Page 1

Frequency Inverter

Convertidor de Frecuencia

Inversor de Freqüência

Frequenzumrichter

Variateur de Vitesse

Преодразователь частоты

Frequentie Regelaar

Frekvensomvandlare

CFW-08

User's Guide

Manual del Usuario

Manual do Usuário

Bedienungsanleitung

Manuel d'utilisation

Руководство пользователя

Gebruikers Handleiding

Användarinstruktioner

Motors | Energy | Automation | Coatings

Page 2

03/2009

FREQUENCY

INVERTER

MANUAL

ATTENTION!

It is very important to check if the

inverter software version is the

same as indicated above.

Series:

CFW-08

Software:

vers

ion5.2

X

Language

:

English

Document

:

0899.5242 / 09

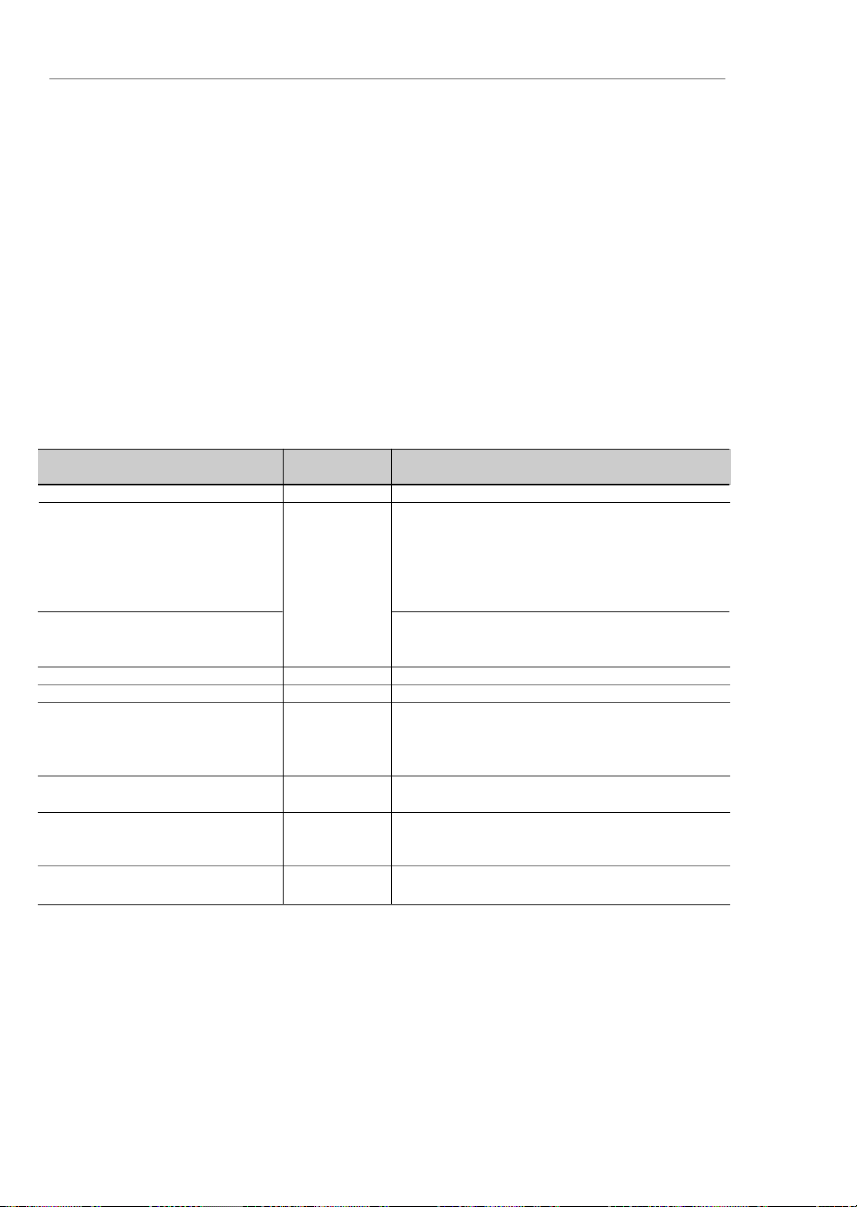

Page 3

2

Summary of Revisions

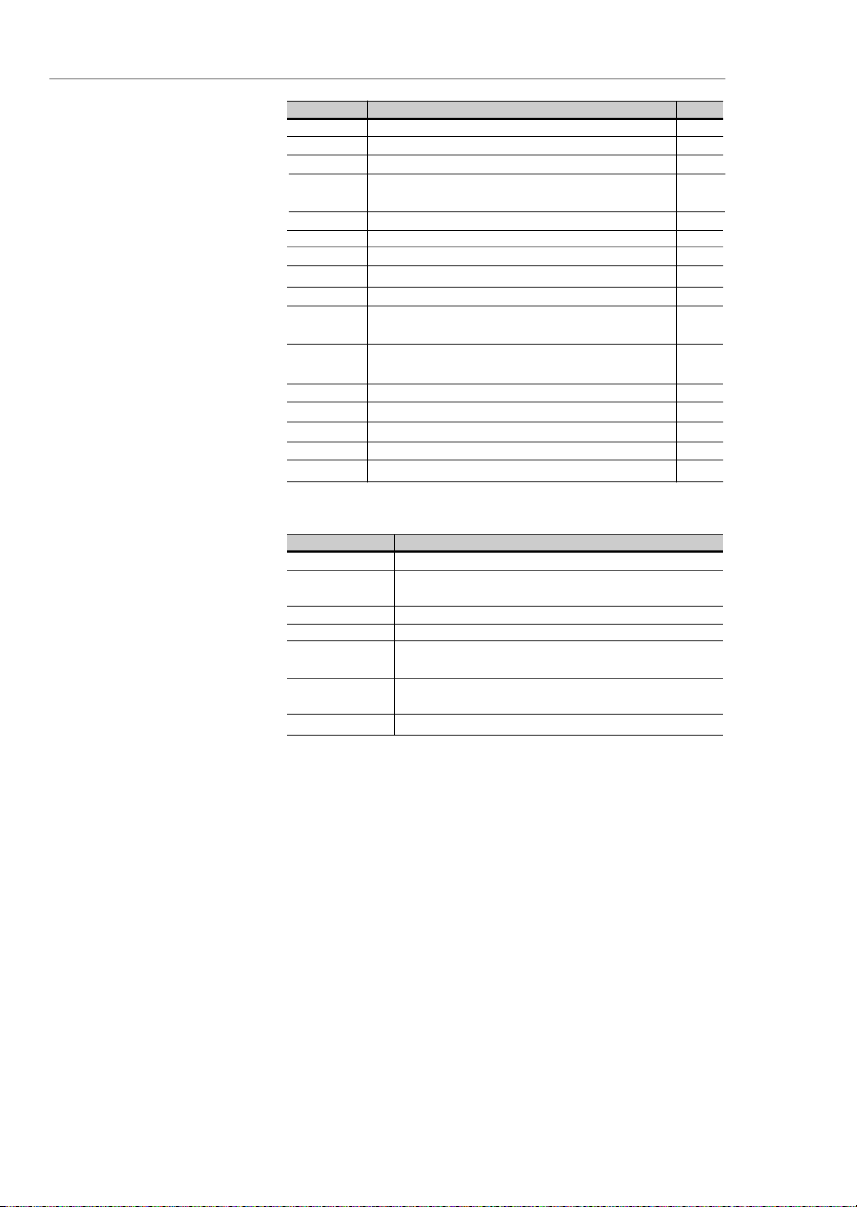

Thetablebelowdescribesallrevisionsmade tothismanual.

Revision

Description

Section

1

First Edition

-2Inclusionof the item 3.3 - European

Refer to item 3.3

EMCDirective -Requirements for

ConformingInstallations

3

GeneralRevision

-4External Parallel Keypadand

Refer to item 8.3

Fix Kit included and

and8.18

GeneralRevision

5

Descriptionchanged of the

Refer to item 8.5

ParallelCable

for the External Parallel Keypad

Item7.5 (SparePart List) removed

ParameterP536 included

Refer to item 6.3.5

andGeneralRevision

6

GeneralRevision

-7Inclusionof new models (22 A, 28 Aand

Refer to item 9.1

33A/200-240 V; 24A and 30 A/380-480V)

Addition of new I/O functions

Refer to item 3.2.5

on the control board

Modificationof circuit breakers table

Refer to item 3.2.3

Modificationof chapter 3

(installationand connections)

Modificationofparameters

Refer to item 4.2.4

incompatibility table

Additionof parameters P253,

Refer to item 6.3

P267and P268

Addition of new functions at parameters

P235, P239, P295and P404

Modificationof factorydefault

Refer to item 6.3.3

valueofparameterP248

Addition of error code E32

Refer to item 7.1

8

GeneralRevision

Inclusion of items into the table of

Refer to item 4.2.4

parametersincompatibility

Changeon the WEG part number

Referto chapter 8

ofthe optional devices

Inclusionof the table containing the

Refer to item 3.1.3.1

airflowrequirementsforpanel mounting

Inclusionof the following optionals:

Referto chapter 8

KRS-485-CFW08,KFB-CO-CFW08,

KFB-DN-CFW08and KAC-120-CFW08

Inclusionof the new versions

Refer to item 2.4

of the control board:A3 and A4

9

TheSleep function wasadded

Referto chapter 6

(parametersP212, P213and P535)

TheAnalogInputDead Zonefunction

wasadded (P233)

TheKDC-24VR-CFW08and

Refer to items 8.9

KDC-24V-CFW08optionmodules

and8.10

wereadded

NewEMC filters wereadded

Refer to item 3.3.4

Noteson the CFW-08 Nema 4X

Referto chapter 2.4

and the 575 V lines were added

Modificationof the gainequation

for the analog inputs

Generalrevision

-

Page 4

Summary

QuickParameterReference,

Fault and Status Messages

I Parameters

....................................................................

8

II FaultMessages

...........................................................

16

IIIOtherMessages

...........................................................

16

CHAPTER 1

Safety Notices

1.1SafetyNotices in the Manual

.....................................

17

1.2SafetyNotices on theProduct

...................................

17

1.3PreliminaryRecommendations

.................................

17

CHAPTER 2

General Information

2.1AboutthisManual

......................................................

19

2.2Software Version

.......................................................

19

2.3About the CFW-08

....................................................

20

2.4CFW-08Identification

...............................................

24

2.5ReceivingandStoring

...............................................

27

CHAPTER 3

Installation and Connection

3.1MechanicalInstallation

..............................................

28

3.1.1Environment

........................................................

28

3.1.2Mounting Specifications

......................................

28

3.1.3

Positioningand Fixing

........................................

31

3.1.3.1PanelMounting

..........................................

32

3.1.3.2SurfaceMounting

.......................................

33

3.2

ElectricalInstallation

.................................................

33

3.2.1Power/GroundingTerminals

..............................

33

3.2.2

Locationof the PowerTerminals,Grounding

TerminalsandControlTerminalConnections

......353.2.3

Power/GroundingWiringand CircuitBreakers

..363.2.4Power Connections

............................................

37

3.2.4.1

ACInput Connection

................................

39

3.2.4.2

OutputConnections

..................................

40

3.2.4.3

GroundingConnections

............................

40

3.2.5

Signaland Control

Connections

.........................

42

3.2.5.1

DigitalInputsas LowLevelActive

(S1:1 to OFF)

...........................................

46

3.2.5.2

DigitalInput as High LevelActive

(S1:1to ON)

.............................................

47

3.2.6TypicalTerminalConnections

.............................

48

3.3

EuropeanEMCDirective-Requirements

forConformingInstallations

......................................

51

3.3.1Installation

...........................................................

51

Page 5

Summary

3.3.2Emission and Immunity LevelsDescription

........

52

3.3.3InverterModels and Filters

..................................

54

3.3.4 EMC FiltersCharacteristics

...............................

57

CHAPTER 4

Keypad (HMI) Operation

4.1Keypad(HMI)Description

.........................................

67

4.2Useof the Keypad(HMI)

...........................................

68

4.2.1KeypadOperation

..............................................

69

4.2.2InverterStatus

.....................................................

70

4.2.3Read-OnlyParameters

.......................................

71

4.2.4Parameter Viewing and Programming

...............

71

CHAPTER 5

Start-up

5.1 Pre-Power Checks

....................................................

74

5.2Initial Power-up

..........................................................

74

5.3Start-up

......................................................................

75

5.3.1

Start-upOperationvia Keypad(HMI)-

Type of Control:LinearV/F (P202 = 0)

...............

76

5.3.2

Start-upOperation viaTerminals-

Control Mode: Linear V/F (P202 = 0)

.................

77

5.3.3

Start-upOperation via Keypad -

Control Mode: Vector(P202 = 2)

........................

78

CHAPTER 6

DetailedParameter Description

6.1Symbols...

.................................................................

83

6.2Introduction

................................................................

83

6.2.1Control Modes (V/F and Vector)

.........................

83

6.2.2V/F Control

.........................................................

83

6.2.3VectorControl (VVC)

..........................................

84

6.2.4FrequencyReferenceSources

...........................

85

6.2.5

Commands

.........................................................

88

6.2.6Local/RemoteOperationModes

........................

88

6.3Parameter Listing

......................................................

89

6.3.1

AccessandRead-onlyParameters-

P000 to P099

.....................................................

90

6.3.2Regulation Parameters- P100 to P199

.............

92

6.3.3 Configuration Parameters- P200 to P398

.......

102

6.3.4 Motor Parameters - P399 to P499

...................

128

6.3.5 Special Function Parameters - P500 to P599

..

131

6.3.5.1Introduction

..............................................

131

6.3.5.2Description

..............................................

131

6.3.5.3PID Start-upGuide

...................................

134

Page 6

Summary

CHAPTER 7

Diagnosticsand Troubleshooting

7.1Faults and PossibleCauses

...................................

141

7.2Troubleshooting

.......................................................

144

7.3ContactingWEG

.....................................................

145

7.4PreventiveMaintenance

..........................................

145

7.4.1CleaningInstructions

.........................................

146

CHAPTER 8

CFW-08Options andAccessories

8.1HMI-CFW08-P

........................................................

149

8.1.1InstructionsforInsertionand Removingof

theHMI-CFW08-P

............................................

149

8.2TCL-CFW08

...........................................................

149

8.3HMI-CFW08-RP

......................................................

150

8.3.1HMI-CFW08-RPInstallation

..............................

150

8.4MIP-CFW08-RP

......................................................

151

8.5 CAB-RP-1, CAB-RP-2, CAB-RP-3, CAB-RP-5,

CAB-RP-7.5, CAB-RP-10

......................................

151

8.6HMI-CFW08-RS

......................................................

151

8.6.1HMI-CFW08-RSInstallation

..............................

152

8.6.2HMI-CFW08-RSStart-up

..................................

152

8.6.3KeypadCopyFunction

.....................................

153

8.7MIS-CFW08-RS

......................................................

153

8.8 CAB-RS-1, CAB-RS-2, CAB-RS-3, CAB-RS-5,

CAB-RS-7.5, CAB-RS-10

......................................

153

8.9 KDC-24VR-CFW08

................................................

154

8.10 KDC-24V-CFW08

.................................................

155

8.11KCS-CFW08

.........................................................

156

8.11.1

InstructionsforKCS-CFW08

InsertionandRemoval

.....................................

157

8.12 KSD-CFW08

........................................................

157

8.13KRS-485-CFW08

.................................................

158

8.14 KFB-CO-CFW08

..................................................

159

8.15 KFB-DN-CFW08

..................................................

160

8.16 KAC-120-CFW08, KAC-120-CFW08-N1M1

KAC-120-CFW08-N1M2

......................................

162

8.17 KMD-CFW08-M1

..................................................

163

8.18KFIX-CFW08-M1, KFIX-CFW08-M2

....................

164

8.19KN1-CFW08-M1, KN1-CFW08-M2

......................

165

8.20RFI Filter

...............................................................

166

8.21Line Reactor

..........................................................

167

8.21.1Application Criteria

.......................................

167

8.22 Load Reactor

........................................................

170

8.23Dynamic Braking

...................................................

171

8.23.1ResistorSizing

..............................................

171

8.23.2Installation

.....................................................

172

8.24SerialCommunication

...........................................

173

Page 7

Summary

8.24.1Introduction

....................................................

173

8.24.2RS-485andRS-232InterfacesDescription

.

174

8.24.2.1RS-485

..............................................

175

8.24.2.2RS-232

..............................................

176

8.24.3Definitions

.....................................................

176

8.24.3.1Used Terms

.......................................

176

8.24.3.2Parameter/Variables Resolution

........

177

8.24.3.3Character Format

..............................

177

8.24.3.4Protocol

.............................................

177

8.24.3.5Execution and MessageTest

.............

180

8.24.3.6MessageSequence

..........................

180

8.24.3.7 Variable Code

...................................

180

8.24.4Message Examples

......................................

181

8.24.5 Variablesand Errors of the Serial

Communication

............................................

181

8.24.5.1 Basic Variables

.................................

181

8.24.5.2 Message Examples with Basic

Variables

............................................

184

8.24.5.3ParametersRelatedtotheSerial

Communication

...................................

185

8.24.5.4ErrorsRelated to the Serial

Communication

.................................

186

8.24.6TimeforRead/Write of Messages

................

186

8.24.7Physical Connection RS-232andRS-485

....

187

8.25Modbus-RTU

.........................................................

188

8.25.1IntroductiontoModbus-RTUProtocol

...........

188

8.25.1.1Transmission Modes

.........................

188

8.25.1.2Message StructureinRTU Mode

......

