Page 1

Page 2

Page 3

05/2008

FREQUENCY

INVERTER

MANUAL

Series:

CFW-10

Software:

version 2.0X

and 2.2X

Language:

English

Document:

0899.5202 / 05

ATTENTION!

It is very important to check if the

inverter software version is the

same as indicated above.

Page 4

4

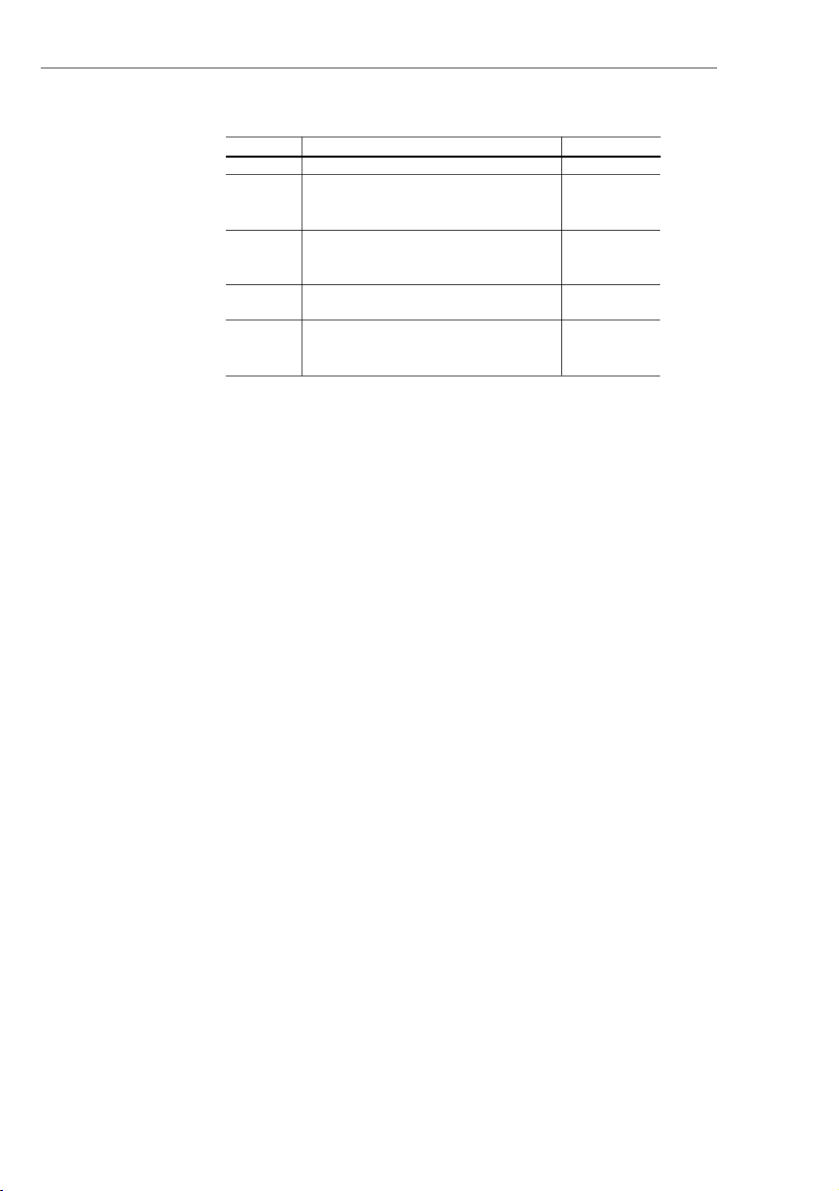

Sumarry of Revisions

Revision

Description

Section

1

First Edition

-

2

Addition of the CFW10 MECII and

-

addition of the EMC filter for MECI.

Generalrevision.

3

Addition of the CFW10 Size III and

-

Addition of the EMC filter for

sizes II and III.

4

CFW10 Plus andClean

-

versions inclusion

5

Inclusion of the three-phase and

-

Cold Plate models, and the

models with Built-in filter.

The table belowdescribesall revisions madeto this manual.

Page 5

CONTENTS

Quick Parameter Reference,

Fault and Status Messages

I

Parameters

...............................................................

08IIFault Messages

........................................................

11

III

Other Messages

........................................................

11

CHAPTER 1

Safety Notices

1.1

Safety Notices in the Manual

.....................................

12

1.2

Safety Notice on The Product

...................................

12

1.3

PreliminaryRecommendations

.................................

12

CHAPTER 2

General Information

2.1

About this Manual

......................................................

14

2.2

Software Version

.......................................................

14

2.3

About the CFW-10

....................................................

15

2.4

CFW-10 Identification

...............................................

19

2.5

Receiving and Storing

...............................................

21

CHAPTER 3

Installation and Connection

3.1

Mechanical Installation

..............................................

22

3.1.1

Environment

........................................................

22

3.1.2

Dimensional of CFW-10

.....................................

22

3.1.3

Mounting Specification

........................................

25

3.1.3.1

Panel Mounting

..........................................

26

3.1.3.2MountingSurface

.......................................

26

3.2

Electrical Installation

..................................................

26

3.2.1

Power and Grounding Terminals

.........................

27

3.2.2 Location of the Power, Grounding and Control

Connections

........................................................

28

3.2.3

Wiring and Fuses for Power and Grounding

.......283.2.4

Power Connections

.............................................

29

3.2.4.1

AC Input Connection

..................................

31

3.2.4.2

Output Connection

.....................................

32

3.2.4.3

Grounding Connections

.............................

32

3.2.5

Signal and Control Connections

.........................

34

3.2.6

Typical Terminal Connections

..............................

36

3.3

European EMC Directive - Requirements for

Conforming Installations

............................................

38

3.3.1

Installation

...........................................................

39

Page 6

CONTENTS

3.3.2 Specification of the Emission and

ImmunityLevels

...................................................

40

3.3.3

Inverter and Filters

...............................................

41

3.3.4 Characteristics of the EMC Filters

......................

43

CHAPTER 4

Keypad (HMI) Operation

4.1

Keypad (HMI) Description

.........................................

47

4.2

Use of the Keypad (HMI)

...........................................

48

4.2.1

Keypad (HMI) Operation

.....................................

48

4.2.2

Inverter Status - HMI Display

...............................

49

4.2.3 Read-Only Variables

...........................................

50

4.2.4

Parameter Viewing and Programming

...............

50

CHAPTER 5

Start-up

5.1 Pre-Power Checks

....................................................

52

5.2 Initial Power-up

..........................................................

52

5.3 Start-up

...................................................................

53

5.3.1 Start-up Operation via Keypad (HMI)

..................

53

5.3.2 Start-up Operation via Terminals

.........................

54

CHAPTER 6

Detailed Parameter Description

6.1

Symbols

...................................................................

55

6.2

Introduction

................................................................

55

6.2.1

V/F (Scalar) Control

............................................

55

6.2.2

FrequencyReference Sources

...........................

56

6.2.3

Commands

.........................................................

59

6.2.4

Local/Remote Operation Modes

.........................

59

6.3

Parameter Listing

.....................................................

60

6.3.1

Access and Read Only Parameters -

P000 to P099

......................................................

61

6.3.2 Regulation Parameters - P100 to P199

..............

62

6.3.3 Configuration Parameters - P200 to P398

.........

71

6.3.4

Special Functions Parameters - P500 to P599

..886.3.4.1

Introduction

.................................................

88

6.3.4.2

Description

................................................

88

6.3.4.3

Startup Guide

............................................

91

Page 7

CONTENTS

CHAPTER 7

Diagnostics and Troubleshooting

7.1 Faults and Possible Causes

.....................................

96

7.2 Troubleshooting

.........................................................

98

7.3 Contacting WEG

.......................................................

99

7.4 Preventive Maintenance

............................................

99

7.4.1 Cleaning Instructions

.........................................

100

CHAPTER 8

Options and Accessories

8.1 RFI Filter

................................................................

101

8.2 Line Reactor

............................................................

102

8.2.1 Application Criteria

...........................................

102

8.3 Load Reactor

..........................................................

104

8.4 Rheostatic Braking

..................................................

104

8.4.1 Sizing

................................................................

105

8.4.2Installation

..........................................................

106

CHAPTER 9

Technical Specifications

9.1 Power Data

.............................................................

108

9.1.1 Power Supply: 200/240 V - Single-phase

.........

108

9.1.2 Power Supply: 200/240 V - Three-phase

..........

108

9.1.3 Power Supply: 110-127 V - Single-phase

.........

109

9.2 Electronic/General Data

..........................................

1108CFW-10 -

Page 8

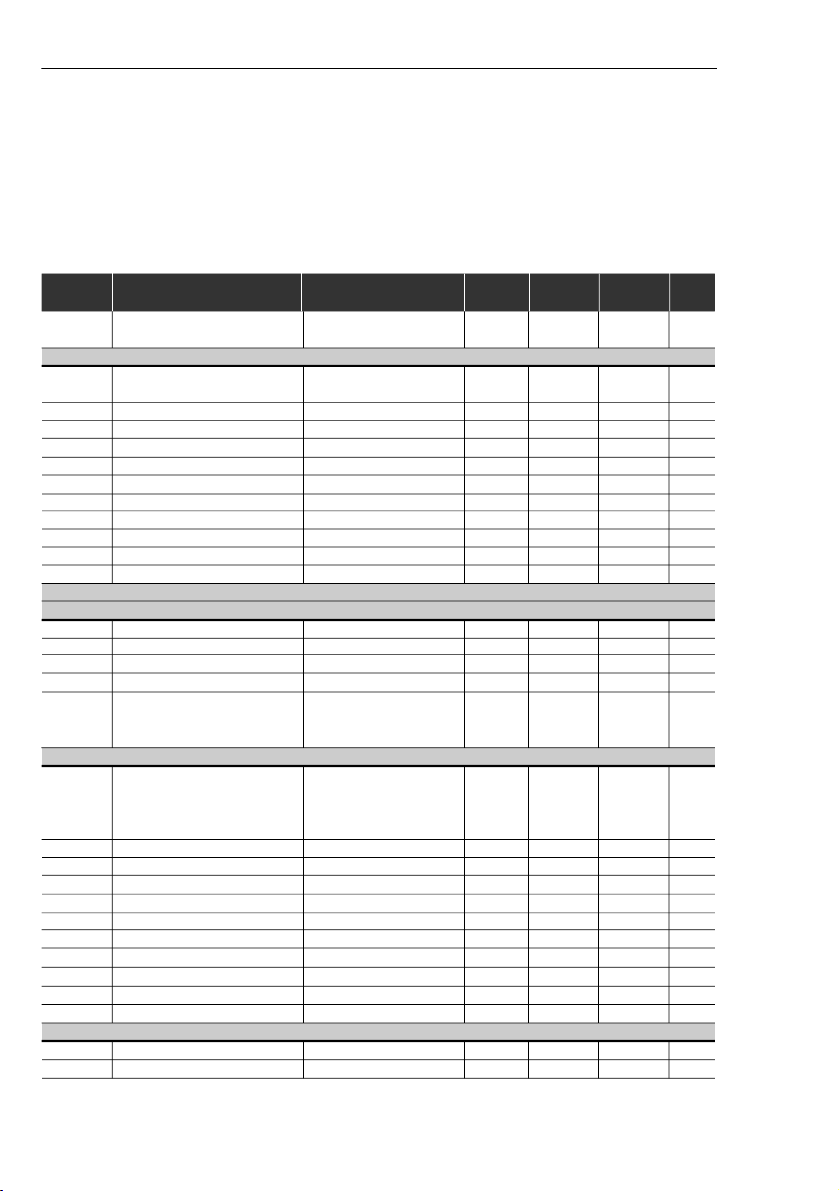

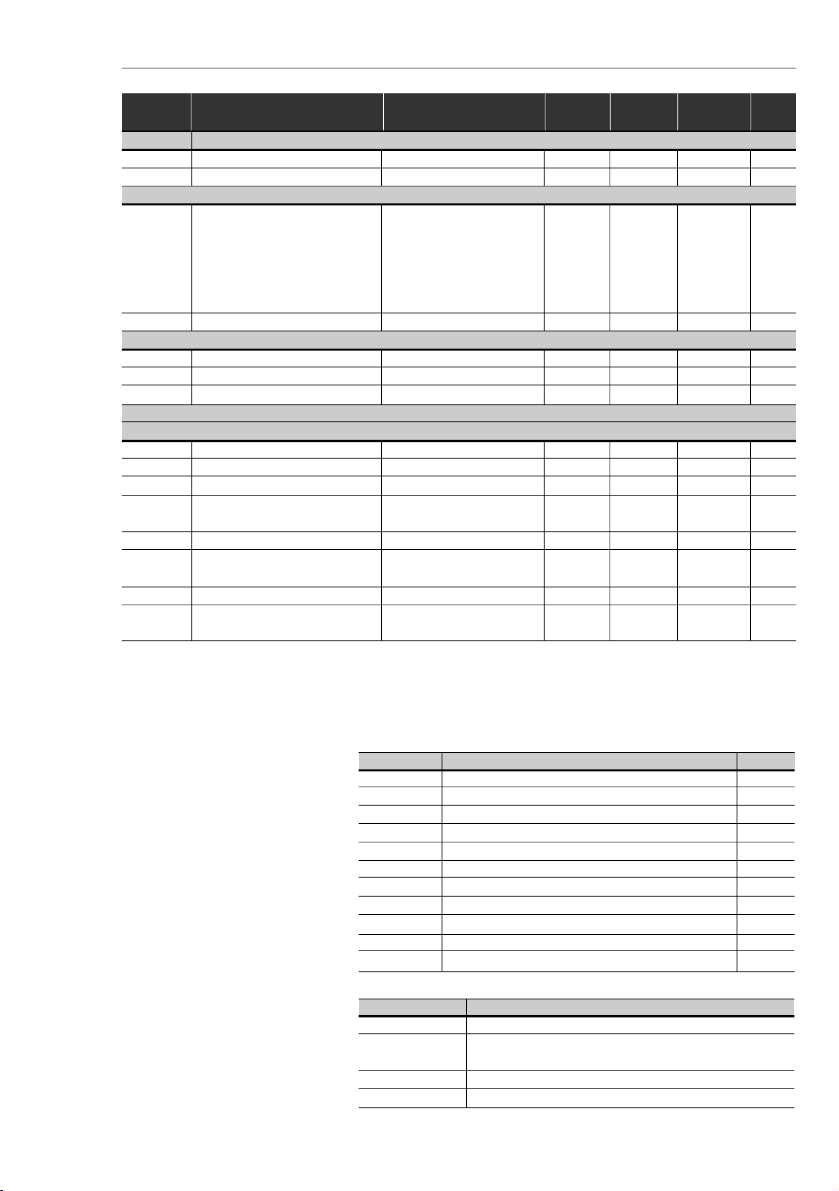

QUICK PARAMETER REFERENCE

Software: V2.0X and 2.2X

Application:

Model:

Serial Number:

Responsible:

Date: / / .

