Webasto Air Top 3500, Air Top 5000 Workshop Manual

Air Heaters

07/2000

Workshop Manual

Air Top 3500

Air Top 5000

Type AT 3500 D (Diesel)

Type AT 5000 D (Diesel)

Air Top 3500/5000

List of Contents

I

List of Contents

1 Introduction

1.1 Scope and Purpose................................. .................................. ................................... ......................... 101

1.1.1 Use of the Air Heaters................................................................................................................. 101

1.2 Meaning of Warnings, Cautions, and Notes.......................................................................................... 101

1.3 Additional Documentation to be used................ .................. ................................... ............................ ... 101

1.4 Safety Information and Regulations....................................................................................................... 101

1.4.1 General Safety Notes.............................. ..................................... .................. ............................. 101

1.5 Legal Provisions for Installation............................. .. .. ........................................... ................................. 102

1.6 Corrections and Improvements.......................... .. .. ........................ ..................... ................................... 103

2 General Description

2.1 Combustion and Heating Air Fan.................................................................................................... ....... 202

2.2 Heat Exchanger..................................................................................................................................... 202

2.3 Burner with Combustion Tube ............................................................................................................... 202

2.4 Control Unit............................................................................................................................................ 203

2.5 Glow Plug / Flame Sensor..................................................................................................................... 203

2.6 Analogue Temperature Limiter.................. ........................ .. .. ................................................................ 203

2.7 Dosing Pump......................................................................................................................................... 203

3 Functional Description

3.1 Control Element ..................................................................................................................................... 301

3.2 Switch on........ ................. ................ ................ ................ ................. ................ ..................................... 301

3.3 Heating Operation........................ ................ ................ ................ ................. ................ ........................ . 303

3.4 Control Idle............................................................................................................................................ 303

3.5 Switch off........................... ................ ................ ......................................................... ................ ........... 303

3.6 Heater Functions when installed in ADR Vehicles................................................................................. 303

3.7 Error Lockout......................................... ................ ................ ................. ................ ............................... 304

4 Technical Data

............................ ......................................................................................................... ........... 401

5 Troubleshooting

5.1 General.................................... ................ ..................................................................... ................ ......... 501

5.2 General Failure Symptoms........................................ ................................... ......................................... 501

5.3 Failure Symptoms during Operational Sequence.................................................................................. 502

5.4 Error Code Output ......................... .................................. ................................... ................................... 503

List of Contents

Air Top 3500/5000

II

6 Functional Checkouts

6.1 General................................................................................................................................................. 601

6.2 Adjustments.......................................................................................................................................... 601

6.2.1 Adjustment of CO

2

Contents ...................................................................................................... 601

6.3 Components Testing......................................... .................................. ................................. ................. 601

6.3.1 Glow Plug / Flame Sensor Resistance Check............................................................................ 601

7 Circuit Diagrams

7.1 General................................................................................................................................................. 701

8 Servicing

8.1 General................................................................................................................................................. 801

8.2 Work on the Heater............................................................................................................................... 801

8.3 Work on the Vehicle.............................................................................................................................. 801

8.4 Heater Test Run......... ................. ................ ................ ................ ....................................................... ... 801

8.5 Servicing...................... ......................................................................................................................... 801

8.6 Visual Inspections and Installation Regulations.................................................................................... 801

8.6.1 Heating Air System..................................................................................................................... 801

8.6.2 Fuel Supply..................... ............................................................................................................ 802

8.6.3 Dosing Pump........................................................................................................................... ... 804

8.6.5 Combustion Air Supply............................................................................................................... 805

8.6.6 Exhaust Line................. .............................................................................................................. 805

8.6.7 Combustion Air Intake and Exhaust Lines......................................................... ......................... 805

8.6.8 Electrical Connections.......................... .................................. ................................... ................. 806

8.7 Removal and Installation........................................... ................................... ......................................... 808

8.7.1 Heater, Removal and Installation................................................................................................ 808

8.8 Initial Operation............................. ................ ................ ................ ................. ....................................... 808

9 Repair

9.1 General................................................................................................................................................. 901

9.1.1 Work on Components after Disassembly ............................. .. ..................... ............................... 901

9.1.2 Modification Procedures............................................................................................................. 901

Air Top 3500/5000

List of Contents

III

9.2 Disassembly and Assembly............................. .. ..................................... .................. ........................ ..... 903

9.2.1 Housing Components / Covers, Removal ......................... ................................... ....................... 903

9.2.2 Temperature Sensor, Replacement................................................... .................................. ....... 904

9.2.3 Temperature Limiter, Replacement............................................................................................. 904

9.2.4 Control Unit, Replacement.......................................................................................................... 904

9.2.5 Combustion and Heating Air Fan (Drive), Replacement ............................................................. 904

9.2.6 Glow Plug / Flame Sensor, Replacement.................................................................................... 905

9.2.7 Burner, Replacement............ .............................. ............................. .............................. .............. 907

9.2.8 Burner Tube, Replacement .......................................................... .................... ........................... 907

9.2.9 Heat Exchanger, Replacement.................................................................................................... 908

10 Packaging, Storage and Shipping

10.1 General................................................................................................................................................ 1001

List of Figures

Air Top 3500/5000

IV

List of Figures

301 Functional Diagram...................... .................................. ................................... ......................................... 302

