Motors | Energy | Automation | Coatings

Frequency Inverter

Convertidor de Frecuencia

Inversor de Freqüência

CFW -11

User's Guide

Manual del Usuario

Manual do Usuário

FREQUENCY

INVERTER

MANUAL

Series: CFW-11

Language: English

Document: 10000280997 / 00

Models: 142...211 A / 220...230 V

105...211 A / 380...480 V

03/2009

Summary of Revisions

Revision Description Chapter

1 First Edition -

2

Index

CHAPTER 1

Safety Instructions

1.1 Safety Warnings in the Manual .....................................................................................................1-1

1.2 Safety Warnings in the Product .....................................................................................................1-1

1.3 Preliminary Recommendations ....................................................................................................1-2

CHAPTER 2

General Instructions

2.1 About the Manual ......................................................................................................................2-1

2.2 Terms and Definitions ..................................................................................................................2-1

2.3 About the CFW-11 .....................................................................................................................2-4

2.4 Identification Labels for the CFW-11 .............................................................................................2-7

2.5 Receiving and Storage ..............................................................................................................2-10

CHAPTER 3

Installation and Connection

3.1 Mechanical Installation ...............................................................................................................3-1

3.1.1 Installation Environment .....................................................................................................3-1

3.1.2 Mounting Considerations ...................................................................................................3-1

3.1.3 Cabinet Mounting ............................................................................................................3-4

3.1.4 Installation of the Inverter Hoisting Eyes ...............................................................................3-5

3.1.5 Installation of the Inverter with Nema 1 Kit (Optional, CFW11XXXXTXON1) on a Wall.............3-6

3.1.6 Access to the Control and Power Terminal Strips ...................................................................3-6

3.1.7 Removal of the Cable Passage Plate ...................................................................................3-8

3.1.8 HMI Installation at the Cabinet Door or Command Panel (Remote HMI) ................................3-8

3.2 Electrical Installation ...................................................................................................................3-9

3.2.1 Identification of the Power and Grounding Terminals ............................................................3-9

3.2.2 Power / Grounding Wiring and Fuses ................................................................................3-10

3.2.3 Power Connections ..........................................................................................................3-14

3.2.3.1 Input Connections ..............................................................................................3-14

3.2.3.1.1 IT Networks ........................................................................................3-15

3.2.3.1.2 Command Fuses .................................................................................3-16

3.2.3.2 Dynamic Braking ................................................................................................3-16

3.2.3.2.1 Sizing the Braking Resistor ....................................................................3-17

3.2.3.2.2 Installation of the Braking Resistor .........................................................3-18

3.2.3.3 Output Connections ...........................................................................................3-19

3.2.4 Grounding Connections ..................................................................................................3-21

3.2.5 Control Connections .......................................................................................................3-22

3.2.6 Typical Control Connections .............................................................................................3-26

3.3 Installation According to the European Directive of Electromagnetic Compatibility .........................3-29

3.3.1 Conformal Installation .....................................................................................................3-29

3.3.2 Standard Definitions ........................................................................................................3-30

3.3.3 Emission and Immunity Levels ...........................................................................................3-31

Index

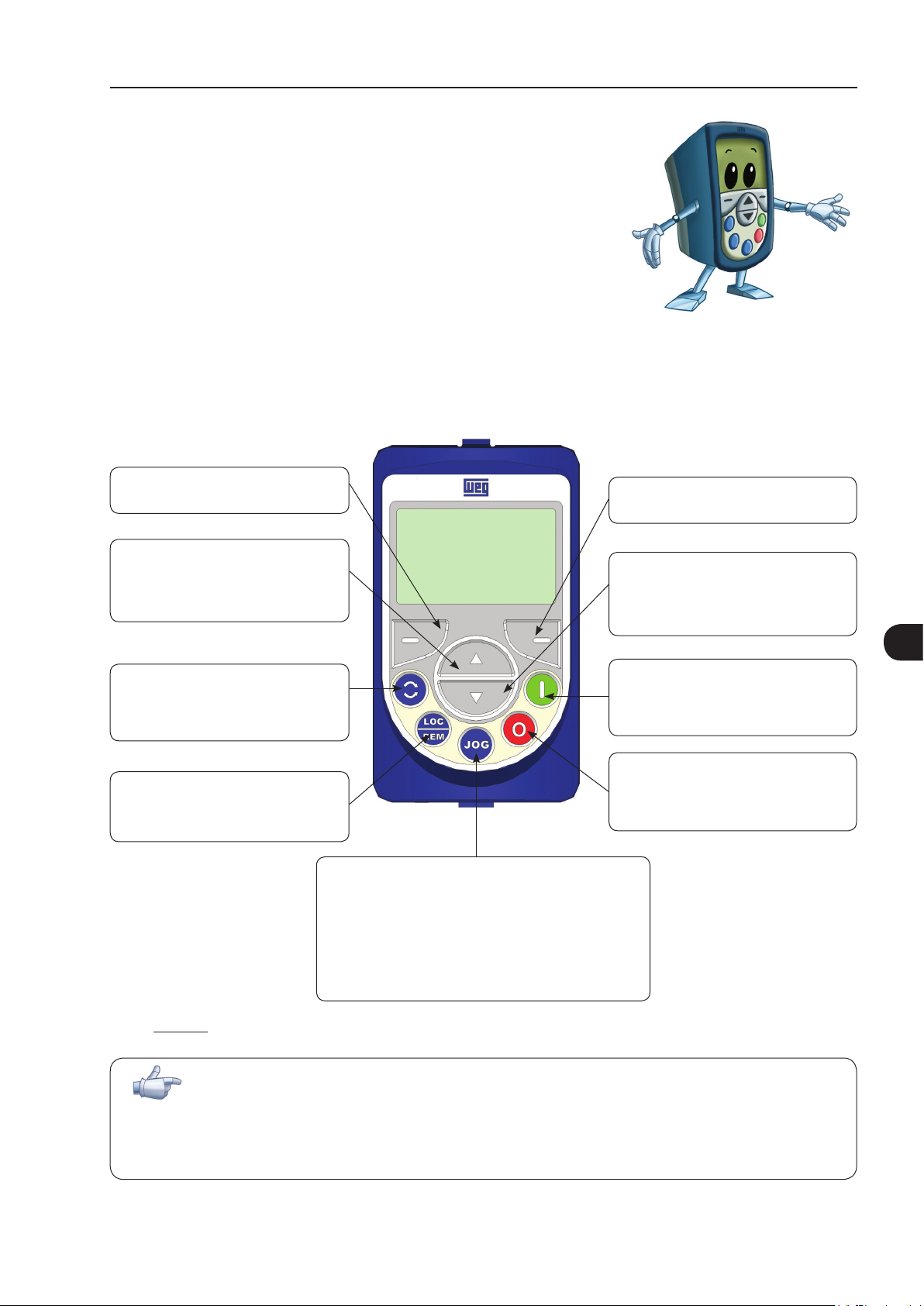

KEYPAD AND DISPLAY

4.1 Integral Keypad - HMI-CFW11 ....................................................................................................4-1

4.2 Parameters Organization .............................................................................................................4-4

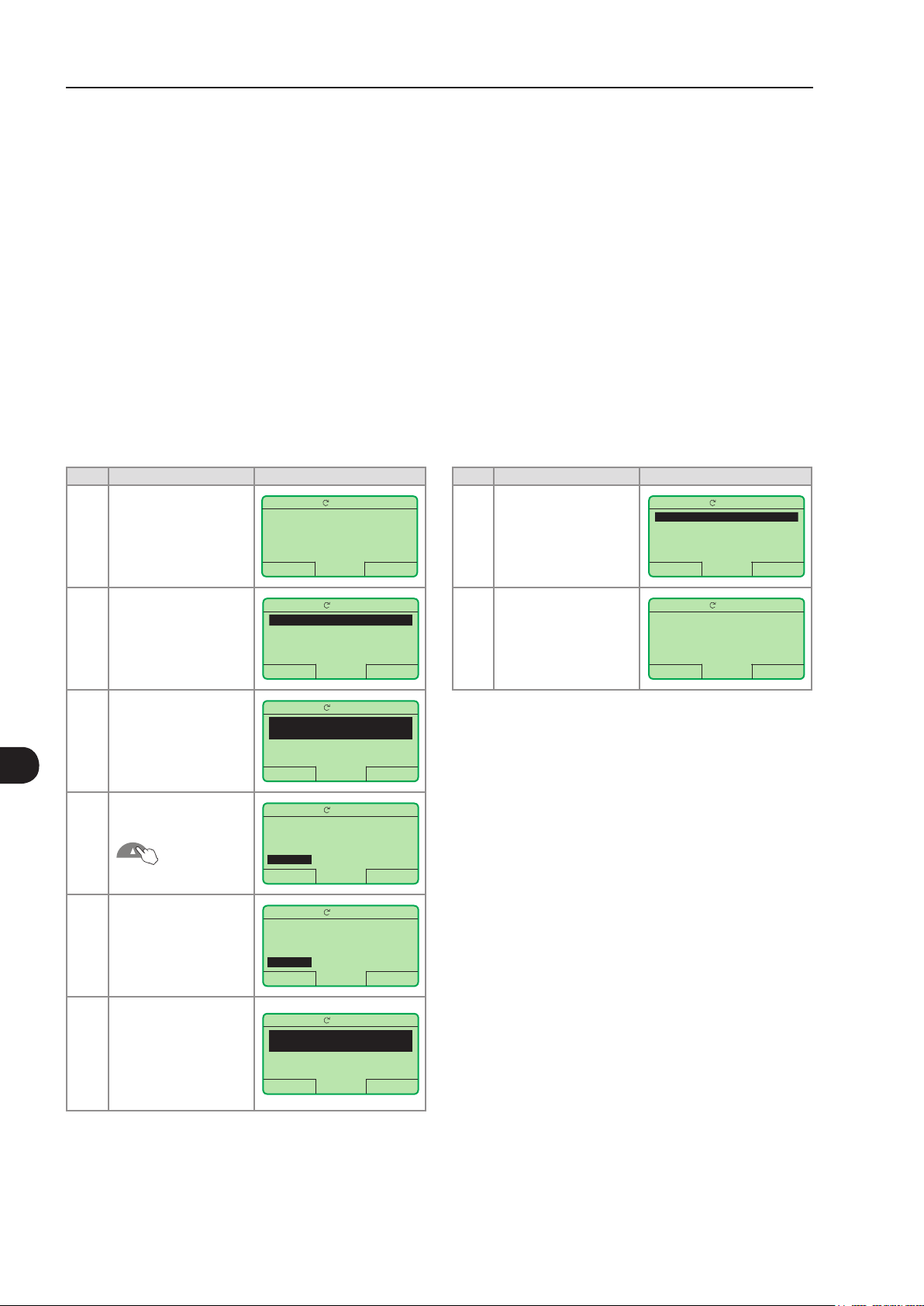

First Time Power-Up and Start-Up

5.1 Prepare for Start-Up ....................................................................................................................5-1

5.2 Start-Up .....................................................................................................................................5-2

5.2.1 Password Setting in P0000 .................................................................................................5-2

5.2.2 Oriented Start-up ..............................................................................................................5-3

5.2.3 Setting Basic Application Parameters ...................................................................................5-5

5.3 Setting Date and Time .................................................................................................................5-8

5.4 Blocking Parameters Modification ................................................................................................5-8

5.5 How to Connect a PC .................................................................................................................5-9

5.6 FLASH Memory Module ..............................................................................................................5-9

CHAPTER 4

CHAPTER 5

CHAPTER 6

Troubleshooting and Maintenance

6.1 Operation of the Faults and Alarms ..............................................................................................6-1

6.2 Faults, Alarms, and Possible Causes .............................................................................................6-2

6.3 Solutions for the Most Frequent Problems ......................................................................................6-5

6.4 Information for Contacting Technical Support ................................................................................6-6

6.5 Preventive Maintenance ...............................................................................................................6-6

6.5.1 Cleaning Instructions .........................................................................................................6-7

CHAPTER 7

Option Kits and Accessories

7.1 Option Kits ................................................................................................................................7-1

7.1.1 Braking IGBT ....................................................................................................................7-1

7.1.2 Nema1 Protection Degree..................................................................................................7-1

7.1.3 Safety Stop According to EN 954-1 Category 3 (Pending Certification) ..................................7-1

7.1.4 24 Vdc External Control Power Supply .................................................................................7-2

7.2 Accessories ................................................................................................................................7-3

CHAPTER 8

Technical Specifications

8.1 Power Data ................................................................................................................................8-1

8.2 Electrical / General Specifications ................................................................................................8-6

8.2.1 Codes and Standards ........................................................................................................8-7

8.3 Mechanical Data ........................................................................................................................8-8

8.4 NEMA1 Kit .................................................................................................................................8-9

SAFETY INSTRUCTIONS

This manual provides information for the proper installation and

operation of the CFW-11 frequency inverter.

Only trained and qualified personnel should attempt to install,

start-up, and troubleshoot this type of equipment.

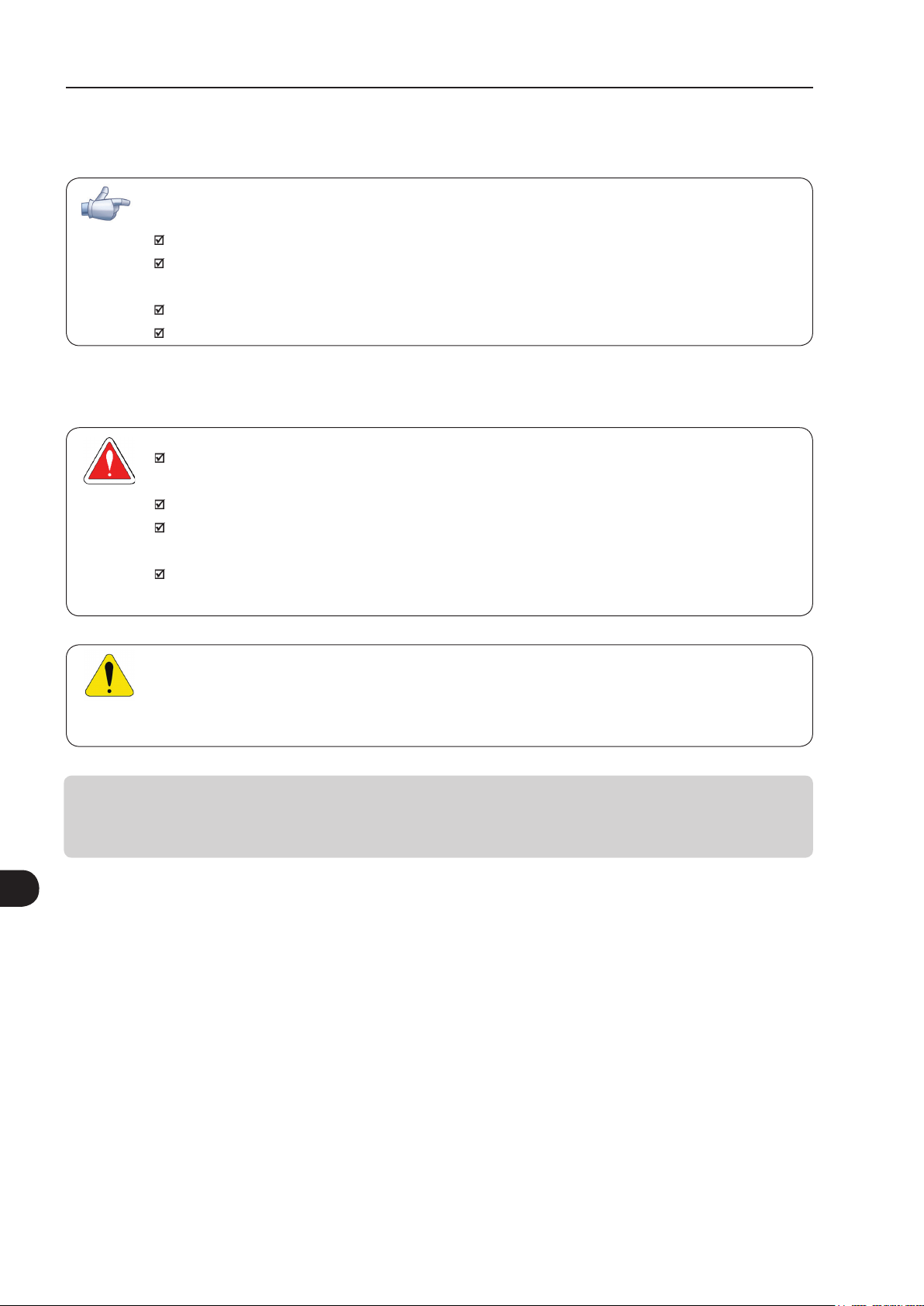

1.1 SAFETY WARNINGS IN THE MANUAL

The following safety warnings are used in this manual:

DANGER!

Failure to follow the recommended procedures listed in this warning may result in death, serious

injury, and equipment damage.

Safety Instructions

1

ATTENTION!

Failure to follow the recommended procedures listed in this warning may result in equipment

damage.

NOTE!

This warning provides important information for the proper understanding and operation of the

equipment.

1.2 SAFETY WARNINGS IN THE PRODUCT

The following symbols are attached to the product and require special attention:

Indicates a high voltage warning.

Electrostatic discharge sensitive components.

Do not touch them.

Indicates that a ground (PE) must be connected securely.

Indicates that the cable shield must be grounded.

Indicates a hot surface warning.

1-1

1

Safety Instructions

1.3 PRELIMINARY RECOMMENDATIONS

DANGER!

Only trained personnel, with proper qualifications, and familiar with the CFW-11 and associated

machinery shall plan and implent the installation, starting, operation, and maintenance of this

equipment.

The personnel shall follow all the safety instructions described in this manual and/or defined by the

local regulations.

Failure to comply with the safety instructions may result in death, serious injury, and equipment

damage.

NOTE!

For the purpose of this manual, quali fied personnel are those trained and able to:

1. Install, ground, power-up, and operate the CFW-11 according to this manual and to the current

legal safety procedures;

2. Use the protection equipment according to the established regulations;

3. Provide first aid.

DANGER!

Always disconnect the main power supply before touching any electrical device associated with the

inverter.

Several components may remain charged with high voltage and/or in movement (fans), even after

the AC power supply has been disconnected or turned off.

Wait at least 10 minutes to guarantee the fully discharge of capacitors.

Always connect the equipment frame to the ground protection (PE).

ATTENTION!

The electronic boards contain components sensitive to electrostatic discharges. Do not touch the

components and terminals directly. If needed, touch first the grounded metal frame or wear an

adequate ground strap.

Do not perform a withstand voltage test on any part of the inverter!

If needed, please, consult WEG.

NOTE!

Frequency inverters may cause interference in other electronic devices. Follow the recommendations

listed in Chapter 3 – Installation and Connection, to minimize these effects.

1-2

NOTE!

Fully read this manual before installing or operating the inverter.

Safety Instructions

ATTENTION!

Operation of this equipment requires detailed installation and operation instructions provided in the

User's Manual, Software Manual and Manual/Guides for Kits and Accessories. Only User's Manual is

provided on a printed version. The other manuals are provided on the CD supplied with the product.

This CD should be retained with this equipment at all times. A hard copy of this information may be

ordered through your local WEG representative.

1

1-3

1

Safety Instructions

1-4

General Instructions

GENERAL INSTRUCTIONS

2.1 ABOUT THE MANUAL

This manual exposes how to install, to start-up in V/f (scalar)

mode, the main characteristics and shows how to troubleshoot

the most common problems of the CFW-11 inverter series frame

size E models.

It is also possible to operate the CFW-11 in the following control modes: V V W, Sensorless Vector and Vector with

Encoder. For further details on the inverter operation with other control modes, refer to the Software Manual.

For information on other functions, accessories, and communication, please refer to the following manuals:

Software Manual, with a detailed description of the parameters and advanced functions of the CFW-11.

Incremental Encoder Interface Module Manual.

I/O Expansion Module Manual.

RS-232/RS-485 Serial Communication Manual.

CANopen Slave Communication Manual.

Anybus-CC Communication Manual.

2

These manuals are included on the CD supplied with the inverter or can be downloaded from the WEG website

at - www.weg.net.

2.2 TERMS AND DEFINITIONS

Normal Duty Cycle (ND): Inverter duty cycle that defines the maximum continuous operation current (I

the overload current (110 % for 1 minute). The ND cycle is selected by setting P0298 (Application) = 0 (Normal

Duty (ND)). This duty cycle shall be used for the operation of motors that are not subjected to high torque loads

(with respect to the motor rated torque) during its operation, starting, acceleration, or deceleration.

I

: Inverter rated current for use with the normal duty (ND) cycle.

RAT-ND

Overload: 1.1 x I

Heavy Duty Cycle (HD): Inverter duty cycle that defines the maximum continuous operation current (I

and the overload current (150 % for 1 minute). The HD cycle is selected by setting P0298 (Application) = 1

(Heavy Duty (HD)). This duty cycle shall be used for the operation of motors that are subjected to high torque

(with respect to the motor rated torque) during its operation, starting, acceleration, or deceleration.

I

: Inverter rated current for use with the heavy duty (HD) cycle.

RAT-HD

Overload: 1.5 x I

RAT-ND

RAT-HD

/ 1 minute.

/ 1 minute.

RAT-ND

) and

RAT-HD

)

Rectifier: Input circuit of inverters that transforms the AC input voltage in DC voltage. It is composed of power

diodes.

Pre-charge Circuit: Charges the DC bus capacitors with limited current, which avoids higher peak currents

at the inverter power-up.

2-1

General Instructions

DC Bus: Inverter intermediate circuit; DC voltage obtained from the rectification of the AC input voltage or

from an external power supply; feeds the output inverter bridge with IGBTs.

Power modules U, V, and W: Set of two IGBTs of the inverter output phases U, V, and W.

IGBT: Insulated Gate Bipolar Transistor; basic component of the output inverter bridge. The IGBT works as an

electronic switch in the saturated (closed switch) and cut-off (open switch) modes.

Braking IGBT: Works as a switch to activate the braking resistors. It is controlled by the DC bus voltage

level.

2

PTC: Resistor which resistance value in ohms increases proportionally to the temperature increase; used as a

temperature sensor in electrical motors.

NTC: Resistor which resistance value in ohms decreases proportionally to the temperature increase; used as a

temperature sensor in power modules.

HMI - Human Machine Interface: it is a device that allows the motor control, and the visualization and

modification of the inverter parameters. The CFW-11 HMI presents keys for the motor command, navigation

keys and a graphic LCD display.

FLASH memory: Non-volatile memory that can be electronically written and erased.

RAM memory: Random Access Memory (volatile).

USB: Universal Serial Bus; is a serial bus standard that allows devices to be connected using the ”Plug and

Play” concept.

PE: Protective Earth.

RFI Filter: Radio-Frequency Interference Filter for interference reduction in the Radio-Frequency range.

PWM: Pulse Width Modulation; pulsed voltage that feeds the motor.

Switching frequency: Frequency of the IGBTs switching in the inverter bridge, normally expressed in kHz.

General enable: When activated, this function accelerates the motor via acceleration ramp set in the inverter.

When deactivated, this function immediately blocks the PWM pulses. The general enable function may be

controlled through a digital input set to this function or via serial communication.

Start/Stop: When enabled in the inverter (start), this function accelerates the motor via acceleration ramp up

to the speed reference. When disabled (stop), this function decelerates the motor via deceleration ramp up to

the complete motor stop; at this point, the PWM pulses are blocked. The start/stop function may be controlled

through a digital input set for this function or via serial communication. The operator keys (Start) and

(Stop) of the keypad work in a similar way.

Heatsink: Metal device designed to dissipate the heat generated by the power semiconductors.

2-2

PLC: Programmable Logic Controller.

°C: Celsius degree.

°F: Fahrenheit degree.

AC: Alternated Current.

Amp, A: Ampères.

CFM: Cubic Feet per Minute; unit of flow.

General Instructions

cm: Centimeter.

DC: Direct Current.

ft: Foot.

hp: Horse Power = 746 Watts; unit of power, used to indicate the mechanical power of electrical motors.

Hz: Hertz.

in: Inch.

kg: Kilogram = 1000 grams.

kHz: Kilohertz = 1000 Hertz.

l/s: Liters per second.

lb: Pound.

m: Meter.

2

mA: Miliampère = 0.001 Ampère.

min: Minute.

mm: Millimeter.

ms: Millisecond = 0.001 seconds.

Nm: Newton meter; unit of torque.

rms: "Root mean square"; effective value.

rpm: Revolutions per minute; unit of speed.

s: Second.

V: Volts.

Ω: Ohms.

