Page 1

LGB

Gas–fired boiler

Control Supplement

LGBLGB

LGB

LGBLGB

-6 -6

-6

-6 -6

LGB LGB

toto

LGB

to

toto

LGB LGB

-20-20

-20

-20-20

Series 2 – Propane gas

CSD-1 Control System

Contents

I. New installation .......... 2

II. Existing installation .... 4

III. Water and steam trim

components .................. 4

IV. Gas piping ................... 5

V. Wiring ........................... 5

Sequence of operation ..... 8

Wiring procedure .............. 8

VI. Leak test procedure ... 10

These terms are used throughout this

manual to bring attention to the

presence of hazards of various risk

levels or to important information

concerning the life of the product.

VII.

Operating instructions 11

VIII. Parts list ..................... 12

Indicates presence of hazards that can cause severe personal injury, death or

substantial property damage.

Indicates special instructions on installation, operation or maintenance that

are important but not related to personal injury or property damage.

This Control Supplement must only be used by a qualified installer/service

technician. Read these instructions completely before beginning the

installation. Failure to follow these instructions can cause severe personal

injury, death or substantial property damage.

Part Number 550-141-816/0304

Page 2

LGB-6 to LGB-20 Series 2 – Control Supplement

I New installation

1. Remove all burners from base box assembly. Remove 3.95 mm natural gas main burner

orifices in manifold. Install 2.40 mm propane gas main burner orifices. Use pipe dope

sparingly only on male ends. Use pipe dope compatible with propane gases. Do not

overtighten orifices.

