Page 1

Webasto AG, Global Comfort Solutions © 2007 All Rights Reserved

Air Conditioning Installation and

Operating Instructions

Blue Cool Premium

Ident.-Nr.: 0903071A

Page 2

D

I

G

I

T

A

L

C

O

N

T

R

O

L

P

A

N

E

L

EDITION DATED 21ST AUGUST 2006

CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 1

Webasto AG - Special Products & Markets

Kraillinger Strasse 5, 82131 STOCKDORF, Germany

Tel. : +49(0) 89 8 57 94 543 Fax : +49(0) 89 8 57 94 753 Website : www.webasto.de

F

U

N

C

T

I

O

N

I

N

G

P

R

I

N

C

I

P

L

E

S

Webasto - Marine Air Conditioning

OVER-BOARD DISCHARGE

CHILLER UNIT

COOL CYCLE LED

COMPRESSOR RUN LED

SET-POINT MODIFICATION

KEYS

BLOWER KEY

AUTO CYCLE SWITCHING LED

HEAT CYCLE LED

MAIN ON/OFF SWITCH

FUNCTION KEY / SECONDARY COMMANDS

CHILLED WATER AIR-CONDITIONING SYSTEMS

OPERATING AND INSTALLATION MANUAL

DIGITAL CABIN

CONTROL PANEL

FLEXIBLE AIR-DUCT

2ND AIR-HANDLER - VERTICAL

SLIM-LINE MODEL

TRANSITION BOX +

SUPPLY AIR-GRILLE

RETURN AIR GRILLE

Tee JUNCTION

TO 2ND AIRHANDLER

TUBULAR INSULATION

AROUND CHILLED

WATER CIRCUIT

PIPING

CHILLER UNIT

ELECTRICAL CONTROL BOX

SEA-WATER PUMP

AIR-HANDLER COMPACT SERIES

CIRCULATION PUMP

CHILLER UNIT

DIGITAL CONTROL

PANEL

NEW ELECTRONICS - 2004 SERIES

ROOM TEMPERATURE OR

SET-POINT TEMPERATURE

OR SECONDARY FUNCTION READ-OUT

Page 3

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 2

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 2

EDITION DATED 21ST AUGUST 2006

CHILLED WATER AIR-CONDITIONING SYSTEMS

OPERATING AND INSTALLATION MANUAL

CONTENTS

Page

1) General information ...................................................................................................

2) Digital Display <CHILLER CONTROL> ..................................................................

2.1 - Drawing Digital Display - Operation Guide........................................................

3) Central Blower Control ...............................................................................................

4) Visual Error Codes Digital Display ............................................................................

5) Cabin Blower Control .................................................................................................

5.1 - Wiring diagram - <CAB> 230V AC Cabin Control ..........................................

6) Programmable Functions Chiller Condensing Units ..................................................

6.1 - Digital Display - Programming access ...............................................................

7) Pratical Installation of Components - Guidelines .......................................................

7.1 - Installation Drawing - Sea Water Pump system .................................................

8) Chilled Water Circuit Installation ................................................................................

8.1 - Integration of Added Heat-Exchangers in Chilled Water Circuit .......................

Golden Rules - Chilled Water Piping Installation .......................................................

Filling and Purging of a Chilled Water Circuit ...........................................................

Examples of Chilled Water Circuit Piping Schematics ..............................................

8.6 - Example Chilled Water Circuit Piping - Small 20000 BTU Chiller ..................

8.7- Example Chilled Water Piping - WBCP24/D Stern Location - 4 Air-Handlers .

8.8 - Example - Catamaran - WBCP36/D - Central Location - 6 Air-Handlers .........

8.9 - Example - Motoryacht - WBCP72/D Twin - Aft location - 10 Air-handlers .....

8F - Air Ducts - Ventilation ..............................................................................................

9) Routine Checks/Trouble Shooting...............................................................................

11) Wiring diagrams .........................................................................................................

11.1 - Wiring diagram single compressor WBCP12/16/20/24/30 - 1 phase................

11.2 - Wiring diagram single/twin compressor - 1/3 phase .......................................

11.3 - Wiring diagram compressor 3/4 - single and 3 phase .....................................

11.4 - Power Supply Schematics - TWIN/CI Chillers - single phase 230V ..............

11.5 - Power Supply Schematics - TWIN/TRI (3) compr. Chillers - 1 phase 230V .

11.6 - Power Supply Schematics - TWIN/TRI (3) compr. Chillers - 3 phase 400V .

11.7 - Wiring Diagram automatic staging secondary AC loads ..................................

11.8 - Wiring Diagram - Running Capacitors - ECOFIT Blowers ............................

11.9 -

Wiring Diagram - Connection 3-Way valve (Lizhan/Zhongli) on TECC card

Webasto AG - Special Products & Markets

Kraillinger Strasse 5, 82131 STOCKDORF, Germany

Tel. : +49(0) 89 8 57 94 543 Fax : +49(0) 89 8 57 94 753 Website : www.webasto.de

3

3

3

4

4

6

7

9

9

11

11

12

12

13

14

15

15

15

16

17

18

19

20

21

22

23

24

24

25

26

26

26

Page 4

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 3

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 3

As from May 2004 all WEBASTO air conditioning units are controlled by a Digital

Display <CHILLER CONTROL> 2004

SERIES which gives access to all functions

necessary for the normal operation of the unit

and attached accessories (blowers, pumps,

etc).

All WEBASTO air conditioning units are

sea-water cooled by means of an AC seawater pump.

In order to start the system you only need to

press the On/Off key on the digital display.

From there on the electronic control unit

takes care of the progressive starting up of

the air conditioning components as well as it

normal functioning.

The digital display will show the present

room temperature of the cabin in which the

digital display is situated or where the main

temperature sensor is located (in case the

optional secondary temperature sensor is

used).

The WEBASTO <CHILLER CONTROL>

digital display allows access to information

and controls at three distinct levels :

Immediate Access - Level 1 :

1) Room temperature read-out in the main 4

LED display window

2) 3 small LED’s to the left indicating the

operating cycle presently active :

- Cool cycle only operation.

- Automatic cycle switching governed by

the end-users entered set-point temperature.

- Heat cycle only operation.

3) 2 set-point keys give immediate access

to the thermostatic set-points for blowercontrol (“Sun” and “Snow” key).

These keys are also used to alter programming values - see here-after chapter 6.

Press and hold one of the set-point selector

keys and wait until the new desired set-point

temperature is obtained. Release the setpoint key.

The display will memorize the value and

return to normal room temperature read-out

after approx. 5 seconds.

Secondary commands and info Level 2 :

The F/Blower key gives immediate access to

a number of secondary commands which

need to be accessed frequently for day to day

operation.

First access is to the blower speed control,

then chilled water temperature read-out, etc.

See hereafter drawing 2.1 for complete list.

Programming Commands - Level 3 :

A number of programming commands that

do not need to be accessed for day to day

operation are hidden and require a special

procedure to enable access and modification.

An access code can be enforced to avoid

accidental modification of programming values.

See Chapter 6 - Page 9.

Start-up delay :

After pushing the On/Off key the LED’s will

display <On> while initializing the system.

Push again to stop operation - the display

will briefly show <Off> before extinction.

The adequate LED to the left (heat, cool , etc)

will come on after approx. 15 seconds and

compressor operation will start after approx.

50 seconds.

The chilled water circulation pump will

come on immediately after system initialization.

New features - 2004 Series :

As from June 2004 all WEBASTO air conditioning units are controlled by a new Digital

Display <AIR CONTROL> 2004 SERIES

2.1 - <CHILLER CONTROL> DIGITAL DISPLAY - OPERATING GUIDELINES

BASIC COMMANDS :

1 - Press to turn on - press again to turn off.

2 - Press to read set-point temperature - hold to raise

set-point temperature.

3 - Press to read set-point temperature - hold to lower

set-point temperature.

4 - Led indicating system working in cool cycle

5 - Led indicating automatic reversed cycle mode is operative

6 - Led indicating system working in heat cycle

7 - Function/Blower Key - immediate access to :

- chilled water temperature read-out ....................

- manual choice of operating cycle (cool only, .....

heat only, etc)

- AC voltage read-out ...........................................

- manual compressor selection On/Off 1 to 4.

- start-up priority compressors 1 to 4....................

- time delay between compressor start-up.............

- individual thermostatic advance compressors ....

- automatic dehumidification cycle during absence

- display time of secondary functions accessible by

F/Blower key

8 - Dedicated Blower speed key ................................

9 - Access to hidden programming functions - see

Chapter 6 - page 9

NB - System stops while displaying 3 lettres <AAA> : safety

cut-out because of persistent low voltage. To restart make sure

voltage level is raised above 195V AC

1 - GENERAL INFORMATION - CHILLER AIR CONDITIONING SYSTEMS

1

3

8

9 -

Push Both Keys Simultaneously

after Display Extinction.