2-3

2

2

General Instructions

2.3 ABOUT THE CFW-11

The CFW-11 frequency inverter is a high performance product designed for speed and torque control of threephase induction motors. The main characteristic of this product is the “Vectrue” technology, which has the

following advantages:

Scalar control (V/f), V V W, or vector control programmable in the same product;

The vector control may be programmed as “sensorless” (which means standard motors without using

encoders) or as “vector control” with the use of an encoder;

The “sensorless” control allows high torque and fast response, even in very low speeds or at the starting;

The “vector with encoder” control allows high speed precision for the whole speed range (even with a

standstill motor);

"Optimal Braking" function for the vector control, allowing the controlled braking of the motor and avoiding

the use of the braking resistor in some applications;

“Self-Tuning” feature for vector control. It allows the automatic adjustment of the regulators and control

parameters from the identification (also automatic) of the motor parameters and load.

2-4

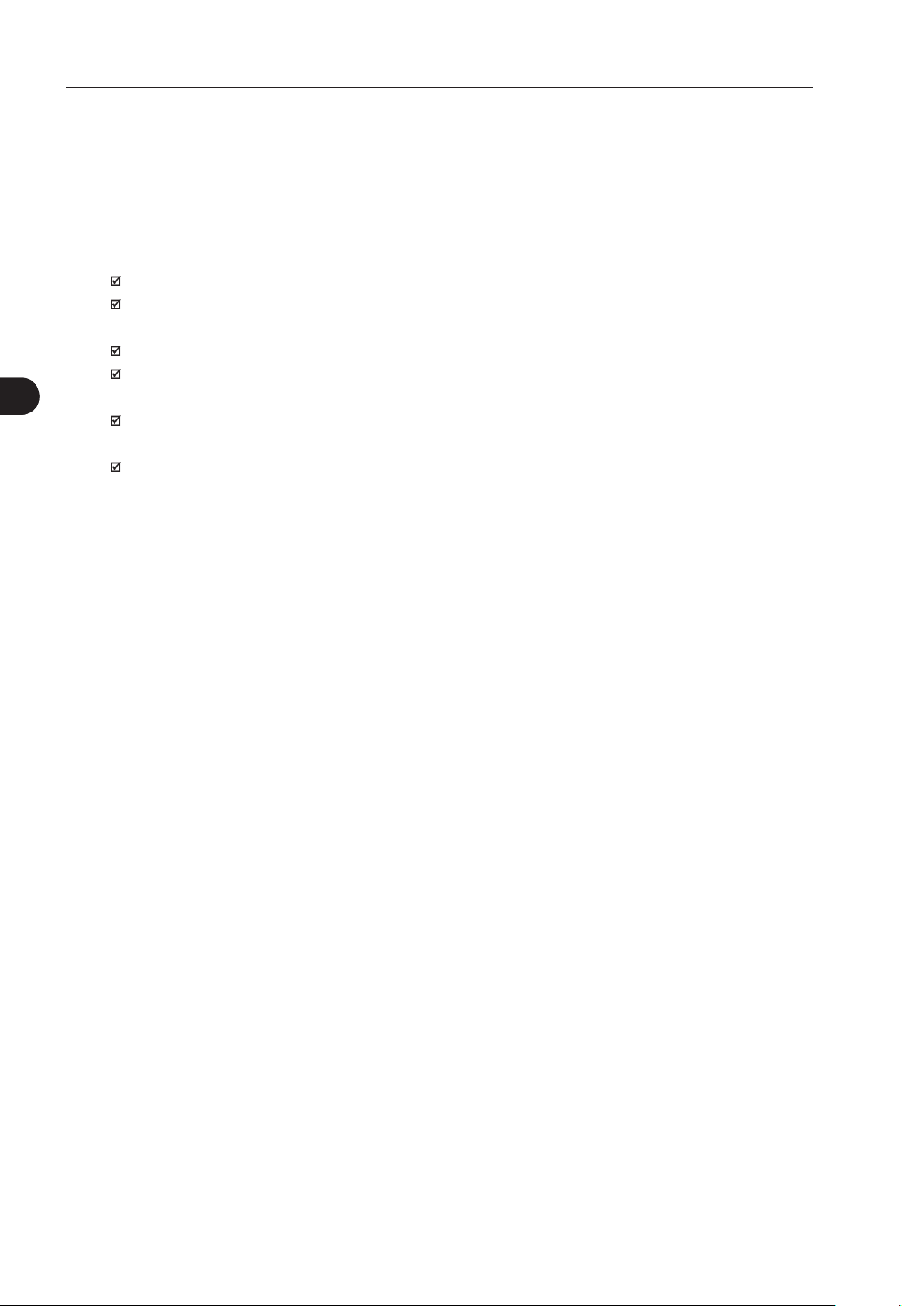

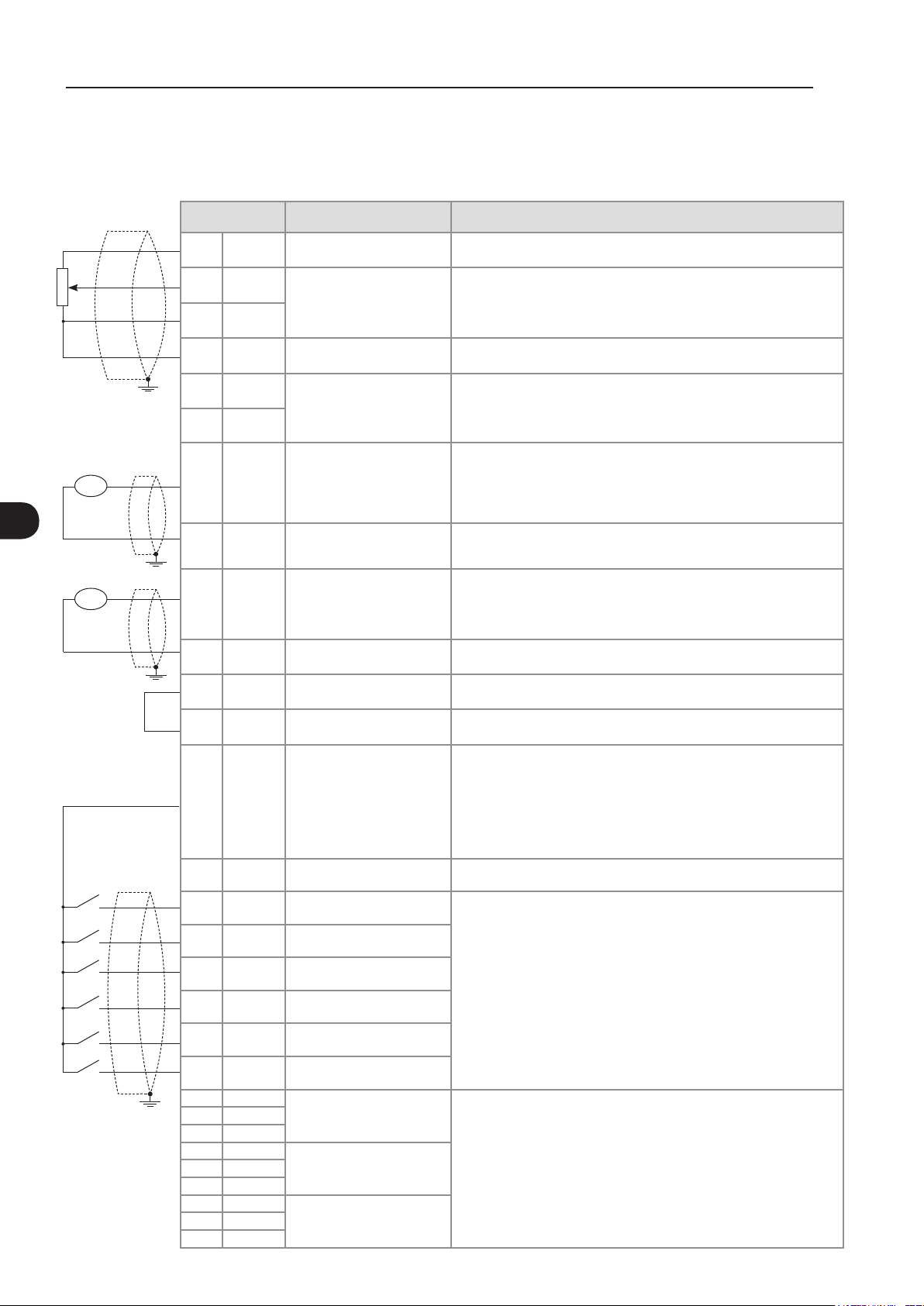

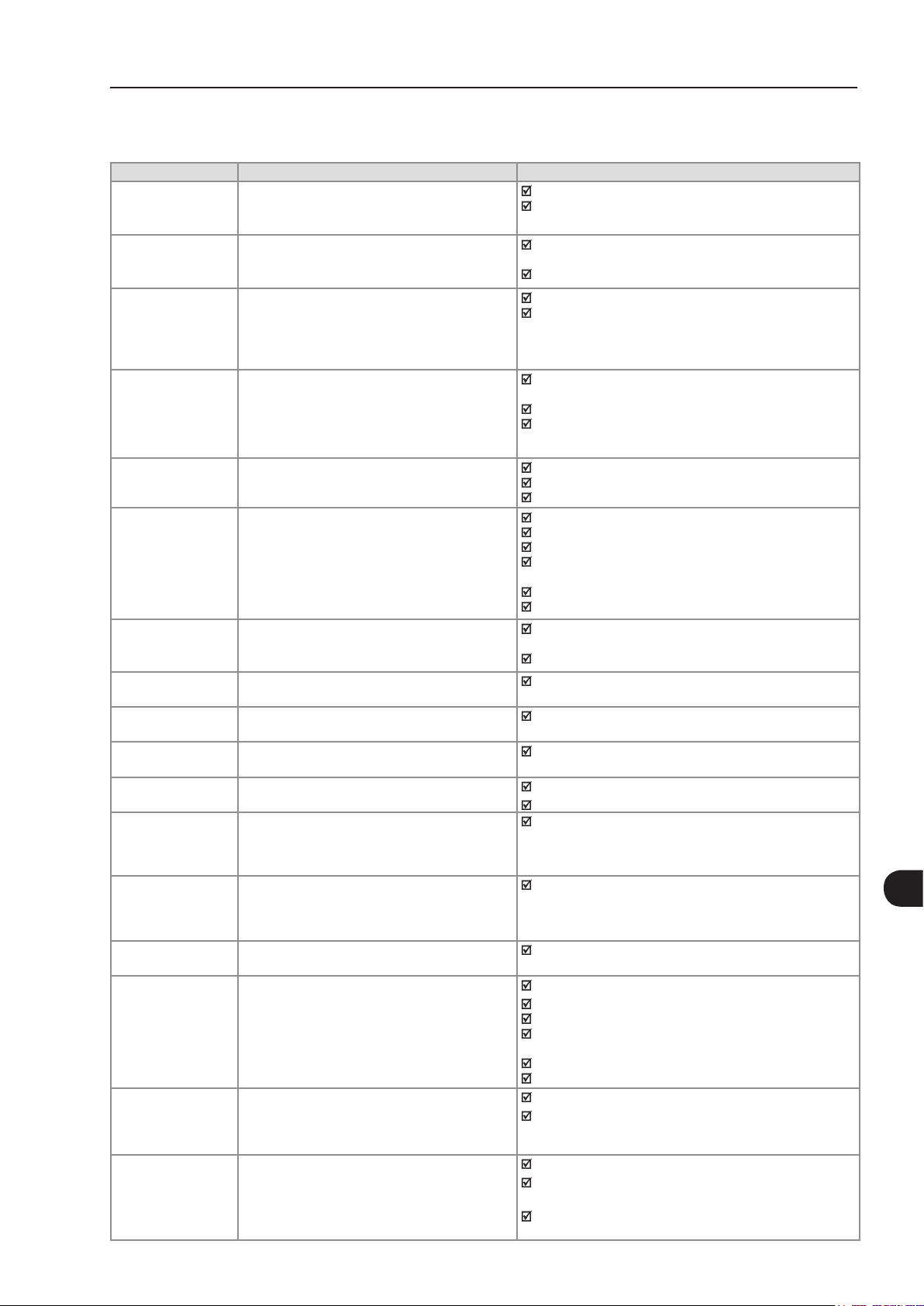

Mains Power

Supply

= DC bus connection

= Braking resistor connection

S/L2

T/L3

Three-phase

rectifier

PE

DCL+

DCL-

RFI Filter

(*)

charge

Pre-

DC+ BR DC-

bank

DC link chokes

DC link capacitor

Braking IGBT

Inverter with

IGBT transistors

(optional)

Feedback:

- voltage

- current

General Instructions

U/T1R/L1

V/T2

Motor

W/T3

PE

2

PC

SuperDrive G2 Software

WLP Software

Keypad

(remote)

Digital

Inputs

(DI1 to DI6)

Analog

Inputs

(AI1 and AI2)

POWER

CONTROL

USB

FLASH

Memory

Module

Control power supply and interfaces

between power and control

Keypad

CC11

Control

Board

with a 32

bits "RISC"

CPU

Accessories

I/O Expansion

(Slot 1 - white)

Encoder Interface

(Slot 2 - yellow)

COMM 1

(Slot 3 - green)

COMM 2

(anybus) (Slot 4)

Analog

Outputs

(AO1 and AO2)

Digital Outputs

DO1 (RL1) to

DO3 (RL3)

(*) The RFI filter capacitor against the ground must be disconnected with IT and grounded delta networks. Refer to the section 3.2.3.1.1 for more

details.

Figure 2.1 - Block diagram for the CFW-11

2-5

2

General Instructions

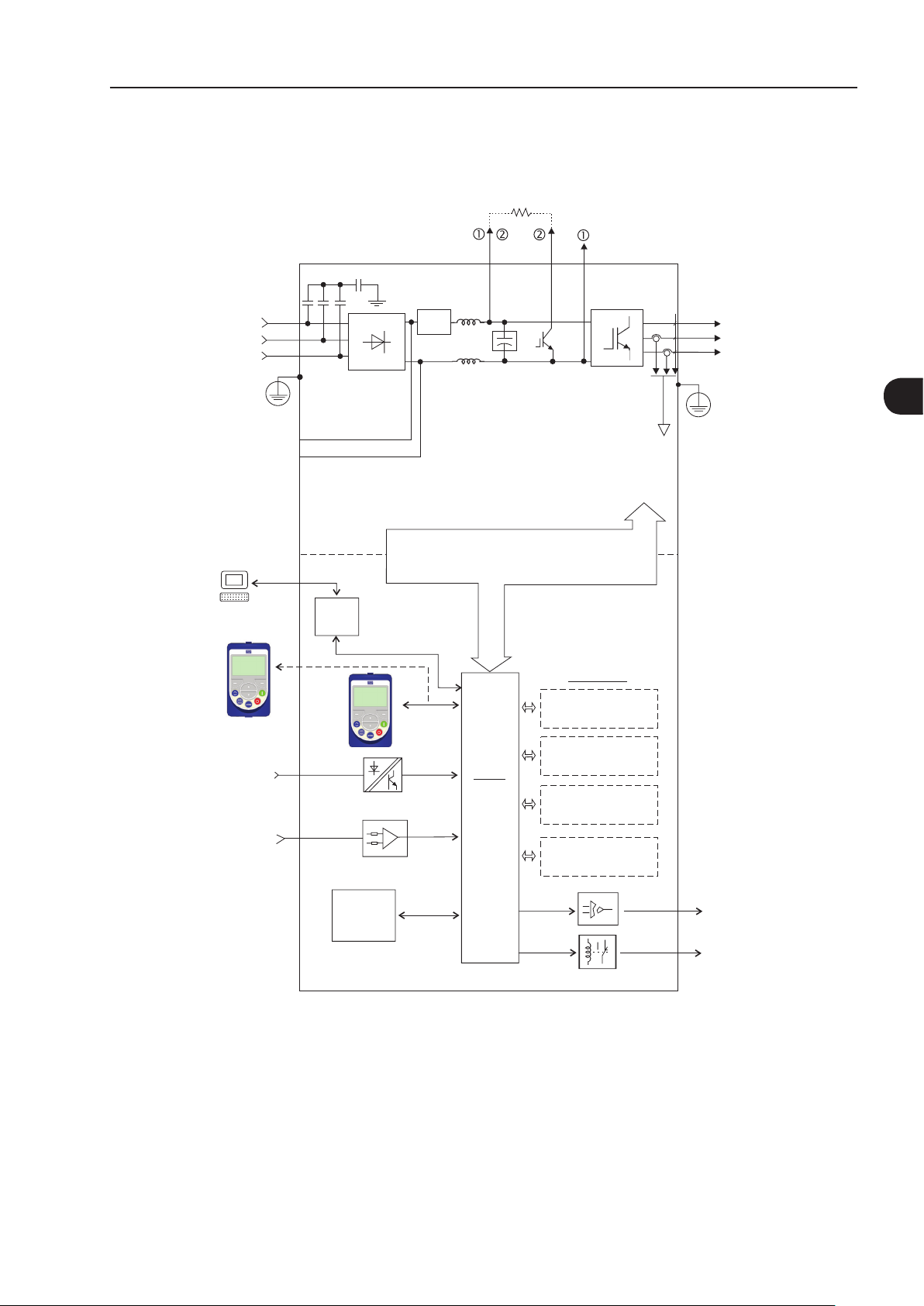

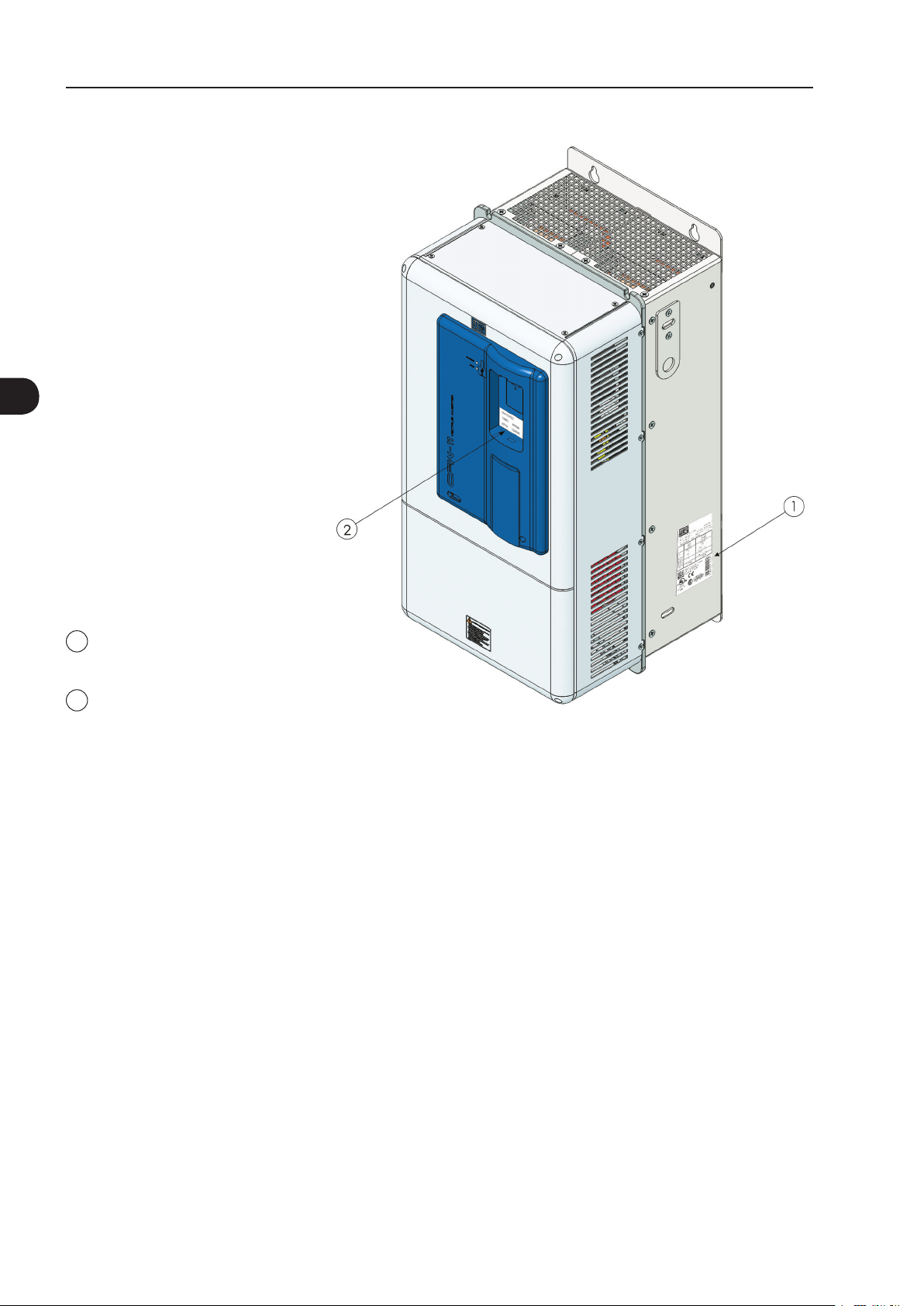

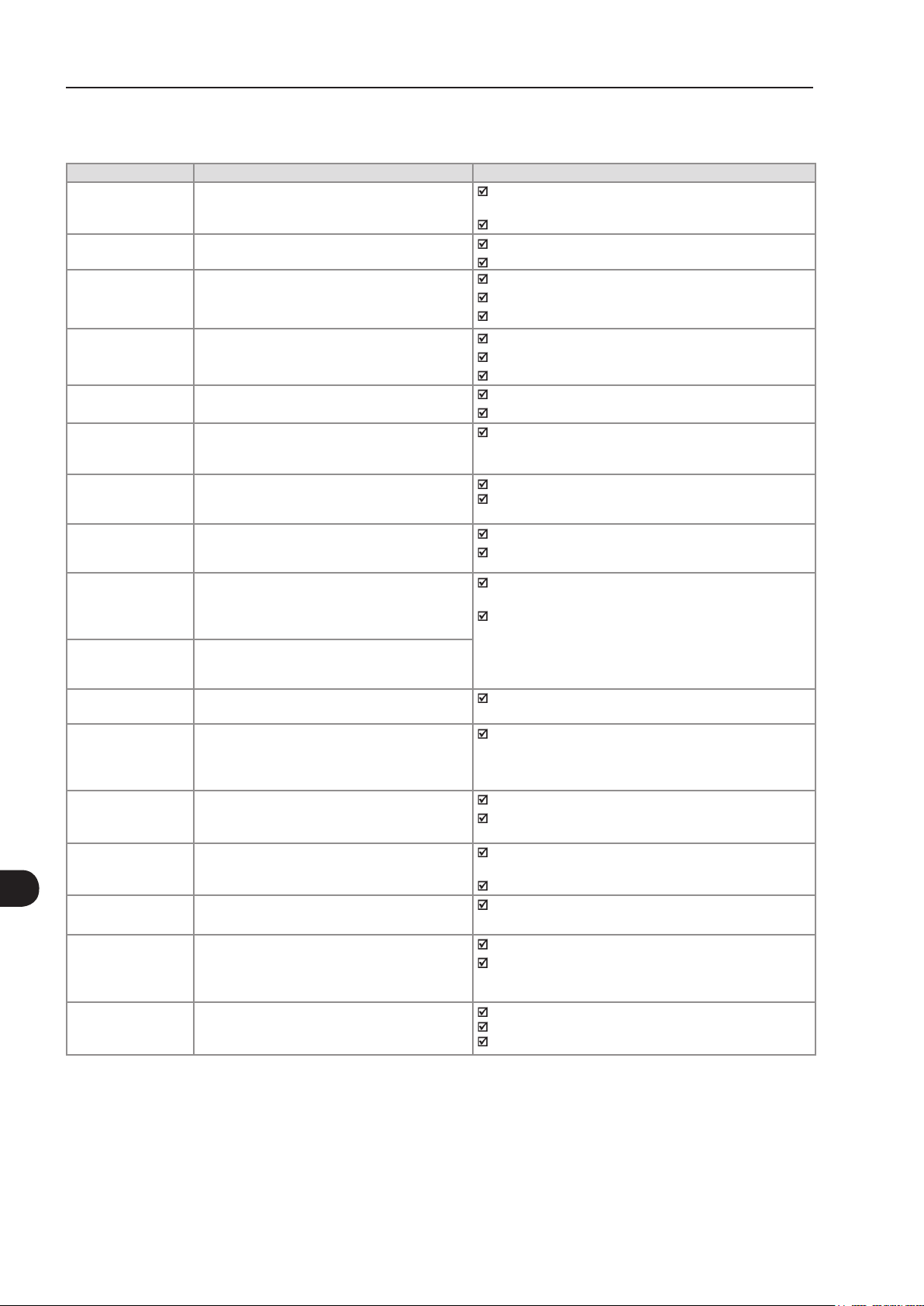

A – Keypad

B – Control rack cover

C – CC11 control board

D – FLASH memory module

E – Control accessory module (refer to the section 7.2)

