Page 1

®

Series 2

Gas-Fired W ater Boilers

Boiler Manual

• Installation

• Startup

• Maintenance

• Parts

This manual must only be used by a qualified h eating installer/service technician. BEFORE ins talling, read

all instructions in this manual and all other information shipped with the boiler. Perf orm steps in the order

given. Failure to comply could result in severe personal injury, death or substantial property damage.

Part number 550-142-783/1012

Page 2

GV90+ Series

2

oAs·FIRED

WATER

BOILER

-

Boiler

Manual

How

it

works

•••

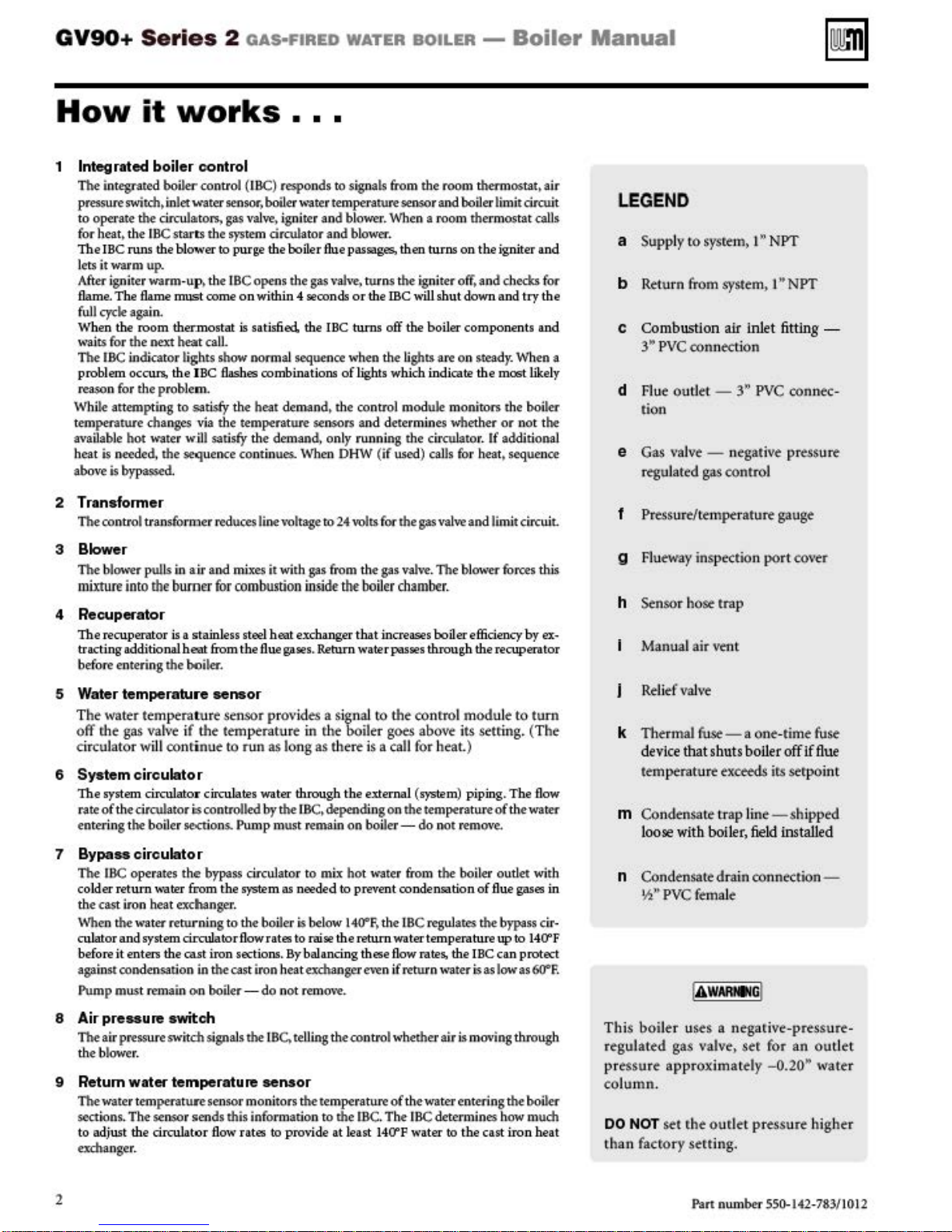

1 Integrated boiler control

The

integrated

pressure switdl, i

to operate

for heat, the I

The JBC runs the biO'\\•

lets it warm up.

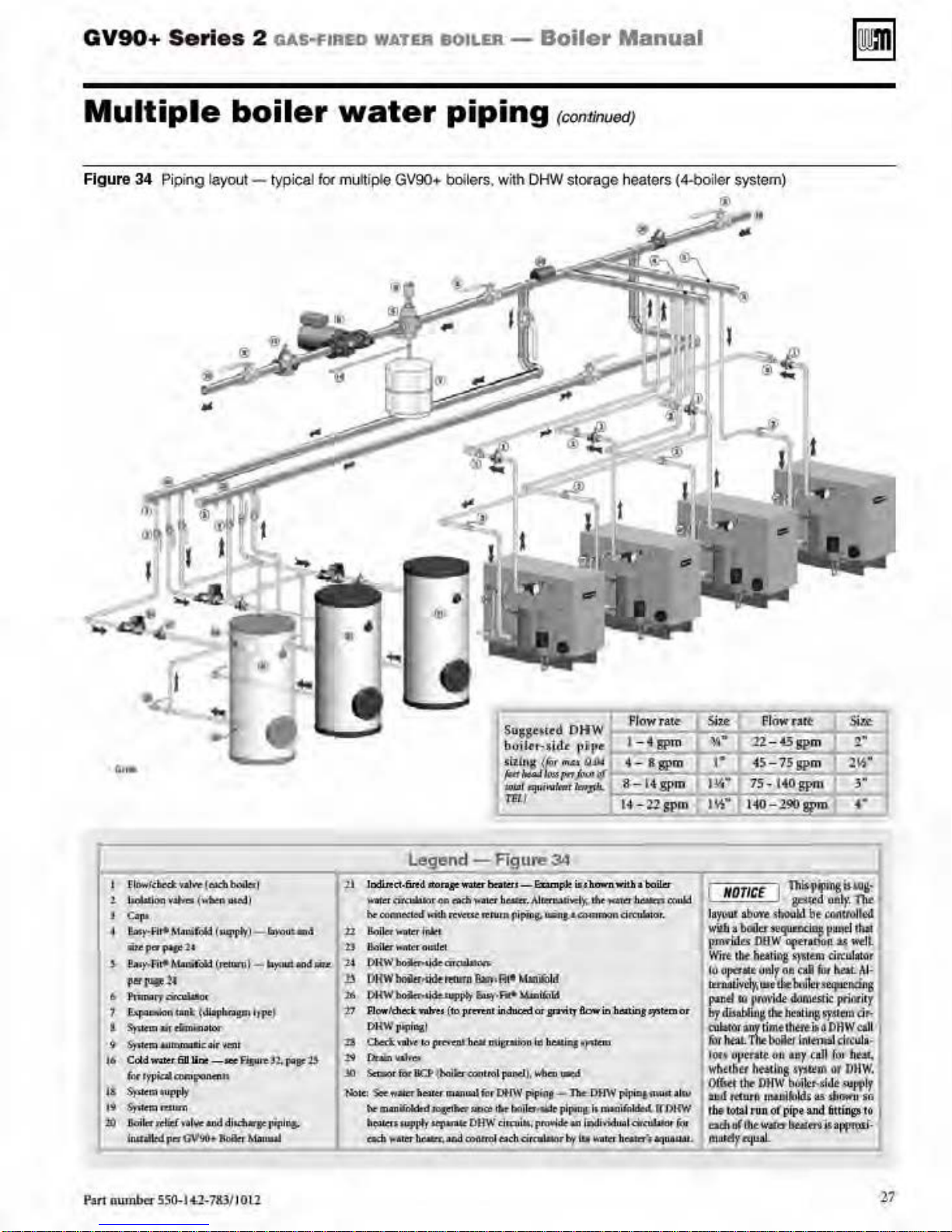

Aft

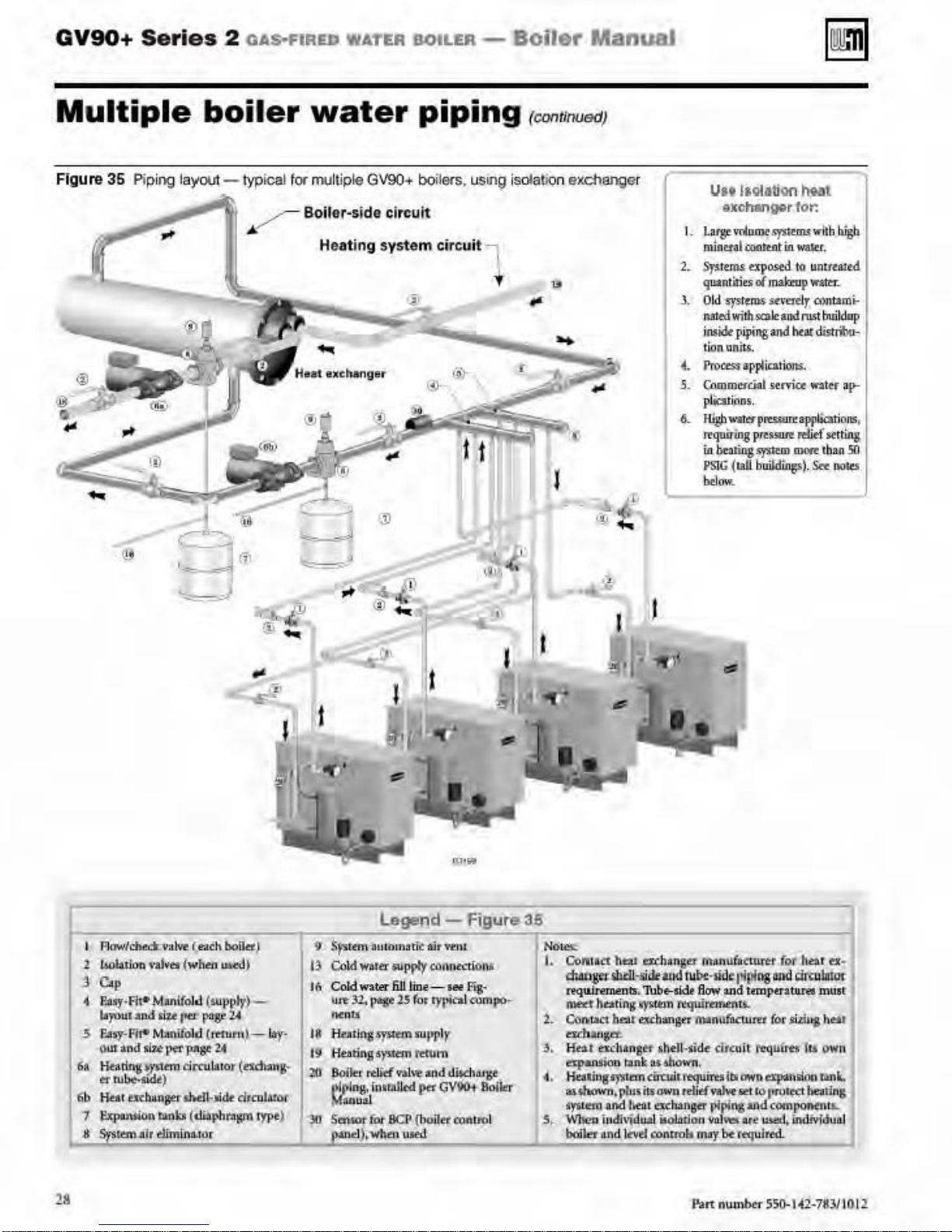

er

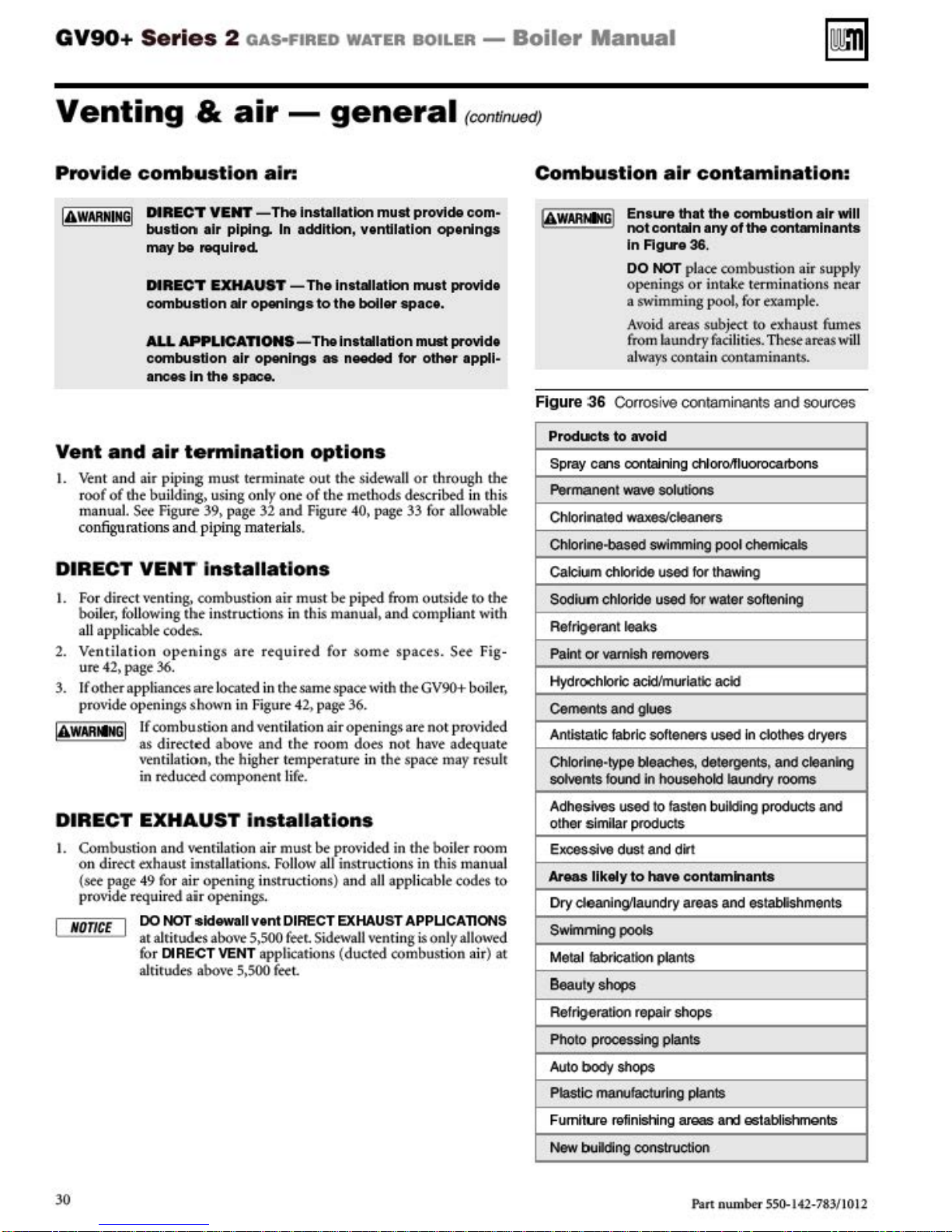

igniter warm· up, the I

flam

e.

The flam

fu

ll

cyde again.

hen

the room thermostat

W

wa

i.ts (or the

The

IBC indicator ligh.ts show nonnal sequence wh

problem occurs, the JBC

reason for the proble

While attempting to satisfy the heat demand,

temperature changes via the temperature sensors a

availab

le hot water w.

is needed, the sequence

heat

above is bypassed.

boiler

control (I BC) responds to signals from the room thermostat,

:n

let water sensor, boiler

the

circulators,

BC

star

ts

the

er

e

must

come

next

beat

call.

m..

tll

satisfy the demand, only running

wa

.ter temperature sensor and boiler limit circuit

gas

valve,

igniter and bl

sys

tem circulator and blower.

to

purge the boiler

DC

opens the

on

within 4 wconds

is

satisfied. the IBC turns off the boiler components

flashes

combinations

conti:nues..

gas

When

ower.

flue

passages, then turns on the igniter

vah-e,

or

of

lights which indica

the

control module m

DHW

2 Transformer

The

control transformer

reduces line

vottage

to

24

volts for the

3 Blower

The

blower pulls

m

ixturt into

4 Recuperator

The recupenttor

trading

additional beat &omthefluega

entering the boiler.

before

5 Water temperatu re sensor

The

wat~r

off

rhe

gas

circulator

6 System

The system circulator circulates water through the external

ra.te

ofthecirculator

entering t

7 Bypa

..

The

IBC

colder return "'a ter from the S)'Stem

th

e cast iron heat exchanger.

Whe

n

the

culatorand

it enters the cast iron sections, By balancing these

before

agai:n.st

condensation

Pump

mU$t re

i:n ai:

r and mixes

lhe

burner for coml

is

a stainless steel beat exchang

t~mptralur~

valv~

if

the

wlll conrinue to

it

with gas

xu:tio

n in

ws,

sensor

provides a signal

temprratur~

run

in the boiler goes

as long as there is a call for heat.)

circulator

i:s

he boil

er

.se<tion$.

controlled

by

Pump m

the

u.<

IBC,

n rema

circulator

operates the bypass circulator to

as needed

water

returning to the boiler

sy

stem circulator

in

the

main on boiler-

flow

cas

t iron heat exchanger e\'en if return

rates

do

Is

to

not rem

&om

side-

the-

er

that increases boaer e

Return waterpasws through the recuperator

depending on the temperatu

in

on

mi.x

hot water

to

prevent condensation

below IW F. the I

rai

se

the

return

m-e.

When a room thermostat caUs

rurns the igniter off,

the me will shut

en the lights are

nd

determines wheth

the

ci:

(if

used)

caJJs for heat. sequen

gas

th

e gas

valve.

and

down

on

steady. When a

te

the most

onitors

er

rculator. If additional

valve

and limit

The bla\\'et

boiler chamber.

fficiency

to

the

conrrol

(S)

boiler -

fro

BC

water temperature

flow

modu

abo~

its setring. (The

'Stem)

piping, The

re

do

not

remove.

m t

he

boil

er

of

regulate$

rate

the

s.

the IBC can protect

water

Is

flue gas

as low as

air

and

checks for

and

try

the

and

bkel

the

boiler

or

not t

he

ce

ci:rcuit.

forces

this

by ex·

le

to

turn

flow

of

the water

outlet with

es

bypass

ci:

up

to l40'"

6Cr

in

r·

f.

