Weidmuller UR67-MP-HP-16DI-12-60M, UR67-MP-78-16DO-12-60M, UR67-MP-78-8DIDO-12-60M, UR67-MP-HP-8DIDO-12-60M, UR67-MP-78-16DI-12-60M Series Manual

...Page 1

Remote-I/O-System u-remote UR67

I/O-Modules IP67 Multiprotocol

Manual

Letʼs connect.

UR67-MP-HP-16DI-12-60M 2426270000

UR67-MP-HP-16DO-12-60M 2426280000

UR67-MP-HP-8DIDO-12-60M 2426290000

UR67-MP-78-16DI-12-60M 2426300000

UR67-MP-78-16DO-12-60M 2426310000

UR67-MP-78-8DIDO-12-60M 2426320000

Page 2

Content

1 About this documentation 3

1.1 Symbols and notes 3

1.2 Complete documentation 3

1.3 Standard data structure 3

2 Safety 4

2.1 General safety notice 4

2.2 Intended use 4

2.3 Legal notice 5

3 System overview 6

3.1 Connection characteristics 6

3.2 Fieldbus characteristics 6

3.3 Web server 7

3.4 Accessories 7

4 Module descriptions 8

4.1 UR67-MP-HP-16DI-12-60M and

UR67-MP-78-16DI-12-60M 8

4.2 UR67-MP-HP-16DO-12-60M and

UR67-MP-78-16DO-12-60M 9

4.3 UR67-MP-HP-8DIDO-12-60M and

UR67-MP-78-8DIDO-12-60M 10

4.4 Connector pin assignment 11

4.5 Technical Data 12

5 Installation and wiring 14

5.1 Preparations for installation 14

5.2 Installing the module and earth connection 14

5.3 Attaching markers 17

5.4 Setting the eldbus protocol 17

5.5 Wiring 17

5.6 Insulation test 17

7 Commissioning 23

7.1 Setting the eldbus protocol 23

7.2 Restoring factory settings using the rotary switch 23

7.3 Commissioning with Ethernet/IP 24

7.4 Commissioning with PROFINET 28

7.5 Parameter settings 32

8 Process data 33

8.1 Process data with Ethernet/IP 33

8.2 Process data with PROFINET 34

9 Diagnostics 35

9.1 Descriptions of errors 35

9.2 Ethernet/IP diagnoses 36

9.3 PROFINET diagnoses 36

10 Web server 37

10.1 Connecting and starting up the web server 37

10.2 Getting to know and arranging the web server 37

10.3 Module settings and diagnostics 39

10.4 Web server in Force mode 41

10.5 Updating rmware 42

11 Disassembly and disposal 43

11.1 Disassembling the u-remote module 43

11.2 Disposing of the u-remote module 43

12 LED displays 44

6 Earthing and shielding 18

6.1 Earthing of shielded cables 18

6.2 Potential ratios 20

6.3 Electromagnetic compatibility (EMC) 20

6.4 Shielding of cables 21

Manufacturer

Weidmüller Interface GmbH & Co. KG

Klingenbergstraße 16

D-32758 Detmold

T +49 5231 14-0

F +49 5231 14-292083

info@weidmueller.com

www.weidmueller.com

Document No. 2484940000

Revision 00/February 2017

22484940000/00/02.2017 Manual UR67-Multiprotocol

Page 3

1 About this documentation

1 About this documentation | Symbols and notes

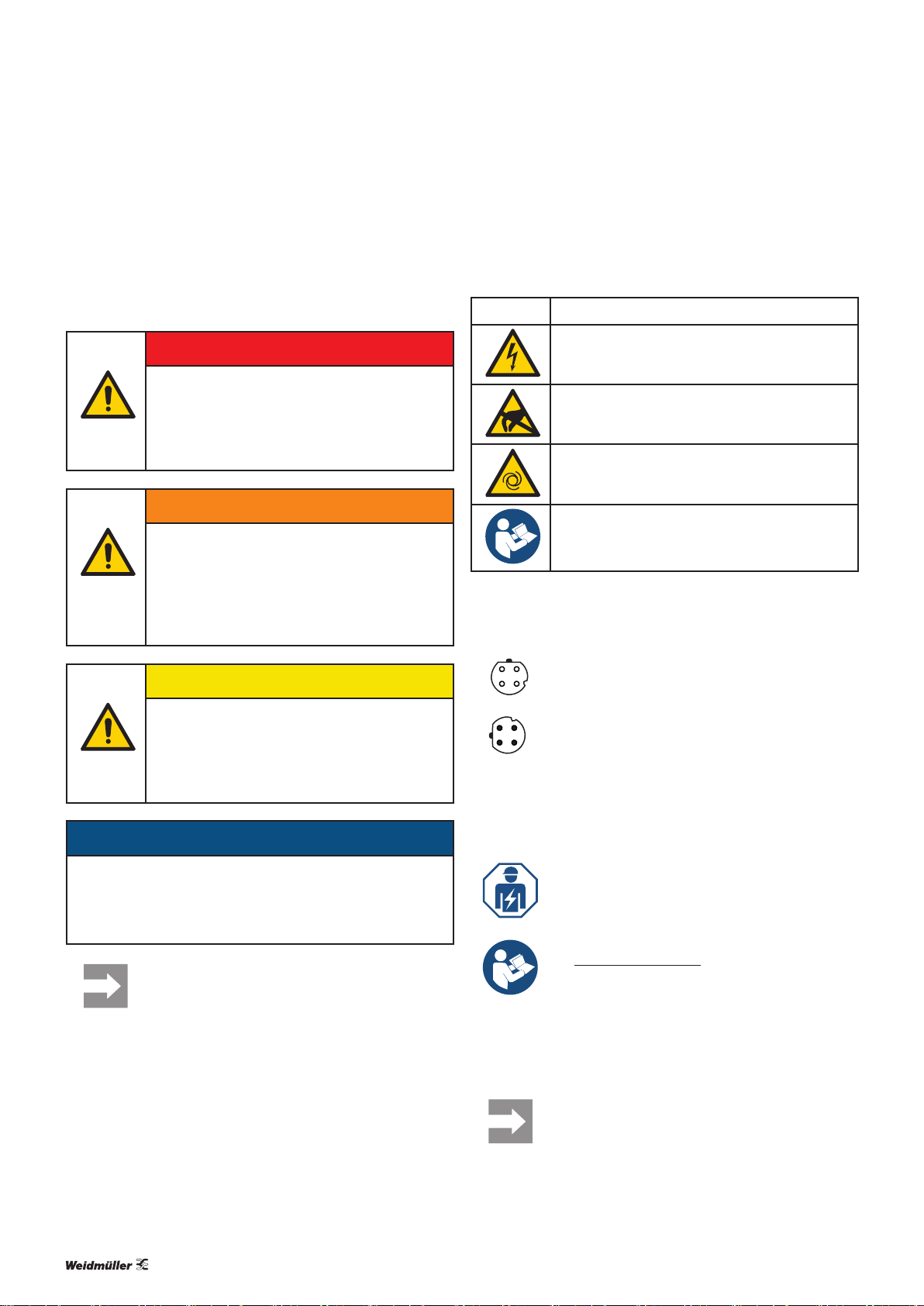

1.1 Symbols and notes

The safety notices in this documentation are designed according to the severity of the danger.

DANGER

Imminent danger to life!

Notes with the signal word “Danger” warn

you of situations that will result in serious

injury or death if you do not follow the

instructions given in this manual.

WARNING

Possible danger to life!

Notes with the signal word “Warning” warn

you of situations that may result in serious

injury or death if you do not follow the

instructions given in this manual.

CAUTION

The situation-dependent safety notices may contain the following warning symbols:

Symbol Meaning

Warning against dangerous electrical voltage

Warning against electrostatically charged

components

Warning against automatic startup

Observe the documentation

▶ All instructions can be identified by the black triangles

next to the text.

– Lists are marked with a tick.

21

Female connections with sockets are illustrated

4

using empty circles.

3

Risk of injury!

Notes with the signal word “Caution” warn

you of situations that may result in injury if

you do not follow the instructions given in

this manual.

ATTENTION

Material damage!

Notes with the signal word “Attention” warn you of hazards

that may result in material damage.

Text next to this arrow are notes that are not

relevant to safety, but provide important information about proper and effective work procedures.

Male connections with pins are illustrated using

34

1

lled circles.

2

1.2 Complete documentation

The documentation is intended for trained electricians who are familiar with national and international laws, provisions and standards.

All documents can also be downloaded from

the Weidmüller website.

1.3 Standard data structure

All information about the structure of data

(e.g.process data and parameters) refers to the

standard data format settings in the module

parameters. These are shown in the Motorola

format.

32484940000/00/02.2017 Manual UR67-Multiprotocol

Page 4

2 Safety

2 Safety | General safety notice

This chapter includes general safety instructions on handling

the UR67 modules. Specic safety instructions for specic

tasks and situations are given at the appropriate places in

the documentation.

All work may only be carried out by trained

electricians who are familiar with the

safety standards that apply to automation

technology.

The documentation must be stored in such a

way that it is accessible to operating staff at

all times.

2.1 General safety notice

When working during ongoing operations, the emergency

stop mechanisms must not be made ineffective.

If faults connected to a u-remote product cannot be rectied,

the product in question must be sent to Weidmüller. Weidmüller assumes no liability if the module is tampered with!

All connected devices must comply with the requirements

set out in EN61558-2-4 and EN61558-2-6. Only cables

and accessories that meet the requirements and provisions

regarding safety, electromagnetic compatibility and, if necessary, telecommunications terminal equipment, as well as the

specications, may be installed. Information on the specic

cables and accessories that are permitted to be installed is

provided in this manual or can be requested from Weidmüller.

