Page 1

The Scholastic Series

School Bus Heater

Operating Instructions

Installation Instructions

Service Parts Listing

For:

Conventional Model

Transit Model (Engine Front)

Transit Model (Engine Rear)

Page 2

TABLE OF CONTENTS

I

Table of Contents

1. Introduction

1.1 Scope and Purpose .................................................... 1-1

1.2 Meaning of Warnings, Cautions and Notes .................................. 1-1

1.3 Additional Documentation to be Used ...................................... 1-1

1.4 General Safety Regulations and Information ................................. 1-1

1.4.1 General Safety Notes ........................................... 1-1

2. General Description

2.1 Scholastic Heater Description ............................................ 2-1

3. Functional Description

3.1 Operating your Webasto Scholastic Heater .................................. 3-1

3.2 Switching On ......................................................... 3-1

3.3 Switching Off ......................................................... 3-2

3.4 Engine Preheating ..................................................... 3-2

3.5 Boost Heating for Engine and Passenger Compartment ......................... 3-2

3.6 Operation with 7-Day Digital Timer Model 1531 ............................... 3-2

3.7 7-Day Digital Timer Programming and Operating Instructions ..................... 3-4

4. Technical Data

4.1 Scholastic Series Heater Data ............................................ 4-1

4.1.1 Scholastic Series Heater Dimensions ............................... 4-2

4.2 Coolant Circulation Pump Data ........................................... 4-3

4.2.1 Coolant Circulation Pump Dimensions ............................... 4-3

4.3 Tray Mount Dimensions ................................................. 4-4

5. Installation

5.1 General Information .................................................... 5-1

5.2 Installation Locations ................................................... 5-1

5.3 Mounting the Heater ................................................... 5-2

5.4 Exhaust Pipe Connection ............................................... 5-2

5.5 Combustion Air Supply ................................................. 5-3

5.6 Plumbing into the Coolant System ......................................... 5-3

5.6.1 General Information ............................................. 5-3

5.6.2 Engine and Passenger Compartment Heating ......................... 5-4

5.6.3 Instructions for Integrating into the Coolant System ..................... 5-5

W

EBASTOSCHOLASTICSERIES

Page 3

TABLEOFCONTENTS

5.7 FuelSystem.........................................................5-7

5.7.1 GeneralDescription.............................................5-7

5.7.2 FuelSupply...................................................5-7

5.7.3 FuelFilter....................................................5-9

5.8 WiringConnections....................................................5-10

5.8.1 GeneralInformation.............................................5-10

5.8.2 ConnectingPowerHarnesstoaConstantPowerSource.................5-10

5.8.3 TimerandSwitchConnections....................................5-11

5.8.4 TimerandSwitchInstallation......................................5-11

5.8.5 WiringDiagram-ScholasticSeriesHeater...........................5-12

5.8.6 WiringDiagram-Chassis/PowerHarnesswithSwitch..................5-13

5.8.7 WiringDiagram-Chassis/PowerHarnesswithSwitch..................5-14

5.8.8 WiringDiagram-Chassis/PowerHarnesswithDigitalTimerModel1531....5-15

5.8.9 WiringDiagram-Chassis/PowerHarnesswithDigitalTimerModel1531....5-16

5.9 InitialOperation.......................................................5-17

W

EBASTOSCHOLASTICSERIES

6. MaintenanceoftheHeater

6.1 AnnualMaintenance...................................................6-1

7. BasicTroubleshooting

7.1 GeneralInformation....................................................7-1

7.2 QuickCheckTroubleshootingMatrix.......................................7-1

7.3 HeaterTestUnit(WebastoP.N.440280)....................................7-2

7.4 TestProcedures......................................................7-3

8. SparePartsListing

SparePartsListing....................................................8-1

II

Page 4

W

EBASTOSCHOLASTICSERIES

TABLE OF CONTENTS

III

List of Figures

2-1 Webasto Scholastic Series Heater ......................................... 2-1

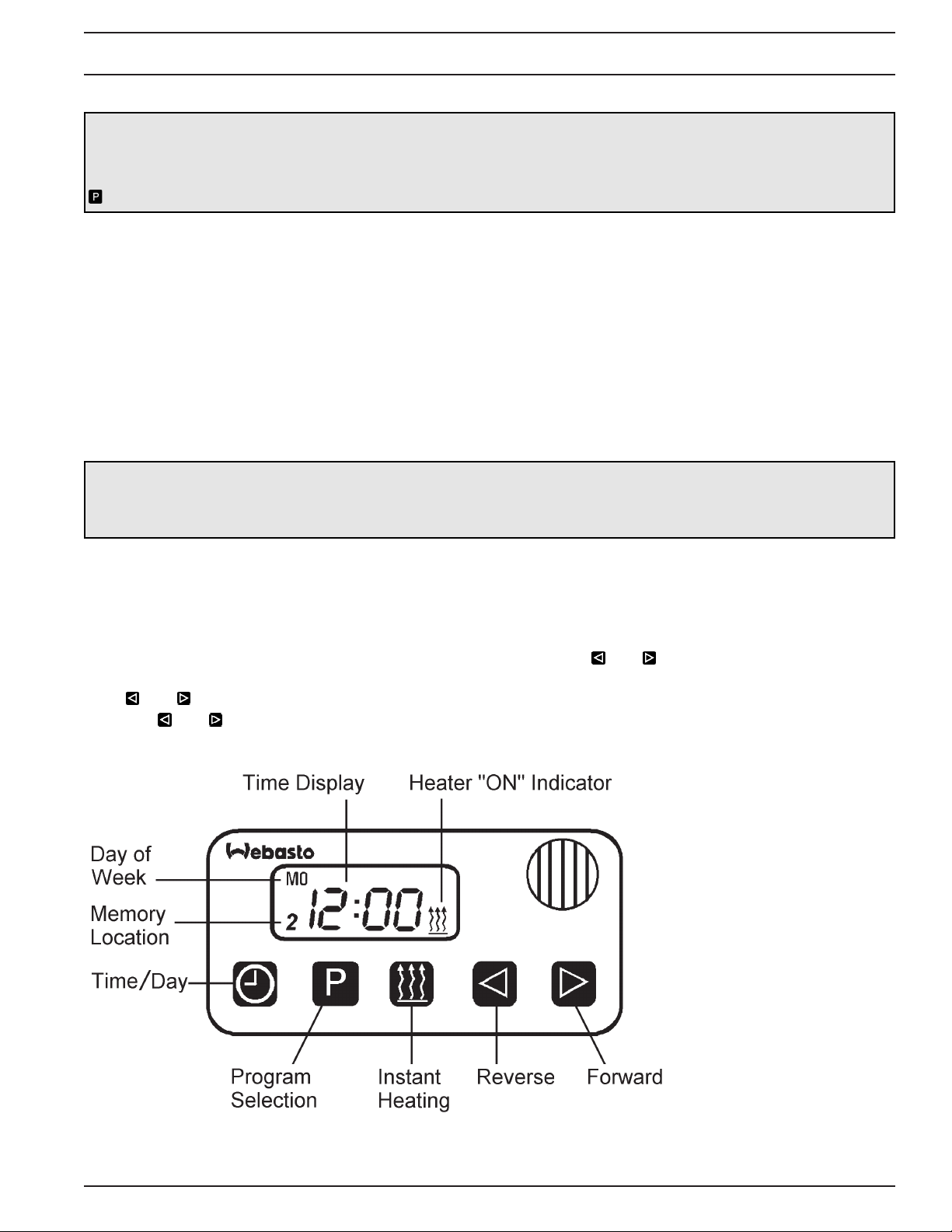

3-1 7-Day Digital Timer – Typical ............................................. 3-3

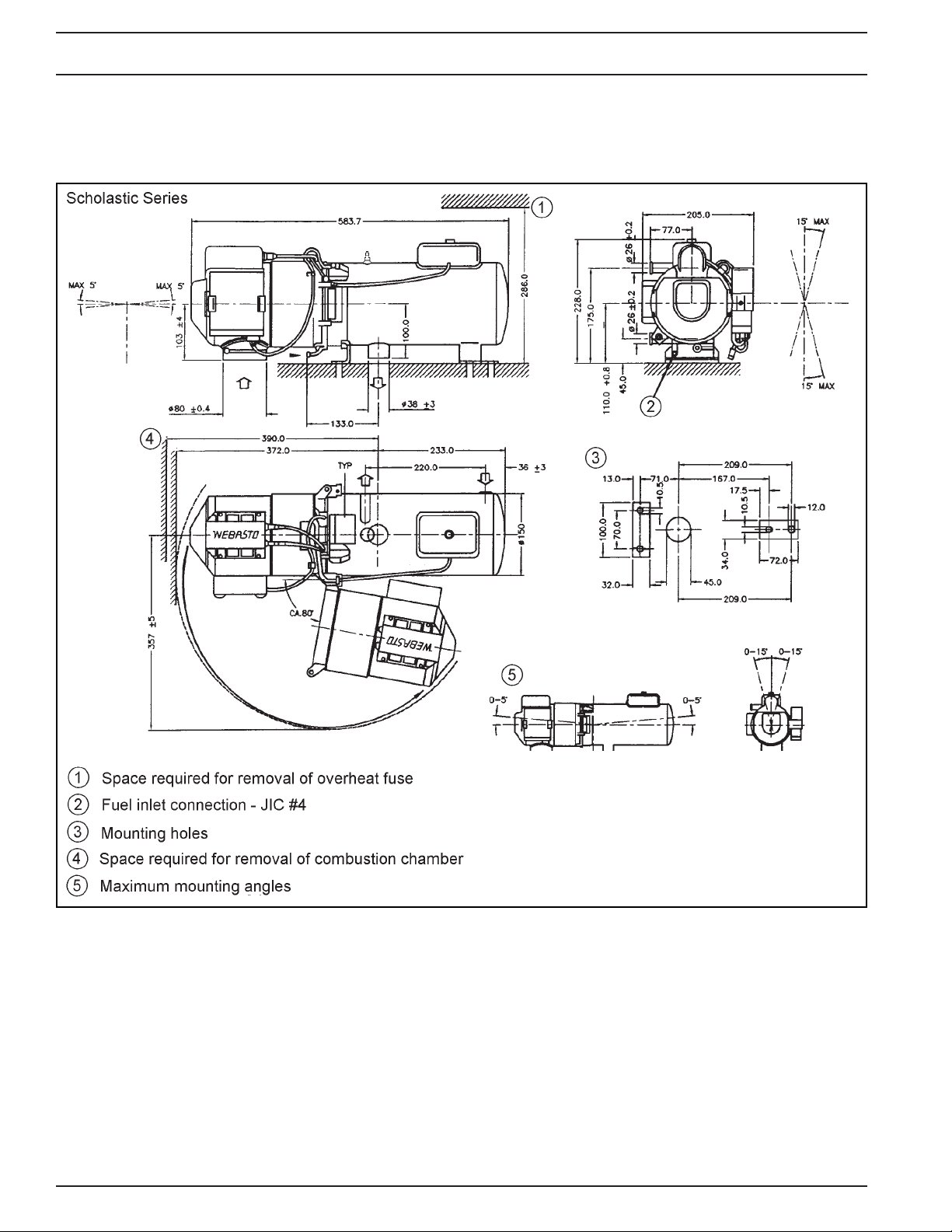

4-1 Scholastic Series Heater Dimensions (Millimeters) ............................. 4-2

