WEG CFW11M G2 0634 T 4 O RB, CFW11M G2 3012 T 4 O RB, CFW-11M G2 RB Series, CFW11M G2 1205 T 4 O RB, CFW11M G2 2409 T 4 O RB User Manual

...Page 1

Motors | Automation | Energy | Transmission & Distribution | Coatings

Regenerative Frequency Converter

CFW11M G2 RB

CFW11W G2 RB

User's Manual

Page 2

User's Manual

Series: CFW-11M G2 RB

CFW-11W G2 RB

Language: English

Document: 10006398151 / 00

Models CFW-11M G2 RB: 634...3012 A/380...480 V

496...2356 A/500...600 V

439...2585 A/660...690 V

CFW-11W G2 RB Models: 780...3705 A/500...690 V

Publication Date: 06/2019

Page 3

Summary of the Revisions

The table below describes all revisions made to this manual.

Version Review Descriprion

- R00 First edition

Page 4

Contents

1 SAFETY INSTRUCTIONS ....................................................................... 1-1

1.1 SAFETY WARNINGS IN THE MANUAL ..........................................................................................1-1

1.2 SAFETY WARNINGS ON THE PRODUCT ...................................................................................... 1-1

1.3 PRELIMINARY RECOMMENDATIONS ..........................................................................................1-2

2 GENERAL INFORMATION ......................................................................2-1

2.1 ABOUT THE MANUAL .....................................................................................................................2-1

2.2 TERMS AND DEFINITIONS USED IN THE MANUAL ....................................................................2-1

2.3 ABOUT THE CFW-11M G2 RB AND CFW-11W G2 RB ................................................................. 2-3

2.4 UC11RB G2 IDENTIFICATION LABEL ............................................................................................2-7

2.5 UP11 G2 AND UP11W G2 IDENTIFICATION LABEL .................................................................... 2-8

2.6 HOW TO SPECIFY THE CONVERTER MODEL (SMART CODE) ............................................... 2-10

2.7 RECEIVING AND STORAGE ......................................................................................................... 2-11

3 INSTALLATION AND CONNECTION .....................................................3 -1

3.1 AIR-COOLED UP11 G2 MECHANICAL INSTALLATION .............................................................. 3 -1

3.1.1 Environmental Conditions .................................................................................................... 3-1

3.1.2 Part List .................................................................................................................................. 3-1

3.1. 3 L i ft i ng ...................................................................................................................................... 3-3

3.1.4 Panel Ventilation .................................................................................................................... 3-4

3.1.5 Panel Mounting of the UP11 G2 ........................................................................................... 3-4

3.1. 6 Pa ne l ....................................................................................................................................... 3 -7

3.2 WATER-COOLED UP11W G2 MECHANICAL INSTALLATION .................................................... 3-9

3.2.1 Environmental Conditions ................................................................................................... 3-9

3.2.2 Part List .................................................................................................................................3 -10

3.2.3 Lifting ....................................................................................................................................3 -11

3.2.4 Panel Mounting of the UP11W G2 ......................................................................................3-12

3.2.5 Panel ......................................................................................................................................3-14

3.2.6 Cooling System .................................................................................................................... 3-17

3.3 UC11 MECHANICAL INSTALLATION .......................................................................................... 3-20

3.4 ELECTRICAL INSTALLATION ...................................................................................................... 3-22

3.4.1 Pre-Charge ........................................................................................................................... 3-22

3.4.2 Busbars ................................................................................................................................ 3-24

3.4.3 Fuses ................................................................................................................................... 3-24

3.4.4 General Wiring Diagram ..................................................................................................... 3-26

3.4.5 Power Connections ............................................................................................................ 3-27

3.4.6 Input and Grounding Connections ................................................................................... 3-31

3.4.7 Terminals Recommended for Power Cables ................................................................... 3-33

3.4.8 Output Connections ...........................................................................................................3-33

3.4.9 Input Filters .......................................................................................................................... 3-34

3.4.9.1 Basic Definitions ..................................................................................................... 3-34

3.4.9.2 How to Specify the Filter Model ........................................................................... 3-34

3.4.10 Synchronism ..................................................................................................................... 3-35

3.4.11 Control Connections ........................................................................................................ 3-39

3.4.11.1 UP11 G2 and UP11W G2 Connections ................................................................. 3-39

3.4.11.2 UC11RB G2 Connections ...................................................................................... 3-41

3.4 .11. 3 Co ne x õ es CC11 ...................................................................................................... 3-46

3.4.11.4 Typical Drives ......................................................................................................... 3-50

3.5 INSTALLATIONS ACCORDING TO THE EUROPEAN ELECTROMAGNETIC

COMPATIBILITY DIRECTIVE ............................................................................................................. 3-50

3.5.1 Conformal Installation ........................................................................................................ 3-50

3.5.2 Definition of the Standards ............................................................................................... 3-51

3.5.3 Emission and Immunity Levels Met .................................................................................. 3-52

Page 5

Contents

4 HMI...........................................................................................................4 -1

4.1 HMI-CFW11M G2 HUMAN MACHINE INTERFACE ...................................................................... 4 -1

4.2 PARAMETER STRUCTURE ........................................................................................................... 4-4

5 ENERGIZATION AND START-UP ........................................................... 5 -1

5.1 PREPARATION AND ENERGIZATION ........................................................................................... 5 -1

5.2 S TA R T-U P ........................................................................................................................................ 5-2

5.2.1 Password Setting in P0000 .................................................................................................. 5-2

5.2.2 Oriented Start-up .................................................................................................................. 5-2

5.3 DATE AND TIME SETTING ............................................................................................................. 5-4

5.4 LOCKING OF PARAMETER MODIFICATION ............................................................................... 5-4

5.5 HOW TO CONNECT A PC .............................................................................................................. 5-4

5.6 FLASH MEMORY MODULE ........................................................................................................... 5-5

5.7 OPERATION WITH A REDUCED NUMBER OF POWER UNITS .................................................. 5-6

6 TROUBLESHOOTING AND MAINTENANCE ........................................6-1

6.1 OPERATION OF THE FAULTS ........................................................................................................ 6 -1

6.2 ALARMS, FAULTS AND POSSIBLE CAUSES ............................................................................... 6-2

6.3 TROUBLESHOOTING THE MOST COMMON PROBLEMS ......................................................... 6-7

6.4 INFORMATION NECESSARY FOR CONTACTING TECHNICAL SUPPORT............................... 6-8

6.5 PREVENTIVE MAINTENANCE ....................................................................................................... 6-8

6.5.1 Cleaning Instructions ..........................................................................................................6-10

7 OPTIONAL ITEMS AND ACCESSORIES ............................................... 7-1

7.1 OPTIONAL ITEMS ............................................................................................................................ 7-1

7.1.1 Connections of the Cooling System with Quick Couplings ............................................... 7-1

7.2 ACCESSORIES .................................................................................................................................7-2

8 TECHNICAL DATA ...................................................................................8 -1

8.1 POWER DATA .................................................................................................................................. 8-1

8.2 ELECTRONICS/GENERAL DATA .................................................................................................. 8-5

8.2.1 Codes and Standards Met ................................................................................................... 8-5

8.3 MECH A N ICAL DATA ....................................................................................................................... 8-6

8.4 CIRCUIT DIAGRAM EXAMPLE .....................................................................................................8 -10

Page 6

Safety Instructions

1 SAFETY INSTRUCTIONS

This manual contains the information necessary for the correct use of the regenerative frequency converter

CFW-11M G2 RB (air cooled) and CFW-11W G2 RB (water cooled).

It was developed to be used by people with proper technical qualification or training to operate this kind of equipment.

1.1 SAFETY WARNINGS IN THE MANUAL

The following safety notices are used in this manual:

DANGER!

Failure to comply with the procedures recommended in this warning may lead to death, serious

injuries and considerable material damages.

ATTENTION!

Failure to comply with the procedures recommended in this warning may lead to material damages.

1

NOTE!

The text provides important information for the full understanding and proper operation of the product.

1.2 SAFETY WARNINGS ON THE PRODUCT

The following symbols are attached to the product as safety warnings:

High voltages present.

Components sensitive to electrostatic discharges. Do not touch them.

Mandatory connection to the protective earth (PE).

Connection of the shield to the ground.

Hot surface.

CFW-11MW G2 RB | 1-1

Page 7

Safety Instructions

1.3 PRELIMINARY RECOMMENDATIONS

DANGER!

1

Only qualified personnel familiar with the CFW-11M G2 RB and CFW-11W G2 RB converters and related

devices must plan or perform the installation, start-up, operation and maintenance of this equipment.

Such personnel must follow the safety instructions described in this manual and/or defined by local

standards.

Failure to comply with the safety instructions may cause risk of death and/or equipment damage.

NOTE!

For the purpose of this manual, qualified personnel are people trained to be able to:

1. Install, ground, power up and operate the CFW-11M G2 RB and CFW-11W G2 RB according to

this manual and the legal safety procedures in force.

2. Use the protective equipment according to the standards.

3. Give first aid.

DANGER!

Always disconnect the general power supply before touching any electrical component connected

to the converter.

Many components may remain charged with high voltages and/or moving parts (fans) even after the

AC power supply input is disconnected or turned off.

Wait for at least ten minutes to guarantee the full discharge of the capacitors.

Always connect the equipment frame to the protective earth (PE) at the proper terminal.

ATTENTION!

Electronic boards have components sensitive to electrostatic discharges. Do not touch the components

or connectors directly. If necessary, first touch the grounded metallic frame or wear a ground strap.

Do not carry out any applied potential test on the converter!

If necessary, contact WEG.

NOTE!

Regenerative frequency converters may interfere in other electronic equipment. Observe the

recommendations of Chapter 3 INSTALLATION AND CONNECTION on page 3-1 to minimize

those effects.

NOTE!

Carefully read this entire manual before installing or operating this device.

ATTENTION!

The operation of this equipment requires detailed installation and operation instructions provided in

the user’s manual and manuals/guides for kits and accessories. Only the user’s manual is supplied

in print. The other manuals can be obtained on WEG website - www.weg.net. A printed copy of this

information may be requested through your local WEG representative.

1-2 | CFW-11MW G2 RB

Page 8

General Information

2 GENERAL INFORMATION

2.1 ABOUT THE MANUAL

This manual contains information for the proper installation and start-up, the main technical data and directions

to troubleshoot the most usual problems of the CFW-11M G2 RB and CFW-11W G2 RB converters.

For information on other functions, accessories and operating conditions, refer to the following manuals:

Programming manual, with the detailed description of the parameters and advanced functions of the CFW-11

RB converter.

Manual of the I/O expansion modules.

Those manuals are available on WEG website - www.weg.net.

2.2 TERMS AND DEFINITIONS USED IN THE MANUAL

Regenerative Frequency Converter: three-phase switched boost-type converter that converts alternating voltage

(AC) of the grid into DC voltage (DC Link). It can absorb energy from the grid (AC) or return energy to it, being used

as a DC voltage supply that feeds one or more output inverters.

Output Inverter: frequency inverter with power circuit supplied by the DC Link coming from the regenerative

frequency converter. It controls the motor.

Normal Duty (ND): Normal Duty (ND); operating duty of the converter that defines the maximum current values

for continuous operation I

(Application) = 0 (Normal Duty (ND)). The output inverter overload duty affects the regenerative frequency converter.

I

: Converter rated current for operation under normal duty (ND). Overload: 1.1 x I

nom-ND

and overload of 110 % for one minute. It is selected by programming P0298

-ND

nom

/ 1 minute.

-ND

nom

2

Heavy Duty (HD): Operating duty of the inverter that defines the maximum current values for continuous operation

I

and overload of 150 % for one minute. It is selected by programming P0298 (Application) = 1 (Heavy Duty

-HD

nom

(HD)). The output inverter overload duty affects the regenerative frequency converter.

I

: Converter rated current for operation under heavy duty (HD). Overload: 1.5 x I

nom-HD

nom

-HD

/ 1 minute.

Current Unbalance (%):

I

- I

YX

Unbalance at power unit X - phase Y =

I

YAVG

I

Y1

=

+ I

Y2

+

N

...

+ I

YN

I

YAVG

YAVG

.10 0

Where:

N = number of power units.

IYN = current of phase Y (U, V or W) of the power unit N (P0815 to P0829).

I

= average current of phase Y.

YAVG

Pre-Charge Circuit: It loads the DC link capacitors with limited current, avoiding high current peaks at the inverter

energization.

DC Link: Converter DC link; voltage in direct current obtained by rectifying the alternate power supply voltage or

through an external source; it feeds the output inverter bridge.

DC+: Positive terminal of the DC Link.

CFW-11MW G2 RB | 2-1

Page 9

General Information

DC-: Negative terminal of the DC Link.

Arm U, V and W: Conjunto de dois IGBTs das fases U, V e W de entrada do conversor regenerativo.

IGB T: Insulated Gate Bipolar Transistor: it is a basic component of the U, V and W arms. It operates like an

electronic switch in the saturated mode (closed switch) and cut off mode (open switch).

2

PTC: Resistor whose resistance value in ohms increases proportionally to the temperature; used as temperature

sensor on motors.

NTC: Resistor whose resistance value in ohms decreases proportionally to the temperature increase; used as

temperature sensor on power packs.

HMI: Human-Machine Interface; it is a device that allows viewing and changing the converter parameters. The

HMI of the CFW-11M G2 RB features control keys for the regenerative frequency converter, navigation keys and

a display.

FLASH Memory: Nonvolatile memory that can be electrically written and erased.

RAM memory: Random access memory.

USB: Universal Serial Bus; serial communication protocol conceived to work according to the plug-and-play

concept.

PE: Protective earth.

RFI Filter: Radio Frequency Interference Filter; filter to reduce interference in the radio frequency band.

PWM: Pulse Width Modulation; pulsing voltage at the input of the regenerative frequency converter.

Switching Frequency: switching frequency of the IGBTs, usually given in kHz.

General enable: When enabled, the converter controls the voltage on the DC link. When disabled, the PWM

pulses will be immediately blocked. It is controlled via digital input programmed for such function.

Heatsink: Piece of metal designed to dissipate the heat generated by power semiconductors.

UP11 G2: Power unit of the CFW-11M G2 RB with air cooling.

UP11W G2: Power unit of the CFW-11W G2 RB with water cooling.

UC11 G2: Control Unit of the CFW-11M G2 RB and CFW-11W G2 RB.

PLC: Programmable logic controller.

Amp, A: Ampere.

°C: Degrees Celsius.

AC: Alternating current.

DC: Direct current.

CFM: Cubic feet per minute; a flow measurement unit.

cm: Centimeter

CV: Brazilian unit of power = 736 Watts; usually used to indicate mechanical power of electric motors.

ft: Foot.

2-2 | CFW-11MW G2 RB

Page 10

General Information

hp: Horse power = 746 Watts; unit of power, usually used to indicate mechanical power of electric motors.

Hz: Hertz.

in: Inch.

kg: Kilogram = 1000 grams.

kHz: Kilohertz = 1000 Hertz.

l/min: Liters per minute.

lb: Pound.

m: Meter.

mA: Milliampere = 0.001 ampere.

min: Minute.

mm: Millimeter.

ms: Millisecond = 0.001 second.

Nm: Newton meter; torque measurement unit.

rms: Root mean square; effective value.

rpm: Revolutions per minute; unit of rotation.

s: Second.

2

V: Volts.

Ω: Ohms.

2.3 ABOUT THE CFW-11M G2 RB AND CFW-11W G2 RB

The CFW-11M G2 RB and CFW-11W G2 RB regenerative frequency converters are the second generation of the

CFW-11M RB and CFW-11W RB regenerative frequency converter line respectively. The main differences in relation

to the previous generation are the following:

Smaller. The CFW-11M G2 RB is shorter and slimmer than the CFW-11M RB, allowing the installation of three

UP11 G2 RB in a panel with columns 800 mm wide and 2000 mm high. The CFW-11W G2 RB is shorter, slimmer

and less deep than the CFW-11W RB, allowing the installation of three UP11W G2 in a panel with columns 800

mm wide, 2000 mm high and 600 mm deep.

More modern. State-of-the-art components have increased the power of the converters.

The CFW-11M G2 RB and CFW-11W G2 RB regenerative frequency converters are high-performance products

that enable the rectification of three-phase lines with the following advantages:

Low harmonic distortion in the input current.

Capacity to return energy to the line (regeneration), enabling high braking torques.

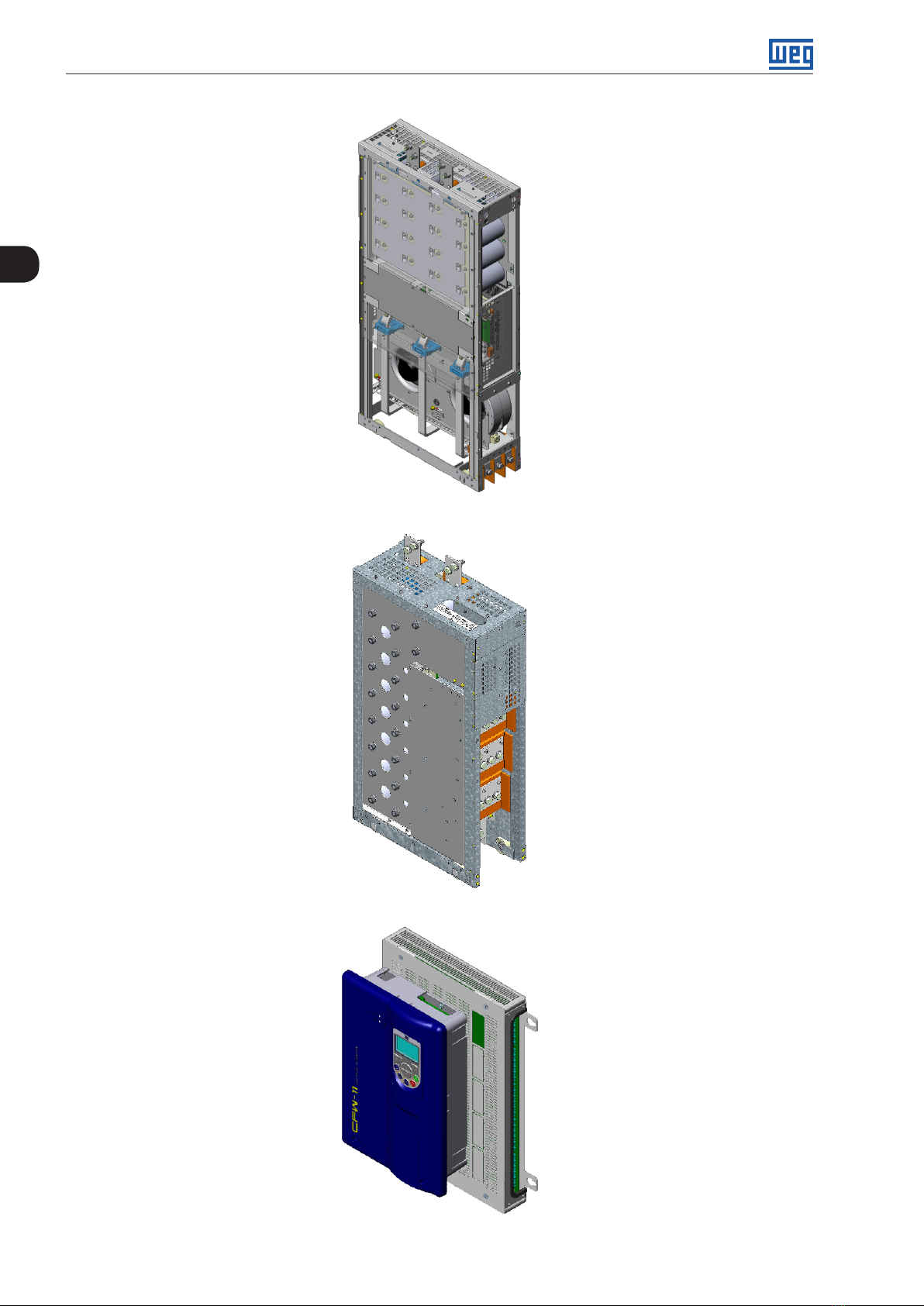

The CFW-11M G2 RB and CFW-11W G2 RB regenerative frequency converters have a modular design, with

configurations containing one to five power units (UP11 G2 or UP11W G2), one control unit (UC11RB G2) and

wiring cables. The modular assembly increases the converter reliability and simplifies its maintenance. There is a

single control unit (UC11RB G2) which can control up to five UP11s G2 or five UP11Ws G2.