501 General Failure Symptoms ............................................................ ................................... ......................... 501

502 Failure Symptoms during Operational Sequence...................................................................................... 502

701 Control Unit Pin Assignment, Air Top 3500/5000 ...................................................................................... 701

702 Automatic Switching Circuit Air Top 3500/5000, 12 V/24 V with Control Element.......................... .. ......... 702

703 Automatic Switching Circuit Air Top 3500/5000, 12 V/24 V with Combination Timer ................................ 703

704 Automatic Switching Circuit Air Top 3500/5000, 12 V/24 V with Combination Timer

and Battery Switch..................................................................................................................................... 704

705 Automatic Switching Circuit Air Top 3500/5000, 24 V ADR Operation with Control Element.................... 705

706 Automatic Switching Circuit Air Top 3500/5000, 24 V ADR Operation

with Control Element and no Auxiliary Drive.............................................................................................. 706

801 Fuel Supply................................................................................................................................................ 802

802 Webasto Fuel Tap............. ................................... .................................. ................................. ................... 803

803 Fuel Tapping from Plastic Tank (tapping via fuel drain plug)..................................................................... 803

804 Fuel Tapping from Plastic Tank (tapping via fitting plate)......................................................................... . 803

805 Pipe/Hose Connection 12 Volt and 24 Volt Installation position horizontal only........................................ 804

806 Dosing Pump, Installation Position ........ .................. .................................. ................................................ 804

807 Fuel Filter................................................................................................................................................... 804

808 Exhaust Muffler, Direction of Flow ................................... ........................ .. ..................... ........................... 805

809 Installation Arrangement of Exhaust Pipe Outlet....................................................................................... 805

810 Removal of the Fuse Holder Mounting Plate ........................................... ................................... ............... 806

811 Fuse Holder Installation Position.................................................................................................... ........... 806

812 Control Element.................................................................................................................. ................ ....... 806

813 Pulling the Connector........................................... .................................. ............................................. .. ..... 806

814 Sample Installation of Air Heater for Air Circulation Mode of Operation................................. .. ................. 807

901 Removal of Housing Components / Covers................................... .. .. ........................................................ 903

902 Disassembly and Assembly............... .................................. ................................... ................................... 906

Air Top 3500/5000

1 Introduction

101

1 Introduction

1.1 Scope and Purpose

This repair shop manual is intended to support

familiarised personnel in the repair of the air heaters

Air Top 3500, Air Top 3500 Volume Plus and

Air Top 5000 of the Diesel type.

1.1.1 Use of the Air Heaters

The air heaters Air Top 3500 and Air Top 5000 are used to

– heat the cabin

– defrost the windscreens

– heat the goods in transport

They are not cleared to be used for heating a

compartment intended for the transportation of dangerous

goods.

The heaters work independently from the vehicle engine

and are connected to the vehicle's fuel and electrical

system. The use in vehicles with water or air cooled

engine is possible.

1.2 Meaning of Warnings, Cautions, and

Notes

WARNINGS, CAUTIONS, and NOTES in this manual

have the following meaning:

WARNING

This heading is used to highlight that non-compliance with

instructions or procedures may cause injuries or lethal

accidents to personnel.

CAUTION

This heading is used to highlight that non-compliance with

instructions or procedures may cause damage to

equipment.

NOTE

This heading is used to highlight and draw specific

attention to information.

1.3 Additional Documentation to be used

This workshop manual contains all information and

procedures necessary for the repair of air heaters

Air Top 3500 and Air Top 5000. The use of additional

documentation is normally not necessary. Operating

instructions/installation instructions and the vehicle

specific installation proposal may be used as

complementary information as necessary.

1.4 Safety Information and Regu lations

The general safety regulations for the prevention of

accidents and the relevant operating safety instructions

have to be observed at all times.

"General Safety Regulations" beyond the scope of these

regulations are detailed in the following.

The specific safety regulations applicable to this manual

are highlighted in the individual chapters by Warnings,

Cautions, and Notes.

1.4.1 General Safety Notes

Within the scope of the StVZO (Road Traffic Licensing

Regulations of the Federal Republic of Germany) "Design

General Approvals" laid down by the Federal Office for

Motor Traffic exist for the Air Heaters Air Top 3500 and

Air Top 5000 with the following official marks of

conformity:

~S306 for Air Top 3500 (Diesel)

~S303 for Air Top 5000 (Diesel)

Installation of the heater is to be performed in accordance

with the installation instructions and must be checked in

case of

a) the vehicle type inspecti on in accordance with

§ 20 StVZO

b) the individual inspection in accordance with

§ 21 StVZO or

c) The examination in accordance with § 19 StVZO

performed by an officially authorised expert or

examiner for road traffic, a vehicle inspector or a

public servant as per section 7.4 a of Annex VIII

to the StVZO.

In the event of c) the installation must be certified on the

acceptance certificate included in the copy of the "General

Operating License" giving details about

– manufacturer

– type of vehicle and

– vehicle identification number.

This validates the "Design General Approval".

The acceptance certificate must be kept with the

vehicle. The year of initial operation must be durably

marked on the identification plate.

The heaters are cleared for heating the passenger and

driver cabin, but not for heating a compartment intended

for the transportation of dangerous goods.