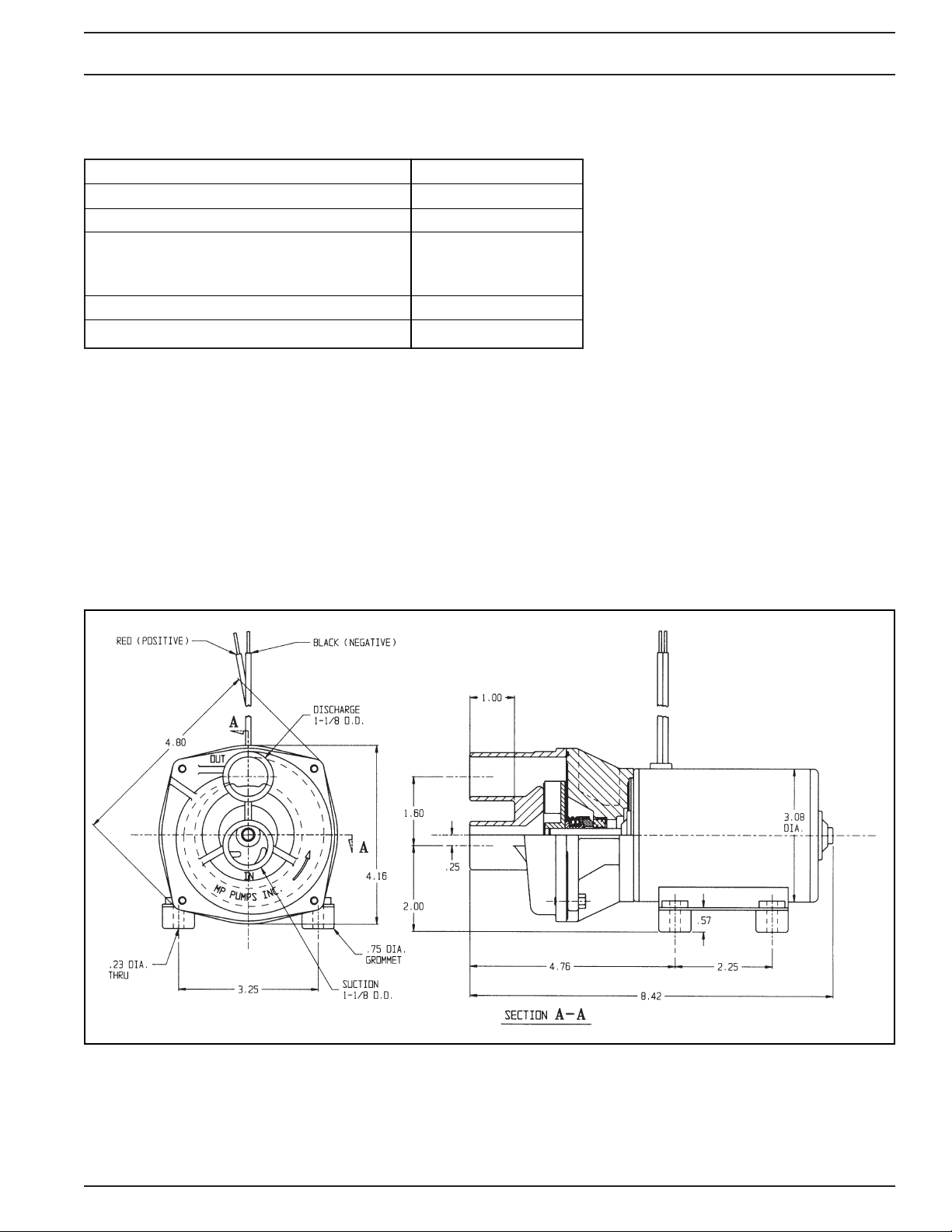

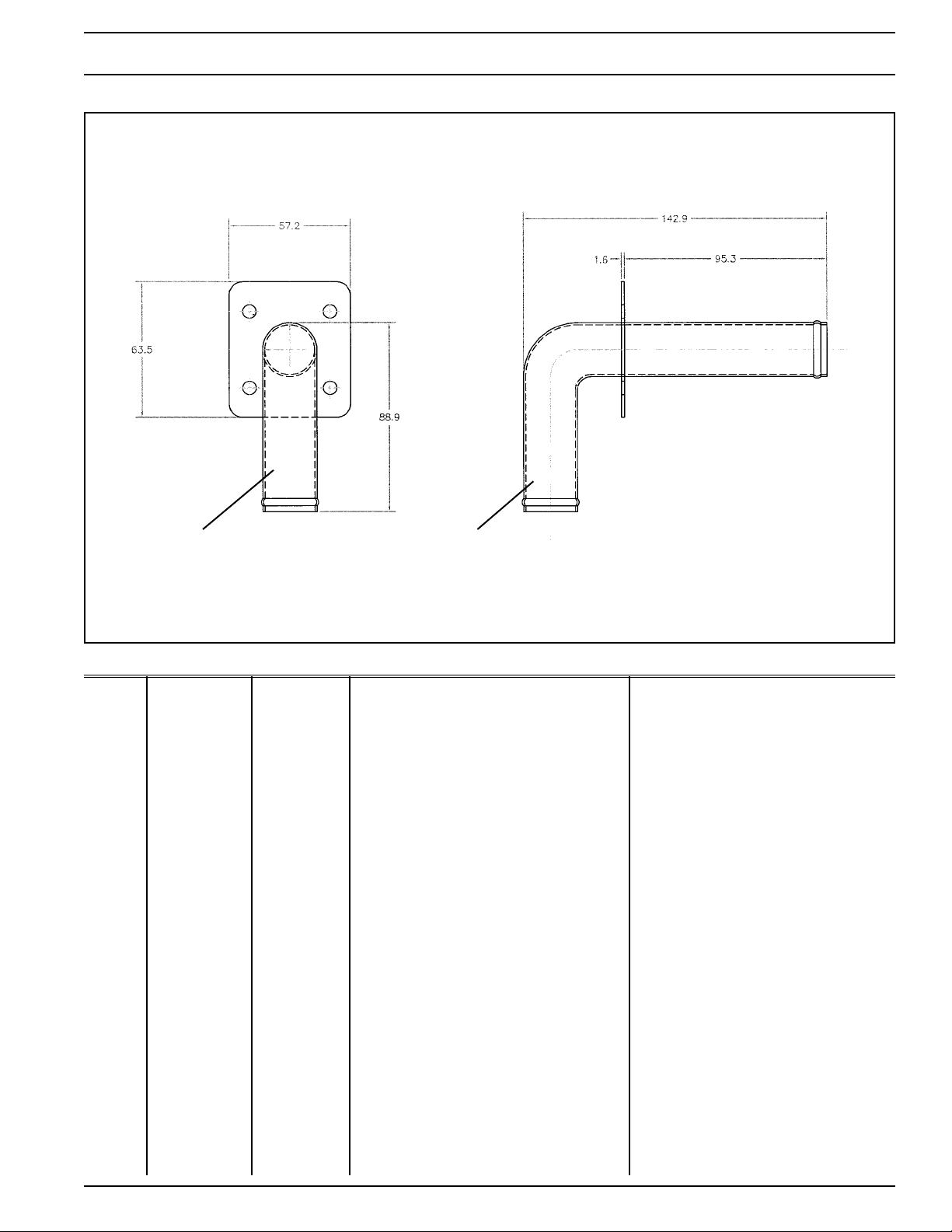

4-2 Coolant Circulating Pump Assembly (P.N. 906017) Dimensions (Inches) ............ 4-3

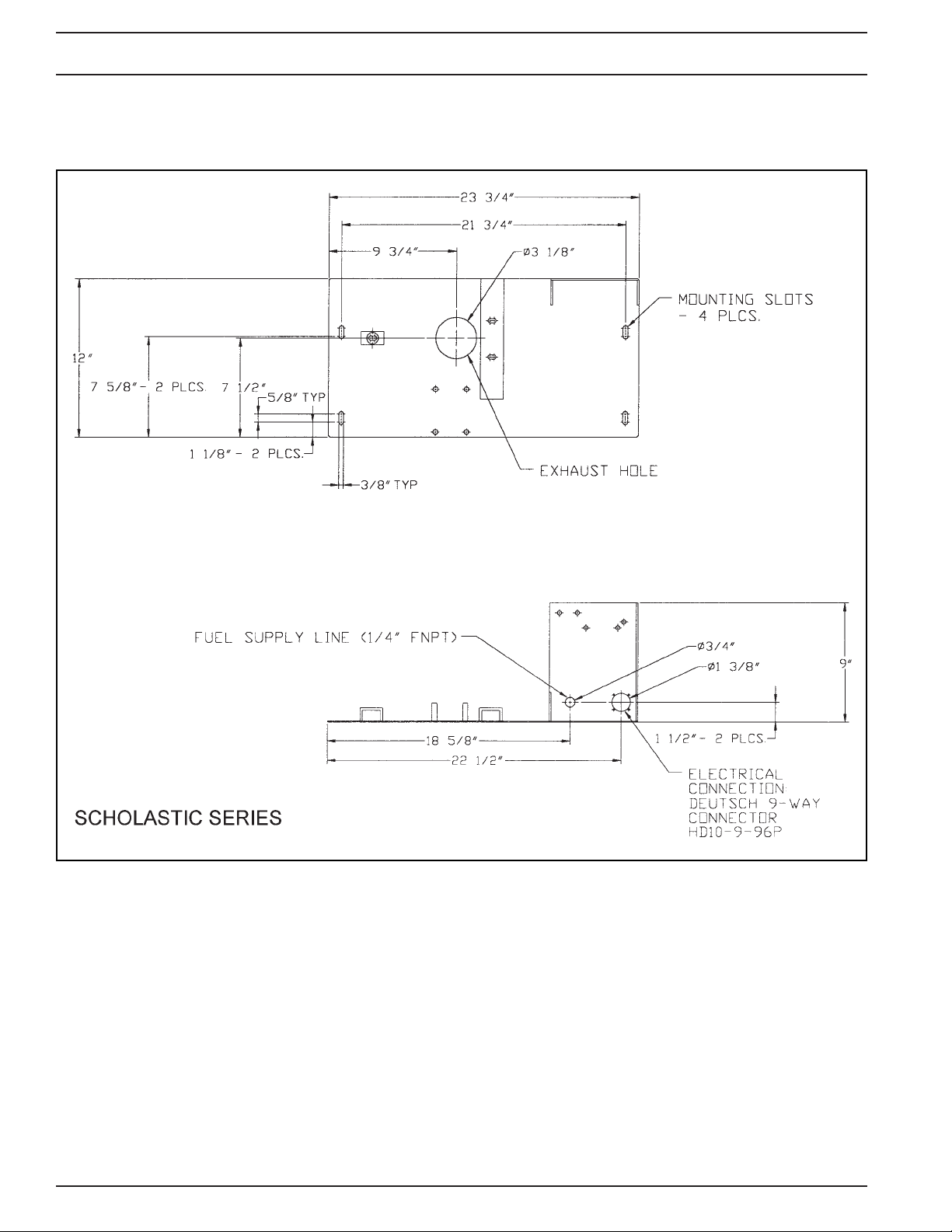

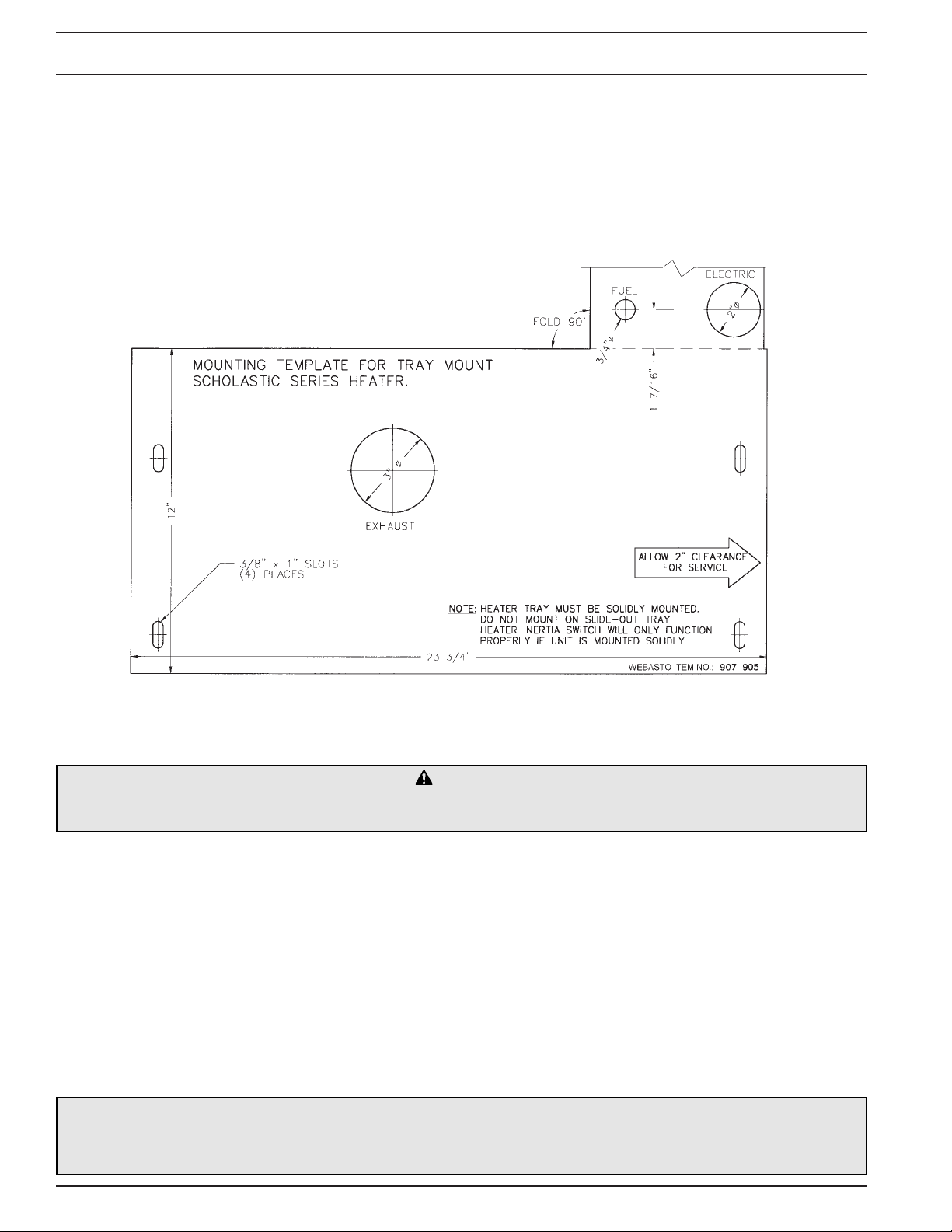

4-3 Tray Mount Dimensions (Inches) .......................................... 4-4

5-1 Installation Locations ................................................... 5-1

5-2 Tray Mount Template (Supplied with Heater Kit) ............................... 5-2

5-3 Typical School Bus Heating Circuit ........................................ 5-3

5-4 Series Plumbing Circuit - Conventional Model ................................ 5-4

5-5 Series Plumbing Circuit - Transit Model (Engine Front) ......................... 5-4

5-6 Series Plumbing Circuit - Transit Model (Engine Rear) .......................... 5-5