188

8.25.2Operation oftheCFW-08inthe

Modbus-RTUNetwork

..................................

191

8.25.2.1RS-232 and RS-485 Interface

Description

.......................................

191

8.25.2.2 InverterConfigurationinthe

Modbus-RTU Network

.....................

191

8.25.2.3AccesstotheInverterData

...............

192

8.25.3Detailed Function Description

......................

195

8.25.3.1Function 01 - Read Coils

..................

195

8.25.3.2Function 03-Read Holding Register

196

8.25.3.3Function 05 - WriteSingle Coil

.........

197

8.25.3.4Function 06-Write SingleRegister

..

198

8.25.3.5Function 15 -Write Multiple Coils

......

198

8.25.3.6Function 16 - WriteMultipleRegisters

199

8.25.3.7Function 43 - Read Device

Identification

.....................................

200

8.25.4Modbus-RTUCommunicationErrors

............

202

8.25.4.1 Error Messages

...............................

203

Page 8

Summary

CHAPTER 9

TechnicalSpecifications

9.1

Power Data

..............................................................

204

9.1.1 200-240 V Power Supply

..................................

204

9.1.2 380-480 V Power Supply

..................................

205

9.2Electronics/GeneralData

........................................

208

9.3WEG Standard IV-PoleMotorData

.........................

2098CFW-08 - QUICK PARAMETER REFERENCE

Page 9

Software: V5.2X

Application:

Model:

SerialNumber:

Responsible:

Date: / / .

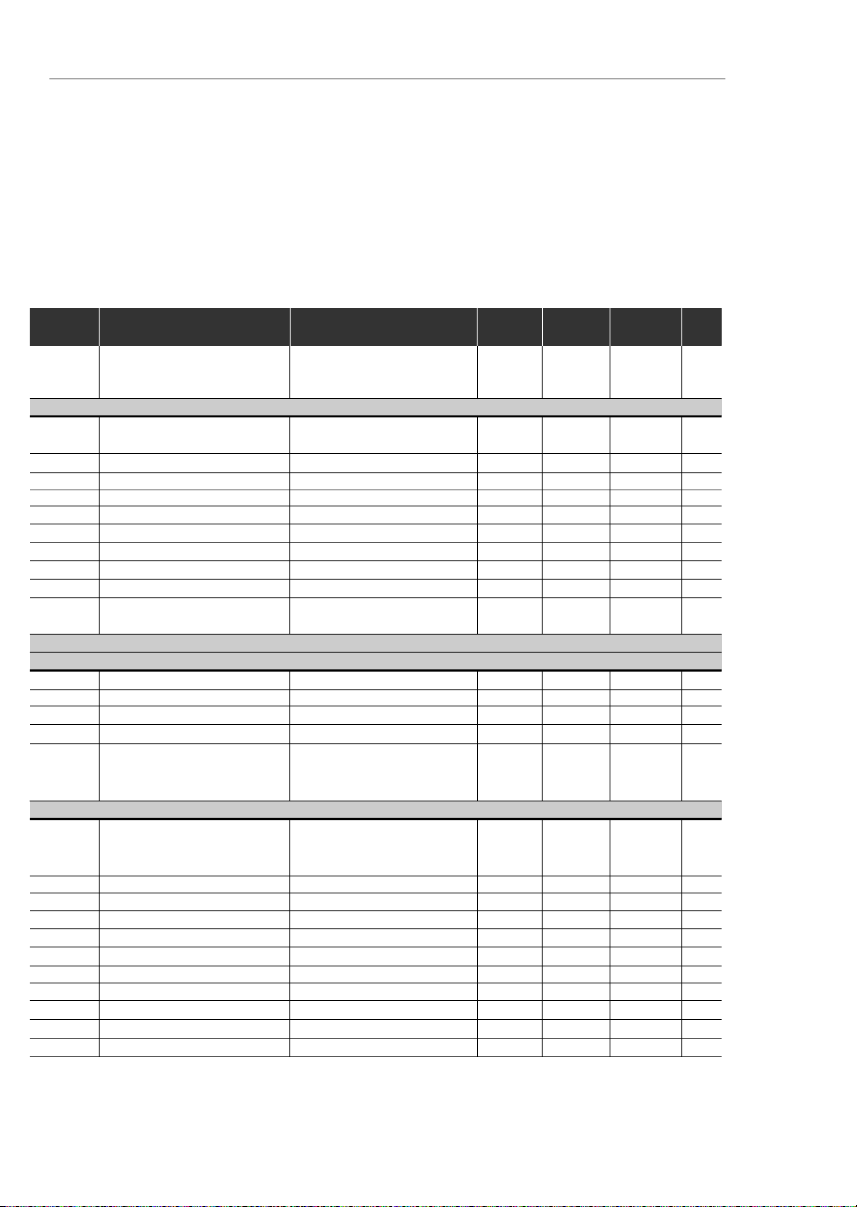

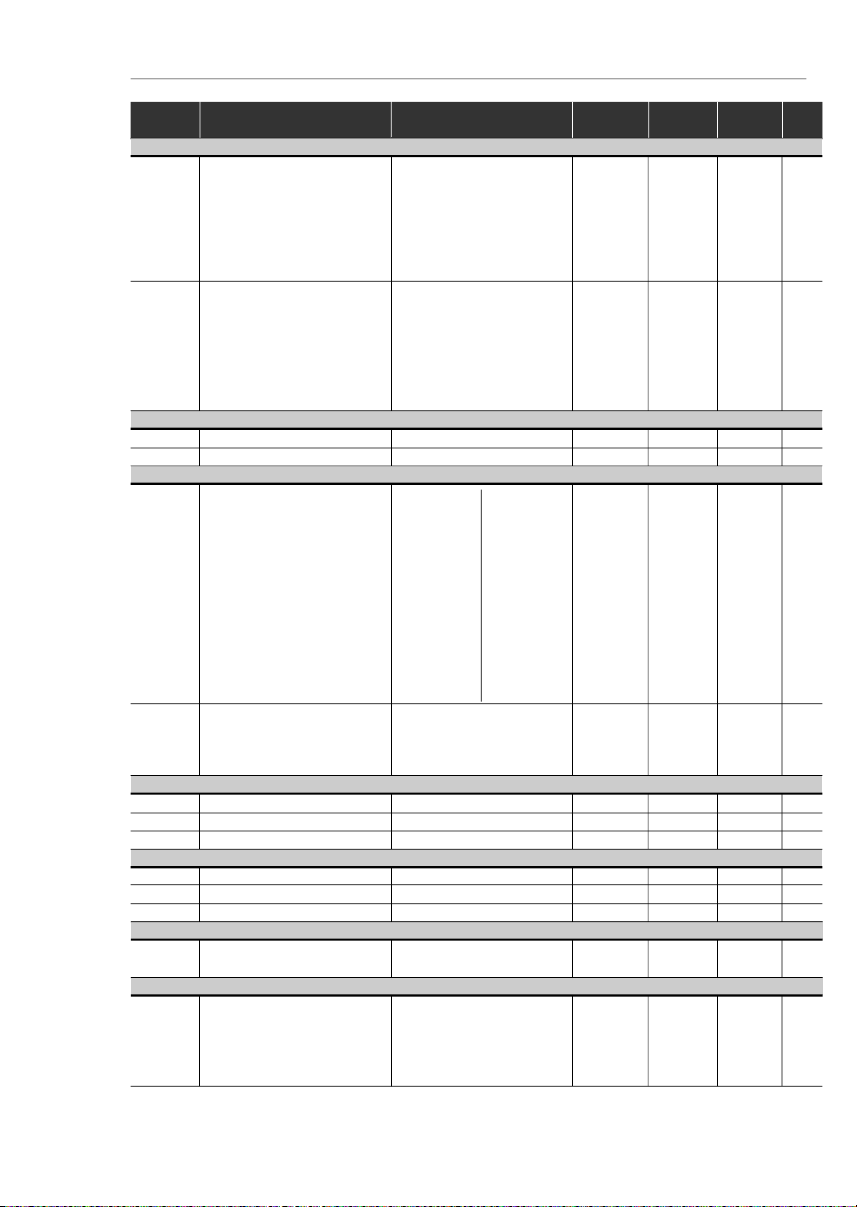

I.Parameters

QUICK PARAMETER REFERENCE, FAULT AND STATUS MESSAGES

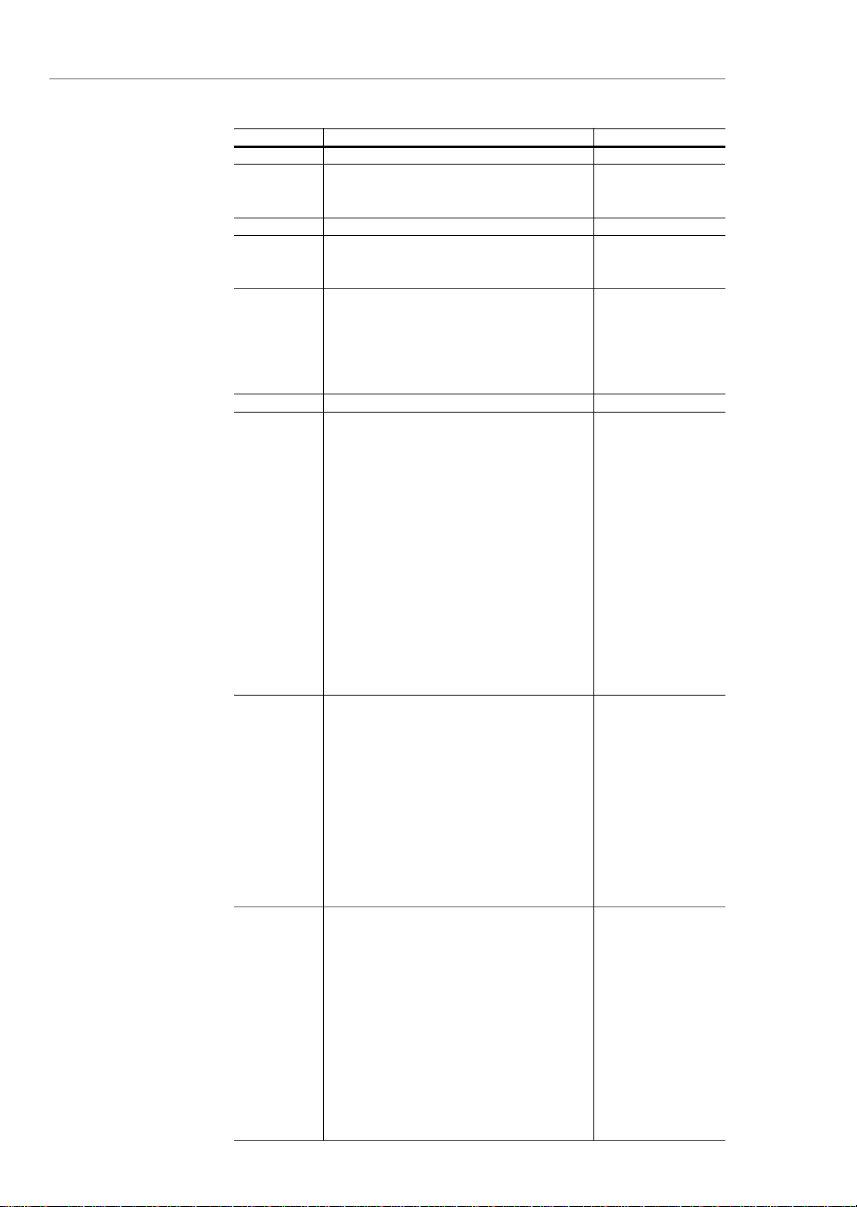

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

P000

ParameterAccess

0 to 4 = Read

0-90

5 = Alteration

6 to 999 = Read

READONL

YPARAMETERS-

P002to P099

P002

FrequencyProportionalValue

0 to 6553

--90

(P208xP005)

P003

MotorOutput Current

0 to 1.5xI

nom

-A90

P004

DCLink Voltage

0 to 862

-V90

P005

Motor Output Frequency

0.00 to 300.0

-Hz90

P007

MotorOutput Voltage

0 to 600

-V90

P008

HeatsinkTemperature

25 to 110

-°C91

P009

(1)

MotorTorque

0.0 to 150.0

-%91

P014

Last Fault

00 to 41

--91

P023

SoftwareVersion

x . y z--

91

P040

PID Process Variable

0 to 6553

--91

(Value% x P528)

