugs and air vent.

Do not use petroleum-based cleaning or sealing

compounds in boiler system. S evere damage to boiler

will result, causing substantial property damage.

Part number 550-141-396/0801

3

PER Series 3 Electric-Hydronic Boilers Installation Instructions

Pre-installation continued

Piping the boiler

After the boiler is secured to the wall, attac h the suppl y

and return piping. Refer t o Table 2 for minimum pipe

sizes.

Install manual shut-off valves in the supply and return

lines to facilitate servicing the boiler. Model PER boilers

are provided with a built-in air elimination system using

a float-type automatic air vent. Refer to the boiler line

drawings and proceed as follows:

1. Install the pressure-temperatur e gauge and ¾"-¼"

bushing in the 1¼" x 1¼" x ¾" tee installed on the

boiler supply connection. See “Dimensions” on

page 12.

2. The ¾" tapping, located to the left of the supply

tapping, must be used for either an automatic

venting device or piped directly to a standard closed

expansion tank.

3. Install the pressure relief valve in the ¾" tapping

located on the top left hand side of the boiler (see

“Dimensions” on page 12). Pipe the relie f valve

outlet to a floor drain or near the floor . Do not pipe

the relief valve to any area where freezing

temperatures might be encountered.

Pipe relief valve discharge line near

floor close to floor drain to eliminate

potential of severe burns. Do not

pipe to any area where freezing

could occur. Do not plug valve or

place any obstruction in discharge

line.

4. Connect the system supply piping to the tapping

located at the right on the top of the boiler casting.

5. Connect the system return piping to the circulato r

flange. When solder fittings are used, be sure that

the gasket is not between the flanges when the solder

connection is made.

6. A Fill-Trol system is supplied with PER boilers

follow the instructions attached to the valve.

