Webasto Air Top Evo 3900, Air Top Evo 3900 B, Air Top Evo 5500 B, Air Top Evo 3900 D, Air Top Evo 5500 D Installation Manual

Page 1

Air Heater

Air Top Evo 3900 / 5500 B (Gasoline)

Air Top Evo 3900

Installation Manual

WARNING!

– Improper installation or repair of Webasto heating and cooling systems can cause fire

or the leakage of deadly carbon monoxide leading to serious injury or death.

– Installation and repair of Webasto heating and cooling systems requires special

Webasto training, technical information, special tools and special equipment.

– NEVER attempt to install or repair a Webasto heating or cooling system unless you

have successfully completed the factory training course and have the technical skills,

technical information, tools and equipment required to properly complete the

necessary procedures.

– ALWAYS carefully follow Webasto installation and repair instructions and heed all

WARNINGS.

– Webasto rejects any liability for problems and damage caused by the system being

installed by untrained personnel.

– Improper installation or installation by untrained personnel voids all warranties on

this product.

/ 5500 D (Diesel)

Page 2

Page 3

Air Top Evo 3900/5500 Table of Contents

Contents Page

1. Safety and General Information 5

1.1 Warning Symbols in this Installation Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Regulation for Installation in the Vehicle 6

2.1 Legal Provisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Position of the Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Fuel Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4 Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Combustion Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Hot Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7 Hot Air Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.8 Automatic Control of the Heating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Purpose of the Air Heater 8

4. Installation 9

4.1 Recommended Installation and Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Air Top EVO 3900/5500 Installation Situation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.4 To Install the Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Optional Mounting Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.6 Factory Plate / Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.7 Installation Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5. Hot Air System 13

5.1 External Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6. Fuel Supply 15

6.1 Vehicles with a Carburetor Equipped Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Vehicles with Fuel Injection Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.3 Vehicles with Diesel Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.4 Fuel Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.5 Fuel Metering Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.6 Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7. Combustion Air Supply 19

8. Exhaust Pipe 20

9. Combustion Air Inlet and Exhaust Lines 21

10.Electrical Connections 22

10.1 Heater Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10.2 Supply Voltage Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

10.3 Control Element (Rheostat) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10.4 Control Element (SmarTemp) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

10.5 Control Element (MC04/05) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11.Circuit Diagrams 27

11.1 Legend for Circuit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12.Starting the Heater for the First Time 32

12.1 Control Element Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

13.Fault Lock-out 34

13.1 Error Code Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

www.webasto.us 3 Webasto Thermo & Comfort N.A., Inc.

Page 4

Table of Contents Air Top Evo 3900/5500

14.Technical Data 35

14.1 Electrical Components: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

14.2 Fuel for Air Top EVO 3900/5500 B (Gasoline): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

14.3 Fuel for Air Top EVO 3900/5500 D (Diesel/Heating Oil): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

15.Version 36

16.Drilling Template 37

www.webasto.us 4 Webasto Thermo & Comfort N.A., Inc.

Page 5

Air Top Evo 3900/5500 Safety and General Information

DANGER

WARNING

CAUTION

OR

1. Safety and General Information

1.1 Warning Symbols in this Installation Manual

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This manual uses a series

of symbols and signal words which are intended to convey the level of importance of the safety messages. The

progression of

symbols is described below. Remember that safety messages by themselves do not eliminate danger and are not a

substitute for proper accident prevention measures.

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury or property damage.

It may also be used to alert against unsafe practices.

These symbols are used to alert the installer to important or useful information

about proper installation of the equipment.

1.2 General Information

Webasto Product North America, Inc. is pleased to provide this installation manual with the AT 3900/5500 air heater.

When installed according to the guidelines stated in this manual, you can expect your customer to enjoy many years of

trouble-free heater operation.

This manual represents our latest effort to produce the best technical documentation possible.

In our efforts towards continuous, ongoing product improvement, we encourage our customers to write to us with

their comments or criticisms concerning this manual and the AT 3900/5500 air heating system.

Please write to us at:

Webasto Product North America, Inc.

Technical Documentation Group

15083 North Road

Fenton, MI 48430

You are also invited to fill out our online questionnaire concerning our technical documentation and web site at:

www.techwebasto.com

If you have any immediate questions concerning this manual, the installation procedures within or the product itself,

please call us at:

(800) 555-4518or send a fax to:(810) 593-6001

www.webasto.us 5 Webasto Thermo & Comfort N.A., Inc.

Page 6

Regulation for Installation in the Vehicle Air Top Evo 3900/5500

2. Regulation for Installation in the Vehicle

Read this installation manual in its entirety before installing this equipment.

2.1 Legal Provisions

2.1.1 The installation and service of Webasto heaters requires special expertise and training. Installations

and servicing of Webasto products by untrained, unauthorized personnel and end-users voids all

warranties and releases Webasto Product North America, Inc. and Webasto authorized distributors, dealers

and their personnel from responsibility for damage to Webasto products, any resulting collateral property

damage and personal injury.

2.1.2 Any use, operation, installation, modification or application of the product not described in Webasto manuals,

or subjecting the product to extreme or unusual conditions beyond the limits of specified performance characteristics is

misuse of the product. Failure to comply with all installation instructions is a misuse of Webasto products. The same

applies for repairs without using genuine Webasto service parts. This will void the heaters “official Marks of

Conformity.”

IMPORTANT!

All relevant state and provincial licensing regulations if any, governing the installation and use of auxiliary

heating devices must be observed!

2.2 Position of the Heater

2.2.1 Parts of the vehicle body and other components in the immediate vicinity of the heater must be protected

against excessive heat and the danger of contamination by fuel or oil.

2.2.2 The internal combustion heater must not pose a fire hazard even when overheated. This requirement is

deemed to have been met if care is taken during installation to ensure an adequate distance from all parts, as well as

adequate ventilation and if fire-resistant materials or heat shields are used.

2.2.3 The model/ Serial plate or a duplicate there of (duplicate model/ Serial plate) must be fitted in such a way that

it is still clearly legible when the heater has been installed in the vehicle.

2.2.4 When positioning the heater, all reasonable precautions must be taken to minimize the risk of personal injury

or damage to items in the vehicle.

2.2.5 A clearly visible indicator within the user's field of vision must show when the heater is switched on or off.

2.3 Fuel Supply

2.3.1 Fuel lines are to be installed in such a way that they remain unaffected by torsional stresses created by vehicle

and engine movement.

2.3.2 Fuel lines must be securely fastened to the vehicle every 12 inches (30 cm) or less along the total length from

heater to fuel tank.

2.3.3 Fuel-carrying components must be protected against excessive heat and are to be installed so that any

drippings or evaporating fuel can neither accumulate nor be ignited by hot components or electrical equipment.

2.3.4 In buses, fuel lines are not to be located in the passenger area or in the driver’s compartment. Fuel supply must

not be by means of gravity or pressurization of the fuel tank.

2.3.5 The fuel tank must be equipped with a vent cap or ventilated in another way (vent line).

2.3.6 When a separate fuel supply is used the fuel filler neck must not be located in the passenger compartment and

must have a tightly fitting cap to prevent any fuel leaks.

Webasto Thermo & Comfort N.A., Inc. 6 www.techwebasto.com

Page 7

Air Top Evo 3900/5500 Regulation for Installation in the Vehicle

2.3.7 The type of fuel and the fuel filler neck must be clearly identified for liquid fuel heaters which have a fuel

supply separate from the vehicle fuel supply.

2.3.8 A label must be affixed to the fuel filler neck warning that the heater must be switched off before refuelling.

An identical warning must also be included in the manufacturer's operating instructions.

2.4 Exhaust System

2.4.1 The exhaust outlet must be positioned in such a way that exhaust fumes cannot get into the interior of the

vehicle through ventilation devices, hot-air inlets or open windows. Also note that exhaust should always point away

from the direction of travel.

2.4.2 Do not route exhaust components within 100 mm (4 inches) of flammable materials such as fuel system

components, polyurethane or similar foam insulation, styene sheet installation, wood and paper products, carpet,

glycol reservoirs, coolant lines, brake lines, electrical wiring, etc.

