Page 1

Motors | Automation | Energy | Transmission & Distribution | Coatings

Frequency Inverter

CFW-11 500...690 V

User's Manual

Page 2

Page 3

FREQUENCY

INVERTER

MANUAL

Document: 10001473218 / 03

Series: CFW-11

Language: English

Models: 2.9...44 A / 500...600 V

2.9...804 A / 500...690 V

Models with Special DC Hardware: 170...804 A / 500...690 V

02/2016

Page 4

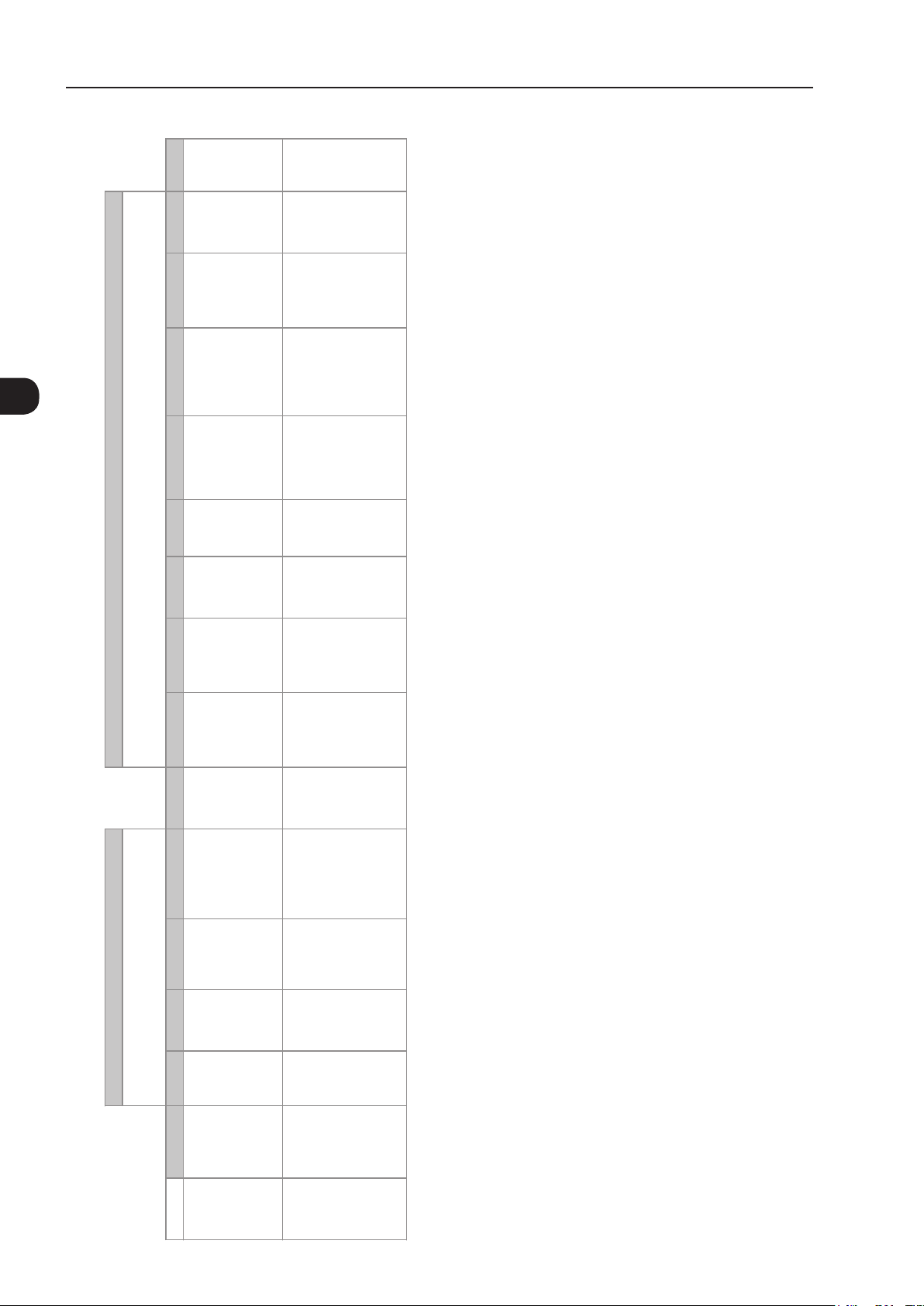

Summary of Revisions

Version Review Description

- R01 First edition

- R02 General revision

- R03 General revision

Page 5

Contents

1 SAFETY INSTRUCTIONS .................................................................. 1-1

1.1 SAFETY WARNINGS IN THE MANUAL ......................................................... 1-1

1.2 SAFETY WARNINGS IN THE PRODUCT ........................................................1-1

1.3 PRELIMINARY RECOMMENDATIONS ........................................................... 1-2

2 GENERAL INSTRUCTIONS .............................................................. 2-1

2.1 ABOUT THE MANUAL .................................................................................2-1

2.2 TERMS AND DEFINITIONS .......................................................................... 2-2

2.3 ABOUT THE CFW-11 ................................................................................... 2-5

2.4 IDENTIFICATION LABELS FOR THE CFW-11 ..............................................2-17

2.5 RECEIVING AND STORAGE ....................................................................... 2-19

3 INSTALLATION AND CONNECTION ............................................... 3-1

3.1 MECHANICAL INSTALLATION ..................................................................... 3-1

3.1.1 Installation Environment .................................................................... 3-1

3.1.2 Mounting Considerations ................................................................... 3-2

3.1.3 Cabinet Mounting .............................................................................. 3-7

3.1.4 Installation of the Inverter Hoisting Eyes - Frame Size E ................... 3-10

3.1.5 Installation of the Inverter with Nema1 Kit (Option, CFW11....T...ON1...) on a

Wall - Frame Size E ..............................................................................................3-11

3.1.6 Access to the Control and Power Terminal Strips .............................. 3-11

3.1.7 Removal of the Cable Passage Plate - Frame Sizes D and E .............. 3-14

3.1.8 HMI Installation at the Cabinet Door or

Command Panel (Remote HMI) .................................................................3-14

3.2 ELECTRICAL INSTALLATION ......................................................................3-14

3.2.1 Identification of the Power and Grounding Terminals ....................... 3-15

3.2.2 Power/Grounding Wiring and Fuses ................................................3-20

3.2.3 Power Connections ...........................................................................3-31

3.2.3.1 Input Connections .............................................................. 3-34

3.2.3.1.1 AC Power Supply Considerations ............................ 3-35

3.2.3.1.2 IT Networks ......................................................... 3-35

3.2.3.1.3 Command Fuses of Pre-charge Circuit ................. 3-37

3.2.3.2 Dynamic Braking ................................................................ 3-38

3.2.3.2.1 Sizing the Braking Resistor ..................................3-38

3.2.3.2.2 Installation of the Braking Resistor - Frame Sizes B, C,

D and E .............................................................................. 3-40

3.2.3.3 Output Connections ............................................................ 3-41

3.2.4 Grounding Connections ................................................................... 3-44

3.2.5 Control Connections ......................................................................... 3-45

3.2.6 Typical Control Connections ............................................................. 3-51

3.3 SAFETY STOP FUNCTION .......................................................................... 3-54

3.3.1 Installation ....................................................................................... 3-56

3.3.2 Operation ........................................................................................ 3-57

3.3.2.1 Truth Table .........................................................................3-57

3.3.2.2 State of Inverter, Fault and Alarm Related to Safety Stop

Function ......................................................................................... 3-57

3.3.2.3 STO Status Indication .........................................................3-57

3.3.2.4 Periodic Test ........................................................................ 3-58

Page 6

Contents

3.3.3 Examples of Wiring Diagrams of Inverter Control Signal ................. 3-59

3.3.4 Technical Specifications .................................................................... 3-60

3.3.4.1 Electrical Control Characteristics ........................................ 3-60

3.3.4.2 Operational Safety Characteristics ...................................... 3-60

3.3.4.3 Certification ........................................................................ 3-61

3.4 INSTALLATION ACCORDING TO THE EUROPEAN DIRECTIVE OF

ELECTROMAGNETIC COMPATIBILITY ..............................................................3-62

3.4.1 Conformal Installation ..................................................................... 3-62

3.4.2 Standard Definitions ........................................................................ 3-63

3.4.3 Emission and Immunity Levels .......................................................... 3-64

4 KEYPAD AND DISPLAY .................................................................... 4-1

4.1 INTEGRAL KEYPAD - HMI-CFW11 ...............................................................4-1

4.2 PARAMETERS ORGANIZATION .................................................................... 4-4

5 FIRST TIME POWER-UP AND START-UP ........................................... 5-1

5.1 PREPARE FOR START-UP .............................................................................. 5-1

5.2 START-UP

5.2.1 Password Setting in P0000 .................................................................5-3

5.2.2 Oriented Start-Up ...............................................................................5-3

5.2.3 Setting Basic Application Parameters .................................................. 5-5

5.3 SETTING DATE AND TIME ........................................................................... 5-9

5.4 BLOCKING PARAMETERS MODIFICATION ................................................. 5-10

5.5 HOW TO CONNECT A PC ......................................................................... 5-10

5.6 FLASH MEMORY MODULE .........................................................................5-10

.................................................................................................... 5-2

6 TROUBLESHOOTING AND MAINTENANCE .................................... 6-1

6.1 OPERATION OF THE FAULTS AND ALARMS .................................................6-1

6.2 FAULTS, ALARMS AND POSSIBLE CAUSES ................................................... 6-2

6.3 SOLUTIONS FOR THE MOST FREQUENT PROBLEMS ...................................6-8

6.4 INFORMATION NECESSARY FOR CONTACTING TECHNICAL SUPPORT ......6-8

6.5 PREVENTIVE MAINTENANCE ...................................................................... 6-9

6.5.1 Cleaning Instructions ....................................................................... 6-10

7 OPTION KITS AND ACCESSORIES ................................................. 7-1

7.1 OPTION KITS .............................................................................................. 7-1

7.1.1 Nema 1 Protection Degree - Frame Sizes B, C and E ..........................7-1

7.1.2 Safety Stop Function ........................................................................... 7-1

7.1.3 24 Vdc External Control Power Supply ...............................................7-1

7.2 ACCESSORIES .............................................................................................7-2

7.2.1 Use of External Dynamic Braking Module DBW03 and DBW04 .......... 7-4

8 TECHNICAL SPECIFICATIONS ........................................................ 8-1

8.1 POWER DATA .............................................................................................. 8-1

8.2 ELECTRONICS/GENERAL DATA ................................................................... 8-7

8.3 CODES AND STANDARDS ........................................................................... 8-8

8.4 CERTIFICATIONS ......................................................................................... 8-8

8.5 MECHANICAL DATA .................................................................................... 8-9

8.6 NEMA 1 KITS ............................................................................................. 8-16

Page 7

1 SAFETY INSTRUCTIONS

This manual provides information for the proper installation and

operation of the CFW-11 frequency inverter.

Only trained and qualified personnel should attempt to install,

start-up, and troubleshoot this type of equipment.

1.1 SAFETY WARNINGS IN THE MANUAL

The following safety warnings are used in this manual:

DANGER!

The procedures recommended in this warning have the purpose of protecting the user against death,

serious injuries and considerable material damage.

Safety Instructions

1

DANGER!

Les procédures concernées par cet avertissement sont destinées à protéger l'utilisateur contre des

dangers mortels, des blessures et des détériorations matérielles importantes.

ATTENTION!

The procedures recommended in this warning have the purpose of avoiding material damage.

NOTE!

The information mentioned in this warning is important for the proper understanding and good

operation of the product.

1.2 SAFETY WARNINGS IN THE PRODUCT

The following symbols are attached to the product and require special attention:

Indicates a high voltage warning.

Electrostatic discharge sensitive components.

Do not touch them.

Indicates that a ground (PE) must be connected securely.

Indicates that the cable shield must be grounded.

Indicates a hot surface warning.

CFW-11 | 1-1

Page 8

1

Safety Instructions

1.3 PRELIMINARY RECOMMENDATIONS

DANGER!

Only trained personnel, with proper qualifications, and familiar with the CFW-11 and associated

machinery shall plan and implent the installation, starting, operation, and maintenance of this

equipment.

The personnel shall follow all the safety instructions described in this manual and/or defined by the

local regulations.

Failure to comply with the safety instructions may result in death, serious injury, and equipment damage.

DANGER!

Seulement personnes avec la qualification adéquate et familiarisation avec le CFW-11 et équipements

associés doivent planifiquer ou implementer l'installation, mise en marche, operation et entretien

de cet équipement.

Cettes personnes doivent suivre toutes les instructions de sécurités indiquées dans ce manuel, et/ou

définies par normes locales.

L'inobservance des instructions de sécurité peut résulter en risque de vie et/ou dommages de cet

équipement.

NOTE!

For the purpose of this manual, qualified personnel are those trained and able to:

1. Install, ground, power-up, and operate the CFW-11 according to this manual and to the current

legal safety procedures.

2. Use the protection equipment according to the established regulations.

3. Provide first aid.

DANGER!

Always disconnect the main power supply before touching any electrical device associated with the

inverter.

Several components may remain charged with high voltage and/or in movement (fans), even after

the AC power supply has been disconnected or turned off.

Wait at least 10 minutes to guarantee the fully discharge of capacitors.

Always connect the equipment frame to the ground protection (PE).

DANGER!

Débranchez toujours l'alimentation principale avant d'entrer en contact avec un appareil électrique

associé au variateur. Plusieurs composants peuvent rester chargés à un potentiel électrique élevé et/

ou être en mouvement (ventilateurs), même après la déconnexion ou la coupure de l'alimentation

en courant alternatif.

Attendez au moins 10 minutes que les condensateurs se déchargent complètement.

Raccordez toujours la masse de l'appareil à une terre protectrice (PE).

1-2 | CFW-11

Page 9

Safety Instructions

ATTENTION!

The electronic boards contain components sensitive to electrostatic discharges. Do not touch the

components and terminals directly. If needed, touch first the grounded metal frame or wear an

adequate ground strap.

Do not perform a withstand voltage test on any part of the inverter!

If needed, please, consult WEG.

NOTE!

Frequency inverters may cause interference in other electronic devices. Follow the recommendations

listed in Chapter 3 INSTALLATION AND CONNECTION on page 3-1, to minimize these effects.

NOTE!

Fully read this manual before installing or operating the inverter.

1

DANGER!

Crushing Hazard

In order to ensure safety in load lifting applications, electric and/or mechanical devices must be

installed outside the inverter for protection against accidental fall of load.

DANGER!

This product was not designed to be used as a safety element. Additional measures must be taken

so as to avoid material and personal damages.

The product was manufactured under strict quality control, however, if installed in systems where its

failure causes risks of material or personal damages, additional external safety devices must ensure

a safety condition in case of a product failure, preventing accidents.

DANGER!