4

5

6

72

H13.2

*

F 3

U230

1C01

etc

P123

etc

*

L 9

1L0.0

etc

*

d 0

*

t 1

*

b A

*Default Values

EDITION DATED 21ST AUGUST 2006

Page 5

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 4

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 4

EDITION DATED 21ST AUGUST 2006

which gives access to all functions necessary

for the normal operation of the unit and

attached accessories (blowers, pumps, etc).

2004 Series Electronic Controls are easily

recognized by their special remobale bezels.

The new 2004 displays are backwards compatibel with the older TCC electronic controller cards. In that case however the dedicated Blower key is not operational.

Continued features - 2000 Series :

A) Automatic blank/sleep mode -

programmable time delay. Factory default : 15

minutes. While in blank/sleep mode the cycle

LED flashes discretely every 20 seconds. To

go back to normal operation push any key.

B) Calibrate all blower speed settings

in real time mode.

It is now possible to calibrate all speed settings (1 to 5) before actually putting the system into service.

To do so enter programming mode with setpoint at 15° C.; proceed to line <6> = speed

5 (max). (see chapter 6 - page 9)

The blower will start to function as soon as

you access code <6>.

Alter the value to the right of code <6> and

the blower speed will immediately change in

real time. When satisfied go to following line

<7> = speed 4 and do the same.

Proceed until lowest speed N° 1 and go back

again to speed N° 5 if not satisfied.

When all speeds are programmed according

to need, validate by pushing on/off key

(<memo> will be displayed briefly).

Attention : Never program speeds

so low that the blower is in danger

of stopping or will not re-start at

that setting.

This will inevitably entail motorwindings burn-out and will not be

covered by the WEBASTO warranty.

C) Infra-Red Remote Control :

Infra-red remote control can be purchased as

an option. This remote control is based on the

standard protocols also used by TV and other

appliances. Although the WEBASTO controls have been chosen so as to avoid interference with most TV models, the end-user

should be aware that in certain cases interference may occur with TV sets or other appli-

ances.

Generaly, it is therefore advisable to avoid

locating a WEBASTO <AIR CONTROL>

display next to other appliances using infrared control units.

D) ACCESS CODE :

The end-user can deny access to all program

settings by introducing an access code (see

page 10 - code <b>). Blower speed and setpoints always remain accessible.

Once an access code is activated, the digital

display will show <Code> if the end-user

tries to access other functions then blower

speed or set-point temperature. To gain full

access push the sun key to reach the code

value as programmed and push the F key

again to gain access to full program settings.

3 - CENTRAL BLOWER CONTROL

The central <CHILLER CONTROL> digital

display which controls general operation of

the condensing unit(s) can also directly control the blower(s) of the saloon/cabin where

the main temperature sensor is located.

This direct blower control is optional and not

all installations use this facility to control a

part of the ship’s blowers.

Blowers in the wheel-house for instance,

where the <CHILLER CONTROL> display

is located, can be directly controlled by the

TECC card. The <FAN> outlet of the TECC

controller card offers manual speed settings

and thermostatic control in the same manner

as the individual cabin controls.

This central blower control is therefore quite

distinct from the secondary Cabin Control

systems where the <AIR CONTROL> digital

display only operates the blower(s) of the

cabin where the display is situated without

any direct link to the main condensing unit.

Any blowers directly connected to the TECC

controller card will be activated after the

cycle LED comes on. However blowers will

only become active if the chilled water temperature is compatible with the enteredsetpoint.

If blower operation cannot be activated the

error code <bA11> will flash briefly and then

remain visible when accessing blower control through F/Blower key.

(See also here-after list of error codes).

Blower operation will only start after a compatibility check with the temperature of the

chilled water circuit.

Example : in <Cool> mode with a set-point

temperature of 21° C., blower operation will

only start after the temperature of the water

circuit has reached 20° C or less. This avoids

start-up of blower operation with a non compatible water circuit temperature.

For these TECC cards it is possible to altogether stop blower operation by choosing the

option <0> after manual blower speed <1>.

This allows to altogether stop blower operation by the main controller card during the

night for example while still continuing to

operate the chiller unit for the rest of the

ship’s air-handlers.

With the <CHILLER CONTROL>, blower

control is completely distinct from compressor operation :

1) Blower control will continue even if compressor operation is thermostatically stopped.

2) Compressor operation will continue even

if the blower is thermostatically stopped.

It is not possible however to operate the

blowers in a different cycle from compressor

operation ; for instance : compressors running in cool cycle and blowers in heat cycle.

In that case compressor operation will have

priority and blower-operation will be stopped

(error code <bA11>).

4. SECONDARY COMMANDS :

The F/Blower key gives immediate access to

commands and displays necessary for day to

day operation. When pushing the F/Blower

key you will see to the left a code which indicates the type of display or command and to

the right the present value.

In order of appearance here-after an explanation of these commands/displays :

a) Blower speed control : < b A>

(0,1,2,3,4,5)

This command preceeded by the letter b

(blower) allows the following settings :

A = automatic blower speed adjusted to tem-

perature differential.

0 = blower stop

1 to 5 = manual Speed Control

Speed control is in real time mode i.e.

changes are effected immediately without

any validation procedure.

Warning :

All following func-

tions need validation before a new

Page 6

value is accepted.

Validation is obtained by pushing

the F/Blower key again and by

going to the next function line.

Then final validation will occur

automatically when the display

goes back to room temperature

read-out or final validation can be

forced by pushing the On/Off key

briefly while still in F mode.

Validation is witnessed by the brief

display of the message <memo>.

b) Read out of chilled water temperature :

<H10.2> (10.2 ° C) - for example.

c) Cycle mode choice : <F 3> (1 to 5)

The following cycle modes can be choosen

manually :

1 = cool cycle only

2 = heat cycle only

3 = automatic cycle switching with reversible

compressor

4 = automatic cycle switching without

reversible compressor

5 = heat cycle only without reversible compressor

d) AC Voltage read-out : < U232>

(232 Volts)

e) Manual on/off Compressor 1 : <1C01>

<1C01> = Compressor 1 on

<1C00> = Compressor 1 off

f) Manual on/off Compressor 2 : <2C01>

<2C01> = on

<2C00> = off

Idem for compressors 3 and 4 - <3C01> and

<4C01>.

g) Start-up Priority Compressors 1 to 4 :

<P123> = 1,2,3,4 ; <P341>=3,4,1,2

<P A> = automatic priority rotation; when

in this priority mode, the starting

order will be changed at every

restart after a thermostatic cut-out.

h) Time delay between compressor start-up :

<L 9> (9 seconds) - programmable

from 1 and 9 seconds.

i) Individual thermostatic advance compres-

sors 1 to 4. In relation to the general chilled

water temperature set-point, it is possible to

differenciate the cut-out temperature for

each compressor.

Factory default setting : <1L0.0> etc

<2L1.2> means compressor 2 will cut out

1.2° before the general set-point value. So

for a general value of 4°, compressor 2 will

cut out at 4 + 1.2 = 5.2 °.

Same is possible for the other compressors.

j) Automatic dehumidification while absent.

factory default setting : <d 0>

0 = non active

1 = 1 cycle per 24H

2 = 2 cycles per 24H etc

k) Display time of secondary functions (F/

Blower key) by periods of 20 seconds.

<t 1> (factory default setting) = display

time 20 seconds.

4. VISUAL ERROR CODES DIGITAL DISPLAY

The following malfunctions will be displayed directly on the digital display by a

code and will be followed by a system halt

(except for <bA11> - see hereafter).

Whenever any of these codes appear the system is stopped for approx. 60 seconds and

then a re-start is attempted.

If for more than 30 minutes the same malfunction occurs, the system will be stopped

completely and the error-code will become

steady.

No more re-starts will be attempted and the

user will have to re-set the system by pushing

the On/Off key or by temporarily cutting off

the AC supply to the system.

List of error-codes and nature of malfunction :

Code <AAA> :

Persistent low voltage (voltage below 195V)

for more than 5 seconds - (see also hereafter

- Trouble-Shooting - Page 19).

Code A01 to A08 :

Pressure safety cut-out of compressors 1 to 4.

The HP(High Pressure) and BP(Low

Pressure) safety switches are directly controlled by the micro-processor inclusing the

time-delays for re-start, etc.

Error codes displayed and probable nature of

anomaly.

<A01> : BP (low pressure) cut-out - com-

pressor 1 - probable causes :

- interrupted or insufficient waterflow in chiller circuit

- sea-water circulation deficient

when running in heat cycle mode

- insufficient refrigerant charging

level

- abnormal sea-water temperature

conditions in heat cycle (sea-water

temperatures under 6° C. approx.)

- first start-up in heat cycle with

very low chilled water circuit tem-

peratures (below 8° C approx.).