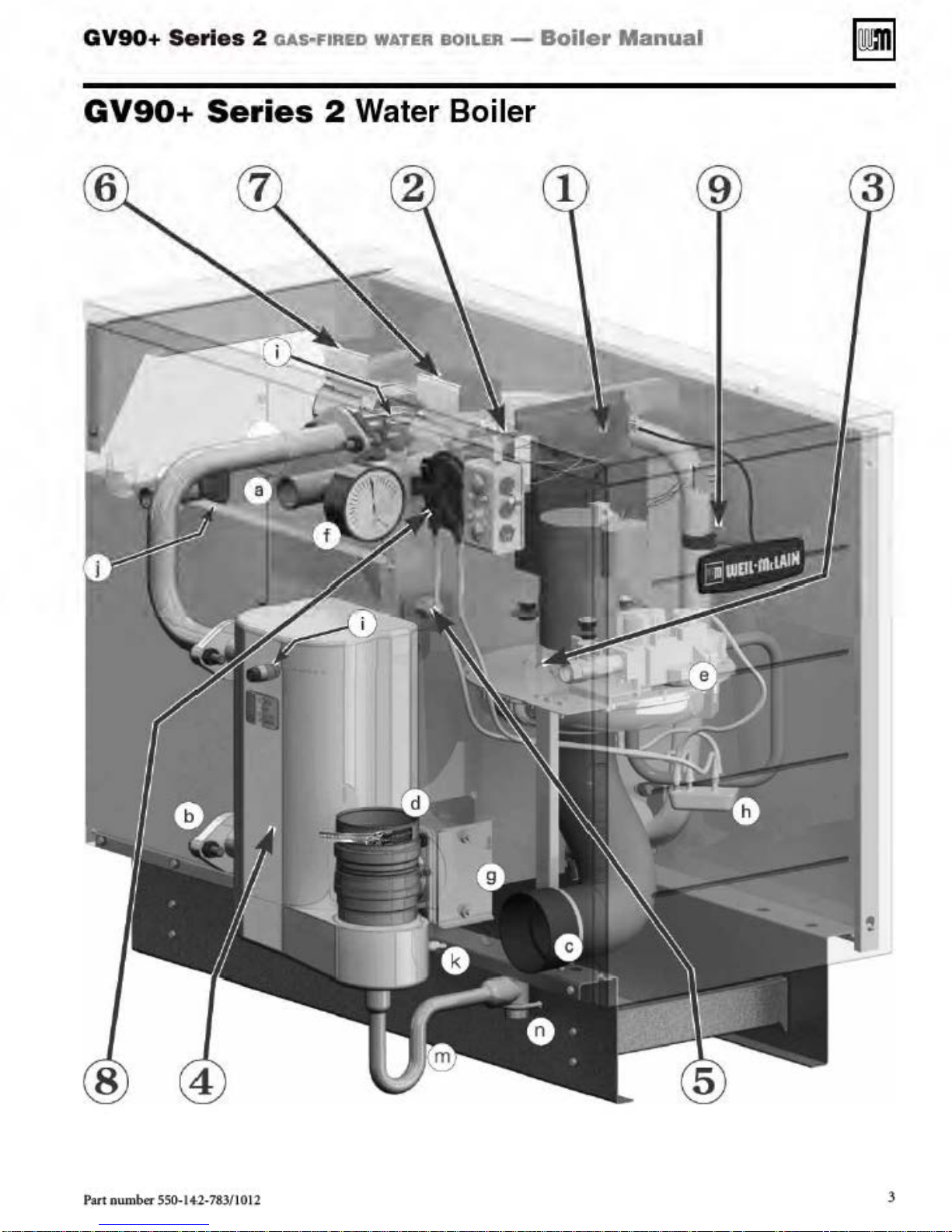

LEGEN

a

b R

c Combustion

y

d

D

Supply to

etu

3"'

FJ

ue outlet -3"'

rn from

P

VC

system>

connecti

1"'

system,

air

lnlet fit

on

PVC

NPT

I" NPT

ting -

conntc·

tion

e Gas

vaJve

regulated

- negati

gas

control

ve

pr~ss

urt

I Pressure/temperature gauge

g

FJueway

inspection port

CO\'tr

h Stnsor hose trap

Manual air

Relief

k Thermal

device

te:mptrature exceeds irs

m Condtnsate trap line

loose

n Condensate drain con

W'

PVC

F

vtnt

vaJ\ ·t

fuse-

a one·time fuse

that shuts boiler off

-sh

with boiler,

field

nection-

female

if

flue

strpo

int

ipped

installed

8

Air

pre

..

ure switch

The

ai:r

pressure switch signals

the blower.

the

IBC.te U

ing the control whether air is moving through

9 Return water temperature sensor

The

water tempera t

sectfons. The sensor sends this Information to the

to

adjust the cirrulator

exchanger.

UI'e

sensor monitors

fl

O\\'

rates

the

temperatu

to

provide at least 140'"

2

IBC

re

of

. The I

the water

P water

entering

BC

determines how m

to

the

boiler

the cast iron beat

uch

Thi

s boile r uses a negarive·

tgulattd

r

pressure

column

00

ha

n facto ry

t

gas valve, ser for

approximately -0.

.

NOT

set rhe

sett

Pan

outle

ing.

number 55

prtssurt

an outl

20"'

t

pr~ssurt

higher

0-

142-783/1012

-

et

water

Page 3

GV90+

Series

2 GAS·FIRED WATER BOILER -

Boiler

Manual

GV90+

Series

2 Water Boiler

Part

num

ber 550-

14-2

-783/10 12

3

Page 4

GV90+

Series

2

oAs·FIRED

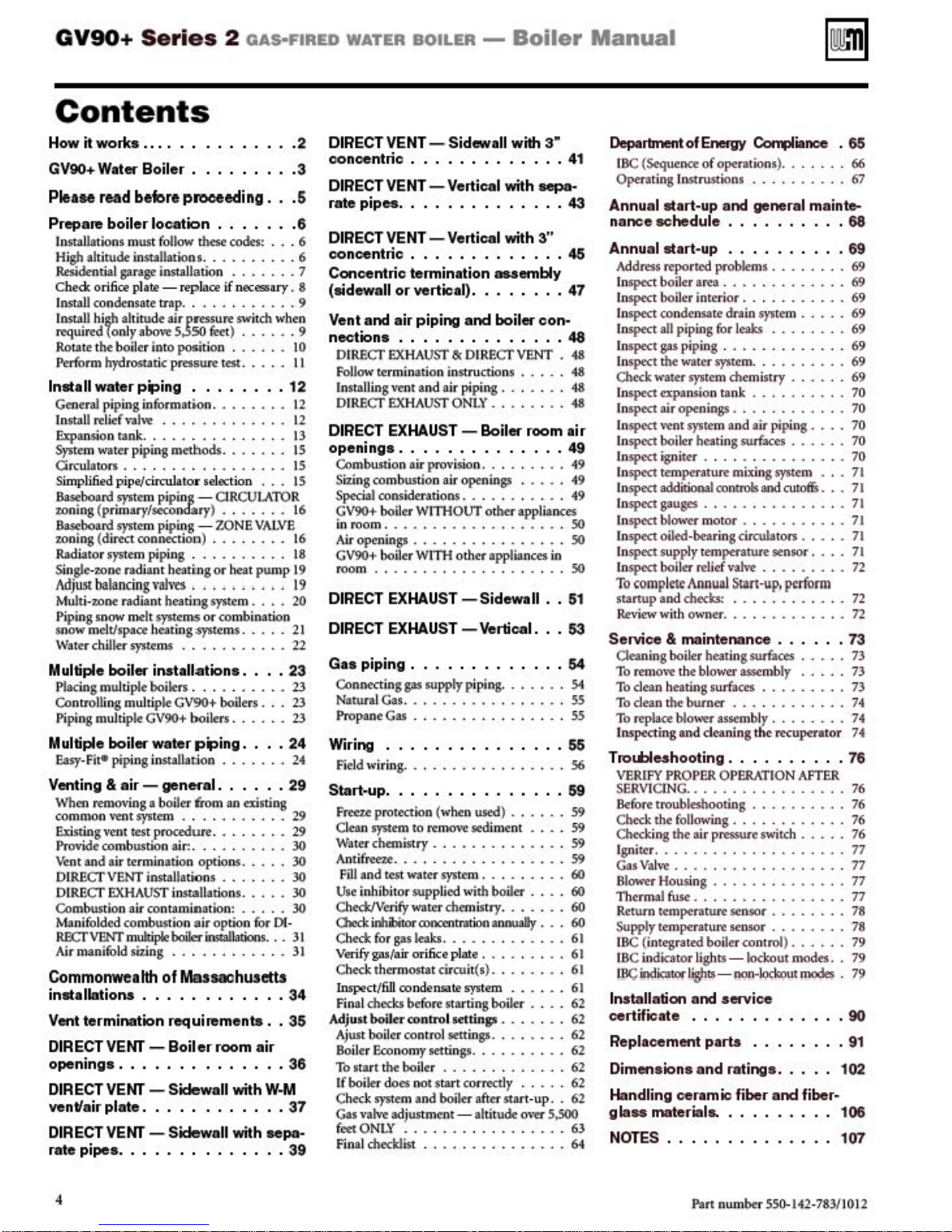

Contents

How

it

works

.....

GV90

+ Water Boiler .

Pie

aM read belore

Pr

epa

re boilerlocat

Installations m

High altitude i:nstallatfons

Residential garage installation

Check orifice plate - replace

Install condensate uap. . .

Install h

required

Rotate t

Perform hydrostatic pressure

In

sta

ll water piping

General

Install reliefvah-e

Exp

ansion tank

Sys

tem water piping m

Orculators

Simplified pipe/cirrulator selection

Baseboard system piping - ORCULATOR

'ZOning

Baseboard system piping -

'ZOning

Radiator system piping

Single·

Ad;wt

Multi·

wne

Piping snow melt systems

snow

melt/space heating

Water

chiller systems . . . . . . . . . . .

u.<

igh

altitude

{onJy above

he

boiler into position

pipi:

ng informat

•..............

.................

(pri:m

arylseco

(d

irect connection)

wne

radiant h

b

alanci

ng

radiant heatiog system . . . .

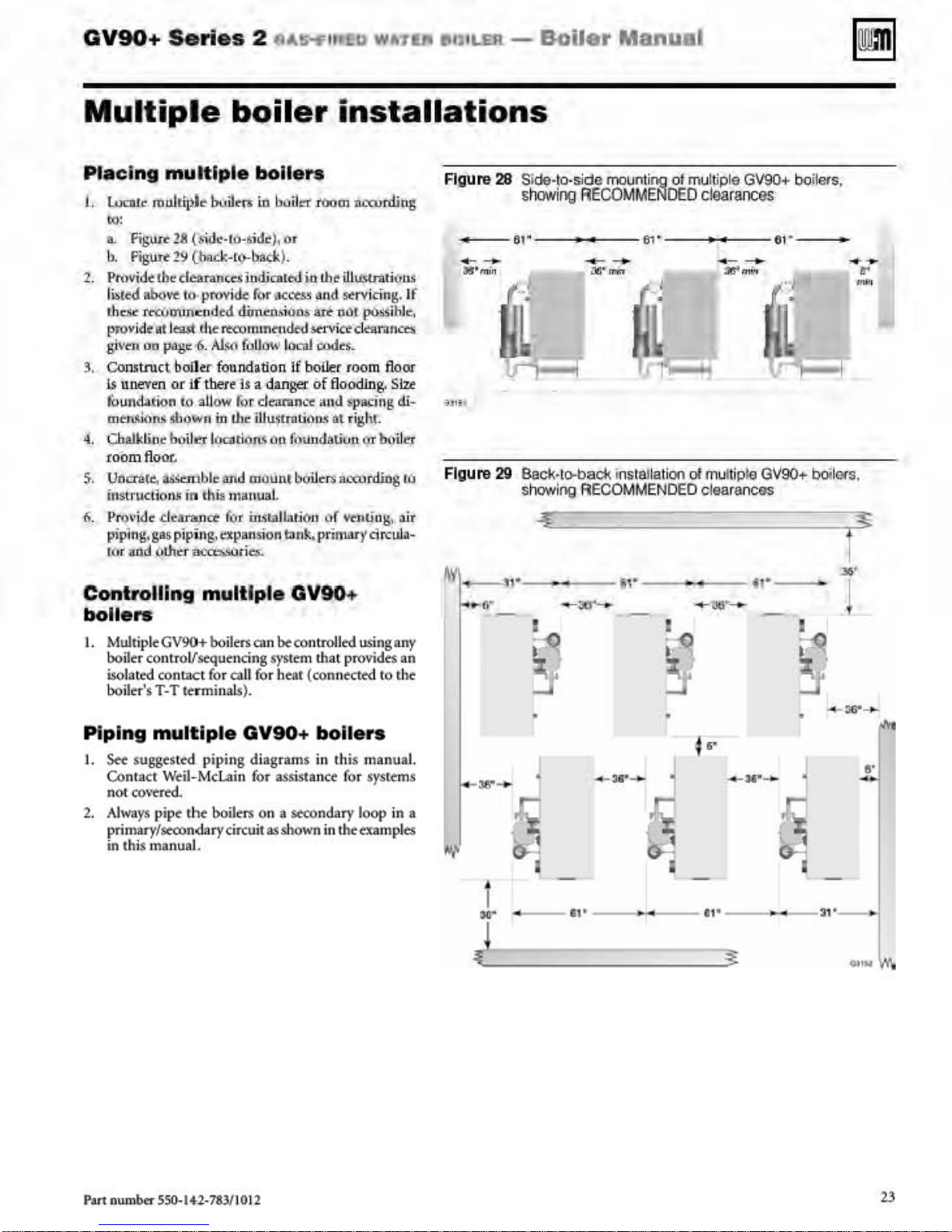

Multiple boil er installat

Placing

mul

tiple

Conuolling multiple CV90+ boilers . . .

