Page 1

Motors | Automation | Energy | Transmission & Distribution | Coatings

Frequency Inverter

Convertidor de Frecuencia

Inversor de Frequência

CFW300

User's Manual

Manual del Usuario

Manual do Usuário

Page 2

User’s Manual

Series: CFW300

Language: English

Document Nº: 10003325037 / 00

Models: Frame Sizes A and B

Publishing Date: 11/2015

Page 3

Summary of Reviews

The information below describes the revisions made to this manual.

English

Version Review Description

-- R00 First edition

ATTENTION!

Check the frequency of the power supply.

In case the power supply frequency is different from the factory setting (check

P403), it is necessary to set:

P204 = 5 for 60 Hz.

P204 = 6 for 50 Hz.

It is only necessary to set these parameters once.

Refer to the programming manual of the CFW300 for further details about the

programming of parameter P204.

Page 4

Contents

1 SAFETY INSTRUCTIONS .................................................................... 1

1.1 SAFETY WARNINGS IN THE MANUAL .................................................... 1

1.2 SAFETY WARNINGS IN THE PRODUCT ................................................. 1

1.3 PRELIMINARY RECOMMENDATIONS ....................................................2

2 GENERAL INFORMATION ..................................................................3

2.1 ABOUT THE MANUAL .............................................................................. 3

2.2 ABOUT THE CFW300 ................................................................................ 3

2.3 TERMINOLOGY .........................................................................................6

2.4 IDENTIFICATION LABEL .........................................................................7

2.5 RECEIVING AND STORAGE .....................................................................8

3 INSTALLATION AND CONNECTION ..................................................9

3.1 MECHANICAL INSTALLATION .................................................................9

3.1.1 Environmental Conditions ..............................................................9

3.1.2 Positioning and Mounting...............................................................9

3.1.2.1 Cabinet Mounting ................................................................9

3.1.2.2 Surface Mounting ............................................................. 10

3.1.2.3 DIN-Rail Mounting .............................................................10

3.2 ELECTRICAL INSTALLATION ................................................................10

3.2.1 Identification of the Power Terminals and Grounding Points .10

3.2.2 Circuit Breakers, Fuses, Grounding and Power ....................... 11

3.2.3 Power Connections .......................................................................12

3.2.3.1 Input Connections .............................................................14

3.2.3.2 Power Supply Reactance ................................................14

3.2.3.3 Dynamic Braking ...............................................................15

3.2.3.4 Output Connections .........................................................16

3.2.4 Grounding Connections ............................................................... 17

3.2.5 Control Connections ....................................................................17

3.2.6 Cable Separation Distance ..........................................................18

3.3 INSTALLATIONS ACCORDING TO EUROPEAN DIRECTIVE OF

ELECTROMAGNETIC COMPATIBILITY .....................................................18

3.3.1 Control Connections .....................................................................19

3.3.2 Emission and Immunity Levels .................................................... 19

3.3.3 Characteristics of the RFI Filter .................................................20

English

4 KEYPAD (HMI) AND BASIC PROGRAMMING ................................21

4.1 USE OF THE KEYPAD TO OPERATE THE INVERTER .........................21

4.2 INDICATIONS ON THE HMI DISPLAY ...................................................21

4.3 OPERATING MODES OF THE HMI ........................................................21

5 FIRST TIME POWER-UP AND START-UP .......................................23

5.1 START-UP PREPARATION ......................................................................23

5.2 START-UP ................................................................................................23

5.2.1 Basic Application...........................................................................24

5.2.2 V/f Type of Control (P202 = 0) ......................................................25

5.2.3 Control Type VV W (P202 = 5).......................................................26

Page 5

Contents

6 TROUBLESHOOTING AND MAINTENANCE ...................................27

English

6.1 FAULTS AND ALARMS ............................................................................27

6.2 SOLUTION FOR THE MOST FREQUENT PROBLEMS ........................27

6.3 INFORMATION NECESSARY FOR CONTACTING TECHNICAL

SUPPORT .......................................................................................................27

6.4 PREVENTIVE MAINTENANCE................................................................28

6.5 CLEANING INSTRUCTIONS ..................................................................29

7 ACCESSORIES ..................................................................................30

8 TECHNICAL SPECIFICATIONS ........................................................31

8.1 POWER DATA ...........................................................................................31

8.2 ELECTRONICS/GENERAL DATA ...........................................................32

8.2.1 Considered Standards ..................................................................33

APPENDIX A - FIGURES .................................................................... 110

APPENDIX B - TECHNICAL SPECIFICATIONS ................................ 113

Page 6

Safety Instructions

1 SAFETY INSTRUCTIONS

This manual provides information for the proper installation and operation of the CFW300

frequency inverter.

It has been written to be used by qualified personnel with suitable training or technical

qualification for operating this type of equipment. The personnel shall follow all the safety

instructions described in this manual and/or defined by the local regulations. Failure to comply

with the safety instructions may result in death, serious injury, and equipment damage.

1.1 SAFETY WARNINGS IN THE MANUAL

The following safety notices are used in the manual:

DANGER!

The procedures recommended in this warning have the purpose of protecting the

user against death, serious injuries and considerable material damage.

ATTENTION!

The procedures recommended in this warning have the purpose of avoiding

material damage.

NOTE!

The information mentioned in this warning is important for the proper

understanding and good operation of the product.

1.2 SAFETY WARNINGS IN THE PRODUCT

The following symbols are attached to the product, serving as safety notices:

English

High voltages are present.

Components sensitive to electrostatic discharge.

Do not touch them.

Mandatory connection to the protective ground (PE).

Connection of the shield to the ground.

CFW300 | 1

Page 7

Safety Instructions

1.3 PRELIMINARY RECOMMENDATIONS

English

DANGER!

Always disconnect the main power supply before touching any electrical

component associated to the inverter. Several components can remain charged

with high voltages or remain in movement (fans) even after the AC power is

disconnected or switched off.

Wait at least ten minutes after turning off the input power for the complete

discharge of the power capacitors.

Always connect the grounding point of the inverter to the protection earth (PE).

DANGER!

The XC10 connector does is not USB compatible, therefore, it cannot be

connected to USB ports.

This connector only serves as the interface between the CFW300 frequency

inverter and its accessories.

NOTES!

Frequency Inverter may interfere with other electronic equipment. In order to

reduce these effects, take the precautions recommended in the Chapter 3

INSTALLATION AND CONNECTION on page 9.

Read the user's manual completely before installing or operating the inverter.

Do not perform any withstand voltage test!

If necessary, contact the manufacturer.

ATTENTION!

Electronic boards have components sensitive to electrostatic discharges.

Do not touch directly on components or connectors.

If necessary, first touch the grounding point of the inverter, which must be

connected to the protection earth (PE) or use a proper grounding strap.

2 | CFW300

Page 8

2 GENERAL INFORMATION

2.1 ABOUT THE MANUAL

General Information

This manual contains information for the proper installation and operation of the inverter,

commissioning, main technical features and how to identify the most usual problems of the

different models of inverters of the CFW300 line.

ATTENTION!

The operation of this equipment requires detailed installation and operation

instructions provided in the quick installation guide, user's manual, programming

manual and communication manuals. The guides are provided in print with their

respective accessory, or can be obtained at WEG website - www.weg.net. A

printed copy of the files can be requested at your local WEG dealer.

NOTE!

It is not the intention of this manual to present all the possibilities for the application

of the CFW300, as well as WEG cannot take any liability for the use of the CFW300

which is not based on this manual.

Part of the figures and tables are available in the annexes, which are divided into APPENDIX

A - FIGURES on page 110 for figures and APPENDIX B - TECHNICAL SPECIFICATIONS on

page 113 for technical specifications.

For further information, refer to the programming manual.

2.2 ABOUT THE CFW300

The CFW300 frequency inverter is a high-performance product which allows speed and torque

control of three-phase induction motors. This product provides the user with the options of

vector (VVW) or scalar (V/f) control, both programmable according to the application.

English

In the vector mode (V VW ), the operation is optimized for the motor in use, obtaining a better

performance in terms of speed regulation.

The scalar mode (V/f) is recommended for simpler applications, such as the activation of most

pumps and fans. In such cases it is possible to reduce the losses in the motor and the inverter

using the "V/f Quadratic", which results in energy savings. The V/f mode is used when more

than a motor is activated by an inverter simultaneously (multimotor applications).

The frequency inverter CFW300 also has functions of PLC (Programmable Logic Controller)

by means of the SoftPLC (integrated) feature. For further details regarding the programming of

those functions, refer to the SoftPLC user's manual of the CFW300.