Electrostatic Discharge

u-remote products can be damaged or destroyed by electrostatic discharge. When handling the products, the neces-

sary safety measures against electrostatic discharge (ESD)

according to IEC61340-5-1 and IEC61340-5-2 must be

observed. The packing and unpacking as well as the installation and disassembly of a device may only be carried out by

qualied personnel.

Fusing

The operator must set up the equipment so that it is protected against overloading. The upstream fuse must be

designed so that it does not exceed the maximum load current. The maximum permissible load current can be found

in the technical data. The operator must decide whether ad-

ditional surge protection is required according to IEC62305.

Voltages that exceed +/-30V may cause the destruction of

the modules. A power supply with secure isolation must be

used.

Earthing (functional earth FE)

Every UR67-MP module is equipped with an earth connection, with the connection point labelled “XE”. Further information is available in chapters 5 and 6.

Shielding

Shielded lines are to be connected with shielded plugs in

compliance with the relevant standard (see chapter 6).

2.2 Intended use

The UR67-MP modules are decentral input and output devices in an Ethernet/IP network or a PROFINET network.

The products are designed for use in industrial automation and may only be used within the scope of the stated

technical specications. The devices to be connected must

comply with the requirements set out in EN61558-2-4 and

EN61558-2-6.

The industrial environment is labelled as such to ensure that

consumers are not directly connected to the public low-voltage network. Additional measures must be taken for use in

the home, and in the business and commercial sectors.

Any intervention in the products hardware or software other

than described in this manual may only be realised by Weidmüller.

Malfunction-free operation is only guaranteed if the housing

is fully assembled. Observance of the documentation is also

part of the intended use.

42484940000/00/02.2017 Manual UR67-Multiprotocol

Page 5

2.3 Legal notice

The UR67-series products comply with the EU Directive

2014/30/EU (EMC Directive).

Components of the following free software products are integrated into the modules:

Component License Link

jQuery MIT

jQuery-custom-

Select

jQuery-i18n MIT

jQuery-overs-

croll

jQuery-ui MIT

JSZip MIT

md5 (as part

of CryptoJS)

snap-svg

underscore MIT

MIT

MIT

MIT

Apache

license 2.0

https://github.com/jquery/jquery/blob/master/

LICENSE.txt

https://github.com/jquery/jquery/blob/master/

LICENSE.txt

https://github.com/jquery/jquery/blob/master/

LICENSE.txt

https://github.com/jquery/jquery/blob/master/

LICENSE.txt

https://github.com/jquery/jquery/blob/master/

LICENSE.txt

https://github.com/Stuk/jszip/blob/master/

LICENSE.markdown

https://code.google.com/archive/p/crypto-js/

wikis/License.wiki

https://github.com/adobe-webplatform/Snap.

svg/blob/master/LICENSE

https://github.com/jashkenas/underscore/blob/

master/LICENSE

2 Safety | Legal notice

52484940000/00/02.2017 Manual UR67-Multiprotocol

Page 6

3 System overview | Connection characteristics

3 System overview

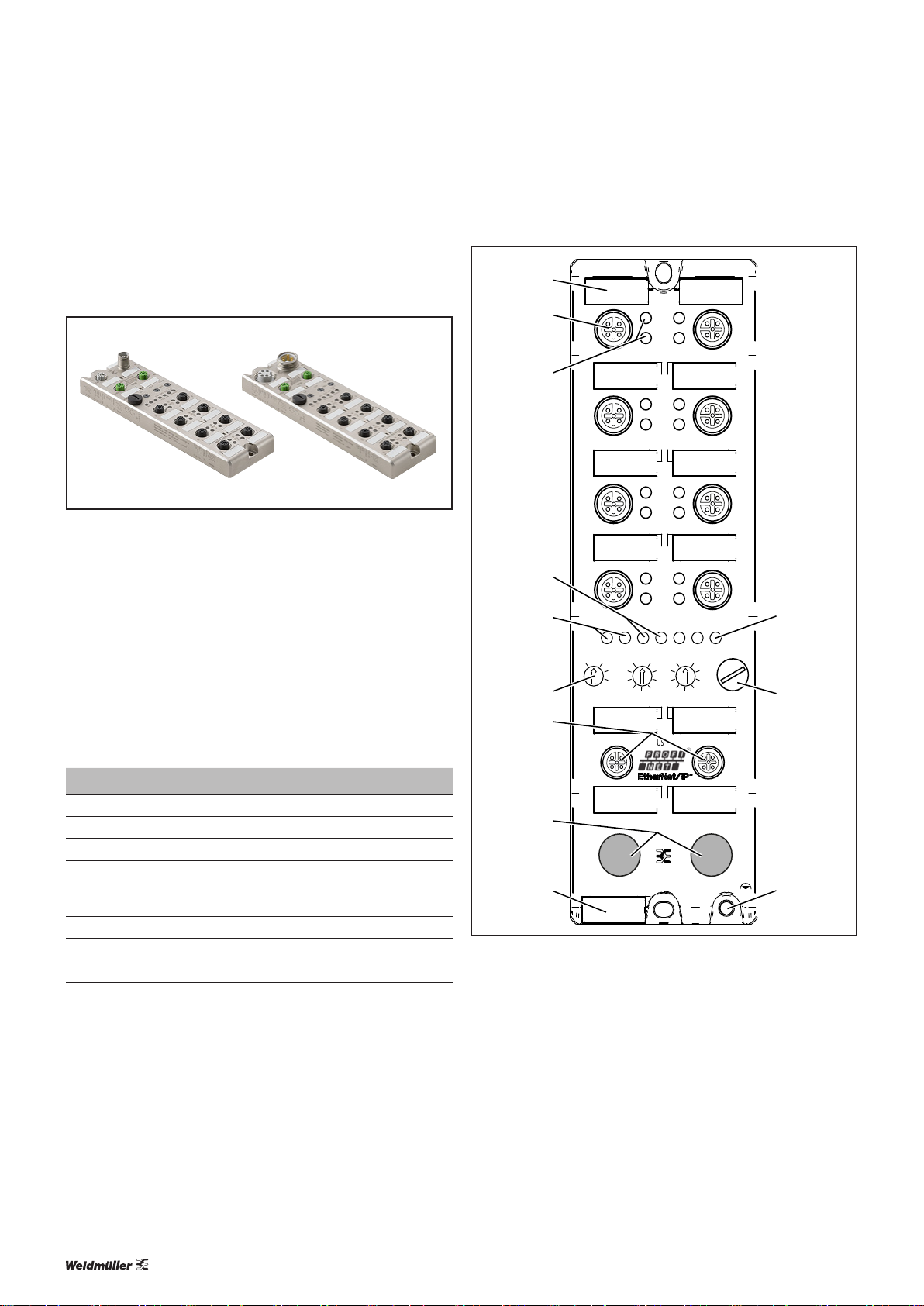

UR67-MP-HP-X (2426270000, 2426280000, 2426290000) UR67-MP-78-X (2426300000, 2426310000, 2426320000)

u-remote IP67 modules for Ethernet/IP and PROFINET

The UR67-MP modules are multi-protocol modules which

use either Ethernet/IP or PROFINET for eldbus communication. The required protocol is selected on the module using

the rotary switch.

The metal housing (zinc diecast, completely encapsulated)

ensures that the modules conform to the IP67 protection

class.

The output current is a maximum of 1.6 A per channel. The

output circuits are electrically isolated from the rest of the

network and from the sensor electronics.

The modules with output functionality support a fail-safe

function, which can be used to set how a channel congured

as an output is to respond to an impaired or interrupted eld-

bus communication.

The UR67-MP modules differ according to their I/O functionality:

– 16 digital inputs (UR67-MP-xx-16DI-12-60M)

– 16 digital outputs (UR67-MP-xx-16DO-12-60M)

– 8 digital inputs and 8 digital outputs (UR67-MP-xx-

8DIDO-12-60M).

The UR67-MP modules feature two different connections for

the power supply:

3.1 Connection characteristics

All connections are colour-coded and therefore cannot be

mixed up:

– Fieldbus network (green): D-coded, 4-pole M12 plug-in

connector (IN and OUT). The maximum transmission rate

is 100Mbps.

– I/O connections (black): 8 A-coded, 5-pole M12 plug-in

connectors

– Power supply connections (grey), variant-specific:

– L-coded, 5-pole M12 connector (IN and OUT).

– 5-pole, 7/8“-connections (IN and OUT)

LED

Each I/O connection is assigned two status LEDs which

change colour and the frequency at which they ash according to the status of the respective connection (seesec-

tion12).

3.2 Fieldbus characteristics

– 5-pole, L-coded M12 connections (UR67-MP-HP-xx)

– 5-pole, 7/8“-connections (UR67-MP-78-xx)

The integrated Ethernet switch with two connections allows

for Ethernet/IP and PROFINET networks to be set up in a line

or ring topology.

Ethernet/IP product characteristics

The rmware for the UR67-MP modules supports the Device Level Ring protocol (DLR) for simple ring topologies in

accordance with the Ethernet/IP specication. DLR allows

modules to switch to an alternative ring segment in the event

of an interruption to the connection. The DLR class of the

modules is “Ring Node, Beacon Based”.

62484940000/00/02.2017 Manual UR67-Multiprotocol

Page 7

3 System overview | Web server

PROFINET product characteristics

The UR67-MP modules support PROFINET IO device IRT

(Isochronous Real-Time). This allows time-critical process

data to be transmitted between the network components in

real time.

The UR67-MP modules use the following protocols:

– DCP: for the automatic allocation of IP addresses

– LLDP: for device detection in the immediate surround-

ings (neighbourhood detection)

– SNMP: for monitoring network components

The UR67-MP modules support the “Device replacement

without interchangeable medium” function. With this function, modules in a PROFINET network can be exchanged

for identical modules without having to reassign the device

name using a programming device.