<A02> : HP (high pressure) cut-out - com-

pressor 1 - probable causes :

- insufficient or non-existent seawater cooling - check sea-water

pump.

- insufficient or interrupted water

flow in chiller circuit when operating in heat cycle.

- too much refrigerant in system call a specialist

- abnormal sea water temperature

conditions in heat cycle (sea-water

temperatures above 20° C approx.)

<A03> : BP cut-out - compressor 2 - for

probable causes see <A01>

<A04> : HP cut-out - compressor 2 - for

probable causes see <A02>

<A05> to <A08> - same as above for compressors 3 and 4 (if present).

If any of these error codes appear too frequently and no appropriate action can be

taken with the available means on board, it is

necessary to call a specialist.

Do not insist with manual re-starts in such

cases as this may cause major damage to the

principal components (compressors, pumps,

etc).

<A09> - absent or defective external air sen-

sor.

<A10> - absent or defective chilled water

sensor.

<bA11> - blower operation from TECC card

impossible because of non-compatible water temperature versus pro-

grammed set-point. This is the only

error code which will not result in

a complete system halt.

<CA11> - all compressors are disactivated

by soft - through F/Blower key : <1C00>,

<2C00>, etc.

To reactivate re-program as follows :

<1C01>, <2C01>, etc

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 5

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 5

EDITION DATED 21ST AUGUST 2006

Page 7

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 6

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 6

EDITION DATED 21ST AUGUST 2006

Individual cabins controlled by WEBASTO

Digital Cabin Controls are completely independent from the central condensing unit i.e.

there is no direct electrical or electronic link

between the cabin control unit and the central

TECC controller.

The chilled water temperature sensor allows

the Cabin Control to ascertain which cycle

(heat or cool) is presently valid.

A Cabin Control can be operated entirely

independently from the main condensing unit

i.e. :

- it can be switched off or turned on at any

time by the end-user

- the end-user can set any temperature set-

point as long as it is compatible with

the general operation mode valid (heat or

cool)

- blower operation can be individually con-

trolled and programmed

2) Flashing of Error Code <bA11> :

If the user programs a set-point temperature

incompatible with the general water circuit

temperature as presently available (for example : set-point requested : 20° C for a room

temperature of 25° C and a water-circuit temperature of 35° C) = Cool cycle requested

with the chilled water circuit obviously

working in heat cycle.

Blower operation will be stopped and error

code <bA11> will blink for approx. 10 seconds.

After that the error code will still be visible

when accessing blower control by the F key.

The error code will disappear and normal

blower operation will resume as soon as the

water circuit temperature drops below 20° C.

Direct read-out of water-circuit temper-

ature at air-handler entry :

All Cabin Controls allow the user to immediately visualize the water-circuit temperature

at the entry of the cabin’s air-handler. (push

F/Blower key - see also drawing here-above).

This feature allows the user to ascertain that

water-circulation is normal through the airhandler without abnormal differences as

compared with the condensing unit water

exit. (Normally temperature rise between

condensing unit exit and air-handler entry

should not exceed approx. 4° C.) Before getting worried however, the first thing to check

is the proper attachment of the cabin control

water temperature sensor to the air-handler

entry and its proper insulation from outside

interference.

5A - DIGTAL CABIN CONTROL TYPE CAB - 230V - 2000 SERIES

This is the most common type of digital

cabin control and includes :

- digital display <AIR CONTROL>

- CAB - 230V controller card in plastic box

- 4 ml display cable

- 2.5 ml chilled water temperature cable

- 4 ml air temperature sensor (optional)

The digital display <AIR CONTROL>

includes an air temp. sensor housed behind

the 2 small openings on the front panel. It is

sometimes necessary however to use the

optional external air-sensor if for instance the

digital display is subject to direct heat induction (sun-rays, instruments from behind, etc)

All CAB controls include an outlet for solenoid water valve control on the entry of the

air-handler.

Solenoid valve control are an optional extra :

Danfoss/Lizhan 3-way solenoid valve systems, where the water-flow is completely

halted when set-point temperature is reached

and the flow returned directly to the returnline through a nozzle.

When using 3-way valves it is possible to

adopt continuous blower operation.

See page 7 - drawing N° 5.1 for full

schematics.

Secondary Commands - <F> key :

The <F> key gives immediate access to commands and displays necessary for day to day

operation. When pushing the F key you will

see to the left a code which indicates the type

of display or command and to the right the

present value.

In order of appearance here-after an explanation of these commands/displays :

a) Blower speed control : <b A>

(0,1,2,3,4,5)

This function is also accessible directly

through the dedicated Blower key.

This command preceeded by the letter b

(blower) allows the following settings :

A = automatic blower speed adjusted to tem-

perature differential.

0 = blower stop

1 to 5 = Manual Speed Control

Speed control is in real time mode i.e.

changes are effective immediately without

any validation procedure.

b) Read out of chilled water temp. :

5 - DIGITAL CABIN BLOWER CONTROL - GENERAL PRINCIPLES

BASIC COMMANDS :

1 - Press to turn on - press again to turn off.

2 - Press to read set-point temperature - hold to raise

set-point temperature.

3 - Press to read set-point temperature - hold to lower

set-point temperature.

4 - Led indicating system working in cool mode

5 - Led indicating manual blower speed control is active

6 - Led indicating system working in heat mode

7 - Function/Blower Key - immediate access to :

- chilled water temperature read-out .......................

- automatic dehumidification cycle during absence

- display time secondary functions accessible by

F/Blower key

8 - blower speed control .............................................

9 - Access to hidden programming functions - see page 7.

*

H13.2

*

d 0

*

t 2

*

b

A

* Default Values

1

3

9 -

Push Both Keys

Simultaneously

after Display Extinction

4

5

6

7

2

8

Page 8

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 7

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 7

EDITION DATED 21ST AUGUST 2006

<h10.2> (10.2 ° C) - example.

c) Control of external heat-source.

<F 1> = normal auto-reverse cycle

(cool/heat) without external heat source.

<F 2> = autoreverse cycle operation with

external heat assistance. In that case the oulet

connectors <HEAT> on the Cabin controller

card are activated together with the

<VALVE> oultlet when heat cycle is selected. This external heat source can be an AC

heating element or any other source such as

ceramic heaters etc

<F 3> = heat operation with external heat

source only. Inthat case the <VALVE> outlet

on the controller card is not activated and

only the <HEAT> connectors are operational.

c) Automatic dehumidification

while

absent.

Factory default setting : <d 0>

0 = non active

1 = 1 cycle per 24H

2 = 2 cycles per 24H etc

d) display time of secondary functions

(F/Blower key) by periods of 20 seconds.

Factory default setting : <t 1> = display

time 20 seconds

Special features - 2000/2004 Series :

See beginning page 4.

Continued features - 2000 Series :

A) Automatic blank/sleep mode - programmable time delay. Factory default : 15 min-

utes. While in blank/sleep mode the cycle

LED flashes discretely every 20 seconds. To

go back to normal operation push any key.

B) Real time modification of all blower

speed settings.

It is now possible to alter all speed settings (1

to 5) before actually putting the system into

service. To do so entrer programming mode

with set-point at 15° C.; proceed to line<6> =

speed 5 (max).

Alter value and blower speed will immediately change in real time. When satisfied go

to following line <7> = speed 4 and do the

same.

Proceed until lowest speed N° 1 and go back

again to speed N° 5 if not satisfied.

When all speeds are programmed according

to need, validate by pushing on/off key

(<memo> will be displayed briefly).

Attention : Never program speeds so

low that the blower is in danger of

stopping or will not re-start at that

setting. This will inevitably entail

motor-windings burn-out and will

not be covered by WEBASTO warranty.

Programming of the CAB - 230V

controller cards :

To access hidden programming functions

raise set-point temperature to 29° or lower to

15° and push On/Off key.

Then push both set-point keys simultaneously for approx. 3 seconds and you will enter

programming mode as explained here-after.

Validation is obtained by pushing the

F/Blower key and by going to the next programming line.

Programming codes available by raising the

set-point to 29° C :

Code <4> : Calibration of chilled water temp

Code <5> : time delay in minutes before the

display goes into sleep mode.

Code <7> : Calibration of room temperature

read-out.