Risque d'écrasement

Afin d'assurer la sécurité dans les applications de levage de charges, les équipements électriques et/

ou mécaniques doivent être installés hors du variateur pour éviter une chute accidentelle des charges.

DANGER!

Ce produit n'est pas conçu pour être utilisé comme un élément de sécurité. Des précautions

supplémentaires doivent être prises afin d'éviter des dommages matériels ou corporels.

Ce produit a été fabriqué sous un contrôle de qualité conséquent, mais s'il est installé sur des systèmes

où son dysfonctionnement entraîne des risques de dommages matériels ou corporels, alors des

dispositifs de sécurité externes supplémentaires doivent assurer des conditions de sécurité en cas de

défaillance du produit, afin d'éviter des accidents.

CFW-11 | 1-3

Page 10

1

Safety Instructions

1-4 | CFW-11

Page 11

General Instructions

2 GENERAL INSTRUCTIONS

2.1 ABOUT THE MANUAL

This manual exposes how to install, to start-up in V/f (scalar) mode,

the main characteristics and shows how to troubleshoot the most

common problems of the 500...600 V and 500...690 V models

of CFW-11 inverter series.

It is also possible to operate the CFW-11 in the following control modes: VV W, Sensorless Vector and Vector

with Encoder. For further details on the inverter operation with other control modes, refer to the programming

manual.

ATTENTION!

The operation of this equipment requires installation instructions and detailed operation provided in

the user's manual, programming manual and manuals/guides for kits and accessories.

The user's manual and the parameters quick reference are supplied in a hard copy together with the

inverter. The user guides are also provided in a hard copy along with the kit/accessories. The other

manuals are available at www.weg.net.

A printed copy of the files available on WEG’s website can be requested at your local WEG dealer.

2

For information on other functions, accessories, and communication, please refer to the following manuals:

Programming manual, with a detailed description of the parameters and advanced functions of the CFW-11.

Incremental encoder interface module manual.

I/O expansion module manual.

RS232/RS485 Serial communication manual.

CANopen Slave communication manual.

Anybus-CC communication manual.

DeviceNet communication manual.

Ethercat communication manual.

Profibus DP communication manual.

Symbinet communication manual.

SoftPLC manual.

CFW-11 | 2-1

Page 12

General Instructions

2.2 TERMS AND DEFINITIONS

2

Normal Duty Cycle (ND): the duty cycle that defines the steady state current value I

and an overload of

nom-ND

110 % during 1 minute. It is selected by programming P0298 (Application) = 0 (Normal Duty - ND). It must

be used for driving motors that are not subject in that application to high torques with respect to their rated

torque, when operating at constant speed, during start, acceleration or deceleration.

I

: inverter rated current for use with normal duty cycle (ND = Normal Duty).

nom-ND

Overload: 1.1 x I

Heavy Duty Cycle (HD): the duty cycle that defines the steady state current value I

/ 1 minute.

nom-ND

and an overload of

nom-HD

150 % during 1 minute. It is selected by programming P0298 (Application) = 1 (Heavy Duty - HD). It must be

used for driving motors that are subject in that application to high torques with respect to their rated torque,

when operating at constant speed, during start, acceleration or deceleration.

I

: inverter rated current for use with heavy duty cycle (HD = Heavy Duty).

nom-HD

Overload: 1.5 x I

/ 1 minute.

nom-HD

Rectier: the input circuit of the inverters that converts the input AC voltage into DC; it is made of thyristors

and power diodes.

Pre-charge Circuit: it charges the DC link capacitors with a limited current, thus avoiding higher current peaks

when powering the inverter.

DC Link: inverter intermediate circuit; DC voltage obtained from the rectification of the AC input voltage or

from an external power supply. It feeds the inverter output IGBTs bridge.

U, V, W Arms: set of two IGBTs forming the inverter output phases U, V, and W.

IGBT: Insulated Gate Bipolar Transistor; it is the output inverter bridge basic component, working as an electronic

switch either in the saturated (closed switch) or in the cut off mode (open switch).

Braking IGBT: works as a switch to activate the braking resistors; it is controlled by the DC bus voltage level.

Gate Driver: circuit used to turn-on and turn-off the IGBTs.

PWM: Pulse Width Modulation; a pulsed voltage that feeds the motor.

Switching Frequency: it is the inverter bridge IGBTs commutation frequency, normally specified in kHz. Also

known as carrier frequency.

Heatsink: It is a metal part designed for dissipating the heat generated by the power semiconductors.

PE: Protective Earth.

MOV: Metal Oxide Varistor.

RFI Filter: Radio-Frequency Interference Filter; a filter that avoids interference in the radiofrequency range.

2-2 | CFW-11

Page 13

General Instructions

PTC: it is a resistor, whose resistance value in ohms increases proportionally to the temperature increase, being

used as temperature sensor in motors.

NTC: it is a resistor, whose resistance value in ohms decreases proportionally to the temperature increase, being

used as temperature sensor in power modules.

HMI: Human-Machine Interface; it is the device that allows the control of the motor, the visualization and the

modification of the inverter parameters; it's also known as keypad. The CFW-11 HMI presents keys for

commanding the motor, navigation keys and a graphic LCD display.

FLASH Memory: it is the nonvolatile memory that can be electrically written and erased.

RAM Memory: Random Access Memory (volatile).

USB: Universal Serial Bus; it's a serial bus standard that allows devices to be connected using the Plug and

Play concept.

General Enable: when activated, it accelerates the motor via acceleration ramp. When deactivated, this

function immediately blocks the PWM pulses. The general enable function can be controlled through a digital

input programmed for this function or via serial communication.

Run/Stop: inverter function that when activated (Run) accelerates the motor with the acceleration ramp until

reaching the speed reference, and when deactivated (Stop) decelerates the motor with the deceleration ramp

down to stop. It can be commanded through a digital input programmed for that function or via serial

communication. The HMI keys

STO: Safe Torque Off; functional safety function available as an option in CFW-11 inverter series. When STO

function is enabled the inverter guarantees that there is no movement of the motor shaft. It's also called safety

stop function in CFW-11 documentation.

PLC: Programmable Logic Controller.

(Run) and (Stop) work in a similar manner.

2

TBD: value to be defined.

ac: alternated current.

dc: direct current.

Amp, A: ampere.

°C: Celsius degree.

CFM: Cubic Feet per Minute; unit of flow.

cm: centimeter.

°F: Fahrenheit degree.

Hz: hertz.

CFW-11 | 2-3

Page 14

General Instructions

ft: foot.

hp: horse power = 746 watts; unit of power, used to indicate the mechanical power of electrical motors.

in: inch.

kg: kilogram = 1000 grams.

kHz: kilohertz = 1000 hertz.

l/s: liters per second.

2

lb: pound.

m: meter.

mA: miliampere = 0.001 ampere.

min: minute.

mm: millimeter.

ms: millisecond = 0.001 seconds.

N.M: newton meter; unit of torque.

rms: root mean square; effective value.

rpm: revolutions per minute; unit of speed.

s: second.

V: volts.

Ω: ohms.

2-4 | CFW-11

Page 15

General Instructions

2.3 ABOUT THE CFW-11

The CFW-11 frequency inverter is a high performance product designed for speed and torque control of

three-phase induction motors. The main characteristic of this product is the "Vectrue" technology, which has the

following advantages:

Scalar control (V/f), VVW or vector control programmable in the same product.

The vector control may be programmed as "sensorless" (which means standard motors without using encoders)

or as "vector control" with the use of an encoder.

The "sensorless" control allows high torque and fast response, even in very low speeds or at the starting.

The "vector with encoder" control allows high speed precision for the whole speed range (even with a standstill

motor).

"Optimal Braking" function for the vector control, allowing the controlled braking of the motor and avoiding

the use of the braking resistor in some applications.

"Self-Tuning" feature for vector control. It allows the automatic adjustment of the regulators and control

parameters from the identification (also automatic) of the motor parameters and load.