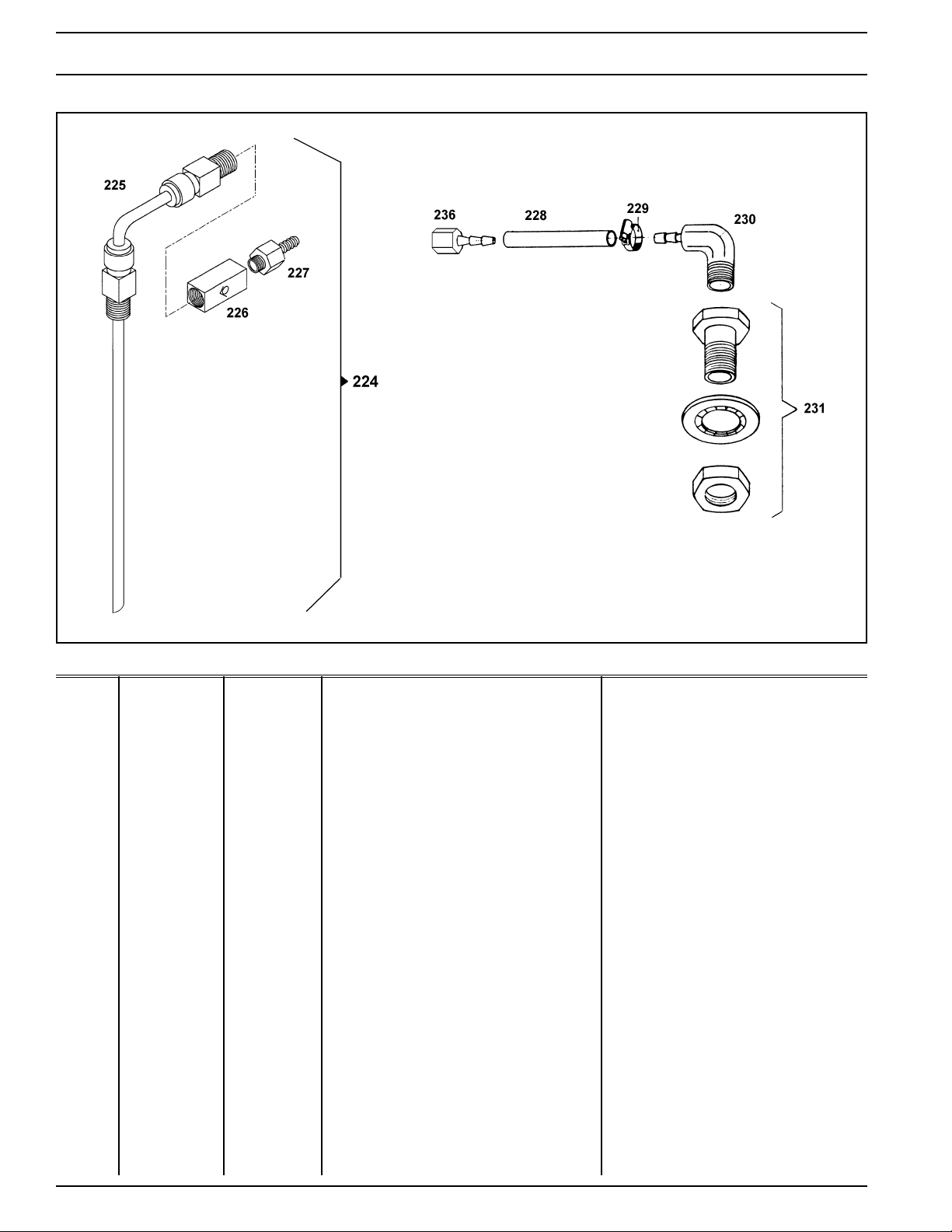

5-7 Fuel Standpipe Installation ............................................... 5-7

5-8 Fuel Line Parameters .................................................. 5-8

5-9 Harness Connection Points ..............................................5-10

5-10 On/Off Switch ........................................................5-11

5-11 7-Day Digital Timer Model 1531 ...........................................5-11

5-12 Wiring Diagram - Scholastic Series Heater ..................................5-12

5-13 Wiring Diagram with Switch ..............................................5-13

5-14 Wiring Diagram with Switch ..............................................5-14

5-15 Wiring Diagram with Timer Model 1531 .....................................5-15

5-16 Wiring Diagram with Timer Model 1531 .....................................5-16

7-1 Test Unit P.N. 440280 .................................................. 7-2

List of Tables

3-1 Digital Timer Instructions ................................................ 3-4

4-1 Scholastic Series Heater Data ............................................ 4-1

4-2 Coolant Circulation Pump Data ........................................... 4-3

7-1 Quick Check Troubleshooting Matrix ....................................... 7-1

7-2 Test Procedures and Results ............................................. 7-3

Page 5

W

EBASTOSCHOLASTICSERIES

1INTRODUCTION

1-1

1. Introduction

1.1 Scope and Purpose

This manual is intended to support authorized Webasto

trained distributors, dealers and personnel in the

installation of the Scholastic Series coolant heater.

Webasto Thermosystems, Inc. does not recommend the

installation and servicing of Webasto products by

untrained, unauthorized personnel or end-users.

Installations and servicing of Webasto products by

untrained, unauthorized personnel and end-users will

release Webasto Thermosystems, Inc. and Webasto

authorized distributors, dealers and personnel from

responsibility for damage to Webasto product or

collateral property and personal injury.

Any use, operation, installation, modification or

application of the product not described in Webasto

manuals, or subjecting the product to extreme or unusual

conditions beyond the limits of specified performance

characteristics is misuse of the product.

Failure to comply with all installation instructions is a

misuse of Webasto product. The same applies for

repairs without using genuine Webasto service parts.

This will void the coolant heaters “Official Marks of

Conformity.”

1.2 Meaning of Warnings, Cautions,

and Notes

Warnings, Cautions and Notes in this manual have the

following meaning:

1.3 Additional Documentation to be

Used

This manual contains all of the information and

procedures necessary for the installation of the

Scholastic Series heater.

The use of additional documentation is normally not

necessary. Vehicle specific installation guides (when

available) may be used as complementary information if

necessary.

1.4 General Safety Regulations and

Information

The general safety regulations for the prevention of

accidents and relevant operating safety instructions must

be observed at all times.

The specific safety regulations applicable to this manual

are highlighted in the individual chapters by Warnings,

Cautions and Notes.

1.4.1 General Safety Notes

The heater may only be installed in vehicles, with a

minimum coolant capacity of 10 litres (2.6 US Gal.).

The heater must not be installed in the passenger

compartments of the vehicle. Should the heater be

installed in such a compartment, the installation box must

be sealed tight against the vehicle interior. There must

be sufficient ventilation of the installation box from the

exterior in order not to exceed a maximum temperature

of 60 °C (140 °F) in the installation box. Excessive

temperatures may cause malfunctions.

NOTE:

This heading is used to highlight and draw specific

attention to information.

CAUTION

This heading is used to highlight that

non-compliance with instructions or procedures may

cause damage to equipment.

WARNING

This heading is used to highlight that

non-compliance with instructions or procedures may

cause injuries or lethal accidents to personnel.

WARNING

Due to the danger of poisoning and suffocation, the

heater must not be operated in enclosed areas, such as

garages or workshops, without an exhaust venting

system, not even if the start-up is activated by the timer

or remote start device.

At filling stations and fuel depots the heater must be

switched off as there is a potential danger of explosions.

Where flammable fumes or dust may build up (e.g. in the

vicinity of fuel, coal, wood, cereal grain deposits or

similar situations) the heater must be switched off to

prevent explosions.

Page 6

1INTRODUCTION

W

EBASTOSCHOLASTICSERIES

1-2

In the vicinity of the coolant heater, a temperature of

85 °C (185 °F) must not be exceeded under any

circumstances (e.g. during body paint work). A violation

of this temperature limit may cause permanent damage

to the electronics.

When checking the coolant level, proceed in accordance

with the vehicle manufacturer’s instructions.

The coolant in the heating circuit of the heater must

contain a minimum of 10% of a quality brand glycol

based anti-freeze.

Extracting combustion air from the vehicle interior is not

permissible under any circumstance.

The exhaust line outlet is to be positioned below the

vehicle floor, to the nearest possible location of the

vehicle’s left side. Exhaust pipes must be routed so that

exhaust fumes will not penetrate into the vehicle’s

interior.

The function of any parts vital for vehicle operation must

not be impaired. Condensation accumulation in the

exhaust line must be directly drained. Acondensation

drain hole may be provided as required.

Electrical lines, switch gear, and control gear of the

heater must be located in the vehicle so that their proper

function cannot be impaired under normal operating

conditions.

The coolant heater may only be operated within the

specified operating voltage range designated by type.

The coolant heater may only be operated with the

specified fuel (Diesel 1, Diesel 2, Arctic grade, Kerosene

and certain military spec. fuels).

For the routing of fuel lines, the following important

regulations must be adhered to:

• Fuel lines are to be installed in such a way that they

remain unaffected by torsional stresses created by

vehicle and engine movement. They must be

protected against mechanical damage. Fuel lines

must be securely fastened to the vehicle every

30 cm. (12 inches) or more often along the total

length from heater to fuel tank. Fuel-carrying parts

are to be protected against excessive heat and are to

be installed so that any dripping or evaporating fuel

can neither accumulate nor be ignited by hot

components or electrical equipment.

• In buses, fuel lines are not to be located in the

passenger area or in the driver’s compartment.

Fuel supply must not be by means of gravity or

pressurization of the fuel tank.

• The fuel tank must either be equipped with a vent

cap or be ventilated in another way (ventilation line).

• The operational state of the heater, i.e. an indication

“On” or “Off”, must be clearly visible to the operator.

Page 7

W

EBASTOSCHOLASTICSERIES

2GENERAL DESCRIPTION

2-1

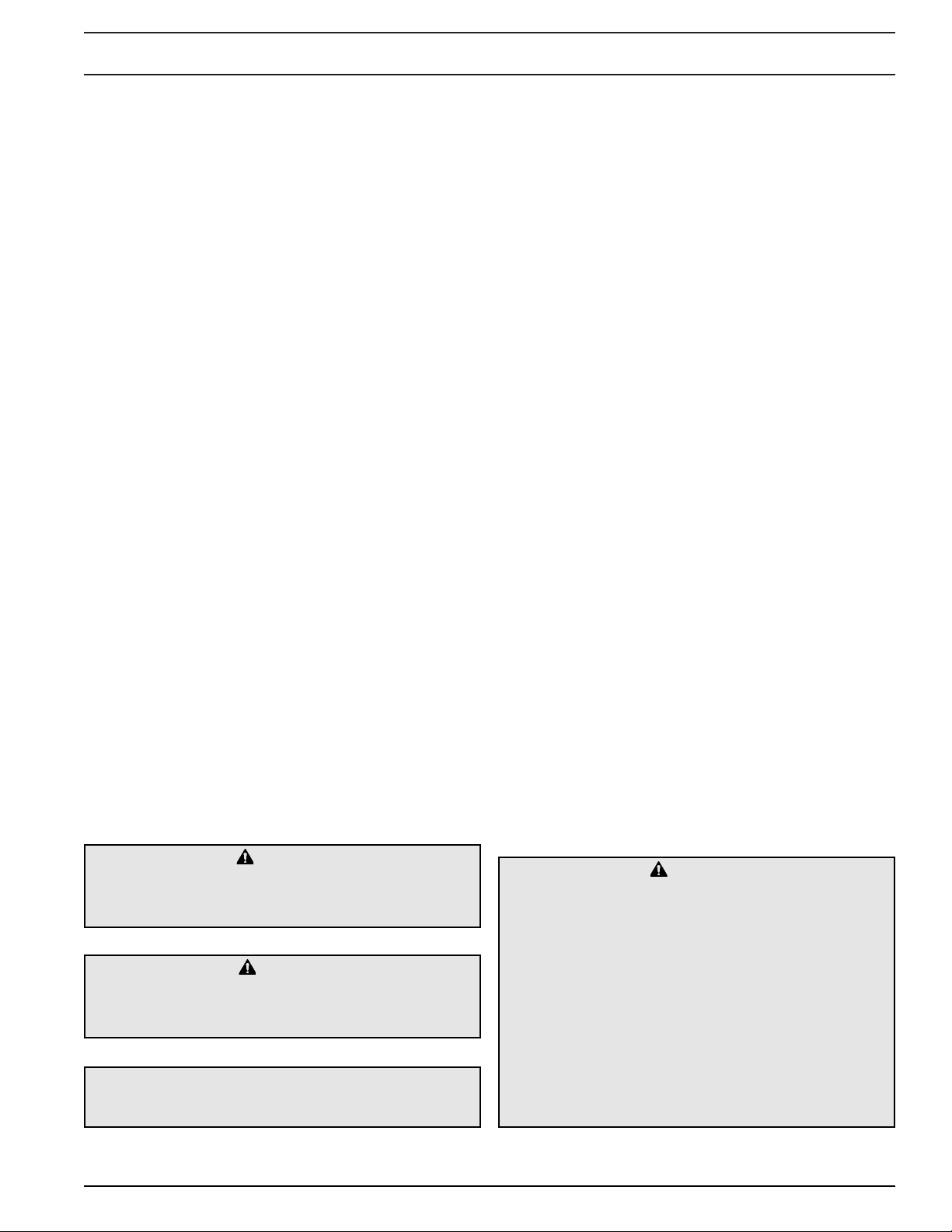

1 Electronic control unit

2 Motor

3 Electronic ignition coil

4 Coupler

5 Combustion air fan

6 Solenoid valve

7 Electrode holder

8 Outlet water pipe - 25 mm (1 in. OD.)

9 Inlet water pipe - 25 mm (1 in. OD.)

The Webasto Scholastic Series Heater has been designed for use on diesel powered school buses. Equipped with

1-inch coolant line connections, heavy-duty coolant pump, single fuel line and additional safety features makes this

an ideal choice for school bus applications.

Webasto Scholastic Series Heaters are designed to:

1. Preheat Engine block of liquid cooled engines to ensure reliable starting in cold weather and to reduce cold start

wear and emissions (white smoke).

