Weider WESY59840 Owner’s Manual

Mode!No.WESY59840

Seria_No.

WritetheseriaUnumberinthe

spaceaboveforfuturereference,

SedaUNumberDecaU(underseat)

Asamanufacturer,wearecom-

mittedto providingcomptete

customersatisfaction.Ifyou

havequestions,or ifthereare

missingordamagedparts,we

will guarantee complete satis-

faction through direct assis-

tance from our factory.

TO AVOID DELAYS, PLEASE

CALL DIRECT TO OUR TOLL-

FREE CUSTOMER NOT LINE.

The trained technicians on our

customer hot tine wil! provide

immediate assistance, free of

charge.

CUSTOMER HOT LINE:

1°877°992°5999

Mon.=Fd., 6 a.m.=6 p.m. MST

Read all precautions and instruc-

tions in this manuat before

using this equipment. Save this

manual for future reference.

TABLE OF CONTENTS

WARNING DECAL PLACEMENT ............................................................. 2

iMPORTANT PRECAUTIONS ................................................................ 3

BEFORE YOU BEGIN ...................................................................... 4

ASSEMBLY ............................................................................... 5

ADJUSTMENTS .......................................................................... 13

CABLE DIAGRAM ......................................................................... 17

EXERCISE GUiDELiNES .................................................................. 18

ORDERING REPLACEMENT PARTS .................................................. Back Cover

LiMiTED WARRANTY .............................................................. Back Cover

Note: A PART iDENTiFiCATiON CHART and a PART LIST/EXPLODED DRAWING are attached in the center of

this manual. Remove the PART iDENTiFiCATiON CHART and PART LIST/EXPLODED DRAWING before begin-

ning assembly.