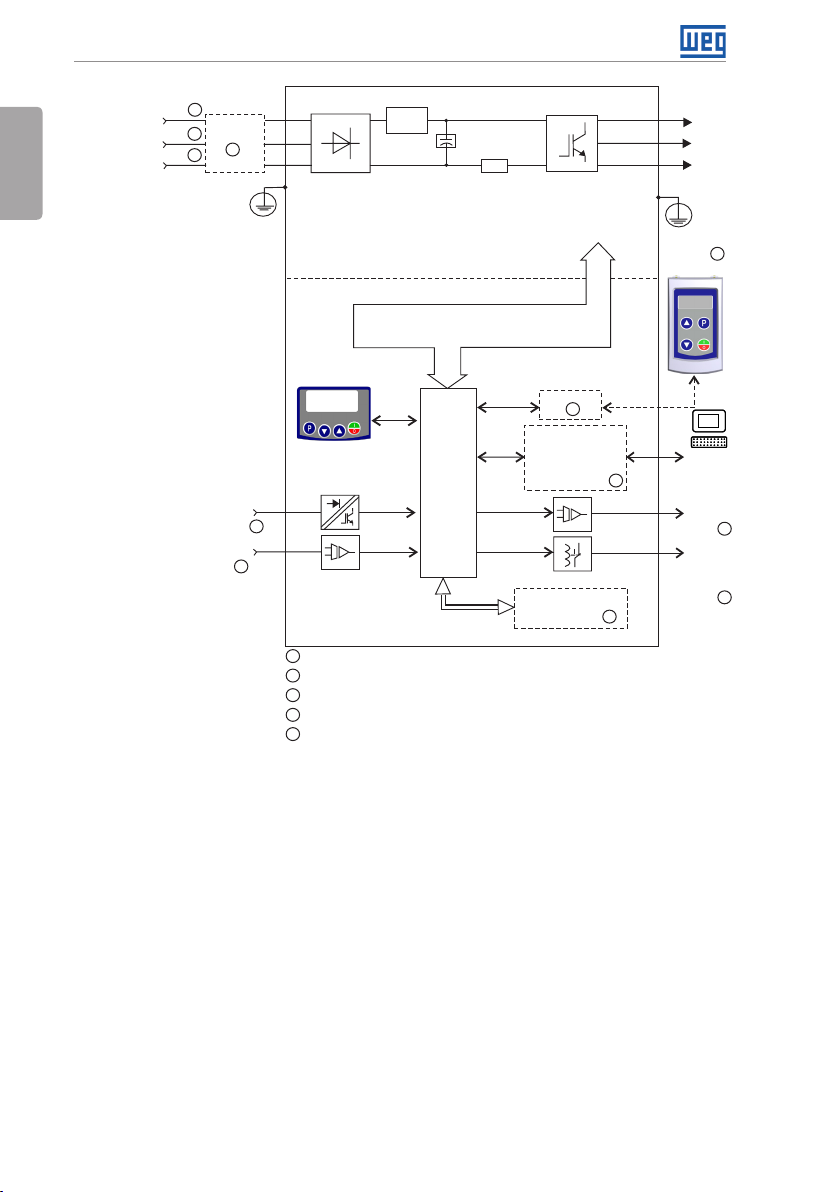

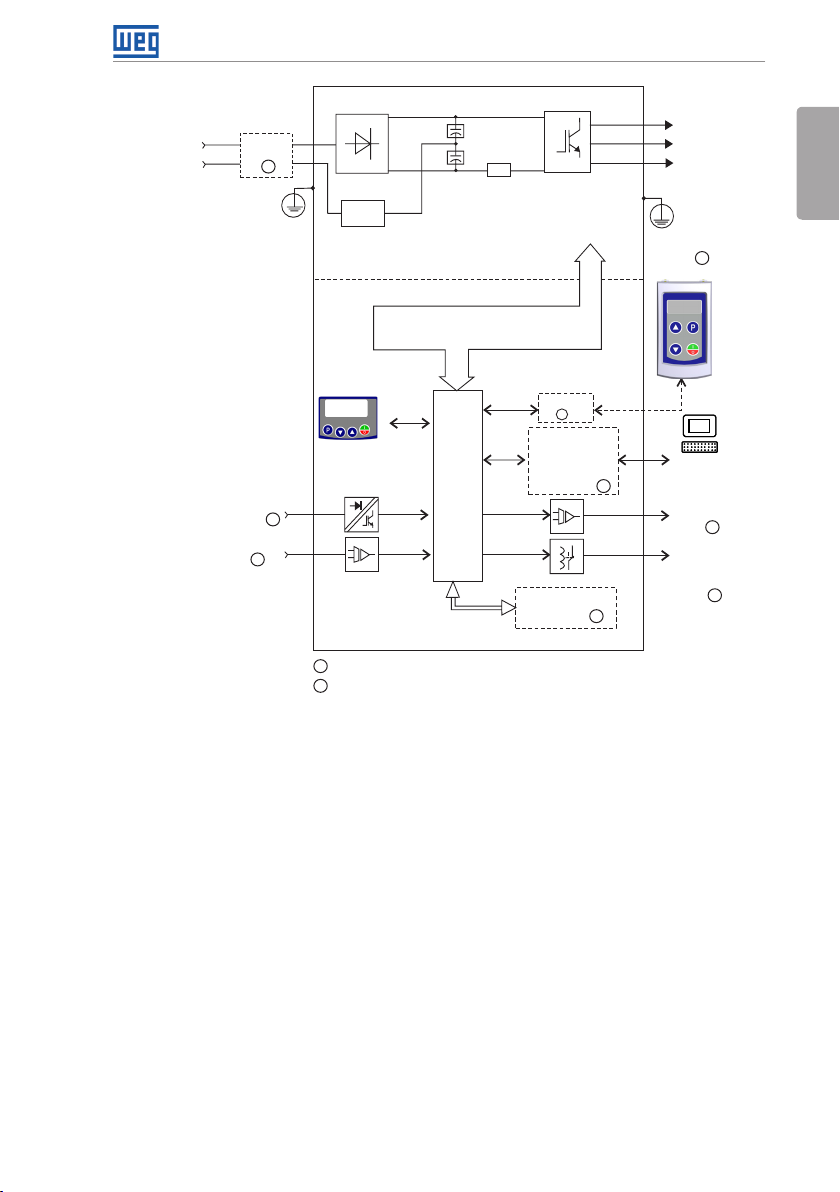

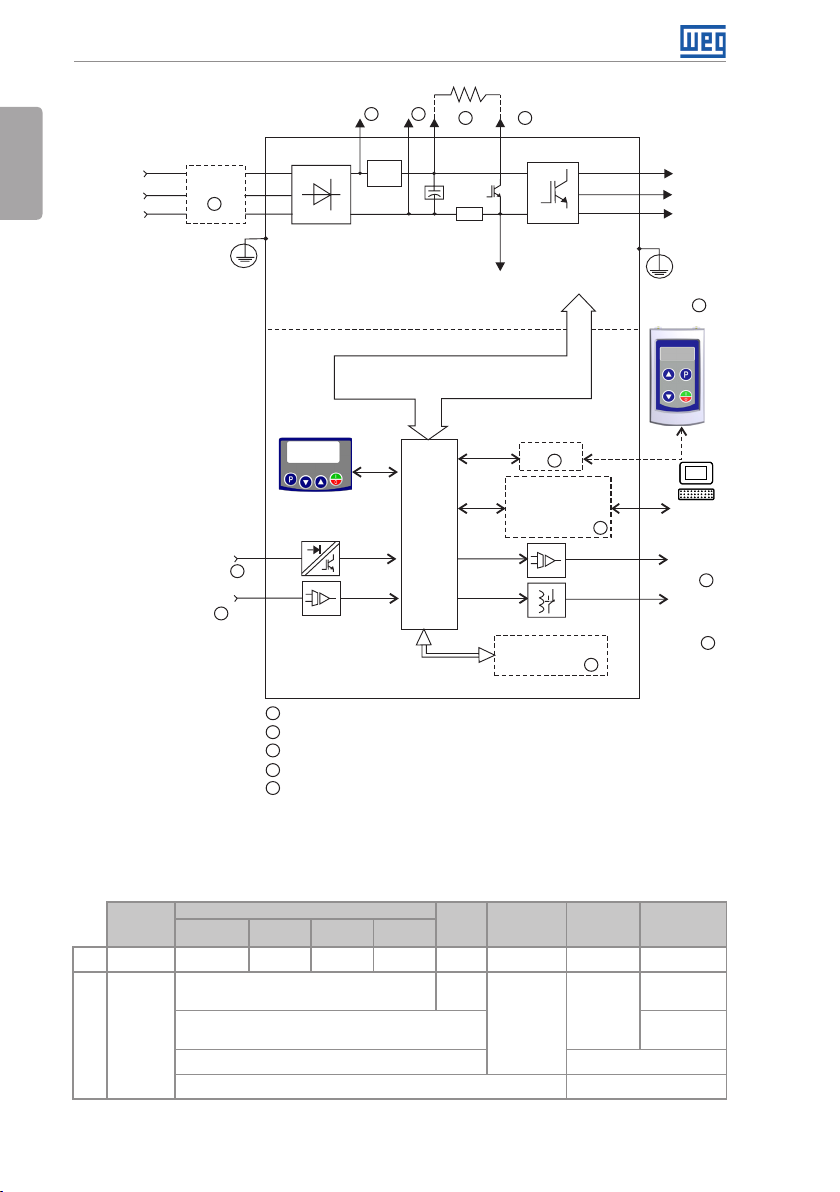

The main components of the CFW300 can be viewed in the blocks diagrams of Figure 2.1 on

page 4, for frame size A 220 V, Figure 2.2 on page 5 for frame size A 110 V and Figure

2.3 on page 6 for frame size B 220 V.

CFW300 | 3

Page 9

General Information

English

supply

S/L2/N (+UD)

R/L1/L (-UD)

Power

T/L 3

1

1

2

Filter RFI

5

PE

Single-phase /

three-phase

rectifier

Power

Preload

DC Link

capacitor

bank

Rsh

Inverter

with IGBT

transistors

U/T1

V/T2

Motor

3~

W/T3

PE

HMI (remote)

3

Control

Digital inputs

(DI1 to DI4)

Analog input

(AI1)

Sources for electronics and interfaces between

HMI

4

4

1

DC power supply connection available for specific models only

2

Three-phase power supply connection available for specific models only

3

Available as accessory

4

Number of Inputs/O utputs depends o n the I/O expansion ac cessory used

5

Available as accessory only in models single-phase

power and control

Control

board

with

CPU

16 bits

RS-485

3

Interfaces (RS-232,

RS-485, USB,

CANopen, Dev iceNet,

Profibus DP or

Bluetooth)

Flash Memory

Module

PC

Software

3

WPS

Analog

output

(AO1)

Digital

output

DO1

(R L1)

4

4

3

Figure 2.1: Block diagram of CFW300 for frame size A 220 V

4 | CFW300

Page 10

Power

supply

L1/L

L2/N

Filter

RFI

1

PE

Single-phase /

three-phase rectifier

Preload

Power

Control

Rsh

DC Link

capacitor

bank

Sources for electronics and interfaces

between power and control

Inverter

with IGBT

transistors

General Information

U/T1

Motor

V/T2

3~

W/T3

PE

1

HMI (remote)

English

Digital inputs

(DI1 to DI4)

Analog input

(AI1)

HMI

2

Control

board

with

CPU

16 bits

Interfaces (RS-232,

CANopen, Dev iceNet,

2

Flash Memory

1

Available as accessory

2

Number of Inputs/O utputs depends o n the I/O expansion ac cessory used

Figure 2.2: Block diagram of CFW300 for frame size A 110 V

RS-485

1

RS-485, USB,

Profibus DP or

Bluetooth)

Module

PC

Software

1

WPS

Analog

output

(AO1)

Digital

output

DO1

(R L1)

2

2

1

CFW300 | 5

Page 11

General Information

English

R/L1/L

Power

supply

S/L2/N

T/L 3

Digital inputs

(DI1 to DI4)

Analog input

Filter RFI

(AI1)

5

Three-phase

rectifier

PE

Power

Control

HMI

3

3

1 1

+UD -UD +BR BR

Preload

Sources for electronics and interfaces between

4 4

Rsh

DC Link

capacitor

bank

power and control

Control

board

with

CPU

16 bits

Inverter

with IGBT

transistors

Braking

IGBT

RS-485

Interfaces (RS-232,

RS-485, USB,

CANopen, Dev iceNet,

Profibus DP or

Bluetooth)

Flash Memory

Module

U/T1

V/T2

Motor

3~

W/T3

PE

2

HMI (remote)

2

2

2

PC

Software

WPS

Analog

output

(AO1)

Digital

output

DO1

(R L1)

3

3

DC power supply connection

1

Available as accessory

2

3

Number of Inputs/O utputs depends o n the I/O expansion ac cessory used

Braking resistor connection

4

Available as accessory only in models single-phase

5

Figure 2.3: Block diagram of CFW300 for frame size B 220 V

2.3 TERMINOLOGY

Tab le 2 .1: Terminology of the CF W300 inverters

Product

and Series

E.g.: CFW300 A 01P6 S 2 NB 20 --- ---

CFW300

Available options

Refer to Table 2.2 on page 7

NB = without braking reostática Sx = special

DB = with braking reostática Blank = standard

20 = IP20 Hx = special hardware

6 | CFW300

Model Identification

Frame

Size

Rated

Current

Phase

Number

Rated

Voltage

Brake

Degree of

Protection

Hardware

Version

Software

Version

Blank =

standard

software

Page 12

General Information

Tab le 2 .2 : Available options for each field of the nomenclature according to the rated current and voltage of the inverter

Frame Size

A

B

Output Rated

Current

01P6 = 1.6 A

02P6 = 2.6 A

04P2 = 4.2 A

06P0 = 6.0 A

01P6 = 1.6 A

02P6 = 2.6 A

04P2 = 4.2 A

06P0 = 6.0 A

07P3 = 7.3 A

01P6 = 1.6 A

02P6 = 2.6 A

04P2 = 4.2 A

06P0 = 6.0 A

07P3 = 7.3 A

01P6 = 1.6 A

02P6 = 2.6 A

04P2 = 4.2 A

06P0 = 6.0 A

07P3 = 7.3 A

10P0 = 10.0 A B = single-phase or three-phase power supply or DC

15P2 = 15.2 A T = three-phase power supply or DC

S = single -phase power supp ly

T = three-phase power supply

D = DC power supply 3 = 280...340 Vdc

N° of Phases

Rated

Volta ge

1 = 110...127 Vac

2 = 200...240 Vac

2 = 200...240 Vac or

280...340 Vdc

Brake

NB

DB

English

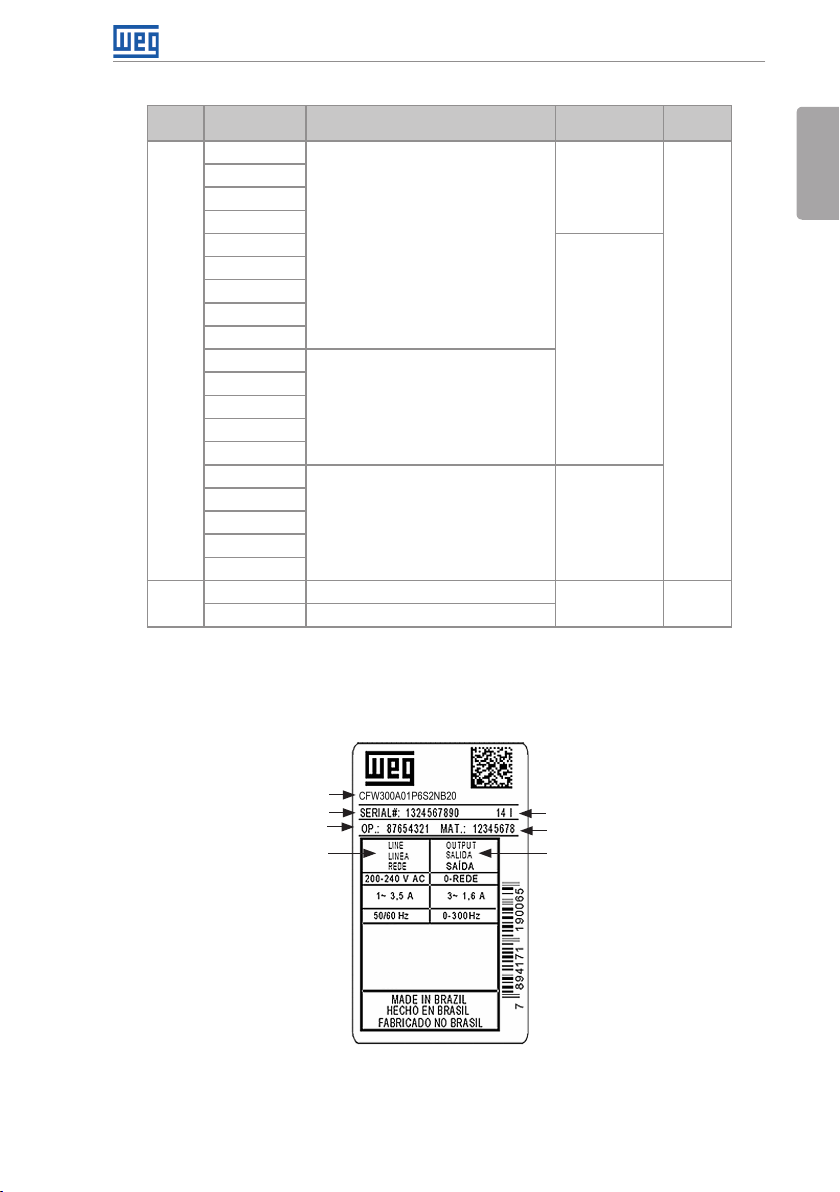

2.4 IDENTIFICATION LABEL

The identification label is located on the side of the inverter. For further details on positioning

the label, refer to Figure A2 on page 110.