Alarm and diagnostic messages

The modules offer extended Ethernet/IP and PROFINET

alarm and diagnostic messages.

Conguration and parameterisation

An EDS le (Ethernet/IP) or a GSDML le (PROFINET) is

needed to congure and parameterise the module in the en-

gineering tool.

The current EDS and GSDML les can be downloaded from the Weidmüller website.

3.4 Accessories

Protective caps

Protection class IP67 is only realised with a completely connected module. This means that all of the connections not

being used must be provided with protective caps.

Size Usage Protective cap Order No.

M12 Sensor connection SAI-SK M12 9456050000

M12 Bus-out and power-out SAI-SK-M12-UNI 2330260000

M12 Bus-in and power-in SAI-SK M12 connector 1781520000

7/8“ Power-Out SAI-7/8-SK-P-F 1422760000

7/8“ Power-In SAI-7/8-SK-P-M 2007270000

Markers

Module and connection markers are available to label equipment. All of the markers can be printed using the Weidmüller

PrintJet ADVANCED (Order No. 1324380000).

Module Markers Order No.

UR67-MP-xx-xxx-60M ESG-M8/20 MC NE WS 1027290000

Conductors and connections

In order to select suitable cables, we recommend referring to

Weidmüller Catalogue 8 or the Product Congurator on the

Weidmüller-Website.

3.3 Web server

The web server can be used to display the UR67-MP module

on a connected PC. This allows you to execute the following

functions for test purposes or during commissioning or service work:

– Query the module status

– Display and change the module parameters

– Access diagnostic information

– Operate the module in Force mode for testing purposes

The description of the web server can be found in chap-

ter10.

72484940000/00/02.2017 Manual UR67-Multiprotocol

Page 8

IN OUT

X01

UR67-MP-78-16DI-12-60M

IN

4

8

3 7

6

5

2

A

DIA

B

XE

OUT

Lnk/Act

P2P1

U

S

16DI

A

DIA

B

A

DIA

B

A

DIA

B

x100

x10

x1

MS NS

BF DIA

0

E/IP

PN

0

0

BUS

1

12

11

10

2

1

7

6

5

4

3

9

8

4 Module descriptions

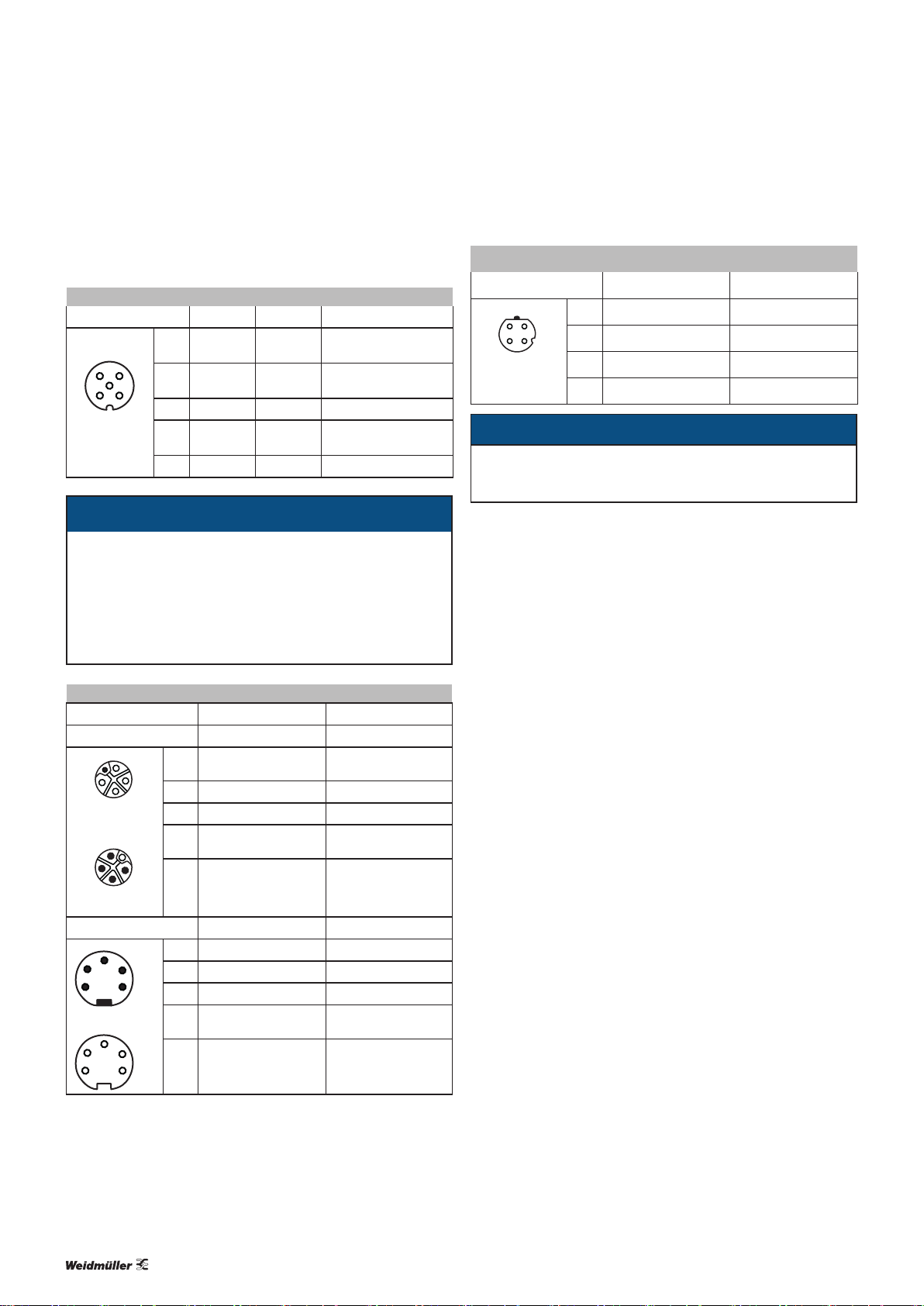

4.1 UR67-MP-HP-16DI-12-60M and

UR67-MP-78-16DI-12-60M

4 Module descriptions | UR67-MP-HP-16DI-12-60M and UR67-MP-78-16DI-12-60M

Left: Input module UR67-MP-HP-16DI-12-60M (Order No. 2426270000)

Right: Input module UR67-MP-78-16DI-12-60M (Order No. 2426300000)

The UR67-MP modules are intended for the decentralised

control in an Ethernet/IP network or a PROFINET network.

The protocol is selected using the rotary switch.

Each module has eight connections (M12, 5-pole, A-coded)

for signal lines as well as connections for the eldbus (M12,

4-pole, D-coded). The power supply is connected via 5-pole,

A-coded M12 or 7/8" connections.

The UR67-MP-xx-16DI-12-60M modules have 16digital inputs (P-switching).

Diagnostic and status LEDs

LED Display Meaning

U

S

1–8 A Yellow Channel A status: On

1 –8 B White Channel B status: On

Lnk/Act

P1, P2

BF/MS Green Device operational (Ethernet/IP)

BF/MS Off No error (PROFINET)

DIA/NS Green Connected: at least one existing connection (Ethernet/IP)

DIA/NS Off No diagnosis available (PROFINET)

LED displays (normal operation); for error messages, see chapter 12

detected

Green System/sensor power supply

Green Ethernet connection to another participant available, link

Product details for UR67-MP-HP-16DI-12-60M and UR67-MP-78-16DI-12-60M

1 Marker connection1

2 I/O connections1 (sensor/actuator)

3 Status LED connection1, channelA/channelB

4 Fieldbus and module status LEDs

5 Lnk/Act status LEDs

6 Rotary switch (for setting the protocol)

7 Fieldbus connection

8 M12 or 7/8" power supply connection

9 Module marker

10 Power supply status LED (U

system/sensor power supply)

S

11 Micro-USB port (not to be used by the customer)

12 Earth connection (M4 thread)

82484940000/00/02.2017 Manual UR67-Multiprotocol

Page 9

4.2 UR67-MP-HP-16DO-12-60M and

IN OUT

X01

UR67-MP-78-16DO-12-60M

IN

4

8

3 7

6

5

2

A

DIA

B

XE

OUT

Lnk/Act

P2P1

USU

L

16DO

A

DIA

B

A

DIA

B

A

DIA

B

x100

x10

x1

MS NS

BF DIA

0

E/IP

PN

0

0

BUS

1

12

11

10

2

1

7

6

5

4

3

9

8

UR67-MP-78-16DO-12-60M

4 Module descriptions | UR67-MP-HP-16DO-12-60M and UR67-MP-78-16DO-12-60M

Left: Output module UR67-MP-HP-16DO-12-60M (Order No. 2426280000)

Right: Output module UR67-MP-78-16DO-12-60M (Order No. 2426310000)

The UR67-MP modules are intended for the decentralised

control in an Ethernet/IP network or a PROFINET network.

The protocol is selected using the rotary switch.

Each module has eight connections (M12, 5-pole, A-coded)

for signal lines as well as connections for the eldbus (M12,

4-pole, D-coded). The power supply is connected via 5-pole,

A-coded M12 or 7/8" connections.

The UR67-MP-xx-16DO-12-60M modules have 16 digital

outputs (P-switching).