Piping multiple CV90+ boil

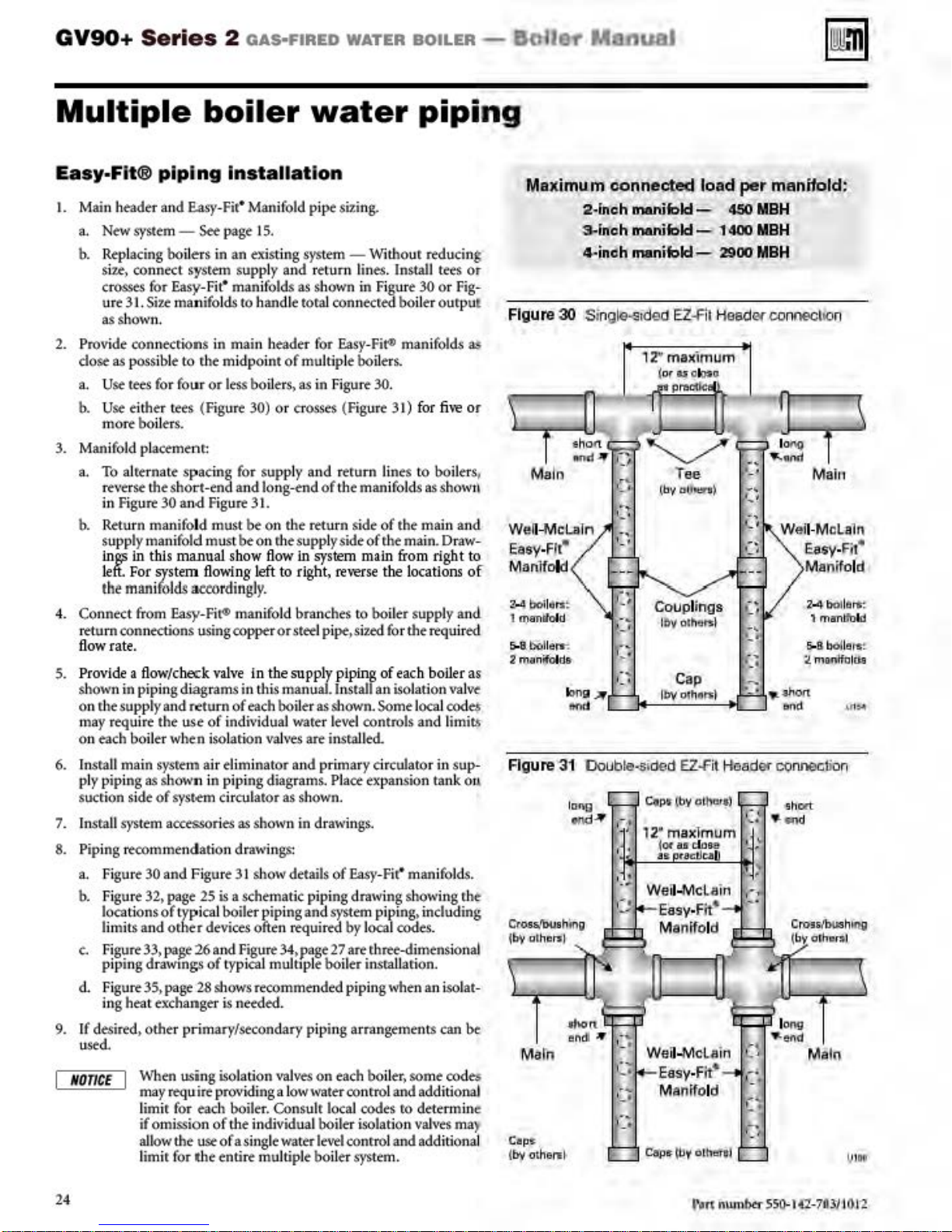

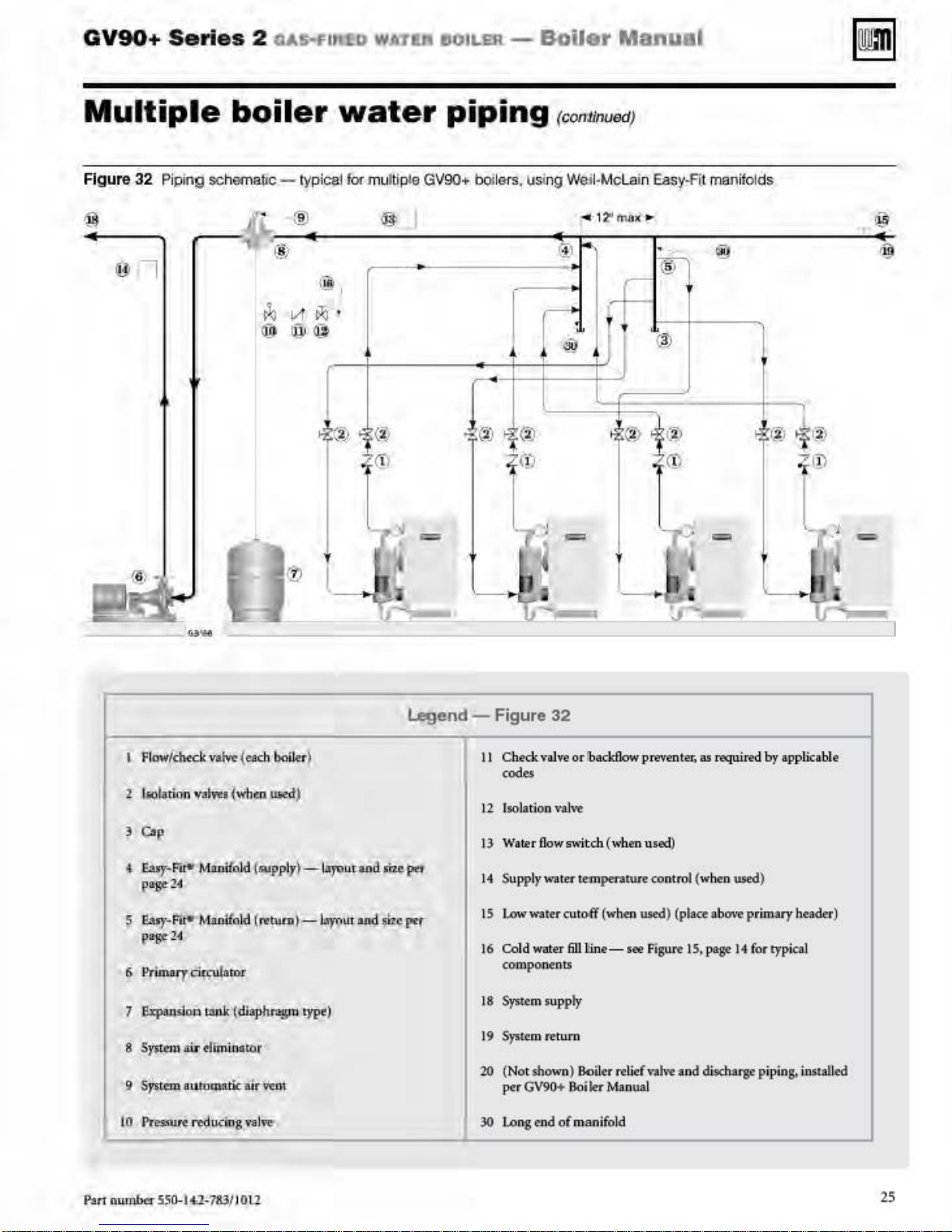

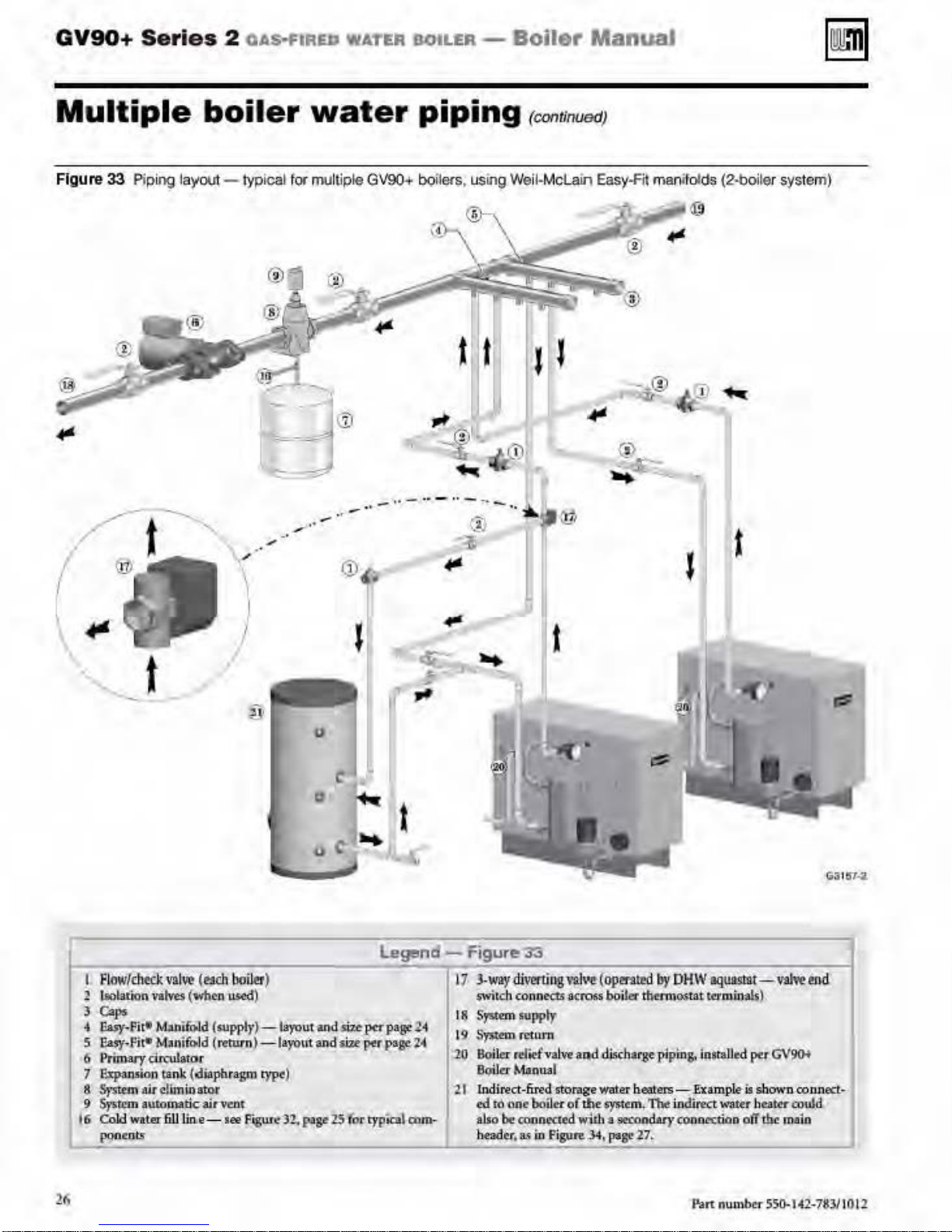

Multiple boil er water

Easy·Fit•

piping installation . . . . . . .

Ventin g & air-

When removing a boiler from an existing

common

Existing vent

Provi

Vent and

DIRECfVENTinstallations

DIRECT

Combust

Ma

RECT

Air manifold sizing . . . . . . . . . . . . 3 1

Commo

in

sta

ven

t system . . . . . . . . . . .

de

nifolded combustion

llati

tes

combustion air:

air termination options

EXHAUST

io

n air contamination: . . . . . 30

VENT multiple

nwe

alth of Mlls

ons

. . . . . .

Vent termination req uiremen

DIRECT VENT- Boiler room air

ope

nings . . . . . . . .

DIRECT VENT-

ve

ntfair plate. . . . . .

DIRECT VENTr

ate pipe

s. . . . . . . .

.

p~eding

ion

n

fonow

these codes:

..........

air press

S.SSO

........

ion

.............

eth

ods

ncf

ary) .......

..........

eati:

ng

vah<S

, , , , , , , , , , 19

or

;Systems.

boi~s

. . . . . . . . . .

piping

genKal ......

t procedure

..........

installations

air

boib

inslallations

Sidewa

Sidewa

...

.......

...

.......

if

necessary. 8

.........

ure switch wh

feet)

......

......

t

est

.....

........

.......

...

ZO

NE VAL

........

or

heat

pum

combinati

ions

ers.

on

. . . . 2 1

....

. . . . .

•...

........

.....

.......

.....

option

(or

Dl

. . . 3 1

saohusetts

......

ts

..

......

ll

with W-M

......

ll

with oepa·

......

VE

WATER

DIRECT VENT

.2

concentric .............

.3

DIRECT VENT

5

rate pi

pes

..............

BOILER

- Sidewa

- Vertical with

6

DIRECT VENT

6

conce

6

1

ntric

Concentric termination assem

(sidewa

9

en

Ve

nt

9

10

II

12

12

12

13

IS

IS

IS

16

16

18

p 19

20

and a

nections

DIRECTEXHAUST&DIRECTVENT .

Follow

termination instructions . . . . . 48

Installing vent a

DI

RECT

DIRECT EXHAU

ope

nings

Combustion

Siring

combu.<Jtio

Special constderations. . . . . . . . . . . 49

9V90+ boiler

tn room . . . . . . . . . . . . . . . . . . .

Air openings . . . . . . . . . . . . . . . .

CV90+ boiler

roon1 . . . . . . . . . . . . . . . . . . . .

DIRECT EXHAU

- Vertical with

.............

ll

or vertica

ir

pipi

..............

nd

EXHAUST

..............

ai:

r provision. . . . . . . . . 49

n air openings . . . . . 49

WITHOUT other appl

WITH other

DIRECT EXHAU

22

23

23

23

23

24

24

29

29

29

30

30

30

30

·

34

35

36

37

39

Gas piping

Connecting

Natural Cas . . . . . . . . . . . . . . . . .

Propane Cas . . . . . . . . . . . . . . . .

Wiri

ng

Field wiring. . . . . . . . . . . . . . . . .

Sta

rt-

Freeze

Clean system to

Water

Antifreeze . . . . . . . . . . . . . . . . . . S9

F

lll

and

Use

inhibit

Check/Ve

Check

Check

Verifygas/airorificeplate . . . . . . . . . 61

Check thermostat circuit(s) . . . . . . . . 61

In

spect/fiJI condensate syst

Final checks before starting boiler . . . . 62

Adjust

Aju.•

n boiler control

Bo

iler

st

art

To

If

boiler does

Ch

eck

Cas

vatve

re.tONLY

Final checklist

.............

gas

suppty pi ping. . . . . . .

...............

up

...............

protection (wh

remo\>e

chemistry . . . . . . . . . . . . . . S9

test wa.ter system . . . . . . . . . 60

or

supplied with boiler . . . . 60

ri

fy water chemistry. . . . . . . 60

imllit:or

boiler control srttinp . . . . . . . 62

c.oncm

for

gas

leaks. . . . . . . . . . . . . 61

Eco

nomy settings. . . . . . . . . . 62

the

boiler

nots

system

and

adjustment - attitude

.................

...............

-

Boiler

ll

with 3"

41

-·

43

3"

45

bly

l)

ng

........

and

boiler con-

47

48

48

air piping . . . . . . . 48

ONLY

. . . . . . . .

48

ST - Boiler room air

49

iances

50

50

appliances in

ST - Sidewa

ST -

Ve

rtical

ll

•..

..

50

51

53

54

S4

SS

SS

55

S6

59

en

u.W)

. . . . . . S9

sediment . . . . S9

tnr:

ion

an

rualy

. . . 60

em

. . . . . . 61

setti:nSJ>

. . . . . . . . 62

.............

tart correctly

boiler after start·up

.....

O\'ft'

62

62

..

62

S.SOO

63

64

Manual

Department of

IBC

(Sequence

Operating lnstrustions

Annual start·up a

nance schedule . . . . . . . . . . 68

Annual start-up . . . . . . . . . . 69

Address reported problems . . . . . . . . 69

Inspect boiler area . . . . . . . . . . . . . 69

Inspect boiler interior . . . . . . . . . . .

Inspect condensate drain syst

Inspect

Inspect gas piping . . . . . . . . . . . . .

Inspect

Check water syst

Inspect expansion tank . . . . . . . . . .

Inspect

Inspect

Inspect boil

Inspect igniter . . . . . . . . . . . . . . .

Inspect t

Inspect

Inspect

Inspect blower mot

Inspect oiled·beari:ng circulaton . . . . .

Inspect supply temperature sensor . . . .

Inspect boiler relief

To

comple1< Annual

startup

Review

Se

rvi

ce

Cleaning boil

To remove the blower assembty . . . . . 73

To

dea

n heating surfaces . . . . . . . . . 73

To

dea

n

To

replace blower assembly

Inspecting and

Tro~eshooting

VERIFY

SERV

ICING

Before troubleshooting . . . . . . . . . .

Check the following . . . . . . . . . . . .

Checking the air pressure

Ig

niter

....................

Gas

Valve

Blower

Thermal

Return temperature sensor . . . . . . . .

Suppty temperature sensor . . . . . . . .

IBC

(integrated boiler control) . . . . . .

IBC

indKat

IBCin<iiolt«

Installation a

ce

rtificate . . . . . .

Replacement

Dimensions

Handling ceramic fiber

glaoo

mat

NOTES ..............

Energy

of

eon-.>liance

operations)

..........

.......

nd general maint

e:n

l . . . . .

all

pipi

ng

for

leaks . . . . . . . .

the

water system. . . . . . . . . .

e:n

l chemist

air

openings . . . . . . . . . . . .

ven

t system and air piping . . . .

er

heati

ng

e:nlpe:ral'Ute

additional

gauge5

and

with

conuok

. . . . . . . . . . . . . . .

or

checks . . . . . . . . . . . . n

owner.

& maintenan

er

heati

the

burner

deaning

ry

. . . . . .

surfaces

mi.xi:

. . . . . . . . . . .

valve

Slan·up,

. . . . . .

ng system . . .

and

cutotfs

. . . . . . . . . n

perform

. . . . . . . . . . . . n

ce

. . . . . . 73

ng

surf:lces

. . . . . . . . . . . . 74

. . . . . 73

........

the recuperator 74

..........

PROPER

Housi

fuse

OPERATION

.................

. . . . . . . . . . . . . . . . . .

ng

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

or Lights - lockout modes. .

l

iglu>-non·~m<><l<!

nd

service

parts

and

ratings. 1

AFTER

switch

. . . . . 76

. . . . 91

and

fiber-

erials. 106

. . .

.

65

66

67

e-

69

69

69

69

69

69

70

70

70

70

70

71

71

71

71

71

71

74

76

76

76

76

77

77

77

77

78

78

79

79

.

79

90

02

107

4

Pan

number

SS0-142· 783/1012

Page 5

GV90+

Series

2

OAS·FtRED

WATER BOILER -

Boiler

Manual

Please

Hazard

The

bring attention

to i

!A

NOTIC

IAwARNIN&l

NOnCE

definitions

following

mportant information

CAUTION 1 lnd

E

read

defined

lnd

perSona

damage.

lnd

perSonal i

damage.

minor

Jndicares

Opt-ration o r maintenance th

no

Installer-

man

boiler> before installin

gi

Uller-

he-ating installer/service technician.

Jn:f'onnation

User - Ha\'t this

qualified service technidan, at

fajlure

sevtrt personal injur

da.mage.

W~itt

the In stallation certificate

terms

to r.he prestnce

icares pr

l injur-J'•

icares pr

icares presence

ptmna

t related

ual

and

.. ·tn.

This manual

to

in the CP numbtr

before

are

used

of

concerning

t.Sence

of

dearh

t.Sence

of

njur)

'• dearh

of

l inj

ury

speda

l

in

to

ptrso

nal inj

Read

all

all

other in

ManuaJ fo

comply wi

throughout

hazards

boiler serviced/inspected by a

y,

of vari

the life

of

hazards thar w

or

substa

hazards that can cause

or

substantial proper

hazards that

or proptrty

srructions

ury

instructions. induding this

for

g.

Perfonn steps in the order

is f

or

r your referen

th th

death or substantia] proptrty

in the space provided on

on

on insrallation.

ar

are i

or

proptrty

mation

use

only

lea

st annually.

e above could result in

page

this

ous risk

the product.

lll

nt ial

will

damage.

mportanr

shipped with

Refe

90

shown.

\Vhen

call

ing

or writing about the

have the boil

label and the

Consider piping and installati

boiler location.

Any claims for damage or shorrage in shipment

must

company by the consignee.

Commonwealth

When the boi

l-er

M..,.chu.setts, comply

This produ

fitter

If antifreeze is used, a reduced pressure back-flow preventer

d.,;ce

tf sidewa

ct

must

.

sha

ll

be

JI

\.'tnt or venr/air is insralled>

er

model nwnber

CP

number

be

filed

immedlatelyagainst

of

Massachusetts

is installed within the Commonwealth

with

<he

be

installed by a licensed plumber or

uStd

.

from

following.

boiler-

from

the

the boi

on

when determining

the

transportati on

see

instructions on

page 34.

proceeding

~WARIM

manual

cause

or

can cause

by

a

r to User's

ce.

if

not already

boiJtr

le

r jacket.

to

lt•ttls or

sevt-

rt

property

sevt-

rt

ty

bur

damage.

th

qualifi

ed

Please

raring

of

gas

When ..,,.,.;cing boiler-

To

before performing maintenance.

To

performing maintenance.

This boil

materials.

on

Boiler operation -

Do

to

Should

tMit

sup.

at

Do not

woter.

e

cian to inspect

the control system and any gas control that has bft.n

under

Combustion air -

DO

It a rltk

Carbon monoxide detector-

Fo

tor is requir

oxide dttecror must be wired

circuit

Fo

that

is

Boiler water-

Thoroughly

neo

exd1anger

due

Do

compounds

system

property

LNkoln

to P<8Yenl

In

wat-er will

exchangers reduces heat transfer,

ri

als,

by

Do

ca

Freeze protection fluid• -

NEVER

Use

systems. Foll

manufucturer.

placeme

m

I

Failure to adhere ro the guidelines

page

can resu

Cleath

or

avoid electric shock, disconnecr electr

avoid

severe

er

contains ceramic t'ibtr

Refe

1

.

r to the

06.

flow

page

not bloc.k

boiler

""erhNUng occur or g

off,

DO

t

~

ci

NOT

rculator.

P.Iy

ll in

severe

substantia] proptrty damage.

burns, allow

WARNING

of combustion or \

personal i

boiler ro cool before

and instructions

..

tum off or disconnect electri

Instead>

sh~r

off the gas supply

a l ocanon externaJ to the apphanct.

UM

thla

Immediately

wate

r.