Code <b> : Program version

Programming codes available when lowering

the set-point to 15° C :

Code <1> - factory setting : 0 - infra-red

remote control :

0 = infra-red remote control disabled

1 = infra-red remote control active

Code <2> : Blower type : Centrifugal or

Cross-Flow. Factory default : 1

0 = centrifugal blowers only

1 = centrifugal + cross-flow

Code <3> : continuous blower operation = 1

thermostatic blower control = 0

Code <4> : integrated air-sensor = 1

external air-sensor = 0

Code <5> : display in Celsius or Fahrenheit

default value = 0

0 = Celsius read-out

1 = Fahrenheit read-out

Code <6> : calibration speed N° 5 (max)

3 x 1 mm²

BROWN

BLACK

BLUE

Chilled Water sensor to be fixed on chilled water entry of Air-handler

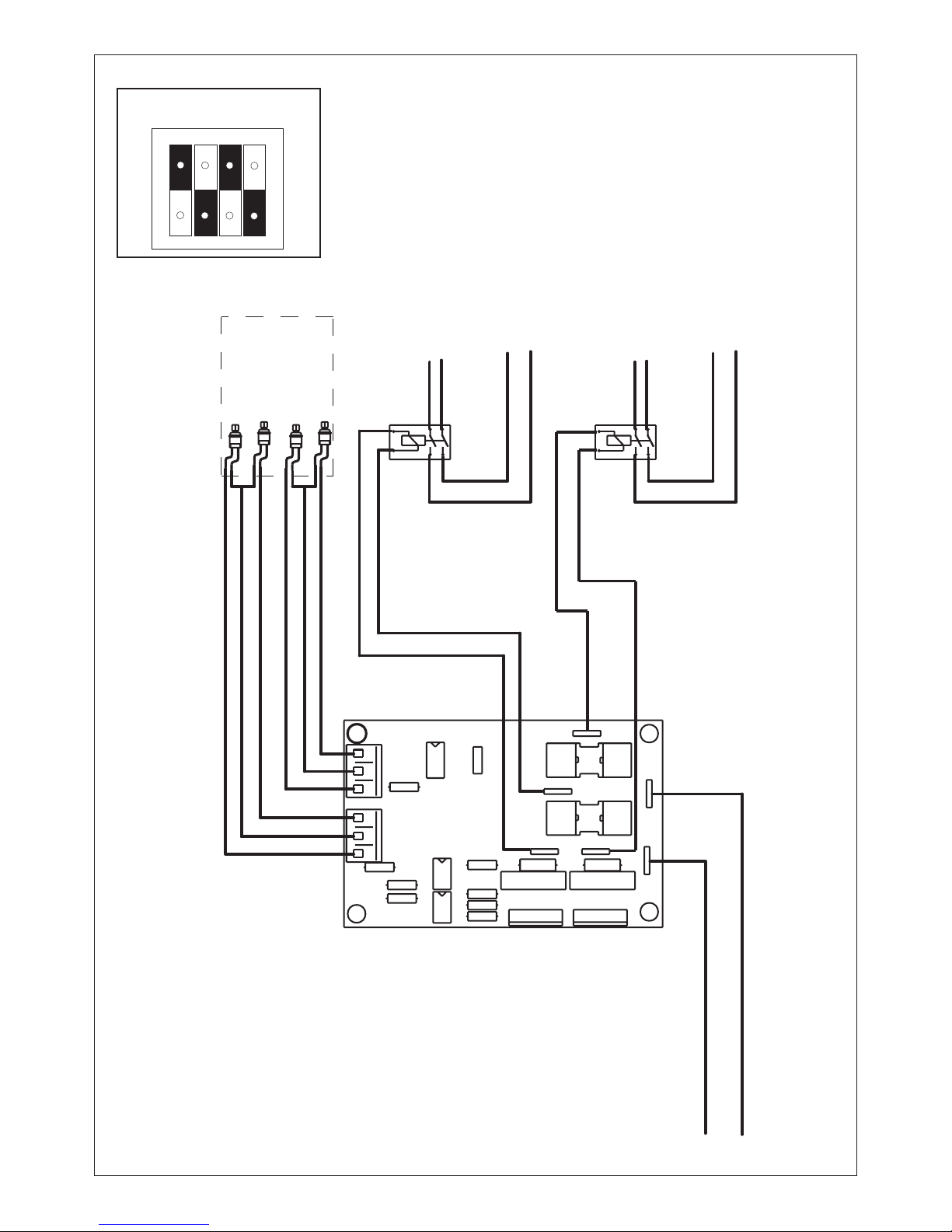

5.1 - ELECTRICAL AND OTHER CONNECTIONS - CABv3 - 230V - DIGITAL CABIN CONTROL

Page 9

Z

A

A

B

1

3

4

230V BOAT SUPPLY

RELAY

24 14 NO

21 11 COM

22 12 NC

A2 A1

AIRHANDLER BLOWER

LIZHAN / ZHONGLI

3-WAY VALVE

L

B

12A

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 8

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 8

EDITION DATED 21ST AUGUST 2006

Code <7> : idem speed N° 4

Code <8> : idem speed N° 3

Code <9> : idem speed N° 2

Code <A> : idem speed N° 1

Code <c> : duration heat cycle dehumidifi-

cation mode in minutes.

Code <d> : duration cool cycle dehumidifi-

cation mode in minutes.

5D - MTH - MECHANICAL THERMOSTAT

The MTH thermostat has a knob control for

setting the desired set-point temperature and

a selector to switch between summer and

winter operation.

See here-after the electrical schematics of

MTH installation.

5E - MTH2 - MECHANICAL THERMOSTAT + 3 SPEED CONTROL

The MTH2 mechanical thermostat incorporates a 3 position selector which can be

linked to a simple 3 speed blower control

system.

See here-after (Photo 5.6) for the components included in this system. The assembly

is delivered with a multi-conductor plug to

avoid cabling errors.

5F - PLANA (Vimar) 3 speed

Thermostats

Based on the modular Plana series by

Vimar with the same features as 5E.

MTH - MECHANICAL THERMOSTAT - CABIN BLOWER CONTROL

SUMMER/WINTER SELECTOR

SET-POINT ADJUSTMENT KNOB

Heat/Cool Selector

On/Off

Switch

3 Speed

Selector

WEBASTO PREWIRED RJ45 CABLE

WEBASTO 3 SPEED

Controller Card

5.6 - WIRING DIAGRAM - MTH BELUX THERMOSTAT + 3 SPEED BLOWER CONTROL

PLANA (VIMAR) MECHANICAL THERMOSTAT + 3 SPEED BLOWER CONTROL

Thermostat

Knob

Blower Speed

Knob (0 + 3)

Heat/Cool

Selector +

On/Off

Selector

Display Cable 4.5 ml

3 Speed Controller

Z

A

A

B

230V BOAT SUPPLY

12A

24 14 NO

21 11 COM

22 12 NC

A2 A1

LIZHAN / ZHONGLI

3-WAY VALVE

AIRHANDLER BLOWER

C NC NO N L

ELECTRONIC VIMAR/PLANA THERMOSTAT

L

B

RELAY

WIRING DIAGRAM - PLANA THERMOSTAT + 3 SPEED CONTROL

Brown

Black

Blue

Blue

Black

Brown

Page 10

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 9

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 9

EDITION DATED 21ST AUGUST 2006

To access the programmable parameters of

the TECC electronic controller proceed as

following :

Raise set-point temperature to the max. i.e.

29° Centigrade. Then turn off system by

pressing the <On/Off> key.

Press simultaneously the 2 set-point keys for

aprox. 3 seconds until you see to the left of

the digital display a single number code indicating the programming line presently valid

and to the right a single ou double read-out

indicating the present programming value.

To go to the next programming line (left single number), press <F> key.

If you modify the programming value (to the

right of the display), you need to validate the

changes made by pressing the <F> key and

go to the next programming line. This step

will validate and memorize the changes

made.

Here-after the explanations regarding the

available programmable functions :

1° Functions accessible by raising the setpoint to 29° C. :

Code <0> - factory setting : +4° Celsius -

lower set-point temperature of the chilled

water circuit when in cool cycle. This value

gives the compressor cut-out point when in

cool cycle.

Adjustment range : between 0°C and +15°C.

Code <1> - factory setting : +7° Celsius higher set-point temperature of the chilled

water circuit when in cool cycle. This value

gives the re-start point of the compressor(s)

after a thermostatic interruption (in cool

cycle).

Adjustment range : between 2°C and +18°C.

Code <2> - factory setting : 40° C. higher

set-point temperature of the chilled water circuit when in heat cycle. This value gives the

cut-out point of the compressor(s) when

functioning in heat cycle.

Set-point temperature adjustable between

30° and 55° C.

Code <3> -factory setting : 37° C. - lower

set-point temperature of the chiller water cir-

cuit when in heat cycle. This value gives the

re-start point of the compressor(s) after a

thermostatic interruption (in heat cycle).

Set-point temperature adjustable between

27° and 52° C.

Code <4> - pre-programmed value : 0 - calibration of the chilled water circuit temperature - possible adjustment between -9° and

+9° C.

Code <5> - factory setting : 15 - time delay

in minutes before the digital display goes

into blank/sleep mode. Cycle LED flashes

discretely to indicate system is operational.

Code <6> - factory setting : 1 - first start up

delay in seconds after connecting AC supply.

Adjustable between 1 and 20 seconds.

Code <7> - factory setting : 0 - calibration

of room temperature read-out. Correction

between +9 and -9° C.

Code <8> - pre-programmed value : 0.

