Page 1

Read and Retain for Future Reference

Industrial Wireless MESH I/O

WI-I/O 9-U2 MESH I/O

Manual

Version 1.2.2

September 2013

Page 2

Weidmuller USA Corporate Headquarters

ATTENTION!

Incorrect termination of supply wires may cause internal damage and will void warranty. To

ensure your WI-I/O 9-U2 module enjoys a long life, double check ALL your connections

with the user manual before turning the power on.

CAUTION:

To comply with FCC RF Exposure requirements in section 1.1310 of the FCC Rules,

antennas used with this device must be installed to provide a separation distance of at

least 20 cm from all persons to satisfy RF exposure compliance.

Avoid:

Operating the transmitter when someone is within 20 cm of the antenna

Operating the transmitter unless all RF connectors are secure and any open

connectors are properly terminated

Operating the equipment near electrical blasting caps or in an explosive atmosphere

All equipment must be properly grounded for safe operations.

All equipment should be serviced only by a qualified technician

SAFETY Notice:

Exposure to RF energy is an important safety consideration. The FCC has adopted a

safety standard for human exposure to radio frequency electromagnetic energy emitted by

FCC regulated equipment as a result of its actions in Docket 93-62 and OET Bulletin 65

Edition 97-01.

821 Southlake Boulevard

Richmond, Virginia 23236

804.794.2877 Main

800.849.9343 Customer & Technical Support

804.794.0252 Fax

info@weidmuller.com

Copyright Weidmüller Interface GmbH & Co. KG | Klingenbergstraße 16 | D-32758 Detmold

Thank you for your selection of the WI-I/O 9-U2 I/O Module. We trust it will give you many

years of valuable service.

1

Page 3

Industry Canada:

This Class [A] digital apparatus complies with Canadian ICES-003.

This device complies with Industry Canada license-exempt RSS standard(s).

Operation is Subject to the following two conditions:

1. This device may not cause interference,

2. This device must accept any interference, including interference that may cause

undesired operation of the device.

This radio transmitter “WI-I/O 9-U2” has been approved by Industry Canada to operate

with the antenna types listed below with the maximum permissible gain and required

antenna impedance for each antenna type indicated. Antenna types not included in this

list, having a gain greater than the maximum gain indicated for that type, are strictly

prohibited for use with this device.

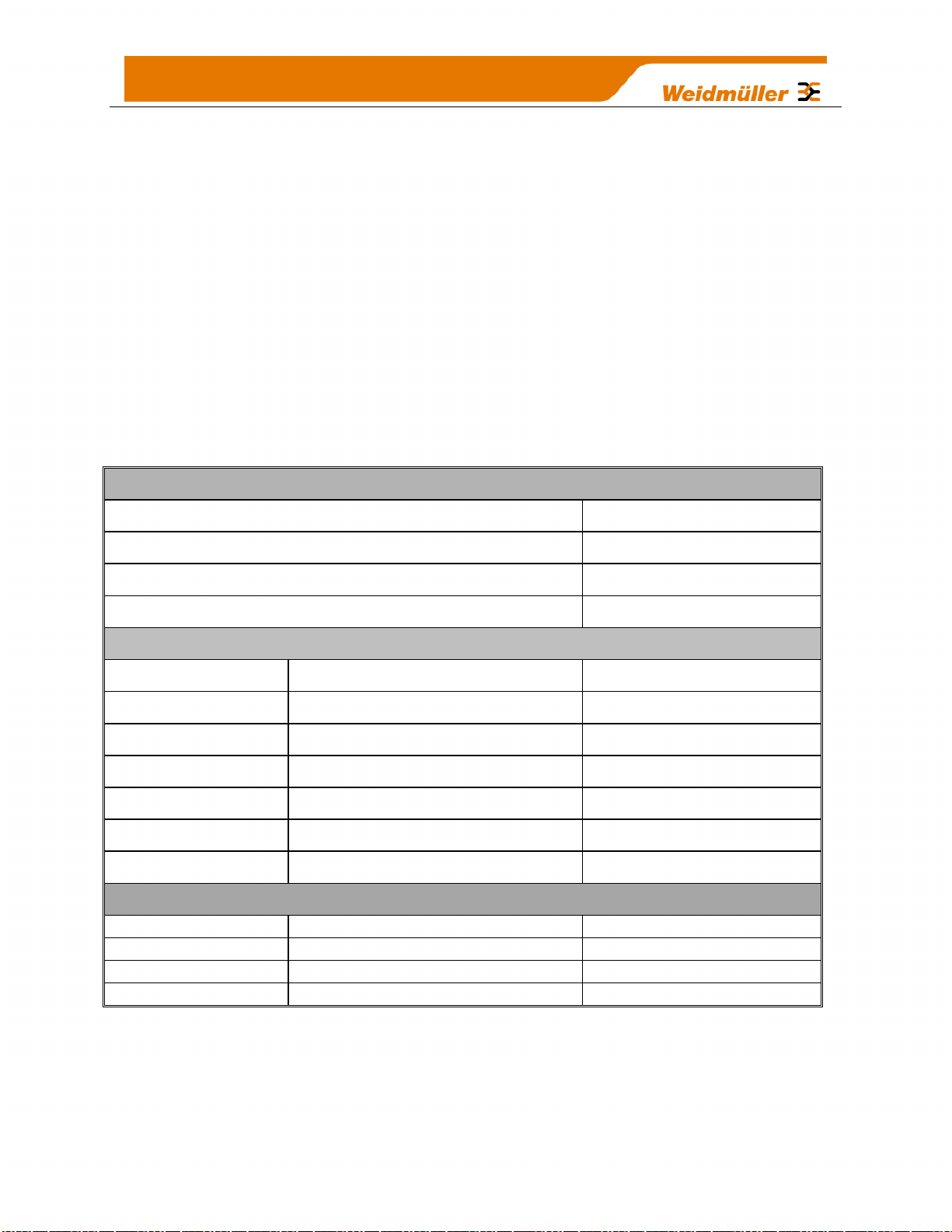

Manufacturer

Model Number

Coax Kit

Net

WEIDMULLER

6720005236

6720005253

5dB Gain

WEIDMULLER

6720005236

6720005255

2dB Gain

WEIDMULLER

6720005235

6720005253

2dB Gain

WEIDMULLER

6720005235

6720005255

-1dB Loss

WEIDMULLER

6720005221

6720005255

4dB Gain

WEIDMULLER

6720005089

Includes 5m Cellfoil

Unity Gain

WEIDMULLER

6720005086

Includes 1m Cellfoil

-2dB Loss

GNU Free Documentation Licence:

Copyright (C) 2009 Weidmuller.

Weidmuller is using a part of Free Software code under the GNU General Public License in

operating the “WI-I/O 9-U2” product. This General Public License applies to most of the

Free Software Foundation’s code and to any other program whose authors commit by

using it. The Free Software is copyrighted by Free Software Foundation, Inc. and the

program is licensed “As is” without warranty of any kind. Users are free to contact

Weidmuller at the following Email Address: support@weidmuller.com for instructions on

how to obtain the source code used for the WI-I/O 9-U2.

A copy of the license is included in “GNU Free Document Licence” at the end of the

manual.

2

Page 4

FCC Notice:

This WI-I/O 9-U2 module uses the “E2_900M Wireless Data Modem” radio and complies

with Part 15.247 of the FCC Rules.

Operation is subject to the following two conditions:

This device may not cause harmful interference

This device must accept any interference received, including interference that may

cause undesired operation.

WI-I/O 9-U2 Radio Telemetry Unit must be installed in a suitable enclosure that provides

mechanical, shock and fire hazard protection.

This device must be operated as supplied by WEIDMULLER. Any changes or modifications

made to the device without the written consent of WEIDMULLER may void the user’s

authority to operate the device.

This device must be installed by professional installers in compliance with 47 CFR Part 15

Subpart C Section 15.203 and 15.205, who will be responsible for maintaining EIRP no

greater than 36 dBm in accordance with 47 CFR Part 15 Subpart C Section 15.247 (b)(2)(4).

In accordance with 47 CFR Part 15 Subpart C Section 15.203 only the following

antenna/coax cable kits combinations can be used.

Manufacturer

Model Number

Coax Kit

Net

WEIDMULLER

6720005236

6720005253

5dB Gain

WEIDMULLER

6720005236

6720005255

2dB Gain

WEIDMULLER

6720005235

6720005253

2dB Gain

WEIDMULLER

6720005235

6720005255

-1dB Loss

WEIDMULLER

6720005221

6720005255

4dB Gain

WEIDMULLER

6720005089

Includes 5m Cellfoil

Unity Gain

WEIDMULLER

6720005086

Includes 1m Cellfoil

-2dB Loss

Part 15 –This device has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part15 of the FCC rules (Code of Federal Regulations

47CFR Part 15). Operation is subject to the condition that this device does not cause

harmful interference.

Notice – Any changes or modifications not expressly approved by WEIDMULLER

could void the user’s authority to operate this equipment.

This Device should only be connected to PCs that are covered by either FCC DoC or are

FCC certified.

3

Page 5

Hazardous Location Notices:

This device complies with

94/9/EC – ATEX Directive

Ex nA IIC T4A, II 3 G, –40 °C ≤ Ta ≤ +60 °C

WARNING: EXPLOSION HAZARD.

Do not disconnect equipment unless power has been switched off or the area

is known to be non-hazardous.

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D;

Tamb -40˚C to +60˚C or non-hazardous locations only.

This equipment shall be installed in accordance with the requirements specified

in Article 820 of the National Electrical Code (NEC), ANSI/NFPA 70-

2011. Section 820-40 of the NEC provides guidelines for proper grounding,

and in particular specifies that the antenna ground (shield) shall be connected

to the grounding system of the building, as close to the point of cable entry as

practical.

This equipment shall be installed in a Restricted Access Location (dedicated

equipment room, service closet, or the like).

The earthing /grounding terminal of the equipment shall be connected to earth

ground in the equipment installation.

“The external power supply installed with this equipment shall be a Listed,

Class 2 power supply, with a rated output between 15 Vdc and 30 Vdc, and

min. 2500mA.”

4

Page 6

IMPORTANT Notice:

WEIDMULLER products are designed to be used in industrial environments, by experienced industrial

engineering personnel with adequate knowledge of safety design considerations.

WEIDMULLER radio products are used on unprotected license-free radio bands with radio noise and

interference. The products are designed to operate in the presence of noise and interference, however in an

extreme case, radio noise and interference could cause product operation delays or operation failure. Like all

industrial electronic products, WEIDMULLER products can fail in a variety of modes due to misuse, age, or

malfunction. We recommend that users and designers design systems using design techniques intended to

prevent personal injury or damage during product operation, and provide failure tolerant systems to prevent

personal injury or damage in the event of product failure. Designers must warn users of the equipment or

systems if adequate protection against failure has not been included in the system design. Designers must

include this Important Notice in operating procedures and system manuals.

These products should not be used in non-industrial applications, or life-support systems, without consulting

WEIDMULLER first.