Diagnostic and status LEDs

LED Display Meaning

U

L

U

S

1–8 A Yellow Channel A status: On

1 –8 B White Channel B status: On

Lnk/Act

P1, P2

BF/MS Green Device operational (Ethernet/IP)

BF/MS Off No error (PROFINET)

DIA/NS Green Connected: at least one existing connection (Ethernet/IP)

DIA/NS Off No diagnosis available (PROFINET)

LED displays (normal operation); for error messages, see chapter 12

Green Actuator power supply

Green System/sensor power supply

Green Ethernet connection to another participant available, link

detected

Product details for UR67-MP-HP-16DO-12-60M and UR67-MP-78-16DO-12-60M

1 Marker connection1

2 I/O connections1 (sensor/actuator)

3 Status LED connection1, channelA/channelB

4 Fieldbus and module status LEDs

5 Lnk/Act status LEDs

6 Rotary switch (for setting the protocol)

7 Fieldbus connection

8 M12 or 7/8" power supply connection

9 Module marker

10 Power supply status LED (U

actuator power supply, US system/sensor

L

power supply)

11 Micro-USB port (not to be used by the customer)

12 Earth connection (M4 thread)

92484940000/00/02.2017 Manual UR67-Multiprotocol

Page 10

4.3 UR67-MP-HP-8DIDO-12-60M and

IN OUT

X01

UR67-MP-78-8DIDO-12-60M

IN

4

8

3 7

6

5

2

A

DIA

B

XE

OUT

Lnk/Act

P2P1

USU

L

8DIDO

A

DIA

B

A

DIA

B

A

DIA

B

x100

x10

x1

MS NS

BF DIA

0

E/IP

PN

0

0

BUS

1

12

11

2

1

7

6

5

4

3

9

8

10

UR67-MP-78-8DIDO-12-60M

4 Module descriptions | UR67-MP-HP-8DIDO-12-60M and UR67-MP-78-8DIDO-12-60M

Left: Input/Output module UR67-MP-HP-8DIDO-12-60M (Order No. 2426290000)

Right: Input/Output module UR67-MP-78-8DIDO-12-60M (Order No. 2426320000)

The UR67-MP modules are intended for the decentralised

control in an Ethernet/IP network or a PROFINET network.

The protocol is selected using the rotary switch.

Each module has eight connections (M12, 5-pole, A-coded)

for signal lines as well as connections for the eldbus (M12,

4-pole, D-coded). The power supply is connected via 5-pole,

A-coded M12 or 7/8" connections.

The UR67-MP-xx-16DI-12-60M modules have 8digital inputs (P-switching) and 8digital outputs.

Diagnostic and status LEDs

LED Display Meaning

U

L

U

S

1–8 A Yellow Channel A status: On

1 –8 B White Channel B status: On

Lnk/Act

P1, P2

BF/MS Green Device operational (Ethernet/IP)

BF/MS Off No error (PROFINET)

DIA/NS Green Connected: at least one existing connection (Ethernet/IP)

DIA/NS Off No diagnosis available (PROFINET)

LED displays (normal operation); for error messages, see chapter 12

Green Actuator power supply

Green System/sensor power supply

Green Ethernet connection to another participant available, link

detected

Product details for UR67-MP-HP-8DIDO-12-60M and UR67-MP-78-8DIDO-12-60M

1 Marker connection1

2 I/O connections1 (sensor/actuator)

3 Status LED connection1, channelA/channelB

4 Fieldbus and module status LEDs

5 Lnk/Act status LEDs

6 Rotary switch (for setting the protocol)

7 Fieldbus connection

8 M12 or 7/8" power supply connection

9 Module marker

10 Power supply status LED (U

actuator power supply, US system/sensor

L

power supply)

11 Micro-USB port (not to be used by the customer)

12 Earth connection (M4 thread)

102484940000/00/02.2017 Manual UR67-Multiprotocol

Page 11

4 Module descriptions | Connector pin assignment

5

3

3

4.4 Connector pin assignment

I/O connections

M12, A-coded 16DI 16DO 8DIDO

1 24V n.c.

3

2

4

2 In B Out B

1

3 GND 0V GND 0V GND 0V

4 In A Out A

5 FE FE FE

ATTENTION

For the system/sensor power supply and the actuator power supply, please only use power supplies that

conform to PELV (Protective Extra Low Voltage) or SELV

(Safety Extra Low Voltage) requirements. Power supplies in accordance with EN61558-2-6 (transformer) or

EN60950-1 (switched-mode power supply) meet these

requirements.

Power supply connection

Plug-in connector Signal Function

M12, 5-pole, L-coded

1

5

4

3

OUT

1

2

3

IN

7/8"

5

2 4

1

1 U

2

2 GND_U

3 GND_U

5

4 UL (+24V)

4

5 FE (PE) Functional earth

1 GND_U

24

2 GND_U

1

3 FE (PE) Functional earth

4 U

5

5 U

(+24V)

S

(+24V)

S

(+24V)

L

L

S

L

S

24V (connections 1–4)

n.c. (connections 5–8)

In B (connections 1–4)

Out B (connections 5–8)

In A (connections 1–4)

Out A (connections 5–8)

System/sensor power

supply

Earth/reference potential U

Earth/reference potential U

Actuator power supply

(electrically isolated)

Earth/reference potential U

Earth/reference potential U

System/sensor power

supply

Actuator power supply

(electrogalvanised)

PROFINET Ethernet/IP

M12, 4-pole, D-coded Signal Function

21

4

3

1 TD+ Transmission data +

2 RD+ Receive data +

3 TD– Transmission data –

4 RD– Receive data –

ATTENTION

The product can be destroyed!

▶ Never place the power supply (24VDC) on the signal

or data lines.

L

S

L

S

112484940000/00/02.2017 Manual UR67-Multiprotocol

Page 12

4.5 Technical Data

4 Module descriptions | Technical Data

Technical data UR67-MP-xx-16DI-12-60M

(2426270000, 242630000)

UR67-MP-xx-16DO-12-60M

(2426280000, 2426310000)

UR67-MP-xx-8DIDO-12-60M

(2426290000, 2426320000)

Bus system

Protocol

Vendor name (for Ethernet/IP)

Product type, number (for Ethernet/IP)

Product type, string (for Ethernet/IP)

Product code (for Ethernet/IP)

VendorID (for PROFINET)

DeviceID (for PROFINET)

EDS file (for Ethernet/IP)

GSDML file (for PROFINET)

Data transmission rate

Transmission method

Auto-negotiation

Switch functionality

Ethernet protocols supported

Connection

34003 (for UR67-MP-HP-16DI-12-60M)

34000 (for UR67-MP-78-16DI-12-60M)

Ping, ARP, DHCP, HTTP, TCP/ IP, BOOTP, beacon-based DLR (Ethernet/IP)

Ping, ARP, LLDP, DCP, HTTP, TCP/ IP, SNMP (PROFINET)

Ethernet/IP, PROFINET

1015

7

General Purpose Discrete I/O

34004 (for UR67-MP-HP-16DO-12-60M)

34001 (for UR67-MP-78-16DO-12-60M)

0x0134 hex

0x18C6 hex

WM_xx_Vz.z-WI-UR67-yyyymmdd.eds

GSDML-Vx.x-WI-UR67-yyyymmdd.xml

10/100 Mbps, Full Duplex (Ethernet/IP)

100 Mbps, Full Duplex (PROFINET)

100BASE-TX

Supported

Integrated, 2 connections

IRT supported (PROFINET)

M12, 4-pole, D-coded

34005 (for UR67-MP-HP-8DIDO-12-60M)

34002 (for UR67-MP-78-8DIDO-12-60M)

Inputs

Number of digital channels

Channel type

Input wiring

Rated input voltage

Input current at 24VDC

Short-circuit-proof

Status indicator

Diagnosis indicator

Connection

Type 3 in acc. with IEC 61131-2 – Type 3 in acc. with IEC 61131-2

Red LED for every M12 socket – Red LED for every M12 socket

16 – 8

NO contact, P-switching – NO contact, P-switching

24VDC – 24VDC

typically 5mA – typically 5mA

Yes – Yes

Yellow LED (channel A)

White LED (channel B)

M12, 5-pole, A-coded – M12, 5-pole, A-coded

– Yellow LED (channel A)

White LED (channel B)

Outputs

Number of digital channels

Channel type

Output wiring

Rated output current per channel

Signal status “1”

Signal status “0”

1)

– 16 8

– NO contact, P-switching NO contact, P-switching

– typically 1.6A in acc. with IEC61131-2 typically 1.6A in acc. with IEC61131-2

– 1.6A 1.6A

– max. 1.6A max. 1.6A

– max. 1mA (specication as per standard) max. 1mA (specication as per standard)

1) In the case of inductive loads in utilisation category DC13 (in acc. withEN60947-5-1), the outputs can operate with currents of 0.5A and a frequency of 1Hz.

2) Technically possible and approved on the following conditions: looped system/sensor power supply – max. 2.5 A; minimum cross-section of power supply wire –

5 x 1.0 mm²; max. ambient temperature – 40°C (104°F)

122484940000/00/02.2017 Manual UR67-Multiprotocol

Page 13

4 Module descriptions | Technical Data

Technical data UR67-MP-xx-16DI-12-60M

(2426270000, 242630000)

Signal level of the outputs

Signal status “1”

Signal status “0”

Short-circuit-proof

Max. current-carrying capacity per mo-

–

– min. (U

– max. 2V max. 2V

– Yes Yes

– 9.0A (12A2)) 9.0A (12A2))

dule

Overload-proof

Status indicator

Diagnosis indicator

Connection

– Yes Yes

– Yellow LED (channel A),

– Red LED, for each channel Red LED, for each channel

– M12 socket, 5-pole, A-coded M12 socket, 5-pole, A-coded

Electronics/sensor power supply

Rated voltage U

S

Voltage range

Electronics current consumption

Sensor voltage

Sensor current consumption

Polarity protection

Status indicator (US)

Connection

Actuator power supply

Rated voltage U

Aux

Voltage range

Potential isolation

Low voltage threshold

Delay time for low voltage detection

Polarity protection

Actuator power supply indicator (U

Connection

)

Aux

– 24 V DC (SELV/PELV)

– 24VDC ± 25%

– Yes

– typically 17 V

– typically 300ms

– Yes

– Green/red LED

– 7/8" plug and socket, 5-pole (UR67-MP-HP-X) M12, 5-pole, L-coded (UR67-MP-78-X)

General data

Type of protection

Ambient temperature

Weight

Enclosure material

Vibration resistance – vibration

Vibration resistance – impact

Tightening torques

M12 plug-in connector

UR67-MP-xx-16DO-12-60M

(2426280000, 2426310000)

– 1V) min. (U

Aux

white LED (channel B)

24 V DC (SELV/PELV)

24VDC ± 25%

typically 60mA

min. (U

max. 200mA (at Tu 30°C)

7/8" plug and socket, 5-pole (UR67-MP-HP-X)

M12, 5-pole, L-coded (UR67-MP-78-X)

IP 67 (only when all ports are either used or sealed)

500g (UR67-MP-HP-X)

520g (UR67-MP-78-X)

Zinc diecast, nickel matt surface nish

– 1.5V)

System

Yes

Green/red LED

-20°C to +70°C

15 g / 5–500 Hz

50 g/11 ms

0.5 Nm

UR67-MP-xx-8DIDO-12-60M

(2426290000, 2426320000)

– 1V)

Aux

Yellow LED (channel A),

white LED (channel B)

1) In the case of inductive loads in utilisation category DC13 (in acc. withEN60947-5-1), the outputs can operate with currents of 0.5A and a frequency of 1Hz.