F – Anybus-CC accessory module (refer to the section 7.2)

G – Bottom front cover

H – Heatsink fan

I – Mounting supports (for through the wall mounting)

J – Hoisting eye

K – Rear part of the inverter (external part for flange mounting)

L – SRB2 Safety stop board

M – Nema1 kit top cover (“hat”)

N – Nema1 kit bottom (Conduit kit)

M

Inverter with Nema1 kit

(optional)

N

2-6

Figure 2.2 - Main components of the CFW-11

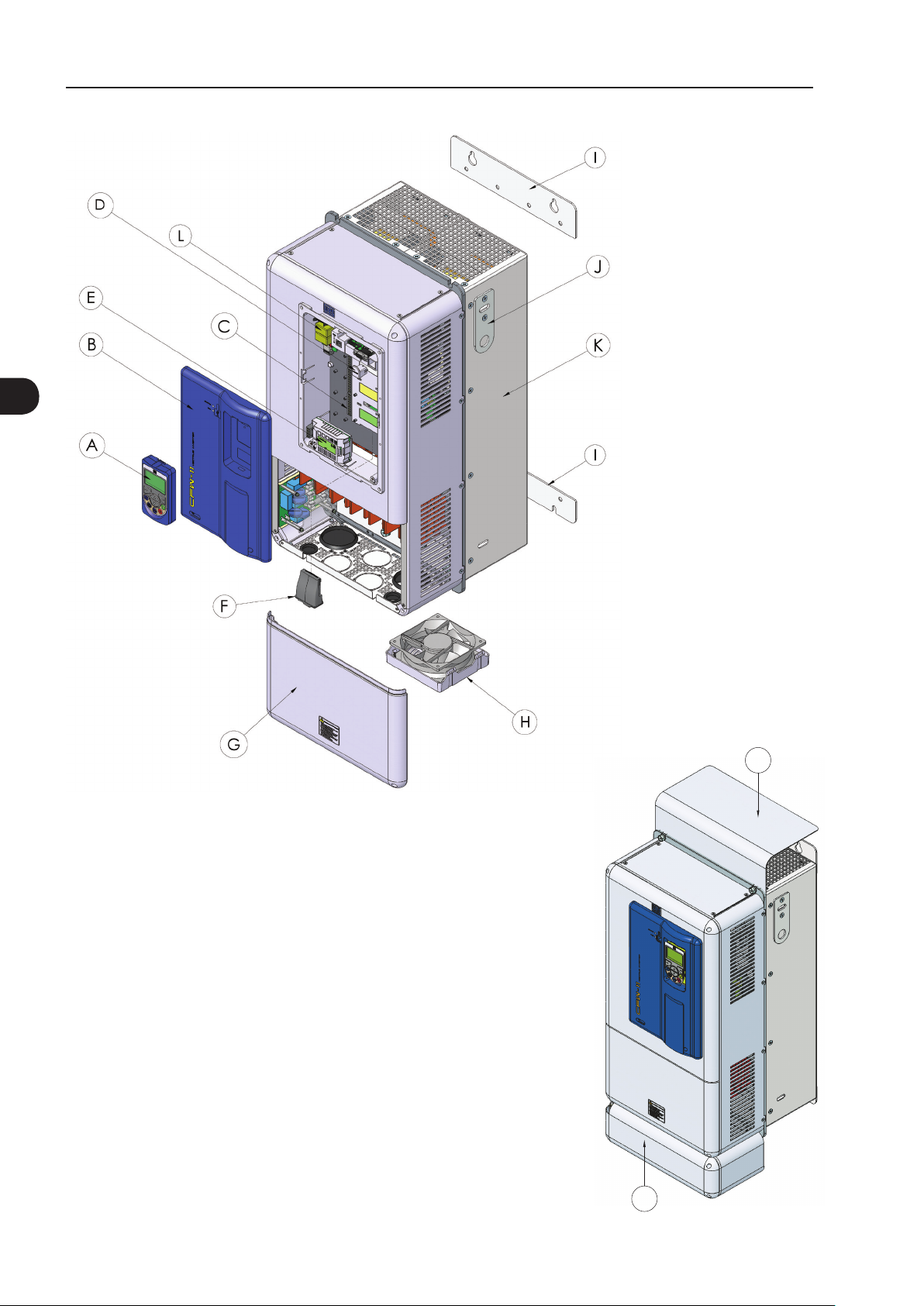

1

USB Connector

2

USB LED

Off: No USB connection

On/Flashing: USB communication is active

3

STATUS LED

Green: Normal operation with no fault or alarm

Yellow: Alarm condition

Flashing red: Fault condition

General Instructions

2

Figure 2.3 - LEDs and USB connector

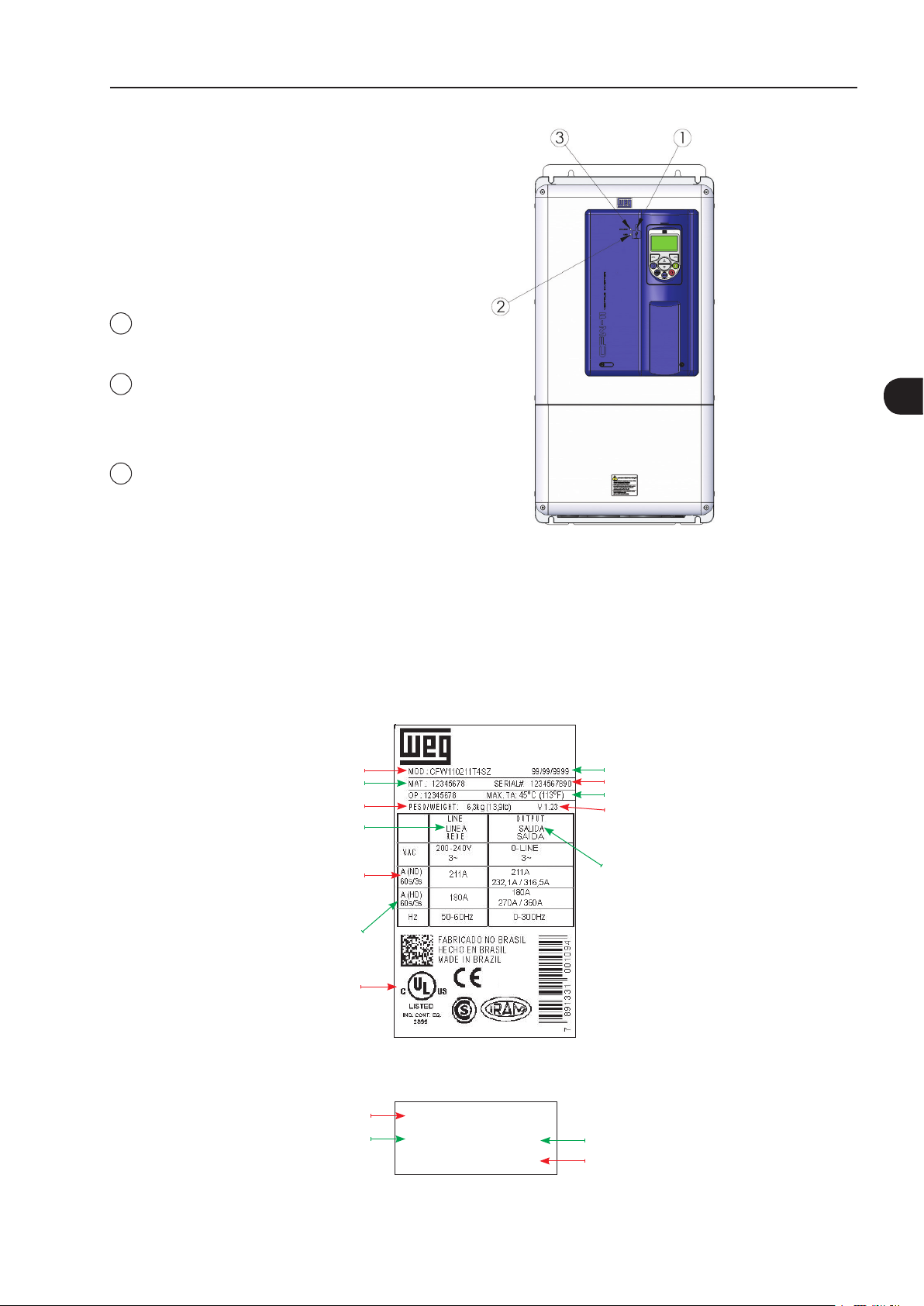

2.4 IDENTIFICATION LABELS FOR THE CFW-11

There are two nameplates on the CFW-11: one complete nameplate is affixed to the side of the inverter and

a simplified one is located under the keypad. The nameplate under the keypad allows the identification of the

most important characteristics of the inverter even if they are mounted side-by-side.

CFW-11 model

WEG part number

Inverter net weight

Input rated data (voltage, number of phases,

rated currents for operation with ND and HD

overload cycles, and frequency)

Current specifications for operation with

normal overload cycle (ND)

Current specifications for operation with

heavy overload cycle (HD)

Available certifications

Manufacturing date (day/month/year)

Serial number

Maximum surrounding air temperature

Software Version

Output rated data (voltage, number of phases,

rated currents for operation with ND and HD

overload cycles, over load currents for 1 min

and 3 s, and frequency range)

(a) Nameplate afxed to the side of the inverter

CFW-11 model

WEG part number

CFW110211T4SZ

12345678

SERIAL#:

(b) Nameplate located under the keypad

Figure 2.4 (a) and (b) - Nameplates

99/99/9999

1234567980

Manufacturing date (day/month/year)

Serial number

2-7

2

General Instructions

1

Nameplate affixed to the

1

side of the heatsink

Nameplate under the keypad

2

Figure 2.5 - Location of the nameplates

2-8

Character

that

identifies

Special

software

Special

hardware

external

power supply

the code

end

for control

Blank=

standard

S1=special

software #1

Blank=

standard

H1=special

hardware #1

Blank=

standard (not

available)

W=24 Vdc

Blank=

standard

(safety stop

function is not

Blank=

standard

(with

internal RFI

external

power supply

for control

available)

Y=with safety

stop function

filter)

General Instructions

according to

EN-954-1

category 3

2

Blank=

standard

(no braking

IGBT)

DB=with

braking

IGBT

Refer to chapter 8 to check option kit availability for each inverter model

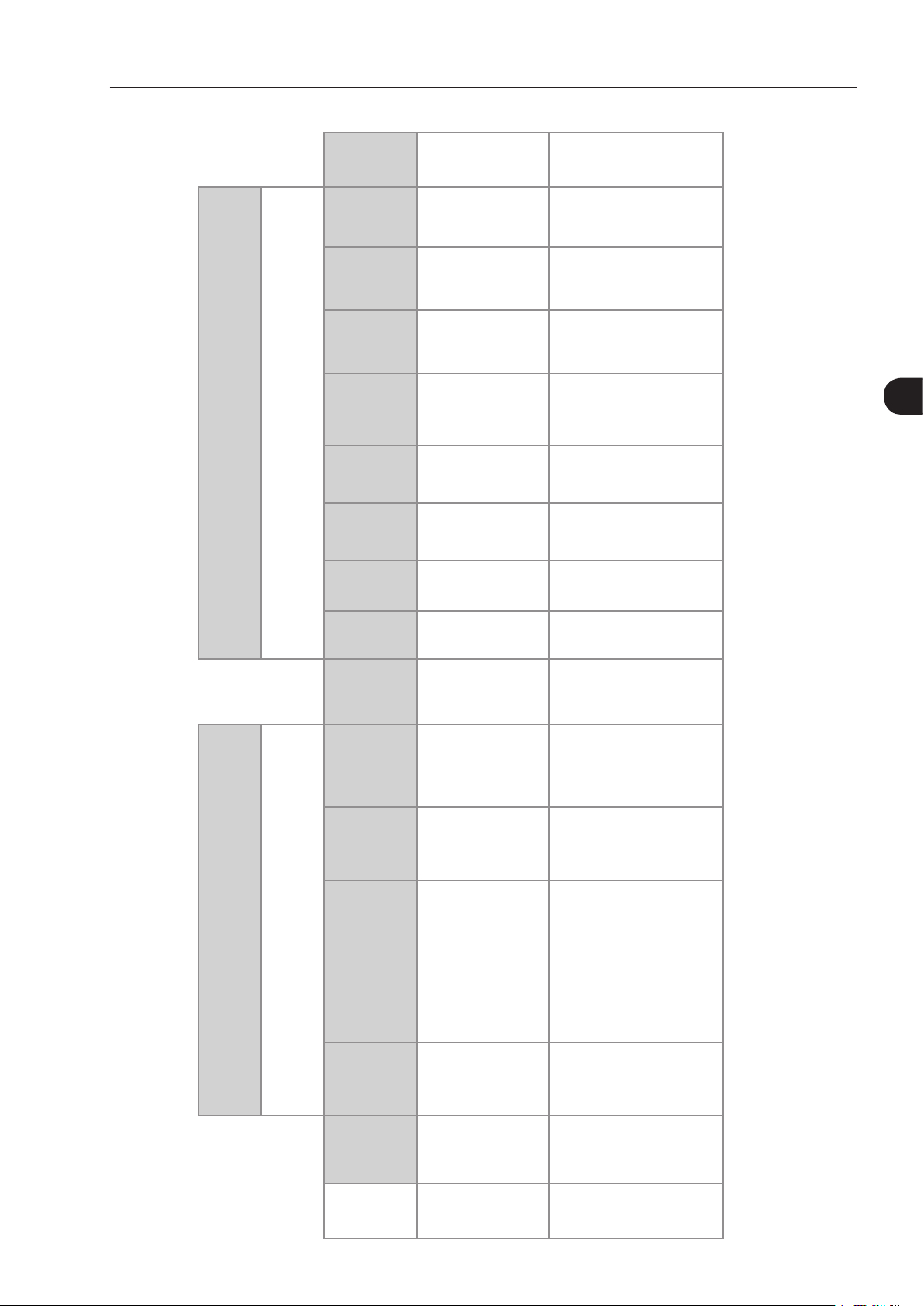

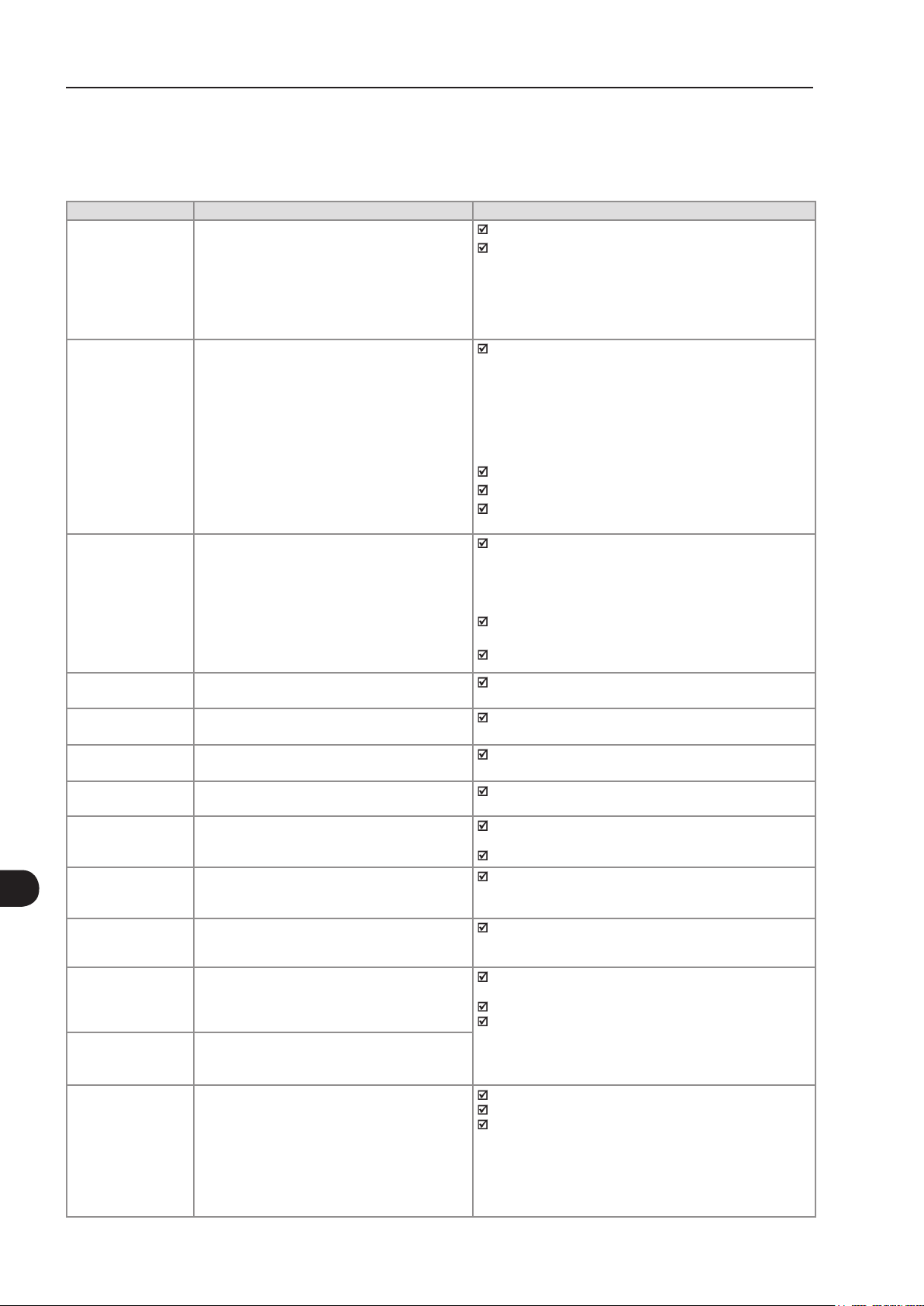

Keypad Braking RFI filter Safety stop 24 Vdc

type

Option kit Enclosure

Power supply

voltage

Number of

power phases

INVERTER MODEL AVAILABLE OPTION KITS (CAN BE INSTALLED IN THE PRODUCT FROM THE FACTORY)

Blank=

standard

keypad

IC=no

Blank=

standard

(IP20)

N1=

S=standard

product

O=product

with option kit

2=220...230 V

4=380...480 V

T=three-phase

power supply

keypad

(blind

Nema1

cover)

technical specifications of the inverters are also presented

Refer to the CFW-11 series frame size E model list in the chapter 8, where the

HOW TO CODIFY THE CFW-11 MODEL (SMART CODE)

Rated output current for use with

the Normal Duty (ND) cycle

WEG CFW-11

frequency

inverter series

Market

identification

(defines

the manual

language and

the factory

Example BR CFW11 0211 T 4 S _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Z

Field

description

220...230 V models:

settings)

2 characters

Available

0142=115 A (HD) / 142 A (ND)

0180=142 A (HD) / 180 A (ND)

0211=180 A (HD) / 211 A (ND)

380...480 V models:

0105=88 A (HD) / 105 A (ND)

0142=115 A (HD) / 142 A (ND)

0180=142 A (HD) / 180 A (ND)

options

0211=180 A (HD) / 211 A (ND)

2-9

2

General Instructions

2.5 RECEIVING AND STORAGE

The CFW-11 frame size E models are supplied packed in wooden boxes.

There is an identification label affixed to the outside of this package, the same one that is affixed to the side

of the CFW-11 inverter.

Follow the instructions below to remove the CFW-11 from the package:

1- Put the shipping container over a flat and stable area with the assistance of another two people;

2- Open the wood crate;

3- Remove all the packing material (the cardboard or styrofoam protection) before removing the inverter.

Check the following items once the inverter is delivered:

Verify that the CFW-11 nameplate corresponds to the model number on your purchase order;

Inspect the CFW-11 for external damage during transportation.

Report any damage immediately to the carrier that delivered your CFW-11 inverter.

If CFW-11 is to be stored for some time before use, be sure that it is stored in a clean and dry location that

conforms to the storage temperature specification (between -25 °C and 60 °C (-13 °F and 140 °F)). Cover the

inverter to prevent dust accumulation inside it.

ATTENTION!

Capacitor reforming is required if drives are stored for long periods of time without power. Refer to

the procedures in item 6.5 - table 6.3.

2-10

INSTALLATION AND CONNECTION

This chapter provides information on installing and wiring the CFW-11.

The instructions and guidelines listed in this manual shall be followed

to guarantee personnel and equipment safety, as well as the proper

operation of the inverter.

3.1 MECHANICAL INSTALLATION

3.1.1 Installation Environment

Avoid installing the inverter in an area with:

Direct exposure to sunlight, rain, high humidity, or sea-air;

Inflammable or corrosive gases or liquids;

Excessive vibration;

Dust, metallic particles, and oil mist.

Installation and Connection

Environment conditions for the operation of the inverter:

Temperature: -10 ºC to 45 ºC (14 °F to 113 °F) - standard conditions (surrounding the inverter).

From 45 ºC to 55 ºC (113 °F to 131 °F) - current derating of 2 % each °C (or 1.11 % each °F) above 45 ºC

(113 °F).

Humidity: from 5 % to 90 % non-condensing.

Altitude: up to 1000 m (3,300 ft) - standard conditions (no derating required).

From 1000 m to 4000 m (3,300 ft to 13,200 ft) - current derating of 1 % each 100 m (or 0.3 % each 100 ft)

above 1000 m (3,300 ft) altitude.

Pollution degree: 2 (according to EN50178 and UL508C) with non-conductive pollution. Condensation shall

not originate conduction through the accumulated residues.