2.5 Combustion Air Inlet

2.5.1 The air for the combustion chamber of the heater must not be extracted from the passenger cabin of the

vehicle.

2.5.2 The air inlet must be positioned in such a way that it cannot be obstructed by other objects.

2.6 Hot Air Inlet

2.6.1 The supply of heating air must consist of either fresh air or recirculated air and must be taken from a clean area

which cannot be contaminated by exhaust fumes from the engine, the internal combustion heater or any other source

in the vehicle.

2.6.2 The inlet line must be protected by a grating or other suitable means.

2.7 Hot Air Outlet

2.7.1 Hot air lines within the vehicle must be positioned or protected in such a way as to exclude all risk of injury or

damage caused by direct contact.

2.7.2 The air outlet must be positioned or protected so that it cannot be obstructed by other objects.

2.8 Automatic Control of the Heating System

When the engine stops, the heating system must cut out automatically and the fuel supply must be stopped within 5

seconds.

The heating system may remain in operation if a manual unit has already been activated.

www.webasto.us 7 Webasto Thermo & Comfort N.A., Inc.

Page 8

Purpose of the Air Heater Air Top Evo 3900/5500

3. Purpose of the Air Heater

The Webasto Air Top EVO 3900/5500 air heaters are designed

– to heat cabins, boats (Diesel Only), trucks, minibuses, vans and motor homes

– to defrost vehicle windows

– to heat cargo

The air heaters operate independently of the engine and are connected to the fuel tank and the electrical system of the

vehicle.

They may be used for vehicles with either water or air-cooled engines.

They are not designed for heating hazardous substances.

Webasto Thermo & Comfort N.A., Inc. 8 www.techwebasto.com

Page 9

Air Top Evo 3900/5500 Installation

9

1

25 24

ØØ

4

151

45

6

423 80

47.5

200

162

8

148

25

3

5

2

7

1. Hot air inlet

2. Hot air outlet

3. Combustion air inlet

4. Exhaust gas outlet

5. Fuel intake

6. Space required for hot air inlet

7. Space required for hot air outlet

8. Space required for removing the heater (service)

9. Cable outlet/Control unit cover (either right or

left)

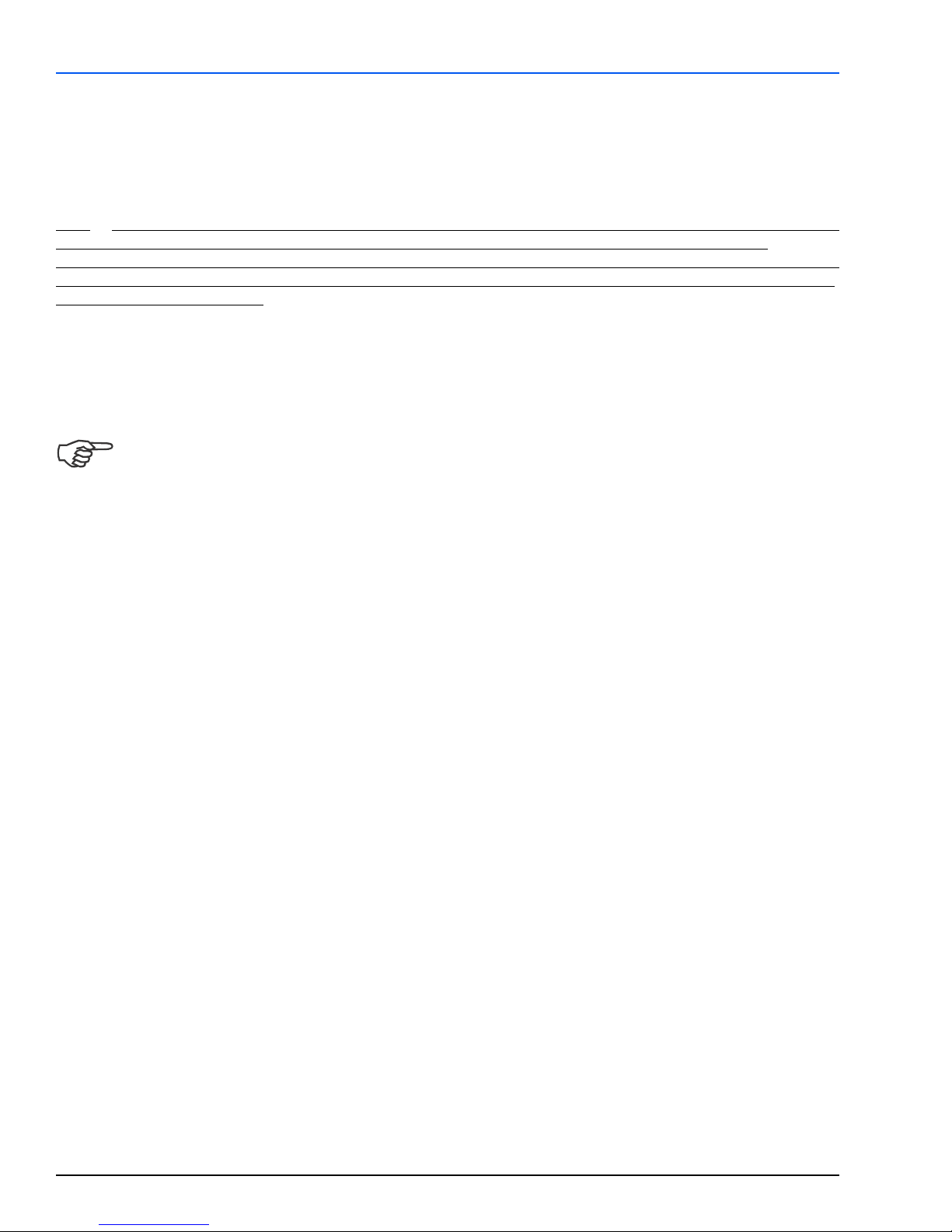

4. Installation

IMPORTANT!

The regulations governing installation on pages 4 and 5 must be adhered to.

The heater must not be operated without the control unit cover (#9 below) (this will cause the heater to

overheat).

4.1 Recommended Installation and Service Tools

• Digital Multi-Meter - Should be a good quality VAO meter.

• 1/2 Heavy-Duty, low speed drill with good quality, sharp drill bits and a selection of hole saws.

• Mounting/ Drilling Templates.

4.2 Air Top EVO 3900/5500 Installation Situation

NOTE:

Check the installation situation of the relevant vehicle type.

4.3 Installation Location

The heater may be fitted both in the interior or on the exterior of the vehicle.

If it is installed on the exterior ensure that the heater is fitted in a position where it is protected from splashing water

and spray.

The heater must be installed in such a way that no water can ingress into it if the vehicle travels through a water hazard

for which that vehicle is licensed.

The openings for the combustion air inlet port, the exhaust outlet port and the fuel line must be sealed if the heater is

installed in the interior. The seal designed and supplied for this purpose must be used (see Figure 4). The same applies

when using the optional mounting plate and closed cell foam gasket (see Figure 5).

Figure 1. Dimensions of the Heater

www.webasto.us 9 Webasto Thermo & Comfort N.A., Inc.