When using the heater in special vehicles (e.g. vehicles

for the transportation of dangerous goods ADR) or in

vehicles not subject to the Road Licensing Regulations

(StVZO) (e.g. ships), the applicable partially regional

regulations must be observed.

1 Introduction

Air Top 3500/5000

102

When installing the Air Top 3500 and Air Top 5000 in

vehicles intended for the transportation of dangerous

goods, the TRS 002 and TRS 003 (Technical Guidelines

for Regulations concerning the transportation of

dangerous goods on roads) must be met in addition to the

StVZO (Road Traffic Licensing Regulations).

The heater must not be installed in the passenger or driver

cabin of busses. Should the heater nevertheless be

installed in such a compartment, the installation box must

be sealed tight against the vehicle inte rior. There must be

sufficient ventilation of the installation box from the

exterior in order not to exceed a maximum temperature of

40 °C in the installation box. Excessive temperatures may

cause malfunctions.

At filling stations and fuel depots the heater must be

switched off as there is a potential danger of

explosion.

Where flammable fumes or dust may build up (e.g. in

the vicinity of fuel, coal, wood, cereal depots, or

similar installations) the heater must be switched off

to prevent explosions.

Due to the danger of poisoning and suffocation the heater

must not be operated, not even with timer, in enclosed

areas such as garages or workshops not equipped with an

exhaust venting facility.

When removing the heater the bottom gasket must be

renewed.

The heat exchanger of the air heater remains

serviceable for a maximum of 10 years and must then

be replaced with an original spare part by the

manufacturer or by one of its authorized wor kshops.

The heater must then be provided with a label

detailing the sales date of the heat exchanger and the

words "original spare part".

When replacing the heat exchanger it is mandatory

to also replace the overheat protection element

(temperature limiter) to avoid possible malfunctions

when using the old temperature limiter.

The heater must be inspected by an expert in time before

the beginning of the heating season.

Should the heater develop strong smoke emissions over

extended periods of time, unusual combustion operating

noise or smell of fuel, the heater must be made

inoperative by removing the fuse and returned into service

only after inspection by Webasto trained personnel.

Claims for warranty may only be made providing evidence

by the claimant that maintenance and safety regulations

have been met.

Ignoring installation instructions and its procedures will

void the warranty by Webasto. The same applies to

unskilled repairs or repairs not using original spare parts.

This will cause loss of the heater's marks of conformity

and thus the vehicle's permit of operation.

1.5 Legal Provisions for Installation

For testing the heater in accordance with § 19, 20, or 21

of the StVZO the following regulations are to be observed

in particular (§ 22 a StVZO):

Testing is performed upon presentation of the operating

and installation instructions of the manufacturer.

The year of the initial operation must be durably marked

on the heater identification plate by the installing person.

Heating Air System

Heating air intake openings must be arranged so that

under normal operating conditions exhaust fumes of the

vehicle engine or air heater are not likely to be sucked in.

Extracting combustion air from the vehicle interior is

prohibited.

Combustion Air Line

The required air for combustion must be taken in from the

exterior.

Within rooms accommodating persons, the combustion

air lines must not have more than four disconnects and a

splash-water protected exterior wall feedthrough. The

disconnects must be sealed in a way not to exceed a leak

rate of 200 l/h at an overpressure of 0.5 mbar.

The line including feedthrough, disconnects, material and

specific type must be described in the installation

instructions.

The line must require tools for installation and removal

and must be protected against damage, and must be

long-time shockproof.

Air Top 3500/5000

1 Introduction

103

Exhaust Line

The heaters must be designed for exhaust emission to the

exterior.

Exhaust lines must be routed so that exhaust fumes are

unlikely to penetrate into the vehicle's interior.

The function of any part of the vehicle essential for

operation must not be impaired. No condensate or water

penetrations may accumulate in the exhaust line. Drain

holes may be provided as required; these must drain the

liquid to the exterior via drain lines sealed against the

vehicle interior.

The exhaust line outlet is to point upwards (with rain

protection), or in case of exhaust venting below the

vehicle floor, to be located at the nearest possible location

of the vehicle's or cockpit side or rear end pointing

downwards.

In compartments accommodating persons, exhaust lines

must not have more than one disconnect and must have

a splash-water protected feedthrough in the exterior wall/

floor. For water, that has penetrated into the exhaust line,

the connection of a drain line with a metal-sealing joint is

permissible. The drain pipe must be routed sealed

through the exterior wall or the vehicle floor.

The heat exchanger, the exhaust line connected, as well

as the possible drain pipe must be sealed so that with an

overpressure double the overpressure of the exhaust

having the maximum permissible exhaust line length – at

least however at an overpressure of 0.5 bar – a total leak

rate of 30 l/h is not exceeded.

The line including feedthrough, disconnects, material and

specific type must be described in the installation

instructions.

The line must require tools for installation and removal

and must be protected against damage, and must be

long-time shockproof.

Metal lines must be used. These may not heat to more

than 110° C should the possibility of body contact exist

within the room interior. Protective devices against body

contact may be fitted.

Should exhaust pipes be routed through rooms

accommodating persons, these pipes shall be renewed

after 10 years using genuine spare parts.

Combustion Air Inlet and Exhaust Outlet

In installations these ports for combustion air entry and

exhaust fume exit must be of such type, that a ball of

16 mm in diameter cannot be inserted.

