Webasto Air Top 2000 ST, Air Top Evo 55, Air Top Evo 40, Air Top Evo 40 D, Air Top Evo 55 D Installation Instructions

Page 1

Boat Air Heaters

Installation Instructions

Air Top 2000 ST

Air Top Evo 40

Air Top Evo 55

Trade names :

Air Top 2000 ST D (Diesel/PME)

Air Top Evo 40 D (Diesel/PME)

Air Top Evo 55 D (Diesel/PME)

Page 2

Improper installation or repair of Webasto heating and cooling

monoxide leading to serious injury or death.

To install and repair Webasto heating and cooling systems you need to have completed a Webasto training course and

have the appropriate technical documentation, special tools and special equipment.

Only genuine Webasto parts may be used. See also Webasto air and water heaters accessories catalogue.

NEVER try to install or repair Webasto heating or cooling systems if you have not completed a Webasto training course,

you do not have the necessary technical skills and you do not have the technical documentation, tools and equipment

available to ensure that you can complete the installation and repair work properly.

ALWAYS carefully follow Webasto installation and repair instructions and heed all WARNINGS.

Webasto rejects any liability for problems and damage caused by the system being installed by untrained personnel.

systems can cause fire or the leakage of deadly carbon

Page 3

Table of Contents

1 About This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

2 Regulations governing installation . . . . . . . . . . . . . . . . . . .50

3 Use / variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4 Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

5 Cold and hot air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

6 Fuel supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

7 Combustion air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

8 Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

10 Wiring diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

11 Initial operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

12 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

13 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

I

Page 4

Air Top 2000 ST / Evo 40 / Evo 55

1About This Document

To enable quick reference to the individual procedures you will find a descriptive symbol on the top outer edge of each page.

Boat Air Heaters

Mechanical system

Electrical system

Heated air

Fuel

Exhaust

Combustion air

Technical Information

Attention

Note

Excerpt from directive

49

Page 5

Technical Information Boat Air Heaters

2 Regulations governing installation

2.1. Statutory regulations governing installation

Permit numbers see Chapter 13, "Technical data".

2.2. Application of combustion heaters on boats

Observe regional authority regulations! Establish which regulations

apply in the area where the boat is to be used. Comply with the

stipulated requirements!

Obtain official approval if necessary!

The cables must be installed and firmly secured such that the wirings

are adequately protected against mechanical and thermal stress.

Requirements relating to the basic unit:

When switched off, it is permissible for combustion heaters to continue

running for max. 40 seconds. Only combustion heaters are to be used

with heat exchangers that are not damaged during their standard

operating period by the reduced afterrunning time of 40 seconds.

2.3. Additional documentation to be used

These installation instructions contain all the information

and instructions necessary to install Air Top 2000 ST / Evo

40 / Evo 55 heaters.

The operating instructions must also be observed.

Air Top 2000 ST / Evo 40 / Evo 55

50

Page 6

Boat Air Heaters Technical Information

Air Top 2000 ST / Evo 40 / Evo 55

3 Use / variants

3.1. Use

The Webasto Air Top 2000 ST, Air Top Evo 40 and Air Top Evo 55 air

heaters are suitable for:

Preheating and heating ship's cabins, cargo holds, passenger and crew

areas

Use on inland waterways and at sea

Sailing and motor boats of approx. 8 to 24 m in length

Not suitable for:

Continuous heating of living areas, houseboats, etc.

Heating and/or drying living creatures

The heaters operate independently of the boat's engine. They are

connected to the boat's fuel tank and electrical system.

3.2. Variants

Air heater for "diesel" fuel (12 or 24 V):

Air Top 2000 ST D (Diesel)

Air Top Evo 40 D (Diesel)

Air Top Evo 55 D (Diesel)

51

Page 7

Technical Information Boat Air Heaters

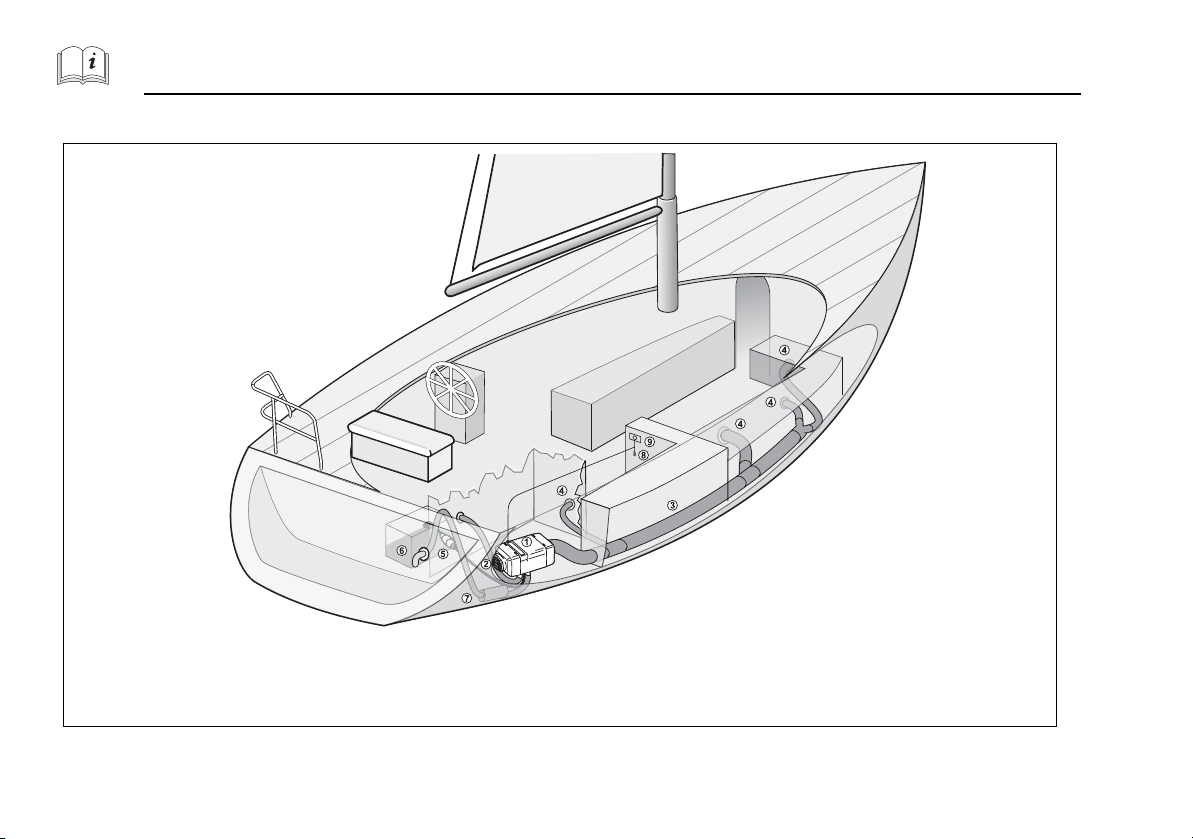

1. Air heater

2. Cold air intake;

3. Hot air hoses;

4. Air outlet;

5. Fuel pump;

6. Fuel tank;

7. Exhaust line;

8. Room temperature sensor;

9. Control element

4Heater

Air Top 2000 ST / Evo 40 / Evo 55

Fig. 1 Installation example

52

Page 8

Boat Air Heaters Technical Information

Air Top 2000 ST / Evo 40 / Evo 55

4.1. Choosing installation location

ATTENTION:

Danger of suffocation!

Do not install heater and exhaust system in accommodation

areas.

Install the heater in a dry location, protected from the ingress of sea

water, excessive vibration, heat, engine exhaust gases and soiling by

fuel or oil (requirement from 2001/56/EC).

Arrange the installation to suit the requirements and type of boat! Take

the following into account: all peripheral components, such as permissible length of the exhaust system, position of the through-hull fitting,

combustion air intake, routing of electrical wiring and cable lengths,

distance from the fuel tank, routing of hot air hoses, fresh air intake,

etc.

Take the following into account: the maximum inclination of the boat

must not result in the ingress of sea water through the exhaust gas

outlet.

The inclination must not cause the heater to come in cont ac t w it h bilge

water.

No obstruction of moving parts (e.g. rudder assembly).

Every reasonable precaution should be taken when positioning the

heater to minimise the risk of injury and damage to personal property

(requirement from 2001/56/EC)

ATTENTION:

Danger of fire!

Do not install in the vicinity of flammable or temperature-

sensitive objects such as sails, fenders, bulkheads, paper,

gas lines, fuel containers, etc.

