Webasto Air Top Evo 3900 B, Air Top Evo 3900 D, Air Top Evo 5500 D, Air Top Evo 5500 B Installation Instructions

Page 1

Luftheizgeräte

Einbauanweisung

Air heaters

Luchtverwarmingsapparaten

Installation Instructions

Montagehandleiding

Air Top Evo 3900

Air Top Evo 5500

Handelsbezeichnungen /Trade names / Handelsnamen:

Air Top Evo 3900 B (Benzin) (petrol) (benzine)

Air Top Evo 3900 D (Diesel/PME) (diesel/PME)

Air Top Evo 5500 B (Benzin) (petrol) (benzine)

Air Top Evo 5500 D (Diesel/PME) (diesel/PME)

Page 2

Page 3

Das unsachgemäße Einbauen oder Reparieren von Webasto Heiz- und Kühlsystemen kann Feuer

verursachen oder zum Austritt von tödlichem Kohlenmonoxid führen. Dadurch können schwere oder tödliche Verletzungen hervorgerufen werden.

Für den Einbau und die Reparatur von Webasto Heiz- und Kühlsystemen bedarf es eines

Webastotrainings, technischer Dokumentation, Spezialwerkzeuge und einer Spezialausrüstung.

Es dürfen nur Originalteile von Webasto verwendet werden. Siehe dazu auch Zubehörkatalog Luft- und

Wasserheizgeräte von Webasto.

Versuchen Sie NIEMALS, Webasto Heiz- oder Kühlsysteme einzubauen oder zu reparieren, wenn Sie das

Webastotraining nicht erfolgreich abgeschlossen und dabei die notwendigen technischen

Fähigkeiten erworben haben und die für einen sachgerechten Einbau und Reparatur nötigen

technischen Dokumentationen, Werkzeuge und Ausrüstungen nicht zur Verfügung stehen.

Befolgen Sie IMMER alle Webasto Einbau- und Reparaturanleitungen, und beachten Sie alle

Warnhinweise.

Webasto übernimmt keine Haftung für Mängel und Schäden, die auf einen Einbau durch ungeschultes Personal zurückzuführen sind.

Improper installation or repair of Webasto heating and cooling systems can cause fire or the leakage of

deadly carbon monoxide leading to serious injury or death.

To install and repair Webasto heating and cooling systems you need to have completed a Webasto

training course and have the appropriate technical documentation, special tools and special equipment.

Only genuine Webasto parts may be used. See also Webasto air and water heaters accessories catalogue.

NEVER try to install or repair Webasto heating or cooling systems if you have not completed a Webasto

training course, you do not have the necessary technical skills and you do not have the technical

documentation, tools and equipment available to ensure that you can complete the installation and

repair work properly.

ALWAYS carefully follow Webasto installation and repair instructions and heed all WARNINGS.

Webasto rejects any liability for problems and damage caused by the system being installed by

untrained personnel.

Page 4

Air Top Evo 3900 / Air Top Evo 5500

Inhaltsverzeichnis

1 Gesetzliche Bestimmungen für den Einbau . . . . . . . . . . . . . 1

2 Verwendung / Ausführung . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Einbau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Typschild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Einbaubeispiel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Heizluftsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Brennstoffversorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Brennluftversorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9 Abgasleitung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10 Brennluftansaug- und Abgasleitungen. . . . . . . . . . . . . . . . 22

11 Elektrische Anschlüsse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

12 Anschlussschema / Schaltplan . . . . . . . . . . . . . . . . . . . . . . . 28

13 Legende für Schaltpläne . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

14 Erstinbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

15 Störabschaltung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

16 Technische Daten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

17 Bohrschablonen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table of contents

1 Statutory regulations governing installation . . . . . . . . . . .51

2 Use / version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4 Type label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

5 Installation example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

6 Hot air system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

7 Fuel supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

8 Combustion air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

9 Exhaust pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

10 Combustion air inlet and exhaust lines . . . . . . . . . . . . . . . .72

11 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

12 Connection diagram/Circuit diagram. . . . . . . . . . . . . . . . . .78

13 Legend for circuit diagrams . . . . . . . . . . . . . . . . . . . . . . . . .87

14 Initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

15 Fault lock-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

16 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

17 Drilling templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

I

Page 5

Air Top Evo 3900 / Air Top Evo 5500 Statutory regulations governing installation

1 Statutory regulations governing installation

The Air Top Evo 3900 and Air Top Evo 5500 heaters have been type-tested

and approved in accordance with Directives ECE R10 and EC 72/245/EEC

(EMC) and ECE R122 and 2001/56/EC (heater) with the following EC permit numbers:

EMC: e1*72/245*2006/96*5529*__ (Air Top Evo 3900 / 5500)

E1 03 5529 (Air Top Evo 3900 / 5500)

Heater: e1*2001/56*2006/119*0255*__ (Air Top Evo 3900)

E1 00 0255 (Air Top Evo 3900)

e1*2001/56*2006/119*0256*__ (Air Top Evo 5500)

E1 00 0256 (Air Top Evo 5500)

Primarily the regulations of Annex VII of the Directive 2001/56/EC and Part

I and Annex 7 of the directive ECE R122 must be observed for the installation.

NOTE:

The specifications of this Directive are binding in the scope of the

Basic Directive EEC/70/156 and/or EC/2007/46 (for new vehicle

models from 29/04/2009) and should also be observed in countries

in which no special regulations exist.

See chapter 1.2, "Extract from directives 2001/56/EC Annex VII and

ECE R122 Part I and Annex 7" and chapter 1.3, "Extract from directives 2001/56/EC Annex IX and ECE R122 Annex 9".

IMPORTANT

Failure to follow the installation instructions and the notes contained

therein will lead to all liability being refused by Webasto. The same applies

if repairs are carried out incorrectly or with the use of parts other than genuine spare parts. This will result in the invalidation of the type approval for

the heater and therefore of its homologation / EC type licence .

NOTE:

For vehicles with an EU permit, no entry in accordance with § 19 Sub-Section 4 of Annex VIII b to the Road Traffic Act is required.

1.1. Application of combustion heaters in vehicles for transporting dangerous goods

Vehicles for the purpose of transporting dangerous goods will be type tested in accordance with the standard ECE R105. The following measures are

derived for our combustion heaters:

• The electrical cable/wiring harness must be sufficiently dimensioned to

prevent overheating. The electrical cable/wiring harness must be sufficiently insulated. All power circuits must be protected with fuses or automatic circuit-breakers.

• The cables must be securely fastened and routed so that they are suffi-

ciently protected against mechanical and thermal loading.

• The combustion heaters must be type-tested in accordance with the

standard ECE R122 (equivalent to EC/2001/56 in the version EC/2006/

119) and comply with the Appendix 9 – Additional regulations for vehicles for transporting dangerous goods.

• The combustion heaters and their exhaust gas routing shall be de-

signed, located, protected or covered so as to prevent any unacceptable

risk of heating or ignition of the load.

• In the event of any leakage of the fuel line, the fuel shall drain to the

ground without coming into contact with hot parts of the vehicle or the

load;

• The exhaust system as well as the exhaust pipes shall be so directed or

protected to avoid any danger to the load through heating or ignition.

Parts of the exhaust system situated directly below the fuel tank shall

have a clearance of at least 100 mm or be protected by a thermal shield.

51

Page 6

Statutory regulations governing installation Air Top Evo 3900 / Air Top Evo 5500

• The combustion heater may only be switched on manually. Programming devices shall be prohibited. The combustion heater may be

switched on again manually after the vehicle engine has been switched

off.

Requirement for basic unit:

A maximum run-on period of 40 seconds is permitted when the combustion heater is switched off. Only combustion heaters with heat exchangers

that are approved for this reduced run-on time of 40 seconds may be used.

1.2. Extract from directives 2001/56/EC Annex VII and ECE R122

Part I and Annex 7

Start of extract.

ANNEX VII

REQUIREMENTS FOR COMBUSTION HEATERS AND THEIR

INSTALLATION

1. GENERAL REQUIREMENTS

1.7.1. / 7.1. (Annex 7) A clearly visible tell-tale in the operator's

field of view shall inform when the combustion heater is switched

on or off.

2. / 5.3. (Part I) VEHICLE INSTALLATION REQUIREMENTS

2.1. / 5.3.1. (Part I) Scope

2.1.1. / 5.3.1.1. (Part I) Subject to paragraph 2.1.2. / 5.3.1.2. (Part

I) combustion heaters shall be installed according to the requirements of this Annex.

2.1.2. / 5.3.1.2. (Part I) Vehicles of category O having liquid fuel

heaters are deemed to comply with the requirements of this Annex.

2.2. / 5.3.2. (Part I) Positioning of heater

2.2.1. / 5.3.2.1. (Part I) Body sections and any other components

in the vicinity of the heater must be protected from excessive heat

and the possibility of fuel or oil contamination.