QUICK PARAMETER REFERENCE, FAULTAND STATUS MESSAGES

I. Parameters

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

P000

Access Parameter

0 to 4, 6 to 999 = Read

0-61

5 = Alteration

READ ONL

YPARAMETERS

- P002 toP099

P002

Fequency Proportional Value

0.0 to 999

--61

(P208 x P005)

P003

Motor Current (Output)

0 to 1.5 x I

nom

-A61

P004

DC Link Voltage

0 to 524

-V61

P005

Motor Frequency (Output)

0.0 to 99.9, 100 to 300

-Hz61

P007

Motor Voltage (Output)

0 to 240

-V61

P008

HeatsinkTemperature

25 to 110

-ºC61

P014

Last Fault

00 to 41

--61

P015

Second Fault Occurred

00 to 41

--61

P016

Third Fault Occurred

00 to 41

--61

P023

Software Version

x.yz--

61

P040

PID Process Variable

0.0 to 999

--62

REGULA

TION PARAMETERS

- P100 toP199

Ramps

P100

Acceleration Time

0.1 to 999

5.0s62

P101

Deceleration Time

0.1 to 999

10.0s62

P102

Acceleration Time Ramp 2

0.1 to 999

5.0s62

P103

Deceleration Time Ramp 2

0.1 to 999

10.0s62

P104

S Ramp

0 = Inactive

0%62

1 = 50

2 = 100

Frequency Reference

P120

Digital Reference Backup

0 = Inactive

1-63

1 = Active

2 = Backup by P121

3 = Active after Ramp

P121

Keypad FrequencyReference

P133 to P134

3.0Hz64

P122

JOG Speed Reference

P133 to P134

5.0Hz64

P124

Multispeed Reference 1

P133 to P134

3.0Hz64

P125

Multispeed Reference 2

P133 to P134

10.0Hz64

P126

Multispeed Reference 3

P133 to P134

20.0Hz64

P127

Multispeed Reference 4

P133 to P134

30.0Hz64

P128

Multispeed Reference 5

P133 to P134

40.0Hz65

P129

Multispeed Reference 6

P133 to P134

50.0Hz65

P130

Multispeed Reference 7

P133 to P134

60.0Hz65

P131

Multispeed Reference 8

P133 to P134

66.0Hz65

Frequency Limits

P133

Minimum Frequency(F

min

)

0.00 to P134

3.0Hz66

P134

Maximum Frequency (F

max

)

P133 to 300

66.0Hz66

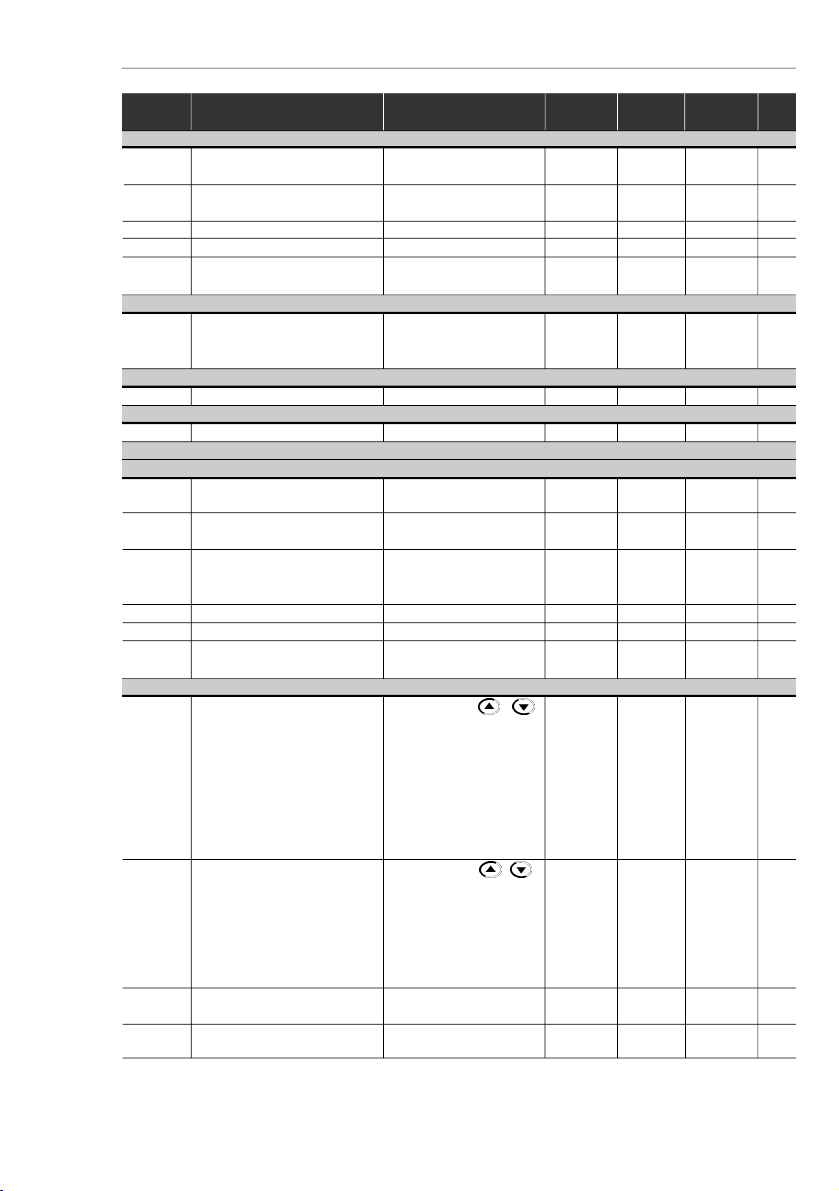

Page 9

9

CFW-10 -

QUICK PARAMETER REFERENCE

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

V/F Control

P136

Manual Torque Boost

0.0 to 100

20.0

(3)

%66(I x R Compensation )

P137

Automatic Torque Boost

0.0 to 100

0.0%67

(AutomaticIxR Compensation)

P138

Slip Compensation

0.0 to 10.0

0.0%68

P142

(1)

(2)

Maximum Output Voltage

0.0 to 100

100%69

P145

(1)

(2)

Field Weakening

P133 to P134

60.0Hz69

Frequency

(F

nom

)

DC Link Voltage Regulation

P151

Actuation Level of the Voltage

Model 100: 360 to 460

430V69

Regulation at the DC Link

Model 200: 325 to 410

380

(Intermediary Circuit)

Overload Current

P156

(2)

MotorOverload Current

0.3 x I

nom

to 1.3 x I

nom

1.2 x P295

A

70

Current Limitation

P169

(2)

Maiximum Output Current

0.2 x I

nom

to 2.0 x I

nom

1.5 x P295

A

71

CONFIGURATION PARAMETERS

- P200 to P398

Generic Parameters

P202

(1)

Control Mode

0 = Linear V/F Control

0-71

1 =

Quadratic V/F

Control

P203

Special Functions Selection

0 = None

0-73

1 = PID Regulator

P204

(1)

Load Parameters with

0 to 4 = Not used

0-73

Factory Setting

5 = Load Factory Default

6 to 999 = Not used

P206

Auto-ResetTime

0 to 255

0s73

P208

Reference Scale Factor

0.0 to 100

1.0-73

P219

(1)

Starting Point of the Switching

0.0 to 15.0

15.0Hz73

FrequencyReduction

Local/Remote Definition

P221

(1)

Speed Reference

0 = HMI Keys /

-74Selection – Local Mode

1 = AI1

2 = EP

3 = HMI Potentiometer

4 to 5 = Reserved

6 = Multispeed

7 = Frequency Input

P222

(1)

Speed Reference Selection -

0 = HMI Keys /

1-74

Remote Mode

1 = AI1

2 = EP

3 = HMI Potentiometer

4 to 5 = Reserved

6 = Multispeed

7 = Frequency Input

P229

(1)

Command Selection-

0 = HMI Keypad

0-74

Local Mode

1 = Terminals

P230

(1)

Command Selection -

0 = HMI Keypad

1-74

Remote Mode

1 = Terminals

0 = For

Inverters

Standard

and Clean

Versions

3 = For

Inverters

Plus

Version

Page 10

10

CFW-10 -

QUICK PARAMETER REFERENCE

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

P231

(1)

Forward/Reverse

0 = Forward

2-75

Selection

1 =Reverse

2 = Commands

Analog Inputs(s)

P234

Analog Input

AI1Gain

0.0 to 999

100%75

P235

(1)

Anal

og Input

AI1

Signal

0 = (0 to 10) V/ (0 to20) mA

0-78

1 =(4to 20) mA

P236

Analog Input AI1 Offset

-120 to +120

0%78

P238

Input Gain(HMI Potentiometer)

0.0 to 999

100%78

P240

InputOffset(HMIPotentiometer)

-120 to +120

0%78

P248

Analog Input (AI1) Filter

0 to 200

200ms78

Time Constant

Digital Inputs

P263

(1)

Digital Input DI1

0 = No Function

1-78

Function

1 = No Function or

P264

(1)

Digital Input DI2

GeneralEnable

5-78

Function

2 = General Enable

P265

(1)

Digital Input DI3

3 = JOG

6-78

Function

4 = Start/Stop

P266

(1)

Digital Input DI4

5 =Forward/Reverse

4-79

Function

6 = Local/Remote

7 = Multispeed

8 = Multispeed using

Ramp2

9 = Forward

10 = Reverse

11 = ForwardwithRamp2

12=ReversewithRamp2

13 = On

14 = Off

15 = Activates

ramp 2

16 = Accelerates EP

17 = Decelerates EP

18 = Acclerates EP with

Ramp2

19 = Decelerates EP with

Ramp2

20 = Without ExternalFault

21 = Error Reset

22=Start/Accelerate EP

23=Decelerate EP/Stop

24 = Stop

25 = Security Switch

26 = Frequency Input

27 = Manual/Automatic

(PID)

P271

Frequency Input Gain

0.0 to 999

200%84

Digital Outputs

P277

(1)

Relay Output RL1 Function

0 = Fs > Fx

7-84

1 = Fe > Fx

2 = Fs = Fe

3 = Is > Ix

4 and 6 = Not Used

5 = Run

7 = Not Fault

Page 11

11

CFW-10 -

QUICK PARAMETER REFERENCE

Read only

Parameter

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

Fx and Ix

P288

Fx Frequency

0.0 to P134

3.0Hz85

P290

Ix Current

0.0 to 1.5 x I

nom

P295A85

Inverter Data

P295

RatedInverter

1.6A85

Current (I

nom

)

2.6

4.0

7.3

10.0

15.2

P297

(1)

Switching Fraquency

2.5 to 15.0

5.0

(4)

kHz

86

DC Braking

P300

DC Braking Time

0.0 to 15.0

0.0s86

P301

DC Braking Start Frequency

0.0 to 15.0

1.0Hz86

P302

BrakingTorque

0.0 to 100

50.0%86

SPECIAL FUNCTION - P500 to P599

PID Regulator

P520

PID Proportional Gain

0.0 to 999

100%94

P521

PID Integral Gain

0.0 to 999

100%94

P522

PID Differential Gain

0.0 to 999

0%94

P525

PID RegulatorSet point

0.0 to 100

0%94

via keypad

P526

Process Variable Filter

0.0 to 10.0

0.1s94

P527

PID Regulator Action Type

0 = Direct

0-94

1 =Reverse

P528

Proc. Var. Scale Factor

0 to 999

100-95

P536

Automatic Setting of P525

0 = Active

0-95

1 = Inactive

(1)

This parameter can be changed only with the inverter disabled (stopped motor).

(2)

ThisParameter cannot bechanged when theroutine "load factorydefault"is excuted(P204=5).

(3)

6 % for the 15.2 A model.

(4)

2.5 kHz for the 15.2 A model.

Display

Description

Page

E00

Output Overcurrent/Short-Circuit

96

E01

DC Link Overvoltage

96

E02

DC Link Undervoltage

96

E04

InverterOvertemperature

97

E05

Output Overload (I x t function)

97

E06

External Fault

97

E08

CPU Error (watchdog)

97

E09

Program MemoryError (checksum)

97

E24

Programming Error

97

E31

Keypad (HMI) Communication Fault

97

E41

Self-Diagnosis Error

97

II. Fault Messages

III.Other Messages

Display

Description

rdy

Inverter is ready to be enabled

Sub

Power supplyvoltage is too low for the inverter

operation (undervoltage)

dcb

Inverterin DC braking mode

EPP

Inverter is loading factory setting

Page 12

12

CHAPTER 1

SAFETYNOTICES

This manual contains necessary information for the correct use of the

CFW-10 Variable FrequencyDrive.

This manual has been written for qualified personnel with suitable

training and technical qualification to operatethis type of equipment.

The following SafetyNotices will be used in this manual:

DANGER!

If the recommended Safety Notices are not strictly observed, it can

lead to serious or fatal injuries of personnel and/or material damage.

ATTENTION!

Failure to observe the recommended SafetyProcedures can lead to

material damage.

NOTE!

The content of this manual supplies important information for the

correct understanding of operation and proper performance of the

equipment.

The following symbols may be attached to the product, serving as

Safety Notice:

High Voltages

Components sensitive to electrostatic discharge. Do not touch

them without proper grounding procedures.

Mandatory connection to ground protection (PE)

Shield connection to ground

DANGER!

Only qualified personnel should plan or implement the installation,

start-up, operation and maintenance of this equipment. Personnel

must review entire Manual before attempting to install, operate or

troubleshootthe CFW-10.

These personnel must follow all safety instructions included in this

Manual and/or defined bylocal regulations.

Failure to complywith these instructions may resultin personnelinjury

and/or equipment damage.

1.3

PRELIMINARY

RECOMMEN-

DA

TIONS

1.2

SAFETYNOTICE

ON THE

PRODUCT

1.1

SAFETY

NOTICES IN THE

MANUAL

Page 13

13

CHAPTER 1 - SAFETY NOTICES

NOTE!

In this manual, qualified personnel are defined as people that are

trained to:

1.

Install, ground, power up and operate the CFW-10 according to

this manual and the local required safetyprocedures;

2.

Use of safety equipment according to the local regulations;

3.

Administer First Aid.

DANGER!

The inverter control circuit (CCP10, DSP) and the HMI-CFW-10 are

not grounded. They are high voltage circuits.

DANGER!

Always disconnect the supply voltage before touching any electrical

component inside the inverter.

Many components are charged with high voltages, even after the

incoming AC power supply has been disconnected or switched OFF.

Waitat least10minutes for the total discharge of the powercapacitors.

Always connect the frame of the equipment to the ground (PE) at the

suitable connection point.

CFW-10 drive must be grounded appropriately for safety purposes

(PE).

ATTENTION!

All electronic boards have compon ents that are sensitive to

electrostatic discharges. Never touchanyoftheelectricalcomponents

or connectors without following proper grounding procedures. If

necessary to do so, touch the properly grounded metallic frame or

use a suitable ground strap.

NOTE!

Inverters can interfere with other electronic equipment. In order to

reduce this interference, adopt the measures recommended in

Section 3 “Installation”.

NOTE!

Read this entire manual carefully and completely before installing or

operating the CFW-10.

Do not apply High Voltage (High Pot) Test on the inverter!

If this test is necessary, contact the Manufacturer.

Page 14

14

This chapter defines the contents and purposes of this manual and

describesthe main characteristicsof the CFW-10 frequency inverter.

Identification,receiving inspections and storage requirements are also

provided.

This Manual is divided into 9 Chapter, providing information to the

user on receiving,installation, start-up and operation:

Chapter 1 -

Safety Notices.

Chapter 2 -

General Informationsand Receiving the CFW-10.

Chapter 3 -

CFW-10 and RFI Filters - Mechanical and Electrical

Installation (power and control circuitry).

Chapter 4 -

Using the Keypad (Human Machine Interface - HMI).

Chapter 5 -

Start-up - Steps tofollow.

Chapter 6 -

Setupand Read-only Parameters-Detailed description.

Chapter 7 -

Solving problems,cleaning instructions and preventive

maintenance.

Chapter 8 -

CFW-10 Optional Devices - Description, technical

characteristics and installation.

Chapter 9 -

CFW-10 ratings -Tables and technical information.

This Manual provides information for the correct use of the CFW-10.

The CFW-10 is veryflexibleandallows the operation in manydifferent

modes as described in this manual.

As the CFW-10 can be applied in several ways, it is impossible to

describe here all of the application possibilities. WEG does not accept

any responsibility when the CFW-10 is not used according to this

Manual.

No part of this Manual may be reproduced in any form, without the

written permission of WEG.

It is important to note the Software Version installed in the CFW-10,

since it defines the functions and theprogramming parameters of the

inverter.

This manual refers to the software version indicated on the inside

cover. For example, the Version1.0Xappliesto versions1.00 to 1.09,

where “X”is a variablethat will change due to minor softwarerevisions.

The Software Version can be read in the Parameter P023.

GENERALINFORMATION

2.1

ABOUTTHIS

MANUAL

2.2

SOFTWARE

VERSION

CHAPTER 2

Page 15

15

CHAPTER 2 -

GENERAL INFORMATION

2.3

ABOUT THE

CFW-10

The CFW-10 frequency inverter is fitted with the V/F (scalar) control

method.

The V/F (scalar) mode is recommended for more simple applications

suchaspumpandfandrives.Inthese casesonecanreduce themotor

and inverter losses by using the "Quadratic V/F" option, that results in

energysaving.

The V/F mode is also used when more than one motor should be

driven simultaneously by one inverter (multimotor application).