Model (Inverter

intelligent code)

Serial number

Production order

Rated input data

(voltage, current and

frequency)

Figure 2.4: Description of the CFW300 identification label

CFW30 0 Side Label

Manufacturing date

(14 corresponds to the

week and I to the year)

WEG stock item

Rated output data

(voltage, current

and frequency)

CFW300 | 7

Page 13

General Information

2.5 RECEIVING AND STORAGE

English

The CFW300 is supplied packed in a cardboard box. There is an identification label affixed to

the outside of the package, identical to the one affixed to the side of the inverter.

Verify whether:

The CFW300 identification label corresponds to the purchased model.

Any damage occurred during transportation.

Report any damage immediately to the carrier.

If the CFW300 is not installed soon, store it in a clean and dry location (temperature between

-25 ºC and 60 ºC (-13 ºF and 140 ºF)), with a cover to prevent dust accumulation inside it.

ATTENTION!

When the inverter is stored for a long period, it becomes necessary to perform

the capacitor reforming. Refer to the procedure recommended in Section 6.4

PREVENTIVE MAINTENANCE on page 28 of this manual.

8 | CFW300

Page 14

3 INSTALLATION AND CONNECTION

3.1 MECHANICAL INSTALLATION

Installation and Connection

3.1.1 Environmental Conditions

Avoid:

Direct exposure to sunlight, rain, high humidity or sea-air.

Inflammable or corrosive gases or liquids.

Excessive vibration.

Dust, metallic particles or oil mist.

Environment conditions permitted for the operation of the inverter:

Temperature surrounding the inverter: 0 ºC to 50 ºC ( 32 ºF to 122 ºF) - IP20.

For temperatures surrounding the inverter higher than the specifications above, it is necessary

to apply a 2 % of current derating for each degree Celsius, limited to an increase of 10 ºC (50 ºF).

Air relative humidity: 5 % to 95 % non-condensing.

Maximum altitude: up to 1000 m (3.300 ft) - rated conditions.

From 1000 m to 4000 m (3.300 ft to 13.200 ft) - 1 % of current derating for each 100 m

above 1000 m of altitude.

Pollution degree: 2 (according to EN50178 and UL508C), with non-conductive pollution.

Condensation must not originate conduction through the accumulated residues.

3.1. 2 Positioning and Mounting

English

The external dimensions and fixing holes, and the inverter net weight (mass) are shown in

Figure B1 on page 116.

Mount the inverter in the upright position on a flat and vertical surface. Allow the minimum

clearances indicated in Figure B2 on page 117, in order to allow the circulation of the cooling

air. Do not install heat sensitive components right above the inverter.

ATTENTION!

When installing two or more inverters vertically, respect the minimum clearance

A + B (as shown in Figure B2 on page 117) and provide an air deflecting plate

so that the heat rising up from the lower inverter does not affect the top inverter.

Provide independent conduits for the physical separation of signal, control and

power cables (refer to Section 3.2 ELECTRICAL INSTALLATION on page 10).

3.1. 2.1 Cabinet Mounting

For inverters installed inside cabinets or metallic boxes, provide proper exhaustion, so that the

temperature remains within the allowed range. Refe r to the dissipated powers i n Table B2 on page 114.

CFW300 | 9

Page 15

Installation and Connection

As a reference, Table 3.1 on page 10 shows the air flow of rated ventilation for each model.

English

Cooling Method: internal fan with air flow upwards.

Tab le 3 .1: Air flow of the internal fan

Model CFM I/s m3/min

A

B

17. 0 8.02 0.48

3.1.2.2 Surface Mounting

Figure B2 on page 117 illustrates the CFW300 installation procedure for surface mounting.

3.1. 2.3 DIN-Rail Mounting

The CFW300 inverter can also be mounted directly on a 35 mm-rail, in accordance with

DIN EM 50.022. For further details, refer to Figure B2 on page 117.

3.2 ELECTRICAL INSTALLATION

DANGER!

The following information is merely a guide for proper installation. Comply with

applicable local regulations for electrical installations.

Make sure the AC power supply is disconnected before starting the installation.

The CFW300 must not be used as an emergency stop device. Provide other

devices for that purpose.

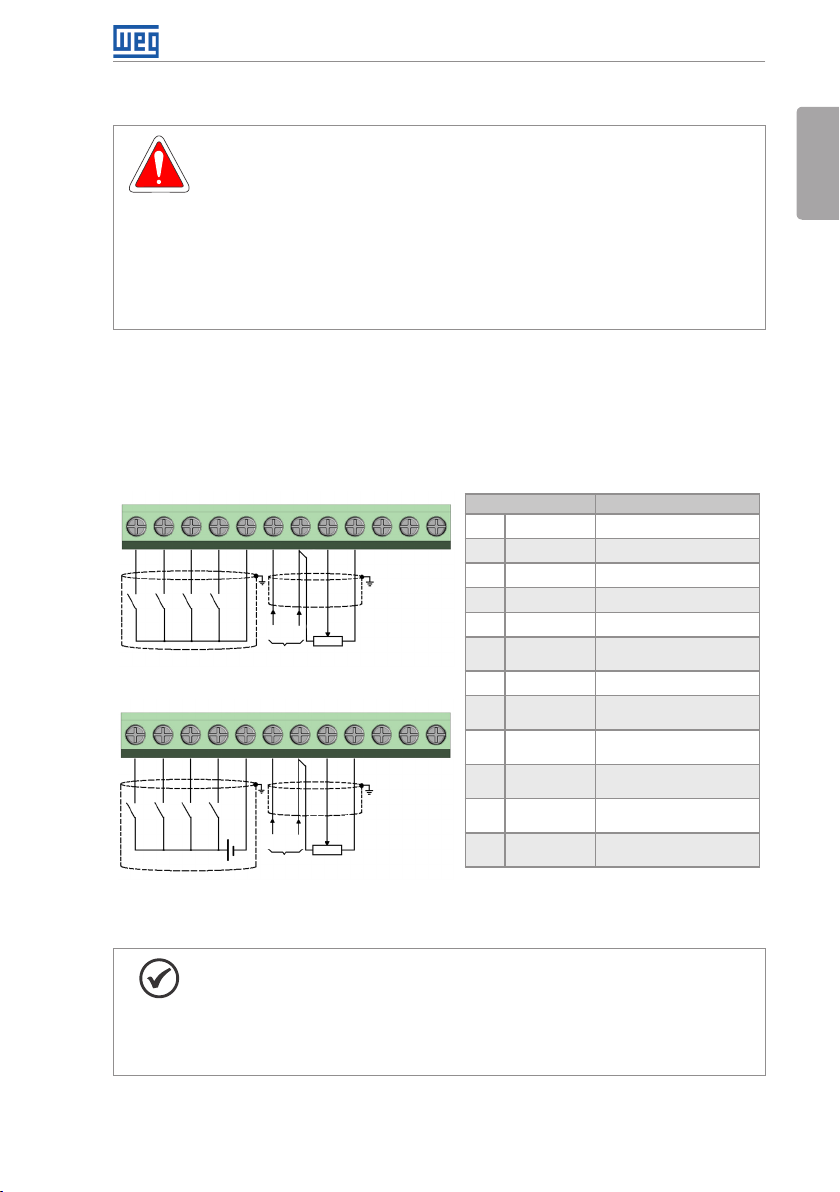

3.2 .1 Identification of the Power Terminals and Grounding Points

The power terminals can be of different sizes and configurations, depending on the model of

the inverter, according to Figure B3 on page 118. The location of the power, grounding and

control connections are shown in Figure B3 on page 118.

Description of the power terminals:

L/L1, N/L2, L3 (R,S,T): power supply connection.

U, V and W: connection for the motor.

-UD: negative pole of the DC power supply.

+UD: positive pole of the DC power supply.

+BR, BR: connection of the braking resistor (available for frame size B models).

PE: grounding connection.

The maximum tightening torque of the power terminals and grounding points must be checked

in Figure B3 on page 118.

10 | CFW300

Page 16

Installation and Connection

DANGER!

Observe the correct DC power supply connection, polarity and terminal positions.

3.2.2 Circuit Breakers, Fuses, Grounding and Power

ATTENTION!

Use proper cable lugs for the power and grounding connection cables. Refer

to Table B1 on page 113 for recommended wiring, circuit breakers and fuses.

Keep sensitive equipment and wiring at a minimum distance of 0.25 m (9.85 in)

from the inverter and from the cables connecting the inverter to the motor.

ATTENTION!

Residual differential interrupter (DR):

When used in the inverter supply, it must have a pick-up current of 300 mA.

Depending on the installation conditions, such as motor cable length and type,

multi-motor drive, etc., the DR interrupter may trip. Check with the manufacturer

the most suitable type for operation with inverters.

NOTE!

The wire gauges listed in Table B1 on page 113 are guiding values. Installation

conditions and the maximum permitted voltage drop must be considered for

the proper wiring sizing.

English

CFW300 | 11

Page 17

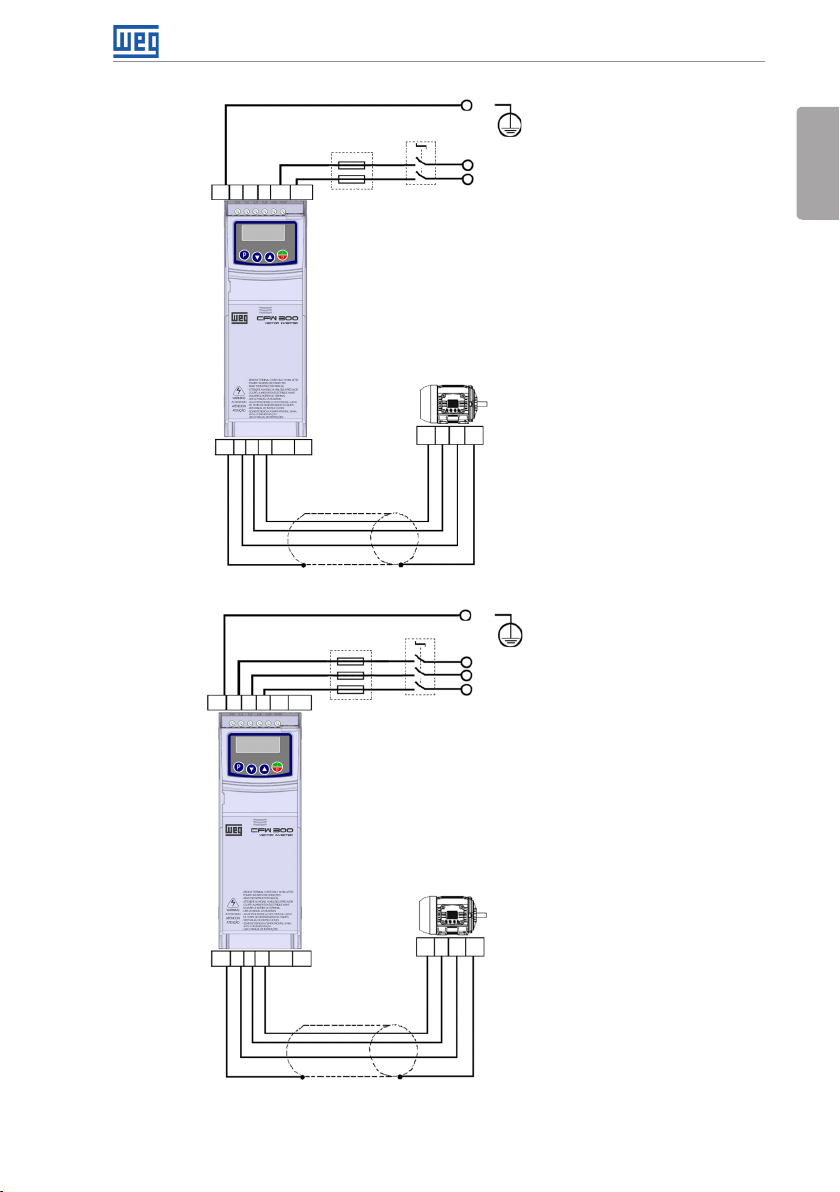

Installation and Connection

3.2.3 Power Connections

English

PE

Power

supply

Negative pole of the DC power supply (-UD)

Disconnecting

PE

+UD-UD

Fuses

switch

Positive pole of the DC power supply (+UD)

UPE

V W

Shielding

Only available for the specific models of frame A (see Table 2.2 on page 7).

(a) Frame size A DC power supply

PE L1 L2L3

U V WPE

Fuses

Disconnecting

switch

PEW V U

Power

supply

PEW V U

PE

L1/L

L2/N

L3

*

12 | CFW300

Shielding

(*) The power ter minal L3 is not available in mo dels of frame size A si ngle-phase

(b) Frame size A single-phase and three-phase power supply

Page 18

PE L2L1

Installation and Connection

PE

Power

supply

Negative pole of the DC power supply (-UD)

+UD-UD

L3

Fuses

Disconnecting

switch

Positive pole of the DC power supply (+UD)

English

U V WPE +BR BR

PE L2L1

U V WPE BR+BR

L3-UD

Shielding

(c) Frame size B DC power supply

Fuses

Disconnecting

switch

+UD

PEW V U

Power

supply

PEW V U

PE

L1/L

L2/N

L3

Shielding

Only available for the 10-A model (see Table 2.2 on page 7).