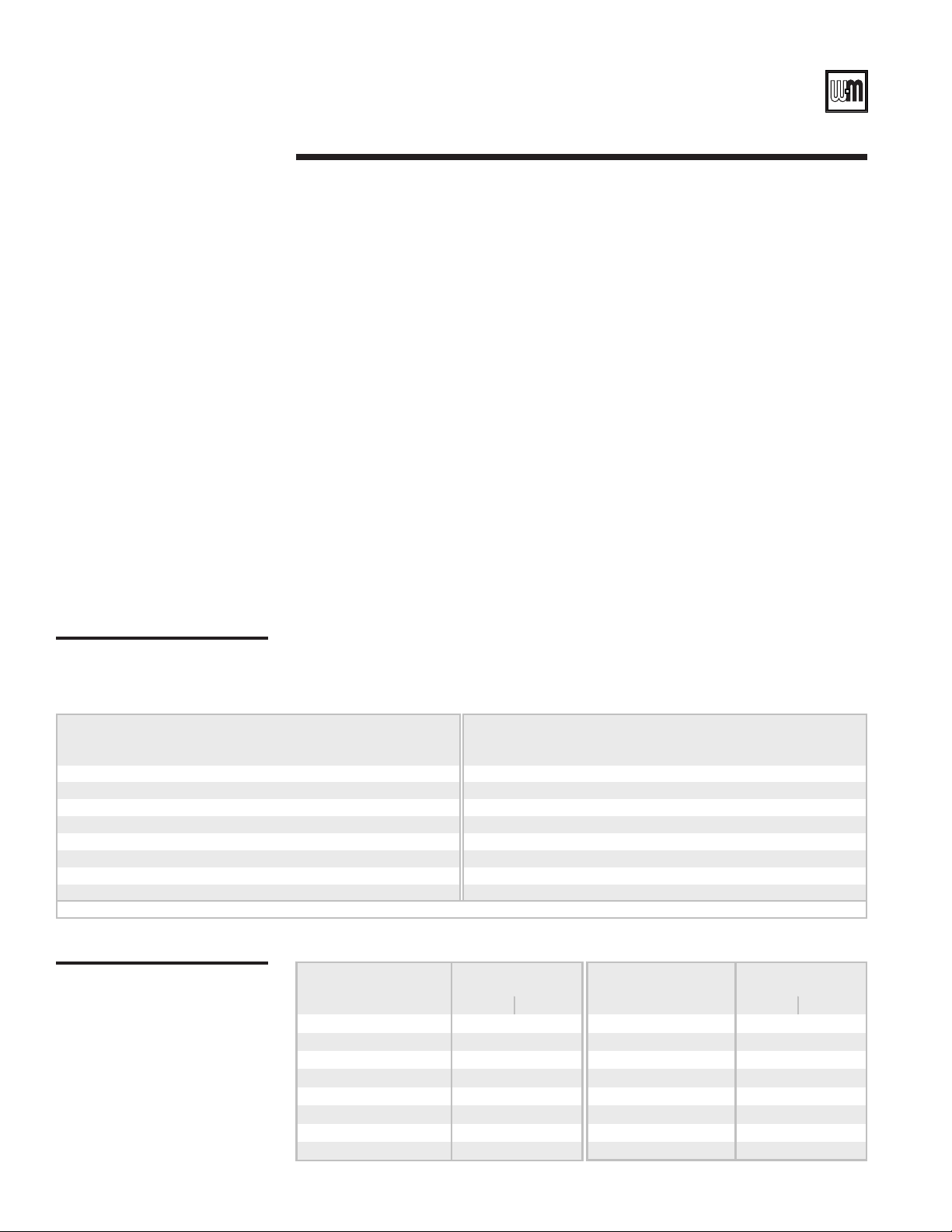

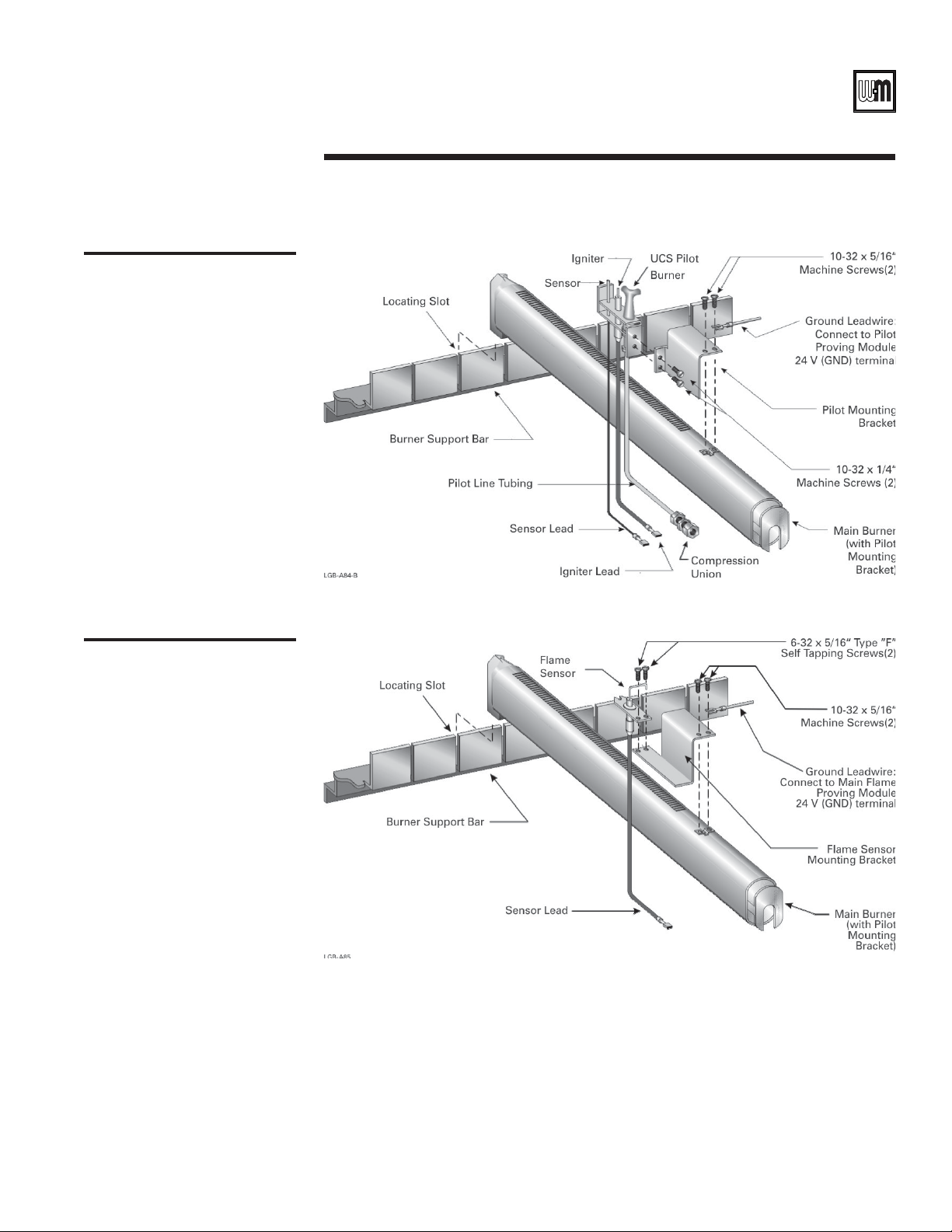

2. Install pilot burners and flame sensor(s). See Figures 1 and 2 (page 3). Follow Table 1,

below for electronic pilot burner (UCS), standing pilot burner (Q327) and flame sensor

locations on manifold.

3. Install gas controls and ignition control panel as shown in Table 2, below and Figure 6

(page 12).

4. Attach pilot switch box to interior jacket panel. See Figure 6 (page 12). Connect

thermocouple from standing pilot to switch box. Cut 60” pilot tubing into 2 pieces to

make connections from pilot valve to pilot switch box and from pilot switch box to

standing pilot.

5. Attach:

a. 550-223-710 label at boiler operating instruction label. Place so that this label reads

first.

b. 550-223-796 label at rating label.

c. Wiring diagram on door (one on each base).

Table 1

Pilot burner and flame sensor

locations

Electronic

Pilot Burner*

Propane

Carton

Table 2

Electronic

Pilot Burner*

Boiler

Model

Number

LGB-6 A and B 1" -- LGB-14 I1"1"

LGB-7 A and B 1" -- LGB-15 J1" 1"

LGB-8 C and D 1" -- LGB-16 J1" 1"

LGB-9 C and D 1" -- LGB-17 J1" 1"

LGB-10 E, F and G 1 ¼" -- LGB-18 K1 ¼"1"

LGB-11 E, F and G 1 ¼" -- LGB-19 L1 ¼"1 ¼"

LGB-12 E, F and G 1 ¼" -- LGB-20 L1 ¼"1 ¼"

LGB-13 H1"1"

Boiler

Model

Number

LGB-6 2--9--6--LGB-14 2 161325 8 21

LGB-7 2--11--7--LGB-15 2 161327 8 22

LGB-8 2--13--8--LGB-16 2 181529 9 24

LGB-9 2--15--9--LGB-17 2 181531 9 25

LGB-10 2--16--9--LGB-18 2 201633 9 27

LGB-11 2--16--9--LGB-19 2 201634 9 27

LGB-12 2--16--9--LGB-20 2 221636 9 29

LGB-13 2 141123 7 19