Chapter 9 shows the different power lines and additional technical

information

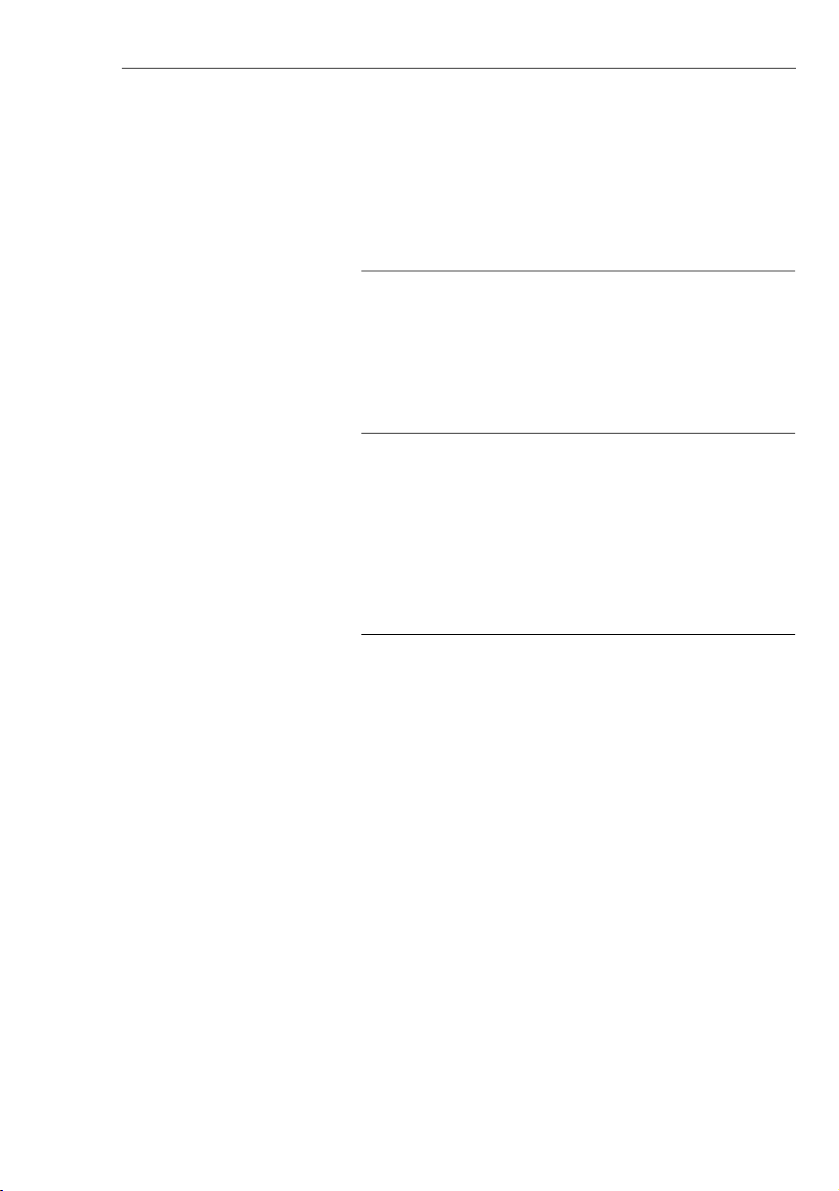

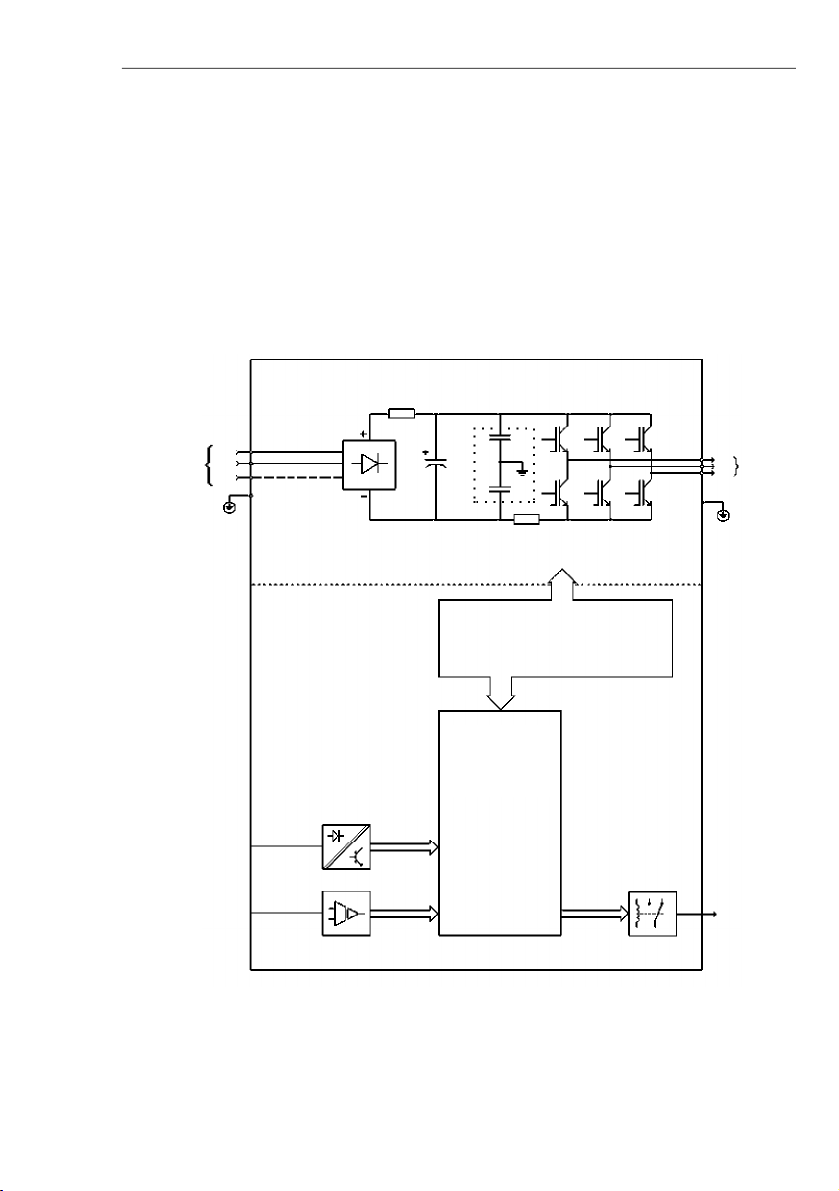

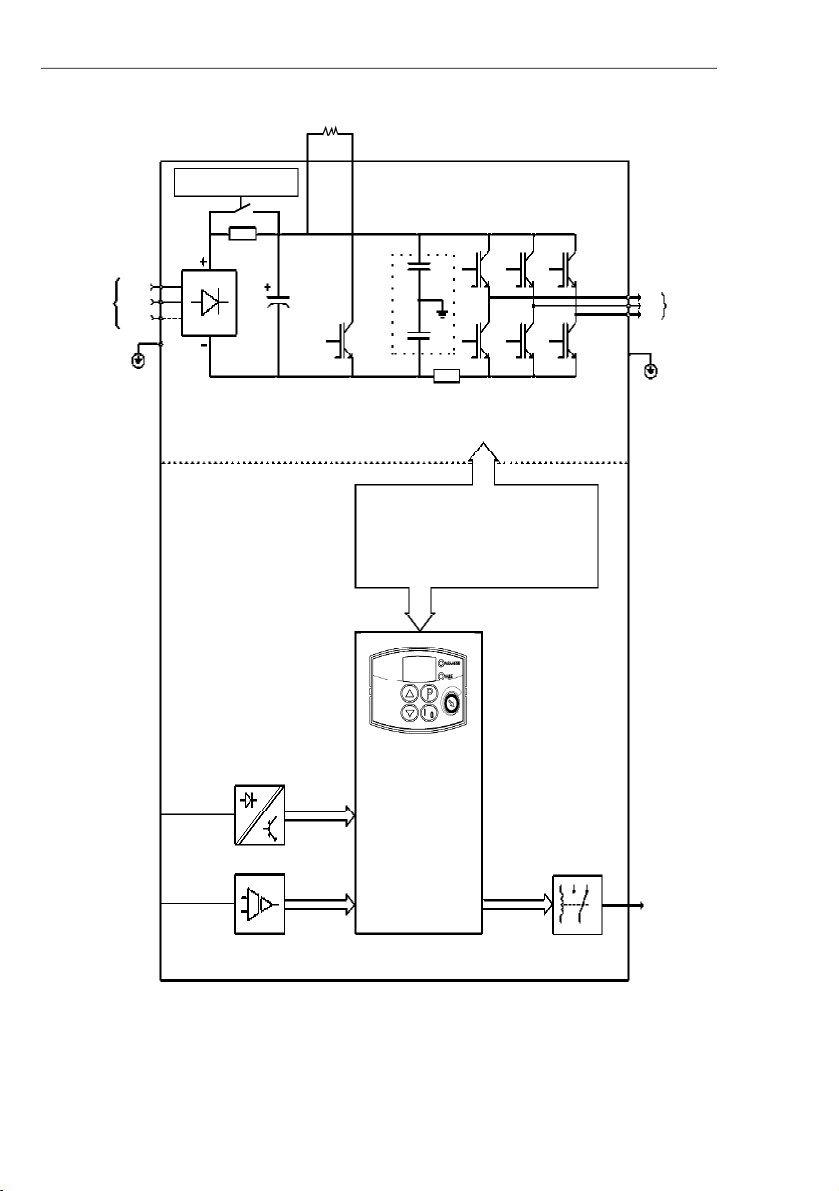

The block diagram below gives a general overviewof theCFW-10.

Figure 2.1

- CFW-10 Block Diagram for models 1.6 A, 2.6 A and 4.0 A / 200-240 V (single-phase)

and 1.6 A, 2.6 A, 4.0 A and 7.3 A/200-240 V (three-phase)

Power

Supply

L/L1

PE

Analog

Input

(AI1)

Digital

Inputs

(DI1 to DI4)

POWER

CONTROL

POWER SUPPLY

AND

CONTROL/POWER

INTERFACES

"CCP10"

CONTROL BOARD

WITH DSP

Relay

Output

(RL1)

Motor

U

V

W

Rsh

NTC

RFI Filter

N/L2

L3

Page 16

16

CHAPTER 2 -

GENERAL INFORMATION

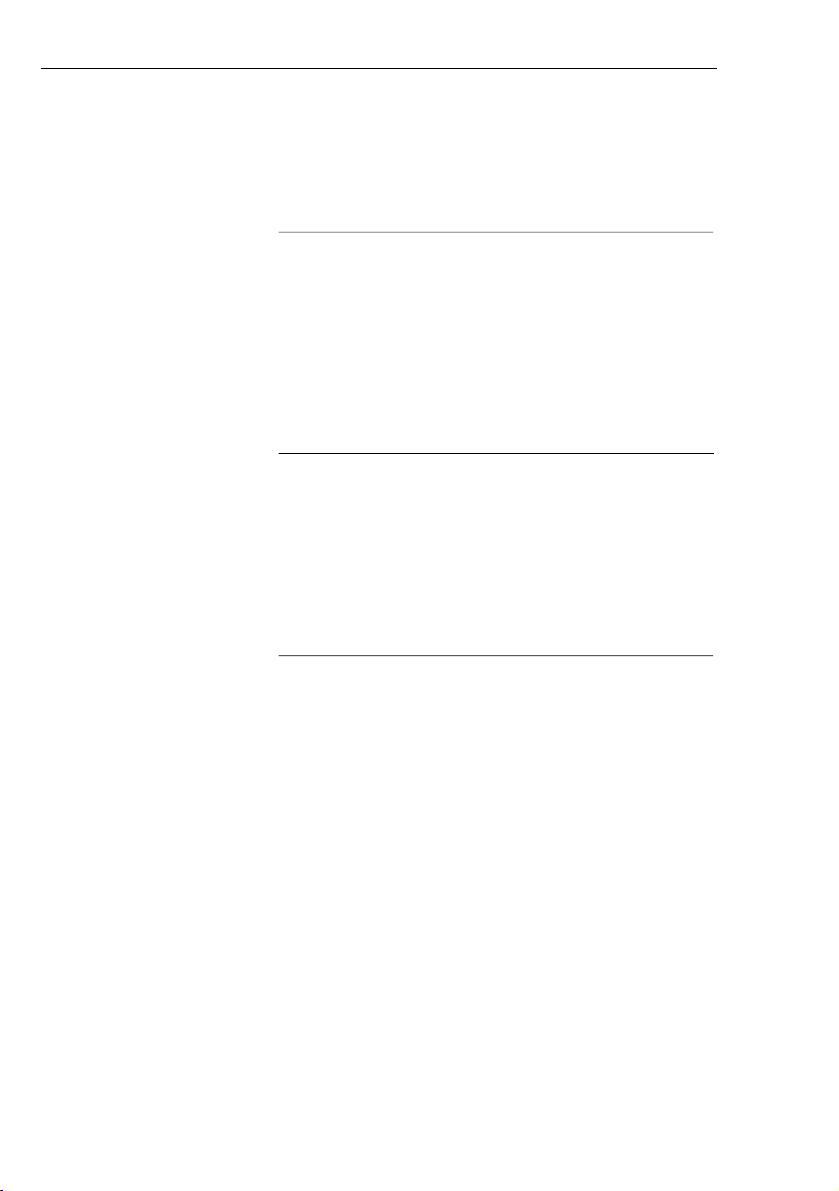

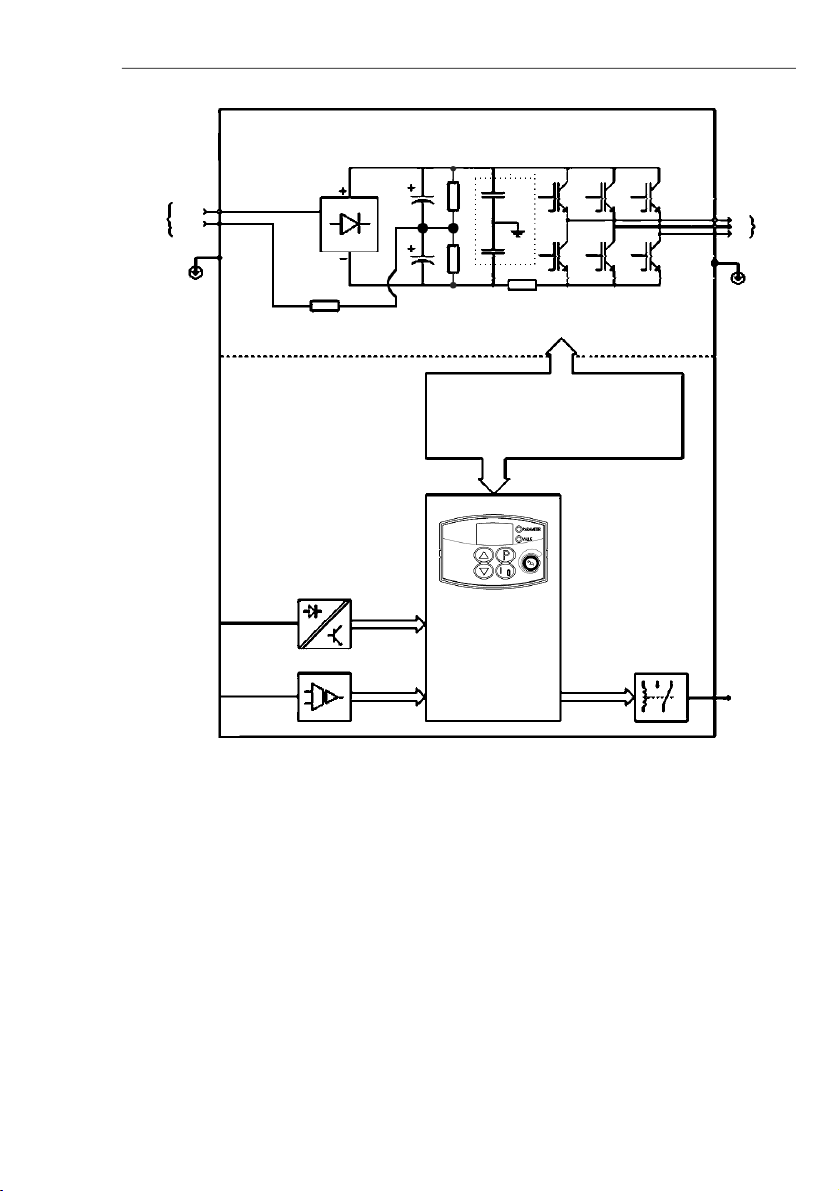

Figure 2.2

- CFW-10 Block Diagram for model 7.3 A and 10.0 A/200-240 V (single-phase)

and 10.0 A and 15.2 A/200-240 V (three-phase)

Power

Supply

L/L1

PE

Analog

Input

(AI1)

Digital

Inputs

(DI1 to DI4)

POWER

CONTROL

POWER SUPPLY FOR

ELETRONICSAND INTERFACE

BETWEENPOWER ANDCONTROL

"CCP10"

CONTROL

BOARD

WITH DSP

Relay

Output

(RL1)

Motor

UVW

Rsh

+UD

RFI Filter

N/L2

BR

Braking Resistor

(Optional)