NOT Insta

of

combustion air contamln.Uon.

r

OII'Cid

Exhaust uni

ed

as

the boil

r Direct

stro

V•nt

i.s

wirtd on the same electrica

ngly recommended.

flu

ted )

to

removeS<'dinlenl

can

to sedimtnr.

not

lL~t

JH:trole

in boiler

may

bedamage<t.

call a

tht

boiler and to

ll

combulllon air Intake whwe there

in the boil

er.

units, a carbon monoxide dttecror

sh

the system

be

damaged by build-up or cor

um-based

S)'Stem.

boiler H any

~h

qil3lifi

ts,

a carbon monoxi

er r

oom

..

ed s

rtp

l.act any

. The carbon mon-

on the

l d rcuir

(without boil er con-

TbehbUI-ellic.iencyheat

deaning

Gaskets

This

can

r

esu

damage.

boiler

0<

piping ,.....t

• ciOMd-toop system. Contin

make-

not

n cause heat exchanger to crac

only

sr.alling the n

moke-t~p

rtduct

an

<I

cause.s

up

water

add

cold

u.se

automoti\·t or standard glycol antifrtt:ze.

freeu-protectlon

ow

nt

boiler system that has used gl

woter. Use

boiler life. Min

tanure. Addition

can

cause intern

w.ter

to

aU guidelines gi,·

Thoroughly

ew

boiler.

be

repeiN<I

thlo boiler

ual

eraJ buil

overheats the mate-

of

oxyge

al corrosion.

hot

bolter. ThennaJ shock

k..

fluids

made

tn

dean

br.

ana flush

on

thi.s

njury,

ica

J supply

and

fiber~lass

<entilation

aupply

air

11111

to

cal

_.,under

ervice

techni-

va:

rt

of

de

detec

same

electri

cal

as

the boiler

ros

ion

or

and seals

lt in substantial

staling

in

the

ot once

ONLY

fre.sh

make-up

dup in heat

n carried in

for

hydronic

the antifreeze

apy

)'cO

re-

I before

-

Part num

ber

550-1+2-783/1012

5

Page 6

GV90+

Series

2

oAs·FIRED

WATER

BOILER

-

Boiler

Manual

Prepare

Installations

Lo<a

l,

srat:t,

provincial, national codes, J

National

Standard for Controls

Boilers,

National

For Canada only: Bi49.i or Bl49.2 Installation Code

Canadian

The

GV90+

perrormance criteria when boiler underwent tests specified in

-latest

1

MOneE

High

GV90+

See

Figure 1 for estimated

input. Multiply the boiler

est

imated high aJtitude i

wi

ll

also

fur

ther info

No mo

s.soo

be

musr

kit instructions, page 10. Note that

checked (and adjus

N

OTICE

Fuel

ANSf/ASME

Ele

EJectricaJ

boiJt r

edirion.

1 For

rhe special instructions located

Insta

from

Al

bo

substantial proprrty damage.

altitude

boil6'

<Mirols

h

ave

a min

rmation.

difications

fee

t above

changed

DO

ar

for DIRECT

altitudes a1x

boiler

must

Gas Code, ANSI Z223.1

ctrical

Code

gas

manifold

th

e Commonwealth

ll

the boi

ti'lpplng

lowin

g.

iler faiJu

Installations

•utofililitAIIy

or

impact on input.

to the

St:a

level. For higher

to

aspttial

ted

if

NOT oldowall

alrirud~s

follow these

and

Safety

CSD-t, when

Code

Pa

rr 1 and any local codes.

and

kr

so

control S)'Stem componrnts

or

spraying water

these

compone

rt,

resulti ng in

inp

ut

at

sea

level

input

nput

. Note that the length

boiler should

high altitude switch.

necessary) followin

vtnt

abo\re

s.soo

VENT

app

we

s.soo

fee

location

codes:

aws,

regulations

- latest edition.

Devices for Automatically Fired

r~uirM.

con

tro

ls

m~

of

Massachusetts, read and foll

on

page 34

or rak'l

nts

to

become wet

severe

personal i

todutt input

altitude as a percentage

b)• this

Refer

be

nece

e-levations

the

gas

DIRECT EXHAUST

feeL

Si

lications (

t

wit

ptrc~ntage

to

the vent

ssary

. the air pressu

Refe

\<alve

outlet pressure

g insrructions on page 63.

dewa

JJ

ducted

and

and

safe

lighting

of

dur

njury,

h

ina~ing

of

the •tenting systttn

supplement l'

for

installatio

r ro the high altitude

APPUCAnONS

venting is only

combustion

ordinanc~.

CSA

C22

.1

and

other

ANSI Z21.13

this manual.

~

ing Optrntion.

cou

ow

protected

ld

cau~

a

death

or

alritudt.

of

St:a

level

to

obrain the

..,r

ns

up

to

re

switdl

mu~

be

allowed

air) nt

Figure

Figure

0

~

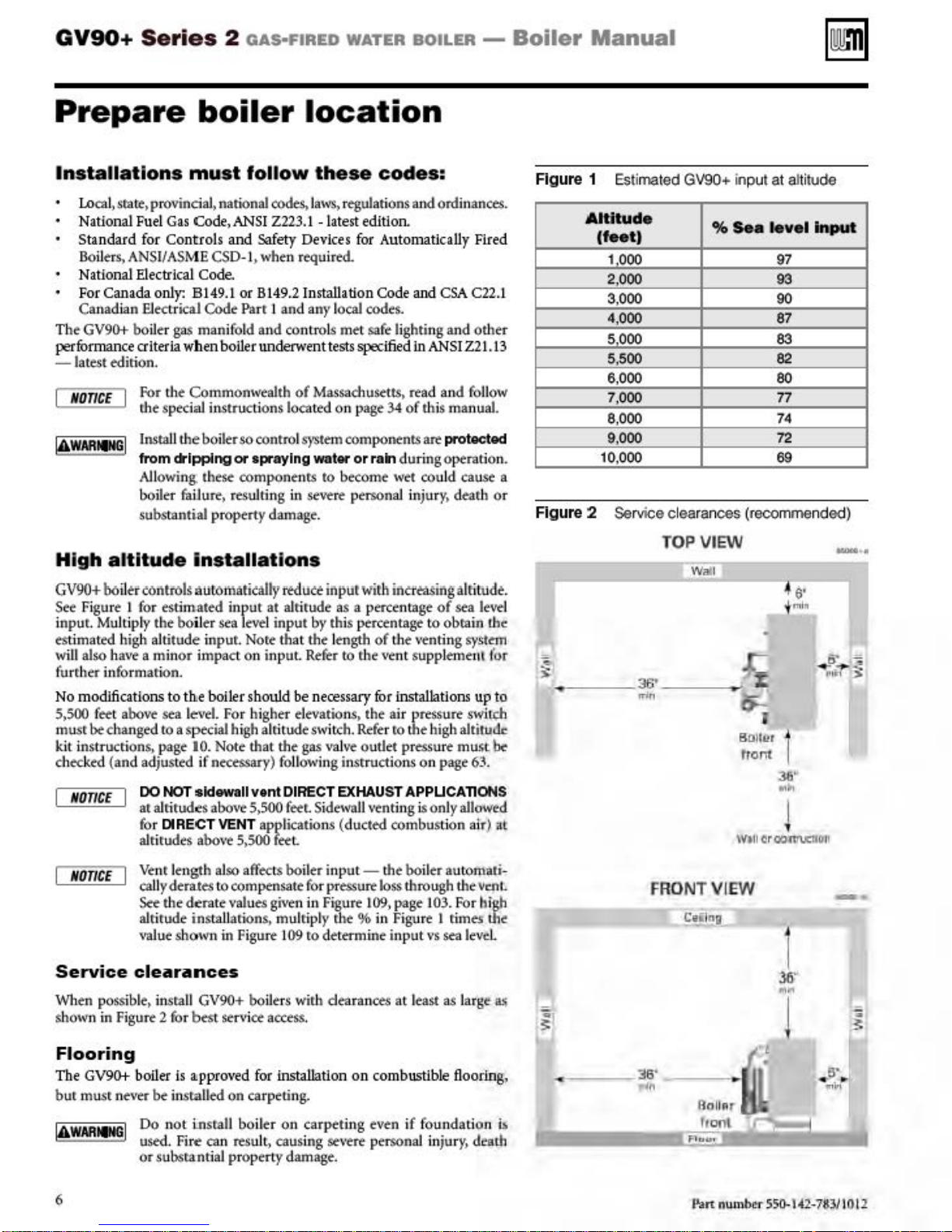

1 Estimaled GV90+ input at altitude

Altitude

(

fee

t )

1 000

2,000

3,000

4,000

5000

5,500

6,000

7,000 77

8,000 74

9.000 72

10,000

2

Service clearances (recommended)

%

Sea

leve

97

93

90

87

83

82

80

69

l

Input

TOP VIEW

W"'l

~

6'

i

ml"

36'

...

i%

-~"""

lir

8GIIL>r

rront

:w

••

I

W•ll

cr

oo:nn.ctlo-1!

'

-··

~

,.

....

>

Ve

M

OnCE

Service

When possible. insrall

shown in Figure 2 for best service

nr length

caJiyderates ro compensate for pressurt

See

the

alrirude

\'ll

]ue show-n in Figure 1

clearances

aJso

affects boil

d~rate

values

inst:a

Uartons, mulriply

GV90+

bo

given in

09

ilers

wir.h

access.

er

ro

Flooring

The

GV90+

bur

mu.sr

6

boiler is • ppr

never be install

Do n

ot

ins

used.

Fi r

~

or

subsran

ove

d for installation on combustible flooring,

ed on carpeting.

rall boil

can resul

tiaJ

er

on carpeting even if foundation

t,

causing severe personaJ i

property damage.

input-

Figure

ihe%

d~ermine

dea.rances at least as large lt.'i

the boil

&oss

109,

in

er

through

page 103. For high

Figure 1 rimes tht'

input

vs

sea leveL

njury,

auromati-

the

vcnL

death

i.-.

::1

3:

FRON

36"

rln

T VIEW

C~lna

R.,.,

hool

Fl

..

..-.

l•.an

num

l

I

~

-

••

!

Ql

ber

550-l-42-783/10

-·

s·

-

~-

j

12

Page 7

GV90+

Serie

s 2

fiA!i

-fll

~o

w

_".,.

IIOlL-1!11

- BaU

er Manua

l

Prepare

boiler

location

Foundati.on

Providt a .sQiid br:lck

is

possible:

When

the

floor ca.n

Whto (hr:

boiJI(-r

When a high

bigh

c:-nOug

-as

the

t.Xmd(nsat~

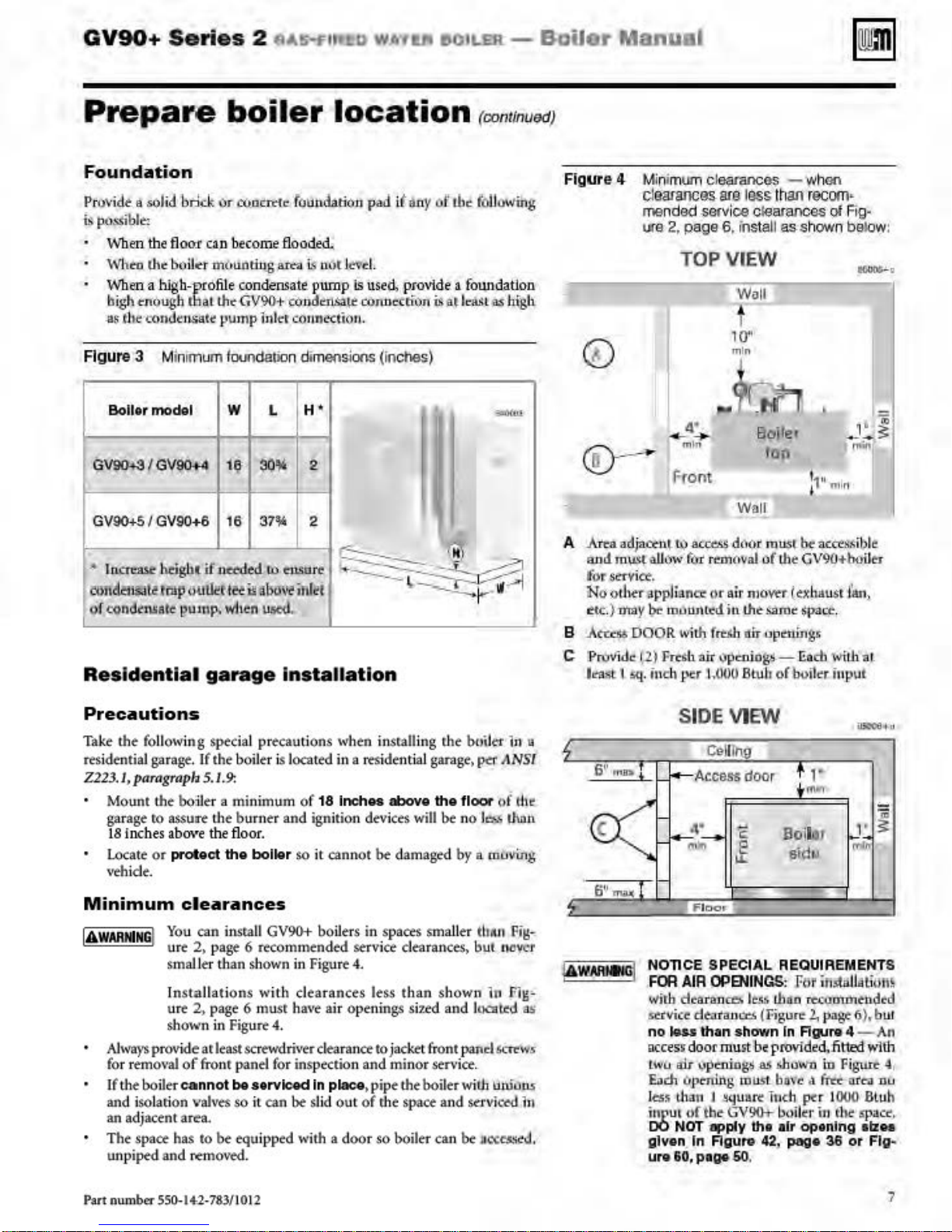

Figure 3 Minimum fll<J!ldalion dimeosians (inches)

Boll

or

model

G~

GV90+S I GV90

• lnCI'tllk

e;mdcmioll

vf

/

GV90+4

heighl

!rnp

condc"nsate

Residential

or

<Q.ocmo

becoll)f

mbuntin_g

-profile

h tl:\at lhr: GV90+ c(mden,sat,t

condensaie

pump inl

w L

11!;

+6

16

if

nttded

iltlil<U~

puJnp.

ilHilluv~

v/Jttn

garage

foundation

flood~

ak:il

is n

ot l.e're

pump

t-r

c(ui.ne<tio

H'

LU

auo

2

2

re

inlet

301'

371'

u&erd.

Installation

~

pad

it

llny

l.

is u

sed,

provide a foWldaiion

cOnnectil)n

u.

-------=

~

---~--

oi'

is

at

the

least

(continued)

Figu

following

as

hfgli

""""

A ..Arta

+-·

~

::..,

B

C !ProVide 1,2) Fresh ait

re 4

Min

imum

ci~(J$

clearancas

mended

ure 2, page 6, inslali

$ervice

TOP

me

VIEW

~

...

4_:..

m

in

Fr

ont

adjact:n~

and

m\!S~

f

ot"

.se-rvict-.

iNo

o

tJ~r

etc

.)

n'my

..Aca.~DOOR

l~mst

1 5q. inch p

«>

allow

for

...

pplilnC'I:'

l,t

m.JwHel;l

IY

er

ac:-cos

~(tval

or

a.

in

ilh

fft'.AA

~

pccios<-~odl

UM)U

- whoo

lliSs than

clearances ol Fi

rocom

as

shown below:

Wall

t

10"

min

f~

El<>iler

t

op

Wal

l

d<l(tl'

mus

()

( l,he GV90,..boile.r

i.r

mowr

th~

samt

nir

upenin~tr.:

Btu'l1

.

~

lko

acct!1~ible.

(~x

haust

fpacc.",

Wfth

or

bolter input

•

1

l

1ln,

g-

al.

Precautions

Take the following

residmtiaJ garage. If the boiler is located

Z223.1,parngraph

Mount

garage ro assutrt the burner

18

Locate

\'fhi

the

inc.bes

or

de.

Minimum

IAWAHNING

I

Alwa

ys

provide ar least screwdri\'fr clearance

for rt:mO\'al

If the boiler c-annot

and iso

lati

an adjacent area.

The

space has

unpiped and

sptcial precautions when installing r.he builer ln u

5.1.

9:

bo

lltr a minimum

abO\~e

the

fl

protect

the

oor.

bolktr

of

18

and

ignition devices will

so

it

clearances

You

can

in.s

mll

GV%+

ure

2.

page 6 recommended servi

smaJ

Je:r than

I

nstallations with

ure

2,

shown in Figure 4.

of

fronr

on

valves

to

~

shown

page 6 musr ha\'f air

pane-l

be

serv~

so

it

can

be

equ

ipped with a

moved.

boiJers in spaces small

in Figu

clearances less th

for inspection

In

be

sl

in

a residential

Inches

cann

re 4.

openings si

place

id out

door

garage)~

above

the

be

ot

be

damaged by a muving

ce

dearances.

an

shown

ud

and

to

jackrt front panel

and

minor

sen·ice.

. pipe

the

boiler

of

rhe

space

and

so

boiler

can

ANSI

floor

of

the

no

J~

thon

er

thA

H Fig-

but

n

ever

lP Fig-

l

tKat.ed

St."t't'\'f'

with uruuus

krvic«< iu

be

ue<:cs.'icd.

as

SI

DE

VIEW

Coll

~

6

1'

mll

ll'

l

- Accessdoor

lhg

t ,.

+

m.,

1i

4.

co:::

11

6

l'I'W(

-i:

l

f'

NOllCE SPECIAL

FOR

AIR

~-lith

dta

&t:tlfic.e dt:tr'ances {Fig

no

klu

occess

s

door

LWO

iti.r

Each

ltl)t-nirtg, mlJst ba\

l

es~

t.lun J

iurut

uf

DO NOT

given

ure

60,

-

...

£

Flocn

OPENINGS: Flif

tan

ceo.

than shown In

must:

ypw.io&S

~uttre

tt,e-

GV90+

apply

In

Aguro

pa;.

50

Bo11~l

"

&i

dll

REQUIREMENTS

lt.'.-t

than

ure

be

lht

.

Agure

provided,fitted

a5

shllWn io

t:

inch ptr I

boilc:r iu the spacr.

air

aptnlng

42, page

it;,tiill•ti<lill

rec~:J"mm

2.

pagt 6).bul

.i

ft«

36

~

,r

"""

tndtd

4 - An

wlth

Fit.'l.trt'

nl'ea

nu

OOtl

Btuh

alzH

or

FJg

4

~

..