2

CFW-11 | 2-5

Page 16

2

General Instructions

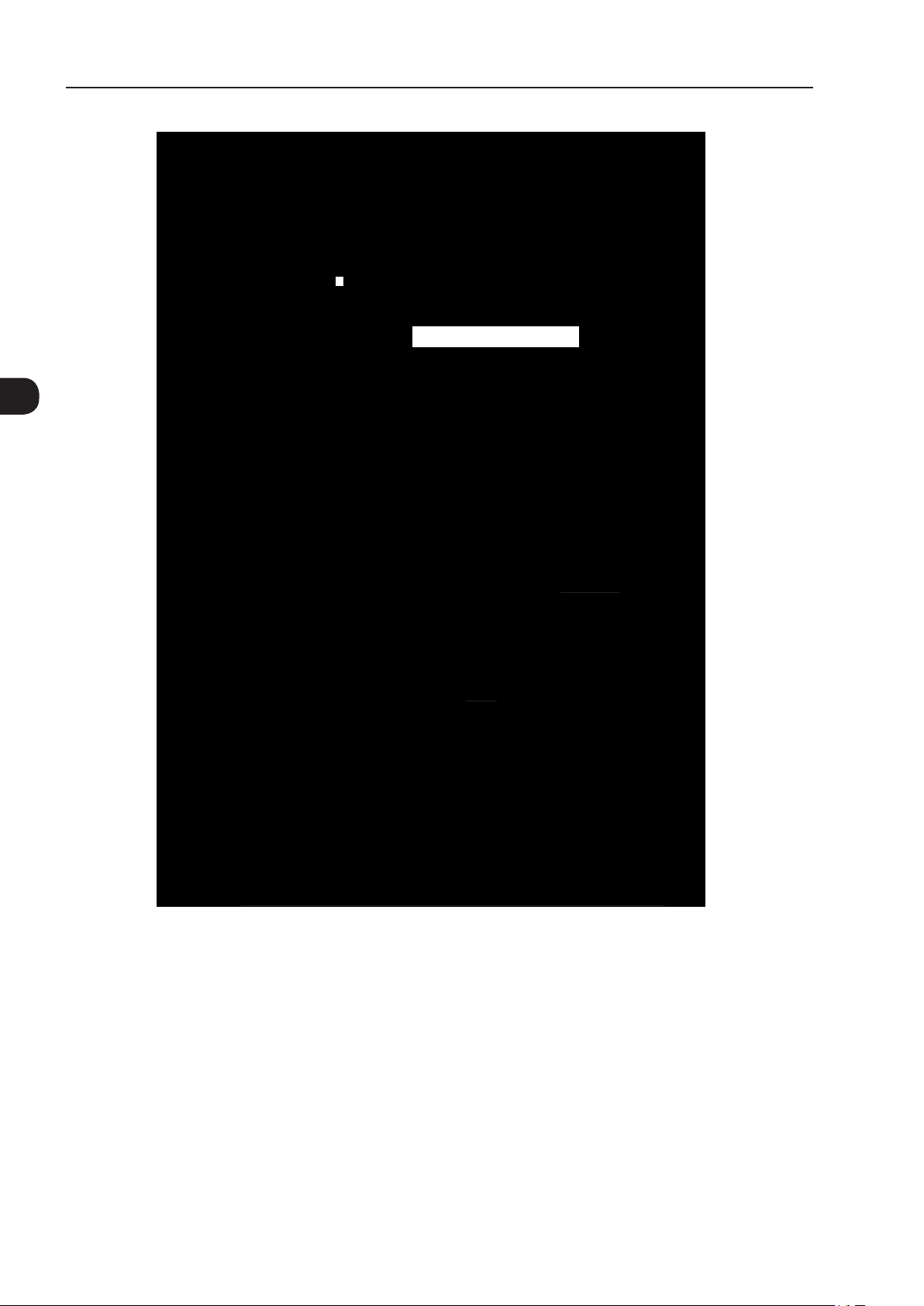

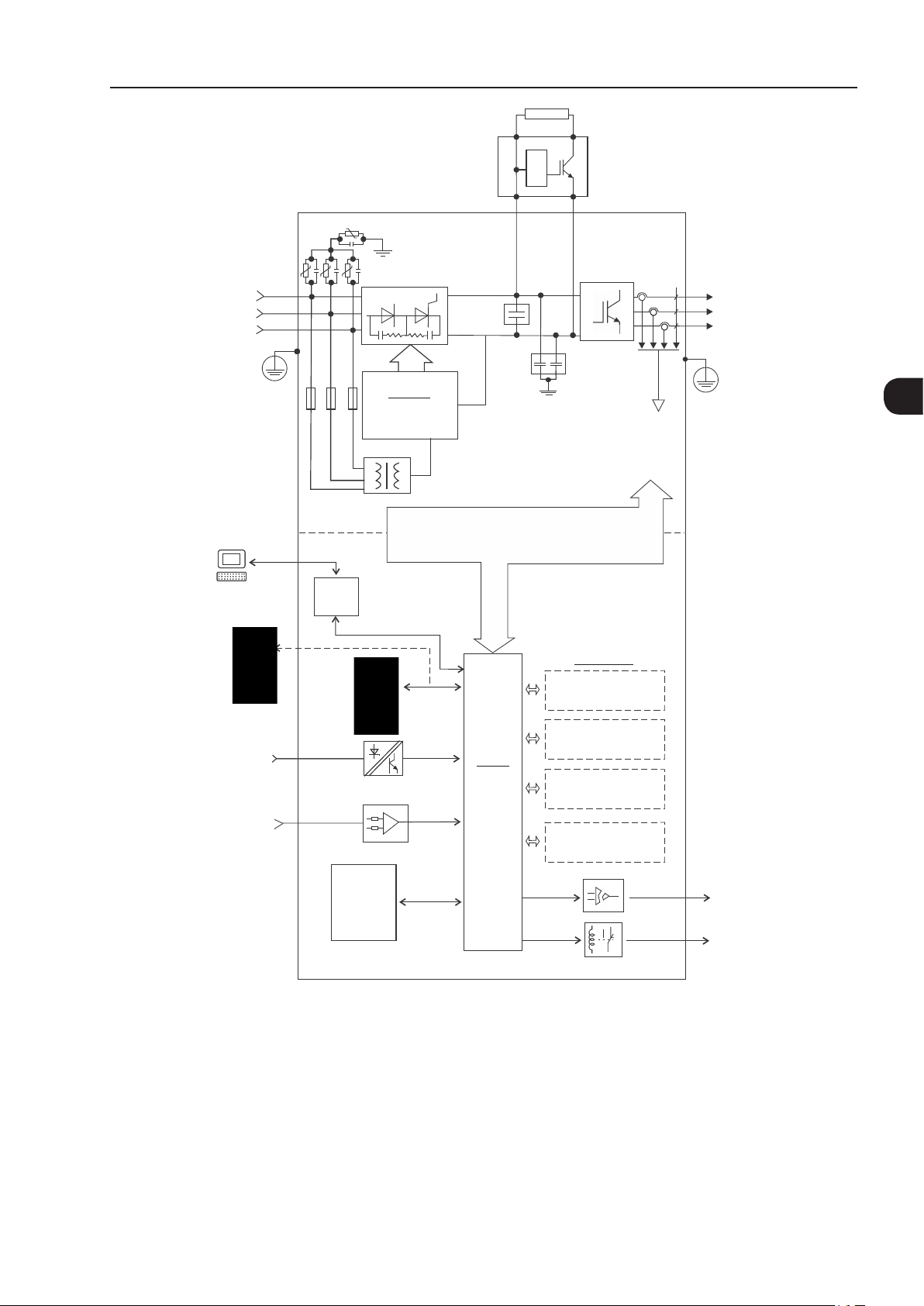

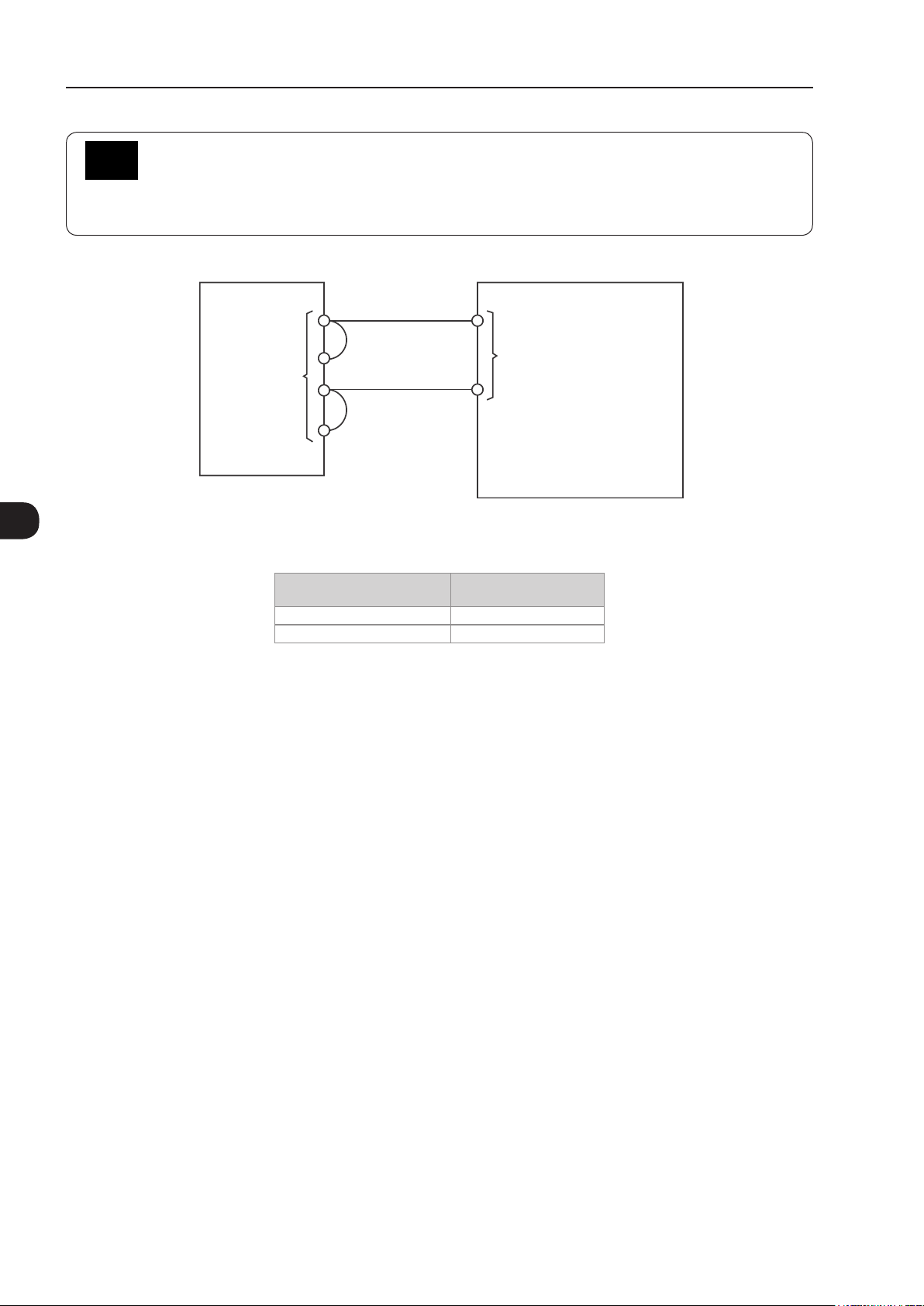

R/L1

Power supply

PC

S/L2

T/L3

PE

RFI filter/MOVs

Three-phase

rectifier

Pre-

charge

(*)

DC Link

chokes

capacitor bank

DC+ DC-BR

DC Link

Power

Control

RFI filter

= DC bus connection

= braking resistor connection

U/T1

V/T2

Motor

W/T3

Inverter

with IGBT

(*)

transistors

PE

Feedback:

- voltage

- current

SuperDrive G2 software

WLP software

Keypad (remote)

Digital inputs

(DI1 to DI6)

Analog inputs

(AI1 and AI2)

(*) The capacitor of RFI filter and MOV connected to the ground must be disconnected with IT network, high impedance grounding network and cornergrounded delta networks. Refer to item Item 3.2.3.1.2 IT Networks on page 3-35.

Figure 2.1 - Block diagram for the CFW -11 - frame sizes B and C

USB

FLASH

memory

module

MMF-03

Control power supply and interfaces

between power and control

Keypad

CC11

Control

board with

a 32 bits

"RISC"

CPU

Encoder interface

(anybus) (Slot 4 )

Accessories

I/O expansion

(Slot 1 - white)

(Slot 2 - yellow)

COMM 1

(Slot 3 - green)

COMM 2

Analog outputs

(AO1 and AO2)

Digital outputs

DO1 (RL1) to

DO3 (RL3)

2-6 | CFW-11

Page 17

General Instructions

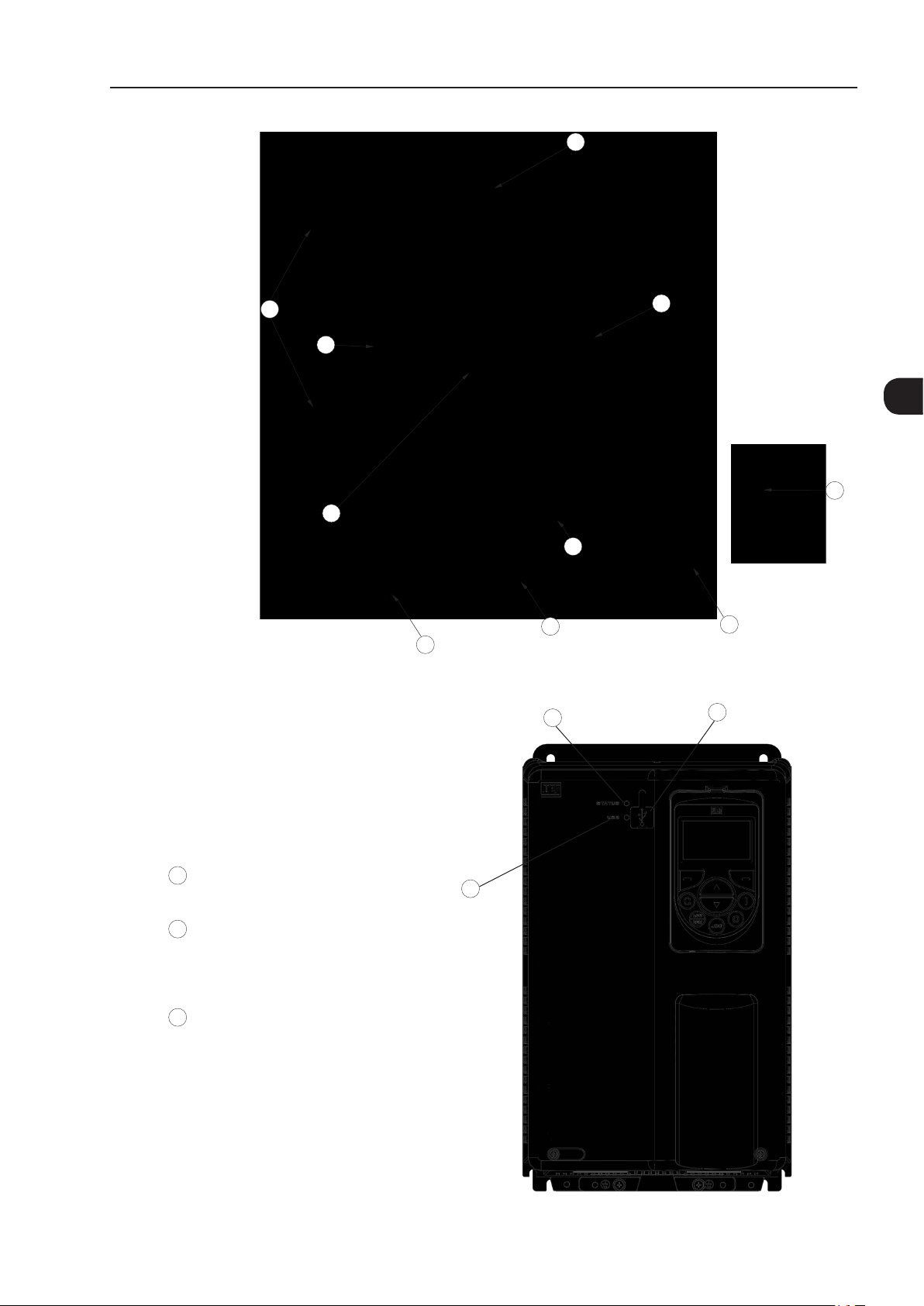

C

A

A - mounting supports

(for through the wall mounting)

B - heatsink

C - top cover

D - fan with mounting support

E - COMM 2 module (anybus)