Electrical lines, switch gear, and control gear of the heater

must be located in the vehicle so that their proper function

cannot be impaired under normal operating conditions.

For the routing of fuel lines and the installation of

additional fuel tanks §§ 45 and 46 of the StVZ O are to be

adhered to.

The most important regulations are: fuel lines are to be

designed in such a way that they remain unaffected by

torsional stresses in the vehicle, engine movement, and

the like. They must be protected against mechanical

damage.

Fuel-carrying parts are to be protected against heat

disturbing operation and are to be arranged so that any

dripping or evaporating fuel can neither accumulate nor

be ignited by hot components or electrical equipment.

In busses fuel lines and fuel tanks may be located neither

in the passenger area nor in the driver's compartment. In

these type of vehicles the fuel tanks must be located such

that they do not pose a direct hazard to the exits in the

event of a fire. Fuel supply must not be by means of

gravity or pressurization of the fuel tank.

Installation Instructions for Webasto Fuel Tanks for

Fuel Supply of Heaters in Vehicles

In busses the installation is not permitted in the

passengers or driver's compartment.

The fuel filler neck must not be located in the passengers

or driver's compartment of any type of vehicle.

The heater operating condition – at least "on" or "off" –

must be clearly visible.

1.6 Corrections and Improvements

Deficiencies, improvements, or proposals for correction of

this workshop manual are to be mailed to:

Webasto Thermosysteme GmbH

Abt. Technische Dokumentation

D-82131 Stockdorf

Telephone: 0 89 / 8 57 94 - 5 42

Telefax: 0 89 / 8 57 94 - 7 57.

1 Introduction

Air Top 3500/5000

104

Page free for notes

Air Top 3500/5000

2 General Description

201

2 General Description

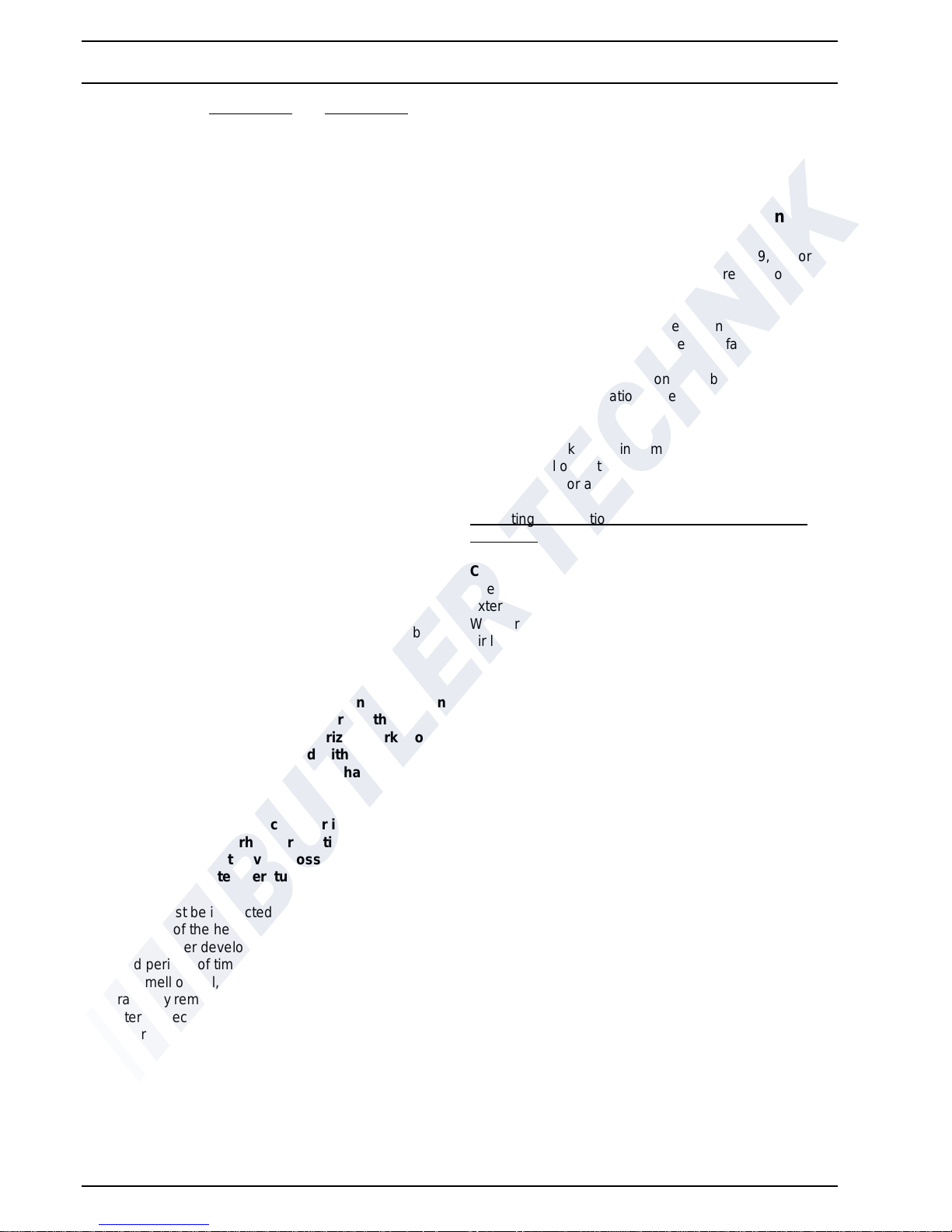

The air heaters Air Top 3500 and Air Top 5000 working to

the evaporator principle of operation basically consist of

the:

– combustion and heating air fan

– heat exchanger

– burner

– combustion tube

– control unit

For control and monitoring the following components are

located inside the air heater:

– control unit

– glow plug / flame sensor

– analogue temperature limiter

– temperature sensor

The heater may be controlled by means of an external

temperature sensor instead of the internal temperature

sensor.