Factory calibration of AC voltage 50 Hz as

displayed on the digital panel when accessing the secondary commands - F/Blower key.

Correction between -20 and +20 Volt.

Code <9> - pre-programmed value : 0 Functioning principle of staging relay :

Value 0 : the relay functions as a staging

relay (see also page 25)

Value 1 : the relay functions as the outlet control for a soleniod valve system for the airhandlers directly controlled by the main

TECC controller.

Value 2 : the relay functions as a witness for

a system halt and general alarm (A01, A02,

A09, etc) :

- contacts closed between C2 and R2 or contacts open between C2 and T2 = no alarm

- contacts open between C2 and R2 or contacts closed between C2 and T2 : general

alarm and system halt.

Value 3 : cycle indication

- contacts closed between C2 and T2 = heat

cycle

- contacts closed between C2 and R2 = cool

cycle

System Halt : contacts closed between C2

and R2.

Code <A> - pre-programmed value : -10.

Factory calibration of AC voltage 60 Hz as

displayed on the digital panel when accessing the secondary commands - F/Blower key.

Correction between -30 and +20 Volt

Code <b> - Program version

Re-intializing the factory default settings :

It is possible to force the program to re-initialize all program values to factory default

settings by the following procedure :

When reading the <b> line as above (through

the 29° set-point), push the <sun> key until

the program version starts to flash. Keep the

<sun> key pushed down until the display

shows <init>.

6 - PROGRAMMABLE FUNCTIONS - CHILLER CONTROL

PROGRAMMING MODE :

To enter programming mode : raise or lower set-point to 29 or 15° C.

Turn off system by pressing <Power> key - 14.

Press simultaneously keys <11>. The display will show to the left

<15>, the number code of the current programming line and to the right

<16> the present value.

To validate and memorize modified parameters press the <F> key (12)

and proceed to the following programming line.

6.1 - DIGITAL DISPLAY <CHILLER CONTROL> - PROGRAMMING ACCESS

11

12

14

15

16

Page 11

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 10

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 10

EDITION DATED 21ST AUGUST 2006

Leave programming mode by pushing

<On/Off> key - you are now back to the factory default settings.

2° Functions accessible when lowering

the set-point temperature to 15° C :

Code <0> - pre-programmed value :195 low AC voltage cut-out value.

Time delay is 5 seconds approx. i.e. the low

voltage situation will have to persist during

more than 5 seconds before cut-out occurs.

After a cut-out the electronic controller resets

and will start a new cycle. So a renewed

attempt to start the compressor will occur

after approx. 90 seconds.

During low-voltage cut-out the display panel

will show the 3 letters <AAA>.

Programming of a cut-out level below 195 V

is done at the entire risk of the operator. It

should be noted that almost all compressor

manufacturers decline all responsibility for

defects resulting from operating the compressors below 195V AC.

Code <1> - factory setting : 0 - infra-red

remote control :

0 = infra-red remote control disabled

1 = infra-red remote control active

Code <2> - factory setting : 0 - choice of

small relay setting indicating cool/heat cycle

operation or alarm status.

0 = cycle indication :

- contacts closed between C1 and T1 = heat

cycle

- contacts closed between C1 and R1 = cool

cycle

System Halt : contacts closed between C1

and R1.

1 = alarm status : the relay functions as a witness for a system halt and general alarm

(A01, A02, A09, etc) :

- contacts closed between C1 and R1 or contacts open between C1 and T1 = no alarm

- contacts open between C1 and R1 or contacts closed between C1 and T1 : general

alarm and system halt.

Code <3> - pre-programmed value : 0 basic choice of blower control :

0 - thermostatic control of blower operation

i.e. blower operation will be interrupted thermostatically when reaching the appropriate

set-point.

1 - un-interrupted blower operation regardless of the thermostatic control.

Code <4> - factory setting : 0 - Choice

between integrated air sensor and external air

sensor :

1 - air sensor integrated in digital display

0 - external air sensor

Code <5> - Display in Celsius or Fahrenheit

default value = 0

0 = display in Celsius

1 = display in Fahrenheit

Code <6> : modification speed N° 5 (max)

Code <7> : idem speed N° 4

Code <8> : idem speed N° 3

Code <9> : idem speed N° 2

Code <A> : idem speed N° 1

Code <b> - factory setting : 0 - access code

value for programming mode.

0 = no access code required

1 to 99 = access code activated

In case you can’t remember your access code

you can gain access to the concerned programming line by typing in the factory

access code : 64

Code <c> - factory setting : 1 - duration in

minutes of heat cycle operation under the

dehumidifying procedure.

Code <d> - factory setting : 1 - duration in

minutes of cool cycle operation under the

dehumidifying procedure.

DIPSWITCHES :

The TECC controller card has a dipswitch

arrangement which should be set and maintained according to the following settings :

1) TECC controller for compressors 1 and 2

only, without the secondary card for compressors 3 and 4 :

2) TECC controller for 3 or 4 compressors,

with secondary card for compr. 3 and 4 :

Warning :

if dipswitches are not set

according to the above configurations i.e.

according to the number of compressors

effectively on line, the TECC controller card

may behave in an unpredictable manner :

- the initialisation <init> can not be completed - card remains blocked on start-up.

- HP/BP alarms for non-existing compressors.

Etc.

1

23

4

OPEN

ATT. DIPSWITCH SETTINGS

BLACK = PUSHED DOWN

1234

OPEN

ATT. DIPSWITCH SETTINGS

BLACK = PUSHED DOWN

Page 12

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 11

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 11

EDITION DATED 21ST AUGUST 2006

7A

) SEA WATER COOLING

Install the pump/strainer assembly in such a

manner that a natural gentle upwards slope

exists from the sea-cock to the pump itself.

See also drawing hereafter - ref. 7.1

It is strongly recommended to install an airbleeder system immediately at the discharge

outlet of the pump. The advice is especially

valid for pumps CLD125/250/350/1000/

1500 and 2000. The CLD2500 and higher

generally will not require a bleeder system to

ensure proper operation.

For ALL boats it is strongly recommended to

install a water-scoop at the entry of the seacock and directed towards the bow of the

boat so that at speed positive pressure builds

up in the supply line to the sea-water pump.

Sea-water cooling exits :

Provide for a separate sea-water exit for each

air-conditioning unit installed even if only

one pump provides cooling for all units.

Introduce shut-off valves for each unit if 1

pump provides cooling for more than 1 airconditioning unit.

This will allow easy priming of the circuit

and also calibration of the sea-water flow for

each air-conditioning unit in case of imbalance in the water tubing lengths.

7B) AIR-HANDLER COILS :

The finned coils of the evaporators and/or

air-handlers are fragile. When during installation the fins of these coils are damaged,

take care to re-align the fins in order not to

impair proper air-flow.

Return air should be filtered to avoid accumulation of dust on the coil fins.

This can be obtained by 2 means :

a) Install WEBASTO supplied return air

grilles which include a filter element behind

the grilles.

b) Install a filtering element just in front of

the return air coil surface. Such filter material can be also obtained from WEBASTO

Marine.

7C) AIR-DUCTS :

Flexible air-ducts need to be of good quality

with sufficiently strong steel or plastic reinforcement. Do not restrict air-flow by

bending the air-ducts too tightly or by accidental local deformation.

Do not install air-ducts of excessive lengths

(+ 2.5 ml); the pressure loss and consequent

reduction of air-flow will seriously diminish

the efficiency of the installation.

If long ducts are an absolute necessity, try to

use rigid PVC piping of equal diameter and

the associated elbows, etc.

PVC piping because of its smooth interior

induces far less friction then standard steel

wire re-inforced flexible ducting.

TO OVER-BOARD OUTLET APPROX. 10 CMS ABOVE WATER-LINE

INSTALLATION OF BLEEDER ADVISABLE

PUMPS SITUATED

AT LEAST 25 CMS BELOW WATER-LINE

SEA-WATER STRAINER

SUCTION GENTLY UPWARDS TO

FACILITATE PRIMING

CLAM-SHELL TYPE THRU-HULL FITTING

WITH SLOTS DIRECTED TOWARDS BOW TO OBTAIN POSITIVE PRESSURE IN SECTION LINE

NB - ALL PIPING AS SHORT AS POSSIBLE WITHOUT

KINKS NOR SYPHONS

WATER-LINE

7.1 - INSTALLATION OF SEAWATER COOLING PUMP AND PIPING

7 - PRACTICAL INSTALLATION OF COMPONENTS - GUIDELINES

Page 13

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 12

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 12

EDITION DATED 21ST AUGUST 2006

8A) PRESSURIZED/NON PRESSURIZED SYSTEMS :

Chilled water circuit can be static non-pressurized or pressurized with membrane type

expansion-tanks.

If the system adopted is static, the expansion

tank should be the highest point of the circuit

while taking into consideration the possible

heeling angle under sail.