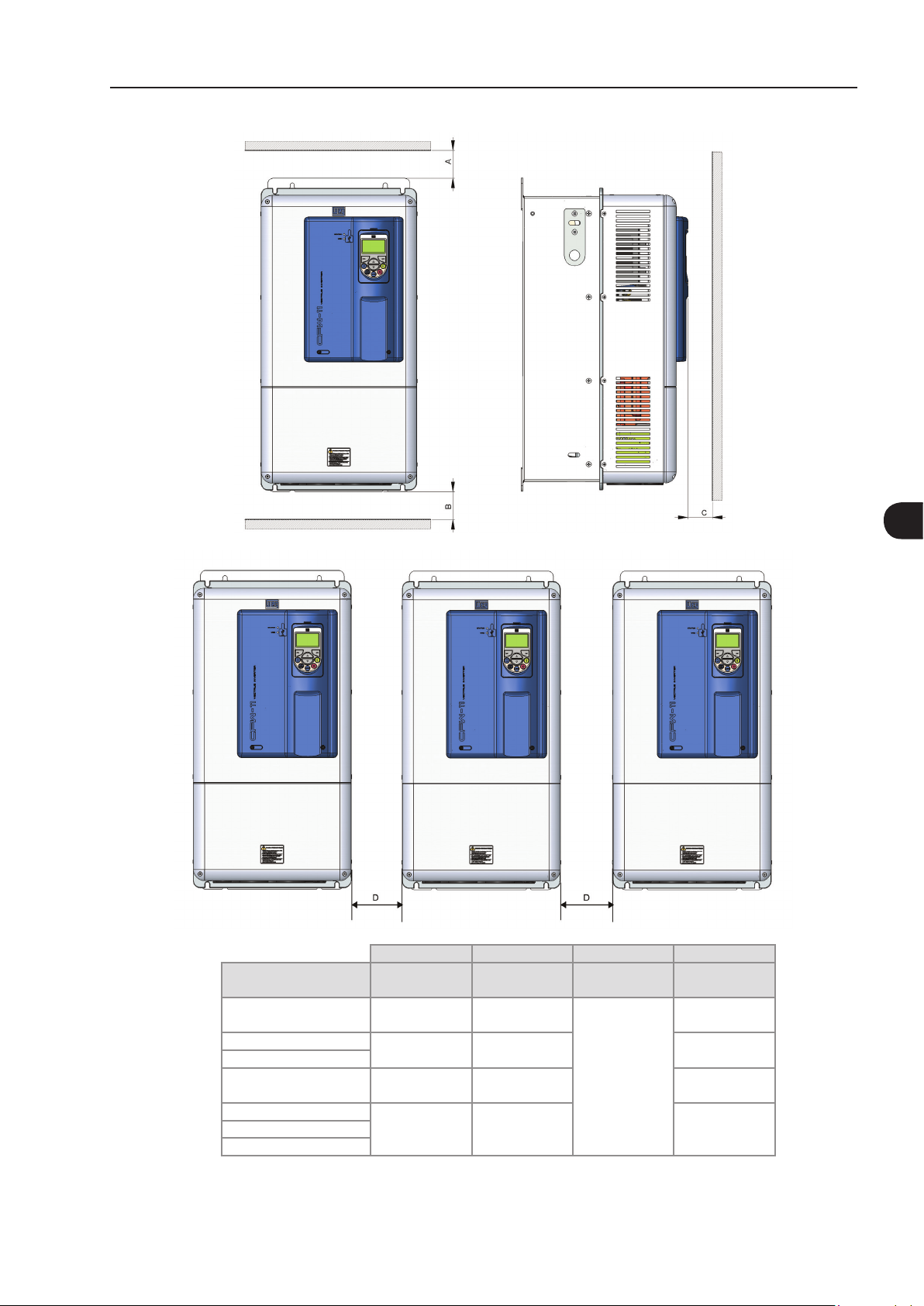

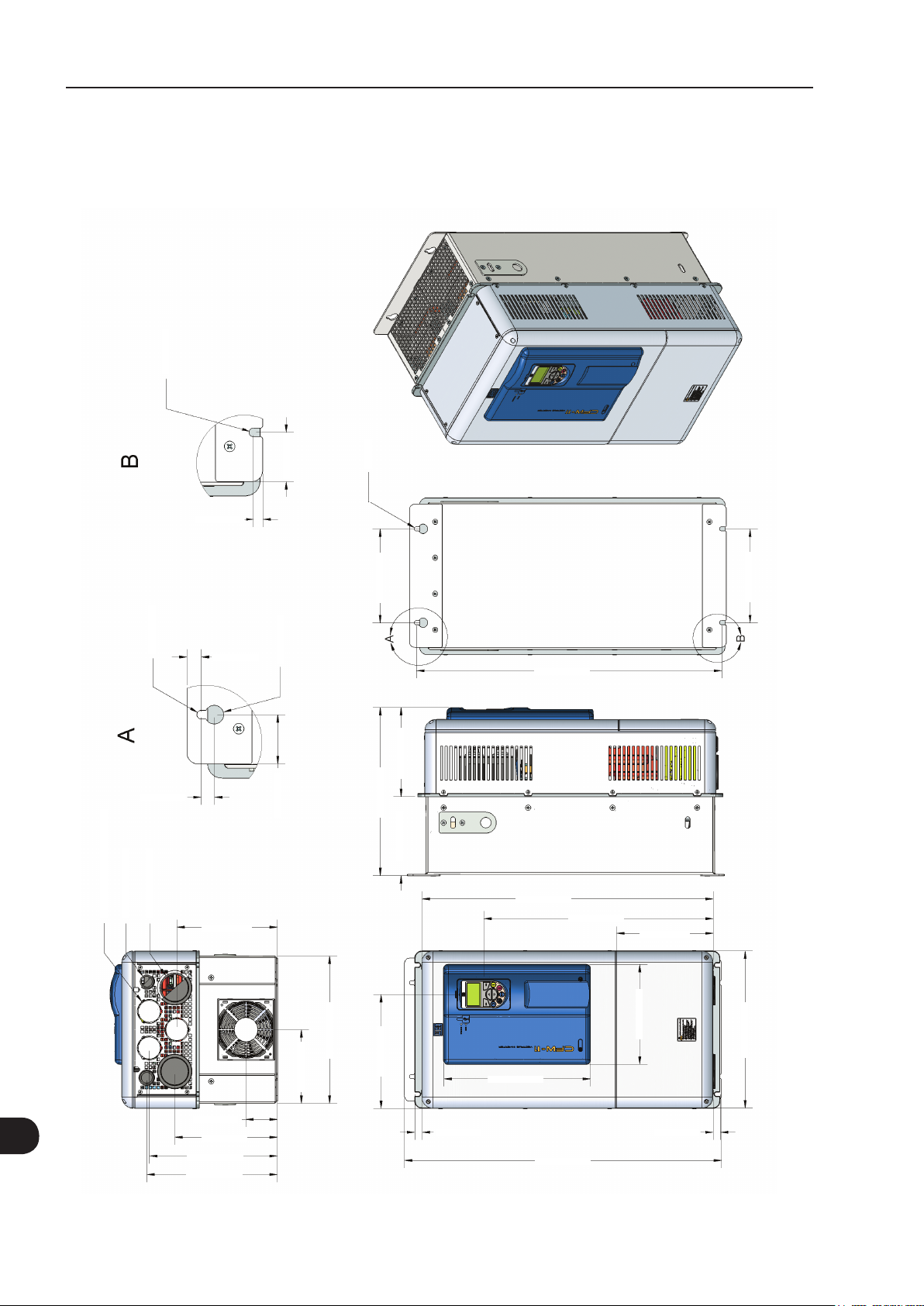

3.1.2 Mounting Considerations

Consult the inverter weight at the table 8.1.

Mount the inverter in the upright position on a flat and vertical surface.

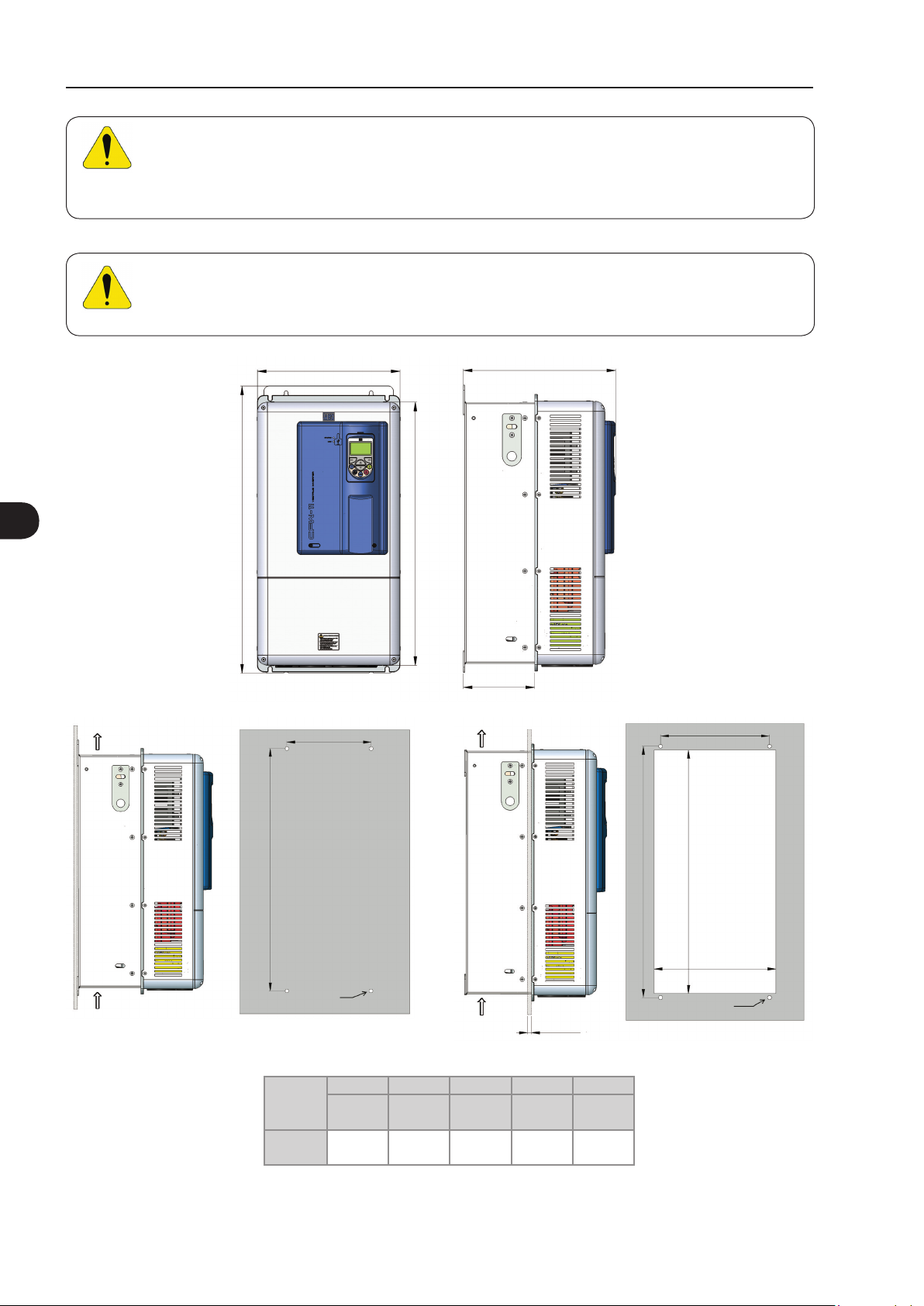

External dimensions and fixing holes position according to the figure 3.1. Refer to the section 8.3 for more

details.

First put the screws on the surface where the inverter will be installed, install the inverter and then tighten the

screws.

3

Minimum mounting clearances requirements for proper cooling air circulation are specified in figure 3.2.

Do not install heat sensitive components right above the inverter.

3-1

Installation and Connection

ATTENTION!

When arranging two or more inverters vertically, respect the minimum clearance A + B (figure 3.2)

and provide an air deflecting plate so that the heat rising up from the bottom inverter does not affect

the top inverter.

ATTENTION!

Provide conduit for physical separation of the signal, control, and power conductors (refer to item

3.2 - Electrical Installation).

3

675 (26.6)

335 (13.2)

200 (7.8)

358 (14.1)

620 (24.4)

168 (6.6)

275 (10.8)

3-2

Air flow

650 (25.6)

(a) Surface Mounting

Model

Frame E M8 M8

Tolerances for dimensions d3 and e3: +1.0 mm (+0.039 in)

Tolerances for remaining dimensions: ±1.0 mm (±0.039 in)

(*) Recommended torque for the inverter mounting (valid for c2 and c3)

Figure 3.1 (a) and (b) - Mechanical installation details - mm (in)

∅ c2

Air flow

c2 c3 d3 e3 Torque (*)

M M

mm

(in)

315

(12.40)

Max. 3 (0.12)

mm

(in)

615

(24.21)

e3

635 (25)

d3

∅ c3

(b) Flange Mounting

N.m

(lbf.in)

20.0

(177.0)

Installation and Connection

3

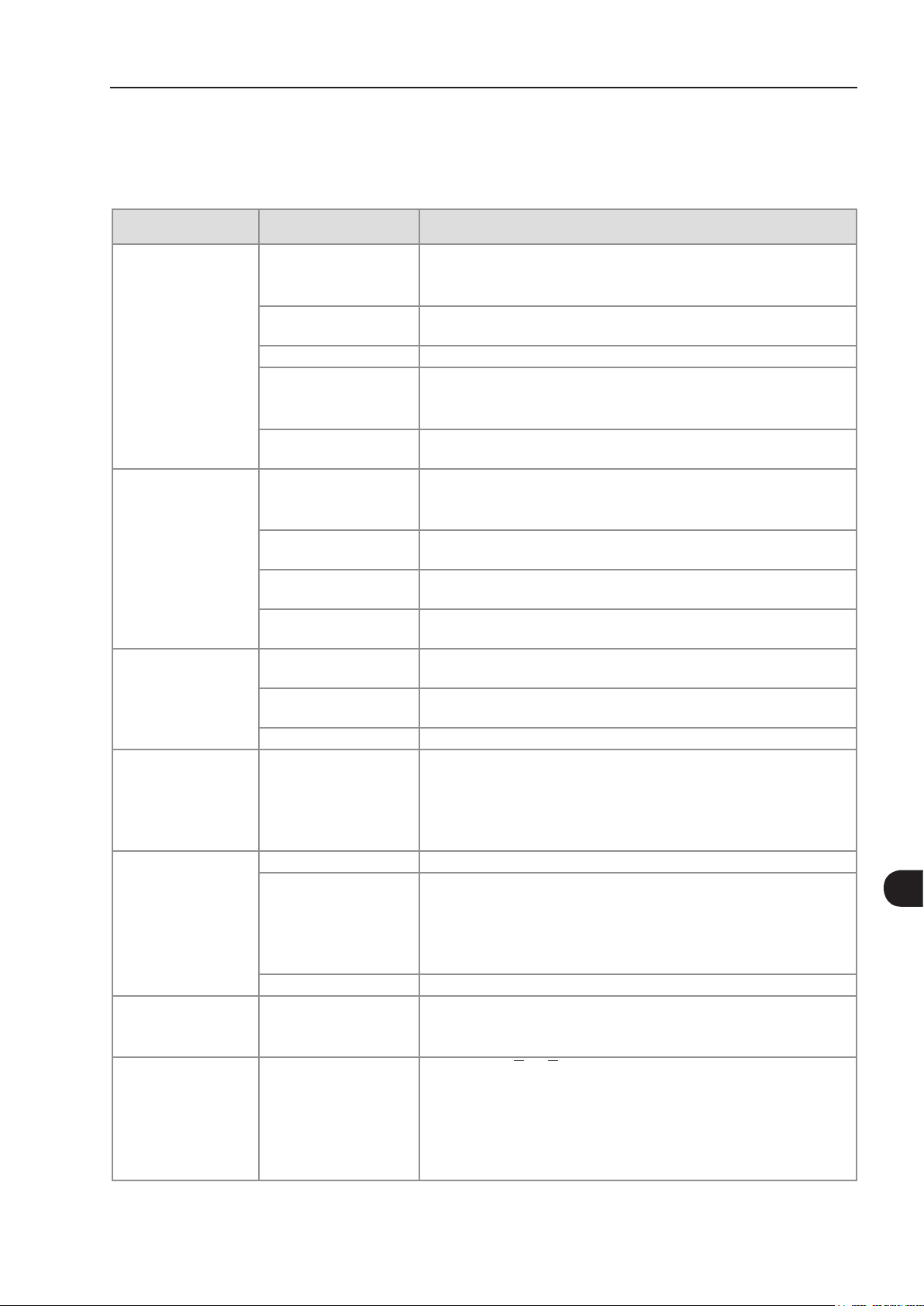

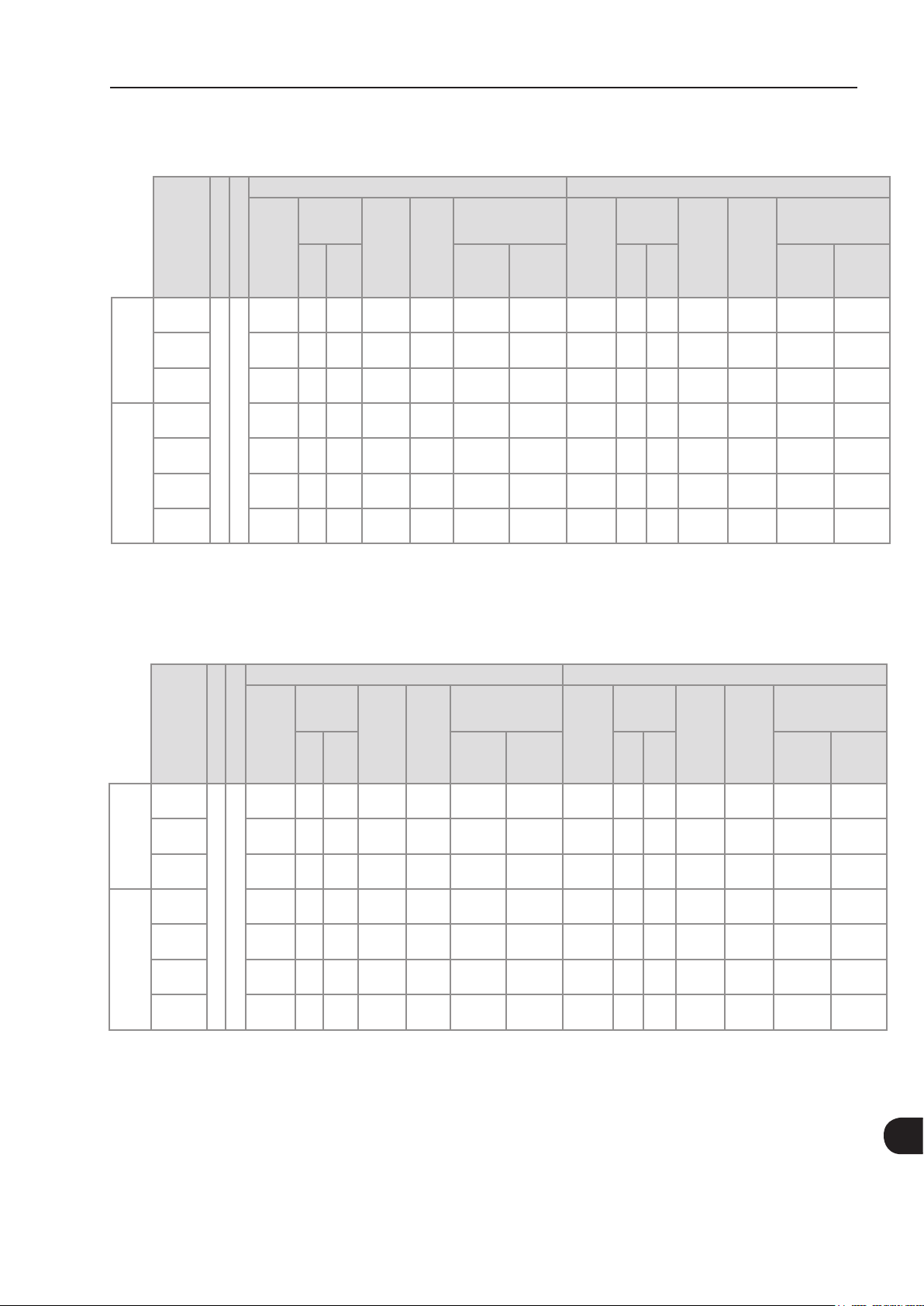

A B C D

Model

CFW11 0142 T 2

CFW11 0180 T 2

CFW11 0211 T 2

CFW11 0105 T 4

CFW11 0142 T 4

CFW11 0180 T 4

CFW11 0211 T 4

Tolerance: ±1.0 mm (±0.039 in)

Figure 3.2 - Free spaces for ventilation, above, below, at the front and at the sides of the inverter

mm

(in)

100

(3.94)

150

(5.91)

100

(3.94)

150

(5.91)

mm

(in)

130

(5.12)

250

(9.84)

130

(5.12)

250

(9.84)

mm

(in)

20

(0.78)

mm

(in)

40

(1.57)

80

(3.15)

40

(1.57)

80

(3.15)

3-3

3

Installation and Connection

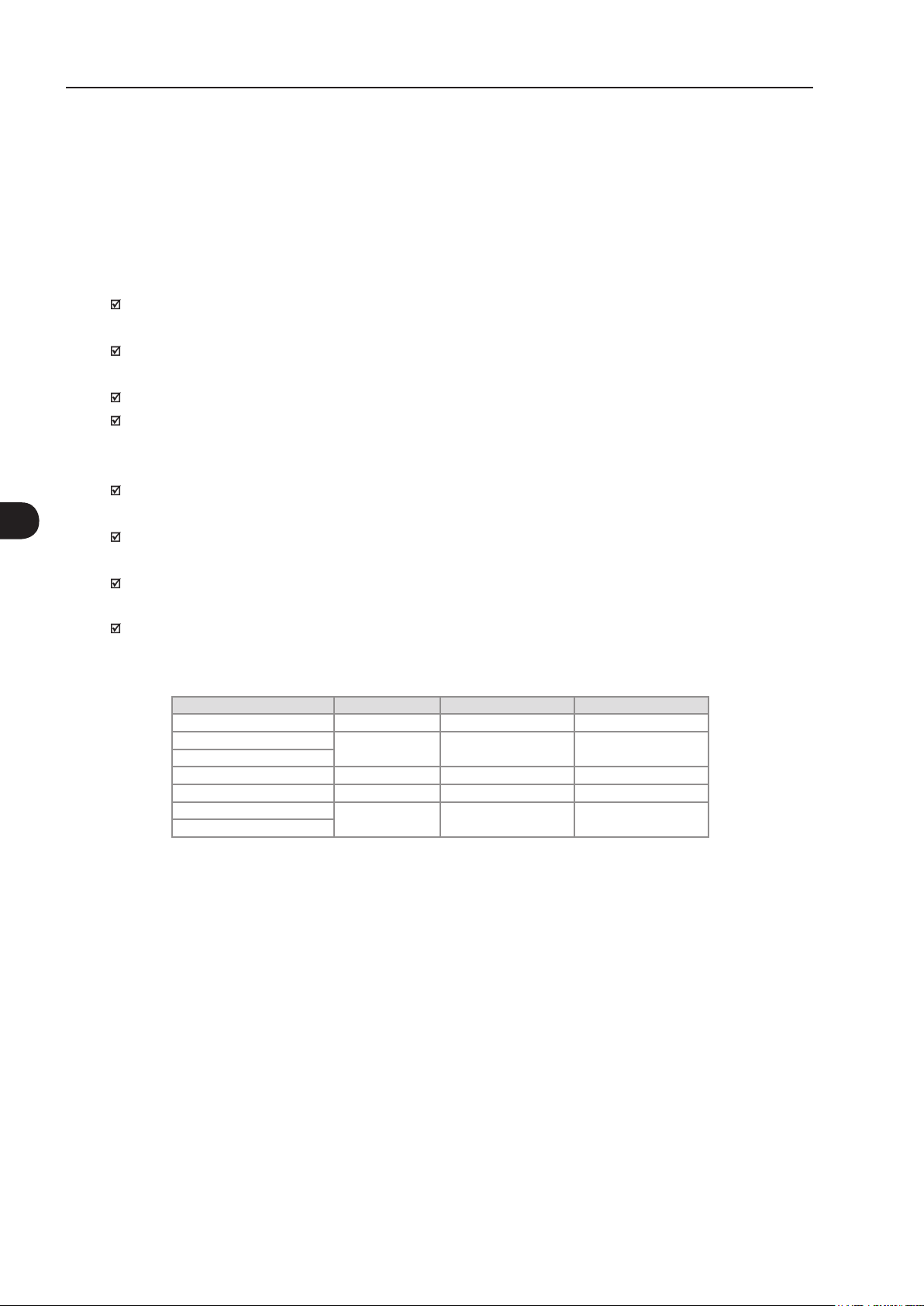

3.1.3 Cabinet Mounting

There are two possibilities for mounting the inverter: through the wall mounting or flange mounting (the heatsink

is mounted outside the cabinet and the cooling air of the power module is kept outside the enclosure). The

following information shall be considered in these cases:

Surface assembly:

Provide adequate exhaustion so that the internal cabinet temperature is kept within the allowable operating

range of the inverter.

The power dissipated by the inverter at its rated condition, as specified in table 8.1 "Dissipated power in

Watts - Through the wall mounting".

The cooling air flow requirements, as shown in table 3.1.

The position and diameter of the mounting holes, according to figure 3.1.

Flange assembly:

The losses specified in table 8.1 "Dissipated power in Watts - Flange mounting" will be dissipated inside the

cabinet. The remaining losses (power module) will be dissipated through the vents.

The inverter securing supports and the hoisting eyes must be removed and repositioned according to the

figure 3.3.

The portion of the inverter that is located outside the cabinet is rated IP54. Provide an adequate gasket for

the cabinet opening to ensure that the enclosure rating is maintained. Example: silicone gasket.

Mounting surface opening dimensions and position/diameter of the mounting holes, as shown in figure 3.1.