Part num

ber

550-1+2

-783/10 12

7

Page 8

GV90+

Series

2

oAs·FIRED

WATER

BOILER

- Bo

ll

er

ManuaJ

Prepare

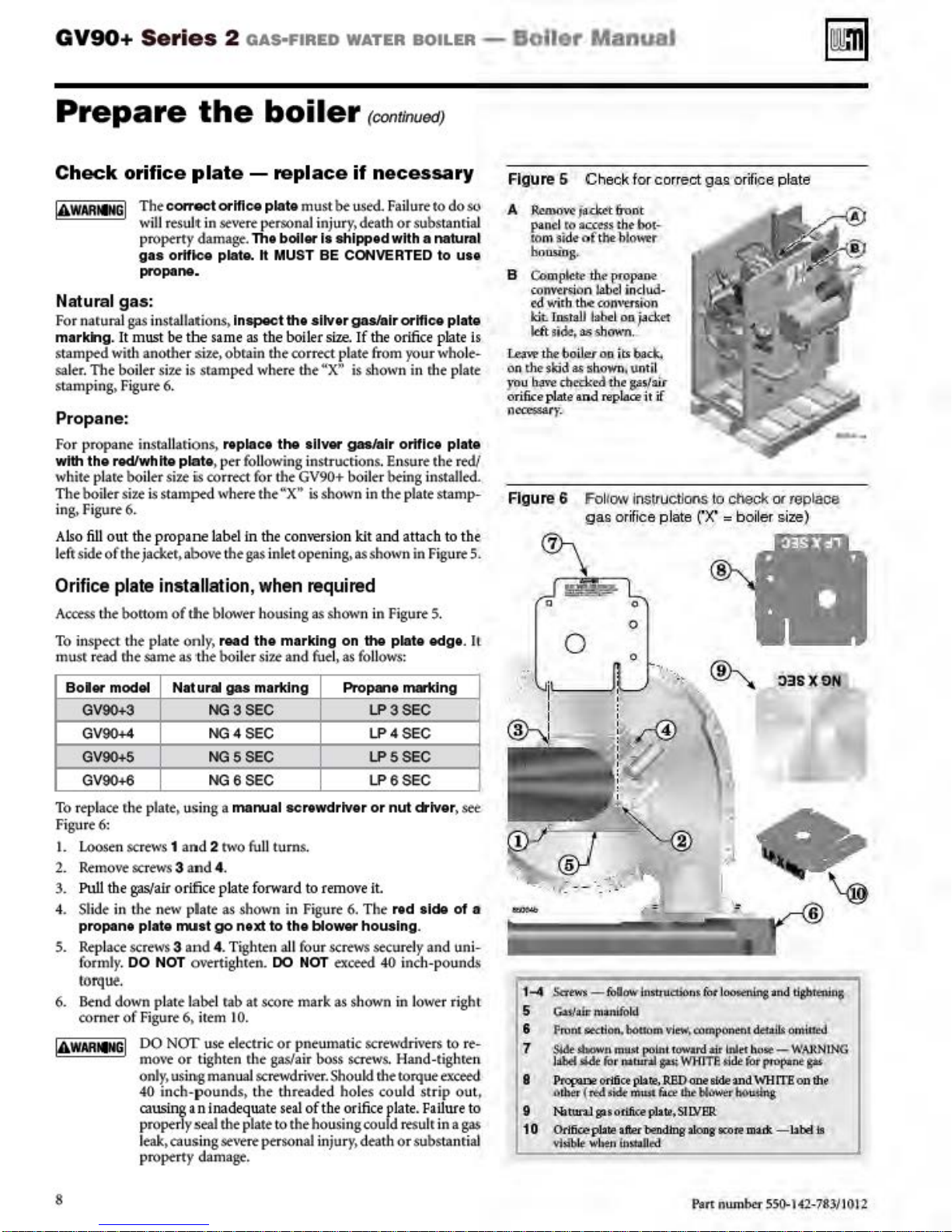

Check

orifice

The COf'l'tltCt ortflce plate must be

will

property damage. The

gas

the

plate -replace

resuJt in

ortflct

propane.

Natural gas:

For n

atura

l

gas

installations.

marking.

stamped with

saler. The boil

stamping.

It

must

anothe

er si

Figure 6.

be

the

r si

u,

7.t

is sramprd where

Propane:

For propane insrallarions,

with

the

redlwhtte

white plate boil

The

boiler

siu

ing. Figure 6.

Also

fill o

ut

lefrside

of

the jacker,abovethegas inlet opening. as shown in Figure 5,

plate

er

siu

is

co

is stamped where the

the

propane

boiler

severe

persona] in

bolltrls

plate. h MUST BE CONVERTED

Inspect

same

obrain the cor

nplac•

as

the

the

boiler

the

sUver

rtct

the

sliver

(continued)

if

necessary

used. FaiJu

jur

y.

death

or

substantial

shipped

size.

plate from

..

X

"'

with a natural

gas/air

If

the

ortflee

orifice

your

is shown in rhe plate

gas/air

orttlc•

rt

to

to

plate

who

, per following instructions. Ensure the

rrtct for the

label

in

GV90+ boil

1

'X

..

th e

com-ersion

er being installed.

is

shown in the plate stamp-

kit

and attac.b

do

so

uu

plate

le-

plate

r

~

to

the

Figure 6 Check

A

:R.emow

p

an~l

to

.m

m

~ide-Qf

housing.

B Co.

mp

lcte1t,el'fopane

connrsion label ind

«1

Wit

h

th.e

kit.

Insr.a.IJ

ld't t

ida

is

~the

on the skid

yo

u

~

ri6ce

11cce658t

Figure 6 Follow insv

,

f;Joil~

8$

~love

chocked

plate and

y.

j

s.cktt.

&oot

aa:~$

thf' bot-

t

he

bl

COP\ttniQn

labt.

l oo. j.:td:d

11$

Mlawn.

oo.lts ba

shown,

thr

n!pl.aoe

gas

or.

for corr

ect

ower

ud

-

ck,.

!Jn

til

g;oi/mr

it

if

uctJons to check

ijice plate

gas

o

r~ice

rx·

= boiler size)

plate

0<

replace

Orifice plate installation, when required

AcctsS the bottom

inspect the plate only.

To

musr read rhe same as ·the boil

Boltr

model

GV90+3

GV90+4

GV90+5

GV90+6

To repl

ace r.he plate . using a maooal

Figur

e6:

1.

Loose

n screws 1

2.

Remove

3.

PuiJ

the

4. Slide in the n

propane plate

5.

Rep

lace screws 3

formly. DO NOT overtighten. DO NOT exceed 40 inch-pound$

torque.

6. lknd down plate label rabat score mark

of Figure 6. it

comer

jAwARtM

I

of

tile blow·

Nat ural

and

er

housi

read

the

er Si7.t

gas

martdng

NG3SEC

NG4SEC

NG5SEC

NG6SEC

2 two full

ng

as shown in Figure 5.

marking

and

on

fuel, as foll

Ptopane

scn

wdrtver

turns.

the

screws 3 and 4.

gas/air

oriffice

plate

forward

ew

plate

as

shown in

nut

go

next to

and

4. Tighten

em

10.

DO

NOI'

use

electric

or tighten

move

onl

y,

usi

ng

4()

inch-pounds. the threaded holes could str

causing

an

properly seal the plate

leak. causingse\rere person

property damage.

r.

he gas/air boss saews. Hand-tighren

manuaJ

SCTtWdri\·er.Shou

inadequate

to

remove it.

Figu

re 6. T

the

bloww housing.

all four screws securely and uni-

as

shown in lower right

or

pnewnatic screwdri\·ers

ki

seal

of th e

orifice

to

the housing could

al

injur

y,

death or substantial

plate edge. It

ows:

mar1dng

LP3SEC

LP4SEC

LPSSEC

LP6SEC

or

nut

Qotver

he

nd

side

rhe torque excted

plate. Failure

resu

to

ip out,

lr in a

.

of

see.

a

re-

to

gas

1-4

.!ia'twi - follow

S

C:a~a.il:'

manifold

6 Fn,nl

7

8 Ptopule Otifict plate.RBDaoe6ideandWHIT.Eon

9

1 0 Orificepbte after bendtng along

~tion.,

$Me

$bcw.ttt mu.tt

llibtf

fll.de

4tbi:r (

ttd

Natw-a:lg:uotifio:e

\liu"b

lt

wl~

lt•itrt~t:Ubnt

lO

skit

r 1At

im.UJ

bouam vi

ew,

po;lnt

t

unl

~

n\11St

~

plate.SIIYE!R

IM

(I'Wa

WH'ITI:-d

dw

fot

l

~lns

campon

nu

dtull.t omiJkd

rd

-aif lltlt1 h

~rhou..~

de

Kote

ttte-

for propane

mack

and lir;htal.ins;

WARN

-

l.tbel

lNG

gM

th~

111

8

P3n

num

ber

SSQ-142-7831101'2

Page 9

GV90+ Series

2

oAs·FIRED

WATER

BOILER

-

Boiler

Manual

Prepare

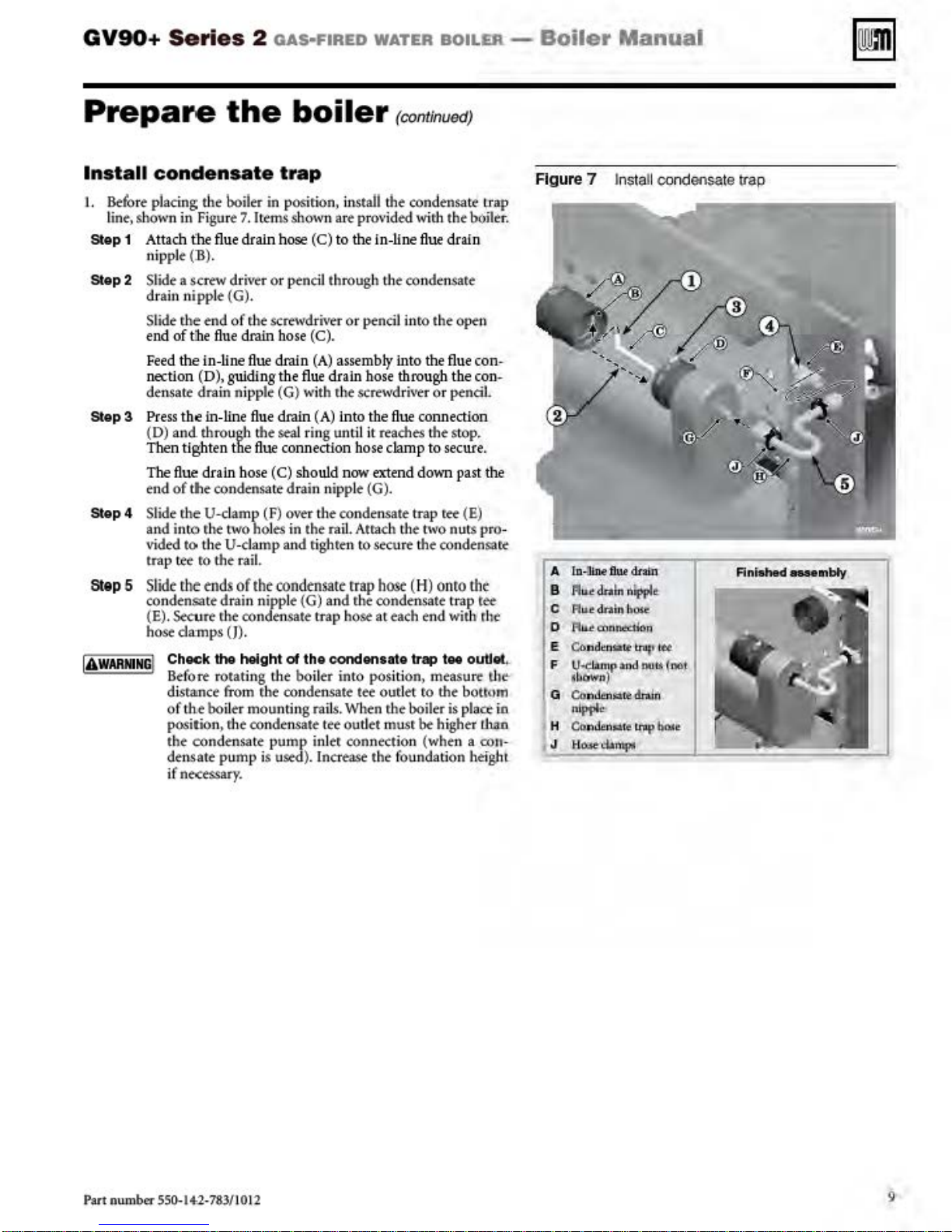

In

sta

ll

cond

I.

Btlo

re

plac

ing

lint, shown

Slop 1 Attach the

Step

2 Slide a

Slop3

Slop4

Step

5

IA

WARNNG

in Figu

nip

ple

(B)

scTtW

dra

in nipp

Slide r.he end

end

of tibe

Feed

the in-line

nection (D), guiding the

densate

Press

the in-lin e

(D)

and

Then tighten tl ie

The

flue

end

of

tile condensate drain n

Slide t

he

and i

nt:o r.he

vided

tc>

trap

tee

Sl

ide

l'he

con

densa

(E). Secure the condensate trap hose at each end with

hose

damps

Choc:k

I

Before

distttnce from the con

of th.e boiler mounting ralls. When the boiler is place io

position, rhe condensate

the

condensa

densate p

if

nt<tSSary.

the

en

sate trap

the

boiler

re 7. Items shown are pr

flue

draJn h

.

driver or

le (G).

boiler

in

pos

'irton,

ose

(C) to the in-liue

prnc

iJ

install the

O\'

through

of r.he screwdri\'fr or ptnci l inro the

flu

dra

in nipple

thro

drain

U-cl

the U-

e draJn b

ugh

amp

two

ose

(C).

flue

drain

(A)

assembly

flue

drain

hose thro

(G)

with r.ht screwdriver or ptnciJ.

flu

e draJn (

the seal r

flue

bose

(C) sho

(F) over the condensate trap tee (E)

holes

damp

A)

into th e

ing

until it reaches

connection b

uld

now

ipp

in the rai

and

l.

righren ro sec

ose

extend

le (G).

Atrach the two nuts pro-

ro the raiL

ends

of

the

te drain n

tho

rotating the boil

ipp

le (G)

(J}.

holght

ump

o1

te

pump

is used). Increase the foundation hefghl

condensate

trap

and r.he condensate trap tee

th

o condonsato

er into

densate

tee

inler connection

hose

pos

t~ oud

outlet musr

(continvedJ

condensate. trap

ided wi

rh

the

flue

drain

the condensare

open

into

the

flue

ugh the con-

flue

connection

the

srop

damp to

ure

ition,

secure

down

past

the

condensate

(H)

on

to

trep , ..

me

asu~

~

ro the bottmn

be

higher Lban

(wh

en a con-

boiler.

con-

.

.

the

the

tht>

outlot,

lhf"'

Figure 7 Insta

A

lo-Outdnin

B

Au..e

draln

nfpplt

c

Flu.t

dni:n bose

'f1u.t

c:anne:.don

0

E Co

n.;Jcnsalf'

F

u~~ud ooL~

•b

-)

G

Con

nipPle

H Con

H~·

J

tnq

den~itt

dn.lri

denAuo

lnlf'

d.amp~

ll

condens<~

•

let

(oot,

hcl.l;e

l

e

trap

Fint.hed

MMtnbty

Part num

ber

550-

14-2

-783/10 12

9

Page 10

GV90+

Series

2

oAs·FIRED

WATER

BOILER

-

Bofler

ManuaJ

Prepare

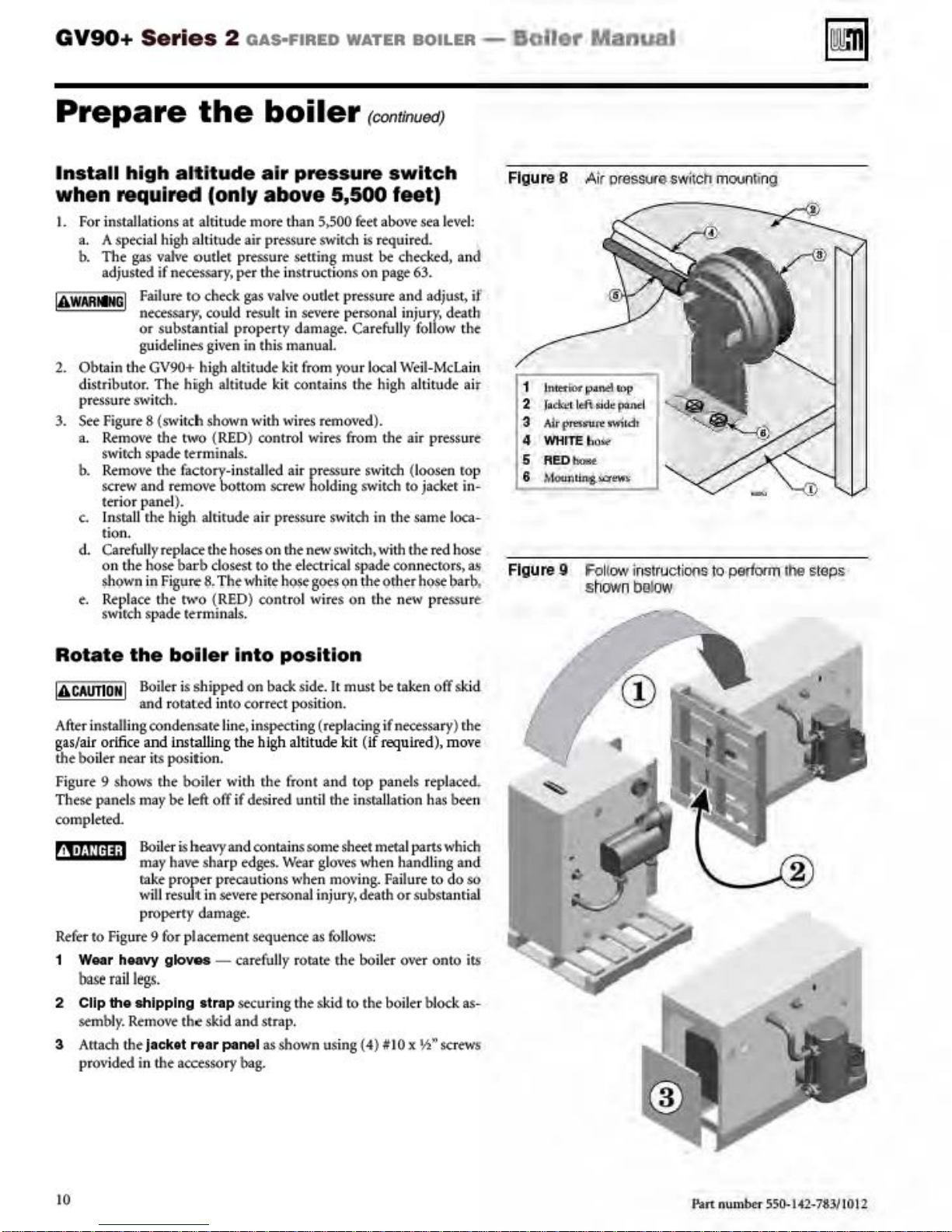

Install high alti

when

1.