(d) Frame size B single-phase and three-phase power supply

Figure 3.1: (a) to (d) Power and grounding connections

CFW300 | 13

Page 19

Installation and Connection

3.2.3.1 Input Connections

English

DANGER!

Provide a disconnect device for the inverter power supply. This device must cut

off the power supply whenever necessary (during maintenance for instance).

ATTENTION!

The power supply that feeds the inverter must have a grounded neutral.

NOTE!

The input power supply voltage must be compatible with the inverter rated

voltage.

Power factor correction capacitors are not needed at the input (L/L1, N/L2,

L3) and must not be installed at the output (U, V, W).

Power supply capacity

Suitable for use in circuits capable of delivering not more than 30.000 A

/ 240 V).

In case the CFW300 is installed in power supplies with current capacity over 30.000 A

symmetrical at (127

rms

it is necessary to use proper protection circuits for those power supplies, such as fuses or

circuit breakers.

3.2.3.2 Power Supply Reactance

In a general way, the inverters of the CFW300 line can be installed directly in the power supply,

without reactance in the supply. However, check the following:

,

rms

In order to prevent damages to the inverter and assure the expected useful life, you must

have a minimum impedance that provides a line voltage drop of 1 %. If the line impedance

(due to the transformers and cabling) is below the values listed in this table, we recommend

the use of a line reactance.

For the calculation of the line reactance necessary to obtain the desired percentage voltage

drop, use:

V

L = 1592 . ΔV .

I

s, rat

. f

e

[ μH]

Seeing that:

ΔV - desired line drop, in percentage (%).

V

- phase voltage in the inverter input, in volts (V).

e

I

- rated current of the inverter output.

s, rat

f - line frequency.

14 | CFW300

Page 20

Installation and Connection

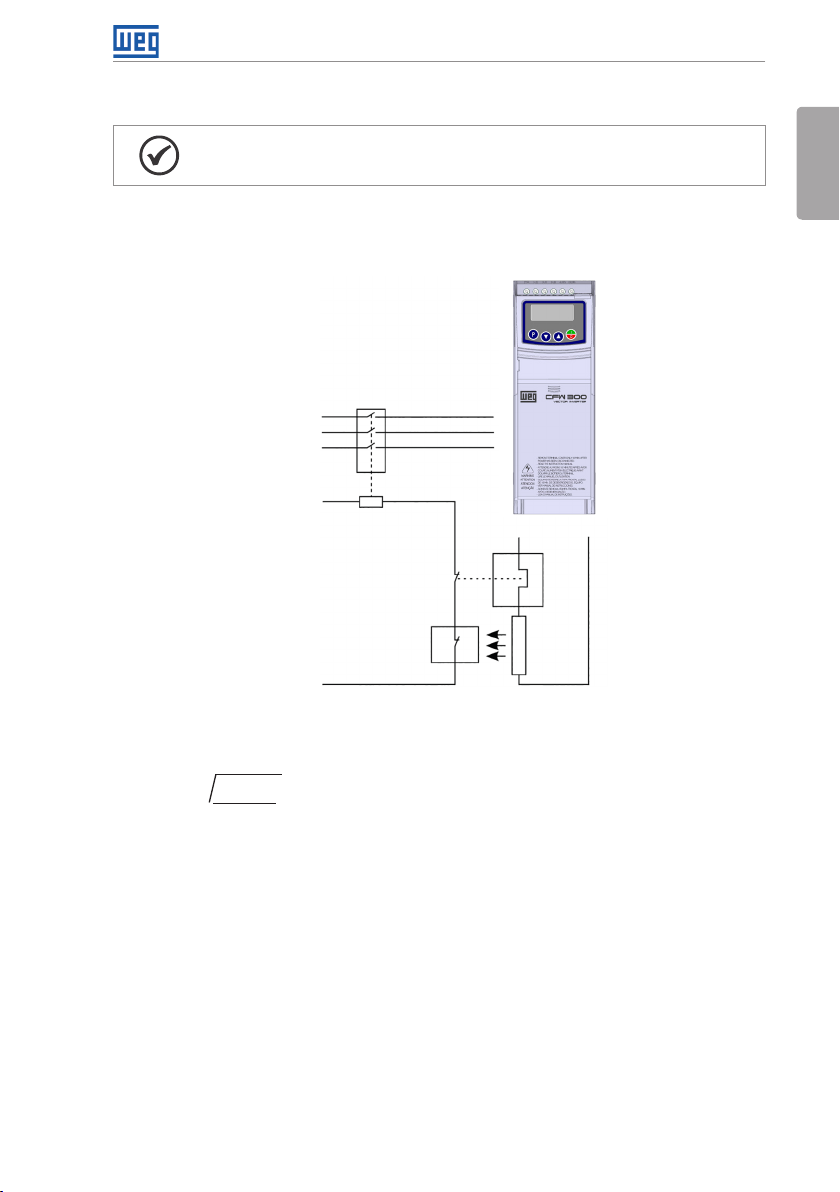

3.2.3.3 Dynamic Braking

NOTE!

The dynamic braking is available from frame size B.

Refer to Table B1 on page 113 for the following specifications of the dynamic braking: maximum

current, resistance, effective current (*) and cable gauge.

English

Input power

supply

power supply

Contactor

Command

Figure 3.2: Installation of brake resistor

Relay

Thermostat

R

S

T

BR+BR

Brake

resistor

(*) The effective braking current can be calculated as follows:

= I

max

tbr

.

5

I

effective

√

(min)

Seeing that: tbr corresponds to the sum of the braking actuation times during the most severe

cycle of five minutes.

The power of the brake resistor must be calculated considering the deceleration time, the inertia

of the load and of the resistive torque.

Procedure to use the dynamic braking:

Connect the brake resistor between the power terminals +BR and BR.

Use a twisted cable for the connection. Separate these cables from the signal and control

wiring.

Dimension the cables according to the application, observing the maximum and effective

currents.

CFW300 | 15

Page 21

Installation and Connection

If the brake resistor is mounted within the cabinet of the inverter, consider its energy when

dimensioning the ventilation of the cabinet.

English

DANGER!

The internal braking circuit and the resistor may be damaged if the latter is not

properly dimensioned and/or if the voltage of the input power supply exceeds the

maximum value permitted. In order to avoid the destruction of the resistor or risk

of fire, the only guaranteed method is the inclusion of a thermal relay in series with

the resistor and/or a thermostat in contact with its housing, connected in such

a way to disconnect the input power supply of the inverter in case of overload,

as shown in Figure 3.2 on page 15.

Set P151 at maximum value when using dynamic braking.

The voltage level on the DC Link for activation of the dynamic braking is defined by the

parameter P153 (level of the dynamic braking).

Refer to the CFW300 programming manual.

3.2.3.4 Output Connections

ATTENTION!

The inverter has an electronic motor overload protection that must be adjusted

according to the driven motor. When several motors are connected to the same

inverter, install individual overload relays for each motor.

The motor overload protection available in the CFW300 is in accordance with

the UL508C standard. Note the following information:

1. Trip current equal to 1.2 times the motor rated current (P401).

ATTENTION!

If a disconnect switch or a contactor is installed at the power supply between the

inverter and the motor, never operate it with the motor spinning or with voltage

at the inverter output.

The characteristics of the cable used to connect the motor to the inverter, as well as its

interconnection and routing, are extremely important to avoid electromagnetic interference in

other equipment and not to affect the life cycle of windings and bearings of the controlled motors.

Keep motor cables away from other cables (signal cables, sensor cables, control cables, etc.),

according to Item 3.2.6 Cable Separation Distance on page 18.

When using shielded cables to install the motor:

Follow the recommendations of IEC60034-25.

Use the low impedance connection for high frequencies to connect the cable shield to the

grounding.

16 | CFW300

Page 22

Installation and Connection

3.2.4 Grounding Connections

DANGER!

The inverter must be connected to a protective ground (PE).

Use a minimum wire gauge for ground connection equal to the indicated in

Table B1 on page 113.

Connect the inverter grounding connections to a ground bus bar, to a single

ground point or to a common grounding point (impedance ≤ 10 Ω).

The neuter conductor of the line that feeds the inverter must be solidly

grounded; however, this conductor must not be used to ground the inverter.

Do not share the grounding wiring with other equipment that operate with high

currents (e.g.: high voltage motors, welding machines, etc.).

3.2.5 Control Connections

The control connections must be made in accordance with the specification of the connector

of the CFW300 control board. Functions and typical connections are presented in Figure 3.3 on

page 17. For further details on the specifications of the connector signals, refer to Chapter

8 TECHNICAL SPECIFICATIONS on page 31.

1

223344556677889

DI1DI1

1

(External supply)

DI4DI4

DI2DI2

DI3DI3

(a) NPN Configuration

24 V

(b) PNP Configuration

GNDGND

(+) A I1 (-)

(0 a 20) mA

(4 a 20) mA

(+) A I1 (-)

(0 a 20) mA

(4 a 20) mA

Figure 3.3: (a) and (b) Signals of C300 control card connector

GNDGND

Counter

clockwise

AI1

(0 a 10) V

Counter

clockwise

AI1

(0 a 10) V

1010111112

+10 V+10 V

Clockwise Clockwise

9

Connector Description

1 DI1 Digital input 1

2 DI2 Digital input 2

3 DI3 Digital input 3

DO1-RL-CDO1-RL-C

DO1-RL-NCDO1-RL-NC

4 DI4 Digital input 4

DO1-RL-NODO1-RL-NO

5 GND Reference 0 V

6 AI1 Analog input 1

7 GND Reference 0 V

8 AI1 Analog input 1

12

9 +10 V Reference +10 Vdc

10 DO1-RL-NC Digital output 1

11 DO1-RL-C Digital output 1

12 DO1-RL-NO Digital output 1

(*) For further information, refer to the detailed specification in

Section 8.2 ELECTRO NICS/GENERAL DATA on page 32.

(Current)

(Tension)

for potentiometer

(NC contact of relay 1)

(Common point of relay 1)

(NO contact of relay 1)

(*)

English

NOTE!

The CFW300 inverters are supplied with the digital inputs configures as active

low (NPN). In order to change the configuration, check the use of parameter

P271 in the programming manual of the CFW300.

Analog input AI1 is set for input 0 to 10 V, in order to change, check parameter

P233 of the programming manual.

CFW300 | 17

Page 23

Installation and Connection

For the correct connection of the control, use:

English

1. Gauge of the cables: 0.5 mm² (20 AWG) to 1.5 mm² (14 AWG).

2. Maximum torque: 0.5 N.m (4.50 lbf.in).

3. Wiring of the connector of the control board with shielded cable and separated from the

other wiring (power, command in 110 V / 220 Vac, etc.), according to Item 3.2.6 Cable

Separation Distance on page 18. If those cables must cross other cables, it must be done

in perpendicularly among them, keeping the minimum separation distance of 5 cm at the

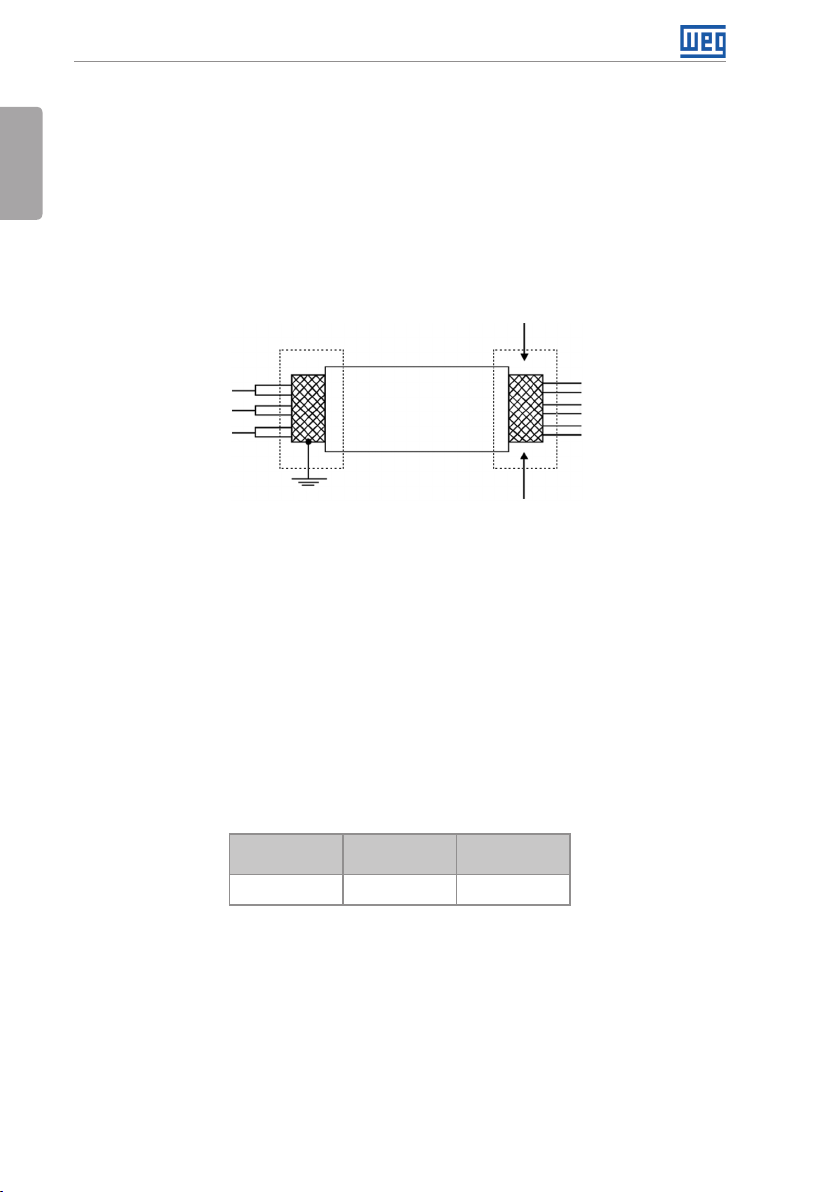

crossing point. Connect the shield according to the figure below:

Insulate with tape

Inverter

side

Do not ground

Figure 3.4: Shield connection

4. Relays, contactors, solenoids or coils of electromechanical brake installed close to the

inverters may occasionally generate interference in the control circuitry. To eliminate this

effect, RC suppressors (with AC power supply) or freewheel diodes (with DC power supply)

must be connected in parallel to the coils of these devices.