A radio license is not required in some countries, provided the module is installed using the aerial and

equipment configuration described in the WI-I/O 9-U2 Installation Guide. Check with your local

distributor for further information on regulations.

Operation is authorized by the radio frequency regulatory authority in your country on a non-protection

basis. Although all care is taken in the design of these units, there is no responsibility taken for sources

of external interference. Systems should be designed to be tolerant of these operational delays.

To avoid the risk of electrocution, the aerial, aerial cable, serial cables and all terminals of the WI-I/O

9-U2 module should be electrically protected. To provide maximum surge and lightning protection, the

module should be connected to a suitable earth and the aerial, aerial cable, serial cables and the

module should be installed as recommended in the Installation Guide

To avoid accidents during maintenance or adjustment of remotely controlled equipment, all equipment

should be first disconnected from the WI-I/O 9-U2 module during these adjustments. Equipment

should carry clear markings to indicate remote or automatic operation. E.g. "This equipment is

remotely controlled and may start without warning. Isolate at the switchboard before attempting

adjustments."

The WI-I/O 9-U2 module is not suitable for use in explosive environments without additional protection.

The WI-I/O 9-U2 operates unlicensed Radio frequencies and proprietary protocols to communicate

over the radio. Nevertheless, if your system is not adequately secured, third parties may be able to

gain access to your data or gain control of your equipment via the radio link. Before deploying a

system make sure you have considered the security aspects of your installation carefully.

Release Notice:

Feb 2013 release of the WI-I/O 9-U2 Wireless I/O User Manual version 1.2.2 which applies to the

version 1.2.2 firmware.

5

Page 7

TABLE OF CONTENTS

CHAPTER 1 - INTRODUCTION ..................................................................................... 12

1.1 Overview ................................................................................................................................................ 12

1.2 Module Structure ................................................................................................................................... 14

1.3 Getting Started ...................................................................................................................................... 15

CHAPTER 2 - INSTALLATION ...................................................................................... 16

2.1 General ................................................................................................................................................... 16

2.2 Power/Supply ......................................................................................................................................... 16

2.2.1 Requirements ................................................................................................................................... 16

2.2.2 Expansion I/O Supply ...................................................................................................................... 18

2.2.3 Internal I/O ....................................................................................................................................... 19

2.2.4 Grounding ........................................................................................................................................ 19

2.3 Radio ...................................................................................................................................................... 20

2.3.1 900 MHz Spread Spectrum radio .................................................................................................... 20

2.3.2 869 MHz Fixed Frequency radio (EU Country Code) ...................................................................... 21

2.3.3 Meshing capability ........................................................................................................................... 21

2.4 Antenna .................................................................................................................................................. 21

Dipole and Collinear antennas. ............................................................................................................ 23

Yagi antennas. ...................................................................................................................................... 25

2.5 Connections ........................................................................................................................................... 26

2.5.1 Bottom panel connections ............................................................................................................... 26

Ethernet port ......................................................................................................................................... 26

USB Device Port for configuration ........................................................................................................ 26

RS-232 port .......................................................................................................................................... 26

RS-485 port with Modbus Support. ...................................................................................................... 27

2.5.2 Side Access Configuration Panel .................................................................................................... 27

“Factory Boot” switch ............................................................................................................................ 28

USB Host port ....................................................................................................................................... 28

Dipswitches ........................................................................................................................................... 28

Front panel connections ....................................................................................................................... 29

2.5.3 Digital / Pulsed Inputs ...................................................................................................................... 30

2.5.4 Digital Outputs (Pulsed Outputs) ..................................................................................................... 31

Digital Output Fail Safe Status ............................................................................................................. 31

2.5.5 Analog Inputs ................................................................................................................................... 33

Differential Current Inputs (AIN 1 & 2 only) .......................................................................................... 33

.............................................................................................................................................................. 33

Single Ended Current Inputs (AIN 3 & 4 only) ...................................................................................... 34

Single Ended Voltage Inputs ................................................................................................................ 35

2.5.6 Analog Outputs ................................................................................................................................ 36

CHAPTER 3 - OPERATION ........................................................................................... 37

3.1 Overview ................................................................................................................................................ 37

3.2 Indications ............................................................................................................................................. 37

6

Page 8

3.2.1 Front Panel Indications .................................................................................................................... 37

3.2.2 Boot Sequence “PWR” LED Indications .......................................................................................... 38

3.2.3 Input / Output Indications ................................................................................................................. 38

Digital Inputs ......................................................................................................................................... 38

Digital Outputs ...................................................................................................................................... 38

Analog Inputs ........................................................................................................................................ 39

Analog Outputs ..................................................................................................................................... 39

3.2.4 Ethernet Indications ......................................................................................................................... 39

3.3 System Design ....................................................................................................................................... 40

3.3.1 Radio Channel Capacity .................................................................................................................. 40

3.3.2 Dual Band Operation ....................................................................................................................... 40

3.3.3 Radio Path Reliability ....................................................................................................................... 40

3.3.4 Design for Failures ........................................................................................................................... 41

3.3.5 Indicating a Communications Problem ............................................................................................ 42

Fail-to-transmit alarm ............................................................................................................................ 42

Fail-to-receive alarm ............................................................................................................................. 42

3.3.6 WIBNet – Communication Registers. .............................................................................................. 42

3.3.7 Testing and Commissioning............................................................................................................. 43

3.4 WIBMesh ................................................................................................................................................ 43

CHAPTER 4 - CONFIGURATION .................................................................................. 45

4.1 First time Configuration ....................................................................................................................... 45

4.1.1 Default IP Address ........................................................................................................................... 45

4.1.2 Changing PC Network Settings ....................................................................................................... 45

4.2 Over the Air Configuration ................................................................................................................... 48

4.3 Module Configuration ........................................................................................................................... 50

4.3.1 Software & Connections .................................................................................................................. 50

Re-Open Previous Project .................................................................................................................... 51

Open Existing Project ........................................................................................................................... 52

Create New Project .............................................................................................................................. 52

4.3.2 Configuration Screens ..................................................................................................................... 52

Project Tree .......................................................................................................................................... 52

Configuration Display ........................................................................................................................... 52

4.3.3 Project Screen ................................................................................................................................. 53

Project Information................................................................................................................................ 53

Password Protection ............................................................................................................................. 53

System Configuration ........................................................................................................................... 53

Radio Communication Security ............................................................................................................ 53

4.3.4 Adding Units ..................................................................................................................................... 53

Create Units .......................................................................................................................................... 53

Default Radio Network Configuration ................................................................................................... 54

Unit Details ........................................................................................................................................... 54

IP Address List ...................................................................................................................................... 55

4.3.5 Mappings ......................................................................................................................................... 55

Write Mapping ....................................................................................................................................... 56

Gather Scatter Mapping ....................................................................................................................... 56

Read Mappings..................................................................................................................................... 56

Mapping Configuration Parameters ...................................................................................................... 57

4.3.6 Startup/Force Configuration ............................................................................................................. 59

Example configuration .......................................................................................................................... 59

4.3.7 Address Map .................................................................................................................................... 60

4.3.8 Standard WI-I/O 9-U2 I/O (Basic I/O) .............................................................................................. 61

7

Page 9

4.3.9 I/O Configuration ............................................................................................................................. 61

Digital Inputs ......................................................................................................................................... 62

Digital Outputs ...................................................................................................................................... 62

Pulsed Outputs ..................................................................................................................................... 62

Analog Inputs ........................................................................................................................................ 63

Analog Outputs ..................................................................................................................................... 64

4.3.10 Serial Expansion I/O ...................................................................................................................... 64

Adding modules .................................................................................................................................... 64

WI-I/O-EX-1-S Expansion I/O Memory Map ......................................................................................... 65

Adding Expansion I/O to Configuration Software ................................................................................. 66

4.3.11 Failsafe Blocks ............................................................................................................................... 66

“Invalid” register state ........................................................................................................................... 67

4.3.12 Sensitivity Blocks ........................................................................................................................... 68

4.3.13 Serial Configuration ....................................................................................................................... 69

Modbus RTU Master ............................................................................................................................ 69

Serial - Expansion I/O ........................................................................................................................... 70

Serial - Modbus RTU Slave .................................................................................................................. 71

4.3.14 Modbus Configuration .................................................................................................................... 71

Modbus TCP Server & RTU Slave ....................................................................................................... 71

Modbus TCP Client & RTU Master....................................................................................................... 72

Mapping parameters ............................................................................................................................. 72

Modbus TCP Mapping Examples ......................................................................................................... 74

Modbus RTU Master ............................................................................................................................ 74

Modbus RTU Master Example ............................................................................................................. 75

RS232/RS485 Modbus Parameters ..................................................................................................... 76

4.4 Web based Configuration ..................................................................................................................... 76

4.4.1 Mesh ................................................................................................................................................ 76

4.4.2 Neighbour RSSI configuration ......................................................................................................... 78

4.4.3 IP Routing ........................................................................................................................................ 79

4.4.4 Radio Settings .................................................................................................................................. 80

4.4.5 Mesh Fixed Routes .......................................................................................................................... 81

Example #1 ........................................................................................................................................... 82

Example #2 ........................................................................................................................................... 83

4.4.6 Module Information Web Page ........................................................................................................ 85

4.4.7 System Tools Web page .................................................................................................................. 86

System Log File .................................................................................................................................... 86

Reading Configuration File ................................................................................................................... 86

Writing Configuration File ..................................................................................................................... 86

Firmware Upgrade – Web Page (Patch File Upgrade)......................................................................... 86

Firmware Upgrade – USB (Full Firmware Upgrade) ............................................................................ 87

Product Reconfiguration ....................................................................................................................... 88

4.4.8 Feature Licence Keys Web Page .................................................................................................... 90

Demonstration Mode ............................................................................................................................ 90

Feature Licence Keys ........................................................................................................................... 90

CHAPTER 5 - DIAGNOSTICS ....................................................................................... 91

5.1 IO Diagnostics ....................................................................................................................................... 91

5.1.1 Watchdog Error Log ......................................................................................................................... 92

5.1.2 Module Information Registers .......................................................................................................... 92

5.1.3 Expansion I/O Error Registers ......................................................................................................... 92

5.2 Connectivity (WibMesh) ....................................................................................................................... 94

LQI (Link Quality Indication) ................................................................................................................. 95

5.3 Neighbour List (WibMesh) .................................................................................................................... 96

8

Page 10

5.4 Neighbour RSSI (WibMesh) .................................................................................................................. 96

5.5 Network Diagnostics (WibMesh) ......................................................................................................... 98

Ping ....................................................................................................................................................... 98

Trace Route .......................................................................................................................................... 99

5.6 Network Statistics (WibMesh) ............................................................................................................ 100

5.7 Monitor Comms ................................................................................................................................... 102

5.7.1 WibMesh – Monitor Radio Comms ................................................................................................ 102

5.7.2 WibMesh - Monitor IP Comms ....................................................................................................... 103

5.7.3 WibNet – Monitor Comms .............................................................................................................. 104

5.8 Statistics (WibMesh & WibNet) .......................................................................................................... 106