When installing in locker or rudder box:

– Only with good ventilation

– Prevent contact with hot parts

– Install a contact barrier around the heating system if

necessary

53

Page 9

Technical Information Boat Air Heaters

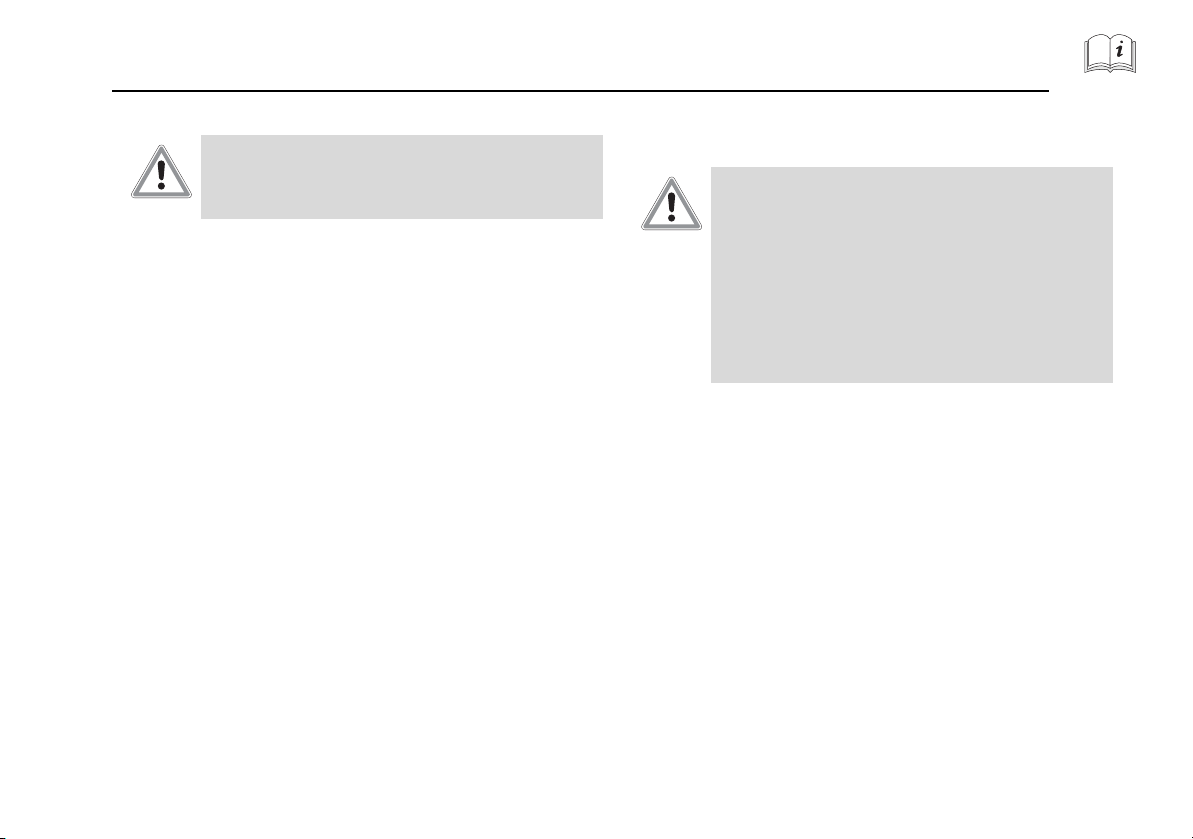

Recommended installation locations (see Fig. 2):

A) In locker or rudder box if it is well ventilated.

Install a contact barrier around the heating system so that sails,

fenders, bulkheads, etc. do not come in contact with hot parts!

B) In the engine compartment of inboard diesel engines. Condition:

cold air intake from outside, combustion air intake from outside or

from engine compartment if this is well ventilated to the outside!

Air Top 2000 ST / Evo 40 / Evo 55

54

Fig. 2 Installing heater in locker (1), rudder box (2) or engine

compartment (3)

Page 10

Boat Air Heaters Technical Information

1

6 5 4

2 3

B AC

2

Air Top 2000 ST / Evo 40 / Evo 55

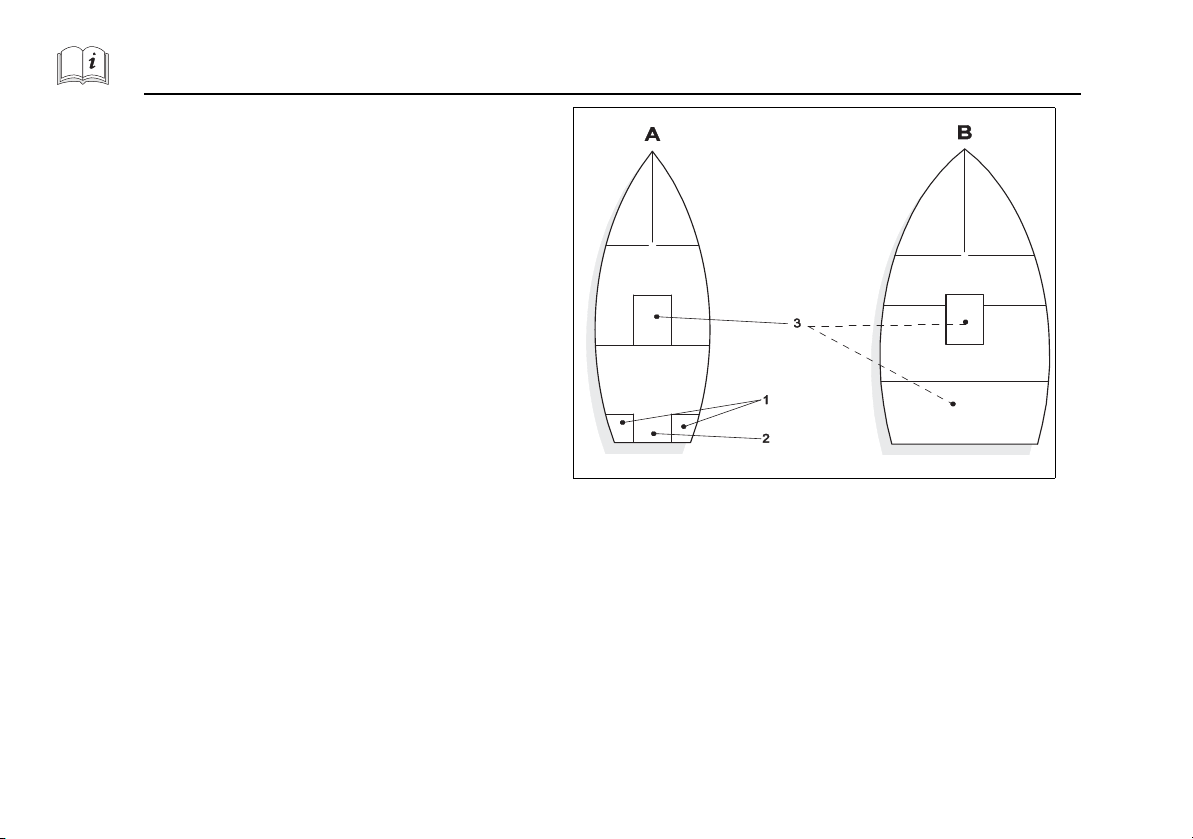

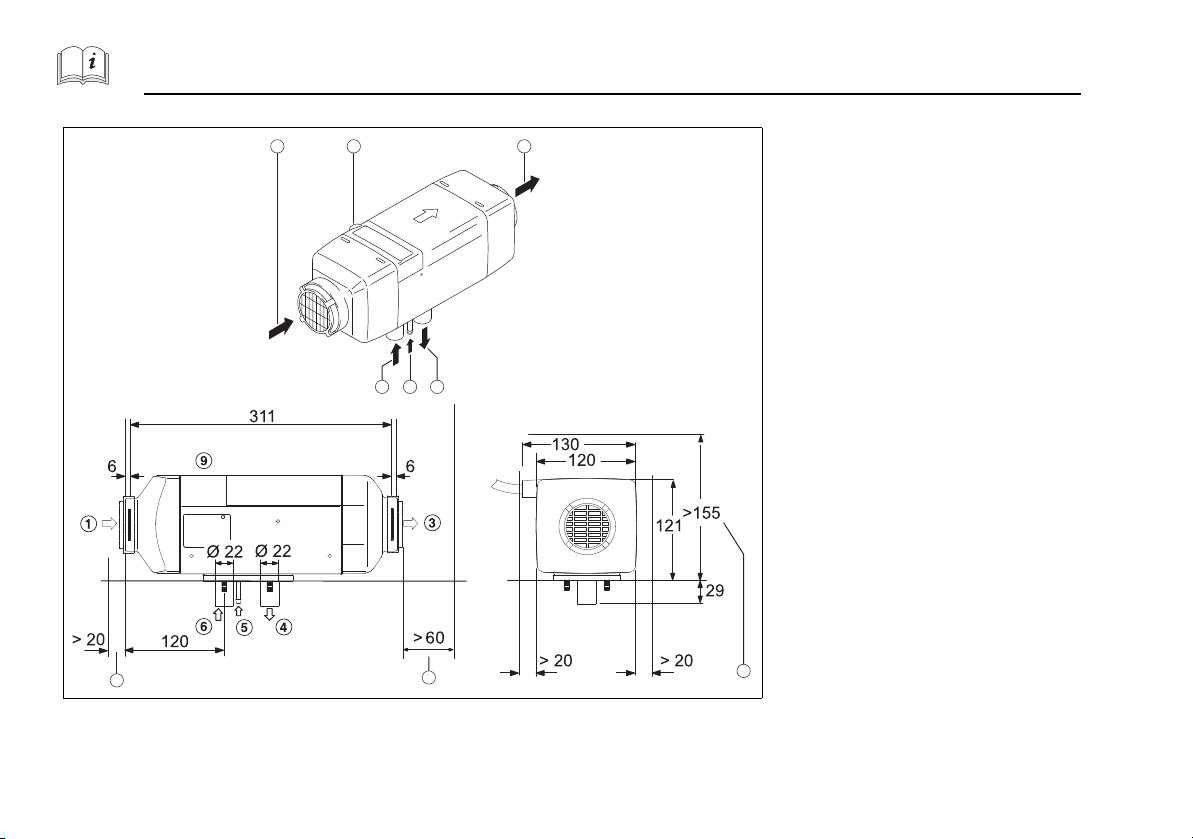

4.2. Heater data

4.2.1. Dimensions Air Top Evo 40 / Air Top Evo 55

1)