2.2.2. / 5.3.2.2. (Part I) The combustion heater shall not constitute

a risk of fire, even in the case of overheating. This requirement

shall be deemed to be fulfilled if the installation ensures an adequate distance to all parts and suitable ventilation, by the use of

fire resistant materials or by the use of heat shields.

2.2.3. / 5.3.2.3. (Part I) In the case of M2 and M3 vehicles, the

heater must not be positioned in the passenger compartment.

However, an installation in an effectively sealed envelope which

also complies with the conditions in paragraph 2.2.2. / 5.3.2.2.

(Part I) may be used.

2.2.4. / 5.3.2.4. (Part I) The label referred to in paragraph 1.4 / Annex 7 paragraph 1.4. or a duplicate, must be positioned so that it

can be easily read when the heater is installed in the vehicle.

2.2.5. / 5.3.2.5. (Part I) Every reasonable precaution should be taken in positioning the heater to minimise the risk of injury and damage to personal property.

2.3. / 5.3.3. (Part I) Fuel supply

2.3.1. / 5.3.3.1. (Part I) The fuel filler must not be situated in the

passenger compartment and must be provided with an effective

cap to prevent fuel spillage.

2.3.2. / 5.3.3.2. (Part I) In the case of liquid fuel heaters, where a

supply separate to that of the vehicle is provided, the type of fuel

and its filler point must be clearly labelled.

52

Page 7

Air Top Evo 3900 / Air Top Evo 5500 Statutory regulations governing installation

2.3.3. / 5.3.3.3. (Part I) A notice, indicating that the heater must

be shut down before refuelling, must be affixed to the fuelling

point. In addition a suitable instruction must be included in the

manufacturer's operating manual.

2.4. / 5.3.4. (Part I) Exhaust system

2.4.1. / 5.3.4.1. (Part I) The exhaust outlet must be located so as

to prevent emissions from entering the vehicle through ventilators,

heated air inlets or opening windows.

2.5. / 5.3.5. (Part I) Combustion air inlet

2.5.1. / 5.3.5.1. (Part I) The air for the combustion chamber of the

heater must not be drawn from the passenger compartment of

the vehicle.

2.5.2. / 5.3.5.2. (Part I) The air inlet must be so positioned or

guarded that blocking by rubbish or luggage is unlikely.

2.6. / 5.3.6. (Part I) Heating air inlet

2.6.1. / 5.3.6.1. (Part I) The heating air supply may be fresh or recirculated air and must be drawn from a clean area not likely to be

contaminated by exhaust fumes emitted either by the propulsion

engine, the combustion heater or any other vehicle source.

2.6.2. / 5.3.6.2. (Part I) The inlet duct must be protected by mesh

or other suitable means.

2.7. / 5.3.7. (Part I) Heating air outlet

2.7.1. / 5.3.7.1. (Part I) Any ducting used to route the hot air

through the vehicle must be so positioned or protected that no injury or damage could be caused if it were to be touched.

2.7.2. / 5.3.7.2. (Part I) The air outlet must be so positioned or

guarded that blocking by rubbish or luggage is unlikely.

2.8. / 5.3.8. (Part I) Automatic control of the heating system

2.8. / 5.3.8.1. (Part I) The heating system must be switched off automatically and the supply of fuel must be stopped within five seconds when the vehicle's engine stops running. If a manual device

is already activated, the heating system can stay in operation.

End of extract.

53

Page 8

Statutory regulations governing installation Air Top Evo 3900 / Air Top Evo 5500

1.3. Extract from directives 2001/56/EC Annex IX and ECE R122

Annex 9

Start of extract.

ANNEX IX / 9

3. Technical specifications for heater units for installation in

dangerous goods transporters (Annex 9)

3.1. General (EX/II, EX/III, AT, FL and OX vehicles)

3.1.1. The combustion heaters and their exhaust gas routing shall

be designed, located, protected or covered so as to prevent any

unacceptable risk of heating or ignition of the load. This requirement shall be considered as fulfilled if the fuel tank and the exhaust system of the appliance conform to the provisions set out in

the points 3.1.1.1 and 3.1.1.2. Compliance with those provisions

shall be verified on the completed vehicle.

3.1.1.1. Any fuel tanks for supplying the appliance shall meet the

following requirements:

a) in the event of any leakage, the fuel shall drain to the

ground without coming into contact with hot parts of the

vehicle or the load;

b) fuel tanks containing petrol shall be equipped with an ef-

fective flame trap at the filler opening or with a closure enabling the opening to be kept hermetically sealed.

3.1.1.2. The exhaust system as well as the exhaust pipes shall be

so directed or protected to avoid any danger to the load through

heating or ignition. Parts of the exhaust system situated directly

below the fuel tank (diesel) shall have a clearance of at least

100 mm or be protected by a thermal shield.

3.1.2. The combustion heater shall be switched on manually. Programming devices shall be prohibited.

3.2. EX/II and EX/III vehicles

Combustion heaters using gaseous fuels are not permitted.

3.3. FL vehicles

3.3.1. The combustion heaters shall be put out of operation by at

least the following methods:

a) intentional manual switching off from the driver’s cab;

b) stopping of the vehicle engine; in this case the heating de-

vice may be restarted manually by the driver;

c) start-up of a feed pump on the motor vehicle for the dan-

gerous goods carried.

End of extract.

54

Page 9

Air Top Evo 3900 / Air Top Evo 5500 Use / version

2 Use / version

2.1. Use of the air heaters

The Webasto Air Top Evo 3900 and Air Top Evo 5500 air heaters are designed

– to heat cabins, boats, trucks, minibuses, vans, ambulances and mo-

torhomes

– to defrost vehicle windows

– to heat cargo

The heaters operate independently of the engine and are connected directly to the fuel tank and the electrical system of the vehicle.

They may be used for vehicles with either water or air-cooled engines.

They are not approved for heating the space in which dangerous goods are

transported.

2.2. Version

Air Top Evo 3900 B (petrol)

Air Top Evo 5500 B (petrol)

Air Heater for "Petrol" Fuel (12 V)

Air Top Evo 3900 D (diesel)

Air Top Evo 5500 D (diesel)

Air Heater for "Diesel" Fuel (12 or 24 V)

55

Page 10

Installation Air Top Evo 3900 / Air Top Evo 5500

3Installation

IMPORTANT

The statutory regulations governing installation (see chapter 1, "Statutory

regulations governing installation") must be adhered to. The requirements

of the latest version of the ADR must also be observed for the installing the

heater into vehicles used to transport hazardous substances.

The heater must not be operated without the control unit cover (this will

cause the heater to overheat).

3.1. Air Top Evo 3900 / Air Top Evo 5500 installation situation

NOTE:

Check the installation situation of the relevant vehicle type.

3.2. Installation location

The heater may be fitted both in the interior or on the exterior of the vehicle.

When using the vehicle in normal road traffic, the heater may only

be installed with contact protection if it is located within reach of

the driver.

If it is installed on the exterior ensure that the heater is fitted in a position

where it is protected from splashing water and spray. The heater must be

installed in such a way that no water can ingress into it if the vehicle travels

through a water hazard for which that vehicle is licensed.

The openings for the combustion air inlet port, the exhaust outlet port and

the fuel pipe must be sealed if the heater is installed in the interior. The seal