CHAPTER 6 - SPECIFICATIONS ................................................................................ 107

6.1 Specifications ...................................................................................................................................... 107

APPENDIX A: DBM TO MW CONVERSION TABLE ................................................. 110

APPENDIX B: I/O STORE REGISTERS ..................................................................... 111

APPENDIX C: EXPANSION I/O REGISTERS ............................................................ 114

APPENDIX D: MODBUS ERROR CODES ................................................................. 116

APPENDIX E: PHYSICAL I/O REGISTERS ............................................................... 118

APPENDIX F: GNU FREE DOCUMENT LICENCE .................................................... 122

9

Page 11

TABLE OF FIGURES

Figure 1 – Module Structure 14

Figure 2 – Power Connectors ......................... 16

Figure 3 – Supply Connections ....................... 16

Figure 4 – Expansion I/O power & RS485 ...... 18

Figure 5 - Earthing .......................................... 20

Figure 6 - Wrapping Coax Connections .......... 23

Figure 7 – Collinear Antenna mounting .......... 24

Figure 8 - Yagi Antenna Mounting .................. 25

Figure 9 – Bottom Panel Connections ............ 26

Figure 10 – RS485 Connections ..................... 27

Figure 11 – Side Access Panel ....................... 27

Figure 12 – Front Panel Connections ............. 29

Figure 13 – Digital / Pulsed Input Wiring ......... 30

Figure 14 – Digital Output Wiring .................... 31

Figure 15 – Digital Output Failsafe Times ....... 32

Figure 16 - Fail-Safe State .............................. 32

Figure 17– Differential Current Inputs ............. 33

Figure 18 – Single Ended Current Inputs ........ 33

Figure 19 – Single Ended Current Inputs ........ 34

Figure 20 – Voltage Inputs .............................. 35

Figure 21 – Analog Outputs ............................ 36

Figure 22 - Boot Sequence ............................. 38

Figure 23 – Network Settings .......................... 46

Figure 24 - Ping ............................................... 46

Figure 25 – Main Welcome Screen ................. 47

Figure 26 - IP Gateway Mode ......................... 48

Figure 27 - Default Gateway ........................... 48

Figure 28 -IP Address Range ......................... 48

Figure 29 - Routing Rule ................................. 49

Figure 30 -Over the air Configuration ............. 49

Figure 31 - Installation ..................................... 51

Figure 32 – Configuration Software ................ 51

Figure 33 - Configuration Screen .................... 52

Figure 34 - Project Information........................ 53

Figure 35 - Create Units .................................. 53

Figure 36 - Unit Details ................................... 54

Figure 37 - ID Address List ............................. 55

Figure 38 - Mappings ...................................... 55

Figure 39 - Gather/Scatter Mapping ............... 57

Figure 40 - Startup/Force . Error! Bookmark not

defined.

Figure 41 - Startup/Force Configuration ......... 60

Figure 42 - I/O configuration ........................... 61

Figure 43 - Digital Inputs ................................. 62

Figure 44 - Digital Output ................................ 62

Figure 45 - Pulsed Outputs ............................. 62

Figure 46 - Analog Inputs Table ..................... 63

Figure 47- Analog Input .................................. 63

Figure 48 - Analog Output .............................. 64

Figure 49 - Expansion I/O ............................... 66

Figure 50 - Failsafe Block Analog ................... 66

Figure 51 - Failsafe Block Digital .................... 66

Figure 52- Invalid Register State .................... 67

Figure 53 - Sensitivity Block ........................... 68

Figure 54 - Modbus TCP/RTU ........................ 69

Figure 55 - Expansion I/O ............................... 70

Figure 56 - Modbus Configuration .................. 71

Figure 57 - Modbus TCP Client Mapping ....... 73

Figure 58 - Modbus TCP Mapping table ......... 74

Figure 59 - Modbus RTU Example ................. 75

Figure 60 - Operating Mode Error................... 75

Figure 61 - Modbus Parameters ..................... 76

Figure 62 - Mesh Configuration ...................... 76

Figure 63 - Neighbour RSSI ........................... 78

Figure 64 - IP Routing ..................................... 79

Figure 65 – Radio Configuration Screen ........ 80

Figure 66 - Mesh Fixed Route#1 .................... 82

Figure 67 - Mesh Fixed Route - Gateway ....... 82

Figure 68 - Mesh Fixed Route - Rep Site #2 .. 83

Figure 69 - Trace Route .................................. 83

Figure 70 - Mesh Fixed Route#2 .................... 83

Figure 71 – Mesh Fixed Route#2 Routing Rules

........................................................... 84

10

Page 12

Figure 72 - Module Information ....................... 85

Figure 73 – System Tools ............................... 86

Figure 74 - Format USB .................................. 87

Figure 75 - Quick Format ................................ 87

Figure 76 - Firmware Files .............................. 87

Figure 77- firmware version ............................ 88

Figure 78 - Side access panel......................... 88

Figure 79 - Firmware Upgrade LED Indications

........................................................... 88

Figure 80 - Product Reconfiguration ............... 89

Figure 81 - Demo Mode Active ....................... 90

Figure 82 - Demo Mode Not Active ................. 90

Figure 83 - Feature License Keys ................... 90

Figure 84- I/O Diagnostics .............................. 91

Figure 85 - Connectivity .................................. 94

Figure 86 – Neighbour List .............................. 96

Figure 87 - Neighbour RSSI ............................ 96

Figure 88 - Multipath Fading ........................... 97

Figure 89 – Network Diagnostics .................... 98

Figure 90 – Trace Route ................................. 99

Figure 91– Network Statistics Period ............ 100

Figure 92 – Network Statistics ...................... 100

Figure 93 – Hourly Statistics ......................... 101

Figure 94 –Daily/Weekly Statistics ................ 101

Figure 95 - Monitor Comms .......................... 102

Figure 96 - IP Communication monitoring .... 103

Figure 97 - WibNet Monitor Comms ............. 104

Figure 98 - – Module Statistics ..................... 106

11

Page 13

Chapter 1 - Introduction

1.1 Overview

The WI-I/O 9-U2 range of I/O modules has been designed to provide standard “off-the-

shelf” telemetry functions, for an economic price. Telemetry is the transmission of data

or signals over a long distance via radio or twisted-pair wire cable.

Although the WI-I/O 9-U2 Series is intended to be simple in its application, it provides

many sophisticated features, which will be explained in the following chapters.

This manual should be read carefully to ensure that the modules are configured and

installed to give reliable performance.

The WI-I/O 9-U2 telemetry module extends the functionality provided by the earlier WI-

I/O 9-X WI-Series modules. It provides on-board I/O via a front mounting 20-way

connector and has provision for extra expansion modules (WEIDMULLER WI-I/O-EX-1S or MODBUS devices) to be connected using a standard RS485 serial connection.

The module can monitor the following types of signals

Digital (on/off) signals - Contact Closure or Switch

Analog (continuously variable) signals – Tank level, Motor speed, temperature,

etc

Pulsed signal - Frequency signal – Metering, accumulated total, rainfall, etc

Internal Signals – Supply voltage, Supply failure, battery status, etc.

The modules monitor the input signals and transmit the values by radio or Ethernet

cabling to another module or modules that have been configured to receive this

information.

The WI-I/O 9-U2 radio has been designed to meet the requirements of unlicensed

operation for remote monitoring and control of equipment. A radio licence is not required

for the WI-I/O 9-U2 in many countries.

Input signals that are connected to the module are transmitted and appear as output

signals on other modules. A transmission occurs whenever a "Change-of-State”, “COS”

occurs on an input signal. A "Change-of-State" of a digital or an internal digital input is a

change from "off" to "on" or vice-versa.

For an analog input, internal analog input or pulse input rate a "Change-of-State" is a

configurable value called “Sensitivity”. The default Sensitivity is 1000 counts (3%) but

can be changed in the Sensitivity Block page.

In addition to change-of-state messages, update messages are automatically

transmitted on a configurable time basis. This update ensures the integrity of the

system.

Pulse inputs counts are accumulated and the total count is transmitted regularly

according to the configured update time.

12

Page 14

The WI-I/O 9-U2 modules transmit the input/output data using radio or Ethernet. The

data frame includes the "address" of the transmitting module and the receiving module,

so that each transmitted message is acted on only by the correct receiving unit. Each

message includes error checking to ensure that no corruption of the data frame has

occurred due to noise or interference. The module with the correct receiving "address"

will acknowledge the message with a return transmission (acknowledgement). If the

original module does not receive a correct acknowledgement, it will retry up to 5 times

before setting the communications fail status of that message. For critical messages,

this status can be reflected on an output on the module for alert purposes. The module

will continue to try to establish communications and retry, each time an update or

change-of-state occurs.

A system can be a complex network or a simple pair of modules. An easy-to-use

configuration procedure allows the user to specify any output destination for each input.

The WI-I/O 9-U2 comes from the factory with WEIDMULLER WibMesh protocol as

standard. This protocol provides enhanced features, including IP addressing, allowing

thousands of modules to exist in a system, and allowing automatic routing of messages

through repeater stations.

The module can also be configured with the Legacy WibNet protocol which provides

operation with existing WEIDMULLER wireless I/O devices (WI-I/O 9-X series and 105

series 869MHz modules).

The module can easily be switched between the two versions by selecting the

appropriate protocol from an inbuilt web page.

Each WI-I/O 9-U2 radio can have up to 24 expansion I/O modules (WEIDMULLER WII/O-EX-1-S) connected by RS485 twisted pair cable. Any input signal at any module

may be configured to appear at any output on any module in the entire system.

Modules can be used as repeaters to re-transmit messages on to the destination

module. Repeaters can repeat messages on the radio channel or from the radio

channel to the serial channel (and serial to radio). The meshing protocol will

automatically select other stations to act as repeaters if required (up to ten hops). Using

Legacy protocol, up to five repeater addresses may be configured for each input-tooutput link.

The units are configured using Configuration software via Ethernet or USB or by

accessing the internal webpages using a web browser. The software configuration is

detailed in Chapter 4 - Configuration.

For web based configuration consult separate Web Page configuration Supplement.

13

Page 15

1.2 Module Structure

Figure 1 – Module Structure

The WI-I/O 9-U2 is made up of a number of basic sections, which all interface with a

central Input and output storage area (I/O Store).

The I/O Data Store provides storage for I/O data as well as providing services to other

processes in the system. The I/O Store provides eight different blocks of data - two

containing input and output bit data, two containing input and output word data, two

containing long-word type data and two containing floating-point data. The two files of

each type in turn support inputs and outputs on the local machine, and data storage for

the gateway function of the machine. These files are mapped into the address map as

described below. There are other registers within the database that can be used for

system management - these will be discussed later in this manual.

The Radio Interface allows the WI-I/O 9-U2 to communicate with other modules within

the system using a proprietary radio protocol called “WIBMesh”. Messages from other

WI-I/O 9-U2 modules are received by the radio port and used to update the input values

in the I/O Data Store. The WIBMesh protocol is an extremely efficient protocol for radio

communications. Radio messages can be sent using exception reporting - that is, when

there is a change of an input signal - or by read/write messages. Each message will be

comprised of multiple I/O values termed as a “block” of I/O). There are also update

messages, which are sent for integrity purposes.