Expansion tanks should always be connected

to the suction side of the circulation pump.

8B) FREE FLOW VERSUS SOLENOID

VALVE CONTROL :

The water-circuit can be free-flow where the

water-flow is continuous through all air-handlers and thermostatic control for each airhandler is obtained by stopping blower operation.

In this case it is advisable to introduce manual ball-valves on each of the air-handler

entries so as to enable balancing out of the

water-flow if necessary.

In case of a solenoid valve system where

each air-handler is equipped with a electrical

solenoid valve controlled by the WEBASTO

Cabin Control, it is not necessary to provide

for other entry valves.

8C) WATER CIRCUIT TEMPERATURE

SENSORS :

To obtain a satisfactorily working system it is

of utmost importance that the water-circuit

temperature sensors are correctly placed

accordingly to WEBASTO specifications.

In order to exclude any erroneous temperature pick-up, WEBASTO provides specific

locations on its condensing units.

These points are short tubular housings

which cross the chilled water outlets at the

following locations :

Single Evaporator Chiller Units :

Exit temperature sensor : the water-circuit

exit on each evaporator is provided with a

tubular transverse housing where this temperature sensor should be placed.

Twin Evaporator Chiller Units (TWIN/CI):

For TWIN-CI modules with 2 compressors

on 1 tray and independent evaporators, the

chilled water sensor is attached to the Tee

junction where the 2 exit pipes of the evapo-

rator meet. The sensor should be properly

insulated against external infuence.

All TWIN-CI units delivered by WEBASTO

come with the sensor already fixed in the

proper location.

8H) ADDED HEAT-EXCHANGERS

The TECC controller card allows to add

heat-exchangers in the chilled water circuit

which can be of all nature :

1) Water/Water exchanger to use the 85/90°

C hot water circulation from a fuel heater

2) Electrical calorifiers

3) Engine heat

Etc

Here-after (Drawing N° 8.1) an example of a

Water/Water exchanger specially adapted for

Webasto fuel heaters .

8 - CHILLED WATER SYSTEM INSTALLATION

ONNECT TO <VALVE> OUTLETS

N TECC CONTROLLER CARD

SPECIAL MARINE 3-WAY VALVE

ASSEMBLY

75/85˚ C WATER FROM FUEL HEATER

RETURN LINE TO FUEL HEATER

RETURN TO FUEL HEATER

MARINE EXCHAN

GER

REF. WBCL005080 OR WBCL005081

CHILLED WATER CIRCUIT OUT

CHILLED WATER CIRCUIT IN

DIRECTLY FROM CHIILER PUMP

DIRECTLY FROM CHIILER PUMP

2 POLE ELECTRICAL WIRE

2 POLE ELECTRICAL WIRE

2 POLE ELECTRICAL WIRE

2 POLE ELECTRICAL WIRE

8.1 - SCHEMATICS - INSTALLATION AND CONNECTION OF WEBASTO HEAT EXCHANGER

Page 14

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 13

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 13

EDITION DATED 21ST AUGUST 2006

8E - CHILLED WATER PIPING

AND ACCESSORIES

Chilled water piping can be in rigid plastic

tubing and/or flexible reinforced hoses.

Internal dimensions of tubing should be in

conformity with piping drawing as supplied by WEBASTO.

PAY SPECIAL ATTENTION TO :

1) ELBOWS

Only use large radius elbows and not short

radius. Short radius elbows entail a flowrate loss of approx. 2.5% per elbow. A succession of 8 short radius elbows will therefore result in total flow-rate reduction of

100% x0.975x0.975x0.975x0.975 etc =

81.66%.

Large radius elbows only result in a flowrate loss of approx. 0.5%.

If no large radius elbows can be found use

2 successive 45° elbows instead.

See also photo to the left.

CHILLED WATER CIRCUIT PIPING

GOLDEN RULES - INSTALLATION OF BASIC COMPONENTS

= SHUT-OFF VALVE

Secondary access with shutoff valve 3/4” - should

always face upwards

Drain valve at lowest part of circuit. Allows full draining of the system after initial pressure tests and also in case of doubt concerning

the exact glycol (anti-freeze) percentage of the mixture.

SHUT-OFF VALVES ON ENTRY AND EXIT

FOR EASY MAINTENANCE

If this line always goes upwards without any down-turn, it can be

used for filling the system ; if not use secondary access and attach

temporary filling hose with temporary filling tank on rooftop, up

and above highest air-handler. Diam. 5/8” or 3/4” transparent.

OPTIONAL RETURN LINE VALVE

LARGE RADIUS ELBOWS ONLY

CIRCULATION PUMP

EXPANSION TANK : If

static- should be highest

part of circuit

8.2 - ELBOWS 90° - CHILLED WATER PIPING

SHORT RADIUS ELBOW

USE LARGE RADIUS

ELBOW ONLY OR 2 X

45° ELBOWS

2) PIPE INSULATION

Only use rubber or synthetic rubber foam

insulation (Armstrong Armaflex or

Rubatex or similar) - do not use polythene

foam insulation.

Do not use split-type open insulation as

this type tends to come apart after a certain

time.

Try to use rigid foam core supports to fix

piping.

See also photo to the right.

8.3 - EXAMPLE WATER PIPING CIRCUIT - 1 CHILLER UNIT + 4 AIR-HANDLERS

FOAM THICKNESS : 9 MM FOR

BOATS UP TO 15/16 M; 13 MM

FOR BOATS OVER 16 ML.

RIGID CORE SPECIAL SUPPORT

ENABLING SOLID FIXING OF TUBING WITHOUT DEFORMATION

ONLY USE RUBBER OR SYNTHETIC

RUBBER FOAM INSULATION

8.4 - TUBING INSULATION

Here-after a summary of the most basic but important guide-lines for success when installing a Chiller piping

System. These Guide-lines cover all items such as insulation, water-piping, etc

Most important pre-liminary remark :

Water-flow rates in a Chiller circulation circuit are approx. 2/3 times as high as the normal flow rates found

a central heating system at home. So pay special attention to all possible flow restrictions !

Page 15

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 14

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 14

EDITION DATED 21ST AUGUST 2006

Insulation foam thickness should be at

least 9 mm for boats up to 15/16 ml and 13

mm for all boats above that length.

Finish off all Tee junstions and others with

self-adhesive foam tape.

3) TEE JUNCTIONS

It is preferable to use oblique Tee junctions

for secondary branching. If 45° Tees are

not available make sure the reduction in

diam. on the secondary line is made after

the junction Tee so as to obtain the largest

possible entry diam.

See photo here-under.

4) ENTRY DIAM. OF AIR-HANDLERS

Always respect the minimum entry diam.

of the air-handlers. Secondary piping to the

air-handlers should not be less than the

prescribed diam.

Here-after list of air-handler entry diameters (all diam. are net internal) :

Model Entry/Exit diam.

4000/4500 BTU 12 mm (1/2”)

6000 BTU 12 mm

9000 BTU 15 mm (5/8”)

12000 BTU 15 mm

16000 BTU 15 mm

24000 BTU 20 mm (3/4”)

5)

ANTI-FREEZE SOLUTION :

It is imperative to add approx. 25% pure glycol to the chilled water-circuit system so as to

avoid accidental freezing of the water-circuit

during the winter and also freezing up of the

condensing unit evaporator(s) should for any

reason the temperature control fail or be

retarded.

There is a general safety cut-out when freezing up an evaporator by means of the Low

Pressure cut-out, but this safety device may

allow a temporary drop of the water-circuit

temperature to approx. -2° C before stopping

the system. Hence the utmost importance of

adding approx. 20% glycol to the water-circuit.

Attention : non-respect of the use of

glycol/water mixture (25% glycol +

75% fresh water) in the chilled

water circulation circuit will void

any WEBASTO warranty.

6) FILLING UP AND PURGING OF A

CHILLED WATER CIRCUIT :

The following procedure is the simplest and

most effective way to prepare a chilled water

circuit, purge it from all air and put it into

operation in the shortest possible time.

Make sure to follow the steps here-under in

the same order :

1) Installation of purging Tee on entry/suction side of circulation pump. This Tee

should enable the temporary connection of a

filling hose of at least 15 mm interior diam.

The filling entry should be directed upwards

and not side-ways or down-wards.

Fit a shut-off valve enabling quick closing of

the access point after completing the filling

procedure.

2) Install a temporary charging recipient (jerrycan etc) in such a way that this recipient is

the highest point of the circuit and that the

hose from the acces Tee to the jerrycan goes

always upwards, never horizontally and

never downwards. It is advisable to use transparent hose from the Tee to the jerrycan.

3) Open all bleeders on all air-handlers.

4) Start filling the circuit from the jerrycan

on the rooftop - watch all bleeder points on

all air-handlers. Close all bleeders immediately when solid water comes out. No further

bleeding from the air-handlers will be

required from there on.