Pre-Charge

L3

Page 17

17

CHAPTER 2 -

GENERAL INFORMATION

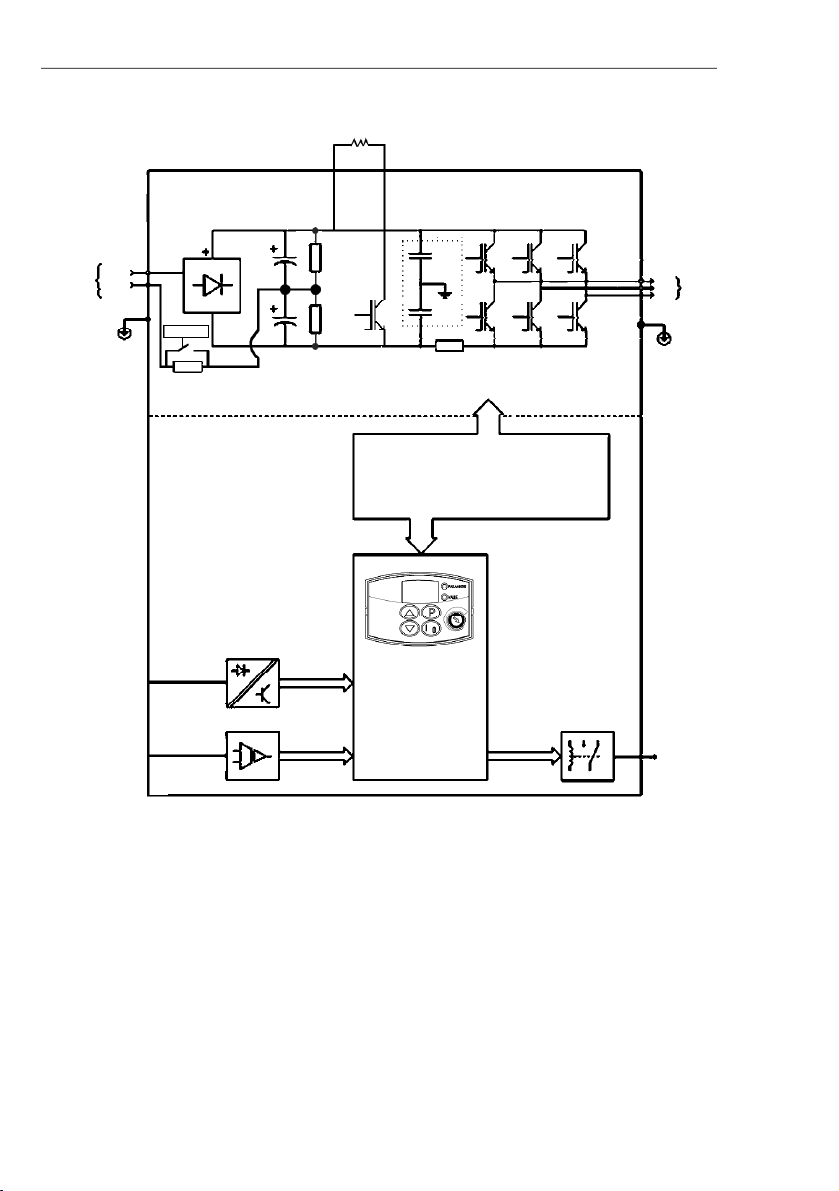

Power

Suplly

L/L1

Analog

Input

(AI1)

Digital

Inputs

(DI1 to DI4)

POWER

CONTROL

POWER SUPPLY FOR

ELETRONICS

AND INTERFACE BETWEEN

POWER AND CONTROL.

"CCP10"

CONTROL

BOARD

WITH DSP

Relay

Output

(RL1)

Motor

UVW

Rsh

NTCPEPE

RFI Filter

N/L2

Figure 2.3

- CFW-10 Block Diagram for model 1.6 A and 2.6 A/110-127 V

Page 18

18

CHAPTER 2 -

GENERAL INFORMATION

Figure 2.4

- CFW-10 Block Diagram for model 4.0 A /110-127 V

Power

Suplly

L/L1

Analog

Input

(AI1)

Digital

Inputs

(DI1 to DI4)

POWER

CONTROL

POWER SUPPLY FOR

ELETRONICSAND INTERFACE

BETWEEN POWER AND CONTROL

"CCP10"

CONTROL

BOARD

WITH DSP

Relay

Output

(RL1)

Motor

UVW

RshPEPE

RFI Filter

N/L2

+UDBRBraking Resistor

(Optional)

Pre-Charge

Page 19

19

CHAPTER 2 -

GENERAL INFORMATION

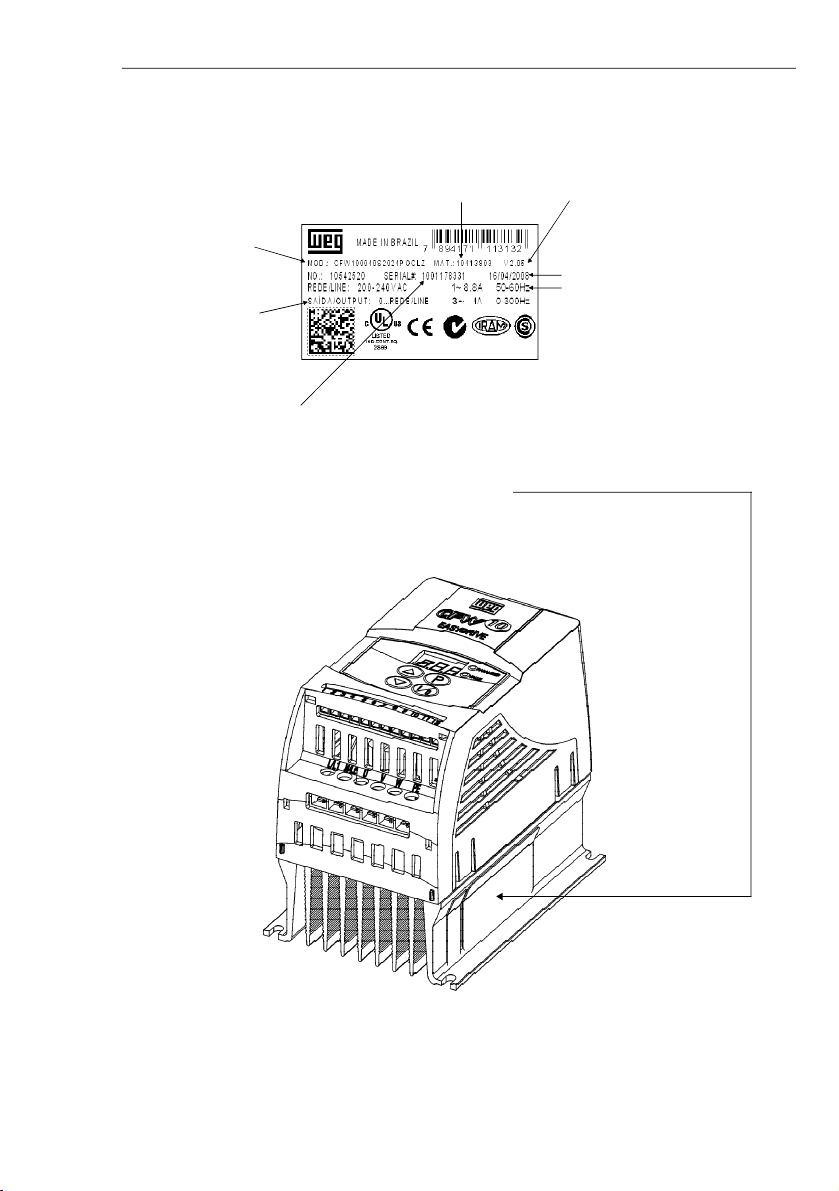

2.4

CFW-10 IDENTIFICATION

Figure 2.5

- Description and Location of the Nameplate

Lateral Nameplate CFW-10

Serial Number

CFW-10 Model

Rated Output Data

(Voltage, Frequency)

Software

Version

Rated Input Data

(Voltage, Current, etc)

Manufacturing Date

WEG

Part Number

Page 20

20

CHAPTER 2 -

GENERAL INFORMATION

NOTE!

The Option field (S or O) defines if the CFW-10 is a standard version or if itwill be equipped with anyoptional devices.

If the standard version is required, the specification code ends here.

The model number has always the letter Z at the end. For example:

CFW100040S2024ESZ = standard 4.0 A CFW-10 inverter, single-phase at 200 V to 240 V input with manual in

English.

If the CFW-10 is equipped with any optional devices, you must fill out all fields in the correct sequence up to the last

optional device, the model number is completed with the letterZ.

HOW TO SPECIFY THE CFW-10 MODEL

CFW-10

0040S2024PO

_ _

_ _

_ _

_ _

Z

Special

Software

Blank =

standard

EndCode

Special

Hardware

Blank =

standard

Rated

Output

Current for

220 to 240 V:

0016 = 1.6 A

0026 = 2.6 A

0040 = 4.0 A

0073 = 7.3 A

0100 = 10.0 A

0152 = 15.2 A

110 to 127 V:

0016 = 1.6 A

0026 = 2.6 A

0040 = 4.0 A

Numberof

phases of

the power

supply

S = single-

phase

T = three-

phase

Manual

Language:

P = Portuguese

E = English

S = Spanish

G = German

Power

supply:2024 =

200 to 240 V

1112 =

110 to 127 V

Options:

S = standard

O = with

options

WEG

Series 10

Frequency

Inverter

Control

Board:

Blank =

standard

control

CL = Clean

PL = Plus

Built-in EMC

filter:

Blank =

standard

FA = with

EMC (class A)

filter

CP = Cold

Plate

heatsink

version

Page 21

21

CHAPTER 2 -

GENERAL INFORMATION

2.5

RECEIVING

AND STORING

The CFW-10 is supplied in cardboard boxes.

Thereis a nameplateon the outside of the packingbox thatisidentical

to that one on theCFW-10.

Check if the:

CFW-10 nameplate data matches with your purchase order.

The equipment has not been damaged during transport.

If any problem is detected, contact the carrier immediately.

If the CFW-10 is not installed immediately, store it in a clean and dry

room (storage temperatures between -25 °C and 60 °C). Cover it to

protect it against dust, dirtor other contamination.

ATTENTION!

When stored for a long time, it is recommended to power up and

keepthedrive runningfor1 hour everyyear. Make suretousea single-

phasepower supply(50 or 60 Hz) that matchesthedrive ratingwithout

connectingthe motor to its output.Afterpowering up thedrive, keep it

off for 24 hours before using it again.

Page 22

22

CHAPTER 3

INSTALLATIONAND CONNECTION

3.1

MECHANICAL

INSTALLATION

3.1.1

Environment

This chapter describes the procedures for the electrical and

mechanical installation of the CFW-10.

These guidelines and suggestions must be followed for proper

operation of the CFW-10.

The location of the inverter installation is an importantfactor to assure

good performanceand high product reliability. For proper installation,

we make the following recommendations:

Avoid direct exposure to sunlight,rain, high moisture and sea air.

Avoid exposure to gases or explosive or corrosive liquids;

Avoid exposure to excessive vibration, dust, oil or any conductive

particles or materials.

Environmental Conditions:

Temperature : 0 ºC to50 ºC (32 ºF to 122 ºF) - nominal conditions,

except for the 15.2 A model with Built-in filter (0 to 40 °C).

Relative Air Humidity: 5 % to 90 % -non-condensing.

MaximumAltitude: 1000 m (3.300 ft) - nominal conditions.

From 1000 m to 4000 m (3.300 ft to 13.200 ft): with 1 % current

derating for each 100 m (330 ft) above 1000 m (3.300 ft).

Pollution Degree: 2 (according to EN50178 and UL508C).

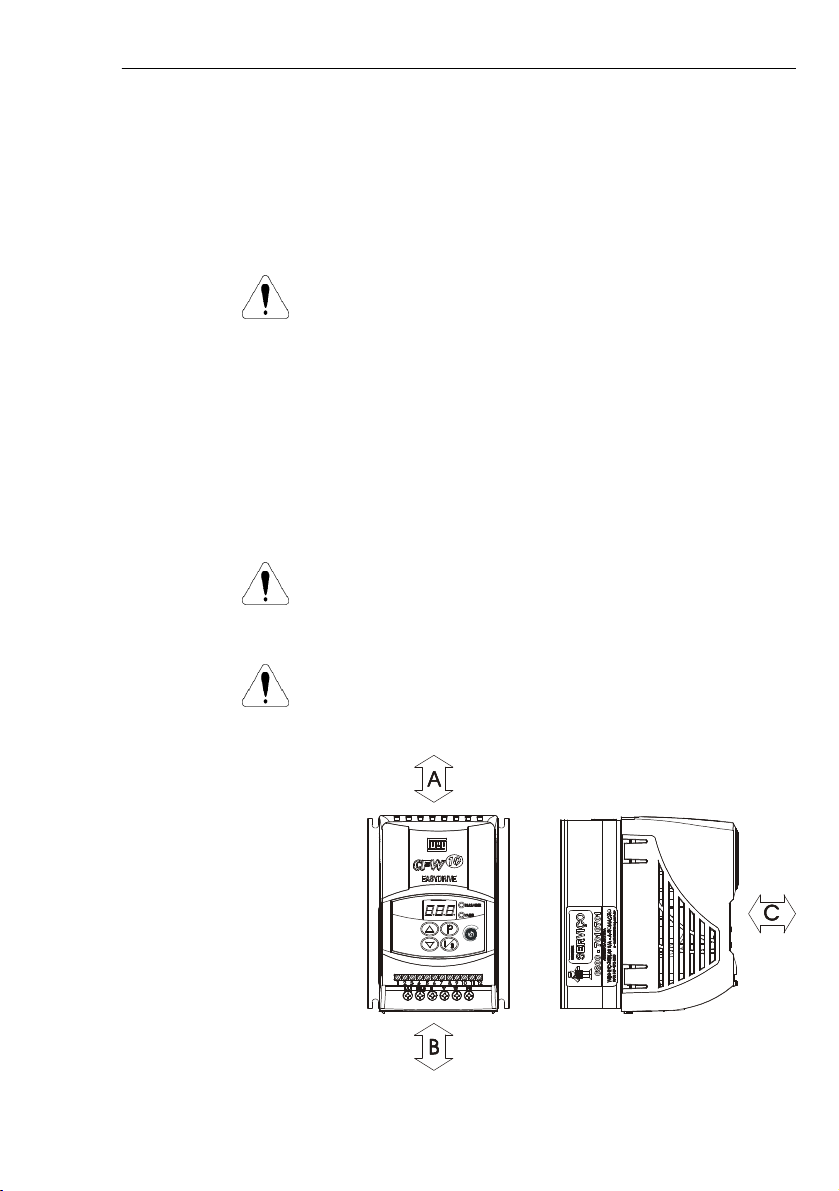

External dimensions and mounting holes for the CFW-10 shall be

according to figure 3.1 and table 3.1.

3.1.2

Dimensional of

CFW-10

MOUTINGBASE

VIEW

FRONTAL

VIEW

SIDE VIEW

(STANDARDVERSION)

Figure 3.1

- Dimensional of CFW-10 - Sizes 1, 2 and 3

SIDE VIEW

(COLDPLATE

VERSION)