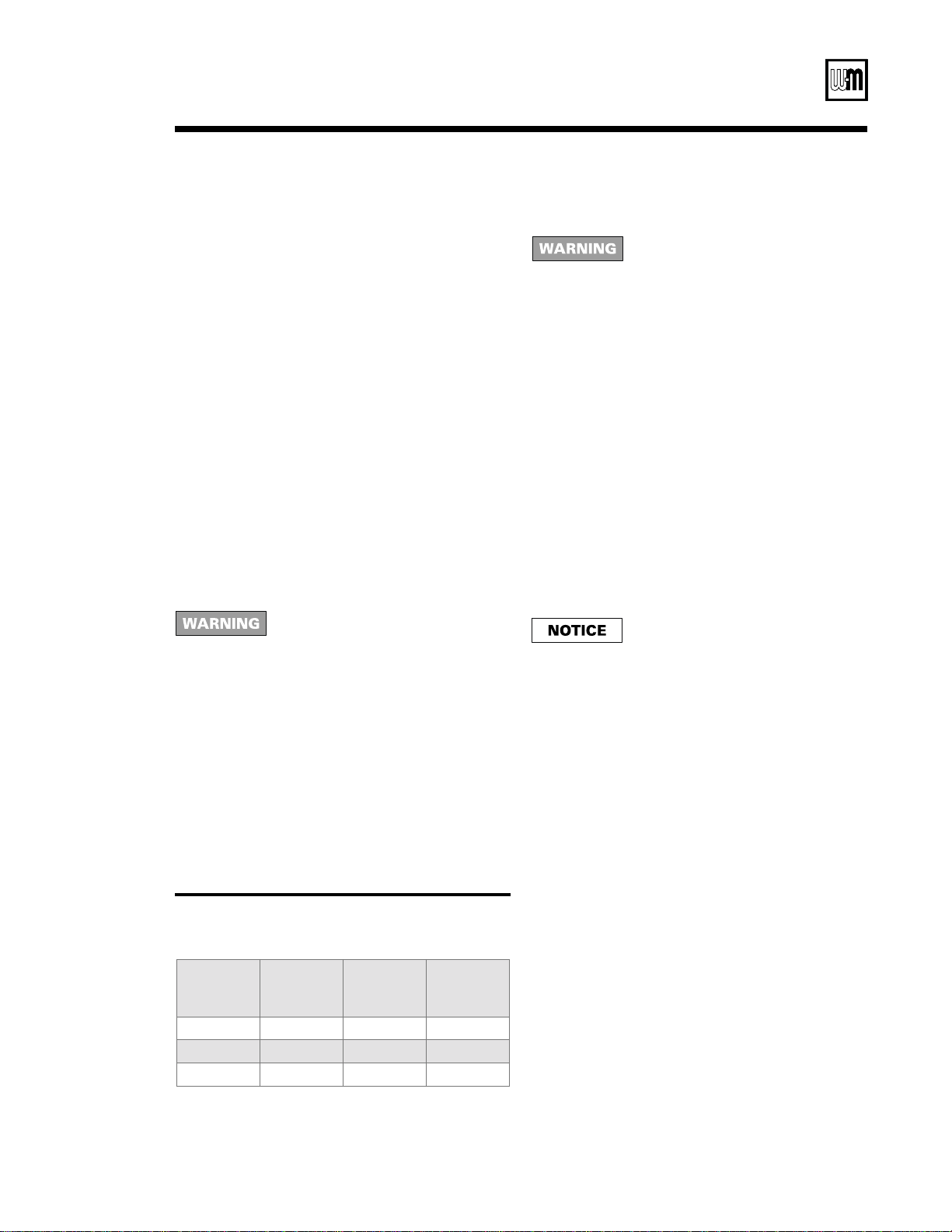

Table 2 Pipe sizes and flow rates

(Recommended minimum pipe size with 20°F

temperature rise through boiler.)

Wiring the boiler

Electric shock hazard. Can cause

severe personal injury or death if

power source, including service

switch on boiler , is not disco nnected

before installing or servicing.

The Model PER electric-hydro nic boilers are pre-wired

for use with 240-volt, single phase, 50/60-hertz power.

Refer to Figure 1 on page 13 fo r the r eduction in boiler

capacity when the line voltage is less than 240 volts.

An opening is provided in the left side of the jacket top

panel for the field wiring. Refer to Dimensions, page

12, and Ratings, page 13, for recommended wire sizes.

All wiring must conform to the requirements of the

National Electrical Code and any additional Nat ional,

State or Local Code Requirements having jurisdiction.

All safety circuit wiring should be N.E.C. Class 1. Do

not use aluminum wire.

When a PER boiler is used in a zoned system, the zone

valves must be powered from an independent source,

and have electrically isolated end switches or isolating

relays wired in parallel to the boiler thermostat

terminals.

Do not attempt to power zone valves

from the transformer in the boiler

control system.

Control system

The control system for the PER electric boiler has

electronic and thermal time delays, which are employ ed

to sequence elements on and to sequence elements off

in reverse order. The contactors used in the system

disconnect all current from the heating elements.

The circulator control utilizes a single pole relay.

Low and high limit functions are combined in a dual

limit control. The control system is operated from a

low voltage transformer.

Boiler

model

number

PER-15 5.20 ¾" ¾"

PER-20 6.90 1" 1"

PER-25 8.60 1¼" 1¼"

4

Maximum

flow rate

GPM

Minimum

supply

pipe size

Minimum

return

pipe size

Part number 550-141-396/0801

PER Series 3 Electric-Hydronic Boilers Installation Instructions

Sequence of operation

Call for heat

1. The thermostat contacts close, energizing the first contactor (2K), the circulator relay

(1K), and the heater in the first thermal time delay (H1).

2. Approximately 15 seconds later, the thermal delay contacts (1C) close energizing the

electronic circuit inside the first electronic time delay (ED1).

3. After approximately 2.5 minutes, the first electronic time delay energizes the second

contactor (3K) and the second thermal time delay heater (H2).

4. This sequence continues until all contactors ar e energized or until the call for heat ends.

Call for heat satisfied

5. The thermostat contacts open, de-energizing the first contact or (2K), the circulator relay

(1K), and the heater in the first thermal time delay (H1).

6. After a minimum of 10 seconds, the contacts in the first the rmal delay (1C) open, instantly

de-energizing the electronic time delay (ED1), the second c ontacto r (3K), and the second

thermal delay heater (H2).

7. This sequence continues until all elements are de-energized.

Limit control operation

8. If the high limit setting is exceeded, the transformer secondary circuit is opened and all

contactors are de-e nergized instantly . It is recommende d that the “high” side of the contro l

be set at 220°F. The “low” side should be set according to the design requirements of the

structure to be heated but never less than 20°F below the “high” setting. The differential

control should be set at a minimum of 20°F.

Part number 550-141-396/0801

5

Loading...

Loading...