Page 1

Air Heater

Air Top 2000 ST D (Diesel)

Air Top 2000 ST B (Gasoline)

Service and Repair Manual

– Improper installation or repair of Webasto heating and cooling systems can cause

fire or the leakage of deadly carbon monoxide leading to serious injury or death.

– Installation and repair of Webasto heating and cooling systems requires special

Webasto training, technical information, special tools and special equipment.

– NEVER attempt to install or repair a Webasto heating or cooling system unless you

have successfully completed the factory training course and have the technical skills,

technical information, tools and equipment required to properly complete the

necessary procedures.

– ALWAYS carefully follow Webasto installation and repair instructions and heed all

WARNINGS.

– Webasto rejects any liability for problems and damage caused by the system being

installed by untrained personnel.

Page 2

Page 3

AIR TOP 2000 ST TABLE OF CONTENTS

Contents Page

1. Introduction 1

1.1 Contents and Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Use of the Air Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Meaning of Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 Safety Information and Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.4.1 Statutory Regulations and Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.4.2 General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Suggestions for Improvements and Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. General Description 5

2.1 Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Burner Insert with Combustion Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Flame Sensor (Gasoline Heaters Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 Ceramic Glow Pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7 Overheating Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.8 Fuel Metering Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Functional Description 9

3.1 Control Element (Rheostat). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2 Switch On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.3 Heating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Control Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.5 Control Pause. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Switch Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.7 Fault Lock-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.7.1 Error Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.7.2 Reset a Fault Lock-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4. Technical Data 13

5. Troubleshooting 15

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 General Error Symptoms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.3 Error Symptoms during Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.4 Error Code Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6. Functional Tests 21

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6.2.1 Setting the CO2 Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 Testing Individual Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.1 Ceramic Glow Pin Resistance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.2 Resistance Test on Flame Sensor (gasoline heaters only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6.3.3 Overheating Sensor Resistance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7. Circuit Diagrams 23

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

www.webasto.us I Webasto Product N.A., Inc.

Page 4

TABLE OF CONTENTS AIR TOP 2000 ST

8. Servicing Work 27

8.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.2 Work on the Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.3 Work on the Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.4 Heater Trial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.5 Servicing Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.6 Visual Inspections and Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.6.1 Hot Air System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.6.2 Fuel Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

8.6.2.1 Fuel Extractor (Standpipe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

8.6.2.2 Fuel Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8.6.3 Fuel Metering Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8.6.3.1 Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8.6.3.2 Installation and Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8.6.4 Fuel Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8.6.5 Combustion Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

8.6.6 Exhaust Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

8.6.7 Combustion Air Inlet and Exhaust Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

8.6.8 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.6.8.1 Heater Connection, Control Element. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.6.8.2 Supply Voltage Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.6.8.3 Control Element (Rheostat) Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.7 Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8.7.1 Heater, Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8.7.1.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8.7.1.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8.8 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

9. Repair 35

9.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

9.1.1 Work on Stripped-down Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

9.1.1.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

9.1.1.2 Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

9.1.2 Remove the Casing Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.1.2.1 Installation of an External Temperature Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

9.2 Dismantling and Assembling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.1 Remove the Casing Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.1.1 Cover for Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.1.2 Grates for Hot Air Inlet and Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.1.3 Cover for Hot Air Inlet and Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.1.4 Top Shell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.1.5 Bottom Shell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.2 Fit the Casing Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.2.1 Bottom Shell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.2.2 Top Shell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.2.3 Cover for Hot Air Inlet and Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.2.4 Grates for Hot Air Inlet and Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.2.5 Cover for Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2.3 Changing the Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

9.2.3.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

9.2.3.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Webasto Product N.A., Inc. II www.techwebasto.com

Page 5

AIR TOP 2000 ST TABLE OF CONTENTS

9.2.4 Changing the Overheating Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.2.4.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

9.2.4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

9.2.5 Changing the Combustion Air Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.2.5.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

9.2.5.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

9.2.6 Changing the Flame Sensor (gasoline heaters only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.2.6.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.2.6.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.2.7 Changing the Ceramic Glow Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.2.7.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.2.7.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.2.8 Changing the Burner Insert, Combustion Pipe and the Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

9.2.8.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

9.2.8.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

10.Product Information 45

www.webasto.us III Webasto Product N.A., Inc.

Page 6

AIR TOP 2000 ST INTRODUCTION

1. INTRODUCTION

1.1 CONTENTS AND PURPOSE

This repair shop manual is intended to assist trained

personnel with repairing both the gasoline and the diesel

versions of the Air Top 2000 ST air heaters.

1.1.1 USE OF THE AIR HEATERS

The Webasto Air Top 2000 ST air heaters are designed

– to heat cabins, boats, trucks, minibuses, vans,

ambulances and motor homes.

– to defrost vehicle windows.

They are not designed for heating cargo areas used to

carry hazardous substances.

The heaters operate independently of the engine and are

connected to the fuel tank and the electrical system of

the vehicle.

They are not designed for installation in vehicles with

water or air-cooled engines.

1.3 ADDITIONAL DOCUMENTATION

This workshop manual contains all the information and

instructions required for repairing Air Top 2000 ST air

heaters. The use of additional documentation is not

normally required. If necessary, the operating /

installation instructions and the installation suggestion

for the specific vehicle may also be used.

1.4 SAFETY INFORMATION AND REGULATIONS

In principle, the general accident prevention regulations

and current works safety instructions are applicable.

The “General safety regulations” that go beyond the

scope of the above regulations are stated below

(see 1.4.2).

Any special safety regulations relevant to this instruction

manual will be highlighted in the relevant sections or text

passages of the procedures.

1.4.1 STATUTORY REGULATIONS AND SAFETY

I

NSTRUCTIONS

1.2 MEANING OF SIGNAL WORDS

Throughout this manual, the signal words DANGER,

WARNING, CAUTION, and NOTE have the following

meanings:

DANGER: This heading and text style is

used to highlight that non-compliance with

instructions or procedures will cause

injuries or lethal accidents to personnel.

WARNING: This heading and text style is

used to highlight that non-compliance with

instructions or procedures may cause

injuries or lethal accidents to personnel.

CAUTION: This heading and text style is

used to highlight that non-compliance with

instructions or procedures may cause

damage to equipment.

NOTE: This heading and text style is used to

highlight and draw attention to information we

feel you would like to have. It could have to do

with procedures and tips that will help you work

more efficiently.

NOTE: The provisions of these Directives are

binding within the United States of America by

FMCSA Directive 393.77 and should similarly be

observed in countries without specific

regulations.

Extract from the Federal Motor Carrier Safety

Administration

Part 393: Parts and Accessories Necessary for Safe

Operation

§393.77 Heaters

(b)(15) Certification required.

Every combustion type heater, shall be marked plainly to

indicate the type of service for which such heater is

designed and with a certification by the manufacturer

that the heater meets the applicable requirements for

such use. For example, "Meets FMCSA Bus Heater

Requirements.”

1.4.2 GENERAL SAFETY INFORMATION

The mouth of the exhaust pipe should be installed

upwards, to the side or, if the exhaust pipe passes under

the floor of the vehicle, to the side or rear limit of the

driver’s cab or the vehicle.

www.webasto.us 1 Webasto Product N.A., Inc.

The function of important parts of the vehicle must not

be adversely affected. It must not be possible for

condensate or water to collect in the exhaust pipe. Drain

holes may be used.

Page 7

INTRODUCTION AIR TOP 2000 ST

The electric cables and controls for the air-conditioning

system must be arranged in the vehicle so that their

proper functioning cannot be adversely affected in

normal operating conditions.

The following points for the installation of fuel lines and

the installation of additional fuel tanks must be observed.

• Fuel pipes must be designed in such a way that

torsion in the vehicle, movements by the engine and

the like do not have a negative effect on their

durability. They must be protected from mechanical

damage.

• Parts that carry fuel must be protected from heat

that will adversely affect their function and

positioned so that dripping or evaporating fuel

cannot collect or ignite on hot parts or on electrical

equipment.

• The fuel lines (Mecanyl hose) must not be

immediately next to the exhaust pipe and must be

thermally insulated if necessary, otherwise they will

pose a fire risk.

• All pipes that come into contact with fuel must have

sealed connections, they must not be damaged in

any way and the must be checked at regular intervals

(at least the same intervals as for inspection of the

vehicle as a whole).