CFW-11MW G2 RB | 2-3

Page 11

General Information

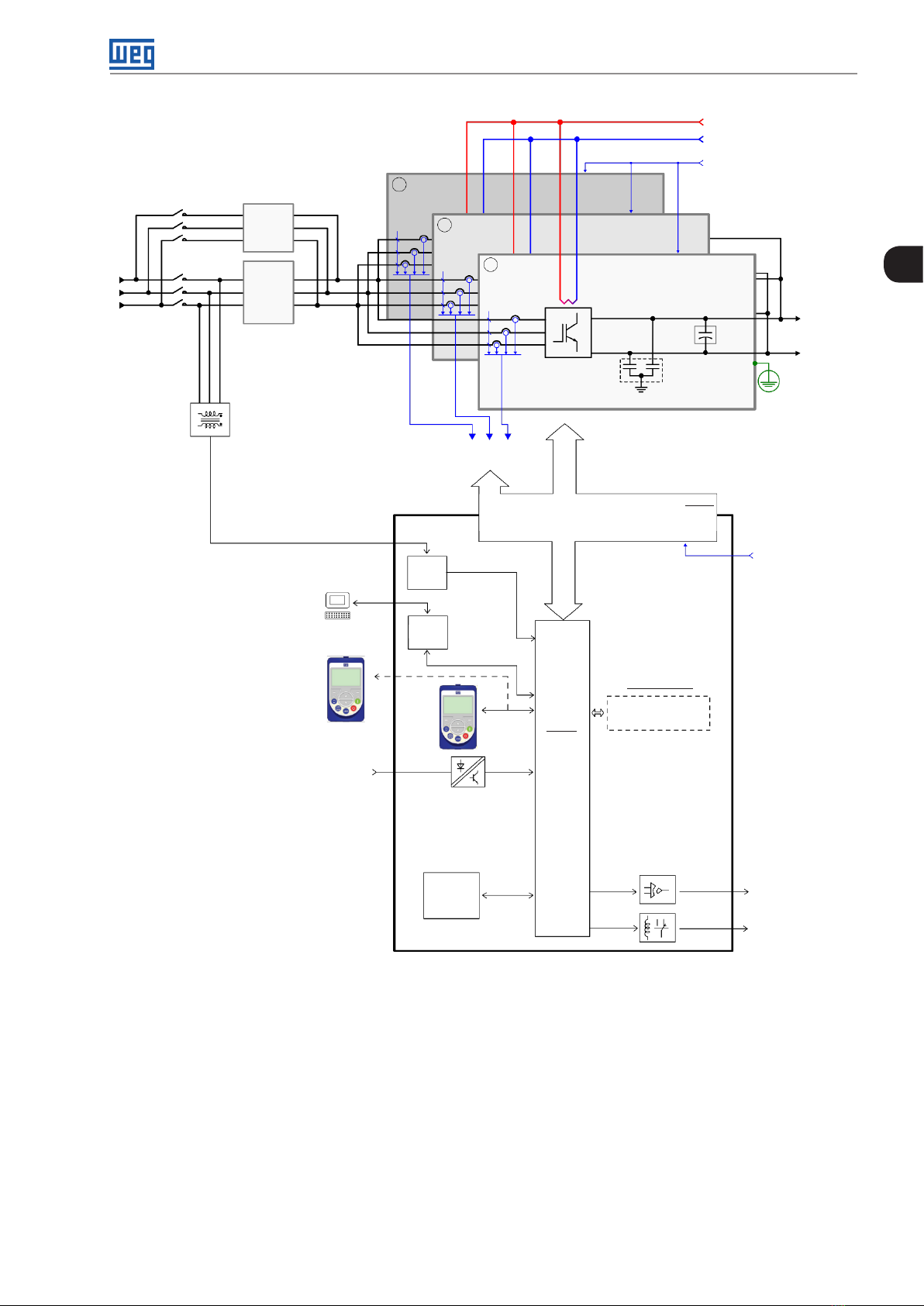

The CFW-11W G2 RB regenerative frequency converter line is water cooled, being smaller than the other converters.

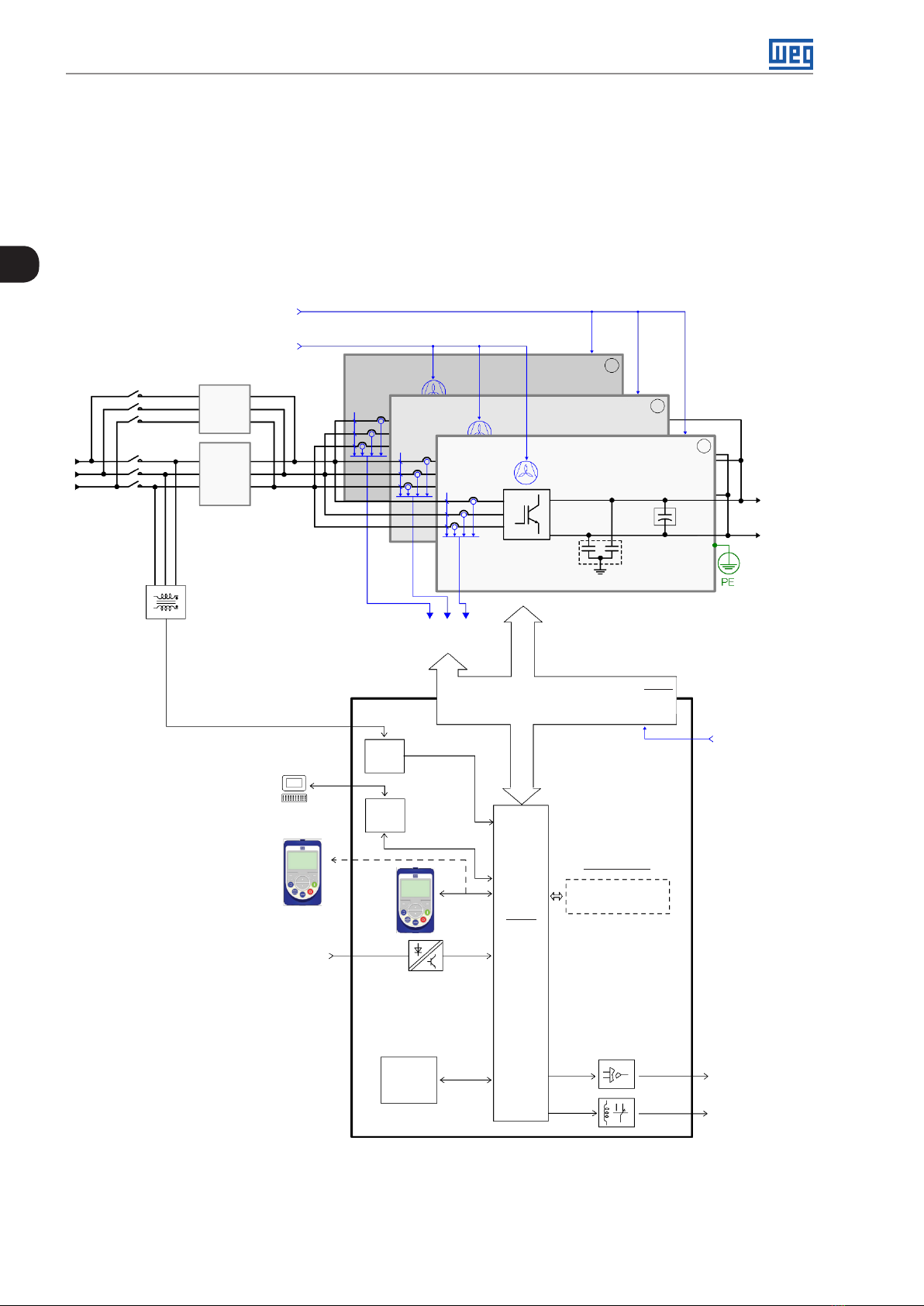

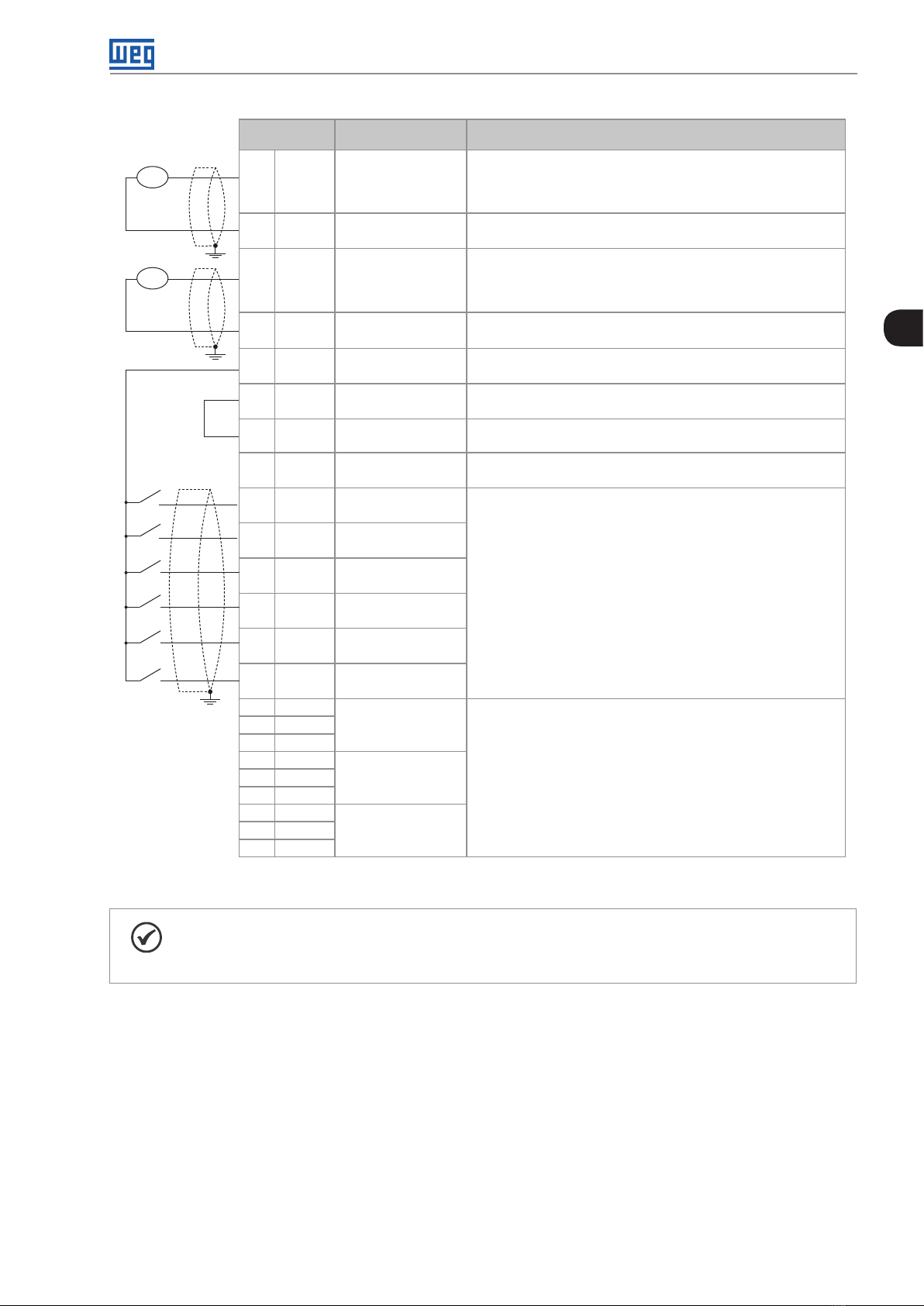

The UP11s, UP11Ws and UC11RB G2 are fed through an external +24 Vdc power supply. Figure 2.1 on page 2-4 and

Figure 2.3 on page 2-6 respectively show the general diagrams of the air-cooled and water-cooled converters,

considering the configuration with three UP11s connected in parallel.

The UC11RB G2 control unit controls the power units. The control unit contains the control rack of the CFW-11

2

line and the ICUP board. This board sends signals to all UP11 G2 or UP11W G2 (PWM, control signals, etc.), and

receives signals from them (current, voltage feedback, etc.).

24 Vdc external power

supply - electronics UP11

220 Vac external power

supply - fans

UP11

3

Pre-

charge

Input

Mains

filter

Synchronism

transformer

PC

SuperDrive G2

software

Power

control

CSR

USB

Feedbacks:

- voltage

- current

IGBT fans

Inverter with

IG B Ts

PMW

Power supplies for electronics

and interfaces between power

and control

UP11

Capacitor

ICUP

2

bank

UP11

1

DC+

DC-

PERFI filter

24 Vdc external

power supply electronics UC11

DC

Output

2-4 | CFW-11MW G2 RB

Accessories

I/O expansion

HMI

(remote)

Digital

inputs (DI1

to DI6)

memory

module

Figure 2.1: General diagram of the CFW11M G2 RB converter

HMI

Flash

CC11

Control

board

with

RISC

32-bit

CPU

(Slot 1 – white)

Analog outputs

(AO1 and AO2)

Digital outputs

DO1 (RL1) to

DO3 (RL3)

Page 12

General Information

Water cooling system

24 Vdc external power

UP11W3

supply - electronics UP11

Pre-

charge

Input

Mains

filter

Synchronism

transformer

PC

SuperDrive G2

software

CSR

USB

UP11W

2

Feedbacks:

- voltage

- current

UP11W

1

Inverter with

IG B Ts

RFI filter

PMW

Power supplies for electronics and

interfaces between power and control

Capacitor

bank

ICUP

DC+

DC

Output

DC-

PE

24 Vdc external

power supply electronics UC11

2

Accessories

I/O expansion

HMI

(remote)

Digital

inputs (DI1

to DI6)

Memory

Module

Figure 2.2: General diagram of the CFW11W G2 RB converter

HMI

Flash

CC11

Control

board

with

RISC

32-bit

CPU

(Slot 1 – white)

Analog outputs

(AO1 and AO2)

Digital outputs

DO1 (RL1) to

DO3 (RL3)

CFW-11MW G2 RB | 2-5

Page 13

General Information

2

Figure 2.3: Air-cooled Power Unit (UP11)

2-6 | CFW-11MW G2 RB

Figure 2.4: Water-cooled Power Unit (UP11W)

Figure 2.5: Control Unit (UC11RB G2)

Page 14

NOTE!

To assemble the complete drive, several additional items are necessary, such as fuses on the DC

power supply of each UP11 or UP11W power unit, external pre-charge circuit and input filters.

NOTE!

It is not necessary to include a current transformer (CT) in the drive for short-circuit protection at the

output against the ground, since each UP11 and UP11W has its own internal protection.

2.4 UC11RB G2 IDENTIFICATION LABEL

The UC11RB G2 identification label is located on the control rack.

WEG material

General Information

2

UC11 model

Serial number

Manufacturing date

(30 corresponds to the

week and L to the year)

Figure 2.6: UC11RB G2 identification label

Identification label

Figure 2.7: Identification label location

CFW-11MW G2 RB | 2-7

Page 15

General Information

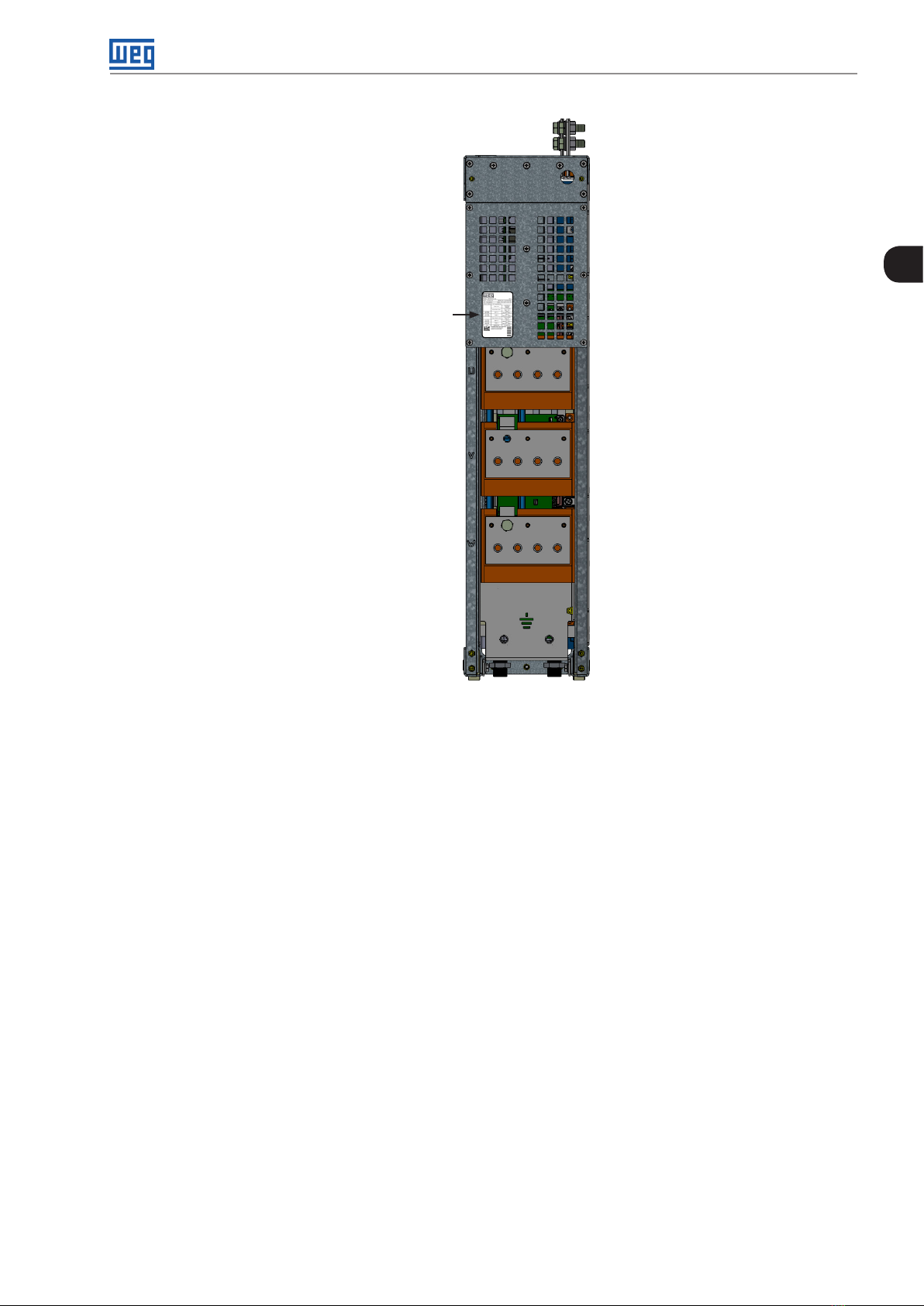

2.5 UP11 G2 AND UP11W G2 IDENTIFICATION LABEL

The identification label is located on the front of the UP11 G2 and UP11W G2.