REGULA

TIONPARAMETERS -

P100 to P199

Ramps

P100

AccelerationTime

0.1 to 999

5.0s92

P101

DecelerationTime

0.1 to 999

10.0s92

P102

Ramp 2 AccelerationTime

0.1 to 999

5.0s92

P103

Ramp2 DecelerationTime

0.1 to 999

10.0s92

P104

S Ramp

0= Inactive

0-92

1 = 50 %

2 = 100 %

Frequency Reference

P120

DigitalReferenceBackup

0= Inactive

1-93

1 = Active

2 = Backup by P121

P121

KeypadReference

P133 to P134

3.00Hz93

P122

JOGSpeedReference

0.00 to P134

5.00Hz94

P124

MultispeedReference1

P133 to P134

3.00Hz94

P125

MultispeedReference2

P133 to P134

10.00Hz94

P126

MultispeedReference3

P133 to P134

20.00Hz94

P127

MultispeedReference4

P133 to P134

30.00Hz95

P128

MultispeedReference5

P133 to P134

40.00Hz95

P129

MultispeedReference6

P133 to P134

50.00Hz95

P130

MultispeedReference7

P133 to P134

60.00Hz95

P131

MultispeedReference8

P133 to P134

66.00Hz95

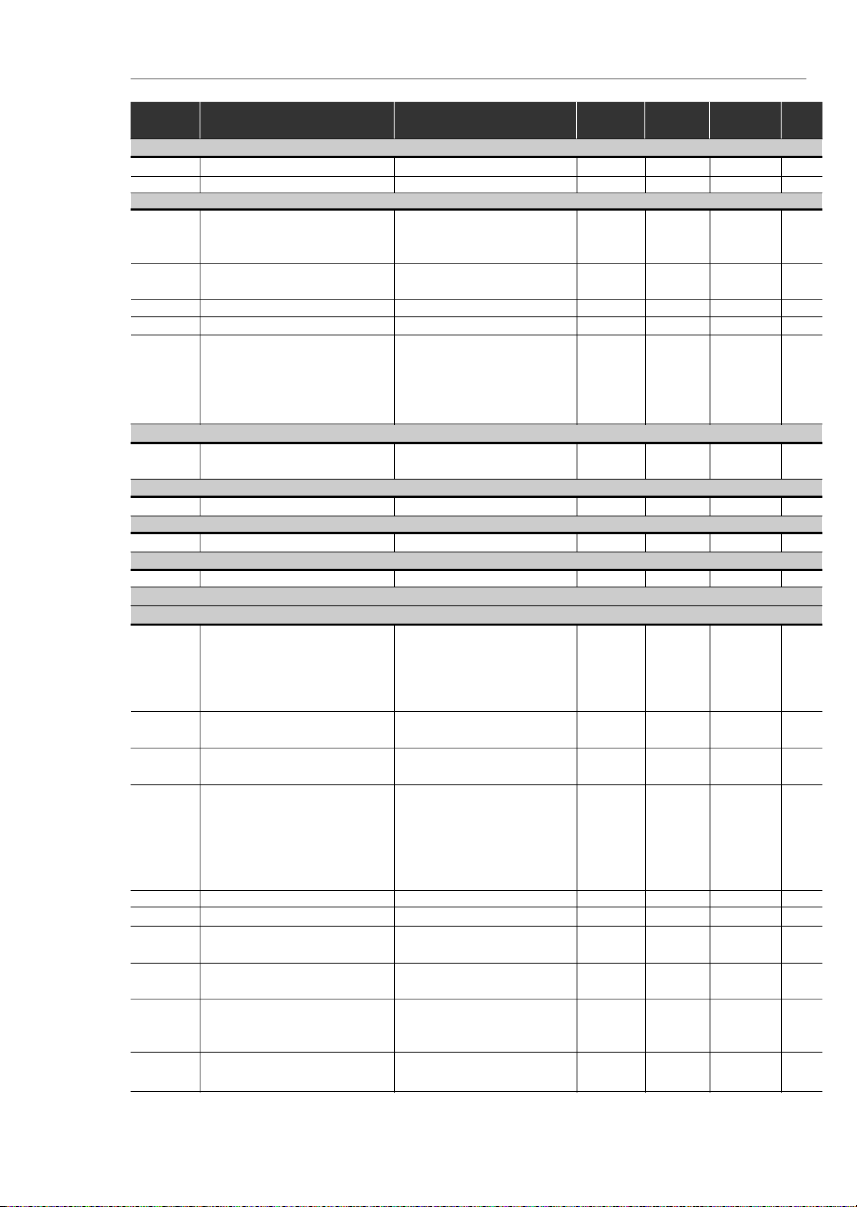

Page 10

9

CFW-08 - QUICK PARAMETER REFERENCE

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

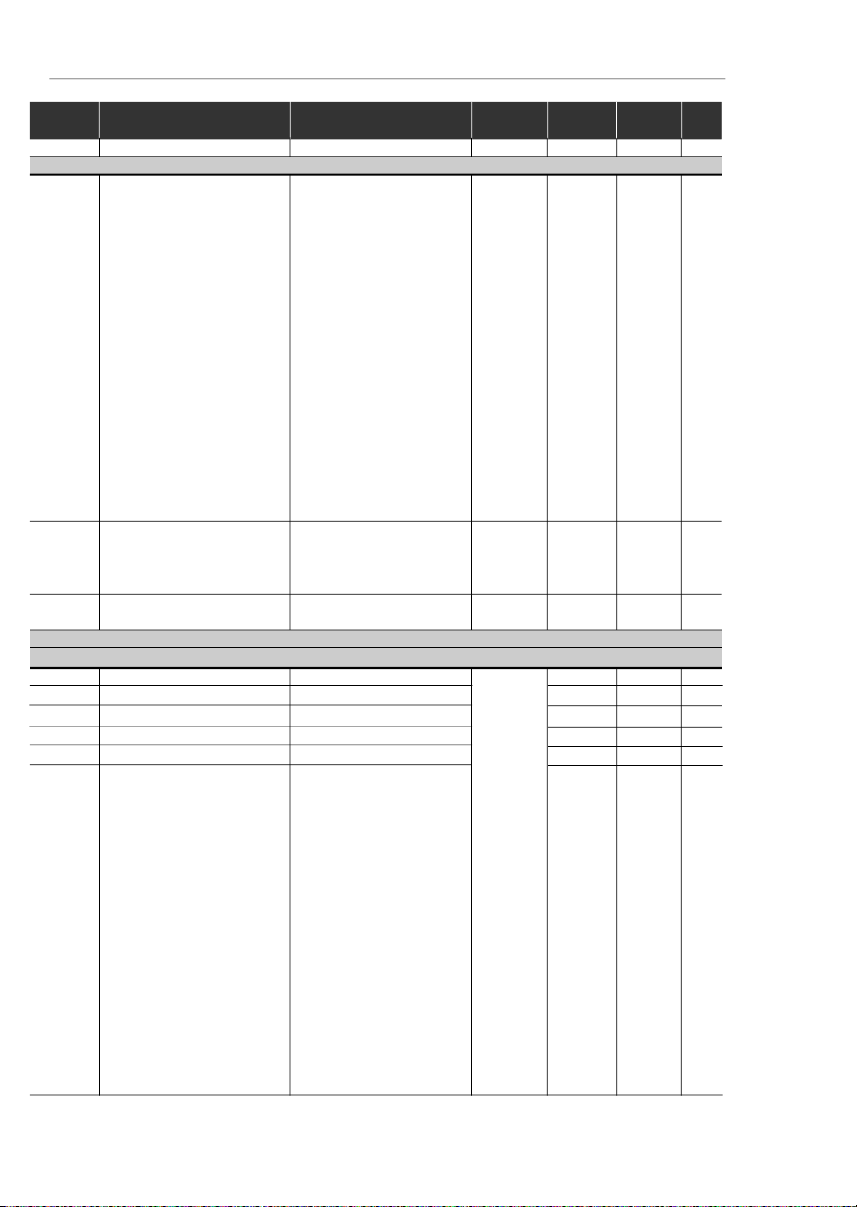

(*)

The factory default of parameter P136 depends on the inverter model as follows:

- models 1.6-2.6-4.0-7.0 A/200-240 V and 1.0-1.6-2.6-4.0 A/380-480 V: P136 = 5.0 %;

- models 7.3-10-16 A/200-240 V and 2.7-4.3-6.5-10 A/380-480 V: P136 = 2.0 %;

- models 22-28-33 A/200-240 V and 13-16-24-30 A/380-480 V: P136 = 1.0 %.

Speed Limits

P133

Minimum Frequency(F

min

)

0.00 to P134

3.00Hz95

P134

MaximumFrequency (F

max

)

P133 to 300.0

66.00Hz96

V/F Control

P136

(2) (*)

ManualTorque Boost

0.0 to 30.0

5.0 or%96

(IxRCompensation)

2.0 or

1.0

(*)

P137

(2)

AutomaticTorqueBoost

0.00 to 1.00

0.00-97

(AutomaticIxR Compensation)

P138

(2)

SlipCompensation

0.0 to 10.0

0.0%97

P142

(2) (3)

Maximum Output Voltage

0 to 100

100%98

P145

(2) (3)

FieldWeakening

P133 to P134

50.00 Hz or

Hz98Frequency(F

nom

)

60.00 Hz

depending

on the

market

DC Link Voltage Regulation

P151

DCLink VoltageRegulation

200 V models: 325 to 410

380V99

Level

400 V models: 564 to 820

780

Overload Current

P156

MotorOverloadCurrent

0.2xI

nom

to 1.3xI

nom

1.2xP401

A

100

Current Limitation

P169

MaximumOutput Current

0.2xI

nom

to 2.0xI

nom

1.5xP295

A

101

Flux Control

P178

(1)

Rated Flux

50.0 to 150

100%101

CONFIGURA

TIONPARAMETERS - P200

to

P398

Generic Parameters

P202

(3)

ControlMode

0 = Linear V/F Control

0-102

(Scalar)

1 = Quadratic V/F Control

(Scalar)

2 = S

ensorlessVectorControl

P203

(3)

SpecialFunction Selection

0 = No function

0-103

1 = PID Regulator

P204

(3)

Load Factory Setting

0 to 4 = No Function

0-104

5 = Loads Factory Default

P205

DisplayDefault Selection

0 = P005

2-104

1 = P003

2 = P002

3 = P007

4, 5 = Not Used

6 = P040

P206

Auto-ResetTime

0 to 255

0s104

P208

ReferenceScale Factor

0.00 to 99.9

1.00-104

P212

Frequencyto Enable the Sleep 0.00 to P134

0.00Hz105

Mode

P213

Time Delayto Activate the

0.1 to 999

2.0s105

SleepMode

P215

(3) (4)

Keypad Copy Function

0 = Not Used

0-106

1 = Copy (inverter

keypad)

2= Paste (keypad

inverter)

P219

(3)

SwitchingFrequency

0.00 to 25.00

6.00Hz107

ReductionPoint

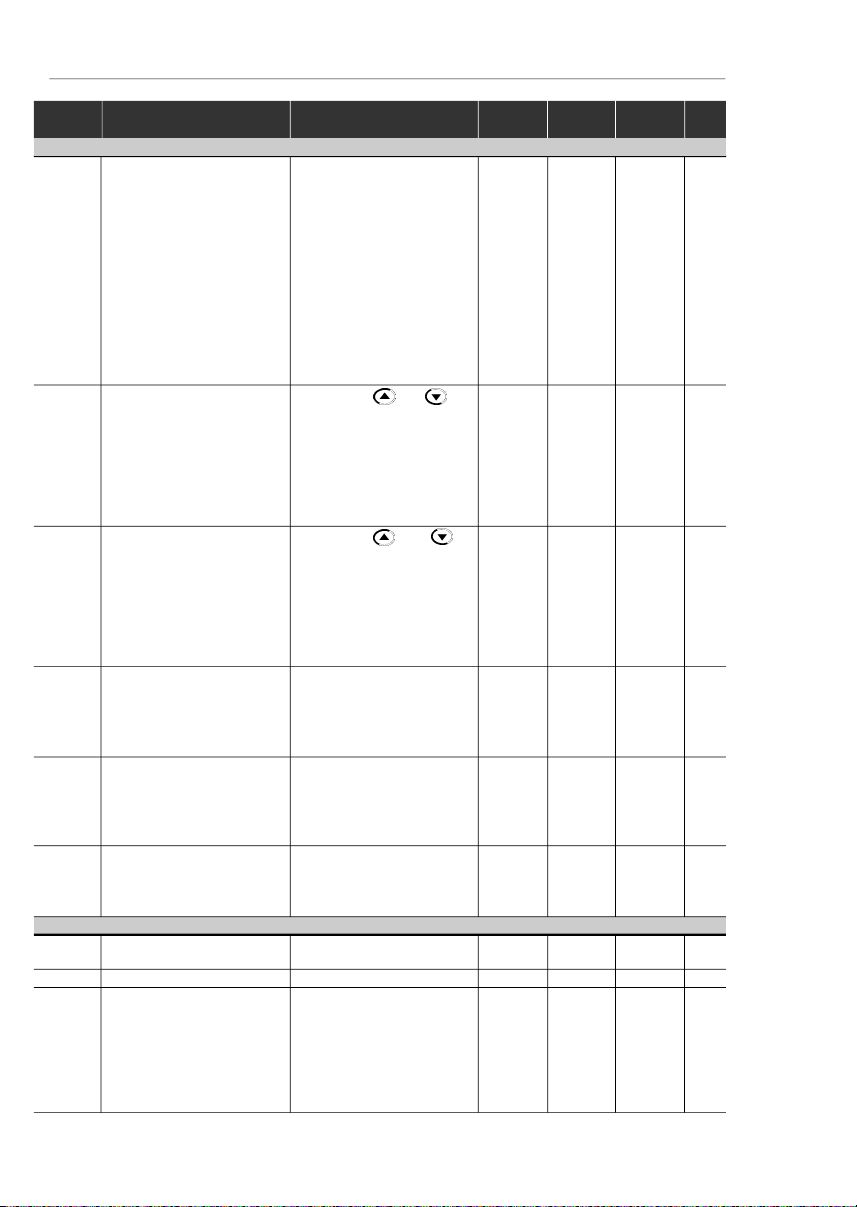

Page 11

10

CFW-08 - QUICK PARAMETER REFERENCE

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

(**)

Only available on the control board A2 (refer to item 2.4). For programming instructions, please, refer to the parameter P235 detailed

description.

Local/Remote Definition

P220

(3)

Local/Remote

0 = Always Local

2-108

Selection Source

1 = Always Remote

2 =HMI-CFW08-P or

HMI-CFW08-RPKeypad

(default:local)

3 =HMI-CFW08-P or

HMI-CFW08-RPKeypad

(default:remote)

4 = DI2 to DI4

5=

SerialorHMI-CFW08-RS

Keypad(default: local)

6=

SerialorHMI-CFW08-RS

Keypad(default:remote)

P221

(3)

FrequencyLocalReference

0 = Keypad and

0-109

Selection

1 = AI1

2, 3 = AI2

4 = E.P.

5 = Serial

6 = Multispeed

7 = Add AI

0

8 = Add AI

P222

(3)

FrequencyRemoteReference

0 = Keypad and

1-109

Selection

1 = AI1

2, 3 = AI2

4 = E.P.

5 = Serial

6 = Multispeed

7 = Add AI

0

8 = Add AI

P229

(3)

LocalCommand Selection

0 =HMI-CFW08-P or

0-109

HMI-CFW08-RPKeypad

1 = Terminals

2 = Serial or

HMI-CFW08-RSKeypad

P230

(3)

RemoteCommand Selection

0 =HMI-CFW08-P or

1-109

HMI-CFW08-RPKeypad

1 = Terminals

2 = Serial or

HMI-CFW08-RSKeypad

P231

(3)

Forward/ReverseSelection

0 = Forward

2-110

- Local and Remote

1= Reverse

2 = Commands

3 = DIx

Analog Input (s)

P233

AnalogInputDead Zone

0= Inactive

1-110

1 = Active

P234

AnalogInputAI1 Gain

0.00 to 9.99

1.00-111

P235

(3) (5)

Analog Input AI1 Function

0 = (0 to 10) V/(0 to 20) mA /

0-112

(-10 to +10) V

(**)

1 = (4 to 20) mA

2 = DI5 PNP

3 = DI5 NPN

4= DI5 TTL

5 = PTC

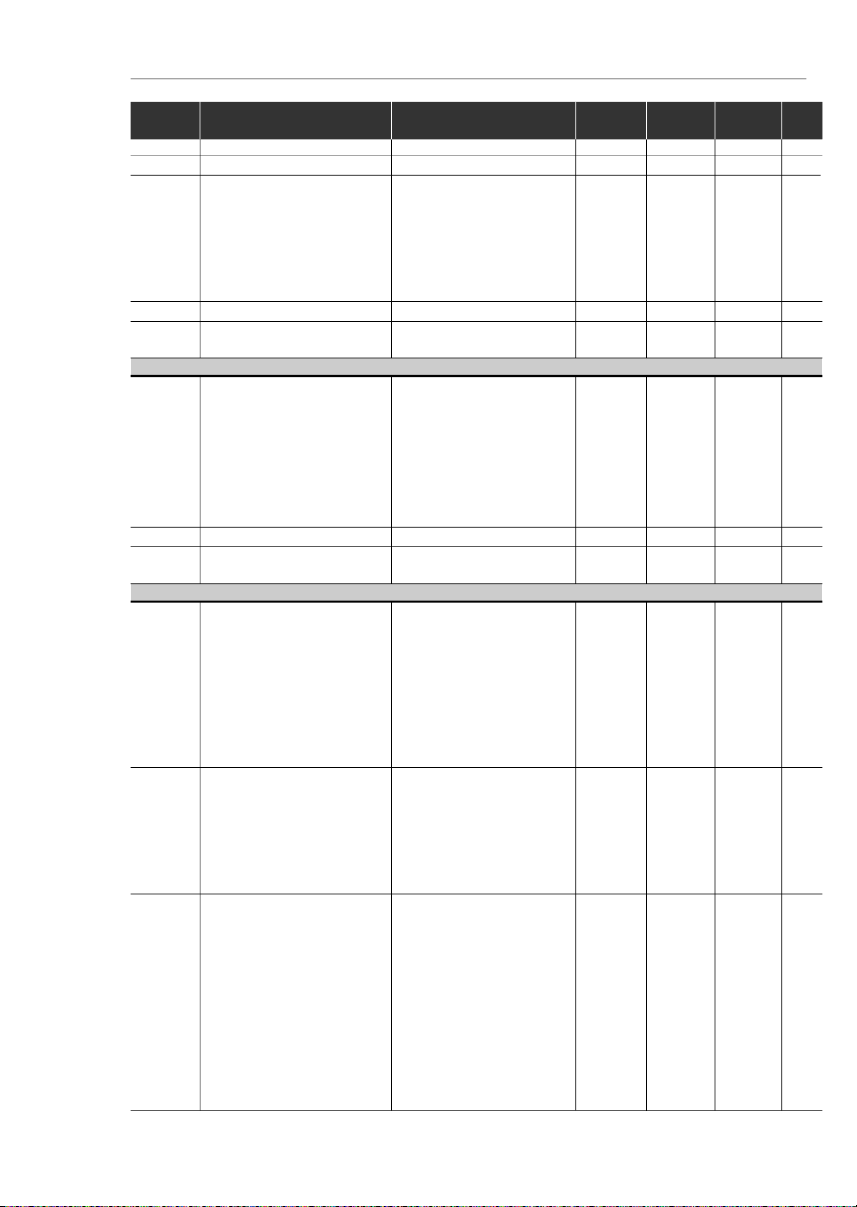

Page 12

11

CFW-08 - QUICK PARAMETER REFERENCE

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

P236

AnalogInputAI1 Offset

-999 to +999

0.0%113

P238

(6)

AnalogInputAI2 Gain

0.00 to 9.99

1.00-113

P239

(3)(5)(6)

Analog Input AI2 Function

0 = (0 to 10) V/(0 to 20) mA/

0-113

(-10 to +10) V

(**)

1 = (4 to 20) mA

2 = DI6 PNP

3 = DI6 NPN

4= DI6 TTL

5 = PTC

P240

(6)

AnalogInputAI2 Offset

-999 to +999

0.0%113

P248

Analog Inputs Filter

0 to 200

10ms113

TimeConstant

Analog Output

P251

(6)

AnalogOutput

0 = Output Frequency (Fs)

0-114

AO Function

1 = InputReference (Fe)

2 = Output Current (Is)

3, 5, 8 = Not Used

4 = MotorTorque

6 = Process Variable (PID)

7 =Active Current

9 = PID Setpoint

P252

(6)

Analog Output AO Gain

0.00 to 9.99

1.00-114

P253

Analog OutputAO Signal

0 = (0 to 10) V/(0 to 20) mA

0-114

1 = (4 to 20) mA

Digital Inputs

P263

(3)

Digital Input DI1Function

0 = No Function or General

0-115

Enable

1 to 7 and 10 to 12 =

GeneralEnable

8 = Forward Run

9 = Start/Stop

13 = FWD Run Using

Ramp2

14 = On

P264

(3)

Digital Input DI2Function

0= Forward/Reverse

0-115

1 = Local/Remote

2 to 6 and 9 to 12 = Not

U

sed

7 = Multispeed (MS2)

8= Reverse

13 = REV Run - Ramp 2

14 = Off

P265

(3) (7)

Digital InputDI3 Function

0= Forward/Reverse

10-115

1 = Local/Remote

2 = GeneralEnable

3 = JOG

4 = No External Fault

5 = Increase E.P.

6 = Ramp 2

7 = Multispeed (MS1)

8 = No Function or

Start/Stop

9 = Start/Stop

10 = Reset

(**)

Only available on the control board A2 (refer to item 2.4). For programming instructions, please, refer to the parameter P235 detailed

description.

Page 13

12

CFW-08 - QUICK PARAMETER REFERENCE

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

11,12 = Not Used

13 = Flying Start Disable

14 = Multispeed (MS1)

UsingRamp 2

15 = Manual/Automatic (PID)

16 = Increase E.P. with

Ramp2

P266

(3)

Digital InputDI4 Function

0= Forward/Reverse

8-115

1 = Local/Remote

2 = GeneralEnable

3 = JOG

4 = No External Fault

5 = Decrease E.P.

6 = Ramp 2

7 = Multispeed (MS0)

8 = Not Used or

Start/Stop

9 = Start/Stop

10 = Reset

11,12, 14 and 15 = Not Used

13 = Flying Start Disable

16 = Decrease E.P. with

Ramp2

P267

(3) (5)

Function of the Digital

0 = FWD/REV

11-115

InputDI5 (only displayed

1 = Local/Remote

when P235 = 2, 3 or 4)

2 = GeneralEnable

3 = JOG

4 = No External Fault

5 = Increase E.P.