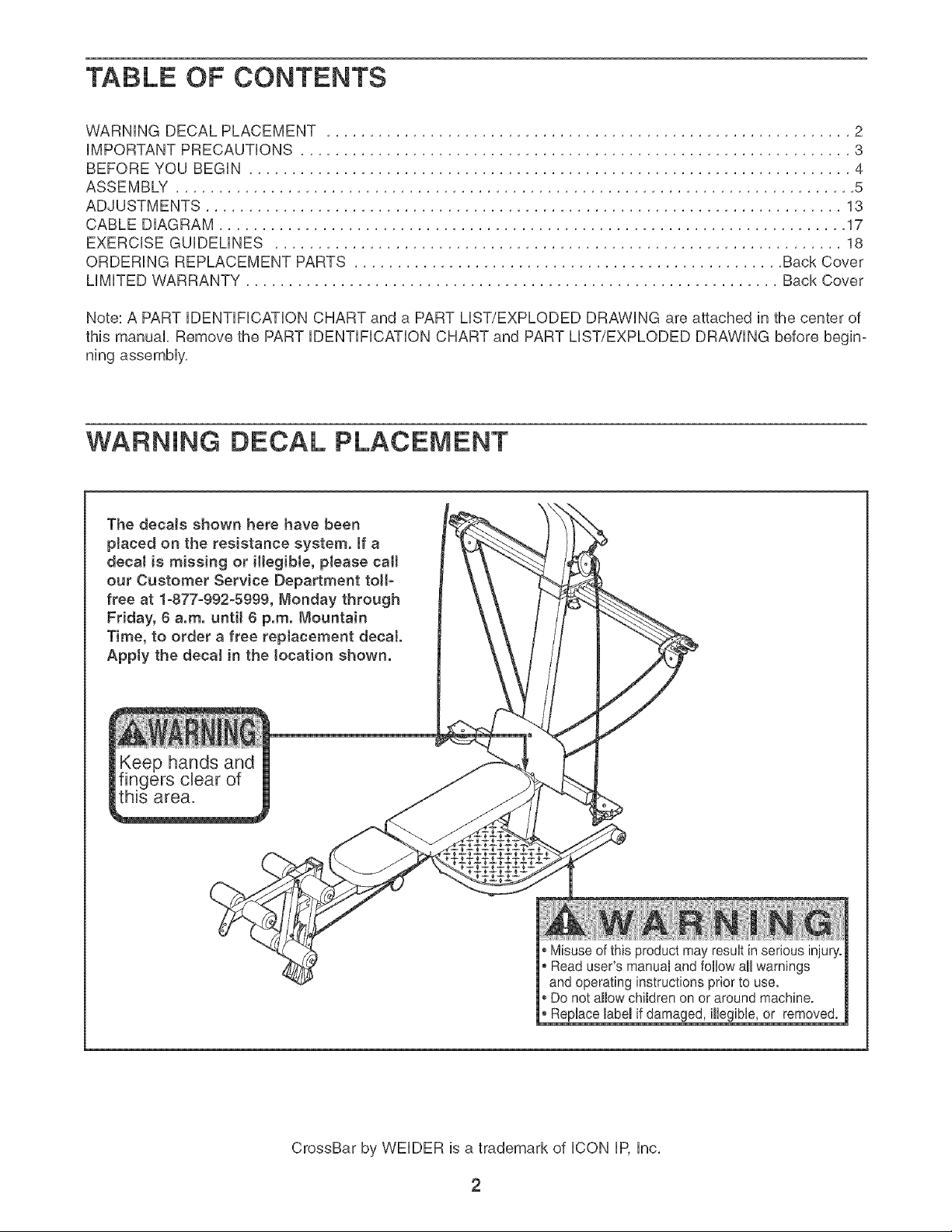

WARNING DECAL PLACEMENT

The decals shown here have been

pJaced on the resistance system. If a

decal is missing or iHegibJe, please call

our Customer Service Department toll-

free at 1-877-992-5999, Monday through

Friday, 8 a.m. until 8 p.m. Mountain

Time, to order a free repJacement decal

Apply the decaJ in the location shown.

ieep hands and

ngers clear of

_s area.

®Misuse of this product may result in serious injury.

Read user's manual and follow all warnings

and operating instructions prior to use.

®Do not allow children on or around machine.

* Replace label ifdamaged, illegible, or removed.

CrossBar by WELDER is a trademark of ICON IP, Inc.

iMPORTANT PRECAUTIONS

AWARNING: Toreducethedskofseriousinjury, readthefollowing important precautions

before using the resistance system.

f. Read all instructions in this manual before

using the resistance system. Use the resist- or while standing on the base plate.

ance system only as described in this manu-

aL f 3. The resistance system is designed to be

2_

ff is the re sponsibiHty of the owner to ensure resistance included with a CrossBar by WEI-

that aH users of the resistance system are DER ' Power Pak. Do not use the resistance

adequately informed of all precautions, system with any other type of resistance.

.

The resistance system is intended for home t4.

use onJy. Do not use the resistance system

in any commercial, rental, or institutional set-

ting ....

4. Keep the resistance system indoors, away

(rein moisture and dust. Do not put the t 5.

resistance system in a garage or covered

patio, or near water.

5. Use the resistance system onJy on a (eve)

surface. Cover the floor beneath the resist-

ance system to protect the fJoor.

6. Make sure that aH parts are properly tight-

ened each time the resistance system is

used. Replace any worn parts (mmediateJy.

7. Keep children under 12 and pets away from

the resistance system at aH times.

three positions closest to the upright base,

used with the included resistance, and the

When adding resistance, both ends of the

resistance bars must rest under the two "U'-

channeJs. Add and remove resistance bars

from the "U _ochannels one resistance bar at

a time.

Keep clear of the area around the "U'-chano

neJs while the resistance system is in use.

Do not add or remove resistance bars from

the "U'ochanneJs while the end of the long

cable is pulled out.

16. AJwaye adjust the resistance bar assembly to

the horizontal position and make sure the

fulcrum knob is secure before using the

resistance system.

17. Make sure the rings on the resistance bars

are pushed against the tray before using the

resistance system.

8. Keep hands and feet away from moving

parts.

9. Always wear atHetic shoes for foot protec-

tion while exercising.

16. The top frame is not designed to be used for

puHoup exercises. Do not hang on the top tern is used.

frame.