Model of the UP11

2

WEG part number

Inverter net weight

Rated input data (voltage, rated

currents for operation under normal

duty and heavy duty, frequency)

Current specifications for

operation under normal duty (ND)

Current specifications for

operation under heavy duty (HD)

MOD.: UP11-01 G2 48 H

MAT.: 13353741 SERIAL#: 1234567890

OP. : 12 34 567 8 MA X. TA: 45 ºC (113 °F )

PESO/WEIGHT: 171 kg (377 lb)

LINK DC

574-970 V DC

A (ND)

60 s/3s

A (HD)

60 s/3s

A (HD)

60s/3s

A (HD)

60s/3s

Hz 50/60 Hz 0-200 Hz

570 A

437 A

758 -1025 VDC

505 A

390 A

FABRICADO NO BRASIL

HECHO EN BR ASIL

MADE IN BR AZIL

OUTPUT

SALIDA

SAÍDA

0-0,71*VDC

VAC 3~

496 A

546 A / 744 A

380 A

570 A / 760 A

0-0,71*VDC

VAC 3~

439 A

483 A / 695 A

340 A

510 A / 680 A

to the week and H to the year)

Serial number

Maximum ambient temperature

around the inverter

Rated output data (voltage, number of

phases, rated currents for operation

under normal duty (ND) and heavy duty

(HD), overload currents for 1 min and 3

s and frequency band).

89 41717 070572

Figure 2.8: UP11 G2 and UP11W G2 identification label

Manufacturing date (48 corresponds

2-8 | CFW-11MW G2 RB

Identification

label

Figure 2.9: Identification label location on the UP11 G2

Page 16

Identification

label

General Information

2

Figure 2.10: Identification label location on the UP11W G2

CFW-11MW G2 RB | 2-9

Page 17

General Information

2.6 HOW TO SPECIFY THE CONVERTER MODEL (SMART CODE)

In order to specify the model of the CFW-11M G2 RB or CFW-11W G2 RB, replace the corresponding fields in the

smart code with the desired rated supply voltage and rated output current for operation under normal duty (ND),

as shown in the example of Table 2.1 on page 2-10.

Table 2.1: Smart code

2

Example BR CF W11M G 2 634 T 4 O _ _ _ _ _ _ Z

Field

denomination

Possible

options

Market

identification

(sets the

language of

the manual

and factory

settings)

2 characters CFW11WG2 =

See the list of models in Chapter 8 TECHNICAL

DATA on page 8-1, which also contains the

WEG Series

11 Generation

2 Modular

Converter

WEG Series 11

Generation 2

Water-Cooled

Modular

Converter

Converter Model Optional Items

See Chapter 7 OPTIONAL ITEMS AND

technical data of the inverters

Rated

current for

use under

normal

duty (ND)

Number

of

phases

T =

threephase

Rated

voltage

4 =

380...480 V

5 =

500...600 V

6 =

660...690 V

Optional

items

O = product

with

optional

item

ACCESSORIES on page 7-1 for

further details on the optional items

Braking Special

RB =

regenerative braking

hardware

Blank =

standard

H1 = special

hardware #1

Special

software

Blank =

standard

S1 = special

sof tware #1

Final

coding

indicator

digit

E.g.: CFW11MG21205T4ORBZ corresponds to a three-phase 1205 A CFW-11M G2 RB converter, with an input

voltage of 380 V to 480 V. The options for the rated current of the CFW-11M G2 RB and CFW-11W G2 RB

converters under normal overload (ND) are respectively found in Table 2.2 on page 2-10 and Table 2.3 on page

2-10, according to the rated input voltage of the converter.

Table 2.2: Rated currents under normal duty (ND) for the CFW-11M G2 RB

380-480 V 500-600 V 660 -690 V

0634 = 634 A 0496 = 496 A 0439 = 439 A

1205 = 1205 A 0942 = 942 A 0834 = 834 A

1807 = 1807 A 1414 = 1414 A 1251 = 1251 A

2409 = 2409 A 1885 = 1885 A 1668 = 1668 A

3012 = 3012 A 2356 = 2356 A 2085 = 2085 A

Table 2.3: Rated currents under normal duty (ND) for the CFW-11W G2 RB

500-690 V

0780 = 780 A

1482 = 1482 A

2223 = 2223 A

2964 = 2964 A

3705 = 3705 A

2-10 | CFW-11MW G2 RB

Page 18

2.7 RECEIVING AND STORAGE

The UP11 and UP11W G2 power units are supplied in a wooden box.

The UC11RB G2 control units are supplied in a cardboard box.

The package bears a copy of the identification label affixed to the converter.

To open the package:

1. Remove the front cover of the package.

2. Remove the styrofoam protection.

Check if:

1. The identification labels correspond to the models purchased.

2. Damages during transportation.

Report any problems immediately to the carrier.

General Information

2

If the products are not immediately installed, store them in a clean and dry place (temperature between -25 ºC

and 60 ºC), with a cover to prevent the ingress of dust.

Figure 2.11: Do not tilt the power units

CFW-11MW G2 RB | 2-11

Page 19

General Information

2

2-12 | CFW-11MW G2 RB

Page 20

Installation and Connection

3 INSTALLATION AND CONNECTION

This chapter describes the procedures for the electrical and mechanical installation of the CFW-11M and

CFW-11W G2 RB. The directions and suggestions must be observed to ensure the safety of people and

equipment and the proper operation of the inverter.

3.1 AIR-COOLED UP11 G2 MECHANICAL INSTALLATION

The power units must be installed in the drive panel appropriately, allowing easy extraction and reinstallation in

case of maintenance. The mounting must be such to avoid damage during the panel transportation.

3.1.1 Environmental Conditions

Avoid:

Direct exposure to sunlight, rain, excessive moisture or marine environment.

Inflammable or corrosive liquids or gases.

Excessive vibration.

Dust, metal particles or oil suspended in the air.

Permissible environment conditions for operation:

Ambient temperature: 0 °C to 45 °C (32 ºF to 113 ºF) - rated conditions (measured around the inverter). From

45 ºC to 55 ºC (113 ºF to 131 ºF) - 2 % of current derating for each Celsius degree above 45 ºC (113 ºF).

Maximum altitude: up to 1000 m (3.300 ft) – rated conditions.

From 1000 m to 4000 m (3.300 ft to 13.200 ft) – 1 % of current derating for each 100 m (330 ft) above 1000 m

(3.300 ft) of altitude.

From 2000 m to 4000 m (6.600 ft to 13.200 ft) - maximum voltage (480 V for models 380...480 V and 690 V for

models 500...690 V) derating of 1.1 % for each 100 m (330 ft) above 2000 m (6.600 ft).

3

Maximum altitude of 4000 m (13.200 ft).

Air relative humidity: 5 % to 95 % non-condensing.

Pollution degree: 2 (according to EN50178 and UL508C), with non-conductive pollution. Condensation must

not cause conduction of the accumulated residues.

3.1.2 Part List

For the panel mounting of the CFW11M G2 RB, it is necessary: UC11RB G2 control set, UP11 G2 power units,

synchronism transformers and cable set to connect the UC11RB G2 to the UP11 G2. Table 3.1 on page 3-1,

Table 3.2 on page 3-2 and Table 3.3 on page 3-2 contain the Part List of the CFW-11M G2 converter.

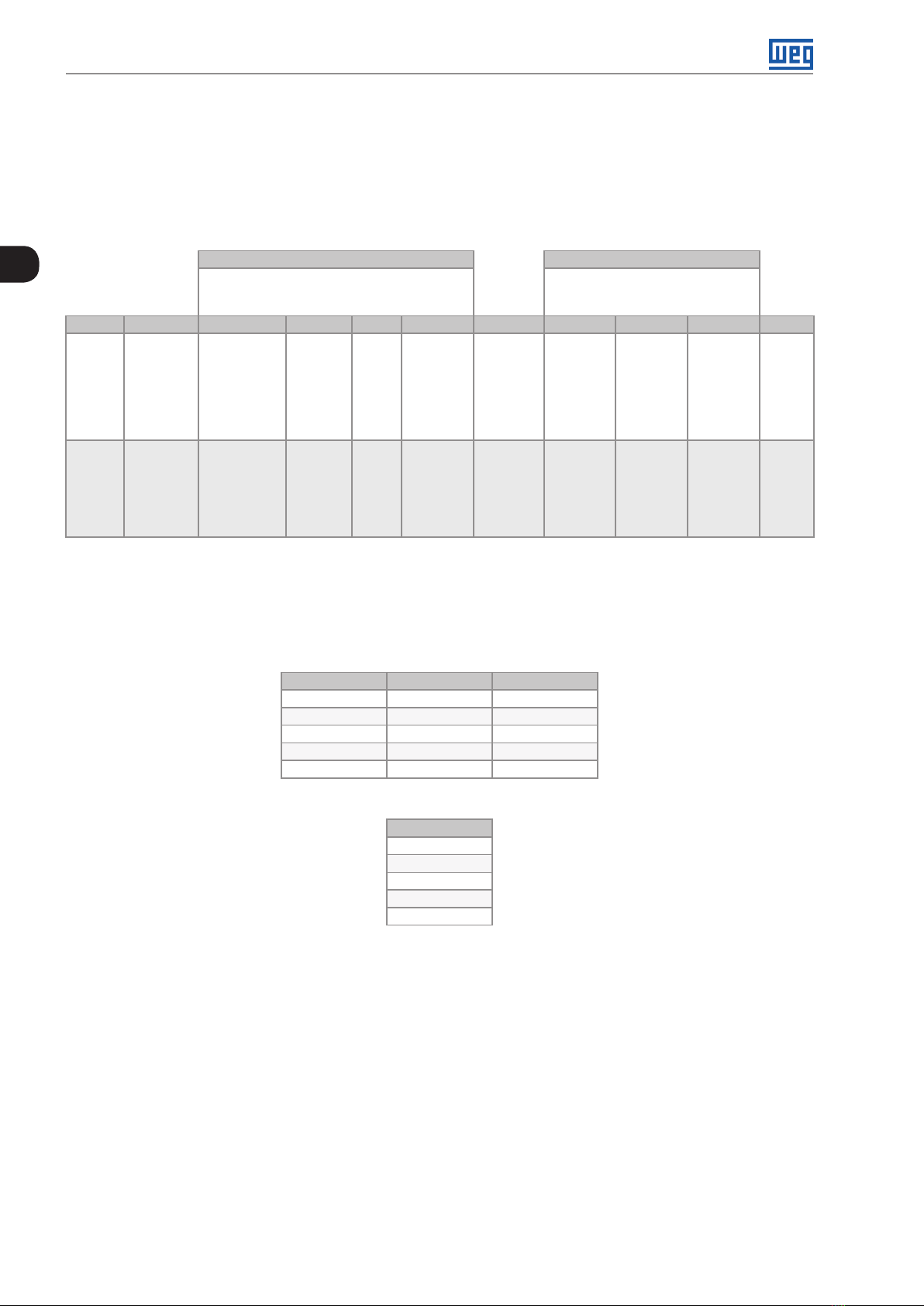

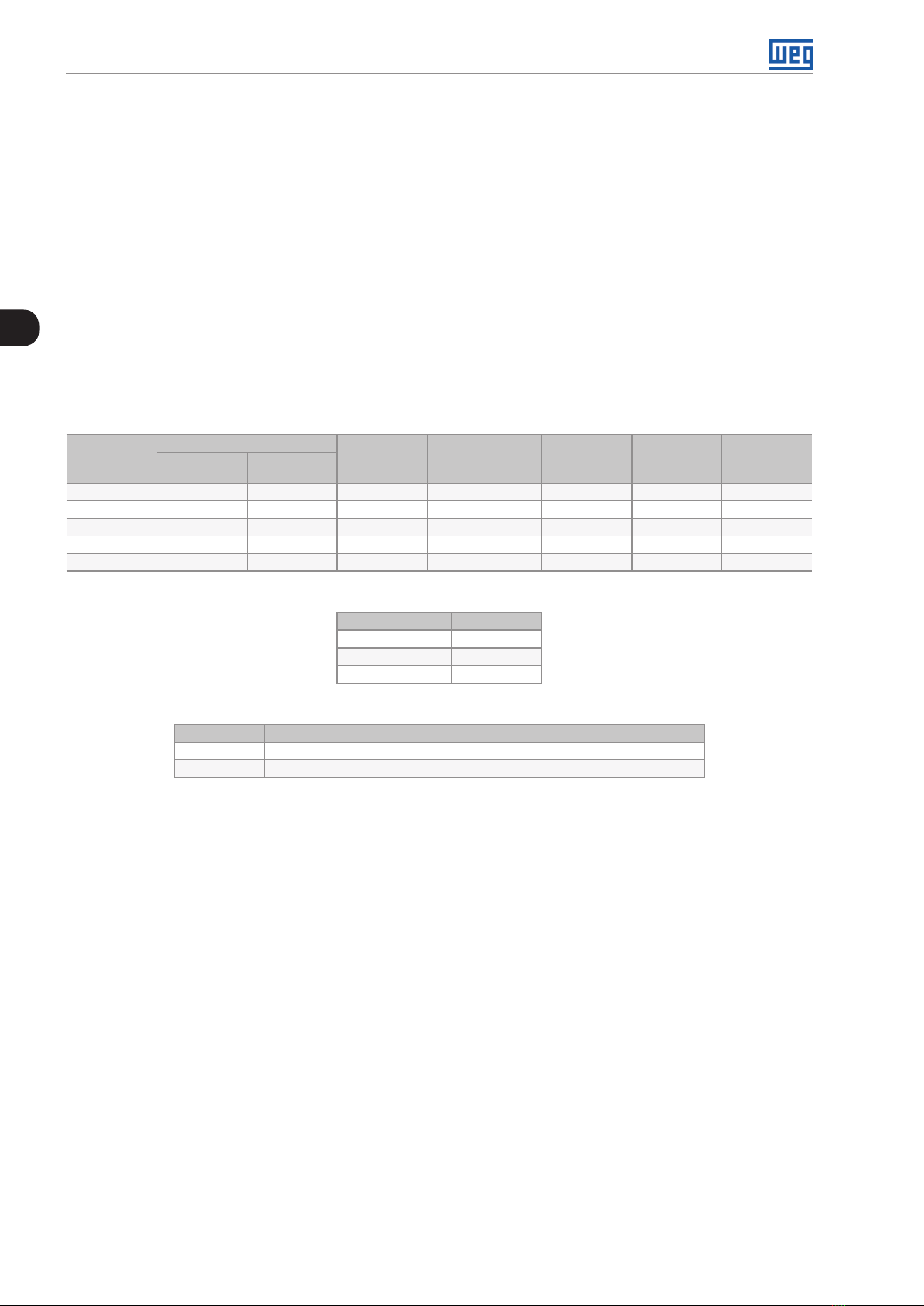

Table 3.1: Part List - Drives CFW-11M G2 RB 380 - 480 V

Qty UP11-02

G2

1 634 515 1 1 1 - 2 1205 979 1 1 2 - 3 1807 14 6 8 1 1 - 1 2

4 2409 1957 1 1 2 1 1

5 3012 2446 1 1 - 3 2

Rated Current [A]

ND HD

Qty UC11RB

G2

Qty

Synchronization

Transformers Set

Qty Cable

Set 2.5 m

Qty Cable

Set 3.0 m

Qty Cable

Set 3.6 m

CFW-11MW G2 RB | 3-1

Page 21

Installation and Connection

Table 3.2: Part List - Drives CFW-11M G2 RB 500 - 600 V

Qty UP11-01

G2

1 496 380 1 1 1 - 2 942 722 1 1 2 - 3 1414 1083 1 1 - 1 2

4 1885 1444 1 1 2 1 1

5 2356 1805 1 1 - 3 2

3

Qty UP11-01

G2

1 439 340 1 1 1 - 2 834 646 1 1 2 - 3 1251 969 1 1 - 1 2

4 1668 1292 1 1 2 1 1

5 2085 1615 1 1 - 3 2

Rated Current [A]

ND HD

Table 3.3: Part List - Drives CFW-11M G2 RB 660 - 690 V

Rated Current [A]

ND HD

Qty UC11RB

G2

Qty UC11RB

G2

Table 3.4: Cable set items

WEG Item Cable Set

13555095 2.5 m Cables

13555150 3.0 m Cables

135 55151 3.6 m Cables

Qty

Synchronization

Transformers Set

Qty

Synchronization

Transformers Set

Qty Cable

Set 2.5 m

Qty Cable

Set 2.5 m

Qty Cable

Set 3.0 m

Qty Cable

Set 3.0 m

Qty Cable

Set 3.6 m

Qty Cable

Set 3.6 m

Table 3.5: Synchronous transformer set items

WEG Item Synchronism Transformer Set

14267304 Synchronism transformer set: input voltage 380 - 480 V

14267307 Synchronism transformer set: input voltage 500 - 690 V

The panel builder must provide the other parts of the drive. Among those parts are the power busbars, pre-charge

circuit, panel fans, protection fuses and input filters.