5. When using the external HMI (refer to Chapter 7 ACCESSORIES on page 30), the cable

that connects to the inverter must be separated from the other cables in the installation,

keeping a minimum distance of 10 cm (3.95 in).

3.2.6 Cable Separation Distance

Provide separation between the control and the power cables according to Table 3.2 on page 18.

Tab le 3 .2 : Separation distance between cables

Output Rated

Current of t he

Inverter

≤ 24 A

Cable Length

≤ 100 m (330 ft)

> 100 m (330 ft)

Minimum

Separation

Distance

≥ 10 cm (3.95 in)

≥ 25 cm (9.85 in)

3.3 INSTALLATIONS ACCORDING TO EUROPEAN DIRECTIVE OF

ELECTROMAGNETIC COMPATIBILITY

The CFW300 inverters feature external RFI filter to reduce electromagnetic interference (refer

to Chapter 7 ACCESSORIES on page 30). Those inverters, when properly installed, meet

the requirements of the directive of electromagnetic compatibility.

These inverters were developed for professional applications only. Therefore, the limits for

emission of harmonic currents established by the EN 61000-3-2 and EN 61000-3-2/A 14

standards are not applicable.

18 | CFW300

Page 24

Installation and Connection

3.3.1 Control Connections

1. Shielded output cables (motor cables) with the shield connected at both ends, motor and

inverter, with low-impedance connection for high frequency.

Maximum motor cable length and conducted and radiated emission levels according to Table

B3 on page 115.

2. Shielded control cables, and keep them away from other cables according to table 3.2 of

the user's manual.

3. Grounding of the inverter according to instructions of item Item 3.2.4 Grounding Connections

on page 17.

4. Grounded power supply.

5. Use short wiring to ground the external filter or inverter.

6. Ground the mounting plate using a flexible braid as short as possible. Flat conductors have

lower impedance at high frequencies.

7. Use sleeves for cable conduits whenever possible.

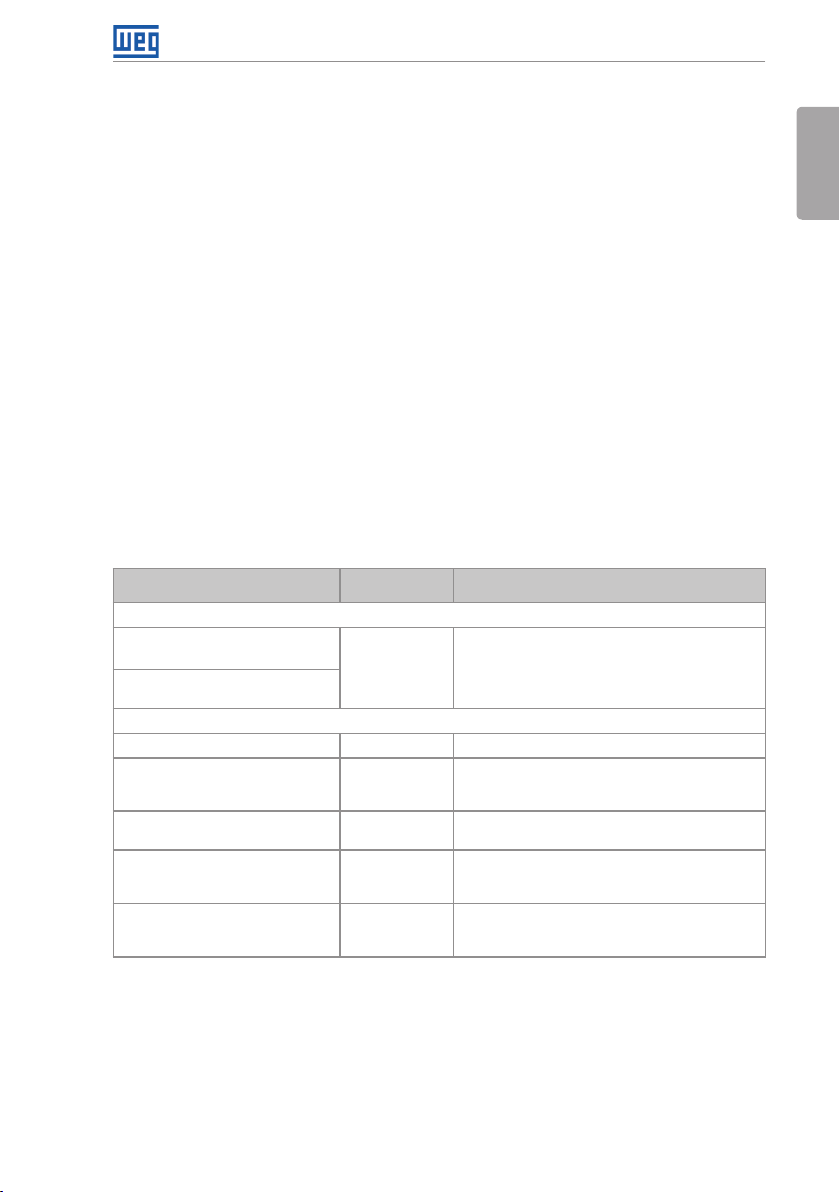

3.3.2 Emission and Immunity Levels

EMC Phenomenon

Emission:

Mains Terminal Disturbance Voltage

Frequency Range: 150 kHz to 30 MHz

Electromagnetic Radiation Disturbance

Frequency Range: 30 MHz to 1000 MHz

Immunity:

Electrostatic Discharge (ESD) IEC 61000-4-2 4 kV for contact discharge and 8 kV for air discharge

Fast Transient-Burst IEC 61000-4-4 2 kV / 5 kHz (coupling capacitor) input cables

Conducted Radio-Frequency

Common Mode

Surges IEC 61000-4-5 1.2/50 μs, 8/20 μs

Radio-Frequency Electromagnetic

Field

Tab le 3 .3 : Emission and immunity levels

Basic

Standard

IEC/EN 61800-3 It depends on the inverter model on the length of the

IEC 61000-4-6 0.15 to 80 MHz; 10 V; 80 % AM (1 kHz)

IEC 61000-4-3 80 to 1000 MHz

motor cable. Refer to Table B3 on page 115

1 kV / 5 kHz control cables and remote HMI cables

2 kV / 5 kHz (coupling capacitor) motor cables

Motor, control and remote HMI cables

1 kV line-to-line coupling

2 kV line-to-ground coupling

10 V/m

80 % AM (1 kHz)

Level

English

Definition of Standard IEC/EM 61800-3: "Adjustable Speed Electrical Power Drives

Systems"

Environments:

First Environment: environments that include domestic installations, as well as establishments

directly connected without intermediate transformer to a low-voltage power supply network

which supplies buildings used for domestic purposes.

CFW300 | 19

Page 25

Installation and Connection

Second Environment: aincludes all establishments other than those directly connected to a

English

low-voltage power supply network that supplies buildings used for domestic purposes.

Categories:

Category C1: inverters with a voltage rating less than 1000 V and intended for use in the First

Environment.

Category C2: inverters with a voltage rating less than 1000 V intended for use in the First

Environment, not provided with a plug connector or movable installations. They must be installed

and commissioned by a professional.

Category C3: inverters with a voltage rating less than 1000 V and intended for use in the

Second Environment only (not designed for use in the First Environment).

NOTE!

A professional is a person or organization familiar with the installation and/or

commissioning of inverters, including their EMC aspects.

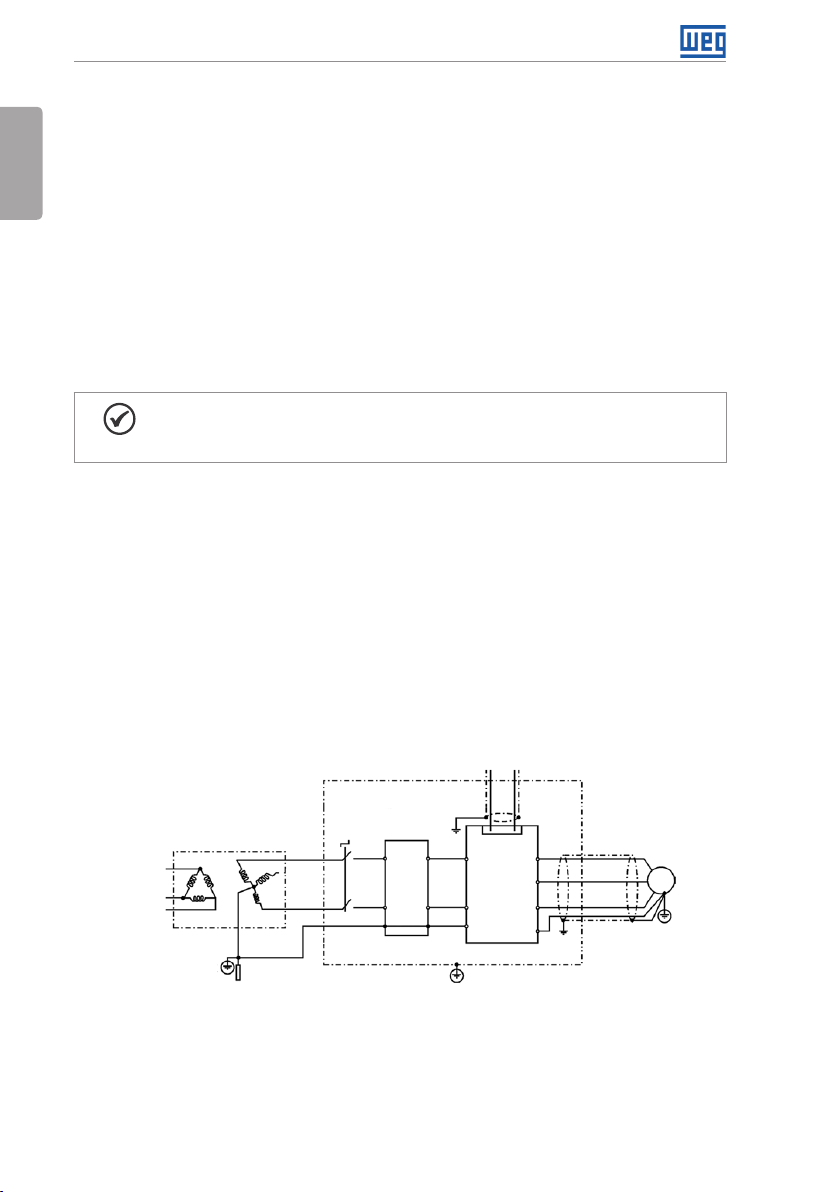

3.3.3 Characteristics of the RFI Filter

CFW300 inverters are installed with external filter when it is intended to reduce the disturbance

conducted from the inverter to the power line in the high frequency band (>150). It is observe

the maximum levels of conducted emission of electromagnetic compatibility standards, such

as EN 61800-3 and EN 55011.

For further details, refer to Section 3.3 INSTALLATIONS ACCORDING TO EUROPEAN DIRECTIVE

OF ELECTROMAGNETIC COMPATIBILITY on page 18.

For further information about the RFI filter model, refer to Table 7.1 on page 30.

The figure below demonstrate the connection of the filter to the inverter:

Signal and control wiring

External input

RFI filter

L1/L L1

L2/N L2

PE PE

Metal panel (when necessary)

1...12

XC1

L1/L

CFW300

L2/N

PE

Protective ground

U

V

W

PE

Motor

Power

supply

Transformer

Grounding

PE

rod

Figure 3.5: Connection of the RFI filter - general conditions

20 | CFW300

Page 26

Keypad (HMI) and Basic Programming

4 KEYPAD (HMI) AND BASIC PROGRAMMING

4.1 USE OF THE KEYPAD TO OPERATE THE INVERTER

Through the HMI, it is possible to command the inverter, visualize and adjust all of its parameters.

The Keypad features the following functions:

Enables/disables the inverter via

Selects (toggles) display

between the parameter

number and its value

(position/content).

Decreases the frequency,

parameter number or

parameter value.

Figure 4.1: HMI keys

Increases the frequency,

parameter number and

parameter value.

acceleration/deceleration ramp

(start/stop, according to P229).

Resets the inver ter after a fault

event.