Messages allow error checking, with the destination address sending a return

acknowledgment. Up to four attempts are made to transmit the message over each hop

of the radio path, if no acknowledgement is received. The WIBMesh protocol is

designed to provide reliable radio communications on an open license-free radio

channel.

The On-Board I/O in the form of - 8 discrete I/O, 2 single ended analog inputs, 2

differential analog inputs, and 2 current sourcing analog outputs. Each discrete I/O can

function as either a discrete input (voltage free contact input) or discrete output

14

Page 16

(transistor output). Each I/O point is linked to separate I/O registers within the I/O Data

Store.

There are also a number of Internal I/O that can be accessed from the I/O Data Store.

These inputs can be used to interpret the status of a single module or an entire system

Battery voltage – The battery terminal voltage displayed as an Analog value.

Loop Supply – Monitors the +24V DC Analog Loop Supply (ALS), used to power

analog current loops and displays this as an Analog value.

Expansion Module Volts – Monitors the Supply voltage of the connected

expansion modules, displayed as an Analog value.

RSSI – Will indicate the radio signal level for the selectable address, reported as

a dB level. Note: Refer to Communication diagnostics functions and Neighbour

RSSI

Comms Fail – A selectable register can indicate a Communications fail for a

particular message transmission.

The Expansion port, allows WI-I/O-EX-1-S expansion I/O modules to be added to the

module. Expansion I/O is dynamically added to the internal I/O of the WI-I/O 9-U2 by

adding an offset to the address.

1.3 Getting Started

Most applications for the WI-I/O 9-U2 require little configuration. The WI-I/O 9-U2 has

many sophisticated features, however if you do not require these features, this section

will allow you to configure the units quickly.

First, read Chapter 2 - “Installation”, which will go through the power supply,

antenna/coax connections and any I/O connections.

Power the WI-I/O 9-U2 and make an Ethernet connection to your PC (refer to Section

4.1 “First time Configuration”)

Configure the Ethernet Interface with an IP address that is compatible with your network

or computer via the Network Configuration webpage.

Save the configuration and the WI-I/O 9-U2 module is now ready to use. For an

instruction on configuration refer to Section 4.1 “Module Configuration

15

Page 17

Chapter 2 - Installation

2.1 General

All WI-I/O 9-U2 Series modules are housed in a plastic enclosure with DIN rail

mounting, providing options for up to 14 I/O points, and separate power &

communications connectors. The enclosure measures 170 x 150 x 33 mm including

connectors. The antenna protrudes from the top

2.2 Power/Supply

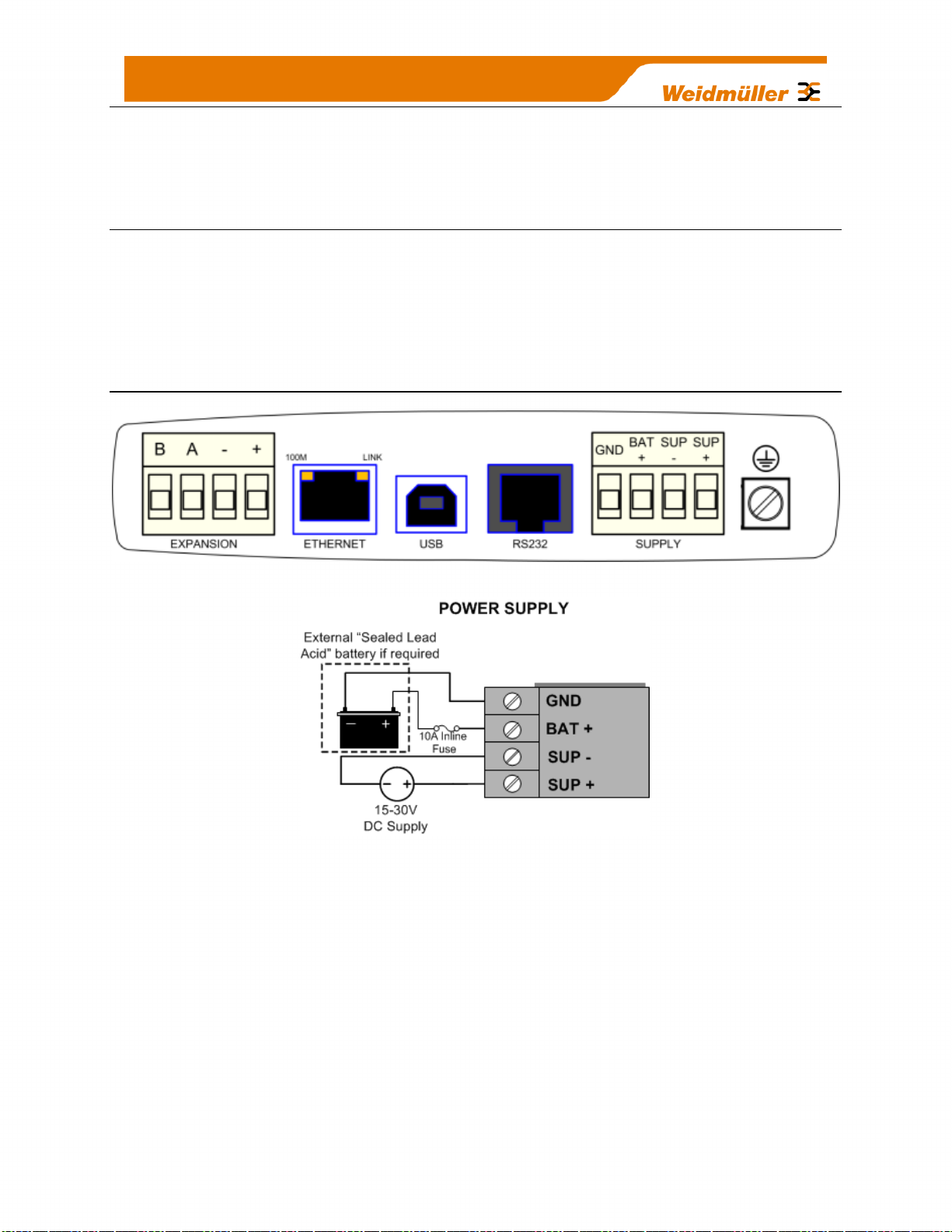

Figure 2 – Power Connectors

Figure 3 – Supply Connections

2.2.1 Requirements

The recommended power options available for the WI-I/O 9-U2 module are as follows.

1. 15 - 30 volt DC power source rated at 37Watts, connected to the “SUP+” &

“SUP-” terminals.

2. 12-15 volt DC power source rated at 24Watts, connected to the “BAT+” &

“GND” terminals

A primary power supply connected to the “SUP+” & “SUP-” terminals will automatically

charge a 13.8V Sealed Lead-Acid battery, if connected to the “BAT+” and “GND”

terminals at up to 1Amp at ambient room temperature (25°C). Battery charge current is

16

Page 18

Current

@ 13.8V

@ 24V

Quiescent Current of the module

200mA

115mA

Module Maximum I/O (4xAI, 2xAO, 8xDO)

500mA

290mA

Peak Transmit current

500mA

290mA

External Expansion I/O

1000mA

575mA

Battery charging

N/A

575mA

Expansion I/O

No Expansion I/O

No Battery fitted (no charging)

1270mA

695 mA

Battery fitted

1555mA

980 mA

Expansion I/O

No Expansion I/O

Current Limit

2200mA

1200 mA

reduced to 0.5A at 60°C. If using a battery it is recommended a 10A inline fuse be fitted

as prevention against battery short circuit.

If utilising option 1 above and the Primary Supply fails the Battery Supply will continue

to power the module without interruption to the operation.

The Supply and Battery charging terminals are hosted on the 4-way connector on the

bottom edge of the module labelled “Supply”

Both Supply and Battery connections have reverse polarity and over voltage protection.

The power supply should be CSA Certified Class 2 approved for normal operation.

If the device is being used in a Class I Div 2 explosive area, the supply must have Class

I Div 2 approval.

When powering the module the power source must be able to provide enough current to

power all module operations, i.e. Quiescent current, Peak Transmit current, Digital and

Analog I/O including loop supply and Battery charging (if applicable).

To calculate the Power Supply current limit, use the following criteria.

The following table shows typical +24V Supply current limits with different module

options enabled. Note: Transmit current is not added as it’s not a constant.

The following table shows typical +13.8V Supply current limits with different module

options enabled. . Note: Transmit current is not added as it’s not a constant.

E.g. If a module is powered by a 24V DC supply and there is no backup battery

connected and it has expansion I/O fitted the minimum current needed is 1.3 Amps

@24V (32Watts).

This is allowing for 290mA Peak Transmit current and up to 1 Amp for expansion I/O