Page 10

Installation Air Top Evo 3900/5500

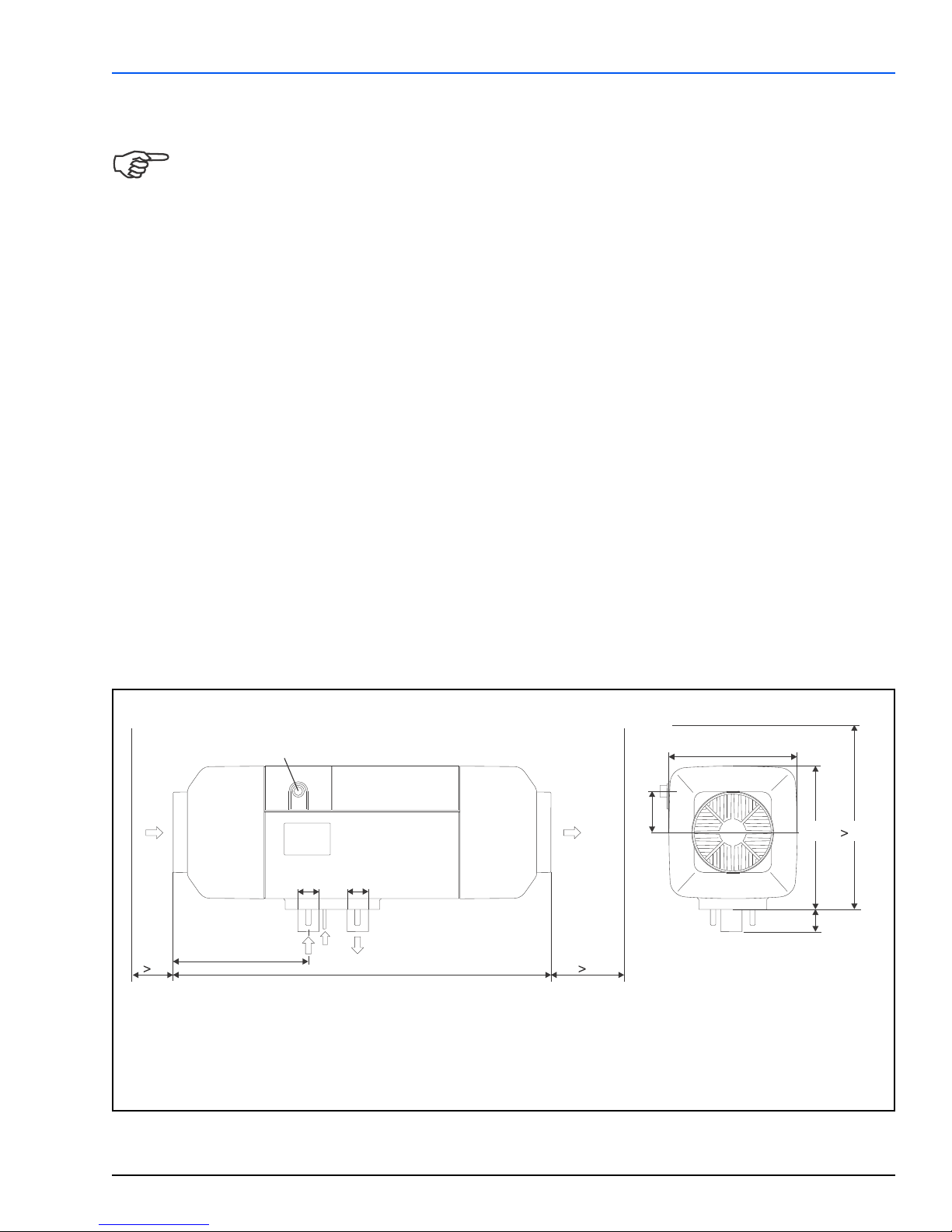

Gasoline Heaters

Diesel Heaters

0 - 90°

0 - 90°

0 - 90°

0 - 90°

0 - 90°

0 - 3 0°

WARNING

Ø7.5

Ø7.5

Ø7.5

Ø26

Ø26

18

12

44

55

4.4 To Install the Heater

The M6 nuts used to install the heater must be tightened with a torque of 6 Nm ±1 Nm (4.4 lb.-ft ± 74 lb.-ft).

The installation dimensions and space requirement for service access are shown in the installation drawing (Figure 1).

The specified horizontal and axial angles must not be exceeded (Figure 2).

Figure 2. Recommended Installation Positions for AT 3900/5500 Heaters

A seal (Figure 4) must be fitted between the heater and the vehicle body. This seal must be replaced each time the

heater is installed. The support area for the heater foot must be flat. A special tools can be purchased from Webasto to

drill the holes and, if necessary, smooth the support area. The seal can compensate for unevenness of max. 1 mm

.

The seal or foam gasket or both must be replaced each time the heater is removed and reinstalled.