2) Technically possible and approved on the following conditions: looped system/sensor power supply – max. 2.5 A; minimum cross-section of power supply wire –

5 x 1.0 mm²; max. ambient temperature – 40°C (104°F)

132484940000/00/02.2017 Manual UR67-Multiprotocol

Page 14

5 Installation and wiring

5 Installation and wiring | Preparations for installation

WARNING

Dangerous contact voltage!

▶ All installation and wiring work must be

carried out with the power supply disconnected.

▶ Make sure that the place of installation

has been disconnected from the power

supply!

5.1 Preparations for installation

Make sure that the permitted environmental conditions for

installation and operation are observed (see Technical data).

Installation position and dimensions

The modules must be installed on a level surface. The instal-

lation dimensions and tightening torques for the xings are

provided in the installation drawings on the following pages.

Unpacking the delivery

▶ Please check the delivery for completeness and transport

damage.

▶ Please report any transport damage immediately to the

respective transport company.

5.2 Installing the module and earth connection

▶ Drill the holes for the fixings (for the drilling dimensions,

see the installation drawings on the following pages).

▶ Affix each module with two screws and a washer (as per

DINEN ISO 7089).

▶ Observe the screw dimension and tightening torques indi-

cated.

Element Torque

M12 plug-in connector 0.5Nm

M12 protective cap 0.5Nm

The modules have an earth connection (“XE”) with an M4

thread for discharging interference currents and for EMC

stability.

▶ Connect the earth connection to the reference earth via a

low-impedance connection.

If the mounting surface is earthed, the connection can be

made directly via the mounting screws.

If the mounting surface is not earthed, use an earthing strap

or a suitable cable!

▶ Connect the earthing strap or the FE cable to the earth

connection (“XE”) using an M4 screw.

ATTENTION

The product can be destroyed by electrostatic discharge!

u-remote products can be destroyed by electrostatic discharge.

▶ Please make sure that personnel and work

equipment are adequately earthed!

▶ Unpack the parts.

▶ Dispose of all packaging in accordance with the local dis-

posal guidelines. The cardboard packaging can be sent

for paper recycling.

142484940000/00/02.2017 Manual UR67-Multiprotocol

Page 15

5 Installation and wiring | Installing the module and earth connection

59.6

M12

I/O

M12

BUS

M12

Power

17.6

354

female

12

M12 I/0

Pin

Function

1

24V

In B

2

GND 0V

3

In A

4

5

FE

24V +25% / -25%; 120mA

24V 200mA

-20 ° ... 70 °C / -4 ° ...158 °F

System Power Supply:

Input Power Supply:

Max. Amblent Temp.:

E/IP

0

1

9

2

P

PN

0

1

9

2

8

7

3

4

6

5

0

1

9

2

8

7

3

4

6

5

3 4

female

12

Bus

Pin

Function

1

TD+

2

RD+

3

TD-

4

RD-

Power

FunctionPin

1

+24V

2

GND UL

3

GND 0V

+24V UL

4

FE

5

1

2

5

female

3

4

200.0

29.8

1 5

2

3 7

4

190.0 ... 192.0

Lnk/Act

0

E/IP

x100

IN OUT

IN

PN

P2P1

A

DIA

B

A

DIA

B

A

DIA

B

A

DIA

B

BF DIA

MS NS

0

x10

BUS

M4x25/30

6

8

U

S

0

x1

X01

M4x25/30

OUT

XE

M4

20.030.7

Installation dimensions UR67-MP-HP-16DI-12-60M (2426270000), UR67-MP-HP-16DO-12-60M (2426280000), UR67-MP-HP-8DIDO-12-60M (2426290000)

152484940000/00/02.2017 Manual UR67-Multiprotocol

Page 16

5 Installation and wiring | Installing the module and earth connection

59.6

M12

I/O

M12

BUS

7/8"

Power

17.3

354

female

12

M12 I/0

Pin

Function

1

24V

In B

2

GND 0V

3

In A

4

5

FE

24V +25% / -25%; 120mA

24V 200mA

-20 ° ... +70 °C / -4 ° ... +158 °F

System Power Supply:

Input Power Supply:

Max. Amblent Temp.:

E/IP

0

1

9

2

P

PN

0

1

9

2

8

7

3

4

6

5

0

1

9

2

8

3

7

4

6

5

3 4

female

12

Bus

Pin

Function

1

TD+

2

RD+

3

TD-

4

RD-

Power

FunctionPin

1

GND UL

2

GND 0V

3

FE

4

+24V

5

+24V UL

1

2

3

female

45

206.0

29.8

1

2

3 7

4

0

Lnk/Act

E/IP

197.0 ... 198.0

x100

IN OUT

IN

PN

P2P1

BF DIA

MS NS

0

x10

BUS

A

DIA

B

A

DIA

B

A

DIA

B

A

DIA

B

5

6

8

U

S

0

x1

X01

OUT

M4x25/30

XE

M4

M4x25/30

20.026.2

Installation dimensions UR67-MP-78-16DI-12-60M (2426300000) , UR67-MP-78-16DO-12-60M (2426310000), UR67-MP-78-8DIDO-12-60M (2426320000)

162484940000/00/02.2017 Manual UR67-Multiprotocol

Page 17

5 Installation and wiring | Attaching markers

5.3 Attaching markers

The module and all ports can be labelled using markers. This

ensures clear allocation at all times during maintenance

work.

▶ Press the labelled marker into the corresponding fixture

opening.

▶ To remove a marker, lever it out carefully using a screw-

driver (2.5 or 3mm).

5.4 Setting the eldbus protocol

The eldbus protocol and the IP address of the module can

be adjusted using the rotary switches (see section 7.1).

5.5 Wiring

WARNING

Dangerous contact voltage!

▶ All installation and wiring work must be

carried out with the power supply disconnected.

▶ Make sure that the place of installation

has been disconnected from the power

supply!

5.6 Insulation test

Insulation tests must always be carried out before each commissioning and in accordance with the respective national

provisions.

ATTENTION

The product can be destroyed by too

high test voltage!

Please observe the following during insulation tests:

– The test voltage within a channel must be

between 24V and max. GND of 30V!*

– A test voltage of max. 500 V can be

applied to all other connection points.

* We recommend connecting 24V and GND at the power

supply plug.

Once the module has been mechanically installed, the wiring

can be carried out in accordance with the wiring plan.

Ensure compliance with the minimum permissible cable bending radius.

All unused ports must be sealed with protective caps in order to achieve protection class

IP67.

172484940000/00/02.2017 Manual UR67-Multiprotocol

Page 18

6 Earthing and shielding

6 Earthing and shielding | Earthing of shielded cables

6.1 Earthing of shielded cables

Electrical and electronic systems must be designed such that

they are largely safeguarded against electrical interference,

thus enabling them to operate securely even in the case of

transient interference voltages.

Electrical interference can be introduced into electric circuits

in a variety of ways. The most frequent causes are due to

inductive interference. In addition, galvanic and capacitive

coupling as well as electrical elds and other processes are

causes for interference voltages. Here, high-frequency voltage

uctuations – known as transients – are the cause of interference with a high level of effectiveness.

Shielded cables increase interference resistance

The sources of interference voltages can rarely be eliminated

and even then not always completely. Thus, it is necessary to

take measures to combat their effect. In general, the more effectively interference voltages can be kept away from circuit

elements or can be discharged, the less electrical circuits are

affected. This can be accomplished in a variety of ways with

varying levels of effectiveness. A very effective measure, in

particular for safeguarding against inductive effects, i.e. ensuring “electromagnetic compatibility” (EMC), is the shielding of electrically functional components to earth potential.

In doing so, for instance, components are installed in metallic, earthed housings and the connecting lines are equipped

with shielding.

Proper use of shielded cables

The shielding of cables will only result in the desired effect if

this is implemented properly. Incorrect earthing or the use of

improper components that perform their task inadequately

reduces or even totally eliminates the effect. Placing the

shielding at any spot on the earth potential will not sufce,

as this earth connection may have no effect on high frequencies. In addition, ground loops must also be taken into consideration. Furthermore, the shielding should be earthed over

a large surface area. Beyond that, the quality of the shield

conductor and earthing accessories is also important.

Weidmüller clamping bracket KLBUE 10-20 SC (Order No. 1712321001)

In general, it can be said that interference from cables can

be combated by routing cables as far away as possible from

each other, keeping the common return as short as possible

and using twisted-pair wire. Far better protection, however,

is provided by completely shielding of all cables. This is the

most effective measure that can be taken against the coupling of interference signals.