Page 23

23

CHAPTER 3 -

INSTALLATION AND CONNECTION

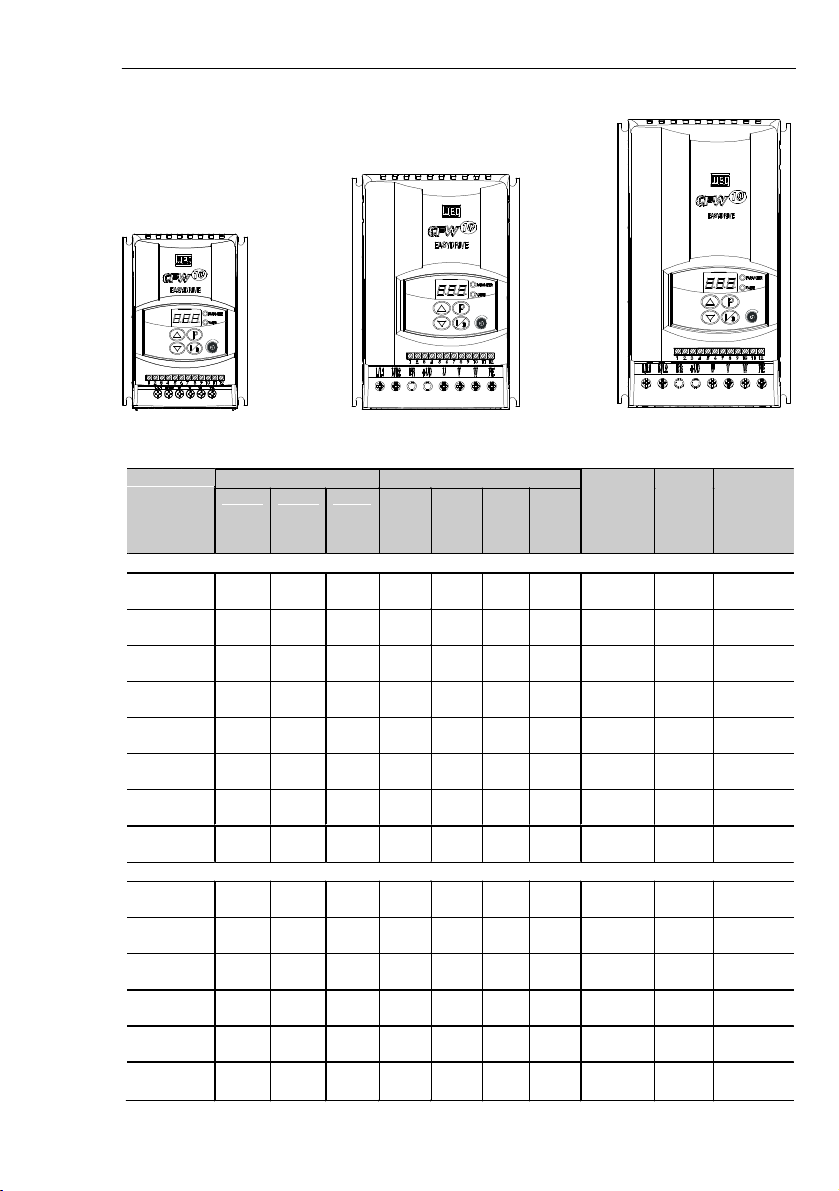

Figure 3.1

- Dimensional of CFW-10 - Sizes 1, 2 and 3

Size 2

Size 3

Size 1

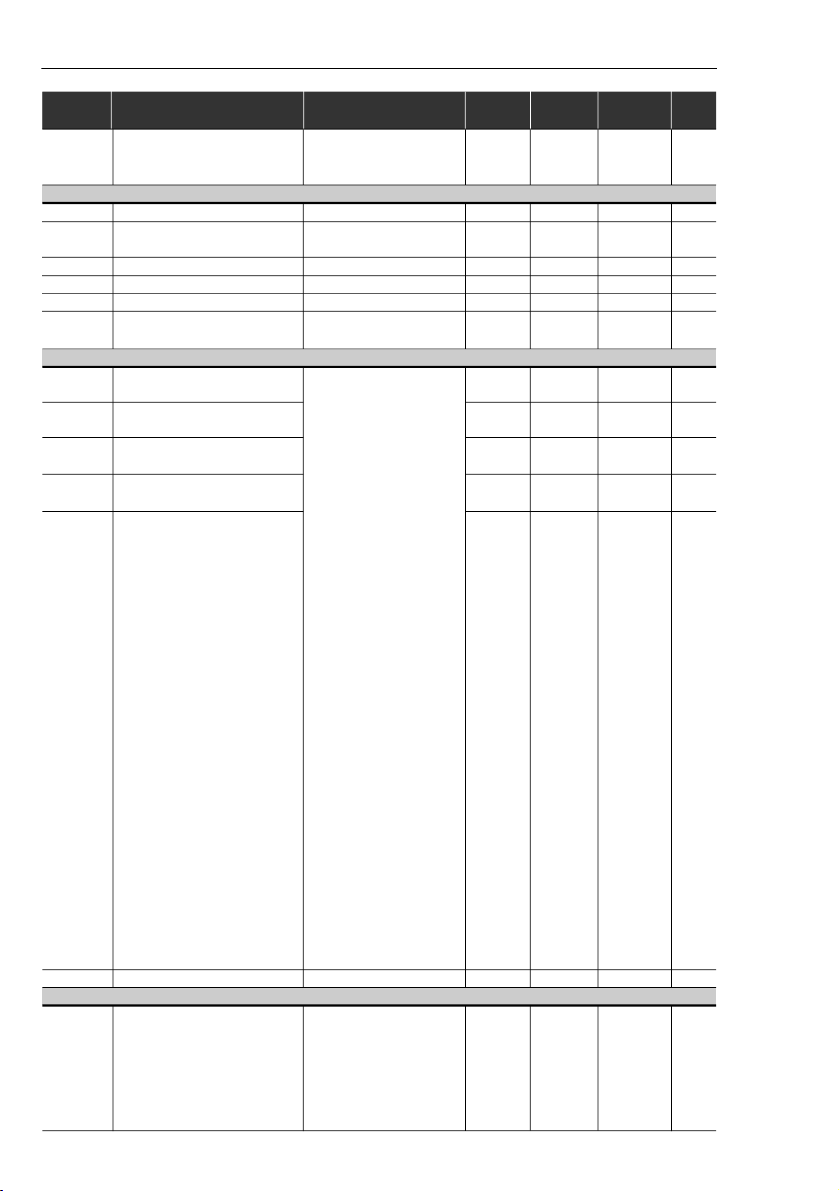

Table 3.1 a)

Installation data (dimensions in mm (in)) – Refer to Section 9.1

Dim ensions

Fixin g Base

Model

WidthL[mm]

(in)

Height

H

[mm]

(in)

DepthP[mm]

(in)

A

[mm]

(in)

B

[mm]

(in)

C

[mm]

(in)

D

[mm]

(in)

Mounting

Scre w

W eight

[kg]

(lb)

Degree of

Prote ction

SING LE

-

PHAS E

1.6 A /

200-240 V95(3.74)

132

(5.20)

121

(4.76)85

(3.35)

120

(4.72)5(0.2)6(0.24)M40.9

(1.98)

IP202.

6 A /

200-240 V95(3.74)

132

(5.20)

121

(4.76)85(3.35)

120

(4.72)5(0.2)6(0.24)M40.9

(1.98)

IP204.

0 A /

200-240 V95(3.74)

132

(5.20)

121

(4.76)85(3.35)

120

(4.72)5(0.2)6(0.24)M40.9

(1.98)

IP207.

3 A /

200-240 V

115

(4.53)

161

(6.34)

122

(4.8)

105

(4.13)

149

(5.83)5(0.2)6(0.24)M41.5

(3.31)

IP2010.

0 A /

200-240 V

115

(4.53)

191

(7.46)

122

(4.8)

105

(4.13)

179

(7.05)5(0.2)6(0.24)M41.8

(3.96)

IP201.

6 A /

110-127 V95(3.74)

132

(5.20)

121

(4.76)85(3.35)

120

(4.72)5(0.2)6(0.24)M40.9

(1.98)

IP202.

6 A /

110-127 V95(3.74)

132

(5.20)

121

(4.76)85(3.35)

120

(4.72)5(0.2)6(0.24)M40.9

(1.98)

IP204.

0 A /

110-127 V

115

(4.53)

161

(6.34)

122

(4.8)

105

(4.

13)

149

(5.83)5(0.2)6(0.24)M41.5

(3.31)

IP20

THREE

-

PHASE

1.6 A /

200-240 V95(3.74)

132

(5.20)

121

(4.76)85(3.35)

120

(4.72)5(0.2)6(0.24)M40.9

(1.98)

IP202.

6 A /

200-240 V95(3.74)

132

(5.20)

121

(4.76)85(3.35)

120

(4.72)5(0.2)6(0

.24)M40.9

(1.98)

IP204.

0 A /

200-240 V95(3.74)

132

(5.20)

121

(4.76)85(3.35)

120

(4.72)5(0.2)6(0.24)M40.9

(1.98)

IP207.

3 A /

200-240 V95(3.74)

132

(5.20)

121

(4.76)85(3.35)

120

(4.72)5(0.2)6(0.24)M40.9

(1.98)

IP2010.

0 A /

200-24

0 V

115

(4.53)

161

(6.34)

122

(4.8)

105

(4.13)

149

(5.83)5(0.2)6(0.24)M41.5

(3.31)

IP2015.

2 A /

200-240 V

115

(4.53)

191

(7.46)

122

(4.8)

105

(4.13)

179

(7.05)5(0.2)6(0.24)M41.8

(3.96)

IP20

Page 24

24

CHAPTER 3 -

INSTALLATION AND CONNECTION

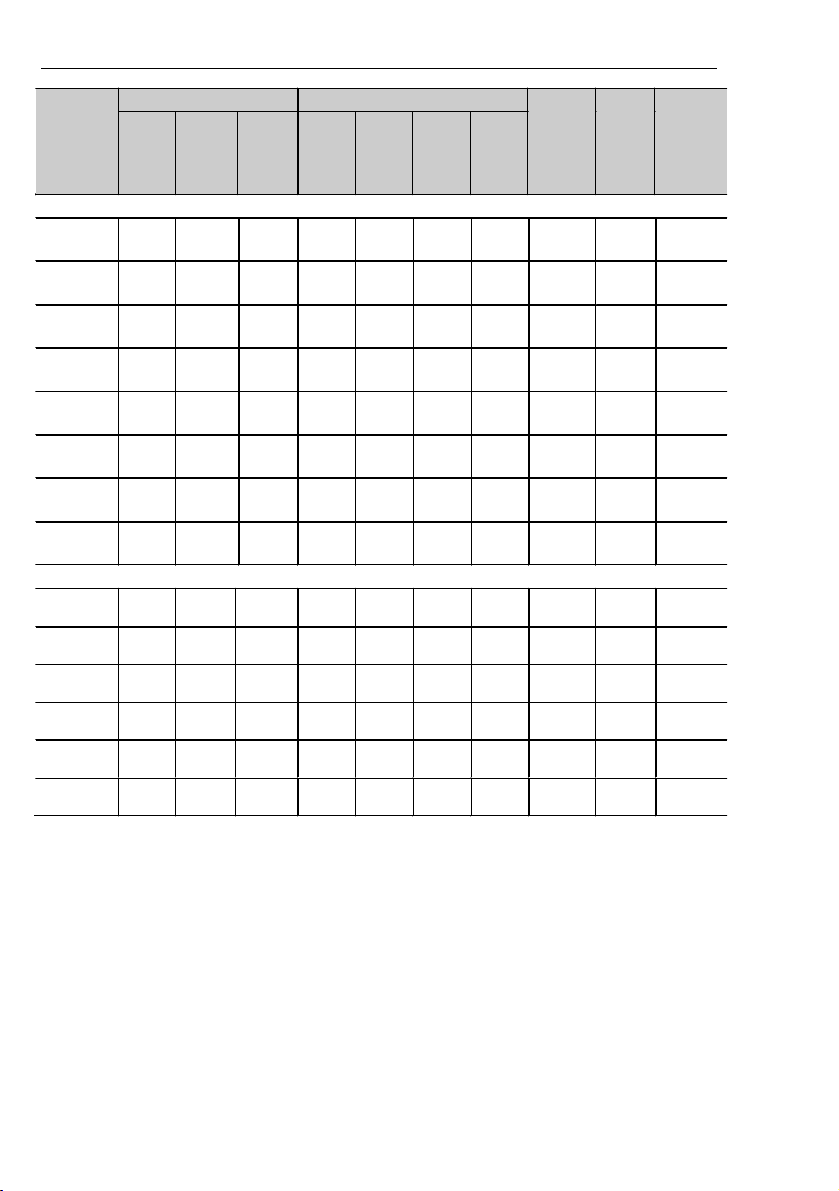

Table 3.1 b)

Cold Plate Version, installation data (dimensions in mm (in)) – Refer to Section 9.1

The Cold Plate version was designed in order to allow mounting the

“CP”CFW-10frequencyinverter in any heatdissipation surface,since

followingrecommendations are fulfilled.

INSTALLATING THE FREQUENCY INVERTER ON THE HEAT

DISSIPATION SURFACE - STEPS

1.

Mark out the positions of the mounting holes on the backing plate

where the frequency inverter will be located (see in figure 3.1

drawing and hole size).

2.

The surface that is in contact with frequency inverter dissipation

surface must be free of dirt and burr. Standard requirements are:

the backing plate flatness (considering an area of 100 mm

2

(0.15 in

2

))

shall be less than 50

m and the roughness less than

10m.

Dim ensions

Fixing Bas e

Model

WidthL[mm]

(in)

Heig ht

H

[mm ]

(in)

DepthP[mm ]

(in)A[mm ]

(in)

B

[mm]

(in)

C

[mm]

(in)

D

[mm]

(in)

Mountin g

Screw

Weight

[kg]

(lb)

Degre e of

Protecti on

SING LE

-

PHAS E

1.6 A /

200-240 V

100

(3.94)

132

(5.20)82(3.23

)90(3.54)

120

(4.72)5(0.2)6(0.24)

M4

0.7

(1.54)

IP202.

6 A /

200-240 V

100

(3.94)

132

(5.20)82(3.23)90(3.54)

120

(4.72)5(0.2)6(0.24)M40.7

(1.54)

IP204.

0 A /

200-240 V

100

(3.94)

132

(5.20)82(3.23)90(3.54)

120

(4.72)5(0.2)6(0.24)M40.7

(1.54)

IP207.

3 A /

200-240 V

120

(4.72)

161

(6.34)82(3.23)

110

(4.33)

149

(5.83)5(0.2)6(0.24)M41.0

(2.20)

IP2010.

0 A /

200-240 V

120

(4.72)

191

(7.46)82(3.23)

110

(4.33)

179

(7.05)5(0.2)6(0.24)M41.2

(2.65)

IP201.

6 A /

110-127 V

100

(3.94)

132

(5.20)82(3.23)90(3.54)

120

(4.72)5(0.2)6(0.24)

M4

0.7

(1.54)

IP202.

6 A /

110-127 V

100

(3.94)

132

(5.20)82(3.23)90(3.54)

120

(4.72)5(0.2)6(0.24)M40.7

(1.54)

IP204.

0 A /

110-127 V

120

(4.72)

161

(6.34)82(3.23)

110

(4.

33)

149

(5.83)5(0.2)6(0.24)M41.0

(2.20)

IP20

THREE

-

PHASE

1.6 A /

200-240 V

100

(3.94)

132

(5.20)82(3.23)90(3.54)

120

(4.72)5(0.2)6(0.24)M40.7

(1.54)

IP202.

6 A /

200-240 V

100

(3.94)

132

(5.20)82(3.23)90(3.54)

120

(4.72)5(0.2)6(0

.24)

M4

0.7

(1.54)

IP204.

0 A /

200-240 V

100

(3.94)

132

(5.20)82(3.23)90(3.54)

120

(4.72)5(0.2)6(0.24)M40.7

(1.54)

IP207.

3 A /

200-240 V

100

(3.94)

132

(5.20)82(3.23)90(3.54)

120

(4.72)5(0.2)6(0.24)M40.7

(1.54)

IP2010.

0 A /

200-24

0 V

120

(4.72)

161

(6.34)82(3.23)

110

(4.33)

149

(5.83)5(0.2)6(0.24)M41.0

(2.20)

IP2015.

2 A /

200-240 V

120

(4.72)

191

(7.46)82(3.23)

110

(4.33)

179

(7.05)5(0.2)6(0.24)M41.2

(2.65)

IP20

Page 25

25

CHAPTER 3 -

INSTALLATION AND CONNECTION

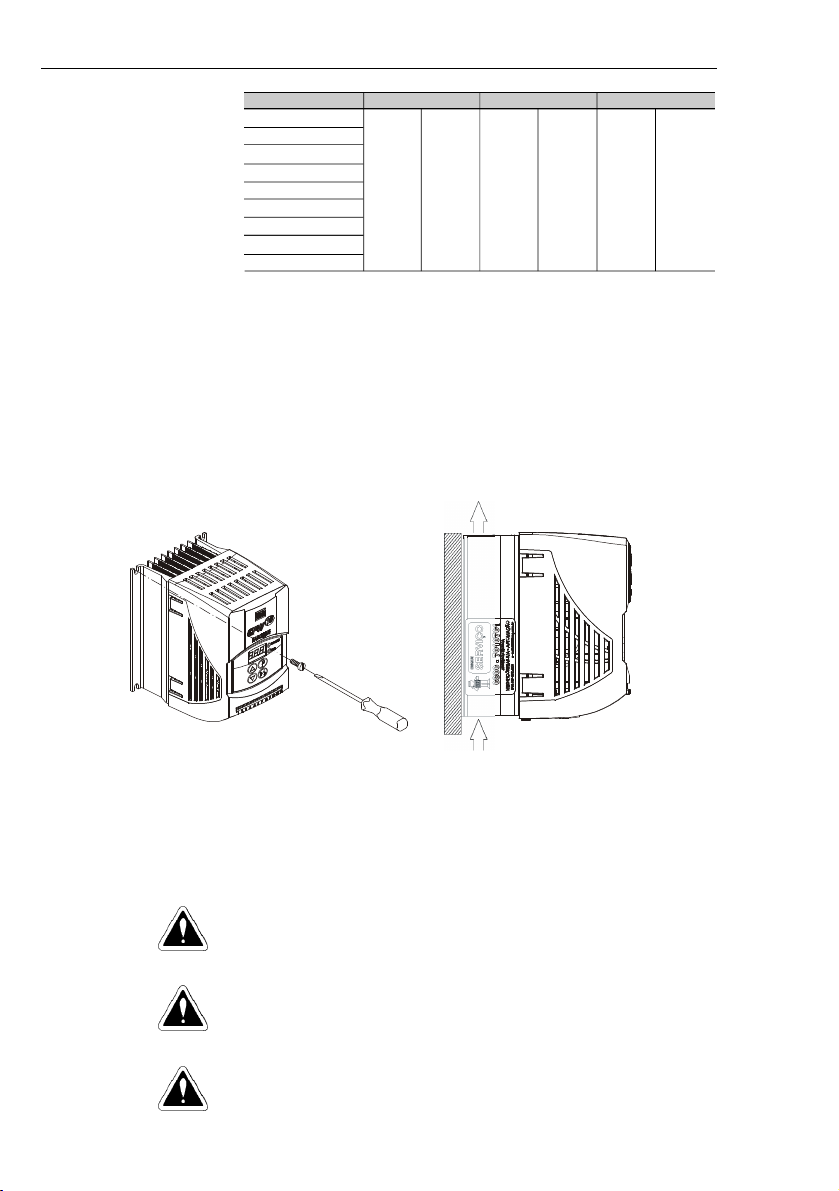

Figure 3.2 and table 3.2 show free space requirements to be left

around the drive.