"IA"w"AR=

2.

3.

required

For installations at altitu

a. A special high altitude air pressure swirch

b.

The

gas

adjust~

IING

=~I

Failure

necessary>

or

gu

Obta

in the GV90+ hi

distributor. The hi

pressure switch.

See

Figure 8

a. Remove the

swirch

spade

b. Remove r.he factory-installed air pressure switch (loosen rop

screw and remove bottom screw holding switch

tt'r'iO

r panel).

c. lnsraU r.he high alri

tion.

d. Cart full

on

$hown in

e.

Replace the

swarch

)• replace the

the hose barb cloStSt

spade te:rmi

the

tude

(only above

de more th

valve

outler

if necessar

substantial

idelin

(sw

Fig"~$.

y)

per the instrucrions

ro

check

couJd

proptrty

e$ given

gh

altitude kit from

gh

altitude kir contains the high altitude air

itch shown with wi

two

(REO)

te:rmi

nal

r.ude

hOStS

Th¢whi!¢

two (RED) cont

naJ

boiler

air

pressure

an

pressure

gas

result in

in this manual

seuing must

valve

oudet pr

St'\'ff't

damage. Carefully follow the

res

contro

l wires from the air pressure

S.SOO

removed}.

(continued)

switch

5,500

personal injur

)'Ou

feet)

feet

abo\re

i.s

r~uirM.

bt

checked,

on

page 63.

essure and adjust,

r l

oca

l Weii-

sea

s.

to

jad:er in-

air pressure switch in the same loca-

on rhe

new

switch. with the

to

the electrical spade connecrors. as

hQI¢g~on !h~

rol wires on

s.

o!'h~rh~bar\>,

r.he

new pressurt:

level:

y,

dearh

Mcta

rtd

and

if

in

hose

Figure 8

1 lntmtw

2

3 Air

4 WHrTEb

5 ReD-

8

Figure 9 Follow instruct

Air

pressure switch

poliJII!:I

COl?

J~1

ld1

sid~

panel

pres-

tuft'

!M"itcb

oilli-

MoUnlin.l-i.::r"""

shown

bgtow

moun~ng

ions

to perloon the steps

Rotate

!A

CAUTIO

After installing condensate line. inspecting (replacing

gas/alr orifice

the boll

Figu

re

These pantls may

completed.

the boi

N I Boileris shipp<d

and rora

and

t'r'

near its position.

9 shows

Bo

may have

rake pr

will

ted

Installing t

r.he

boiler with

bt

left

iler

i.s

h

ope

resuJt in

ler Into

eavy

sha

r precautions when mO\'ing. Failure

position

on

back side.lt must

inro correct position.

he

high allilude kit (

r.he

front and

off

if desir

ed

unr

il

rhe insrallarion h

and contain

rp edges.

St\'frt

s some sheet metal parts which

Wear giO\'fS

persona] in

jur

top

when h

y.

death

If

property damage.

Refer

to

Figure 9 for placement sequence

1 W

ear

hNYY gk>ves - cartfully roratt

base rail

2 Clip

sembly. Remove

3 Attach the )ack

pr

legs.

the

shipping strap securing the skid

O\<ided

in the accessory

th~

skid and strap.

tt

rtar

panel as shown using (4)

bag.

as foll

r.he

ows:

boiler over onto its

to

the boiler block as-

b<

taken

off

skid

if

necessary) r.he

required), m

panels replaced.

and

or

substanri

II

Ox

ove

as

bet-

ling and

to

do

S6

al

~»screws

n

10

P.an ntunber SS0-142-7M/1012

Page 11

GV90+

Series

2

oAs·FIRED

WATER

BOILER-

Boiler

Manual

Prepare

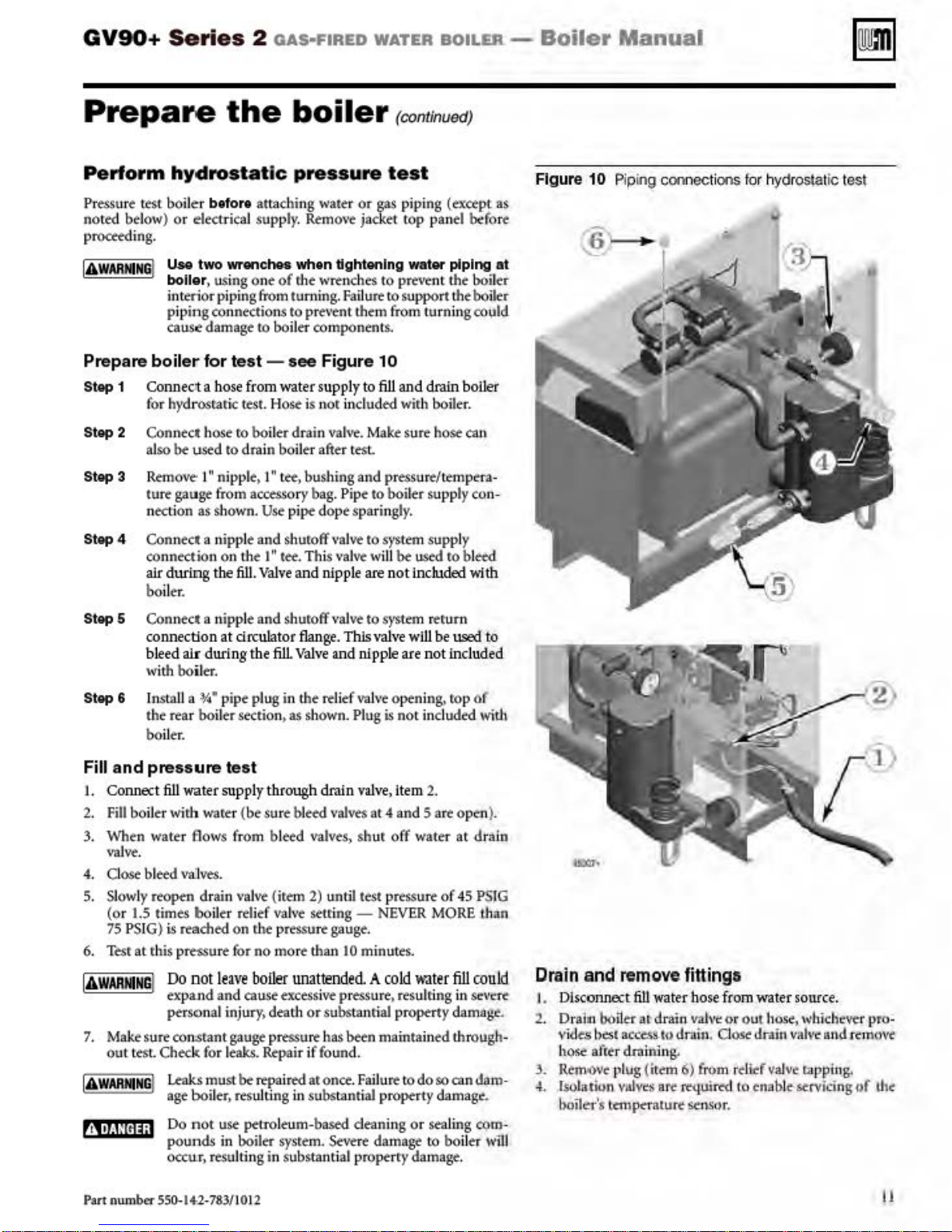

Perform

Pressure test boiler

no

ted

pro<t<ding.

IA

WARNING

Prepare

Stop 1 Connec>t a

Step 2

Step

3 Rtmo

Step

4 Connect a nipple and shuroff

hydrostat

bel

ow)

or electrical supply. Remo

Use

I

bollar, using

interior pipi

piping connections to prevent them from

caus.e

boiler

for h)rd

Connect

also

be

ture gauge

nection as shown.

connection on the 1"

alr dwilng tbe

the

befor•

two

wrenches

ng

damage

lor

test-see

bose

from water supply to

rosraric test.

h

ose

ro boil

used

to

dra

ve

I" nipple. I" tee, bushing

from

611. Valve

boiler.

boiler

ic

pressure

attaching water

ve

wh.en dghtenlng water piping

one

of

rhe wrenches

from turning.

to boiler

Fallu~

components.

Figure

or

gas

jacket

to

to

10

test

(continvedJ

fill

Hose

is nor included with boiler.

er dr

ain

vahre.

Mak

e sure hose can

in boiler after test

and

pressure/tempera-

accesso

ry bag. Pipe to boiler supply con-

Use

pipe do

tee

pe

sparin

gly.

valve

to system supply

.

This

val~

w

ill

be

and nipple are not

piping

top

panel before

preve

nt

support

turnin

aod

drain

used

included

(exctpl

the

ro bl

as

at

boil~r

the boi

ll"r

goo~.Jid

boiler

eed

"ith

Figure 10

Pip

ing connecli

ons

for

hydr

osta

lic l

esl

Step

5 Connect a nipple and shuroff

Step

c-Onnec.ti.on

bleed

wi

th boil

6 Insta

the rear boil

at

drc.ula

alr

during the

er.

ll

a

o/4

• pipe plug in

er section, as shown. Plug

boiler.

Fill and

I. Connect

2. Fill boiler wirh

3. ·

4.

5.

6.

IA

WARNNG

1.

I

AWARMNGI Leaks

t~j•Of!Hj;l

pressure

611

when

wate

\'lllve.

Close

bl

eed val

Slow

ly reopen drain val

(or

1.5

times boiJ

75 PSI G)

Tesr

Make sure

out test.

Ls

reached

at this pressure for no more than

I

Do

expa.nd

personal injur

co~rant

Check

age

Do

pounds

occur, r

test

water supply through drain v

wate

r (

be

r flows from bl

ves.

tr

rel

on

nolleave boiler

and cause excessi

gauge pressure has

fo

r l

eaks.

mu

st

be

boiler, resulting in substantial property damage .

not use

petrO

in boiler

esu

lting in substantial properr,• damage.

valve

to system rerum

tor

flange

. This

valve

will

fill

Valve

and nipple are not included

the

rtlitf

va

h·e opening. rop

is

not

alve

,ltem

sure bl

eed

valves

at 4 and 5 are op01).

eed

valves,

ve

(item

2)

ief valv

e setti

<he pressure

unattended. A co

y,

death or substanti

Repair if

rtpa

ired aronce.

leum-based deaning or sealing

sysrem.

shur off water at

until test pressure of 45

ng-

NEVER

gauge.

10

minutes.

ld

ve

pressure, resulting in

al

property

been

maintained through-

found.

Failure

t:odoso

Severe

damage

be

1.lSled

incl

uded

2.

MORE

ll~ler

fill

dama.g

can

to

boila

to

of

wi

th

dta

ln

PSIG

than

rould

Si!\'t're

e.

dam·

CQm

wm

-

Drain

2. Dr

3.

4..

and

remo

1.

Disconne.:.t

al11 bobt:r

vidt.s

best

access

h~

after

cl.rnining..

Rto:m

JI)\'e l'lug {itmi

lso

la.tion

viti

boiler's temp«ature

ve fittingo

fi1l

water

hose

at drain vahll:

to dmln.

6)

from rditfvalve

\'ell: at<"

m.Luif'C!'d

Sc.'nSor.

from

water source.

or

out

hose, w

dost

drain

valve

rappU\8;

10 enable servicing

hic

hever pro-

tu

ld reJnovt

uf

th(

Part num

ber

550-14-2-783/1012

11

Page 12

GV90+ Series

2

oAs·FIRED

WATER

BOILER

-

Boiler

ManuaJ

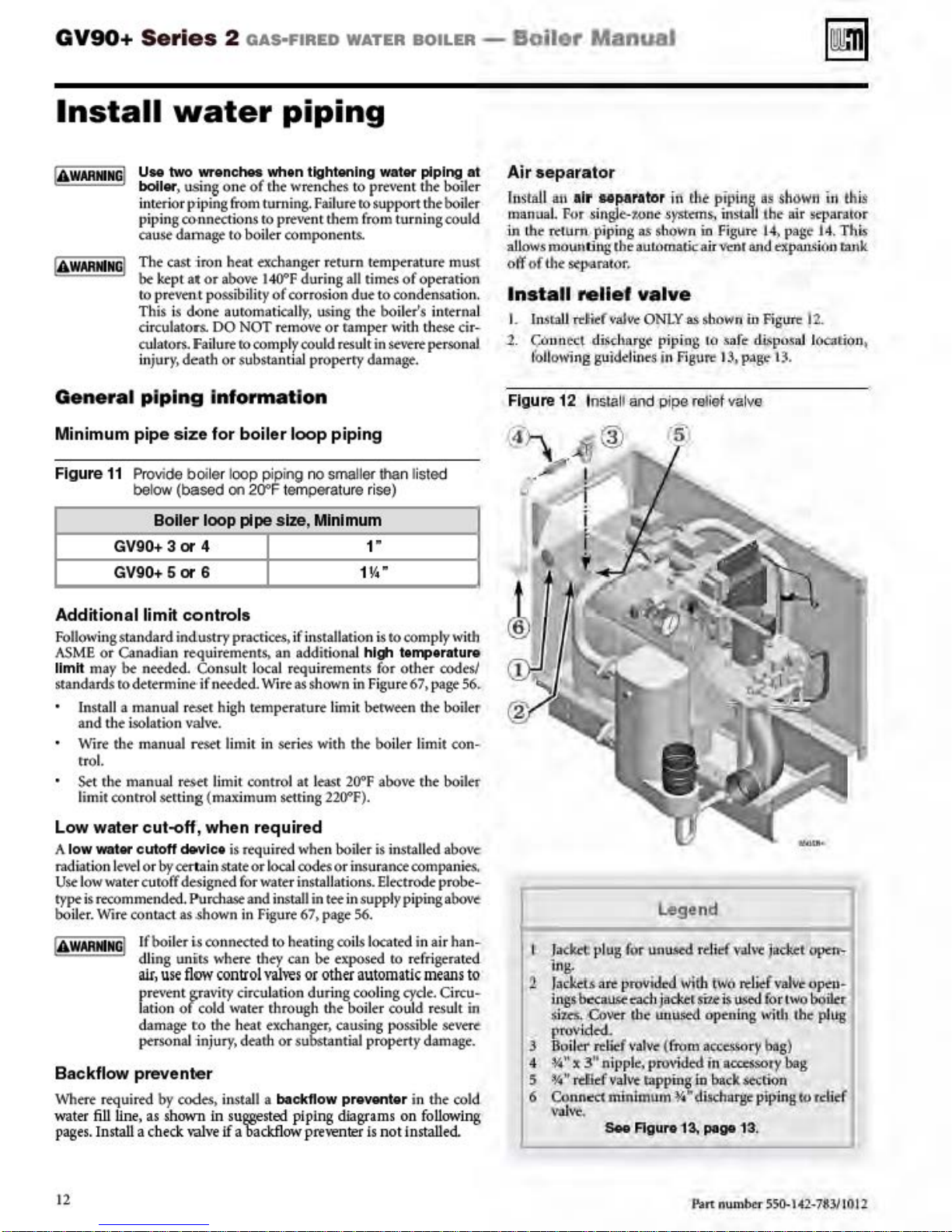

Install

water

Use two wrenches when tightening water piping

boller, using one

interior

piping

cause damage to boiler component:s.

The

be

to

This is

ci

cuJators.

i

piping

ronntction.s

cast

iron

kept

al

or

prevtn.t possib

done

rculators.

Fa

njury,

death or substanti

General piping I

Minimum

Figure

Additional

Follow

ASME

llmtt

standards

lnsta

and

\\fi

rro

Set

limit conrrol

pipe

siz:e

11

Provide

below (based on 20'F tempera

GV90+ 3 or 4

GV90+ 6 or 6

ing standard industry pracri

or Canadian

may

be

to determine·

JJ

a manual r

th

e isolation

re

the manual

l.

the manual r

boi

Boiler

limit

net<led. Consult locaJ

loop

controls

r

equir~men

if

e-set

valve.

reset

es-et limit control at least

St-rting

piping

of r.he wrenches

from

turning.

to

pre\re

heat exchanger r

above 1

DO

llu

nform

for

ler loop piping no smaller lhan li

needed.

high temperature limit

(maximum setring

4WF during

ility of

corrosion

auromaticall

NOT

~

ro comply could result in

boiler

pipe

limit in series with the boil

y, using the boiler's

rtmove

al

ati

on

loop

size,

ces.

if installation

ts,

an

additio

r~ui

Wir~

as

to

prevent

Failure

ro support the boiler

nt

them from turning could

eturn

temperature

all

times

due

to condensatio

or

ramprr

prope-rty

with these cir-

k\'t'rt

damage.

piping

ture ri

se)

Minimum

1"

i.s

to comply wi

nal

high temperature

remen

ts

for other

shown in Figure 67. page 56.

between

er limit con·

200F

above the boiler

2200F).

the

of

optrarion

interna

pe-rSOnal

sted

the boiler

at

boiler

mu.s~

n.

th

codes/

Air

separator

lnst•ll

ali

air N)>lrator

rnanua

l.

Fur

.single-1.onc--

in

Lht-

rrlllrn piping

aiJ.ows

m01,11lting

off

of

the

In

st a

ll reli

l

L

ln.stalJ

1. Connect discharge pip ing 10 safe di

tb

llow'i

r.be

s<poararor

ef valv

t<litf

val""

ng

guiddblt<-$

Figure 12 Install

(

4}~,.\i

.. ,

..

j®

,.....

" r

.syskr

a&-

:shown

aut.omatic

.

ONLY

in

and

pipe

in

tli<

e

as sbown in Figut.

Figure

relief

j·

r

'

pipi.ng

ns..

in

ait

as

install the

Figi,Jrt

J4> page 1

Vtor and

..