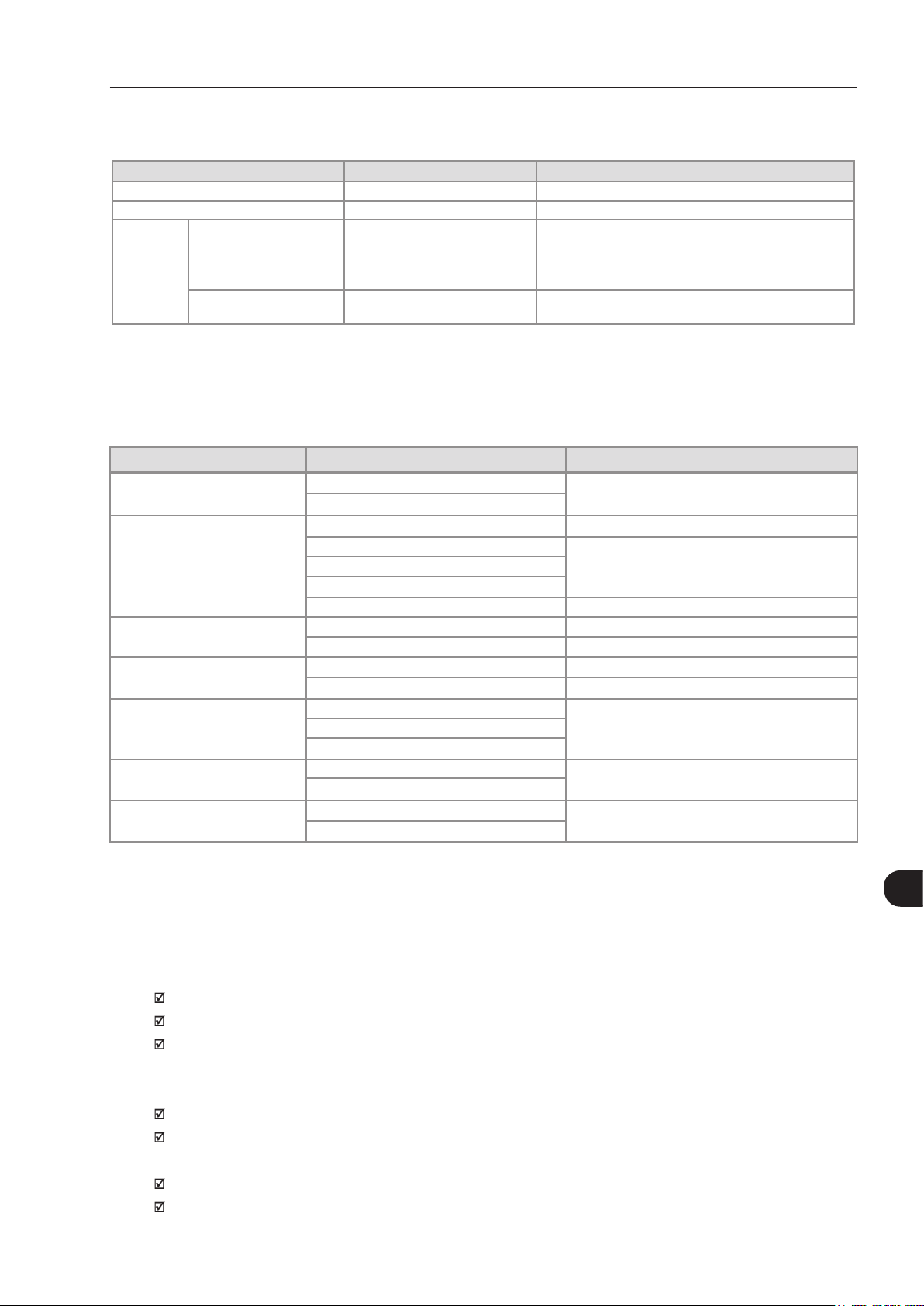

Table 3.1 - Cooling air ow for frame size E models

Model CFM I/s m³/min

CFW11 0142 T 2 138 65 3.9

CFW11 0180 T 2

CFW11 0211 T 2

CFW11 0105 T 4 138 65 3.9

CFW11 0142 T 4 180 95 5.1

CFW11 0180 T 4

CFW11 0211 T 4

265 125 7.5

265 125 7.5

3-4

Installation and Connection

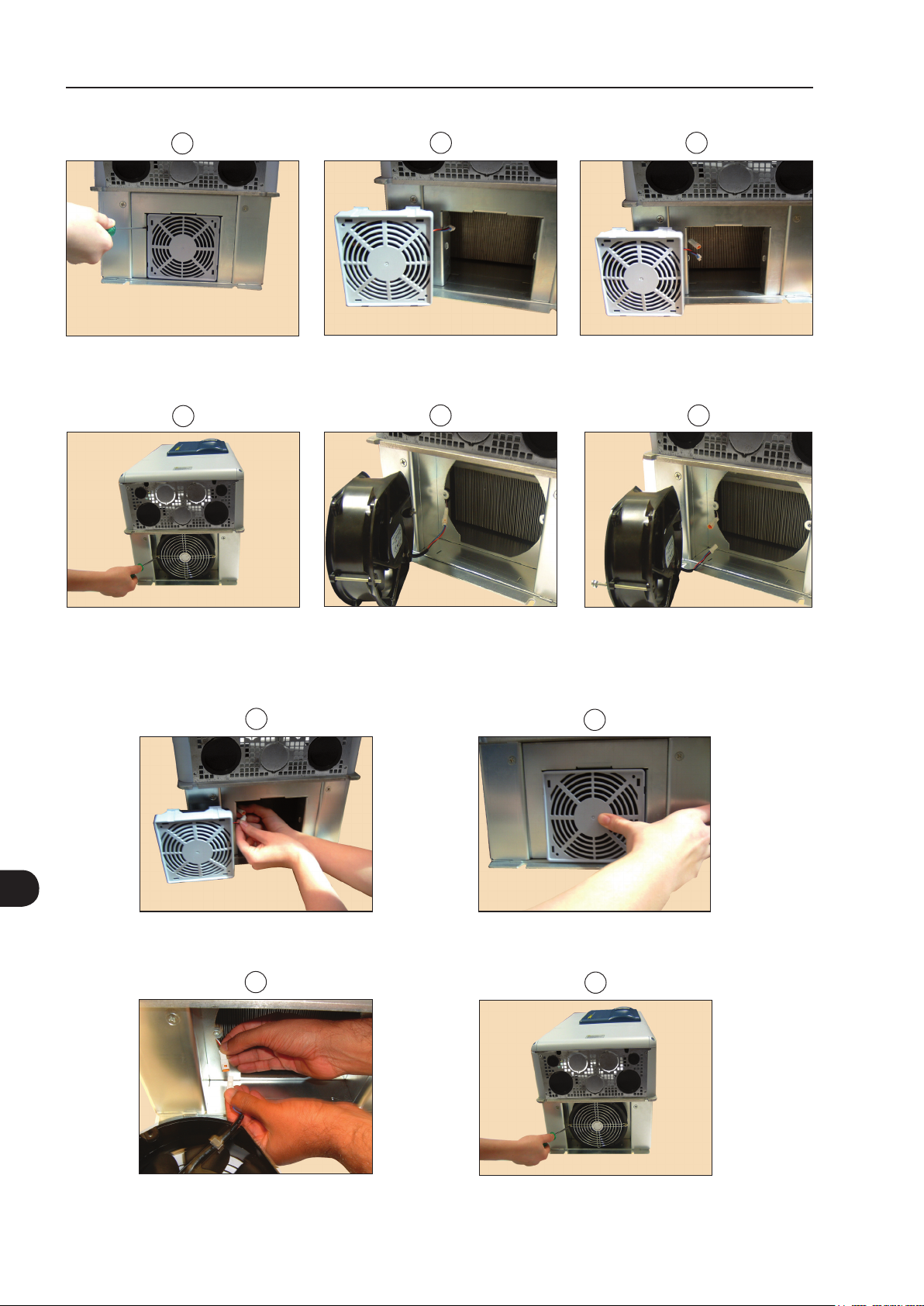

321

654

3

Figure 3.3 - Repositioning the mounting supports

3.1.4 Installation of the Inverter Hoisting Eyes

Two hoisting eyes for the inverter lifting, which are mounted at the inverter sides (rear part), are supplied. By

inverting their position, as showed in the figure 3.4, 2 points for hoisting the inverter, which are very useful

during the mechanical installation of the inverter, are obtained.

Figure 3.4 - Installation of the inverter hoisting eyes

3-5

Installation and Connection

3.1.5 Installation of the Inverter with Nema1 Kit (Optional, CFW11XXXXTXON1) on a Wall

Fixing holes position and diameter according to the figure 3.1.

External dimensions of the inverter with Nema1 kit according to the section 8.4.

Fasten the inverter.

Install the Nema1 kit top on the inverter as showed in the figure 3.5 using the 2 M8 screws supplied with

the product.

3

Figure 3.5 - Installation of the Nema1 kit top (“hat”)

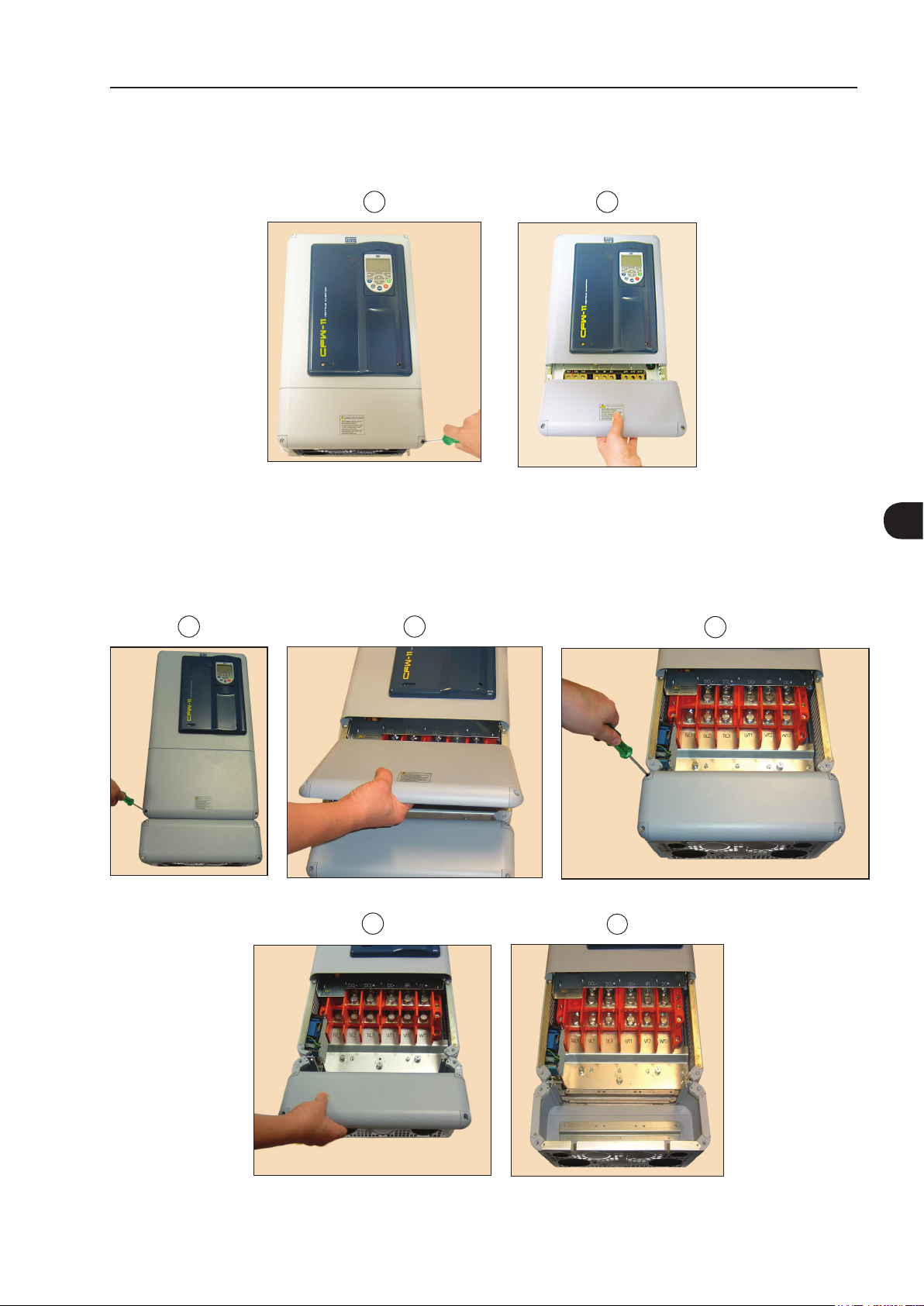

3.1.6 Access to the Control and Power Terminal Strips

In order to get access to the control terminal strips, the HMI and the cover of the control rack must be removed,

as showed in the figure 3.6.

321

3-6

Figure 3.6 - HMI and control rack cover removal

Installation and Connection

In order to get access to the power terminal block, the bottom front cover must be removed, as showed in the

figure 3.7.

21

Figure 3.7 - Bottom front cover removal

At the CFW11 0180 T 2 O N1, CFW11 0211 T 2 O N1, CFW11 0180 T 4 O N1 and CFW11 0211 T 4 O

N1 inverters (supplied with Nema1 kit), it is also necessary to remove the front cover of the Nema1 kit bottom

part in order to be able to execute the power section electric installation – see the figure 3.8.

1 2

4

5

3

3

Figure 3.8 - Removal of the Nema1 kit bottom front cover at the CFW11 0180 T 2 O N1, CFW11 0211 T 2 O N1,

CFW11 0180 T 4 O N1 and CFW11 0211 T 4 O N1 inverters in order to get access to the power terminal block

3-7

Installation and Connection

3.1.7 Removal of the Cable Passage Plate

When it is not necessary neither IP20 nor Nema1 protection degree, the cable passage plate may be removed

in order to make the inverter electric installation easier. Remove the 4 M4 screws, according to the procedure

presented in the figure 3.9.

3

1

2

3

Figure 3.9 - Removal of the cable passage plate

3.1.8 HMI Installation at the Cabinet Door or Command Panel (Remote HMI)

28.5 [1.12]

23.5 [0.93]

113.0 [4.45]

35.0 [1.38]

103.0 [4.06]

23.4 [0.92]

16.0 [0.63]

∅4.0 [0.16] (3X)

65.0 [2.56]

Figure 3.10 - Data for the HMI installation at the cabinet door or command panel – mm [in]

The keypad frame accessory can also be used to fix the HMI, as mentioned in the table 7.2.

3-8

3.2 ELECTRICAL INSTALLATION

DANGER!

The following information is merely a guide for proper installation. Comply with applicable local

regulations for electrical installations.

DANGER!

Make sure the AC power supply is disconnected before starting the installation.

ATTENTION!

Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit

protection must be provided in accordance with applicable local codes.

Installation and Connection

3.2.1 Identification of the Power and Grounding Terminals

R/L1, S/L2, T/L3: AC power supply.

U/T1, V/T2, W/T3: motor connection.

DC+: this is the positive potential terminal in the DC bus circuit.

BR: braking resistor connection.

DC-: this is the negative potential terminal in the DC bus circuit.

DCL+: positive pole of the rectifier output voltage.

DCL-: negative pole of the rectifier output voltage.

3

Ground

(4xM8, 4xM5)

Figure 3.11 - Power terminals and grounding points of the CFW-11 series frame size E models

3-9

Installation and Connection

3.2.2 Power / Grounding Wiring and Fuses

ATTENTION!

Use proper cable lugs for the power and grounding connection cables.

3

ATTENTION!

Sensitive equipment such as PLCs, temperature controllers, and thermal couples shall be kept at a

minimum distance of 0.25 m (9.84 in) from the frequency inverter and from the cables that connect

the inverter to the motor.

DANGER!

Improper cable connection:

- The inverter will be damaged in case the input power supply is connected to the output terminals

(U/T1, V/T2, or W/T3).

- Check all the connections before powering up the inverter.

- In case of replacing an existing inverter by a CFW-11, check if the installation and wiring is according

to the instructions listed in this manual.

ATTENTION!

Residual Current Device (RCD):

- When installing an RCD to guard against electrical shock, only devices with a trip current of 300 mA

should be used on the supply side of the inverter.

- Depending on the installation (motor cable length, cable type, multimotor configuration, etc.), the

RCD protection may be activated. Contact the RCD manufacturer for selecting the most appropriate

device to be used with inverters.

NOTE!

The wire gauge values listed in table 3.2 are merely a guide. Installation conditions and the maximum

permitted voltage drop shall be considered for the proper wiring sizing.

Input fuses

Use High Speed Fuses at the input for the protection of the inverter rectifier and wiring. Refer to table 3.2

for selecting the appropriate fuse rating (I2t shall be equal to or less than indicated in table 3.2, consider

the cold (and not the fusion) current extinction value).

In order to meet UL requirements, use class J fuses at the inverter supply with a current not higher than the

values of table 3.2.

Optionally, slow blow fuses can be used at the input. They shall be sized for 1.2 x the rated input current of

the inverter. In this case, the installation is protected against short-circuit, but not the inverter input rectifier.

This may result in major damage to the inverter in the event of an internal component failure.