6 = Ramp 2

7 = Multispeed (MS2)

8 =

No Function

or Start/Stop

9 = Start/Stop

10 = Reset

11and 12 = Not Used

13 = Disables Flying Start

14 and 15 = Not Used

16 = Increase E.P. with

Ramp2

P268

(3) (5) (6)

Function of the Digital

0 = FWD/REV

11-115

InputDI6 (only displayed

1 = Local/Remote

when P239 = 2, 3 or 4)

2 = GeneralEnable

3 = JOG

4 = No External Fault

5 = Decrease E.P.

6 = Ramp 2

7 = Not Used

8 =

No Function

or Start/Stop

9 = Start/Stop

10 = Reset

11and 12 = Not Used

13 = Disables Flying Start

14 and 15 = Not Used

16 = Decrease E.P. with

Ramp2

Page 14

13

CFW-08 - QUICK PARAMETER REFERENCE

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

(*) It is not possible to set P297 = 7 (15 kHz) in vector control mode(P202 = 2) or when the external serial keypad (HMI-CFW08-RS) is used.

According

to the

inverter

model

DigitalOutput(s)

P277

(3)

RelayOutput RL1 Function

0 = Fs > Fx

7-120

1 = Fe > Fx

2 = Fs = Fe

3 = Is>Ix

4 and 6 = Not Used

5 = Run

7 = No Fault

P279

(3) (6)

RelayOutput RL2 Function

0 = Fs > Fx

0-120

1 = Fe > Fx

2 = Fs = Fe

3 = Is > Ix

4 and 6 = Not Used

5 = Run

7 = No Fault

Fx and Ix

P288

Fx Frequency

0.00 to P134

3.00Hz122

P290

IxCurrent

0 to 1.5xI

nom

1.0xI

nom

A

122

Inverter Data

P295

(3)

RatedInverter

300 = 1.0 A

-

122

Current(I

nom

)

301 = 1.6 A

302 = 2.6 A

303 = 2.7 A

304 = 4.0 A

305 = 4.3 A

306 = 6.5 A

307 = 7.0 A

308 = 7.3 A

309 = 10 A

310 = 13 A

311= 16A

P297

(3)

SwitchingFrequency

4 = 5.0

4

kHz

122

5 = 2.5

6 = 10

7 = 15

(*)

DC Braking

P300

DCBraking Time

0.0 to 15.0

0.0s124

P301

DC Braking StartFrequency

0.00 to 15.00

1.00Hz124

P302

DCBraking Current

0.0 to 130

0.0%124

Skip Frequencies

P303

Skip Frequency 1

P133 to P134

20.00Hz125

P304

Skip Frequency 2

P133 to P134

30.00Hz125

P306

Skip BandRange

0.00 to 25.00

0.00Hz125

Serial Communication Interface I

P308

(3)

InverterAddress

1 to 30 (Serial WEG)

1-125

1to 247(Modbus-RTU)

Flying Start and Ride-Through

P310

(3)

FlyingStartandRide-Through

0= Inactive

0-126

1 = Flying Start

2 = Flying Start and

Ride-Through

3= Ride-Through

312 = 22 A

313 = 24 A

314 = 28 A

315 = 30 A

316 = 33 A

Page 15

14

CFW-08 - QUICK PARAMETER REFERENCE

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

P311

VoltageRamp

0.1 to 10.0

5.0s126

Serial Communication Interface II

P312

(3)

SerialInterface Protocol

0 = Serial WEG

0-127

1 = Modbus-RTU9600 bps

without parity

2 = Modbus-RTU9600 bps

with odd parity

3 = Modbus-RTU9600 bps

witheven parity

4 = Modbus-RTU19200 bps

without parity

5 = Modbus-RTU19200 bps

with odd parity

6 = Modbus-RTU19200 bps

witheven parity

7 = Modbus-RTU38400 bps

without parity

8 = Modbus-RTU38400 bps

with odd parity

9 = Modbus-RTU38400 bps

witheven parity

P313

SerialInterfaceWatchdog

0 = Disabling by ramp

2-127

Action

1 = General disable

2 = Shows only E28

3 = Goes to local mode

P314

SerialInterfaceWatchdog

0.0= Disables the function

0.0s128

Timeout

0.1to 99.9 = Setvalue

MOTORPARAMETERS- P399 to P499

Rated Parameters

P399

(1) (3)

Rated MotorEfficiency

50.0 to 99.9

%

128

P400

(1) (3)

RatedMotor Voltage

0 to 600

V

128

P401

RatedMotorCurrent

0.3xP295 to 1.3xP295

A

128

P402

(1)

RatedMotor Speed

0 to 9999

rpm

129

P403

(1) (3)

Rated Motor Frequency

0.00 to P134

Hz

129

P404

(1) (3)

RatedMotor Power

0 = 0.16 HP / 0.12 kW

-

129

1 = 0.25 HP / 0.18 kW

2 = 0.33 HP / 0.25 kW

3 = 0.50 HP / 0.37 kW

4 = 0.75 HP / 0.55 kW

5 = 1 HP / 0.75 kW

6 = 1.5 HP / 1.1 kW

7 = 2 HP / 1.5 kW

8 = 3 HP / 2.2 kW

9 = 4 HP / 3.0 kW

10 = 5 HP / 3.7 kW

11 = 5.5 HP / 4.0 kW

12 = 6 HP / 4.5 kW

13 = 7.5 HP / 5.5 kW

14 = 10 HP / 7.5 kW

15 = 12.5 HP / 9.2 kW

16 = 15 HP / 11.2 kW

17 = 20 HP / 15.0 kW

According

to the

inverter

model

(motor

matched

to the

inverter-

referto

item 9.3)

and sales

market

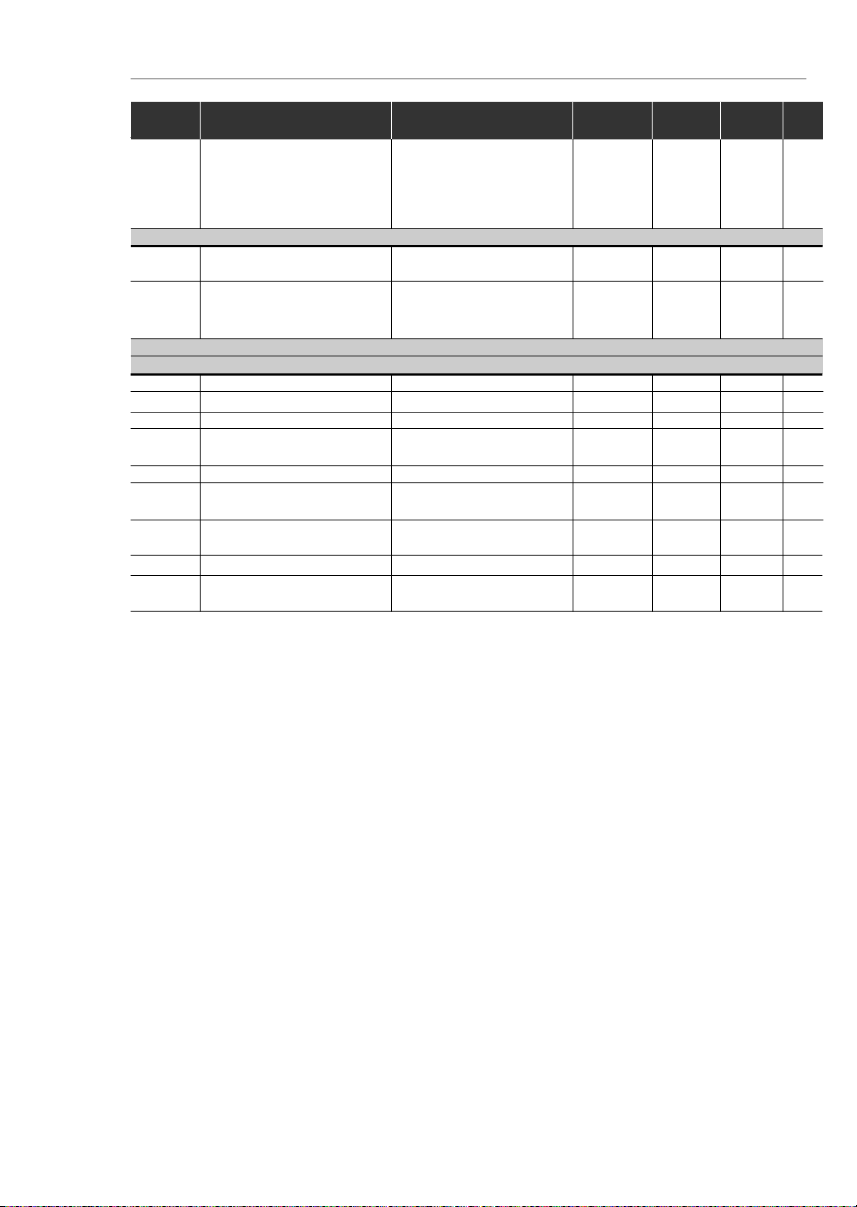

Page 16

15

CFW-08 - QUICK PARAMETER REFERENCE

Parameter

Function

Adjustable Range

Factory

Unit

User

Page

Setting

Setting

Notesfound on the Quick ParameterReference:

(1)

This parameter is only displayedin vector mode (P202 = 2).

(2)

This parameter is only displayed in scalar mode P202 = 0 or 1.

(3)

Thisparametercanbechangedonlywhen the inverter is disabled (stopped motor).

(4)

Thisparameteris onlyavailable withHMI-CFW08-RS.

(5)

Theanaloginputvalueisrepresentedbyzerowhenitis notconnectedtoan externalsignal.

In order to use an analog input as a digital input with NPN logic (P235 or P239 = 3), it is

necessary to connect a 10 k

resistor from terminal 7 to 6 (AI1) or 8 (AI2) of the control

terminalstrip.

(6)

Thisparameteris only available in the CFW-08Plusversion.

(7)

Theparameter value changesautomaticallywhenP203 = 1.

P407

(3)

RatedMotor Power

0.50 to 0.99

-

130

Factor

Measured Parameters

P408

(1) (3)

RunSelf-Tuning

0 = No

0-130

1 = Yes

P409

(3)

Motor Stator Resistance

0.00 to 99.99

130

SPECIAL FUNCTION - P500 to P599

PID Regulator

P520

PIDProportionalGain

0.000 to 7.999

1.000-138

P521

PIDIntegralGain

0.000 to 9.999

1.000-138

P522

PIDDifferentialGain

0.000 to 9.999

0.000-138

P525

Setpoint (Via Keypad) of the

0.00 to 100.0

0.00%138

PIDRegulator

P526

Process VariableFilter

0.01 to 10.00

0.10s138

P527

PIDAction

0 = Direct

0-138

1= Reverse

P528

Process Variable

0.00 to 99.9

1.00-139

Scale Factor

P535

Wake up Band

0.00 to 100.00

1.00%139

P536

Automatic Setting of P525

0 = Active

0-140

1= Inactive

Accordingto

theinverter

model

(referto

item 9.3)

Accordingto

theinverter

model

Page 17

16

CFW-08 - QUICK PARAMETER REFERENCE

Display

Description

Page

E00

Outputovercurrent/short-circuit

/outputgroundfault

141

E01

DClinkovervoltage

141

E02

DClink undervoltage

142

E04

Overtemperatureat the powerheatsink

orin the

142

inverterinternalair

E05

Outputoverload (Ixt function)

142

E06

Externalfault

142

E08

CPUerror(Watchdog)

142

E09

Programmemoryerror (Checksum)

142

E10

Keypadcopy function error

142

E14

S

elf-tuningroutine (estimation of the motor

142

parameters)error

E22,

E25

,

Serialcommunication error

142

E2

6 andE27

E24

Programmingerror

142

E28

Serialinterface Watchdog timeout error

143

E31

Keypadconnectionfault(HMI-CFW08-RS)

143

E32

Motorovertemperature(externalPTC)

143

E41

Self-diagnosisfault

143

II.FaultMessages

III.OtherMessages

Display

Description

rdy

Inverteris readyto be enabled

Sub

Powersupply voltage is too lowfor the inverter

operation(undervoltage)

dcbr

InverterinDC brakingmode

auto

Inverterisrunningself-tuningroutine

copy

Keypadcopy function in progress (only available in

theHMI-CFW08-RS) -inverter to keypad

past

Keypadcopy function in progress (only available in

theHMI-CFW08-RS) -keypadtoinverter

Srdy

Inverterin the sleep rdymode

Page 18

17

CHAPTER1

SAFETYNOTICES

This Manual contains necessary information for the correct

useof the CFW-08frequencyinverter.

This Manual was developed for qualified personnel with

suitabletrainingandtechnicalqualificationtooperatethistype

ofequipment.

Thefollowingsafetynotices are usedinthismanual:

DANGER!

Ifthe recommendedsafetynoticesare notstrictlyobserved,it

canleadtoseriousorfatalinjuriesofpersonneland/ormaterial

damage.

ATTENTION!

Failureto observe the recommended safety procedures can

lead to material damage.

NOTE!

This notice provides important information for the proper

understandingandoperationof the equipment.

Thefollowingsymbolsmaybeattachedtotheproduct,serving

assafetynotice:

High Voltages.

Componentssensitive to electrostaticdischarge.Donot

touch them without proper grounding procedures.

Mandatory connection to ground protection (PE).

Shield connection to ground.

DANGER!

Only qualified personnel should plan or implement the

installation, start- up, operation and maintenance of this

equipment. Personnel must review entire Manual before

attemptingto install, operateortroubleshootthe CFW-08.

Thesepersonnel must follow all safety instructions included

inthismanualand/or definedbylocal regulations.

Failure to comply with these instructions may result in

personnelinjuryand/orequipmentdamage.

1.3

PRELIMINARY

RECOMMENDA

TIONS

1.2

SAFETYNOTICES

ONTHE PRODUCT

1.1

SAFETYNOTICESIN

THEMANUAL

Page 19

18

CHAPTER 1 - SAFETY NOTICES

NOTE!

Inthis manual,qualified personnelare definedas peoplethatare

trainedto:

1.

Install,ground, powerupandoperatethe CFW-08according

tothis manual andthe local required safetyprocedures;

2.

Useofsafetyequipment according to the local regulations;

3.

Administer First Aid.

DANGER!

Theinvertercontrol circuit (ECC3, DSP) and the HMI-CFW08-P

arehighvoltagecircuitsand are notgrounded.

DANGER!

Always disconnect the supply voltage before touching any

electricalcomponentinsidethe inverter.

Many components are charged with high voltage and/or in

movement (fans), even after the incomingAC power supply has

beendisconnectedor switchedOFF. Waitatleast10 minutesfor

thetotal discharge of the power capacitors.

Alwaysconnecttheframeof the equipmentto theground(PE)at

thesuitable connectionpoint.

ATTENTION!

All electronic boards have components that are sensitive to

electrostatic discharges. Never touch any of the electrical

components or connectors without following proper grounding

procedures. If necessary to do so, touch the properly grounded

metallicframe or use a suitable ground strap.

NOTE!

Inverterscan interferewithotherelectronicequipment.Inorderto

reduce this interference, adopt the measures recommended in

chapter3-InstallationandConnection.

NOTE!

ReadthisentiremanualbeforeinstallingoroperatingtheCFW-08.

Do not apply high voltage(high pot)test on theinverter!

If this test is necessary, contact WEG.

Page 20

19

Thischapterdefines thecontentsand purposesof thismanu-

al and describes the main characteristics of the

CFW-08

frequency inverter. Identification, receiving inspections and

storagerequirementsare also provided.

Thismanualis divided into 9 chapters,providinginformation

to the user on how receive, install, start-up and operate the

CFW-08.

Chapter 1 -

Safetynotices.

Chapter 2 -

Generalinformationandreceivingthe CFW-08.

Chapter 3 -

RFIfilters,mechanical and electrical installation

(powerand controlcircuit).

Chapter 4 -

Using the keypad (Human Machine Interface -

HMI).

Chapter

5 -

Start-upandstepsto follow.

Chapter

6 -

Setup and read only parameters detailed

description.

Chapter

7 -

Solving problems, cleaning instructions and

preventivemaintenance.

Chapter 8 -

CFW-08 optional devices description, technical

characteristicsand installation.

Chapter 9 -

CFW-08ratings,tablesandtechnicalinformation.

This manual provides information for the correct use of the

CFW-08. This frequency inverter is very flexible and allows

the operation in many different modes as described in this

manual.

AstheCFW-08canbeappliedin severalways,itisimpossible

todescribehere all oftheapplicationpossibilities.WEGdoes

not accept any responsibility when the CFW-08 is not used

accordingto thismanual.

Nopartofthismanualmaybereproducedinanyform,without

thewrittenpermissionofWEG.

It is important to note the software version installed in the

CFW-08, since it definesthefunctionsand the programming

parameters of the inverter.

This manual refers to the software version indicated on the

insidecover.Forexample,theversion3.0Xappliestoversions

3.00 to 3.09, where “X” is a variable that will change due to

minor software revisions. The operation of the CFW-08 with

these software revisions are still covered by this version of

themanual.

Thesoftwareversion can be read in theparameterP023.

GENERALINFORMATION

2.1

ABOUTTHIS

MANUAL

2.2

SOFTWARE

VERSION

CHAPTER2

Page 21

20

CHAPTER 2 - GENERAL INFORMATION

2.3

ABOUTTHECFW-08

TheCFW-08frequencyinverterprovidestwocontroloptions:

vector control (VVC: voltage vector control) or V/F (scalar);

bothtypesof control can be setaccordingtotheapplication.