3-2 | CFW-11MW G2 RB

Page 22

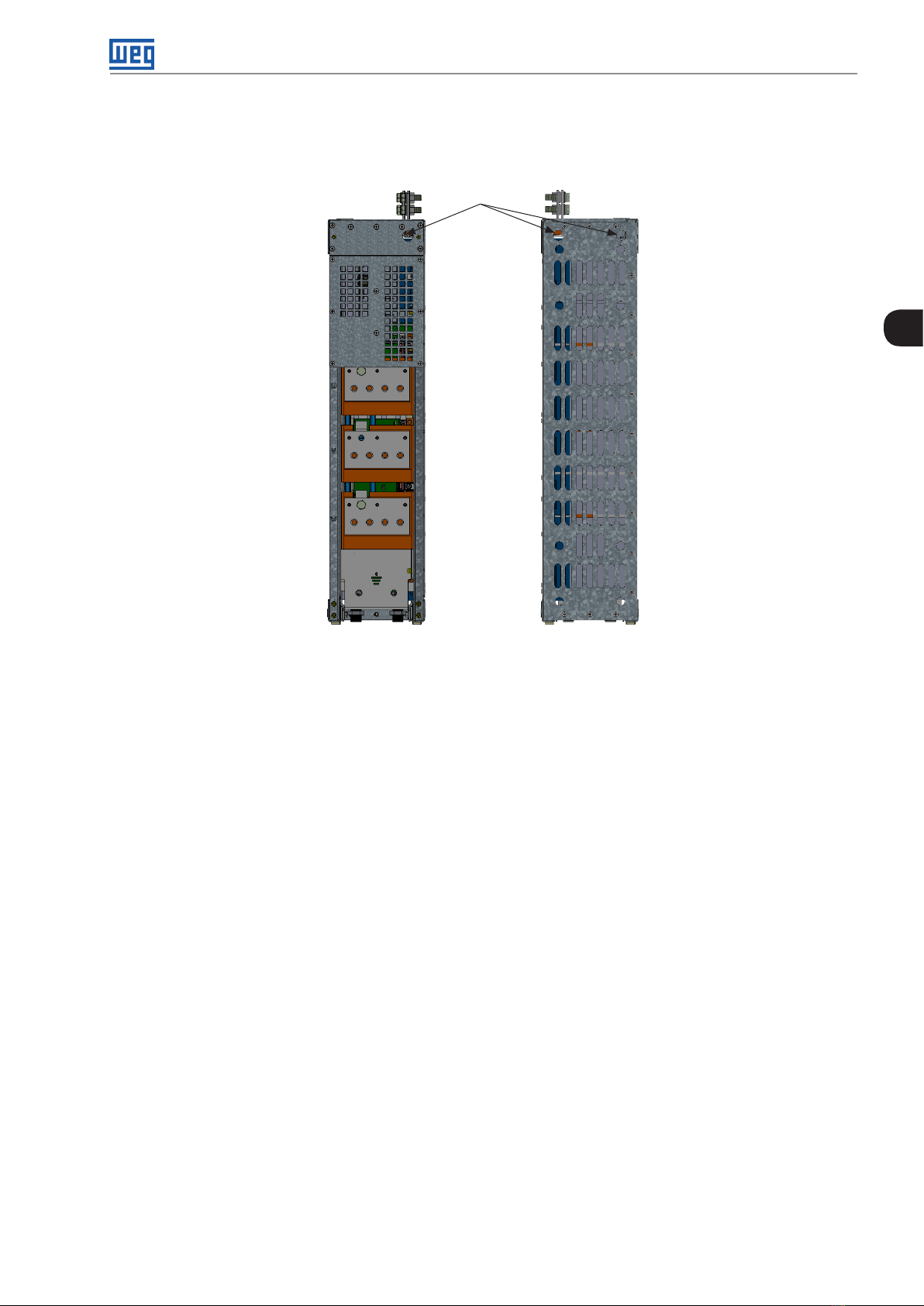

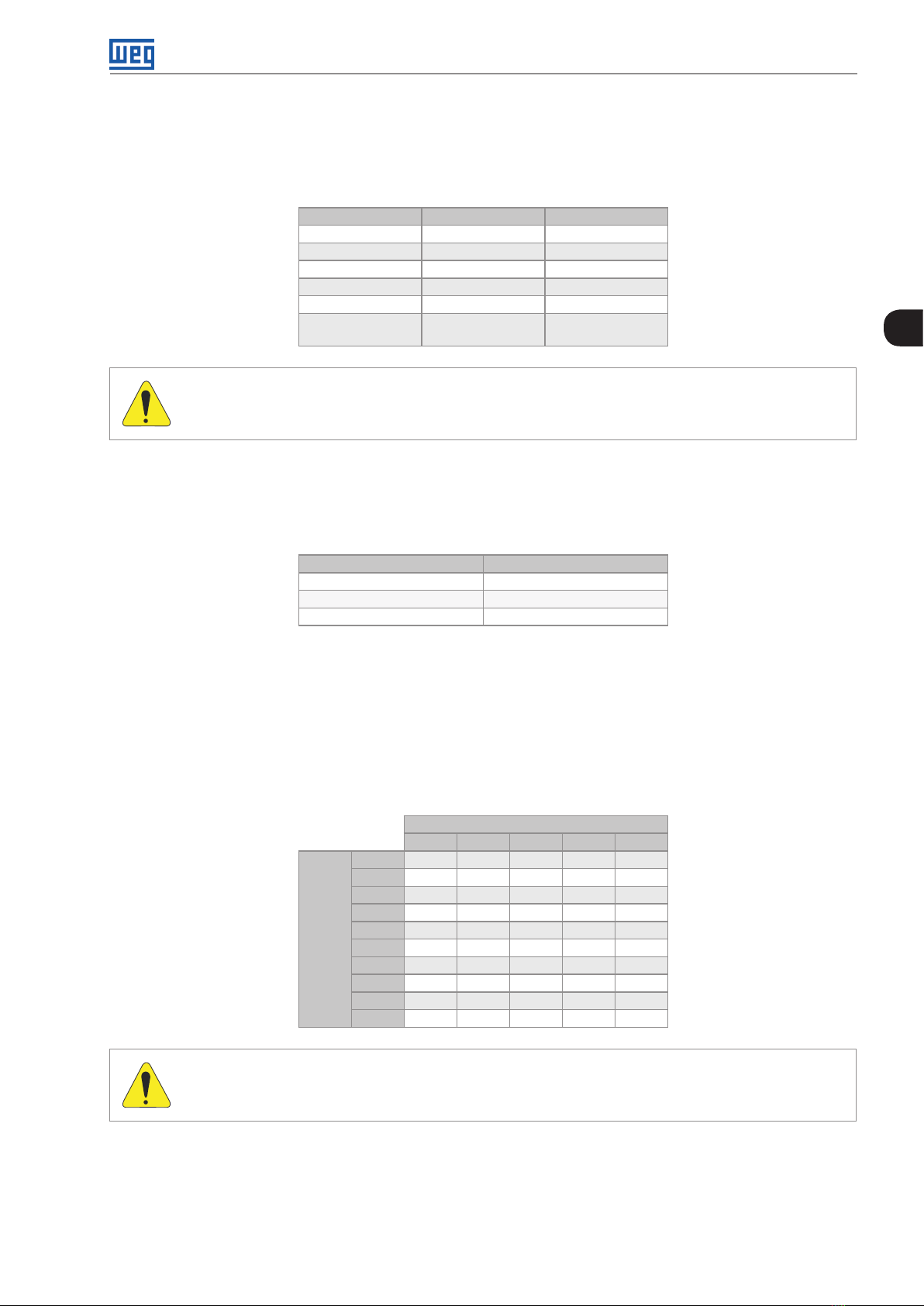

3.1.3 Lifting

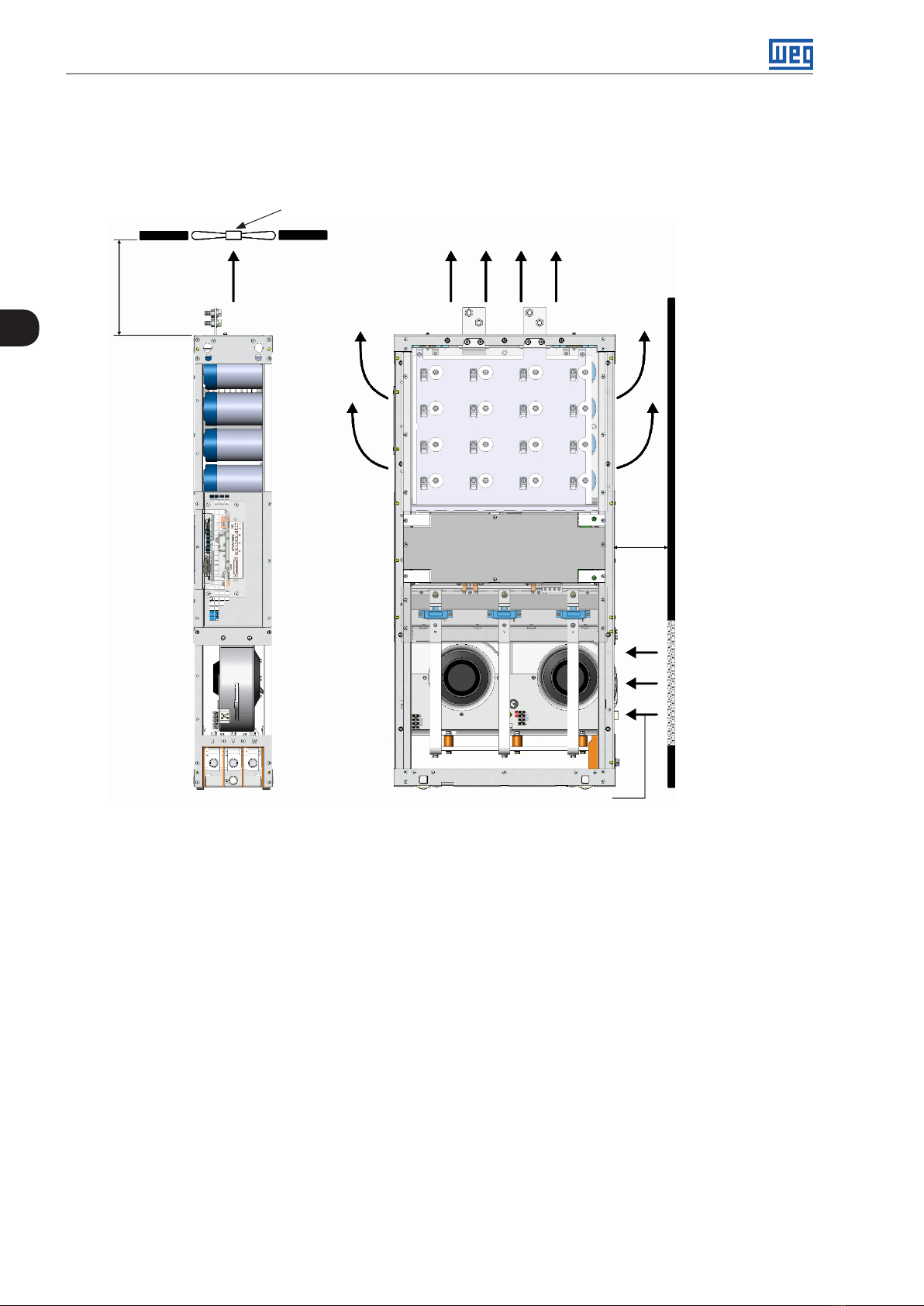

Figure 3.1 on page 3-3 shows the position of the lifting lugs.

Lifting lugs

Installation and Connection

3

Front view Back view

Figure 3.1: UP11 G2 lifting lugs

CFW-11MW G2 RB | 3-3

Page 23

Installation and Connection

3.1.4 Panel Ventilation

The efficiency of the panel ventilation depends on the equipment installed inside the panel, such as fans, air inlets

and filters. The internal fan of the UP11 G2 is not enough to cool the entire panel.

Panel fan (when required)

Air outlet

Air outlet

[10.0] 250

3

[6.0]

150

Air inlet

Figure 3.2: Clearances for ventilation in mm [in]

The total air flow of the power unit fans is 1150 m3/h (320 l/s; 677 CFM).

3.1.5 Panel Mounting of the UP11 G2

To install the UP11 G2 in panels, the following fastening hardware is necessary:

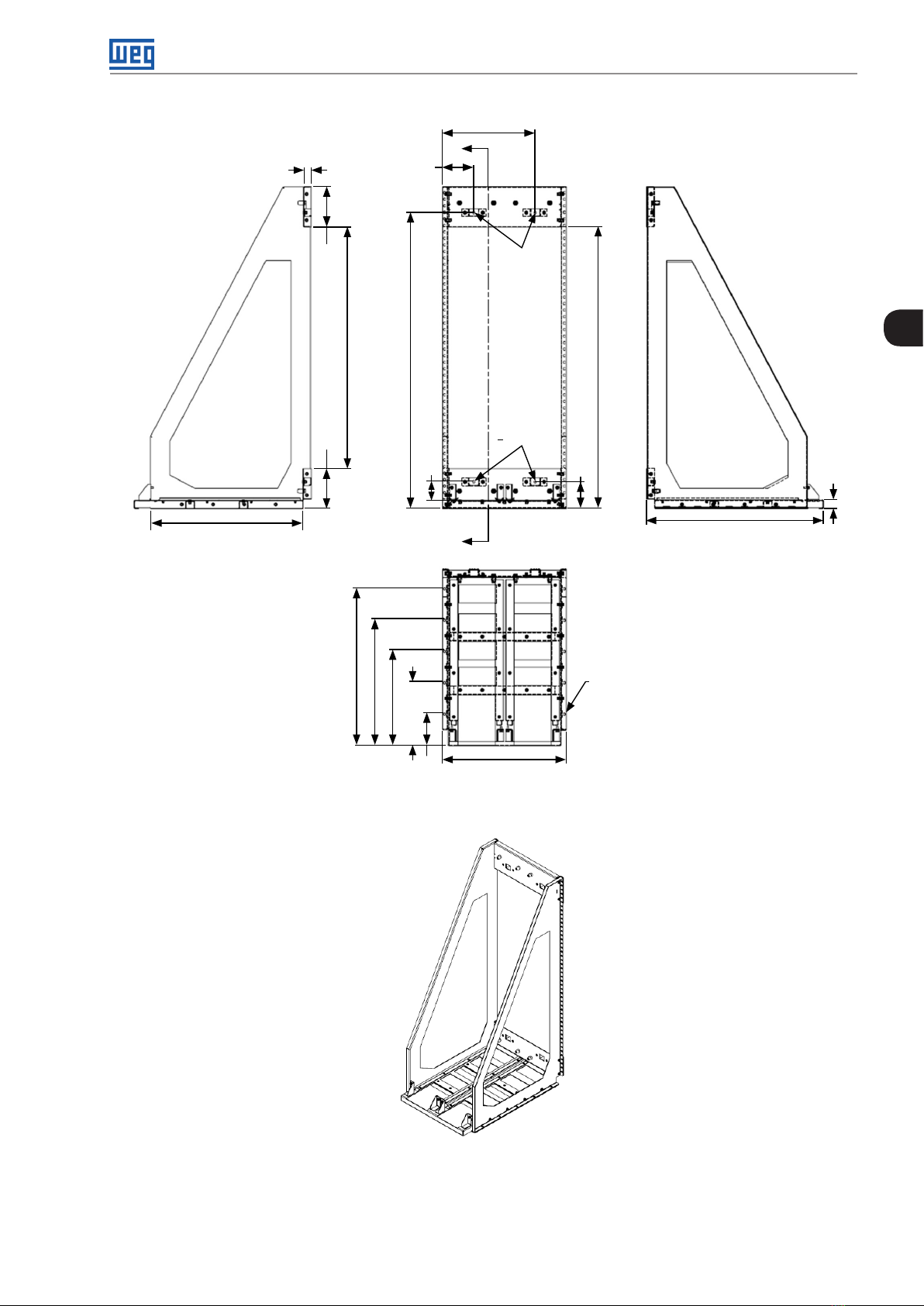

Rack 2 G2 allows the mounting of 1 or 2 modules side by side in 600 mm wide panels.

Ventilation

openings on the

front surface of

the panel

Rack 3 G2 allows the mounting of 1, 2 or 3 modules side by side in 800 mm wide panels.

3-4 | CFW-11MW G2 RB

Page 24

30.1 [1.19]

15 5 . 2 [ 6.11]

199.7 [4.71]

926.7 [36.48]

Installation and Connection

354.7 [13.96]

A

Ø9.2 [0.36]

3

1134.5 [44.67]

1079.3 [42.49]

582 [22.91]

SECTION A-A

A

474.4 [18 . 6 8]

Ø9.2 [0.36]

102.5 [4.04]

Ø9.2 [0.36]

32.6 [1. 28]

670.8 [26.72]

152.6 [6.01]

69.9 [2.75]

602.5 [23.72]

482.5 [19]

38 2.5 [14.27]

242.5 [9.55]

122.5 [4.82]

Figure 3.3: Dimensions of Rack 2 G2 in mm [in]

CFW-11MW G2 RB | 3-5

Page 25

Installation and Connection

459.6 [18 .1]

30.1 [1.19]

15 5 . 2 [ 6.11]152.6 [6.01]

A

224.6

[8.84]

Ø9.2 [0.36]

3

926.7 [36.48]

1134.5 [44.67]

102.5 [4.04]

582 [22.93] 678.8 [26.72]

SECTION A-A

602.5 [23.72]

482.5 [19]

36 2.5 [14.27]

242.5 [9.55]

122.5 [4.82]

Ø9.2 [0.36]

A

684.7 [26.96]

1234.5 [48.6]

68.3 [2.69]

Ø9.2 [0.36]

32.6 [1. 28]

3-6 | CFW-11MW G2 RB

Figure 3.4: Dimensions of Rack 3 G2 in mm [in]

Page 26

Installation and Connection

3

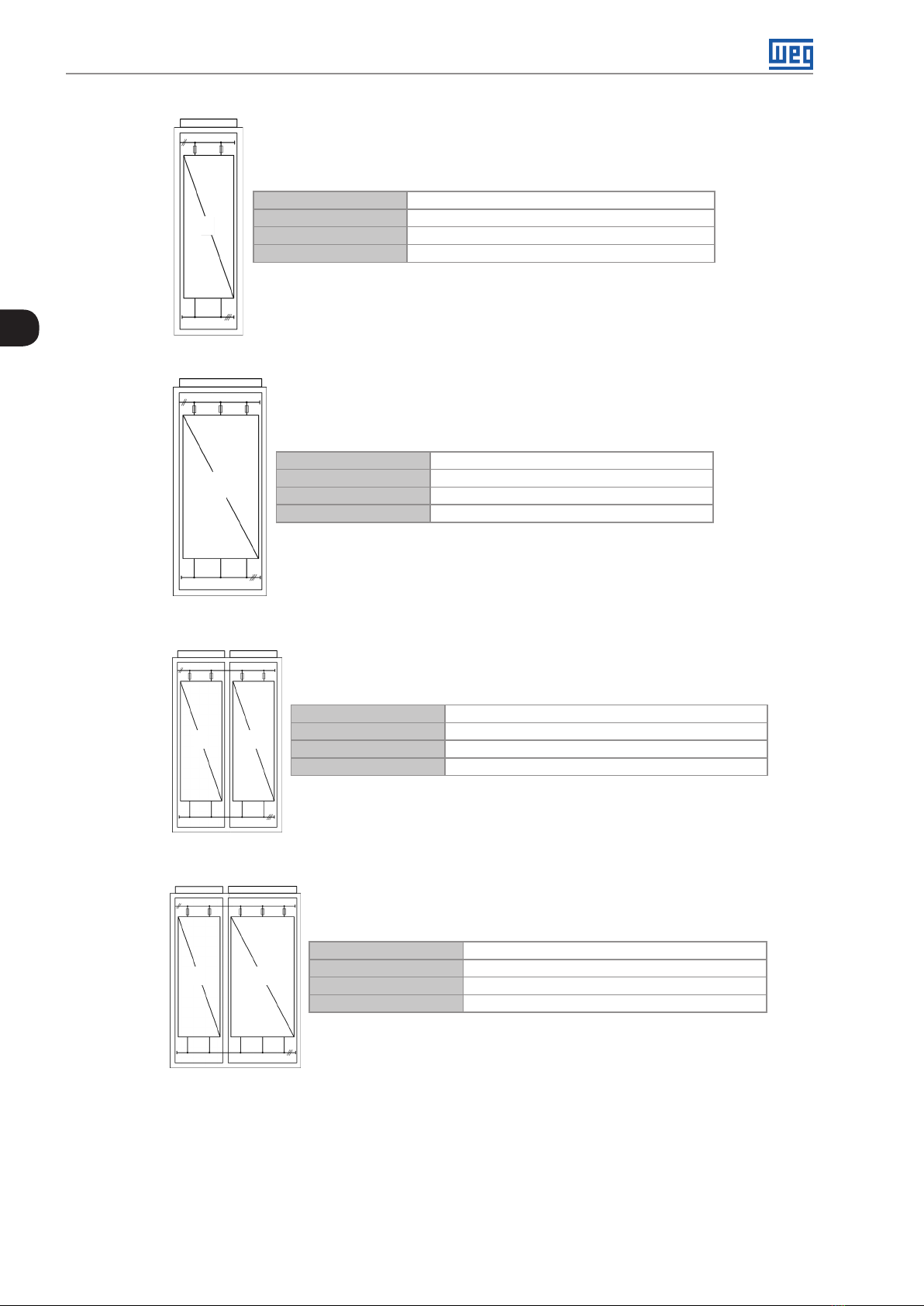

Figure 3.5: Insertion of the UP11 G2 power modules into the Rack 3 G2

3.1.6 Panel

According to the quantity of UP11 G2 of the drive, minimum dimensions are necessary for the panels. Table 3.6

on page 3-10, Table 3.7 on page 3-10, Table 3.8 on page 3-10, Table 3.10 on page 3-19 and Table 3.11 on page

3-19 contain the minimum dimensions of the panel according to the quantity of UP11 G2 used.