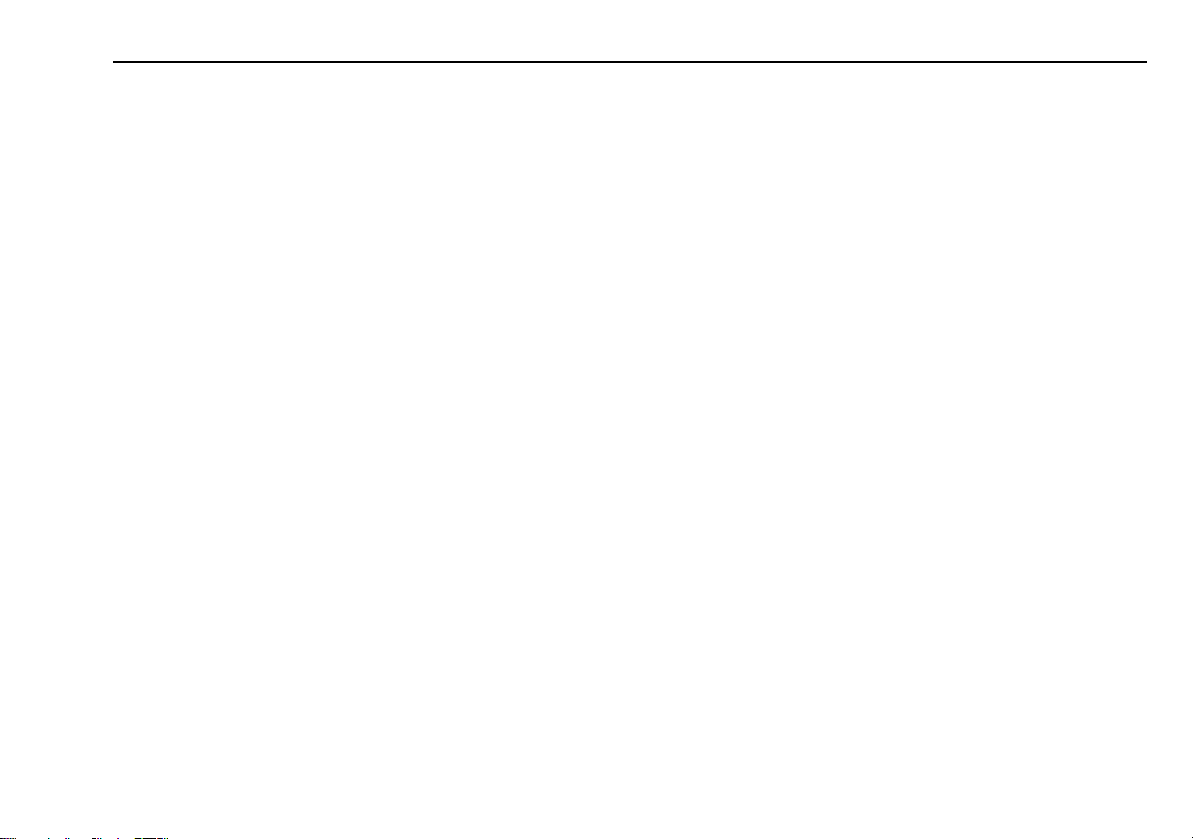

designed and supplied for this purpose must be used (see Figure 3).

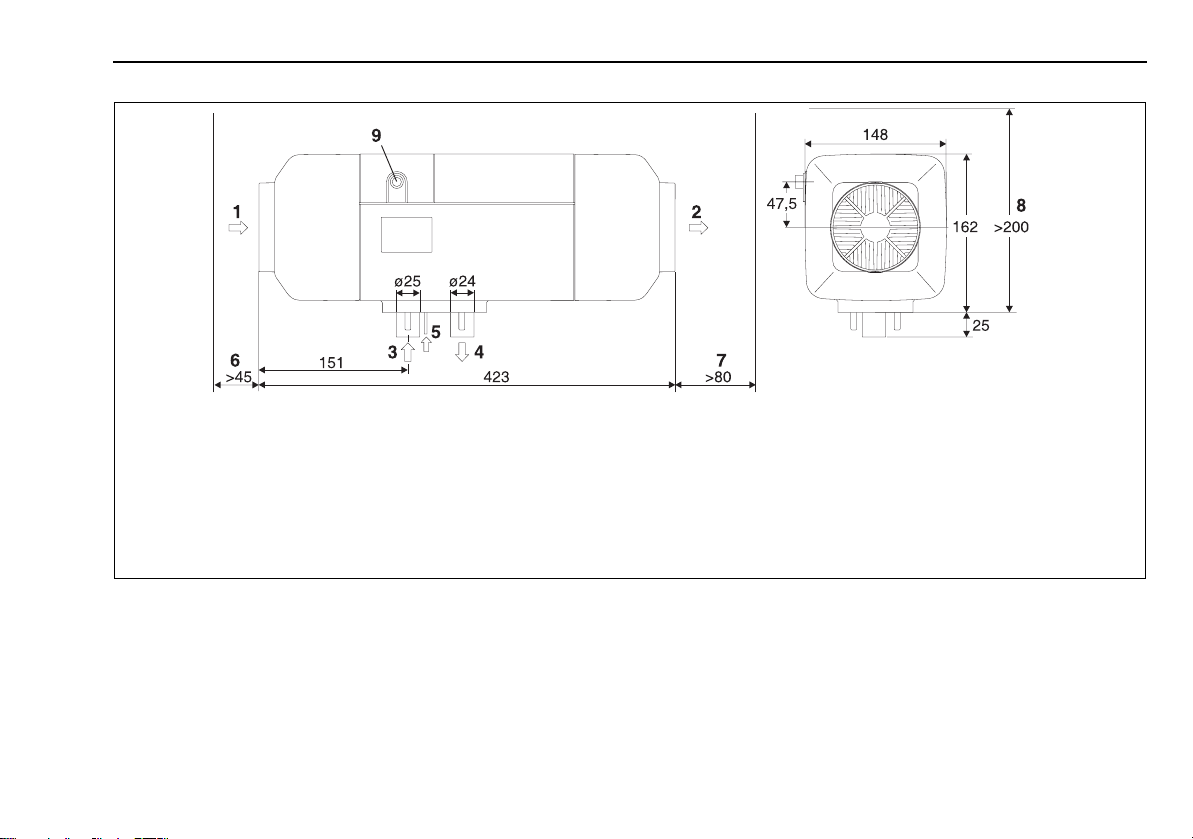

3.3. To install the heater

The M6 nuts must be tightened with a torque of 6 Nm (-0 Nm,+1 Nm) for

installing the Air Top Evo 3900 or Air Top Evo 5500 heater.

The installation dimensions and space requirement for service access are

shown in the installation drawing (Figure 1). The specified horizontal and

axial angles must not be exceeded (Figure 2).

A seal (Figure 3) must be fitted between the heater and the vehicle body.

This seal must be replaced each time the heater is installed. The support area for the heater foot must be flat. A special tools can be purchased from Webasto to drill the holes and, if necessary, smooth the support area. The seal can compensate for unevenness of max. 1 mm

IMPORTANT

After installation, check that the casing is not in contact with any parts of

the vehicle body. A failure to do this may result in the hot air fan blocking.

.

56

Page 11

Air Top Evo 3900 / Air Top Evo 5500 Installation

1Hot air inlet

2 Hot air outlet

3 Combustion air intake

4 Exhaust fume outlet

5 Fuel intake

Fig. 1 Dimensions of the heater

6 Space requirement for hot air inlet

7 Space requirement for hot air outlet

8 Space requirement for removing the heater

9 Cable outlet (either right or left)

57

Page 12

Installation Air Top Evo 3900 / Air Top Evo 5500

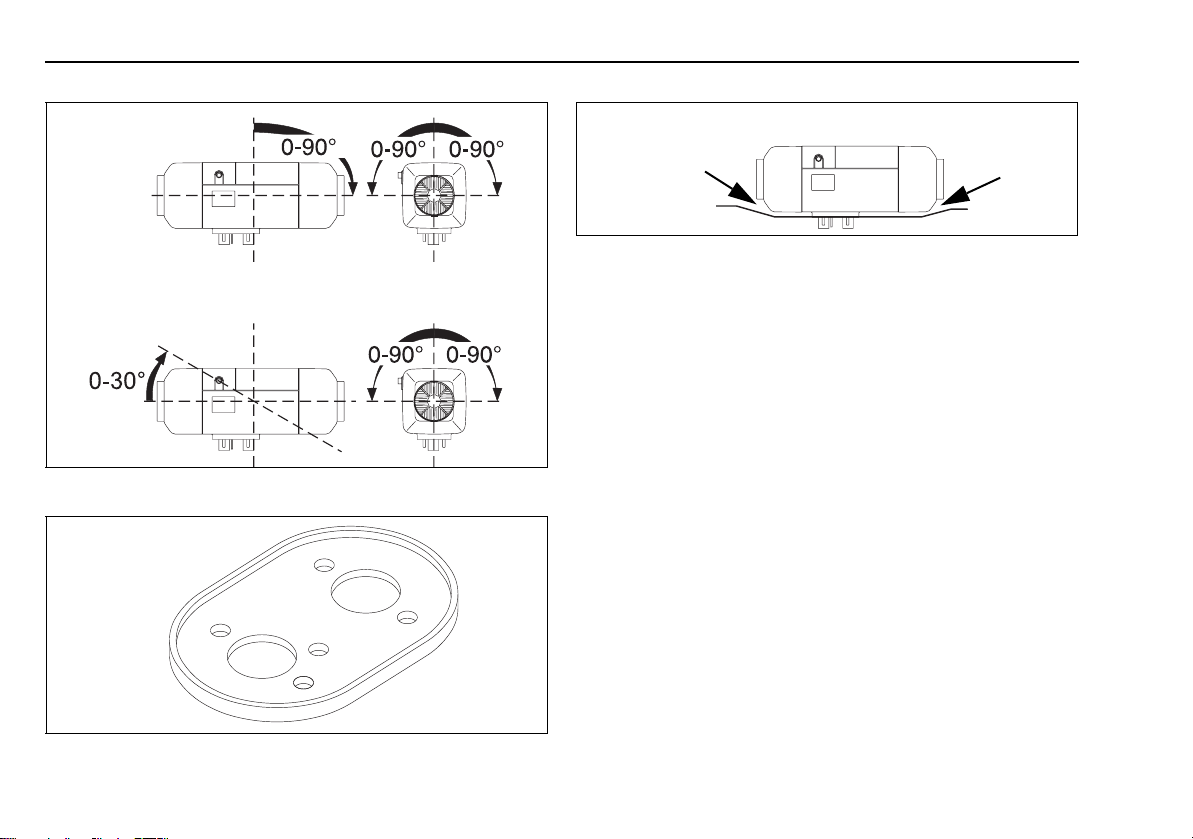

Diesel heaters

Petrol heaters

Fig. 2 Approved installation position

Ensure that all moving parts can move easily.