17

Page 19

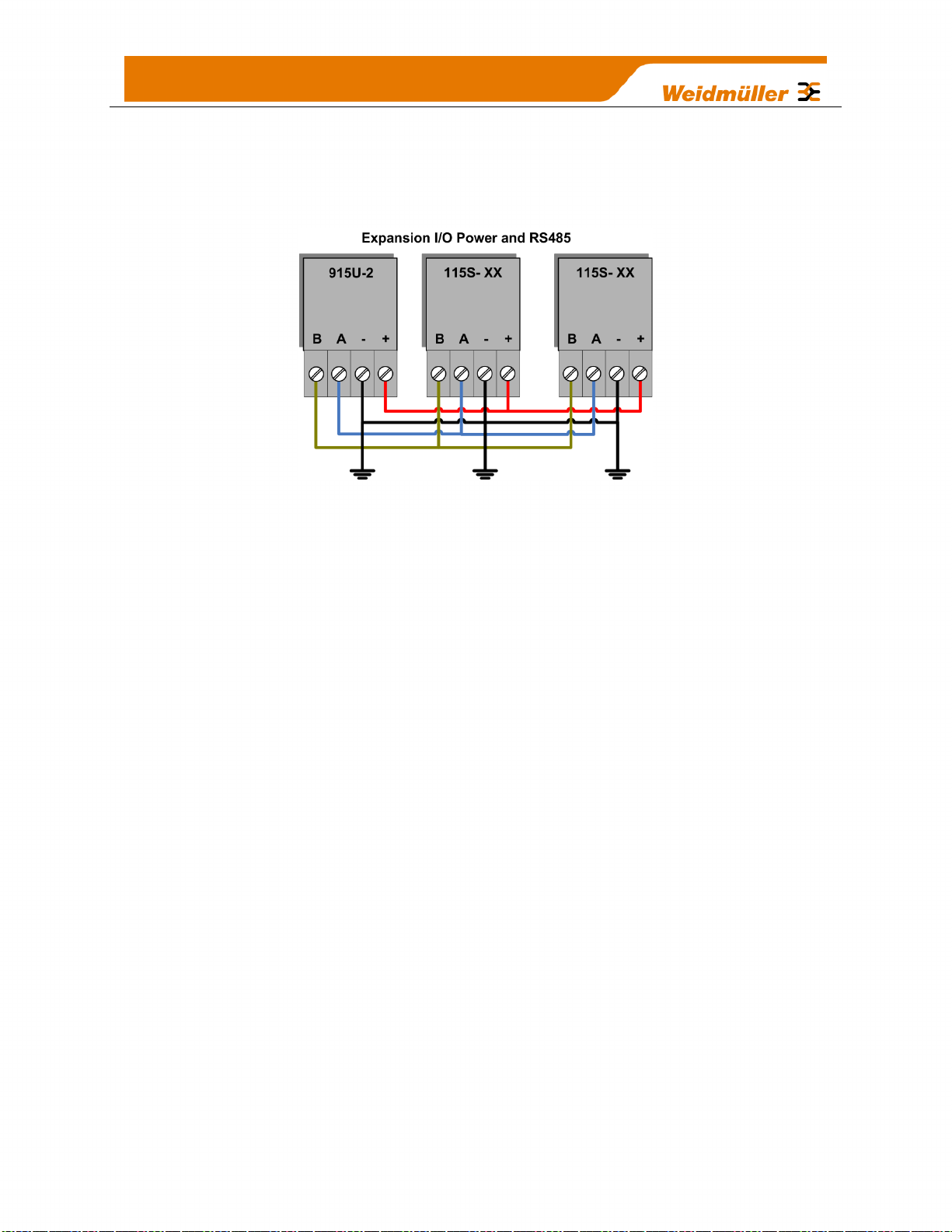

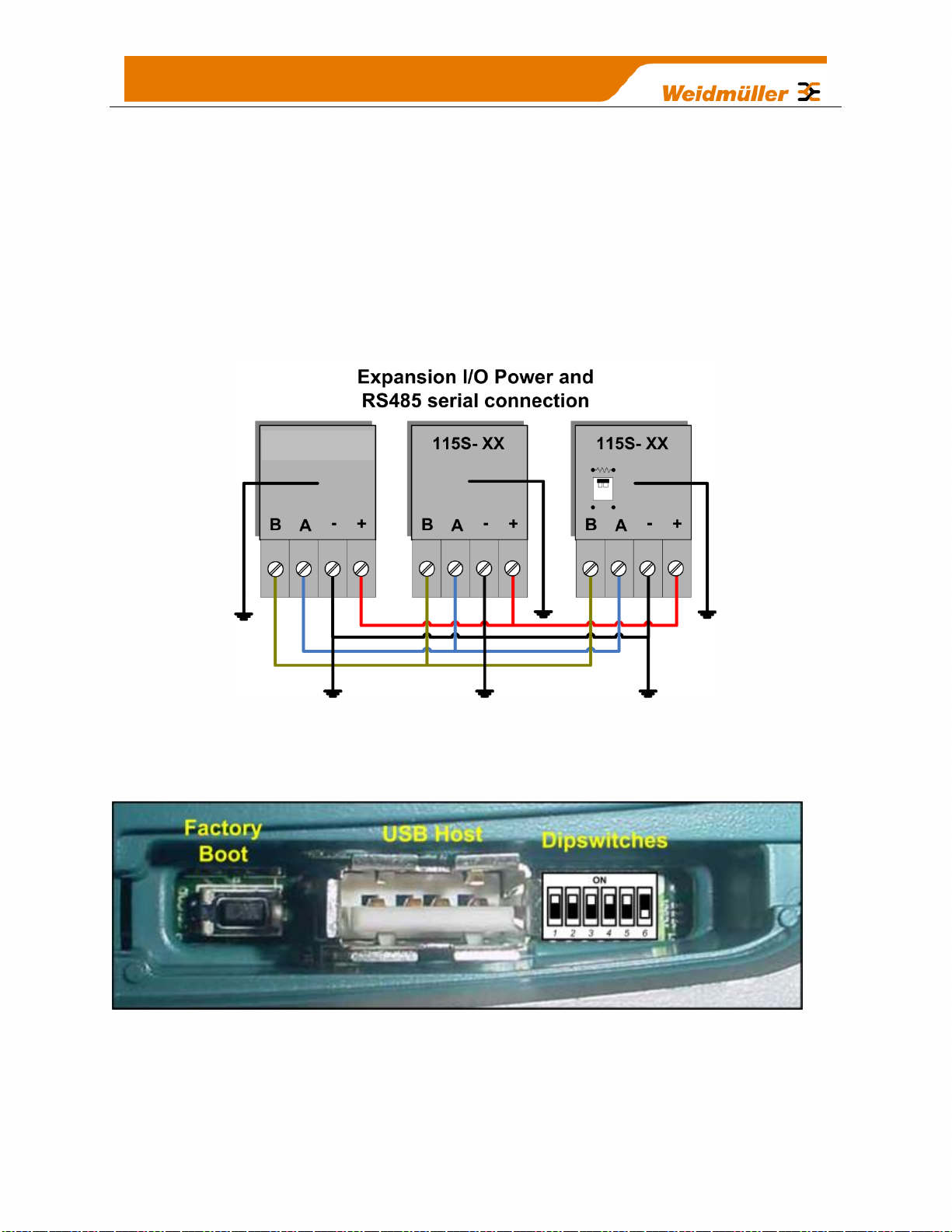

2.2.2 Expansion I/O Supply

To allow increased I/O Capacity, a second 4-way terminal labelled “Expansion I/O”

provides a +12 Volt supply (up to 1A) and RS485 communications for any WI-I/O-EX-1S serial expansion I/O modules.

Figure 4 – Expansion I/O power & RS485

As a guide when using the I/O power connection from the WI-I/O 9-U2, the number of

I/O modules is limited to three x WI-I/O-EX-1-S-11(using inputs), one x WI-I/O-EX-1-S12, or one x WI-I/O-EX-1-S-13.

If more I/O Modules are required, you will need to calculate the overall current

consumption using the following criteria and power the modules from an external

supply.

WI-I/O-EX-1-S Module Static Current drain = 120mA

WI-I/O-EX-1-S Digital Inputs require 13mA per active input

WI-I/O-EX-1-S Digital Outputs require 25mA per active output

WI-I/O-EX-1-S Analog Inputs and Outputs require 50mA per I/O when operating at

20mA

E.g. a single WI-I/O-EX-1-S-11 using inputs only has a current consumption of

approximately 320mA so you could connect up to three WI-I/O-EX-1-S-11 modules to

the Expansion port without overloading the on board I/O power supply.

A single WI-I/O-EX-1-S-12 using all analog inputs and digital outputs has a current

consumption of approximately 720mA so you could only connect one.

Keep in mind that when calculating the current consumption for the expansion I/O, the

maximum available current from the onboard power supply is 1 Amp. If the overall

Expansion I/O current consumption is over the 1 Amp maximum an external power

source will be required.

18

Page 20

2.2.3 Internal I/O

The internal supply voltages can be monitored by reading the register locations below.

See Section 5.1 “IO Diagnostics” for details on how this can be done.

The values can also be mapped to a register or an analog output on another module

within the radio network.

30005 Local Supply voltage (0-40V scaling)

30006 Local 24V loop voltage (0-40V scaling) – Internally generated +24V

supply used for analog loop supply. Maximum Current limit is 100mA

30007 Local Battery voltage (0-40V scaling)

30008 WI-I/O-EX-1-S Supply Voltage (0-40V scaling)

38005 – 38008 Floating Point Registers, also indicate the Supply voltage, Battery

Voltage, +24V Supply and WI-I/O-EX-1-S Supply voltages but in a

voltage scale.

To calculate the supply voltages from the register value use the following calculation

There are no dedicated discrete low voltage alarm indicators however each supply

voltage does have a High and a low Set point Status which can be used for this type of

alarm.

See section 4.3.9 “Analog Inputs” for details on how to configure these alarms.

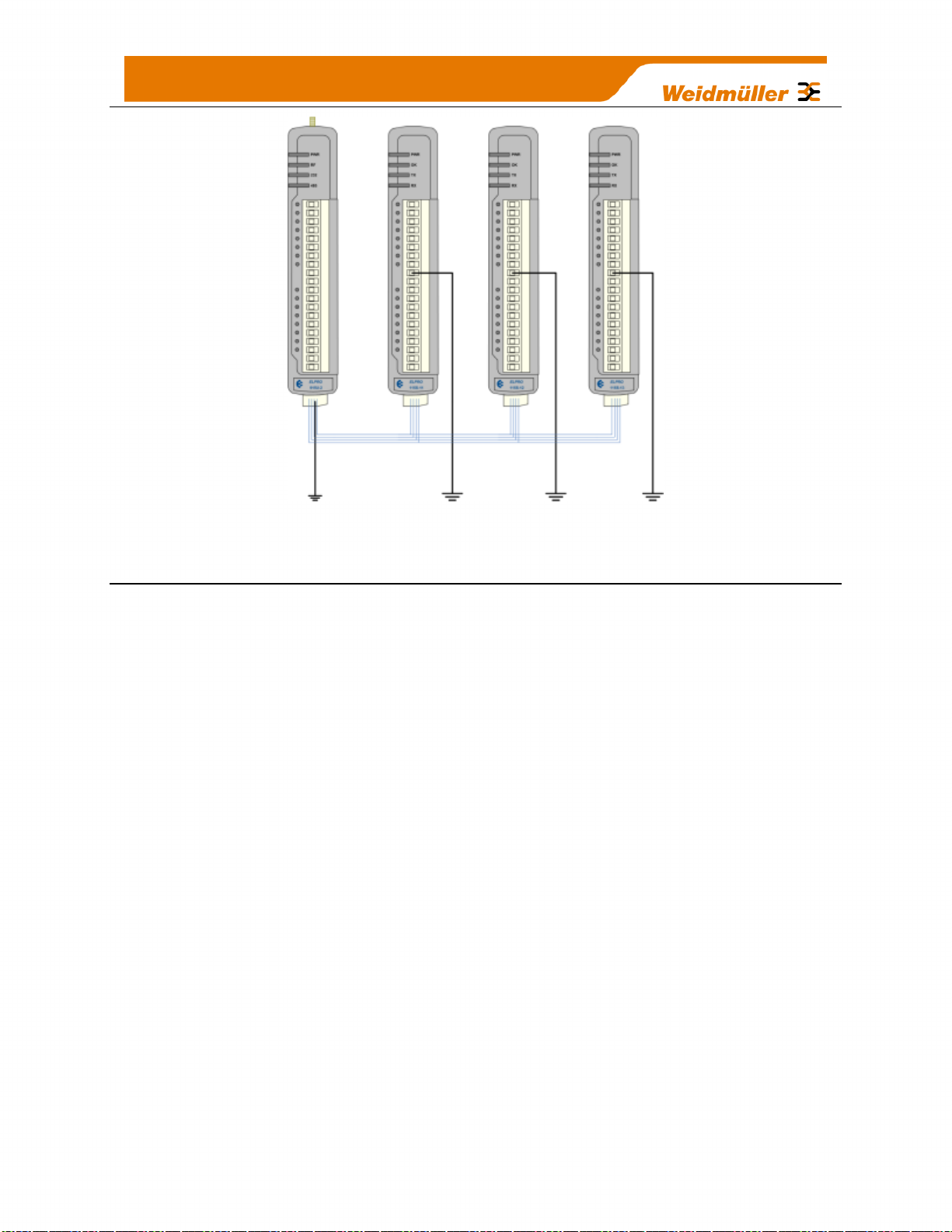

2.2.4 Grounding

To provide maximum surge and lightning protection each module should be effectively

earthed / grounded via a "GND" terminal on the module – this is to ensure that the

surge protection circuits inside the module are effective. The module should be

connected to the same common ground or earth point as the enclosure “earth” and the

antenna mast “earth”.