3-10

Installation and Connection

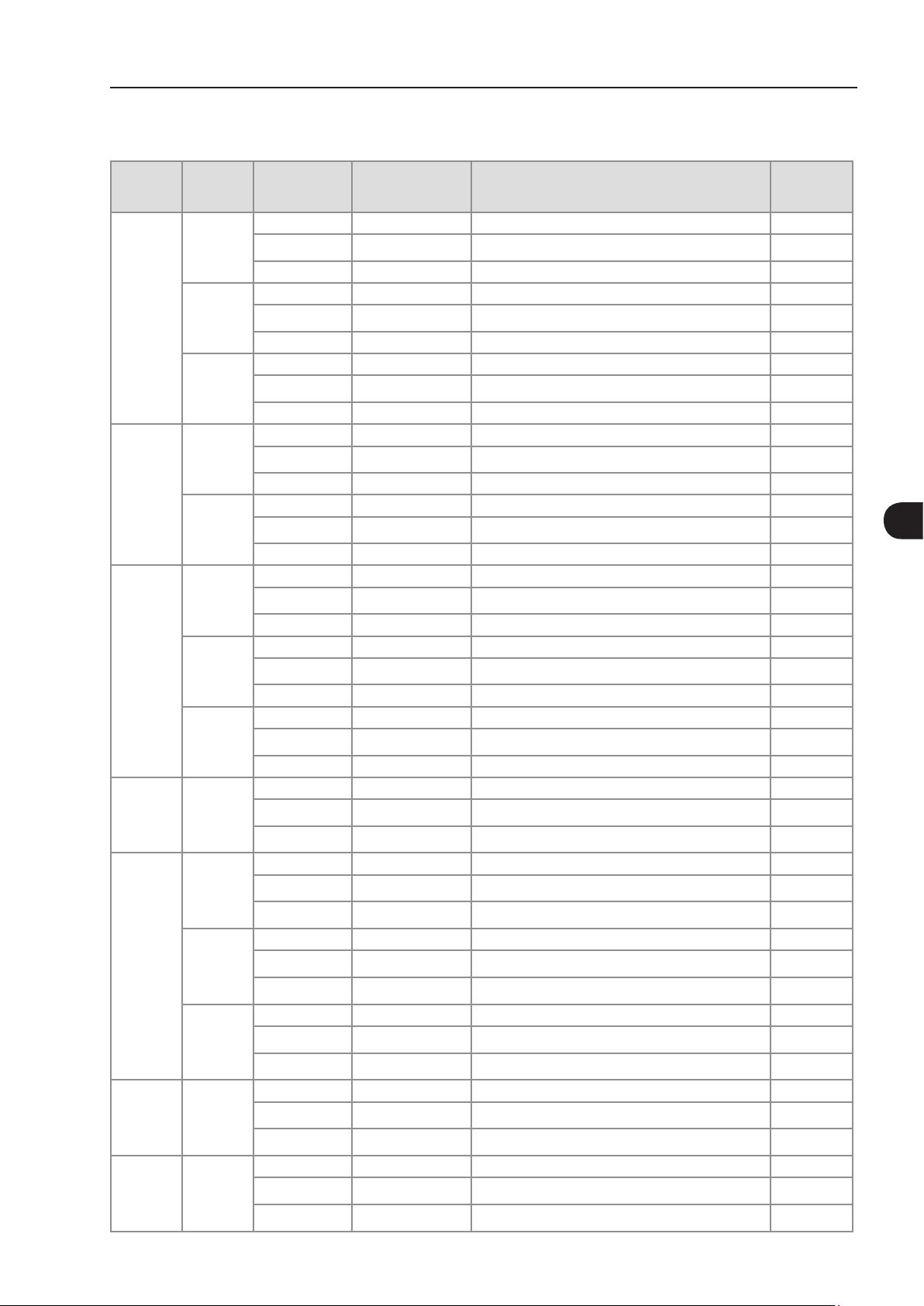

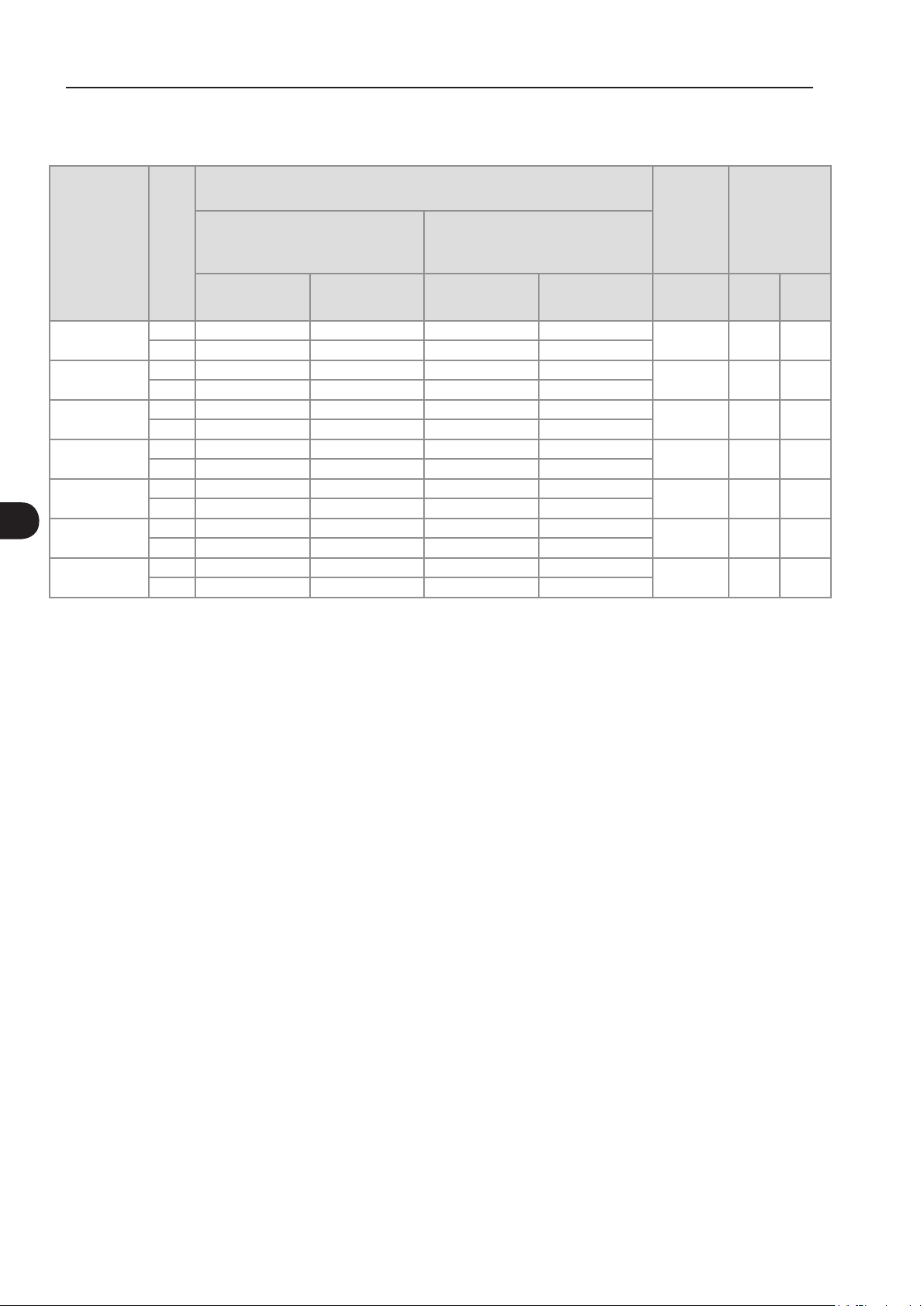

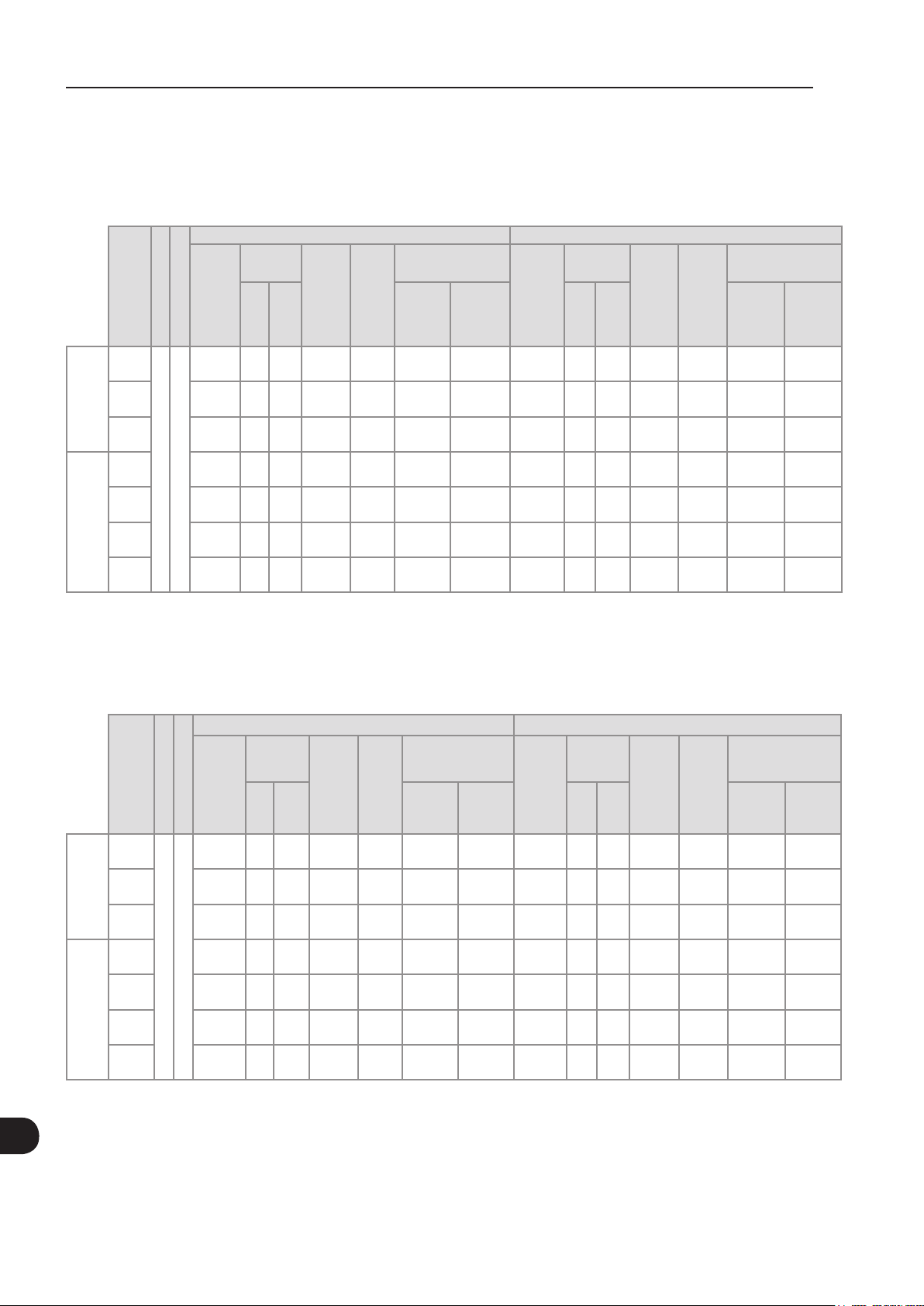

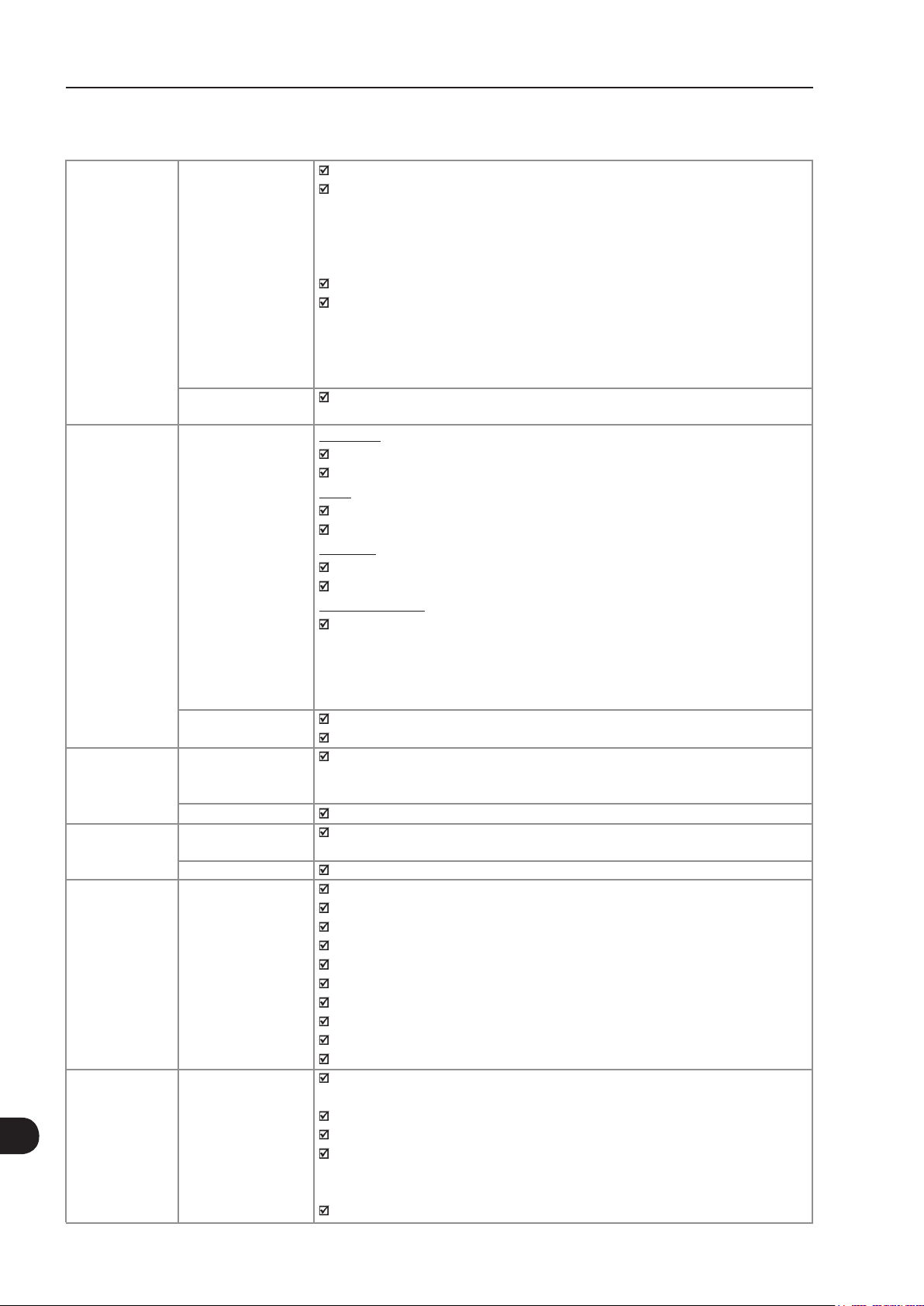

Table 3.2 - Recommended Wire size/ Fuses - use only copper wire [75 ºC (167 °F)]

Model

CFW11 0142 T 2

CFW11 0180 T 2

CFW11 0211 T 2

CFW11 0105 T 4

CFW11 0142 T 4

CFW11 0180 T 4

CFW11 0211 T 4

Terminals

Frame

R/L1,S/L2,T/L3,

U/T1,V/T2,W/T3,

DC+,DC-, DCL+,DCL-

R/L1,S/L2,T/L3,

U/T1,V/T2,W/T3,

DC+,DC-, DCL+,DCL-

R/L1,S/L2,T/L3,

U/T1,V/T2,W/T3,

DC+,DC-, DCL+,DCL-

R/L1,S/L2,T/L3,

U/T1,V/T2,W/T3,

DC+,DC-, DCL+,DCL-

E

R/L1,S/L2,T/L3,

U/T1,V/T2,W/T3,

DC+,DC-, DCL+,DCL-

R/L1,S/L2,T/L3,

U/T1,V/T2,W/T3,

DC+,DC-, DCL+,DCL-

R/L1,S/L2,T/L3,

U/T1,V/T2,W/T3,

DC+,DC-, DCL+,DCL-

Power terminal

Bolt

(wrench/screw

head type)

M8 (hexagonal

phillips screw)

M5 and M8

(hexagonal

phillips screw)

M10

(hexagonal

screw)

M5 and M8

(hexagonal

phillips screw)

M10

(hexagonal

screw)

M5 and M8

(hexagonal

phillips screw)

M8

(hexagonal

phillips screw)

M5 and M8

(hexagonal

phillips screw)

M8

(hexagonal

phillips screw)

M5 and M8

(hexagonal

phillips screw)

M10

(hexagonal

screw)

M5 and M8

(hexagonal

phillips screw)

M10

(hexagonal

screw)

M5 and M8

(hexagonal

phillips screw)

Recommended

torque

N.m (lbf.in)

15 (132.75)

M5:

3.5 (31.0);

M8:

10 (88.5)

30 (265.5)

M5:

3.5 (31.0);

M8:

10 (88.5)

30 (265.5)

M5:

3.5 (31.0);

M8:

10 (88.5)

15 (132.75)

M5:

3.5 (31.0);

M8:

10 (88.5)

15 (132.75)

M5:

3.5 (31.0);

M8:

10 (88.5)

30 (265.5)

M5:

3.5 (31.0);

M8:

10 (88.5)

30 (265.5)

M5:

3.5 (31.0);

M8:

10 (88.5)

2

70

70

Wire size

AWG Terminals

2/0

(or 2x4)

4/0

(or 2x2)

4/0

(or 2x2)

300

(or 2x1)

2/0

(or 2x4)

4/0

(or 2x2)

4/0

(or 2x2)

300

(or 2x1)

Over-

load

class

HD 50 1/0

ND 70 2/0

HD/ND 35 2

HD

ND

HD/ND 50 1

HD

ND

HD/ND 70 2/0

HD 35 2

ND 50 1

HD/ND 25 4

HD 50 1/0

ND 70 2/0

HD/ND 35 2

HD

ND

HD/ND 50 1

HD

ND

HD/ND 70 2/0

mm

(or 2x25)

120

(or 2x35)

120

(or 2x35)

150

(or 2x50)

(or 2x25)

120

(or 2x35)

120

(or 2x35)

150

(or 2x50)

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Fuse

Fuse

[A]

200 39200

200 218000

250 218000

125 39200

200 39200

200 218000

250 218000

I2t

[A2s]

3

3-11

Installation and Connection

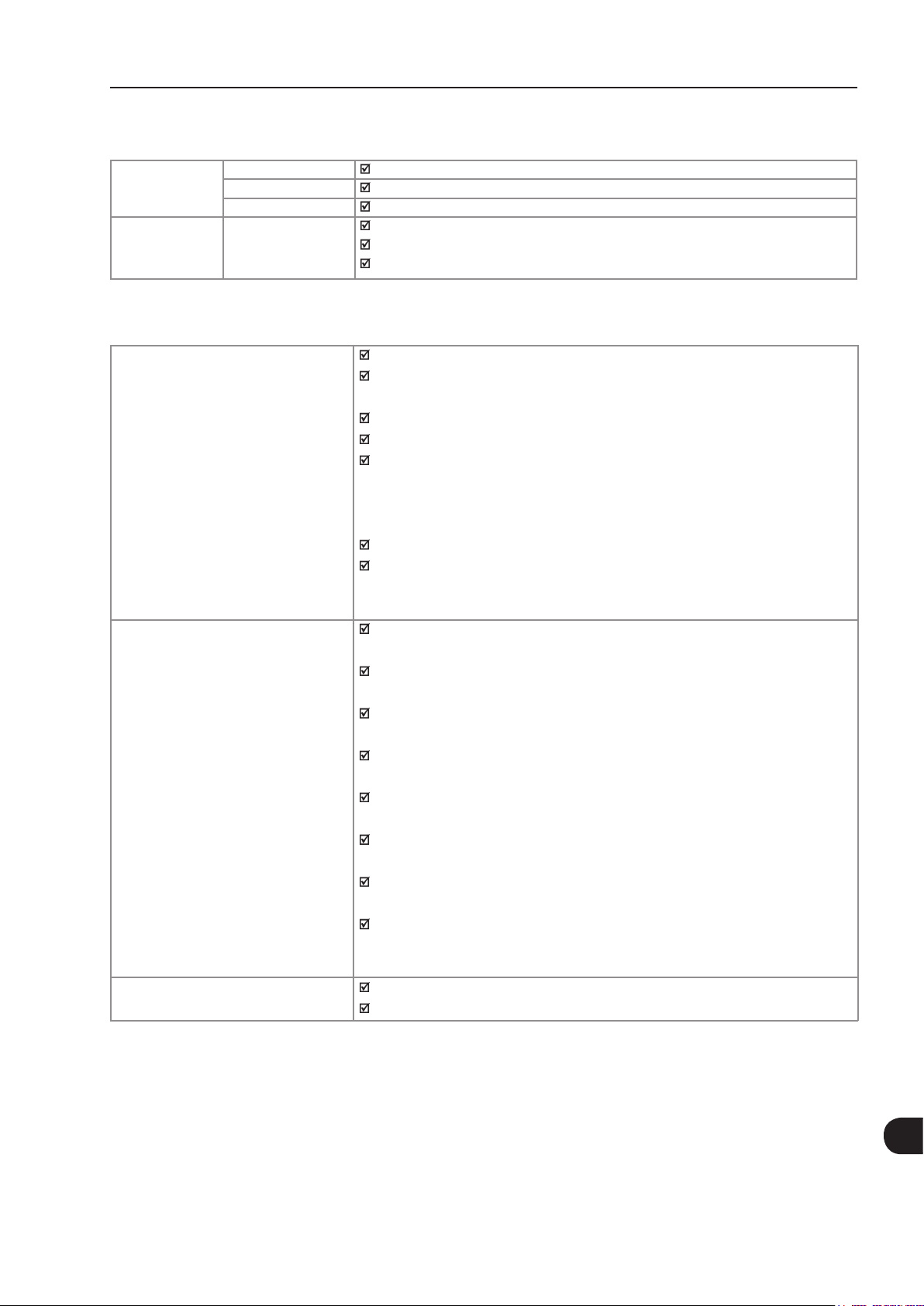

Table 3.3 (a) - Recommended cable lugs for power connections (cable gauges in mm²)

3

Wire size

[mm2]

25

35

50

70

120 M10

150 M10

Stud size Manufacturer Ring lug, P/N

M5

M8

M10

M5

M8

M5

M8

M10

M5

M8

M10

Hollingsworth RM 25 -5

Tyco 33468 59975-1 1

Hollingsworth RM 25-8 H 6.500 1

Burndy (FCI) YA3CL

Tyco 33470 59975-1 1

Hollingsworth RM 25-10

Tyco 33471 59975-1 1

Hollingsworth RM 35-5 H 6.500 1

Burndy (FCI) YA2CL2

Tyco 330301

Hollingsworth RM 35-8 H 6.500 1

Burndy (FCI) YAC2CL

Tyco 322870 59975-1 1

Hollingsworth RM 50-5 H 6.500 1

Burndy (FCI) YA1CL2

Tyco 36915

Hollingsworth RM 50-8 H 6.500 1

Burndy (FCI) YA1CL

Tyco 36916

Hollingsworth RM 50-10 H 6.500 1

Burndy (FCI) YA1CL4

Tyco 36917

Hollingsworth RM 70-5 H 6.500 1

Burndy (FCI) YA26L2

Tyco 321869

Hollingsworth RM 70-8 H 6.500 1

Burndy (FCI) YA26L

Tyco 321870

Hollingsworth RM 70-10

Burndy (FCI) YA26L4

Tyco 321871

Hollingsworth RM120-10 H 6.500 1

Burndy (FCI) YA29L4

Tyco 322252

Hollingsworth RM150-10 H 6.500 1

Burndy (FCI) YA30L24

Tyco 322252

Crimping (installation) tool P/N

H 6.500

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U3CRT

H 6.500

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U2CRT

59975-1

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U2CRT

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U1CRT

Hand tool: 1490748-1,

U-die: 1490413-5 + 1490414-3

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U1CRT

Hand tool: 1490748-1,

U-die: 1490413-5 + 1490414-3

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U1CRT

Hand tool: 1490748-1,

U-die: 1490413-5 + 1490414-3

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U26RT

Hand tool: 1490748-1,

U-die: 1490413-6 + 1490414-3

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U26RT

Hand tool: 1490748-1,

U-die: 1490413-6 + 1490414-3

H 6.500

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U26RT

Hand tool: 1490748-1,

U-die: 1490413-6 + 1490414-3

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U29RT

Hydraulic pump: 1804700-1 (electric) or 1583659-1

(foot pump), 1583662-1 -2 or -3 (1.8 m, 3 m or 6 m)

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U30RT

Hydraulic pump: 1804700-1 (electric) or 1583659-1

(foot pump), 1583662-1 -2 or -3 (1.8 m, 3 m or 6 m)

Number of

crimps

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3-12

Installation and Connection

Table 3.3 (b) - Recommended cable lugs for power connections (cable gauges in AWG)

Wire size

[AWG/

kcmil]

4

2

1

1/0 M8

2/0

4/0 M10

300 M10

Stud size Manufacturer Ring lug, P/N Crimping tool P/N

Hollingsworth R 410 H 6.500 1

M5

M8

M10

M5

M8

M5

M8

M10

M5

M8

M10

Burndy (FCI) YA4CL2

Tyco 33468 59975-1 1

Hollingsworth R 4516 H 6.500 1

Burndy (FCI) YA4CL3

Tyco 33470 59975-1 1

Hollingsworth R 438 H 6.500 1

Burndy (FCI) YA4CL4

Tyco 33471 59975-1 1

Hollingsworth R 210 H 6.500 1

Burndy (FCI) YA2CL2

Tyco 330301 59975-1 1

Hollingsworth R 2516 H 6.500 1

Burndy (FCI) YA2CL

Tyco 322870 59975-1 1

Hollingsworth R 110 H 6.500 1

Burndy (FCI) YA1CL2

Tyco 330301 59975-1 1

Hollingsworth R 1516 H 6.500 1

Burndy (FCI) YA1CL

Tyco 322870 59975-1 1

Hollingsworth R 138 H 6.500 1

Burndy (FCI) YA1CL4

Tyco 321600 59975-1 1

Hollingsworth R 10516 H 6.500 1

Burndy (FCI) YA25L

Tyco 36916

Hollingsworth R 2010 H 6.500 1

Burndy (FCI) YA26L2

Tyco

Hollingsworth R 20516 H 6.500 1

Burndy (FCI) YA26L

Tyco 321870

Hollingsworth R 2038 H 6.500 1

Burndy (FCI) YA26L4

Tyco 321871

Hollingsworth R 4038 H 6.500 1

Burndy (FCI) YA28L4

Tyco 36932

Hollingsworth R30038 H 6.500 1

Burndy (FCI) YA30L24

Tyco 322252

321869

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U4CRT

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U4CRT

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U4CRT

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U2CRT

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U2CRT

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U1CRT

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U1CRT

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U1CRT

Dieless tool: MY29-3 or Y644 or Y81;

Tool+U-die: Y46 or Y35 or Y750 / U25RT

Tool+U-die: Y46 or Y35 or Y750 / U26RT

Tool+U-die: Y46 or Y35 or Y750 / U26RT

Tool+U-die: Y46 or Y35 or Y750 / U26RT

Tool+U-die: Y46 or Y35 or Y750 / U28RT

Tool+U-die: Y46 or Y35 or Y750 / U30RT

Hydraulic pump: 1804700-1 (electric) or 1583659-1

(foot pump), 1583662-1 -2 or -3 (1.8 m, 3 m or 6 m)

Hand tool: 1490748-1,

U-die: 1490413-5 + 1490414-3

Dieless tool: MY29-3 or Y644 or Y81;

Hand tool: 1490748-1,

U-die: 1490413-6 + 1490414-3

Dieless tool: MY29-3 or Y644 or Y81;

Hand tool: 1490748-1,

U-die: 1490413-6 + 1490414-3

Dieless tool: MY29-3 or Y644 or Y81;

Hand tool: 1490748-1,

U-die: 1490413-6 + 1490414-3

Dieless tool: MY29-3 or Y644 or Y81;

Hand tool: 1490748-1,

U-die: 1490413-8 + 1490414-3

Dieless tool: MY29-3 or Y644 or Y81;

Number of

crimps

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3-13

Installation and Connection

3.2.3 Power Connections

3

PE

R

S

T

Power

Supply

Disconnect

Switch

3.2.3.1 Input Connections

DANGER!

Provide a disconnect device for the input power supply of the inverter.

This device shall disconnect the input power supply for the inverter when needed (for instance, during

servicing).

ATTENTION!

A contactor or another device that frequently disconnects and reapplies the AC supply to the inverter

in order to start and stop the motor may cause damage to the inverter power section. The drive is

designed to use control signals for starting and stopping the motor. If used for that purpose, the input

device must not exceed one operation per minute otherwise the inverter may be damaged.

PE R S T U V W PE

Shielding

Fuses

Figure 3.12 - Power and grounding connections

PE W V U

ATTENTION!

The power supply that feeds the inverter shall have a grounded neutral. In case of IT networks, follow

the instructions described in item 3.2.3.1.1.

NOTE!

The input power supply voltage shall be compatible with the inverter rated voltage.

NOTE!

Power factor correction capacitors are not needed at the inverter input (R, S, T) and shall not be

installed at the output of the inverter (U, V, W).

AC power supply considerations

The CFW-11 inverters are suitable for use on a circuit capable of deliviering up to a maximum of 100,000 A

symmetrical (230 V / 480 V).

3-14

rms

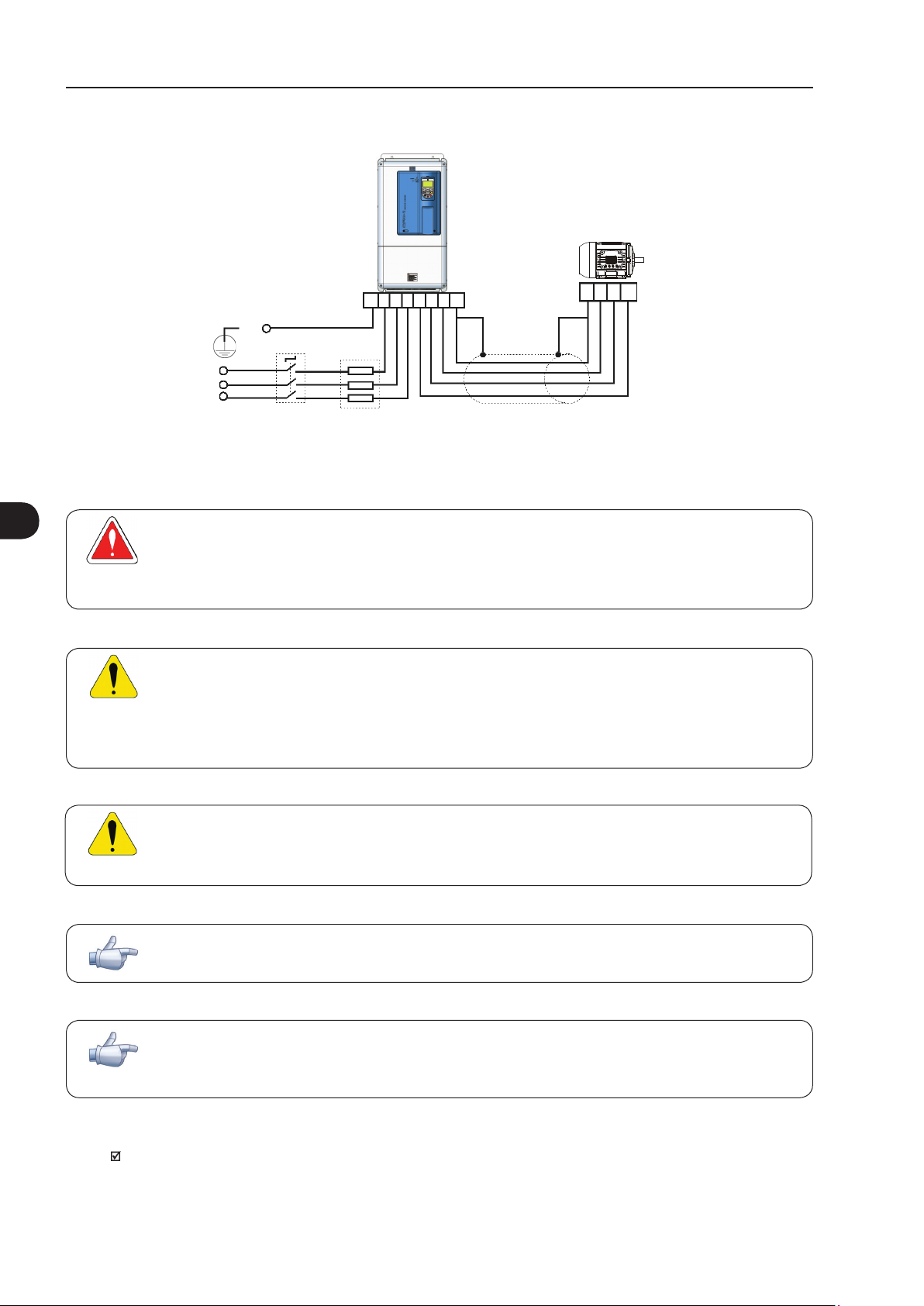

3.2.3.1.1 IT Networks

ATTENTION!