NOTE: If any damage or leaks are found on

the fuel line, the heater must not be used until

the damage has been rectified by an authorized

Webasto workshop.

Put the heater out of action by removing the

fuse.

Installation regulations for Webasto fuel tanks for

supplying fuel to heaters in vehicles:

• The tank must not be installed in the passenger or

driver’s cabin of buses.

• The fuel filler neck must not be inside the passenger

or driver’s cabin in any vehicle.

• Fuel tanks for normal or super grades of petrol must

not be immediately behind the front trim of the

vehicle. They must be separated from the engine in

such a way that in the event of an accident the fuel

will not be expected to ignite. This does not apply to

tractor units with an open driver’s seat.

The air heater’s heat exchanger can be used for a

maximum of 10 years and must then be replaced by the

manufacturer or one of its authorized workshops using a

genuine spare part. A label must then be affixed to the

heater showing the date of sale and the wording

“Genuine spare part”.

When you change the heat exchanger it is essential that

you also replace the overheating protection element

(overheating sensor) to prevent possible function faults

caused by using the old overheating sensor.

The Air Top 2000ST air heaters are prepared for interior

installation and sealing directly on the cabin floor or a

cabin wall. Non-release connections must be used in the

interior for combustion air and exhaust pipes with the

accessories available from Webasto.

The seal between the heater mounting and the vehicle

floor must always be installed; otherwise harmful

emissions may get into the interior of the vehicle.

The hot and combustion air intake openings must be

positioned in such a way that no water can ingress into

them if the vehicle drives through a water hazard for

which it has been approved.

For passenger carrying vehicles such as shuttle busses,

transit busses, and coaches, where the heater is to be

installed in the passenger cabin, a protective cover or

installation box should be installed over the heater to

prevent contact with hot surfaces by passengers and

heat sensitive objects.

The protective cover or installation box must have

sufficient external ventilation to ensure that a maximum

temperature of 40°C (104°F) is not exceeded in the box.

Malfunctions may occur if the temperature exceeds this

level.

The heater must be switched off at filling stations and

fuel tank farms because of the risk of explosion.

Wherever inflammable vapors or dust may form (for

example near fuel, coal, wood dust or cereal stores or the

like), the heater must be switched off because of the risk

of explosion.

The heater must not be operated in enclosed areas, such

as garages or workshops without an exhaust emissions

extraction system, not even using the timer, because of

the risk of asphyxiation and poisoning.

In the event of lengthy heavy smoke development,

unusual combustion noise or a smell of fuel, the heater

must be put out of action by removing the fuse and must

not be started again until it has been examined by

Webasto-trained personnel. Liability claims can only be

lodged if the claimant can prove that he has complied

with the servicing and safety instructions.

Overheating

Keep hot air inlet and hot air outlet free of dirt and other

items. Dirty, blocked air lines can cause the heater to

shut down due to overheating.

After an overheating lock-out, check that the air system

is clear, remove any materials that may block the air flow

and have any damage to the air lines repaired by an

Webasto Product N.A., Inc. 2 www.techwebasto.com

Page 8

AIR TOP 2000 ST INTRODUCTION

authorized Webasto workshop. After this the heater

lock-out can be cancelled by switching it off and then on

again. If this action does not produce the required

success (if the heater overheats again) take it to a

Webasto-authorized workshop. Never remove the

grating over the air inlet of the heater.

The air outlet jets or air vents with adjustable flaps must

always be opened to some extent so that the air flow

through the heater is not completely blocked. At least

one air vent must be prevented from being closed.

If the heater is installed in a storage area, you must

ensure that no inflammable substances are kept in this

area and that other material does not restrict the air

supply to the heater.

Air lines must be securely fixed to the heater (using pipe

clips, for example) and all other connection points (for

example vents).

IMPORTANT! The errors described below are to

be avoided at all costs:

• Do not stand on the heater or place or throw any

heavy objects on the heater.

• Do not place any items of clothing, textiles or similar

materials over the heater or in front of the hot air

inlet side and hot air outlet.

• The flow of hot air from the heater must not be

restricted or blocked by highly inflammable

substances or materials such as rags, cleaning wool,

etc.

• Inflammable or explosive substances and gases must

not be placed near or in contact with the heater, the

hot air line, the flow of hot air or the exhaust pipe.

• The heater must not be cleaned with a high pressure

cleaner.

• Do not switch the heater off at the main battery

switch or battery isolation switch since otherwise it is

possible that it may suffer long term damage if it is

switched off frequently using the battery isolation

switch and this can cause damage and negative

influences on the function of the heater.

NOTE: Failure to follow the installation

instructions and the notes contained therein will

lead to all liability being refused by Webasto

The same applies if repairs are carried out

incorrectly or with the use of parts other than

genuine spare parts. This invalidates the type

approval for the heater and its homologation /

EC type permit.

You must read the operating manual before starting the

heater for the first time.

1.5 SUGGESTIONS FOR IMPROVEMENTS AND

CHANGES

Complaints, improvement suggestions or corrections

relating to this workshop manual should be addressed to

Webasto Product North America, Inc.

Technical Documentation Group

15083 North Road

Fenton MI 48430

Phone: 810.593.6000

Fax: 810.593.6001

www.webasto.us 3 Webasto Product N.A., Inc.

Page 9

AIR TOP 2000 ST GENERAL DESCRIPTION

2. GENERAL DESCRIPTION

The Air Top 2000 ST air heater is based on the evaporator

principle and essentially consists of the following:

– the drive unit with a combustion and hot air blower

– the heat exchanger

– the burner insert with combustion pipe

– the control unit

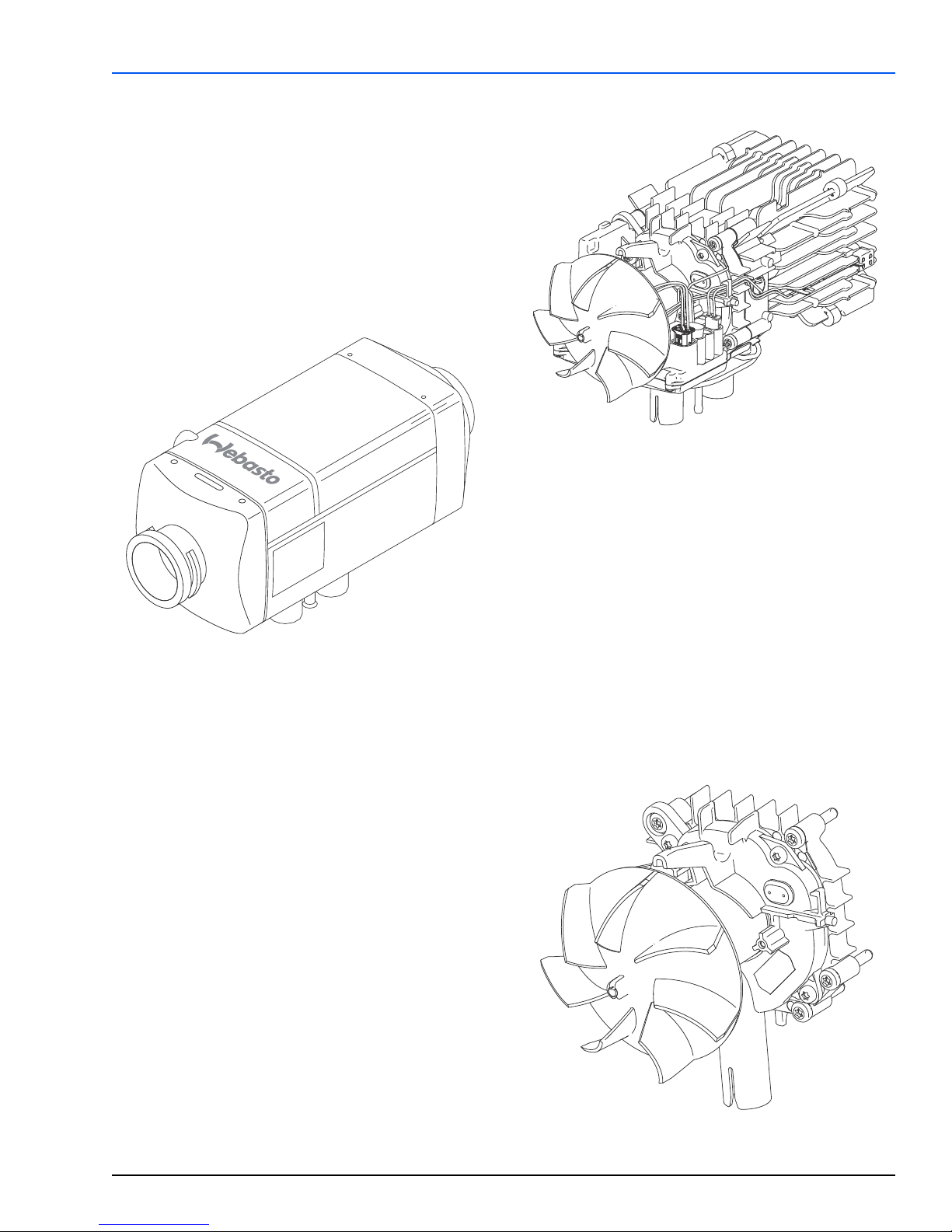

Figure 2: Air Top 2000 ST Air Heater without Casing

Figure 1: Air Top 2000 ST Air Heater

To control and monitor it, the heater has

– a control unit with temperature sensor

– a flame sensor (gasoline heaters only)

– a ceramic glow pin

– an overheating sensor

inside it.

All Air Top 2000 ST heaters can also be controlled using

an external temperature sensor.

The fuel supply is provided from an external source using

a metering pump.

If a fault occurs, an error code will be output in the

display of the combination or standard timer. If the

heater has a control element, the ON control light will

flash.

2.1 DRIVE UNIT

The drive unit consists of the drive motor, the

combustion air blower, the heat air blower and the

intake casing.

The combustion air blower supplies the air required for

the combustion process from the combustion air inlet to

the burner insert.

The removable hot air blower transports the hot air from

the hot air inlet via the heat exchanger to the hot air

outlet.

In addition, the heater can be checked using a personal

computer (see PC heater diagnostic operating manual).

www.webasto.us 5 Webasto Product N.A., Inc.

Figure 3: Drive Unit

Page 10

GENERAL DESCRIPTION AIR TOP 2000 ST

Burner insert

Combustion

pipe

Internal

temperature sensor

Wiring

harness

Component

plug sockets

2.2 HEAT EXCHANGER

The heat generated by the combustion process is

transferred to the air transported by the combustion and

hot air blowers in the heat exchanger.

2.4 CONTROL UNIT

The control unit is the central component for ensuring

the function is maintained and for monitoring the

heater’s operation. A temperature sensor in the control

unit is designed to control the room temperature. An

external temperature may also be connected to all the

heaters.

If a fault occurs, an error code will be output in the

display of the combination timer. If the heater has a

control element, the ON control light will flash.

In addition, the heater can be checked using a personal

computer (see PC heater diagnostic operating manual).

Figure 4: Heat Exchanger

2.3 BURNER INSERT WITH COMBUSTION PIPE

The fuel is distributed over the burner cross-section in the

combustion pipe in the burner insert. The mixture of fuel

and air burns in the combustion pipe, thus causing the

heat exchanger to become hot.

Figure 6: Control Unit

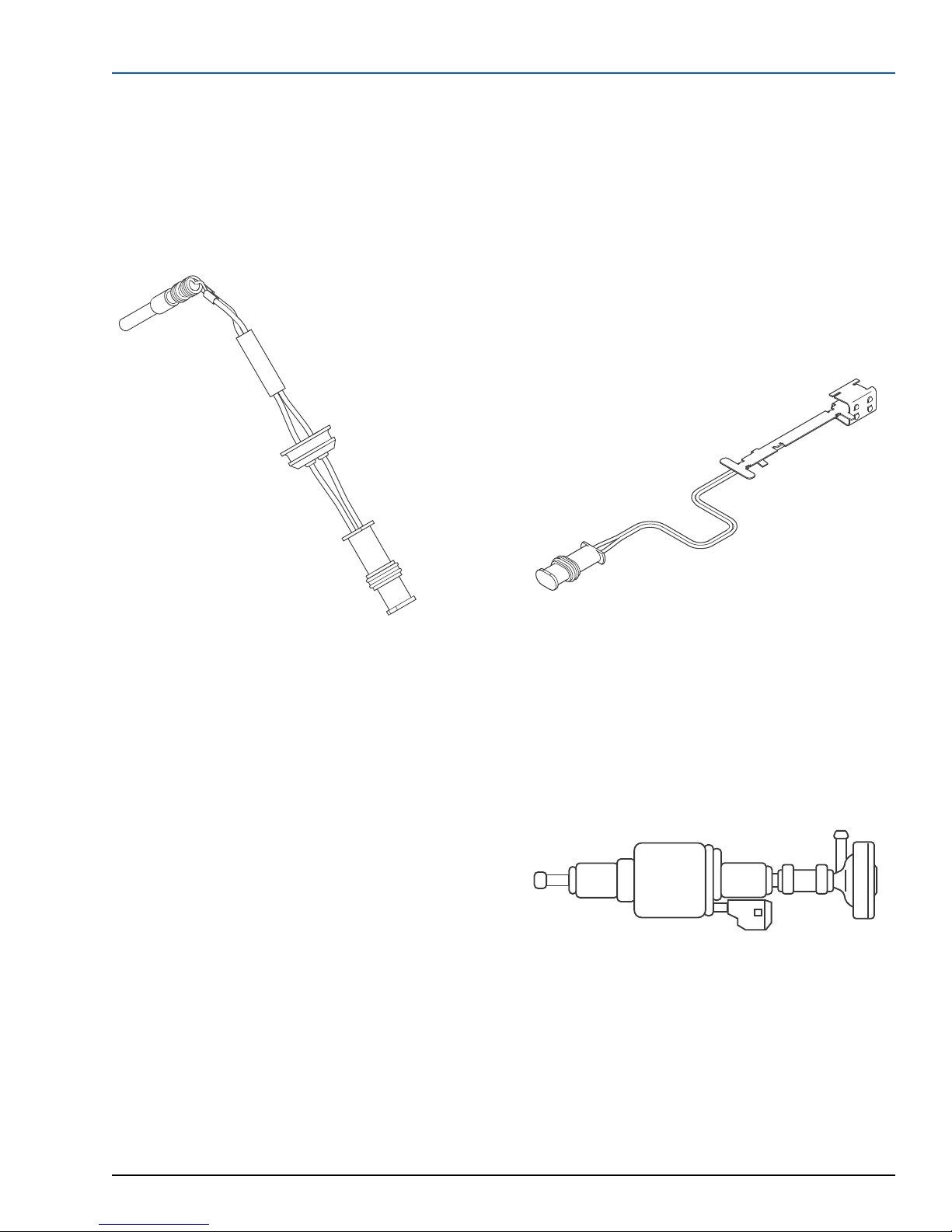

2.5 FLAME SENSOR (GASOLINE HEATERS ONLY)

The flame sensor is a low-ohm PTC resistor, which

changes its resistance depending on the heat emitted by

the flame.

This change in resistance is analyzed by the control unit

so that the flame status is monitored whenever the

heater is operating.

Figure 5: Burner Insert with Combustion Pipe

Webasto Product N.A., Inc. 6 www.techwebasto.com

Figure 7: Flame Sensor

Page 11

AIR TOP 2000 ST GENERAL DESCRIPTION

2.6 CERAMIC GLOW PIN

The mixture of fuel and air is ignited by the glow plug

when the heater is started. The glow pin takes the form

of an electrical resistor and is positioned in the burner

insert on the side away from the flame.

2.7 OVERHEATING SENSOR

The overheating sensor measures the temperatures in the

rib area of the heat exchanger whenever the heater is

operating. The control unit evaluates the signal and

protects the heater from hot air outlet temperatures

above 150 °C and surface temperatures above 80 °C by

shutting down the combustion process and blowing cold

air over the heater.

The heater then suffers a fault lock-out and can be

restarted by being switched off and then on again (see

3.2).