The WI-I/O 9-U2 has a dedicated Earth connection screw on the bottom end plate next

to the Supply terminals. All EARTH wiring should be minimum 2mm² - 14 AWG

If using the WI-I/O 9-U2 with serial Expansion I/O modules then all expansion modules

must have a separate earth connection from the front terminal back to the common

earth or ground point. See Figure 5 - Earthing below

19

Page 21

Figure 5 - Earthing

2.3 Radio

The following radio variants are available in the WI-I/O 9-U2 dependent on the country

of operation.

2.3.1 900 MHz Spread Spectrum radio

The radio uses frequency hopping spread spectrum modulation, which is a method of

transmitting radio signals by switching the carrier among many frequency channels,

using a pseudo random sequence called a hop set.

There are two hopsets; each one using a different pseudo random sequence of 50

channels, that cycle through the sequence and switch to a different channel after each

radio transmission.

The radio operates in the 902-928 MHz ISM band which is split into two frequency

bands, 902-914 MHz (Low) and 915–928 MHz (High).

In America and Canada, the WI-I/O 9-U2 can use both high and low bands - however in

other countries, i.e. Australia only the 915-928MHz band is available

Some countries use fewer channels, e.g. New Zealand uses 18 Channels in the

frequency band 922.75 -927.00MHz.

The frequency band can be changed in countries that allow the two bands to be used by

selecting the Hopset on the Radio Configuration webpage of the module. The Hopset

will only display the Frequency bands available for the model and country.

The receiver is continually scanning all channels within the hop-set and when a valid

data packet is received; it locks on to the channel and receives the data.

20

Page 22

A spread-spectrum transmission offers some advantages over a fixed-frequency

transmission.

Spread-spectrum signals are more resistant to narrowband interference.

They are difficult to intercept or eavesdrop because of the pseudorandom

transmission sequences.

Transmissions can share a frequency band with other types of conventional

transmissions with minimal interference.

2.3.2 869 MHz Fixed Frequency radio (EU Country Code)

This radio operates in the unlicensed fixed frequency band of 869 MHz. There are two

frequencies, the first operating at 869.525 MHz with a maximum transmit power level of

500 mW and is regulated with a 10% duty cycle on the channel. This duty cycle limit

requires that the module does not transmit for more than 10 % of the total operating

time which means other users of the unlicensed frequency are able to transmit without

interference. The second frequency operates at 869.875MHz with a transmit power

level of 5mW and no duty cycle regulation on the channel which means the module can

freely transmit as often as is needed.

Note: Care must be taken to ensure the duty cycle limit is not exceeded when

using the 869.525MHz frequency.

2.3.3 Meshing capability

The WEIDMULLER WIBMesh protocol is based on the “Ad hoc On Demand Distance

Vector” (AODV) routing algorithm which is a routing protocol designed for ad hoc

networks.

AODV is capable of unicast routing and is an on demand algorithm, meaning that it

builds and maintains these routes only as long as they are needed by the source

devices.

The Protocol creates a table, which shows the connection routes to other device in the

system. The Protocol uses sequence numbers to ensure the routes are kept as current

as possible. It is loop-free, self-starting, and can scale to a large numbers of nodes.

See section 3.4 “WIBMesh” for more details on configuration.

2.4 Antenna

The WI-I/O 9-U2 module will operate reliably over large distances. The distance that

can be reliably achieved will vary with each application and depend on the type and

location of antennas, the degree of radio interference, and obstructions (such as hills or

trees) to the radio path.

21

Page 23

Typical reliable distances are detailed below, however longer distances can be

Maximum Gain per region

Country

Max Gain (dB)

USA / Canada

6

Australia / New Zealand

0

Europe

0

Typical Antenna Gains

Part No

Antenna

Gain (dB)

DG900

Whip with 15’ (5m) cable

-2

6720005089

Dipole with 15’ (5m) cable

0

SG900-EL

5dBi Collinear (3dBd)

5

SG900-6

8dBi Collinear (6dBd)

8

YU6-900

6 element Yagi

10

YU16-900

16 element Yagi

15

Typical Coax Losses (900MHz)

CC3-SMA

10’ (3m) Cellfoil Coax

-1dB

CC10-SMA

33’ (10m) Cellfoil Coax

-3dB

CC20-SMA

66’ (20m) Cellfoil Coax

-6dB

achieved if antennas are mounted in elevated locations – such as on a hill or on a radio

mast.

Using the 900 MHz Spread Spectrum radio the distances achievable will be:

USA/Canada 15 miles - 6dB net gain antenna configuration permitted (4W EIRP)

Australia/NZ 12 km - Unity gain antenna configuration (1W EIRP)

To achieve the maximum transmission distance, the antennas should be raised above

intermediate obstructions so the radio path is true “line of sight”. Because of the

curvature of the earth, the antennas will need to be elevated at least 15 feet (5 metres)

above ground for paths greater than 3 miles (5 km). The modules will operate reliably

with some obstruction of the radio path, although the reliable distance will be reduced.

Obstructions that are close to either antenna will have more of a blocking effect than

obstructions in the middle of the radio path. For example, a group of trees around the

antenna is a larger obstruction than a group of trees further away from the antenna.

The WI-I/O 9-U2 module provides a range of test features, including displaying the

radio signal strength. Line-of-sight paths are only necessary to obtain the maximum

range. Obstructions will reduce the range however, but may not prevent a reliable path.

A larger amount of obstruction can be tolerated for shorter distances. For very short

distances, it is possible to mount the antennas inside buildings. All radio paths require

22

Page 24

testing to determine if they are reliable - refer section 5.6 “Network Statistics” Where it

Figure 6 - Wrapping Coax Connections

is not possible to achieve reliable communications between two modules, then a third

module may be used to receive the message and re-transmit it. This module is referred

to as a repeater. This module may also have input/output (I/O) signals connected to it

and form part of the I/O network - refer to Chapter 4 Configuration of this manual.

An antenna should be connected to the module via 50 ohm coaxial cable (e.g. RG58,

RG213, Cellfoil, etc) terminated with a male SMA coaxial connector. The higher the

antenna is mounted, the greater the transmission range will be, however as the length

of coaxial cable increases so do cable losses. For use on unlicensed frequency

channels, there are several types of antennas suitable for use. It is important antennas

are chosen carefully to avoid contravening the maximum power limit on the unlicensed

channel - if in doubt refer to your distributor.

The net gain of an antenna/cable configuration is the gain of the antenna (in dBi) less

the loss in the coaxial cable (in dB).

The net gain of the antenna/cable configuration is determined by adding the antenna

gain and the cable loss. For example, a 6 element Yagi with 70 feet (20 metres) of

Cellfoil cable has a net gain of 4dB (10dB – 6dB).

Connections between the antenna and coaxial cable

should be carefully taped to prevent ingress of

moisture. Moisture ingress in the coaxial cable is a

common cause for problems with radio systems, as it

greatly increases the radio losses.

We recommend that the connection be taped, firstly

with a layer of PVC Tape, then with a vulcanising

tape such as “3M 23 tape”, and finally with another

layer of PVC UV Stabilised insulating tape. The first

layer of tape allows the joint to be easily inspected

when trouble shooting as the vulcanising seal can be

easily removed.

Where antennas are mounted on elevated masts, the

masts should be effectively earthed to avoid

lightning surges. For high lightning risk areas, surge

suppression devices between the module and the antenna are recommended. If the

antenna is not already shielded from lightning strike by an adjacent earthed structure, a

lightning rod may be installed above the antenna to provide shielding.

Dipole and Collinear antennas.

A collinear antenna transmits the same amount of radio power in all directions - and

they are easy to install and use because they do not need to be aligned to the

destination. The dipole antenna with integral 15 ‘cable does not require any additional

coaxial cable; however a cable must be used with the collinear antennas.

Collinear and dipole antennas should be mounted vertically, preferably 1 wavelength

away from a wall or mast to obtain maximum range.

23

Page 25

Figure 7 – Collinear Antenna mounting

24

Page 26

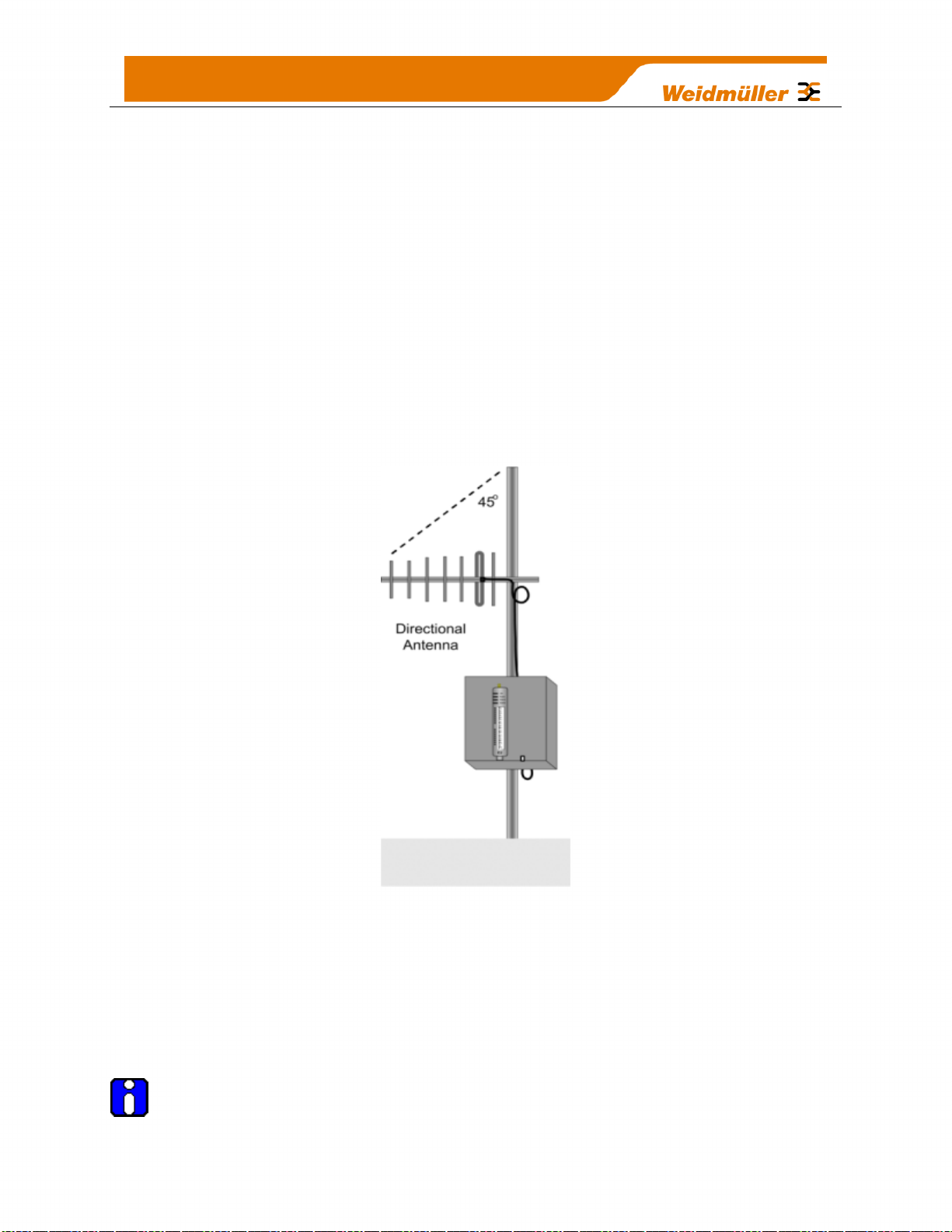

Yagi antennas.