Panel Width At least 600 mm

1

Panel Height At least 2000 mm

Panel Depth At least 800 mm

Weight Capacity 118 kg

Figure 3.6: Panel data for a drive with 1 UP11 G2

CFW-11MW G2 RB | 3-7

Page 27

Installation and Connection

Panel Width At least 600 mm

2

Panel Height At least 2000 mm

Panel Depth At least 800 mm

Weight Capacity 212 kg

3

Figure 3.7: Panel data for a drive with 2 UP11 G2

Panel Width At least 800 mm

3

Panel Height At least 2000 mm

Panel Depth At least 800 mm

Weight Capacity 310 kg

Column A Column B

2

Column A Column B

2 3

2

Figure 3.8: Panel data for a drive with 3 UP11 G2

Panel Width At least 600 mm (Column A) + 600 mm (Column B)

Panel Height At least 2000 mm

Panel Depth At least 800 mm

Weight Capacity 212 kg (Column A) + 212 kg (Column B)

Figure 3.9: Panel data for a drive with 4 UP11 G2

Panel Width At least 600 mm (Column A) + 800 mm (Column B)

Panel Height At least 2000 mm

Panel Depth At least 800 mm

Weight Capacity 212 kg (Column A) + 310 kg (Column B)

3-8 | CFW-11MW G2 RB

Figure 3.10: Panel data for a drive with 5 UP11 G2

Page 28

Installation and Connection

3

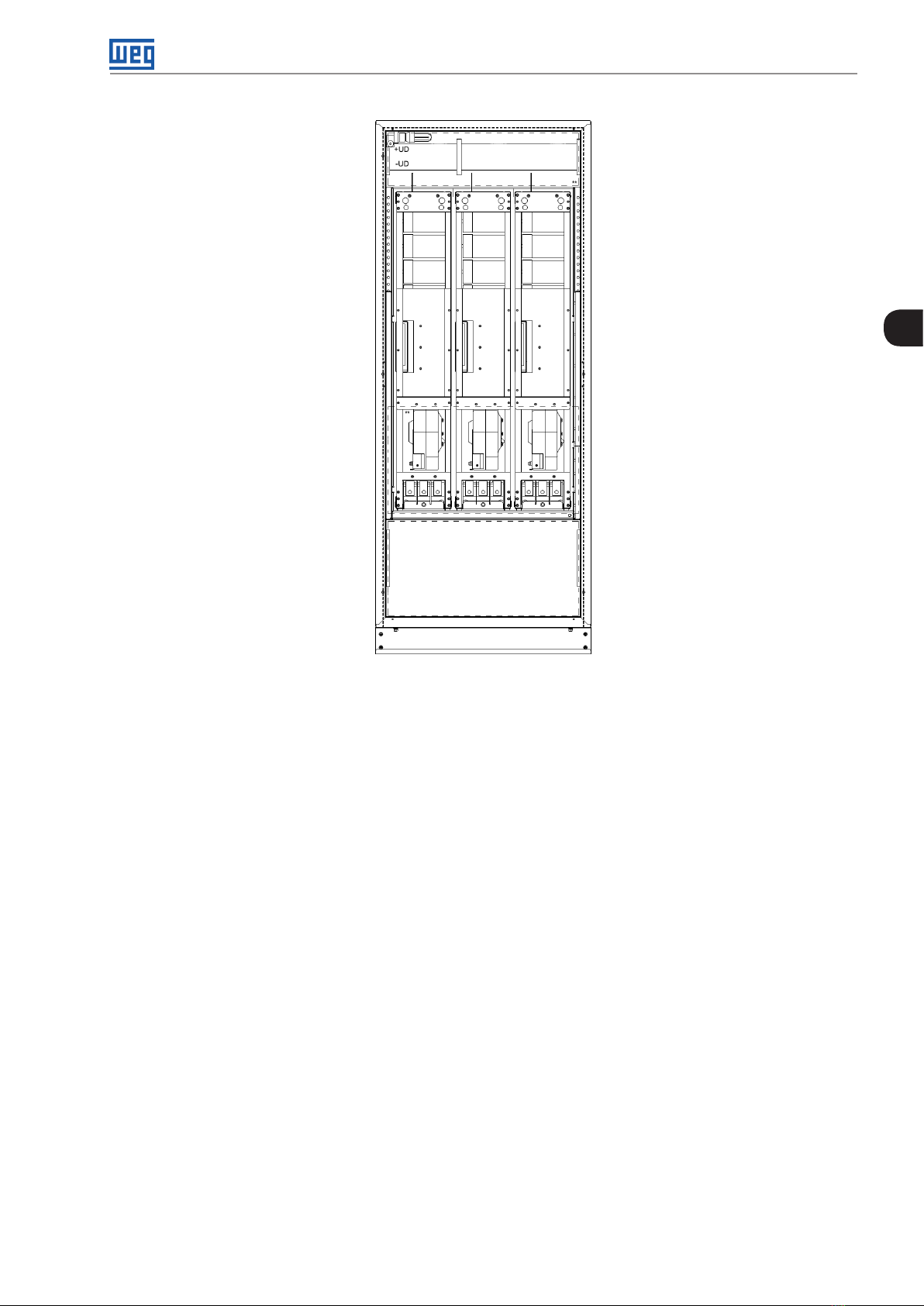

Figure 3.11: Column with 3 UP11 G2 installed

3.2 WATER-COOLED UP11W G2 MECHANICAL INSTALLATION

The power units must be installed in the drive panel appropriately, allowing easy extraction and reinstallation in

case of maintenance. The mounting must be such to avoid damage during the panel transportation.

3.2.1 Environmental Conditions

Avoid:

Direct exposure to sunlight, rain and high humidity.

Inflammable or corrosive liquids or gases.

Dust, metal particles or oil suspended in the air.

Environment conditions permitted for operation:

Ambient temperature: 0 °C to 45 °C (32 ºF to 113 ºF) - rated conditions (measured around the inverter). From

45 ºC to 55 ºC (113 ºF to 131 ºF) - 0.5 % of current derating for each Celsius degree above 45 ºC (113 ºF).

Coolant input temperature: 0 ºC to 45 ºC (32 ºF to 113 ºF) according to the coolant used. From 45 ºC to 55 ºC

(113 ºF to 131 ºF) - 1 % of current derating for each Celsius degree above 45 ºC (113 ºF).

Coolant flow: 20 l/min.

Maximum altitude: up to 1000 m (3.300 ft) – rated conditions.

From 1000 m to 4000 m (3.300 ft to 13.200 ft) – 1 % of current derating for each 100 m (330 ft) above 1000 m

(3.300 ft) of altitude.

CFW-11MW G2 RB | 3-9

Page 29

Installation and Connection

From 2000 m to 4000 m (6.600 ft to 13.200 ft) - maximum voltage (690 V for models 500...690 V) derating of

1.1 % for each 100 m (330 ft) above 2000 m (6.600 ft).

Maximum altitude of 4000 m (13.200 ft).

Air relative humidity: 5 % to 95 % non-condensing.

Pollution degree: 2 (according to EN50178 and UL508C), with non-conductive pollution. Condensation must

not cause conduction of the accumulated residues.

3

3.2.2 Part List

For the panel mounting of the CFW11W G2 RB, it is necessary: control set, UP11W G2 power units and cable

sets to connect the UC11RB G2 to the UP11W G2. Table 3.1 on page 3-1 contains the part list of the CFW11W

G2 inverter.

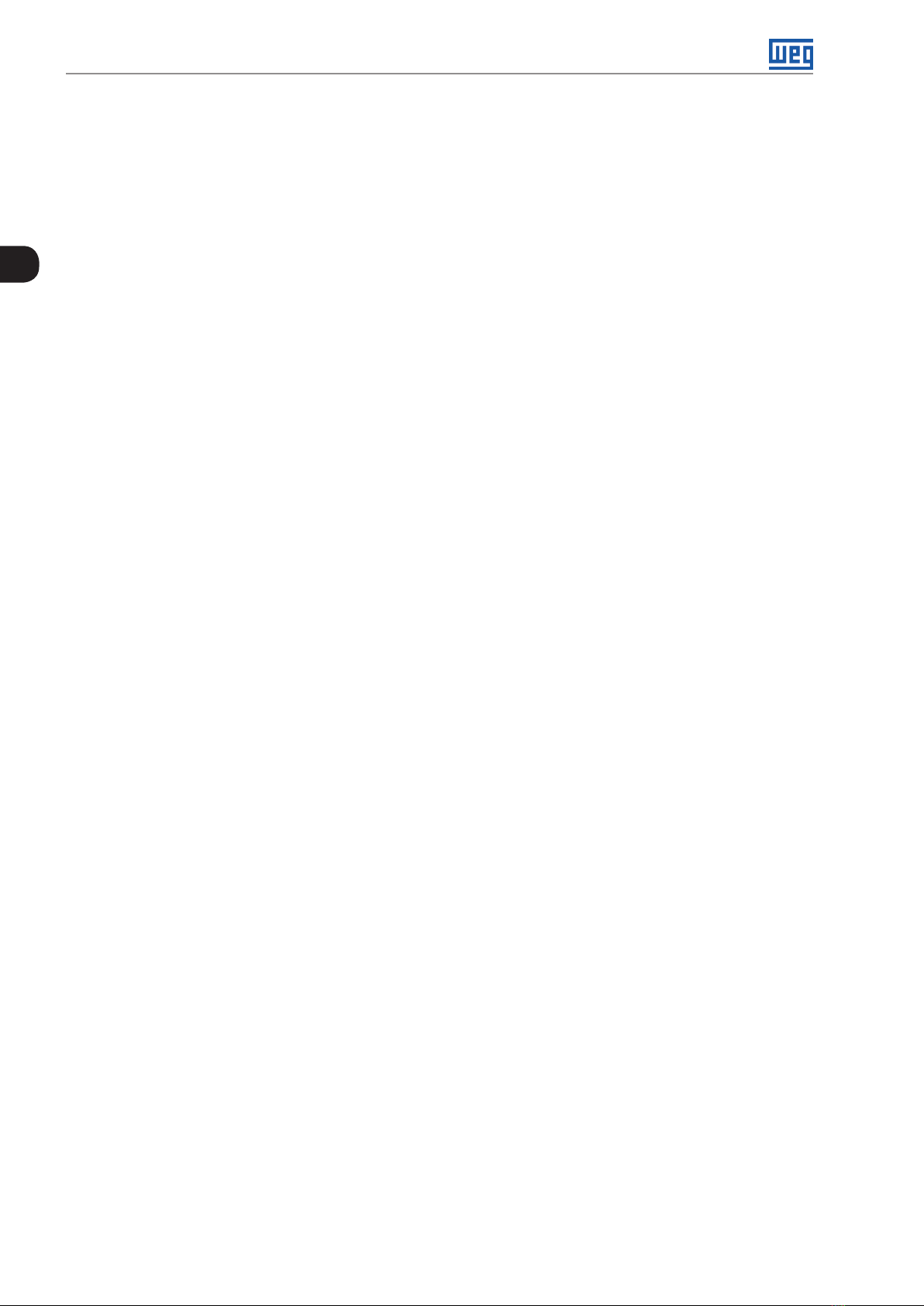

Table 3.6: Part List - CFW-11W G2 500 - 600 V Drives

Qty

UP 11W- 01 G2

1 780 640 1 1 1 - 2 148 2 1216 1 1 2 - 3 2223 1824 1 1 - 1 2

4 2964 2432 1 1 2 1 1

5 3705 3040 1 1 - 3 2

Rated Current [A]

ND HD

WEG Item Synchronism Transformer Set

14267304 Synchronism transformer set: input voltage 380 - 480 V

14267307 Synchronism transformer set: input voltage 500 - 690 V

Qty UC11 G2

Table 3.7: Cable set items

WEG Item Cable Set

13555095 2.5 m Cables

13555150 3.0 m Cables

135 55151 3.6 m Cables

Table 3.8: Synchronous transformer set items

Qty

Synchronization

Transformers Set

Qty Cable

Set 2.5 m

Qty Cable

Set 3.0 m

Qty Cable

Set 3.6 m

The panel builder must provide the other parts of the drive. Among those parts are the power busbars, pre-charge

circuit, panel internal cooling, protection fuses and input filters.

3-10 | CFW-11MW G2 RB

Page 30

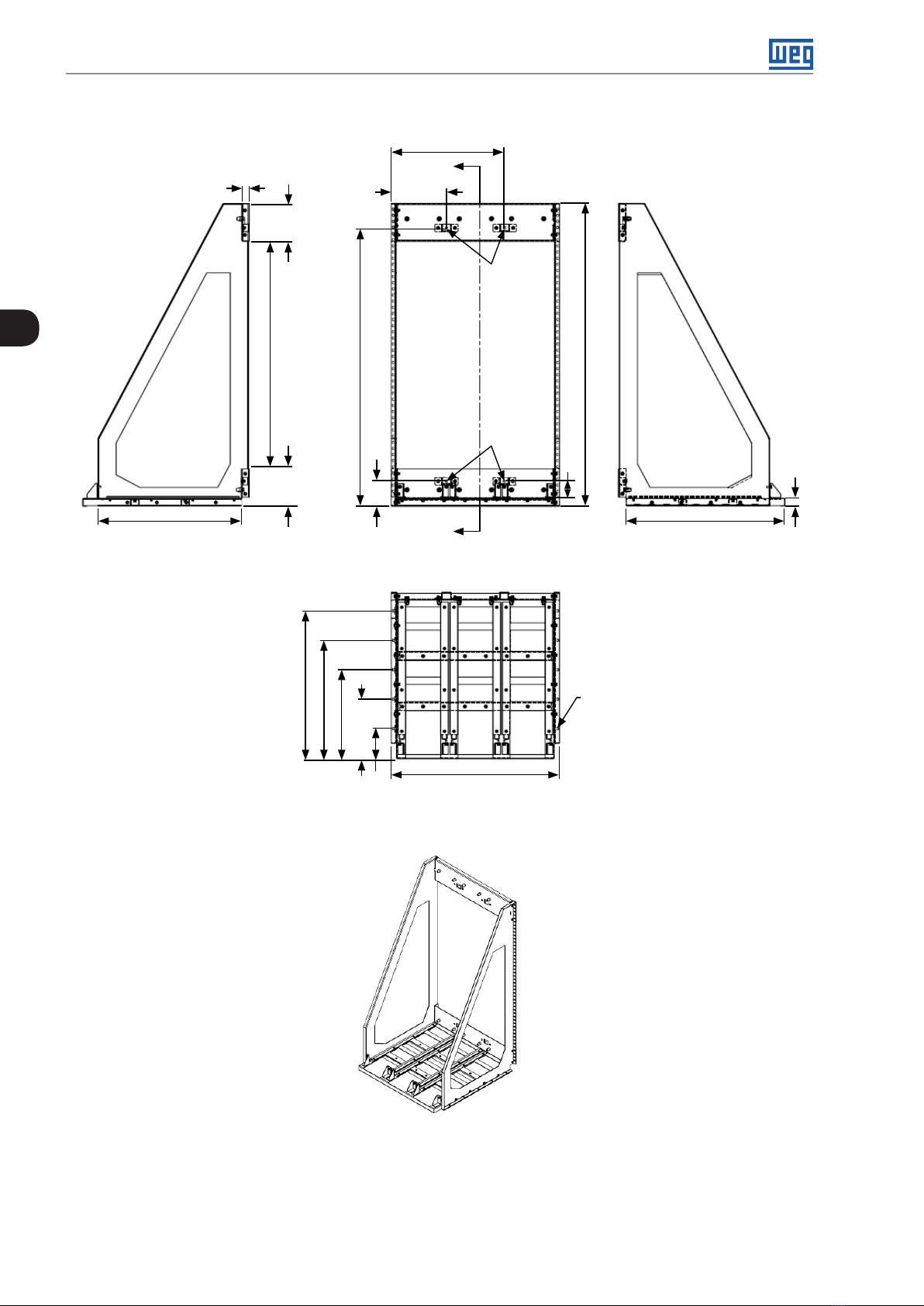

3.2.3 Lifting

Figure 3.1 on page 3-3 shows the position of the lifting lugs.

Lifting lugs

Installation and Connection

3

Front view Back view

Figure 3.12: UP11W G2 lifting lugs

CFW-11MW G2 RB | 3-11

Page 31

Installation and Connection

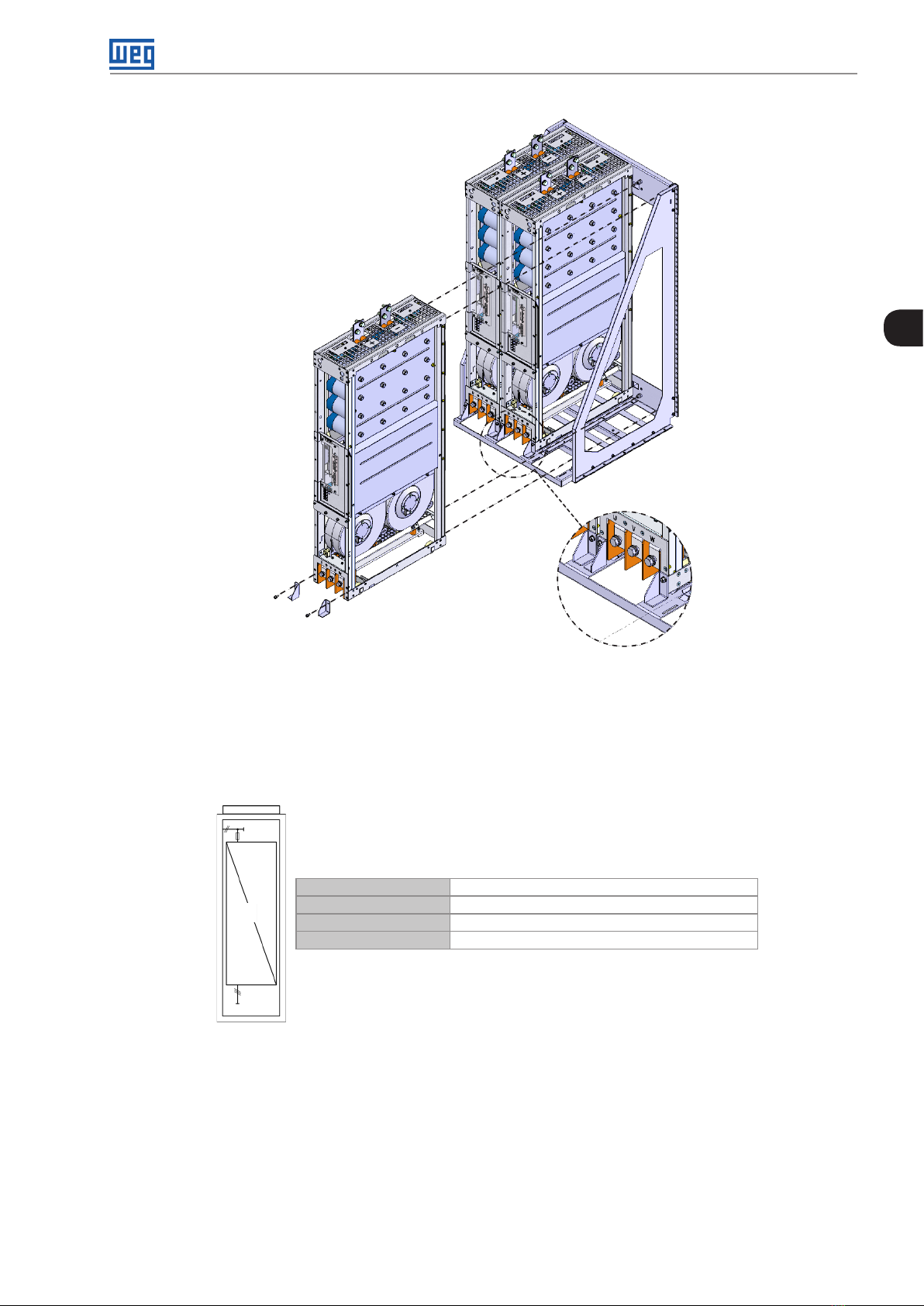

3.2.4 Panel Mounting of the UP11W G2

To install the UP11W G2 in panels, the following mounting accessories are necessary:

Rack 2 G2 allows the mounting of 1 or 2 modules side by side in 600 mm wide panels.