F - option board/accessory module

G - FLASH memory module MMF-03

H - front cover

I - keypad

J - SRB2A safety stop board

Figure 2.2 - Main components of the CFW-11 - frame sizes B and C

G

B

2

I

J

F

E

D

3

H

1

USB connector

1

USB LED

2

Off: no USB connection

On/Flashing: USB communication is active

3

STATUS LED

Green: normal operation with no fault or alarm

Yellow: alarm condition

Flashing red: fault condition

Figure 2.3 - LEDs and USB connector

2

CFW-11 | 2-7

Page 18

2

General Instructions

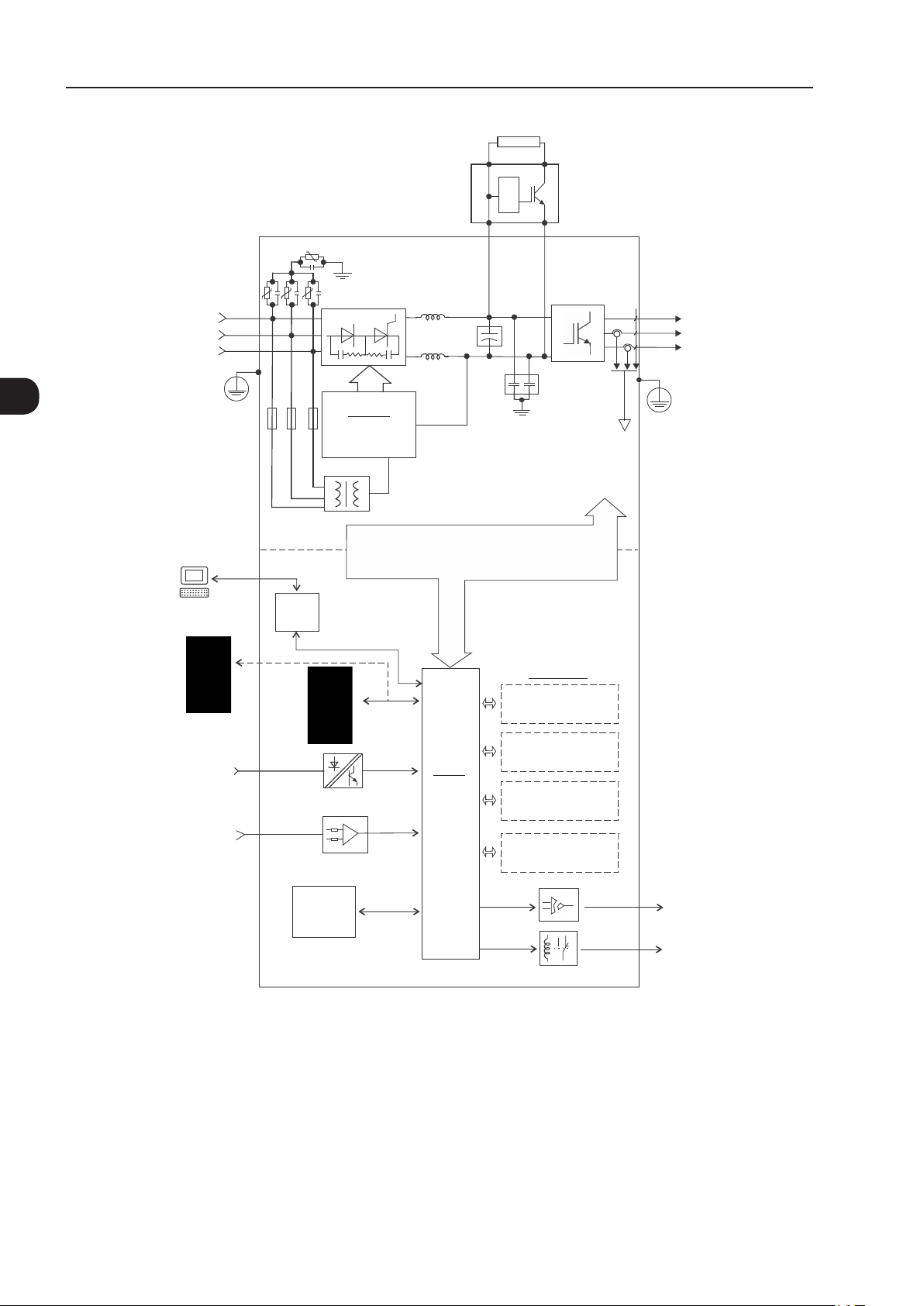

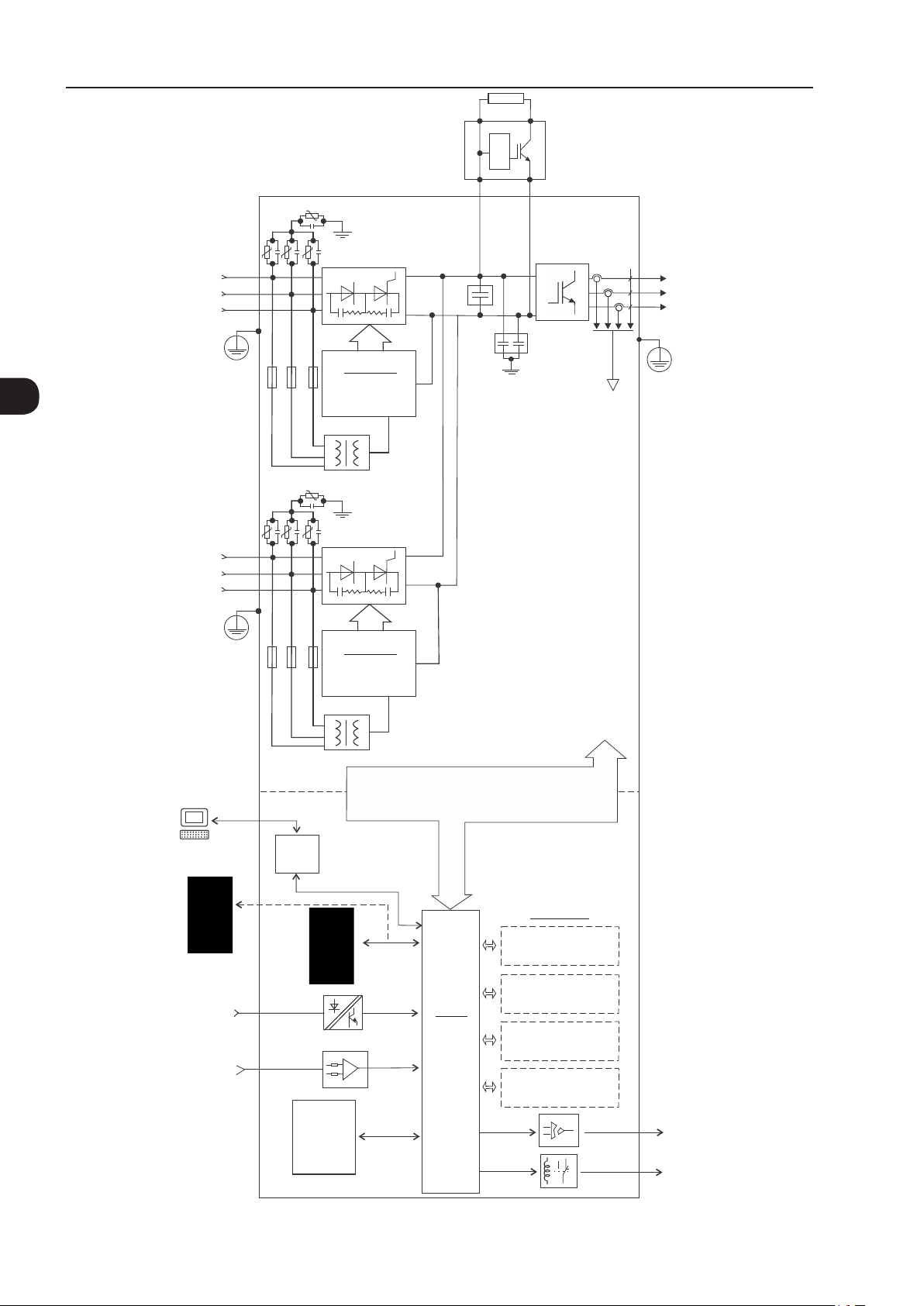

R/L1

Power supply

PC

S/L2

T/L3

PE

RFI filter/MOVs

Three-phase

rectifier

Pre-

charge

(*)

DC Link

chokes

capacitor bank

DC+ DC-BR

DC Link

Power

Control

RFI filter

= DC bus connection

= braking resistor connection

U/T1

V/T2

Motor

W/T3

Inverter

with IGBT

transistors

PE

Feedback:

- voltage

- current

SuperDrive G2 software

WLP software

Keypad (remote)

Digital inputs

(DI1 to DI6)

Analog inputs

(AI1 and AI2)

(*) The capacitor of RFI filter and MOV connected to the ground must be disconnected with IT network, high impedance grounding network and corner-

-grounded delta networks. Refer to Item 3.2.3.1.2 IT Networks on page 3-35.

Figura 2.4 - Block diagram for the CFW -11 - frame sizes D and E

USB

FLASH

memory

module

MMF-03

Control power supply and interfaces

between power and control

Keypad

CC11

Control

board with

a 32 bits

"RISC"

CPU

Encoder interface

(anybus) (Slot 4 )

Accessories

I/O expansion

(Slot 1 - white)

(Slot 2 - yellow)

COMM 1

(Slot 3 - green)

COMM 2

Analog outputs

(AO1 and AO2)

Digital outputs

DO1 (RL1) to

DO3 (RL3)

2-8 | CFW-11

Page 19

General Instructions

I

D

L

J

E

C

B

K

2

A

F

H

G

Inverter with Nema1 kit

(option - only frame size E)

I

M

A - keypad

B - control rack cover

C - CC11 control board

D - FLASH memory module MMF-03

E - control accessory module (refer to the Section 7.2 ACCESSORIES on page 7-2)

F - Anybus-CC accessory module (refer to the Section 7.2 ACCESSORIES on page 7-2)

G - bottom front cover

H - heatsink fan

I - mounting supports (for through the wall mounting)

J - hoisting eye

K - rear part of the inverter (external part for flange mounting)

L - SRB4 safety stop board

M - Nema1 kit - only frame size E

Figure 2.5 - Main components of the CFW-11 - frame sizes D and E

CFW-11 | 2-9

Page 20

General Instructions

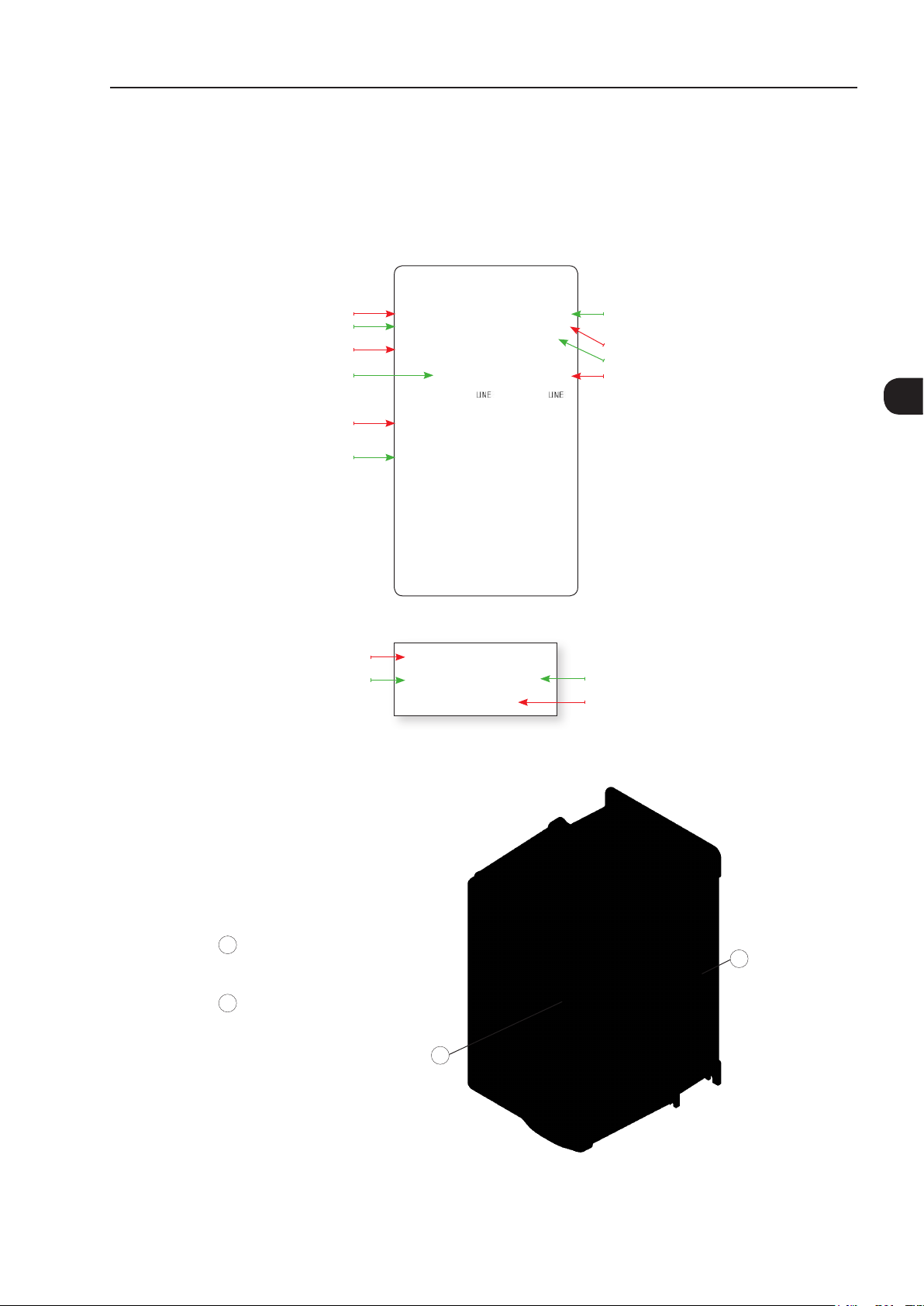

Power

supply

R/L1

S/L2

T/L3

RFI filter/MOVs

Three-phase

rectifier

External braking

module

(Optional)

(*)

DC+

Braking

resistor

DC-

U/T1

V/T2

W/T3

Motor

2

PE

PC

SuperDrive G2 software

WLP software

Keypad (remote)

Digital inputs

(DI1 to DI6)

Analog inputs

(AI1 and AI2)

Power

Control

USB

chokes

CPC 11

Pre-charge

control

Keypad

DC Link

Control power supply and interfaces

between power and control sections

CC11

Control

board with

32-bit

"RISC"

CPU

bank

DC link capacitor

Encoder interface

IGBT

inverter

RFI filter

Accessories

I/O expansion

(Slot 1 - white)

(Slot 2 - yellow)

COMM 1

(Slot 3 - green)

COMM 2

(anybus) (Slot 4)

PE

Feedback:

- voltage

- current

FLASH

memory

module

MMF-03

(*) The capacitor of RFI filter and MOV connected to the ground must be disconnected with IT network, high impedance grounding network and cornergrounded delta networks. Refer to Item 3.2.3.1.2 IT Networks on page 3-35.

(a) Frame sizes F and G CFW-11 block diagram - Standard models with alternating current feeding

Analog outputs

(AO1 and AO2)

Digital outputs

DO1 (RL1) to

DO3 (RL3)

2-10 | CFW-11

Page 21

DC supply

General Instructions

PC

SuperDrive G2 software

WLP software

Keypad (remote)

Digital inputs

(DI1 to DI6)

Analog inputs

(AI1 and AI2)

Power

Control

USB

DC+

DC Link capacitor bank

Control power supply and interfaces

between power and control sections

Keypad

CC11

CC11

Control

board with

32-bit

"RISC" CPU

DC-

IGBT

inverter

Feedback:

- voltage

RFI filter

Accessories

I/O expansion

(Slot 1 - white)

Encoder interface

(Slot 2 - yellow)

COMM 1

(Slot 3 - green)

(anybus) (Slot 4)

- current

COMM 2

U/T1

V/T2

W/T3

PE

Motor

2

FLASH

memory

module

MMF-03

(b) Frame sizes F and G CFW-11 block diagram - Models with DC voltage feeding (Special DC Hardware)

Figure 2.6 - (a) and (b) - Block diagram for the CFW-11 - frame sizes F and G

Analog outputs

(AO1 and AO2)

Digital outputs

DO1 (RL1) to

DO3 (RL3)