Installthe drive on a verticalposition, following the recommendations

listed below:

1)

Install the drive on a flat surface.

2)

Do not install heat sensitive components immediately above the

drive.

ATTENTION!

When there are other devices installed at thetop and at thebottomof

the drive, respect the minimum recommended distance (A + B) and

deflect the hot air coming from the device below.

ATTENTION!

Provide independent conduits for signal , control and power

conductors.(Refer to Electrical Installation).Separate the motorcables

from the other cables.

3.1.3

Mounting

Specification

3.

Use (M4) mounting screws in order tofasten the frequency inver-

ter to the base plate.

4.

After drilling the holes, clean the contact surface of the backing

plate and coat it with a thin thermal paste layer, or with a heat

conducting foil or similar product (approx. 100

m).5.Continue the mechanical installation as indicated in Chapter3.1.

6.

Electrical installation shall be performed as indicated in the

Chapter 3.2.

ATTENTION!

After operation, check P008. This parametermust not exceed 90 ºC.

Figure 3.2

- Free-space for Cooling

Page 26

26

CHAPTER 3 -

INSTALLATION AND CONNECTION

3.1.3.1

Panel

Mounting

When drives are installed inside panels or inside closed metallic

boxes,

proper cooling is required to ensure that the temperature

aroundthedrive willnot exceedthemaximumallowable temperature.

Refer to Section 9.1 for Power Dissipation data.

3.1.3.2

Mounting

Surface

Figure 3.3 shows the installation procedure of the CFW-10 on a

mounting surface.

Figure 3.3

- Mounting Procedures for the CFW-10

3.2

ELECTRICAL INSTALLATION

DANGER!

The information below will be a guide to achieve a proper installation.

Follow also all applicable local standards for electrical installations.

DANGER!

Be sure the AC input power has been disconnected before making

any terminal connection.

DANGER!

The CFW-10 shall not be used as an emergency stop device. Use

additional devices proper for this purpose.

Air Flow

Table 3.2

- Free space requirements

CFW-10 Model

1.6 A/ 200-240 V

2.6 A/ 200-240 V

4.0 A/ 200-240 V

7.3 A/ 200-240 V

10.0 A/200-240 V

15.2 A/200-240 V

1.6 A/ 110-127 V

2.6 A/ 110-127 V

4.0 A/ 110-127 V

ABC

30 mm

1.18 in

50 mm

2 in

50 mm

2 in

Page 27

27

CHAPTER 3 -

INSTALLATION AND CONNECTION

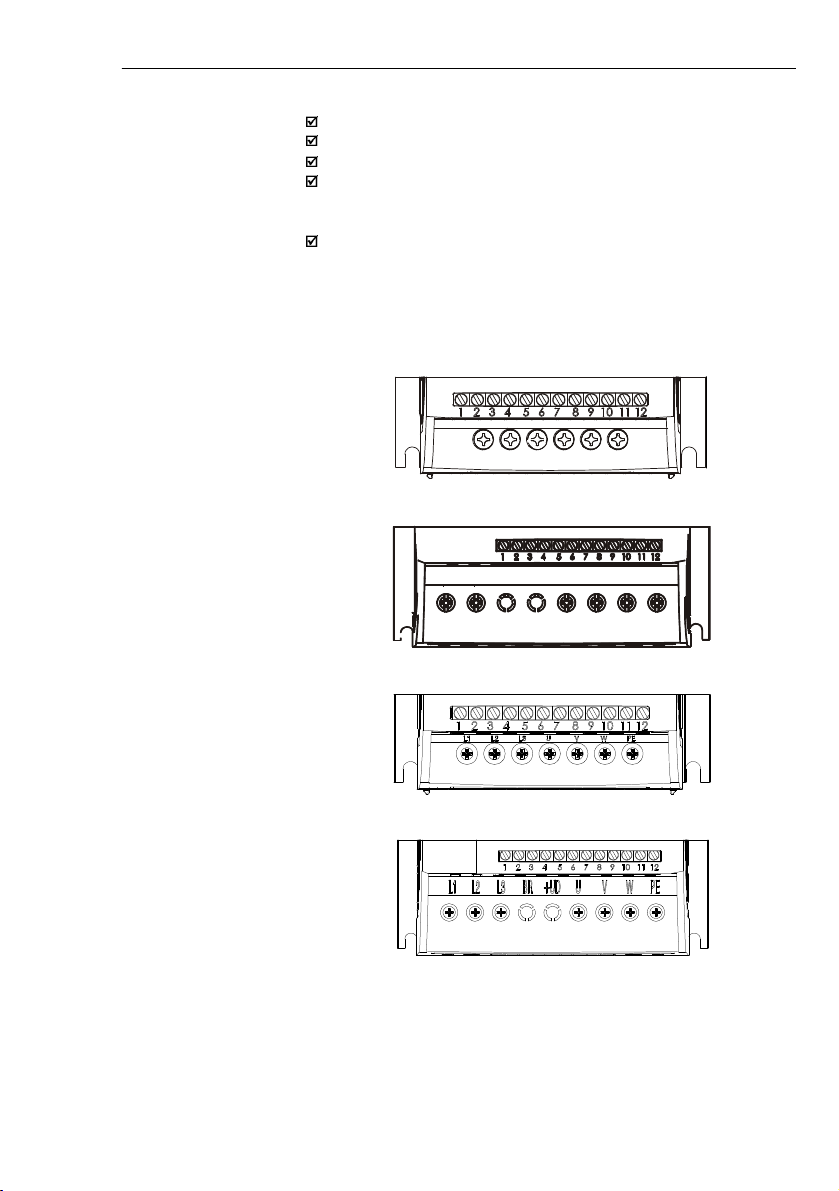

a) Models 1.6 A, 2.6 A and 4.0 A/200-240 V and1.6Aand 2.6 A/110-127 V (single-phase)

b) Models 7.3 A and 10 A/200-240 V and 4.0 A/110-127 V (single-phase)

L/L1

N/L2UVWPE

L/L1 N/L2 BR + UD U V W PE

c) Models 1.6 A, 2.6 A, 4.0 A, 7.3 A/200-240 V (three-phase)

d) Models 10.0 A and 15.2A/200-240 V (three-phase)

3.2.1

Power and

Grounding

Terminals

Description of the Power Terminals:

L/L1, N/L2, L3: AC power supply.

U, V and W: Motor connection.

PE: Grounding connection.

BR: Connection terminal for the braking resistor. Not available for

1.6 A, 2.6 A and 4 A/200-240 V and1.6 A and 2.6 A/110-127 V and

7.3 A/200-240 V three-phase models.

+UD: Positive connection terminal (DC Link). This terminal is used

to connect the braking resistor (connect also the BR terminal). Not

available for 1.6A, 2.6 A and 4.0 A/200-240 V and 1.6 A and 2.6A/

110-127 V and 7.3A/200-240 V three-phase models.

Figure 3.4 a) b) c) d) -

CFW-10 Power Terminals

Page 28

28

CHAPTER 3 -

INSTALLATION AND CONNECTION

3.2.3

Wiring and Fuses for

Power and Grounding

ATENTION!

Provide at least 0.25 m (10 in) spacing between low voltage wiring

and drive/motor cables. For instance:PLC’s, temperature monitoring

devices, thermocouples, etc.

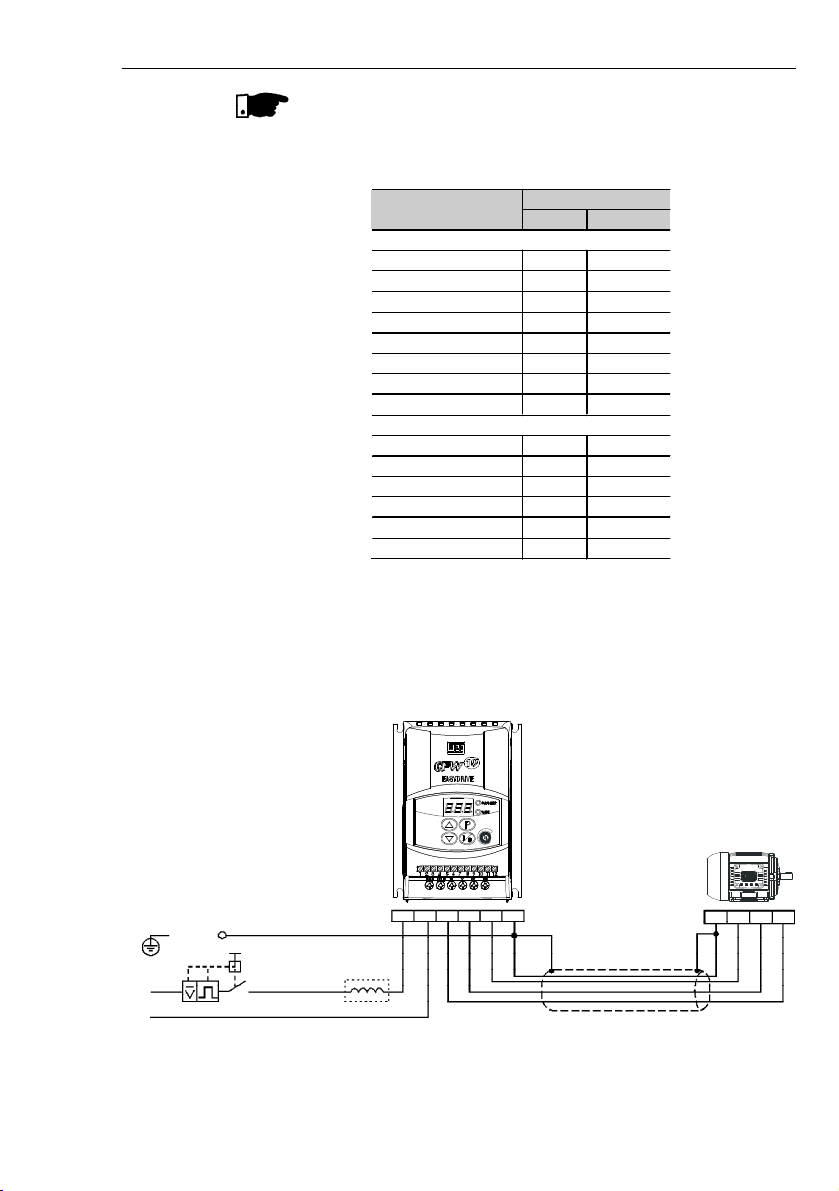

Table 3.3 presents minimum cable diameter and circuit breakerrating

for the CFW-10. Tightening torque shall be as indicated in table 3.4.

All power wiring (cooper) shall be rated for 70 ºC minimum.

Table 3.3

- Recommended wire cross-section and circuit-breakers - use (70 ºC) copper

wiresonly

3.2.2

Location of the Power,

Grounding and Control

Connections

Control XC1

Power

Figure 3.5

- Location of the Power and Control Connections

Circuit-Breaker

Rated In verter

Current [A]

Motor

Wiring

[mm ²]

Groundi ng

Wiring

[mm²]

Power

Cables

[mm ²]

Maxim um

Cables

[mm²]

Current

WEG

Model

SINGLE

-

PHASE MODELS

1.6 (200

-

240 V )

1.5

2.5

1.5

2.56MPW 25

-

6.3

1.6 (110

-

127 V )

1.5

2.5

1.5

2.510MPW25

-

10

2.6 (200

-

240 V )

1.5

2.5

1.5

2.510MPW25

-102.6 (110

-

127 V )

1.5

2.5

2.5

2.516MPW25

-164.0 (200

-

240 V )

1.5

2.5

1.5

2.516MPW25

-164.0 (110

-

127 V )

1.5

4.0

2.5

4.020MPW25

-207.3 (200

-

240 V )

2.5

4.0

2.5

4.020MPW25

-2010.0 (200

-

240 V)

2.5

4.04.0

4.025MPW25

-25THREE

-

PHASE MO DELS

1.6 (200

-

240 V )

1.5

2.5

1.5

2.5

2.5

MPW 25

-

2.5

2.6 (200

-

240 V )

1.5

2.5

1.5

2.5

6.3

MPW 25

-

6.3

4.0 (200

-

240 V )

1.5

2.5

1.5

2.510MPW25

-107.3 (200

-

240 V )

2.5

4.0

2.5

4.015MPW25

-1510.0 (200

-

240 V)

2.5

4.0

4.0

4.020MPW25

-2015.2 (200

-

240 V)

4.0

4.0

4.0

4.025MPW25

-

25

Page 29

29

CHAPTER 3 -

INSTALLATION AND CONNECTION

NOTE!

Cable dimensions indicated in table 3.3 are reference values only.

Installation conditions and the maximum acceptableline voltage drop

shall be considered when sizing the power cables.

Table 3.4

- Recommended tightening torques for power connections

a) Models 1.6 A, 2.6 A and 4.0 A/200-240 V and 1.6 A and 2.6 A/110-127 V (single-phase)

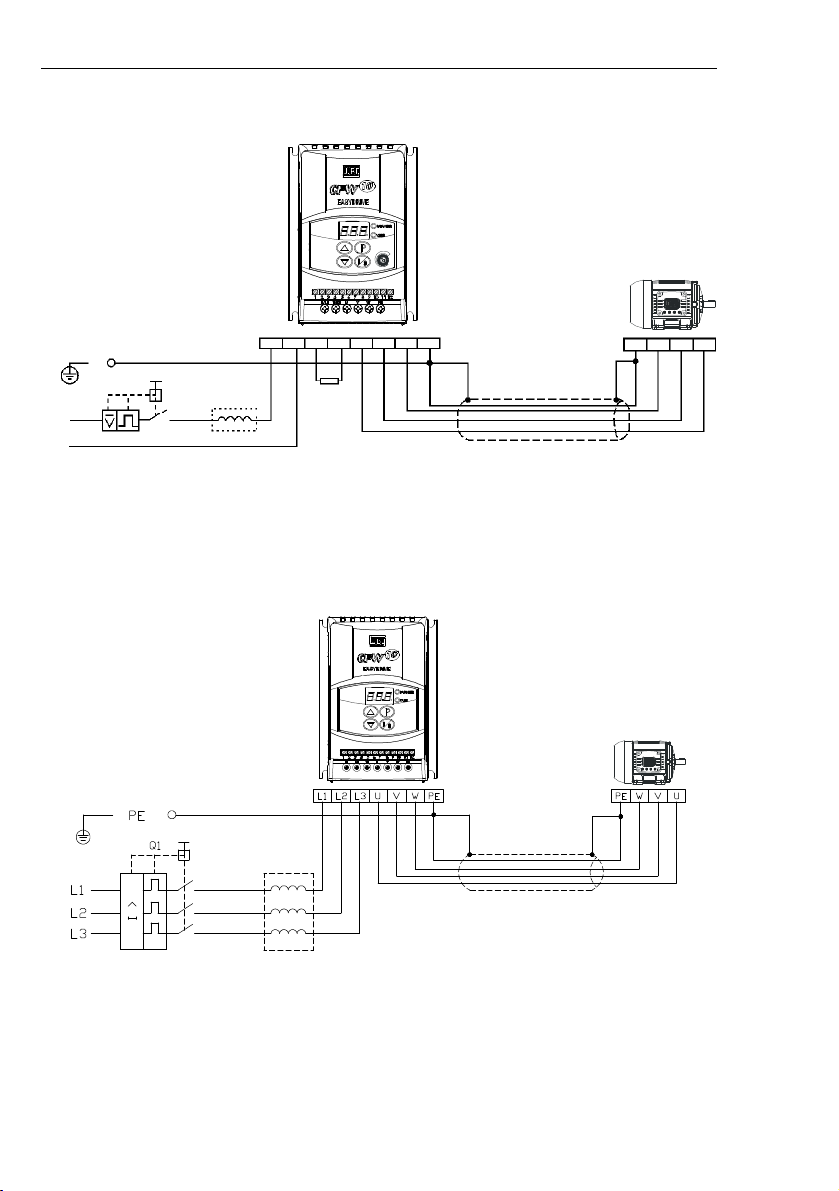

3.2.4

Power Connections

POWER SUPPLY

L/L1

PE

PEUV

W

SHIELDING

Q1

N/L2UVWPE

N/L2

L/L1

Figure 3.6 a)

- Groundingand power supply connections

Power Cables

Model

N.m

Lbf.in

SINGLE

-

PHASE

1.6 A / 200

-

240 V

1.0

8.68

2.6 A / 200

-

240 V

1.0

8.68

4.0 A / 200

-

240 V

1.0

8.68

7.3 A / 200

-

240 V

1.76

15.62

10.0 A / 200

-

240 V

1.76

15.62

1.6 A / 110

-

127 V

1.0

8.68

2.6 A / 110

-

127 V

1.0

8.68

4.0 A /

110-127 V

1.76

15.62

THREE

-

PHASE

1.6 A / 200

-

240 V

1.0

8.68

2.6 A / 200

-

240 V

1.0

8.68

4.0 A / 200

-

240 V

1.0

8.68

7.3 A / 200

-

240 V

1.0

8.68

10.0 A / 200

-

240 V

0.5

4.4

15.2 A / 200

-

240 V

0.5

4.4

Page 30

30

CHAPTER 3 -

INSTALLATION AND CONNECTION

b) Models 7.3 Ato 10 A/200-240 V and 4.0A/110-127 V (single-phase)

POWER SUPPLY

SHIELDING

c) Models 1.6A, 2.6 A, 4.0 A and 7.3A/200-240 V (three-phase)

Figure 3.6 b) c)

- Grounding and power supply connections

POWER SUPPLY

L/L1

PE

PEUV

W

SHIELDING

Q1

N/L2UVWPE

N/L2

L/L1

+UD

BR

Braking

Resistor

Page 31

31

CHAPTER 3 -

INSTALLATION AND CONNECTION

SHIELDING

BRAKING

RESISTOR

Figure 3.6 d)

- Grounding and power supply connections

d) Models 10.0 A and 15.2A/200-240 V (three-phase)

DANGER!