11. The resistance system is designed to sup-

port a maximum user weight of 306 pounds.

12. Pull on the mowpuJJey cable only while sitting

on the bench or standing on the base plate.

PuH on the high pulley cabJes onJy white sit-

ting on the bench, with the seat in one of the

18. if you purchase the optional lat bar, always

disconnect it from the short cables when

performing an exercise that does not require

it.

19. Make sure the storage knob is in place and

fully tightened each time the resistance sys-

20. Make sure that the cables remain on the puF

leys at all times, if the eabJes bind as you are

exercising, stop immediateJy and make sure

that the cables are on the pulleys. RepJace aH

cables at least every two years.

21. ff you fee( pain or dizziness while exercising,

stop immediateJy and begin cooling down.

kWARNmNG: Beforebeginnin,thisoranyexerciseprogram,consultyourphysician.This

is especially important for persons over the age of 35 or persons with pre-existing health prob)ems.

Read aH instructions before using. (CON assumes no responsibility for personal injury or property

damage sustained by or through the use of this product.

3

BEFORE YOU BEGIN

Thank you for sebcting the innovative CrossBar by

WELDER''_MAX resistance system, The resistance sys-

tem offers a sebction of stations designed to develop

every major muscb group of the body, Whether your

goal is to tone your body, build dramatic muscle size

and strength, or improve your cardiovascular system,

the resistance system will help you to achieve the spe-

cific results you want,

For your benefit, read this manuaJ carefully before

using the resistance system, if you have questions

ASSEMBLED

DiMENSiONS:

Height: 82 in,

Width: 66in_

Depth: 80 in,

Fulcrum Knob

Upright

after reading this manual, phase call our Customer

Service Department tolPfree at 1°877°992-5999,

Monday through Friday, 6 a,m, until 6 p,m, Mountain

Time (excluding holidays), To help us assist you, please

note the product model number and serial number

before calling, The model number is WESY59840, The

serial number can be found on a decal attached to the

resistance system (see the front cover of this manual),

Before reading further, please review the drawing below

and familiarize yourself with the parts that are labeled,

Top Frame

Lat Tower

High Pulley

Resistance Bars

--"U"oChannel

Storage Knob

Backrest

Curl Pad

Curl Bar

Leg

Low Pulley

Base Hate

Seat

Seat Knob

4

Tighten all parts as you assemble them, unless

instructed to do otherwise.

This manua! iSdesigned to ensure that the resist-

most PeOPb, However, it iSimpo_ant to reanize

that the versatile resistance system has many

parts and that the assembly Process w!Htake

time. Most peopJefind that by setting aside p!enty

d t!me, assembly wi!! go smooth!y:

Before beginning assembly, carefully read the

following information and instructions:

Assembly requires two persons.

Place all parts in a cleared area and remove the

packing materials. Do not dispose of the packing

materials until assembly is completed.

• For help identifying smafl parts, use the PART

IDENTIFICATION CHART, Note: Some small

parts may have been pre-attached for shipping. If

a part is not in the parts bag, check to see if it

has been pre-attached.

As you assemble the resistance system, make

sure all parts are oriented as shown in the draw-

ings.

The inc!uded AHen wrenches and the follow-

ing tools (not included) are required for assem-

bly:

Two adjustable wrenches

One rubber maltet

One standard screwdriver _.;_

One Phillipsscrewdriver _=C_-_D

Lubricant, such as grease or petroleum jelty,

and soapy water.

Assembly wiii be more convenient if you have a

socket set, a set of open-end or closed-end

wrenches, or a set of ratchet wrenches,

Before beginning assembly, make sure that

you have read and understand the informa-

tion in the box above.

Attach two Plastic Feet r53_ and two Large Plastic

Feet/102/to the Base Ill with four M4 x 16mm

Screws (62/.

Attach the Upright _3} Io the Base (11 with two

MIO x 66mm Carriage Bolts (83L two MIO x

72mm Bolts (64/. and four MIO Nylon Locknuts

/76 as shown. Note: This step will be easier to

complete if the Upright and Base are tipped

on their sides.