CFW-11 | 2-11

Page 22

2

General Instructions

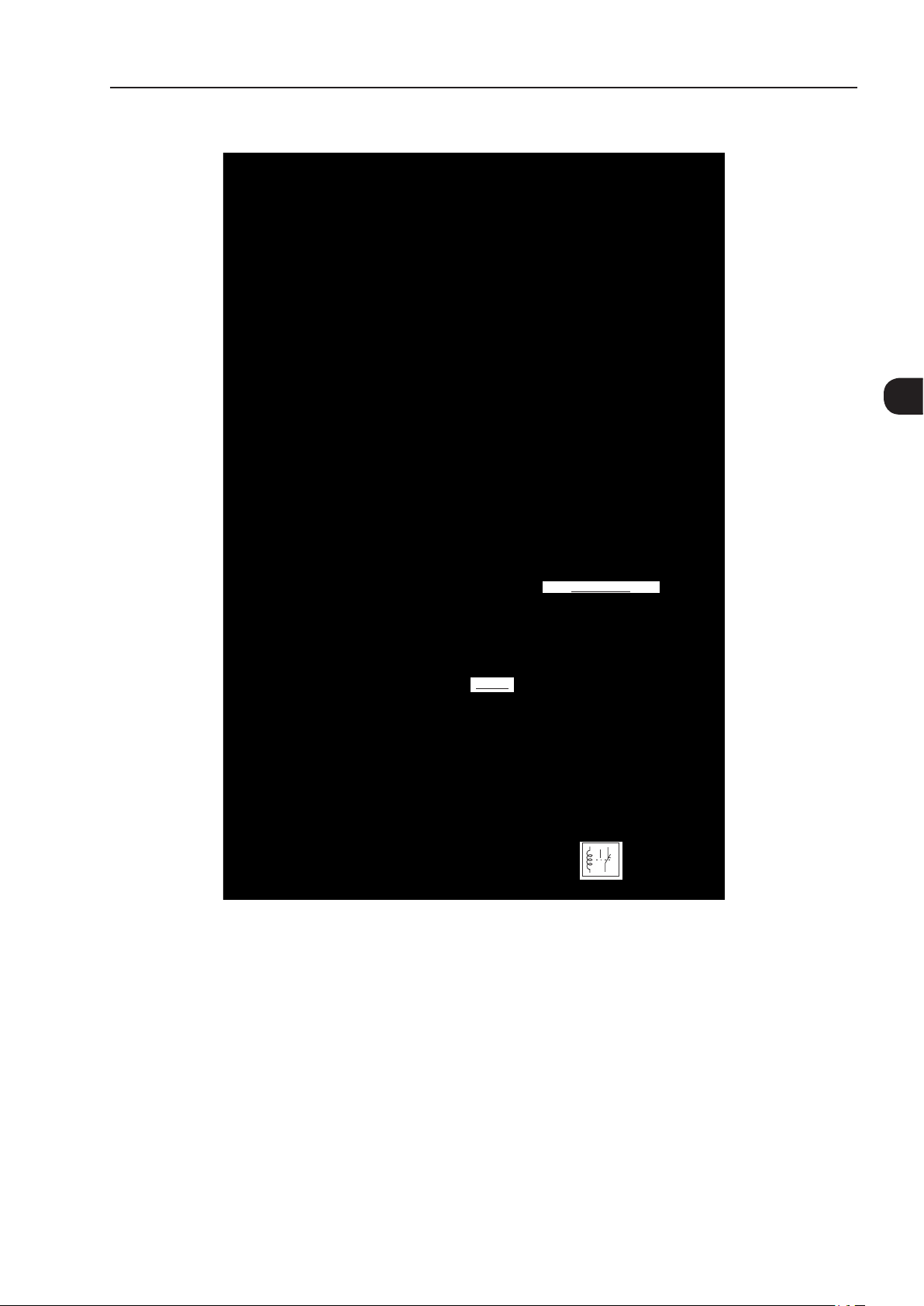

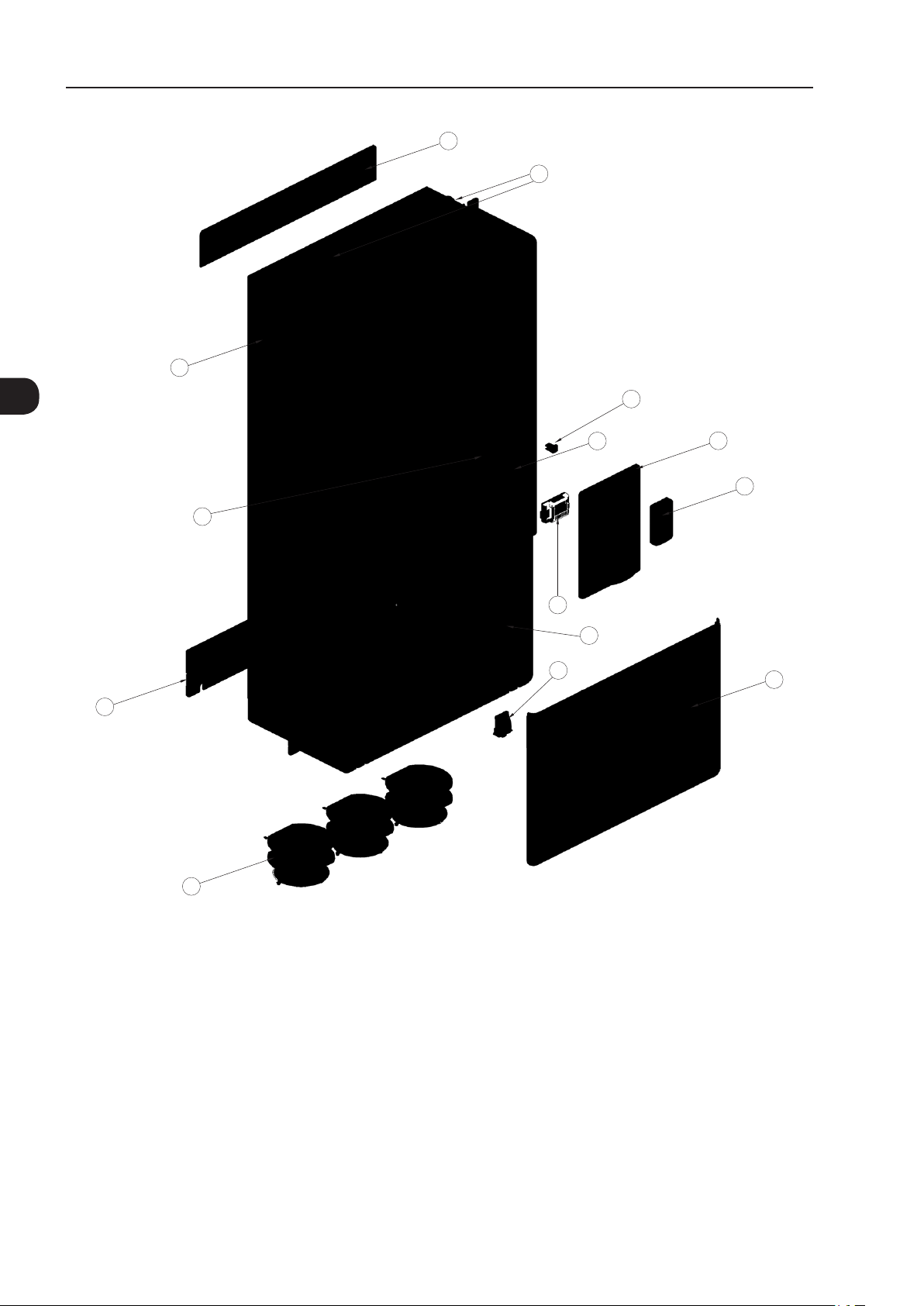

K

I

J

D

C

L

B

A

I

H

A - keypad

B - control rack cover

C - CC11 control board

D - FLASH memory module MMF-03

E - control accessory module

F - Anybus-CC accessory module

G - bottom front cover

H - bheatsink fan

I - mounting supports (for surface mounting)

J - hoisting eye

K - rear part of the inverter (external part for flange mounting)

L - SRB3 safety stop board

E

F

G

2-12 | CFW-11

Figure 2.7 - CFW-11 main components - frame sizes F and G

Page 23

External braking

module

(Accessory)

General Instructions

Braking

resistor

Power

supply

SuperDrive G2 software

WLP software

R/L1

S/L2

T/L3

PE

PC

RFI filter/MOVs

Three-phase

Rectifier

Pre-charge

Power

Control

USB

(*)

CPC 11

control

Control power supply and interfaces

between power and control sections

DC+

RFI filter

DC Link capacitor bank

DC-

IGBT

inverter

Feedback:

- voltage

- current

U/T1

V/T2

W/T3

PE

Motor

2

Accessories

I/O expansion

(Slot 1 - white)

Keypad (remote)

Digital inputs

(DI1 to DI6)

Analog inputs

(AI1 and AI2)

FLASH

memory

module

MMF-03

(*) The RFI filter capacitor and MOV connected to the ground must be disconnected with IT and corner-grounded delta networks. Refer to Item 3.2.3.1.2

IT Networks on page 3-35.

Figure 2.8 - Block diagram of standard models of CFW-11 frame size H (584 A and 625 A models) with alternating current

Keypad

CC11

Control

board with

32-bit

"RISC" CPU

feeding

Encoder interface

(Slot 2 - yellow)

COMM 1

(Slot 3 - green)

COMM 2

(anybus) (Slot 4)

Analog outputs

(AO1 and AO2)

Digital outputs

DO1 (RL1) to

DO3 (RL3)

CFW-11 | 2-13

Page 24

2

General Instructions

R1/L1-1

Power

S1/L2-1

supply

T1/L3-1

PE

RFI filter/MOVs

Three-phase

rectifier

CPC 11-1

Pre-charge

External braking

module

(Accessory)

(*)

control

Braking resistor

DC+

DC Link capacitor bank

DC-

IGBT

inverter

RFI filter

Feedback:

- voltage

- current

U/T1

V/T2

W/T3

Motor

PE

RFI filter/MOVs

R2/L1-2

Power

S2/L2-2

supply

T2/L3-2

PE

Power

PC

SuperDrive G2 software

WLP software

Keypad (remote)

Digital inputs

(DI1 to DI6)

Analog inputs

(AI1 and AI2)

(*) The capacitor of RFI filter and MOV connected to the ground must be disconnected with IT network, high impedance grounding network and

corner-grounded delta networks. Refer to Item 3.2.3.1.2 IT Networks on page 3-35.

Figure 2.9 - Block diagram of standard models of CFW-11 frame size H (758 A and 804 A models) with alternating current

Control

USB

FLASH

memory

module

MMF-03

(*)

Three-phase

rectifier

CPC 11-2

Pre-charge

control

Keypad

Control power supply and interfaces

between power and control sections

Accessories

I/O expansion

(Slot 1 - white)

Encoder interface

CC11

Control

board with

32-bit

"RISC" CPU

(Slot 2 - yellow)

COMM 1

(Slot 3 - green)

COMM 2

(anybus) (Slot 4)

Analog outputs

(AO1 and AO2)

Digital outputs

DO1 (RL1) to

DO3 (RL3)

2-14 | CFW-11

Page 25

DC power supply

General Instructions

PC

SuperDrive G2 software

WLP software

Keypad (remote)

Digital inputs

(DI1 to DI6)

Analog inputs

(AI1 and AI2)

Power

Control

USB

DC+

DC Link capacitor bank

Control power supply and interfaces

between power and control sections

Keypad

CC11

Control

board with

32-bit

"RISC" CPU

DC-

RFI filter

IGBT

inverter

Feedback:

- voltage

- current

Accessories

I/O expansion

(Slot 1 - white)

Encoder interface

(Slot 2 - yellow)

COMM 1

(Slot 3 - green)

COMM 2

(anybus) (Slot 4)

U/T1

V/T2

W/T3

Motor

PE

2

FLASH

memory

module

MMF-03

Figure 2.10 - Block diagram of CFW-11 frame size H models with DC voltage feeding (special hardware DC)

Analog outputs

(AO1 and AO2)

Digital outputs

DO1 (RL1) to

DO3 (RL3)

CFW-11 | 2-15

Page 26

General Instructions

K

I

J

2

D

C

L

E

M

F

I

B

A

G

H

A - keypad

B - control rack cover

C - CC11 control board

D - FLASH memory module MMF-03

E - control accessory module

F - Anybus-CC accessory module

G - bottom front cover

H - heatsink fan

I - mounting supports (for surface mounting)

J - hoisting eye

K - rear part of the inverter (external part for flange mounting)