Figure 8: Ceramic Glow Pin

Figure 9: Overheating Sensor

2.8 FUEL METERING PUMP

The metering pump is a combined transport, metering

and shut-off system for supplying fuel from the vehicle’s

tank to the heater.

Figure 10: Fuel Metering Pump DP 30.2/3 (with Damper)

www.webasto.us 7 Webasto Product N.A., Inc.

Page 12

AIR TOP 2000 ST FUNCTIONAL DESCRIPTION

3. FUNCTIONAL DESCRIPTION

3.1 CONTROL ELEMENT (RHEOSTAT)

The control element is designed to switch the heater on

and off, adjust the required room temperature (intake

temperature between 5 °C and 35 °C) and to reset the

heater after a fault.

The green LED serves as the On indicator (LED

permanently lit up) and as a fault signal (LED flashes).

3.2 SWITCH ON

Set the control element to the required temperature.

If the hot air temperature is lower than the nominal

temperature, the heater will start.

NOTE: If the temperature of the hot air intake

is above the set nominal temperature, only the

motor for the hot and combustion air blower

will start (control pause). Special feature: The

control pause speed is 0 rpm if boat heaters are

used.

The function of the flame sensor is checked. If

the flame sensor now reports “light”, the

system will attempt to cool the flame sensor for

60 seconds. If the flame sensor still reports

“light” the control unit will suffer a fault lockout. If another monitored component has

suffered a fault, the fault lock-out will take

effect without any slow down time.

Start

When the heater is switched on, the ON signal light will

be lit and the glow plug will be switched on (cycled). The

motor for the hot and combustion air blower will be set

to approx. 50% of its maximum speed.

After approx. 40 seconds the fuel metering pump will

start, and the flame formation will begin. To improve the

starting quality the metering pump and combustion air

blower are started with different frequencies and speeds.

After a further 95 seconds (gasoline) or 110 seconds

(diesel) the glow pin will be switched off and the

existence of the flame established.

Automatic Restart

If no flame is detected, the starting procedure will be

repeated. The glow plug will be switched on again

(cycled). The motor for the hot and combustion air

blower will be set to approx. 25% of its maximum speed.

After approx. 30 seconds (petrol) or 50 seconds (diesel)

the fuel metering pump will start, and the flame

formation will begin. After a further 65 seconds (petrol)

or 90 seconds (diesel) the glow plug will be switched off

and the existence of the flame established.

If the heater has again failed to ignite properly, the

heater will be shut down using a fault slow down

procedure at maximum speed after 180 seconds and will

suffer a fault lock-out.

NOTE: After a restart the heater will suffer a

fault lock-out. To reset the fault switch the

heater off briefly (min. 2 seconds) and switch

back on.

3.3 HEATING MODE

While the heater is operating, the combustion gases pass

through the heat exchanger. During this process the

combustion heat is given off to the walls of the heat

exchanger, absorbed by the hot air transported by the

hot air blower and fed into the interior of the vehicle.

The temperature of the hot air intake is measured by a

temperature sensor on the intake side of the heater or an

external temperature sensor. If the measured

temperature is lower than the value set on the control

element, the output of the heater is increased to

maximum heat output.

To increase the burner service life when it is used

continuously the transport capacity of the metering

pump is reduced for 10 seconds every 10 minutes.

In addition, heating mode is interrupted every 8 hours in

the same way as for a control pause.

3.4 CONTROL MODE

In control mode the blower speed and the metering

pump delivery rate are dependent on the heat output.

The glow pin is switched off.

www.webasto.us 9 Webasto Product N.A., Inc.

Page 13

FUNCTIONAL DESCRIPTION AIR TOP 2000 ST

3.5 CONTROL PAUSE

After the temperature set on the control element has

been reached, the heat output is reduced. The speed of

the heating and combustion air blower and the delivery

rate of the metering pump are reduced.

If, at minimum heat output, the intake temperature set

on the control element is exceeded, the metering pump

is shut down and the combustion process ended. To

burn off the flame properly the blower speed falls after

20 seconds to low-fire rate speed and then returns to the

initial speed after 15 seconds, after which it falls to the

control pause speed in 3 minutes, where it remains for

the entire control pause.

The control pause speed on boat heaters is 0.

If the temperature set on the control element is not

observed at the temperature sensor, the heater will

restart.

NOTE: Changes to the setting on the control

element are implemented by the control unit

and heater after a delay.

3.6 SWITCH OFF

3.7 FAULT LOCK-OUT

The control unit has identified errors on individual heater

components and faults during the starting procedure and

in operation. The heater is switched off and goes into

fault lock-out if the following conditions occur:

• No repeated or incorrect start

• Temperature sensor defective

• Overheating sensor interrupt or short circuit

• Overheating sensor installed incorrectly

• Glow pin interrupt or short circuit

• Blower motor overload or blocked or short circuit or

break

• Flame sensor interrupt or short circuit

• Error in the metering pump or overheating guard

circuit (start phase only)

• Under voltage below 10.5 V / 21 V for longer than

20 seconds

• Over voltage above 16 V / 32 V for longer than 6

seconds

• Control module defective

When the heater is switched off, the ON control LED on

the control element goes out. If no fuel has been

transported or if the heater is in the control pause, the

heater is switched off immediately without a slow down

time.

If the fuel transport has been started, it is ended

immediately when the heater is switched off. The heater

is switched off using the same method as the transition

from control mode to control pause. The device is then

switched off automatically.

NOTE: The heater may be switched on again

during the slow down time. In this case the

slow down time is completed and the heater is

then restarted.

The fuel supply is stopped if the heater overheats. The

heater continues to run in the same way as if it is

switched off manually. After it stops the control unit will

be set to fault lock-out. After the slow-down phase the

control module is set to fault lock-out if the overheating

counter is greater than the value programmed in the

data record (currently 20).

The overheating is indicated by the indicator flashing

10 times.

Rectify the cause of the fault.

To reset the fault, switch the heater off briefly (at least

2 seconds) and then on again.

Webasto Product N.A., Inc. 10 www.techwebasto.com

Page 14

AIR TOP 2000 ST FUNCTIONAL DESCRIPTION

3.7.1 ERROR MONITOR

The overheat, incorrect start and flame failure errors are

counted and cause the heater to suffer a fault lock-out

after an error has occurred the maximum number of

times.

The incorrect start counter FSZ is incremented by 1 each

time the heater fails to start and decremented by 1 each

time it starts correctly, but does not fall below 0. If the

incorrect start counter reaches its maximum value of 7,

the heater will go into the heater lock-out status HGV.

The error counter SZ is incremented by 1 with each error

for which there is no separate counter. The error counter

is reset to 0 at the start of control mode. If the error

counter reaches its maximum value of 10, the heater will

go into the heater lock-out status HGV.

The overheating counter ÜHZ is incremented by 1 each

time the heater overheats. If the overheating counter

reaches its maximum value of 20, the heater will go into

the heater lock-out status HGV.

The flame failure counter FAZ is increased by 1 each time

the flame fails during heating mode. The counter is

decremented by 1 each time the heater is in control

mode.

If the FAZ reaches a value of 6, the heater will go into

fault lock-out mode and the permanent flame failure

counter FAZP will be incremented by 1. In control mode

the permanent flame failure counter FAZP will be

decremented by 1. When the heater is burning properly

again, the FAZP will return to 0 after a few control cycles.

If the permanent flame failure counter exceeds its

maximum value of 6, however, the heater will go to

permanent heater lock-out status (error code F13).

3.7.2 RESET A FAULT LOCK-OUT

The various fault lock-outs can be reset as follows.

Fault lock-out: Switch heater off using the

control element and then on

again after more than 2 sec.

Heater fault lock-out: Remove the fuse and reinsert it

Permanent heater

fault lock-out: Delete the error with the

PC diagnostic tool

www.webasto.us 11 Webasto Product N.A., Inc.

Page 15

AIR TOP 2000 ST TECHNICAL DATA

4. TECHNICAL DATA

Except where limit values are specified, the technical data

listed in the table refer to the usual heater tolerances of

±10% at an ambient temperature of +20 °C (+68 °F) and

at the rated voltage and in rated conditions.

Electrical components:

The control unit, combustion air blower (drive), metering

pump, timer, glow plug and control element are

designed for 12 V or 24 V.