62

53_I _,

/ / /

/// //1//_

64

_102

L

_62

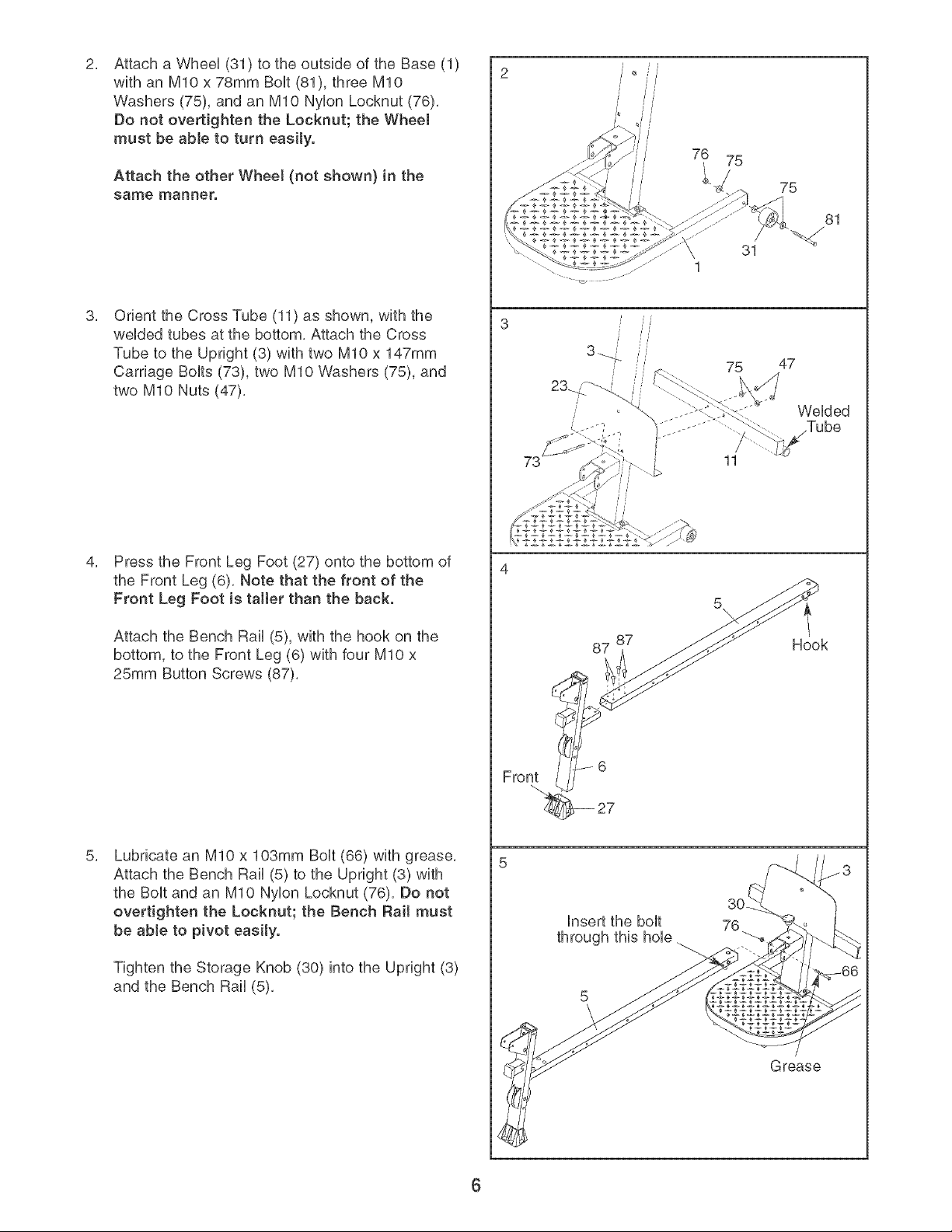

Attacha Wheel(31)totheoutsideoftheBase(1)

withanMIOx78mmBolt(81),threeMIO

Washers(75),andanMIONylonLocknut(76),

Donotovertightenthe Locknut;the Wheel

mustbeableto turn easity.