* From left burner

Flame Sensor*

No. 1No. 2No. 1No. 2No. 1No. 2 No. 1No. 2No. 1No. 2No. 1No. 2

Gas control arrangement

Standing

Pilot Burner*

Propane

Carton

Boiler

Model

Number

Inlet Pipe Size

Left base Right base Left base Right base

Flame Sensor*

Boiler

Model

Number

Standing

Pilot Burner*

Inlet Pipe Size

Part Number 550-141-816/03042

Page 3

I New installation – continued

Figure 1

Pilot burner assembly, typical

CSD-1 Control System – Propane gas

Figure 2

Main flame sensor assembly

Part Number 550-141-816/0304 3

Page 4

LGB-6 to LGB-20 Series 2 – Control Supplement

II Existing installation Conversion from natural gas to propane gas

This conversion is to be installed by a Weil-McLain distributor or other

qualified agency in accordance with the manufacturer’s instructions and all

codes and requirements of the authority having jurisdiction. Failure to

follow instructions could result in serious injury or property damage. The

qualified agency performing this work assumes responsibility for this

conversion.

For your safety, turn off electrical power supply before making any electrical

connections to avoid possible electrical shock hazard.

1. These instructions are for use with Propane Control Cartons as listed in Gas Control

Arrangement, Table 2 (page 2).

2. Remove jacket door(s) and access panel(s).

3. Disconnect wiring and tubing from existing pilot burner and main flame sensor.

4. Remove all burners. Remove 3.95 mm natural gas main burner orifices in manifold. Install

2.40 mm propane gas main burner orifices. Use pipe dope sparingly only on male ends.