Rack 3 G2 allows the mounting of 1, 2 or 3 modules side by side in 800 mm wide panels.

[14.161]

[1.18 5 ]

30.1

[4.909]

124.7

359.7

H

3

[6 .11]

155. 2

[0.362]

∅ 9.2

501.7

[19.752]

784.5

[30.886]

[0.362]

∅ 9.2

884.5

[34.823]

[19.047]

483.8

SECTION H-H

32.6

227. 6

[8.9 61]

478.5

[18.837]

358.5

[14 .113]

12 7. 5

[50.2]

H

238.5

[9.388]

118 . 5

[4.664]

[19.0 83]

484.7

95

[3.73 6]

[21.8 0 3]

553.8

[0.362]

∅ 9.2

[1.283]

3-12 | CFW-11MW G2 RB

Figure 3.13: Dimensions of Rack 2 G2 in mm [in]

Page 32

[19]

483.8

SECTION A-A

[1.2]

30.1

Installation and Connection

[18 .1]

459.7

[8.8]

224.7

[6 .1]

155. 2

[19.8]

501.7

[30.9]

784.5

[9]

227.7

[5]

12 7. 5

A

[0.4]

∅ 9.2

[36]

914.1

[0.4]

3

∅ 9.2

[1.3]

[3.7]

94.9

A

[21.8]

553.8

32.6

[18.8]

478.5

[14 .1]

358.5

[9.4]

238.5

[4.7]

118 . 5

[27]

684.7

[0.4]

∅ 9.2

Figure 3.14: Dimensions of Rack 3 G2 in mm [in]

CFW-11MW G2 RB | 3-13

Page 33

Installation and Connection

3

Figure 3.15: Insertion of the UP11W power modules into the Rack 3 G2

3.2.5 Panel

The minimum panel dimensions are subject to the quantity of UP11Ws G2 of the drive. Table 3.6 on page 3-10,

Table 3.7 on page 3-10, Table 3.8 on page 3-10, Table 3.10 on page 3-19 and Table 3.11 on page 3-19 contain

the minimum dimensions of the panel according to the quantity of UP11W G2 used.

3-14 | CFW-11MW G2 RB

Page 34

Installation and Connection

Panel Width At least 600 mm

1

Panel Height At least 2000 mm

Panel Depth At least 600 mm

Weight Capacity 89 kg

3

Figure 3.16: Panel data for a drive with 1 UP11W G2

Panel Width At least 600 mm

2

Panel Height At least 2000 mm

Panel Depth At least 600 mm

Weight Capacity 156 kg

3

Column A Column B

2

2

Figure 3.17: Panel data for a drive with 2 UP11W G2

Panel Width At least 800 mm

Panel Height At least 2000 mm

Panel Depth At least 600 mm

Weight Capacity 227 kg

Figure 3.18: Panel data for a drive with 3 UP11W G2

Panel Width At least 600 mm (Column A) + 600 mm (Column B)

Panel Height At least 2000 mm

Panel Depth At least 600 mm

Weight Capacity 156 kg (Column A) + 156 kg (Column B)

Figure 3.19: Panel data for a drive with 4 UP11W G2

CFW-11MW G2 RB | 3-15

Page 35

Installation and Connection

Column A Column B

2 3

Panel Width At least 600 mm (Column A) + 800 mm (Column B)

Panel Height At least 2000 mm

Panel Depth At least 600 mm

Weight Capacity 156 kg (Column A) + 227 kg (Column B)

3

Figure 3.20: Panel data for a drive with 5 UP11W G2

3-16 | CFW-11MW G2 RB

Figure 3.21: Column with 3 UP11W G2 installed

Page 36

3.2.6 Cooling System

Figure 3.22 on page 3-17 shows the details of the coolant inlet and outlet.

Installation and Connection

Coolant inlet

Coolant outlet

Figure 3.22: Detail of the coolant inlet and outlet

Table 3.9 on page 3-17 contains detailed specifications of the UP11W G2 cooling system.

Table 3.9: Cooling system specifications

Coolant Inlet Temperature

Fluid Temperature Increase

Coolant Flow 20 l/min

Maximum Flow Allowed 30 l/min

Maximum System Pressure in Relation

to the Atmosphere

Load Loss on the Inver ter Heatsink

Coolant Inlet and Outlet Fit tings Used on

the Inverter

(1) Considering the 20 l/min flow and the composition of 90 % of water and 10 % of glycol in the coolant.

(1)

From 0 ºC to 45 ºC (32 ºF to 113 ºF) according to the coolant used; see Table 3.12

on page 3-19. From 45 ºC to 55 ºC (113 ºF to 131 ºF) with output current derating

6 °C (46 ºF)

6 bar (600 kPa)

(1)

0.84 bar (84 kPa)

Stainless steel bulkhead fitting for 16 mm tube, M24X1.5 thread and 24° taper

(DIN 3861/ISO 8434-1). According to Figure 3.23 on page 3-17

3

M24X1. 5 thread

Tube gauge 16 mm

internal taper of 24°

(DIN 3861 / ISO 8434-1)

Figure 3.23: Details of the hydraulic connection on the product

CFW-11MW G2 RB | 3-17

Page 37

Installation and Connection

ATTENTION!

It is recommended to use stainless steel hydraulic connections in the application cooling system.

Figure 3.14 on page 3-13 shows a simplified diagram of a closed cooling system for the UP11W G2.

Degassiing Valve

Over Pressure Valve

Diaphragm

accumulator

3

Temperature transmitter

Pressure transmitter

Flow transmitter

TT PT FT

Flow indicators

Bypass valve

Heat

ex-changer

FI

UP11W

Figure 3.24: Simplified example of a closed cooling system

UP11W UP 11W

FI FI FI FI

UP11W UP11W

The bypass valve is necessary for the temperature control and protection against condensation. The diaphragm

accumulator ensures a quite constant pressure in the cooling system even when great variations occur in the

coolant temperature. The pump provides the continuous coolant flow; it is recommended that such pump be

made of stainless steel. The acceptable differential pressure in the cooling circuit in relation to the atmosphere

must not exceed 6 bar. That must be guaranteed by the over pressure valve.

ATTENTION!

The hoses that connect the cooling system to the UP11W G2 must not conduct electricity.

ATTENTION!

The acceptable differential pressure in the cooling circuit in relation to the atmosphere must not

exceed 6 bar.

ATTENTION!

The cooling circuits of the UP11W G2 must not be connected in series in the cooling system circuit.

NOTE!

WEG RSW cooling system can be used for cooling the CFW11W G2 RB. For further information,

refer to the RSW User's Manual.

3-18 | CFW-11MW G2 RB

Page 38

Installation and Connection

The water used in the coolant must meet the specifications of Table 3.10 on page 3-19. The coolant must not

contain any organic sediments or active chemical agents. The coolant is composed of demineralized water,

corrosion inhibitor and ethylene glycol.

Table 3.10: Water specification

Characteristic Unit Value

pH 6 - 8

Hardness °dH < 10

Conductivity µS/cm < 10

Chlorine mg/l < 10

Iron mg/l < 0.1

Maximum particle

size

ATTENTION!

Do not use sea or tap water in the coolant.

The specifications of the inverter output current informed in Chapter 8 TECHNICAL DATA on page 8-1 are for a

coolant temperature between 10 and 45 °C (50 ºF to 113 ºF), and the composition according to Table 3.11 on

page 3-19.

µm < 300

3

Table 3.11: Coolant composition for temperature from 10 to 45 °C (50 ºF to 113 ºF)

Component Proportion

Demineralized water 88.5 %

Ethylene glycol 10 %

Inhibitor CorteC VpCI-649 1. 5 %

For the inverter operation at temperatures below 10 °C (50 ºF), the concentration of ethylene glycol in the coolant

must be increased. The increase of the percentage of ethylene glycol reduces the coolant specific heat and the

system heat exchange capacity. Therefore, if the inverter operates with a quantity of ethylene glycol above the

specification of Table 3.11 on page 3-19 and coolant temperature of 45 °C (113 ºF), the output current must be

derated. As the ethylene glycol concentration is normally increased to reduce the coolant freezing point, the coolant

temperature reduction can compensate the current derating. Table 3.12 on page 3-19 shows the maximum

percentage of the output current as a function of the ethylene glycol concentration and the coolant temperature.

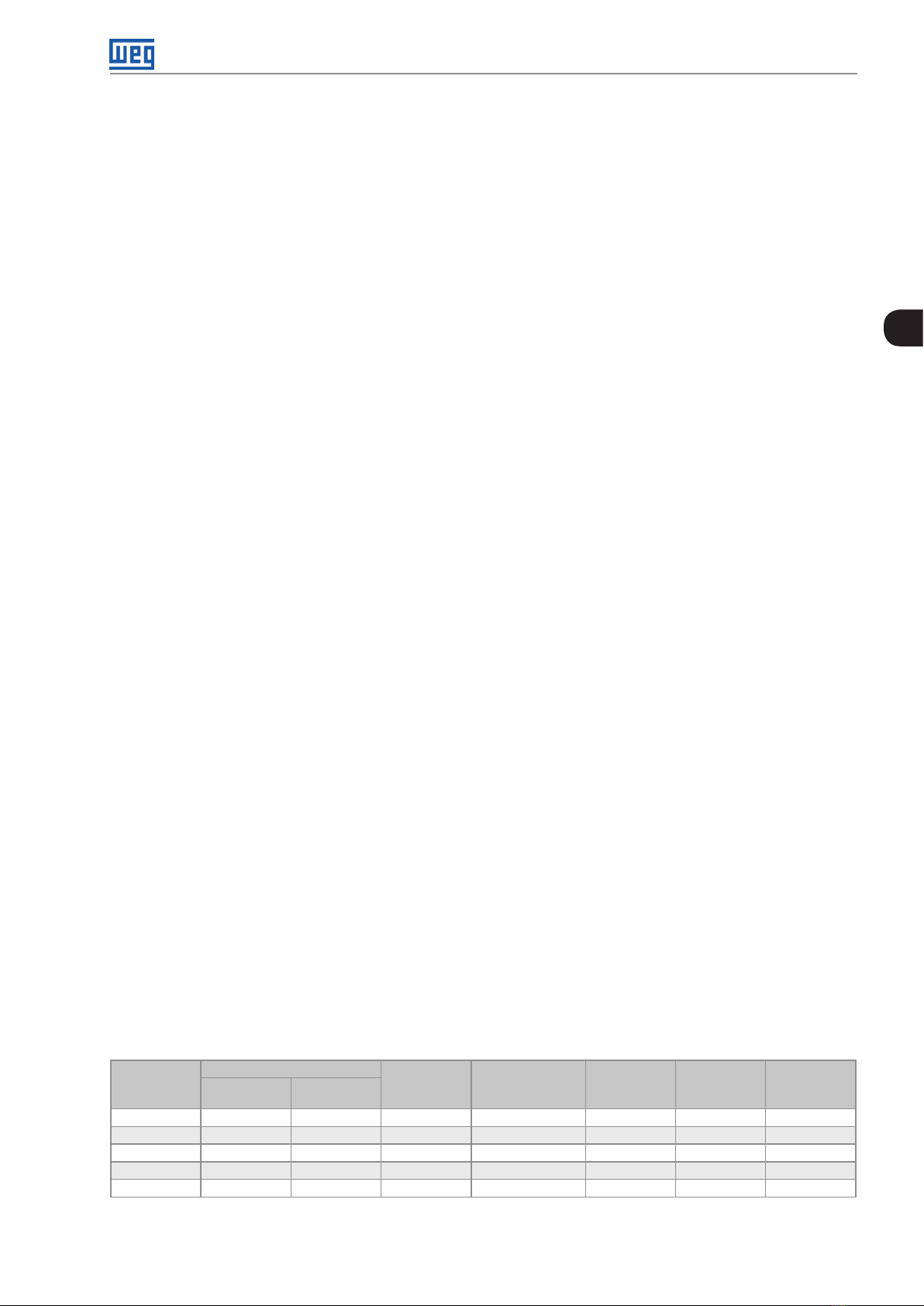

Table 3.12: Maximum percentage of the output current as a function of the ethylene glycol concentration and the coolant temperature

Glycol Concentration

10 % 20 % 30 % 40 % 50 %

37 °C 100 % 100 % 100 % 100 % 100 %

39 °C 100 % 100 % 100 % 100 % 98 %

41 °C 100 % 100 % 100% 98 % 96 %

43 °C 100 % 100 % 98 % 96 % 94 %

45 °C 100 % 98 % 96 % 94 % 92 %

47 °C 98 % 96 % 94 % 92 % 90 %

49 °C 96 % 94 % 92 % 90 % 88 %

51 °C 94 % 92 % 90 % 88 % 86 %

Coolant Temperature

53 °C 92 % 90 % 88 % 86 % 84 %

55 °C 90 % 88 % 86 % 84 % 82 %

ATTENTION!

To prevent corrosion, always add 1 % of the inhibitor CorteC VpCI-649 to the coolant.

Condensation may occur when the incoming water temperature is significantly lower than the ambient temperature.

The water temperature to avoid condensation varies according to the air relative humidity and ambient temperature.

The temperature at which the water vapor contained in the air turns into liquid as small water drops is known as

"dew point".

CFW-11MW G2 RB | 3-19

Page 39

Installation and Connection

Table 3.13 on page 3-20 shows the dew point in relation to the air relative humidity and to the ambient temperature

for an atmospheric pressure of 1 atm. If the water temperature is lower than the indicated value, condensation

may occur.

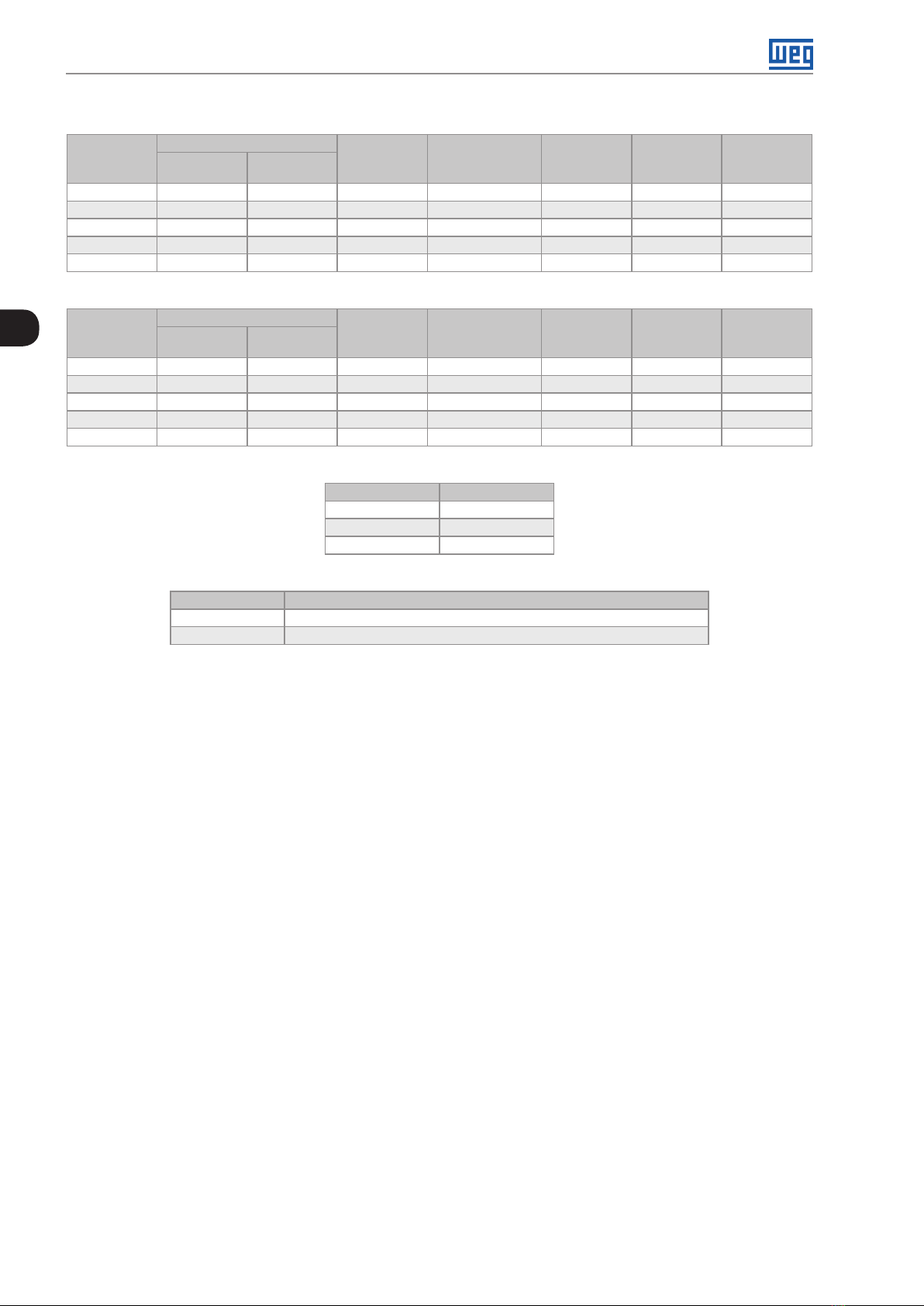

Table 3.13: Dew point in relation to the air relative humidity and ambient temperature (°C)

Air Relative Humidity

5 % 10 % 20 % 30 % 40 % 50 % 60 % 70 % 80 % 90 %

10°C <0 <0 <0 <0 <0 0 .1 2.6 4.8 6.7 8.4

20°C <0 <0 <0 1.9 6 9.3 12 14.4 16.4 18.3

25°C <0 <0 0.5 6.2 10.5 13.8 16.7 19 .1 21.3 23.2

30°C <0 <0 4.6 10.5 14.9 18.4 21.4 23.9 26.2 28.2

35°C <0 <0 8.7 14.8 19.4 23 2 6.1 28.7 31 3 3 .1

3

Ambient

Temperature

40°C <0 2.6 12.7 19.1 23.8 2 7. 6 30.7 33.5 35.9 38

45°C <0 6.3 16.8 23.4 28.2 3 2.1 35.4 38.2 40.7 43

ATTENTION!

The water temperature must always be higher or equal to the dew point.