~pus·aJ

1$,

pt.~g-e-13

valve

shown

!Ur

dpatts

12.

.

ir1

th

is

-separator

4.

This

i(,o

tank

IOGition

•

Low

wa1er

A low water cutoff

radiation l

Use

low

type is rtcommended.

boiler. \"'ire contact as

cut-off, when required

dcwlc•

e-.-e

l or

by

~tain

wate

r cutoff designed for water instaJJations. Electrode probe-

If boil

er

units where they can

dling

air , u

se

pr~\rt

nt

Jation

of

damage

personal injury. dearh or substantial property damage.

is required when boil

stat~

or local codes or

Pur

chase and i

.shown

i.s

connected

in

Figur~

nstall

in tee in supply

67. page 56.

to

heating roil

be

fl

ow

control

gravity circulation during cooling cyde. Circu·

cold

r:o

the hear exchanger, causing possible

\'lllws

wat~r

through the boil

or other

Backflow prevent<!"

\"/here required by codes. install a backflow preventer in the cold

water

fill

pages. Install

Une, as

t2

a c.

shown

beck

\'alve

in

s

uggested

if

a

backflow

piping

pre't<enter

er

is insralled above

i

nsuranc~

s located in air han-

exposed

companies.

piping~

to

refrigerated

automatic

er coul

d r

diagram

s on fo

is not installed

mean

esuJt

seveTe

llowing

s to

in

Legend

)atlo.-t plug

lng.

2

fad<tls

i.n

gtb.:c:au.~racl

$ius.

alt.

proVIded

-C/J\'<r

fclr

unused rcllef V'

1

jad:et

the

unu>«i optnln

rn:rvtclt<L

3 Boil

4

5

6 Connect

er

relid' \'liiV< (from ll«c$$Ory bag)

'4"

x 3

••

nippl~.

provided in

~··

fditf

vah't tapping in back

\'31\'C,

min1mw'n1i,.

S..

flgur•1

oli\'

t

Jackt

W!U

r t

W6

re

lief

valVe

$'iU:

i

ti,I;Sed

for two bOtltr

.g

Wid>

acccssory-bag

.$b:ti<>n

c,l.ilicharg'e

3,

pogoo

r..art

plp.

ing

13

.

nwuber SSO-l42-7iU/IOil

.....

"~"''"'

op6i-

the

plug

to

rdid'

Page 13

GV90+ Series

2

OAS·FIRED

WATER BOILER -

Boiler

Manual

Install

Figure

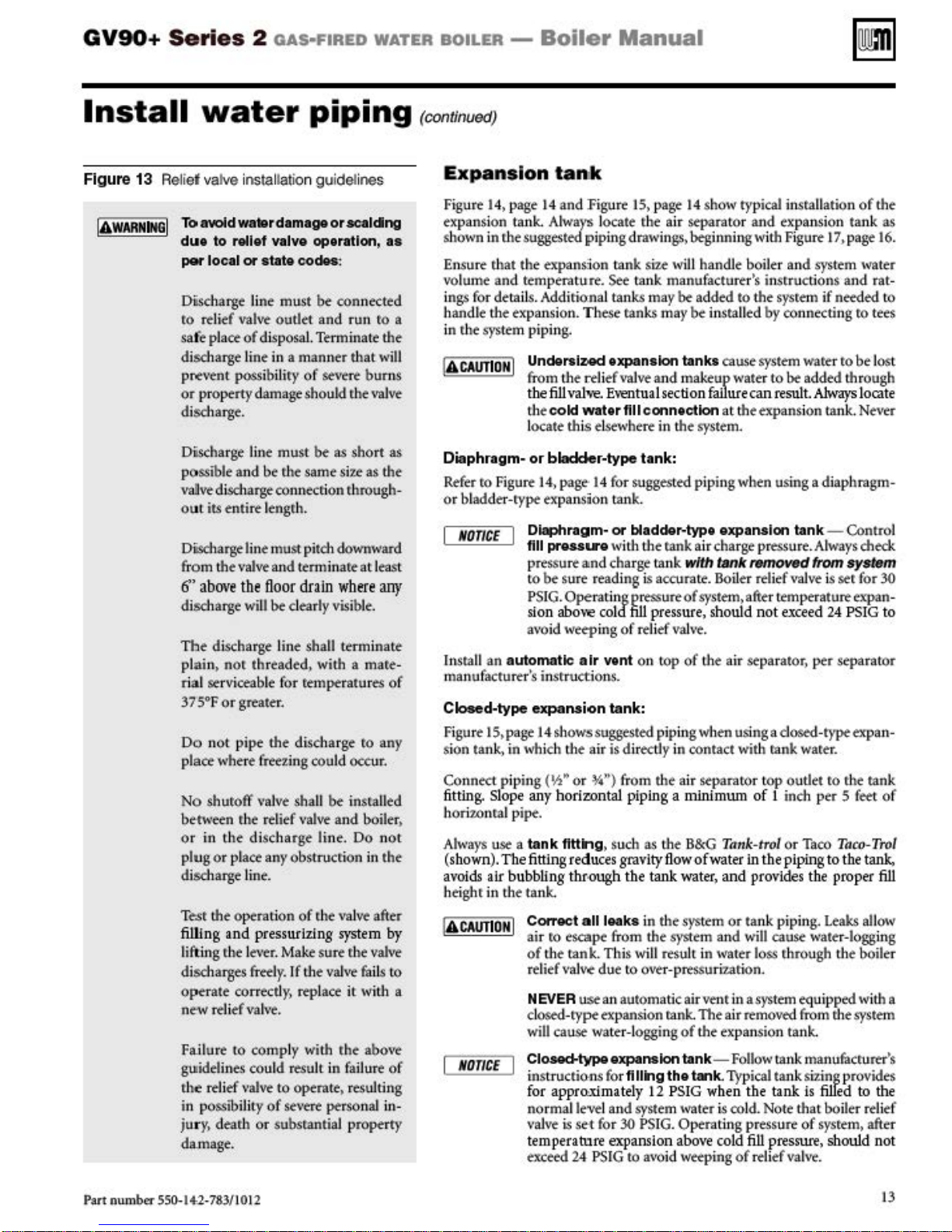

13 Relief valve installation guidelines

IAwARNIN61

To avoid

du•

per

Discharge line

ro rtli

safe place

discharge li

p~•ttn

or proptrty

disdlarge.

Dischar

po

\~vt

out its entire l

Discharge

f'rom

6'

discharge

The

plai

rial

37

Do not

place where

No

betweton r.he relief valw and boiler.

or in the discharge line. Do n

plug or pl

discharge line.

fur

filling and pressurizing

l

disdlarges flffly. If !he

Optne-w

Failure

guidelin

r.htin possib

jury, dear.h

da.mage.

water

w.-rd•m•ge

to relief VIIYe

loc•l

or st.te

ef

valve

of

disposaL Terminate the

nt

t

possibiliry

damage should r.he

ge

line

ssible

and

discharge connecti

line must pitch downward

the

valve

above

the

will

discharge line shall terminate

n,

nor thread

se

rviceable for temperatur

5°F

Or grt:ater.

pi

pt

(reezing could occur.

shuroft' valve sha

ace

the operati

ift

ing r.he le•;er. Make sure r.he

piping

or

op•mlon,

codM-

:

must

be

con

outlet

and

in a manner

of severt bums

must

be

as

be r.he

same sir.e

on r.hrough-

engr.

h.

and tenninart

floor

drain

bt

dearly

vis

ed,

with a mare-

the discharge ro

ll

be

any obstruction in the

on

or r.he \'al

vah'f fail

rate corr

rf'lief vah·

rf'liei'

ectly,

repl

ace

e.

to

comply with

es could resu

\•alw

ili

ty

of

or subsrantial property

lt

in failure or

to

optnate. resultin

se\·e:re person

acalclng

nected

run ro a

that

\'ll]vt

short

as

at least

where

ibl

e.

es

insralled

ve

after

system

valve

it with a

r.he

above

al

• •

will

as

the

any

o(

any

ot

by

s to

g

in-

(continued)

E

xpansion tank

Figure 14. page 14 and Figure 15. page 14 show typical insrallation

expansion tank. Al

shown in r.he suggested piping drawings. beginning wi

Ensure r.hat the expanslon tank

volume

ngs for detai

i

handle

in

and temperatu-re.

th

e expansion. These

r.

he system pipin

Diaphragm·

Refer

ro Figure

or

bladder-type

NOnCE

ll

an

Insta

manufacturtr

automatk

way$

locate r.he air separator and expansion tank

size

w

iJI

handle boil

Set'

tank manufacturer's instructions and rat-

ls.

Add

iri

onal ta

nks

may

be

added to the

ranks may

g.

UndeniZCid

from

th

the

fiU\•ah-e.

th

ecokt

locate this elsewhere in the system.

or

blaclcler-type tank:

14

,

page

expansion tanks cause system

e r.tli

ef

\'lllve

E\'entual

water

flllconntcUon at the expansion tank.

·14 for suggest

be

installed

and makeup water to

section

fallucecan

ed

piping when using a diaphragm-

expansion tank.

Diaphragm·

flU

prNSU'e

pressure

to

be

sure r

PSI G.

Operating pressure

sion abo\

avo

id weeping of relief vah·e.

's

instructions.

o.-

wi

a~nd

char

e:ad

ing

-e

cold

air

wnt

bladdor·typt expansion tank- Control

th th

e rank air char

ge

tank

with

tank

is

accurate. Boiler reli

of

fill

on

pressure

system. after temperaturt

, should not

top

of the air separator, per separator

th

Figure 17, page

er and system water

sysrem

by connecting

be

resul

ge

pressure. Always ched::

removed

ef

\oalve

exceed

Closed-type expansion tank:

Figure IS, page 14 shows suggested piping

sion tank, in which the air is dirtctly in contact with rank

Connect piping

fitting.

Slope

hori1..0nra

Always

(

a>'oids

heighr in the tank.

shown

NO

TICE

use a

). The

air bubbling

(Y:t,.

or ·W') from

any

horizontal

l pipe.

tank

fitting. such

fittlng

reduc

the

COI'I"eCt

air ro escape from the system and

of

th

e tank. This will

rdiefval

NEVER

dosed-type-expansion rank. The air

will

Cl~type

instructio-ns for

for

normal level and system water

va

t

ern

excttd

v.e

use

cause water-l

appr<>Ximately

lw

i.s

se

peca

ture expansion

24 PSIG

piping a minimum

as the

es grav

ity

<>Ugh

the

tank wate

aU

leaks in

due ro over-prtssuri:zarion.

an

automatic a

oggi

expansion tank-

ftUk'lg

12

·t for 30

PSJG.

to

a\ro

when

usingadosed-typeexpan-

the

air separaror t

of t

B&G

Tnnk-trol or Taco

flo

w of wate

the

system

result in water loss

ir

ng

of

the

PSIG

Operating pressu

abo\'e

id wetping

r In

r, and

provides

or

tank piping.

will

venr

in asysttm equipped wi

~moved

the expansion tank.

Follow

tank. Typical tank

when

the

i.s

co

ld. Note that boiler relitf

cold

fill

of

reli

op

outlet ro r.he tank

inch

the

plplng

cause water-logging

r.hrough the boiler

tank

tank

re

presSW"e

ef

vahre.

of

the

as

16.

if needed ro

r.o

tees

ware

r robe l

os

added through

t.

Always

locate

Never

from

sy.tem

is

ser for 30

expan

24

PSIG

to

warer.

per 5 feet of

Taco-Tro

to the

tank,

the

proper

fill

le:aks

alloo.v-

th

from rhesystem

man

ufac[Uru's

si'z:

ing provides

is

fill

ed to

the

of

sysrem. after

, should

not

t

-

l

a

Part num

ber 550-

14-2

-783/10 12

13

Page 14

GV90+

Series

2

OAs-t'IRED

WATER BOILER -

Boil

er ManuaJ

Install

Figure

14

Pip

bladdllf•lype

1" N

water

ing to single-zone system using diaphr

expansio

PT (su

ppty from

piping

n tank.

1"tee, return to 1

Boiloc conn

(cononuedJ

"'

recuperator

®

t

agm

ectio

· or

ns

are

Figur

e 15 Pi

ping

closed-type expansion

lan

k

Pipe

NOnCE

NO

nCE

diaphragm-or

tom

of

the

Pipe dosed-

separator.

type

theairseparat

tank IOC'<ltion, as shown abc

1

Rtli

ef

vah·e discharge piping-

2

Isolation

3 F

iJI

4 Di

s

how

5 Air separator

t4

\<al\'d

valve

aphragm-type

n in the suggesttd pipi

provide with

with

diaphrngm

pi

pe air oudet to

dOS<-I)'pe

UUlk.s

bladder·l)'peexp

(air

in

contact with

or.

Alv.a

ys

connect

we and

stt- page t 2

txpanston

automatic air wnr ONLY

-typt expansion

expans

tank-

ng

drawings

ion

rank

ansion rank.s

water)

the

fill

line

in

the

al

ways

in this

when

ranks

when used

to

tank.s

to

to

the

ex

suggested

Legend

locate

as

manual

used

wi

th

the

bo

t·

the

top of

pan

sion

piping

l

8 Cold

7 S'r•l=

8 $ys\o:m

10 PfclsWe

11

12.

13 Tank fittlng

Jill

line.With

wb,..

rtquited

pi\lll'lit

~)

.u~plyp

n;wro

i'edllcing valVe

Quk-k>Jill

C

IU<M-

i

ll

the

b)'lll>ss

cyl"'

:~

ugg

esctd

.bac~owpteventerilr

by

c<ld•• t<et Figute

iuin

piping

valve, wbel) u

E'ltj>I'>Ml6o

piphl8

$

wh.m

1

ranlt-

d.rawiqp

15

USc~

sed

alw

oys

iu

thi5

Ch

eck valve

foi

typioil cOm-

!o.:a~e

o.<

Slwwu

manua

l

Page 15

GV90+ Series

2 OAS·FIRED WATER BOILER -

Boiler

Manual

Install

Syste m

NOTICE

Ci

rculato

IAWARNING

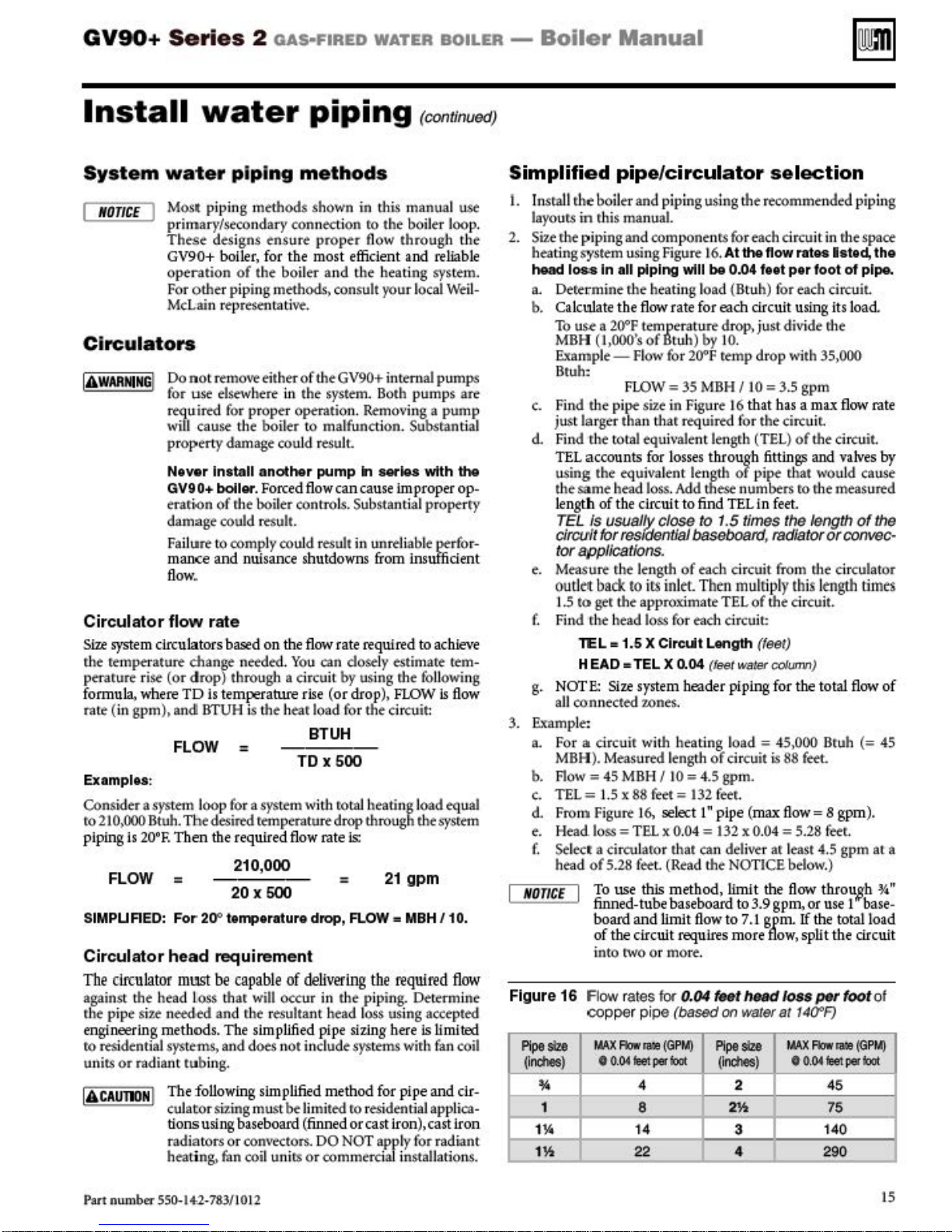

Circulator flow

Size

r.

he temperature change needtd.