Fuel supply is provided by an external dosing pump.

In case of a heater malfunction an error code is output to

the display of the combination timer. When equipped with

a control element, the operating indicator light will flash.

The heater may be additionally checked using a personal

computer (refer to operating instructions for PC heater

fault diagnosis).

Air Heater Air Top 3500/5000

2 General Description

Air Top 3500/5000

202

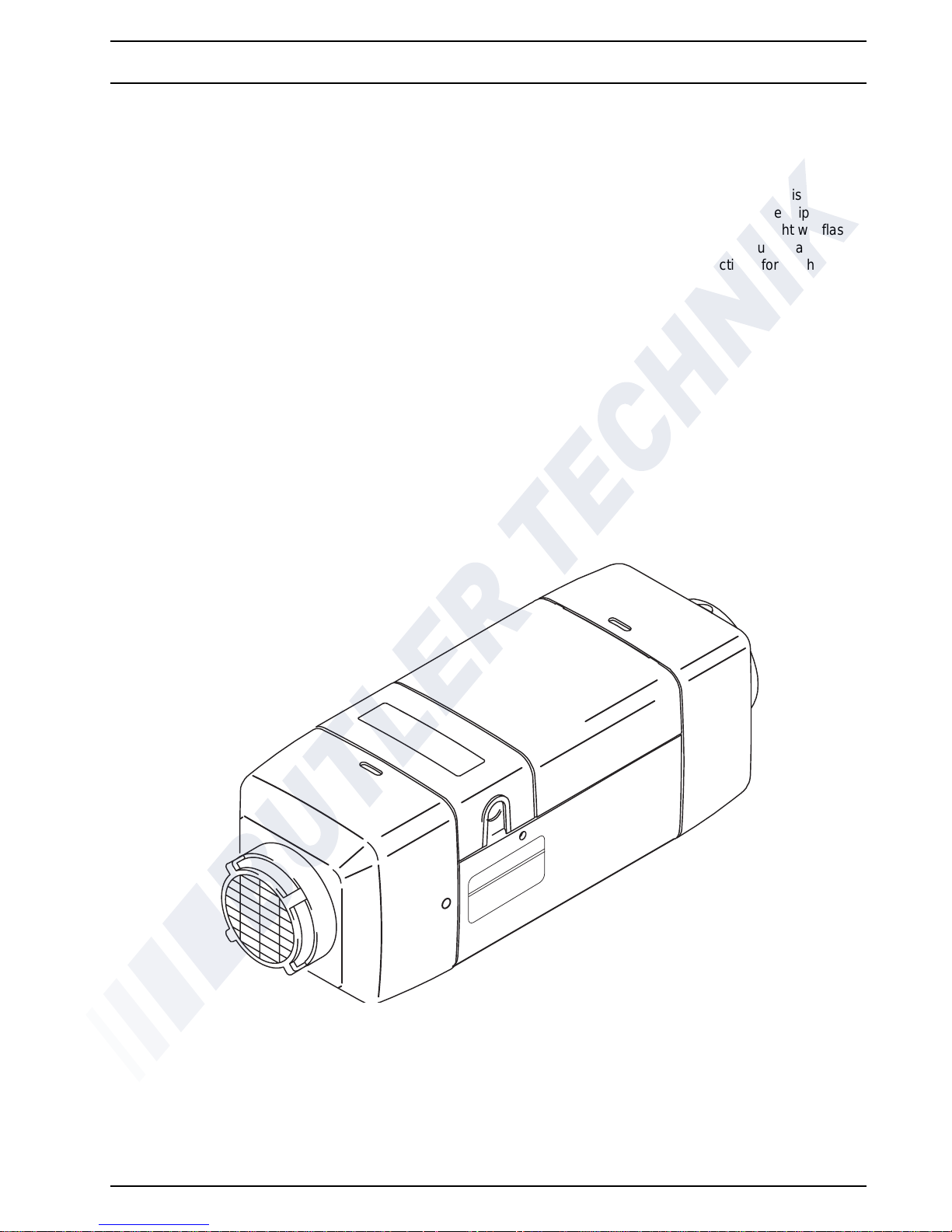

2.1 Combustion and Heating Air Fan

The combustion and heating air fan delivers the air

necessary for combustion from the combustion air inlet

into the burner. The fan also supplies heating air to the

heating air outlet.

2.2 Heat Exchanger

Within the heat exchanger the air delivered by the

combustion and heating air fan is charged with the heat

generated by combustion.