Cold air inlet

2) Cable outlet (optionally on right or left)

3) Hot air outlet

4) Exhaust gas outlet

5) Fuel inlet

6) Combustion air inlet

A) Space requirements for hot air outlet

B) Space requirements for cold air inlet

C) Space requirements for removing heater

Fig. 3 Dimensions and space requirements [mm] Air Top Evo 40 / Air Top Evo 55

55

Page 11

Technical Information Boat Air Heaters

1

6 5 4

2 3

B

A

C

4.2.2. Dimensions Air Top 2000 ST

Air Top 2000 ST / Evo 40 / Evo 55

1) Cold air inlet

2) Cable outlet (optionally on right or left)

3) Hot air outlet

4) Exhaust gas outlet

5) Fuel inlet

6) Combustion air inlet

A) Space requirements for hot air outlet

B) Space requirements for cold air inlet

C) Space requirements for removing heater

Fig. 4 Dimensions and space requirements [mm] Air Top 2000 ST

56

Page 12

Boat Air Heaters Technical Information

Air Top 2000 ST / Evo 40 / Evo 55

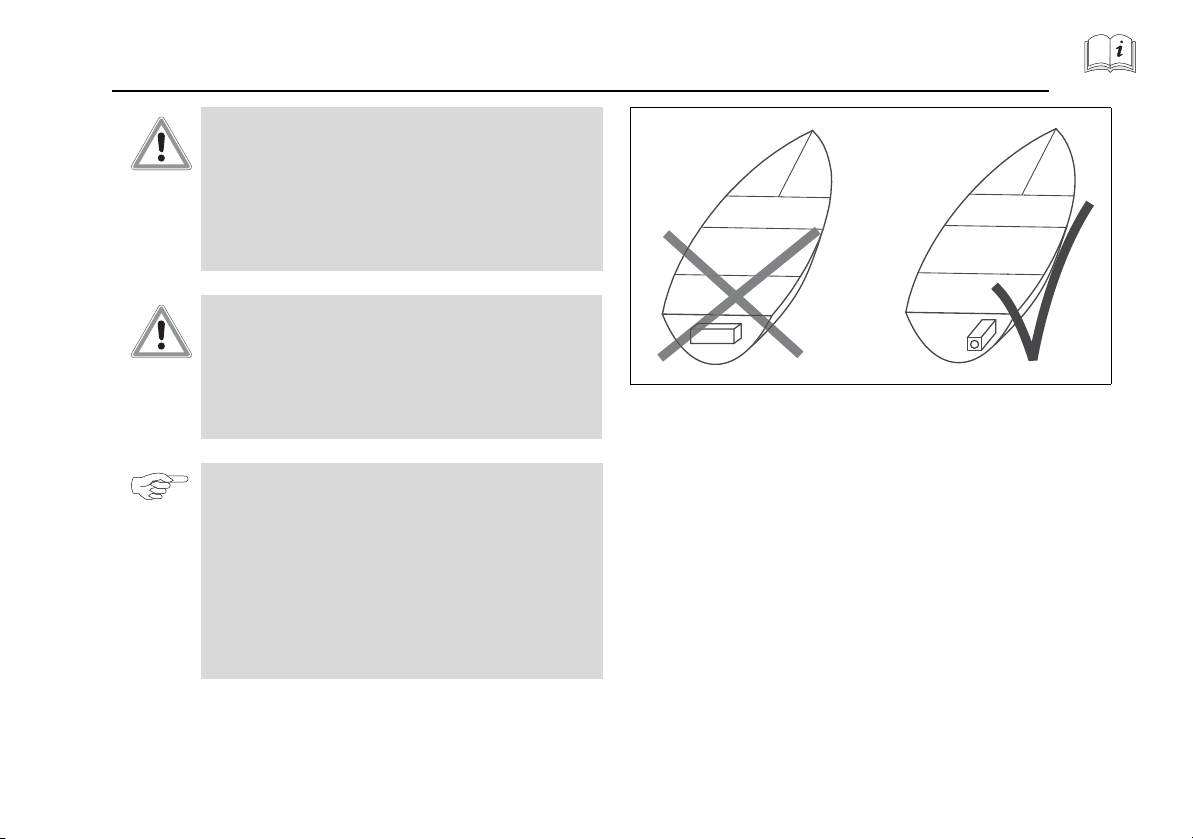

ATTENTION:

Danger of drowning!

There is a danger of drowning when drilling into the boat's

outer skin! Drilling below the water line can cause the boat

to sink!

If the boat is in the water: check the drilling location! Have

leak sealing equipment available beforehand and familiarise

yourself with possible escape routes!

ATTENTION:

A blockage in the heating air rotor can cause the

heater to overheat!

Damage to heater

Make sure that the casing of the heater is clear, i.e. does

not make contact with any other parts, in installed position (see Fig. 7).

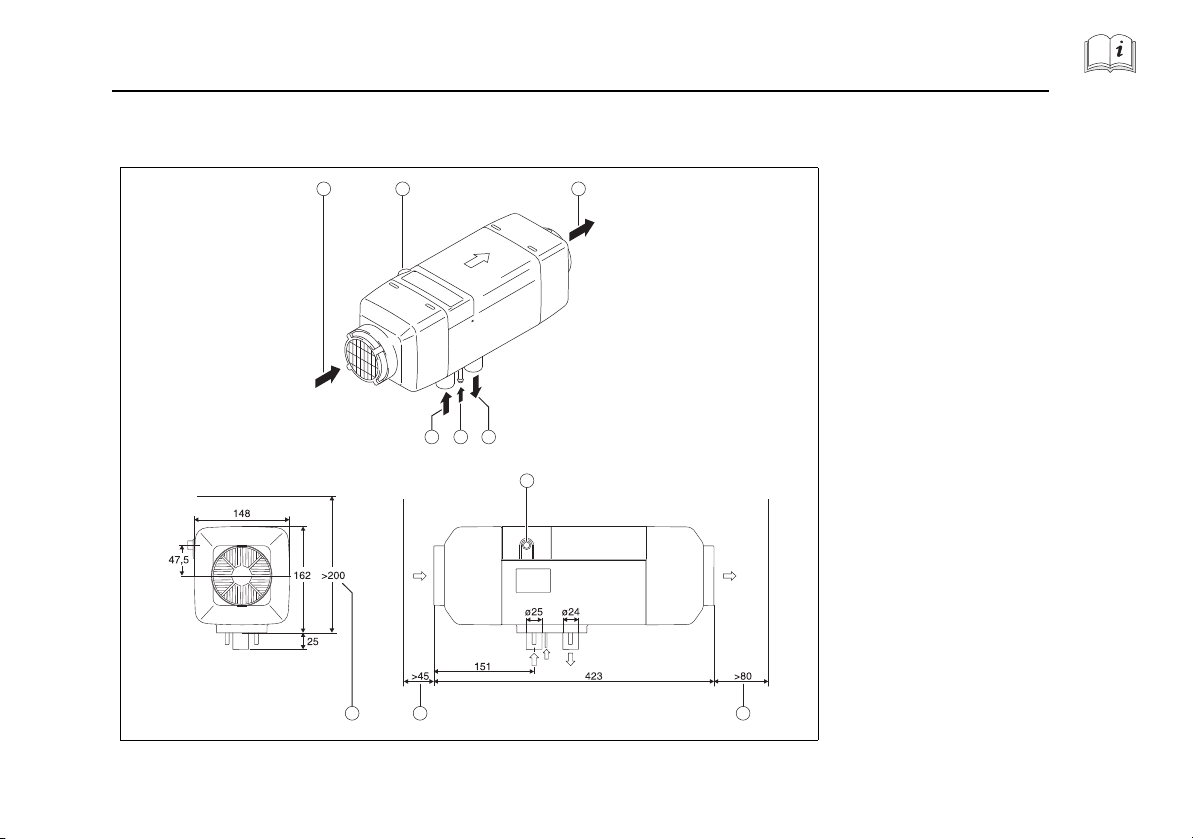

NOTE:

Installation positions: observe possible inclination of

boat!

Recommended installation position: exhaust gas outlet

routed downward, heater parallel to longitudinal axis of

boat.

Do not install transversely in sailing boats!

Exception: if heater is primarily operated when boat is

moored or in motor boats then installation transverse to

longitudinal axis is permissible.

Fig. 5 Install heater in longitudinal direction in sailing boats!

4.3. Heater mounting

• Securely mount the heater (vibration, swell)! Use the supplied bracket

and rubber seal under the base.

• This rubber seal must be replaced each time the heater is reinstalled.

• The M6 nuts must be tightened to 6 Nm (-0 Nm, +1 Nm) to mount

the base.

57

Page 13

Technical Information Boat Air Heaters

Fig. 6 Mounting Air Top with bracket

NOTE:

After installation check that the casing is not in contact with

any part of the boat's body. Failure to do this may result in

the heating air fan blocking.

Fig. 7 Ensure ease of movement of all moving parts!

Air Top 2000 ST / Evo 40 / Evo 55

.

ATTENTION:

There is a danger of drowning when drilling into the

boat's outer skin!

Drilling below the water line can cause the boat to sink!

If the boat is in the water: check the drilling location!

Have leak sealing equipment available beforehand and

familiarise yourself with possible escape routes!