2. Boost heating levels with the engine running. The heater will boost the heating system in cold weather when an

engine is running at light loads, even at high speeds or idling. The heat rejection of modern diesel engines to the

coolant, especially in school buses, is often not adequate to heat the vehicle’s interior.

3. Increase Safety by providing higher levels of heat for quick defrosting of windshield and side glass for greatly

improved visibility.

2. General Description

2.1 Scholastic Heater Description

Fig. 2-1: Webasto Scholastic Series Heater

10 Ignition electrodes

11 Fuel nozzle

12 Overheat fuse

13 Control thermostat

14 Overheat limiter

15 Heat exchanger

16 Exhaust pipe

17 Combustion air swirler

18 Combustion tube

19 Flame detection photocell

20 Fuel pump (single line, no return)

21 Fuel connection pipe (JIC #4)

22 Combustion air intake

23 Reduction gearing

24 Nozzle preheat cartridge

25 Preheat thermostat

26 Bleed screw

Page 8

W

EBASTOSCHOLASTICSERIES

3FUNCTIONAL DESCRIPTION

3-1

3. Functional Description

3.1 Operating your Webasto Scholastic Heater

Before switching the Webasto heater on, set vehicle-heating system to the “Heat” position and open any shut off

valves. Depending on the type of control installed in the instrument panel of the vehicle, the heater can be operated

by the following methods.

WARNING

Due to the risk of carbon monoxide poisoning and asphyxiation, the heater must never be operated in closed spaces

such as garages and workshops without adequate exhaust extraction.

WARNING

Due to the risk of fire or explosion, the heater must be switched off while refueling and at fueling stations.

WARNING

Due to the risk of explosion, the heater must never be operated in areas where explosive materials, fumes or dusts

may be present.

3.2 Switching On

Timer: Switch:

Using a Timer:

Upon pressing the “Instant Heat” button on the timer face, the “Operation Indicator” on the timer lights up and the

heater begins operation.

Using a Switch:

When the switch is used for switching “ON” the Webasto heater, the “Operation Indicator” integrated in the switch is

illuminated.

Heater Start-up Sequence:

The heater motor and coolant circulating pump begin operation. After approximately 10 to 25 seconds the fuel

solenoid valve opens and fuel is sprayed into the combustion chamber. At the same time, the electronic ignition coil

produces a high voltage (8000 V) spark at the tip of the ignition electrodes and the mixture of fuel and air in the

combustion chamber is ignited. As soon as combustion is detected by the photo resistor (flame detector), the

electronic ignition coil is de-energized and combustion continues on its own (ignition process is only required to ignite

the flame). At this point the heater is working and producing heat.

The Webasto heater will cycle on and off until:

1. The Webasto heater is switched off.

2. Time has elapsed on the timer.

3. The vehicle battery voltage drops below 10.5V.

4. The Webasto heater runs out of fuel.

5. A fault lock out occurs, indicated by the operating indicator light being off during the cool down cycle (as would

happen during an overheat situation).

Page 9

3FUNCTIONAL DESCRIPTION

W

EBASTOSCHOLASTICSERIES

3-2

3.3 Switching Off

When heating is no longer required, switch the Webasto heater off. The fuel solenoid valve halts the fuel supply,

combustion stops and the indicator light turns off. The Combustion air fan and the water pump remain on for another

2-3 minutes (after run cycle) purging the combustion chamber of any fumes.

3.4 Engine Preheating

1. Set the timer 30 min. to 1 hr. before you want to start the engine. The heater will start up at the set time. (See

timer operating instructions). Or switch the toggle switch or “Instant On” switch on your timer in the vehicle dash

to “ON”. The heater will start up.

2. When the run time has elapsed on your timer or engine preheating is no longer required, switch the Webasto

heater “OFF”. The heater will begin a brief after-run (cool down) cycle.

3.5 Boost Heating for Engine and Passenger Compartment

1. Switch the toggle switch (or the “Instant On” button of the timer) in the vehicle dash to “On”. The heater will start

up if the coolant temperature is below 75 °C (167 °F). Above this temperature only the water pump will run.

2. When boost heating is no longer required, switch the Webasto heater “Off”. The heater will begin a brief after-run

(cool-down) cycle.

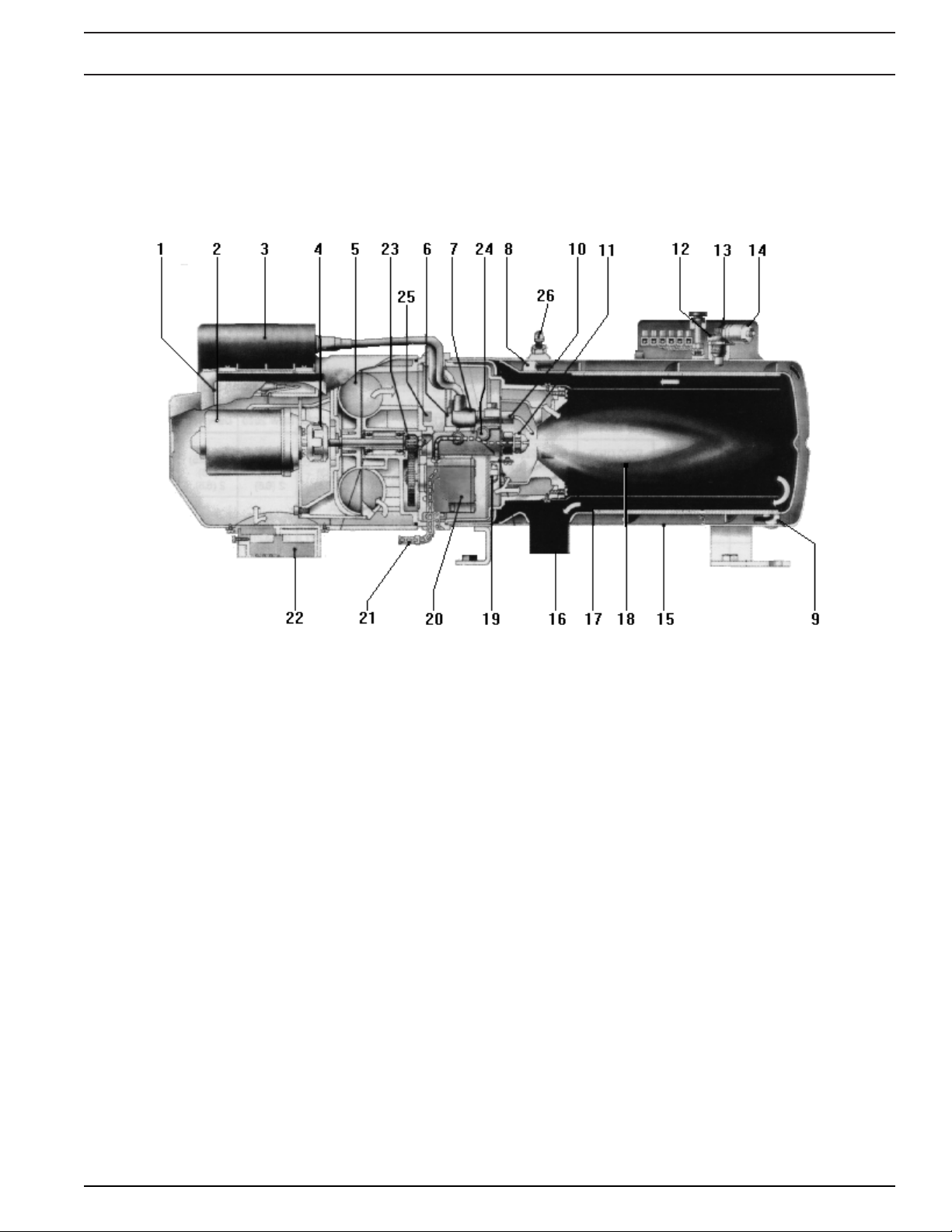

3.6 Operation with 7-Day Digital Timer Model 1531

The digital timer with 3 time settings permits the Webasto heater to be switched on and off instantly, or automatically

at 3 programmable starting times.

The operating time of the heater can be pre-selected. It is possible to program 3 different heating programs

according to your individual needs.

Only one preset starting time can be activated at any one time. When the ignition is switched on, the current time of

the day and the day of the week are displayed.

When the heater is in operation, the display and the buttons of the timer are illuminated.

Programmed Heater Operation

Three memory locations numbered 1 to 3 are available. Each memory location can be assigned a given time

together with the day of the week.

Pre-selected Starting Times

The pre-selected starting time is the time at which the heater will be switched on automatically.

We recommend that memory locations 1 and 2 be used for presetting starting times within 24 hours of setting the

timer.

Memory location 3 can be used for a starting time within the next 7 days of setting the timer.

NOTE:

If the heater is switched on while the engine is at operating temperatures above 68 °C (155 °F) only the operation

indicator and the coolant circulation pump will be activated. The engine coolant temperature must fall below 68 °C

(155 °F) at the heater before the heater will begin heating operation.

NOTE:

Switching the Webasto heater on during the cool-down or “after-run” period is allowed. The heater will revert to

normal operational mode.

Page 10

W

EBASTOSCHOLASTICSERIES

3FUNCTIONAL DESCRIPTION

3-3

Operating Time

The period of time during which the heater is in operation is referred to as operating time. The heater remains in

operation for as long as the operating time has been preset.

Heater operation can be pre-selected for any time from as little as 1 minute to a maximum of 120 minutes (factory

preset is 60 minutes).

Remaining Operating Time

The remaining operating time refers to the period of time the heater still continues to remain in operation. It can only

be changed while heater is in operation.

Fig. 3-1: 7-Day Digital Timer Model 1531

Setting the Digital Timer

After the power has been connected, all symbols on the digital display are flashing. The time of the day and the day

of the week must be set.

All flashing displays and symbols of the timer can be set by means of the and buttons.

If the and buttons are not pressed within 5 seconds, the currently displayed time or function will be stored.

When the and buttons are pressed for more than 2 seconds, the quick digit advance mode is activated.

NOTE:

If the ignition is switched off while the heater is in operation, the remaining operating time of 5 minutes flashes on the

timer display and the heater continues to operate for this period of time. See “Remaining Operating Time” to adjust

this time setting.

NOTE:

We recommend that memory locations 1 and 2 be used for presetting starting times within a 24 hour period of setting

the timer. Memory location 3 can be reserved for a starting time within the next 7 days of setting the timer. Location

3 is useful for occasional weekend or field trip operations outside of the normal schedule. By repeatedly pressing the

button, starting time program 1, 2 or 3 can be viewed and preset.

Page 11

3FUNCTIONAL DESCRIPTION

W

EBASTOSCHOLASTICSERIES

3-4

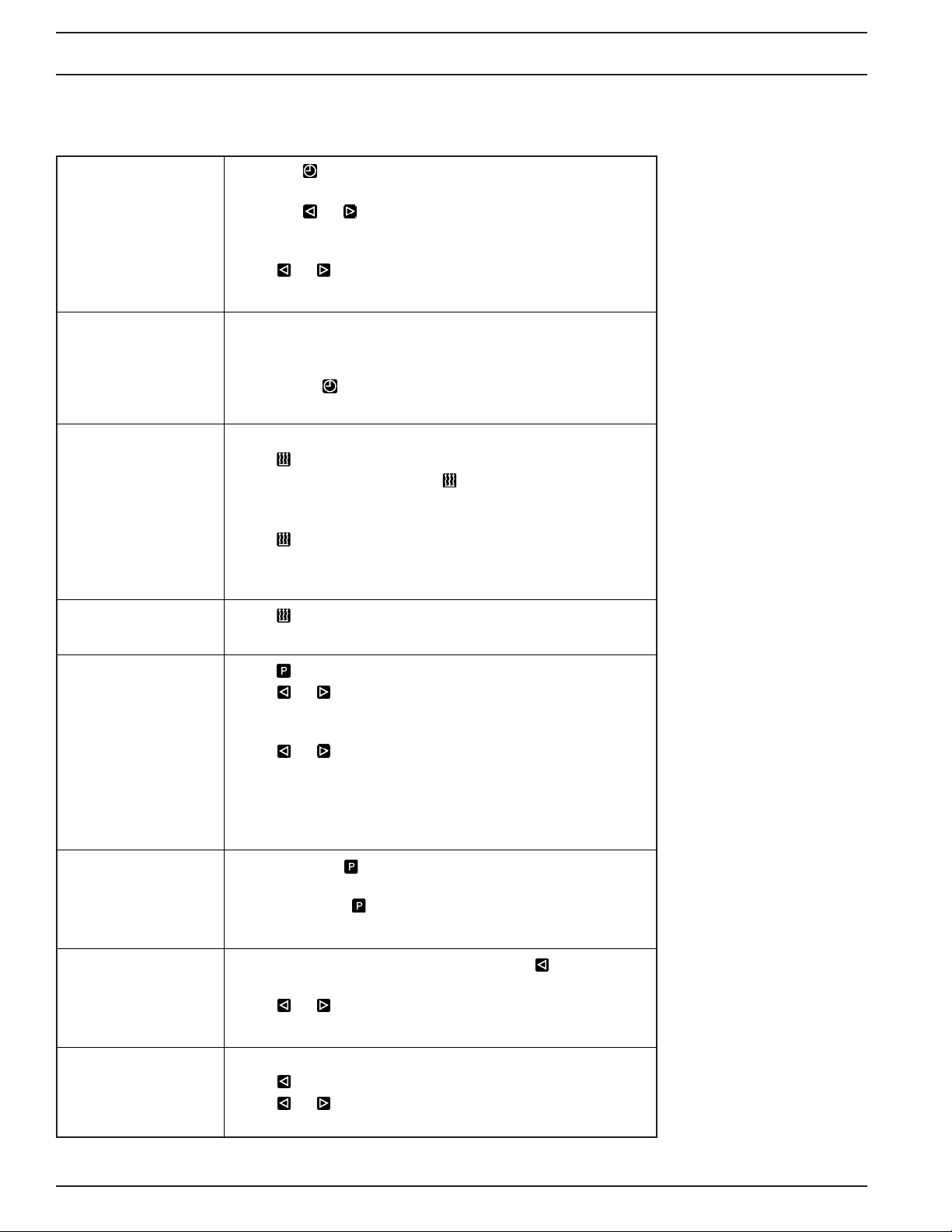

3.7 7-Day Digital Timer Programming and Operating Instructions

Setting the time and

day of the week

Viewing the time

Switching heater on

for instant heater

operation

Switching the

heater off

Programming

heater-starting time

Recalling/canceling

pre-selected times

Programming

duration of

operating time

Setting the

remaining

operating time

Press the button for more than 2 seconds.