L - SRB3 safety stop board

M - shield for the control cables

Figure 2.11 - CFW-11 main components - frame size H

2-16 | CFW-11

Page 27

General Instructions

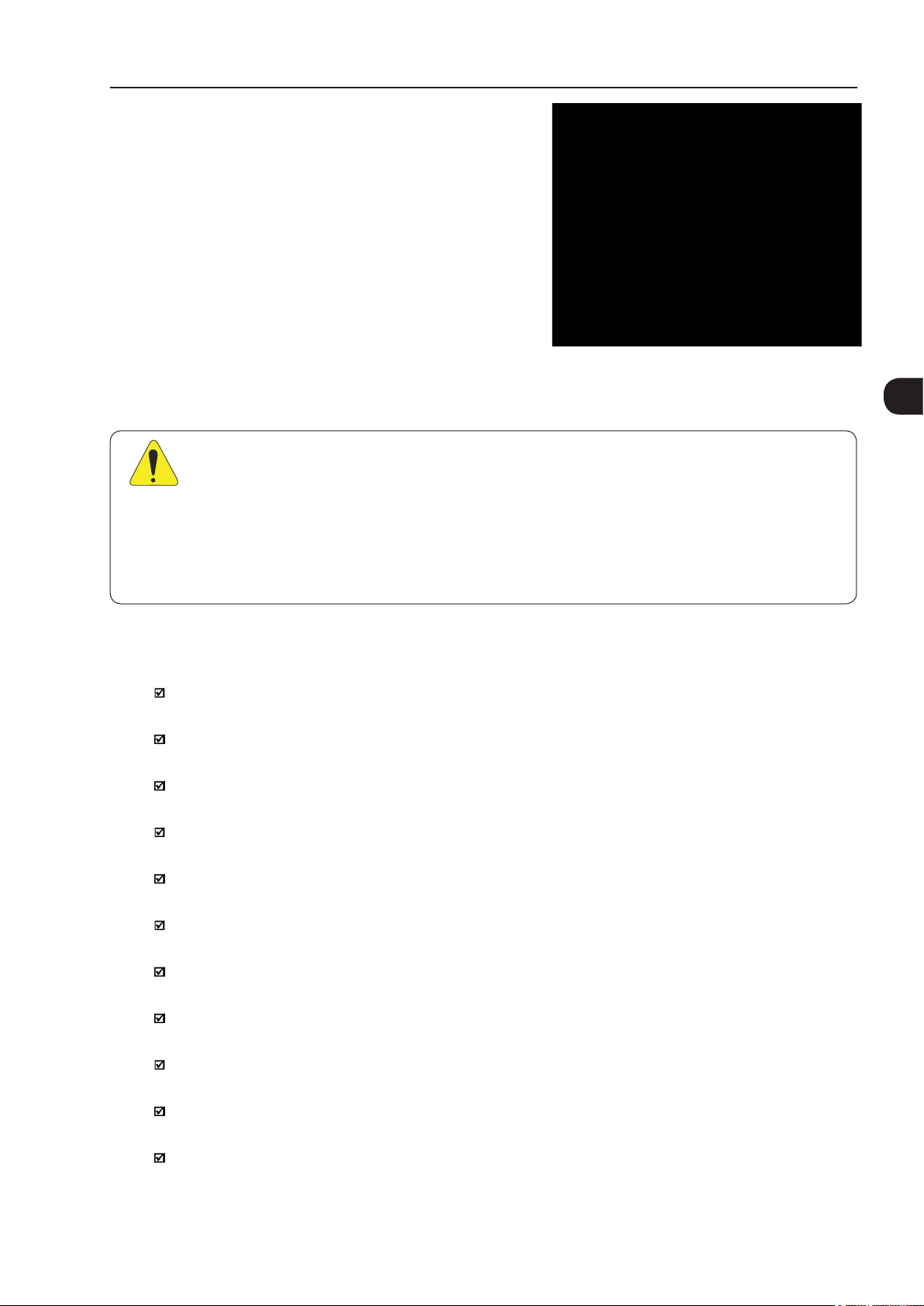

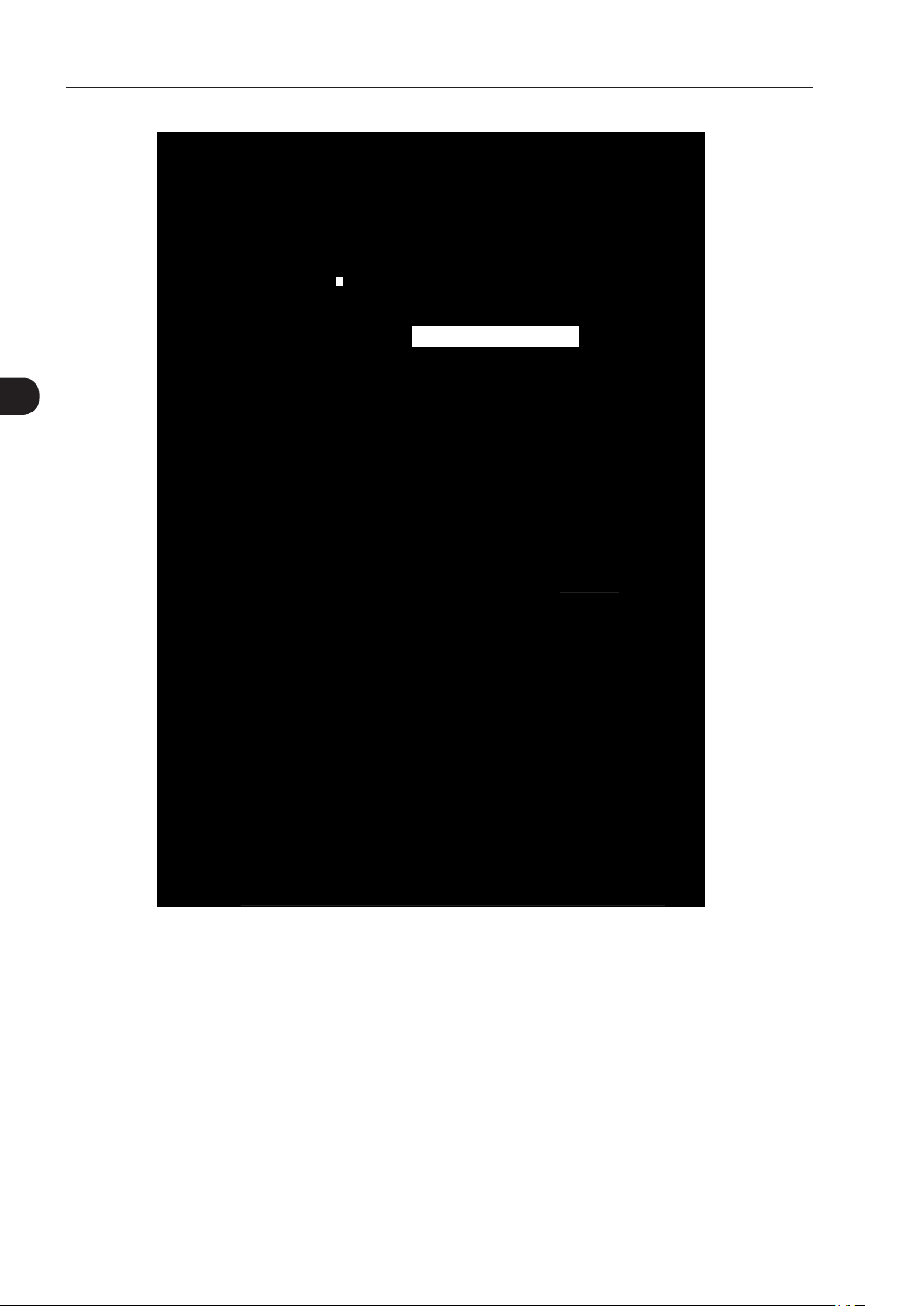

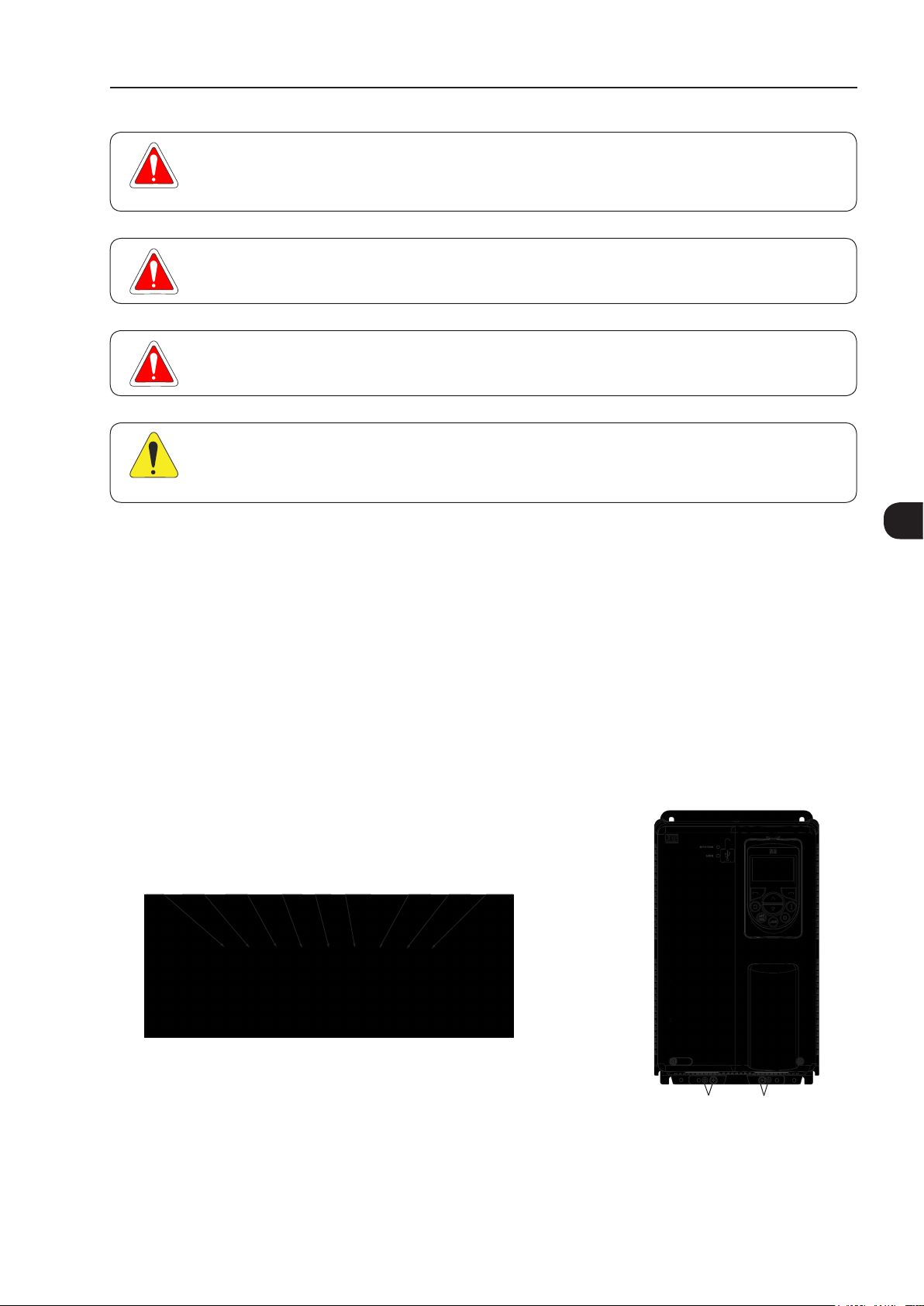

2.4 IDENTIFICATION LABELS FOR THE CFW-11

There are two nameplates on the CFW-11: one complete nameplate is affixed to the side of the inverter and

a simplified one is located under the keypad. The nameplate under the keypad allows the identification of the

most important characteristics of the inverter even if they are mounted side-by-side.

CFW-11 model

WEG part number

Inverter net weight

Rated input data (voltage, number of phases,

rated currents for operation with ND and HD

overload cycles, frequency)

Current specifications for operation with

normal overload cycle (ND)

Current specifications for operation with

heavy overload cycle (HD)

CFW-11 model

WEG part number

Manufacturing date (48 corresponds

to week and H to year)

Serial number

Maximum surrounding air temperature

Rated output data (voltage, number of phases,

rated currents for operation with ND and HD

overload cycles, over load currents for 1 min

and 3 s, frequency range)

(a) Nameplate afxed to the side of the inverter

BRCFW110044T6OYZ

11799018

SERIAL#:

(b) Nameplate located under the keypad

Figure 2.12 - (a) and (b) - Nameplates

1013933619

48 H

Manufacturing date

(48 corresponds to

week and H to year)

Serial number

2

Nameplate affixed to the side of the

1

heatsink

Nameplate under the keypad

2

Figure 2.13 - Location of the nameplates

1

2

CFW-11 | 2-17

Page 28

General Instructions

2

Character

that

identifies

the code

end

Special

software

Special

hardware

power supply for

control

Blank =

standard

E.g.:

S1 =

Blank =

standard

DC= feeding

with DC (only

Blank =

standard (not

available)

W = 24 Vdc

Blank =

standard (Safety

Stop function is

not available)

Blank =

standard

internal

RFI filter

(3)

NB =

without

Blank =

standard

special

software #1

valid for frame

sizes F and G)

H1 = special

hardware #1

external power

supply for control

Y = Safety

Stop according

to EN-954-1

category 3

(5)

NF =

without

RFI filter

(4)

braking

IGBT

(2)

IC = no

keypad

Blank =

standard

(6)

(7)

(1)

N1 = Nema1

Refer to Chapter 7 OPTION KITS AND ACCESSORIES on page 7-1, to check option kit availability for each inverter model

Option kit Enclosure type Keypad (HMI) Braking RFI filter Safety stop 24 Vdc external

Power supply

voltage

Number of

power phases

21 = IP21

Blank =

standard

S =

standard

product

O =

(8)

(9)

6 = 500...690 V

5 = 500...600 V

T = three-

phase power

supply

Inverter Model Available Option Kits (Can Be Installed in the Product from the Factory)

Rated

output

current for

use with

the Normal

Duty (ND)

cycle

According

Table 8.1

on page

8-2 and

(blind cover)

product

with option

kit

Table 8.3

on page

8-4

Refer to Chapter 8 TECHNICAL SPECIFICATIONS on page

8-1, for a list of models for the CFW-11 series and for a

complete inverter's technical specification

HOW TO CODIFY THE CFW-11 MODEL (CODIFICATION)

2-18 | CFW-11

Example BR CFW11 0044 T 6 S _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Z

WEG

Market

Field

CFW-11

frequency

inverter

series

identification

(defines

the manual

language and

description

the factory

settings)

2 characters

Available

options

(1) Standard for frame sizes B and C: IP21.

Standard for frame size D: IP20/NEMA1.

Standard for frame sizes E, F, G and H: IP20.

Standard for frame sizes F, G and H with special hardware DC: IP00.

(2) Standard keypad (HMI-CFW11).

(3)Braking transistor (IGBT) is incorporated in all models of frame sizes B, C, D, and E as standard.

(4) Only valid for frame sizes D and E.

(5) Only valid for frame sizes B, C and D.

(6) Only valid for frame sizes B, C, D and E.

(7) Only valid for frame sizes D, E, F and G.

(8) Only valid for frame sizes B and C.

(9) Only valid for frame sizes D, E, F, G and H.

Page 29

General Instructions

2.5 RECEIVING AND STORAGE

The CFW-11 is packaged and shipped in a cardboard box for models of frames B, and C.

The frame sizes D, E, F, G and H models are supplied packed in wooden boxes.

There is an identification label affixed to the outside of the package, identical to the one affixed to the side of

the inverter.

To open the package:

1. Remove the package front cover.

2. Take out the polystyrene foam protection.

Verify whether:

1. The CFW-11 nameplate corresponds to the purchased model.

2. Any damage occurred during transportation.

Report any damage immediately to the carrier that delivered your CFW-11 inverter.

If the CFW-11 is not installed soon, store it in a clean and dry location (temperature between -25 °C and 60 °C

(-13 °F and 140 °F), with a cover to prevent dust accumulation inside it.

ATTENTION!

When the inverter is stored for a long period, it becomes necessary to perform the capacitor reforming.

Refer to the procedure in the Section 6.5 PREVENTIVE MAINTENANCE on page 6-9 in the Table

6.3 on page 6-9.

2

CFW-11 | 2-19

Page 30

2

General Instructions

2-20 | CFW-11

Page 31

3 INSTALLATION AND CONNECTION

This chapter provides information on installing and wiring the CFW-11.

The instructions and guidelines listed in this manual shall be followed

to guarantee personnel and equipment safety, as well as the proper

operation of the inverter.

3.1 MECHANICAL INSTALLATION

3.1.1 Installation Environment

NOTE!

The inverter are designed for indoor use only.

Avoid:

Installation and Connection

Direct exposure to sunlight, rain, high humidity, or sea-air.

Inflammable or corrosive gases or liquids.

Excessive vibration.

Dust, metallic particles, and oil mist.

Environment conditions for the operation of the inverter:

Temperature (standard conditions (surrounding the inverter), no frost allowed):

- 10 ºC to 50 ºC (14 ºF to 122 ºF) for frame sizes B, C and D models.

- 10 ºC to 45 ºC (14 ºF to 113 ºF) for frame sizes E, F and G models.

- 10 ºC to 40 ºC (14 ºF to 104 ºF) for frame size H.

From 40 ºC to 45 ºC (104 ºF to 113 ºF) for frame size H: 1 % of current derating for each Celsius degree

above maximum temperature as specified in item above.

From 50 ºC to 60 ºC (122 °F to 140 °F) for frame sizes B, C and D models and from 45 ºC to 55 ºC (113

ºF to 131 ºF) for frame sizes E, F, G and H models: 2 % of current derating for each Celsius degree above

maximum temperature as specified in item above.

3

Altitude: up to 1000 m (3.300 ft) above sea level - standard conditions (no derating required).

From 1000 m to 4000 m (3.300 ft to 13.200 ft) above sea level - 1 % of current derating for each 100 m

(330 ft) above 1000 m (3.300 ft) altitude.

CFW-11 | 3-1

Page 32

Installation and Connection

From 2000 m to 4000 m (6.600 ft to 13.200 ft) above sea level - reduction of maximum voltage (600 V for

500...600 V models and 690 V for 500...690 V models) of 1.1 % for each 100 m (330 ft) above 2000 m

(6.600 ft).

Note that derating specified in items above applies also to dynamyc braking IGBT (columm effective braking

current (I

Humidity: from 5 % to 95 % non-condensing.

Pollution degree: 2 (according to EN50178 and UL508C) with non-conductive pollution. Condensation

shall not originate conduction through the accumulated residues.

) of Table 3.10 on page 3-40).

effective

3.1.2 Mounting Considerations

Consult the inverter weight at the Table 8.1 on page 8-2, Table 8.2 on page 8-3, Table 8.3 on page 8-4

and Table 8.4 on page 8-5.

3

Mount the inverter in the upright position on a flat and vertical surface.

External dimensions and fixing holes position according to the Figure 3.1 on page 3-3, Figure 3.2 on page

3-4 and Figure 3.2 on page 3-4. Refer to the Section 8.5 MECHANICAL DATA on page 8-9, for more

details.

First mark the mounting points and drill the mouting holes. Then, position the inverter and firmly tighten the

screws in all four corners to secure the inverter.

Minimum mounting clearances requirements for proper cooling air circulation are specified in Figure 3.3 on page

3-5, Figure 3.5 on page 3-9 and Figure 3.4 on page 3-6.

Inverters of frame sizes B and C can be arranged side-by-side with no clearance required between them. In this

case, the top cover must be removed as shown in Figure 3.3 on page 3-5.

Do not install heat sensitive components right above the inverter.

ATTENTION!

When arranging two or more inverters vertically, respect the minimum clearance A + B (Figure 3.3 on

page 3-5, Figure 3.5 on page 3-9 and Figure 3.4 on page 3-6) and provide an air deflecting

plate so that the heat rising up from the bottom inverter does not affect the top inverter.

ATTENTION!

3-2 | CFW-11

Provide conduit for physical separation of the signal, control, and power conductors (refer to Section

3.2 ELECTRICAL INSTALLATION on page 3-14).

Page 33

Installation and Connection

B1

b2

A1

E1

(a) Dimension external

a2

C1

D1

a3

3

b3c3

e3

Air flow

(b) Montagem em superfície (c) Montagem em ange

A1 B1 C1 D1 E1 a2 b2 c2 a3 b3 c3 d3 e3 f3 Torque

Model

Frame

Size B

Frame

Size C

Frame

Size D

Tolerances for dimensions d3 and e3: +1.0 mm (+0.039 in).