2.3 Burner with Combustion Tube

Inside the burner insert fuel is distributed across the

combustion tube fuel cross section. Combustion of the

fuel/air mixture takes place within the combustion tube to

heat the heat exchanger.

or

Combustion tube

Burner

Combustion tube

Burner with shield

Air Top 3500/5000

2 General Description

203

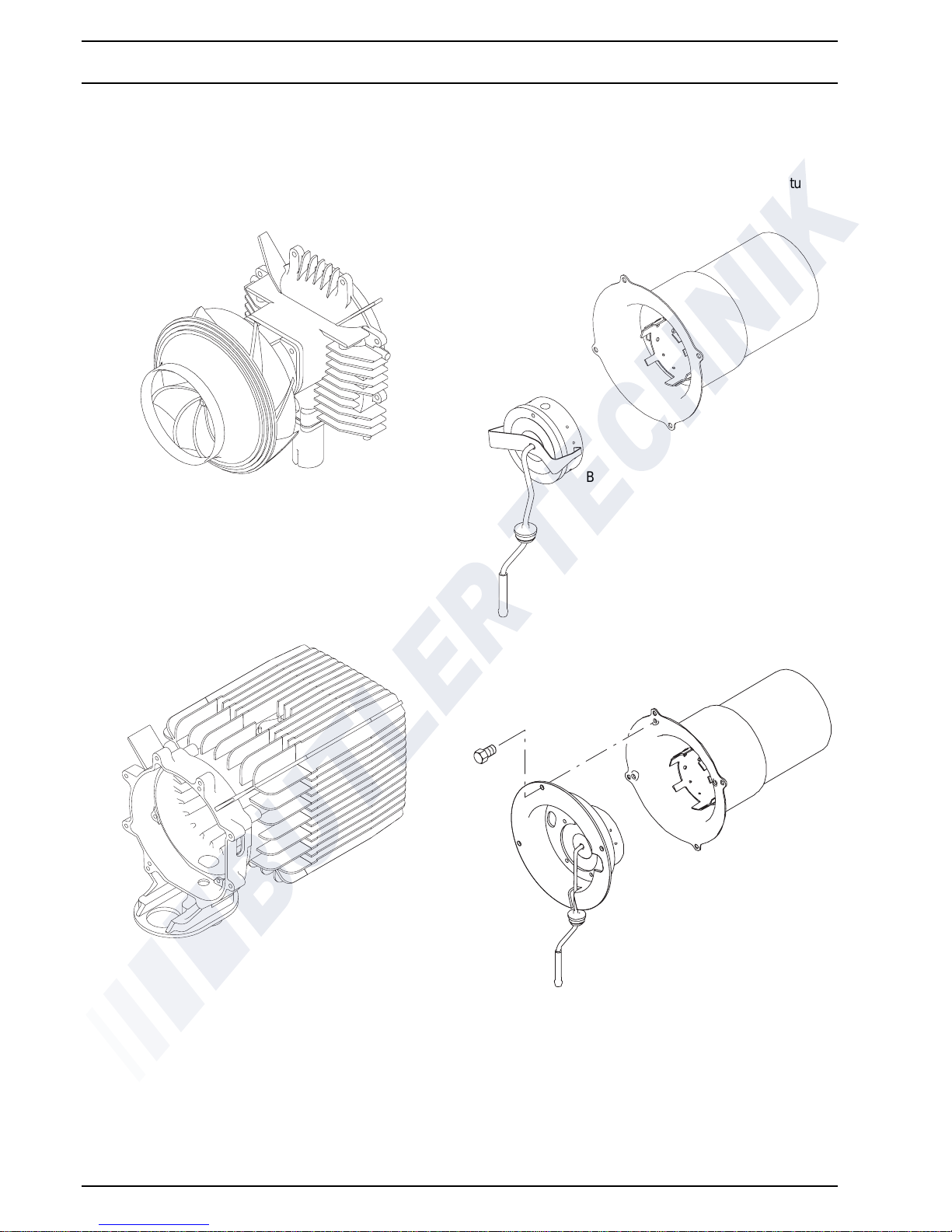

2.4 Control Unit

The control unit ensures control and monitoring of

combustion operation. A temperature sensor plugged on

the control unit is used for temperature control. On all

heaters this temperature sensor may be substituted with

an externally mounted temperature sensor.

In case of a heater malfunction an error code is output

to the display of the combination timer. When equipped

with a control element, the operating indicator light will

flash.

The heater may be additionally checked using a personal

computer (refer to operating instructions for PC heater

fault diagnosis).

2.5 Glow Plug / Flame Sensor

The glow plug also functions as flame sensor.

The glow plug ignites the fuel/air mixture during heater

start. The glow plug represents an electrical resistance

and is located on the side of the burner exposed to the

flame.

When operating as a flame sensor the glow plug behaves

like a low Ohm PTC resistor changing its resistance

dependent on its heat-up by the flame.

The signals are routed to the control unit for processing.

The flame sensor monitors the flame-up condition

throughout the heater time of operation.

2.6 Analogue Temperature Limiter

The analogue temperature sensor protects the heater

against undue high operating temperatures. For

protection against overheating the temperature limiter

responds at a heating air temperature higher than

150° C. The control unit disconnects the dosing pump

circuit and deactivates the heater with a run-down. After

cooling down the circuit is re-established. The heater may

be reactivated by switching the heater off and on again

using the control element.

2.7 Dosing Pump

The dosing pump is a combined delivery, dosing and

shut-off system for the fuel supply of the heater out of the

vehicle fuel tank.