Figure 3. Hole Pattern

Figure 4. Seal

Webasto Thermo & Comfort N.A., Inc. 10 www.techwebasto.com

Page 11

Air Top Evo 3900/5500 Installation

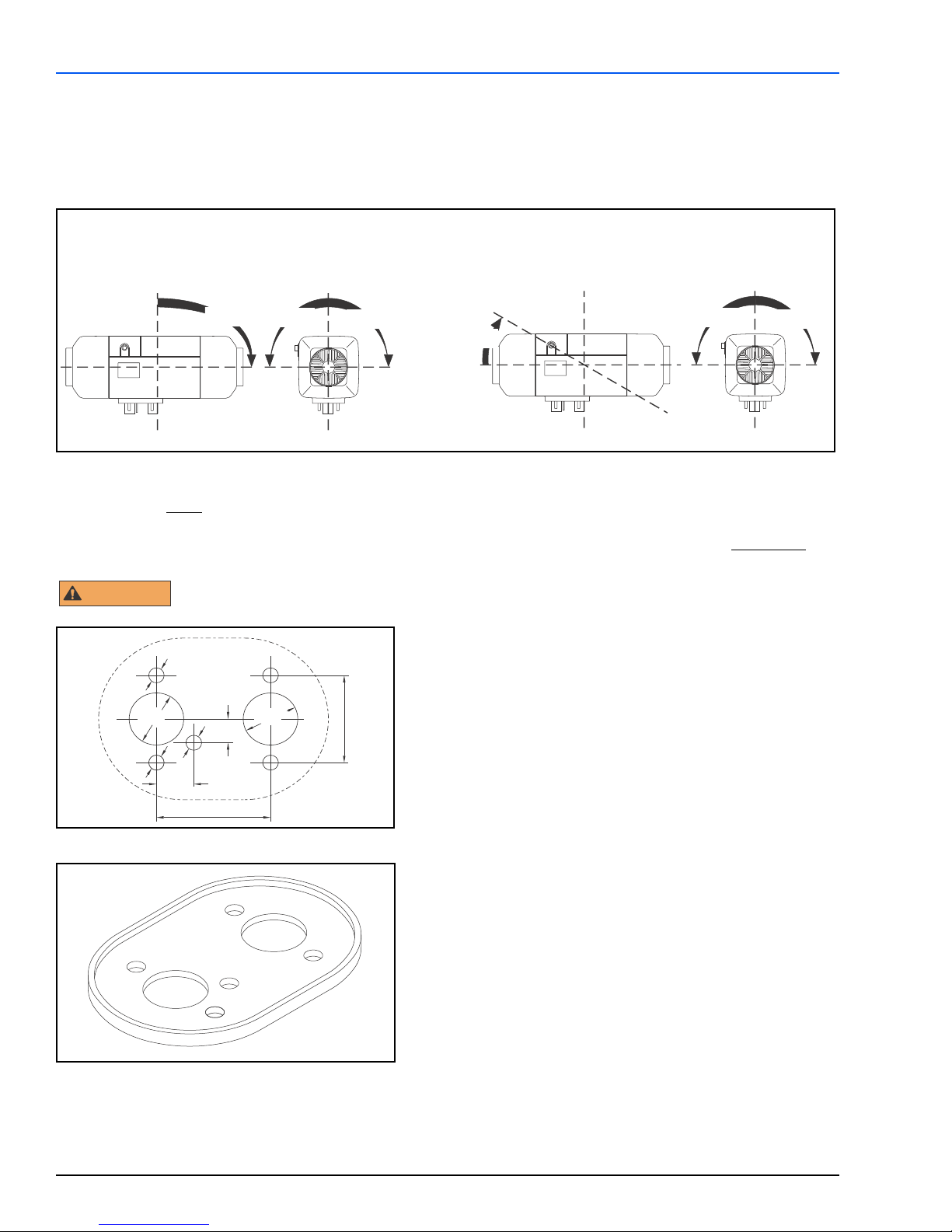

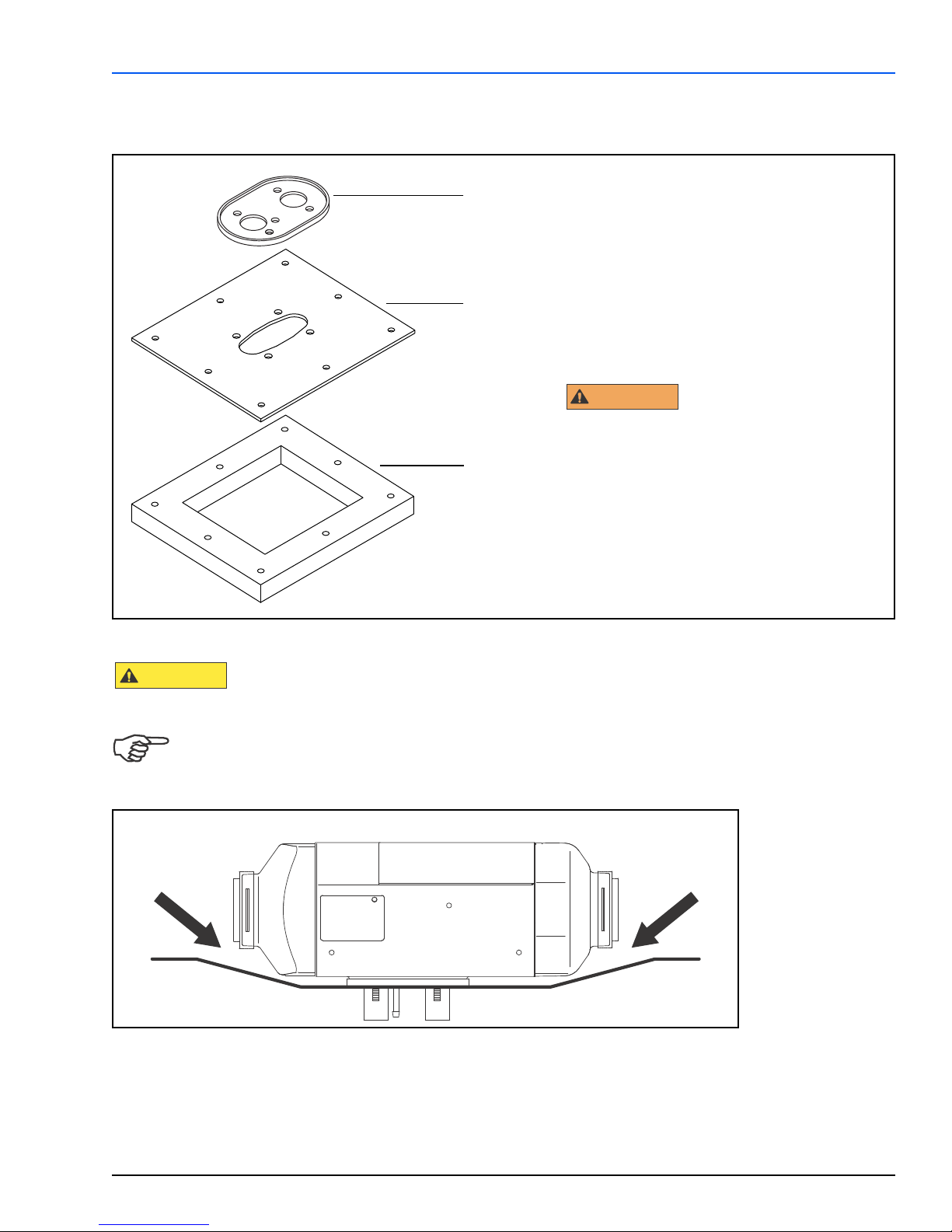

1

2

3

1. Seal - Heater to vehicle floor or optional

mounting plate.

2. Mounting plate - Facilitates installation on

corrugated vehicle floors.

3. Closed Cell Foam Gasket - Seals area

between mounting plate and vehicle floor.

The seal or foam gasket or

both must be replaced

each time the heater is

removed and re-installed.

A mounting plate template is provided in the

installation kit for locating the heater on the floor

of the vehicle. All recommended hole locations

and sizes are included.

WARNING

CAUTION

Ensure that all moving part can move freely

4.5 Optional Mounting Plate

Figure 5. Mounting with optional mounting plate

When using the optional mounting plate and closed cell foam gasket, do not over tighten

the mounting bolts. Doing so will cause the mounting plate to warp and result in stress

damage to the heater and fan motor.

IMPORTANT!

After installation, check that the heater casing is not in contact with any parts of the vehicle body.

A failure to do this may result in the hot air fan binding internally (Figure 6).

Figure 6. Installation

4.6 Factory Plate / Label

The model/serial number plate of the heater must be positioned so that it cannot be damaged and must be clearly

legible when the heater is installed (otherwise a duplicate model plate must be used).

Inapplicable years must be erased from the model plate.

www.webasto.us 11 Webasto Thermo & Comfort N.A., Inc.

Page 12

Installation Air Top Evo 3900/5500

1

2

3

4

5

6

7

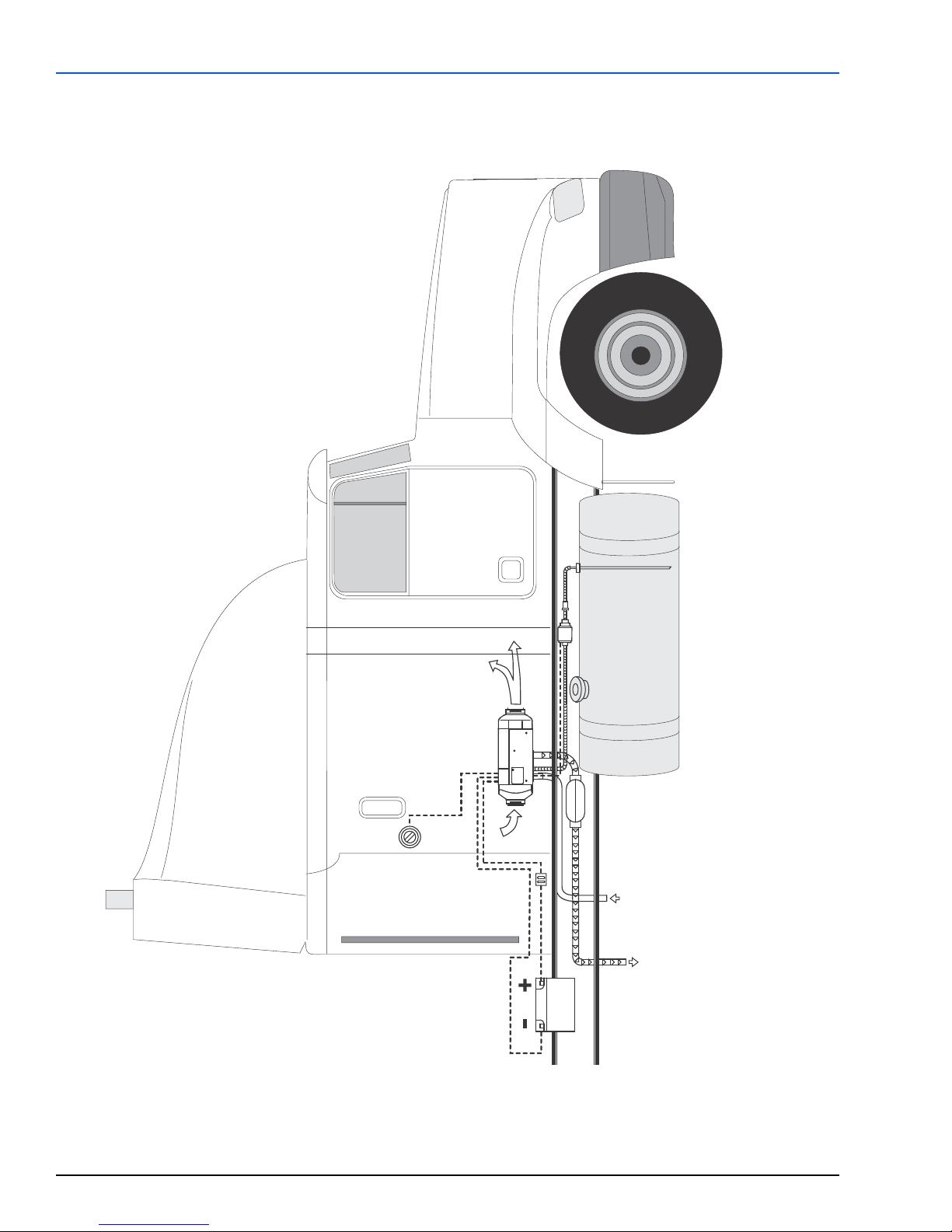

1 Control Element (Rheostat)

2 AT 3900/5500 EVO Heater

3 Fuel Metering Pump

4 Fuel Filter (Optional)

5 Fuel Satndpipe

6 Exhaust Muffler (Optional)

7 Fuse Block

4.7 Installation Example

Figure 7. Installation example with heater in stalled under-bunk. (Recirculation mode)