A Yagi antenna provides high gain in the forward direction, but lower gain in other

directions. This may be used to compensate for coaxial cable loss for installations with

marginal radio path.

The Yagi gain also acts on the receiver, so adding Yagi antennas at both ends of a link

provides a double improvement.

Yagi antennas are directional. That is, they have positive gain to the front of the

antenna, but negative gain in other directions.

Hence, Yagi antennas should be installed with the central beam horizontal and must be

pointed exactly in the direction of transmission to benefit from the gain of the antenna.

The Yagi antennas may be installed with the elements in a vertical plane (vertically

polarised) or in a horizontal plane (horizontally polarised), however both antenna must

be in the same plane for maximum signal. If the antenna are mounted in different planes

the receive signal level will be reduced by around 30dB.

Figure 8 - Yagi Antenna Mounting

For a two-station installation, with both modules using Yagi antennas, horizontal

polarisation is recommended. If there are more than two stations transmitting to a

common station, then the Yagi antennas should have vertical polarisation, and the

common (or “central” station should have a collinear (non-directional) antenna.

Note that Yagi antennas normally has a drain hole on the folded element the drain hole should be located on the bottom of the installed antenna.

25

Page 27

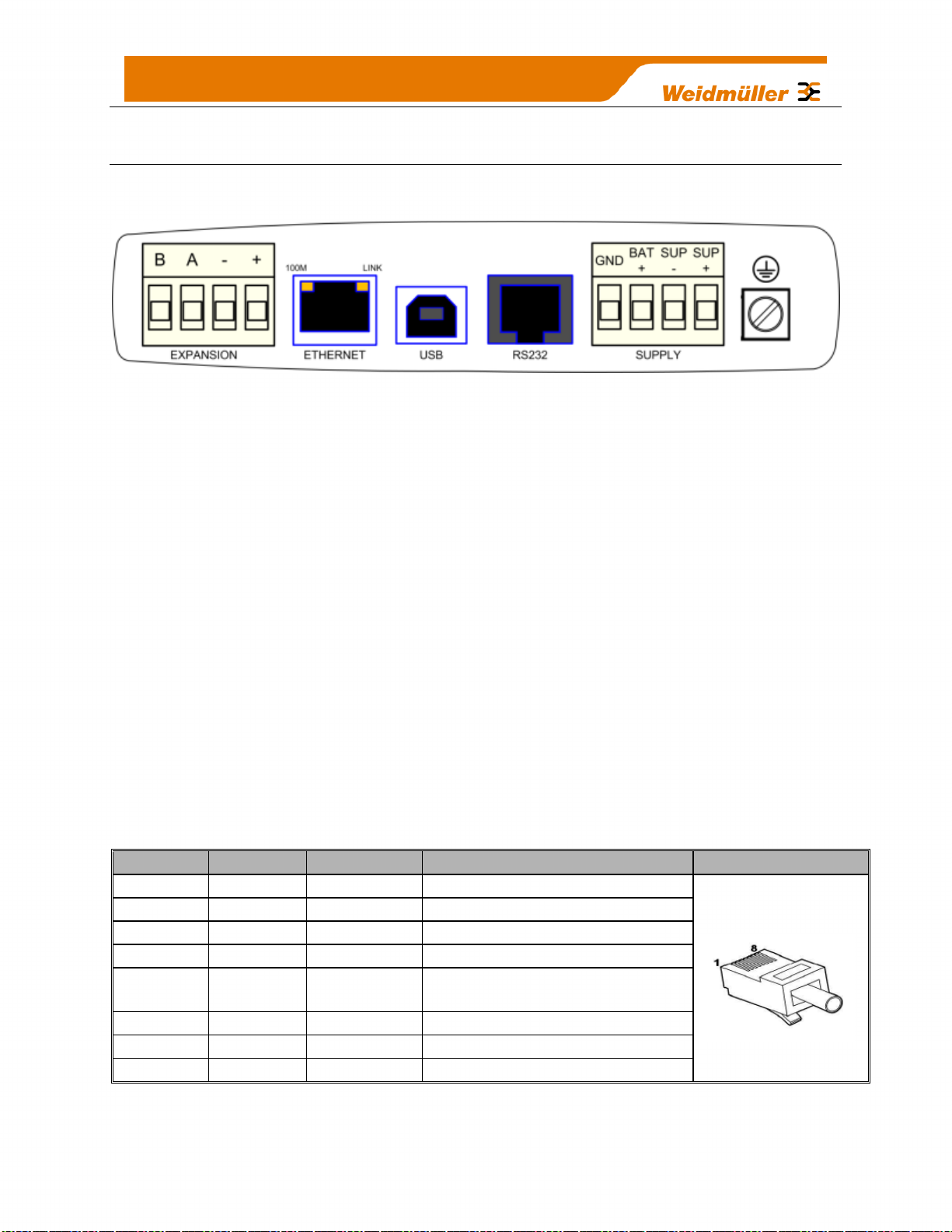

2.5 Connections

RJ-45

Signal

Required

Signal name

Connector

1

RI Ring Indicator

2

DCD Data Carrier Detect

3

DTR Y Data Terminal Ready

4

GND Y Signal Common

5

RXD

Y

Receive Data (from WI-I/O 9-

U2)

6

TXD

Y

Transmit Data (to WI-I/O 9-U2)

7

CTS Clear to Send

8

RTS Request to Send

2.5.1 Bottom panel connections

Figure 9 – Bottom Panel Connections

Ethernet port

The WI-I/O 9-U2 modules provides a standard RJ-45 Ethernet port compliant to IEEE

802.3 10/100 BaseT. This port provides full access to the module, including

configuration, diagnostics, log file download and firmware upload, of both the local and

remote units.

Additionally the Ethernet port can provide network connectivity for locally connected

third-party devices with Ethernet functionality.

USB Device Port for configuration

The WI-I/O 9-U2 module also provides a USB-device (USB-B) connector. This

connector provides configuration of the device and remote configuration access to other

devices in the radio network.

RS-232 port

The WI-I/O 9-U2 module provides an RS-232 serial port, which supports operation at

data rates up to 230,400 baud. This port supports MODBUS protocol.

The RS-232 port is provided by an RJ-45 connector wired as a DCE according to EIA562 Electrical Standard.

26

Page 28

RS-485 port with Modbus Support.

WI-IO 9-U2

The WI-I/O 9-U2 module provides an RS-485 serial port, which supports operations at

data rates up to 230,400 baud. Default baud rate is 9600 baud, No Parity, 8 data bits

and 1 stop bit which match the WI-I/O-EX-1-S serial expansion modules defaults. This

port Supports MODBUS protocol.

The RS-485 port terminal is hosted on the 4 way “Expansion” connector on the bottom

edge of the module. An on-board RS485 termination resistor provides line attenuation

for long runs. As a general rule moreover, a termination resistors should be placed at

each end of the RS485 cable. When using Expansion I/O module remember to

switch in the termination resistor on the end module.

Figure 10 – RS485 Connections

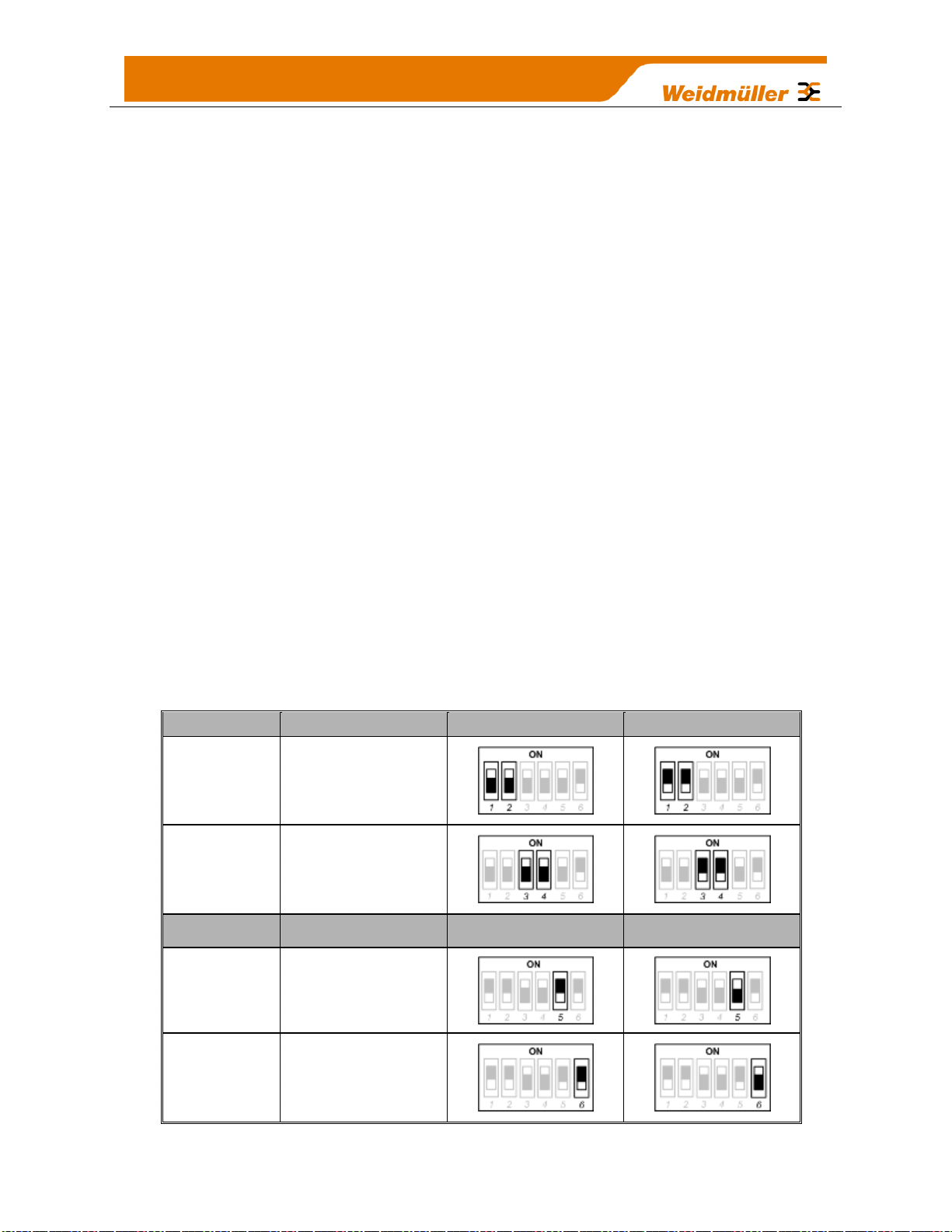

2.5.2 Side Access Configuration Panel

Figure 11 – Side Access Panel

On the side of the module is a small access cover that hides a “Factory Boot” switch,

USB Host port and a small bank of dipswitches that are used for Analog input

voltage/current selection, External Boot and Default configuration settings.