• Determine space requirements and installation position

– Air Top 2000 ST:

see Fig. 3 and Fig. 7

– Air Top Evo 40 / Air Top Evo 55:

see Fig. 4 and Fig. 8

• Do not exceed inclination angle (see Fig. 8).

• Recommendation: flexible mounting (vibration decoupling, noise reduction)!

• Secure the heater onto the bracket with bolts.

• Recommendation when mounting on outer skin on FRP boats: laminate wooden panel onto the fastening location from the inside to

prevent drilling through the outer skin.

58

Fig. 8 Permissible installation positions of diesel-operated air

heaters

ATTENTION:

The base seal must be replaced when removing and

reinstalling a heater.

Page 14

Boat Air Heaters Technical Information

Air Top 2000 ST / Evo 40 / Evo 55

• Except for the year of installation, remove all the year numerals on

the type label.

• Secure heater. Tighten the M6 nuts to 6 Nm (–0 Nm, +1 Nm).

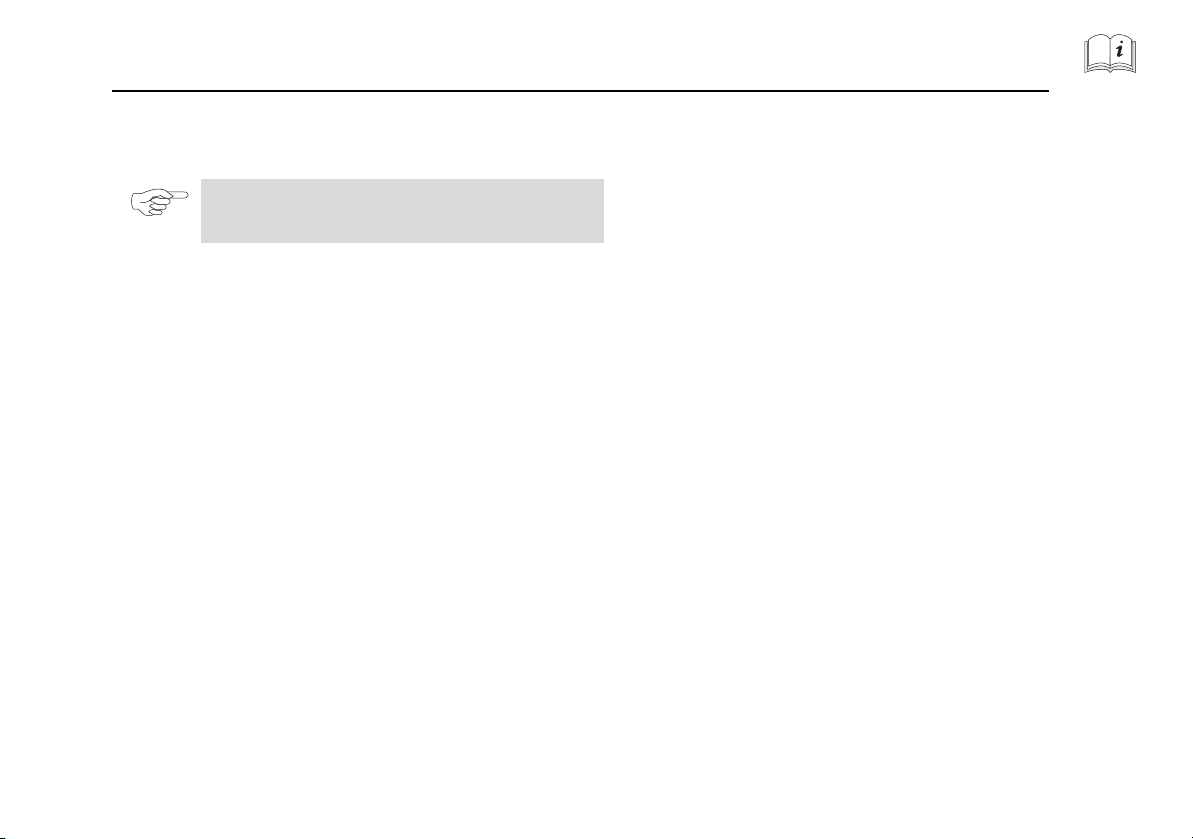

NOTE:

After installing the heater, the type label should be clearly

visible in a well-protected position.

• If the type label is not visible after installing the heater: use the type

label duplicate.

59

Page 15

Cold and hot air Boat Air Heaters

Air intake from well-ventilated locker Air intake with intake hose directly

from outside

5 Cold and hot air

Air Top 2000 ST / Evo 40 / Evo 55

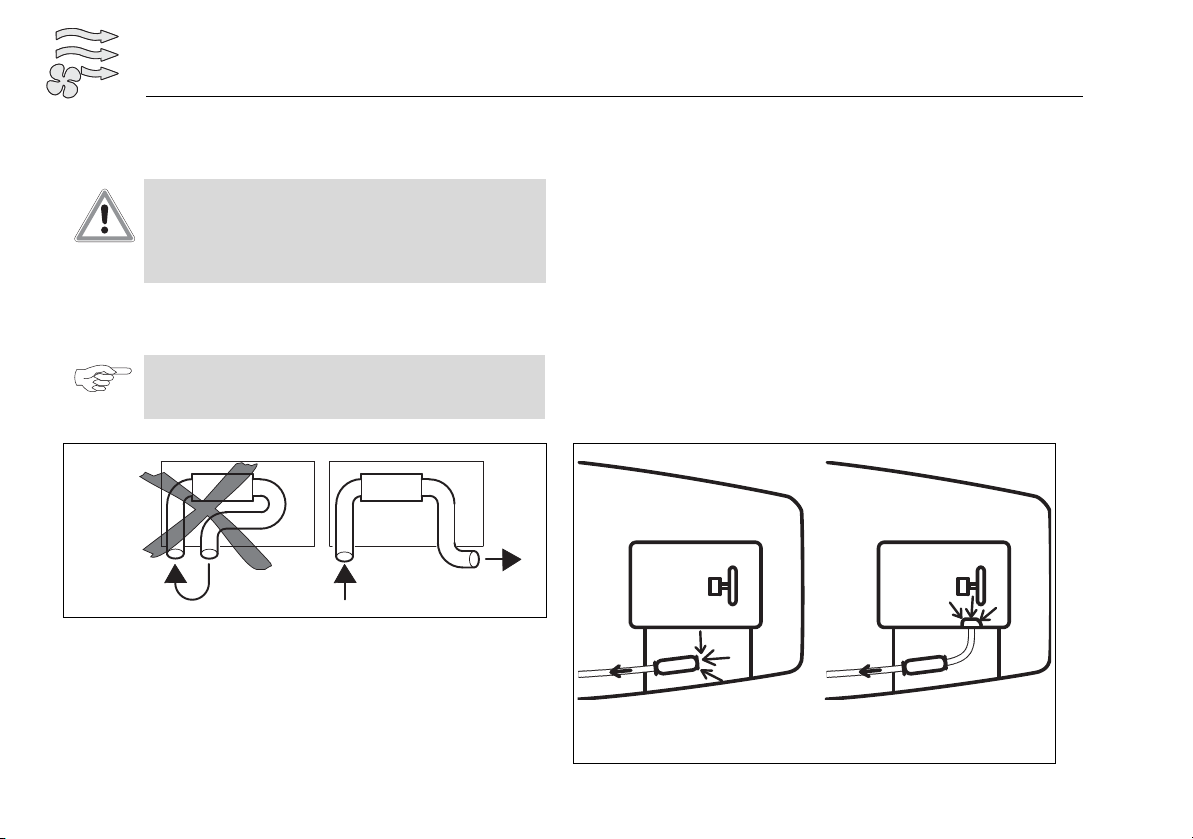

5.1. General

ATTENTION:

Danger of suffocation!

The cold air intake must be from a clean area with no exhaust gases.

Cold air intake never from the engine compartment!

It must not be possible for stowed articles to block the intake opening

(requirement from 2001/56/EC).

NOTE:

The direct intake of hot air must be avoided (see Fig. 9).

It is not permitted to short-circuit the air flow.

Fig. 9 Cold air inlet and hot air outlet

5.2. Fresh air mode

Cold air is drawn in from the outside, heated and blown into the boat's

interior. This renews the cabin air and reduces humidity. Ensure there are

enough ventilation openings in the cabins! A room temperature sensor

must be installed for temperature control, preferably in the saloon. In

summer, ventilation is also possible (when comfort control element is

used).

Draw in cold air directly from lockers or rudder boxes if they are dry,

clean and free of odours and exhaust gases.

For proper ventilation, ensure the intake diameter = 1.5 x hose diameter of the heater.

Otherwise, use an intake hose for intake from the outside.

Prevent water from entering through the intake opening.

60

Fig. 10 Air intake

Page 16

Boat Air Heaters Cold and hot air

Air Top 2000 ST / Evo 40 / Evo 55

NOTE:

For fresh air mode, a room temperature sensor must be

installed in the cabins to be heated.

5.3. Recirculated air mode

In recirculated air mode, the air to be heated is taken from the interior

area. The advantage of this is that heating takes place faster due to more

effective heat utilisation. However, the humidity is not reduced or the

room air not renewed in this mode.

No room temperature sensor needs to be installed. The heater uses the

sensor integrated in the control unit.

5.4. Position of hot air openings

WARNING:

Risk of injury!

Do not blow hot air directly onto living creatures or

temperature-sensitive objects.