Fig. 4 Installation

Fig. 3 Seal

58

Page 13

Air Top Evo 3900 / Air Top Evo 5500 Type label

4Type label

The model plate must be positioned so that it cannot be damaged and

must be clearly legible when the heater is installed (otherwise a duplicate

model plate must be used).

Inapplicable years must be erased from the model plate.

59

Page 14

Installation example Air Top Evo 3900 / Air Top Evo 5500

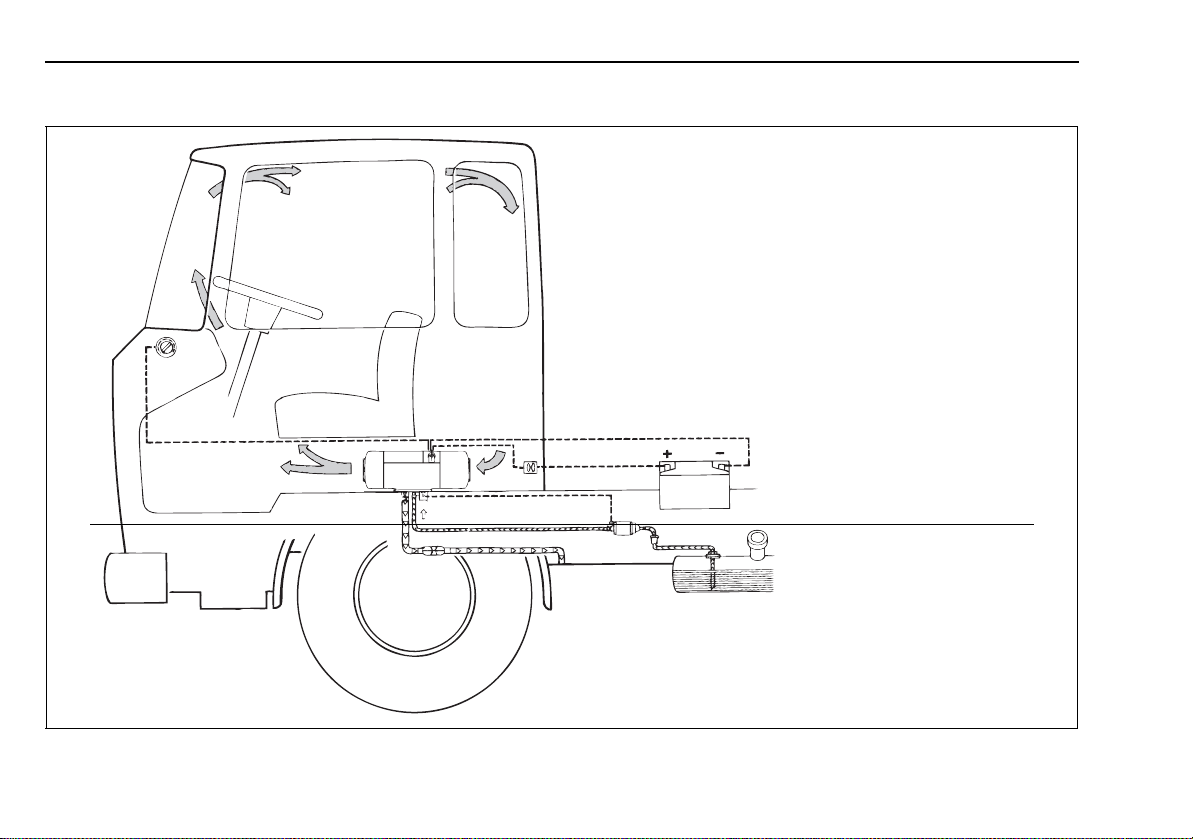

5 Installation example

1 Control element

2Heater

3 Metering pump

4 Fuel filter (accessory)

5 Tank connector

6 Exhaust silencer (accessory)

7Fuse

1

7

2

4

3

6

5

Maximum

water passage height

Fig. 5 Installation example for air heater in recirculation mode

60

Page 15

Air Top Evo 3900 / Air Top Evo 5500 Installation example

5.1. Design as system

The variants Air Top Evo 3900 AM and Air Top Evo 5500 AM enable up to

4 heaters to be operated in one system.

Here Unit 1 is defined as the master heater and others as slave heaters. The

heater control and an external temperature sensor (T) are connected to the

master heater (see wiring diagram in Figure 34, 36 and 38). The slave heater is connected in accordance with the wiring diagram (see Figure 39). The

units communicate with each other via a serial bus system.

This system can therefore be individually adapted to the applications by

combining several heaters.

Bus System

Unit 1 Unit 2 Unit 3 Unit 4

IMPORTANT

The use of an Air Top Evo 3900 AM or Air Top Evo 5500 AM system is not

approved for dangerous goods transports (ADR)!

Fig. 6 System design

61

Page 16

Installation example Air Top Evo 3900 / Air Top Evo 5500

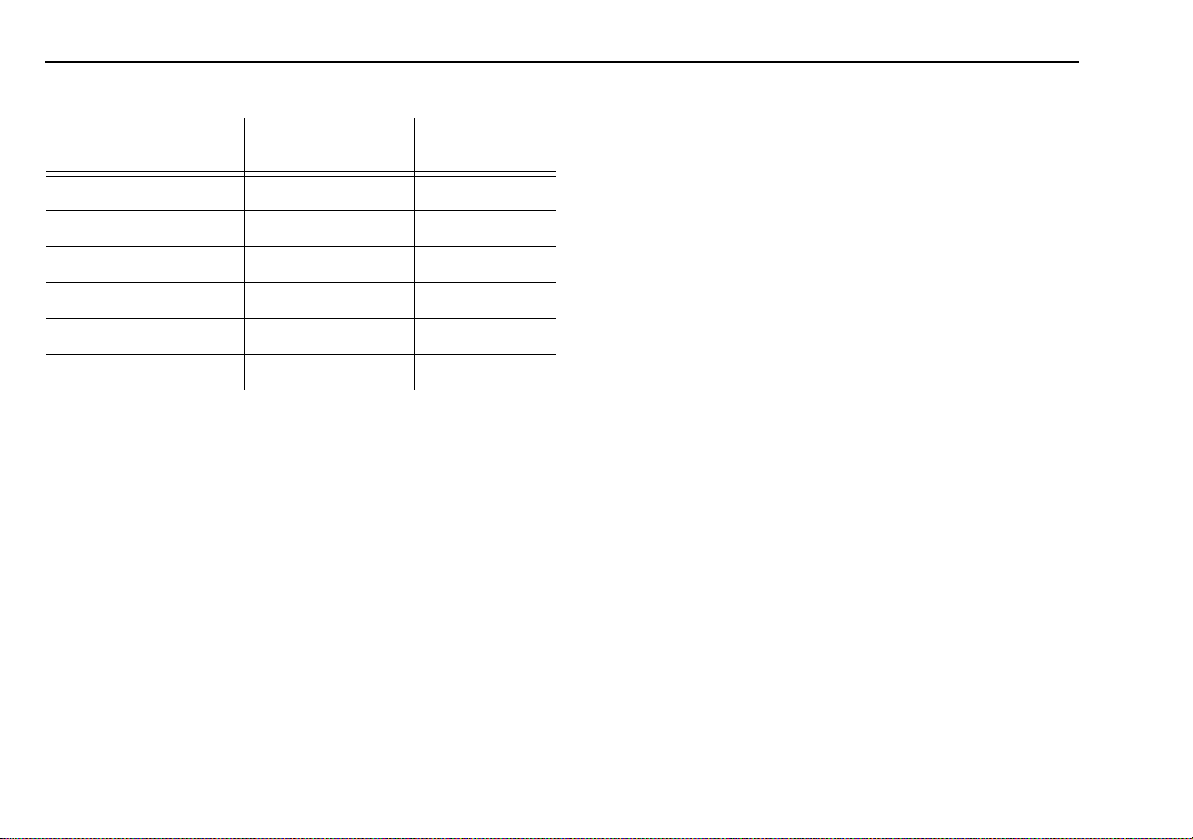

5.2. Heating Capacity of Entire System

Heating Capacity

Range

1.5 - 3.9 kW Air Top Evo 3900 1

1.5 - 5.5 kW Air Top Evo 5500 1

1.5 - 7.8 kW Air Top Evo 3900 2

1.5 - 11.0 kW Air Top Evo 5500 2

1.5 - 16.5 kW Air Top Evo 5500 3

1.5 - 22.0 kW Air Top Evo 5500 4

NOTE:

It is only permitted to install heating systems with Air Top Evo heaters of

the same output type.