27

Page 29

“Factory Boot” switch

Switch

Function

Current

Voltage

DIP 1 & 2

Analog Input #3

DIP 3 & 4

Analog Input #4

Switch

Function

Disabled

Enabled

DIP 5

Not used

DIP 6

Setup Mode

The “Factory Boot” switch is used for factory setup and diagnostics. This switch should

not normally be used, except if advised by WEIDMULLER support.

USB Host port

This port is a USB Host (Master port), which can interface with USB storage devices for

data logging (Future) and for upgrading the module Firmware – See section 4.4.7

“System Tools” for details on how this is done.

Dipswitches

The Dipswitches are used to select a number of functions within the module; the table

below indicates the different switch positions.

Dipswitches 1 to 2 – Selection for measuring Current or Voltage on Analog Input

3. Set DIP switches ON to measure Current (0-20mA) and OFF for Voltage (05VDC).

Dipswitches 3 to 4 – Selection for measuring Current or Voltage on Analog Input

4. Set DIP switches ON to measure Current (0-20mA) and OFF for Voltage (05VDC).

Dipswitch 5 – DIP Switch not used

Dipswitch 6 – When set to ON (Enabled) and the module is restarted; it will boot

up with a known factory default configuration including a default IP address for

Ethernet connection. (Refer to Chapter 4 - “Default IP Address”).

Note: When dipswitch is ON, Radio and I/O functionality is disabled.

28

Page 30

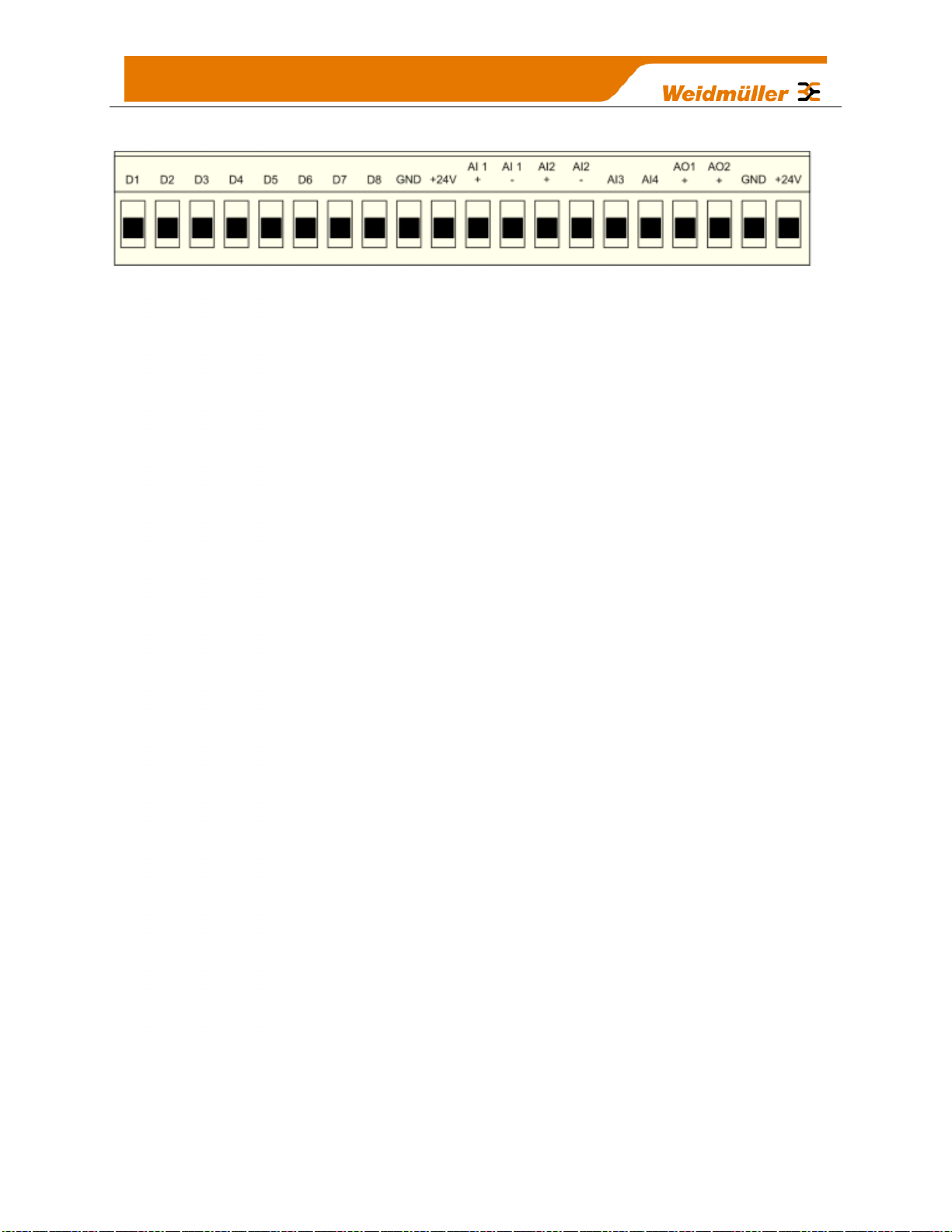

Front panel connections

Figure 12 – Front Panel Connections

The WI-I/O 9-U2 front panel provides connections for the following

Eight Digital Input /Output (DIO1-8).

Two 12 bit, 0.1% accuracy differential analog inputs.

Two single ended 12 bit, 0.1% accuracy analog inputs.

Two 13 bit, 0.1% accuracy current sourcing analog outputs.

Connection terminals for Common and +24V Analog Loop Supply (ALS

maximum current limit is 100mA).

29

Page 31

2.5.3 Digital / Pulsed Inputs

WI-IO 9-U2

Each digital I/O channel on the WI-I/O 9-U2 can act as either an input or an output. The

input/output direction is automatically determined by the connections and configuration

of the I/O.

If you have an I/O channel wired as an input but operate the channel as an output. No

electrical damage will occur however, the I/O system will not operate correctly.

If operating the channel as an output and performing a “read inputs” on this location it

will indicate the status of the output.

Marked D1-8 the Digital inputs share the same terminals as the Digital outputs on the

WI-I/O 9-U2 module.

A digital input is activated by connecting the input terminal to EARTH or Common,

either by voltage-free contact, TTL Level, or transistor switch.

Each digital input has an orange indication LED that will turn on when the input has

been connected to a GND or common.

Figure 13 – Digital / Pulsed Input Wiring

Digital inputs 1 to 4 can be used as pulsed inputs.

The maximum pulse frequency is 50 KHz for Input 1 & 2 and 1 KHz for Input 3 & 4.

Digital/Pulsed inputs are suitable for TTL signal Level, NPN-transistor switch devices or

voltage-free contacts (relay/switch with debounce capacitor).

Frequencies greater than 1 KHz need to use a TTL logic drive or an external pull-up

resistor (1KΩ to V+). Pulsed inputs are converted to two different values internally. First

is the Pulse Count, which is an indication of how many times the input has changed

state over a configured time period. Secondly there is a Pulse Rate which is an analog

input derived from the pulse frequency. E.g. 0 Hz = 4mA and 1 KHz = 20mA.

All Pulsed Input counts are stored in non-volatile Ram so in the event of a power fail or

the module being reset the values will be saved.

30

Page 32

WI-IO 9-U2

2.5.4 Digital Outputs (Pulsed Outputs)

Digital outputs are open-collector transistors and are able to switch loads up to 30VDC,

200mA.

The 8 digital outputs share the same terminals as the digital input. These terminals are

marked D1-8.

Figure 14 – Digital Output Wiring

When active, the digital outputs provide a transistor switch to EARTH (Common).

To connect a digital output, refer to “Figure 14” above. A bypass diode (IN4004) is

recommended to protect against switching surges for inductive loads such as relay

coils.

The digital channels D1-4 on the WI-I/O 9-U2 module can be used as pulse outputs with

a maximum output frequency of 10 KHz.

Digital Output Fail Safe Status

As well as indicating the Digital Output status (on / off), the LEDs can also indicate a

communications failure by flashing the Output LED. This feature can be utilised by

configuring a Fail Safe time and status on the “I/O – digital Output” screen in the

Configuration software as shown below.

31

Page 33

Figure 15 – Digital Output Failsafe Times

The Fail Safe Time is the time the output counts down before activating a Fail Safe

state.

Normally this would be configured for a little more than twice the update time of the

mapping that is sending data to it.

This is because the Fail Safe Timer is restarted whenever it receives an update. If we

send two successive updates and fail to receive both of these messages then the timer

counts down to zero and activates the Failsafe state.

If the Failsafe state is enabled (ON) this will indicate with the LED flashing briefly OFF

and the digital output will turn on.

If the Failsafe state is disabled (OFF) this will indicate with the LED flashing briefly ON

and the digital output will turn off.

Figure 16 - Fail-Safe State

32

Page 34

2.5.5 Analog Inputs

Figure 17– Differential Current Inputs

Figure 18 – Single Ended Current Inputs

WI-IO 9-U2

WI-IO 9-U2

The WI-I/O 9-U2 provides two floating differential analog inputs and two grounded single-ended

analog inputs.

Analog Input 1 & 2 will automatically measure Current (0-20 mA) or Voltage (0-25V) depending

on what is connected to the input.

Analog input 3 & 4 must be configured to measure Current (0-20mA) or Voltage (0-5V) via the

DIP switches under the Side Access Configuration Panel (See Section 2.5.2 ).

An internal 24V Analog Loop Supply (ALS) provides power for any current loops with a

maximum current limit of 100mA.

The LEDs have an analog diagnostic function and will indicate the status of the input.

If the current is less than 3.5 mA the LED will be off and if greater than 20.5mA the LED will be

on. The LED will flicker with the duty cycle relative to the analog reading in this range.