Attach the other Wheel (not shown} in the

same manner.

Orient the Cross Tube (11) as shown, with the

welded tubes at the bottom, Attach the Cross

Tube to the Upright (3) with two MIO x 147mm

Carriage Bolts (73), two MIO Washers (75), and

two MIO Nuts (47),

Press the Front Leg Foot (27) onto the bottom of

the Front Leg (6), Note that the front of the

Front Leg Foot is taller than the back.

75

81

31

/

75

11

47

Welded

Attach the Bench Rail (5), with the hook on the

bottom, to the Front Leg (6) with four MIO x

25mm Button Screws (87),

Lubricate an MIO x 103mm Bolt (66) with grease,

Attach the Bench Rail (5) to the Upright (3) with

the Bolt and an MIO Nylon Locknut (76), Do not

overtighten the Locknut; the Bench Bait must

be able to pivot easily.

Tighten the Storage Knob (30) into the Upright (3)

and the Bench Rail (5),

87

87

Insert the bolt 76

through this hole

Hook

Grease

6

Attach the Lat Tower (4) to the Upright (3) with

6. 6

four M10 x 25mm Button Screws (87), and four

M10 Lock VVashers (103).

Attach the Name Hate (89) to the Lat Tower (4)

with two M4 x 16mm Screws (62).

Attach two Eyebolts (34) to the Top Frame (10)

with two M8 Washers (59) and two M8 Nylon

Locknuts (65). Do not overtighten the Locknuts;

the Eyebolts must be able to rotate freely.

Attach the Top Frame (10) to the Lat Tower (4)

with two M10 x 65mm Button Screws (70), two

M10 Washers (75), and the Top Frame Cover

(93), Make sure that the Eyebolts (34) are ori-

ented as shown in the inset drawing. If they

are not, turn the Top Frame around and reat-

tach it.

59

65

34

"\..

89

7O

62

75

_3

10

103 87

65

/

Attach the Leg Lever (7) to the Front Leg (6) with

a Long Pin (107) and a Cotter Pin (108),

Side View

10.