Heater Number of

Units

62

Page 17

Air Top Evo 3900 / Air Top Evo 5500 Hot air system

6 Hot air system

NOTE:

The heater must not be integrated into the vehicle’s air system.

Inside the control unit there is a temperature sensor, which operates the

heater in the appropriate heat output range in conjunction with the control

element depending on the intake temperatures and the position of the setpoint generator. The heat output is controlled such that after the selected

interior temperature has been reached quickly, it is then kept at this selected value.

Both recirculation and fresh air modes are possible.

For fresh air mode it must be ensured that the hot air is taken from an area

protected from splashing water and spray and in such a way that no water

can ingress into the heater if the vehicle travels through a water hazard for

which that vehicle is licensed.

NOTE:

For fresh air mode an external temperature sensor must be fitted in the appropriate zone.

Recommended internal diameter of the main section of the hot air line:

90 mm for the Air Top Evo 5500 80 mm for the Air Top Evo 3900

NOTE:

Only materials that can permanently withstand temperatures of at least

130 °C may be used for the hot air line. The hot air opening is to be positioned in such a way that the air is not blown on to any parts that cannot

withstand the heat.

IMPORTANT

In vehicles used to transport people, the air outlet opening is to be directed

in such a way that it is at least 20 cm away from all body parts.

Maximum pressure drop between the inlet and outlet side of the hot air

line:

Air Top Evo 3900 2.0 hPa

Air Top Evo 5500 3.0 hPa

1 hPa corresponds to 1 mbar corresponds to 10 mm water column.

The heaters check the internal temperature rise automatically each time

they are switched on. If this is above the specified limits, the start is cancelled and error messages F10 is displayed. To ensure that the heater functions stably, the flow resistance of the connected hot air system must be

reduced.

The points table for air guide parts in the Webasto catalogue may be used

to design the hot air system.

The hot air hose must be secured at its connection points.

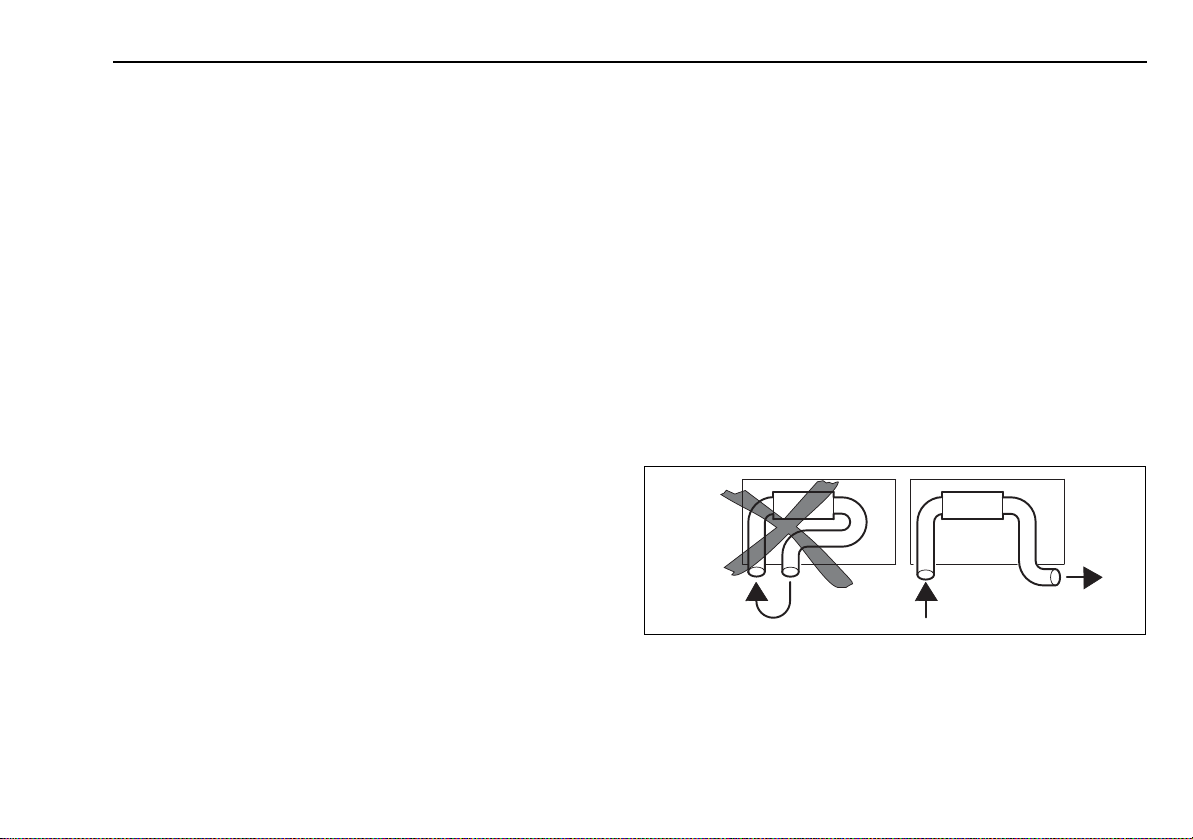

If the heater is used in recirculation mode without a hot air guide, do not

short circuit the hot air flow.

Fig. 7 Hot air inlet and hot air outlet

IMPORTANT

If you use the heater without a hot air inlet hose, the inlet grille supplied

with the heater must be used at all times.

63

Page 18

Hot air system Air Top Evo 3900 / Air Top Evo 5500

NOTE:

The installation must be checked for:

– Air short circuit between the vehicle’s heating system and the heater air

inlet

– Air short circuit between the heater’s air inlet and the heater’s air outlet

(Figure 7)

Fig. 8 Hot air inlet with inlet grille

If you use an installation box the air vent must be sealed in such a way that

no hot air can get into the installation box.

6.1. External temperature sensor

For fresh air mode an external temperature sensor must be fitted in the appropriate zone.

6.1.1. To install the external temperature sensor

The external temperature sensor must be installed at medium height in the

passenger cabin on vertical surfaces if possible in the area that requires

heating.

The temperature sensor must not

– be in the direct current of hot air (from the vehicle’s own heating system

or the hot air heater).

– by close to heat sources (for example the vehicle’s own heating system).

– be placed in direct sunlight (for example on the dashboard).

– be installed behind curtains or the like.

64

Page 19

Air Top Evo 3900 / Air Top Evo 5500 Fuel supply

7 Fuel supply

The fuel is taken from the vehicle fuel tank or from a separate fuel tank.

The values for the maximum pressure at the fuel extraction point are

shown in Figure 9.

Permissible fuel inflow height

H (m)

0,00 0,2

1,00 0,11

2,00 0,03

Maximum fuel intake height S

(m)

0,00 -0,10

0,50 -0,06

1,00 -0,02

Only for ADR:

transport international des marchandises dangereuses par route) governing fuel tanks, part 9 para. 9.2.4.7, must be adhered to.

A sign must be affixed to the fuel filler neck warning that the heater must

be switched off before refuelling.

The statutory regulation of ADR (Accord européen relatif au

At max. perm. pressure (bar)

in fuel line

At max. perm. negative pres-

sure (bar) in the fuel tank

l1 + l2 ≤ 10 m

l

≤ 1.2 m

2

l

≤ 8.8 m

2

Fig. 9 Fuel supply

65

Page 20

Fuel supply Air Top Evo 3900 / Air Top Evo 5500

7.1. Vehicles with carburettor engines

The fuel may only be extracted using the special Webasto fuel extractor

(see Figure 10) as close to the tank as possible. The connect may be made

in either the supply or return line, in which case the return line must lead

almost to the base of the tank (see Figure 11).

The fuel extractor must be fitted in such a way that any air or gas bubbles

are automatically discharged towards the tank (see Figure 10).

from tank

to metering pump

Fig. 10 Webasto fuel extractor

The fuel extractor should not be located near the engine, as gas bubbles

may form in the lines on account of heat radiated from the engine. This

may cause problems during combustion.

to engine

7.2. Vehicles with injection engines

When installing the heater in a vehicle with fuel injection system, it is important to establish whether the vehicles fuel pump is located inside or

outside the tank.

If the fuel pump is located inside the tank, fuel can only be extracted from

the return line using the Webasto fuel extractor (see Figure 10), in which

case it must be checked to ensure that the fuel return pipe in the tank terminates near the bottom of the fuel tank (see Figure 11 for details of the

minimum distance from the bottom of the tank). If this is not the case Webasto fuel extractor (see Figure 11, 12 and 13) may be used.

If the fuel pump is installed outside the tank, the fuel connection may also

be made between the tank and the fuel pump, again using only the Webasto fuel extractor (see Figure 10).

7.3. Vehicles with diesel engines

The fuel must be taken from the vehicle fuel tank or from a separate tank

(see Figs. 11, 12 and 13). This separate fuel pick-up precludes any effect of

pressure.

NOTE:

The tank fitting must be made from metal!

7.4. Fuel lines

Only steel, copper and plastic lines of plasticised, light and temperaturestabilised PA 11 or PA 12 (e.g. Mecanyl RWTL) pursuant to DIN 73378 may

be used for the fuel lines.