In order to be able to use the frame size E CFW-11 inverter in IT networks (neutral conductor not

grounded or grounded via a high ohmic value resistor) or in corner-grounded delta systems, it is

necessary to remove the RFI filter capacitor and the MOV connected to the ground by changing the

position of the J1 jumper on the PRT1 board from

PRT1 board

Installation and Connection

(XE1) to “NC”, according to the figure 3.13.

3

(a) Location of the PRT1 board (inverter without the bottom front cover)

321

(b) Procedure for disconnecting the RFI lter and the MOV connected to the

ground – necessary for using the inverter in IT or corner-grounded delta networks

Figure 3.13 (a) and (b) - Location of the PRT1 board and procedure for disconnecting the RFI lter and the MOV connected

to the ground – necessary for using the inverter in IT or corner-grounded delta networks

3-15

3

Installation and Connection

3.2.3.1.2 Command Fuses

Besides the RFI filter capacitors and the MOV’s, the PRT1 board also has 3 fuses for protecting the inverter

command circuit.

The PRT1 board location is presented in the figure 3.13 (a).

The location of the PRT1 fuses is presented in the figure 3.13 (b).

See below the specification of the used command fuses:

Slow blow fuse 0.5 A / 600 V;

Manufacturer: Cooper Bussmann;

Part number: FNQ-R-1/2;

WEG part number: 10411493.

Consider the following items for the use of protection devices on the supply side of the inverter such as residual

current devices or isolation monitors:

- The detection of a phase-to-ground short-circuit or an insulation fault shall be processed by the user, i.e., the

user shall decide whether to indicate the fault and/or block the inverter operation.

- Contact the RCD manufacturer for selecting the most appropriate device to be used with inverters in order to

avoid nuisance tripping due to the high frequency leakage currents that flow through the leakage capacitances

of the inverter, cable, and motor system to the ground.

3.2.3.2 Dynamic Braking

ATTENTION!

For the CFW-11 frame size E models, only those with the DB option (CFW11XXXXTXODB) have the

braking IGBT incorporated to the product.

The braking torque that can be obtained from the frequency inverter without braking resistors varies from 10 %

to 35 % of the motor rated torque.

Braking resistors shall be used to obtain higher braking torques. In this case, the energy regenerated in excess

is dissipated in a resistor mounted externally to the inverter.

This type of braking is used in cases where short deceleration times are desired or when high inertia loads are

driven.

For the vector control mode, there is the possibility of using the “Optimal Braking”, eliminating in many cases

the need of dynamic braking use.

3-16

NOTE!

Set P0151 and P0185 to their maximum values (400 V or 800 V) when using dynamic braking.

Installation and Connection

3.2.3.2.1 Sizing the Braking Resistor

The following application data shall be considered for the adequate sizing of the braking resistor:

- Desired deceleration time;

- Load inertia;

- Braking duty cycle.

In any case, the effective current value and the maximum braking current value presented in table 3.4 shall

be respected.

The maximum braking current defines the minimum braking resistor value in ohms.

The DC bus voltage level for the activation of the dynamic braking function is defined by parameter P0153

(dynamic braking level).

The power of the braking resistor is a function of the deceleration time, the load inertia, and the load torque.

For most applications, a braking resistor with the value in ohms indicated in table 3.4 and the power of 20 %

of the rated driven motor power. Use wire type resistors in a ceramic support with adequate insulation voltage

and capable of withstanding high instantaneous power with respect to rated power. For critical applications with

very short deceleration times and high inertia loads (ex.: centrifuges) or short duration cycles, consult WEG for

the adequate sizing of the braking resistor.

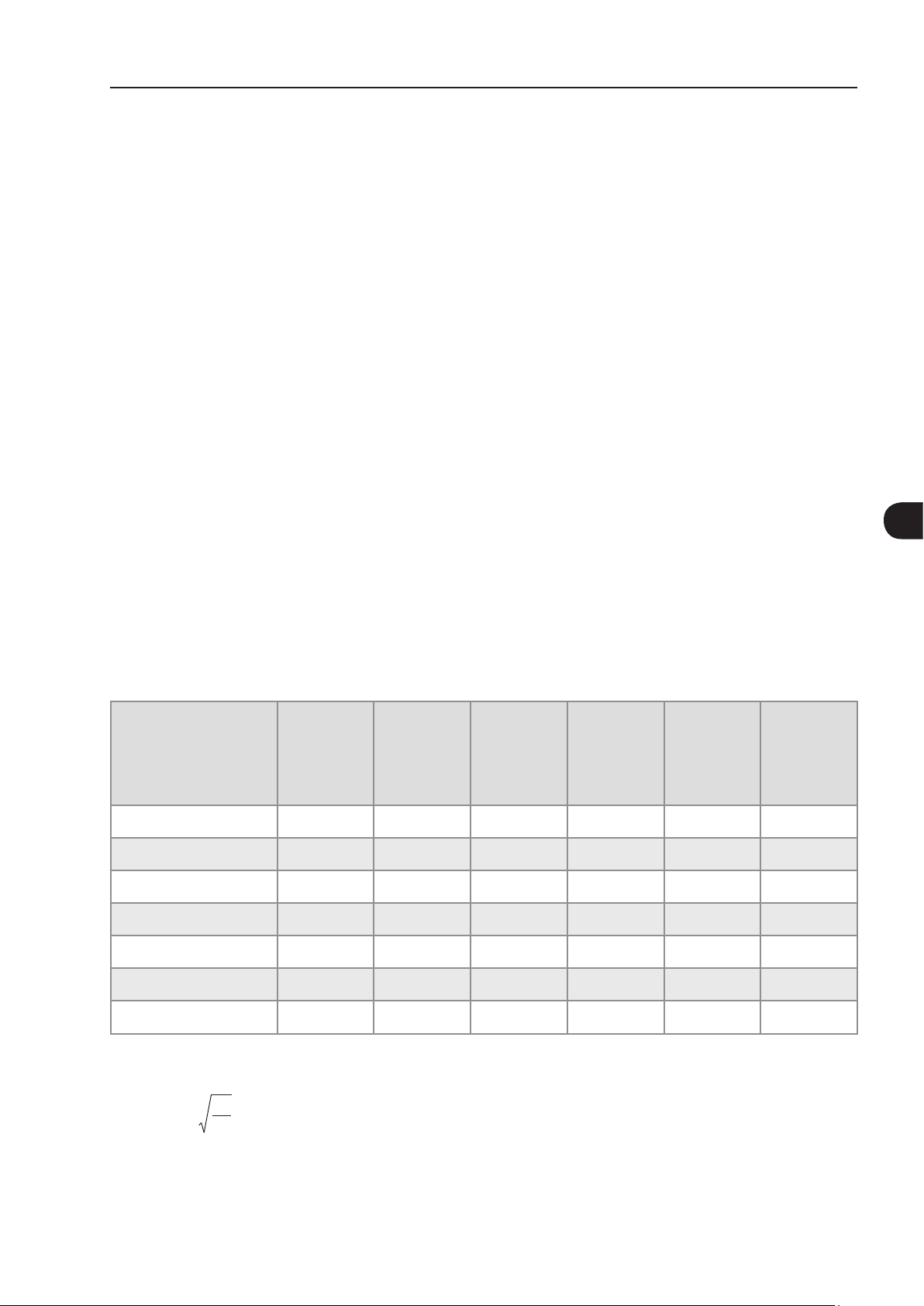

Table 3.4 - Dynamic braking specications

Maximum

braking

Inverter model

CFW11 0142 T 2 O DB 266.7 106.7 142.0 30.2 1.5

CFW11 0180 T 2 O DB 266.7 106.7 180.0 48.6 1.5

CFW11 0211 T 4 O DB 333.3 133.3 211.0 53.4 1.2

CFW11 0105 T 4 O DB 186.0 148.8 105.0 47.4 4.3 50 (1)

CFW11 0142 T 4 O DB 266.7 213.3 142.0 60.5 3.0

CFW11 0180 T 4 O DB 266.7 213.3 180.0 97.2 3.0

CFW11 0211 T 4 O DB 363.6 290.9 191.7 80.8 2.2

(1) The effective braking current presented is just an indicative value, because it depends on the braking duty cycle. The effective braking current

can be obtained from the equation below, where tbr is given in minutes and corresponds to the sum of all braking times during the most severe

cycle of 5 (five) minutes.

t

I

= I

effective

5

(2) The P

(3) For specifications on the recommended terminal type (bolt and tightening torque) for the connection of the braking resistor (terminals DC+

and PR values (maximum and mean power of the braking resistor respectively) presented are valid for the recommended resistors and

max

for the effective braking currents presented in table 3.4. The resistor power shall be changed according to the braking duty cycle.

and BR), refer to the DC+ terminal specification at the table 3.2.

max

br

x

current

(I

max

[A]

)

Maximum

braking power

(peak value)

(P

max

[kW]

(2)

)

Effective

braking

current

(I

)

effective

[A]

(1)

Dissipated

power (mean

value) in

the braking

resistor (PR)

[kW]

Recommended

resistor

(2)

[Ω]

Power wire

size (terminals

DC+ and

(3)

BR)

[mm2 (AWG)]

70 (2/0) or

2x 25 (2x 4)

120 (4/0) or

2x 35 (2x 2)

150 (300) or

2x 50 (2x 1)

70 (2/0) or

2x 25 (2x 4)

120 (4/0) or

2x 35 (2x 2)

120 (250) or

2x 50 (2x 1)

3

3-17

3

Installation and Connection

3.2.3.2.2 Installation of the Braking Resistor

Install the braking resistor between the power terminals DC+ and BR.

Use twisted cable for the connection. Separate these cables from the signal and control cables. Size the cables

according to the application, respecting the maximum and effective currents.

If the braking resistor is installed inside the inverter cabinet, consider its additional dissipated energy when sizing

the cabinet ventilation.

Set parameter P0154 with the resistor value in ohms and parameter P0155 with the maximum resistor power

in kW.

DANGER!

The inverter has an adjustable thermal protection for the braking resistor. The braking resistor and

the braking transistor may damage if parameters P0153, P0154, and P0155 are not properly set or

if the input voltage surpasses the maximum permitted value.

The thermal protection offered by the inverter, when properly set, allows the protection of the resistor in case of

overload; however, this protection is not guaranteed in case of braking circuitry failure. In order to avoid any

damage to the resistor or risk of fire, install a thermal relay in series with the resistor and/or a thermostat in contact

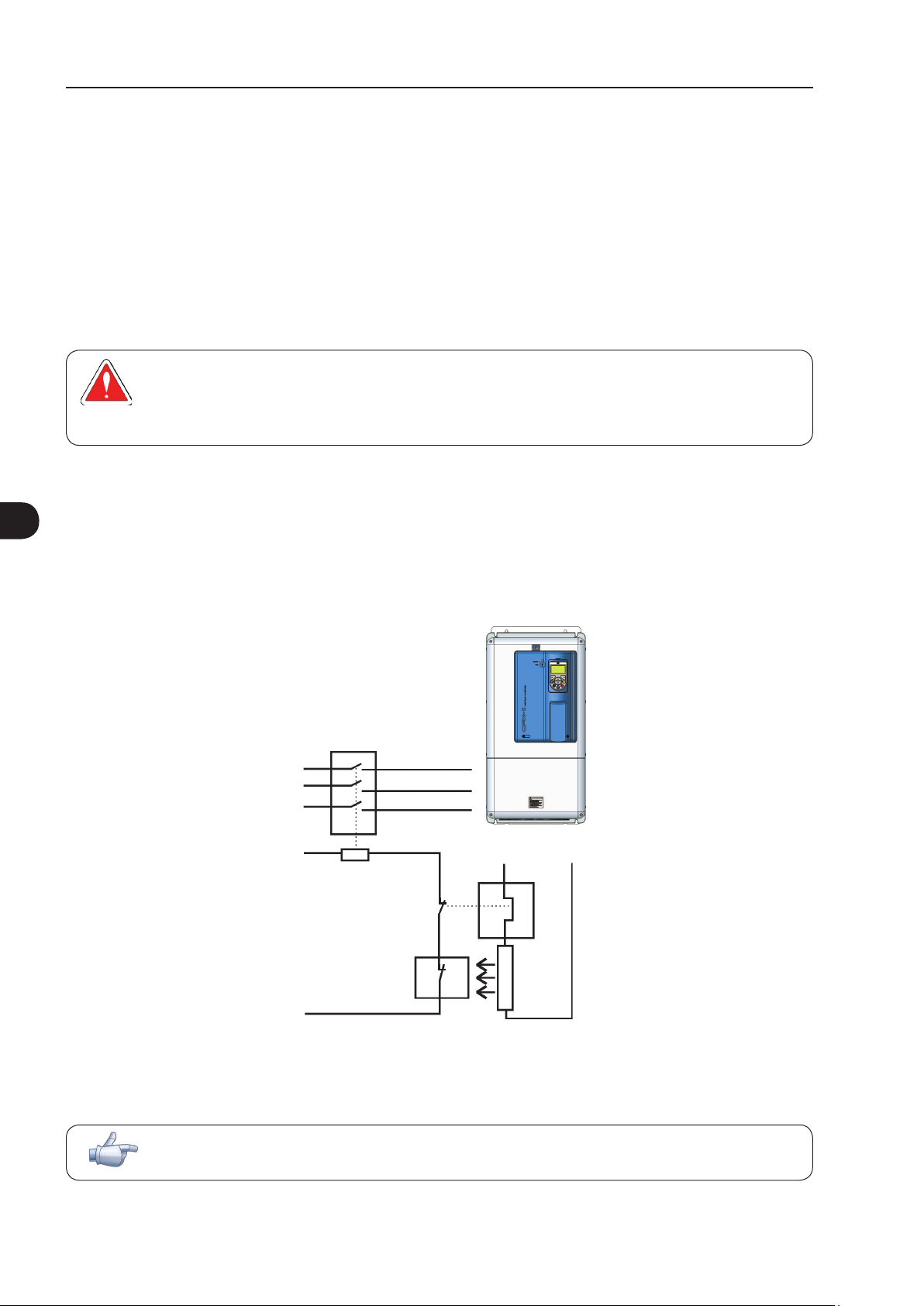

with the resistor body to disconnect the input power supply of the inverter, as presented in figure 3.14.

Power

supply

Control power

supply

CFW-11

Contactor

R

S

T

BR

Thermal

relay

Thermostat

Figure 3.14 - Braking resistor connection

DC+

Braking

resistor

3-18

NOTE!

DC current flows through the thermal relay bimetal strip during braking.

3.2.3.3 Output Connections

ATTENTION!

The inverter has an electronic motor overload protection that shall be adjusted according to the

driven motor. When several motors are connected to the same inverter, install individual overload

relays for each motor.

ATTENTION!

The motor overload protection available at the CFW-11 is in accordance with the IEC60947-4-2

and UL508C standards.

Important considerations for the UL508C:

Trip current equal to 1.25 times the motor rated current (P0401) adjusted in the oriented start-up

menu.

The parameter P0159 maximum setting (Motor Thermal Class) is 3 (Class 20).

The parameter P0398 maximum setting (Motor Service Factor) is 1.15.

ATTENTION!

If a disconnect switch or a contactor is installed between the inverter and the motor, never operate

them with a spinning motor or with voltage at the inverter output.

Installation and Connection

3

The characteristics of the cable used for the inverter and motor interconnection, as well as the physical location

are extremely important to avoid electromagnetic interference in other equipment and to not affect the life cycle

of motor windings and motor bearings controlled by inverters.

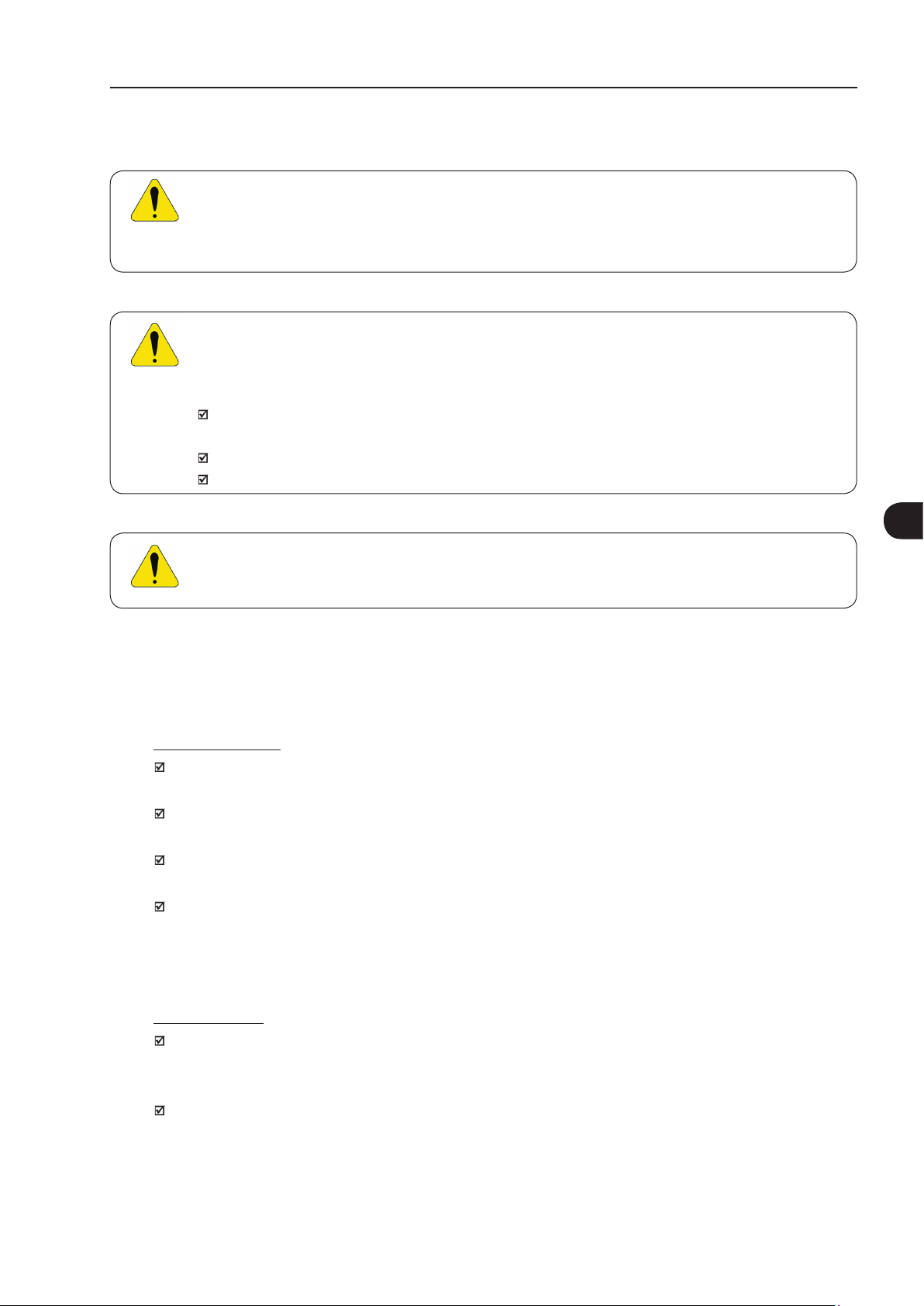

Recommendations for the motor cables:

Unshielded Cables:

Can be used when it is not necessary to meet the European directive of electromagnetic compatibility

(89/336/EEC).

Keep motor cables away from other cables (signal cables, sensor cables, control cables, etc.), according to

table 3.5.

The emission of the cables may be reduced by installing them inside a metal conduit, which shall be grounded

at both ends.

Connect a fourth cable between the motor ground and the inverter ground.

Note:

The magnetic field created by the current circulation in these cables may induce current in close metal pieces, heat

them, and cause additional electrical losses. Therefore, keep the 3 (three) cables (U, V, W) always together.

Shielded Cables:

Are mandatory when the electromagnetic compatibility directive (89/336/EEC) shall be met, as defined by

the standard EN 61800-3 “Adjustable Speed Electrical Power Drive Systems”. These cables act mainly by

reducing the irradiated emission in the radio-frequency range.

In reference to the type and details of installation, follow the recommendations of IEC 60034-25 “Guide

for Design and Performance of Cage Induction Motors Specifically Designed for Converter Supply” – refer

to a summary in figure 3.15. Refer to the standard for further details and eventual modifications related to

new revisions.

3-19

3

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

V

U

W

Installation and Connection

Keep motor cables away from other cables (signal cables, sensor cables, control cables, etc.), according to

table 3.5.

The grounding system shall be well interconnected among the several installation locations such as the

grounding points of the motor and the inverter. Voltage difference or impedance between the several points

may cause the circulation of leakage currents among the equipment connected to the ground, resulting in

electromagnetic interference problems.

Table 3.5 - Minimum separation distance between motor cables and all other cables

Cable length Minimum separation distance

≤ 30 m (100 ft) ≥ 10 cm (3.94 in)

> 30 m (100 ft) ≥ 25 cm (9.84 in)

PE

U

PE

VW

PE

SCu

PEs

o

o

o

o

o

o

o

o

o

o

o

o

o

AFe

Symmetrical shielded cables: three concentric conductors with or without a ground conductor,

symmetrically manufactured, with an external shield of copper or aluminum.

Notes:

(1) SCu = copper or aluminum external shielding.

(2) AFe = steel or galvanized iron.

(3) PE = ground conductor.

(4) Cable shielding shall be grounded at both ends (inverter and motor). Use 360º connections for a low impedance to high-frequencies. Refer

to figure 3.16.

(5) For using the shield as a protective ground, it shall have at least 50 % of the power cables conductivity. Otherwise, add an external ground

conductor and use the shield as an EMC protection.

(6) Shielding conductivity at high-frequencies shall be at least 10 % of the power cables conductivity.