34

107

34

6

7

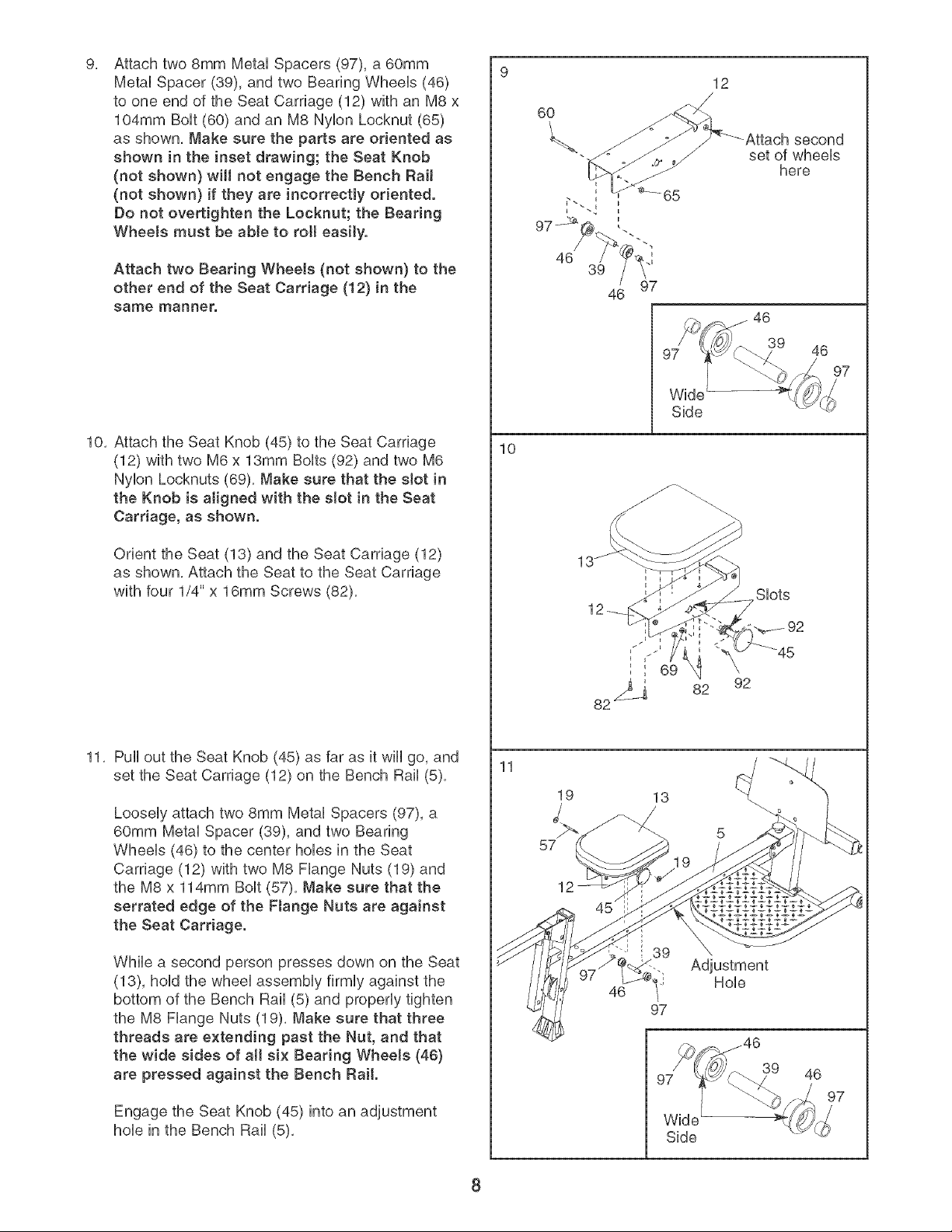

Attach two 8mm Metal Spacers (97), a 60mm

9, 9

Metal Spacer (39), and two Bearing Wheeb (46)

to one end of the Seat Carriage (12) with an M8 x

104mm BoUt(60) and an M8 Nybn Locknut (65)

as shown, Make sure the parts are oriented as

shown in the inset drawing; the Seat Knob

(not shown} will not engage the Bench Rail

(not shown} if they are incorrectly oriented.

Do not overtighten the Locknut; the Bearing

Wheels must be able to roll easily.

Attach two Bearing Wheels (not shown} to the

other end of the Seat Carriage (!2) in the

same manner.

6O

46

39

46

12

second

set of wheels

here

97

Side

10, Attach the Seat Knob (45) to the Seat Carriage

(12) with two M6 x 13mm BoUts(92) and two M6

Nybn Locknuts (69), Make sure that the slot in

the Knob is aligned with the slot in the Seat

Carriage, as shown.

Orient the Seat (13) and the Seat Carriage (12)

as shown, Attach the Seat to the Seat Carriage

with four 1/4" x 16mm Screws (82),

11, Pull out the Seat Knob (45) as far as it will go, and

set the Seat Carriage (12) on the Bench Rail (5),

Loosely attach two 8mm Metal Spacers (97), a

60mm Metal Spacer (39), and two Bearing

Wheels (46) to the center hobs in the Seat

Carriage (12) with two M8 Flange Nuts (19) and

the M8 x 114mm Bolt (57), Make sure that the

serrated edge of the Flange Nuts are against

the Seat Carriage.

While a second person presses down on the Seat

(13), hold the wheel assembly firmly against the

bottom of the Bench Rail (5) and properly tighten

the M8 Flange Nuts (19), Make sure that three

threads are extending past the Nut, and that

the wide sides of aH six Bearing Wheels (46)

are pressed against the Bench Rail.

Engage the Seat Knob (45) into an adjustment

hob in the Bench Rail (5),

10

11

57

19

12

46

Slots

82 92

13

/

5

\

Adjustment

Hob

97

39 46

)7

Side

8

Loading...

Loading...