Time display flashes.

Press the or button to set time of day.

Wait 5 seconds. Time is now stored.

Day of week flashes.

Press or button to set day of week.

Wait 5 seconds. Day of week is now stored.

With ignition “ON”:

Continuous display of current time and day of the week.

With ignition “OFF”:

Briefly press button. Display of current time and weekday

appears for 5 seconds.

With ignition “ON”:

Press button. Heater is switched on (continuous heating)

and continues to operate until button is pressed again or

ignition is switched off.

With ignition “OFF”:

Press button. Heater is switched on for the preset

operating time (the factory-set heater operating duration is

60 minutes).

Press button. Heater begins cool-down (after-run) cycle

and is switched off thereafter.

Press button. Memory location number flashes.

Press or button to preset starting time.

Wait 5 seconds. Preset starting time is now stored.

Day of week flashes.

Press or button to set day of week.

Wait 5 seconds. Day of week is now stored.

The number of memory location remains on the display.

The timer is now in the programmed mode and switches

heater on at the preset time.

To recall: Press button until the desired memory location

number is displayed. Read off preset time.

To cancel: Press button repeatedly until no memory

location numbers are visible on the display.

The heater must be switched off. Press the button.

Operating time flashes.

Press or button to set operating duration time

(between 1 and 120 minutes).

Heater must be in operation.

Press button. Remaining operating time flashes.

Press or button to set remaining operating time.

Wait 5 seconds. Remaining operating time is now stored.

Table 3-1: Digital Timer Instructions

Page 12

W

EBASTOSCHOLASTICSERIES

4TECHNICAL DATA

4-1

4. Technical Data

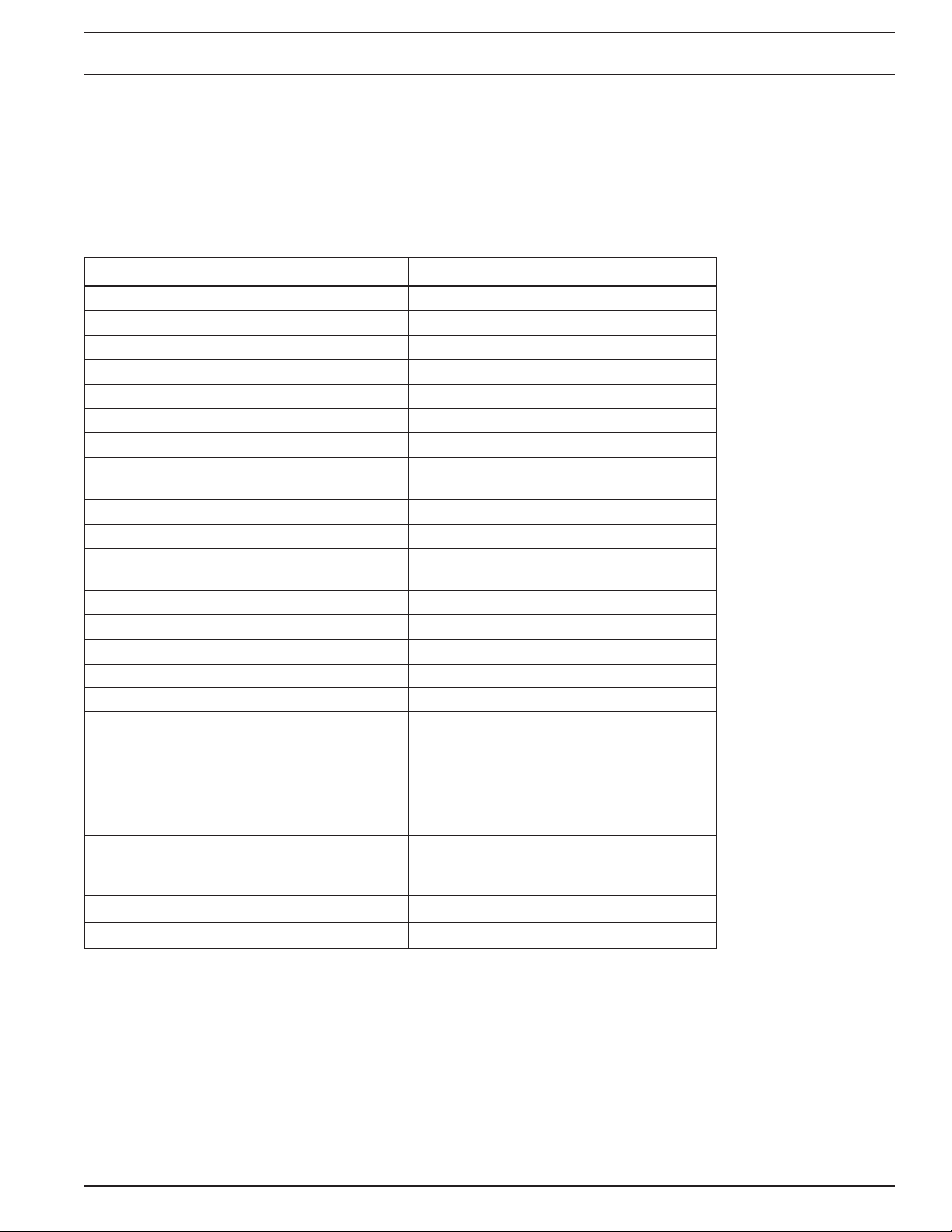

4.1 Scholastic Series Heater Data

The following data is subject to the normal tolerance for heaters, if no tolerance is specified.

This is approximately +/-10% in an ambient of 20 °C (68 °F) at nominal voltage.

Heater Scholastic Series

Design Coolant heater with high-pressure nozzle

Heat Output kW (BTU/hr) 13.1 (45,000)

Fuel Diesel #1 Diesel #2 and Arctic

Fuel Consumption l/hr (gal/hr) 1.5 (0.4)

Rated Voltage (V) 12

Operating Voltage (V) 10 - 14

Power Consumption w/o Water pump (W) 60

Permissible Ambient Temperature

during Operation °C (°F) -40 ... +60 (-40 ... +140)

Storage Temperature °C (°F) +85 max. (185 max.)

Min. Capacity of Cooling System l (gal) 10 (2.6)

Permissible Operating Pressure

of Coolant bar (psi) 0.4-2(06-29)

CO in Exhaust Gas ppm 32

CO2 in Exhaust Gas % by Vol. 10 +/-0.5

NOx in Exhaust Gas ppm 70

HC in Exhaust Gas ppm <5

Emission Bacharach 1

Dimensions of Heater L 584 (23)

W 205 (8.1)

mm (inch) H 228 (9)

Dimensions of Heater Enclosure L 603 (23.75)

W 305 (12)

mm (inch) H 254 (10)

Dimensions of Heater Tray Mount L 603 (23.75)

W 305 (12)

mm (inch) H 228 (9)

Weight on Tray kg (lb.) 27 (60)

Weight of Heater incl. Control Unit kg (lb.) 15 (33)

Table 4-1: Scholastic Series Heater Data

Page 13

4TECHNICAL DATA

W

EBASTOSCHOLASTICSERIES

4-2

4.1.1 Scholastic Series Heater Dimensions

Fig. 4-1: Scholastic Series Heater Dimensions (Millimeters)

Page 14

W

EBASTOSCHOLASTICSERIES

4TECHNICAL DATA

4-3

4.2 Coolant Circulation Pump Data

Flow Rate l/hr (US gal/min) 3406 - 4542 (15 - 20)

Rated Voltage (V) 10 - 14

Power Consumption (W) 72

Dimensions L 214 (8.42)

W 106 (4.16)

mm (inch) H 106 (4.16)

Weight kg (lb.) 2.5 (5.5)

Hose connection mm (inch) OD. 28.5mm (1-1/8)

Table 4-2: Coolant Circulation Pump Data

4.2.1 Coolant Circulating Pump Dimensions

Fig. 4-2: Coolant Circulating Pump Assembly (P.N. 906017) Dimensions (Inches)

Page 15

4TECHNICAL DATA

W

EBASTOSCHOLASTICSERIES

4-4

4.3 Tray Mount Dimensions

Fig. 4-3: Tray Mount Dimensions (Inches)

Page 16

W

EBASTOSCHOLASTICSERIES

5INSTALLATION

5-1

5. Installation

5.1 General Information

Webasto will take you step by step through the installation process to ensure successful operation for years to come.

The installation must be performed in accordance with the installation instructions provided in this manual.

NOTE:

This manual does not cover all possible installations. This manual is a general guideline only. For special

applications or installations differing from what is described in this manual, contact Webasto Thermosystems directly

at 1-800-555-4518 for further information.

5.2 Installation Locations

Fig. 5-1: Installation Locations

WARNING

Due to the risk of carbon monoxide poisoning and asphyxiation, the heater must never be installed inside the

passenger compartment.

Heater is to be installed in an existing enclosure (spare battery compartment) on the driver’s (road) side of vehicle.

The installation template provided with heater kit must be used.

Do not mount to the slide-out tray. The heater and tray must be mounted solidly. The heater inertia safety switch will

only function properly if the heater and tray are mounted solidly.

The heater should be installed as low as possible in the cooling system to assure static bleeding of the heater and the

circulating pump.

NOTE:

The coolant circulating pump is not self-priming. Always prime coolant circulating pump, heater and cooling circuit

before initial starting of heater. See section 5.9 “Initial Operation.”

Page 17

5INSTALLATION

W

EBASTOSCHOLASTICSERIES

5-2

5.3 Mounting the Heater

Tray Kit mounting in existing enclosure on vehicle, i.e. battery box.

1. Ensure that the enclosure is large enough to accommodate the heater. Use the installation template provided

with the heater kit.

2. The installation enclosure must provide adequate ventilation for combustion air requirements [20 cm² (4 in²)].

3. Lay the supplied installation template in the enclosure. Center punch the exhaust, fuel, electrical and 4 mounting

hole locations.

4. Drill all required holes to the dimensions as shown on the template.

5. Solidly bolt the tray with heater mounted inside the enclosure.

Fig. 5-2: Tray Mount Template (Supplied with Heater Kit)

5.4 Exhaust Pipe Connection

WARNING

Due to the risk of carbon monoxide poisoning and asphyxiation, exhaust system components must be routed in a

manner that prevents exhaust fumes from entering the passenger compartment.

1. Insert the supplied flexible exhaust pipe to the heater and fasten with the exhaust clamp. Fasten the outlet end to

the chassis with the “P” clamp provided.

2. The exhaust system must discharge on the street (driver) side of vehicle. The discharge opening of the exhaust

pipe must not point in the direction of travel, and so located that any clogging caused by snow or mud is not to

be expected.

The exhaust pipe I.D. 38 mm (1 1/2”) can have a length up to 5 m (16’) and may have several bends totaling no more

than 270° overall.

Rigid exhaust pipe may be used; bends must be formed (smallest bending radius 85 mm (3 3/8”). Do not weld pipe to

make 90° corners. Any condensation water in the exhaust pipe must be discharged. If necessary, drill a drain hole at

the lowest point.

NOTE:

Route the exhaust components in a way that prevents them from touching vehicle parts that may be damaged by

heat (brake lines, electrical wiring, hoses, etc.). Do not direct exhaust outlet towards heat sensitive vehicle

components.

Page 18

W

EBASTOSCHOLASTICSERIES

5INSTALLATION

5-3

WARNING

Due to the risk of carbon monoxide poisoning and asphyxiation, never draw combustion air from inside the vehicles

passenger compartment.

5.5 Combustion Air Supply

1. Never draw combustion air from inside the vehicle, or from areas where fumes or gases can accumulate.

2. The installation housing must provide adequate ventilation for combustion air requirements [20 cm² (4 in²)].

Fig. 5-3: Typical School Bus Heating Circuit

5.6.1 General Information

An efficient heating system must have an adequate supply of hot water to all heater cores. The amount of hot water

available to a typical three or four heater-core system depends on the water pumps capability and the amount of

restriction within the coolant system.

The Webasto heater is equipped with a high-performance circulating pump designed specifically for bus heating

applications, and when plumbed in accordance with the following instructions, will maximize the heating systems

efficiency.

The coolant-circulating pump (bottom of Enclosure or Tray) must be mounted at least 150 mm (6”) below the lowest

permissible coolant level of the vehicles cooling system. Aminimum of 10% of a good quality antifreeze should be

maintained in the cooling system at all times. Heater and water pump fit 25.4 mm (1”) ID. heater hose meeting SAE

20 R3 specifications. Silicone hose requires special hose clamps.

NOTE:

Heater hose must meet SAE 20 R3 specifications. Silicone heater hose requires special hose clamps. Hose clamps

must be tightened to 5 Nm (45 lb/in.) torque.