2 General Description

Air Top 3500/5000

204

Page free for notes

Air Top 3500/5000

3 Functional Description

301

3 Functional Description

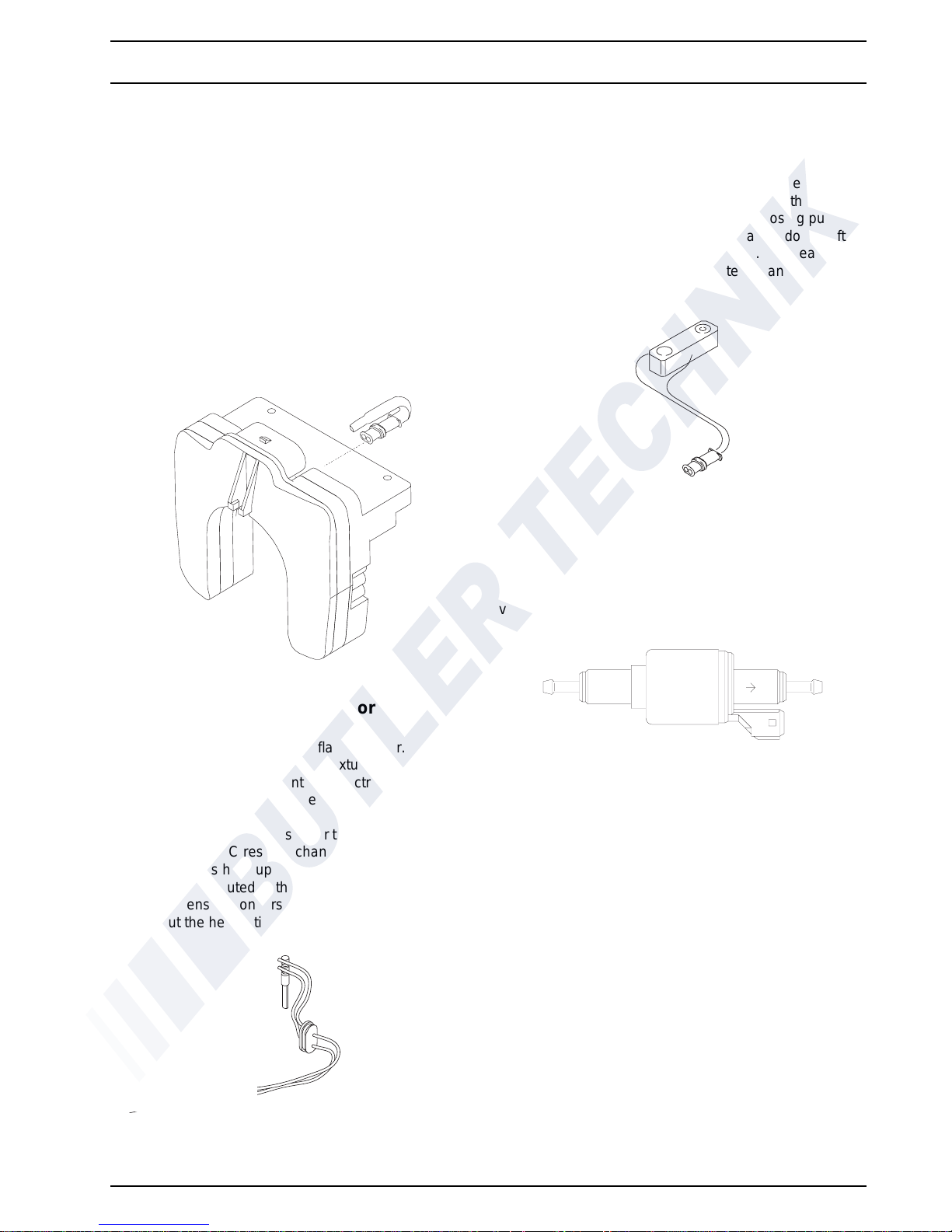

(Fig. 301)

3.1 Control Element

The control element is used to switch the heater on and

off, to set the desired room temperature (air intake

temperature between 5° C and 35° C), to reset the heater

after a malfunction with error lockout and to adjust the

CO

2

value.

The integrated green LED indication is used as

• operating indicator light (LED permanently on)

• error code/overheat indicator (LED flashes)

NOTE

Only applicable to ADR operation!

When applying electrical power with the control element

still set to "on", e.g. by closing the battery switch, the

control unit will go in error lockout. For re-activation the

control element must be momentarily switched off and on

again.

3.2 Switch on

The control element is to be set to the desired

temperature. When switching the heater on the operating

indicator light will illuminate. The motor of the combusti on

and heating air fan runs up at low speed.

NOTE

If the temperature of the combustion air taken in exceeds

the set temperature, the heater will enter control idle. With

the combustion air temperature below the set

temperature, the starting sequence commences.

The function of the glow plug/flame sensor is checked.

Should the glow plug/flame sensor already signal at this

stage "bright" for longer than 60 seconds, there will be a

150 second run-down and an error lockout of the control

unit. A malfunction of another component monitored

causes an error lockout without run-down.

Start

The glow plug/flame sensor is activated. After

approximately 22 seconds the dosing pump is put into

operation and combustion commences. After

116 seconds the glow plug is deactivated and the flame

sensor becomes active. After 136 seconds a check is

performed to verify a proper burning of the flame.

Detection of a flame will cause the flame to be stabilised

for 50 seconds by burning at 1.5 kW.