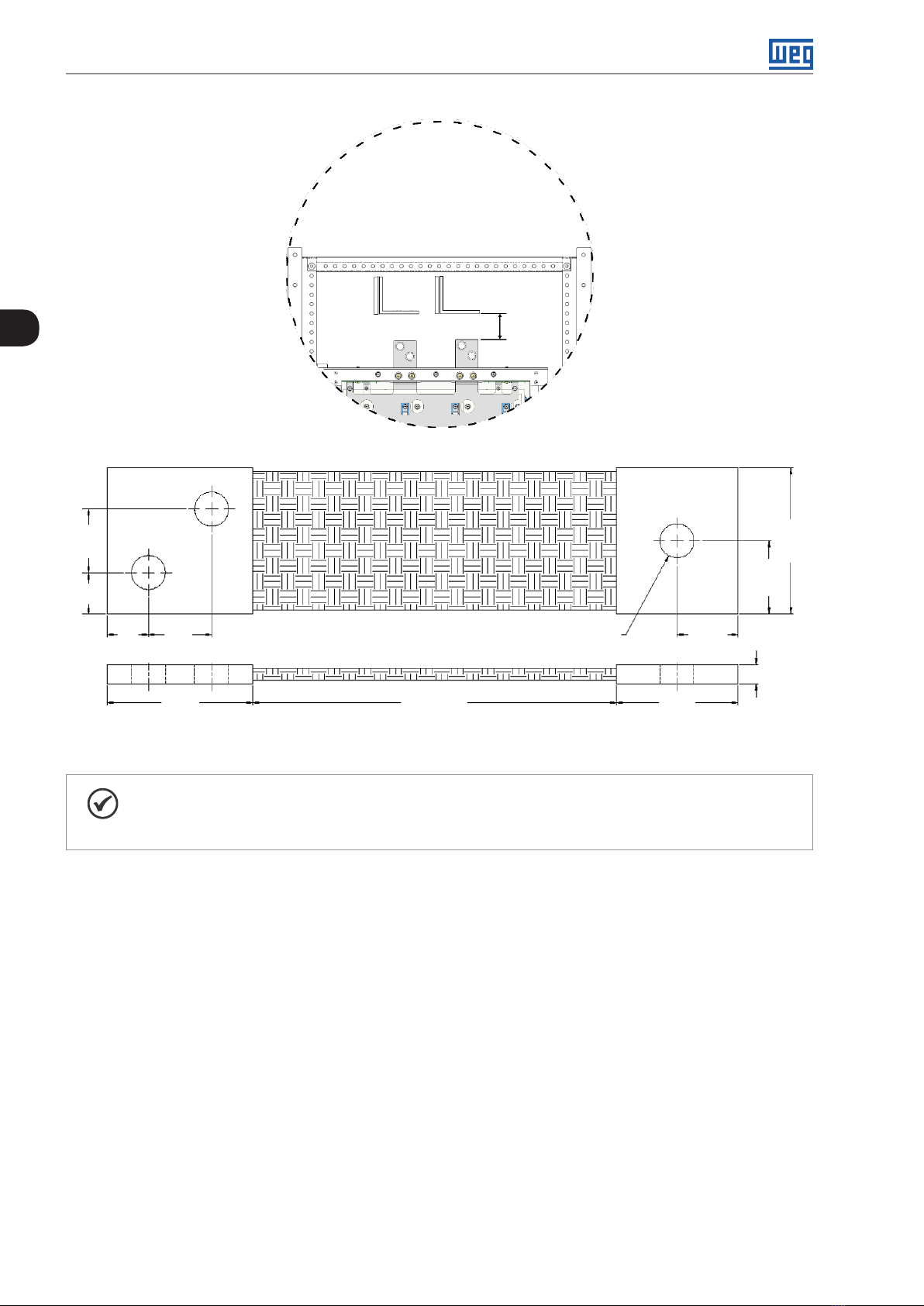

3.3 UC11 MECHANICAL INSTALLATION

Mounting of the UC11RB G2 on the panel door: control rack with flange mount and ICUP board shield mounted

inside the door. The control rack is mounted with four screws M3 (recommended torque: 0.5 N.m).

ICUP

3-20 | CFW-11MW G2 RB

Figure 3.25: Example of mounting of the control rack in the panel

Page 40

Installation and Connection

ø 5.2 (4X)

(0.20)

(5.64)

143.3

286.5

Figure 3.26: Mounting of the control rack and necessary slots in mm (in)

[11. 2]

283.6

190

(7. 4 8)

R8 (4X)

(11.28)

186.5

(7.34)

7 (0.27)

(0.32)

93.3

(3.67)

2 (0.08)

11

(0.43)

290

(11.42)

7 (0.27)

3

[1.6]

41.5

292

[11. 5]

[0.2]

R4 (4x)

Figure 3.27: Mounting of the base of the ICUP module in mm (in)

The shield of the ICUP board is mounted with four screws M6 (recommended torque: 8.5 N.m).

CFW-11MW G2 RB | 3-21

Page 41

Installation and Connection

3.4 ELECTRICAL INSTALLATION

DANGER!

The following information is intended to be a guide for proper installation. Comply with applicable

local regulations for electrical installations.

DANGER!

Make sure the power supply is disconnected before starting the connections.

3

ATTENTION!

The CFW-11M G2 RB and CFW-11W G2 RB can be connected to circuits with short-circuit capacity

of up to 100000 symmetric Arms (maximum 480 V/690 V).

ATTENTION!

The short-circuit protection of the converter does not provide short-circuit protection for the feeder

circuit. The short-circuit protection of the feeder circuit must be provided in accordance with the

applicable local regulations.

3.4.1 Pre-Charge

The resistors of the pre-charge circuit must be sized according to the following criteria:

Maximum voltage.

Maximum energy.

Power overload capacity of the resistors during the pre-charge period (energy dissipation capacity).

Table 3.14: Sizing of the pre-charge

Peak current during the pre-charge (A) 0.82 x (V

Energy stored in the capacitor bank (J)

Pre-charge duration

(1) This calculation considers the use of the same number of power units in the regenerative frequency

converter and in the inverter connected to the motor. When the CFW11M RB G2 or CFW11W RB G2 feeds

several other inverters, you must consult WEG for the correct sizing of the pre-charge resistor.

(1)

(1)

UP11- 01 G2 N.0.012.V

UP11- 02 G 2 N.0.024.V

UP11W-01 G2 N.0.014.V

UP11- 01 G2 0.1.N.R

UP11- 02 G 2 0.2.N.R

UP11W-01 G2 0 .11.N.R

Being R the ohmic value of the resistor used on each phase and N the number of regenerative power units.

Table 3.15 on page 3-22 contains the maximum ohmic value that can be applied to the pre-charge resistors.

/R)

line

2

line

2

line

2

line

3-22 | CFW-11MW G2 RB

Table 3.15: Maximum pre-charge resistor value for the CFW11M G2 RB

Nº. of UP11s

1 5.0 Ω 11.0 Ω 7.5 Ω

2 2.5 Ω 3.8 Ω 5.0 Ω

3 1.5 Ω 2.5 Ω 3.5 Ω

4 1.2 Ω 2.0 Ω 2.5 Ω

5 1.2 Ω 1.8 Ω 2.0 Ω

Power Supply

380-480 V

Power Supply

500-600 V

Power Supply

660 -690 V

Page 42

Installation and Connection

Table 3.16: Maximum pre-charge resistor value for the CFW11W G2 RB

N° of UP11Ws 500-690 V

1 5.5 Ω

2 3.0 Ω

3 2.0 Ω

4 1.4 Ω

5 1.2 Ω

E.g.:

In a drive consisting of three regenerative power units plus three output power units whose line voltage at the

converter input is 690 Vrms (UP11-01 G2), the values obtained will be as follows:

3

Energy stored in the capacitor bank: 3 x 0.012 x 690

2

= 17x139.6 J.

Using three 3 Ω resistors (one per phase), each resistor must withstand 5,713.2 J.

The manufacturer of the resistor can inform the energy the component withstands.

The peak current during the pre-charge will be 188.6 A and the pre-charge duration will be 0.9 s.

KPCR

QPCR

R

Mains

K1

Filter

AC

Fuses

CFW11M G2 RB

or

CFW11W G2 RB

DC+ DC+

U U

DC

Fuses

V V

W W

DC- DC-

CF W 11M G 2

or

CF W 11W G 2

(*)

Synchronism

KSINC

QSINC

Motor

11

Stop

12

11

S

OFF

12

220 Vac

external

(*) If only one power unit is used at the output, it is not necessary to use fuses on the DC Link.

13 13

S

ON

14 14 21 21

A1

+RC +RC +RC +RC +RC

KA1

A2 A2 A2 A2 A2 A2

CC11 (D O1)

A1 A1 A1 A1 A1

15 13 43

KT1 KA2 KA2

16

18

18

KA1

44

XC12 2

XC123

KPCR

XC1: 21

KA2

22 22

KA2 K1KPCR

Figure 3.28: Example of a pre-charge activation circuit

14 44

KSINCKT1

CFW-11MW G2 RB | 3-23

Page 43

Installation and Connection

The power supply of the CFW-11M G2 RB or CFW-11W G2 RB regenerative frequency converters can be done via

contactor or motorized circuit breaker (represented by K1), observing that its command must be interlocked with

the command of the KPCR pre-charge contactor. Figure 3.28 on page 3-23 shows an example of a recommended

pre-charge circuit with the simplified power and control diagrams. The digital relay output DO1 of the CC11 board

must be configured with the "Pre-Charge OK" function (P0275 = 25). This relay must be used to command the

pre-charge contactor and the main contactor (motorized circuit breaker). In addition, the duration of the pre-charge

must be timed to protect the components of the auxiliary circuit (resistors, contactor). This function is performed

by a timing relay with on-delay, represented in Figure 3.28 on page 3-23 by RT1. The KSINC contactor ensures

that the synchronism circuit will only be powered after the completion of the pre-charge. The QPCR and QSINC

circuit breakers protect the pre-charge and synchronism circuits respectively.

3

3.4.2 Busbars

The panel busbars must be sized according to the converter output current and the drive input current. It is

recommended to use copper busbars. In case it is necessary to use aluminum busbars, it is necessary to clean

the contacts and use an anti-oxidant compound. If the compound is not used, any copper and aluminum joint

will undergo accelerated corrosion.

3.4.3 Fuses

Fuses must be installed at the input of each power unit, that is, each power unit must be individually proteced

with fuses at their input.

Ultrafast type fuses (UR) must be used at the input.

For UL conformity, use class J fuses at the converter power supply with current not above the values of

Table 3.17 on page 3-24.

Table 3.17: Recommended fuses

Recommended WEG Fuses

Model Current (A) Voltage (V) Duty

UP11- 02 G 2

UP11- 01 G2

UP11W-01 G2

634

515 HD

496

380 HD

439

340 HD

780

640 HD

380-480

500-600

660-690

500-690

ND

ND

ND

ND

In (A) Modelo

800 FNH3FEM-800Y-A

630 FNH3FEM-630Y-A

550 FNH3FEM-550Y-A

1000 FNH3FEM-1000Y-A

NH aR

Flush End

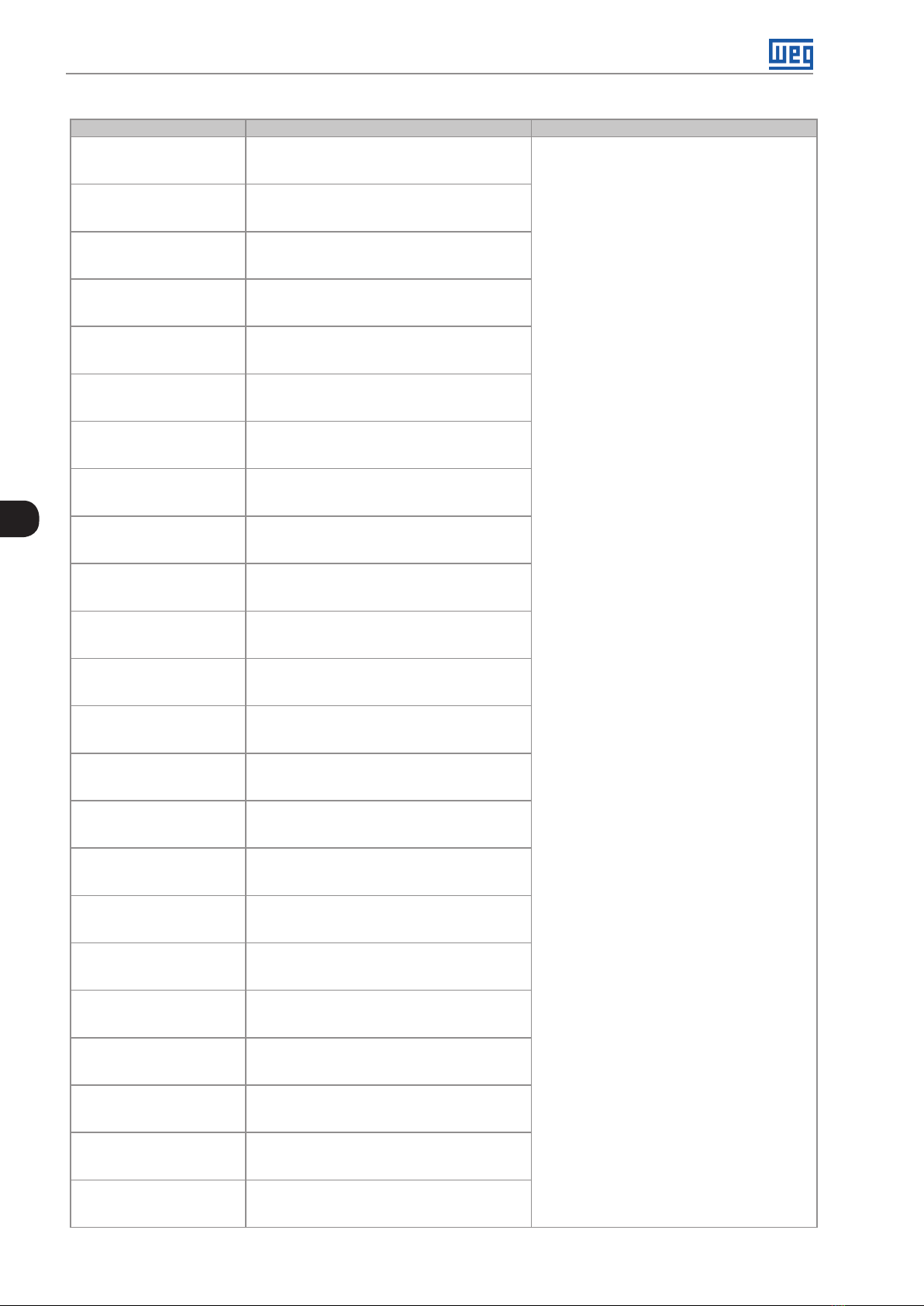

In Figure 3.29 on page 3-25 and Figure 3.30 on page 3-25 the fuse connection schemes are presented.

NOTE!

As noted in Figure 3.29 on page 3-25, when using one regenerative UP11 plus one output UP11,

no DC fuses are required.

3-24 | CFW-11MW G2 RB

Page 44

Mains

Filter protection

(circuit breaker

or fuses)

Filter

Installation and Connection

3

Mains

Filter protection

(circuit breaker

or fuses)

Filter

AC Fuses

Figure 3.29: Fuse connection diagram for one regenerative UP11 plus one output UP11

DC Fuses

AC Fuses

Figure 3.30: Fuse connection diagram for three regenerative UP11s plus three output UP11s

CFW-11MW G2 RB | 3-25

Page 45

Installation and Connection

3.4.4 General Wiring Diagram

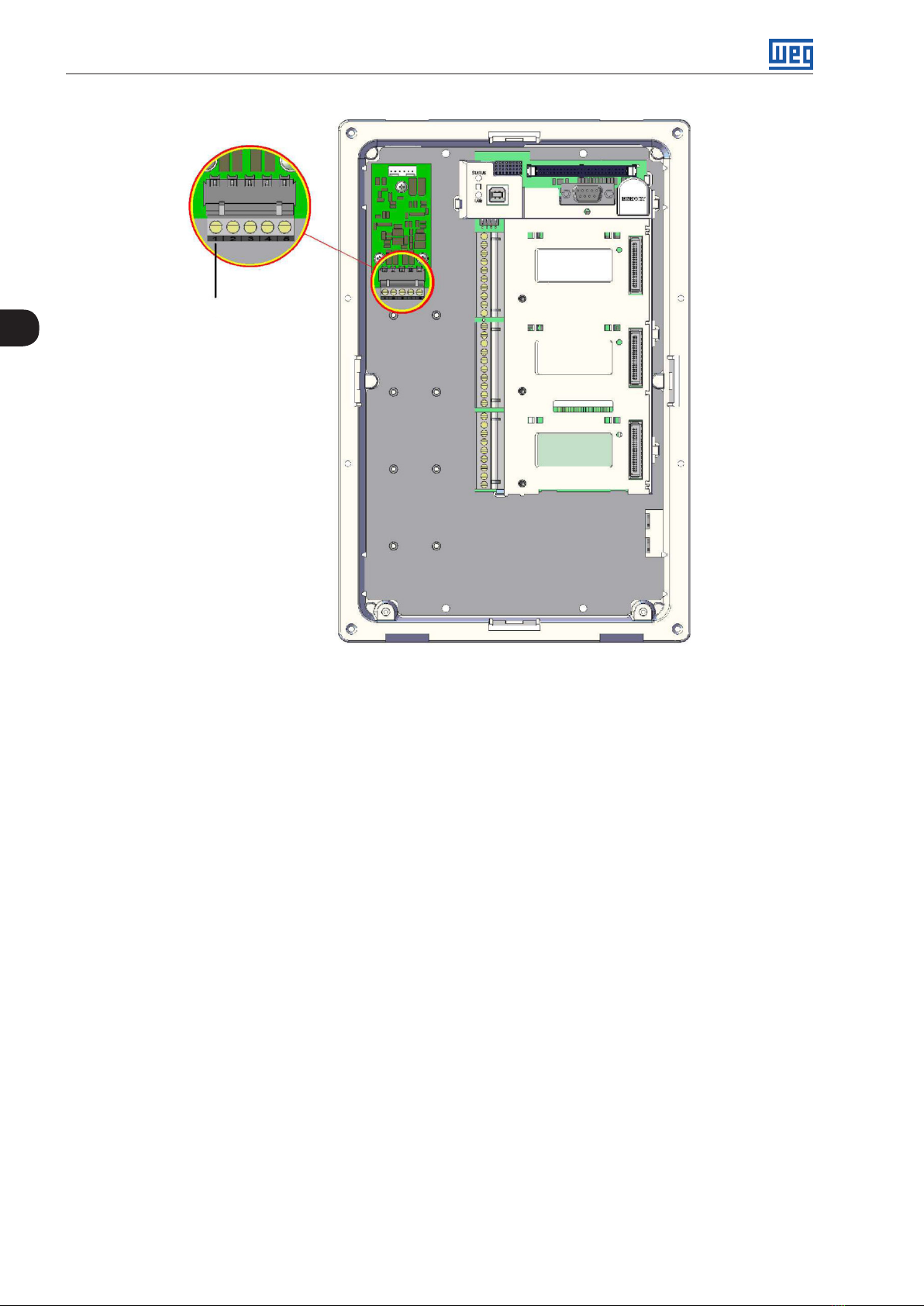

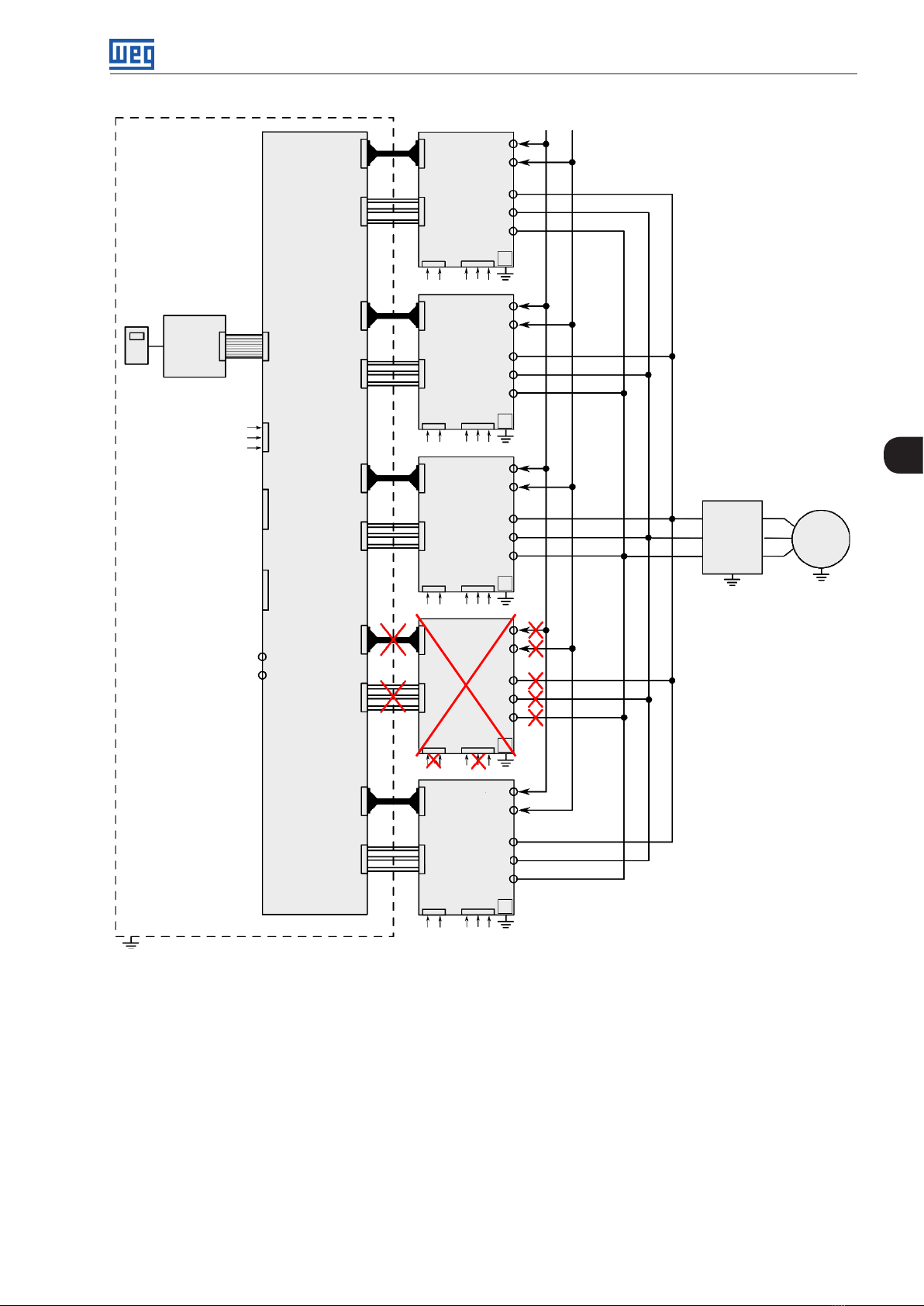

Figure 3.31 on page 3-26 shows the general diagram for a converter with five Power Units (UP11). It shows

the connections between the Control Unit UC11RB and the PUs (Connectors DB25 XC40 and Fiber Optics),

power connections of the PUs (DC+, DC-, U, V, W and GND), and auxiliary power supply connections of the

cooling (220 V), of the UP11 (24 Vdc) and of the UC11 (24 Vdc). For a reduced number of UP11, connect them

in increasing order (1, 2, 3, etc.), leaving the last positions without connection. This diagram is valid for both

air-cooled UP11 G2 and water-cooled UP11W G2, except for the XC33 connector (fan connection), which does

not exist on the UP11W G2.