5.6 Plumbing into the Coolant System

Page 19

5INSTALLATION

W

EBASTOSCHOLASTICSERIES

5-4

5.6.2 Engine and Passenger Compartment Heating

WARNING

Potential skin and eye burn risk. When working on the coolant system, allow the engine and coolant to cool down

and open the radiator cap carefully.

Heater Cores arranged in Series

A series heating system works in this fashion:

Heated water (coolant) from the engine travels through the first heater core in the circuit, then on to the next heater

core in the circuit, and on to the next, etc. Each core adds some restriction, resulting in decreased water flow. Not

only is water flow reduced, but also water temperature is reduced by each successive heater core resulting in the last

core receiving water that is usually too cool to be effective. A fuel fired Webasto heater equipped with a high capacity

coolant pump can significantly increase the available heat supplied to a series plumbed system. The advantages are

increased coolant volume and flow through the system ensuring efficient interior heating through all heater cores.

Fig. 5-4: Series Plumbing Circuit - Conventional Model

Fig. 5-5: Series Plumbing Circuit - Transit Model (Engine Front)

Page 20

W

EBASTOSCHOLASTICSERIES

5INSTALLATION

5-5

Fig. 5-6: Series Plumbing Circuit - Transit Model (Engine Rear)

5.6.3 Instructions for Integrating into the Coolant System

STOP!

CAREFULLY READ AND UNDERSTAND THE FOLLOWING INSTRUCTIONS BEFORE PROCEEDING WITH

INSTALLATION!

1. Remove the radiator cap and release system pressure.

2. Close the shut off valves for heating system, if so equipped, or pinch off the supply and return line with hose

clamping pliers.

3. Plumb into the system as shown in figure 5.4 or 5.5.

Two long brass 90° elbows with mounting flanges have been provided for making connections into existing

coolant lines. To install:

- remove heater hose access cover(s) running down left side of floor inside bus at a location over top of

heater installation.

- find and identify heating circuit supply hose. This is the hose you will use to plumb the Webasto heater

into the system.

- locate and mark suitable location on floor (above heater) where brass elbows will be installed.

NOTE: Whenproperly installed, the elbows should protrude down into the heater enclosure area where they

can be easily connected to the coolant pump inlet and heater outlet.

- once you are satisfied with the location, making certain there are no obstructions, you can now bore 2 holes

32 mm (1-1/4”) through the floor.

- from inside the bus, drop elbows down through the floor and align with the heating circuit supply hose, inlet

elbow pointing forward and outlet elbow rearward.

- secure elbow flanges to floor with sheet metal screws.

4. From inside the heater enclosure, connect the inlet elbow (supply) to the coolant pump and the outlet elbow to

the Webasto heater outlet with rubber elbows and fittings provided.

5 From inside the bus, cut the previously identified heating supply hose at a point where it can be connected to the

inlet and outlet elbows.

6. Connect the heater supply line running from the engine to the inlet elbow. Connect the other cut end of the

supply line to the outlet elbow.

7 . Secure all hose connections with hose clamps.

Page 21

5INSTALLATION

W

EBASTOSCHOLASTICSERIES

5-6

8 Remove hose clamping pliers and/ or open shut off valves.

9. Purge air from the Webasto heater by opening the bleeder valve screw (see page 2-1, figure 2-1, item 26).

10. Top off engine coolant as per engine manufacturer’s recommendations and re-install the radiator cap.

Do not install the previously removed heater hose access covers at this time. Hose connections will require

inspection and re-tightening of clamps once installation is completed and tested (see section 5.9 “Initial Operation”).

NOTE:

Heater hose must meet SAE 20 R3 specifications. Silicone heater hose requires special hose clamps. Hose clamps

must be tightened to 5 Nm (45 lb/in.) torque.

Page 22

W

EBASTOSCHOLASTICSERIES

5INSTALLATION

5-7

5.7 Fuel System

5.7.1 General Description

The fuel is drawn from the vehicles fuel tank through a fuel standpipe. This standpipe can be utilized on vehicles with

a threaded port in the fuel tank for this purpose.

IMPORTANT! Keep the fuel standpipe 50 mm (2”) from bottom of the fuel tank.

5.7.2 Fuel Supply

Fig. 5-7: Fuel Standpipe Installation

The fuel standpipe and fuel line must be installed according to these instructions to ensure proper heater operation.

1. Cut or extend universal fuel standpipe to length, approx. 50 mm (2”) off fuel tank bottom. Slash cut standpipe

end on a 45° angle to help prevent clogging.

NOTE:

After fuel standpipe has been cut to length, remove all burrs from cut inlet end. Check valve directional indication

mark (arrow or symbol) must point in direction of fuel source (fuel tank).

Page 23

5INSTALLATION

W

EBASTOSCHOLASTICSERIES

5-8

2. Install the universal fuel standpipe and 3/8” check valve. Check valve directional indication mark (arrow or

symbol) must point in direction of fuel source (fuel tank).

- use 1/4” or 1/2” spare port on fuel tank and install fuel standpipe securely in fuel tank, use pipe thread sealant

on all pipe threads.

3. Route and secure fuel line from heater to fuel tank. Do not route fuel line over frame rails, always route through

or under the frame rail. Use grommets to protect fuel line whenever routed through holes.

4. Connect fuel line to fuel standpipe using 3 mm (1/8”) fuel hose meeting SAE 30RI specifications.

CAUTION

On School Bus applications, fuel lines must not cross over top of the vehicle frame rails. Check local and State

codes and regulations for exceptions.

CAUTION

Fuel lines must be secured every 30 cm (12 inches) or less and kept clear of hot exhaust components and moving

parts (driveshaft, wheels, etc.).

NOTE:

Use supplied hose clamps to secure fuel line connections.

Fig. 5-8: Fuel Line Parameters

A = Suction height 2.0 m (6’6”) maximum

A+B = Suction length 10 m (33’) maximum

Page 24

W

EBASTOSCHOLASTICSERIES

5INSTALLATION

5-9

5.7.3 Fuel Filter

Your heater is equipped with a spin-on fuel filter. Fuel filters require changing at least annually and in cases of dirty

fuel more often.

The fuel filter assembly should be mounted securely between the vehicle frame rails close to the fuel tank. After

installation, before the heater is fired for the first time, the fuel filter MUST be filled with CLEAN diesel fuel. When

replacing the fuel filter, this procedure must be repeated to ensure proper firing and operation.

CAUTION

Check local and State codes and regulations for fuel filter mounting locations.

CAUTION

To prevent fuel nozzle failure, always use CLEAN fuel from a known CLEAN source for priming fuel systems and

filters.

NOTE

The Webasto Scholastic Series heater is equipped with an internal self-priming fuel pump.

Page 25

5INSTALLATION

W

EBASTOSCHOLASTICSERIES

5-10

5.8 Wiring Connections

5.8.1 General Information

The control unit is equipped with low voltage protection, therefore it is imperative to keep vehicle batteries in good

condition. Red labeling or markings indicating 12 volts identify electrical components for the Scholastic Series heater.

Green labeling or markings indicates 24 volt components, which are not suitable for this version of heater.

CAUTION

To protect the electronic control unit when welding is performed on the vehicle, the heaters main power supply wires

must be disconnected from the main power source and temporarily grounded to the chassis.

NOTE

The Webasto heating system will not perform to your satisfaction with weak batteries.

Fig. 5-9: Harness Connection Points (Overview)

5.8.2 Connecting Power Harness to a Constant Power Source

1. Route and secure the wire harness from the Webasto heater to constant power source and cut harness to length.

2. Connect the positive leads to a 30 amp. circuit breaker connected to a constant power source.

3. Connect ground lead to ground stud.

Refer to wiring diagrams on pages 5-13, 5-14, 5-15 and 5-16 appropriate to your installation.

CAUTION

Leave round waterproof harness to heater enclosure connector (P1) uncoupled until completion of heater installation.

Chassis Ground Power Source

Circuit Breaker - 30A

(Main Power)

Fuses

Harness Connector - P1

Switch or

Optional

Timer

Heater Enclosure

Page 26

5.8.4 Timer and Switch Installation

1. Locate appropriate switch knock-out (blank) on instrument panel for heater On/Off switch or select a suitable

location in the vehicle dash for the (optional) timer.

2. Remove switch knock-out and replace with appropriate switch. Timer is supplied with a removable

stick-on drilling template.

3. Route and secure switch harness from the heater to the vehicle dashboard. If possible use existing hole in fire

wall/ panel or drill in suitable location. Protect the harness with a grommet whenever passing through fire

wall/ panel holes.

4. Connect the terminals to the switch or timer. See pages 5-13, 5-14, 5-15 and 5-16 for complete wiring details.

CAUTION

Make sure there is enough space behind the dash for the switch or timer and wire connections before cutting any

holes.

CAUTION

To prevent damage to electrical and mechanical components, check for clearance before drilling into panels and

frame members.

W

EBASTOSCHOLASTICSERIES

5INSTALLATION

5-11

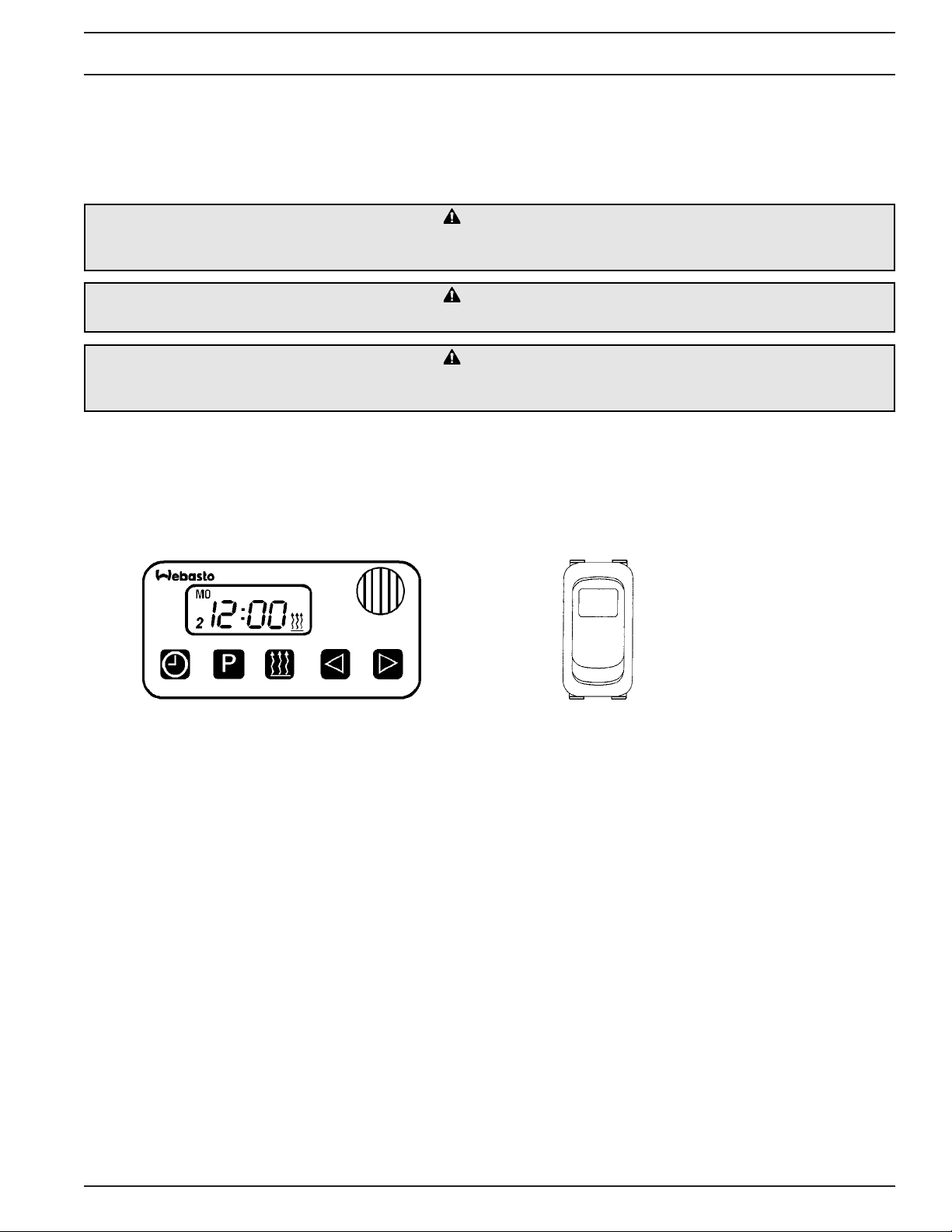

5.8.3 Timer and Switch Connections

Fig. 5-10: On/Off Switch

Fig. 5-11: 7-Day Digital Timer Model 1531

For switch connection details (pin-outs) see wiring diagrams (fig.5-13, 5-14)

on pages 5-13 and 5-14 appropriate to your installation.

1 Vehicle Dash Lights (Optional)

2 Terminal 86 of Relay K1

4 Chassis Ground (Negative)

8 To Control Unit Terminal Location B3

10 To Vehicle Ignition Signal (Positive)

11 Terminal 87 of Relay K1 or Constant

12 Chassis Ground (Negative)

3, 5, 6, Not Used

7 and 9

Pin-Out

Connect To:

For timer connection details (pin-outs) see

wiring diagrams (fig.5-15, 5-16) on pages 5-15

and 5-16 appropriate to your installation.