Tolerances for remaining dimensions: ±1.0 mm (±0.039 in).

(*) Recommended torque for the inverter mounting (valid for c2 and f3).

mm

(in)mm(in)mm(in)

190

(7.48)

220

(8.67)

300

(11.81)

293

(11.53)

378

(14.88)

504

(19.84)

mm

(in)mm(in)mm(in)mm(in)

227

(8.94)71(2.79)

293

(11.52)

305

(12.00)

Figure 3.1 - (a) to (c) - Mechanical installation details - frame sizes B, C and D

136

(5.36)

135

(5.32)

∅ c2

316

(12.44)

405

(15.95)

550

(21.65)

150

(5.91)

150

(5.91)

200

(7.88)

300

(11.81)

375

(14.77)

525

(20.67)

Air flow

M

M5

M6

M8

mm

(in)

175

(6.89)

195

(7.68)

275

(10.83)

Max. 3 mm

(0.12 in)

mm

(in)mm(in)mm(in)mm(in)

255

(10.04)

142.5

(5.61)

182.5

(7,18)

262

(10.31)

180

(7.09)

206

(8.11)

287

(11.30)

d3

∅ c3

272

(10.71)

346

(13.62)

487

(19.17)

M

M5

M6

M8

N.m

(lbf.in)

5.0

(44.2)

8.5

(75.2)

20.0

(177.0)

(*)

CFW-11 | 3-3

Page 34

Installation and Connection

A1

B1

C1

3

B1

a2 a2

a2 a2

A1

E1

E1

(a) Dimension external

D1

C1

a3

a3

b2

b2

∅ c2

Air flow Air flow

(b) Surface mounting (c) Flange mounting

A1 B1 C1 D1 E1 a2 b2 c2 a3 b3 c3 d3 e3

Model

Frame

Size E

Frame

Size F

Frame

Size G

Frame

Size H

Tolerance for dimensions d3 and e3: +1.0 mm (+0.039 in).

Tolerance for remaining dimensions: ±1.0 mm (±0.039 in).

mm

(in)

335

(13.2)

430

(16.93)

535

(21.06)

686.0

(27.00)

mm

(in)

375

(26.6)

1156

(45.51)

1190

(46.85)

1319.7

(51.96)

mm

(in)

358

(14.1)

360

(14.17)

426

(16.77)

420.8

(16.57)

mm

(in)

168 (6.6)

169

(6.65)

202

(7.95)

171.7

(6.76)

(48.58)

(49.76)

1414.0

(55.67)

Figure 3.2 - (a) to (c) - Mechanical installation details - frame sizes E, F, G and H

c2

mm

(in)

620

(24.4)

1234

1264

mm

(in)

200 (7.8)

150

(5.91)

200

(7.87)

175.0

(6.89)

mm

(in)

650

(25.6)

1200

(47.24)

1225

(48.23)

1350.0

(53.15)

Max. 3 mm

Max. 3mm (0.12)

(0.12)

M

M8

M10

M10

M10

mm

(in)

275

(10.8)

350

(13.78)

400

(15.75)

595.0

(23.43)

b3

b3

d3

d3

c3

∅ c3

mm

(in)

M

635 (25) M8

1185

(46.65)

1220

(48.03)

1345.0

(52.95)

M10

M10

M10

e3

e3

mm

(in)

315

(24.21)

391

(15.39)

495

(19.49)

647.0

(25.47)

mm

(in)

615

(24.21)

1146

(45.12)

1182

(46.53)

1307.0

(51.46)

3-4 | CFW-11

Page 35

Installation and Connection

A

B

(a) Minimum top, bottom, and front clearance requirements for air circulation

(1.18) 30 (1.18) 30

C

A B C

Model

Frame

Size B

Frame

Size C

Frame

Size D

Tolerance: ±1.0 mm (±0.039 in)

mm

(in)

40

(1.57)45(1.77)10(0.39)

110

(4.33)

110

(4.33)

mm

(in)

130

(5.12)10(0.39)

130

(5.12)10(0.39)

mm

(in)

3

* Dimensions in mm [in]

(b) Minimum side clearance requirements

(c) Only frame sizes B and C: side-by-side mounting - No clearance required between inverters if top cover is removed

Figure 3.3 - (a) to (c) - Free spaces around inverter for ventilation - frame sizes B, C and D

CFW-11 | 3-5

Page 36

Installation and Connection

D D

A

AB

3

C

B

C

3-6 | CFW-11

D D

A B C D

Model

Frame Sizes

E, F, G and H

Tolerance: ±1.0 mm (±0.039 in).

Figure 3.4 - Free spaces around inverter for ventilation - frame sizes E, F, G and H

mm

(in)

150

(5.91)

mm

(in)

250

(9.84)

mm

(in)

20

(0.78)

mm

(in)

80

(3.15)

Page 37

Installation and Connection

3.1.3 Cabinet Mounting

There are two possibilities for mounting the inverter: through the wall mounting or flange mounting (the heatsink

is mounted outside the cabinet and the cooling air of the power module is kept outside the enclosure). The

following information shall be considered in these cases:

Surface Mounting:

Provide adequate exhaustion so that the internal cabinet temperature is kept within the allowable operating

range of the inverter.

The power dissipated by the inverter at its rated condition, as specified in Table 8.1 on page 8-2 to Table

8.4 on page 8-5 "Dissipated power in Watts - through the wall mounting".

The cooling air flow requirements, as shown in Table 3.1 on page 3-8.

The position and diameter of the mounting holes, according to Figure 3.1 on page 3-3, Figure 3.2 on

page 3-4 and Figure 3.2 on page 3-4.

Flange Mounting:

Frame Sizes B, C and D:

The losses specified in Table 8.1 on page 8-2 and Table 8.3 on page 8-4 "Dissipated power in Watts -

flange mounting" will be dissipated inside the cabinet. The remaining losses (power module) will be dissipated

through the vents.

The mounting supports shall be removed and repositioned as illustrated in Figure 3.5 on page 3-9.

The portion of the inverter that is located outside the cabinet is rated IP54. Provide an adequate gasket for

the cabinet opening to ensure that the enclosure rating is maintained. Example: silicone gasket.

Mounting surface opening dimensions and position/diameter of the mounting holes, as shown in Figure 3.1

on page 3-3.

Frame Size E:

3

The losses specified in Table 8.1 on page 8-2 and Table 8.3 on page 8-4 "Dissipated power in Watts -

flange mounting" will be dissipated inside the cabinet. The remaining losses (power module) will be dissipated

through the vents.

The inverter securing supports (position I of Figure 2.5 on page 2-9) and the hoisting eyes (position J of

Figure 2.5 on page 2-9) must be removed and repositioned according to the Figure 3.6 on page 3-10

and Figure 3.7 on page 3-10.

For models 53 A, 63 A, 80 A and 107 A, the portion of the inverter that is located outside the cabinet

is rated IP54. Provide an adequate gasket for the cabinet opening to ensure that the enclosure rating is

maintained. Example: silicone gasket.

CFW-11 | 3-7

Page 38

3

Installation and Connection

Mounting surface opening dimensions and position/diameter of the mounting holes, as shown in Figure 3.2

on page 3-4.

Frame Sizes F, G and H:

ATTENTION!

The part of the inverter that stays outside the cabinet is rated IP20.

The power specified in Table 8.1 on page 8-2 to Table 8.4 on page 8-5 under "Dissipated power in

Watts - flange mounting" will be dissipated inside the cabinet. Use Table 8.1 on page 8-2 and Table 8.3

on page 8-4 for inverters with AC power supply and Table 8.2 on page 8-3 and Table 8.4 on page

8-5 for inverters with DC power supply. The other losses (power modules) will be dissipated at the external

ventilation duct.

The inverter mounting supports and the hoisting eyes must be removed. Refer to the Figure 3.8 on page

3-11, positions I and J.

Dimensions of the flange-mounting opening and the diameters of the securing holes must be according to

the Figure 3.2 on page 3-4.

Table 3.1 - Minimum required cabinet cooling air ow

Frame Size CFM I/s m³/min

B 42 20 1.2

C 96 45 2.7

D 132 62 3.7

E 265 125 7.5

F 460 217 13

G 680 321 19.3

H 1100 520 31.2

3-8 | CFW-11

Page 39

Installation and Connection

321

654

3

Figure 3.5 - Repositioning the mounting supports - frame sizes B, C and D

CFW-11 | 3-9

Page 40

Installation and Connection

3

21

3

654

Figure 3.6 - Repositioning the mounting supports - frame size E

3.1.4 Installation of the Inverter Hoisting Eyes - Frame Size E

Two hoisting eyes for the inverter lifting, which are mounted at the inverter sides (rear part), are supplied. By

inverting their position, as shown in Figure 3.7 on page 3-10, two points for hoisting the inverter, which are

very useful during the mechanical installation of the inverter, are obtained.

3-10 | CFW-11

Figure 3.7 - Installation of the inverter hoisting eyes frame size E

Page 41

Installation and Connection

3.1.5 Installation of the Inverter with Nema1 Kit (Option, CFW11....T...ON1...) on a Wall -

Frame Size E

Fixing holes position and diameter according to the Figure 3.2 on page 3-4 for frame size E models.

External dimensions of the inverter with Nema1 kit according to Section 8.6 NEMA 1 KITs on page 8-16.

Fasten the inverter.

Install the Nema1 kit on the inverter as shown in Figure 3.8 on page 3-11 using the two M8 screws supplied

with the product.

3

Figure 3.8 - Installation of the Nema1 kit in frame size E model

3.1.6 Access to the Control and Power Terminal Strips

Frame Sizes B and C:

It is necessary to remove the keypad and the front cover in order to get access to the control and power terminal

strips.

321

Figure 3.9 - Removal of keypad and front cover - frame sizes B and C

CFW-11 | 3-11

Page 42

Installation and Connection

Frame Sizes D and E:

It is necessary to remove the keypad (HMI) and the control rack cover in order to get access to the control

terminal strip (see Figure 3.10 on page 3-12). In order to get access to the power terminal strip, remove the

bottom front cover (see Figure 3.11 on page 3-12).

1 2 3

3

Figure 3.10 - HMI and control rack cover removal - frame sizes D and E

1 2

Figure 3.11 - Bottom front cover removal - frame sizes D and E

3-12 | CFW-11

Page 43

Installation and Connection

Frame Sizes F, G and H:

In order to get access to the control terminals, it is necessary to remove the HMI and the control rack cover, as

showed in Figure 3.12 on page 3-13.

1 2 3

Figure 3.12 - Removal of the HMI and the control rack cover - frame sizes F, G and H

In order to get access to the power terminals, it is necessary to remove the bottom front cover, as shown in

Figure 3.13 on page 3-13.

1 2

Figure 3.13 - Removal of the bottom front cover, to access to the power supply and motor connection terminals -

frame sizes F, G and H

In order to connect the power cables (line and motor), remove the bottom plate, as shown in Figure 3.14 on

page 3-13. In this case the protection degree of the inverter bottom part will be reduced.

3

Figure 3.14 - Removal of the bottom plate, to access the power terminals - frame sizes F, G and H

CFW-11 | 3-13

Page 44

Installation and Connection

3.1.7 Removal of the Cable Passage Plate - Frame Sizes D and E

When it is not necessary neither IP20 nor Nema1 protection degree, the cable passage plate may be removed

in order to make the inverter electric installation easier. Remove the four M4 screws, according to the procedure

presented in Figure 3.15 on page 3-14.

3

1

2

3

Figure 3.15 - Removal of the cable passage plate - frame sizes D and E

3.1.8 HMI Installation at the Cabinet Door or Command Panel (Remote HMI)

28.5 [1.12]

23.5

[0.93]

113.0 [4.45]

65.0 [2.56]

35.0 [1.38]

103.0 [4.06]

23.4 [0.92]

16.0 [0.63]

∅4.0 [0.16] (3X)

Figure 3.16 - Data for the HMI installation at the cabinet door or command panel - mm [in]

The keypad frame accessory can also be used to fix the HMI, as mentioned in Table 7.1 on page 7-3.

3.2 ELECTRICAL INSTALLATION

DANGER!

The following information is merely a guide for proper installation. Comply with applicable local

regulations for electrical installations.

3-14 | CFW-11

Page 45

DANGER!

Les informations suivantes constituent uniquement un guide pour une installation correcte. Respectez

les réglementations locales en vigueur pour les installations électriques.

DANGER!

Make sure the AC power supply is disconnected before starting the installation.

DANGER!

Vérifiez que l'alimentation secteur CA est débranchée avant de commencer l'installation.

ATTENTION!

Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit

protection must be provided in accordance with applicable local codes.

3.2.1 Identification of the Power and Grounding Terminals

Installation and Connection

3

R/L1, S/L2, T/L3: AC power supply connection.

U/T1, V/T2, W/T3: motor connection.

DC-: this is the negative potential terminal in the DC bus circuit.

BR: braking resistor connection (frame sizes B, C, D and E only).

DC+: this is the positive potential terminal in the DC bus circuit.

R/L1 S/L2 T/L3

BR

DC+DC-

U/T1

V/T2

W/T3

Figure 3.17 - Grounding and power terminals of frame sizes B and C models

Grounding

CFW-11 | 3-15

Page 46

Installation and Connection

3

R/L1 S/L2 T/L3

DC+DC-

BR

Figure 3.18 - Grounding and power terminals of frame size D models

U/T1

V/T2

W/T3

Grounding

3-16 | CFW-11

Grounding

(4xM8, 4xM5)

Figure 3.19 - Grounding and power terminals of frame size E models

Page 47

Installation and Connection

(a) Terminals for AC power supply and motor connection (terminals R/L1, S/L2 and T/L3 are not assembled in inverters with

special hardware DC)

3

DC-

DC+

(b) Terminals for DC power supply connection (only available in inverters with special hardware DC)

Figure 3.20 - (a) and (b) - Grounding and power terminals of frame size F models

CFW-11 | 3-17

Page 48

Installation and Connection

3

U/T1

R/L1

(a) Terminals for AC power supply and motor connection (terminals R/L1, S/L2 and T/L3 are not assembled in inverters with

special hardware DC)

V/T2

S/L2

DC-

W/T3

T/L3

DC+

(b) Terminals for DC power supply connection (only available in inverters with special hardware DC)

3-18 | CFW-11

Figure 3.21 - (a) and (b) - Grounding and power terminals of frame size G models

Page 49

Installation and Connection

(a) Models 584 and 625 A (b) Models 758 A and 804 A

DC-

DC+

3

(c) Frame size H

Figure 3.22 - (a) to (c) - Grounding and power terminals of frame size H models

CFW-11 | 3-19

Page 50

3

Installation and Connection

3.2.2 Power/Grounding Wiring and Fuses

ATTENTION!

Use proper cable lugs for the power and grounding connection cables.

ATTENTION!