Use a disconnecting device at the driveAC-input power supply. This

device shall be capable of disconnecting the drive from the power

supply when necessary (for maintenance purposes, for instance).

ATTENTION!

The drive AC-input power supply shall have a grounded neutral

conductor.

NOTE!

The AC-input voltage shall matchthe drive rated voltage.

Supply line capacity:

The CFW-10 is capable ofwithstanding up to 30.000 symmetrical

rms Amperes at 127 V/240 V.

If the CFW-10 is installed in networks with higher symmetrical rms

currents (> 30.000 Amps), an appropriate protection mean shall

be provided (fuses or circuit breaker).

Line Reactors

The use of line reactors is dependent upon several factors. Refer to

Chapter 8.2 in order to understand these requirements.

NOTE!

Capacitors for power factor correction are not required at the input

(L/L1, N/L2, L3) and shall not be connected at the output (U, V, W).

3.2.4.1

AC Input

Connection

Page 32

32

CHAPTER 3 -

INSTALLATION AND CONNECTION

Rheostatic Braking

For the drives with the rheostatic braking optional,the brakingresistor

shall be installed externally. Refer to figure 8.4 for correct braking

resistor installation. Size the braking resistor according to the

application and respecting the maximum admissible current for the

braking circuit.

Use twisted pair to connect the braking resistor to the drive. Run this

cable separately from the signal and control cables. If the braking

resistor is installed inside the drive panel, the additional resistor heat

dissipation shall be considered when defining the panel ventilation.

DANGER!

The drive must be grounded for safetypurposes (PE).

The ground connection must comply with the local regulations. For

grounding purposes, use cables with cross sections as indicated in

table 3.3. Make the ground connection to a grounding bar or to the

general grounding point (resistance

10 ohms).

DANGER!

The grounding wiring shall be installedaway fromequipment operating

with high currents (forinstance:high voltage motors, welding machines,

etc).

If several drives are used together,refer to figure 3.7.

3.2.4.3

Grounding

Connections

3.2.4.2

Output

Connection

The drive has electronic protection against motor overload. This

protectionshall be set according to the specific motor. Whenthesame

drive is connected to several motors, individual overload relays shall

be used for each motor protection.

ATTENTION!

If a disconnecting switch or a contactor is inserted between the drive

output andthe motor input,donotoperate them when motor is running

or when driveis enabled. Maintaintheelectrical continuity of the motor

cable shield.

Page 33

33

CHAPTER 3 -

INSTALLATION AND CONNECTION

NOTE!

Do not use the neutral conductor for groundingpurposes.

ATTENTION!

The AC input for the drive supply must have a grounded neutral

conductor.

Electromagnetic Interference

(

EMI)

Shieldedcable or metallic conduitshall be used for motor wiring when

electromagnetic interference (EMI) caused by the drive interferes in

the performance of otherequipment. Connectone endof the shielding

to the drive grounding point and the other end to the motor frame.

Motor Frame

Always ground the motor frame. Ground the motor in the panel where

the drive is installed or ground it to the drive. The drive output wiring

mustbe laid separatelyfrom the input wiring as well as from the control

and signalcables.

Figure 3.7

- Grounding connections for more than one drive

GROUNDINGBAR

Page 34

34

CHAPTER 3 -

INSTALLATION AND CONNECTION

3.2.5

Signal and

Control

Connections

The signal (analog input) and control connections (digital inputs and

relay output) are made on the XC1 connector of control board (see

location in figure 3.5).

Figure 3.8

- Description of the XC1 terminal of the control board

XC1 Terminal

1

DI12DI23DI34DI45GND6AI17GND8AI19+10 V10NC11Common

12NODescription

Factory Default Function

Digital Input 1

General Enable (remote mode)

Digital Input 2

FWD/REV (remotemode)

Digital Input 3

Local/Remote

Digital Input 4

Start/Stop (remote mode)

0 V Reference

Analog Input 1

Freq.Reference

(remotemode)

0 V Reference

Analog Input(voltage)

FrequencyReference (remote)

Potentiometer Reference

Relay NC Contact

No Fault

Relay Output - common point

Relay NO Contact

No Fault

Specifications

4 isolated digital inputs

Minimum High Level: 10 Vdc

Maximum High Level: 30 Vdc

Maximum Low Level: 3 Vdc

Input current: -11 mA @ 0 Vdc

Max. input current: -20 mA

Not interconnected with PE

Current:(0 to 20) mA or (4to 20)mA

Imped

ance:500Resolu

tion:7

bits

Not interconnected with PE

Voltage

: 0 to 10 Vdc

Impedance:100 k

Resolution: 7 bits

Max. input voltage: 30 Vdc

+10 Vdc, ± 5 %, capacity: 2 mA

CW

CCW

5k

Contact capacity:

0.5 A / 250 Vac

1.0 A / 125 Vac

2.0 A / 30 Vdc

(+)

(- )

Relay

10

12

11

NOTE!

If the input current from (4 to 20) mA is used as standard, do not

forget to set the Parameter P235 which defines the signal type at

AI1.

The analog input AI1 and the Relay output, (XC1:6…12) are

not available on Clean version of the CFW-10.

(0 to 20) mA

(4 to 20) mA

Not available on Clean version

Page 35

35

CHAPTER 3 -

INSTALLATION AND CONNECTION

Figure 3.9

- Shield connection

Connect to earth

Do not

ground

Inverter

side

Insulate with

tape

4) For wiring distances longer than 50 m (150 ft), the use of

galvanic isolators is required for the XC1:6to XC1:9 analog signals.

5)

Relays, contactors, solenoids or eletromagnetic braking coils

installed near inverters can eventually generate interferences

in the control circuit. To eliminate this interference, connect RC

suppressor in parallel with the coils of AC relays. Connect

free-wheeling diode in case of DC relays.

6) When analog reference (AI1) is used and the frequency

oscillates (problem caused by electromagnetic interference)

connect XC1:7 to the inverter grounding bar

.

During the signal andcontrol wire installation note the following:

1) Cable cross section: (0.5 to 1.5) mm² / (20 to 14)AWG.

2) Max. Torque:0.50 N.m (4.50lbf.in).

3)

XC1 wiring must be connected with shielded cables and

installed at least 10 cm

(3.9 in)

minimum separately from other

wiring (power, control at 110/220

V, etc)

for

lengths

upto100 m

(330 ft)

and 25 cm

(9.8 in)

minimum for total lengths over

100 m

(330 ft)

.

If the crossing of these cables is unavoida ble, i nstall them

perpendicular, maintainin g a mimim um separation distance

of 5

cm (2

in) at the crossing po int.

Connect the shield as shown below:

Page 36

36

CHAPTER 3 -

INSTALLATION AND CONNECTION

3.2.6

Typical

Terminal

Connections

Connection 1

With the

factory default programming

, it is posible to operate the

inverterin

local mode

with the minimum connectionsshown in figure

3.6 (Power) and without control connections. This operation mode is

recommended for users who are operating the inverter for the first

time as initial learning about equipment. Note that anyconnection is

needed on control terminal.

Forstart-up accordingtothis operationmode, refer to Chapter

5.Connection 2

Command enabling viaterminals.

S1: FWD/REV

S2: Local/Remote

S3: Start/Stop

R1: Potentiometer for

Speed Setting

Figure 3.10

- Wiring for Connection 2

DI1 - No Function (HMI) or

GeneralEnabling (Terminals)

DI2 -FWD/REV

DI3 -Local/Remote

GND

AI1 (0.4 to 20 mA)

GND

AI1 (0 to 10 Vdc)

+10 VNCCommonNODI4 - No Function (HMI) or

Start / Stop (Terminals)

S1

1234567891011

12

5 K

NOTE!

Thefrequencyreference can besentvia AI1 analog input(as shown

in figure above), via keypad HMI-CFW10, or via any other source

(see description of Parameters P221 and P222).

When a line fault occurs by using thistype of connection with switch

S3 at position "RUN", the motor will be enabled automatically as

soon as the line is re-established.

Function 2 configuration is not possible on CFW-10 Clean version.

S2S3Not available on Clean version

Page 37

37

CHAPTER 3 -

INSTALLATION AND CONNECTION

Figure 3.11

- Wiring for Connection 3

NOTE!

S1

andS2are push buttons, NO and NC

conta

ct, respectively.

The speed reference can be realized via Analog Input AI1 (as in

connection 2), via keypad (HMI-CFW10), or via any other source

(See description of parameters P221 and P222).

When a line fault occurs by using this connection with the motor

running and the S1 and S2 switches are in original position (S1

openned and S2 closed), the inverter will not be enabled

automatically as soon as the line is re-restablished.

The drive will be enabled only when S1switch is closed. (Pulse on

the “Start” digital input).

The Start/Stop function is described in Chapter 6.

S1: Start

S2: Stop

S3: FWD/REV

DI1 - Start (Start)

DI2 - Stop (Stop)

DI3 -Local/Remote

GND

AI1 (0.4 to 20 mA)

GND

AI1 (0 to 10 Vdc)

+10 VdcNCCommonNODI4 - Forward/Reverse

S3

S2

1234567891011

12

S1

Connection 3

Start/Stop function enabling (three-wire control):

Set DI1 to Start: P263 = 13

Set DI2 to Stop: P264 = 14

Set P229 = 1 (commands viaterminals) if you want the 3-wire control

in local mode.

Set P230 = 1 (commands viaterminals) if you want the 3-wire control

in remote mode.

FWD / REV Selection:

Program P265 = 5 (DI3) or P266 = 5 (DI4), according to the selected

digital input (DI).

If P265 and P266

0, the direction of rotation is always FWD.

Page 38

38

CHAPTER 3 -

INSTALLATION AND CONNECTION

Connection 4

Enabling of the FWD/REV function:

Set DI1 to Forward Run : P263 = 9

Set DI2 to Reverse Run: P264 = 10

Make sure the inverter commands are via terminals, i.e., set

P229 = 1 to local mode.

NOTE!

The speed reference can be realized via Analog Input AI1 (as in

connection 2), via keypad (HMI), or via any other source (see

description of parameters P221 and P222).

When aline fault occurs in this connection mode with switch S1 or

switch S2 is closed, the motor will be enabled automatically as

soon as the line is re-restablished.

Figure 3.12

- Wiring for Connection 4

DI4 - No Function / Ramp

Enabling

S1 open: Stop

S1 closed: Forward Run

S2 open: Stop

S2 closed: ReverseRun

DI1 - Forward Run

DI2 - Reverse Run

DI3 -Local/Remote

GND

AI1 (0.4 to 20 mA)

GND

AI1 (0 to 10 Vdc)

+10 VdcNCCommon

NO

S2

S1

1234567891011

12

The CFW-10 inverter series was designed considering all safety and

EMC (ElectroMagnetic Compatibility) aspects.

The CFW-10 units do not have an intrinsic function until connected

with other components(e. g. a motor). Therefore, the basic product is

not CE marked for compliance with the EMC Directive. The end user

takes personal responsibility for the EMC compliance of the whole

in stal lation. H owever, when i nsta lled ac co rd ing t o th e

recommendations described in theproduct manual and including the

recommended filters and EMC measures the CFW-10 fulfill all

requirements of the (EMC Directive 89/336/EEC) as defined by the

EN61800-3 "EMC Product Standard for Adjustable Speed

Electrical Power Drive Systems -

specific standard for variable

speed drives.

The conformity of the complete CFW-10 series is based on tests

performed on sample models. ATechnical Construction File (TCF)

was prepared, checked and approved by a Competent Body.

3.3

European EMC

Directive -

Requirements

for Conforming

Installations

Page 39

39

CHAPTER 3 -

INSTALLATION AND CONNECTION

Figure 3.13 below shows the EMC filters connection.

3.3.1

Installation

Figure 3.13

- EMC filter connection - general condition

The following items are required in order to have an appropriated

installation:

1)

The motor cable shall be armored, or installed inside a metallic

conduitor trunking with equivalent attenuation.Ground the screen/

metallic conduit at both ends (inverter and motor).

2)

Control (I/O) and signal wiring shall be shielded or installed inside

a metallic conduitortrunking with equivalentattenuation.as possible.

3)

The inverter and the external filter shall be closely mounted on a

common metallic back plate. Ensure a good electrical connection

between the inverter heatsink, the filter frame and the back plate.

4)

The wiring betweenthe filter and the inverter shall be kept as short.

5)

The cable shield (motor and control) shall be solidly connected to

the common back plate, using metallic brackets.

6)

Grounding shall be performedasrecommended in this user’sguide.

7)

Use short and thick cables to ground the external filter or inverter.

When an external filter is used, ground only the filter (input) - the

inverter ground connection is performed through the metallic back

plate.

8)

Ground the back plate using a braid, as short as possible. Flat

conductors(e.g.braids or brackets) have lower impedance at high

frequencies.

9)

Use cable glands whenever possible.

Transformer

Grounding rod

Protective Grounding

Motor

PE

CFW-10

L2/N

L1/LPEPE

XC1

1 to 12

U

Controling and signal wiring

VWPE

L1/L

L2/NL2L1PEExternal

input RFI

filter

Metalic cabinet when necessary

Page 40

40

CHAPTER 3 -

INSTALLATION AND CONNECTION

EMC phenomenon

Emission:

Conducted emissions (mains

terminal disturbance voltage - freq

band 150 kHz to 30 MHz)

Radiated emissions (electromagnetic

radiation disturba nce - freq band

30 MHz to 1000 MHz)

Immunity:

Electrostatic discharge (ESD)

Fast Transient-Burst

Conducted radio-frequency

common mode

Surge

Radio-frequency electromagnetic field

Basic standard

for test method

IEC/EN61800-3

IEC 61000-4-2

IEC 61000-4-4

IEC 61000-4-6

IEC 61000-4-5

IEC 61000-4-3

Level

“First environment”

(1)

, restricted distribution

(3)

Class B, or;

“First environment”

(1)

, restricted distribution

(4) (5)

Class A1, or;

“Second environment”

(2)

, unrestricted distribution

(3)(6)

Classe A2

Note:

It depends on the drive model and on the motor

cable length (Refer to table 3.5.2).

“First environment”

(1)

, restricted distribution

(4) (5)

6 kV contact discharge

4 kV/2.5 k Hz (capacitive clamp) input cable; 2 kV/

5 kHz control cables; 2 kV/5 kHz (capacitive

clamp) motor cable;

0.15 to 80 MHz; 10 V;

80

% AM (1

kHz) - motor

control and remoteKeypad cable

HMI Remote

1.2/50s, 8/20

s;1 kV coupling line to line;

2 kV coupling line to earth

80 to 1000 MHz; 10 V/m; 80 % AM (1 kHz)

3.3.2

Specification of the

Emissionand Immunity

Levels

Notes:

(1)

"First environment": environment that includes domestic

premises. It also includes establishments directly connected

without intermediate transformers to a low-voltage powersupply

network which supplies buildings used for domestic purposes.