Page 27

5INSTALLATION

W

EBASTOSCHOLASTICSERIES

5-12

5.8.5 Wiring Diagram – Scholastic Series Heater

Fig. 5-12: Wiring Diagram - Scholastic Series Heater

Page 28

W

EBASTOSCHOLASTICSERIES

5INSTALLATION

5-13

5.8.6 Wiring Diagram – Chassis / Power Harness with Switch

Fig. 5-13: Wiring Diagram - Chassis / Power Harness with Switch

0030777A

Option 1345-03

Page 29

5INSTALLATION

W

EBASTOSCHOLASTICSERIES

5-14

5.8.7 Wiring Diagram – Chassis / Power Harness with Switch

Fig. 5-14: Wiring Diagram - Chassis / Power Harness with Switch

0030522A

Option 1345-03

Page 30

W

EBASTOSCHOLASTICSERIES

5INSTALLATION

5-15

5.8.8 Wiring Diagram – Chassis / Power Harness with Digital Timer Model 1531

Fig. 5-15: Wiring Diagram - Chassis / Power Harness with Digital Timer Model 1531

0030778

Option 1345-04

Page 31

5INSTALLATION

W

EBASTOSCHOLASTICSERIES

5-16

5.8.9 Wiring Diagram – Chassis / Power Harness with Digital Timer Model 1531

Fig. 5-16: Wiring Diagram - Chassis / Power Harness with Digital Timer Model 1531

0030512

Option 1345-04

Page 32

W

EBASTOSCHOLASTICSERIES

5INSTALLATION

5-17

5.9 Initial Operation

1. Check your installation for:

- loose nuts and bolts.

- exhaust pipe routing and clamp tightness.

- loose hose clamps.

- routing and securing of wiring and heater hoses.

- kinked or pinched hoses.

- battery connection and polarity.

- disconnect control thermostat on Webasto heat exchanger (red and green wire, see page 2-1, figure 2-1,

position 13).

2. Top off or refill cooling system with coolant as per engine manufacturer’s recommendations.

3. Connect power/ switch extension harness to waterproof plug.

4. Open shut-off valves and driver’s heater valve.

5. Set heater controls to maximum heat position and turn offAir Conditioning if applicable.

6. Switch “On” Webasto heater and check:

- green indicator light on.

- circulating pump in operation.

7. Start the vehicle engine and run it at a fast idle for 10 minutes to purge air from the Webasto coolant heater and

all of the heat exchangers. While the engine is running check:

- hose connections for leaks.

- coolant level in the expansion tank and add coolant as needed.

- use bleeder valve screw on top of Webasto heat exchanger to purge out any trapped air (see page 2-1, figure

2-1, item 26).

8. Shut off the engine.

9. Plug in control thermostat, the blower motor starts and the fuel pump primes the fuel lines. After 10 to 25 sec. the

fuel solenoid opens and the electronic ignition coil ignites the air fuel mixture.

NOTE

Installations with long fuel lines may require a second start attempt to prime the fuel system. Cycle switch or timer off

and on to reset control unit. Coolant temperature must be below 68 °C (155 °F) at heater before heater will begin

heating operation.

10. Allow heater to run until coolant is hot and heater cycles off. During this period, monitor system for any coolant or

fuel leaks.

NOTE

The engine temperature gauge may read a lower temperature depending on the location of the temperature sensor

on the engine.

11. Temperature differential between water inlet and outlet should not exceed 10 °C (18 °F) during heating operation.

12. Switch “Off” Webasto heater.

13. Re-tighten hose clamps to 5 Nm. (45 lb/in.) and inspect installation for leaks.

14. Install any panels and access covers removed during installation.

Page 33

5INSTALLATION

W

EBASTOSCHOLASTICSERIES

5-18

15. Complete the warranty card and send to Webasto Thermosystems (There is an area on the last page of this

manual for recording information that is useful when calling for technical support).

16. Install the enclosure cover if equipped. Installation is now complete.

NOTE

Necessary information to complete the warranty card can be found on the name plate on top of the heater burner

head. The completion of the warranty card will ensure full warranty coverage. Please mail completed warranty card

within 30 days of purchase to register your heater.

Page 34

W

EBASTOSCHOLASTICSERIES

6HEATER MAINTENANCE

6-1

6. Heater Maintenance

6.1 Annual Maintenance

The Webasto heater requires a minimum of maintenance to operate.

To keep your Webasto heater in good working order, the following maintenance procedures should be performed

annually before each heating season:

Enclosure Area

- clean the heater and enclosure area of any accumulated debris or dust with compressed air.

- inspect all components for wear and damage.

Electrical System

- check all wiring harnesses for damage and corrosion, repair or replace if required.

- check the condition of the batteries and the connections.

- load test the batteries and replace if necessary.

NOTE

For major repairs and service parts, return to your authorized Webasto Thermosystems Specialist.

Exhaust System

- check the exhaust system carefully for restrictions or corroded areas. Replace worn or damaged exhaust

components as necessary.

Fuel System

- replace the fuel filter (prime) and inspect the fuel line for wear and damage. Repair or replace if necessary.

Burner System

- swing open the burner head, clean the flame detection (photo eye), pull out the combustion chamber, inspect

and clean the inside area of the heat exchanger. Replace the fuel nozzle if necessary (annually). Reinstall

the combustion chamber and close up the burner head.

Operational Check

- Run your heating system for at least 15 minutes.

- Check all water and fuel connections for leakage. Check tightness of all hose clamps if necessary.

NOTE

The heater will not function properly or to your satisfaction with weak batteries.

NOTE

Operate your Webasto heater at least once a month for 10 minutes.

CAUTION

Annual maintenance requires basic product knowledge and maintenance procedures and should only be performed

by Webasto trained and certified, skilled personnel. Ask your Webasto representative about training clinics.

Page 35

W

EBASTOSCHOLASTICSERIES

7BASIC TROUBLESHOOTING

7-1

7. Basic Troubleshooting

7.1 General Information

This section describes troubleshooting procedures for the Scholastic Series coolant heater. Troubleshooting is

normally limited to the isolation of defective components.

CAUTION

Troubleshooting requires profound knowledge about structure and theory of operation of the heater. Troubleshooting

may only be performed by Webasto trained and certified, skilled personnel.

Before troubleshooting, check for and eliminate the following causes for problems:

- fuel supply (plugged fuel filter or pinched fuel line)

- corrosion of battery terminals

- corrosion of electrical wiring, connections and fuses

- loose contacts or wrong crimping on connectors

- shut-down initiated by temperature limiter (automatic reset)

- shut-down initiated by overheat fuse (replace fuse)

- shut-down initiated by inertia switch (manual reset)

Table 7-1: Quick Check Troubleshooting Matrix

7.2 Quick Check Troubleshooting Matrix

NOTE

After the correction of a problem or defect, a functional test of the heater as installed in the vehicle must be

performed.

Page 36

7BASIC TROUBLESHOOTING

W

EBASTOSCHOLASTICSERIES

7-2

7.3 Heater Test Unit (Webasto P.N. 440280)

The tester unit has been designed to quickly check the proper operation of the various heater components. By using

the tester in place of the heater control unit, you are able to manually control the heater to test components and

actually operate the unit in heating mode.

The actual testing is completed in two steps, first you perform an individual component test and then a manual start

and run test, both designed to pinpoint actual problems in the heater system.

Fig. 7-1: Test Unit P.N. 440280

LED - input power to heater

LED - control thermostat

LED - flame detector

On/Off switch - water pump

On/Off switch - motor

Push button - ignition spark coil

Push button - fuel solenoid valve

Page 37

W

EBASTOSCHOLASTICSERIES

7BASIC TROUBLESHOOTING

7-3

7.4 Test Procedures

1. Setup

- Remove connector blocks from heater control unit, inspect for loose wires, corrosion and proper wire

connections.

- Plug control unit connector blocks into tester.

- Set heater switch/timer to “ON” and turn vehicle heater valve to “FULL” mode (if equipped).

- Proceed to component test procedures.

2. Component Test Procedures and Results

WARNING

Do not attempt to test fire or run heater with burner head open. Ensure burner head is properly closed and secured

in place.

NOTE

Make sure the Water Pump and Motor Switches , are in the off position before connecting to the heater.

If not

- test input voltage at control

terminals B4(+) and B2(-)

- check battery connections

- check battery voltage

- test temperature fuse (if equipped)

- test overheat limiter

- test solenoid valve

- check electrode gap

- test ignition spark coil

ResultTest Step

BATTERY LED unit lights up

CONTROL THERMOSTAT LED

lights up

Tester connected

Push FUEL SOLENOID VALVE

button several times

clicking of solenoid should be heard

sparking should be heard

Push IGNITION SPARK COIL

button

Turn MOTOR switch “ON“

motor should run

- reset *inertia switch

- test motor

Turn WATER PUMP switch “ON“

pump should run

- test pump

Table 7-2: Test Procedures and Results

* Inertia Switch:

All 12 volt Scholastic Series heaters are equipped with a manual reset inertia switch usually located in the vicinity of

the burner head (look for a device with a round diaphragm red in color and about the size of a 25 cent piece on top).

The purpose of this switch is to stop heater operation in the event the vehicle is involved in an accident or receives a

strong impact shock, i.e. hitting a curb. This is done automatically by opening the combustion fan motor circuit,

stopping air and fuel delivery.

When troubleshooting, check to make certain inertia switch has not been tripped. Resetting is accomplished by

depressing the red diaphragm on top of the switch. You should hear an audible click when switch resets.

- test switch/ timer

- test control thermostat on heater

Normal operating range

- approx. 75 °C (167 °F) or higher

open (no heat required)

- approx. 68 °C (155 °F) or lower

closed (heat required)

Page 38

7BASIC TROUBLESHOOTING

W

EBASTOSCHOLASTICSERIES

7-4

3. Manual test running of heater

- Turn the WATER PUMP switch “ON”

- Turn the MOTOR switch “ON”

- Push and hold the FUEL SOLENOID VALVE button “ON” (starts fuel flow to combustion chamber)

- Push and hold the IGNITION SPARK COIL button “ON” (starts electrodes sparking) until combustion has

taken place.

Test Results:

- LED lights and combustion achieved

- operation normal

- Combustion achieved but no LED light

- check flame detector

- Combustion not achieved and no LED light

- check fuel nozzle

- check fuel pressure

- check for blocked fuel lines (dirt or ice)

- check ignition electrodes for damage and set gap

- Heater should now be in heating mode and will continue to run until you release the fuel solenoid valve

button which stops fuel flow and extinguishes the flame immediately.

NOTE:

Hold IGNITION SPARK COIL button ON until FLAME DETECTOR LED Lights or combustion is heard, then

release; in any case do not hold button on for more than 15 seconds or damage to the coil may result.

- Allow the heater to continue running for approximately 30 seconds (cool down) after which, turn the

WATER PUMP switch and the MOTOR switch “OFF”.

- Once the manual test run has been successfully completed, set the heater switch/ timer to “OFF”, remove the

tester and reconnect the control unit. Once done, set the switch/timer to “ON”; if heater or a heater

component does not respond, the control unit is defective; replace the control unit and retest the heater.

NOTE:

If flame does not stop when the FUEL SOLENOID VALVE button is released, turn MOTOR switch OFF to stop

heater. Check and repair fuel solenoid valve accordingly.

NOTE:

Since the heater operates in the 68 °C (155 °F) to 75 °C (167 °F) On to Off/ Off to On range, and the vehicle engine

may be hot [e.g. coolant above 75 °C (167 °F)], the heater will not start until the coolant temperature is below

68 °C (155 °F). THIS IS NORMAL and does not indicate a problem.

Page 39

W

EBASTOSCHOLASTICSERIES

8SPARE PARTS LIST

8-1

No Fig. 1 92119B Basic Scholastic Heater 12V Complete – replacement heater

only.

No Fig. 1 NA Burner Head with Control Unit 12V Completely mounted and

connected.

2 1 287962 Control Unit 12V

3 1 362107 Clip for Control Unit

4 4 470562 Screw Self-tapping M3.5 x 14

5 1 101838 Electronic Ignition Unit 12V

6 2 404918 Socket

7 X 178624 High Tension Ignition Cables Ø 7mm; per meter

8 2 176494 Electrode Plug

10 1 350427 Air Intake Bellows

11 4 432377 Screw M4 x 12

12 4 152269 Serrated Lock Washer

13 1 316199 Clamp

14 1 436216 Protection Cap

15 2 101660 Warning Label

22 3 488631 Screw with Washer M5 x 12

24 1 42505A Flange

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 1Scholastic Series

Subject to modification

Page 40

8SPARE PARTS LIST

W

EBASTOSCHOLASTICSERIES

8-2

25 2 432377 Screw M4 x 12

26 2 152269 Serrated Lock Washer M4.3

27 1 425060 Motor 12V

28 1 113665 Plastic Tie

29 2 350516 Coupling Exchange in pairs

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 1Scholastic Series

Subject to modification

Page 41

W

EBASTOSCHOLASTICSERIES

8SPARE PARTS LIST

8-3

35 1 412147 Cable Harness 6 Way plug (Item 36)

36 1 352969 Terminal Block 6 Way

38 4 148210 Hex Socket Head Cap Screw M5 x 35

39 4 152552 Spring Washer B5

40 1 301841 Motor Support

41 1 373001 Impeller with Shaft

42 1 378313 Bearing Set Parts for mounting the fan shaft

assembly.