4.2 INDICATIONS ON THE HMI DISPLAY

Inverter status

Direction of

rotation

Unit of measurement

(it refers to the value

of the main display)

English

Main display

Figure 4.2: Display areas

Bar graph to

monitor the

variable

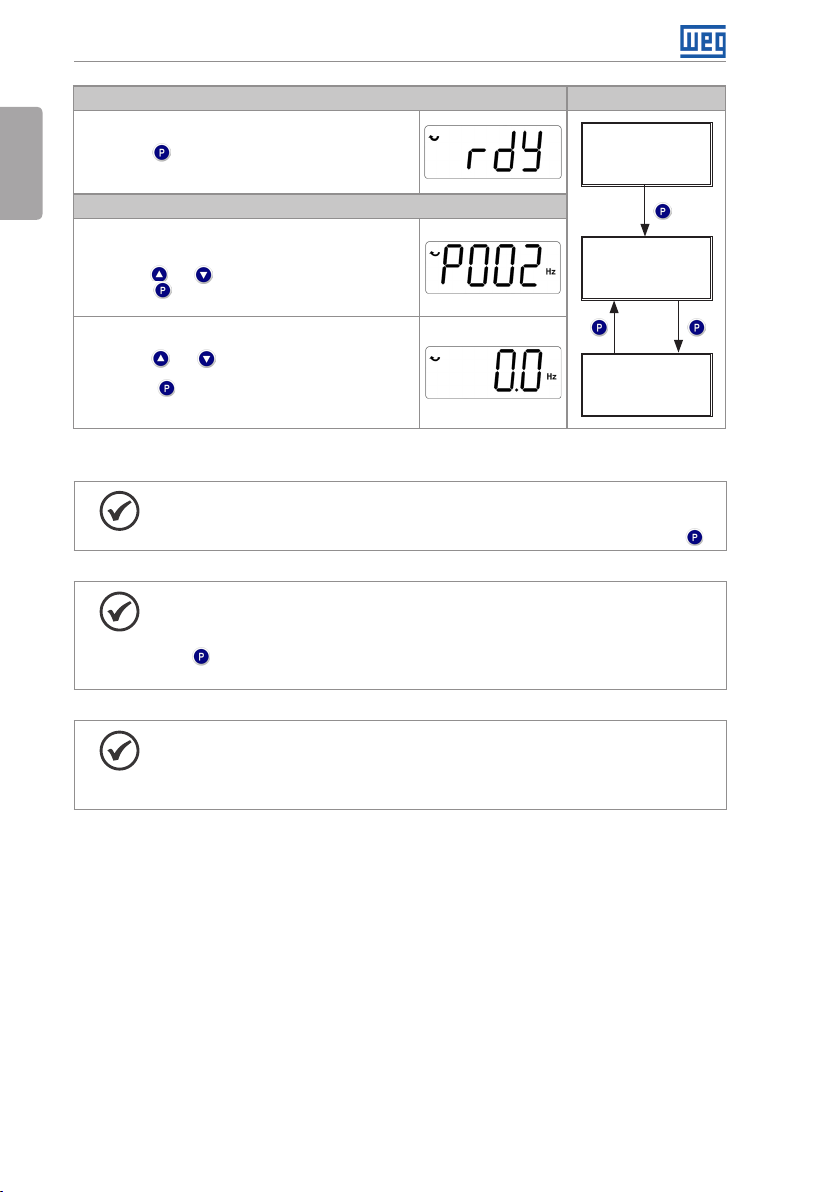

4.3 OPERATING MODES OF THE HMI

When energizing the inverter, the initial state of the keypad remains in the start-up mode as

long as there is no fault, alarm, undervoltage or any key is pressed.

The setting mode is composed of two levels: level 1 allows the navigation through the

parameters. And level 2 allows the edition of the parameter selected at level 1. At the end of

this level the modified value is saved when the key is pressed.

Figure 4.3 on page 22 illustrates the basic navigation of the operating modes of the HMI.

CFW300 | 21

Page 27

Keypad (HMI) and Basic Programming

English

It is the initial state of the HMI after its successful power-up

(without the occurrence of faults, alarms or undervoltage)

Press key to go to level 1 of the setting mode - selection

of parameters. Pressing any other key also switches to

setting mode

Level 1:

This is the first level of the setting mode. The parameter

number is shown on the main display

Use keys and to find the desired parameter

Press key to go to level 2 of the setting mode - change

of the parameter values

Level 2:

The parameter value is shown on the main display

Use keys and to set the new value in the selected

parameter

Press key to confirm the modification (save the new

value). After confirming the modification, the HMI returns to

level 1 of the setting mode

NOTE!

When the inverter is in the fault state, the main display indicates the number

of the fault in the format Fxxx. Navigation is allowed after activation of key .

NOTE!

When the inverter is in the alarm state, the main display indicates the number

of the alarm in the format Axxx. The navigation is allowed after the activation of

key ; thus, the indication "A" goes to the unit of measurement display until the

situation causing the alarm is solved.

Monitoring Mode

Setting Mode

Figure 4.3: HMI operating modes

Monitoring

Setting

level 1

Setting

level 2

22 | CFW300

NOTE!

A list of parameters is presented in the quick reference of the parameters. For

further information about each parameter, refer to the CFW300 programming

manual.

Page 28

5 FIRST TIME POWER-UP AND START-UP

5.1 START-UP PREPARATION

First Time Power-Up and Start-Up

The inverter must have already been installed according to Chapter 3 INSTALLATION AND

CONNECTION on page 9.

DANGER!

Always disconnect the main power supply before making any connection.

1. Check if the power, grounding and control connections are correct and firm.

2. Remove all the materials left behind from the installation work from inside the inverter or the

cabinet.

3. Verify the motor connections and if its voltage and current are within the inverter rated value.

4. Mechanically uncouple the motor from the load. If the motor cannot be uncoupled, make

sure that any speed direction (forward or reverse) will not result in personnel injury and/or

equipment damage.

5. Close the inverter or cabinet covers.

6. Measure the power supply and verify if it is within the allowed range, according to Chapter

8 TECHNICAL SPECIFICATIONS on page 31.

7. Apply power to the input: close the input disconnecting switch.

8. Check the result of the first time power-up:

The HMI display indicates:

English

Figure 5.1: HMI display when powering up

5.2 START-UP

This section describes the power-up of the inverter with HMI operation, using the minimum

connections of Figure 3.1 on page 13 and without connections in the control terminals.

Furthermore, two types of control will be considered: V/f control (scalar) and vector control

VV W. For further details on the utilization of these types of control refer to the CFW300

programming manual.

CFW300 | 23

Page 29

First Time Power-Up and Start-Up

DANGER!

English

High voltages can be present, even after the disconnection of the power supply.

Wait at least 10 minutes for full discharge.

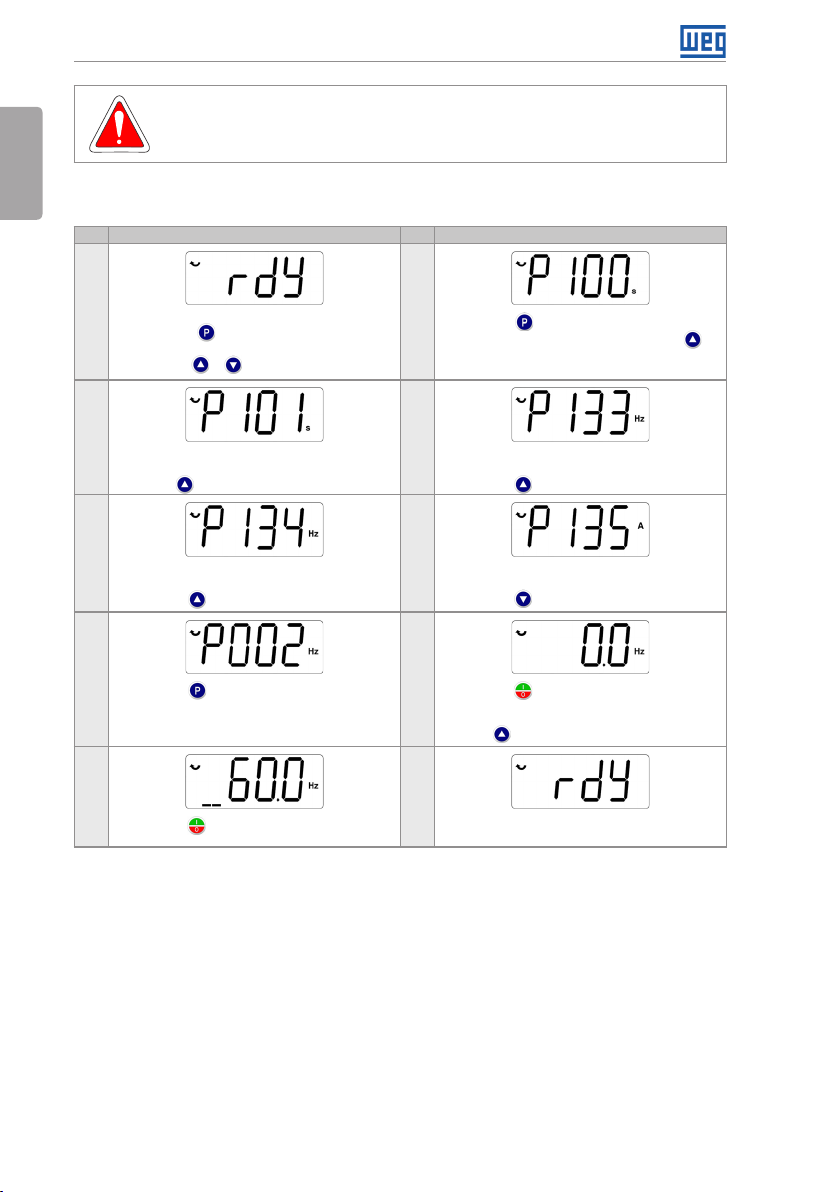

5.2.1 Basic Application

Seq Display Indication/Action Seq Display Indication/Action

Initialization mode

1

Press key to enter the first level of the

parameterization mode

Press keys o r to select th e parameter P100

3 4

If necessary, change the content of "P101 -

Deceleration Time"

Use key to select the parameter P133

5 6

If necessary, change the content of "P134 -

Maximum Speed"

Press key for the next parameter

7 8

Press key to view the parameter content

9 10

Press key . The motor will dece lerate to a stop

Figure 5.2: Sequence for basic application

2

Press key if you need to change the content

of P100 - "Acceleration Time" or press key for

the next parameter

If necessary, change the content of "P133 -

Minimum Speed"

Press key for the next parameter

If necessa ry, change the c ontent of "P135 - Outpu t

Maximum Current"

Press key to select parameter P002

Press key that the motor will accelerate up to

3.0 Hz (factory default set ting of P133 - Minimum

Frequency)

Press and hold it until it reaches 60.0 Hz

When the motor stops, the display will indicate

"ready"

24 | CFW300

Page 30

First Time Power-Up and Start-Up

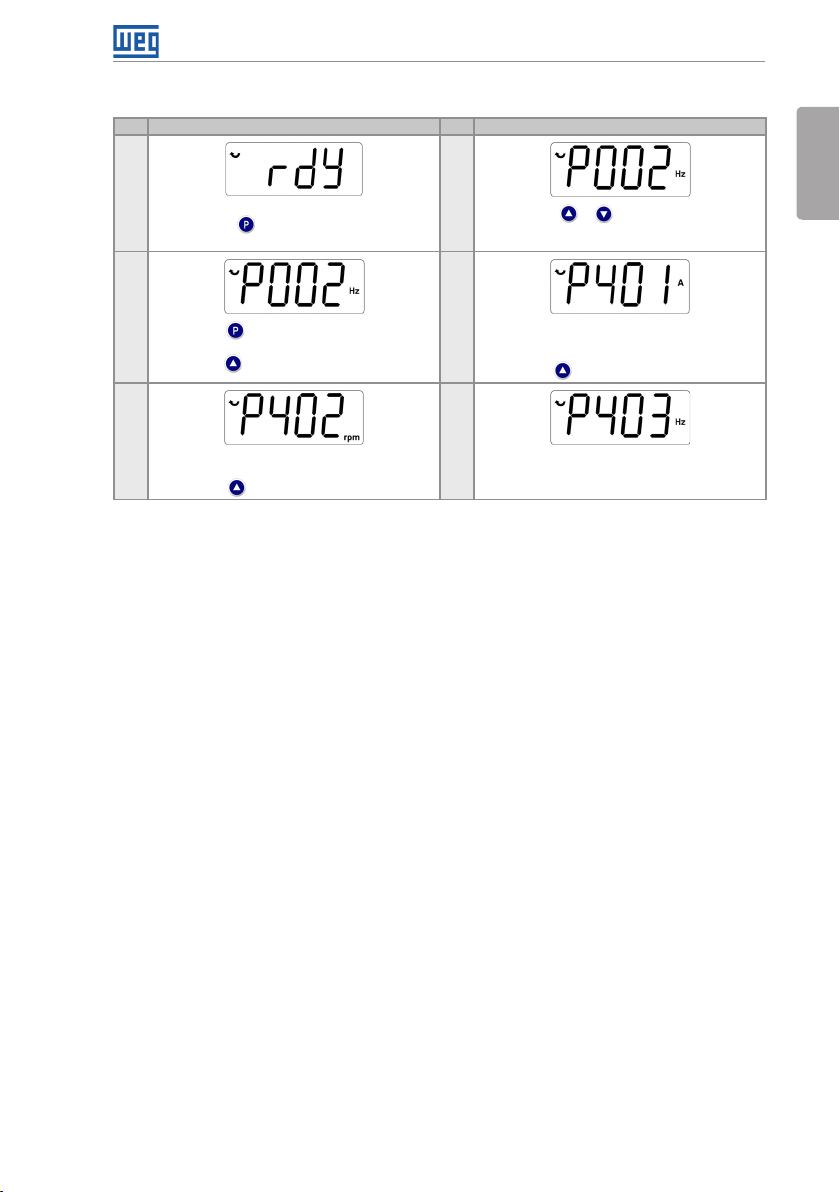

5.2.2 V/f Type of Control (P202 = 0)

Seq Display Indication/Action Seq Display Indication/Action

1

Initialization mode

Press key to enter the first level of the

parameterization mode

3

Press key i f you need to chan ge the content of

"P202 - Type of Control" for P202 = 0 (V/f)