Use pipe dope compatible with propane gases. Do not overtighten orifices.

5. Remove and discard existing electronic pilot burner from pilot burner tube. Replace with

electronic pilot burner in carton.

6. Attach Q327 standing pilot to burner tube in kit. Connect pilot tubing and thermocouple

to pilot.

7. Re-install burners. See Table 1 (page 2) for location of pilot burners and flame sensor(s).

8. Attach pilot switch box to jacket. See Figure 6 (page 12). Connect thermocouple to pilot

switch box. Cut 60” pilot tubing into 2 pieces to make connections from tee in pilot line to

pilot switch box and from pilot switch box to standing pilot.

9. Remove natural gas valve train.

10. Install propane gas valve train and fittings from carton (See page 5, section IV, paragraph

4 of this Supplement).

11. Re-install access panel(s).

12. See Figure 6, page 12 for propane piping.

13. Wire per wiring instructions and wiring diagrams, pages 5-9. Add splices as needed.

14. Attach:

a. 550-223-710 label at boiler operating instruction label. Place so that this label reads

first.

b. 550-223-796 label at rating label.

c. Wiring diagram over diagram on door (one on each base).

15. To place in operation, follow instructions on constant burner pilot light-up label and

boiler operating label.

16. Replace jacket doors.

III Water and steam trim components

1. Install water or steam trim components as required by CSD-1 latest edition. See the boiler

manual for tapping locations.

a. Water boilers require:

• a manual reset high temperature limit control in addition to the standard

automatic reset limit control.

• a manual reset low water cutoff.

b. Steam boilers require:

• a manual reset high pressure limit control in addition to the standard automatic

reset limit control.

• a manual reset low water cutoff in addition to the standard automatic reset low

water cutoff.

Part Number 550-141-816/03044

Page 5

CSD-1 Control System – Propane gas

IV Gas piping

1. Contact gas supplier to size pipes, tanks and regulator.

a. Inlet gas pressure to manual main shut-off gas valve —

minimum 11” W.C., maximum 13” W.C.

b. If pressure to gas valve exceeds 13” W.C., install 100% lock-up gas pressure regulator

upstream of hand valve.

2. Remove gas supply knockout disc from jacket panel.

3. Follow good piping practices.

4. Pipe joint compound (pipe dope) must be resistant to corrosive action of liquefied

petroleum gases. Apply sparingly only to male threads of pipe joints.

5. Install drip leg at inlet of gas connection to boiler. Where local utility requires, extend drip

leg to floor.

6. Install ground joint union when required for servicing.

7. Support piping by hangers, not by boiler or its accessories.

8. Purge all air from supply piping.

9. Before operating boiler, check boiler and its gas connections for leaks.

Do not check for gas leaks with an open flame – BUBBLE TEST. Failure to

use bubble test or test for leaks can cause severe personal injury, death or

substantial property damage.

a. Close manual main shut-off valve during any pressure testing at less than 13” W.C.

b. Disconnect boiler and gas valve from gas supply piping during any pressure test

greater than 13” W.C.

V

Wiring

For your safety, turn off electrical power supply before making any electrical

connections to avoid possible electrical shock hazard.

1. All wiring must be installed in accordance with the requirements of the National Electrical

Code and any additional national, state or local code requirements having jurisdiction. All

wiring must be N.E.C. Class 1.

2. The boiler must be electrically grounded in accordance with the National Electrical Code,

ANSI/NFPA No. 70-latest edition. Use 105 °C. thermoplastic wire, or equivalent, if any of

the original wire must be replaced (except for pilot spark, sense and ground wires).

3. Supply wiring to the boiler must be No. 14 gauge or heavier. Install in conduit.

4. A separate electrical circuit with a fused disconnect switch (15 amp. recommended) should

be used for the boiler.

5. Refer to wiring diagrams, Figure 3 (pages 6 and 7) and Figure 5 (page 9). See section,

“Wiring procedure” on page 8.

6. Figure 5 on page 9 is the Field Wiring Diagram. See Figure 3, pages 6 and 7, for the

schematic and ladder wiring diagrams.