The best type of shielding consists of a braided mesh sleeve

that uses individual wires made of non-magnetic materials

(copper, aluminium). The braided mesh should be sufciently

large and also be as thick as possible. For cables that are

equipped with foil shields, it is necessary to be aware of the

low mechanical strength and the low current-carrying capacity of the shielding.

In practice, the shield is still often twisted and connected

to a terminal point. There is very high attenuation (voltage

drop) on these connections, especially for high-frequency

interference. Therefore, this type of shielding should not be

used, even for short cable lengths. The shielding of the cable

is practically negated and can, at best, be helpful for lowfrequency interference. We recommend that there is a large

amount of surface contact with the braided shield of the

cable.

There are generally four distinct types of coupling:

– Galvanic coupling

– Capacitive coupling

– Inductive coupling

– Radiation coupling

182484940000/00/02.2017 Manual UR67-Multiprotocol

Page 19

6 Earthing and shielding | Earthing of shielded cables

These types of interference usually occur mixed together, but

they can be categorised as follows:

– Electromagnetic fields

– Ripple voltage (50Hz)

– Lightning

– Interference pulses (current, voltage)

– Transient surge voltages

– Radio interference

– ESD (electrostatic discharge)

– Burst

– Mains feedback

Another area of concern as regards shield

contact is the “ow” within the conductor. Temperature changes caused by the current lead

to changes in the conductor cross-section. A

rigid contact can therefore only be partially

effective. A self-adjusting contact is what is

really required. Weidmüller's clamping bracket

products (KLBÜ series) provide the perfect solution to meet this challenge..

When installing ground connections on shielding, it is generally also important that no earth loops are created. The

smaller the earth loop, the less the danger of the induction

of interference voltages. It is therefore most suitable to have

apurely neutral-point installation.

The following sketches show the possible shielding connections to protective earth.

A one-sided connection of the shielding protects against capacitive coupling of interference voltages.

System 1 System 2

1HF1MM

∬

If you use a two-sided shielding connection, make sure that

compensating current (different earth potentials) does not

ow through the cable shield.

System 1 System 2

Use of a clamping bracket

Effective shielding

It is important that the shielding is not positioned on the

earth of the connected component, but on the protective

earth. In the case of components that are installed in a metal

housing, the shielding must be positioned to this housing. If

no earthed housing is available, the shielding is positioned

on a separate earth.

If you wish to avoid the disadvantages associated with creating an earth loop with two-sided shields, it is recom mended

you connect one side of the shield through ahigh impedance.

System 1 System 2

For longer lengths of shielded cables, such as if a sensor

must be added to a control panel, a potential difference

between both end points must not be ignored.

However, such shield conductors are relatively expensive

and also require more time in working with them. Another

possibility would be to place an additional voltage equalising

cable between the measurement location and the control

panel. The shield can then be hooked up on both sides.

192484940000/00/02.2017 Manual UR67-Multiprotocol

Page 20

6 Earthing and shielding | Potential ratios

A high-impedance earth connection is also another option.

In the control panel, the shield is then connected to the earth

potential, and the shield has a high-impedance connection to

earth at the measurement location via a gas discharge tube.

This solves the problem of a potential transfer and 50-Hz

humming.

For non-isolated measurement locations, two gas discharge

tubes must be installed. One connects the shield to earth,

and the other connects it to the non-isolated measurement

location. This method prevents a galvanic coupling between

the measurement circuit and the earthed measurement

location.

Shield connection

Earth

Measuring point

1 4

5

TS

2 3

IN

OUT

Summary

Earthing is a key element for the reliable functioning of an

electrical system in the event of interference. In this regard,

HF-related aspects must be taken into consideration. Only

the proper use of materials and a well thought-out circuit

design will lead to success.

6.2 Potential ratios

Ensuring EMC

To ensure EMC, the following basic principles must be observed during installation of the u-remote modules:

– Proper, extensive earthing of inactive metal parts

– Correct shielding of cables and equipment

– Proper layout of wires – cabling

– Creation of a uniform reference potential and earthing

ofall electrical equipment

– Special EMC measures for special applications

(e.g. frequency converters, servo drives)

– Contactors and relay coils must be equipped with the

corresponding interference suppressors.

– Devices and function units with higher interferance poten-

tial have to be capsuled if necessary.

Earthing of inactive metal parts

The earthing of all inactive metal parts reduces the inuence

of coupled interference. For this purpose, all inactive metal

parts (such as switch cabinets, cabinet doors, support beams,

mounting plates, DIN rails, etc.) must be con nected to each

other over a large surface area with low impedance, whereby

a uniform reference potential is ensured for all control unit

elements.

Required measures:

– Removal of the insulating layer around screw connec-

tions. Protection of connection points against corrosion

– Connection of moving earthed components (cabinet

doors, separated mounting plates, etc.) through short

earthing straps with large surfaces

– When possible, avoid using aluminium parts, because alu-

minium oxidises easily and in this respect is unsuited for

earthing

The reference potentials of system/input supply and output

supply are galvanically isolated from each other.

6.3 Electromagnetic compatibility (EMC)

u-remote products completely meet EMC requirements. EMC

planning, however, is necessary prior to installation.

Aspects to consider include all potential interference sources

such as galvanic, inductive and capacitive couplings, as well

as radiation couplings.

PE connection

The connection from earth to the PE (protective earth) connection must be done centrally.

WARNING

Possible danger to life!

In the event of a fault, the earth must never

take on a dangerous contact voltage, which is

why it must be connected to a PE conductor.

Unearthed operation

In the event of unearthed operation, the corresponding safety regulations must be observed.

202484940000/00/02.2017 Manual UR67-Multiprotocol

Page 21

6 Earthing and shielding | Shielding of cables

Sensor and actuator lines

To avoid antenna effects caused by looped lines, all lines that

go to a certain sensor or actuator should be combined in one

cable.

Cabinet design according to EMC guideline:

1 Earthing strips

Earthing strips must be used for connecting inactive metal

parts if it is not possible to connect two large pieces of metal. Use short earthing strips with large surfaces.

2 Clamping bracket for signal cables

If shielded signal cables are used, the shield must be at-

tached to the clamping bracket (KLBÜ series) on the busbar

over a large surface. The braided shield must cover and make

good contact with a large part of the clamping bracket.

3 Mounting plate

The support beam for holding control components must be

connected to a large part of the cabinet housing.

4 Busbar

The busbar must be connected via the rail holding xture.

The cable shields are xed to the busbar.

5 Protective earth conductor rail

The protective earth conductor rail must likewise be attached

to a large part of the mounting plate, and it must be connected to the protective earth conductor system via an external cable with a cross-section of at least 10 mm

discharge interference current.

2

, in order to

6 Protective earth terminal strip

The protective earth terminal strip must be connected to the

protective earth conductor rail in a neutral-point conguration.

7 Cable to protective conductor system (earthing

point)

The cable must be connected to a large part of the protective

conductor system.

See also:

EMC Directive 2014/30/EU

24567

3

1

6.4 Shielding of cables

To prevent the coupling of interference voltages and the de-

coupling of interference elds in cables, only shielded cables

made from well-conducting material (copper or aluminium)

with braided shielding and a coverage of at least 80 %

should be used in the design of a cable shield.

212484940000/00/02.2017 Manual UR67-Multiprotocol

Page 22

6 Earthing and shielding | Shielding of cables

Only when a cable shield is connected to the local reference potential on both sides is it possible to achieve optimal

shielding against electric and magnetic elds. Exceptions

are possible, for example, with high-impedance, symmetrical

or analogue signal cables. If a shield is attached on only one

side, this merely achieves an isolation against electric elds.

ATTENTION

Material damage!

Requirements for effective shielding design:

– The shield connection to the shield bus should be low

impedance

– The shield must be connected directly at its entrance

into the system

– Keep cable ends as short as possible

– Do not use cable shields for equipotential bonding

When connecting a data cable using a sub-D connector, the

connection must be made through the connector’s shield

collar and never through pin 1.

The data cable’s shield must be attached to the shield bus

with the insulation stripped away. The shield is to be connected and attached with clamping brackets or similar metal

xing devices. The shield bus must be connected to the reference potential surface through a low impedance (e.g.fastening point with a separation of 10 to 20cm). The brackets

must surround and make contact with a large part of the

shield.

Isolation of the cable shield should be avoided. Instead, it

should be routed into the system (for example, the switch

cabinet) up to the interface connection.

ATTENTION

Shielding of eld bus cables

When shielding eld-bus cables, the installation guidelines

for the respective eld buses must be observed. (See the

websites of the eld bus organisations.)

Material damage!

If it is only possible to have a one-sided shield connection

for reasons specic to the circuit or equipment, the second

side of the cable shield can be routed to the local reference

potential via a capacitor (with short connections). To prevent disruptive discharges when interference pulses occur,

a varistor or a resistor can also be wired in parallel to the

capacitor.

As an alternative, a doubled version (galvanically isolated)

can be used, whereby the inner shield is connected on one

side and the outside shield is connected on both sides.

Equipotential bonding

If system components are positioned separately from each

other, potential differences may arise, provided that:

– Power is provided from different sources

– The earthing is implemented at different system parts,

despite the cable shields being connected at both sides

A voltage equalising cable must be used for equipotential

bonding.

WARNING

Possible danger to life!

The shield must not be used for equipotential

bonding!

The following features are essential for a voltage equalising

cable:

– In the case of cable shields on both ends, the impedance

of the equalising cable must be considerably smaller than

that of the shield connection (maximum 10 % of its

impedance)

– When the length of the equalising cable is less than

200m, its cross-section must be at least 16 mm

cable is greater than 200m in length, a cross-section of

at least 25 mm

– Large-surface connection with the PE conductor or the

earthing and corrosion protection are requirements for

long-term safe operation

– They must be made of copper or galvanised steel

– In order to keep the enclosed area as small as possible,

the equalising cable and signal cable must be routed as

close to each other as possible

2

is necessary.