No flame detection will initiate a repeat start.

2nd Start (Repeat Start)

For this purpose the dosing pump is switched off and the

glow plug is activated. After 40 seconds the dosing pump

is reactivated.

After another 40 seconds the glow plug is deactivated and

20 seconds later the flame is checked. Detection of a

flame will cause the flame to be stabilised for

approximately 50 seconds by burning at 1.5 kW.

Should flame detection at that time be still negative, there

will be a run-down of the combustion and heating air fan

at full speed (approx. 5000 rpm) with an error lockout after

180 seconds.

NOTE

After the first repeat start the heater enters an error

lockout condition. For error lockout reset the heater must

be switched off (at least for 2 seconds) and switched on

again.

3 Functiona l Description

Air Top 3500/5000

302

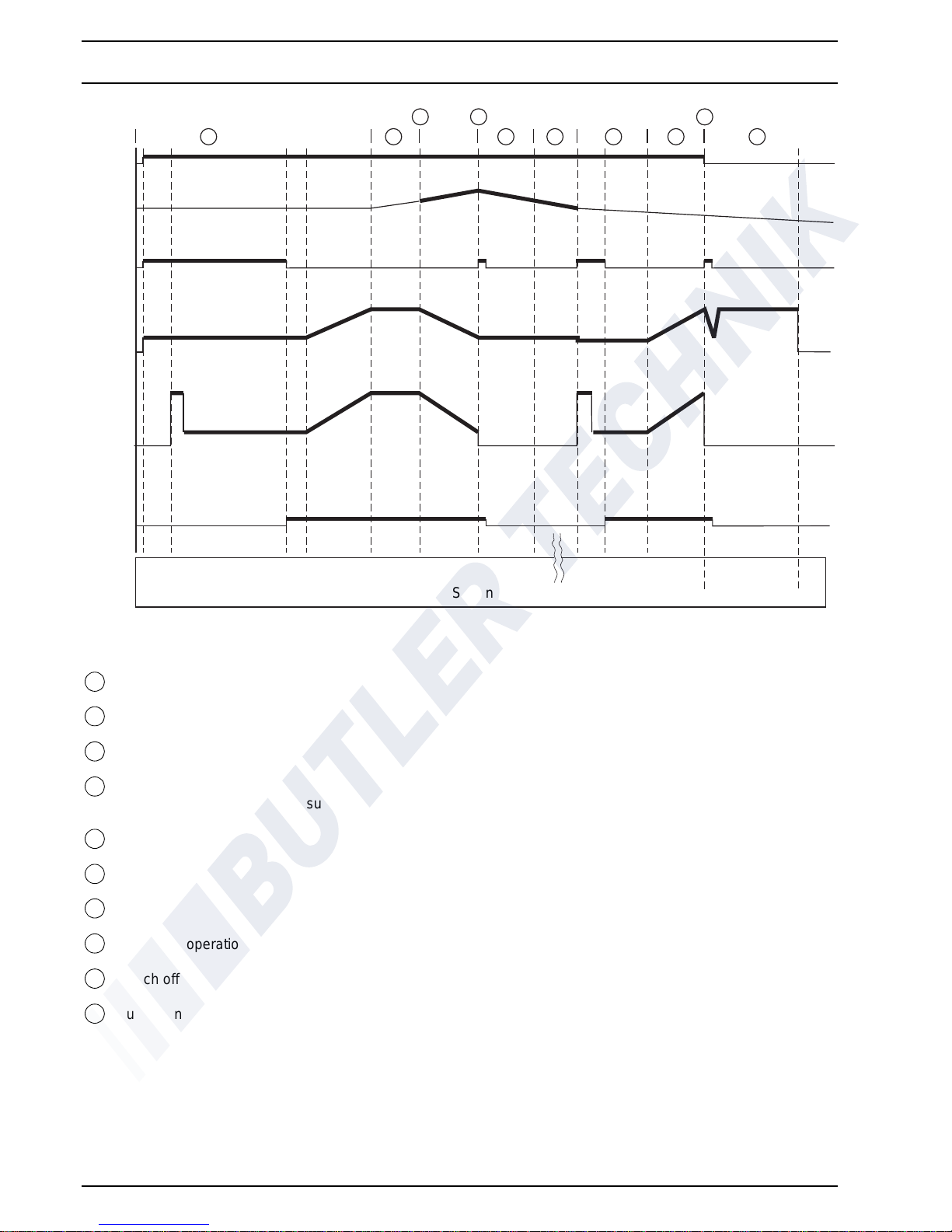

1Start

2 Controlled operation

3 Rated (set) value achieved

4 Rated (set) value exceeded

(e.g. due to reduced heat consumption)

5 Run-down

6 Control id le

7Start

8 Controlled operation (increased heat consumption)

9 Switch off

10 Run-down

A

= Control element

B

= Temperature sensor

C

= Glow plug

D

= Combustion and heating air fan

E

= Dosing pump

F

= Flame sensor

Fig. 301 Functional Diagram

Ein

A

0

1

1 2

3 4

5 6 7 8

9

10

B

C

0

1

100%

90%

60%

30%

0

D

2,0 (2,8)* Hz

0,5 Hz

0

E

F

0

1

020

116

124

174

Sekunden

(180)

*) AT5000

Seconds

on

on

Loading...

Loading...