Webasto Thermo & Comfort N.A., Inc. 12 www.techwebasto.com

Page 13

Air Top Evo 3900/5500 Hot Air System

5. Hot Air System

NOTE:

The heater must not be integrated into the vehicle’s air system.

Both recirculation and fresh air modes are possible.

For fresh air mode it must be ensured that the inlet (hot) air is taken from an area protected from splashing water and

spray and in such a way that no water can ingress into the heater if the vehicle travels through a water hazard for

which that vehicle is licensed.

NOTE:

For fresh air mode, an external temperature sensor must be fitted in the appropriate zone. The standard pause speed

for the blower motor is 0 rpm if the external temperature sensor is used

Inside the control unit there is a temperature sensor, which operates the heater in the appropriate heat output range in

conjunction with the control element depending on the intake temperatures and the position of the set point

generator. The heat output is controlled such that after the selected interior temperature has been reached quickly, it is

then kept at this selected value.

The internal diameter of the main section of the hot air line should be:

90 mm (3.54 in.) minimum for the Air Top EVO 5500

80 mm (3.14 in.) minimum for the Air Top EVO 3900

NOTE:

Only materials that can permanently withstand temperatures of at least 130°C (266°F) may be used for the hot air line.

The hot air opening is to be positioned in such a way that the air is not blown on to any parts that cannot withstand

the heat.

IMPORTANT!

In vehicles used to transport people, the air outlet opening is to be directed in such a way that it is

at least 20 cm (8 in.) away from all body parts.

Maximum pressure drop between the inlet and outlet side of the hot air line:

Air Top EVO 3900 2.0 hPa

Air Top EVO 5500 3.0 hPa

1 hPa corresponds to 1 mbar corresponds to 10 mm Water Column (0.4 inches Water Column).

The heaters check the internal temperature rise automatically each time they are switched on. If this is above the

specified limits (150°C / 302°F), the start is cancelled and error messages F10 (Overheat code) is displayed. To ensure

that the heater functions stably, the flow resistance of the connected hot air system must be reduced.

The hot air hose must be secured at its connection points.

If the heater is used in recirculation mode, for example, in the under bunk compartment of a truck’s sleeper, without a

hot air directional outlet grille, do not short circuit the hot air flow.

Figure 8. Hot air inlet and hot air outlet (recirculation mode)

www.webasto.us 13 Webasto Thermo & Comfort N.A., Inc.

Page 14

Hot Air System Air Top Evo 3900/5500

External temperature sensor

Cover

IMPORTANT!

If you use the heater without a hot air inlet hose, the inlet grille supplied with the heater must be

used at all times.

NOTE:

The installation must be checked for:

– Air short circuit between the vehicle’s heating system and the heater air inlet.

– Air short circuit between the heater’s air inlet and the heater’s air outlet (Figure 8).

Figure 9. Hot air inlet with inlet grille

If you use an installation box the air vent must be sealed in such a way that no hot air can get into the installation box.

5.1 External Temperature Sensor

The installation of an external temperature sensor is recommended if the heater is operated in fresh air mode.

5.1.1 To Install the External Temperature Sensor

The external temperature sensor must be installed at medium height in the passenger cabin on vertical surfaces if

possible in the area that requires heating.

The temperature sensor must not

– be in the direct current of hot air (from the vehicle’s own heating system or the hot air heater).

– by close to heat sources (for example the vehicle’s own heating system).

– be placed in direct sunlight (for example on the dashboard).

– be installed behind curtains or the like.

Figure 10. External temperature sensor - optional

Webasto Thermo & Comfort N.A., Inc. 14 www.techwebasto.com

Page 15

Air Top Evo 3900/5500 Fuel Supply

iØ2mm

iØ2mm

iØ2mm

iØ2mm

I

2

I

2

I

1

I

1

max.3m

H

S

I

2

I

1

+

10 m

1.2 m

8.8 m

I

1

I

2

Figure 11. Fuel supply

a= 6Ø

8Ø

10Ø

12Ø

0-60°

Ø5

0-60° 0-60°

0-60° 0-60°

0-60°

From Tank

To Engine

To Fuel Metering Pump

6. Fuel Supply

The fuel is taken from the vehicle fuel tank or from a

separate fuel tank. The values for the maximum pressure at

the fuel extraction point are shown in Figure 11.

Permissible fuel inflow height H At max. pressure in fuel line

0.00 m (0.00 in.) 0.2 bar (2.9 PSI)

1.00 m (39.4 in.) 0.11 bar (1.6 PSI)

2.00 m (78.7 in.) 0.03 bar (0.44 PSI)

Maximum fuel intake height S At max. negative pressure in the

0.00 m (0.00 in.) -0.10 bar (-1.45 PSI)

0.50 m (19.7 in.) -0.06 bar (-0.87 PSI)

1.00 m (39.4 in.) -0.02 bar (-0.29 PSI)

fuel tank

A sign must be affixed to the fuel tank’s filler neck warning

that the heater must be switched off before refuelling.

6.1 Vehicles with a Carburetor Equipped Engine

The fuel may only be extracted using the special Webasto fuel extractor (see Figure 12) as close to the tank as possible.

The connection may be made in either the supply or return line, in which case the return line must lead almost to the

base of the tank (see Figure 13).

The fuel extractor must be fitted in such a way that any air or gas bubbles are automatically discharged towards the

tank (see Figure 12).

Figure 12. Webasto fuel extractor

The fuel extractor should not be located near the engine, as gas bubbles may form in the lines on account of heat

radiated from the engine. This may cause problems during combustion.

www.webasto.us 15 Webasto Thermo & Comfort N.A., Inc.

Page 16

Fuel Supply Air Top Evo 3900/5500

*

25

Minimum distance 25 mm (1 in.)

Only use this Standpipe on fuel

tanks constructed from metal

Hole pattern

6.2 Vehicles with Fuel Injection Engines

When installing the heater in a vehicle with fuel injection system, it is important to establish whether the fuel pump is

located inside or outside the tank.

If the fuel pump is located inside the tank, fuel can only be extracted from the return line using the Webasto fuel

extractor (see Figure 12), in which case it must be ensured that the return line continues almost to the bottom of the

tank (see Figure 13 for details of the minimum distance from the bottom of the tank). If this is not the case Webasto

fuel extractors or standpipes (see Figures 13, 14 and 15) may be used.

If the fuel pump is installed outside the tank, the fuel connection may also be made between the tank and the fuel

pump, again using only the Webasto fuel extractor (see Figure 12).

6.3 Vehicles with Diesel Engines

The fuel must be taken from the vehicle fuel tank or from a separate tank (see Figs. 13, 14 and 15). This separate fuel

pickup precludes any effect of pressure.

Figure 13. Webasto fuel standpipe

NOTE:

The tank fitting must be made from metal!

6.4 Fuel Lines

Only steel, copper and plastic lines of plasticized, light and temperature-stabilized PA 11 or PA 12 (e.g. Mecanyl RWTL)

pursuant to DIN 73378 may be used for the fuel lines.