The components temperature sensor and flame monitor

(only petrol heater) are not designed for a specific

voltage.

Fuel for Air Top 2000 ST B (gasoline):

The fuel specified by the manufacturer must be used.

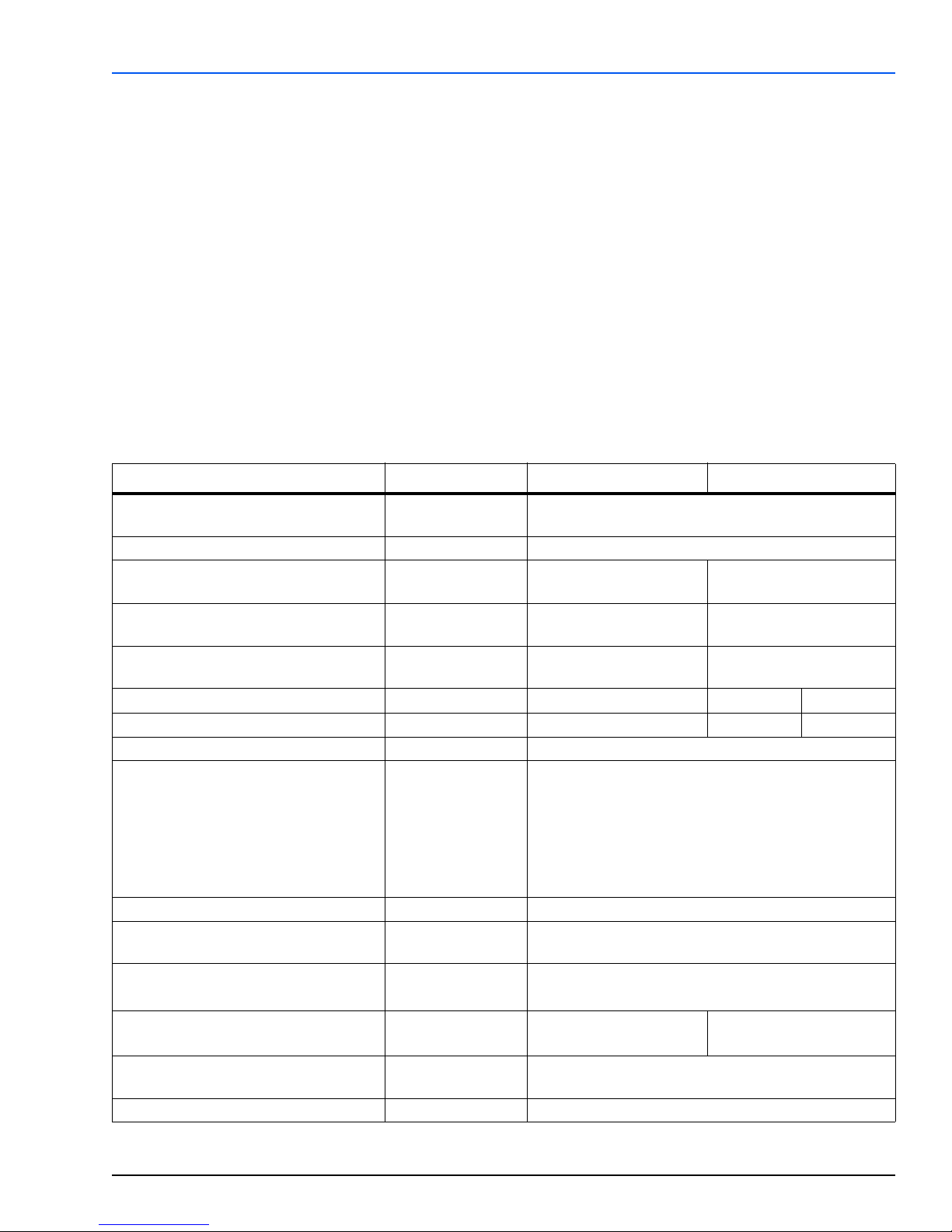

HEATER Operation AT 2000 ST B AT 2000 ST D

Typ e Te st Pe r mi t EM C

Heater

Model Air heater with evaporator burner

Heat Output kW

Btu/h

Fuel Gasoline Diesel #1, #2, Arctic, PME

Fuel Consumption l/h

gal/h – US

Rated Voltage 12 V 12 V 24 V

Operating Voltage Range V 10.5 - 16 V 10.5 - 16 V 21 - 32 V

Rated Power Consumption Control Range 14 - 29 Watts

Maximum Ambient Temperature:

Heater -operation

-warehouse

Dosing Pump -operation

-warehouse

Control Element -operation

-warehouse

Max. Combustion Air Inlet Temperature –40 °C... +20 °C (–40 °F... +68 °F)

Adjustment Range For Interior

Temperature

Delivery Rate For Hot Air At Fan Speed against 0.5 mbar

Co

In Exhaust Gas

2

(permanent function range)

Heater Dimensions

Length X Width X Height

Weight Of Heater 2.6 kg (5.73 lb)

Control Range 1.0 - 2.0 kW

Control Range 0.14...0.27

Control Range +5 °C... +35 °C (+41 °F... +95 °F)

against .00725 PSI

1 kW

2 kW

Fuel for Air Top 2000 ST D (diesel/PME):

The diesel fuel specified by the vehicle manufacturer

must be used.

We know of no negative influences due to additives.

If fuel is extracted from the vehicle’s tank, follow the

additive instructions issued by the vehicle manufacturer.

If you change to low-temperature fuel, the heater must

be operated for approx. 15 minutes so that the fuel

system is filled with the new fuel.

The Air Top 2000 ST D heater is also licensed for use with

PME (bio-diesel), which complies with ASTM D6751 and

DIN EN 14214.

e1*72/245*95/54*1085*--

e1*2001/56*0022*--

0.9 - 2.0 kW

3415 - 6830

0.037...0.071

–40 °C... +40 °C (–40 °F... +104 °F)

–40 °C... +85 °C (–40 °F... +185 °F)

–40 °C... +20 °C (–40 °F... +68 °F)

–40 °C... +85 °C (–40 °F... +185 °F)

–40 °C... +75 °C (–40 °F... +167 °F)

–40 °C... +85 °C (–40 °F... +185 °F)

Max. 93 m

Max. 55 cfm at 4750 rpm

5.0... 8.0

9.0... 12.5

311 mm L X 120 mm W X 121 mm H

12.25 in L X 4.72 in W X 4.76 in H

3

/h at 4750 rpm

3074 - 6830

and Kerosene

0.12...0.24

0.032...0.063

5.0... 8.0

9.0... 12.5

Table 1. Technical data

www.webasto.us 13 Webasto Product N.A., Inc.

Page 16

AIR TOP 2000 ST TROUBLESHOOTING

5. TROUBLESHOOTING

5.1 GENERAL

This section describes how to identify and remedy faults

on the Air Top 2000 ST air heater.

If a fault occurs, an error code will be output in the

display of the combination timer. If the heater has a

control element, the ON control light will flash. In

addition, the heater can be checked using a personal

computer (see PC heater diagnostic operating manual).

CAUTION: Troubleshooting work demands

precise knowledge of the structure and

theory of operation of the various

components and must be carried out by

trained personnel only.

If in doubt, refer to sections 2 and 3 for a description of

how the functions interact.

CAUTION: The troubleshooting guide is

restricted to the localization of defective

components. The following potential

sources of malfunctions have not been

included and should always be checked so

that they can then be excluded as the cause

of the particular fault:

• Corrosion on plugs

• Loose plug contacts

• Poor crimp contacts on plugs

• Corroded cables and fuses

• Corroded battery terminals

If you wish to check individual components, the electrical

plug connectors on the control unit must be

disconnected.

Conduct a function test in the vehicle after rectifying

each fault.

5.2 GENERAL ERROR SYMPTOMS

The following table lists the possible error symptoms.