Inthevectorcontrolmode,themotorperformanceisoptimized

relatingto torque and speed regulation.

The"Self-Tuning"function,availableinvectorcontrol,permits

the automatic setting of the inverter parameter from the

identification(alsoautomatic)of the parametersof the motor

connectedatthe inverteroutput.

The V/F (scalar) mode is recommended for simpler

applicationssuchas pumpandfandrives.In thesecasesone

can reduce the motor and inverter losses by using the

"QuadraticV/F" option, thatresultsinenergysaving.

TheV/Fmodeisalsousedwhenmorethanonemotorshould

be driven simultaneously by one inverter (multimotor

application).

For power ratings and furthertechnical information, refer to

Chapter9.

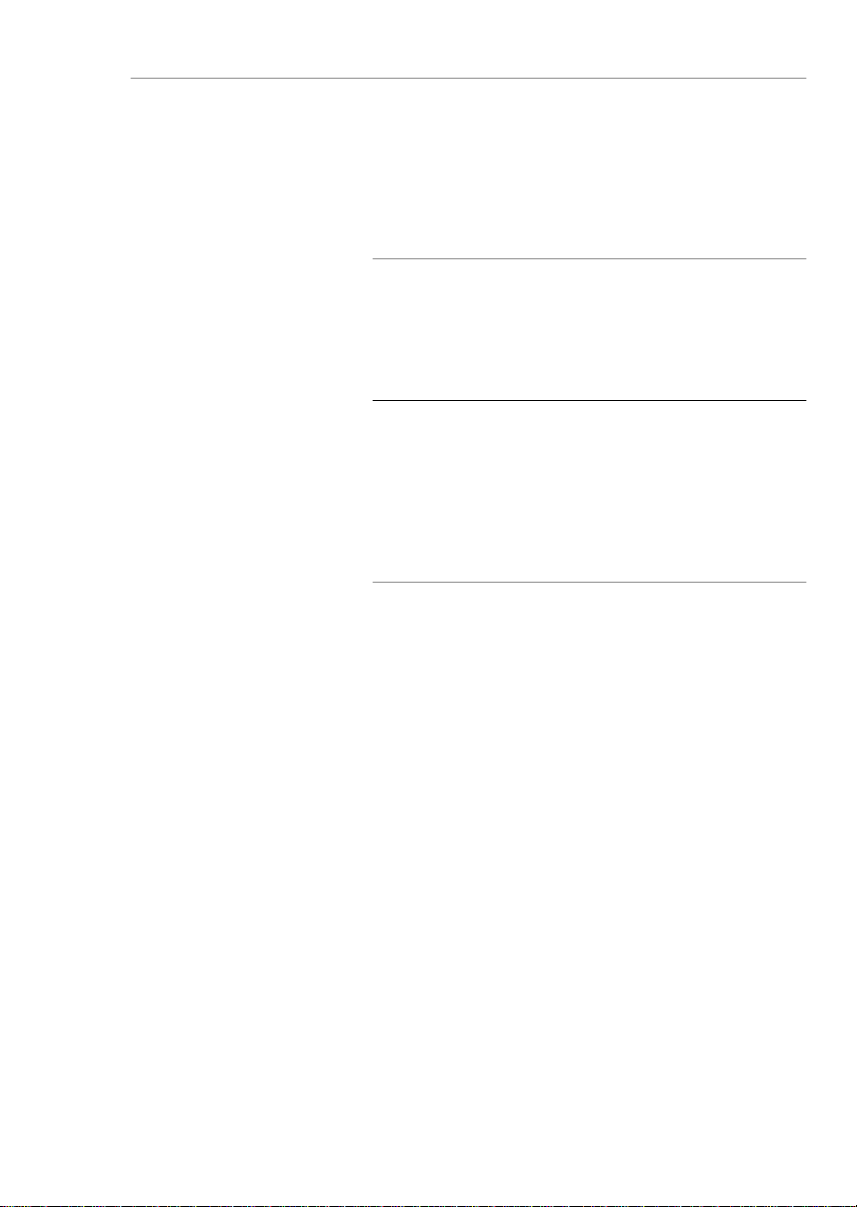

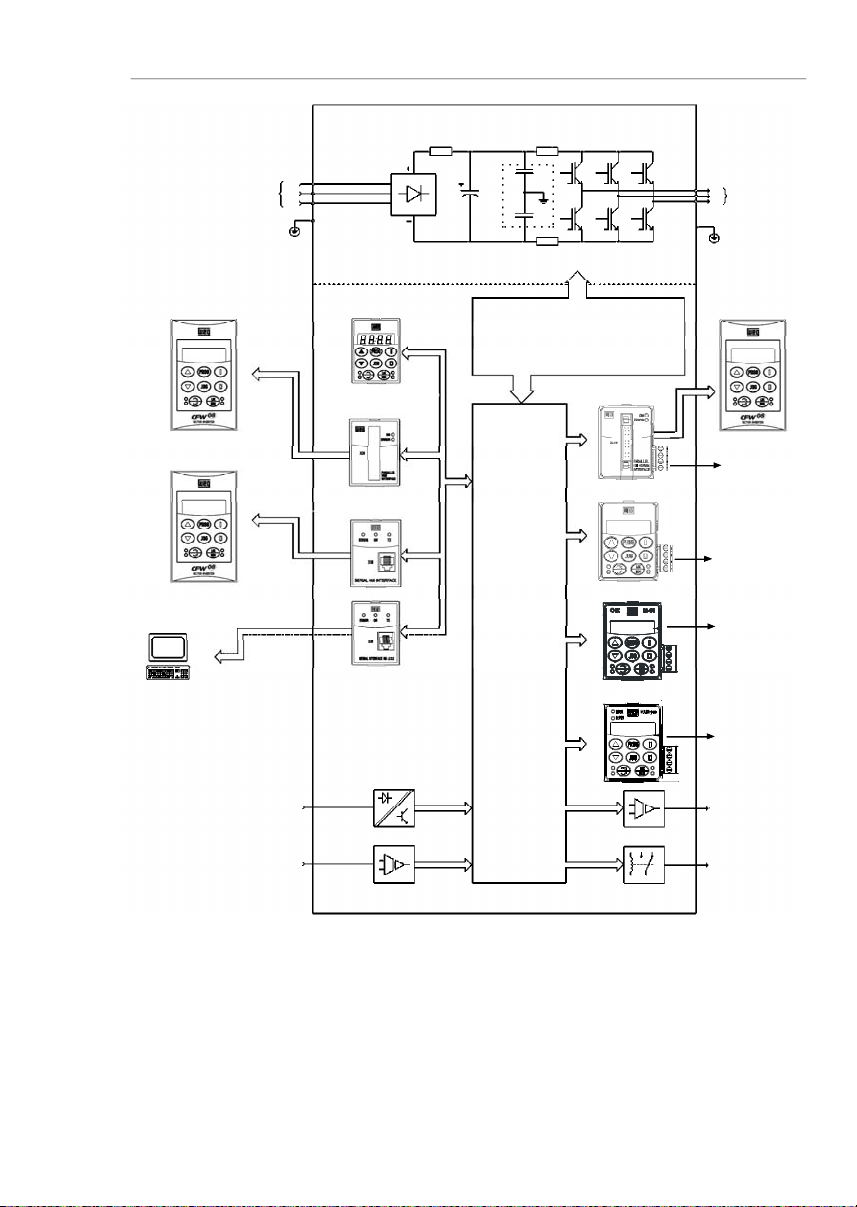

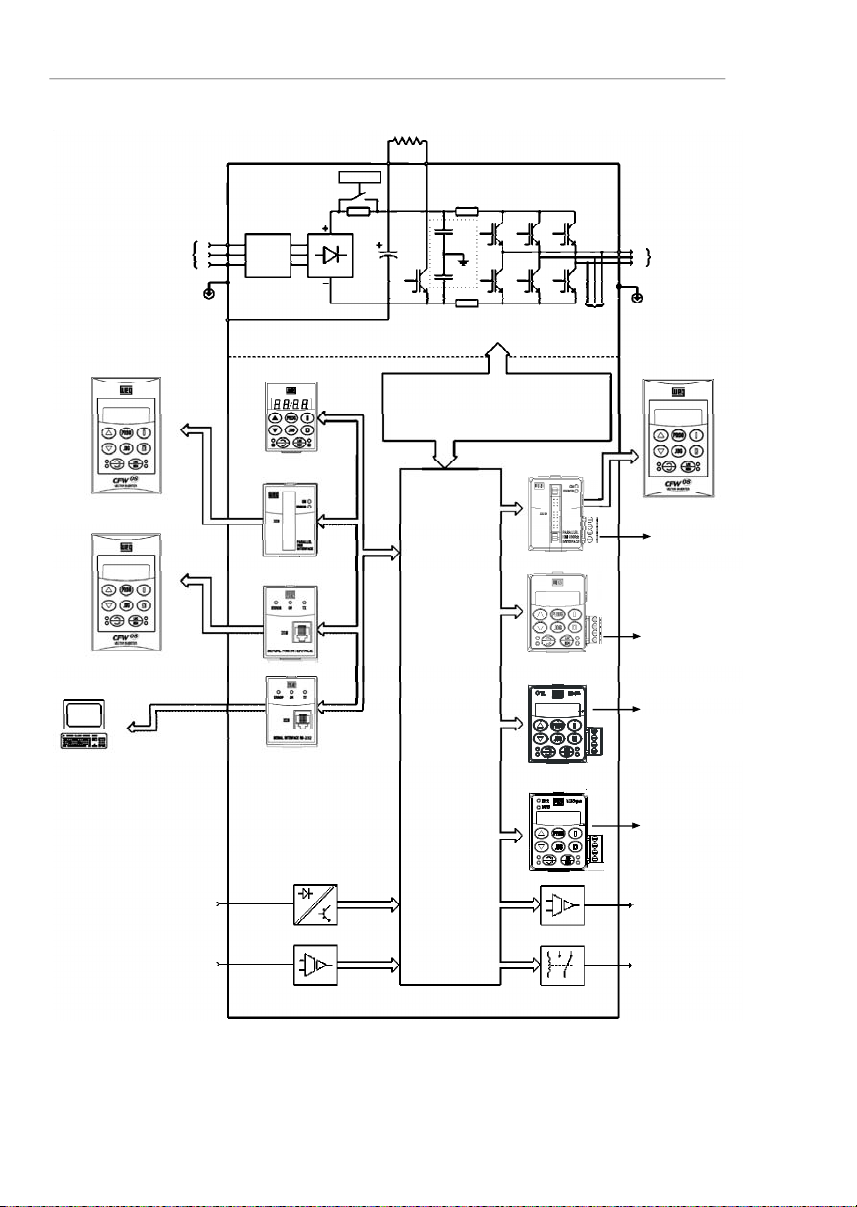

The block diagram below gives a general overview of the

CFW-08.

Page 22

21

CHAPTER 2 - GENERAL INFORMATION

Figure 2.1

- Block diagram for the models:

1.6-2.6-4.0-7.0A/200-240V and 1.0-1.6-2.6-4.0A/380-480V

Power

Supply

RST

PE

HMI-CFW08-RS

PC-Software

SuperDrive

Analog

Inputs

(AI1andAI2)

Digital

Inputs

(DI1to DI4)

Interface

RS-232KCS-CFW08

Interface

MIS-CFW08-RS

or

HMI-CFW08-P

POWER

CONTROL

POWER SUPPLIESAND

CONTROL/POWER

INTERFACES

"ECC3"

CONTROL

BOARD

WITHDSP

Motor

UVW

Rsh2

Rsh1

NTC

PE

RFIFilter

HMI-CFW08-RP

Interface

MIP-CFW08-RP

or

or

Analog

Output

(AO)

Relay

Output

(RL1andRL2)

CANopen

or

DeviceNet

KRS-485

KFB-COorKFB-DN

RS-485

24 V Power

Supply

24 V Power

Supply

HMI-CFW08-RP

KDC-24VR-CFW08

KDC-24V-CFW08

Page 23

22

CHAPTER 2 - GENERAL INFORMATION

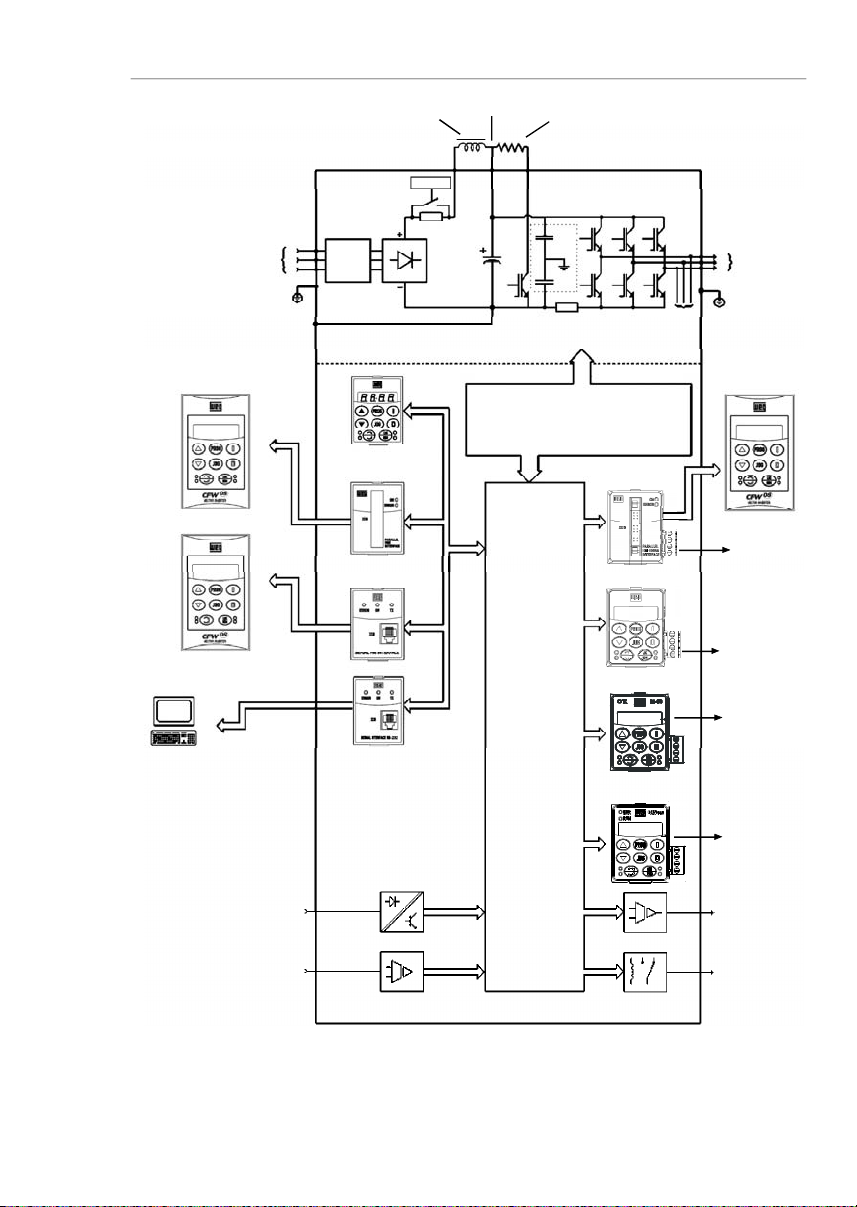

Figure 2.2

- Block diagram for the models:

7.3-10-16-22 A/200-240Vand 2.7-4.3-6.5-10-13-16A/380-480V

Note:

models 16 A and 22 A/200-240 V are not fitted with optional RFI filter.

Redede

Alimentação

R

STRFI

Suppressor

Filter

(optional)

HMI-CFW08-RS

PC-Software

SuperDrive

Analog

Inputs

(AI1andAI2)

Digital

Inputs

(DI1to DI4)

Interface

RS-232KCS-CFW08

Interface

MIS-

CFW08-RS

HMI-CFW08-P

POWER

CONTROL

POWER SUPPLIESAND CONTROL

/POWERINTERFACES

"ECC3"

CONTROL

BOARD

WITHDSP

Motor

UVW

Rsh2

Rsh1

RPC

Pré-Carga

Braking Resistor

(Externaland Optional)

BR

+UD

PE

-UD

Voltage

Feedback

PE

or

or

RFI

Filter

or

Interface

MIP-

CFW08-RP

HMI-CFW08-RP

Analog

Output

(AO)

Relay

Output

(RL1andRL2)

CANopen

or

DeviceNet

KRS-485

KFB-COorKFB-DN

RS-485

24 V Power

Supply

24 V Power

Supply

HMI-CFW08-RP

KDC-24VR-CFW08

KDC-24V-CFW08

Page 24

23

CHAPTER 2 - GENERAL INFORMATION

Figure 2.3

- Block diagram for the models:

28-33A/200-240 V and24-30 A/380-480 V

Note:

models 28 A and 33 A/200-240 V are not fitted with optional RFI filter.