Since the lines normally cannot be routed with a constant rising gradient, the internal diameter must not be allowed to

exceed a certain size. Air or gas bubbles will accumulate in lines with an internal diameter of more than 2 mm and

these will cause malfunctions whilst the heater is operating if the lines sag or are routed downwards. The diameters

specified in Figure 11 will ensure that bubbles do not form.

The lines should not be routed downwards from the metering pump to the heater.

Unsupported fuel lines must be secured to prevent them from sagging. They must be installed in such a way that they

cannot be damaged by flying road debris and high temperatures

The fuel lines must be secure at the connections using hose clamps to prevent their slipping.

Webasto Thermo & Comfort N.A., Inc. 16 www.techwebasto.com

(exhaust line).

Page 17

Air Top Evo 3900/5500 Fuel Supply

Plastic tank

Sealing ring

Sealing ring

Tan k F i tti n g

Tank Connector

Figure 14. Fuel supply from plastic tank drain screw

Figure 15. Fuel supply from plastic tank fitting

Clamp

Bubble

Bubble

Wrong

Correct

Air Top EVO 3900/5500 12 and 24 Volt - Diesel

Figure 18. Fuel metering pump DP 30.2 / 30.3

Preferably

15° - 90°

Air Top EVO 3900/5500 12 Volt - Gasoline

6.4.1 Connecting Two Fuel Lines with a Coupler Hose

The correct procedure for connecting fuel lines with hosing is shown in Figure 16. Ensure that there are no leaks.

Figure 16. Fuel line / coupler hose connection

6.5 Fuel Metering Pump

The fuel metering pump is a combined delivery,

metering and shut-off system and is subject to

certain installation criteria (see Figures 11 and

18).

6.5.1 Installation Location

It is advisable to install the metering pump in a

cool place. The maximum ambient temperature

must not exceed +20 °C (68 °F) for gasoline

heaters at any time during operation.

The metering pump and fuel lines must not be

installed within range of the radiated heat from

hot vehicle parts. A heat shield must be used if

necessary

.

www.webasto.us 17 Webasto Thermo & Comfort N.A., Inc.

Page 18

Fuel Supply Air Top Evo 3900/5500

A

Ø 5

0° - 90°

6.5.2 Installation and Attachment

The metering pump must be secured with a vibration-damping mounting. Its installation position is limited as shown in

Figure 18 in order to ensure effective automatic bleeding.

As a result of the risk of corrosion, only genuine Webasto parts may be used for the plug connections between the

metering pump and the metering pump wiring harness.

6.6 Fuel Filter

Only a Webasto filter is allowed to be used if the fuel is expected to be contaminated. Install vertically if possible,

however at least horizontally (check flow direction).

IMPORTANT!

Do not substitute the Webasto supplied fuel filter with a non Webasto replacement. Irregular

heater operation may result.

Figure 19. Fuel filter

Webasto Thermo & Comfort N.A., Inc. 18 www.techwebasto.com

Page 19

Air Top Evo 3900/5500 Combustion Air Supply

7. Combustion Air Supply

Under no circumstances may the combustion air be taken from areas occupied by people. The combustion air intake

opening must not point in the direction of travel. It must be located so that it cannot become clogged with dirt and

road debris.

NOTE:

An intake silencer must be fitted if the intake hose length is shorter than 0.6 m.

NOTE:

The combustion air must be extracted using a combustion air line from a position that is as cool as possible and

protected from splashing water.

Do not use an exhaust line as the combustion air line since otherwise the metering pump cable from the combustion

air inlet port may be damaged.

The combustion air opening must not be under the minimum water drive-through level permitted for the vehicle.

See the regulations for the installation for further regulations.

www.webasto.us 19 Webasto Thermo & Comfort N.A., Inc.

Page 20

Exhaust Pipe Air Top Evo 3900/5500

Ø

6.5

0-90° 0-90°

8. Exhaust Pipe

Rigid pipes of unalloyed or alloyed steel with a minimum wall thickness of 1.0 mm (3/64 in.) or flexible piping of alloyed

steel only must be used as exhaust line.

The exhaust pipe is secured to the heater using a clamping collar, for example. See the ‘regulations for installation’ for

other requirements.

The exhaust muffler should ideally be installed near the heater.

The heater may also be operated without a muffler.

Figure 20. Exhaust muffler - exhaust flow is non-directional (arbitrary)

Webasto Thermo & Comfort N.A., Inc. 20 www.techwebasto.com

Page 21

Air Top Evo 3900/5500 Combustion Air Inlet and Exhaust Lines

Figure 21. Prevent the formation of condensate

Figure 22. Lines must not point in the direction of travel

Figure 23. Avoid the lines becoming clogged with dirt

10°

10°

The exhaust pipe must be securely attached no further

than 150 mm (6 in.) from the end of the exhaust pipe

to ensure that the angle of 90° ± 10° is maintained.

Discharge direction almost vertical 90° ± 10°

Installation position

Figure 24. Exhaust pipe opening

9. Combustion Air Inlet and Exhaust Lines

Both lines are to be installed falling away from the

heater. If this is not possible, a condensate drain hole

with a diameter of 4 mm (5/32 in.) must be made at its

lowest point.

The lines must not point to the front of the vehicle.

The lines must be located so that they cannot become

clogged with dirt and road debris.

Length of the combustion air inlet and exhaust lines in total:

With muffler: max. 2.0 m

Without muffler: max. 5.0 m

NOTE:

If the exhaust line is over 2 m in length the lines must be insulated

(to prevent falling below the dewpoint)

Internal diameter of the lines:

Combustion air line: 24 mm

exhaust line (metal): 24 mm

Minimum bending radius: 50 mm

Total bends:

Combustion air line: max. 270°

Exhaust line: max. 270°.

IMPORTANT!

If the exhaust pipe ends other than as shown in Figure 24, it will pose a fire risk.

www.webasto.us 21 Webasto Thermo & Comfort N.A., Inc.

Page 22

Electrical Connections Air Top Evo 3900/5500

F = 20A (12V)

F = 15A (24V)

Figure 26. Fuse holder - weather sealed

10. Electrical Connections

All the cables and wires that are not required must be insulated against accidental shorting or grounding.

NOTE:

The electrical connection is made as shown in the system circuit diagram (Figure 37).

10.1 Heater Connection

To connect the wiring harness, remove the control unit cover on the heater and connect the wiring harness plug to the

control unit.

Figure 25. To remove the control unit cover

NOTE:

Raise the control unit cover on both sides using a blunt blade (Figure 25 arrows).

Before using the heater for the first time, fit the control unit cover in place on the heater to prevent the escape of hot

air (heater overheating).

The cable passage of the cover can be placed at either the left or right side.

To ensure that the cable passage in the control unit cover seals perfectly, the cable grommet is to be adjusted

appropriately on the wiring harness.

10.2 Supply Voltage Connection

Ideally from the vehicle’s central electrical system or at the batteries.

A weather sealed fuse holder is to be fitted to protect the heater

(supplied with the heater harness).

IMPORTANT!

The Air Top EVO 3900/5500 requires 6.25 amps @ 12 volts or 12.5 amps @ 24 volts during start-up.

The main power connection has to be made at a circuit designed to sustain this load without

voltage drop. Cigar lighter sockets and auxiliary power outputs for C.B. radio’s and other

electronic accessories are not considered adequate power supplies for the Air Top EVO 3900/5500.

Webasto Thermo & Comfort N.A., Inc. 22 www.techwebasto.com

Page 23

Air Top Evo 3900/5500 Electrical Connections

Shaft requires a 12 mm (15/32 in.)

hole to mount.

Figure 27. Control element (rheostat)

Figure 28. Installation of the control element - correct

Figure 29. Installation of the control element - incorrect

External temperature sensor

Cover

Figure 30. External temperature sensor - optional

10.3 Control Element (Rheostat)

The wiring harness is prepared for connection to the

control element.

Simply pull on the connector housing to unplug the

connector.

The connector housing can be locked (self-locking

action) by simply pulling on the wiring harness.

Locate the control element in a convenient location.