Press key to select parameter P401

5

If necessa ry, change the c ontent of "P402 - Motor

Rated Speed"

Press key for the next parameter

Figure 5.3: Sequence for V/f control

2

Press keys or to select parameter P202

4

If necessary, change the content of parameter

"P401 - Motor Rated Current" according to the

nameplate

Press key for the next parameter

6

If necessa ry, change the c ontent of "P403 - Motor

Rated Frequency"

English

CFW300 | 25

Page 31

First Time Power-Up and Start-Up

5.2.3 Control Type VV W (P202 = 5)

English

Seq Display Indication/Action Seq Display Indication/Action

1

Initialization mode

Press key to enter the first level of the

parameterization mode

3 4

Press key to change the content of "P202 -

Type of Contro l" for P202 = 5 (V VW ). Use key

5 6

If necessa ry, change the c ontent of "P399 - M otor

Rated Efficiency" according to the nameplate

Press key for the next parameter

7 8

If necessa ry, change the c ontent of "P401 - Motor

Rated Current"

Press key for the next parameter

9 10

If necessa ry, change the c ontent of "P403 - Motor

Rated Frequency"

Press key for the next parameter

11 12

If necessa ry, change the co ntent of "P407 - Motor

Rated Power factor"

Press key for the next parameter

2

Press keys or to select parameter P202

Press key to save the change of P202

Use key to select parameter P399

If necessa ry, change the co ntent of "P400 - Motor

Rated Voltage"

Press key for the next parameter

If necessa ry, change the c ontent of "P402 - Motor

Rated Speed"

Press key for the next parameter

If necessa ry, change the c ontent of "P404 - Motor

Rated Power"

Press key for the next parameter

If necessary to make the self-tuning, change the

value of P408 to "I"

13 14

During the self-tuning, the HMI will show "Auto",

and the bar will indicate the operation progress

15

If necessa ry, change the c ontent of "P409 - Sta tor

Resistance"

Figure 5.4: Sequence for VV W control

26 | CFW300

When the self-tuning is completed, it wi ll return to

the (comp) Initialization Mode

Page 32

Troubleshooting and Maintenance

6 TROUBLESHOOTING AND MAINTENANCE

6.1 FAULTS AND ALARMS

NOTE!

Refer to the CFW300 quick reference and the programming manual for further

information on each fault or alarm.

6.2 SOLUTION FOR THE MOST FREQUENT PROBLEMS

Tab le 6 .1: Solution for the most frequent problems

Problem Point to be Verified Corrective Action

Motor will not

start

Motor speed

oscillates

Too high or

too low motor

speed

Display is off HMI connections 1. Check the connections of the inverter external HMI

Incorrect wiring 1. Check all power and control connections.

Analog reference

(if used)

Incorrect settings 1. Check if the parameter values are correct for the application

Fault 1. Check whether the inverter is disabled due to a fault condition

Motor stall 1. Decrease the motor overload

Loose connections 1. Stop the inverter, turn off the power supply, check and tighten all

Defective speed

reference potentiometer

Oscillation of the external

analog reference

Incorrect settings

(reference limits)

Control signal of the

analog reference

(if used)

Motor nameplate 1. Check whether the used motor matches the application

Power supply voltage 1. Rated values must be within the limits specified below:

Mains supply fuses open 1. Replace the fuses.

1. Check if the external signal is properly connected

2. Check the status of the control potentiometer (if used)

2. Increase P136, P137 (V/f)

the power connections

2. Check all the internal connections of the inverter

1. Replace the potentiometer

1. Identif y the cause of the o scillatio n. If the cause is e lectrica l noise, use

shielded cables or separate them from the power or command wiring

2. Interconnect the GND of the analog reference to the grounding

connection of the inverter

1. Check whether the values of P133 (minimum speed) and P134

(maxi mum speed) a re properl y set for the used m otor and appli cation

1. Check the level of the reference control signal

2. Check the setting (gain and offset) of parameters P232 to P240

200 / 240 V power supply: - Min: 170 V - Max: 264 V

110 / 127 V power supply: - Min: 93 V - Ma x: 140 V

English

6.3 INFORMATION NECESSARY FOR CONTACTING TECHNICAL SUPPORT

For technical support or servicing, it is important to have the following information in hand:

Inverter model.

Serial number and manufacturing date listed in the product nameplate (refer to Section 2.4

IDENTIFICATION LABEL on page 7).

Installed Software version (refer to P023).

Data on the application and inverter settings.

CFW300 | 27

Page 33

Troubleshooting and Maintenance

6.4 PREVENTIVE MAINTENANCE

English

DANGER!

Always turn off the mains power supply before touching any electrical component

associated to the inverter.

High voltages may still be present even after disconnecting the power supply.

To prevent electric shock, wait at least ten minutes after turning off the input

power for the complete discharge of the power capacitors. Always connect the

equipment frame size to the protective ground (PE). Use the adequate connection

terminal at the inverter.

ATTENTION!

The electronic boards have electrostatic discharge sensitive components.

Do not touch the components or connectors directly. If necessary, first touch the

grounded metallic frame size or wear a ground strap.

Do not perform any withstand voltage test: if necessary, consult WEG.

The inverters require low maintenance when properly installed and operated. Table 6.2 on page

28 presents the main procedures and time intervals for preventive maintenance. Table 6.3

on page 29 provides recommended periodic inspections to be performed every 6 months

after the inverter start-up.

Tab le 6 .2 : Preventive maintenance

Maintenance Interval Instructions

Fan replacement After 40000 operating hours Replacement

Electrolytic

capacitors

If the inverter

is stocked (not

being used):

“Reforming”

Inverter is being

used: replace

Every year from the

manufacturing date printed on

the inver ter identification label

(refer to Section 2.5 RECEIVING

AND STORAGE on page 8).

Every 10 years Contact WEG technical suppor t to obtain

Apply power to the inverter (voltage between

220 and 230 Vac, single-phase/three-phase or

DC (according to the model of the inver ter), 50 or

60 Hz) for at least one hour. Then, disconnect

the power supply and wait at least 24 hours

before using the inverter (reapply power)

replacement procedures

28 | CFW300

Page 34

Troubleshooting and Maintenance

Tab le 6 .3 : Recommended periodic inspections - ever y 6 months

Component Abnormality Corrective Action

Terminals, connectors Loose screws Tighten

Loose connectors

Fans / Cooling systems

Printed circuits boards Accumulation of dust, oil, humidity, etc. Clean

Power module / Power

connections

DC Link capacitors Discoloration / odor / electrolyte leakage Replace

Power resistors Discoloration Replace

Heatsink Accumulation of dust Clean

(*) The CFW300 fan can b e easily replaced as shown in Figure A 5 on page 112.

(*)

Dirty fans Clean

Abnormal acoustic noise Replace the fan

Blocked fan Clean or replace

Abnormal vibration

Dust in the cabinet air filter

Odor Replace

Accumulation of dust, oil, humidity, etc. Clean

Loose connections screws Tighten

Expanded or broken safety valve

Frame size expansion

Odor

Dirt

English

6.5 CLEANING INSTRUCTIONS

When it is necessary to clean the inverter, follow the instructions below:

Ventilation system:

Disconnect the inverter power supply and wait for 10 minutes.

Remove the dust from the cooling air inlet by using a soft brush or cloth.

Remove the dust from the fan blades by using compressed air.

Cards:

Disconnect the power supply of the inverter and wait for 10 minutes.

Disconnect all the cables of the inverter, identifying all of them in order to reconnect them

correctly.

Remove the plastic cover and the plug-in module (refer to Chapter 3 INSTALLATION AND

CONNECTION on page 9 and APPENDIX B - TECHNICAL SPECIFICATIONS on page

113).

Remove the dust accumulated on the cards using and anti-static brush using and/or ion

compressed air gun.

Always use grounding strap.

CFW300 | 29

Page 35

Accessories

7 ACCESSORIES

The accessories are hardware resources that can be added to the application. Thus, all models

English

can receive all the presented options.

The accessories are installed in the inverters easily and quickly using the "Plug and Play" concept.

The accessory must be installed or modified with the inverter power supply off. They may be

ordered separately, and will be shipped in individual packages containing the components and

the manuals with detailed instructions for the product installation, operation and programming.

The CFW300 inverters have two slots for simultaneous connection of the accessories:

Slot 1 - Communication accessory or external HMI (see Figure A3 on page 111).

Slot 2 - Input and output (I/O) expansion accessory (see Figure A4 on page 111).

Tab le 7.1: Accessory models

WEG Item Name Description

Communication Accessories

13015223 CFW300-CRS485 RS-485 communication module

130146 96 CFW300-CUSB USB communication module (2 m cable attached)

13 0146 74 CFW300-CRS232 RS-232 communication module

13014718 CFW300-CCAN CANopen and DeviceNet communication module

13015 05 5 CFW300-CPDP Profibus DP communication module

13014672 CFW300-CBLT Bluetooth communication module

Input and Output (I/O) Expansion Accessor y

13015 05 0 CFW300-IOAR Input and output expansion module: 1 analog input, 1 analog output

13015 051 CFW300-IODR Input and output expansion module: 4 digital inputs and 3 relay outputs

13015 05 2 CFW300-IOAENC Input and output expansion module: 1 analog input, 2 analog outputs

13015 05 4 CFW300-IOADR Input and output expansion module with remote control: 1 NTC input, 3

13014675 CFW300-KHMIR CFW30 0 remote HMI kit (CFW300-CRS485 + 3 m cable attached)

130146 93 CFW300-MMF Flash memory module (1 m cable attached)

13015 615 CFW300-KFA RFI filter kit CFW300 frame size A

13015 616 CFW300-KFB RFI filter kit CF W300 frame size B

and 3 relay outputs

and input for incremental encoder

relay outputs and 1 input for infrared sensor (infrared sensor, NTC and

remote control with battery included)

External HMI

Flash Memory Module

RFI Filter Accessory

30 | CFW300

Page 36

8 TECHNICAL SPECIFICATIONS

8.1 POWER DATA

Technical Specifications

Power Supply:

Tolerance: -15 % to +10 %.

Frequency: 50/60 Hz (48 Hz to 62 Hz).

Phase imbalance: ≤ 3 % of the rated phase-to-phase input voltage.

Overvoltage according to Category III (EM 61010/UL 508C).

Transient voltages according to Category III.

Maximum of 10 connections per hour (1 every 6 minutes).

Typical efficiency: ≥ 97 %.

Classification of chemically active substances: level 3C2.

Mechanical condition rating (vibration): level 3M4.

Audible noise level: < 60dB.

For further information about the technical specifications, refer to APPENDIX B - TECHNICAL

SPECIFICATIONS on page 113.

English

CFW300 | 31

Page 37

Technical Specifications

8.2 ELECTRONICS/GENERAL DATA

English

Control Method Types of control:

Output frequency 0 to 400 Hz, resolution of 0.1 Hz

Performance V/F control Speed regulation: 1 % of the rated speed (with slip compensation)

Vector control

(VV W)

Inputs Analog 1 insulated input. Levels: (0 to 10) V or (0 a 20) mA or (4 to 20) m A

Digital 4 isolated inputs

Outputs Relay 1 relay with NO/NC contact

Power supply 10 Vdc power supply. Maximum capacity: 50 mA

Safety Protection Overcurrent/phase-phase short circuit in the output

Integral keypad

(HMI)

Enclosure IP20 Frames sizes A and B

Standard keypad 4 keys: Star t/Stop, Up arrow, Down arrow and Programming

Tab le 8 .1: Electronics/general data

- V/f (Scalar)

- VV W: voltage vector control

PWM SVM (Space Vector Modulation)

Speed variation range: 1:20

Speed regulation: 1 % of the rated speed

Speed variation range: 1:30

Linearity error ≤ 0.25 %

Impedance: 100 kΩ for voltage input, 500 Ω for current input

Programmable functions

Maximum voltage permitted in the input: 30 Vdc

Programmable functions

- active high (PNP): maximum low level of 10 Vdc

minimum high level of 20 Vdc

- active low (NPN): ma ximum low level of 5 Vdc

minimum high level of 10 Vdc

Maximum input voltage of 30 Vdc

Input current: 11 mA

Maximum input current: 20 mA

Maximum voltage: 250 Vac

Maximum current: 0.5 A

Programmable functions

Under/overvoltage

Motor overload

Overtemperature in the power module (IGBTs)

Fault / external alarm

Programming error

LCD Display

View/edition of all parameters

Indication accuracy:

- current: 5 % of the rated current

- speed resolution: 0.1 Hz

32 | CFW300

Page 38

Technical Specifications

8.2 .1 Considered Standards

Tab le 8 .2 : Considered standards

Safety standards UL 508C - power conversion equipment

Electromagnetic

compatibility

(EMC)

standards

Mechanical

standards

(*) Compliance with standards upon installation of external RFI filter. See Chapter 3 INSTALLATION AND CONNECTION

on page 9.