All areas in the boat can be evenly heated with an appropriate air

distribution system. For this purpose, branch off several side branches

from the main line to reach all cabins. The air, and therefore the heat

flow, can be influenced by suitable selection of the branches and hose

diameters.

See the accessories catalogue for branches, connecting elements, Yjunctions, air outlets, etc. made from temperature-resistant material.

A free flow of air into the cabins provides the most effective cabin

heating and air circulation!

Only use one or two air outlets per cabin!

5.5. Properties of cold and hot air ducts

Recommended inside diameter of main hot air duct:

• 80 mm for Air Top 2000 ST

• 80 mm for Air Top Evo 40

• 90 mm for Air Top Evo 55

NOTE:

Only materials with a thermal resistance of 130 °C (shortterm 150 °C) are to be used for the hot air duct.

5.6. Layout of cold and hot air ducts

ATTENTION:

Use without cold air intake hose

Risk of injury by rotating heating air rotor

If used without the cold air intake hose, install the sup-

plied mesh guard over the intake

Maximum differential pressure between intake and pressure side of

heater:

• Air Top 2000 ST: 2.0 hPa

• Air Top Evo 40: 2.0 hPa

• Air Top Evo 55: 3.0 hPa

ATTENTION:

The heating output will be reduced if this pressure differential is exceeded.

61

Page 17

Cold and hot air Boat Air Heaters

5.7. Installing cold and hot air ducts

Do not route the ducts through the bilge.

Hot air ducts in damp areas: use temperature-resistant, flexible, metal

spiral-reinforced plastic hoses.

Secure cold and hot air ducts at all connections.

In stowage areas:

Use a perforated metal cover, for example, to protect the ducts from

damage by cargo.

Recommended:

Routing through bulkheads:

Use wall lead-through as shown in Fig. 11.

See the Webasto accessories catalogue.

Secure ducts:

– With hose clips at all connecting elements.

– Prevent from chafing, see Fig. 12.

Recommendation

for routing hoses through area not to be heated: insulate the hose sections to prevent heat loss.

Air Top 2000 ST / Evo 40 / Evo 55

Fig. 11 Recommended duct lead-through in bulkheads

Fig. 12 Recommended routing around corners

62

Page 18

Boat Air Heaters Cold and hot air

A: in 9 m sailing boat

B: in 11 m sailing boat

C: in 13 m sailing boat

1) Cold air intake

2) Y-junction or T-piece

3) Air outlet

Air Top 2000 ST / Evo 40 / Evo 55

5.8. Silencer in air duct

Recommendation: For Air Top 2000 ST / Evo 40 / Evo 55 units with short

air duct, use silencer on intake and/or outlet side (reduction in noise

level). See the accessories catalogue.

Fig. 13 Silencer for reducing noise level

5.9. Air routing examples

2000ST

EVO 40

EVO 55

Fig. 14 Heating air routing examples

The main duct must not be reduced from 90 to 80 mm for Air Top Evo 55!

If 90 mm is not possible throughout, it is better to use Y-junction 90/80/

80 and thus create two 80 mm main ducts.

63

Page 19

Cold and hot air Boat Air Heaters

37' sailing boat

1 Branch 90/60/90

2 Air outlet Ø 60 mm, can

be closed off

3 Y-junction 90/90/90

4 Air outlet Ø 90 mm, open

5 Y-junction 60/60/60

6 Air outlet Ø 90 mm, can

be closed off

7 T-piece 90/60/90

43' sailing boat

5.10. Installation examples:

Air Top 2000 ST / Evo 40 / Evo 55

Fig. 15 Installation examples:

64

Page 20

Boat Air Heaters Fuel

1) Fuel pump

2) Fuel extractor

3) Tank extracting device

4) Fuel tank

5) Fuel line

6) Heater

Air Top 2000 ST / Evo 40 / Evo 55

6Fuel supply

6.1. General

ATTENTION:

Danger of fire!

If the heater takes the fuel from a separate additional tank,

the fuel type and the filler neck must be clearly marked.

(Requirement from 2001/56/EC).

The fuel filler neck must not be located in the interior of the boat and

must be fitted with a well-sealing cap to prevent fuel from escaping

(requirement from 2001/56/EC).

Protect the boat hull/components in the vicinity of the heater from

heat/contamination by fuel/oil!

NOTE:

– Fuel take-off must take place with virtually no pressure.

– If taking fuel from the return line make sure that the line

is not blocked by non-return valves.

Fig. 16 Example of fuel supply Air Top heaters

6.2. Fuel extraction

The following alternatives are available for extracting fuel for the heater:

6.2.1. Tank extracting device

• Fuel take-off directly from the boat's fuel tank.

• Plastic fuel tanks: install the tank extracting device in the tank fitting.

Do not drill into a plastic fuel tank.

• For suitable tank extracting device for metal tanks see the accessories

catalogue or scope of delivery.

65

Page 21

Fuel Boat Air Heaters

Air Top 2000 ST / Evo 40 / Evo 55

6.3. Fuel extractor

Fig. 17 Installing a tank extracting device in metal tank

Install the tank extracting device as shown in Fig. 17:

1) Shorten the immersion tube: the end should be approx. 25 mm

above the bottom of the tank or high enough that fuel for the boat

engine always remains in the tank. Cut the tube diagonally.

Deburr the cut edges.

2) Drill a hole in the tank or tank fitting from above.

Use suitable drilling attachment.

Grease the drill bit and drilling surface beforehand (to catch small

drilling chips).

3) Fit the tank fitting into the hole and screw tight (the seal is slightly

compressed).

6.2.2. Fuel take-off coupling

If there is an unused fuel take-off coupling already fitted in the boat's fuel

tank then use it.

Do not take fuel from the drain plug at the bottom of the tank as dirt or

water can be drawn in from the drain.

66

Fig. 18 Fuel extractor

The fuel extractor is a special T-piece with an integrated bubble separator.

It can be installed in the supply line to the engine if no pre-supply pump

is installed in the fuel tank or in the return line from the engine if it almost

reaches the bottom of the fuel tank. Take into account the diameters of

the installed pipes when selecting the fuel extractor.

See the Webasto accessories catalogue for a suitable fuel extractor.

6.4. Pipe lengths and delivery head

When installing the fuel line make sure that it is kept as short as possible.

See Fig. 19.

The pipe must be installed such as to protect it from being damaged.

The fuel line must be installed in cool areas to avoid bubbles being

formed by the effect of heat. High fuel temperatures can cause the heater

to malfunction.

Page 22

Boat Air Heaters Fuel

H

1

D

1

l

1

l

2

l

2

H

2

l

1

D

2

S

2

D

2

D

1

S

1

Air Top 2000 ST / Evo 40 / Evo 55

The fuel lines must be secured using state-of-the-art fastening elements.

Do not damage the fuel line.

Intake side:

D1: Inside diameter of fuel line = 2 mm.

: Fuel level (tank above fuel pump) [m]

H

1

: Fuel level (tank below fuel pump) [m]

S

1

l

: Length of fuel line [m]

1

Pressure side:

D2: Inside diameter of fuel line = 2 mm.

H

: Height difference between heater and fuel pump

2

(heater above fuel pump) [m]

S

: Height difference between heater and fuel pump

2

(heater below fuel pump) [m]

l

: Length of fuel line [m]

2

Fig. 19 Fuel supply

Fuel level (tank above fuel

[m]

pump), H

1

Maximum permissible fuel pressure at take-off

[bar]

point, p

1

H1 = 0 -0.1 < p1 <+0.5

0 < H1 <1 -0.1 < p1 <+0.4

1 < H1 <2 -0.1 < p1 <+0.3

Fuel level (tank below fuel

[m]

pump), H

2

<1.3 -0.1 < p1 <+0.5

0 <H

2

Maximum permissible fuel pressure at take-off

[bar]

point, p

1

67

Page 23

Fuel Boat Air Heaters

1) Fuel pipe connection

Parameter Value

Length of intake pipe l

Length of pressure pipe l

Length of intake pipe l

Height difference between heater and fuel pump

(heater above fuel pump) H

Height difference between heater and fuel pump

(heater below fuel pump) S

6.4.1. Pipe material

Only use steel or plastic fuel lines made from light and temperatureresistant PA11 or PA12 (e.g. Mecanyl-RWTL) in accordance with DIN

73378 as the fuel pipes.

6.4.2. Connecting 2 fuel lines to a hose

Fig. 20 shows the correct connection of fuel lines to a hose.

Make sure there are no leaks!

Fig. 20 Pipe/hose connection

[m] max. 5

1

[m] max. 10

2

+ length of pressure pipe l2 [m] max. 12

1

[m]

2

[m]

2

max. 3

max. 1

Air Top 2000 ST / Evo 40 / Evo 55

Fuel line material (metal/plastic): observe regional/national

regulations!

ATTENTION:

Danger of fire!

• The fuel lines in the engine compartment must be made

of metal and the connecting hoses between the individual components of fire-resistant material (as per DIN EN

ISO 7840)!

• If the fuel pump is equipped with a plastic fuel damper

(e.g. Air Top 2000 ST Diesel) it must be protected with a

protective sleeve (see accessories catalogue) when installed in the engine compartment.

• Only use fire-resistant fuel filters in accordance with ISO

7840 for installation in the engine compartment.

For installation kits for metal fuel lines see the accessories catalogue.

68

Fig. 21 Stainless steel hose clips

Page 24

Boat Air Heaters Fuel

Air Top 2000 ST / Evo 40 / Evo 55

NOTE:

– Only use stainless steel hose clips to secure plastic lines.