The control element is not affected by temperature.

Temperature is monitored inside the heater or via an

optional external temperature sensor (see Figure 30).

NOTE:

The fibre optic lens must be in contact with the rotary

knob.

NOTE:

The rotary knob must sit flush with the bezel (Figure

28) not above it as illustrated in Figure 29.

NOTE:

As an option an external temperature sensor may be

installed in the passenger cabin (see page12).

See installation instructions included with the sensor

or see the service instructions in the Workshop

manual for further information.

www.webasto.us 23 Webasto Thermo & Comfort N.A., Inc.

Page 24

Electrical Connections Air Top Evo 3900/5500

Figure 31. Control element (SmarTemp)

Figure 32. SmarTemp drilling dimensions

10.4 Control Element (SmarTemp)

The Control Panel should be installed in a suitable location on a flat surface if possible in a visible area.

– Connect control panel to existing connectors on

heater-unit wiring harness (see “Connections

Diagrams Section”)

– Use the drilling dimensions (fig. 32) to lightly mark the

two mounting holes.

– (Optional Step) To route wire harness through the

mounting surface, drill an 8mm hole. Make sure to

push harness through the hole before installing

terminals into connector housing)

– Secure the SmarTemp Control using the two supplied

#4 screws.

– Follow the electrical pin-out fig. 33 to install the

supplied harness connector and harness adaptors.

– Apply any warning or caution stickers that are

supplied with the SmarTemp Control.

– Observe the installation / operating manual supplied

for proper menu setup.

NOTES:

– Always make sure there are no obstacles behind the

mounting location prior to drilling.

– Ensure good readability when selecting installation

location.

– Observe information on adhesive labels and colored

markings when connecting the control element to

vehicles wiring harness.

Webasto Thermo & Comfort N.A., Inc. 24 www.techwebasto.com

Page 25

Air Top Evo 3900/5500 Electrical Connections

Figure 35. Installing control element MC04/05

Figure 33. Air Top 3900/5500 EVO with SmarTemp Control - connection diagram

10.5 Control Element (MC04/05)

The Control Panel should be installed in a suitable location (on a flat surface if possible) in a visible area.

– Use Drilling Template for Control Panel MC04/05 for cut-out and holes (see “drilling templates”)

– Connect Control Panel to existing connectors on heater-unit wiring harness (see “Connection diagram/Circuit

diagram”)

– Pre-mount control unit in cut-out

– Lightly press fastening screws into holes and screw in

– Carefully clip on trim frame

NOTES:

– Control Panel is only intended for installation in

passenger compartment

– Ensure good readability when selecting installation

location

– Observe information on adhesive labels and colored

markings when connecting Control Panel to vehicle

wiring harness

www.webasto.us 25 Webasto Thermo & Comfort N.A., Inc.

Page 26

Electrical Connections Air Top Evo 3900/5500

Observe coloured markings

Control Panel MC04/05

Heater units

wiring harness

Optional connection for:

- Telestart/Thermo Call

- Webasto Thermo Test Diagnose

3 2 1

6 5 4

9 8 7

12 11 10

12V

24V

Combination Timer 1531

Adapter Harness

P/N 9008440A

Brown

Battery Negative (12, 4)

Red

Battery Positive (11)

Black

Battery Positive

or Ignition Signal (10)

Grey

Lights (1)

(optional)

Figure 35. Connection diagram for Air Top EVO 3900/5500 with control element MC04/05

10.5.1 Control Element (1531 Combi Timer)

Figure 36. Air Top EVO 3900/5500 with combination timer 1531 - connection diagram

Webasto Thermo & Comfort N.A., Inc. 26 www.techwebasto.com

Page 27

Air Top Evo 3900/5500 Circuit Diagrams

Item Description Comment

A1 Heater Air Top EVO 3900/5500

A2 Control module

B2 Temperature sensor Internal

B3 Overheating sensor Overheating guard

B4 Temperature sensor External

E Ceramic glow pin

F1 Fuse 24 V 15 A/12 V 20 A Flat fuse SAE J 1284

F2 Fuse 20 A Flat fuse SAE J 1284

F3 Fuse 15 A Flat fuse SAE J 1284

H1 LED, green (in item S1) Indicator

H3 LED red (in item P) Light in immediate heat button,

ready indicator, Switch-on

indicator

H4 Heating symbol in the display

(item P)

Indicator

H5 Light (in item P) Display and button lights

H6 Light (at least 1.2 W) Switch-on indicator pumping

device

K Relay with free wheeling diode for vehicle fan

M1 Motor Combustion and hot air fan

M3 Motor Vehicle fan

P Combination Timer (1531) Timer and setpoint generator

R1 Resistor 620 Ohm With internal temperature sensor

only

S1 Control element Set point generator switch

S2 1 or 2 pin disconnecting switch Emergency Stop switch

S3 Switch On and for pumping device

S5 Switch CO

2

setting

S6 Switch Ventilation or boost

S7 Momentary contact switch Immediate heat button remote

control

S8 Battery isolation switch

V1 Diode

V12 Diode

X1 Plug connector, 2-pin To item A2 (B)

X2 Plug connector, 2-pin To item A2 (V)

X3 Plug connector, 2-pin To item A2 (U)

X4 Plug connector, 2-pin To item A2 (Z)

X5 Plug connector, 2-pin To item A2 (Y)

X6 Plug connector, 2-pin To item A2 (X)

X7 12-pin plug connection To item A2 (1)

X8 Plug connector, 2-pin

X9 Plug connector, 4-pin x3 (a,b,c) To item S

X10 Plug connector, 2-pin

X11 Plug connector, 2-pin To item Y1

X12 12-pin plug connection To item P

X13 Plug connector, 8-pin

X14 Plug connector, 8-pin

Y1 Metering pump

Y2 Solenoid valve for pumping device

11. Circuit Diagrams

11.1 Legend for Circuit Diagrams

Cable colors

(where applicable)

blue

bl

brown

br

yellow

ge

green

gn

grey

gr

orange

or

red

rt

black

sw

violet

vi

white

ws

www.webasto.us 27 Webasto Thermo & Comfort N.A., Inc.

Page 28

Circuit Diagrams Air Top Evo 3900/5500

Figure 37. Standard wiring diagram for the Air Top EVO 3900/5500, 12 / 24 Volt with control element (Rheostat)

Webasto Thermo & Comfort N.A., Inc. 28 www.techwebasto.com

Page 29

Air Top Evo 3900/5500 Circuit Diagrams

Figure 38. Standard wiring diagram for the Air Top EVO 3900/5500, 12 / 24 Volt with control element (SmarTemp)

www.webasto.us 29 Webasto Thermo & Comfort N.A., Inc.

Page 30

Circuit Diagrams Air Top Evo 3900/5500

Figure 39. Standard wiring diagram for the Air Top EVO 3900/5500, 12 / 24 Volt with control element (MC04/05)

Webasto Thermo & Comfort N.A., Inc. 30 www.techwebasto.com

Page 31

Air Top Evo 3900/5500 Circuit Diagrams

Figure 40. Standard wiring diagram for the Air Top EVO 3900/5500, 12 / 24 Volt with control element (1531 combi timer)

www.webasto.us 31 Webasto Thermo & Comfort N.A., Inc.

Page 32

Starting the Heater for the First Time Air Top Evo 3900/5500

Control Element

Changes to the settings

on the control element

are implemented after

a delay.

!

Rotary knob for:

- Switching on and off

- Setting the room temperature

Resetting after a fault cut-out

-

Indicator / Error code display

12. Starting the Heater for the First Time

After you have installed the heater, bleed the fuel supply system carefully.

NOTE:

As a result of the low fuel consumption the heater must be switched on several times to fill the fuel line and prime the

system.

Conduct a trial of the heater to check all the connections for leaks and to ensure that they are secure. If the heater

suffers a fault during operation, the fault must be located and remedied.