Part Number 550-141-816/0304 5

Page 6

LGB-6 to LGB-20 Series 2 – Control Supplement

Part Number 550-141-816/03046

Page 7

CSD-1 Control System – Propane gas

Figure 3

Wiring diagram

Part Number 550-141-816/0304 7

Page 8

LGB-6 to LGB-20 Series 2 – Control Supplement

V

Sequence of operation

Wiring – continued

1. Operating control begins startup sequence.

a. Limit control contacts are closed.

2. Pilot proving module energized.

a. Pilot solenoid opens.

b. Pilot ignition spark begins.

c. Pilot ignites.

d. Pilot proves.

On failure to sense pilot flame, the pilot-proving module will wait 5

minutes, then retry for ignition. Upon 2 consecutive pilot flame failures,

the control will lockout and illuminate the red lockout light.

3. Main flame proving module energized from pilot proving module.

a. Secondary gas valve opens.

b. Main gas valve opens to low fire position.

c. Main burners ignite at low fire.

d. Main flame sensor proves low fire carryover.

e. Main gas valve opens to high fire position.

f. Main burners increase to high fire.

On failure to sense main flame, the main flame-proving module will

lockout and illuminate the red lockout light.

4. For dual base assembly - operating control energizes controls for each base assembly at the

same time. See steps 1 through 3 above.

5. Boiler shuts down when operating control satisfied.

If the boiler locks out, the alarm contacts on the terminal strip (terminals

A1 and A2) close. These contacts are rated to 15 amps, 250 V. To reset the

boiler, push the red lockout button.

Wiring procedure

1. Determine right or left electrical supply wiring.

2. Attach electrical junction box(es) to inside jacket end

panel. Screws and nuts are provided. For dual base

boilers, use offset nipples (provided) to connect

junction boxes together (as at right), then hang

junction boxes by screwing top box to boiler jacket.

See Figure 4.

3. Attach control transformer(s) to junction box(es).

4. Drill 1/8” hole in interior jacket panel midway between

ignition control panel and left jacket panel. Mount

wire support clip using sheet metal screw (furnished).

5. Complete wiring per diagrams, Figure 3 (pages 6

and 7) and Figure 5 (page 9). Terminate at secondary

gas valve in valve junction box with wirenuts and

strain relief provided.

“Hot” side of line voltage to boiler

must be wired directly to limit

circuit, then fed to transformer

primary(ies).

Dual Base: “R” terminal of

secondaries are to supply power

to bases independently of each

other. Do not wire “R” terminals

together.

6. Install pilot proving and main flame proving ground

connections as shown in Figures 1 and 2 and wiring

diagram. Route wires through wire support clip.

Figure 4

Junction box assembly

dual base boilers

Part Number 550-141-816/03048

Page 9

Figure 5

Field wiring diagram

CSD-1 Control System – Propane gas

Part Number 550-141-816/0304 9

Page 10

LGB-6 to LGB-20 Series 2 – Control Supplement

VI Leak test procedure

1. Remove red (MV) and blue (PV) wires from main gas valve.

2. Close main test firing valve attached to the manifold.

3. Check that both leak test valves are closed and remove plugs.

4. Attach manometer to first leak test valve.

5. Open first leak test valve and check for pressure.

6. Close first leak test valve and remove manometer.

7. Attach manometer to second leak test valve.

8. Apply call for heat to boiler.

9. Check that electronic pilot proves.

10. Open second leak test valve and check for pressure.

11. Close second leak test valve and remove manometer.

12. Remove call for heat to boiler.

13. Reinstall plugs on leak test valves.

14. Connect wiring to main gas valve.

15. Open main test firing valve attached to the manifold.

When checking for pressure at the leak test valves, any small pressure

reading is normal. If the pressure continues to increase after opening the

leak test valve, the upstream valve is leaking and should be replaced.

Part Number 550-141-816/030410

Page 11

CSD-1 Control System – Propane gas

VII Operating instructions

A. This boiler is equipped with a pilot which must be lighted by hand. When lighting the

pilot, follow these instructions exactly. The gas supply to this pilot is controlled by Pilot

switch box. This boiler is also equipped with an ignition device which automatically lights a

second pilot. The gas supply to this pilot is controlled by the Gas control. Do not try to

light this pilot by hand.