Figure 3.15 - Motor connection cables recommended by IEC 60034-25

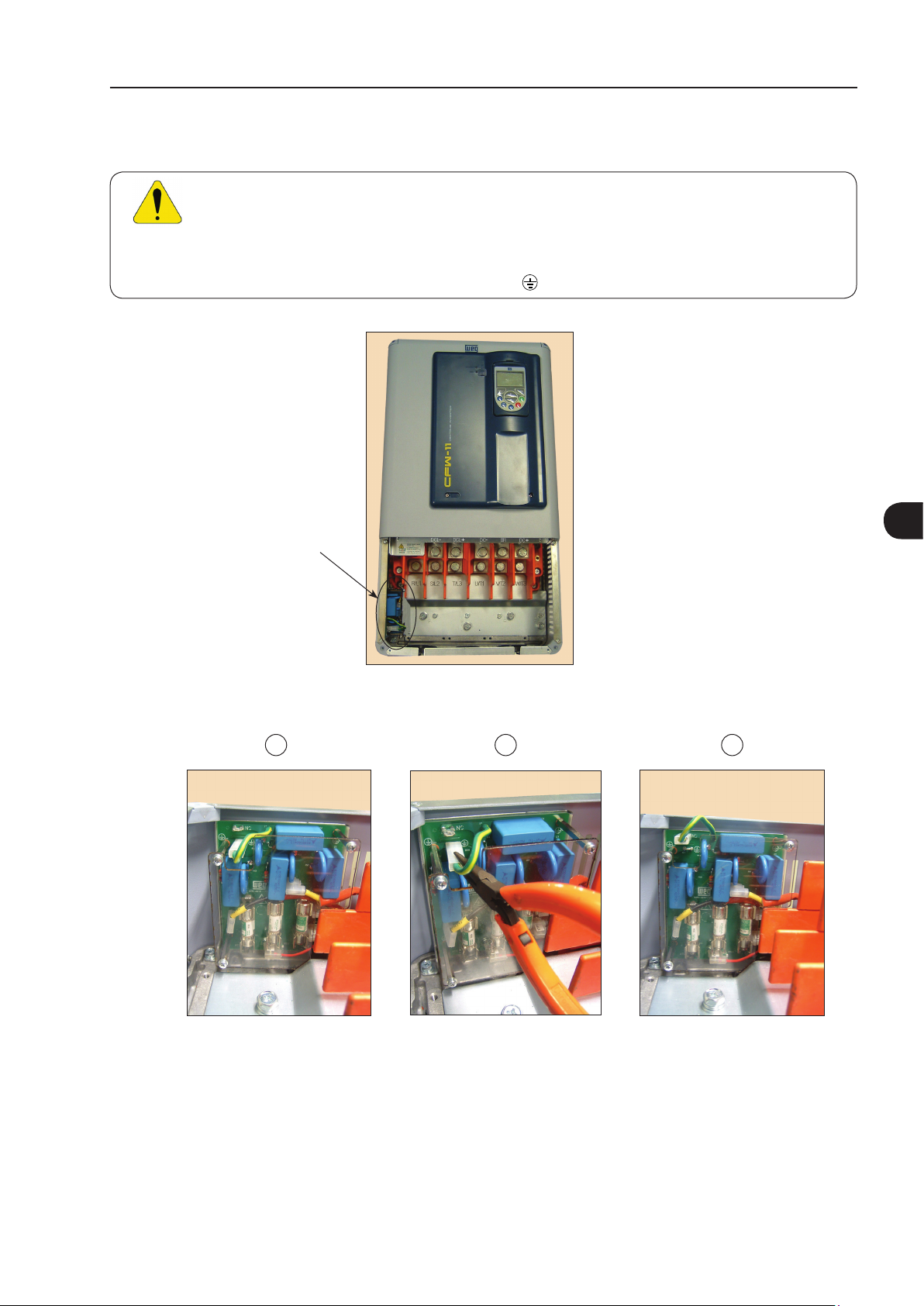

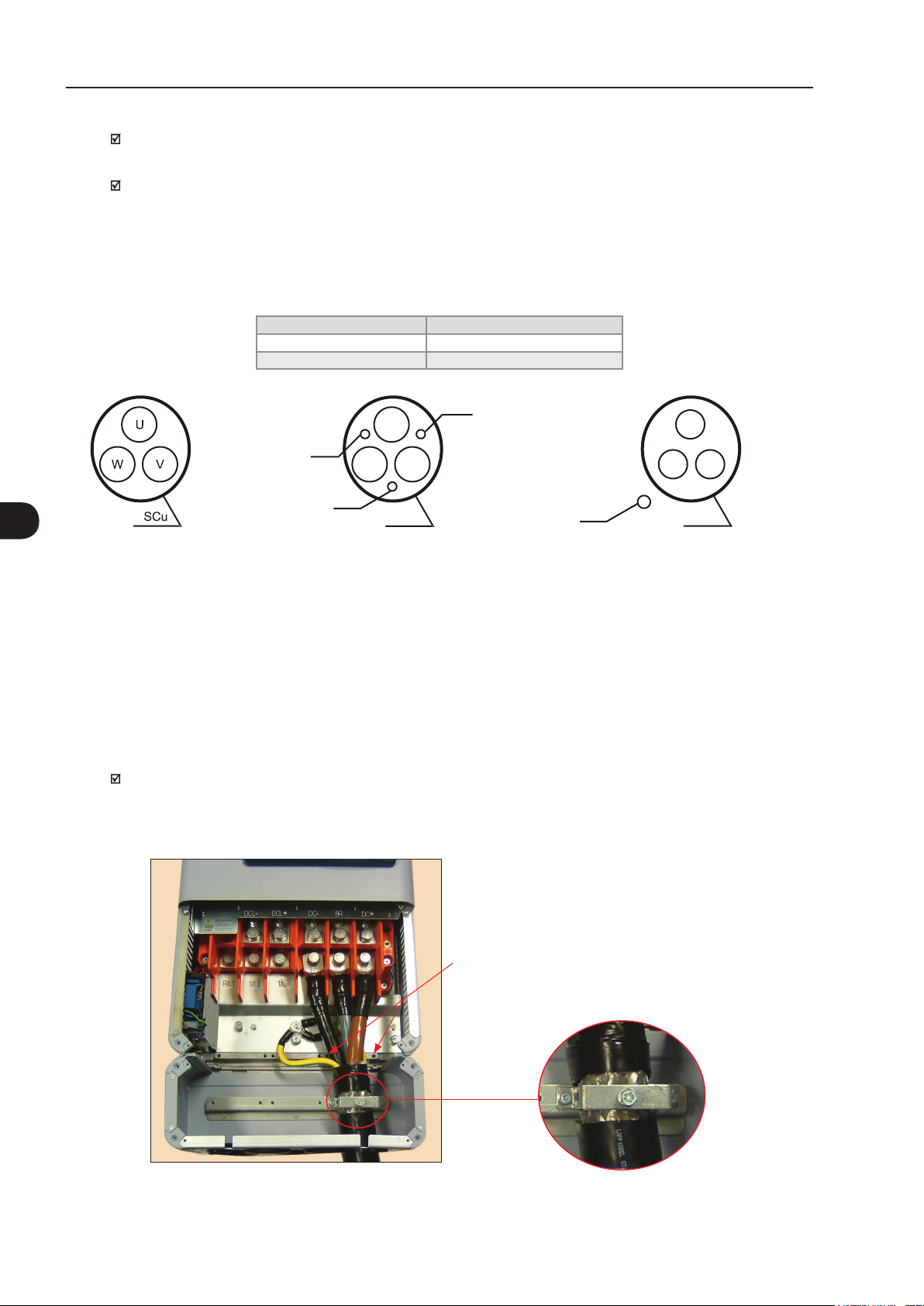

Connection of the motor cable shield to ground: Make a connection with low impedance for high frequencies.

Example in the figure 3.16. In inverters without the Nema1 kit, connect the motor cable shield to the ground

in a similar mode, with the clamp at the inverter inner part, according to the figure 3.16.

Assemble the grounding

clamp in this position when

it's not used Nema1 kit.

Figure 3.16 - Example of the motor cable shield connection at the inner part of the Nema1 kit supplied with the product

3-20

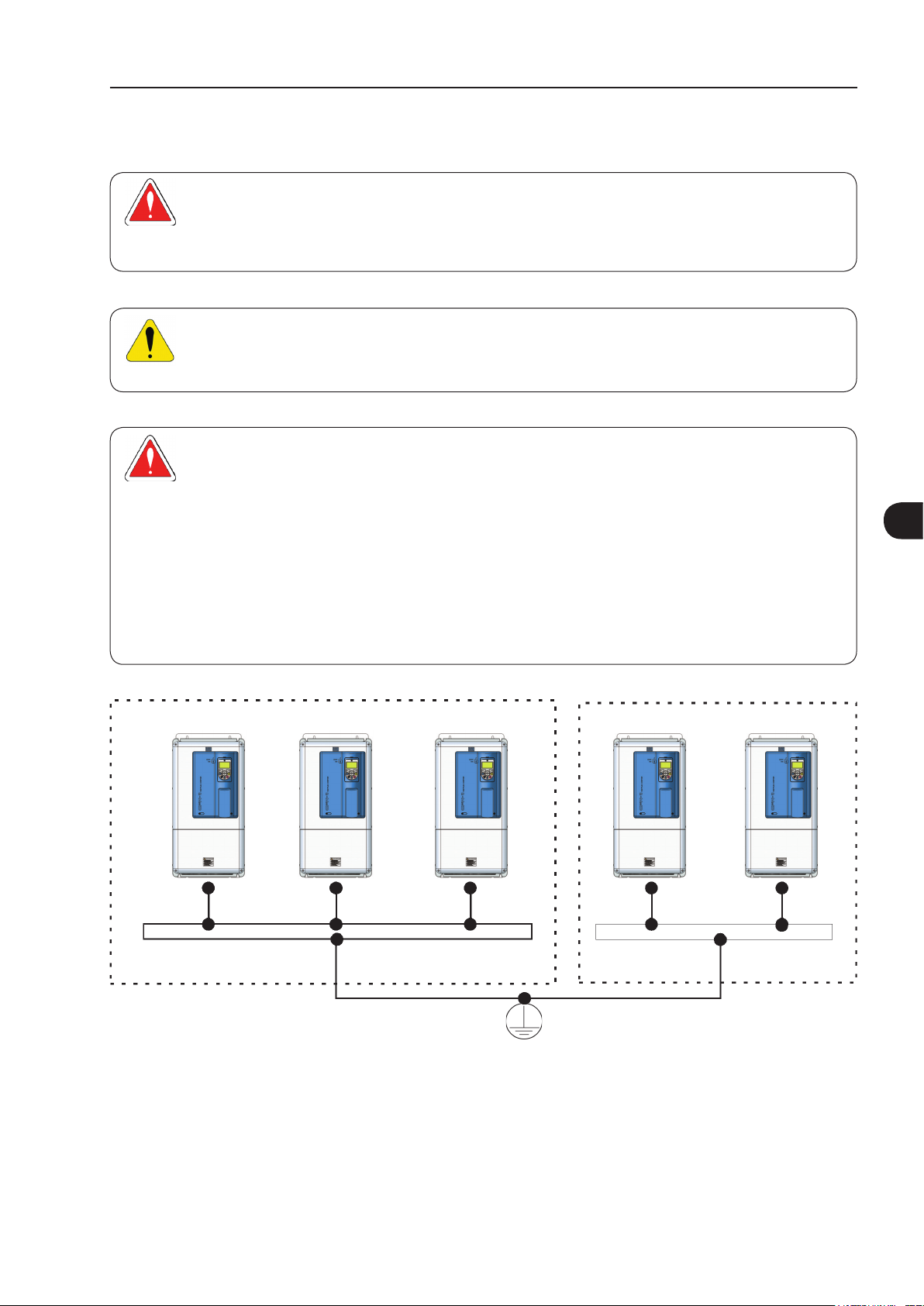

3.2.4 Grounding Connections

DANGER!

Do not share the grounding wiring with other equipment that operate with high currents (ex.: high

power motors, soldering machines, etc.). When installing several inverters, follow the procedures

presented in figure 3.17 for the grounding connection.

ATTENTION!

The neutral conductor of the network shall be solidly grounded; however, this conductor shall not

be used to ground the inverter.

DANGER!

The inverter shall be connected to a Protective Ground (PE).

Observe the following:

- Minimum wire gauge for grounding connection is provided in table 3.2. Conform to local regulations

and/or electrical codes in case a different wire gauge is required.

- Connect the inverter grounding connections to a ground bus bar, to a single ground point, or to

a common grounding point (impedance ≤ 10 Ω).

- To comply with IEC 61800-5-1 standard, connect the inverter to the ground by using a single

conductor copper cable with a minimum wire gauge of 10 mm2, since the leakage current is greater

than 3.5 mA AC.

Installation and Connection

3

CFW-11 #1 CFW-11 #2

Internal cabinet ground bus bar

CFW-11 #N

Figure 3.17 - Grounding connections with multiple inverters

CFW-11 #1

CFW-11 #2

3-21

Installation and Connection

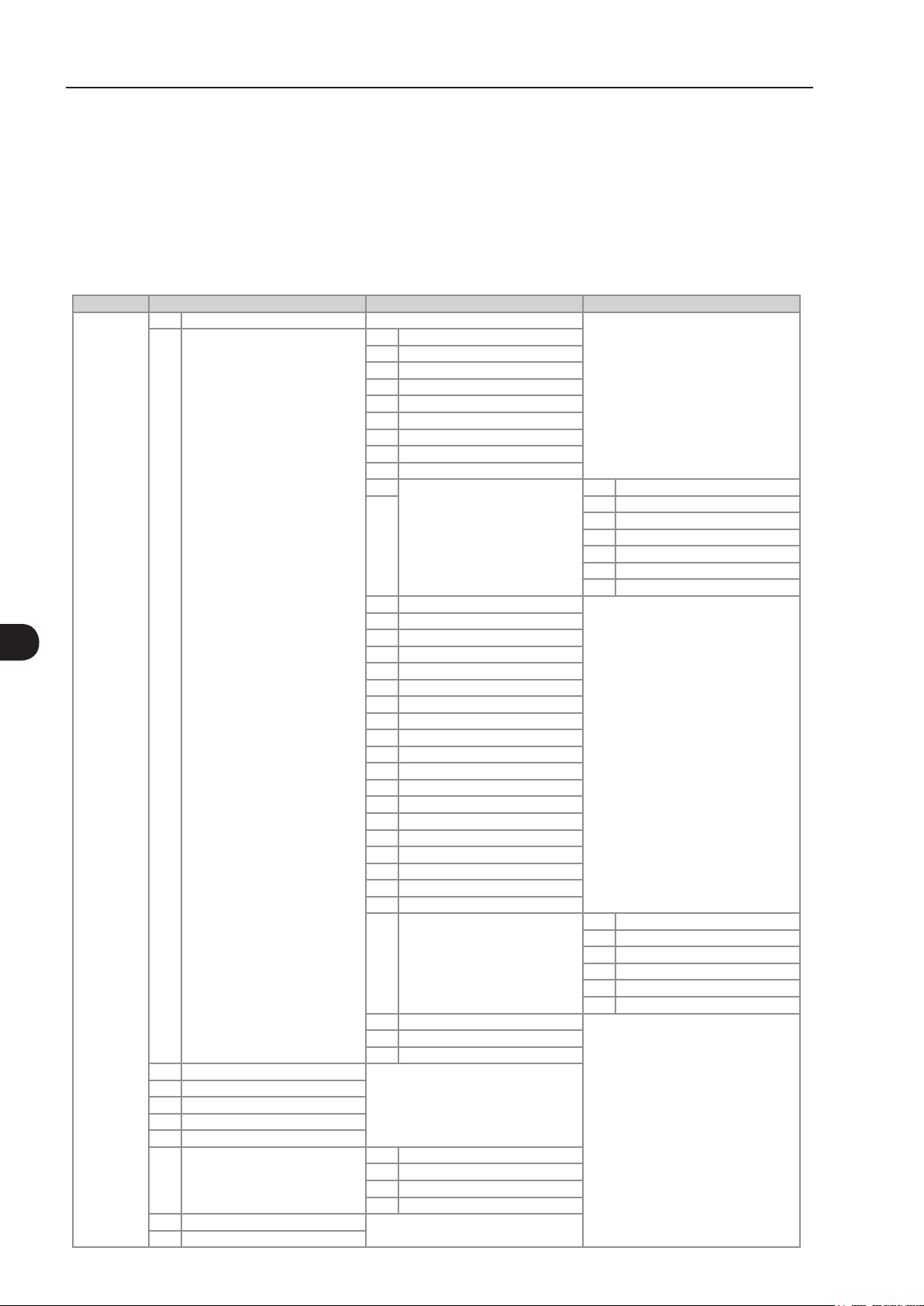

3.2.5 Control Connections

The control connections (analog inputs/outputs, digital inputs/outputs), shall be performed in connector XC1

of the CC11 control board.

Functions and typical connections are presented in figures 3.18 (a) and (b).

Connector XC1 Factory Default Function Specifications

CW

≥5kΩ

CCW

rpm

1 +REF

2 AI1+

3 AI1-

4 REF-

5 AI2+

6 AI2-

7 AO1

Positive reference for

potentiometer

Analog input #1:

Speed reference (remote)

Negative reference for

potentiometer

Analog input #2:

No function

Analog output #1:

Speed

Output voltage:+5.4 V, ±5 %.

Maximum output current: 2 mA

Differential

Resolution: 12 bits

Signal: 0 to 10 V (RIN=400 kΩ) / 0 to 20 mA / 4 to 20 mA (RIN=500 Ω)

Maximum voltage: ±30 V

Output voltage: -4.7 V, ±5 %.

Maximum output current: 2 mA

Differential

Resolution: 11 bits + signal

Signal: 0 to ±10 V (RIN=400 kΩ) / 0 to 20 mA / 4 to 20 mA (RIN=500 Ω)

Maximum voltage: ±30 V

Galvanic Isolation

Resolution: 11 bits

Signal: 0 to 10 V (RL ≥ 10 kΩ) / 0 to 20 mA / 4 to 20 mA (RL ≤ 500 Ω)

Protected against short-circuit.

3

amp

3-22

AGND

8

(24 V)

9 AO2

AGND

10

(24 V)

11 DGND

12 COM

13 24 Vdc

14 COM

15 DI1

16 DI2

17 DI3

18 DI4

19 DI5

20 DI6

21 NC1

22 C1

23 NO1

24 NC2

25 C2

26 NO2

27 NC3

28 C3

29 NO3

Figure 3.18 (a) - Signals at connector XC1 - Digital inputs working as 'Active High'

Reference (0 V) for the analog

outputs

Analog output #2:

Motor current

Reference (0 V) for the analog

outputs

Reference (0 V) for the 24 Vdc

*

power supply

Common point of the digital

inputs

24 Vdc power supply 24 Vdc power supply, ±8 %.

Common point of the digital

inputs

Digital input #1:

Start / Stop

Digital input #2:

Direction of rotation (remote)

Digital input #3:

No function

Digital input #4:

No function

Digital input #5:

Jog (remote)

Digital input #6:

2nf ramp

Digital output #1 DO1 (RL1):

No fault

Digital output #2 DO2 (RL2):

N > NX - Speed > P0288

Digital output #3 DO3 (RL3):

N* > NX - Speed reference >

P0288

Connected to the ground (frame) through impedance: 940 Ω resistor in

parallel with a 22 nF capacitor.

Galvanic Isolation

Resolution: 11 bits

Signal: 0 to 10 V (RL ≥ 10 kΩ) / 0 to 20 mA / 4 to 20 mA (RL ≤ 500 Ω)

Protected against short-circuit.

Connected to the ground (frame) through impedance: 940 Ω resistor in

parallel with a 22 nF capacitor.

Connected to the ground (frame) through impedance: 940 Ω resistor in

parallel with a 22 nF capacitor.

Capacity: 500 mA.

Note: In the models with the 24 Vdc external control power supply

(CFW11XXXXXXOW) the terminal 13 of XC1 becomes an input, i.e., the

user must connect a 24 V power supply for the inverter (refer to the section

7.1.4 for more details). In all the other models this terminal is an output,

i.e., the user has a 24 Vdc power supply available there.

6 isolated digital inputs

High level ≥ 18 V

Low level ≤ 3 V

Maximum input voltage = 30 V

Input current: 11 mA @ 24 Vdc

Contact rating:

Maximum voltage: 240 Vac

Maximum current: 1 A

NC - Normally closed contact;

C - Common;

NO - Normally open contact.

CW

≥5kΩ

CCW

rpm

Installation and Connection

Connector XC1 Factory Default Function Specifications

1 +REF

2 AI1+

3 AI1-

4 REF-

5 AI2+

6 AI2-

7 AO1

Positive reference for

potentiometer

Analog input #1:

Speed reference (remote)

Negative reference for

potentiometer

Analog input #2:

No function

Analog output #1:

Speed

Output voltage:+5.4 V, ±5 %.

Maximum output current: 2 mA

Differential

Resolution: 12 bits

Signal: 0 to 10 V (RIN= 400 kΩ) / 0 to 20 mA / 4 to 20 mA (RIN= 500 Ω)

Maximum voltage: ±30 V

Output voltage: -4.7 V, ±5 %.

Maximum output current: 2 mA

Differential

Resolution: 11 bits + signal

Signal: 0 to ±10 V (RIN= 400 kΩ) / 0 to 20 mA / 4 to 20 mA (RIN= 500 Ω)

Maximum voltage: ±30 V

Galvanic Isolation

Resolution: 11 bits

Signal: 0 to 10 V (RL ≥ 10 kΩ) / 0 to 20 mA / 4 to 20 mA (RL ≤ 500 Ω)

Protected against short-circuit.

amp

AGND

8

(24 V)

9 AO2

AGND

10

(24 V )

11 DGND

12 COM

13 24 Vdc

14 COM

15 DI1

16 DI2

17 DI3

18 DI4

19 DI5

20 DI6

21 NC1

22 C1

23 NO1

24 NC2

25 C2

26 NO2

27 NC3

28 C3

29 NO3

Figure 3.18 (b) - Signals at connector XC1 - Digital inputs working as 'Active Low'

Reference (0 V) for the analog

outputs

Analog output #2:

Motor current

Reference (0 V) for the analog

outputs

Reference (0 V) for the 24 Vdc

*

power supply

Common point of the digital

inputs

24 Vdc power supply 24 Vdc power supply, ±8 %.

Common point of the digital

inputs

Digital input #1:

Start / Stop

Digital input #2:

Direction of rotation (remote)

Digital input #3:

No function

Digital input #4:

No function

Digital input #5:

Jog (remote)

Digital input #6:

2nf ramp

Digital output #1 DO1 (RL1):

No fault

Digital output #2 DO2 (RL2):

N > NX - Speed > P0288

Digital output #3 DO3 (RL3):

N* > NX - Speed reference >

P0288

Connected to the ground (frame) through impedance: 940 Ω resistor in

parallel with a 22 nF capacitor.

Galvanic Isolation

Resolution: 11 bits

Signal: 0 to 10 V (RL ≥ 10 kΩ) / 0 to 20 mA / 4 to 20 mA (RL ≤ 500 Ω)

Protected against short-circuit.

Connected to the ground (frame) through impedance: 940 Ω resistor in

parallel with a 22 nF capacitor.

Connected to the ground (frame) through impedance: 940 Ω resistor in

parallel with a 22 nF capacitor.

Capacity: 500 mA.

Note: In the models with the 24 Vdc external control power supply

(CFW11XXXXXXOW) the terminal 13 of XC1 becomes an input, i.e., the user

must connect a 24 V power supply for the inverter (refer to the section 7.1.4

for more details). In all the other models this terminal is an output, i.e., the

user has a 24 Vdc power supply available there.

6 isolated digital inputs

High level ≥ 18 V

Low level ≤ 3 V

Input voltage ≤ 30 V

Input current: 11 mA @ 24 Vdc

Contact rating:

Maximum voltage: 240 Vac

Maximum current: 1 A

NC - Normally closed contact;

C - Common;

NO - Normally open contact.

3

3-23

Installation and Connection

NOTE!

Remove the jumper between XC1:11 and 12 and install it between XC1:12 and 13 to use the digital

inputs as 'Active Low'.

Slot 5

Slot 1 (white)

Slot 2 (yellow)

3

Slot 3 (green)

Slot 4

Figure 3.19 - Connector XC1 and DIP-switches for selecting the signal type of the analog inputs and outputs

The analog inputs and outputs are factory set to operate in the range from 0 to 10 V; this setting may be

changed by using DIP-switch S1.

Table 3.6 - DIP-switches conguration for the selection of the signal type for the analog inputs and outputs

Signal Factory Default Function DIP-switch Selection Factory Setting

AI1 Speed Reference (remote) S1.4

AI2 No Function S1.3

AO1 Speed S1.2

AO2 Motor Current S1.1

OFF: 0 to 10 V (factory setting)

ON: 4 to 20 mA / 0 to 20 mA

OFF: 0 to ±10 V (factory setting)

ON: 4 to 20 mA / 0 to 20 mA

OFF: 4 to 20 mA / 0 to 20 mA

ON: 0 to 10 V (factory setting)

OFF: 4 to 20 mA / 0 to 20 mA

ON: 0 to 10 V (factory setting)

OFF

OFF

ON

ON

Parameters related to the analog inputs and outputs (AI1, AI2, AO1, and AO2) shall be programmed according

to the DIP-switches settings and desired values.

Follow instructions below for the proper installation of the control wiring:

1) Wire gauge: 0.5 mm² (20 AWG) to 1.5 mm² (14 AWG);

2) Maximum tightening torque: 0.50 N.m (4.50 lbf.in);

3) Use shielded cables for the connections in XC1 and run the cables separated from the remaining circuits

(power, 110 V / 220 Vac control, etc.), as presented in table 3.7. If control wiring must cross other cables

(power cables for instance), make it cross perpendicular to the wiring and provide a minimum separation

of 5 cm (1.9 in) at the crossing point.

3-24

Installation and Connection

Table 3.7 - Minimum separation distances between wiring

Cable Length

≤ 30 m (100 ft) ≥ 10 cm (3.94 in)

> 30 m (100 ft) ≥ 25 cm (9.84 in)

Minimum Separation

Distance

4) The adequate connection of the cable shield is shown in figure 3.20. Figure 3.21 shows how to connect

the cable shield to the ground.

Isolate with tape

Inverter

side

Do not ground

Figure 3.20 - Shield connection

3

Figure 3.21 - Example of shield connection for the control wiring

5) Relays, contactors, solenoids or coils of electromechanical brakes installed close to the inverter may eventually

create interferences in the control circuitry. To eliminate this effect, RC suppressors (with AC power supply)

or free-wheel diodes (with DC power supply) shall be connected in parallel to the coils of these devices.

3-25

Installation and Connection

3.2.6 Typical Control Connections

Control connection #1 - Start/Stop function controlled from the keypad (Local Mode).

With this control connection it is possible to run the inverter in local mode with the factory default settings. This

operation mode is recommended for first-time users, since no additional control connections are required.

For the start-up in this operation mode, please follow instructions listed in chapter 5.

Control connection #2 - 2 - Wire Start/Stop function (Remote Mode).