– Metal pipes: ensure cleanliness and neatness while

carrying out the work! Remove all soiling and burrs from

the connection points prior to assembly!

– Do not overtighten union nuts (otherwise leaks may

occur).

– Route the fuel lines as straight as possible and at a slight

incline so that air bubbles escape towards the heater.

– Secure the line at regular intervals to prevent sagging,

avoid kinks.

– Keep away from heat sources. Use heat shield if

necessary!

– Inside ø of fuel line = 2 mm, larger diameters will cause

problems due to gas bubbles.

6.5. Fuel pump

Air Top 2000 ST heaters must only be operated with the fuel pump DP 30.

Air Top Evo 40 / Air Top Evo 55 heaters must only be operated with the

fuel pump DP 42.

The fuel pump is a combined delivery, metering and shut-off system and

is subject to certain installation criteria (see Fig. 22 (DP 30) or Fig. 23 (DP

42) for installation positions).

The fuel pump is controlled with a separate wiring harness and feeds the

fuel into the combustion chamber of the heater depending on the

required heating capacity. Due to the individual delivery strokes, the

separate fuel pumps make a ticking noise during operation.

6.5.1. Installation location

The fuel pump must not be installed within the radiated head range of

hot components. Fit a heat shield if necessary. The fuel pump should be

preferably installed close to the fuel tank.

Install the pump in a dry/cool area. Do not install in the bilge.

Check the direction of flow of the pump.

For permissible ambient temperature see Chapter 13, "Technical data".

6.5.2. Installation and attachment

The installation position is restricted (maximum inclination angle and

axial installation position of fuel pump) as illustrated in Fig. 22 (DP 30) or

Fig. 23 (DP 42).

The arrow shows the direction of flow.

69

Page 25

Fuel Boat Air Heaters

Air Top 2000 ST / Evo 40 / Evo 55

Use the flexible mount to install the fuel pump

(reduces the transmission of structure-borne noise/ticking)!

(see Fig. 24).

Fig. 24 Flexible mount of fuel pump

Fig. 22 DP30 Fuel pump installation position

Fig. 23 DP42 Fuel pump installation position

70

NOTE:

Recommended installation: mount on solid and sturdy part

of boat.

Page 26

Boat Air Heaters Fuel

0° - 90°

Air Top 2000 ST / Evo 40 / Evo 55

6.6. Fuel filter

Fig. 26 Fuel filter, installation position and direction of flow

Fig. 25 Fuel line mounting

• Recommended fuel line mounting: Distance from fuel pump ≥ 20 cm

or with a bend to avoid structure-borne noise being transmitted

through the pipe.

• Fuel line secured to wall and not too close to the fuel pump.

Install a suitable fuel filter (e.g. Webasto fuel filter) if dirty fuel is to be

expected. Wherever possible install vertically, deviating by no more than

90° (see Fig. 26).

NOTE:

Pay attention to installation position and direction of flow.

71

Page 27

Fuel Boat Air Heaters

6.7. Auxiliary tank

ATTENTION:

If an auxiliary tank is required for the fuel supply to the

heater:

It must only be installed by a specialist company for marine

applications (with the necessary knowledge of the required

standards, regulations and directives)!

6.8. Special requirements for heaters in boats with petrol engine

ATTENTION:

Petrol-operated heaters are not permitted in recreational

boats covered by ISO 9094. Local regulations and special

safety requirements must be complied with.

Specific requirements apply to the installation of diesel-operated

heaters in petrol engine boats:

• The heater must be supplied with fuel from a separate diesel tank

which must comply with the valid regulations for diesel tanks in boats.

• Do not install heaters wherever flammable petrol vapours can form,

i.e. especially in engine compartments, fuel tank compartments and

rooms directly annexed to them.

• The combustion air intake must come from the outside and not from

the engine compartment!

• Do not route exhaust pipes through engine or tank compartments.

Air Top 2000 ST / Evo 40 / Evo 55

72

Page 28

Boat Air Heaters Combustion air

Air Top 2000 ST / Evo 40 / Evo 55

7 Combustion air supply

7.1. Combustion air intake line

Combustion air intake line: must be arranged that it cannot be blocked

by objects

Keep combustion air intake line as short as possible

Mounting of combustion air intake line: with a hose clip at the intake

connection piece of the heater and with pipe clamps or cable ties on

fixed built-in components.

7.2. Combustion air intake from a well-ventilated area (locker, stowage compartment or engine compartment)

No through-hull fitting required

The intake area must be at ambient pressure and sufficiently ventilated

to the outside!

Intake from engine compartment: the ventilation fan in the engine

compartment must not produce an overpressure or negative pressure

in the engine compartment.

Intake point: no intake of exhaust gases from heater or engine!

Fit a cap over the end of the hose to prevent water ingress (if no

through-hull fitting is used).

7.3. Combustion air intake directly from outside

Use a separate through-hull fitting if intake from a ventilated area is

not possible.

Arrange the end of the combustion air intake line as a gooseneck, as

illustrated. Prevent water from entering through the intake opening.

Do not position the through-hull fitting in the direction of travel (other-

wise backpressure and water ingress may occur in the intake pipe).

Fig. 27 Combustion air intake line not in direction of travel

Drill a drain hole at the lowest point as illustrated in Fig. 27.

Route hose free of kinks.

NOTE:

A combustion air intake line is required.

A minimum length is not specified.

73

Page 29

Combustion air Boat Air Heaters

Air Top 2000 ST / Evo 40 / Evo 55

NOTE:

The combustion air intake line with silencer must not exceed

a max. length of 2.0 m.

7.4. Properties of combustion air intake line

CAUTION:

The exhaust pipe can be confused with the combustion air intake line!

Damage to fuel pump cable

Fit the exhaust pipe only to the exhaust outlet socket cou-

pling

Do not use a metal combustion air intake line

Combustion air intake line Value

Inside diameter 25 mm

Smallest bending radius 50 mm

Max. sum of all bends 270°

7.5. Combustion air intake silencer

NOTE:

A combustion air intake silencer must be installed if the

length of the combustion air intake line is less than 0.5 m.

74

Page 30

Boat Air Heaters Exhaust

1) Heater

2) Combustion air intake line

3) Flexible stainless steel exhaust pipe

4) Condensed-water drain

5) Exhaust silencer

6) Insulation

7) Gooseneck

8) Through-hull fitting

Air Top 2000 ST / Evo 40 / Evo 55

8 Exhaust system

8.1. General 8.2. Exhaust gas outlet

ATTENTION:

Generation of heat by incorrect positioning of exhaust pipe outlet!

Injuries or damage to property caused by fire

Pay attention to installation position.

Outlet arrangement:

Position the exhaust gas outlet where no splash water can enter the

boat.

Recommendation:

Sailing boats: in stern transom.

Motor boats: in side wall.

ATTENTION:

Danger of suffocation!

Do not position the exhaust gas outlet below or next to

ventilation equipment, window openings or the heating

air inlet

At least 60 cm above the water line so that no water can enter when

the boat is heeling

Not in direction of travel of the boat (high wind pressure)

Do not connect to engine or generator exhaust system (higher pres-

sures; damage to heater!)

Fig. 28 Exhaust system

Not where it can be easily covered, e.g. by fender.

75

Page 31

Exhaust Boat Air Heaters

1) Gasket

2) Counterflange

3) Bolt/washer/nut

4) Side wall

5) Webasto mark

Through-hull fitting:

Choice of design and installation position to minimise rain water in-

gress!

Only use genuine Webasto through-hull fittings! Fit insulation plate ex-

actly for thermal isolation from the side wall (minimisation of water ingress)!

If additional sealing is required: use only heat-resistant sealing compound!

Through-hull fitting: cannot be closed; not with self-opening flaps!

Mount through-hull fitting with pipe socket angled upward.

Air Top 2000 ST / Evo 40 / Evo 55

Fig. 29 Through-hull fitting

NOTE:

Avoid drawing in exhaust gas with the combustion air.

76

Page 32

Boat Air Heaters Exhaust

Air Top 2000 ST / Evo 40 / Evo 55

8.3. Notes on exhaust pipe

The exhaust pipe must be secured to the heater with a clamp suitable for

the exhaust pipe.

Use suitable insulation material to avoid the dew point dropping below

the minimum value.

Keep exhaust pipe as short as possible.

No contact with temperature-sensitive objects such as electrical wir-

ing, water lines, plastic parts, sails or boat hull!

8.4. Length of exhaust pipe and combustion air intake line

For the Air Top 2000 ST / Evo 40 / Evo 55, the following maximum total

lengths of the combustion air intake line and exhaust pipe must be complied with:

– With exhaust silencer: max. 2.5 m

– Without exhaust silencer: max. 5.0 m.

Properties of exhaust pipe

ATTENTION:

The exhaust pipe can be confused with the combustion air intake line!

Damage to fuel pump cable

Fit the exhaust pipe only to the exhaust outlet socket cou-

pling

Exhaust line Value

Internal diameter 24 mm

Smallest bending radius 50 mm

Max. sum of all bends 270°

Minimum length 0.5 m

Exhaust silencer

Use the genuine Webasto exhaust silencer provided! It considerably reduces noise. There are no restrictions in terms of installation position and

direction of flow.

Do not drill a condensation drain hole in the silencer (this will cause exhaust to escape)!