perature rise

formula, where

rate (in gpm). and

I

system c.irculators based

water

wa

te r piping me

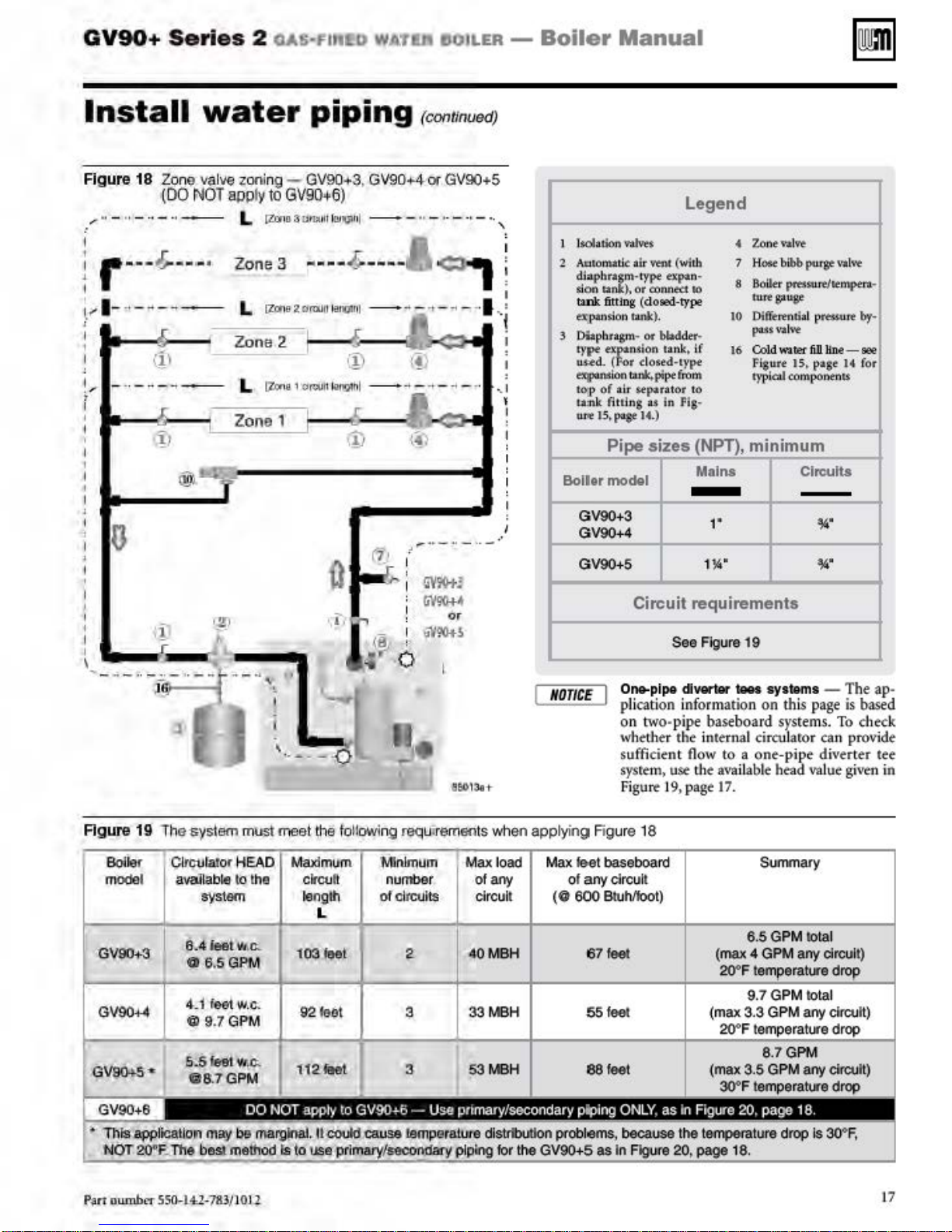

Most piping

primary/seco n

These

GV90+ boiler , for the

oprration

For othe

McLain r

rs

Do

no

for

u.st elsewhere in

rtqu-irtd

w

ill

cause the

pr

operty

Ntver

GV90+

erarioon

damage

Failure

maJKe

flo

w.

(o r

drop

TD

BTUH

methods

dary

designs

of

the boiler

r piping

tprtktltath

t remove either

for pr

ope

boiler

damage

Install

another

bollcw. Forced

of

rhe boiler controls. Substantial pr

could

rtsult.

to

comply coul

and

nuisance shutdowns from insuffident

rate

on

} throu

is

temperature rue (o r drop),

is the hear load

FLOW =

Examplu

Consi

to

210,000

piping

:

der a sys

Btuh. Tbe

is

20'F.

tem loop for a system with

desir<d

temperature

Then

the required

210,000

FLOW =

20x

SIMPUREO:

Circulator

Th

e circulator

against the head Loss that

r.

he pipe si

engineering

ro residential systems.

units

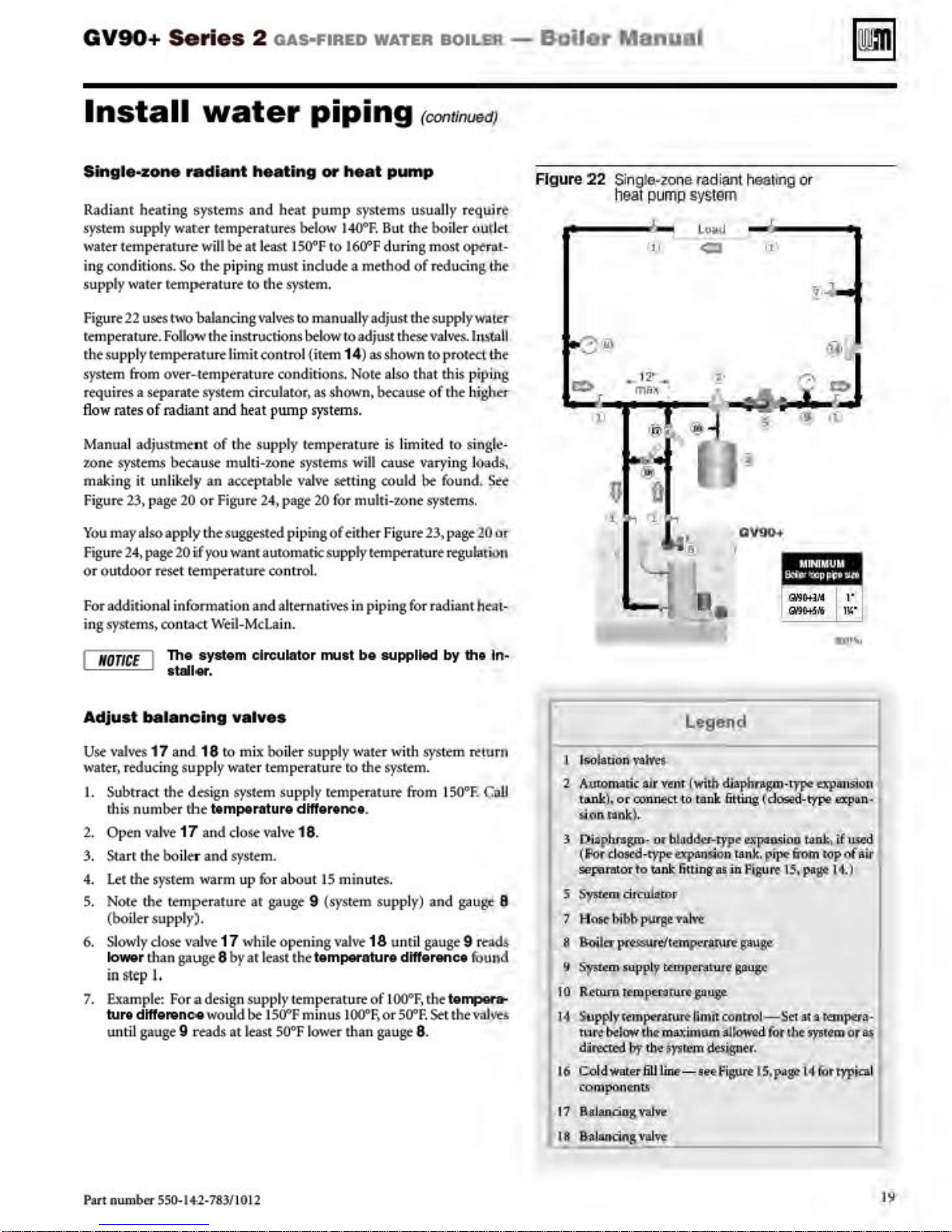

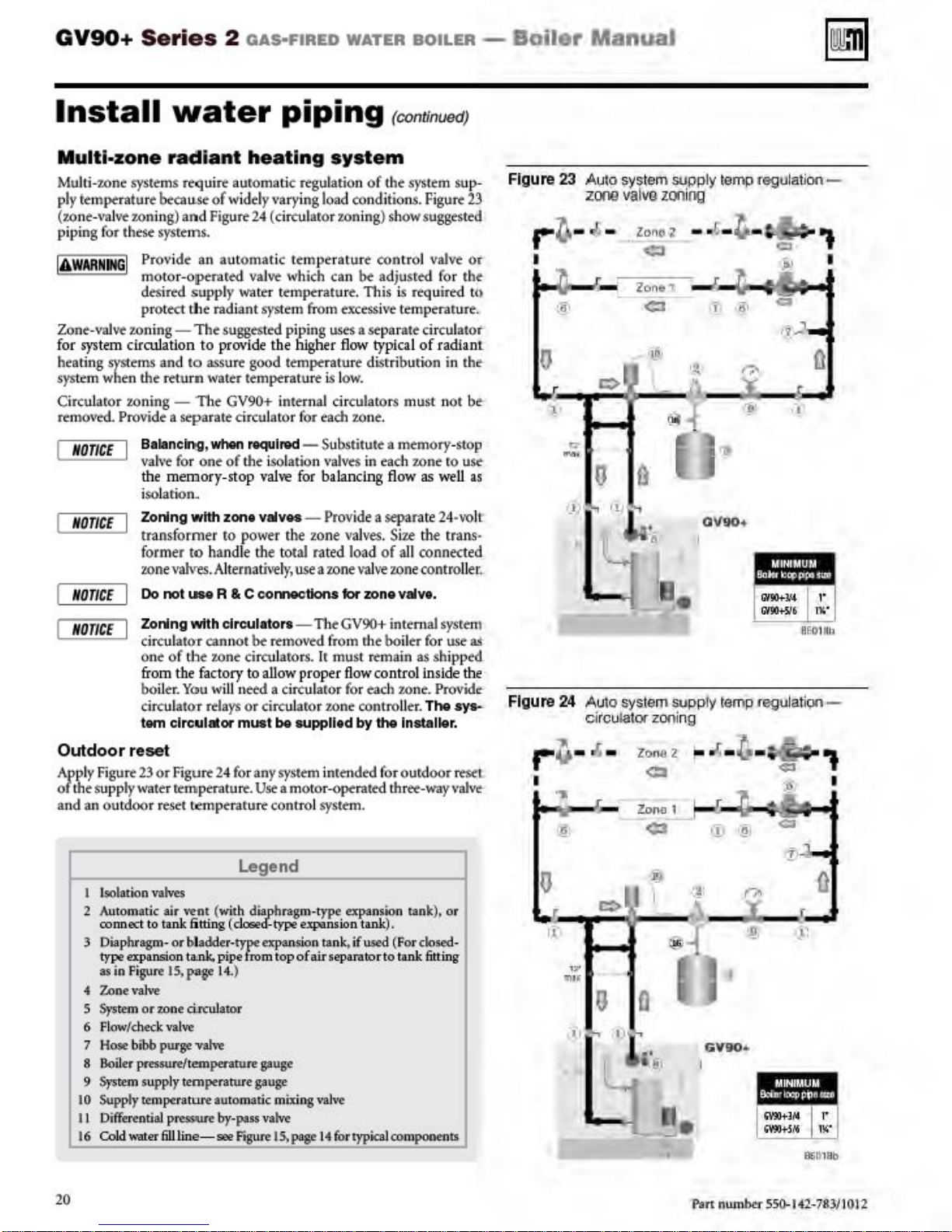

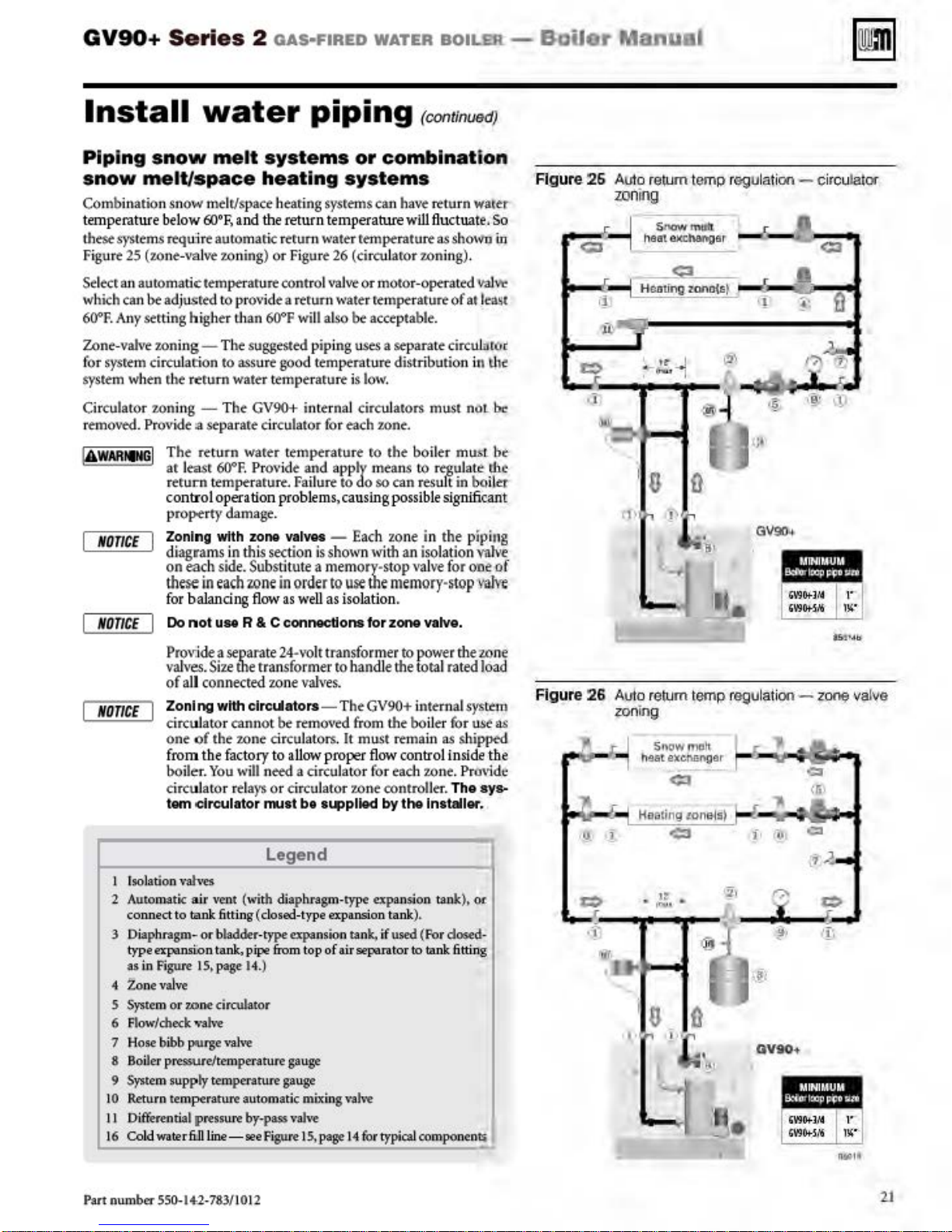

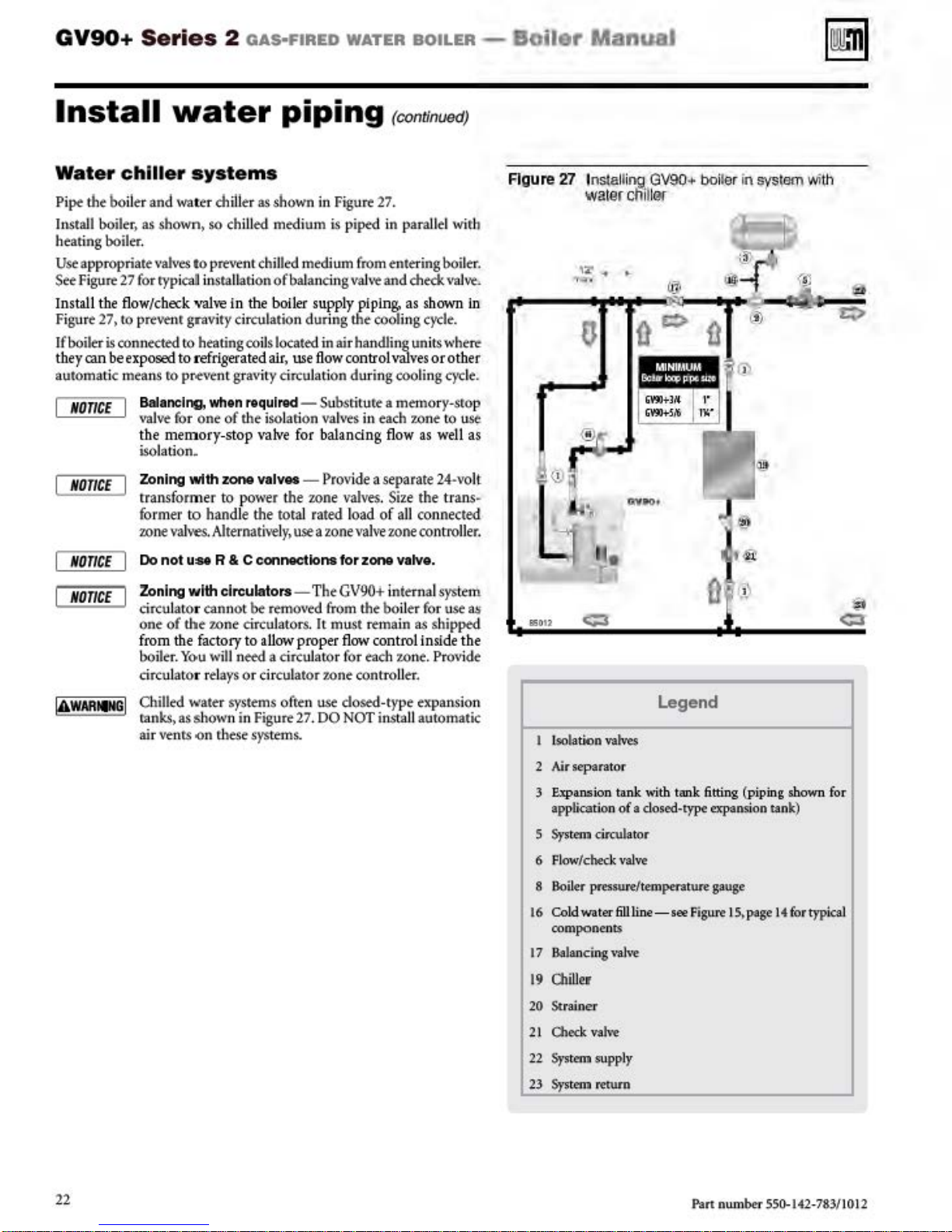

or