Error Symptom Possible Cause Remedy

Heater cuts out automatically No combustion after start

and restart

ON indicator flashes

Flame extinguishes during operation

ON indicator flashes

Heater overheats

ON indicator flashes

Battery voltage too low

ON indicator flashes

Switch heater off and then on again

Switch heater off and then on again

Check that the hot air system is clear,

allow the heater to cool, switch heat off

briefly and then on again

Charge battery

Switch heater off and then on again

Heater produces black smoke Combustion air and/or exhaust system

Table 2. General Error Symptoms

www.webasto.us 15 Webasto Product N.A., Inc.

blocked

Check that the combustion air and

exhaust systems are clear

Page 17

TROUBLESHOOTING AIR TOP 2000 ST

5.3 ERROR SYMPTOMS DURING FUNCTION

The following table lists the possible error symptoms in

the order in which they may occur during operation.

In the event of a fault, the error is to be located using this

table and rectified. It is important that the error

symptom is correctly identified.

If the error symptom is not included in this table or the

fault is not found under the specific error symptom

heading, in an emergency you can contact our

technicians on our service hotline (see last page).

Error Symptom Occurrence Remedy

No start and no illumination of the

LED on the control element

No start but LED is lit Immediate The heater goes straight to control pause when

Immediate Incorrect cabling, defective fuse

There are statuses that are the same as errors.

NOTE: Every fault is indicated by the flashing

LED on the control element after the slow down

time has finished. If the other components are

OK, a defective control unit may be the cause of

all the faults.

it is switched on, whereby the control pause

speed is 0 rpm for a boat heater.

Table 3. Error Symptoms during Function

Webasto Product N.A., Inc. 16 www.techwebasto.com

Page 18

AIR TOP 2000 ST TROUBLESHOOTING

5.4 ERROR CODE OUTPUT

If the heater is fitted with a combination timer, an error

code output will appear on the display of the timer after

a fault occurs.

Error

Code

F 00 Control unit error 01 Control unit error

Error (group)

Additional Information during PC

Diagnostics

81 EOL checksum error

11 Incorrectly coded control unit or

incorrect heater (fuel type) installed (the

heater will not work if this error occurs)

91 Neutrally coded or disabled control unit

(the heater will not work if this error

occurs)

NOTE: The error code is output if the heater is

fitted with a control element after an error has

occurred by the switch-on indicator/error code

indicator flashing. After 5 seconds of fast

flashing, the error code will be output by a

sequence of long flash pulses, the number of

flashes is shown in the table below (for example

F04 – 4 long flash pulses).

Remedy

Replace control unit

92 Maintain command failed (the heater

will not work if this error occurs)

18 Customer bus defective

F 01 No start 02 Even after the restart, no flame has

formed

82 No start in test

F 02 Flame failure 03 The flame has gone out during

operation and has not reformed after a

restart attempt

83 The flame has gone out during a

heating cycle more than FAZ times

(EEPROM)

F 03 Under-voltage or

over-voltage

84 The voltage was less than 10.5 V or

21 V for longer than 20 seconds

04 The voltage was more than 16 V or

32 V for longer than 6 seconds

Check fuel supply

(tank empty, lines blocked)

Clean burner insert,

Gasoline:

Replace flame sensor

Diesel:

Replace overheating sensor / control unit

Check fuel supply

(tank empty, lines blocked)

Clean burner insert,

Gasoline:

Replace flame sensor

Diesel:

Replace overheating sensor / control unit

Charge battery

Table 4. Troubleshooting (page 1 of 3)

www.webasto.us 17 Webasto Product N.A., Inc.

Page 19

TROUBLESHOOTING AIR TOP 2000 ST

Error

Code

F 04 Premature flame

F 05 Flame sensor

F 06 External

F 07 Metering pump

F 08 Drive unit

Error (group)

recognition

interrupt or short

circuit

(gasoline heaters

only)

temperature sensor

break or short circuit

interrupt or short

circuit

(combustion and

hot air blower)

break or short circuit

Additional Information during PC

Diagnostics

05 A flame was detected before

combustion had started

1A Flame sensor circuit

The switched cable of the element has a

short circuit to earth

9A Flame sensor circuit

Break or short circuit to +Ub

14 Temperature sensor circuit

Short circuit to earth

94 Temperature sensor circuit break or

short circuit to +Ub

88 Break or short circuit to +Ub

08 Short circuit to earth

89 Break or short circuit to +Ub

09 The switched drive unit cable

(combustion and hot air blower) has a

short circuit to earth or the drive unit is

overloaded

Remedy

Diesel: Replace overheating sensor /

control unit

Gasoline: Replace flame sensor

Replace flame sensor

Replace flame sensor

Check cables / replace temperature sensor

Check cables and terminating resistor /

replace temperature sensor

Check cables / replace metering pump

Check cables / replace metering pump

Replace drive unit (combustion and hot air

blower)

Eliminate the cause of the blockage /

difficulty in movement

Replace drive unit (combustion and hot air

blower)

15 Burner motor block guard has tripped

95 Burner motor blocking detection has

tripped

F 09 Glow pin interrupt

or short-circuit

Table 5. Troubleshooting (page 2 of 3)

8A Glow pin:

Break or short circuit to +Ub

19 Glow circuit

The switched cable of the element has a

short circuit to earth

Replace glow pin

Replace glow pin

Webasto Product N.A., Inc. 18 www.techwebasto.com

Page 20

AIR TOP 2000 ST TROUBLESHOOTING

Error

Code

F 10 Overheating 06 The overheating fault lock-out has

F 11 Overheating sensor

F 12 Heater fault

Error (group)

interrupt or short

circuit

lock-out

Additional Information during PC

Diagnostics

tripped (heater overheated)

17 Incorrect application or illegal

insulation (ÜHS gradient too high)

AB Overheating sensor circuit break or

short circuit to +Ub

1B Overheating sensor circuit.

The switched cable of the element has a

short circuit to earth

07 The heater fault lock-out has been

activated

Remedy

Find and remove the cause of the

overheating

NOTE

If no other cause can be found for the

overheating, the pressure losses caused by

the hot air distribution (too many

resistance points) are too high or a hot air

filter is soiled

Replace overheating sensor

Replace overheating sensor

Remove the fuse and then refit it

NOTE

The following error has occurred several

times:

Fault counter more than

3 times

Incorrect start counter more than

9 times

Overheating counter more than

3 times

F 14 Overheating sensor

incorrect position

F 15 Nominal sensor

break

Table 6. Troubleshooting (page 3 of 3)

97 Incorrect position of overheating

sensor (ÜHS gradient too low)

9B Nominal value potentiometer circuit

break or short circuit to +Ub

Position the overheating sensor correctly

Check cables / replace control element

www.webasto.us 19 Webasto Product N.A., Inc.

Page 21

AIR TOP 2000 ST FUNCTIONAL TESTS

6. FUNCTIONAL TESTS

6.1 GENERAL

This section describes the tests conducted on the heater

when it is installed and not installed to verify that it is in

working order.

WARNING: The heater must not be

operated in enclosed areas such as garages

and workshops without an emissions

extraction system.

6.2 SETTINGS

6.2.1 SETTING THE CO2 CONTENT

The CO2 content in the emissions is set using the

adjustment knob on the control element. At a constant

blower speed the volume of fuel is controlled by

changing the metering pump cycle.

CAUTION: The CO

must be calibrated.

The heater must be switched off.

1. Connect the CO

line to minus.

2

2. Turn the adjustment knob on the control element to

the centre setting. The heater will start and go

automatically to low-fire rate mode.

measuring instruments

2

5. If the CO

CO

2

value is within this range, disconnect the

2

line from minus. This saves the setting.

NOTE: The heater will now run in normal

mode again and can be switched off as normal

using the control element. The heater is set at

the factory to match the fitted combustion air

blower.

6.3 TESTING INDIVIDUAL COMPONENTS

CAUTION: For function tests always break

the connection between the control unit

and the component you wish to test.

6.3.1 CERAMIC GLOW PIN RESISTANCE TEST

NOTE: The resistance test must be carried out

with an ohmmeter suitable for small resistance

values. A resistance test with a simple digital

multimeter is too inaccurate to find the precise

values. A new glow plug can be measured to

act as a reference.

The glow pin should have the following values in the

test:

Glow plug: 12 V (red) 24 V (green)

Resistance at 25 °C (77 °F):

0.263 ... 0.323 Ohm 1.125 ...1.375 Ohm

Test current: < 5 mA < 5 mA

NOTE: If the heater can be adjusted, the

operating indicator will flash as if the control

unit has suffered an error.