3

UC11 R B

ICUP

XC40AUH1...WL1

XC40XC40XC40XC40XC40

+UD

-UD

UP11

+UD -UD

U

V

UH...WLUH...WLUH...WLUH...WLUH...WL

XC33

11

222

220 Vac

XC6

111

222

24 Vcc

W

1

333

+UD

-UD

CC11

HMI

XC60

XC60

UP11

U

V

W

1

2

3

24 VCC

XC33

220 Vac

XC6

24 Vcc

1

+UD

Not

Digital

XC40C XC40B

used

XC33

XC5 XC67 XC9

inputs

1

220 Vac

UP11

24 Vcc

XC6

-UD

U

V

W

U

V

Filter

W

Mains

1

+UD

Not

BR

used

Error_BR

XC40D

UP11

-UD

U

V

W

XC33

220 Vac

XC6

1

1

2

24 Vcc

3

1

2

+UD

-UD

3-26 | CFW-11MW G2 RB

XC6

1

2

24 Vcc

U

V

W

1

3

UP11

UH5...WL5 UH4...WL4 UH3...WL3 UH2...WL2XC40E

XC33

1

2

220 Vac

Figure 3.31: General wiring diagram

Page 46

3.4.5 Power Connections

Mains

R

S T PE

Filter

U

V W PE

DC-

W W WV V VU U U

DC- DC-DC+ DC+ DC+

Installation and Connection

+

Output

-

DC

3

Fuses

Figure 3.32: Power and grounding connections

The DC+ and DC- connections of the UP11 G2 and UP11W G2 are fastened with 4 screws M12X35 (recommended

torque: 60 N.m); see Figure 3.33 on page 3-27 and Figure 3.34 on page 3-28.

DC- DC+

Figure 3.33: DC output terminals of the UP11 G2

CFW-11MW G2 RB | 3-27

Page 47

Installation and Connection

DC+ DC-

3

Figure 3.34: DC output terminals of the UP11W G2

DC+: Positive pole of the DC output voltage.

DC-: Negative pole of the DC output voltage.

On the UP11 G2 (air-cooled), the U, V and W connections are made through 3 screws M12X45 (recommended

torque: 60 N.m; see Figure 3.35 on page 3-29. The screw used to fasten the grounding cable of the UP11 G2

is M12X25 (recommended torque: 60 N.m).

3-28 | CFW-11MW G2 RB

Page 48

Installation and Connection

3

Figure 3.35: Input terminals U, V, W and ground on the UP11 G2

On the UP11W G2 (water-cooled), the U, V and W connections are made through 12 screws M12X25 (recommended

torque: 60 N.m; see Figure 3.36 on page 3-30). Two screws M12X25 (recommended torque: 60 N.m) are used

to fasten the grounding cable of the UP11W G2.

CFW-11MW G2 RB | 3-29

Page 49

Installation and Connection

U

V

3

W

Figure 3.36: Input terminals U, V, W and ground on the UP11W G2

U, V and W: connections to the filter.

: Grounding cable connection.

For a better current distribution between the UP11 G2 or UP11W, it is recommended that their output connections

be interconnected through a single paralleling busbar. The length of the cables between the UP11 G2 or UP11W

and the paralleling busbar must be as short as possible.

ATTENTION!

The output cables U, V and W of the UP11 G2 and UP11W G2 must have the same length.

ATTENTION!

If a busbar is used for parallelism of the power units, the filter cables must be distributed as evenly as

possible in the connection to the paralleling busbar, as shown in Figure 3.37 on page 3-31. Distance

"L" must be kept constant.

3-30 | CFW-11MW G2 RB

Page 50

Mains

R

S T PE

Filter

Installation and Connection

DC Output

DC+ DC+ DC+DC- DC- DC-

3

U

V

W

PE

U

Fuses

Paralleling

busbar

Figure 3.37: Recommended distribution for the filter cables

3.4.6 Input and Grounding Connections

ATTENTION!

Use proper lugs for the power and grounding connection cables.

ATTENTION!

Sensitive equipment, such as PLCs, temperature controllers and thermocouple cables, should be at

least 0.25 m away from the converter and from the cables connecting the input filter to the converter.

V V V

U U

W W W

L

L

L

L

L

L

L

L

L

L

L

L

Grounding

busbar

Phase U

Phase V

Phase W

DANGER!

Incorrect cable connection:

Check all the connections before energizing the converter.

In case of replacement of an existing converter by a CFW-11M G2 RB, check if all the installation

and wiring connected to it complies with the instructions of this manual.

DANGER!

Provide a disconnecting device for the converter power supply. This device must cut off the inverter

power supply whenever necessary (during maintenance, for instance).

CFW-11MW G2 RB | 3-31

Page 51

Installation and Connection

ATTENTION!

The supply voltage must not exceed the converter rated values (see Table 8.1 on page 8-2 and

Table 8.2 on page 8-3).

ATTENTION!

Capacitors for power factor correction must not be used at the input (U, V, W).

3

NOTE!

The gauges indicated in Table 3.18 on page 3-32 and Table 3.19 on page 3-33 are reference values

only. For the proper wiring sizing, consider the installation conditions and the maximum permissible

voltage drop.

Use two parallel cables with the gauge indicated in Table 3.18 on page 3-32 to interconnect connections U, V

and W of the UP11 with the paralleling busbar (filter output).

Table 3.18: Connection cables U, V and W

Model Current (A) Voltage (V) Duty

UP11- 02 G 2

UP11- 01 G2

UP11W-01 G2

634

515 HD (2X ) 185

496

380 HD (2X) 120

439

340 HD (2X) 120

780

640 HD (4X) 95

380-480

500-600

660-690

500-690

ND (2X) 300

ND (2X) 185

ND (2X) 150

ND (4X) 120

Minimum Cable Cross

Section (mm²)

ATTENTION!

Cables U, V and W of all phases of all UP11 G2 and UP11W G2 must have the same length to prevent

current unbalance.

The characteristics of the cable used to connect the converter to the filter, as well as its interconnection and

routing, are extremely important to avoid electromagnetic interference in other devices.

DANGER!

Do not share the grounding wiring with other devices that operate with high currents (e.g., high power

motors, welding machines, etc.).

ATTENTION!

The neutral conductor of the line that powers up the converter must be solidly grounded; however,

this conductor must not be used to ground the converter.

DANGER!

The converter must be connected to a protection grounding (PE).

Observe the following:

Connect the converter grounding points to a specific grounding rod or specific grounding point or

to the general grounding point (resistance ≤ 10 Ω).

Use a minimum cable gauge for connection to the ground as indicated in Table 3.19 on page 3-33.

if local standards require different gauges, they must be observed.

For compatibility with IEC 61800-5-1, use at least one 10 mm² copper cable to connect the converter

to the protective earth, since the leakage current is higher than 3.5 mA AC.

3-32 | CFW-11MW G2 RB

Page 52

Installation and Connection

Use the cables with the gauge indicated in Table 3.19 on page 3-33 to ground the UP11 power units.

Table 3.19: Grounding cables

Model Current (A) Voltage (V) Duty

UP11- 02 G 2

UP11- 01 G2

UP11W-01 G2

634

515 HD 185

496

380 HD 120

439

340 HD 120

780

640 HD (2X) 95

380-480

500-600

660-690

500-690

ND 300

ND 185

ND 150

ND (2X ) 120

Minimum Cable Cross

Section (mm²)

3.4.7 Terminals Recommended for Power Cables

Table 3.20: Terminals recommended for power cables

Cable Gauge

[mm²]

95 M12

120 M12

150 M12

185 M12

300 M12

Screw Manufacturer Lug Terminal, Code Crimping Tool, Code

Hollingsworth RM95 -12 Hydraulic tool H6-500 1

Tyc o XCT 95-12

Hollingsworth RM120 -12 Hydraulic tool H6-500 1

Burndy (FCI) YA 28L

Hollingsworth RM15 0 -12 Hydraulic tool H6-500 1

Burndy (FCI) YA 3 0 L

Hollingsworth RM18 5 -12 Hydraulic tool H6-500 1

Burndy (FCI) YA31L

Hollingsworth RM3 0 0-12 Hydraulic tool H6-500 1

Burndy (FCI) YA36L 2

UNIPRESS 6/120 +COF+CHARG

Item TE: 2107475-2

Tool without die: MY29-3 or Y644 or Y81

Tool+die: Y35 or Y750 / U29RT

Tool without die: Y644 or Y81

Tool+die: Y35 or Y750 / U30RT

Tool without die: Y644 or Y81

Tool+die: Y35 or Y750 / U31RT

Tool without die: Y644 or Y81

Tool+die: Y35 or Y750 / U36RT

3

Number of

Crimps

1

1

1

1

1

3.4.8 Output Connections

The DC link and each UP11 G2 or UP11W G2 can be interconnected with flexible braids as in the example of

Figure 3.38 on page 3-34, sized to withstand the DC link current, according to Table 8.1 on page 8-2. Figure

3.39 on page 3-34 shows an example of a flexible braid used by WEG.

CFW-11MW G2 RB | 3-33

Page 53

Installation and Connection

-UD +UD

3

Figure 3.38: Side view of the connections of the flexible braids and fuses

26

(1.02)

17

(0.67)

17

(0.67)26(1.02)

60

(2.36)

Braided wire gauge: AWG-40

Figure 3.39: Example of flexible braid - mm (in)

E

E

60

(2.36)

30

(1.18 )

Ø 14 (3x)

(0.55)

25

(0.98)

8±1

50

(1.97)

NOTE!

It is important that all the flexible braids have the same length (defined by dimension "E"), which will

depend on the panel construction.

3.4.9 Input Filters

3.4.9.1 Basic Definitions

For the operation of the regenerative frequency converter, it is necessary to use an input filter to eliminate the

circulation of high frequency currents generated by the switching of the regenerative frequency converter IGBTs

on the power grid. In this manual, input filters are the components connected between the power grid and the

regenerative frequency converter input.

3.4.9.2 How to Specify the Filter Model

WEG has input filters ready to be used with each of its regenerative frequency converters. To specify the model of

the input filter, enter the voltage and current values into the respective smart code fields for rated supply voltage

and rated input current, as in the example of Table 3.21 on page 3-35.

3-34 | CFW-11MW G2 RB

Page 54

Installation and Connection

Table 3.21: Smart code of the input filters

Example WLCL 0634 T 4

Field denomination WEG filter Filter rated current Number of phases Rated voltage

Available options

Check Table 3.22 on

page 3-35 and Table

3.23 on page 3-35

Table 3.22: Rated current of the input filters for the UP11 G2 (air cooling)

380-480 V 500-600 V 6 60 -690 V

0634 = 634 A 0496 = 496 A 0439 = 439 A

1205 = 1205 A 0942 = 942 A 0834 = 834 A

1807 = 1807 A 1414 = 1414 A 1251 = 1251 A

2409 = 2409 A 1885 = 1885 A 1668 = 1668 A

3012 = 3012 A 2356 = 2356 A 2085 = 2085 A

Table 3.23: Rated current of the input filters for the UP11W G2 (water cooling)

500-690 V

0780 = 780 A

1482 = 1482 A

2223 = 2223 A

2964 = 2964 A

3705 = 3705 A

T = three-phase

4 = 380...480 V

5 = 500...600 V

6 = 660...690 V

3

3.4.10 Synchronism

The CFW-11M G2 RB and the CFW-11W G2 RB monitor the line voltage (R, S and T) at the converter input by means

of a synchronism board and two transformers. The signals obtained are used in the control of the regenerative

frequency converter.

The synchronism circuit wiring diagram can be seen in Figure 3.28 on page 3-23. The KSINC contactor must

be closed together with the main contactor K1. It is recommended to use a circuit breaker (QSINC) to protect the

synchronism transformers.

T1

UP11 G 2

or

UP11W G2

U DC+

V

W

DC-

UC11RB G2

XC1:1

CSR11

Mains

K1

Filter

R

S

T

QSINC

KSINC

H1

H2

H1

H2

Figure 3.40: Synchronism wiring diagram

T2

X1

X2

X1

XC1:2

XC1:4

XC1:5

XC50

XC50

CC11

CFW-11MW G2 RB | 3-35

Page 55

Installation and Connection

H1

H2

X1

X2

3

Figure 3.41: Synchronism transformer

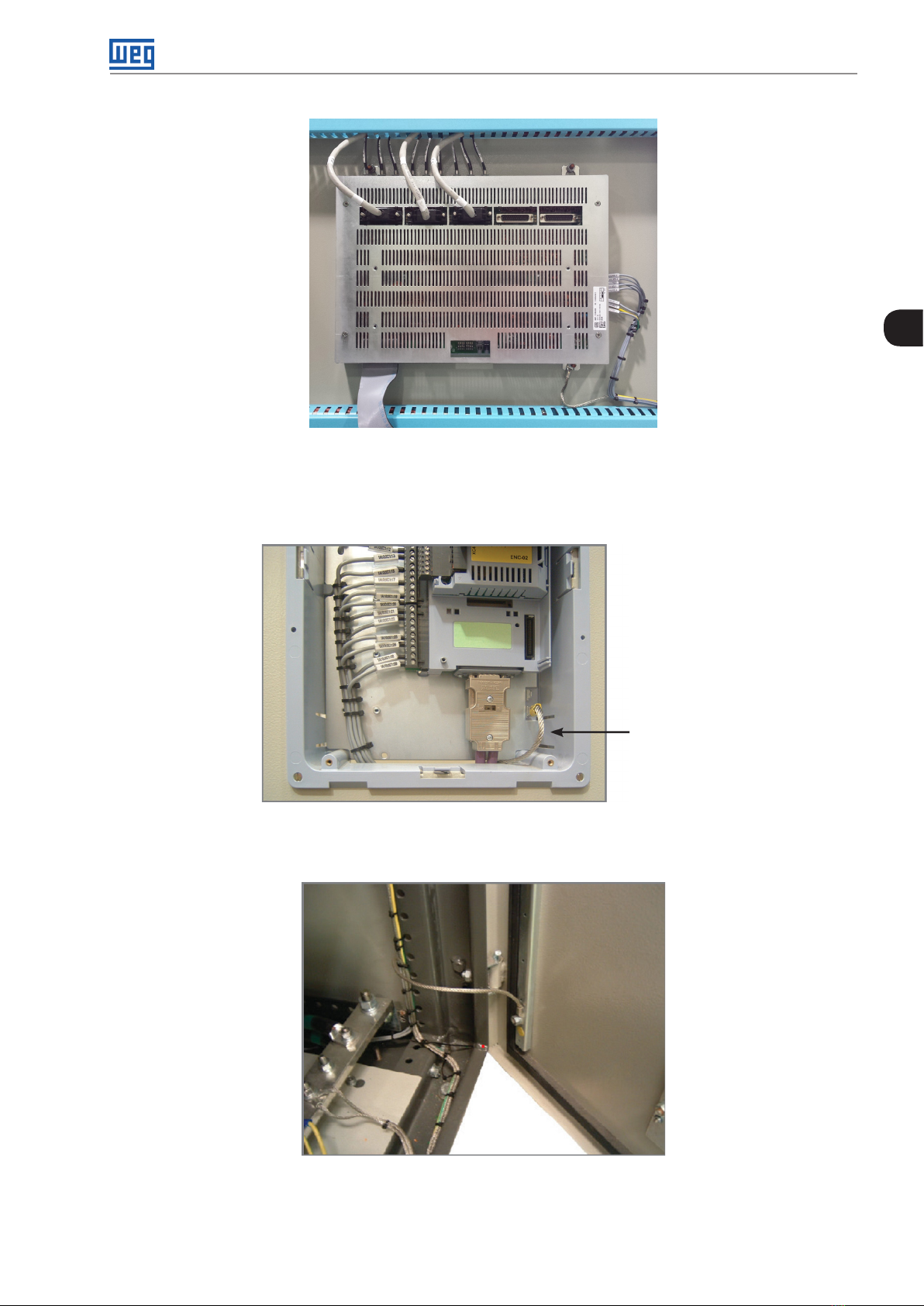

WEG supplies the synchronism transformers for panel mounting. Figure 3.42 on page 3-36 shows this mounting.

ATTENTION!

The shield of the synchronism transformers must be grounded.

Figure 3.42: Mounting example of the transformers

Table 3.14 on page 3-22 shows the specification of the synchronism transformer

Table 3.24: Synchronism transformer specifications

Input Voltage of CFW11-11M/W G2 RB 380 V - 480 V 500 V - 690 V

Rated voltage of the primary H1-H2 480 V 690 V

Transformer ratio NS/N

f (frequency) 50 Hz/60 Hz

S (power) 2.5 VA

Voltage tolerance ± 1 %

Steady state overvoltage 10 %

Insulation Class 1.1 k V

Class B

Insulation

Primary to secondary 3000 Vca / 1 min

Primary to shield 3000 Vca / 1 min

Primary to enclosure 3000 Vca / 1 min

Be in accordance wit UL508 standard as the insulation material and manufacturing