Power

Supply

RST

RFI

Suppressor

Filter

(optional)

HMI-CFW08-RS

PC-Software

SuperDrive

Analog

Inputs

(AI1andAI2)

Digital

Inputs

(DI1to DI4)

Interface

RS-232KCS-CFW08

Interface

MIS-

CFW08-RS

HMI-CFW08-P

POWER

CONTROL

POWER SUPPLIESAND

CONTROL/POWER

INTERFACES

"ECC3"

CONTROL

BOARD

WITHDSP

Motor

UVW

Rsh1

RPC

Pré-Carga

Braking Resistor

(optional)

BR

DCRPE-UD

Voltage

Feedback

PE

or

or

RFI

Filter

or

Interface

MIP-

CFW08-RP

HMI-CFW08-RP

DCLink Inductor

(optional)

+UD

Analog

Output

(AO)

Relay

Output

(RL1andRL2)

CANopen

or

DeviceNet

KRS-485

KFB-COorKFB-DN

RS-485

24 V Power

Supply

24 V Power

Supply

HMI-CFW08-RP

KDC-24VR-CFW08

KDC-24V-CFW08

Page 25

24

CHAPTER 2 - GENERAL INFORMATION

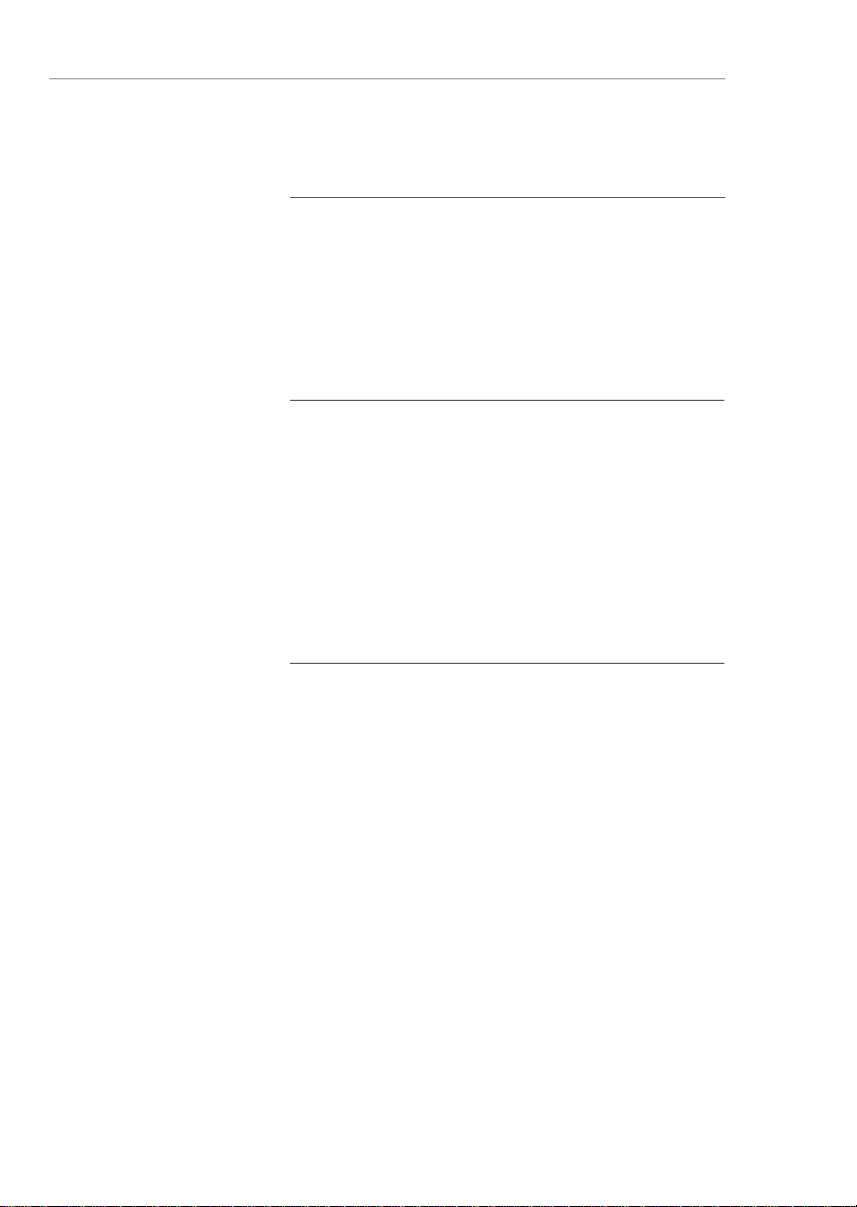

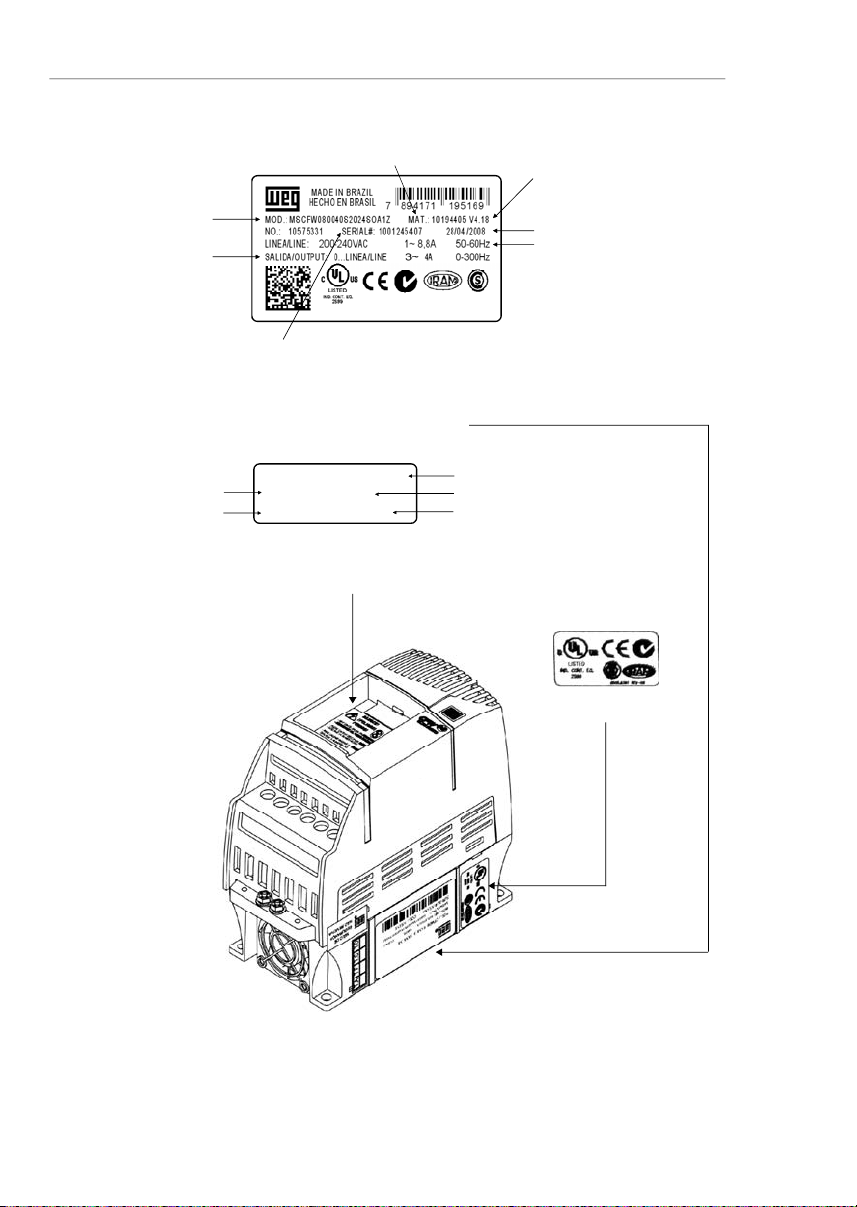

Figure 2.4

- Description and location of the nameplates on the CFW-08

2.4

CFW-08IDENTIFICATION

SoftwareVersion

ManufacturingDate

WEG Part Number

SerialNumber

CFW-08Model

(IntelligentCode)

RatedOutput Data

(Voltage, Frequency)

Lateral Label of the CFW-08

Frontal Nameplate of the CFW-08 (under the keypad)

Note:

toremove the

keypad,refer to the

instructions

inthe item 8.1.1

(figure8.2).

WEG Part Number

SerialNumber

CFW-08Model (IntelligentCode)

SoftwareVersion

ManufacturingDate

CertificationStiker

MSCFW080100T3848SOA1Z

10194356 V 4.18

1001208557 18/04/2008

RatedInputData

(Voltage,Current, etc)

Page 26

25

CHAPTER 2 - GENERAL INFORMATION

CFW-08

0040

B

2024

E

O

_ _

_ _

_ _

_ _

_ _

_ _

Z

Rated Output

Current for:

220 to 240 V:

0016 = 1.6 A

0026 = 2.6 A

0040 = 4.0 A

0070 = 7.0 A

0073 = 7.3 A

0100 = 10 A

0160 = 16 A

0220 = 22 A

0280 = 28 A

0330 = 33 A

380 to 480 V:

0010 = 1.0 A

0016 = 1.6 A

0026 = 2.6 A

0027 = 2.7 A

0040 = 4.0 A

0043 = 4.3 A

0065 = 6.5 A

0100 = 10 A

0130 = 13 A

0160 = 16 A

0240 = 24 A

0300 = 30 A

Number of

phases of

the power

supply:S = single

phase

T = three

phase

B = single

phase or

three phase

Manual

Language:P=Portuguese

E= English

S = Spanish

Power

Supply:2024 =

200to 240 V

3848 =

380 to 480 V

5060

(**)

=

500-600 V

Options:

S = standard

O = with

options

Degree of

Protection:

Blank=s

tandard

N1= Nema 1

N4= Nema

4X

(**)

Human

Machine

Interface:

Blank=standard

SI = without

interface

(with dummy

panel)

WEG Series 08

Frequency

Inverter

Control Board:

Blank=

standard

controlA1=c

ontrol 1

(Plus Version)A2=control2(Plus Version

with Als +/-

10 V)

A3 = control 3

(Plus version

with CANopen

protocol)

(*)

A4 = control 4

(Plus version

with

DeviceNet

protocol)

(*)

A5 = control

5

(**)

(for

Multipump

application)

Special

Software:

Blank=standard

EndCode

RFIFilter:

Blank=standard

FA=

CategoryC2RFI

filter

(internal or

footprint)

Special

Hardware:

Blank=standard

HOW TO SPECIFY THE CFW-08MODEL:

NOTES!

Theoption field (S or O)defines if theCFW-08 is a standard version or if it will be equippedwith anyoptional devices.Ifthe

standardversion is required, the specificationcodeendshere.

ThemodelnumberhasalwaystheletterZ at the end. For example:

CFW080040S2024ESZ=standard4.0ACFW-08inverter,single-phase at (200 to 240) V input,withmanual in English.

IftheCFW-08 is equipped with anyoptionaldevices, you must fill out all fields in the correct sequence up tothelastoptional

device,the model numberiscompletedwiththe letter Z.

Thus,for instance if the product above isrequired withNema 1 degree of protection:

CFW080040S2024EON1Z=

standardC

FW-08inverter,4.0A,single-phase,200-240V input,withmanualin Englishlanguage

and with kit for Nema1 degree of protection.

(*)-The versionsA3 and A4 of the control board shall be used only with the KFB-CO-CFW08 and with the KFB-DN-CFW08, respectively (refer to item 8.14 and 8.15). The parallel keypad, the

serial remote keypad, the parallel remote keypad, and the serial protocol (Modbus and WEG) cannot be used with these versions of the control board.

(**) -

For these models, contact WEG.

Page 27

26

CHAPTER 2 - GENERAL INFORMATION

Fortheeffectofthiscode,thestandardproduct is conceived

asfollows:

-CFW-08 with standard control board.

-

Degree of protection:

N

ema

1 for the models 22 A,

28 A and 33 A/ 200-400 V and also 13 A,16 A, 24 A

and 30 A/380-480 V, IP20 for the other models.

CFW-08 Plus - A1 is composed of the inverter and the

controlboard1. Example: CFW080040S2024PO

A1Z.CFW-08 Plus - A2 is composed of the inverter and the

control board 2. Example: CFW080040S2024PO

A2Z.Thesemodelsarefactorysetforbipolaranaloginputs(-10V

to +10 V).

Thisconfigurationislostwhenthefactorydefaultparameters

areloaded (P204 = 5). Refer to the detailed descriptionof

parametersP204 andP235forfurtherinformation.

CFW-08 Plus - A3 is composed of the inverter, the KFB-

CO-CFW08kitandtheCANopencommunicationprotocol.

Example:CFW-080040S2024PO

A3Z.CFW-08 Plus - A4 is composed of the inverter, the KFB-

DN-CFW08kitandtheDeviceNetcommunicationprotocol.

Example:CFW080040S2024PO

A4Z.CFW-08 Multipump -A5 is composed of the inverter and

thecontrolboard5,usedformultipumpsystemapplications.

7.0A, 16.0 A, 22 A, 28 A and 33 A /200-240 V and for all

380-480 V models are just available with three-phase

powersupply.

A Category C2 RFI filter (optional)can be installedinside

the inverter in models 7.3 A and 10 A/200-240 V (single-

phase) and 2.7A, 4.3 A, 6.5 A, 10 A, 13 A, 16A, 24 A and

30A/380-480 V.Models 1.6A, 2.6A and 4.0A/200-240 V

(single-phase)and 1.0A, 1.6A, 2.6Aand4.0A/380-480V

can be providedmounted on a footprint CategoryC2 RFI

filter(optional).

Thelistingoftheexistingmodels(voltage/current)isshown

initem 9.1.

Page 28

27

CHAPTER 2 - GENERAL INFORMATION

The CFW-08is supplied in cardboard boxes.

Theoutsideofthepackingboxhasa nameplatethatisidentical

tothat on the CFW-08.

Please check if the CFW-08is the one you ordered.

Checkifthe:

CFW-08nameplatedatamatcheswithyourpurchaseorder.

Theequipmenthas not been damaged duringtransport.

Ifanyproblem isdetected,contactthe carrier immediately.

If the CFW-08 is not installed immediately,store it in a clean

anddryroom(storage temperatures between -25 °C [-13 °F]

and 60 °C [140 ºF]). Cover it to protect against dust, dirt or

othercontamination.

ATTENTION!

When theinverterisstoredfor alongtime,it is recommended

to power the inverter up for 1 hour every year. Make sure to

use a power supply with the following characteristics for all

models (200-240 V or 380-480 V): 220 V, single-phase or

three-phase,50 Hz or 60 Hz, withoutconnectingthemotorto

thedriveoutput.Afterpoweringupthe drive,keepitoff for 24

hoursbeforeusingitagain.

2.5

RECEIVING

AND

STORING

Page 29

28

CHAPTER3

INSTALLATION ANDCONNECTION

Thischapterdescribestheproceduresforthe electricaland

mechanicalinstallationoftheCFW-08.Theseguidelines

andsuggestionsmust be followed for proper CFW-08

operation.

The location of the inverterinstallation is an important factor

to assure good performance and long useful life for its

components. For proper installation, we make the following

recommendations:

Avoid direct exposure to sunlight, rain, high moisture and

sea air;

Avoidexposuretoexplosiveorcorrosivegasesandliquids;

Avoid exposure to excessive vibration, dust, oil or any

conductiveparticles in the air.

Environment conditions:

Temperature: 0 ºC to 40 ºC (32 ºF to 104 ºF ) - nominal

conditions.From40ºCto50 ºC (32ºF to122ºF)-with2%

currentderatingfor each 1 ºC (1.8 ºF) degreeabove40 ºC

(104ºF).

Relativeairhumidity:5 % to 90 %-non-condensing.

Maximumaltitude: 1000m (3,300ft) -nominalconditions.

From 1000 m to 4000 m (3,300 to 13123.3 ft) - with 1 %

currentreduction for each 100 m (328 ft) above 1000 m

(3,300ft).

From2000m (6561.6ft) to 4000 m (13123.3ft)- avoltage

reduction of 1.1 % every 100 m (328 ft) above 2000 m

(6561.6ft).