Sensitive equipment such as PLCs, temperature controllers, and thermal couples shall be kept at a

minimum distance of 0.25 m (9.84 in) from the frequency inverter and from the cables that connect

the inverter to the motor.

DANGER!

Wrong cable connection:

- The inverter will be damaged if the power supply is connected to the output terminals (U/T1, V/T2,

or W/T3).

- Check all the connections before powering up the inverter.

- When replacing an existing inverter by a CFW-11, check if the installation and wiring is according

to the instructions listed in this manual.

DANGER!

Mauvaise connexion des câbles:

- Le variateur sera endommagé si l’alimentation d’entrée est connectée aux bornes de sortie (U/T1,

V/T2 ou W/T3).

- Vérifier toutes les connexions avant de mettre le variateur sous tension.

- En cas de remplacement d’un variateur existant par un CFW-11, vérifier si l’installation et le câblage

sont conformes aux instructions figurant dans ce manuel.

ATTENTION!

Residual Current Device (RCD):

- When installing an RCD to guard against electrical shock, only devices with a trip current of 300 mA

should be used on the supply side of the inverter.

- Depending on the installation (motor cable length, cable type, multimotor configuration, etc.), RCD

nuisance trips may occur. Contact the RCD manufacturer for selecting the most appropriate device

to be used with inverters.

NOTE!

The wire gauges listed in Table 3.2 on page 3-21 are orientative values. Installation conditions and

the maximum permitted voltage drop must be considered for the proper wiring sizing.

3-20 | CFW-11

Page 51

Installation and Connection

Input fuses:

Use High Speed Fuses at the input for the protection of the inverter rectifier and wiring refer to Table 3.2 on

page 3-21 for selecting the appropriate fuse rating (I2t must be equal to or less than indicated in Table 3.2

on page 3-21, consider the cold (and not the fusion) current extinction value).

In order to meet UL requirements, use class J fuses at the inverter supply with a current not higher than the

values of Table 3.2 on page 3-21.

Optionally, slow blow fuses can be used at the input they must be sized for 1.2 x the inverter rated input

current. In this case, the installation is protected against short-circuit, but not the inverter input rectifier. This

may result in major damage to the inverter in the event of an internal component failure.

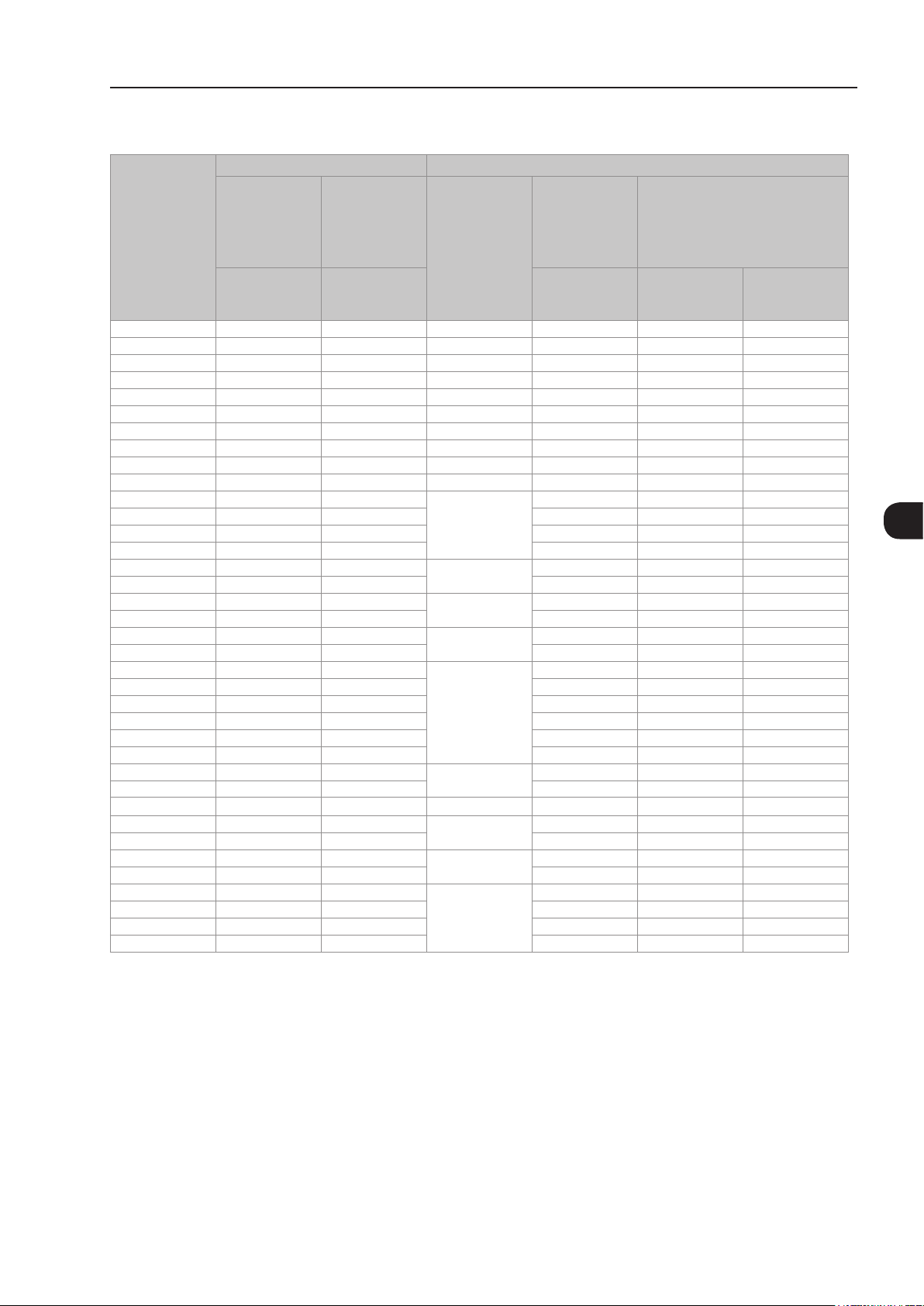

Table 3.2 - Recommended wire size/fuses - use copper wire (75 ºC (167 ºF)) - frame size B, 500 to 600 Vac supply voltage

Model

CFW110002T5

CFW110004T5

CFW110007T5

CFW110010T5

CFW110012T5

CFW110017T5

Power Terminals

Terminals

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(1)

(PE)

(1)

(PE)

(1)

(PE)

(1)

(PE)

(1)

(PE)

(1)

(PE)

Screw

Thread/

Screw

Head Type

M4

(Slotted

and Phillips

head)

(comb)

M4

(Phillips

head)

M4

(Slotted

and Phillips

head)

(comb)

M4

(Phillips

head)

M4

(Slotted

and Phillips

head)

(comb)

M4

(Phillips

head)

M4

(Slotted

and Phillips

head)

(comb)

M4

(Phillips

head)

M4

(Slotted

and Phillips

head)

(comb)

M4

(Phillips

head)

M4

(Slotted

and Phillips

head)

(comb)

M4

(Phillips

head)

Recommended

Torque

N.m (lbf.in)

1.2 (10.8)

1.7 (15.0) 2.5

1.2 (10.8)

1.7 (15.0) 2.5

1.2 (10.8)

1.7 (15.0) 2.5

1.2 (10.8)

1.7 (15.0)

1.2 (10.8)

1.7 (15.0)

1.2 (10.8)

1.7 (15.0)

Overload

Class

HD/ND

HD/ND

HD/ND

HD/ND 2.5 14

HD/ND 2.5 12

HD/ND 4 10

Wire Size Recommended Fuse

mm

1.5

1.5

1.5

2

AWG

14

14

14

Wire

Terminal

Bype

Pin

terminal

Ring

tongue

Pin

terminal

Ring

tongue

Pin

terminal

Ring

tongue

Pin

terminal

Ring

tongue

Pin

terminal

Ring

tongue

Pin

terminal

Ring

tongue

I²t UL WEG Fuse

[A²s] [A] In[A] Model

1250 20 20 FNH00-20K-A

1250 20 20 FNH00-20K-A

1250 20 20 FNH00-20K-A

1250 20 20 FNH00-20K-A

1250 25 25 FNH00-25K-A

1250 40 35 FNH00-35K-A

3

CFW-11 | 3-21

Page 52

Installation and Connection

Table 3.3 - Recommended wire size/fuses - use copper wire (75 ºC (167 ºF)) - frame size C, 500 to 600 Vac supply voltage

3

Power Terminals

Model

CFW110022T5

CFW110027T5

Terminals

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(1)

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(1)

(PE)

Screw

Thread/

Screw

Head Type

M5

(Pozidriv

head)

M5 (Phillips

head)

M5

(Pozidriv

head)

M5

(Phillips

Recommended

Torque

N.m (lbf.in)

2.7 (24.0)

3.5 (31.0)

2.7 (24.0)

3.5 (31.0)

Overload

Class

ND/HD 6 10

ND/HD 10 8

head)

M5

(Pozidriv

head)

M5

(Phillips

2.7 (24.0)

ND/HD 10 8

3.5 (31.0)

CFW110032T5

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(1)

(PE)

head)

M5

(Pozidriv

head)

M5

(Phillips

2.7 (24.0)

ND/HD 10 6

3.5 (31.0)

CFW110044T5

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(1)

(PE)

head)

(1) There is a plastic cover in front of the DC- terminal at the frame sizes B and C inverters. It is necessary to break off that cover in order to get access to

this terminal.

Wire Size Recommended Fuse

I²t UL WEG Fuse

[A²s] [A] In[A] Model

mm

2

AWG

Wire

Terminal

Bype

Pin

terminal

7.200 40 40 FNH00-40K-A

Ring

tongue

Pin

terminal

7.200 50 50 FNH00-50K-A

Ring

tongue

Pin

terminal

7.200 60 63 FNH00-63K-A

Ring

tongue

Pin

terminal

7.200 60 80 FNH00-80K-A

Ring

tongue

3-22 | CFW-11

Page 53

Installation and Connection

Table 3.4 - Recommended wire size/fuses - use copper wire (75 ºC (167 ºF)) - frame size D, 500 to 690 Vac supply voltage

Model

CFW110002T6

CFW110004T6

CFW110007T6

CFW110010T6

CFW110012T6

CFW110017T6

CFW110022T6

CFW110027T6

CFW110032T6

CFW110044T6

Power Terminals

Terminals

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

Screw

Thread/

Screw

Head Type

M4

(Slotted and

Phillips head)

(comb)

M5

(Phillips

head)

M4

(Slotted and

Phillips)

(comb)

M5

(Phillips

head)

M4

(Slotted and

Phillips)

(comb)

M5

(Phillips

head)

M4

(Slotted and

Phillips(

(comb)

M5

(Phillips

head)

M4

(Slotted and

Phillips)

(comb)

M5

(Phillips

head)

M4

(Slotted and

Phillips)

(comb)

M5

(Phillips

head)

M4

(Slotted and

Phillips)

(comb)

M5

(Phillips

head)

M4

(Slotted and

Phillips)

(comb)

M5

(Phillips

head)

M4

(Slotted and

Phillips)

(comb)

M5

(Phillips

head)

M4

(Slotted and

Phillips)

(comb)

M5

(Phillips

head)

Recommended

Torque

N.m (lbf.in)

1.2 (10.8)

3.5 (31.0) 2.5

1.2 (10.8)

3.5 (31.0) 2.5

1.2 (10.8)

3.5 (31.0) 2.5

1.2 (10.8)

3.5 (31.0)

1.2 (10.8)

3.5 (31.0)

1.2 (10.8)

3.5 (31.0)

1.2 (10.8)

3.5 (31.0)

1.2 (10.8)

3.5 (31.0)

1.2 (10.8)

3.5 (31.0)

1.2 (10.8)

3.5 (31.0)

Overload

Class

HD/ND

HD/ND

HD/ND

HD/ND 2.5 14

HD/ND 2.5 12

HD/ND 4 10

HD/ND 6 10

HD/ND 10 8

HD/ND 10 8

HD/ND 10 6

Wire Size Recommended Fuse

mm

1.5

1.5

1.5

2

AWG

14

14

14

Wire

Terminal

Type

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

terminal

Ring

tongue

I²t UL WEG Fuse

[A²s] [A] In[A] Model

Pin

7200 20 20 FNH00-20K-A

Pin

7200 20 20 FNH00-20K-A

Pin

7200 20 20 FNH00-20K-A

Pin

7200 20 20 FNH00-20K-A

Pin

7200 25 25 FNH00-25K-A

Pin

7200 40 35 FNH00-35K-A

Pin

7200 50 40 FNH00-40K-A

Pin

7200 50 50 FNH00-50K-A

Pin

7200 60 63 FNH00-63K-A

Pin

7200 60 80 FNH00-80K-A

3

CFW-11 | 3-23

Page 54

Installation and Connection

Table 3.5 - Recommended wire size/fuses - use copper wire (75 ºC (167 ºF)) - frame size E, 500 to 690 Vac supply voltage

3

Model

CFW110053T6

CFW110063T6

CFW110080T6

CFW110107T6

CFW110125T6

CFW110150T6

Power Terminals

Terminals

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

R/L1 - S/L2 - T/L3 -

U/T1 - V/T2 - W/T3

DC+, DC-

(PE)

Screw

Thread/

Screw

Head Type

M8

(hexagonal

screw)

M5 and M8

(hexagonal

phillips

screw)

M8

(hexagonal

screw)

M5 and M8

(hexagonal

phillips

screw)

M8

(hexagonal

screw)

M5 and M8

(hexagonal

phillips

screw)

M8

(hexagonal

screw)

M5 and M8

(hexagonal

phillips

screw)

M8

(hexagonal

screw)

M5 and M8

(hexagonal

phillips

screw)

M8

(hexagonal

screw)

M5 and M8

(hexagonal

phillips

screw)

Recom-

mended

Torque

N.m (lbf.

in)

15

(132.75)

M5:

3.5 (31.0)

M8:

10 (88.5)

15

(132.75)

M5:

3.5 (31.0)

M8:

10 (88.5)

15

(132.75)

M5:

3.5 (31.0)

M8:

10 (88.5)

15

(132.75)

M5:

3.5 (31.0)

M8:

10 (88.5)

15

(132.75)

M5:

3.5 (31.0)

M8:

10 (88.5)

15

(132.75)

M5:

3.5 (31.0)

M8:

10 (88.5)

Wire Size Recommended Fuse WEG

Overload

Class

HD 10 6

ND 25 4

HD/ND 25 4

HD 25 5

ND 35 2

HD/ND 25 4

HD 25 3

ND 35 2

HD/ND 25 4

HD 50 1

ND 50 1

HD/ND 35 2

HD 50 1

ND 50 1/0

HD/ND 35 2

HD 50 1/0

ND 70 2/0

HD/ND 50 1

mm

2

AWG

I²t UL WEG Fuse

Terminals

[A²s] [A] In[A] Model

Ring

39200 100 80

tongue

Ring

39200 100 100

tongue

Ring

39200 125 125

tongue

Ring