5) Isolate the 230V supply to the circulation

pump so as to be able to switch the circulation pump on and off manually. The easiest

method is to connect a temporay lead to the

circulation pump with a manual switch.

Make sure the jerrycan on the roof is at least

half full at that stage.

Start circulation pump shortly for approx. 15

seconds and stop it. You will notice massive

air bubbles going upwards through the filling

hose.

Repeat this for several times until such

moment that the air bubbles going upwards

through the filling hose become small

enough to leave the pump on continuously

without cavitating.

6) Leave the pump on continuously for at

least 45 minutes. You will notice a contiuous

small stream of bulbles going upwards and

solid water going downwards.

7) Help the final purging of the system by

selectively closing the shut-off valves on all

air-handlers so as to force the waterflow

through the other air-handlers. This will finish purging any residual air that may have

been trapped in any individual air-handler.

8) When the pump is running without any

cavitation noise and no further small air-bubbles go upwards from the Tee junction on the

pump entry, stop the circulation pump, close

the shut-off valve and disconnect the temporary filling station.

9) With this method there is absolutely no

need to purge at each individual air-handler

provided the filling hose has a sufficiently

large diameter and always goes upwards to

the filling tank on the rooftop.

10) Remark for pressurized systems only

After satisfactory purging of all air in the system, close valve on Tee entry to the suction

pump with pump running so as to build up

maximum pressure in the system.

Then if necessary increase pressure by opening valve to pressurized water system.

11) Refilling after leak :

Never refill system with fresh water only; be

sure to always maintain glycol mixture of

between. 20 and 25% glycol - 75/80% fresh

water.

WATER-FLOW - MAIN BRANCH

WATER-FLOW - SECONDARY

8.5 - TEE JUNCTIONS

45° TEE

JUNCTION

90° TEE JUNCTION

WATER-FLOW

LEAVE AMPLE ROOM BEFORE

REDUCING PIPE DIAMETER

Page 16

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 15

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 15

EDITION DATED 21ST AUGUST 2006

9. ROUTINE CHECKS

CHILLED WATER

CIRCULATION PUMP

- SHUT-OFF VALVE

1

23

4

5

6

1 = 24000 BTU

2 = AIR-HANDLER 12000 BTU - SALOON

3 = AIR-HANDLER 6000 BTU - OWNERS CABIN

4 = AIR-HANDLER 4500 BTU - GUEST CABIN

5 = AIR-HANDLER 4500 BTU - GUEST CABIN

6 = EXPANSION TANK

D12 = INTERIOR DIAM. 12 MM - 1/2"

D15 = INTERIOR DIAM. 15 MM - 5/8"

D20 = INTERIOR DIAM. 20 MM - 3/4"

D20

D15

D12

D20

D15

D15

D15

D15

D20

D12

D12

D12

D12

D12

8.7 - EXAMPLE N° 2 - MONO-HULL WITH WBCP24/D - STERN LOCATION + 4 AIR-HANDLERS

TYPICAL SCHEMATICAL EXAMPLES OF CHILLED WATER CIRCUITS

Here-after a certain number of examples of typical chilled water circuit piping lay-outs

- SHUT-OFF VALVE

CHILLED WATER CIRCULATION

PUMP

EXPANSION TANK

D12 = INTERIOR DIAM. 15 MM - 5/8"

D15 = INTERIOR DIAM. 12 MM - 1/2"

D15

D12D12

D15

D12

D12

D15

18000 BTU

AIR-HANDLER

9000 BTU

AIR-HANDLER

9000 BTU

8.6 - EXAMPLE N° 1 - SMALL 18000 BTU CHILLER - CENTRAL LOCATION + 2 AIR-HANDLERS

Page 17

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 16

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 16

EDITION DATED 21ST AUGUST 2006

- SHUT-OFF VALVE

36000 BTU

FLOW CALIBRATION VALVES

1

2

3

4

5

6

7

1 = CHILLED WATER CIRCULATION PUMP

2 = 12000 BTU AIR-HANDLER - MAIN SALOON

3 = 12000 BTU AIR-HANDLER - MAIN SALOON

4 = 6000 BTU CABIN AIR-HANDLER

5 = 6000 BTU CABIN AIR-HANDLER

6 = 6000 BTU CABIN AIR-HANDLER

7 = 6000 BTU CABIN AIR-HANDLER

8 = EXPANSION TANK

9 = RETURN COLLECTOR 4 + 1

D12 = INTERIOR DIAM. 12 MM - 1/2"

D15 = INTERIOR DIAM. 15 MM - 5/8"

D20 = INTERIOR DIAM. 20 MM - 3/4"

8

D20

D20

D15

D15

D15

D15

D15

D15

D15

D15

D15

D15

D20

D20

D12

D12

D12

D12

D12 D12

D12 D12

9

8.8 - EXAMPLE N° 3 - CATAMARAN WITH WBCP36/D - CENTRAL LOCATION + 6 AIR-HANDLERS

Page 18

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 17

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 17

EDITION DATED 21ST AUGUST 2006

1

2

3

4

5

6

7

8

9

10

1 = 72000 BTU

2 = EXPANSION TANK

3 = CHILLED WATER CIRCULATION PUMP

4 = 16000 BTU AIR-HANDLER - WHEELHOUSE

5 = 16000 BTU AIR-HANDLER - MAIN SALOON

6 = 12000 BTU AIR-HANDLER - OWNERS CABIN

7 = 9000 BTU AIR-HANDLER - GUEST CABIN N˚1

8 = 9000 BTU AIR-HANDLER - GUEST CABIN N˚ 2

9 = 6000 BTU AIR-HANDLER - GUEST CABIN N˚ 3

10 = 6000 BTU AIR-HANDLER - GUEST CABIN N˚4

D12 = INTERIOR DIAM. 12 MM - 1/2"

D15 = INTERIOR DIAM. 15 MM - 5/8"

D20 = INTERIOR DIAM. 20 MM - 3/4"

D25 = INTERIOR DIAM. 25 MM - 1"

- SHUT-OFF VALVE

SOLENOID VALVE WITH

METERED BY-PASS

D25

D25

D25

D25

D20

D20

D20

D20

D20

D20

D15

D15

D15

D15

D12

D12

D12

D12

LENGTHS TO COMMON

EXIT AND ENTRY SHOULD

BE BALANCED

8.9 - EXAMPLE N° 4 - M/Y WITH WBCP72/D TWIN - STERN LOCATION + 10 AIR-HANDLERS

Page 19

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 18

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 18

EDITION DATED 21ST AUGUST 2006

8F - AIR DUCTING - VENTILATION

1) MINIMUM AIR-GRILLE SECTIONS

In order to obtain an acceptable noise level at

max. blower speed certain requirements as

regards grille and ducts sections should be

observed.

Also the size of the transition boxe behind

the supply air-grille is important.

See table here-under to choose correct grille

sections according to BTU rating.

2) DUCT TYPE

Flexible air-ducts should be of high quality

with sufficiently strong steel spiral reinforcement to avoid accidental crushing.

Spiral type ducts should be extended to their

maximum possible length to obtain max.

interior smoothness.

For very long duct sections preference should

be given to rigid ducts (in PVC for example)

which offer a far greater smoothness than

flexible spiral type ducting and therefore will

greatly reduce internal friction.

For very short lengths non-insulated ducts

may possibly be used. Over greater lengths it

is advisable to use insulted type ducts to

avoid condensation on the outside of the airducts.

AIR/HANDLER-WBCC SUPPLY AIR GRILLE RETURN AIR GRILLE DUCT DIAM. DUCT DIAM.

MODEL MODEL/ SECTION cm² MODEL/SECTION cm² <1.8 M DUCT LEN. >1.8 M DUCT LEN.

4000/4500 BTU

6000 BTU

9000 BTU

12000 BTU

16000 BTU or

16000 BTU

24000 BTU

32000 BTU

1 x 8x4” 150 cm²

1 x 10x4” 190 cm²

1 x 12x4” 235 cm²

1 x 10x5” 250 cm²

1 x 12x6” 390 cm²

2 x 10x4” 380 cm²

2 x 10x5” 500 cm²

2 x 12x5” 650 cm²

1 x 12x5” 325 cm²

1 x 11x8” 490 cm²

1 x 11x8” 490 cm²

1 x 14x7” 550 cm² or

1 x 14x10” 800 cm2

1 x 14x12” 1000 cm²

2 x 14x10” 1600 cm²

80 mm

100 mm

100 mm

125 mm

125 mm

125 mm

2 x 125 mm

2 x 125 mm

100 mm

125 mm

125 mm

150 mm

150 mm

150 mm

2 x 150 mm

2 x 150 mm

3) BLOWER OUTLETS

90° turns with flexible ducts directly from

blower outlets should be avoided at all costs

as they introduce severe restrictions in the

air-flow.