Since the lines normally cannot be routed with a constant rising gradient,

the internal diameter must not be allowed to exceed a certain size. Air or

gas bubbles will accumulate in lines with an internal diameter of more than

4 mm and these will cause malfunctions whilst the heater is operating if

66

Page 21

Air Top Evo 3900 / Air Top Evo 5500 Fuel supply

Hole pattern

Only use a tank connector if the fuel

tank is made from metal

Minimum distance 25 mm

Fig. 11 Webasto tank connector

Plastic tank

Sealing ring

Fig. 12 Fuel pick-up from the plastic tank

(Pick-up via tank drain screw)

the lines sag or are routed downwards. The diameters specified in Figure 9

will ensure that bubbles do not form.

The lines should not be routed downwards from the metering pump to the

heater.

Sealing ring

Tank connector

Tank fitting

Fig. 13 Fuel pick-up from the plastic tank

(Pick-up via tank fitting)

Unsupported fuel lines must be secured to prevent them sagging. They

must be installed in such a way that they cannot be damaged by flying road

chippings and high temperatures

The fuel lines must be secure at the connections using hose clips to prevent

their slipping.

(exhaust line).

67

Page 22

Fuel supply Air Top Evo 3900 / Air Top Evo 5500

7.4.1. Connecting two pipes with a hose

The correct procedure for connecting fuel lines with hosing is shown in Figure 14.

Ensure that there are no leaks.

Correct

Clip

Wrong

Bubble

Fig. 14 Pipe / hose connection

7.5. Metering pump

The metering pump is a combined delivery, metering and shut-off system

and is subject to certain installation criteria (see Figures 9, 15 and 16).

7.5.1. Installation location

The metering pump must be installed in a cool place as close as possible to

the tank (see Figure 9). The maximum ambient temperature must not exceed +20 °C for petrol heaters at any time during operation.

The metering pump and fuel lines must not be installed within range of the

radiated heat from hot vehicle parts. A heat shield must be used if necessary.

Bubble

Air Top Evo 3900 / Air Top Evo 5500 12 Volt - petrol

Preferably

15° - 90°

Metering

pump

Fig. 15 Metering pump DP 2 with damper

Installation position

Air Top Evo 3900 / Air Top Evo 5500

12 Volt and 24 Volt - diesel

Horizontal installation

Fig. 16 Metering pump DP 30.2

Installation position

Installation position of damper

Installation

position of

damper

68

Page 23

Air Top Evo 3900 / Air Top Evo 5500 Fuel supply

7.5.2. Installation and attachment

The metering pump must be secured with a vibration-damping mounting

(for example a rubberised clip). Its installation position is limited as shown

in Figures 15 and 16 in order to ensure effective automatic bleeding.

As a result of the risk of corrosion, only genuine Webasto parts may be

used for the plug connections between the metering pump and the metering pump wiring harness.

7.6. Fuel filter

Only a Webasto filter, order no. 487 171, is allowed to be used if the fuel

is expected to be contaminated. Install vertically if possible, however at

least horizontally (check flow direction).

0° - 90°

Fig. 17 Air Top Evo 3900 and Air Top Evo 5500 fuel filter

69

Page 24

Combustion air supply Air Top Evo 3900 / Air Top Evo 5500

8 Combustion air supply

Under no circumstances may the combustion air be taken from areas occupied by people. The combustion air intake opening must not point in the

direction of travel. It must be located so that it cannot become clogged

with dirt.

NOTE:

An intake silencer must be fitted if the intake hose length is shorter than

0.6 m.

NOTE:

The combustion air must be extracted using a combustion air line from a

position that is as cool as possible and protected from splashing water.

Do not use an exhaust line as the combustion air line since otherwise the

metering pump cable from the combustion air inlet port may be damaged.

The combustion air opening must not be under the minimum water drivethrough level permitted for the vehicle.

See the statutory regulations for the installation for further regulations.

70

Page 25

Air Top Evo 3900 / Air Top Evo 5500 Exhaust pipe

9 Exhaust pipe

Rigid pipes of unalloyed or alloyed steel with a minimum wall thickness of

1.0 mm or flexible piping of alloyed steel only must be used as exhaust line.

The exhaust pipe is secured to the heater using a clamping collar, for example. See the statutory regulations for other requirements.

Fig. 18 Exhaust silencer

Arbitrary flow direction

Fig. 19 Exhaust silencer for boat applications

Flow direction and installation position arbitrary

The exhaust silencer should ideally be installed near the heater.

The heater may also be operated without a silencer.

71

Page 26

Combustion air inlet and exhaust lines Air Top Evo 3900 / Air Top Evo 5500

10 Combustion air inlet and exhaust lines

Both lines are to be installed falling away from the heater. If this is not possible, a condensate drain hole with a diameter of 4 mm must be made at

its lowest point.

Fig. 22 Avoid the lines becoming clogged with dirt

IMPORTANT

Fig. 20 Prevent the formation of condensate

The lines must not point to the front of the vehicle.

Fig. 21 The lines must not end pointing towards the front of the vehicle

The lines must be located so that they cannot become clogged with dirt.

If the exhaust pipe ends is other than as shown in the Figure 23 it will pose

a fire risk.

Length of the combustion air inlet and exhaust lines in total:

With exhaust silencer: max. 2.0 m

Without exhaust silencer: max. 5.0 m

NOTE:

If the exhaust line is over 2 m in length the lines must be insulated (to prevent falling below the dew point)

Internal diameter of the lines:

Combustion air line: 25 mm

Exhaust line (metal): 24 mm

Minimum bending radius: 50 mm

Total bends:

Combustion air line: max. 270°

Exhaust line: max. 270°

72

Page 27

Air Top Evo 3900 / Air Top Evo 5500 Combustion air inlet and exhaust lines

An attachment is required no further than 150 mm from the end of the

exhaust pipe to ensure that the angle of 90° ± 10° is achieved

Discharge direction almost vertical 90° ± 10°

Fig. 23 Exhaust pipe opening

Installation position

Only for ADR: The statutory regulation of ADR (Accord européen relatif au

transport international des marchandises dangereuses par route) governing the routing of the exhaust line, part 9 para. 9.2.4.7, must be adhered

to.

73

Page 28

Electrical connections Air Top Evo 3900 / Air Top Evo 5500

11 Electrical connections

All lines that are not required must be insulated at their free end.

NOTE:

If the combination or standard timer is used, a touch-sensitive switch may

be installed in the sleeping section to act as a remote control and improved

convenience. The connections must be made as shown in the circuit diagrams in Figures 36 and 37.

The electrical connection is made as shown in the system circuit diagram

(Figures 34 to 39).

11.1. Connection for installing the heater in a hazchem vehicle (ADR)

To install the Air Top Evo 3900 D and Air Top Evo 5500 D heaters in

hazchem vehicles, the requirements of ADR/RID part 9 para. 9.2.4.7 –

Combustion heating systems, must also be satisfied. The electrical connection is made as shown in the circuit diagram in Figure 35 and 39.

NOTE:

The switch S3 must be installed in such a way that a positive potential is

connected to appropriate input of the control module when a pumping device is switched on.

IMPORTANT

All ADR functions are ineffective if there is no earth at control unit input

X6/1 when the system is switched on.

The control unit continues to run briefly for a maximum of 40 seconds and

then switches to the "ADR lock-out" operating mode when a positive voltage is connected to control unit input X6/1 (auxiliary power take-off on) or

the engine is switched off.

IMPORTANT

In accordance with the regulations of the act governing the road/rail haulage of hazardous materials, heaters are only allowed to be taken into service with a special manually operated switch fitted in the cab.

If the system is equipped with a combination timer, ensure that contact 4

on the combination timer remains free. The heater can then only be taken

into service using the immediate heat button.

The use of other timers in ADR vehicles is not permitted.

11.2. Heater connection

To connect the wiring harness, remove the control unit cover on the heater

and connected the wiring harness plug to the control unit.

Fig. 24 Removing control unit cover

NOTE:

Raise the control unit cover on both sides using a blunt blade (Figure 24

arrows).

Before using the heater for the first time fit the control unit cover to prevent the illegal escape of hot air (heater overheating).

74

Page 29

Air Top Evo 3900 / Air Top Evo 5500 Electrical connections

The cable passage can be placed at either the left or right side.

To ensure that the cable passage in the control unit cover seals correctly,

the cable grommet is to be adjusted appropriately on the wiring harness.

11.3. Supply voltage connection

Ideally from the vehicle’s central electrical system.

An additional blade terminal fuse holder is to be fitted to protect

the heater (supplied with the heater). The fuse holder may only be

installed in the interior of the vehicle.

Fig. 25 Remove the fastening plate on the fuse holder

F = 15 A (24 V)

F = 20 A (12 V)

Fig. 26 Fuse holder, installation position

75

Page 30

Electrical connections Air Top Evo 3900 / Air Top Evo 5500

11.4. Control element connection

The wiring harness is prepared for connection to the control element.