2

If the

Wiring of inductances

In case of inductive loads we recommend a suppressor

circuit directly on the load. The ground (PE/FE) must be positioned star-shaped according to the standards.

222484940000/00/02.2017 Manual UR67-Multiprotocol

Page 23

7 Commissioning

7 Commissioning | Setting the eldbus protocol

WARNING!

Manipulation of the controller!

During commissioning, the system may be

manipulated to such an extent that this can

result in risks to life and material damage.

▶ Make sure that system components can-

not start up unintentionally!

The procedures applied during commissioning depend on

which eldbus protocol has been chosen and which controller is being used.

7.1 Setting the eldbus protocol

The eldbus protocol and the module behaviour in the network are set using the rotary switches. The module adopts

and saves these settings upon the next instance of the power supply being switched on.

The eldbus protocol can only be set

(changed) if the module is using the factory

settings.

Any changes made to the position of the

rotary switch only take effect once the power

supply has been switched off and back on

again.

Setting Protocol Function

The previously saved network settings are used.

000 Ethernet/IP

001 to 254 Ethernet/IP

255 to 298 Ethernet/IP

299 Ethernet/IP

300 to 399 PROFINET Network parameters are allocated via DCP.

900 to 999

(Exception: 979)

979 – Restoring factory settings

Only use DHCP/BOOTP if a suitable server is

in the network which can assign the network

parameters to the module.

▶ Restore the factory settings using the rotary switch

(seesection7.2).

▶ Turn the left rotary switch (“x100”) to a value from 0 to 3.

▶ Turn the middle rotary switch (“x10”) to a value from 0 to

9.

▶ Turn the right rotary switch (“x1”) to a value from 0 to 9.

▶ Switch the power supply off and back on again

The modules adopts the news settings.

If an invalid setting has been made, the BF/MS LED will ash

red three times.

When in the delivery condition, the network parameters are requested via DHCP/BOOTP.

The last byte of the IP address is overwritten with

the set value (192.168.1.XXX).

The network parameters are requested via DHCP/

BOOTP, but are not saved.

The factory settings for the IP address are used

(192.168.1.1).

– Invalid setting

2 1 0

0

E/IP

0

0

PN

x100

Example: Setting the value of „210“ (IP address 192.168.1.210 for Ethernet/IP)

The following table shows the rotary switch settings possible.

x10

x1

7.2 Restoring factory settings using the rotary switch

The module‘s factory settings can be restored via the rotary

switch. The protocol settings can be reset in the same way.

The Factory settings web server function

does not reset the protocol settings.

▶ Turn the left rotary switch (“x100”) to the value 9.

▶ Turn the middle rotary switch (“x10”) to the value 7.

▶ Turn the right rotary switch (“x1”) to the value 9.

▶ Switch the power supply off and back on again

The module is reset to factory settings.

232484940000/00/02.2017 Manual UR67-Multiprotocol

Page 24

7 Commissioning | Commissioning with Ethernet/IP

9 7 9

0

E/IP

0

0

PN

x100

Restoring factory settings using the rotary switch

x10

7.3 Commissioning with Ethernet/IP

The description in this section uses the commissioning of

Studio 5000 Logix Designer from RockwellAutomation in

online operation as an example.

Requirements

Before you start the commissioning work, the following re-

quirements must be fullled.

– The controller must be in operation.

– The UR67 modules must be completely installed and

wired up.

– The controller and UR67 modules must be connected via

Ethernet, and a PC/laptop must be likewise connected

using the controller software.

– The module must be set to Ethernet/IP with a unique IP

address using the rotary switch (seesection7.1).

– The power supply must be turned on.

x1

Connecting the module to the Ethernet/IP network

▶ Open the Studio 5000 software.

▶ Create a new project or open an existing project.

If the communication path for the controller is out-of-date or

has not been specied, this must be specied before establishing the rst connection.

▶ Click on the Connections menu and select Who‘s

Active.

▶ In the Who‘s Active dialogue box, select the controller

used.

▶ Establish a connection to the controller (GoOnline).

If your project does not match the project on the controller,

load your project onto the controller (Download) or transfer

the project from the controller to Studio 5000 (Upload). The

controller must be in programming mode in both cases.

All projects downloaded from Studio 5000 to the

controller irrevocably overwrite any projects saved

on the controller.

▶ Use the mouse to right-click on I/O Configuration/... in

the Controller Organiser or the Backplane subfolder.

▶ Click Discover Modules.

The Select Module Type window opens.

MAC addresses

Each module has a unique MAC address allocated by the

manufacturer and which cannot be changed by the user. The

MAC address is printed on the side of the module.

Installing the EDS le

All of the module variants are described in les named

WM_xx_Vz.z-WI-UR67-yyyymmdd.eds. (where xx

stands for the ten-digit module order number, z.z for the

software version, and yyyymmdd for the le issue date).

All EDS les are stored together in an archive le named

DeviceDescription.zip

▶ Open the Studio 5000 software.

▶ Download and unpack the archive file from the Weidmül-

ler website.

▶ In the Tools menu within the Studio 5000 software,

select the EDS Hardware Installation Tool option.

▶ Follow the installation wizard.

.

Selecting the Ethernet/IP inter face

▶ Select the required Ethernet/IP interface and click Cre-

ate.

The New Module window opens.

242484940000/00/02.2017 Manual UR67-Multiprotocol

Page 25

7 Commissioning | Commissioning with Ethernet/IP

Configuring the Ethernet/IP interface

▶ Enter a name for the interface and define the required IP

address settings.

▶ Click OK.

The Ethernet/IP interface is created in the Controller Or-

ganiser.

▶ In the Controller Organiser, right-click on Ethernet in

the Ethernet/IP interface that you have just created.

▶ Click Discover Modules.

The Select Module Type window opens.

Selecting the module

▶ Select the required UR67-MP module and click Create.

The New Module window opens.

Entering the module name

▶ Enter a name for the module.

▶ Click Change.

The Module Denition window opens.

Selecting the connection type

▶ Select the connection type.

The connection type determines which process

and diagnostic data is provided to the module.

The connection types provided for the respective modules are shown in the “Connections and

assembly objects” section.

▶ Click OK.

The Module Denition window is closed.

▶ Click the Connections tab in the New Module window.

252484940000/00/02.2017 Manual UR67-Multiprotocol

Page 26

Register connections

▶ Set the Requested Packet Interval (RPI) and the form of

communication (unicast or multicast) and confirm by

clicking OK.

The RPI selected must be greater than 1ms.

Connections and assembly object

The UR67-MP modules support the connection types Exclusive Owner, Input Only and Listen Only.

Exclusive Owner

▶ Select the Exclusive Owner connection type for independ-

ent connections, which are to be used to transfer both

input and output data.

An Exclusive Owner connection is independent of all other

connections. A UR67-MP module can only accept one Exclusive Owner connection.

The Exclusive Owner connection type is available solely for

modules with output functionality (UR67-MP-xx-16DO-12-

60M and UR67-MP-xx-8DIDO-12-60M).

Input Only

▶ Select the Input Only connection type for independent

connections, which are to be used to solely transfer input

data.

An Input Only connection is independent of all other connections. A UR67-MP module can accept multiple Input Only

connections.

The Input Only connection type is available for all modules.

Listen Only

▶ Select the Listen Only connection type for dependent

connections, which are to be used to solely transfer input

data.

A Listen Only connection is dependent on other connections

that are not of the Listen Only type. If the last connection on

which a Listen Only connection is dependent is terminated,

7 Commissioning | Commissioning with Ethernet/IP

this Listen Only connection will likewise be terminated. A

UR67-MP module can accept multiple Listen Only connections.

The Listen Only connection type is available for all modules.

Select the instance ID of the assembly object to decide

whether the module adds diagnostic data to the process

data.

Connection

type

Exclusive

Owner

Input Only

Listen Only

Dia

gnostics

Yes

No

Yes

No

Yes

No

Instance ID

Input: 101 – 7 bytes 6 bytes

Output: 100 – 2 bytes 1 byte

Conguration: 105 – 64 bytes 32 bytes

Input: 102 – 3 bytes 3 bytes

Output: 100 – 2 bytes 1 bytes

Conguration: 105 – 64 bytes 32 bytes

Input: 101 4 bytes 7 bytes 6 bytes

Output: 193 0 bytes 0 bytes 0 bytes

Input: 102 3 bytes 3 bytes 3 bytes

Output: 193 0 bytes 0 bytes 0 bytes

Input: 101 4 bytes 7 bytes 6 bytes

Output: 192 0 bytes 0 bytes 0 bytes

Input: 102 3 bytes 3 bytes 3 bytes

Output: 192 0 bytes 0 bytes 0 bytes

Length for UR67-MP-xx-...-

12-60M

16DI 16DO 8DIDO

Initial connection parameter settings

The conguration tools produced by other controller manufacturers may also request that users enter other parameters

in order to set up a communication connection between the

I/O scanner and the module.

Parameter

Transport mode Input Only Exclusive Owner Exclusive Owner

Trigger mode Cyclic

Requested Packet Interval (RPI) Minimum 1ms, Standard 5ms

Output data (O->T) connection parameters

Real-time transfer format Heartbeat 32-bit run/idle header

Connection type POINT2POINT

Assembly instance ID 193 100

Data type USINT

Data length 0 bytes 2 bytes 1 byte

UR67-MP-xx-...-12-60M with diagnosis

16DI 16DO 8DIDO

262484940000/00/02.2017 Manual UR67-Multiprotocol

Page 27

7 Commissioning | Commissioning with Ethernet/IP

Parameter

UR67-MP-xx-...-12-60M with diagnosis

16DI 16DO 8DIDO

Input data (T->O) connection parameters

Real-time transfer format Connection is pure data and modeless

Connection type MULTICAST

Assembly instance ID 101

Data type USINT

Data length 4 bytes 7 bytes 6 bytes

Parameterising the module with Ethernet/IP

▶ In the Controller Organiser, switch to .../Controller Tags.