Pollution degree: 2 (according to EN50178 and UL508C)

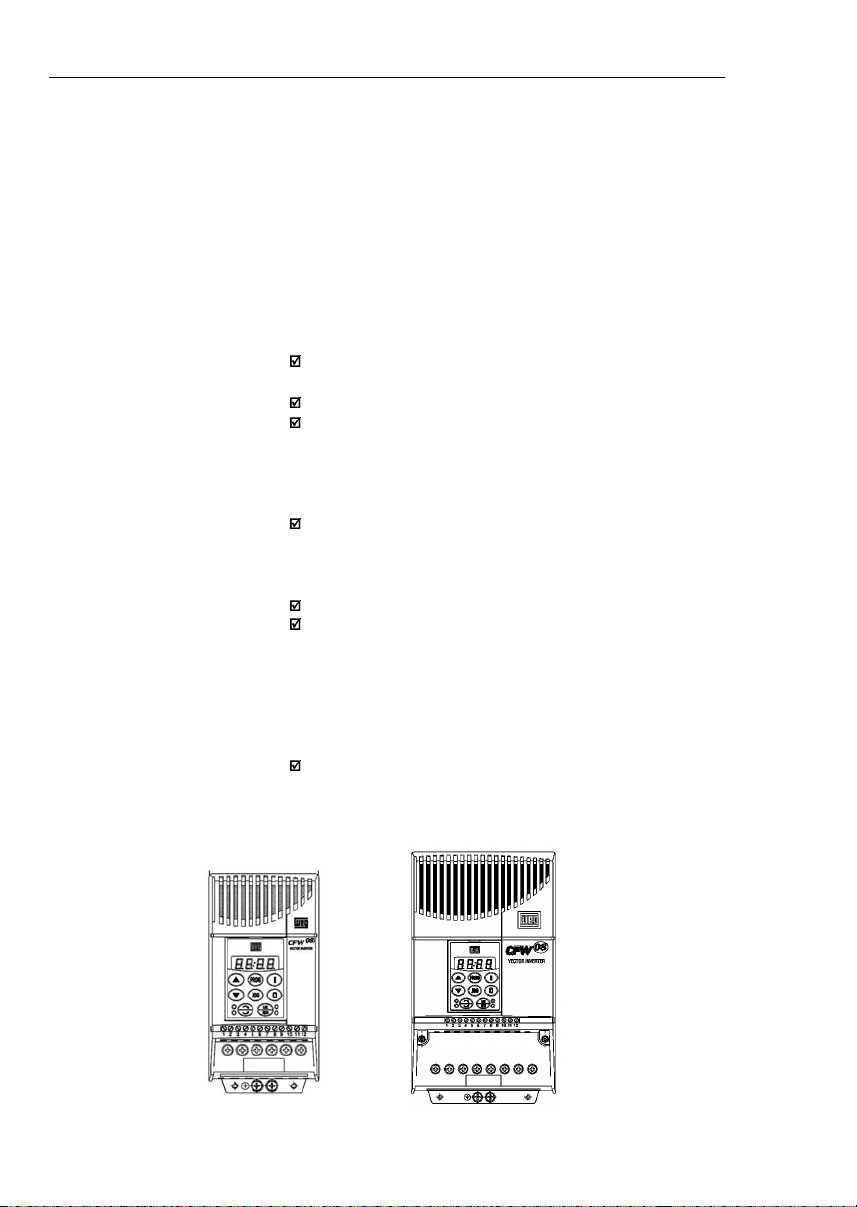

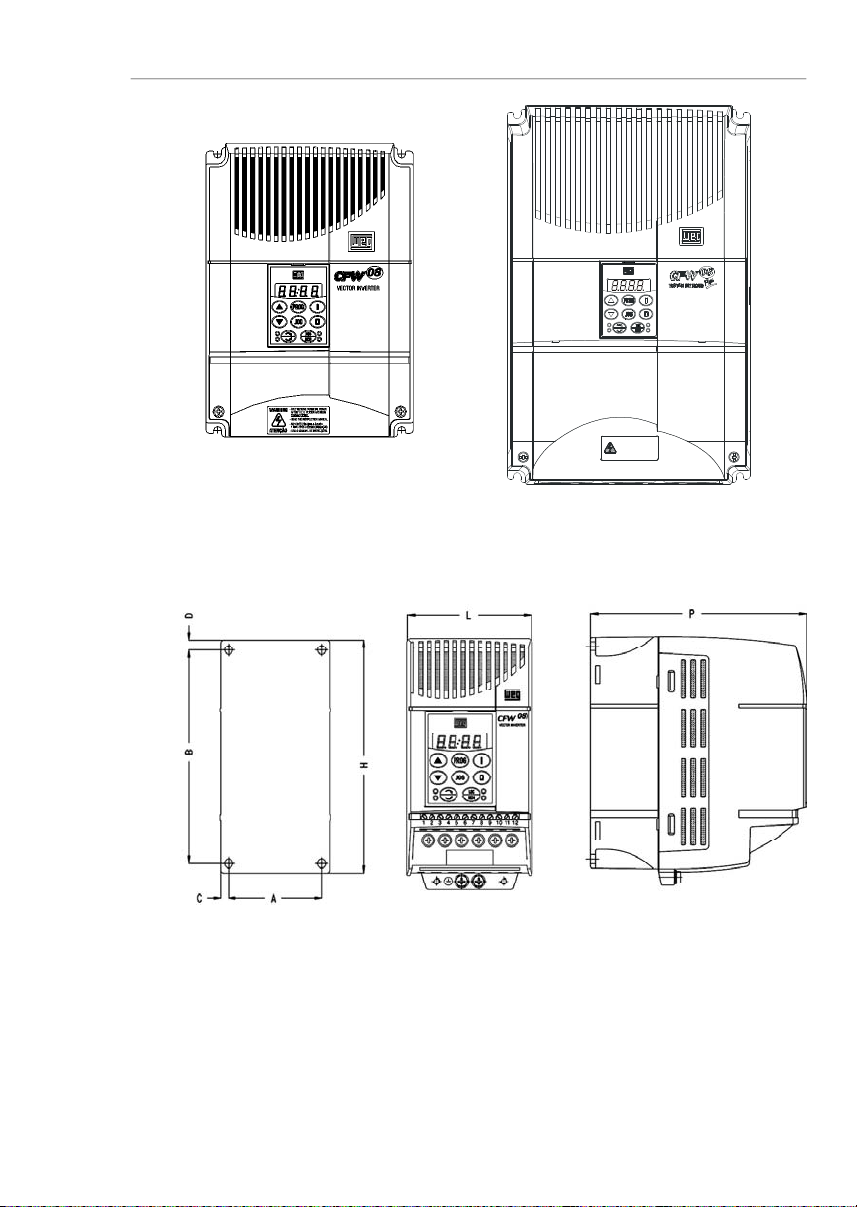

The figure 3.1 and the table 3.1, provides external mounting

specifications,and externalfixingholesof theCFW-08.

3.1

MECHANICAL

INSTALLATION

3.1.1

Environment

3.1.2

CFW-08Mounting

Specifications

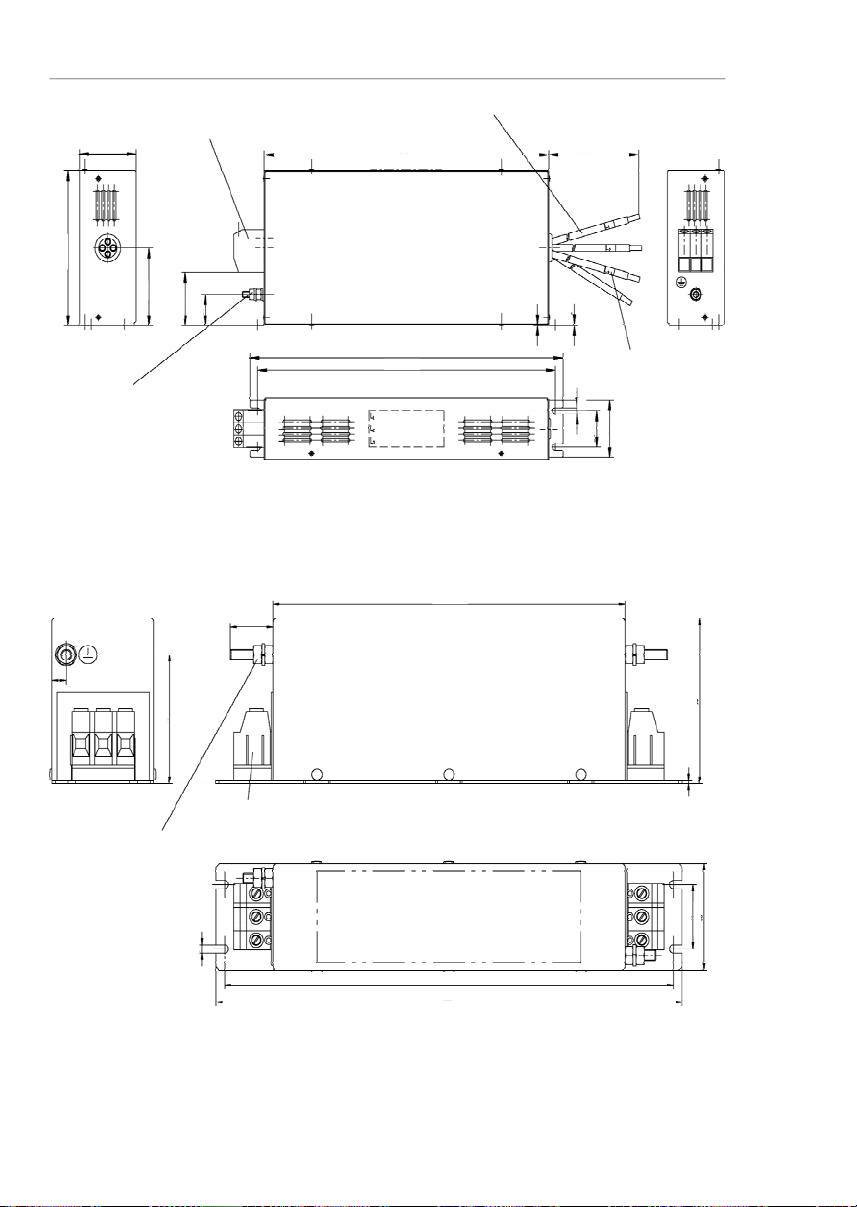

Figure 3.1

- CFW-08 mounting specifications

Page 30

29

CHAPTER 3 - INSTALLATION

AND CONNECTION

Figure 3.1 (cont.)

- CFW-08 mounting specifications

VIEW OF THE

MOUNTINGBASE

FRONTAL

VIEW

LATERALVIEW

1MIN.A PÓSADESENERGIZAÇÃO.

-SOMENTE REMOVAATAMPA

-LEIA OMANUALDE INSTRUÇÕES.

ATENÇÃO

-READ THEINSTRUCTIONSMA NUAL.

AFTER1 MIN.POWERHA SBEEN

-ONLYREMOVE TERMINALCOVER

WARNING

DISCONNECTED.

Page 31

30

CHAPTER 3 - INSTALLATION

AND CONNECTION

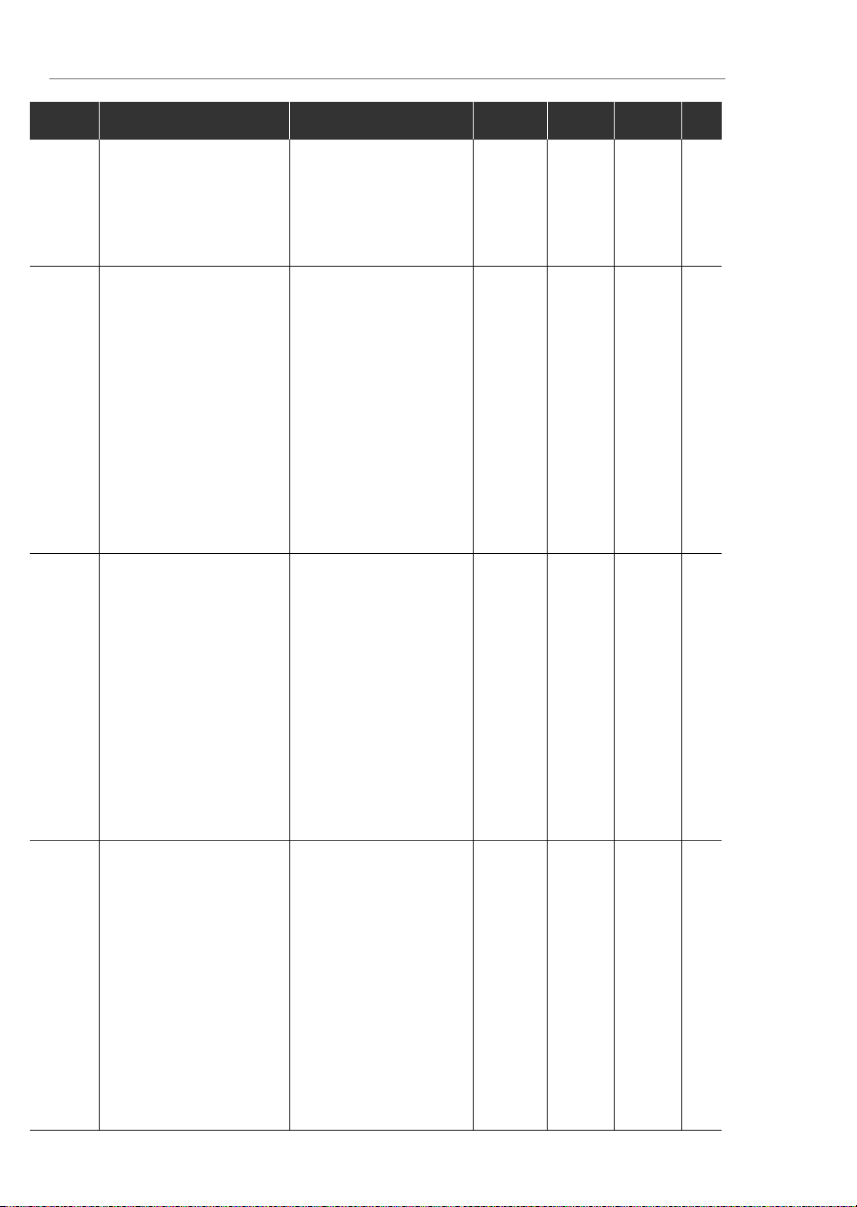

Inverter

Model

1.6A / 200-240 V

2.6A / 200-240 V

4.0A / 200-240 V

7.0A / 200-240 V

7.3A / 200-240 V

10A / 200-240 V

16A / 200-240 V

22A/200-240V

28A/200-240V

33A/200-240V

1.0A / 380-480 V

1.6A / 380-480 V

2.6A / 380-480 V

2.7A / 380-480 V

4.0A / 380-480 V

4.3A / 380-480 V

6.5A / 380-480 V

10A / 380-480 V

13A / 380-480 V

16A / 380-480 V

24A/380-480V

30A/380-480V

Width L

mm

(in)75(2.95)75(2.95)75(2.95)75(2.95)

115

(4.53)

115

(4.53)

115

(4.53)

143

(5.63)

182

(7.16)

182

(7.16)75(2.95)75(2.95)75(2.95)

115

(4.53)75(2.95)

115

(4.53)

115

(4.53)

115

(4.53)

143

(5.63)

143

(5.63)

182

(7.16)

182

(7.16)

HeightH

mm

(in)

151

(5.95)

151

(5.95)

151

(5.95)

151

(5.95)

200

(7.87)

200

(7.87)

200

(7.87)

203

(7.99)

290

(11.41)

290

(11.41)

151

(5.95)

151

(5.95)

151

(5.95)

200

(7.87)

151

(5.95)

200

(7.87)

200

(7.87)

200

(7.87)

203

(7.99)

203

(7.99)

290

(11.41)

290

(11.41)

Depth P

mm

(in)

131

(5.16)

131

(5.16)

131

(5.16)

131

(5.16)

150

(5.91)

150

(5.91)

150

(5.91)

165

(6.50)

196

(7.71)

196

(7.71)

131

(5.16)

131

(5.16)

131

(5.16)

150

(5.91)

131

(5.16)

150

(5.91)

150

(5.91)

150

(5.91)

165

(6.50)

165

(6.50)

196

(7.71)

196

(7.71)Amm

(in)64(2.52)64(2.52)64(2.52)64(2.52)

101

(3.98)

101

(3.98)

101

(3.98)

121

(4.76)

161

(6.33)

161

(6.33)

64

(2.52)

64

(2.52)64(2.52)

101

(3.98)64(2.52)

101

(3.98)

101

(3.98)

101

(3.98)

121

(4.76)

121

(4.76)

161

(6.33)

161

(6.33)Bmm

(in)

129

(5.08)

129

(5.08)

129

(5.08)

129

(5.08)

177

(6.97)

177

(6.97)

177

(6.97)

180

(7.08)

260

(10.23)

260

(10.23)

129

(5.08)

129

(5.08)

129

(5.08)

177

(6.97)

129

(5.08)

177

(6.97)

177

(6.97)

177

(6.97)

180

(7.09)

180

(7.09)

260

(10.23)

260

(10.23)

Cmm(in)5(0.20)5(0.20)5(0.20)5(0.20)7(0.28)7(0.28)7(0.28)11(0.43)11(0.43)11(0.43)5(0.20)5(0.20)5(0.20)7(0.28)5(0.20)7(0.28)7(0.28)7(0.28)11(0.43)11(0.43)11(0.43)11(0.43)Dmm

(in)6(0.24)6(0.24)6(0.24)6(0.24)5(0.20)5(0.20)5(0.20)10(0.39)10(0.39)10(0.39)6(0.24)6(0.24)6(0.24)5(0.20)6(0.24)5(0.20)5(0.20)5(0.20)10(0.39)10(0.39)10(0.39)10(0.39)

Mounting

ScrewM4(5/32)M4(5/32)M4(5/32)M4(5/32)M4(5/32)M4(5/32)M4(5/32)

M5

(3/16)

M5

(3/16)M5(3/16)M4(5/32)M4(5/32)M4(5/32)M4(5/32)M4(5/32)M4(5/32)M4(5/32)M4(5/32)M5(3/16)M5(3/16)M5(3/16)M5(3/16)

Weigth

kg

(lb)

1.0

(2.2)

1.0

(2.2)

1.0

(2.2)

1.0

(2.2)

2.0

(4.4)

2.0

(4.4)

2.0

(4.4)

2.5

(9.8)

6

(2.36)6(2.36)

1.0

(2.2)

1.0

(2.2)

1.0

(2.2)

2.0

(4.4)

1.0

(2.2)

2.0

(4.4)

2.0

(4.4)

2.0

(4.4)

2.5

(5.5)

2.5

(5.5)6(2.36)6(2.36)

Degreeof

Protection

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20/Nema1

IP20/Nema1

IP20/Nema1

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

IP20 / Nema 1

IP20 / Nema 1

IP20 / Nema 1

Dimensions

Fixing base

Table 3.1

- CFW-08 dimensions for mechanical installation of the several models

(*)

These modelsare Nema 1 only withthe KN1-CFW08-MX optional.

Page 32

31

CHAPTER 3 - INSTALLATION

AND CONNECTION

When installingtheCFW-08,free spacearound the inverter

must be left as indicated in figure 3.2.