B. BEFORE OPERATING THE MANUAL PILOT, smell all around the appliance area for gas.

Be sure to smell next to the floor because some gas is heavier than air and will settle on the

floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Do not use this appliance if any part has been under water. Immediately call a qualified

service technician to inspect the appliance and to replace any part of the control system

and any gas control, which has been under water.

Starting

boiler

This document is intended only as a supplement to the LGB Gas-Fired Boiler Manual. Follow

all instructions in the Manual, including those regarding start-up (found in Section VIII,

“Placing boiler in operation”).

1. STOP! Read the safety information above.

2. Set the Operating control to lowest setting.

3. Turn off all electrical power to the appliance.

4. Remove the Base access shield.

5. Close the Pilot shut-off valve connected to Manual main shut-off valve.

Close Manual main shut-off valve.

6. Wait five (5) minutes to clear out any gas. Then smell for gas, including

near the floor. If you smell gas, STOP! Follow “B” in the safety information

above. If you don’t smell gas, go to the next step.

7. Open the Pilot shut-off valve.

8. Press and hold the reset lever on the Pilot switch box. Manually light the

pilot while holding the lever down. Air in the gas supply line will have to

purge through the line before sufficient gas will reach the pilot.

9. After purging all air, hold the Pilot switch box lever for about 1 minute to

heat the thermocouple.

10. Release the Pilot switch box lever. The pilot should remain lit.

11. Open the Manual main shut-off valve and follow the sequence below.

12. This appliance is also equipped with an ignition device which automatically

lights the second pilot. Do not try to light this pilot by hand.

13. Turn on all electric power to the appliance.

14. Set Operating control to desired setting.

15. If the appliance will not operate, turn off gas to the appliance by closing

the Manual main shut-off valve and Pilot shut-off valve. Call your service

technician or gas supplier.

16. Replace Base access shield and Front panel.

Part Number 550-141-816/0304 11

Page 12

VIII

Parts

list

Figure 6

LGB-6 to LGB-20 Series 2 – Control Supplement

Ref. No. Description Size Vendor/Part Number Weil-McLain Part Number

1 Main flame sensor Honeywell 392956 511-724-274

2

3 Manual main shut-off valve

4 Secondary gas valve

6 Pilot burner, standing-repair kit propane

7 Pilot burner, electronic-repair kit propane

8

9 Pilot proving module

10 Main flame proving module

11 Impulse relay

12 Push-button switch

13 Lens cover

14 Light bulb

15

16 Pilot shut-off valve Kinco-Balon P2R 511-246-340

17 Pilot switch box Johnson Controls L62GB-3C 511-330-229

18 Thermocouple 48" Honeywell Q309A 511-724-245

19 Firing valve

20 Leak test valve Kinco-Balon P2R 511-246-340

21 Pilot tubing, alum. ¼ O.D. x .032-20" long

22 Pilot tubing, alum. ¼ O.D. x .032-60" long

*Contact local Weil-McLain distributor/agent for current replacement part and order number.

Main burner with pilot bracket Weil-McLain 512-200-055

Main flame sensor bracket Weil-McLain 423-300-420

1" Kinco-Balon 500 511-246-325

1 ¼" Kinco-Balon 600 511-246-330

1" Honeywell V8943A1003 511-044-191

1 ¼" Honeywell V8943A1111 511-044-192

Main gas valve5

Main burner with pilot bracket Weil-McLain 512-200-055

Pilot burner bracket Weil-McLain 460-005-624

1" Honeywell V8944L1033 511-044-346

1 ¼" Honeywell V8944L1041 511-044-218

Weil-McLain 383-300-410

Weil-McLain 383-300-411

United Technologies 1003-615 511-330-086

United Technologies 1003-60 511-330-085

Potter-Brumfield S89R-11ABD1-24 510-350-226

Honeywell AML21CBA2AA

Eaton Controls ZZ1K11810K

Honeywell AML51-C10R

Eaton Controls ZZ0PM0ZA

TI-¾ #85 (Available at Local Supply House)

Honeywell V8046C1014

Johnson Controls H91ABG

1" Watts FBV3-06 511-246-290

1 ¼" Watts FBV3-07 511-246-292

1 ½" Watts FBV3-08 511-246-294

Available at Local Supply House

511-624-580

511-624-581

511-044-039Pilot solenoid

Part Number 550-141-816/030412

Loading...

Loading...