12.1 Control Element Description

12.1.1 Rheostat

Figure 41. Control element (Rheostat)

12.1.2 SmarTemp Control

Figure 42. Control element (SmarTemp Control)

Webasto Thermo & Comfort N.A., Inc. 32 www.techwebasto.com

Page 33

Air Top Evo 3900/5500 Starting the Heater for the First Time

12.1.3 MC-04/05

Figure 43. Control element (MC-04)

The MC-05 control element has one additional function called “Altitude” ( ). Altitude correction is used when

operating the heater in higher than 1,200 m above sea level (not available for MC04 M and MC04 SPM)

12.1.4 1531 Combi Timer

Figure 44. Control element (1531 Combi Timer)

www.webasto.us 33 Webasto Thermo & Comfort N.A., Inc.

Page 34

Fault Lock-out Air Top Evo 3900/5500

13. Fault Lock-out

The control unit continuously monitors the heater operation. The control unit identifies errors on individual heater

components and faults during operation. Should the control unit experience component errors and operational faults,

the heater will be shut down.

The heater is shut down (fault lock-out) if:

– No or incorrect start

– Temperature sensor defective

– Overheating sensor interrupt or short circuit

– Overheating sensor installed incorrectly

– Ceramic glow pin interrupt or short circuit

– Fan motor overload or blocked or short circuit or interrupt

– Error in the fuel metering pump or overheating guard circuit (start phase only)

– Under voltage less than 10 V or over voltage greater than 15 V and for longer than 20 seconds (on 12 V heater)

– Under voltage less than 20 V or over voltage greater than 32 V and for longer than 20 seconds (on 24 V heater)

– Control unit defective

–Overheating

The fuel supply is stopped if the heater overheats.

The heater continues to run in the same way as if it is switched off manually.

After the heater stops the control unit will be set to fault lock-out.

Overheating is indicated by the indicator flashing 10 times.

Rectify the cause of the fault.

To reset the fault, switch the heater on and off briefly (at least 2 seconds).

If serious faults, such as overheating or no start, occur frequently, the heater will be set to fault lock-out (F 12) and can

be restarted by disconnecting the supply voltage (e.g. removing the fuse).

13.1 Error Code Output

NOTE:

An error code is generated on the control element indicator light after an error has occurred. When determining the

generated code, there will be a series of 5 fast flashes after which, the error code will be generated by a sequence of

long flash pulses, count only the long flash pulses to obtain the code. Error codes are shown in the table below.

If the heater is fitted with a combination timer, an error message will appear on the display of the timer after a fault

occurs. If the control element is used, the error number is indicated by the indicator light flashing:

F 00 Control unit error / incorrect parameter set / warm start recognition

F 01 No start (after 2 attempts to start) / no flame formation

F 02 Flame failure (repeated more than 3 times)

F 03 Under voltage or over voltage

F 04 Premature flame recognition

F 06 Temperature sensor interrupt or short circuit

F 07 Metering pump interrupt or pump short circuit

F 08 Fan motor interrupt or short circuit or overload or blocked

F 09 Ceramic glow pin interrupt or short circuit

F 10 Overheating: Resulting in permanent heater fault lock-out

F 11 Overheating sensor interrupt or short circuit

F 12 Heater lock-out

F 13 Heater lock-out permanent

F 14 Overheating sensor incorrect position

F 15 Set point generator interrupt

Webasto Thermo & Comfort N.A., Inc. 34 www.techwebasto.com

Page 35

Air Top Evo 3900/5500 Technical Data

14. Technical Data

Except where limit values are specified, the technical data refer to the usual heater tolerances of ±10% at an ambient

temperature of +20 °C (68 °F) and at the rated voltage and in rated conditions.

14.1 Electrical Components:

Control unit, motor, metering pump, lamp in the timer and ceramic glow pin / flame monitor are designed for either 12

or 24 Volt.

14.2 Fuel for Air Top EVO 3900/5500 B (Gasoline):

The fuel specified by the vehicle manufacturer must be used.

14.3 Fuel for Air Top EVO 3900/5500 D (Diesel/Heating Oil):

The diesel fuel specified by the vehicle manufacturer must be used. Heating oil may also be used as long as it complies

to the normal quality available on the North American market.

We know of no negative influences due to additives.

If fuel is extracted from the vehicle’s tank, follow the additive instructions issued by the vehicle manufacturer.

If you change to low-temperature fuel, the heater must be operated for approx. 20 minutes so that the fuel system is

filled with the new fuel.

The Air Top EVO 3900/5500 heater is also licensed for use with PME (bio-diesel), which complies with DIN EN 14214.

Heater Operation Air Top EVO 3900/5500 B Air Top EVO 3900/5500 D

Type test permit EMC

Heater

Model Air heater with evaporator burner

Heat output Control range 1.7 - 3.9 (5.5) kW (5800 - 13307 BTU) 1.5 - 3.9 (5.5) kW (5118 - 13307

Fuel Gasoline Diesel/PME

Fuel consumption Control range 0.17 - 0.39 (0.57) kg/h

0.19 - 0.46 (0.73) I/h

Rated voltage 12 V 12 / 24 V

Operating voltage range 10.5 - 16 V 10.5 - 16 /21 - 32 Volt

Rated power consumption Control range 15 - 45 (116) W

Max. ambient temperature:

Heater: - Operation

Metering pump - Operation

Control element - Operation

Maximum combustion air inlet temperature -40... +20 °C (-40... +68 °F)

Adjustment range for interior temperature Control range +5... +35 °C (+41... +95 °F)

Delivery rate for hot air

at fan speed

CO

in the exhaust fumes

2

(normal function range)

Heater dimensions Length 423 ± 2 mm (16.65 ± 0.08 in.)

Weight 5.9 kg (13 lb)

- Storage

- Storage

- Storage

Against 0.5 mbar

1 kW

2 kW

1.7 kW: 5.0 - 8.0%

3.5/5.0 kW: 9.0 - 12.5%

e1*72/245*95/54*1221*00

e1*2001/56*0021*00

e1*2001/56*0020*00

0.15 - 0.39 (0.55) kg/h

0.18 - 0.47 (0.66) I/h

-40... +40 °C (-40... +104 °F)

-40... +85 °C (-40... +185 °F)

-40... +20 °C (-40... +68 °F)

-40... +85 °C (-40... +185 °F)

-40... +75 °C (-40... +167 °F)

-40... +85 °C (-40... +1854 °F)

max. 132 (200) m

at 3900 (5500) rpm

Width 148 ± 1 mm (5.82 ± 0.04 in.)

Height 162 ± 1 mm (6.37 ± 0.04 in.)

3

/h

1.5 kW: 5.0 - 8.0%

3.5/5.0 kW: 9.0 - 12.5%

BTU)

www.webasto.us 35 Webasto Thermo & Comfort N.A., Inc.

Page 36

Version Air Top Evo 3900/5500

15. Version

Air Top EVO 3900/5500 B (Gasoline)

Air heater for gasoline (12 V)

Air Top EVO 3900/5500 D (Diesel)

Air heater for Diesel/heating oil (12 or 24 V)

Webasto Thermo & Comfort N.A., Inc. 36 www.techwebasto.com

Page 37

Air Top Evo 3900/5500 Drilling Template

Ø

7.5

Ø

7.5

Ø

7.5

Ø

26

Ø

26

18

12

44

55

98

R2

63

16. Drilling Template

Figure 45. Drilling Template for Heater Installation (Dimensions in millimeters)

Figure 46. Drilling Template for MC04/05 Control Panel

www.webasto.us 37 Webasto Thermo & Comfort N.A., Inc.

Page 38

Notes Air Top Evo 3900/5500

www.webasto.us 38 Webasto Thermo & Comfort N.A., Inc.

Page 39

Air Top Evo 3900/5500 Notes

www.webasto.us 39 Webasto Thermo & Comfort N.A., Inc.

Page 40

Org. 05/2009 Rev. 6/2013 P/N LIT909385B

Webasto Thermo & Comfort N.A., Inc.

15083 North Road

Fenton, MI 48430

Technical Assistance Hotline

USA: (800) 555-4518

Canada: (800) 667-8900

www.webasto.us

www.techwebasto.com

Loading...

Loading...