WEG Electric CFW500 Catalog Page

Motors | Automation | Energy | Transmission & Distribution | Coatings

CFW500

Variable Speed Drive

Machinery Drive

Endless possibilities

With modern design, the variable speed drive CFW500 is a high performance VSD for applications that

require speed and torque control of three-phase induction motors. The equipment has sensorless vector

control, closed loop vector control or scalar V/f. It also has SoftPLC, which adds PLC (programmable

logic controller) functions, Pump Genius, which adds dedicated functions for pumping systems and

selectable plug-in modules, that provide a flexible and optmized solution for any application.

Performance

Flexibility

Innovation

WEG Quality

Sensorless or closed loop vector control, VVW or Scalar V/f

Advanced resources for total control of the application

Expansible number of inputs and outputs as well as functions

using plug-in modules with plug-and-play philosophy

Surface or DIN rail mounting, including side-by-side installation

SoftPLC - built-in PLC functionalities

USB communication port available with plug-in module

All VSDs are factory tested at full load conditions and

maximum operational temperature

Diagnostics and protections

Variable Speed Drive - CFW5002

Current range from 1,0 to 56 A (0,25 kW / 0,33 HP to 30 kW /

40 HP) with supply voltages 200-240, 380-480 or 500-600 V

Dedicated functions for pumping systems using Pump Genius

Built-in braking IGBT (optional)

Fieldbus communication modules for the most used

industrial networks, like CANopen, DeviceNet, Profibus-DP,

Operating ambient temperature up to 50 °C without derating

EtherNet-IP, Profinet-IO or Modbus-RTU

Ideal for machinery manufacturer

Free WLP and SuperDrive G2 programming

softwares available at

Conformal Coating class 3C2 for greater protection of

electronic boards against corrosive atmospheres

Internal RFI filter to reduce high-frequency

electromagnetic interference signals

www.weg.net

Single or three-phase power supply in

200-240 V, 380-480 V or 500-600 V

Memory card for data transfers without the

necessity to power the CFW500 up

Certifications

Variable Speed Drive - CFW500 3

Simplified Programming and Operation

Operating Interface (HMI)

J

Monitoring, setting of all parameters as well as commands

J

Up to three parameters indication on the display, according to user selection

J

Oriented start-up and grouped parameters

Menu to select the

group of parameters

Unit of measurement

CFW500 status

Secondary display

(value of the main

display)

variable monitoring

Soft keys function

Note: the operating interface (HMI) of the CFW500 is not removable. For remote operation of the HMI, use the CFW500-HMIR accessory, according to the

accessory table on page 15.

Bar for

Main display

Remote Operating Interface (HMI)

Solutions for machine consoles and panels.