Diesel Unit:

3. Set the CO

value by turning the adjustment knob.

2

Turning it anti-clockwise will reduce the CO

whilst turning it clockwise will increase it. The

measured CO

content at low-fire rate (1.5 kW)

2

must be between 5.0% and 8.0%. In high-fire

mode, the CO

content should be 10.3 +/- 0.5% v/v

2

after the setting has been made.

Gasoline Unit

4. The CO

content may only be measured when the

2

unit is at operating temperature. The unit must be

run for at least 8 minutes for this purpose. After

this the CO

content is to be set to 6.1 - 6.2% v/v in

2

low-fire mode (1 kW). In high-fire mode, the CO

content should be 9.9 +/- 0.4% v/v after the setting

has been made.

value,

2

6.3.2 RESISTANCE TEST ON FLAME SENSOR

GASOLINE HEATERS ONLY)

(

If you conduct this test with a digital multimeter, the

flame sensor must have the following values:

Cold Testing:

Resistance at 25 °C (77 °F): 2.6 ... 3.4 Ohm

Test current: < 5mA

Hot Testing:

Resistance at 800 – 1000 °C: 12 ... 15 Ohm

Resistance at 1472 – 1832 °F: 12 ... 15 Ohm

Test current: < 5 mA

(ceramic rod at red heat over length of approx. 20 mm)

2

www.webasto.us 21 Webasto Product N.A., Inc.

Page 22

FUNCTIONAL TESTS AIR TOP 2000 ST

2260

2240

2220

2200

2180

2160

2140

2120

2100

2080

2060

10 12 14 16 18 20 22 24 26 28 30

Resistance in Ohm

Temperature in °C

Temperature in °F

50 53.6 57.2 60.8 64.4 68 71.6 75.2 78.8 82.4 86

6.3.3 OVERHEATING SENSOR RESISTANCE TEST

If you conduct this test with a digital multimeter, the

overheating sensor must have the values shown in the

following diagram:

Characteristic resistance values of a

PT 2000 overheating system

in a temperature range of 10 °C to 30 °C (50 °F to 86 °F)

Conversion chart (°C to °F):

10 °C = 50 °F

12 °C = 53.6 °F

14 °C = 57.2 °F

16 °C = 60.8 °F

18 °C = 64.4 °F

20 °C = 68 °F

22 °C = 71.6 °F

24 °C = 75.2 °F

26 °C = 78.8 °F

28 °C = 82.4 °F

30 °C = 86 °F

Webasto Product N.A., Inc. 22 www.techwebasto.com

Page 23

AIR TOP 2000 ST CIRCUIT DIAGRAMS

X6

X2

X4

X5

X1

X3

X1 = Combustion and hot air blower connection

X2 = Ceramic glow pin connection

X3 = Overheating sensor connection

X4 = Metering pump connection

X5 = Flame sensor connection (gasoline heaters only)

X6 = Wiring harness connection

7. CIRCUIT DIAGRAMS

7.1 GENERAL

The Air Top 2000 ST heater can be controlled with the

control element (nominal value adjuster/switch) or a

combination timer.

The circuit diagrams (Fig. 12 and Fig. 13) show the

possible circuits for 12 and 24 V with:

• Control element

• Combination timer

Fig. 11 shows the plug assignment on the control unit.

Fig. 14 shows the schematic connection of the

combination timer.

Figure 11: Plug Assignment

www.webasto.us 23 Webasto Product N.A., Inc.

Page 24

CIRCUIT DIAGRAMS AIR TOP 2000 ST

GROUND

BATTERY

X2/X3/X4/X5

1

2

X10

12

21

X11

1

2

0,5mm

sw

0,5mm

0,5mm

0,5mm

rt

bl

ws

4

2

3

1

X9

H1

S1

30

S3

4

ge

rt

B2

1

ge

br

2

E

X2

bl

1

2

B3

X3

1

bl

2

X4

X10

Y1

0,5mm

0,5mm

0,5mm

sw

s

sw/bl

w

2

1

R1

B4

X8

17

3

br

12V

rt

24V

gn

ge

12

13

11

2

10

16

4

1

A1

A2

F1

X6

X6

1

br

br

2

X1

M1

M

2

X5

br

1

B1

9

8

0,5mm

0,5mm

0,5mm

br

gn/ws

7

12

5

X11

6

1

2

3

S6

3

15

14

X6

bl

2

1

X8

br

0,5mm

X6

5

X1

1

2

X8

3

41

2

X9

*To use vent mode, connect to ground through a switch (S3) for proper operation.

If ventilation mode is not desired, leave pink wire disconnected and protect from grounding.

No heating operation with pink wire grounded!

20 Ga Pink - *for ventilation mode only!

Diagnostic K cable

W bus

CO

2

setting

Input pin (pin 16/plug X6), cable color on wiring harness: pink):

“Ventilation” (fan speed depends on the position of the control element)

If you use an external temperature sensor (B4), the resistor (R1) is replaced by the temperature sensor (B4).

NOTE - Typical Connection for Trucks

If this connection is made to battery positive (terminal 30), permanent heating is possible with the

ignition switched off. In this case no connection must be made to terminal 15/75.

NOTE - Typical Connection for Buses

With positive from terminal (15/75) to connection 10:

Permanent operation for immediate heat as long as the ignition is switched on.

Without positive at connection 10:

Heating time is variably programmable (10 min to 120 min), default setting 120 min.

1

2

3

4

5

6

7

Cable Colors

bl

br

ge

gn

gr

or

rt

sw

vi

ws

Blue

Brown

Yel low

Green

Grey

Orange

Red

Black

Violet

White

Cable Cross-sections

< 7.5 m

7.5 – 15 m

0.75

mm

2

1.5

mm

2

2.5

mm

2

4.0

mm

2

1.5 mm

2

2.5 mm

2

4.0 mm

6.0 mm

1.0

mm

2

1.0 mm

2

1.0 mm

2

0.75 mm

2

2

2

Standard cable

Item Designation Comment

A1 Heater Air Top 2000 ST

A2 Control unit

B1 Flame sensor Gasoline heaters only

B2 Temperature sensor Internal

B3 Overheating sensor Overheating guard

B4 Temperature sensor External

E Ceramic glow pin

F1 Fuse 15A (max. 20A) Flat fuse SAE J 1284

F2 Fuse max. 15 A Flat fuse SAE J 1284

H1 LED, green (in item S1) Indicator

H3 LED, red Immediate heat button light

Ready indicator, switch-on indicator

H4 Heating symbol in the

display (in item P)

Indicator

H5 Light (in item P) Display and button lights

M1 Motor Combustion and hot air fan

P Combination timer

(1531)

Timer and temperature control

Item Designation Comment

R1 Resistor 620 Ω With internal temperature sensor

only

S1 Control element Switch and temperature control

S4 Switch (optional) Ventilation

S6 Switch CO

2

setting

X1 Plug connector, 4-pin to item A2

X2 Plug connector, 2-pin to item A2

X3 Plug connector, 2-pin to item A2

X4 Plug connector, 2-pin to item A2

X5 Plug connector, 2-pin to item A2

X6 Plug connector, 18-pin to item A2

X8 Plug connector, 2-pin

X9 Plug connector, 4-pin to item S1

X10 Plug connector, 2-pin to item Y1

X11 Plug connector, 2-pin

X12 Plug connector, 12-pin to item P

Y1 Fuel metering pump

Figure 12: System Circuit Diagram 12V/24V with Control Element (Rheostat Switch)

Webasto Product N.A., Inc. 24 www.techwebasto.com

Page 25

AIR TOP 2000 ST CIRCUIT DIAGRAMS

Diagnostic K cable

W bus

CO

2

setting

Input pin (pin 16/plug X6), cable color on wiring harness: pink):

“Ventilation” (fan speed depends on the position of the control element)

If you use an external temperature sensor (B4), the resistor (R1) is replaced by the temperature sensor (B4).

NOTE - Typical Connection for Trucks

If this connection is made to battery positive (terminal 30), permanent heating is possible with the

ignition switched off. In this case no connection must be made to terminal 15/75.

NOTE - Typical Connection for Buses

With positive from terminal (15/75) to connection 10:

Permanent operation for immediate heat as long as the ignition is switched on.

Without positive at connection 10:

Heating time is variably programmable (10 min to 120 min), default setting 120 min.

1

2

3

4

5

6

7

Cable Colors

bl

br

ge

gn

gr

or

rt

sw

vi

ws

Blue

Brown

Yel low

Green

Grey

Orange

Red

Black

Violet

White

Cable Cross-sections

< 7.5 m

7.5 – 15 m

0.75

mm

2

1.5

mm

2

2.5

mm

2

4.0

mm

2

1.5 mm

2

2.5 mm

2

4.0 mm

6.0 mm

1.0

mm

2

1.0 mm

2

1.0 mm

2

0.75 mm

2

2

2

Standard cable

Item Designation Comment

A1 Heater Air Top 2000 ST

A2 Control unit

B1 Flame sensor Gasoline heaters only

B2 Temperature sensor Internal

B3 Overheating sensor Overheating guard

B4 Temperature sensor External

E Ceramic glow pin

F1 Fuse 15A (max. 20A) Flat fuse SAE J 1284

F2 Fuse max. 15 A Flat fuse SAE J 1284

H1 LED, green (in item S1) Indicator

H3 LED, red Immediate heat button light

Ready indicator, switch-on indicator

H4 Heating symbol in the

display (in item P)

Indicator

H5 Light (in item P) Display and button lights

M1 Motor Combustion and hot air fan

P Combination timer

(1531)

Timer and temperature control

Item Designation Comment

R1 Resistor 620 Ω With internal temperature sensor

only

S1 Control element Switch and temperature control

S4 Switch (optional) Ventilation

S6 Switch CO

2

setting

X1 Plug connector, 4-pin to item A2

X2 Plug connector, 2-pin to item A2

X3 Plug connector, 2-pin to item A2

X4 Plug connector, 2-pin to item A2

X5 Plug connector, 2-pin to item A2

X6 Plug connector, 18-pin to item A2

X8 Plug connector, 2-pin

X9 Plug connector, 4-pin to item S1

X10 Plug connector, 2-pin to item Y1

X11 Plug connector, 2-pin

X12 Plug connector, 12-pin to item P

Y1 Fuel metering pump

GROUND

BATTERY

X2/X3/X4/X5

1

2

X10

12

21

X11

1

2

15

30

S3

4

ge

rt

B2

1

ge

br

2

E

X2

bl

1

2

B3

X3

1

bl

2

X4

X10

Y1

0,5mm²

0,5mm²

0,5mm²

sw

s

sw/bl

w

2

1

R1

B4

X8

17

3

br

12V

rt

24V

gn

ge

12

13

11

2

10

16

4

1

A1

A2

F1

X6

X6

1

br

br

2

X1

M1

M

2

X5

br

1

B1

9

8

0,5mm²

0,5mm²

0,5mm²

br

gn/ws

7

12

5

X11

6

1

2

3

S6

3

15

14

X6

bl

2

1

X8

br

0,5mm²

X6

5

LIGHTS

58

IGNITION

F2

2

6

9

11101

712 4

P

X12

H5

H4

H3

8

67

rt

0,5mm²

0,5mm²

0,5mm²

0,5mm²

sw

bl

ws

6

9

3

12

X12

X1

1

2

X8

OPTIONAL

*To use vent mode, connect to ground through a switch (S3) for proper operation.

If ventilation mode is not desired, leave pink wire disconnected and protect from grounding.

No heating operation with pink wire grounded!

20 Ga Pink - *for ventilation mode only!

Figure 13: System Circuit Diagram 12V/24V with Combination Timer Model 1531

www.webasto.us 25 Webasto Product N.A., Inc.

Page 26

CIRCUIT DIAGRAMS AIR TOP 2000 ST

3 2 1

6 5 4

9 8 7

12 11 10

12V

24V

Combination Timer 1531

Adapter Harness

P/N 9008440A

Brown

Battery Negative (12, 4)

Red

Battery Positive (11)

Black

Battery Positive

or Ignition Signal (10)

Grey

Lights (1)

(optional)

Figure 14: Schematic Connection of the Combination Timer Model 1531

Webasto Product N.A., Inc. 26 www.techwebasto.com

Page 27

AIR TOP 2000 ST SERVICING WORK

8. SERVICING WORK

8.1 GENERAL

This section describes the servicing work that can be

carried out on the heater when it is installed.

8.2 WORK ON THE HEATER

Disconnect the main power cable from the vehicle’s

battery before carrying out any work on the heater. The

main battery power must not be disconnected whilst the

heater is operating or slowing down as a result of the risk

of the heater overheating and the overheating guard

thus being tripped. If you wish to carry out extensive

repair work on the heater, it may be a good idea to

remove it completely.

Refer to the relevant installation instructions and the

installation proposal for the heater for the specific vehicle

for repairs that necessitate the installation position being

changed.

8.3 WORK ON THE VEHICLE

CAUTION: A temperature of 85 °C (185 °F)

must not be exceeded in the vicinity of the

heater in any circumstances (for example

when completing painting work on the

vehicle).

8.4 HEATER TRIAL

WARNING: The heater must not be

operated in enclosed areas such as garages

and workshops without an emissions

extraction system, even if the heater is

equipped with a timer.

CAUTION: The heater must not be

operated without the cover for the control

unit as this will cause it to overheat.

The following servicing work is to be carried out to

maintain the functional reliability of the heater:

• Check the hot air inlet and outlet for dirt and foreign

bodies. (Dirty or blocked hot air lines may cause

overheating.)

• Clean the exterior of the heater (avoid the ingress of

water).

• Check the electrical connections for contact

corrosion and to ensure that they are secure.

• Check the exhaust and combustion air lines for signs

of damage and to ensure that they are clear.

• Replace the fuel filter if there is one.

• Check the fuel line and filter for leaks.

8.6 VISUAL INSPECTIONS AND INSTALLATION

INSTRUCTIONS

8.6.1 HOT AIR SYSTEM

CAUTION: The integration of the heater

into the vehicle’s own air system is not

permitted as a result of the high pressure in

the vehicle’s system.

Inside the control unit there is a temperature sensor,

which operates the heater in the appropriate heat output

range in conjunction with the control element depending

on the intake temperature and the position of the control

element’s dial. The heat output is set so that after the

selected interior temperature has been reached quickly, it

is then kept at this selected value. Alternatively, the

heaters can be operated with an external temperature

sensor (see 9.1.2).

NOTE: Only materials that can permanently

withstand temperatures of at least 130 °C may

be used for the hot air line.

Maximum pressure drop between the inlet and outlet

side of the hot air line 1.5 hPa (corresponds to 1.5 mbar /

15 mm WC).

8.5 SERVICING WORK

NOTE: The heater should be operated for

approximately 20 minutes every 4 weeks to

prevent mechanical parts seizing.

The heater requires no servicing. However, it should be

checked at regular intervals, at the latest at start of the

heating period (the time after which the heater will be

used due to adverse weather conditions) by Webastotrained personnel.

www.webasto.us 27 Webasto Product N.A., Inc.

If this value is exceeded, the heat output may be reduced

as a result of the hot air outlet temperature control.

The internal diameter of the main section of the hot air

line should be 60 mm.

When using narrower lines, the permissible pressure drop

is exceeded more quickly.

The hot air hose must be secured at its connection

points.

The heater can be used on the air inlet and outlet side if

it is used in an air circulation system with grates. Do not

short circuit the flow of hot air.

Page 28

SERVICING WORK AIR TOP 2000 ST

CAUTION: In vehicles used to transport

people, the air outlet opening is to be

installed in such a way that it is at least 20

cm away from all body parts.

The heater checks the internal temperature rise

automatically each time it is switched on. If this is above

the specified limits, the start is cancelled and error

messages F10 is displayed. To ensure that the heater

functions stably, the flow resistance of the connected hot

air system must be reduced.

If a filter is used for the hot air, it must have the following

properties:

• The air flow must not carry any inflammable and/or

harmful fibers or particles into the heater or the

interior of the vehicle.

• The filter material must be able to withstand

temperatures of at least 60 °C.

• The filter must be resistant to all the substances that

may be drawn in with the hot air (for example

moisture, salt, fuel vapors, etc.).

• The resistance of the filter must be taken into