(2)

"Secondenvironment": environment thatincludesall establishments

other than thosedirectlyconnected to alow-voltage power supply

network which supplies buildings used forindustrial purposes.

(3)

Unrestricteddistribution:mode of sales distribution in which the

supply of equipment is not dependenton the EMC competence

of the customer or user forthe application of drives.

(4)

Restricted distribution: mode of sales distribution in which the

manufacturer restricts the supply of equipment to suppliers,

customers or users who separately or jointly have technical

competenceinthe EMC requirements of the application of drives.

(source: these definitions were extracted from the product

standard IEC/EN61800-3 (1996) + A11 (2000))

Page 41

41

CHAPTER 3 -

INSTALLATION AND CONNECTION

3.3.3

Inverterand

Filters

Table 3.5.2 shows the inverter models, its respective EMC filter and

the EMC category classification. Refer to section 3.3.2 for EMC

category description and to secti on 3.3.4 for external filters

characteristics.

Table 3.5.1

-

List of frequency drive models, EMC filters and EMC categories

(5)

For installation in residential environments with conducted

emission level Class A1 (according to table 3.5.2), please,

consider the following:

This is a product of restricted sales distribution class according

to the product standard IEC/EN61800-3 (1996) +A11 (2000). In

a domestic envi ronment this product may cause radio

interference in which case the user may be required to take

adequate measures.

(6)

When installingdrivesthat meet ClassA2 for conducted emission

level, i.e. industrial environment and unrestricted distribution

(according to table 3.5.2), observe the following:

This product is specifically designed for use in industrial low-

voltage power supply networks (public networks) that not supply

residential buildings. This product may cause radio frequency

interference in a domestic environment.

Inverter Model with

Built-in EMC Filter

(single

-

phase)

EMC Class

1.6

A / 200

-

240

V

2.6

A / 200

-

240

V

4.0

A /

200-240V7.3

A / 200

-

240V10.0

A / 200

-

240

V

Class A1.

Maximum motor cable length

7

meters

(22.9 ft)

.

Class A2.

Maximum motor cable length

50

meter

s (164 ft)

.

Switching frequency

5kHz.

Page 42

42

CHAPTER 3 -

INSTALLATION AND CONNECTION

Note:

Maximum switching frequency is 5 kHz.

Table 3.5.2

- List of frequency drive models, EMC filters and EMC categories

NOTE!

The CFW -10 inverters with three-phase supply do not have EMC

filters.

Inverter Model

(single

-

phase)

Input RFI

Filter

EMC Class

1.6

A / 200

-

240V2.6

A / 200

-

240V4.0

A / 200

-

240V1.6

A / 110

-

127V2.6

A / 110

-

127VFootprint / Booksize

Model:

B84142A0012R212

(EPCOS)

Standard

Model:

B84142

-

A20-R

(EPCOS)

Class A1.

Maximum motor cable length is

30 meters

(98.4 ft)

.

Class A2.

Maximum motor cable

length is

50 meters

(164 ft)

.

Class B.

Maximum motor cable length is

5 meters

(16.4 ft)

.

7.3

A / 200

-

240

V

4.0

A / 110

-

127VF

ootprint

/Booksize

Model

:

B84142B18R212

(EPCOS)

Class A1.

Maxi

mum motor cable length is

30 meters

(98.4 ft)

.

Class A2.

Maximum motor cable length is

50 meters

(164 ft)

.

Class B.

Maximum motor cable length is

5 meters

(16.4 ft)

.

7.3

A / 200

-

240V4.0

A / 110

-

127V(EPCOS)

Standard

Model:

B84142

-

A20-R

(EPCOS)

Class

A1.

Maximum motor cable length is

25 meters

(82 ft)

.

Class A2.

Maximum motor cable length is

40 meters

(131.2 ft)

.

Class B.

Maximum motor cable length is

5 meters

(16.4 ft)

.

10.0

A / 200

-

240VF

ootprint

/ B

ooksize

Model:

B84142B22R21

2

(EPCOS)

Class A1.

Maximum motor cable length is

30 meters

(98.4 ft)

.

Class A2.

Maximum motor cable length is

40 meters

(131.2 ft)

.

Class B.

Maximum motor cable length is

5 meters

(16.4 ft)

.

10.0

A / 200

-

240VStandard

Model

:

B84142

-

A30-R

(EPCOS)

Class A

1.

Maximum motor cable length is

30 meters

(98.4 ft)

.

Class A2.

Maximum motor cable length is

50 meters

(164 ft).

Class B.

Maximum motor cable length is

3 meters

(9.8 ft)

.

Page 43

43

CHAPTER 3 -

INSTALLATION AND CONNECTION

3.3.4

Characteristics of the EMC Filters

Footprint / Booksize Model B84142A0012R212 (EPCOS)

Supply voltage: 250 V, 50/60 Hz

Current: 12 A

Weight: 0.95 Kg (2.1 lb)

a) Model footprint/booksize B84142A0012R212 (EPCOS)

Figure 3.14 a)

- Drawing of the footprint / bookside filter

Terminals 2.5 mm

2

Tightening torque of screw

max. 0.5 Nm

3 x litzwire 2.5 mm

2

3 x wire and sleeve DIN 46228-A2, 5-10

105505 x 45 º

175

ø

1

1

5.5

149.8±0.2

162±0.3

5.5

85±0.2

80±0.2

5.5

33.5

7.5

4 x M4 x 7

170 x 5

PE M5 x 12

25

25

Note:

Figure dimensions are in mm.

Page 44

44

CHAPTER 3 -

INSTALLATION AND CONNECTION

Figure 3.14 b)

- Drawing of the footprint / booksize filter

Footprint / booksize Model B84142B18R212 (EPCOS)

Supply Voltage: 250 V, 50/60 Hz

Current: 18 A

Weight: 1.3 kg (2.9 lb)

b) Footprint/booksize model B84142B18R212 (EPCOS)

Terminals 2.5 mm

2

Tightgning torque of screw

max. 0.5 Nm

3 x litzwire 2.5 mm

2

3 x wire and sleeve DIN 46228-A2, 5-10

125505 x 45 º

204

ø

1

1

5.5

149±0.2

191±0.3

5.5

105±0.2

100±0.2

5.5

37.5

7.5

4 x M4 x 7

170 x 5

PE M5 x 12

25

25

Note:

Figure dimensions are in mm.

Page 45

45

CHAPTER 3 -

INSTALLATION AND CONNECTION

Figure 3.14 c)

- Drawing of the footprint / booksize filter

Footprint / booksize Model B84142B22R212 (EPCOS)

Supply voltage: 250 V, 50/60 Hz

Current: 22 A

Weight: 1.4 kg (3 lb)

c) Footprint/booksize Model B84142B22R212 (EPCOS)

Terminals 6 mm

2

Tightgning torque of screw

max. 1.2 Nm

3 x litzwire 4 mm

2

3 x wire and sleeve DIN

46228-A2,5-10

125505 x 45 º

234

ø

1

1

5.5

179±0.2

221±0.3

5.5

105±0.2

100±0.2

5.5

37.5

7.5

4 x M4 x 7

170 x 5

PE M5 x 12

25

25

Note:

Figure dimensions are in mm.

Page 46

46

CHAPTER 3 -

INSTALLATION AND CONNECTION

Standard Model: B84142 -A20-R

Supply voltage: 250 V, 50/60 Hz

Current: 20 A

Weight: 1 kg (2.2 lb)

Figure 3.15 a) b)

- Drawing of the Standard Filter

a) Standard Model:B84142-A20-R (EPCOS)

Standard Model: B84142 -A30-R

Supply voltage: 250 V, 50/60 Hz

Current: 30 A

Weight: 1 kg (2.2 lb)

b) Standard Model:B84142-A30-R (EPCOS)

Terminals 6 mm²

50.8±0.3

6.3

0.8±0.1

40±1

112084

Terminals

6 mm²

40±1

24±1

PE M5 x 20

99

130

4.3±0.1

105

95.2

24±1

16±1

68

Terminals 4 mm²

50.8±0.3

6.3

20

11

0.8±0.1

35±1

4.3±0.1

105

95.2

16±1

24±168±184Terminals

4 mm²

24±1

35±1

PE M5 x 20

121±1

99±1±1

±1

Note:

Figure dimensions are in mm.

Note:

Figure dimensions are in mm.

NOTE!

The declaration of conformity CE is available on the website

www.weg.net or on the CD, which comes with the products.

Page 47

47

CHAPTER 4

KEYPAD(HMI) OPERATION

This chapter describes the CFW-10 operation via Human-Machine

Interface (HMI), providing the following information:

General keypad description (HMI);

Use of the keypad (HMI);

Inverter parameters arrangement;

Alteration mode parameters (programming);

Description ofthe status indicators.

4.1

KEYPAD (HMI)

DESCRIPTION

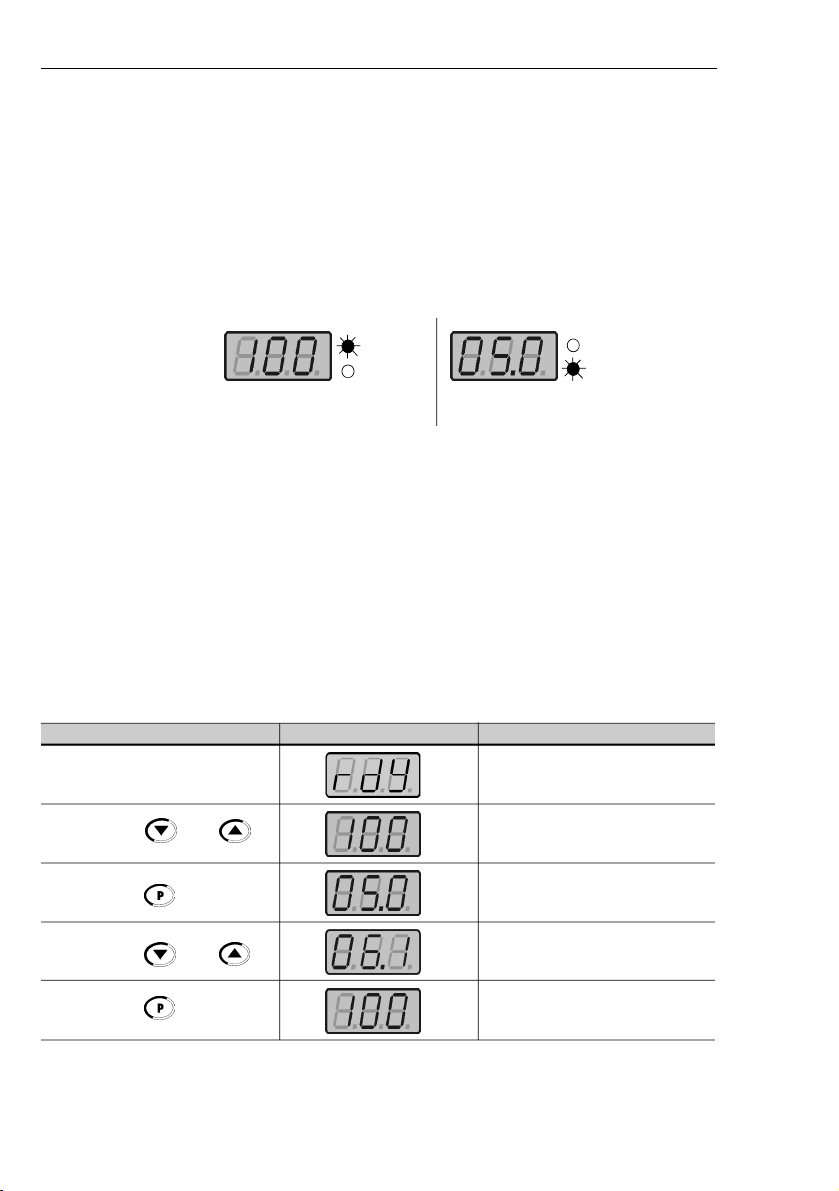

The standard CFW-10 keypad has a LED display with 3 digits of 7

segments, 2 status LEDs and 4 keys. Figure 4.1 shows the front

view of the keypad and indicates the position of the Display and the

status LEDs. CFW-10Plus versionstill has a potentiometer for speed

setting.

Functions of the LED Display:

The Led Display shows the fault and status messages (see Quick

Parameter Reference, Fault and Status), the parameter number and

its value.

Functions of the LED´s “Parameter” and “Value”:

Inverterindicatesthe parameter number:

Green Led OFF and red Led ON.

Inverterindicatesthe parameter content:

Green Led ON and red Led OFF.

Potentiometer Function

Increase/Decrease the speed (only available on Plus version)

LED Display

LED "Parameter"

LED "Value"

Potentiometer (Only

available on Plus version)

Figure 4.1

- CFW-10 keypad (HMI)

Page 48

48

CHAPTER 4 - KEYPAD (HMI) OPERATION

The Keypad (HMI) is a simple interface that allows inverter operation/

programming.This interface has the following functions:

Indication of the inverter status and operation variables;

Fault indication and diagnostics;

Viewing and programming parameters;

Inverter operation (key ) and

speed reference setting (keys and );

Potentiometer for the output frequencyvariation (only in the Plus

version).

4.2

USE OF THE

KEYPAD

(HMI)

Basic Functions of the Keys:

Enables/disables the invertervia acceleration/deceleration ramp (run/

stop). Resets the inverter after a fault trip.

Selec

ts (commutates) the display between parametyernumber/value

(position/content).

Increasesthefrequency, theparameternumberorthe parametervalue.

Decreases the frequency, the parameter number or the parameter

value.

4.2.1

Keypad (HMI)

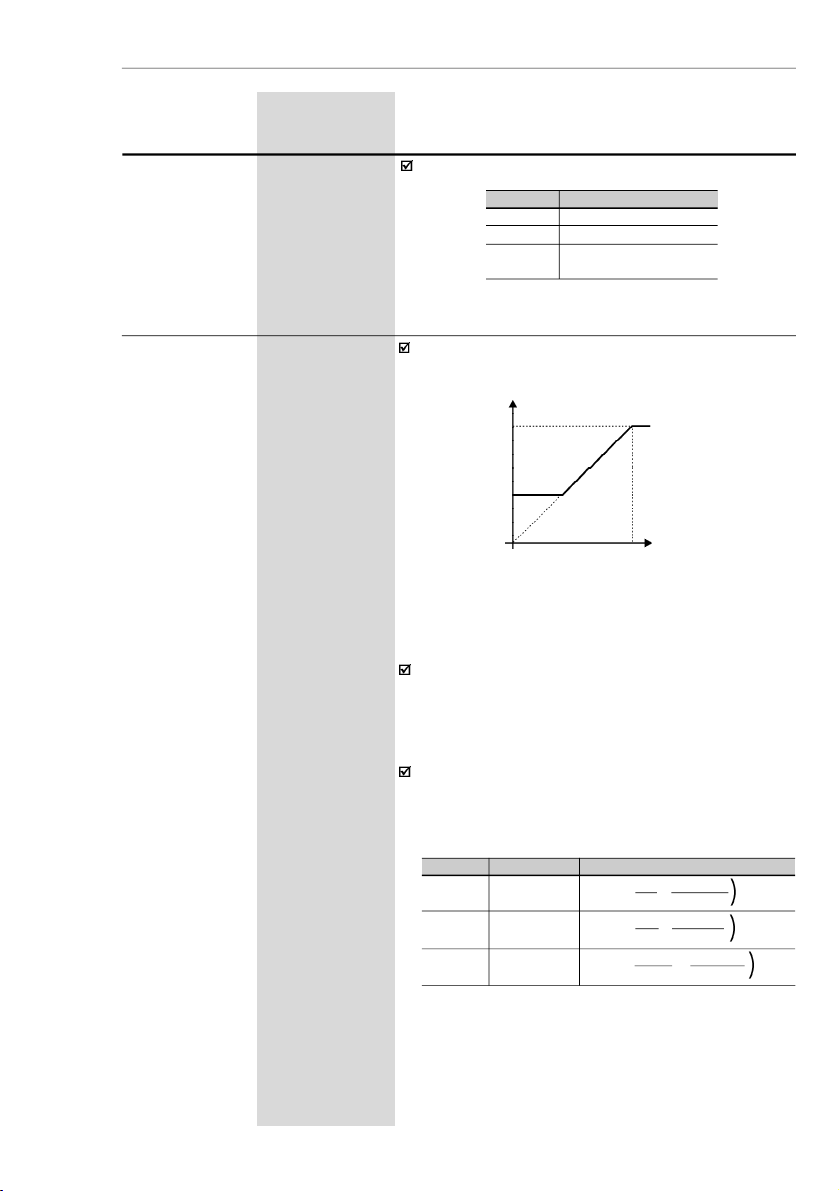

Operation