4

Variable Speed Drive - CFW500

CFW500-HMIR

Accessory

Flexibility and Performance

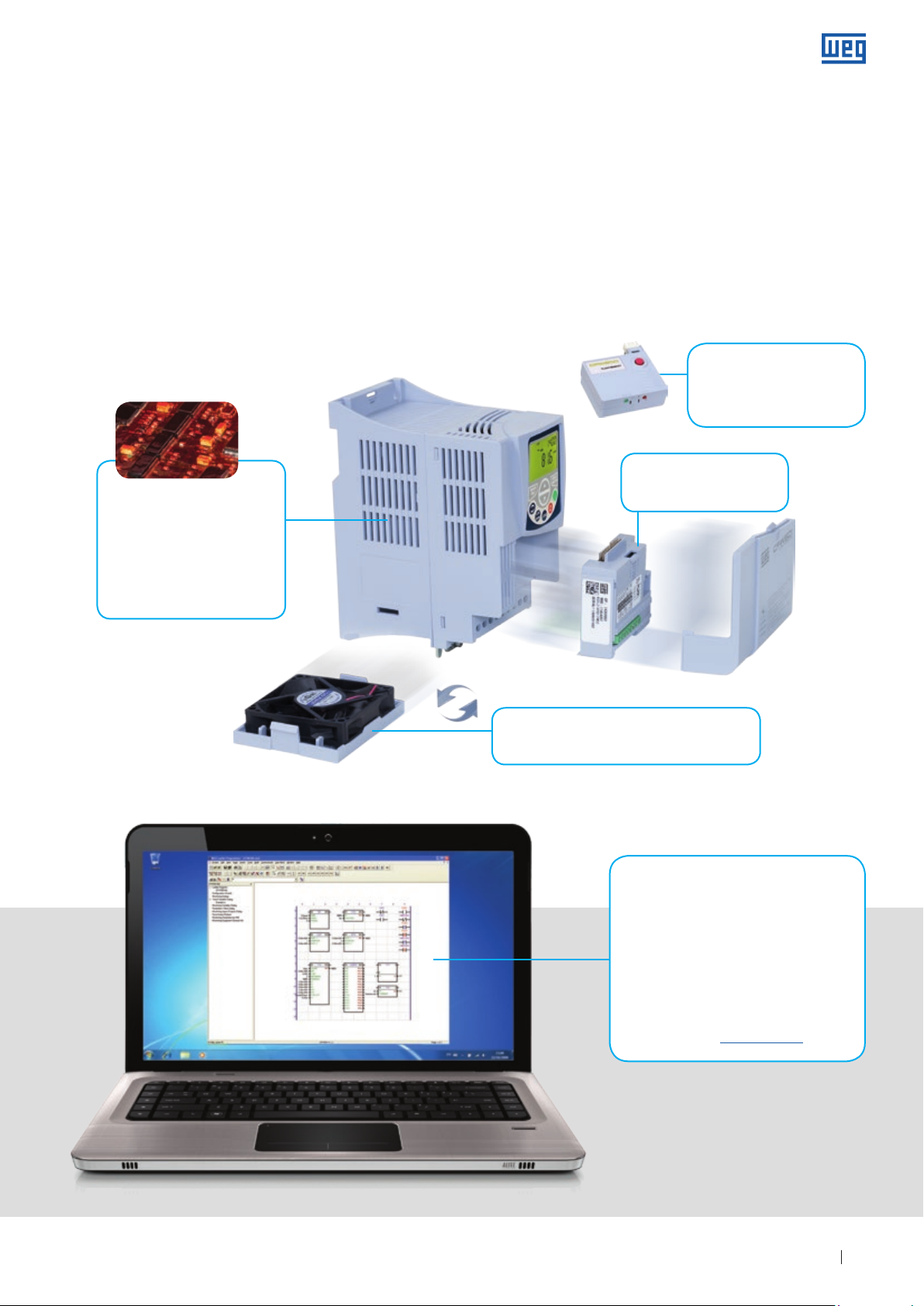

The CFW500 has a modern design and it can be selected according to the application requirements, providing flexibility with

excellent performance. The VSD gives the user the possibility to choose the plug-in module that best fits his application, or to

use the standard version, that comes with the CFW500-IOS plug-in module. All plug-in modules comes with one RS485 port

as standard.

The installation of the CFW500 is simple and its configuration and operation is intuitive with the navigation menus of the

operating interface (HMI) with built-in LCD display. By using the flash memory module, it is possible to download the

existing setting from one CFW500 to other units without powering them up.

Conformal Coating

Improved 3C2 class of coating

on the internal circuits of all

versions and extra 3C3 Class

coating (optional) according to

IEC 60721-3-3 ensures

improved protection in

environments with corrosive

chemicals.

Flash Memory Module

(CFW500-MMF Accessory)

Download/Upload the settings to

other CFW500 units without the

need to power them up

Plug-In Modules

Selectable according to

the application.

Easily Removable Fan

The quick change system ensures simple and

fast fan maintenance.

.

SoftPLC

It is a software resource added to

the CFW500 which allows the user

to implement and debug logic

projects equivalent to a small PLC

(Programmable Logic Controller),

customizing and integrating the

CFW500 to the application. The

free WLP programming software

is available at:

www.weg.net

.