All WEBASTO blowers (except on 24000

BTU models) can be rotated through 45°

steps so as to obtain a straight-line outlet

from the blower. This facility should be used

whenever possible.

See also drawing to the right.

4) TRANSITION BOXES

Transition boxes behind supply air-grilles

essentially serve the following purpose :

Serve as an expansion volume for the airflow to be reduced in velocity and therefore

reduce air noise when crossing the outlet

louvres.

It follows therefore that the depth of the transition box is an important factor to allow dispersion of the air-flow

The table to the right gives the necessary

information as to the minimum dimensions

advisable for such transition boxes.

5) RETURN GRILLE OFFSET

It is best to avoid placing a return air grille

directly opposite the finned coil surface of an

air-handler. This will inevitably allow propagation of direct blower-motor noise through

the grille.

Always try to offset the grille so as to chicane the return air to the coil inlet.

This will lower direct noise propagation in a

significant manner.

AIR FLOW

AIR FLOW

BLOWER ROTATED TO

MINIMZE FRICTON LOSSES

H

H

DUCT DIAM. MINIMUM VALUE OF “H”

80 mm 100 mm

100 mm 120 mm

125 mm 140 mm

150 mm 165 mm

8.11 - TRANSITION BOX INFORMATION

Deflection curve for longitudinal

entry transition boxes

NB : For duct lengths over 1.80 ml, it may be possible to use the nominal duct diameter (for example 100 mm - 6000 BTU

model), if instead of spiral type flexible ducts, rigid perfectly smooth interior ducts are used.

8.10 - ROTATABLE BLOWER OUTLETS

Page 20

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 19

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 19

EDITION DATED 21ST AUGUST 2006

When starting up an air conditioning unit it is

advisable to carry out a certain number of

control routines to ensure proper functioning

of the unit.

- always check (especially after a long

absence) the functioning of the sea water

cooling system. Immediately stop the system

if no sea-water comes out of the pump exit

after compressor starts up.

- periodically check the air filter in the return

air grilles. Clean if necessay.

- check condensation drain from the evaporator drain pan.

- take care not to damage the air-ducts. A

damaged air-duct may stop air flow through

the evaporator, freeze up the evaporator and

subsequently damage the compressor.

- when preparing for winter lay-up take care

to rince all sea-water circuits with a freshwater/glycol solution (20% or more depending on local winter conditions).

10.TROUBLE SHOOTING

1) No sign of live : check main electrical supply, fuses, etc.

2) The digital display shows 3 lettres

<AAA>. This means a persistent state of low

voltage (less than 195 V AC). The system

will re-start as soon as the voltage level

climbs above cut-out level and the system

will then re-start after a time-delay of 1

minute approx.

3) The compressor will start but no sea-water

circulation can be observed :

- check sea-cock to sea-water pump.

- check sea-water strainer

- check if pump turns

- if the pump does not turn with the compressor working, check power-supply from

the main control unit box to the pump.

4) Compressor and pump work but no correct

operation in either cool or heat cycle :

- during the heat cycle with too slow a seawater circulation you may actually freeze up

the sea-water in the cupro-nickel condenser

and completely block the system.

- check voltage level. Do not operate a system with a persistent voltage level below

195 V AC.

- check freon charge if operation is still not

satisfactory, after having checked all the

above points.

5) The compressor works but is subject to

intermittent stops without having attained

the desired set-point temperature.

- the HP and BP (if present) pressure safety

switches stop the compressor because of

abnormal working pressures either on the

high or on the low side. Check proper functioning of the cooling circuit. Check ventilator/blower system for obstructions.

- incorrect freon charge (over-charge or

insufficient charge level).

See also here-above : Error

codes/interrupted system operation.

6) The heat cycle takes very long to get started.

- normal if the sea-water temperature is very

low. If sea-water temperature drops below

approx. 8° C. the heat cycle becomes much

less effective and takes long to get properly

started.

7) The heat cycle functions very well but the

compressors stops by means of the high

pressure safety switch.

- the heat cycle functions with a very high

sea-water temperature and therefore the

high pressure side exceeds the safety limit.

You may try to remedy this situation by

slightly restricting the sea-water flow but not

so much as to freeze up the condenser. Do

not forget to open up the sea-water circulation again when switching back to

<COOL>.

Page 21

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 20

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 20

EDITION DATED 21ST AUGUST 2006

11 - WIRING DIAGRAMS - ALL CHILLER MODELS Page

11.1 - Wiring Diagram single/twin compressor WBCP16/30 - 1 phase .....................................

11.2 - Wiring Diagram Compressors 1 and 2 - 1 or 3 phase ....................................................

11.3 - Wiring Diagram Compressors 3 and 4 - 1 or 3 Phase ....................................................

11.4 - Wiring schematics -supply cables for TWIN/CI compressor units - single phase ..........

11.5 - Wiring schematics - supply cables for TRI/CI (3) compressor units - single phase ......

11.6 - Wiring schematics - supply cables for TRI/CI (3) compressor units - 3 phase ..............

11.7 - Wiring schematics - supply cables for QUATRO/CI (4) compressor units - 3 phase .....

11.8 - Wiring Diagram - automatic staging relay - secondary AC loads ..................................

11.9 - Wiring Diagram - blower motor running capacitors .......................................................

Minimum Cable Sections per Chiller Model (Ground Wires not shown) :

Model Description Voltage Phase Section mm2

SINGLE COMPRESSOR UNITS

WBCP20 230 1 2 x 2.5 mm2

WBCP24 230 1 2 x 2.5 mm2

WBCP30 230 1 2 x 4 mm2

WBCP36 230 1 2 x 4 mm2

WBCP42 230 1 2 x 6 mm2

WBCP48 230 1 2 x 6 mm2

TWIN COMPRESSOR UNITS (CI models - 2 independent refrigerant circuits)

(Section per Compressor - for single supply line increase section accordingly)

WBCP40/D TWIN 230 1 2 x 2.5 mm2

WBCP52/D TWIN 230 1 2 x 2.5 mm2

WBCP64/D TWIN 230 1 2 x 4 mm2

WBCP72/D TWIN 230 1 2 x 4 mm2

WBCP84/D TWIN 230 1 2 x 6 mm2

WBCP96/D TWIN 230 1 2 x 6 mm2

WBCP84/D TWIN 400 3 3 x 2.5 mm2

WBCP96/D TWIN 400 3 3 x 2.5 mm2

TRI-COMPRESSOR UNITS (CI models - 3/4 independent refrigerant circuits)

(Section per Compressor - for single supply line increase section accordingly)

WBCP108/D TRI 230 1 2 x 4 mm2

WBCP126/D TRI 230 1 2 x 6 mm2

WBCP126/D TRI 400 3 3 x 2.5 mm2

WBCP144/D TRI 230 1 2 x 6 mm2

WBCP144/D TRI 400 3 3 x 2.5 mm2

WBCP180/D TRI 400 3 3 x 4 mm2

WBCP216/D TRI 400 3 3 x 4 mm2

WBCP252/D TRI 400 3 3 x 6 mm2

WBCP288/D QUATRO 400 3 3 x 4 mm2

WBCP336/D QUATRO 400 3 3 x 6 mm2

21

22

23

24

24

25

25

26

26

Page 22

220V

220V

COMP1

PUMP2

FAN

VA LV E

PUMP1

PUMP2

COMP2

COMP1

FAN

VA LV E

PUMP1

HP

BP

HP

BP

AC SUPPLY 230V

SEAWATER PUMP

CIRCULATION PUMP

BLOWER

C1R1T1

C2

R2

T2

RUN

CAPA

REVER. VALVE

S

R

C

DIGIT.

DISPL.

AIR

SENSOR

WATER

SENSOR

GND

+

-

DIPSWITCH SELECTOR

CYCLE

INDICATOR RELAY

AC LOAD

STAGING RELAY

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 21

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 21

EDITION DATED 21ST AUGUST 2006

11.1 - WIRING DIAGRAM WBCP UNITS - 230V 1 PHASE - 16000 TO 30000 BTU- 1 COMPRESSOR

(For single compressors 36 to 48000 BTU, a power-relay is used - refer to drawing 11.2 - page 22)

1

23

4

OPEN

ATT. DIPSWITCH SETTINGS

BLACK = PUSHED DOWN

Page 23

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 22

2004 SERIES - CHILLER SYSTEMS - OPERATION AND INSTALLATION MANUAL - PAGE : 22

EDITION DATED 21ST AUGUST 2006

DIPSWITCH SELECTOR

AC SUPPLY 230V/ELECTRONICS/PUMPS

AC SUPPLY COMPR. 2

TO COMPR. 2

SEAWATER PUMP

CIRCULATION PUMP

BLOWER

REVER.VALVES

HP

BP

HP

BP

AC SUPPLY COMPR. 1

TO COMPR. 1

C1

R1T1C2

R2

T2

GND

PUMP1

PUMP2

VA LV E