Table 3.2 shows the

required free spaces.

Installtheinverterinverticalpositionaccordingtothefollowing

recommendations:

1)

Installtheinverterona flat surface.

2)Donotinstallheatsensitivecomponentsimmediatelyabove

the

inverter.

ATTENTION!

When inverters are installed side by side, maintain the

minimumrecommendeddistanceB.

W

hen inverters are installed top and bottom, maintain the

minimum recommended distance

A+ C and deflect the hot

aircomingfrom theinverterbelow.

ATTENTION!

Provide independent conduits for signal, control and power

conductorsseparation(refertoitem3.2-ElectricalInstallation).

Useseparateconduitsortrunkingforcontrolandpowerwiring

(seeitem 3.2 - Electrical Installation).

Figure 3.2

- Free spaces for cooling

3.1.3

Positioningand Fixing

Page 33

32

CHAPTER 3 - INSTALLATION

AND CONNECTION

CFW-08Model

1.6A / 200-240 V

2.6A / 200-240 V

4.0A / 200-240 V

7.0A / 200-240 V

1.0A / 380-480 V

1.6A / 380-480 V

2.6A / 380-480 V

4.0A / 380-480 V

7.3A / 200-240 V

10A / 200-240 V

16A / 200-240 V

2.7A / 380-480 V

4.3A / 380-480 V

6.5A / 380-480 V

10A / 380-480 V

22A / 200-240 V

13A / 380-480 V

16A / 380-480 V

28A/200-240V

33A/200-240V

24A/380-480V

30A/380-480V

ABCD30 mm

1.18 in

5 mm

0.20 in

50 mm

2 in

50 mm

2 in

35 mm

1.38 in

15 mm

0.59 in

50 mm

2 in

50 mm

2 in

40 mm

1.57 in

30 mm

1.18 in

50 mm

2 in

50 mm

2 in

50 mm

2 in

40 mm

1.57 in

60 mm

2.36 in

50 mm

2 in

Table 3.2

- Recommendedfree spaces

When invertersare installedinside closedmetallic panels or

boxes provide suitable air exhaustion by ensuring that the

ambient temperature remains within the allowed range. For

wattlosses refer to item 9.1of this manual.

For reference, table 3.3 shows the cooling airflow for each

invertermodel.

Inverter Cooling Method:

internal fan, flow direction from

thebottomto the top.

3.1.3.1

PanelMounting

Table 3.3

- Coolingair flow requirements

CFW-08 Inverter Model

CFM

I/s

m3/min

4.0

A, 7.0

A/200V2.6

A, 4.0

A/400V6.0

2.8

0.17

7.3

A, 10

A, 16

A/200V6.5

A, 10

A/400V18.0

8.5

0.5113A, 16

A/400V18.0

8.5

0.5122A/200V22.0

10.4

0.6228A/200V24

A/400V36.0

17.0

1.0233A/200V30

A/400V44.0

20.8

1.25

Page 34

33

CHAPTER 3 - INSTALLATION

AND CONNECTION

3.1.3.2

SurfaceMounting

Figure 3.3 shows the surface installation procedures of the

CFW-08.

Figure 3.3

- Mounting procedures for CFW-08

3.2

ELECTRICAL

INSTALLATION

DANGER!

The information below will be a guide to achieve a proper

installation. Also follow all applicable local standards for

electricalinstallations.

DANGER!

Be sure the AC input power has been disconnected before

makinganyterminalconnection.

DANGER!

Do not use the CFW-08 as an emergencystop device. For

thispurposeprovideother additional mechanical means.

Thepowerconnectionterminalscanbe of differentsizesand

configurations,dependingontheinvertermodel,as shownin

figure3.4.

Descriptionofthepowerterminals:

L/L1,N/L2 and L3 (R, S ,T):AC powersupply.

Themodels of thelinevoltage200-240V (excepting7.0A,

16A, 22A, 28A, and33A) canbeoperatedon twophases

(single-phaseoperation)withoutratedcurrentreduction.In

this case the AC power supplycan be connected to any2

terminalsof the 3 inputsterminals.

U,V,W: connectiontothemotor.

3.2.1

Power/ Grounding

Terminals

AIR FLUX

Page 35

34

CHAPTER 3 - INSTALLATION

AND CONNECTION

-UD:negativepoleof the DClinkcircuitis notavailable on

themodels 1.6A-2.6A-4.0A-7.0A/200-240V and models

1.0 A-1.6 A-2.6 A-4.0 A/380-480 V. It is used when the

invertersuppliedby DC voltage(withtheterminal+UD).In

order to avoid an incorrect braking resistor connection

(mountedoutsidethe inverter),thereis a protectiverubber

plug on this terminal, which must be removed if the –UD

terminalhastobeused.

BR:Connectionforthebrakingresistor.

Notavailableonthemodels1.6A-2.6A-4.0A-7.0A/200-240V

andonthemodels1.0A-1.6A-2.6A-4.0A/380-480V.

+UD: positive pole of the DC link circuit, notavailable on

the models 1.6A-2.6 A-4.0A-7.0A/200-240V and on the

models 1.0 A-1.6 A-2.6 A-4.0 A/380-480 V. It is used to

connectthebrakingresistor(withtheBR terminal)orwhen

the inverter shall be supplied by with DC voltage (jointly

withthe –UDterminal.

DCR: Connection for the external DC link circuit inductor

(optional).Itisonlyavailable on themodels28Aand 33A/

200-240 V and on the models 24 Aand 30 A/380-480 V.

c) 22 A/200-240 V and 13-16A/380-480 V models

b)7.3-10-16A/200-240 V and2.7-4.3-6.5-10A/380-480V models

a)1.6-2.6-4.0-7.0A/200-240 Vand 1.0-1.6-2.6-4.0A/380-480 Vmodels

Figure 3.4 a) to c)

- Power terminals

L3UVWL/L1

N/L2

-Ud

BR+Ud

L3

L/L1

N/L2

UVW1R2S3T4U5V6W7-UD8BR9+UD

LINE

MOTOR

Page 36

35

CHAPTER 3 - INSTALLATION

AND CONNECTION

3.2.2

Location of the Power

Terminals,Grounding

TerminalsandControl

TerminalConnections

ControlXC1

Power

Grounding

a)1.6-2.6-4.0-7.0-7.3-10-16A/200-240Vand

1.0-1.6-2.6-2.7-4.0-4.3-6.5-10A/380-480Vmodels

Figure 3.5 a) and b)

- Location of the power, grounding and

control connections

b)22-28-33A/200-240V and 13-16-24-30A/380-480 V models

ControlXC1

Power

Grounding

Figure 3.4 (cont.) d)

- Power terminals

d) 28-33 A/200-240V and 24-30A/380-480 V models

1R2S3T4U5V6W7

-UD8BR9+UD

LINE

MOTOR10DCR

Page 37

36

CHAPTER 3 - INSTALLATION

AND CONNECTION

3.2.3

Power/Grounding

Wiringand

Circuit Breakers

ATTENTION!

Install the inverter and power cables distant from sensitive

equipmentand wiringsby0.25m (0.82 ft),forinstancePLCs,

temperaturecontrollers,thermocouplecables,etc.

Usetherecommendedwirecrosssectionandcircuitbreakers

as shownin table 3.4. Use onlycopper wire (70 ºC [158 ºF]).

NOTE!

Thewire sizing in table3.4shallbeusedas reference values

only. The exact wire sizing depends on the installation

conditionsand the maximum acceptable line voltage drop.

Therecommendedtightening torque is shownintable3.5.

ATTENTION!

The use of mini circuit breakers (MBU) is not recommended

duetothelevel of the magneticprotection.

Table 3.4

- Recommendedwiring and circuit breakers – use only copper wire (70 ºC [158 ºF])

Page 38

37

CHAPTER 3 - INSTALLATION

AND CONNECTION

Model

1.6A / 200-240 V

2.6A / 200-240 V

4.0A / 200-240 V

7.0A / 200-240 V

7.3A / 200-240 V

10.0A / 200-240 V

16.0A / 200-240 V

22.0A / 200-240 V

28.0A / 200-240 V

33.0A / 200-240 V

1.0A / 380-480 V

1.6A / 380-480 V

2.6A / 380-480 V

2.7A / 380-480 V

4.0A / 380-480 V

4.3A / 380-480 V

6.5A / 380-480 V

10.0A / 380-480 V

13.0A / 380-480 V

16.0A / 380-480 V

24.0A / 380-480 V

30.0A / 380-480 V

GroundingWiring

N.m

Lbf.in

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

0.5

4.34

Power Cables

N.m

Lbf.in

1.0

8.68

1.0

8.68

1.0

8.68

1.0

8.68

1.76

15.62

1.76

15.62

1.76

15.62

1.76

15.62

1.76

15.62

1.76

15.62

1.2

10.0

1.2

10.0

1.2

10.0

1.76

15.62

1.2

10.0

1.76

15.62

1.76

15.62

1.76

15.62

1.76

15.62

1.76

15.62

1.76

15.62

1.76

15.62

Table 3.5

- Recommended tighteningtorque for power andgrounding connections

3.2.4

PowerConnections

a) 1.6-2.6-4.0-7.0A/200-240 V and 1.0-1.6-2.6-4.0A/380-480V models - Threephase power supply

Typeof Screwdriverfor

thePowerTerminal

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

PhilipsNumber PH2

PozidrivNumber PZ2

PozidrivNumberPZ2

PhilipsNumber PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

PozidrivNumberPZ2

PozidrivNumberPZ2

Figure 3.6 a)

- Powerand grounding connections

PERSTPowerSupply

CircuitBreaker

PE

T

Q1

R

STUVW

PE

Shielding

PEWV

U

Page 39

38

CHAPTER 3 - INSTALLATION

AND CONNECTION

c) 1.6-2.6-4.0-7.3-10A/ 200-240 V models - Singlephase power supply

Figure 3.6 b) and c)

- Powerand grounding connections

(*)

Incase of single-phase powersupply with phase and neutral cable, connect only the phasecable to the

circuit breaker.

(**)

In the 1.6A -2.6 A and 4.0A models, the terminals to connect the braking resistor are not available.

PE

PE

T

Q1

RSTUVWPE

Shielding

PE

-Ud

BR+Ud

Braking

Resistor

(**)

(referto item

8.23)

WVU

Phase

Neutral

PowerSupply

Circuit Breaker

(*)

b) 7.3-10-16-22A/200-240 V and 2.7-4.3-6.5-10-13-16A/380-480V models -Three phase powersupply

PERSTPowerSupply

PE

T

Q1

RSTUVWPE

Shielding

PE

-Ud

BR+Ud

Braking

Resistor

(referto item

8.23)

WVU

CircuitBreaker

Page 40

39

CHAPTER 3 - INSTALLATION

AND CONNECTION

Figure 3.6 d)

- Powerand grounding connections

d) 28-33A / 200-240V and 24-30A / 380-480 V models - Three phase powersupply

DANGER!

Provide anAC disconnecting switch to switch OFF the input

powertothe inverter. Thisdeviceshalldisconnecttheinverter

from the AC input supply when required (e. g. during

maintenanceservices).

ATTENTION!

Acontactoror anotherdevicethatfrequentlydisconnectsand

reapplies the AC supply to the inverter in order to startand

stop the motor may cause damage to the inverter power

section.The driveis designed to use control input signals for

startingand stoppingthe motor.Ifused,theinputdevicemust

not exceed one operation every 6 minutes otherwise the

invertermay be damaged.

ATTENTION!

TheAC input for the inverter must have a grounded neutral

conductor.

NOTE!

TheACinputmustbecompatiblewiththeinverterratedvoltage

Power supply line capacity:

30kArms symmetrical amperes, 200-480 Vacmaximum,

whenprotected by fuses ratedmaximum of 200 % device

inputcurrent. Voltageis thesameasthedevicemaximum

inputvoltage. Inordertocomplywith theUL standard,UL

recognizedfuses must be used.

3.2.4.1

ACInput Connection

PE

T

Q1

RSTUVWPE

Shielding

PE

-Ud

BR+Ud

Braking Resistor

WVU

Phase

PowerSupply

DCR

DCLink

Inductor

(Optional)

PE

RST

CircuitBreaker

Page 41

40

CHAPTER 3 - INSTALLATION

AND CONNECTION

3.2.4.3

Grounding

Connections

IftheCFW-08isinstalledinnetworkswhichcansupplymore

than 30.000 Arms, you must provide suitable protection

circuitssuchasfuses and circuit breakers.

DC link inductor / line reactors

Therequirementsforuseofline reactorsorDC link inductor

dependonseveral application factors. Refer to item8.21.

NOTE!

Capacitorsfor power factor correctionarenotrequiredatthe

input(L/L1,N/L2,L3orR,S,T)andtheymustnotbeconnected

atthe output (U,V,W).

The inverter is provided with electronic protection against

motoroverload.This protection must be set according to the

specificmotor.Whenthesameinverterdrivesseveralmotors,

use individual overload relays for each motor. Maintain the

electricalcontinuityofthemotor cable shield.

ATTENTION!

If a disconnect switch or a contactor is inserted in the motor

supplyline, do not operatethem with motor running or when

inverter is enabled. Maintain the electrical continuity of the

motorcable shield.

Dynamic braking (DB)

When inverterswith dynamic braking (DB) are used, the DB

resistorshall be mountedexternally. Figure 8.31 shows how

to connect the braking resistor. Size it according to the

application,notexceedingthemaximumcurrentof thebraking

circuit. For the connection betweeninverter and the braking

resistor, use twisted cable. Provide physical separation

betweenthis cable and the signal and control cables. When

the DB resistor is mounted inside the panel, consider watt

lossgeneratedwhendefining thepanelventilation.

DANGER!

Theinvertermustbe grounded to a protective earth (PE) for

safetypurposes.

The earth or ground connection must comply with the local

regulations.Forgrounding,use cableswithcrosssectionsas

indicated in table 3.4. Make the ground connection to a

grounding bar or tothe generalgrounding point (resistance

10 ohms).

DANGER!

Do not share the ground wiring with other equipment that

operateswithhighcurrents(forinstance:highvoltagemotors,

weldingmachines,etc).Ifseveralinvertersareusedtogether,

refertofigure 3.7.

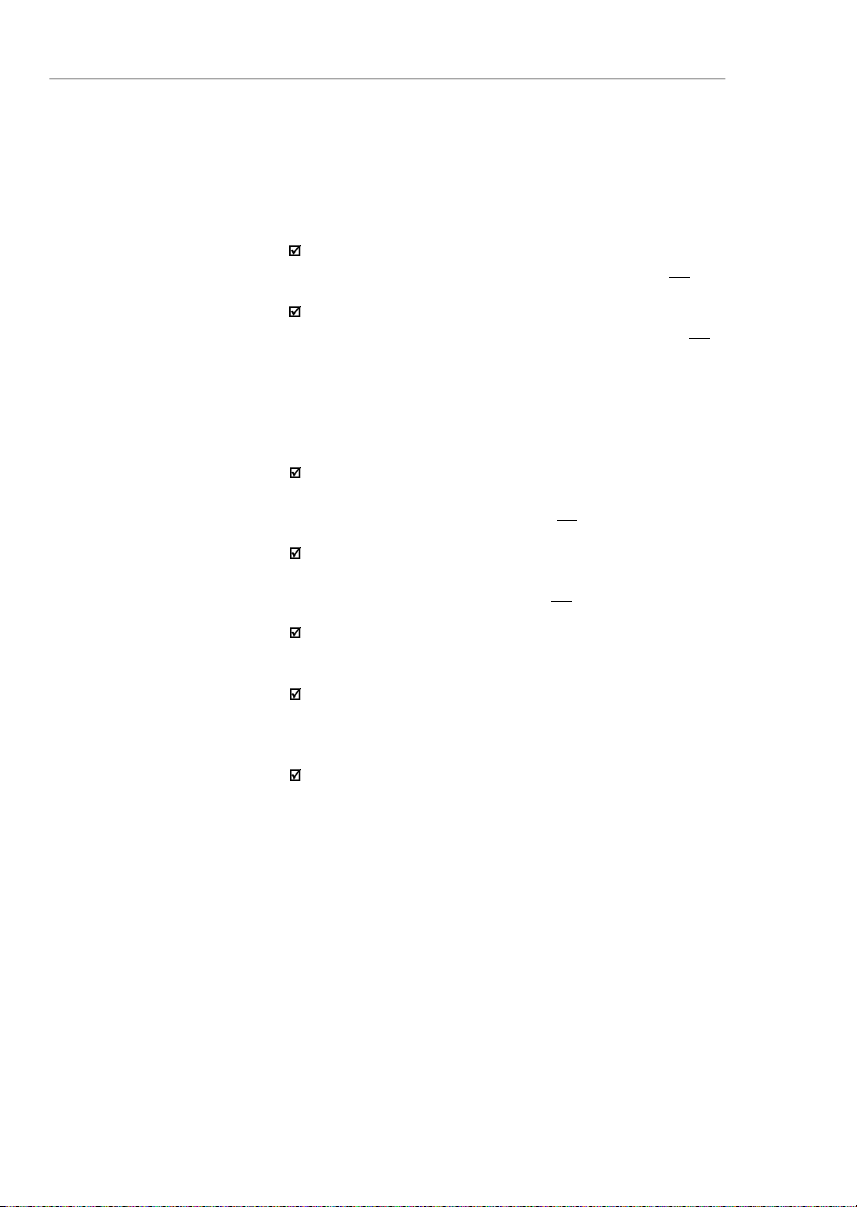

3.2.4.2