UL 840 - insulation coordination including clearances and creepage distances for electrical

equipment

EN61800-5-1 - safety requirements electrical, thermal and energy

EN 50178 - electronic equipment for use in power installations

EN 60204-1 - safety of machiner y. Electrical equipment of machines. Part 1: general requirements

Note: the final assembler of the machine is responsible for installing a safety stop device and a

supply disconnecting device

EN 60146 (IEC 146) - semiconductor converters

EN 61800-2 - adjustable speed electrical power drive systems - part 2: general requirements

Rating specifications for low voltage adjustable frequency AC power drive systems

EN 61800-3 - adjustable speed electrical power drive systems - part 3: EMC product standard

including specific test methods

EN 55011 - limits and methods of measurement of radio disturbance characteristics of industrial,

(*)

scientific and medical (ISM) radio-frequency equipment

CISPR 11 - industrial, scientific and medical (ISM) radio-frequency equipment - electromagnetic

disturbance characteristics - limits and methods of measurement

EN 61000-4 -2 - electromag netic compat ibility (EM C) - part 4: testin g and measure ment techni ques

- section 2: electrostatic discharge immunity test

EN 610 00-4-3 - el ectromagne tic compatib ility (EMC) - pa rt 4: testing and m easureme nt technique s

- section 3: radiated, radio-frequency, electromagnetic field immunity test

EN 61000-4-4 - electromagnetic compatibility (EMC) - part 4: testing and measurement techniques

- section 4: electrical fast transient/burst immunity test

EN 61000-4-5 - electromagnetic compatibility (EMC) - part 4: testing and measurement techniques

- section 5: surge immunity test

EN 61000-4-6 - electromagnetic compatibility (EMC) - part 4: testing and measurement techniques

- section 6: immunity to conducted disturbances, induced by radio-frequency fields

EN 60529 - degrees of protection provided by enclosures (IP code)

UL 50 - enclosures for electrical equipment

IEC 60721-3-3 - classification of environmental conditions

English

CFW300 | 33

Page 39

Manual del Usuario

Serie: CFW300

Idioma: Español

Documento Nº: 10003325037 / 00

Modelos: Tamaño A y B

Fecha: 11/2015

Page 40

Sumario de las Revisiones

La información a seguir describe las revisiones llevadas a cabo en este manual.

Versión Revisión Descripción

- R00 Primera edición

¡ATENCIÓN!

Verificar la frecuencia de la red de alimentación.

En caso de que la frecuencia de la rede de alimentación sea diferente del

ajuste de fábrica (verificar P403) será necesario programar:

P204 = 5 para 60 Hz.

P204 = 6 para 50 Hz.

Español

Solamente será necesario efectuar esa programación una vez.

Consulte el manual de programación del CFW300 para más detalles sobre la

programación del parámetro P204.

Page 41

Sumario

1 INSTRUCCIONES DE SEGURIDAD .................................................39

1.1 AVISOS DE SEGURIDAD EN EL MANUAL ............................................39

1.2 AVISOS DE SEGURIDAD EN EL PRODUCTO .......................................39

1.3 RECOMENDACIONES PRELIMINARES ................................................40

2 INFORMACIONES GENERALES ...................................................... 41

2.1 SOBRE EL MANUAL ............................................................................... 41

2.2 SOBRE EL CFW300 .................................................................................41

2.3 NOMENCLATURA ...................................................................................44

2.4 ETIQUETA DE IDENTIFICACIÓN............................................................45

2.5 RECEPCIÓN Y ALMACENAMIENTO .....................................................46

3 INSTALACIÓN Y CONEXIÓN ............................................................47

3.1 INSTALACIÓN MECÁNICA .....................................................................47

3.1.1 Condiciones Ambientales .............................................................47

3.1.2 Posicionamiento y Fijación ..........................................................47

3.1.2.1 Montaje en Tablero ............................................................48

3.1.2.2 Montaje en Superficie ......................................................48

3.1.2.3 Montaje en Riel DIN ..........................................................48

3.2 INSTALACIÓN ELÉCTRICA ....................................................................48

3.2.1 Identificación de los Bornes de Potencia y Puntos de Puesta a

Tierra ........................................................................................................48

3.2.2 Cableado de Potencia, Puesta a Tierra, Disyuntores y Fusibles

49

3.2.3 Conexiones de Potencia...............................................................50

3.2.3.1 Conexiones de Entrada .................................................... 52

3.2.3.2 Reactancia de la Red .......................................................52

3.2.3.3 Frenado Reostático ..........................................................53

3.2.3.4 Conexiones de Salida .......................................................54

3.2.4 Conexiones de Puesta a Tierra ...................................................55

3.2.5 Conexiones de Control .................................................................55

3.2.6 Distancia para Separación de Cables ........................................56

3.3 INSTALACIONES DE ACUERDO CON LA DIRECTIVA EUROPEA DE

COMPATIBILIDAD ELECTROMAGNÉTICA ................................................56

3.3.1 Instalación Conforme ....................................................................57

3.3.2 Niveles de Emisión y Inmunidad Atendida ................................57

3.3.3 Filtro Supresor de RFI ..................................................................58

Español

4 HMI Y PROGRAMACIÓN BÁSICA ....................................................60

4.1 USO DE LA HMI PARA OPERACIÓN DEL CONVERTIDOR ................. 60

4.2 INDICACIONES EN EL DISPLAY DE LA HMI ........................................60

4.3 MODOS DE OPERACIÓN DE LA HMI ....................................................60

5 ENERGIZACIÓN Y PUESTA EN FUNCIONAMIENTO ..................... 62

5.1 PREPARACIÓN Y ENERGIZACIÓN ........................................................ 62

5.2 PUESTA EN FUNCIONAMIENTO ...........................................................62

5.2.1 Aplicación Básica ..........................................................................63

5.2.2 Tipo de Control V/f (P202 = 0) ......................................................64

5.2.3 Tipo de Control VV W (P202 = 5) ..................................................65

Page 42

Sumario

6 DIAGNÓSTICO DE PROBLEMAS Y MANTENIMIENTO .................66

6.1 FALLAS Y ALARMAS ...............................................................................66

6.2 SOLUCIÓN DE LOS PROBLEMAS MÁS FRECUENTES ......................66

6.3 DATOS PARA CONTACTO CON LA ASISTENCIA TÉCNICA ..............66

6.4 MANTENIMIENTO PREVENTIVO ...........................................................67

6.5 INSTRUCCIONES DE LIMPIEZA ...........................................................68

7 ACCESORIOS ....................................................................................69

8 ESPECIFICACIONES TÉCNICAS .....................................................70

8.1 DATOS DE POTENCIA .............................................................................70

Español

8.2 DATOS DE LA ELECTRÓNICA/GENERALES .......................................71

8.2.1 Normas Consideradas ..................................................................72

ANEXO A - FIGURAS .......................................................................... 110

ANEXO B - ESPECIFICACIONES TÉCNICAS ................................... 113

Page 43

Instrucciones de Seguridad

1 INSTRUCCIONES DE SEGURIDAD

Este manual contiene las informaciones necesarias para el uso correcto del convertidor de

frecuencia CFW300.

El mismo fue desarrollado para ser utilizado por personas con capacitación o calificación técnica

adecuadas para operar este tipo de equipo. Estas personas deben seguir las instrucciones de

seguridad definidas por las normas locales. No seguir las instrucciones de seguridad puede

derivar en riesgo de muerte y/o daños en el equipo.

1.1 AVISOS DE SEGURIDAD EN EL MANUAL

En este manual son utilizados los siguientes avisos de seguridad:

¡PELIGRO!

Los procedimientos recomendados en este aviso tienen como objetivo proteger

al usuario contra muerte, heridas graves y daños materiales considerables.

¡ATENCIÓN!

Los procedimientos recomendados en este aviso tienen como objetivo evitar

daños materiales.

¡NOTA!

Las informaciones mencionadas en este aviso son importantes para el correcto

entendimento y bom funcionamiento del producto.

Español

1.2 AVISOS DE SEGURIDAD EN EL PRODUCTO

Los siguientes símbolos están pegados al producto, sirviendo como aviso de seguridad::

Tensiones elevadas presentes.

Componentes sensibles a descarga electrostática.

No tocarlos.

Conexión obligatoria a la tierra de protección (PE).

Conexión del blindaje a la tierra.

CFW300 | 39

Page 44

Instrucciones de Seguridad

1.3 RECOMENDACIONES PRELIMINARES

¡PELIGRO!

Desconecte siempre la alimentación general antes de tocar cualquier componente

eléctrico asociado al convertidor. Muchos componentes pueden permanecer

cargados con altas tensiones y/o en movimiento (ventiladores), incluso después

de que la entrada de alimentación CA haya sido desconectada o apagada.

Aguarde por lo menos 10 minutos para garantizar la total descarga de los

condensadores. Siempre conecte el punto de puesta a tierra del convertidor a

tierra de protección (PE).

Español

¡PELIGRO!

El conector XC10 no presenta compatibilidad USB, por lo tanto, no puede ser

conectado a puertas USB.

Ese conector sirve solamente de interfaz entre el convertidor de frecuencia

CFW300 y sus accesorios.

¡NOTAS!

Los conver tidores de frecuencia pueden interferir en otros equipos electrónicos.

Siga los cuidados recomendados en el Capítulo 3 INSTALACIÓN Y CONEXIÓN

en la página 47, para minimizar estos efectos.

Lea completamente este manual antes de instalar o operar este convertidor.

No ejecute ningún ensayo de tensión aplicada en el convertidor.

En caso de que sea necesario, consulte el fabricante.

¡ATENCIÓN!

Las tarjetas electrónicas poseen componentes sensibles a descarga

electrostática. No toque directamente los componentes o conectores. En caso

de que sea necesario, toque antes el punto de puesta a tierra del convertidor, el

que debe estar conectado a tierra de protección (PE) o utilice pulsera de puesta

a tierra adecuada.

40 | CFW300

Page 45

Informaciones Generales

2 INFORMACIONES GENERALES

2.1 SOBRE EL MANUAL

Este manual presenta informaciones para la adecuada instalación y operación del convertidor,

puesta en funcionamiento, principales características técnicas y de cómo identificar y corregir

los problemas más comunes de los diversos modelos de convertidores de la línea CFW300.

¡ATENCIÓN!

La operación de este equipo requiere instrucciones de instalación y de

operación detalladas, suministradas en el guía de instalación rápida, manual del

usuario, manual de programación y manuales de comunicación. Las guías son

suministradas impresas con su respectivo accesorio, o pueden ser obtenidos

en el sitio web de WEG - www.weg.net. Puede ser solicitada una copia impresa

de los archivos por medio de su representante local WEG.

¡NOTA!

No es la intención de este manual agotar todas las posibilidades de aplicación

del CFW300, ni la WEG puede asumir ninguna responsabilidad por el uso del

CFW300 que no esté basado en este manual.

Parte de las figuras y de las tablas están a disposición en los anexos, los cuales se dividen

en ANEXO A - FIGURAS en la página 110 para figuras y ANEXO B - ESPECIFICACIONES

TÉCNICAS en la página 113 para especificaciones técnicas.

Para más informaciones, consultar el manual de programación.

Español

2.2 SOBRE EL CFW300

El convertidor de frecuencia CFW300 es un producto de alta performance que permite el

control de velocidad y de torque de motores de inducción trifásicos. Este producto proporciona

al usuario las opciones de control vectorial (VVW ) o escalar (V/f), ambos programables de

acuerdo a la aplicación.

En el modo vectorial (V V W) la operación es optimizada para el motor en uso, obteniéndose

un mejor desempeño en términos de regulación de velocidad.

El modo escalar (V/f) es recomendado para aplicaciones más simples como el accionamiento

de la mayoría de las bombas y ventiladores. En esos casos es posible reducir las pérdidas

en el motor y en el convertidor, utilizando la opción "V/f Cuadrática", lo que resulta en ahorro

de energía. El modo V/f también es utilizado cuando es accionado más de un motor, por un

convertidor simultáneamente (aplicaciones multimotores).

El convertidor de frecuencia CFW300 también posee funciones de CLP (Controlador Lógico

Programable) a través del recurso SoftPLC (integrado). Para más detalles referentes a la

programación de esas funciones, consulte el manual del usuario SoftPLC del CFW300.

Los principales componentes del CFW300 pueden ser visualizados en el diagramas de bloques

de la Figura 2.1 en la página 42, para lo Tamaño A 220 V, Figura 2.2 en la página 43 para

lo Tamaño A 110 V y Figura 2.3 en la página 44 para el Tamaño B 220 V.

CFW300 | 41

Page 46

Informaciones Generales

Red de

alimentación

R/L1/L (-UD)

S/L2/N (+UD)

T/L 3

1

1

2

Filtro RFI

5

PE

Rectificador

monofásico o

trifásico

Potencia

Precarga

Banco de

condensadores

Link CC

Rsh

Convertidor

con