Simply pull on connector housing to unplug the connector.

The connector housing can be locked (self-locking action) by simply pulling

on the wiring harness.

NOTE:

The fibre optic cable must be in contact with the rotary knob

NOTE:

As an option an external temperature sensor may be installed in the passenger cabin (see page 64).

Fig. 28 Installation of the control element

Fig. 29 Installation of the control element (incorrect)

Fig. 27 Control element

76

Page 31

Air Top Evo 3900 / Air Top Evo 5500 Electrical connections

11.5. Installation Instructions for Control Panel MC04/05

Install control panel:

The control panel should be installed in a suitable location (on a flat surface

if possible) in the area visible to the driver.

– Use Drilling Template for control panel MC04/05 for cut-out and holes

(see chapter 17, "Drilling templates");

– Connect control panel to existing connectors on heater-unit wiring har-

ness (see chapter 12, "Connection diagram/Circuit diagram");

– Premount control unit in cut-out;

– Lightly press fastening screws into holes and screw in;

– Carefully clip on trim frame.

NOTES:

– control panel is only intended for installation in passenger compart-

ment;

– Ensure good readability when selecting installation location;

– Observe information on adhesive labels and coloured markings when

connecting control panel to vehicle wiring harness.

Fig. 30 Installing Control Panel MC04/05

77

Page 32

Connection diagram/Circuit diagram Air Top Evo 3900 / Air Top Evo 5500

12 Connection diagram/Circuit diagram

Combination timer 1531

Adapter wiring harness

grey: Terminal 58

black: Terminal 15

red: Terminal 30

brown: Terminal 31

Fig. 31 Air Top Evo 3900 and Air Top Evo 5500 with combination timer connection diagram

78

Page 33

Air Top Evo 3900 / Air Top Evo 5500 Connection diagram/Circuit diagram

Control Panel MC04/05

Observe coloured markings

Optional connection for:

- Telestart/Thermo Call (12 V only)

- Webasto Thermo Test Diagnose

Heaters wiring

harness

Fig. 32 Connection Diagram for Air Top Evo 3900 and Air Top Evo 5500 with Control Panel MC04/05

79

Page 34

Connection diagram/Circuit diagram Air Top Evo 3900 / Air Top Evo 5500

MC04 heater control

Connection for Webasto Thermo Test diagnosis

Observe coloured markings

Control line

heaters

wiring harness

Connection for Webasto

Thermo Test diagnosis

... Connection to additional

heaters

W bus +

heater 2

heater 1

X5

Remove resistor for external

temperature sensor

Fig. 33 Connection diagram for Air Top Evo 3900/5500 as system (connection of combination timer 1531 and setpoint generator is also possible)

80

Page 35

Air Top Evo 3900 / Air Top Evo 5500 Connection diagram/Circuit diagram

Fig. 34 System wiring diagram for the Air Top Evo 3900 and Air Top Evo 5500, 12 V/24 V with control element and vehicle fan,

for legend see pages 87 and 88

81

Page 36

Connection diagram/Circuit diagram Air Top Evo 3900 / Air Top Evo 5500

Fig. 35 System wiring diagram for the Air Top Evo 3900 and Air Top Evo 5500, 24 V ADR operation with control element,

for legend see pages 87 and 88

82

Page 37

Air Top Evo 3900 / Air Top Evo 5500 Connection diagram/Circuit diagram

Fig. 36 System wiring diagram for the Air Top Evo 3900 and Air Top Evo 5500, 12 V/24 V with combination timer and vehicle fan,

for legend see pages 87 and 88

83

Page 38

Connection diagram/Circuit diagram Air Top Evo 3900 / Air Top Evo 5500

Fig. 37 System wiring diagram for the Air Top Evo 3900 D and Air Top Evo 5500 D, 12 V/24 V with combination timer and electrical battery

isolation switch, for legend see pages 87 and 88

84

Page 39

Air Top Evo 3900 / Air Top Evo 5500 Connection diagram/Circuit diagram

Fig. 38 System wiring diagram for the Air Top Evo 3900 D and Air Top Evo 5500 D, 12 V/24 V with Control Panel MC04/05 and vehicle fan,

for legend see pages 87 and 88

85

Page 40

Connection diagram/Circuit diagram Air Top Evo 3900 / Air Top Evo 5500

Fig. 39 System wiring diagram for Air Top Evo 3900 and Air Top Evo 5500 “Slave Heater”, 12 V/24 V diesel, for legend, see Page 87 and 88

86

Page 41

Air Top Evo 3900 / Air Top Evo 5500 Legend for circuit diagrams

13 Legend for circuit diagrams

Cable cross-sections

< 7.5 m 7.5 - 15 m

Cable colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

blue

brown

yellow

green

grey

orange

red

black

violet

white

0.75 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

2

2

2

2

2

1.0 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

2

2

2

2

2

87

Page 42

Legend for circuit diagrams Air Top Evo 3900 / Air Top Evo 5500

Item Description Comment

A1 Heater Air Top Evo 3900/5500

A2 Control module Control unit 1580

B2 Temperature sensor Internal

B3 Overheating sensor Overheating guard

B4 Temperature sensor External

E Glow plug / Flame monitor

F1 Fuse 15 A (24 V)

F2 Fuse 4 A Blade fuse SAE J 1284

F3 Fuse 1 A Flat fuse SAE J 1284

F4 Fuse 4 A Blade fuse SAE J 1284

F5 Fuse Value in [A] to be selected depend-

H1 LED green (in item S1) Indicator

H2 LED red (in item P) Light in immediate heat button,

H3 Heating symbol in the display

H4 Light bulb/LED

H5 Light bulb/LED Switch-on indicator pumping device

K Relay

M1 Motor Combustion and hot air fan

M3 Motor Vehicle fan

P Combination timer (1531) Timer and setpoint generator

R Resistor In adapter wiring harness

R1 Resistor 620 Ω With internal temperature sensor

or 20 A (12 V)

(in item P)

(in item P and S)

with free-wheeling diode

Flat fuse SAE J 1284

not contained in wiring harness

not contained in wiring harness

ing on line cross-section

ready indicator,

Switch-on indicator

Indicator

Display and button lighting

for vehicle fan

only

Item Description Comment

S Control Panel MC04/05 On/Off switch, setpoint generator

S1 Basic heater control On/Off switch and setpoint genera-

S2 Switch Ventilation

S3 Switch CO2 setting

S4 Push button External instant heat button

S5 Switch Pumping devices/

S6 Switch, single or two-pin Isolation switch

S7 Battery isolation switch Electronically controlled isolation

S8 Switch Boost (e.g. door contact on ambu-

X1-X7 Plug connector on item A2

X8a Plug connector to item S3

X8b Plug connector Connection of additional heaters

X9a Plug connector on item S or S1

X9b Plug connector on item S or S2

X9c Plug connector W bus, optional connection of Tele-

X10-X12 Plug connector

X13 Plug connector to item Y1

X14 Plug connector to item P

X15 Plug connector Connection of additional heaters

X16 Plug connector W bus

X17-X18 Plug connector

Y1 Metering pump

Y2 Solenoid valve/pump Pumping devices/

and selector switch for additional

functions

tor

auxiliary drive

switch

lance)

via serial bus interface

start (12 V) or Thermo Call

via serial bus interface

auxiliary drive

88

Page 43

Air Top Evo 3900 / Air Top Evo 5500 Initial start-up

14 Initial start-up

After you have installed the heater, bleed the fuel supply system carefully.

NOTE:

As a result of the low fuel consumption the heater must be switched on

several times to fill the fuel line.

Until the fuel lines have been filled the heater may switch into a fault lockout for safety reasons - see chapter 15, "Fault lock-out".

Conduct a trial of the heater to check all the connections for leaks and to

ensure that they are secure. If the heater suffers a fault during operation,

the fault must be located and remedied.

14.1. Initial installation/initial operation of Air Top Evo system

Installation

1. Installation of heaters according to the installation instructions

2. The resistor R1 (Fig. 33) must be removed on all slave heaters

3. Ensure that the electrical connections are in accordance with the sys-

tem wiring diagram (Fig. 34, Fig. 36, Fig. 38)

4. Installation of the heater control and external temperature sensor

NOTE:

The master heater is only configured as the master if a heater control and

an external temperature sensor is detected.

Initial start-up

1. Start master heater with controls

=> Master heater "starts up"

2. Then produce connection between Master and Slave 1 (see system

wiring diagram)

=> Slave 1 heater switches into "Ventilation" state

3. Produce connection from Slave 1 to Slave 2

(see system wiring diagram)

=> Slave 2 heater switches into "Ventilation" state

4. Teach additional slave heaters (repeat Point 2 and 3)

5. Switch off master heater with heater control

=> Initial start up completed

NOTE:

Teaching a slave heater is only possible for a limited time (120 sec)! If this

time is exceeded, teaching is no longer possible and the system must be

reset (see Workshop Manual ).