To prevent impermissible vibration, the exhaust silencer itself must be secured with a clip to fixed parts of the boat at 50 cm intervals.

The heater can also be operated without a silencer.

For suitable models see the Webasto accessories catalogue.

Fig. 30 Approved hose clamps for mounting exhaust pipes

77

Page 33

Exhaust Boat Air Heaters

Air Top 2000 ST / Evo 40 / Evo 55

Condensed-water drain

Fit a condensed-water drain (non-rusting) if the exhaust pipe is longer

than 2 m!

A) With a T-piece at the lowest point in the exhaust pipe or

B) If the heater itself is at the lowest point: use an exhaust connection

piece with an integrated condensed-water drain.

For suitable components see the Webasto accessories catalogue.

Use a container or drain hose to collect the condensation water.

Different versions of the condensed-water drain fitting are available.

Fig. 31 Condensed-water drain fitting

8.5. Thermal insulation

Observe the following points when installing the exhaust pipe:

Avoid contact between the hot exhaust pipe and temperature-sensi-

tive objects such as electrical wiring, water lines, plastic parts, sails or

boat hull!

If contact with persons/objects is possible during heating: Insulate the

exhaust pipe or fit contact barrier! For suitable exhaust insulation materials see the Webasto accessories catalogue.

Fig. 32 Exhaust pipe insulation sheathing

Surface temperature ≤ 80 °C!

Minimum distance from walls ≥ 20 mm.

8.6. Gooseneck

Last section of exhaust pipe: gooseneck sloping downward to the outlet

(due to possible ingress of water)!

Height of gooseneck: ≥ 20 cm.

78

Page 34

Boat Air Heaters Electrical system

Air Top 2000 ST / Evo 40 / Evo 55

9 Electrical Connections

The free ends of all lines that are not required must be insulated!

9.1. Electrical system, general

• Observe all information and safety precautions!

• Install a clearly visible operation indicator to show whether the heat-

ing is switched on or off (requirement from 2001/56/EC). This is already integrated in the Webasto control elements.

• Install all wiring harnesses and electrical components in dry and pro-

tected areas!

• The free ends of all lines that are not required must be insulated.

• If there is highly sensitive electronic equipment on board, special

electrical interference suppression measures may be necessary. Contact an authorised Webasto partner.

• Do not touch exposed PCBs of the unit (electrostatic discharge).

• For connector designations see the legend and wiring diagrams,

Page 87.

9.2. Wiring harnesses

Fig. 33 and Fig. 34 show the wiring harnesses for Air Top 2000 ST and

Air Top Evo 40 / Air Top Evo 55

Fig. 33 Wiring harness Air Top 2000 ST

79

Page 35

Electrical system Boat Air Heaters

40/55

Fig. 34 Wiring harness Air Top Evo 40 / Air Top Evo 55

NOTE:

Use a blunt blade on both sides to remove the control unit

cover (Fig. 35 arrows).

Air Top 2000 ST / Evo 40 / Evo 55

Fig. 35 Removing control unit cover

9.3. Connecting heater

To connect the heater, remove the control unit cover on the heater and

plug in the wiring harness connector at the control unit. Connect voltage

supply.

To prevent the hot air escaping (heater overheating), reattach the control

unit cover prior to initial operation.

The cable lead-through can be either on the left or right.

Correspondingly position the cable grommet on the wiring harness to

ensure that the cable lead-through is sealed off in the control unit cover.

ATTENTION:

To enable afterrunning, the heater must not be shut down

(disconnected from the power supply).

An electrical battery disconnector can be installed in the

electrical circuit (see wiring diagram Fig. 52).

80

Page 36

Boat Air Heaters Electrical system

“a”

X7

Air Top Evo 40 /

Air Top Evo 55

X6

Air Top 2000 ST

X5 sw/bl

ge

X5

Air Top 2000 ST / Evo 40 / Evo 55

Air Top 2000 ST:

The connector for the Air Top 2000 ST must be plugged in as far as point

"a".

See Fig. 36.

Fig. 36 Connector to heater control unit

Air Top Evo 40 / Air Top Evo 55:

Remove and dispose of the protective cap on the control unit. Plug

connector X5 of the wiring harness for the room temperature sensor into

this socket.

See Fig. 37.

Fig. 37 Plugging in room temperature sensor at control unit

Correspondingly position the cable grommet on the wiring harness to ensure that the cable lead-through is sealed off in the control unit cover.

Route the wiring harness out of the heater and fit the cover (possible in

both directions).

The heater must not be operated without the control unit cover (this will

cause the heater to overheat).

9.4. Power supply

• Power supply to heater: from the boat's service battery (not the starter battery for the engine due to risk of discharge).

Connect the red cable to the "+" terminal of the battery.

This connection should always be made before the main switch to

enable heater afterrunning.

Connect the brown cable to earth directly at the battery.

• The wiring harness for the Air Top Evo 40 / Air Top Evo 55 includes

cable K (Fig. 34, colour red/black) for optional control of a battery

disconnector or an additional operation indicator. If not required for

this purpose, insulate the end of the cable.

• Keep power supply cables as short as possible. Shorten the cables if

necessary.

• Cross section of connection cables: 4.0 mm².

If cable lengths > 7.5 m: 6.0 mm²

• When extending cables, make sure the total cross section is adequate and the insulation matches.

• The heater must be protected with a fuse (F1).

F = 20 A (12 V)

F = 15 A (24 V)

• If the MC04 control element is used with the Air Top Evo 40 / Air Top

Evo 55 a 1A fuse (F3) must be inserted in the fuse holder.

• The fuse must be installed splash water-protected in the interior.

• Distance of the main fuse from the "+" battery terminal: 1m

81

Page 37

Electrical system Boat Air Heaters

Fig. 38 Fuse holder on wiring harness

9.5. Temperature control

Install a room temperature sensor in the boat's interior (mandatory for

fresh air operation)!

The heater continually compares the set temperature (value set at the

control element) and the actual temperature (measured at the room temperature sensor) and automatically adjusts the heating capacity.

ATTENTION:

The Air Top heater is a separate system that operates

independently of the engine with integrated temperature

control.

An additional automatic control system for the purpose of

controlling the temperature is not permitted.

Air Top 2000 ST / Evo 40 / Evo 55

9.5.1. Installing room temperature sensor

Mount the sensor in a favourable/suitable position in the room to be

heated.

The distance to the control element is 2.5 m due to the cable length.

Use a room temperature sensor with a 5 m long cable for greater distances, see the Webasto accessories catalogue.

The position has a decisive effect on the control characteristics!

NOTE:

– In largest cabin to be heated

– In position at average room temperature

– At half the room height if possible

– On a vertical interior wall if possible, not directly on an

outside wall

Not in the air flow of hot air outlets

Not within the range of the companionway

Not in the vicinity of heat sources

Not behind cushions or curtains

Not in direct sunlight

82

Page 38

Boat Air Heaters Electrical system

ge

sw/bl

X12

X11

sw

rt

Air Top 2000 ST / Evo 40 / Evo 55

9.5.2. Connecting room temperature sensor

Route the cable of the room temperature sensor up to the installation location of the control element. Here connect the sensor cable to the main

wiring harness, see Fig. 40.

Plug cable of room temperature sensor with the white connector housing

X11 into the socket on the main wiring harness.

9.6. Control element

This control switches the heater ON/OFF and defines the setpoint for the

interior temperature.

Position: mount in the interior such that it is easily accessible, visible and

protected from water. The position has no effect on the control characteristics!

Fig. 39 Room temperature sensor for registering interior

temperature

Fig. 40 Wiring of room temperature sensor

Various control elements with different functions are available, see the

accessories catalogue.

NOTE:

Only pull on the connector housing to unplug the

connector.

The connector housing will lock (self-locking action) by pulling on the wiring harness.

83

Page 39

Electrical system Boat Air Heaters

ge, sw/bl

gn/ws,

X9a

X9b

Air Top 2000 ST

Air Top Evo 40 / Air Top Evo 55

9.6.1. Rotary switch

Connect the control element (ON/OFF and temperature preselection)

with rotary potentiometer directly to the wiring harness.

See Fig. 42.

Air Top 2000 ST:

Connector X9: preinstalled connector for control element.

Use the red/white (rt/ws) cable for the ventilation switch (option). When

using a ventilation switch install an earthing cable leading to the switch.

See Fig. 41

Air Top Evo 40 / Air Top Evo 55:

Plug connector X9a (red, blue, white, black wires) with blue marking into

the connector at the control element.

Connector X9b with the red marking is not required.

See Fig. 41

Air Top 2000 ST / Evo 40 / Evo 55

Fig. 42 Control element

Fig. 43 Installing the control element

Fig. 41 Control element wiring

84

Fig. 44 Installing the control element (wrong)

Page 40

Boat Air Heaters Electrical system

MC04 control element

Observe colour markings

Optional connection for:

– Telestart / ThermoCall

– Webasto Thermo Test

Diagnosis

Heater

wiring harness

Air Top 2000 ST / Evo 40 / Evo 55

9.6.2. Air Top Evo control element MC04 Marine

The MC04 heater control element features additional operating modes

such as ECO, PLUS and VENTILATION.

The MC04 can only be used in combination with Air Top Evo heaters.

– Make a 98 mm wide x 63 mm high cutout for the MC04.

– Connect the control element to the two connectors on the heater wir-

ing harness, paying attention to the labels on the wiring harness as

well as the colour coding on the connectors.

See Fig. 41 (connector X9a and X9b), as well as Fig. 46.