43 1 412244 O-ring

44 1 22567A Blower Casing

45 2 298964 Rubber Grommet Left side

46 2 299995 Rubber Grommet Right side

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 2Scholastic Series

Subject to modification

Page 42

8SPARE PARTS LIST

W

EBASTOSCHOLASTICSERIES

8-4

50 1 322083 Solenoid Valve 12V

51 1 386650 Small Parts for Solenoid Valve For item 50

52 1 260487 O-ring 12 x 1.5

53 1 267279 Hexagon Screw M6 x 16

54 1 152560 Spring Washer B6

55 1 278971 Clamp

56 2 274313 Ignition Electrode

58 1 147699 Screw M4 x 6

59 1 215171 Flame Detector

60 1 453048 Retaining Ring

61 1 378232 Disc

62 1 88641A High Pressure Fuel Nozzle 0.35 GPH 60°

65 1 275476 Pressure Pipe Complete

66 1 150754 Banjo Screw

67 2 151157 Gasket Ring A10 x 14

68 1 92170A Fuel Supply Line Complete (# 4 JIC)

70 2 277282 Hexagon Socket Head Cap Screw M4 x 30

71 2 152544 Spring Washer B4

72 1 63314A Fuel Pump Single line, 10 bar (145 psi)

74 1 355836 Pressure Control Valve

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 3Scholastic Series

Subject to modification

Page 43

W

EBASTOSCHOLASTICSERIES

8SPARE PARTS LIST

8-5

75 1 310344 Filter Screen

77 1 260738 Gasket

80 2 488631 Screw with Washer

82 1 412198 Nozzle Holder

83 1 410799 Pre-heat Element 12V

84 1 19723B Holding Strap

85 1 298816 Bracket

86 1 104012 Pre-heat Thermostat

No Fig. 1 82399A Pre-heat Harness See item 186 for reference

87 4 488631 Screw with Washer

88 1 102861 Nozzle Holder Plate

89 1 371289 Straight Spur Gear

90 1 152390 Retaining Ring 6 x 0.7

No Fig. X 143820 ISOFLEX LDS 18 Special Hi-temp Grease In 100g

tube. Use on fuel pump gears.

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Page 44

8SPARE PARTS LIST

W

EBASTOSCHOLASTICSERIES

8-6

100 1 487627 Protection Cap

104 1 147702 Screw M4 x 8

105 1 319430 Clamp Ø 8mm

107 1 273481 Screw

108 1 273473 Bracket

109 1 298816 Joint

121 1 406287 Overheat Fuse 138 °C: Identification color – white

wires

127 1 354902 Control Thermostat 75 °C: Green and red wires

130 1 608719 Temperature Limiter 104 °C: Green wires

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 4Scholastic Series

Subject to modification

Page 45

W

EBASTOSCHOLASTICSERIES

8SPARE PARTS LIST

8-7

139 1 114499 Bleeding Valve

140 1 352497 Securing Cotter Pin 6.3 x 90

141 1 352152 Cable Clamp

142 1 26553A Combustion Chamber

143 1 91216A Heat ExchangerAssembly Yellow color with 1 inch coolant

connections

149 2 461555 Nut with Washer M6

150 2 32087A Eye Bolt AM6 x 45

151 2 420565 Slotted Pin 6 x 16

152 1 279110 Well Plug

153 1 289329 Angle Support

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 5

Scholastic Series

Subject to modification

Page 46

8SPARE PARTS LIST

W

EBASTOSCHOLASTICSERIES

8-8

167 1 905103 ON / OFF Switch 12V

168 1 905797 7-Day Digital Timer Kit Model 1531 12V Includes harness

item 170 and frame item 172

169 1 88195A 7-Day Digital Timer Model 1531 12V Timer only

170 1 88436A Harness – Timer To item 168, 169

171 1 467936 Light Bulb 12V To item 168, 169

172 1 474630 Mounting Frame To item 168, 169 (for flush panel

mounting)

No Fig. 1 475866 Mounting Housing To item 168, 169 (for under, over or

surface of panel mounting)

173 1 906008 Harness – Internal (from control unit Use in conjunction with external

to main power/ switch connector) harness item 174

174 1 905815 Harness – External (from main power Use in conjunction with internal

/ switch connector to batteries and harness item 173

switch/ timer)

175 1 328529 6-Pin Female Connector Housing From control unit to vehicle wiring

176 2 901542 5-Pin Female Connector Housing To relay

177 1 178713 2-Pin Female Connector Housing

179 1 620286 3-Pin Female Connector Housing Preheat harness

180 1 620285 3-Pin Male Connector Housing

181 1 14878A Fuse Box Use with item 182

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 6Scholastic Series

Subject to modification

Page 47

W

EBASTOSCHOLASTICSERIES

8SPARE PARTS LIST

8-9

182 2 24981A Fuse 15Amp Use with item 181

182 1 103992 Fuse 20 Amp Use with item 181

183 7 178705 1-Pin Female Connector Housing

184 3 620295 Ring Connector Yellow M8

186 1 82399A Preheat Harness

No Fig. 1 900012 Inertia Switch

No Fig. 1 906026 Inertia Switch Harness

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Page 48

8SPARE PARTS LIST

W

EBASTOSCHOLASTICSERIES

8-10

Figure 7

Scholastic Series

Subject to modification

179 1 620286 3-Pin Female Connector Housing Used on preheat harness item 186

180 1 620285 3-Pin Male Connector Housing Used on item 173 at preheat

connection

182 2 24981A Fuse 15Amp Used with item 181

182 1 103922 Fuse 20 Amp Used with item 181

187 2 901398 Relay 12V Used with item 176

188 4 176389 Connector – Male Used with male connector housings

189 16 176591 Connector – Female 6.3 Used with female connector

housings

190 1 178799 1-Pin Male Connector Housing Used on inertia switch harness

195 1 342777 8-Pin Male Connector Housing Used on timer harness item 170

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Page 49

W

EBASTOSCHOLASTICSERIES

8SPARE PARTS LIST

8-11

1 2 901265 Elbow – Brass 90° with Mounting Through floor connection

Flange

No Fig. 1 901045 Formed Hose Coolant pump to heat exchanger

inlet

No Fig. 2 901213 Formed Hose Gates 21488

No Fig. 8 902024 Hose Clamp ET-20

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 8

Scholastic Series

Subject to modification

11

Page 50

8SPARE PARTS LIST

W

EBASTOSCHOLASTICSERIES

8-12

224 1 906647 Fuel Standpipe – Complete Includes items 225,226, 227, 232,

233, 234, 235 Includes 1/2 x 1/4

NPT bushing (not shown)

225 1 906118 Fuel Standpipe – Single Line Standpipe only – does not include

tank-boss

226 1 900029 Check Valve – One way

227 1 900004 Barb Fitting

228 X 903709 Fuel Line 1/4” ID. Per meter

229 6 379670 Clamp – Fuel Line 12 mm

230 1 603362 Barb Fitting 90° – Fuel Line

231 1 603364 Bulkhead Fitting Assembly – NPTF Used with mounting tray/ enclosure

232 1 902014 Nut

233 1 902015 3/4” Flat Washer

234 1 902016 Rubber Gasket

235 1 902013 Tank-Boss Fitting

236 1 901299 Barb Fitting JIC #4 x 1/4” Hose Connects fuel line to heater

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 9

Scholastic Series

Subject to modification

Page 51

W

EBASTOSCHOLASTICSERIES

8SPARE PARTS LIST

8-13

1 1 900400 Fuel Filter Head Used with part 900001

2 1 900001 Fuel Filter – FF 104 Used with part 900400

3 2 900401 1/2 x 1/4 Bushing Used with part 900400

4 2 901293 Barb Fitting 1/4” MNPT x 1/8” Hose Used with part 900400

No Fig. 1 905707 Mount Bracket for Fuel Filter Head Used with part 900400

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 10

Scholastic Series

Subject to modification

1

2

3

4

Page 52

8SPARE PARTS LIST

W

EBASTOSCHOLASTICSERIES

8-14

1 1 900731 Tray Mount

No Fig. 1 901235 Enclosure Cover

No Fig. 1 901233 Enclosure Base

No Fig. 4 905388 Rubber Grommet 1-3/4” Dia. Groove

No Fig. 1 15527A Stainless Steel Exhaust Tube Includes end-cap

ø38mm x 1m

No Fig. X 353221 Stainless Steel Exhaust Tube Per meter

ø38 mm

No Fig. 1 367400 Exhaust Clamp ø39... 42 mm

No Fig. 1 126830 P-Clamp To secure exhaust tube to vehicle

No Fig. 1 24046A End-cap (open) Exhaust tube outlet

No Fig. 1 600050 Frame Mounting Brackets – 1 Pair To mount heater to vehicle frame

(some modification required)

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 11

Scholastic Series

Subject to modification

1

Page 53

W

EBASTOSCHOLASTICSERIES

8SPARE PARTS LIST

8-15

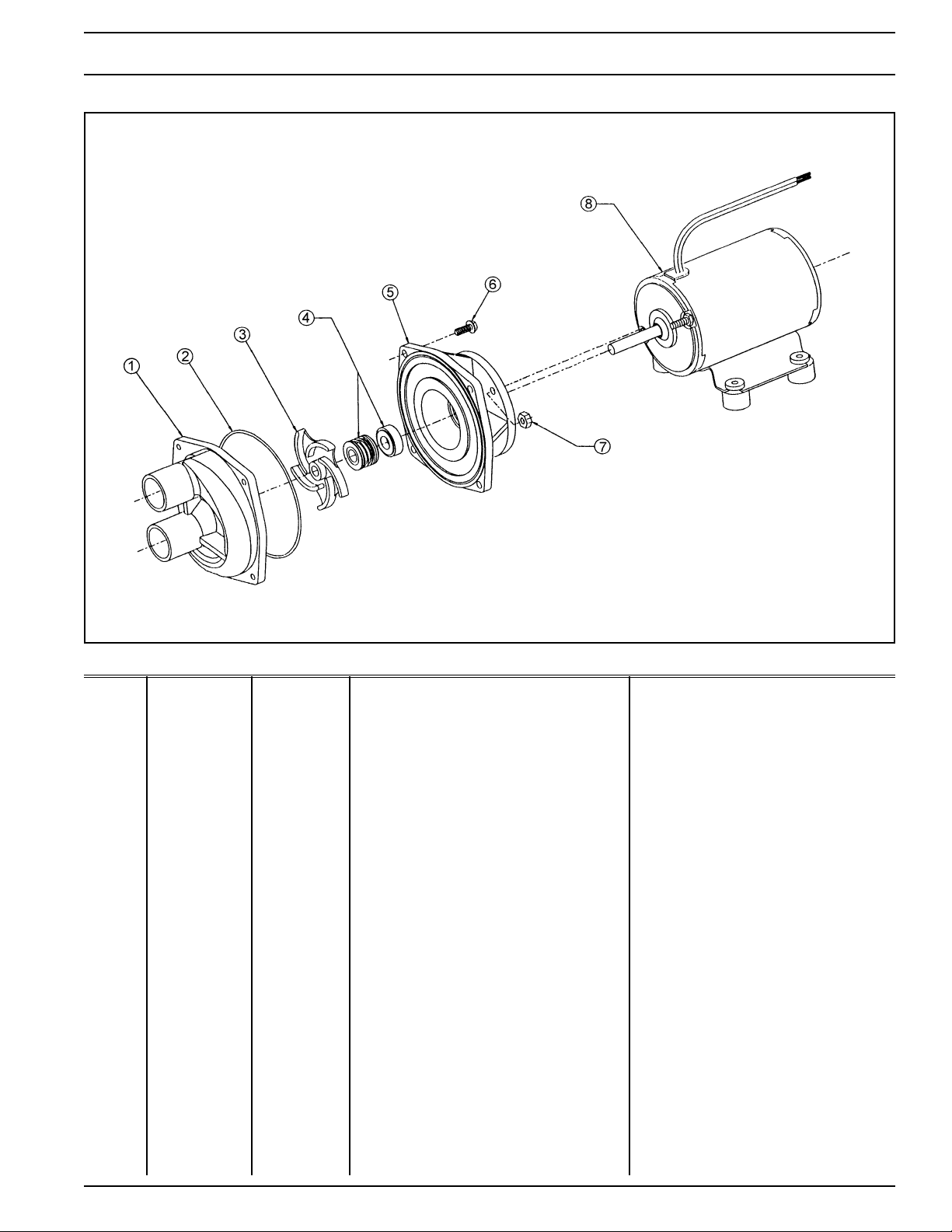

1 1 901000 Housing – Impeller MP # 28842

2 1 901013 O-ring MP # 28613

3 1 901015 Impeller MP # 28727

4 1 901017 Seal Assembly MP # 28984

5 1 901019 Adapter MP # 28733

6 4 901021 Screw MP # 28834

7 2 Hex Nut – 10-32

8 1 901023 Motor 12V MP # 28985

No Fig. 2 176591 Connector – Female 6.3

No Fig. 1 178713 Female Connector Housing

No Fig. 1 620322 Insul Tube ø8mm x 42mm Protective loom for wires

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 12

Scholastic Series

Subject to modification

Page 54

8SPARE PARTS LIST

W

EBASTOSCHOLASTICSERIES

8-16

255 1 310646 Gauge for Setting Ignition Electrodes

256 1 440280 Diagnostic Testing Unit

258 1 600190 Fuel Pressure Gauge with Adapter

No Fig. 1 905491 Extension Harness for Testing Unit 5 feet in length

No Fig. 1 406244 Combustion Chamber Puller

No Fig. 1 Exhaust Gas Analyzer

No Fig. 1 699745 Workshop Manual

ITEM QUANTITY PART NO. DESCRIPTION REMARKS

Figure 13

Scholastic Series

Subject to modification

Page 55

Webasto Thermosystems Inc.

North America

3333 John Conley Drive

Lapeer, MI 48446

Phone (810) 245-2400

Toll-free (800) HEATER-1

Fax (810) 664-7720

Technical Assistance Hotline

USA: (800) 555-4518

Canada: (800) 667-8900

Org. 2/2001 50000058A

www.webasto.com

Loading...

Loading...