Variable Speed Drive - CFW500

5

Variable Speed Drive - CFW500

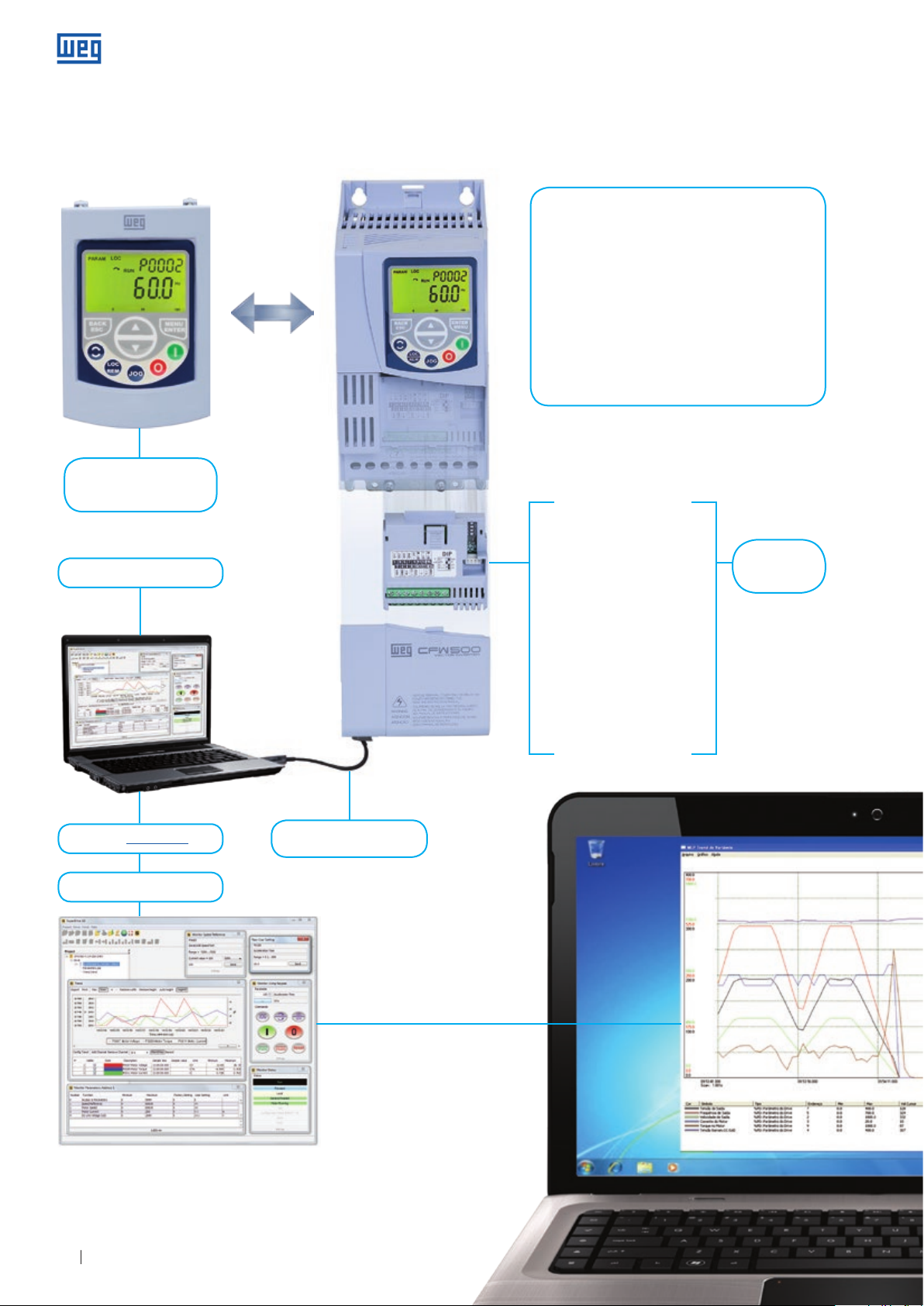

Connectivity

The CFW500 can be connected to the main

fast industrial Fieldbus communication

networks, with protocols used worldwide

such as CANopen, Profibus-DP, DeviceNet,

Profinet and EtherNet, according to the plugin module selected.

In addition, all plug-in modules come with

serial interface RS485 Modbus-RTU built-in.

Remote operating interface

(CFW500-HMIR accessory)

(HMI)

Easy operation and view

Free at

www.weg.net

SuperDrive G2

USB Connection

(CFW500-CUSB accessory)

I/O expansion:

IOS (standard, included in the

version with plug-in), IOD, IOAD, IOR

Functionality expansion:

Incremental encoder

USB

Fieldbus communication

protocols:

CANopen

DeviceNet

RS232

RS485

Profibus-DP

EtherN et-IP

Modbus-TCP

Profinet-IO

Selectable

plug-in

modules

6

Variable Speed Drive - CFW500

Features

J

Special engineering units (RPM, ºC, Nm, mA, %, kW,

kWh, among others)

J

Password to protect the parameters

J

Backup of all parameters (via SuperDrive G2 software, or

plugin memory MMF)

J

Possibility to save up to two different settings on the

memory of the CFW500

J

Setting of the switching frequency according to the

application requirements

J

Speed reference via electronic potentiometer

J

Multispeed with up to eight programmable speeds

J

Slip compensation

J

Manual or automatic torque boost (V/F scalar mode) or

self-adjustment (VVW and vector modes)

J

Acceleration/deceleration ramps

J

“S” type ramp

J

DC braking

J

Internal dynamic braking (except frame size A)

J

PID controller to control processes in closed loop

J

Flying start / Ride-through

J

Sleep mode

J

Skip frequencies or frequency ranges function adjustable

J

Overload and overtemperature protection

J

Overcurrent protection

J

DC link voltage supervision

J

Fault log

Using the SuperDrive G2 software, it is possible to change,

monitor and view graphically the variables of the CFW500

on a personal computer.

Tren d Fun c t i o n

Trend charts for online monitoring of parameters and other

variables within the SuperDrive G2 software.

7

Loading...

Loading...