– Provisionally fit the control element in the cutout.

– Lightly press the fastening screws into the holes and screw in. Care-

fully clip on the trim frame

Fig. 45 Connection diagram Air Top Evo 40 / Air Top Evo 55 with

MC04 control element

Fig. 46 Installing MC04 control element

85

Page 41

Electrical system Boat Air Heaters

X8

Air Top 2000 ST / Evo 40 / Evo 55

9.6.3. Combi timer

Use the adapter wiring harness to install the Combi timer and connect it

as shown in the wiring diagram (See “Wiring diagrams” from Page 87).

Use the fuses F2 and, if necessary, also F4 for separate display lighting.

9.6.4. Telestart / ThermoCall Air Top Evo 40 / Air Top Evo 55:

Connector X9c (brown, red, green/white) can be connected to the optional Telestart remote control or the ThermoCall remote control.

Fig. 47 Connector for Telestart / ThermoCall / Webasto Thermo Test

9.7. PC diagnosis

Air Top 2000 ST:

The wires (gn/ws, br/ws) are used to read out any faults and the operating

hours and enable CO

agnosis (only for Webasto service workshops).

Fit the X8 connector housing (supplied).

Air Top Evo 40 / Air Top Evo 55:

Connector X9c (see Fig. 47) can also be used for Webasto Thermo Test

PC Diagnosis.

Use connector X8 (brown cable colour) for CO

basto service workshops).

Fig. 48 Connector for CO2 calibration

9.8. Fuel pump

The wiring harness for the fuel pump is normally routed out of the

combustion air intake connection piece. Pull out the stowed cable (do not

push back in). Connect it to the fuel pump. The polarity is irrelevant. Use

an extension cable if it is not long enough (accessory).

calibration with the Webasto Thermo Test PC Di-

2

calibration (only for We-

2

86

Page 42

Boat Air Heaters Electrical system

Air Top 2000 ST / Evo 40 / Evo 55

10 Wiring diagrams

Fig. 49 Wiring diagram Air Top 2000 ST with rotary switch and ventilation switch (optional)

for legend see Page 92

87

Page 43

Electrical system Boat Air Heaters

Air Top 2000 ST / Evo 40 / Evo 55

Fig. 50 Wiring diagram Air Top 2000 ST with Combi timer,

for legend see Page 92

88

Page 44

Boat Air Heaters Electrical system

K

Air Top 2000 ST / Evo 40 / Evo 55

Fig. 51 Wiring diagram Air Top Evo 40 / Air Top Evo 55 with rotary switch and ventilation switch (optional)

for legend see Page 92

89

Page 45

Electrical system Boat Air Heaters

Air Top 2000 ST / Evo 40 / Evo 55

IGN

Fig. 52 Wiring diagram Air Top Evo 40 / Air Top Evo 55, with Combi timer,

for legend see Page 92

90

Page 46

Boat Air Heaters Electrical system

K

Air Top 2000 ST / Evo 40 / Evo 55

Fig. 53 Wiring diagram Air Top Evo 40 and Air Top Evo 55, with control element Air Top Evo Multi Control (MC04),

for legend see Page 92

91

Page 47

Electrical system Boat Air Heaters

Air Top 2000 ST / Evo 40 / Evo 55

10.1. Legend to wiring diagrams

Item

Description Remarks

A1 Heater Air Top 2000 ST/

A2 Control unit Control unit 1574

B1 Flame monitor only for Air Top 2000 ST

B2 Temperature sensor Inside

B3 Overheat sensor Overheating protection

B4 Room temperature sensor Outside

E Glow plug / flame monitor for Air Top Evo 40 / Air Top Evo 55 glow

F1 Fuse 24 V 15A / 12V 20A Blade type fuse SAE J 1284

F2 Fuse 4A not included in wiring harness

F3 Fuse 1A Blade type fuse SAE J 1284

F4 Fuse 4A not included in wiring harness

H1 LED green (in Item S1) Operating indicator

H2 LED red (in Item P) Lighting: Quick Heating button,

H3 Heating symbol on display

(in Item P)

H4 Lamps (in Item P and S) Display and button lighting

K Wire for voltage supply Can be optionally used for additional. op-

M1 Motor Combustion air and heating air blower

P Combination digital timer 1531 Combination digital timer and setpoint

R Resistor In adapter wiring harness

S Control element Air Top Evo

Multi Control (MC04)

Air Top Evo 40 / Air Top Evo 55

(for Air Top 2000 ST)

control unit 1580

(for Air Top Evo 40 / Air Top Evo 55)

petrol units

plug only

Ready indicator,

ON indicator

Operating indicator

eration indicator (<6 W) or battery disconnector

sensor

ON switch, selector switch for additional

functions and temperature selector

Item

Description Remarks

S1 Rotary switch control element ON switch and temperature selector

S2 Switch Ventilation

S3 Switch CO

S4 Pushbutton External Quick Heating button

S6 Switch, 1 or 2-pin Disconnector

S7 Battery disconnector electronically controlled disconnector

V1/V2Blocking diode min. 500 mA

X1-

Plug connection -

X17

Y1 Fuel pump Air Top 2000 ST: DP30

setting

2

max. 500 mA

Air Top Evo 40 / Air Top Evo 55: DP 42

10.1.1. Cable cross-sections

Cable < 7.5 m 7.5 - 15 m

0.75 mm2

2

1.0 mm

2

1.5 mm

2

2.5 mm

2

4.0 mm

NOTE:

Wires/components shown with dashed lines are optional

and not included in the scope of delivery / in the wiring

harness.

1.0 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

2

2

2

2

2

92

Page 48

Boat Air Heaters Electrical system

2

4

5

6

Air Top 2000 ST / Evo 40 / Evo 55

10.1.2. Cable colours 10.1.3. Reference numbers

Abbreviation Colour

bl

br

ge

gn

gr

or

rt

sw

vi

ws

blue

brown

yellow

green

grey

orange

red

black

violet

white

Positive at connection 10:

1

Continuous heating mode with quick heating function for as long

as ignition is on.

All heater versions: W-bus diagnosis connection.

Heater versions with control element Air Top Evo Multi Control

(MC04) and Combi timer:

ThermoCall connection

Telestart connection (only 12 V).

Heater version Master:

Slave heater connection (yellow/blue wire).

Pre-assembled wire included in Slave scope of delivery.

setting (see workshop manual).

CO

2

3

If connected, continuous heating mode is possible with ignition

switched off.

Must not be connected to the battery plus terminal in this case!

Tie back.

Room temperature sensor.

Wiring harness adapter is optionally available.

7

93

Page 49

Mechanical system Boat Air Heaters

Air Top 2000 ST / Evo 40 / Evo 55

11 Initial operation

NOTE:

Observe the safety information given in the operating

instructions!

Carefully read the operating instructions before operating

the heater.

Carefully bleed the fuel supply system after installing the heater.

11.1. Installation / initial operation of Air Top Evo System

Installation

1. Install the heater in accordance with the installation instructions

2. Connect in accordance with the wiring diagram (See

“Schakelschema's” on Page 136.)

3. Install the heater control element and room temperature sensor

12 Faults

If a malfunction occurs, the operating indicator will show a flash code or

the Combi timer a fault code F .

Follow the instructions in the workshop manual to rectify a fault.

94

Page 50

Boat Air Heaters Technical Information

Air Top 2000 ST / Evo 40 / Evo 55

13 Technical data

If no limit values are specified, the technical data will refer to the usual

heater tolerances of 10% at an ambient temperature of +20 °C and at

the rated voltage.

13.1. Electrical components

The control unit, lamp in the timer and glow plug are designed for either

12 V or 24 V operation.

The timer (not including lamp), blow-out temperature sensor, room

temperature sensor and exhaust gas temperature sensor are designed for

both operating voltages.

13.2. Fuel for Air Top 2000 ST / Evo 40 / Evo 55 (diesel)

Diesel fuel in accordance with DIN EN 590 is to be used.

There are no known adverse effects of using additives.

When changing to low-temperature fuel, the heater must be operated

for approx. 15 minutes to fill the fuel system with the new fuel.

The units Air Top 2000 ST D, Air Top Evo 40 D and Air Top Evo 55 D are

also approved for use with biodiesel (FAME) conforming to

DIN EN 14214.

95

Page 51

Page 52

Bei mehrsprachiger Ausführung ist Deutsch verbindlich.

Die Telefonnummer des jeweiligen Landes entnehmen Sie bitte dem Webasto Servicestellenfaltblatt oder der Webseite Ihrer jeweiligen Webasto

Landesvertretung.

In multilingual versions the German language is binding.

The telephone number of each country can be found in the Webasto service center leaflet or the website of the respective Webasto representative of your

country.

Bij een meertalige versie is de Duitse versie bindend.

Het telefoonnummer van het betreffende land kunt u vinden op het Webasto Servicepuntenoverzicht of de website van de Webastovestiging in uw land.

Webasto Thermo & Comfort SE

Postfach 1410

82199 Gilching

Germany

Visiting address:

Friedrichshafener Str. 9

82205 Gilching

Germany

Internet: www.webasto.com

Technical Extranet: http://dealers.webasto.com

Nur innerhalb von Deutschland

Tel.: 0395 5592 229

E-mail: kundencenter@webasto.com

Ident-Nr. 9031359A •09/14 • Errors and omissions excepted • Printed in Germany • © Webasto Thermo & Comfort SE, 2014

Loading...

Loading...