89

Page 44

Initial start-up Air Top Evo 3900 / Air Top Evo 5500

14.2. Resetting Air Top Evo System

If for some reason (communication error, time expired, etc.) teaching has

not functioned, it is possible to reset the system to its original state.

1. Switch master heater into "Ventilation" mode

2. De-energise/pull fuse

NOTE:

All connected heaters must be disconnected from Terminal 30!

3. Connect voltage and repeat teaching process (see "Initial installation/

initial operation").

90

Page 45

Air Top Evo 3900 / Air Top Evo 5500 Fault lock-out

15 Fault lock-out

The control unit has identified errors on individual heater components and

faults during the operation.

The heater is shut down (fault lock-out) if:

– No or incorrect start

– Temperature sensor defective

– Overheating sensor interrupt or short circuit

– Overheating sensor installed incorrectly

– Glow plug interrupt or short circuit

– Fan motor overload or blocked

or short circuit or interrupt

– Error in the metering pump or overheating guard circuit (start phase on-

ly)

– Undervoltage < 10.5 or overvoltage > 16 V, longer than 20 seconds (for

12 V heater)

– Undervoltage < 20.5 or overvoltage > 31 V, longer than 20 seconds (for

24 V heater)

– Control unit defective

–Overheating

The fuel supply is stopped if the heater overheats.

The heater continues to run in the same way as if it is switched off manually.

After it stops the control unit will be set to fault lock-out.

The overheating is indicated by the indicator flashing 10 times.

Rectify the cause of the fault.

To reset the fault switch the heater on and off briefly (at least 2 seconds).

If serious faults like overheating or failure to start occur frequently, then the

heater will be locked permanently (F12). It can be returned to operation by

disconnecting the supply voltage with the heater switched on (e.g. remove

fuse and install again).

Repairs must only be carried out by specialist personnel trained by Webasto.

91

Page 46

Fault lock-out Air Top Evo 3900 / Air Top Evo 5500

15.1. Error code output

NOTE:

The error code is output if the heater is fitted with a control element after

an error has occurred by the switch-on indicator/error code indicator flashing. After 5 seconds of fast flashing, the error code will be output by a sequence of long flash pulses, the number of flashes is shown in the table

below.

If the heater is fitted with a combination timer, an error message will appear on the display of the timer after a fault occurs:

F 00 Control unit error / incorrect parameter set /

warm start recognition

F 01 No start / no flame formation

F 02 Flame failure (repeated >3)

F 03 Undervoltage or overvoltage

F 04 Premature flame recognition

F 06 Temperature sensor interrupt or

temperature sensor short-circuit

F 07 Metering pump interrupt or metering pump short circuit

F 08 Fan motor interrupt or fan motor short circuit

or fan motor overload or fan motor blocked

F 09 Glow plug interrupt or glow plug short circuit

F 10 Overheating

F 11 Overheating sensor interrupt or

overheating sensor short circuit

F 12 Heater lock-out

F 14 Overheating sensor incorrect position

F 15 Setpoint generator interrupt

Air Top Evo System:

The displayed error codes (F00 - F15) for an Air Top Evo system match an

error on the master heater. If an error occurs on the slave heater, only the

service code is output (operation indicator flashes with 1 sec. on and 1 sec.

off).

92

Page 47

Air Top Evo 3900 / Air Top Evo 5500 Technical data

16 Technical data

Except where limit values are specified, the technical data refer to the usual

heater tolerances of ± 10 % at an ambient temperature of + 20 °C and at

the rated voltage and in rated conditions.

16.1. Electrical components

Control unit, motor, metering pump, lamp in the timer and glow plug /

flame monitor are designed for either 12 V or 24 V.

The timer, overheating sensor and temperature sensor component are not

dependent on voltage.

16.2. Fuel for Air Top Evo 3900 B (petrol) Fuel for Air Top Evo 5500 B (petrol)

The fuel specified by the manufacturer in accordance with DIN EN 228

must be used

16.3. Fuel for Air Top Evo 3900 D (diesel) Fuel for Air Top Evo 5500 D (diesel)

The diesel fuel specified by the manufacturer in accordance with DIN EN

590 must be used.

We know of no negative influences due to additives.

If fuel is extracted from the vehicle’s tank, follow the additive instructions

issued by the vehicle manufacturer.

If you change to low-temperature fuel, the heater must be operated for approx. 15 minutes so that the fuel system is filled with the new fuel.

The Air Top Evo 3900 and Air Top Evo 5500 D heaters are also licensed for

use with PME (bio-diesel), which complies with DIN EN 14214 .

93

Page 48

Technical data Air Top Evo 3900 / Air Top Evo 5500

Values in brackets apply to the expanded heating capacity "Plus", which can be activated with the MC heater control.

Heater Operation Air Top Evo 3900 B Air Top Evo 5500 B Air Top Evo 3900 D Air Top Evo 5500 D

Type test permit EMC: e1*72/245*2006/96*5529*__ (Air Top Evo 3900 / 5500)

Heater: e1*2001/56*2006/119*0255*__ (Air Top Evo 3900)

Model Air heater with evaporation burner

Heat output Control range 1.7 to 3.5 (3.9) kW 1.7 to 5.0 (5.5) kW 1.5 to 3.5 (3.9) kW 1.5 to 5.0 (5.5) kW

Fuel Petrol

Fuel consumption Control range

Rated voltage 12 V 12/24 V

Operating voltage range 10.5 to 16 V 10.5 to 16 V/20.5 to 31 V

Rated power consumption Control range 15 to 40 (55) W 15 to 95 (130) W 15 to 40 (55) W 15 to 95 (130) W

Permissible ambient temperature:

Heater – Operation

– Storage

Metering pump – Operation

– Storage

Heater control – Operation

– Storage

Permissible combustion-air intake temperature

0.18 to 0.37 (0.41) kg/h

0.23 to 0.48 (0.54) l/h

E1 03 5529 (Air Top Evo 3900 / 5500)

E1 00 0255 (Air Top Evo 3900)

e1*2001/56*2006/119*0256*__ (Air Top Evo 5500)

E1 00 0256 (Air Top Evo 5500)

EN 228

0.18 to 0.52 (0.57) kg/h

0.23 to 0.69 (0.75) l/h

–40°C to +40°C

–40°C to +85°C

–40°C to +20°C

–40°C to +85°C

–40°C to +75°C

–40°C to +85°C

–40°C to +20°C

0.16 to 0.37 (0.41) kg/h

0.19 to 0.44 (0.49) l/h

Diesel/PME

EN 590

DINEN14214

0.16 to 0.52 (0.57) kg/h

0.19 to 0.63 (0.69) l/h

94

Page 49

Air Top Evo 3900 / Air Top Evo 5500 Technical data

Heater Operation Air Top Evo 3900 B Air Top Evo 5500 B Air Top Evo 3900 D Air Top Evo 5500 D

Adjustment range for interior

temperature

Volume flow of heating air against 0.5

CO2 in exhaust gas

(permitted function range)

Heater dimensions Length 423 ± 2 mm

Heater weight 5.9 kg

Control range +5 °C to +35 °C

max. 132 (139) m3/h max. 200 (220) m3/h max. 132 (139) m3/h max. 200 (220) m3/h

mbar

1.7 kW: 5.0 to 8.0 %

3.5/5.0 kW: 9.0 to 12.5 %

Width 148 ± 1 mm

Height 162 ± 1 mm

1.5 kW: 6.5 to 8.0 %

3.5/5.0 kW: 9.0 to 12.5 %

95

Page 50

Technical data Air Top Evo 3900 / Air Top Evo 5500

96

Page 51

Air Top Evo 3900 / Air Top Evo 5500 Drilling templates

17 Drilling templates

Seal

ø7.5

NOTE:

Max. base unevenness around

the seal: 1 mm

Fig. 40 Heater drilling template

ø29

ø7.5

18

ø7.5

12

55

ø28

44

97

Page 52

Drilling templates Air Top Evo 3900 / Air Top Evo 5500

98

Page 53

Air Top Evo 3900 / Air Top Evo 5500 Drilling templates

Fig. 41 Drilling Template for Control Panel MC04/05

99

Page 54

Drilling templates Air Top Evo 3900 / Air Top Evo 5500

100

Page 55

Im Fall einer mehrsprachigen Version ist Deutsch verbindlich.

In multilingual versions the German language is binding.

Bij een meertalige versie is de Duitse versie bindend.

Webasto AG

Postfach 80

D - 82132 Stockdorf

Germany

National:

Hotline: 01805 93 22 78

Hotfax: 0395 5592 353

Hotmail: technikcenter@webasto.com

www.webasto.de

International:

www.webasto.com

http://dealers.webasto.com

(€ 0,14 aus dem deutschen Festnetz)

Ident-Nr. 1312464C • 10/10 • Änderungen und Irrtümer vorbehalten • Gedruckt in Deutschland • © Webasto AG, GCS 2010

Loading...

Loading...