The controller tags for the parameters bear the name of the

module, followed by “:C”, the parameter name, the port designation and the pin designation.

The conguration assembly instance depends on the module

and is as follows:

– 32words (64bytes) for UR67-MP-xx-16DO-12-60M

– 16words (32bytes) for UR67-MP-xx-8DIDO-12-60M

Configuration assembly instance: UR67-MP-xx-16DO-12-60M

Parameter Port Channel Value range

Word0 Surveillance Timeout Connection 1 A (Pin4) 0 to 255

Word1 Surveillance Timeout Connection 1 B (Pin2) 0 to 255

Word2 Surveillance Timeout Connection 2 A (Pin4) 0 to 255

... ... ... ... ...

Word13 Surveillance Timeout Connection 7 B (Pin2) 0 to 255

Word14 Surveillance Timeout Connection 8 A (Pin4) 0 to 255

Word15 Surveillance Timeout Connection 8 B (Pin2) 0 to 255

Word16 Fail Safe Connection 1 A (Pin4) 0 to 2

Word17 Fail Safe Connection 1 B (Pin2) 0 to 2

Word18 Fail Safe Connection 2 A (Pin4) 0 to 2

... ... ... ... ...

Word29 Fail Safe Connection 7 B (Pin2) 0 to 2

Word 30 Fail Safe Connection 8 A (Pin4) 0 to 2

Word31 Fail Safe Connection 8 B (Pin2) 0 to 2

Controller tags

▶ Enter the required parameter values for each output chan-

nel.

A detailed description of the individual parameters and their

availability can be found in section7.5.

Conguration assembly instance

Using the conguration assembly instance, the “Fail Safe”

and “Surveillance Timeout” parameters can be determined

for each individual output channel. A detailed description of

the individual parameters and their availability can be found

in section7.5.

The conguration assembly instance is available solely for

modules with output functionality (UR67-MP-xx-16DO-12-

60M and UR67-MP-xx-8DIDO-12-60M) and the Exclusive

Owner connection type. The assembly instance ID is 105.

Configuration assembly instance: UR67-MP-xx-8DIDO-12-60M

Parameter

Word0 Surveillance Timeout Connection 5 A (Pin4) 0 to 255

Word1 Surveillance Timeout Connection 5 B (Pin2) 0 to 255

Word2 Surveillance Timeout Connection 6 A (Pin4) 0 to 255

... ... ... ... ...

Word5 Surveillance Timeout Connection 7 B (Pin2) 0 to 255

Word6 Surveillance Timeout Connection 8 A (Pin4) 0 to 255

Word7 Surveillance Timeout Connection 8 B (Pin2) 0 to 255

Word8 Fail Safe Connection 5 A (Pin4) 0 to 2

Word9 Fail Safe Connection 5 B (Pin2) 0 to 2

Word10 Fail Safe Connection 6 A (Pin4) 0 to 2

... ... ... ... ...

Word13 Fail Safe Connection 7 B (Pin2) 0 to 2

Word14 Fail Safe Connection 8 A (Pin4) 0 to 2

Word15 Fail Safe Connection 8 B (Pin2) 0 to 2

Connection

Channel Value range

272484940000/00/02.2017 Manual UR67-Multiprotocol

Page 28

7.4 Commissioning with PROFINET

The description in this section uses commissioning with the

Siemens SIMATIC Manager Step7 as an example. (V5.5 SP2

and higher).

Requirements

Before you start the commissioning work, the following re-

quirements must be fullled.

– The controller must be in operation.

– The UR67 modules must be completely installed and

wired up.

– The controller and UR67 module must be connected via

Ethernet, and a PC/laptop must also be connected.

– The module must be set to PROFINET using the rotary

switches (seesection7.1).

– The power supply must be turned on.

MAC addresses

Each module has a unique MAC address allocated by the

manufacturer and which cannot be changed by the user. The

MAC address is printed on the side of the module.

Installing the GSDML le

A description of all module variants is provided in the

le named GSDML-Vx.x-WI-UR67-yyyymmdd.xml.

(where x.x stands for the software version and yyyym-

mdd for the le issue date). The GDSML le and the associated bitmap les are stored together in the archive le

DeviceDescription.zip

▶ Download and unpack the archive file from the Weidmül-

ler website.

▶ Always store the supplied bitmap files for vis-

ualising the modules in the same folder as

the GSDML file.

.

7 Commissioning | Commissioning with PROFINET

Selecting the GSDML file

▶ Select the file that you would like to install.

▶ Click Install.

▶ When the installation is complete, click Close.

▶ Update the device catalogue via Options/Update cata-

log.

The UR67 modules associated with the current le describing the device are now listed in the device catalogue.

Connecting the module to the PROFINET network

▶ To set up a new project, click File/New in SIMATIC Man-

ager.

The New Project window opens.

▶ Enter a name for the new project (e.g. UR67_Station1)

and click OK.

The new project is displayed in SIMATIC Manager.

Projects must not be open in the hardware

conguration tool while the GSDML le is being

installed!

▶ Close any open projects before installing the

GSDML files!

▶ Start SIMATIC Manager.

▶ In the hardware configuration tool, navigate to Options/

Install GSD file.

▶ Select the directory in which you have stored the file

describing the device.

The les available are displayed.

Creating a new project

282484940000/00/02.2017 Manual UR67-Multiprotocol

Page 29

▶ Select the project in SIMATIC Manager

▶ Select the controller type via Insert/Station (e.g.

SIMATIC 300).

7 Commissioning | Commissioning with PROFINET

Adding a station

▶ Double-click on the project name so that the station

(SIMATIC 300) is displayed below in the directory tree.

▶ Click on the station (SIMATIC 300).

▶ Double-click Hardware on the right-hand side of the win-

dow.

The hardware conguration tool (HW Cong) opens.

Selecting a mounting rail

▶ Double-click on the mounting rail or drag it to the left-

hand side of the window using the mouse.

The mounting rail (UR) is displayed with the open positions.

Profile rail with open positions

Hardware configuration tool

▶ The device catalogue is displayed on the right-hand side

of this window. If this does not occur, open the catalogue

via View/Catalog.

▶ In the device catalogue, select the mounting rail in use

(e.g. SIMATIC 300/RACK-300).

▶ Click on the second line of the UR table.

▶ From the catalogue, select the control unit in use and its

version (inscription on the control unit, e.g. 314-GEH04-

...).

292484940000/00/02.2017 Manual UR67-Multiprotocol

Page 30

7 Commissioning | Commissioning with PROFINET

▶ Click on the network line in the configuration window.

▶ In the device catalogue, select the module under PROFI-

NET IO/Additional field devices/ I/O /WIUR67.

▶ Double-click on the module or drag it to the subnet line.

The module is added to the subnet.

Selecting the controller version

▶ Double-click on the respective version, or use the mouse

to drag it to the second position in the table on the lefthand side of the window.

The Ethernet interface properties window opens.

Ethernet interface properties

Connecting the UR67-MP module

Viewing and changing device names

PROFINET devices are addressed in PROFINET via a unique

device name. These names can be freely assigned; however,

they can only be used once in the network.

▶ Double-click on the module.

The Properties... window opens.

▶ Enter the designated IP address and the subnet mask for

the controller.

▶ Click on New.

The New Industrial Ethernet subnet properties window

opens.

▶ Enter a name for the subnet and confirm by clicking OK.

▶ Select the new subnet in the Ethernet interface prop-

erties window and confirm by clicking OK.

Module properties

The device name must match the name that has

been assigned to the module.

302484940000/00/02.2017 Manual UR67-Multiprotocol

Page 31

7 Commissioning | Commissioning with PROFINET

▶ Change the device names as required.

▶ Check whether the displayed IP address is correct and

whether the controller and module are in the same Ethernet subnet.

▶ Confirm the settings by clicking OK.

All settings only take effect once they have been

loaded into the module/control unit (see below).

Assigning a device name to a UR67-MP module

To assign a device name to a module, the PC must be connected to the module via a PROFINET connection.

▶ Select the module.

▶ Open the dialogue box PLC/Ethernet/Assign device

name.

– The IO controller must support the “Device replacement

without interchangeable medium/PG” function.

– The neighbouring PROFINET devices of the module to be

exchanged must support the “Device replacement with-

out interchangeable medium/PG” function.

– The function must be activated for the IO controller.

– The PROFINET network topology must be configured and

match the real topology.

– The device to be exchanged-in must be set to its factory

settings.

If the user intends to use the “device replacement

without interchangeable medium/PG” function,

the device to be exchanged-in must be reset to its

factory settings before being swapped in.

“Device replacement without interchangeable medium/PG”

can be congured in STEP 7.

▶ In the hardware configuration tool, double-click the

PROFINET IO port (PN-IO) for the controller in order to

open the PN-IO properties... window.

▶ Activate Support device exchange without

exchangeable medium and close the window by click-

ing OK

Assigning a device name

▶ Select the UR67-MP module required.

▶ Click Assign name.

▶ Close the dialogue box.

Device replacement without interchangeable medium/PG

The UR67-MP modules support the “Device replacement

without interchangeable medium/PG” function. Modules in a

PROFINET network can be exchanged for identical modules

without having to reassign the device name using a programming device.

The IO controller (e.g. a controller) assigns the module

exchanged-in the device name based on the congured to-

pology and the real neighbourhood relationship determined

by the IO devices. In order to use the “Device replacement

without interchangeable medium/PG”, the following require-

ments must therefore be fullled: