Page 1

Luft-Heizgeräte

Air Heaters

03/2003

Workshop Manual

Air Top 2000 STC

Trade names:

Air Top 2000 STC B (petrol)

Air Top 2000 STC D (diesel)

Page 2

Improper installation or repair of Webasto heating and cooling systems can cause fire or the

leakage of deadly carbon monoxide leading to serious injury or death.

To install and repair Webasto heating and cooling systems you need to have completed a

Webasto training course and have the appropriate technical documentation, special tools

and special equipment.

Only genuine Webasto parts may be used. See also Webasto air and water heaters

accessories catalogue.

NEVER try to install or repair Webasto heating or cooling systems if you have not completed

a Webasto training course, you do not have the necessary technical skills and you do not

have the technical documentation, tools and equipment available to ensure that you can

complete the installation and repair work properly.

ALWAYS carefully follow Webasto installation and repair instructions and heed all

WARNINGS.

Webasto rejects any liability for problems and damage caused by the system being installed

by untrained personnel.

Page 3

Air Top 2000 STC Table of Contents

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

1.1 Contents and purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

1.1.1 Use of air heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

1.2 Meaning of signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

1.2.1 General safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

2 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

2.1 Drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

2.2 Heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

2.3 Burner with combustion chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

2.4 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

2.5 Flame monitor (petrol heater only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

2.6 Glow plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

2.7 Overheating sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

2.8 Fuel pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

3 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

3.1 Control element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

3.2 Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .301

3.3 Heating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .301

3.4 Control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

3.5 Control pause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

3.6 Switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .302

3.7 Heater functions in ADR vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

3.8 Fault switch-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

3.8.1 Fault monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .303

3.8.2 Resetting fault switch-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .303

4 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

4.1 General technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

4.1 Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

5.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

5.2 General fault symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .501

5.3 Fault symptoms during operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .502

5.4 Fault code output (hexadecimal / Webasto Thermo Test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 503

5.5 Fault code output (flashing or FXX output). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .506

6 Function checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

6.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

6.2 Required test and measuring equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

6.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603

6.3.1 Setting the CO2 content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .603

6.3.2 CO2 setting for reference heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603

6.4 Testing individual components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604

I

Page 4

Table of Contents Air Top 2000 STC

6.4.1 Component: burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 605

6.4.2 Testing resistance of flame monitor (petrol heater only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 606

6.4.3 Component: glow plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608

6.4.4 Component: drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 610

6.4.5 Component: overheating temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 611

6.4.6 Component: control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612

6.4.7 Component: heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 613

7 Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 701

7.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 701

7.2 System wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 702

7.3 Legends to system wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 704

7.4 Pin assignments plug connection X6, 18-pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 705

8 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801

8.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801

8.2 Working on the heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801

8.3 Working on the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801

8.4 Heater test run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801

8.5 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801

8.6 Visual inspection and installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801

8.6.1 Heating air system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801

8.6.2 Fuel supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 802

8.6.2.1 Fuel take-off, general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 802

8.6.2.2 Permissible fuel pressure fuel line lengths. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 802

8.6.2.3 Fuel take-off via tank drain plug (from plastic or metal fuel tank) . . . . . . . . . . . . . . 803

8.6.2.4 Webasto tank extracting device for plastic fuel tank . . . . . . . . . . . . . . . . . . . . . . . . 803

8.6.2.5 Webasto tank extracting device for metal tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . 803

8.6.2.6 Fuel lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 803

8.6.2.7 Connecting 2 fuel lines with a hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 804

8.6.3 Fuel pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 804

8.6.3.1 Installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 804

8.6.3.2 Installation and attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 804

8.6.4 Fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 805

8.6.5 Combustion air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 805

8.6.6 Exhaust line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 805

8.6.7 Exhaust silencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 805

8.6.8 Combustion air intake and exhaust pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 806

8.6.9 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 806

8.6.9.1 Heater and control element connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 806

8.6.9.2 Supply voltage connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 806

8.6.9.3 Control element connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 807

8.7 Removing and installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 809

8.7.1 Removing and installing heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 809

8.7.1.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 809

8.7.1.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 809

8.8 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 809

II

Page 5

Air Top 2000 STC Table of Contents

9 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901

9.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901

9.1.1 Work on stripped down components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901

9.1.1.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901

9.1.1.2 Visual inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901

9.1.2 Carrying out modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .901

9.1.2.1 Installing of an external room temperature sensor. . . . . . . . . . . . . . . . . . . . . . . . . .901

9.2 Dismantling and assembling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 902

9.2.1 Removing casing parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 902

9.2.1.1 Cover for electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .902

9.2.1.2 Grille for heating air inlet and outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 902

9.2.1.3 Cover for heating air inlet and outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .902

9.2.1.4 Upper casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 902

9.2.1.5 Lower casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 902

9.2.2 Fitting the casing parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 902

9.2.2.1 Lower casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 902

9.2.2.2 Upper casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 902

9.2.2.3 Cover for heating air inlet and outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .902

9.2.2.4 Grille for heating air inlet and outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 902

9.2.2.5 Cover for electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .902

9.2.3 Replacing control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .904

9.2.3.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 904

9.2.3.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .904

9.2.4 Replacing the overheating temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 904

9.2.4.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 904

9.2.4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .904

9.2.5 Replacing drive unit (drive motor, combustion air fan and intake housing). . . . . . . . . . . . . . . . . . . . 904

9.2.5.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 904

9.2.5.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .904

9.2.6 Replacing flame monitor (petrol heater only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .905

9.2.6.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 905

9.2.6.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .905

9.2.7 Changing glow plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 907

9.2.7.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 907

9.2.7.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .907

9.2.8 Replacing burner, combustion chamber and heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 909

9.2.8.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 909

9.2.8.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .909

10 Packaging/storage and shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1001

10.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1001

III

Page 6

Table of Illustrations Air Top 2000 STC

Table of Illustrations

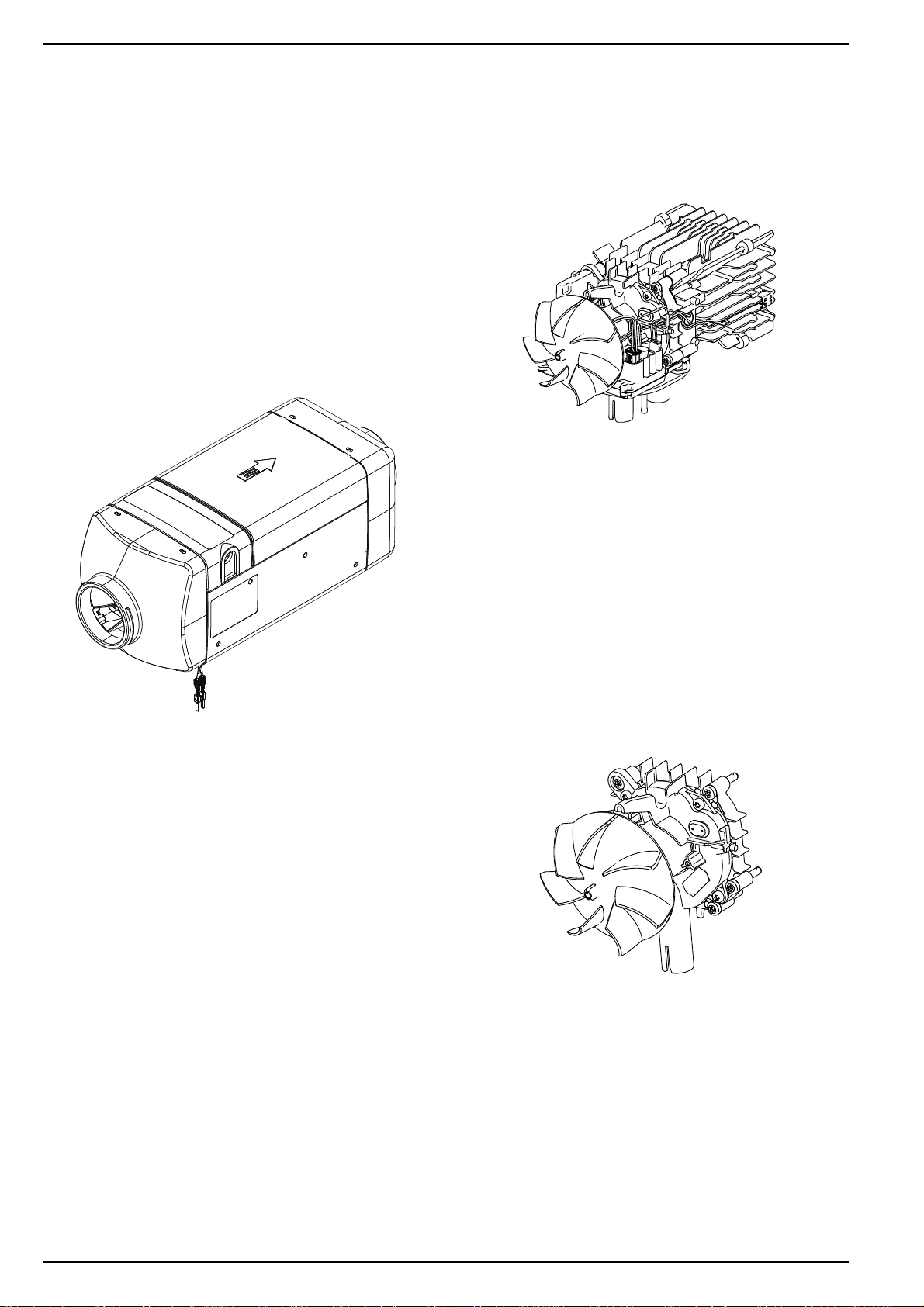

Fig. 201 Air heater Air Top 2000 STC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Fig. 202 Air Top 2000 STC air heater without casing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Fig. 203 Drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

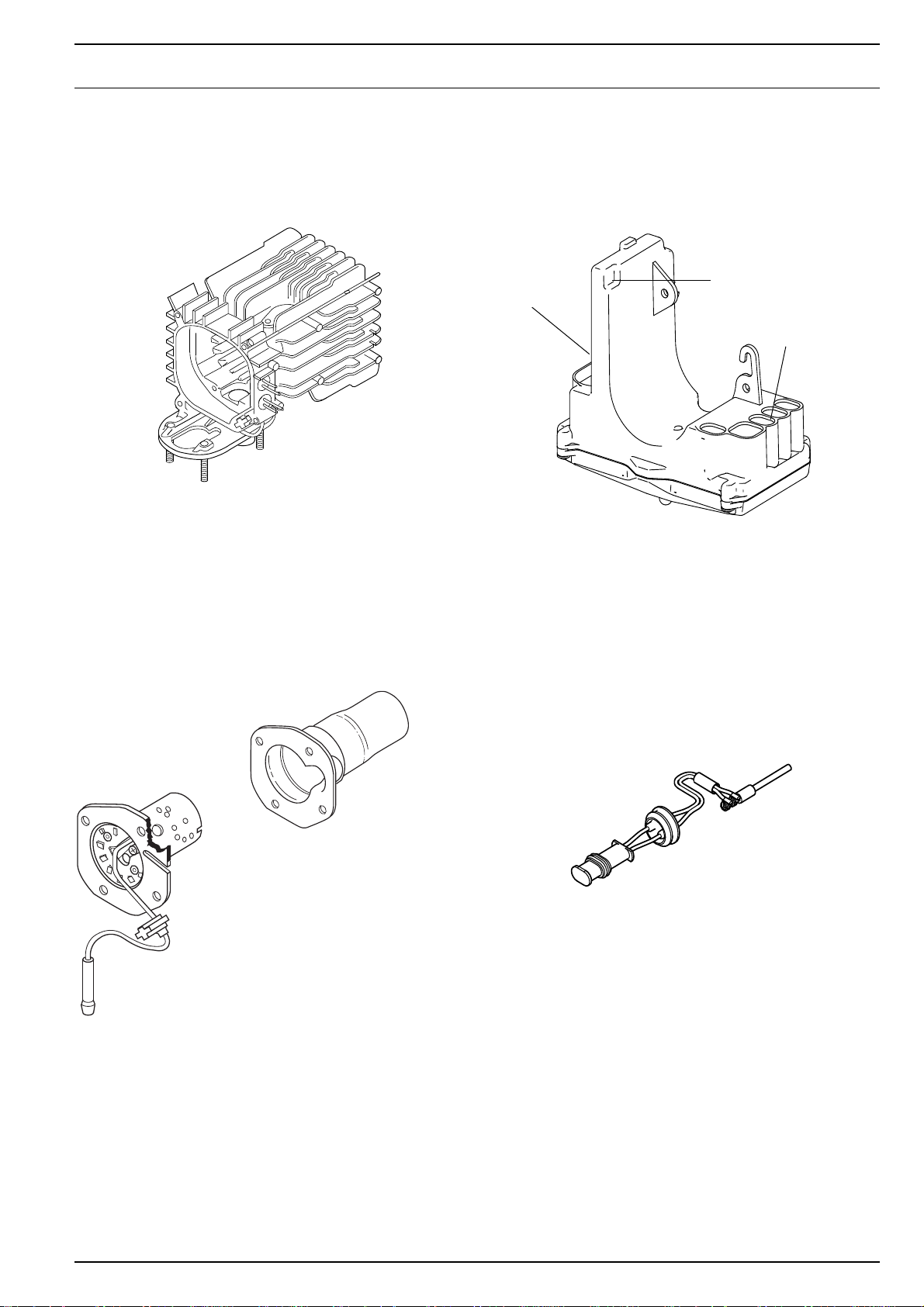

Fig. 204 Heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Fig. 205 Burner with combustion chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Fig. 206 Control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Fig. 207 Flame monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

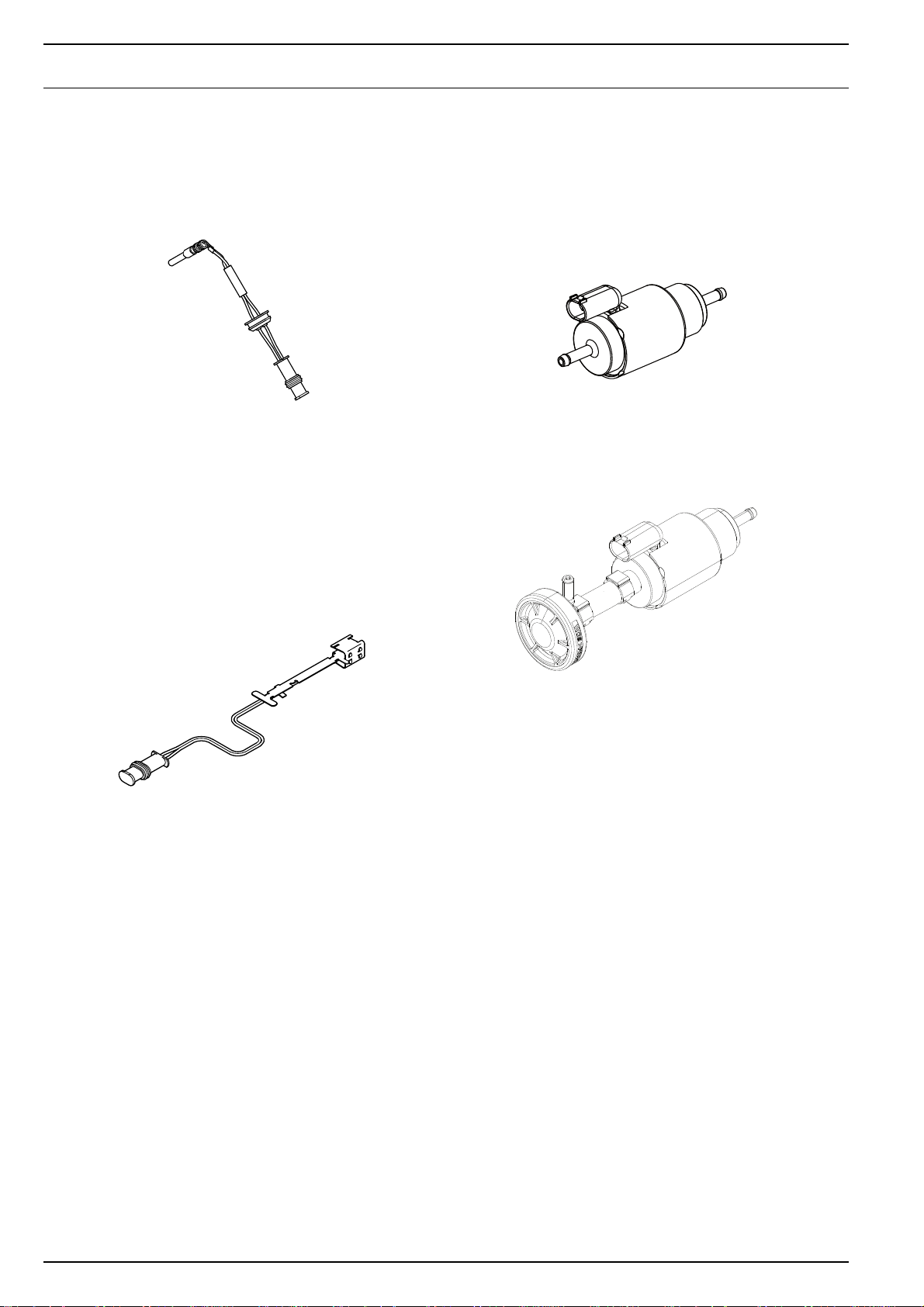

Fig. 208 Glow plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Fig. 209 Overheating sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Fig. 210 Fuel pump DP42 (petrol) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Fig. 211 Fuel pump DP42 (diesel) with diaphragm damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Fig. 401 Technical Data Air Top 2000 STC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

Fig. 402 Setpoints Air Top 2000 STC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Fig. 501 General fault symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

Fig. 502 Fault symptoms during operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 502

Fig. 603 Component overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 602

Fig. 601 Characteristic resistance values of an overheating temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 611

Fig. 701 Connector assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 701

Fig. 702 System wiring diagram Air Top 2000 STC, 12 V/24 V with rotary switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 702

Fig. 703 Systems wiring diagram Air Top 2000 STC, 12 V/24 V with MultiControl. . . . . . . . . . . . . . . . . . . . . . . . . . . 702

Fig. 704 System wiring diagram Air Top 2000 STC D, 12 V/24 V ADR operation with SmartControl . . . . . . . . . . . . . 703

Fig. 705 System wiring diagram Air Top 2000 STC D, 12 V/24 V ADR operation with rotary switch . . . . . . . . . . . . . 703

Fig. 706 System wiring diagram Air Top 2000 STC, 12 V/24 V with combination timer . . . . . . . . . . . . . . . . . . . . . . . 704

Fig. 801 Fuel line lengths, inside diameter and height differences (fuel tank, heater) to fuel pump . . . . . . . . . . . . . . 802

Fig. 802 Fuel take-off via tank drain plug (plastic or metal fuel tank). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 803

Fig. 803 Webasto tank extracting device (plastic fuel tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 803

Fig. 804 Webasto tank extracting device (metal fuel tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 803

Fig. 805 Pipe/hose connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 804

Fig. 806 DP42 fuel pump (installation position, petrol) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 804

Fig. 807 DP42 fuel pump, installation position, diesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 804

Fig. 808 Fuel filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 805

Fig. 809 Exhaust silencer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 805

Fig. 810 End of exhaust pipe, installation position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 806

Fig. 811 Removing mounting plate on fuse holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 806

Fig. 812 Fuse holder, installation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 806

Fig. 813 Rotary switch control element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 807

Fig. 814 Disconnecting the connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 807

Fig. 815 Installation example of heater in recirculated air mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 808

Fig. 901 Installing an external room temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901

Fig. 902 Removing / fitting casing parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 903

Fig. 903 Replacing control unit, combustion air fan and overheating temperature sensor . . . . . . . . . . . . . . . . . . . . . 906

Fig. 904 Changing glow plug, replacing flame monitor, burner and heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . 908

Fig. 905 Starting air hole in burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 910

IV

Page 7

Air Top 2000 STC 1 Introduction

1 Introduction

1.1 Contents and purpose

This workshop manual is designed to assist trained personnel

in repairing both the petrol and the diesel versions of the Air

Top 2000 STC air heaters.

1.1.1 Use of air heaters

The Webasto Air Top 2000 STC air heaters are designed:

– to heat cabins, boats, commercial vehicles, minibusses,

vans/transporters, ambulances and motor homes.

– to defrost vehicle windows.

They are not approved for heating cargo areas used to carry

dangerous goods/hazardous substances.

The heaters operate independently of the engine and are

connected directly to the fuel tank and the electrical system

of the vehicle.

They may be used for vehicles with either water or air-cooled

engines.

1.2 Meaning of signal words

Throughout this manual, the signal words CAUTION, ATTEN-

ION and NOTE have the following meanings:

T

CAUTION

This signal word is used to highlight operating instructions or

procedures which, if not followed or not followed correctly,

may result in personal injury or fatal accidents.

ATTENTION

This signal word is used to highlight operating instructions or

procedures which, if not followed or not followed correctly,

may result in damage to the equipment or its components.

NOTE

This signal word is used to draw your attention to a special

feature.

1.2.1 General safety information

The mouth of the exhaust pipe should be installed facing

ownwards, to the side or, if the exhaust pipe passes under

d

the floor of the vehicle, up to the side or rear limit of the

driver's cab or of the vehicle.

The function of important parts of the vehicle must not be

adversely affected. It must not be possible for condensation

or water to collect in the exhaust pipe. Drain holes may be

used.

The electrical cables, switchgear and control units for the

heater must be arranged in the vehicle such that their function is not impaired under normal operating conditions.

Compliance with §§ 45 and 46 StVZO (German road vehicle

registration regulation) must be ensured for the installation

of fuel lines and the installation of additional fuel tanks.

The main points of this regulation:

– Fuel lines must be designed in such a way that torsion in

the vehicle, engine movements and similar do not have a

negative effect on their durability. They must be

protected from mechanical damage.

– Parts that carry fuel must be protected from heat that

could adversely affect their function and positioned such

that dripping or evaporating fuel cannot collect or ignite

on hot parts or on electrical equipment.

The heat exchanger of the air heater can be used for a

maximum period of 10 years and must then be replaced

with a genuine spare part by the manufacturer or an

authorised workshop. A label must then be affixed to

the heater showing the date of sale and the wording

"Genuine Spare Part".

When you change the heat exchanger it is also necessary that

you replace the overheating protection element (overheating

sensor) to prevent possible malfunctions caused by using the

old overheating sensor.

The Air Top 2000 STC heaters are prepared for interior installation and and sealing directly on the driver's cab floor or

wall. Non-release connections must be used in the interior for

combustion air and exhaust pipes for Webasto accessories.

The seal between the heater mounting and the vehicle floor

must always be installed otherwise harmful exhaust gases

may get into the vehicle interior.

The heating air and combustion air intake openings must be

positioned in such a way that no water can enter them when

the vehicle is driven through water at permissible levels.

The heater must not be installed in the driver's or passenger's

compartment of busses (vehicle class M2 and M3). If the

heater is nevertheless installed in such a place, the casing

must be tightly sealed from the vehicle interior. The casing

must have sufficient external ventilation to ensure a maximum temperature of 40 °C is not exceeded in the box. Faults

may occur if the temperature exceeds this level.

Due to the risk of explosion, the heater must be switched off

at filling stations and facilities.

Due to the risk of explosion, the heater must be switched off

wherever inflammable vapours or dust can form (e.g. in the

vicinity of fuel, coal, wood dust or grain stores or similar).

Due to the risk of asphyxiation and poisoning, the heater

must not be operated in enclosed areas such as garages and

workshops without an emissions extraction system even if

you use the timer.

101

Page 8

1 Introduction Air Top 2000 STC

Overheating

In the event of prolonged smoke accumulation, unusual combustion noise or smell of fuel, the heater must be shut down

by removing the fuse and must not be started again until it

has been examined by Webasto-trained personnel. Liability

claims can only be asserted for proven compliance with the

maintenance and safety information by the claimant.

Installation regulations for Webasto fuel tanks for supplying

fuel to heaters in vehicles:

• The tanks must not be installed in the passenger's

compartment or driver's cab of busses.

• The fuel filler neck must not be inside the passenger's

compartment or driver's cab in any vehicle.

• Petrol fuel tanks must not be installed directly behind the

front panelling of the vehicle. They must be separated

from the engine in such a way that in the event of an

accident the fuel cannot ignite. This does not apply to

tractor units with an open driver's seat.

Due to the potential fire risk, the fuel lines (Mecanyl hose)

must not make direct contact with the exhaust pipe and must

be thermally insulated wherever necessary.

All fuel pipes must have sealed connections, they must not be

damaged in any way and must be checked at regular intervals

(at least at the same intervals as the vehicle inspection).

Keep the heating air inlet and heating air outlet free of dirt

and foreign objects. Dirty, blocked air lines can cause the

heater to shut down due to overheating.

After the heater has shut down due to overheating, check

that the air system is clear, remove any materials that may

block the air flow and have any damage to the air lines

repaired by an authorised Webasto workshop. The heater

lock-out can then be cancelled by switching the heater off

and on again. If this action does not produce the required

success (if the heater overheats again), take it to a Webasto

authorised workshop. Never remove the grill over the air inlet

of the heater.

The air outlet jets or air vents with adjustable flaps must

always be opened by a certain extent so that the air flow

through the heater is not completely blocked. At least one air

vent must be unclosable.

If the heater is installed in a storage area you must ensure

that no flammable substances are kept in this area and that

other material does not restrict the air supply to the heater.

Air lines must be securely fixed to the heater (pipe clips) and

all other connection points (vents).

ATTENTION

The points described below must be avoided:

NOTE

If any damage or leaks are found on the fuel line, the heater

must not be used until the damage has been rectified by an

authorised Webasto workshop.

Put the heater out of action by removing the fuse.

• Do not step on the heater and do not place or throw any

heavy objects onto the heater.

• Do not place any items of clothing, fabrics or similar

materials over the heater or in front of the heating air

intake side and the heating air outlet.

• The flow of hot air from the heater must not be restricted

or blocked by highly flammable substances or materials

such as rags, cleaning wool etc.

• Flammable or explosive substances and gasses must not

be placed near or in contact with the heater, the hot air

line, the hot air flow or the exhaust pipe.

• The heater must not be cleaned with a high-pressure

cleaner.

• Do not frequently switch off the heater at the main

battery switch or battery disconnector otherwise the

heater may suffer long-term damage and malfunctions.

NOTE

Failure to follow the installation instructions and the notes

contained therein will lead to all liability being refused by

Webasto.

The same applies if repairs are carried out incorrectly or with

the use of parts other than genuine spare parts. This will

result in the invalidation of the type approval for the heater

and therefore of its homologation / EC type licence.

102

Carefully read the operating instructions before operating the

heater.

Page 9

Air Top 2000 STC 1 Introduction

Page for notes

103

Page 10

2 General description Air Top 2000 STC

2 General description

The Air Top 2000 STC air heater is based on the evaporator

principle and essentially consists of:

– Drive unit (combustion air fan, heating air fan and drive

motor)

– Heat exchanger

– Burner with combustion chamber

– Control unit

– Glow plug

– Housing parts

– Base seal

Fig. 202 Air Top 2000 STC air heater without casing

2.1 Drive unit

The drive unit consists of the drive motor, combustion air fan,

eating air fan and the intake casing.

h

The combustion air fan supplies the air required for the

combustion process through the combustion air inlet into the

combustion chamber.

The heating air fan feeds the hot air from the hot air inlet via

the heat exchanger to the hot air outlet.

Fig. 201 Air heater Air Top 2000 STC

The following control and monitoring components are

integrated in the heater:

– Control unit with room temperature sensor

– Flame monitor (petrol heater only)

– Glow plug

– Overheating sensor

All Air Top 2000 STC heaters can also be controlled using an

optional external room temperature sensor.

The fuel is supplied from the external fuel tank by a fuel

pump.

Fig. 203 Drive unit

201

Page 11

Air Top 2000 STC 2 General description

Combustion

chamber

Burner

Wiring

harness

Internal

room temperature

sensor

Component plug

2.2 Heat exchanger

In the heat exchanger, the heat generated by the combustion

process is transferred to the air delivered by the heating air

fan.

Fig. 204 Heat exchanger

2.3 Burner with combustion chamber

2.4 Control unit

The control unit is the central component for ensuring

t

rouble-free operation. It monitors the components,

evaluates the sensor signals and controls heating operation.

Fig. 206 Control unit

In the burner, the fuel is distributed over the metal fibre

vaporator (mesh) in the combustion chamber. The fuel/air

e

mixture burns in the combustion chamber, thus heating the

heat exchanger.

Fig. 205 Burner with combustion chamber

2.5 Flame monitor (petrol heater only)

The flame monitor is a low-impedance PTC resistor which

hanges its resistance as a function of the heat emitted by the

c

flame.

This change in resistance is evaluated by the control unit so

that the flame status is monitored throughout the heating

operation.

Fig. 207 Flame monitor

202

Page 12

2 General description Air Top 2000 STC

2.6 Glow plug

The fuel/air mixture is ignited by the glow plug when the

heater is started. The glow plug is designed as an electrical

resistor and is positioned in the burner on the side opposite

the flame.

Fig. 208 Glow plug

2.7 Overheating sensor

The overheating sensor measures the temperature in the fin

rea of the heat exchanger while the heater is operating. The

a

control unit evaluates the signal, regulates the heating air

outlet temperature and controls the overheating shut-down

function.

.

2.8 Fuel pump

The fuel pump is a combined delivery, metering and a shuto

ff system for supplying fuel to the heater. The Air Top 2000

STC heater must be operated with the fuel pump DP 42.

Fig. 210Fuel pump DP42 (petrol)

Fig. 209 Overheating sensor

Fig. 211Fuel pump DP42 (diesel) with diaphragm damper

203

Page 13

Air Top 2000 STC 2 General description

Page for notes

204

Page 14

3 Function description Air Top 2000 STC

3 Functional description

3.1 Control element

The control element is used to:

• Switch the heater on and off.

• Set the required room temperature (intake temperature

between approx. 5 °C and 35 °C).

• Reset the heater after a malfunction.

• Display fault codes:

– Control elements with display: the fault code is

shown on the display.

– Control elements without display: the fault code is

indicated by the indicator lamp flashing in defined

sequences.

NOTE

ADR operation:

The heater is in ADR lock-out mode after an ADR shutdown.

This mode is cancelled after switching the heater off and on

again.

3.2 Switching on

Set the control element to the required temperature.

he heater will start up if the heating air temperature is lower

T

than the set temperature.

NOTE

Only the heating air fan will start up if the room temperature

is higher than the set temperature.

The heating air fan will not start up if an external room tem-

perature sensor is connected.

The flame monitor is checked. If the flame monitor now signals "light", the system will attempt to cool the flame monitor

for 60 seconds. If the flame monitor still signals "light" the

control unit will be locked out. If there is a malfunction in any

another monitored component fault lock-out will take place

with no afterrunning period.

Automatic restart

The starting procedure will be repeated if no flame is

detected. The glow plug is switched on again (clocked). The

motor of the heating and combustion air fan is set to approx.

25% of its maximum speed.

The fuel pump starts after approx. 30 seconds (petrol) or 50

seconds (diesel) and the flame begins to form. After a further

65 seconds (petrol) or 90 seconds (diesel) the glow plug is

switched off and the presence of a flame established.

If the heater again fails to ignite properly, after a 180 second

fault afterrun phase at maximum speed the heater will be

shut down and is in fault lock-out mode.

NOTE

The heater will assume fault lock-out mode after a restart.

Briefly switch the heater off and on (for at least 2 seconds) to

reset fault lock-out.

3.3 Heating mode

Combustion gasses flow through the heat exchanger during

heater operation. The combustion heat is transferred to the

walls of the heat exchanger, absorbed by the heating air

blown in by the heating air fan and blown into the vehicle

interior.

The temperature of the heating air intake is measured by a

room temperature sensor on the intake side of the heater or

an external room temperature sensor. If the measured temperature is lower than the value set on the control element,

the heating capacity will be increased to maximum.

To extend the service life of the burner the delivery rate from

the fuel pump is reduced for 10 seconds every 10 minutes

during continuous operation.

In addition, heating mode is interrupted every 8 hours in the

same way as for a control pause.

Start

When the heater is switched on, the ON indicator lamp

comes on and the glow plug is switched on (clocked). The

motor of the heating and combustion air fan is set to approx.

50% of its maximum speed.

The fuel pump starts after approx. 40 seconds and the flame

begins to form. To improve the starting characteristics, the

fuel pump and the combustion air fan are started at different

frequencies and speeds.

After a further 95 seconds (petrol) or 110 seconds (diesel) the

glow plug is switched off and the presence of a flame established.

301

3.4 Control mode

In control mode, the speed of the heating and combustion air

an and the fuel pump delivery rate are dependent on the

f

heating capacity. The glow plug is switched off.

3.5 Control pause

The heating capacity is reduced on reaching the temperature

set on the control element. The speed of the heating and

combustion air fan and the delivery rate of the fuel pump are

reduced.

Page 15

Air Top 2000 STC 3 Function description

If, at minimum heating capacity, the intake temperature set

on the control element is exceeded, the fuel pump will be

shut down and combustion stops. To allow the flame to burn

out properly, the speed of the heating and combustion air fan

drops to partial load speed after 20 seconds, returns to the

initial speed after 15 seconds and then drops to the control

pause speed after 3 minutes where it remains during the

entire control pause phase.

The control pause speed for boat heaters is 0.

The heater will restart if the temperature at the room temperature sensor drops below the set temperature.

NOTE

Changes to the settings on the control element are implemented by the control unit/heater with a time delay.

3.6 Switching off

The ON indicator lamp on the control element goes out when

he heater is switched off. If no fuel has yet been delivered or

t

if the heater is in control pause mode, the heater will be

switched off immediately with no afterrunning period.

If fuel delivery has already begun it will stop immediately

when the heater is switched off. The heater is switched off in

the same way as the transition from control mode to control

pause. The heater is then switched off automatically.

NOTE

It is possible to switch the heater back on during the afterrunning period. In this case, afterrunning is completed and the

heater is then restarted.

3.7 Heater functions in ADR vehicles

NOTE

O

nly for Air Top 2000 STC diesel heaters that are installed in

vehicles for transporting dangerous goods (ADR):

Afterunning period will remain unchanged if the heater is

switched off at the control element.

A brief afterrunning period (max. 40 seconds) is started automatically when:

• The vehicle's engine is shut down

• A pumping device is placed into operation.

The control unit is in "fault lock-out" mode after an ADR shutdown. The control element must be set to "OFF" before starting up again.

3.8 Fault switch-off

The control unit detects faults in individual heater compo-

ents and malfunctions during start-up and operation. The

n

heater shuts down and assumes fault lock-out when:

• No repeated or faulty start-up

• Room temperature sensor defective

• Overheating sensor interrupted or short-circuited

• Overheating sensor installed incorrectly

• Glow plug interrupted or short-circuited

• Drive motor overloaded or blocked or short-circuited or

interrupted

• Flame monitor interrupted or short circuited

• Fault in fuel pump electrical circuit or in overheating

protection (only during start phase)

• Undervoltage below 10.5 V/21 V for longer than 20

seconds

• Overvoltage above 16 V/32 V for longer than 6 seconds

• Control unit defective

The fuel supply shuts down in the event of overheating. The

heater continues to run (afterrunning period) as when

switched off manually. Following the afterrunning period the

control unit is in fault lock-out mode if the count of the overheating counter is greater than the value programmed in the

data set (currently 20).

• Control element with display: the overheating fault code

is shown on the display.

• Control element without display: the overheating fault

code is indicated by the operating indicator flashing in

defined sequences.

Rectify fault.

Briefly switch the heater on and off (for at least 2 seconds) to

reset fault lock-out.

302

Page 16

3 Function description Air Top 2000 STC

3.8.1 Fault monitoring

Overheating, incorrect start and flame failure faults are

counted and, after the maximum number of permissible

faults have been exceeded, result in heater lock-out.

The incorrect start counter is incremented by 1 each time the

heater fails to start and decremented by 1 each time it starts

correctly, but never falls below 0. If the incorrect start counter reaches the maximum permissible value of 7, this indicates that the heater is in heater lock-out mode (HGVP).

The fault counter is incremented by 1 for each malfunction,

which does not have its own counter. The fault counter is

reset to 0 at the start of control mode. If the fault counter

reaches the maximum permissible value of 10, this indicates

that the heater is in heater lock-out mode.

The overheating counter is incremented by 1 each time the

heater overheats. If the overheating counter reaches the

maximum permissible value of 20, this indicates that the

heater is in heater lock-out mode.

The flame interruption counter (FAZ) is incremented by 1

each time the flame fails during heating mode. The counter

is decremented by 1 each time the heater assumes control

mode.

If the flame interruption counter reaches a value of 3 the

heater will assume fault lock-out mode and the permanent

flame interruption counter is incremented by 1. In control

mode, the permanent flame interruption counter is decremented by 1. When the heater is burning properly again, the

permanent flame interruption counter will return to 0 after a

few control cycles. If the permanent flame interruption counter exceeds the maximum permissible value of 3, the heater

will assume heater lock-out mode.

3.8.2 Resetting fault switch-off

1. Switch on the heater

2. There is a fault and it is detected by the control unit

as a malfunction

3. The fault code is shown on the control element

4. If set, cancel heater lock-out (as described in the fol-

lowing)

4.1. The heater detects a fault as a malfunction

4.2. Fault switch-off followed by fault lock-out

4.3. The fault code is shown on the control element

5. Switch off the heater

6. Determine cause of fault (e.g. with or without fault

code, visual inspection of fuses and plug connections,

...)

7. Rectify fault

8. Switch on the heater

9. Reset fault lock-out

10. The heater assumes control mode

Certain faults add to the fault count in the fault code mem-

ry. The heater assumes heater lock-out mode when the

o

number of faults in the fault code memory exceeds a limit

value. The maximum number of fault in the fault code memory and the limit value of the fault code memory is defined by

Webasto.

303

Reset heater lock-out

Heater lock-out can be reset:

– With Webasto Thermo Test PC diagnostics (WTT)

– or by switching on the heater.

Pull fuse F1 for at least 10 s.

Switch off the heater.

Reinsert fuse F1.

Switch on the heater.

Reset permanent heater lock-out

Only for "OE" heater variants that are integrated in bus sys-

tems.

The lock-out can only be released with the vehicle-specific

computer diagnosis system.

Page 17

Air Top 2000 STC 3 Function description

Page for notes

304

Page 18

4 Technical Data Air Top 2000 STC

4 Technical data

Wherever no limit values are specified, the technical data in

the table refer to the standard heater tolerances of ±10% at

an ambient temperature of +20 °C and at rated voltage

under standard conditions.

Fuel for Air Top 2000 STC B (petrol):

The fuel in accordance with DIN EN 228 as specified by the

vehicle manufacturer should be used.

Fuel for Air Top 2000 STC D (diesel/FAME):

The diesel fuel in accordance with DIN EN590 specified by the

Electrical components:

The control unit, drive motor for heating air and combustion

air fan as well as the glow plug are designed for 12 Volt or

24 Volt.

vehicle manufacturer must be used. Class EL fuel oil (not L

fuel oil) can also be used provided it complies with the normal

quality as per DIN 51603 available in the German market.

There are no known adverse effects of using additives.

The temperature sensor and flame monitor (only petrol

heater) are not designed for specific voltages.

If fuel is taken from the vehicle's fuel tank, follow the additive

instructions issued by the vehicle manufacturer.

When changing to low-temperature fuel, the heater must be

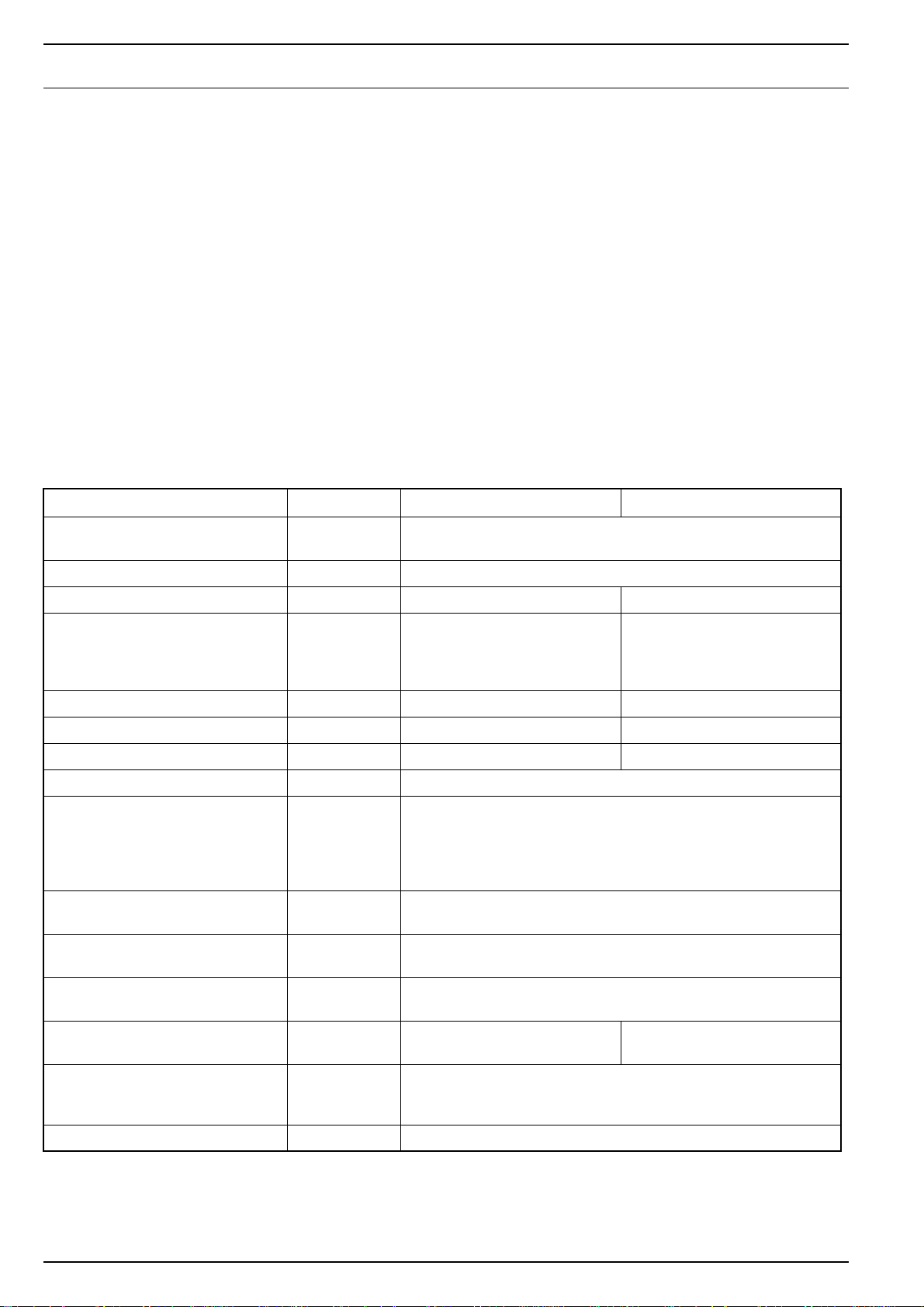

4.1 General technical data

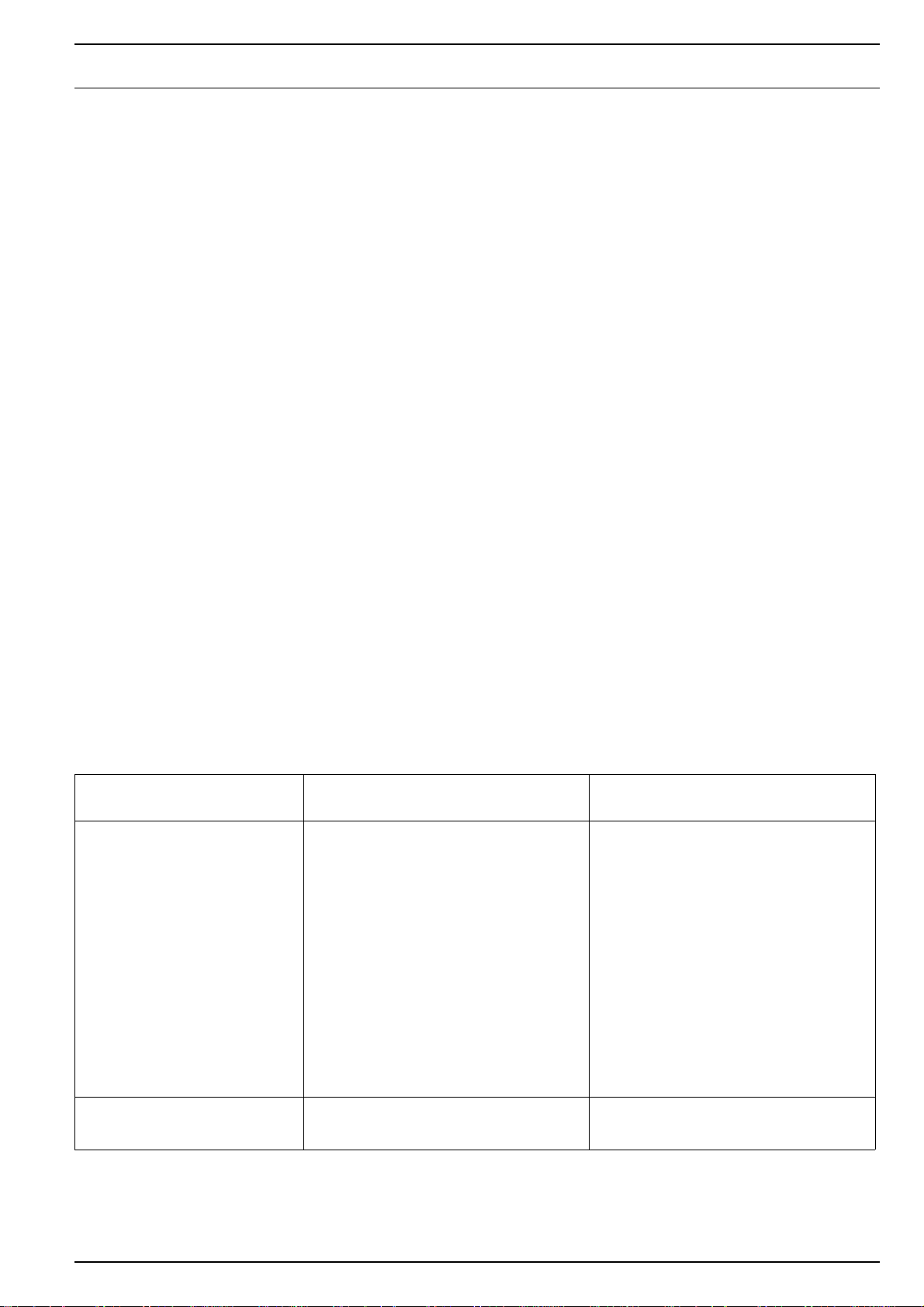

Heater Op

Type approval EMC

Design Air heater with evaporator burner

Heat flow Control range 1.0 - 2.0 kW 0.9 - 2.0 kW

eration Air Top 2000 STC B Air Top 2000 STC D

E1 R10- 04 1085

Heater

E1 R122- 00 0216

Fuel Petrol

DIN EN 228

DIN 51625

Fuel consumption Control range 0.1 - 0.2 kg/h (0.14 - 0.27 l/h) 0.1 - 0.21 kg/h (0.12 - 0.24 l/h)

Rated voltage 12 Volt 12 / 24 Volt

Operating voltage range 10.5 - 16 Volt 10.5 - 16 / 20.5 - 31 Volt

Rated power consumption Control range 14-29 W

Permissible ambient temperature:

Heater: - Operation

- Storage

Fuel pump: - Operation

- Storage

Permissible combustion air intake temperature

Adjustment range for interior temperature

Volumetric heating air flow rate

at motor speed

CO2 in exhaust gas (permitted function

range)

-40 to + 20 °C (petrol), -40 to + 30 °C (diesel),

Control range +5 to + 35 °C

at 0.5 mbar max. 93 m3/h

1 kW

2 kW

5.0 - 8.0 %

9.0 - 12.5 %

-40 to + 40 °C

-40 to + 85 °C

-40 to + 85 °C

-40 to + 20 °C

t 4750 U/min

a

Diesel/FAME

DIN EN 590

DIN 51603

DIN EN 14214

5.0 ... 8.0 %

9.0 ... 12.5 %

Heater dimensions Length 311 ± 2 mm

Width 120 ± 1 mm

Height 121 ± 1 mm

Weight 2.6 kg

Fig. 401 Technical Data Air Top 2000 STC

401

Page 19

Air Top 2000 STC 4 Technical Data

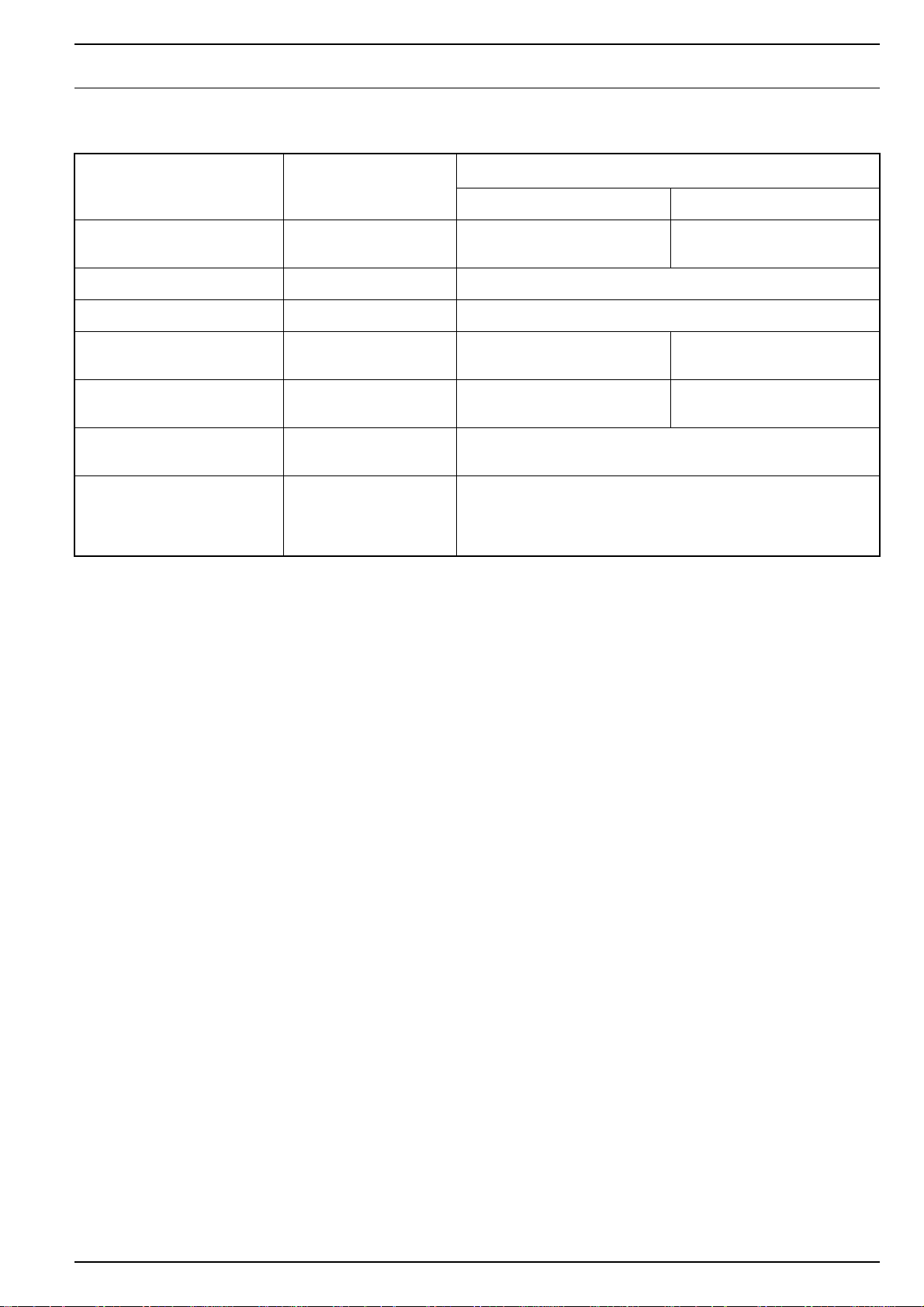

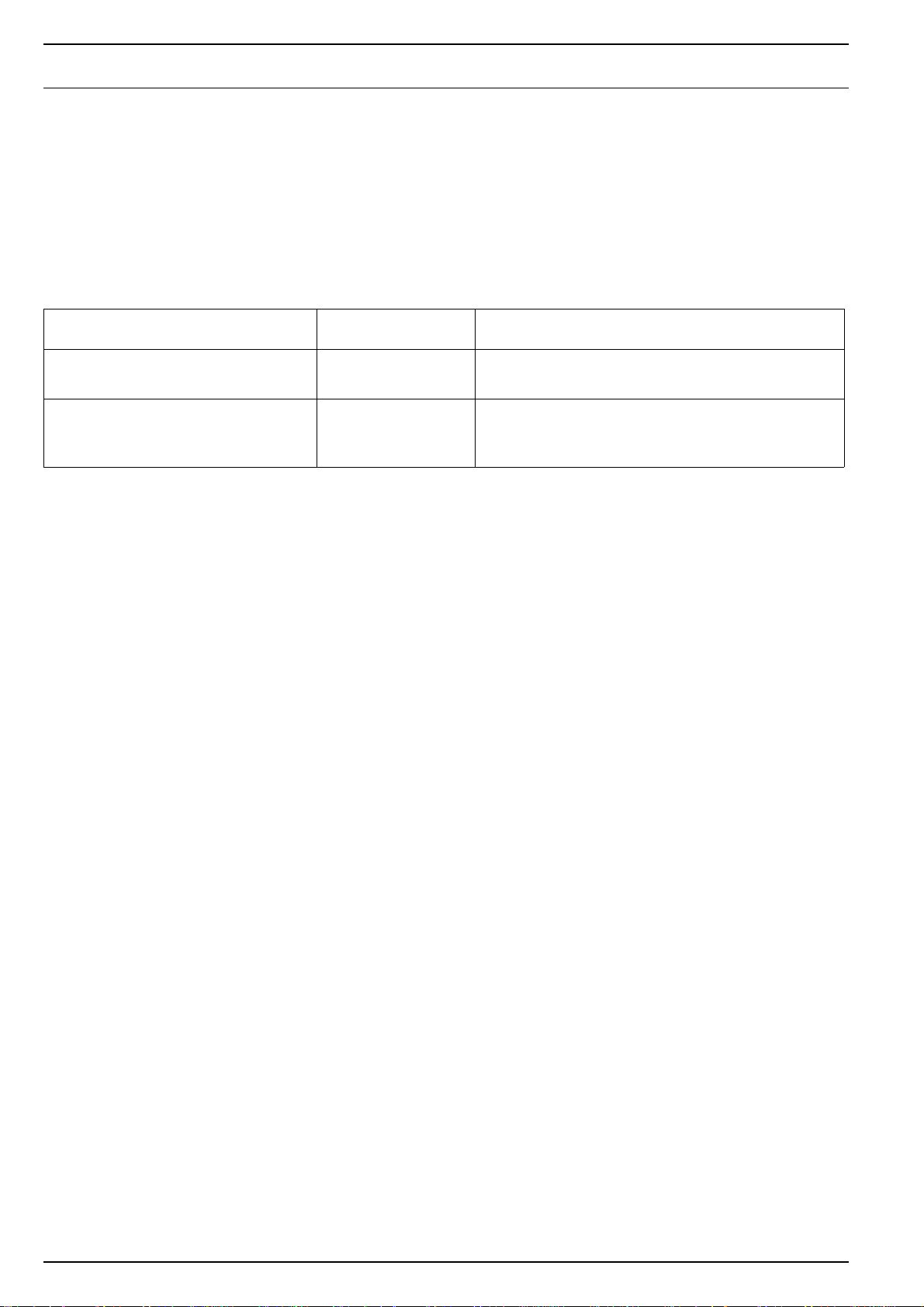

4.1 Setpoints

Heater Operation Air Top 2000 STC B and Air Top 2000 STC D

12 Volt 24 Volt

Glow plug At 25 ºC

Test current: < 5 mA

Drive motor Outside < 6 Ohm

Overheating temperature sensor at 25 ºC 2 - 2.5 Ohm

Undervoltage shut-down

(tripping time > 20 s )

Overvoltage shut-down

(tripping time > 6 s )

Flame monitor (cold test) At 25 ºC

Test current: < 5 mA

Flame monitor (hot test) At 800 – 1000 °C

Test current: < 5 mA

(ceramic rod red-hot over

approx. 20 mm length)

Red mark

0.263 - 0.323 Ohm

≤ 10.5 V ≤ 20.5 V

≥ 15 V ≥ 31 V

Green mark

1.125 - 1.375 Ohm

2.6 - 3.4 Ohm

12 - 15 Ohm

Fig. 402 Setpoints Air Top 2000 STC

402

Page 20

4 Technical Data Air Top 2000 STC

Page for notes

403

Page 21

Air Top 2000 STC 5 Troubleshooting

5 Troubleshooting

5.1 General information

This section describes how to identify and remedy faults in

the Air Top 2000 STC heater.

If a malfunction occurs, a fault code will be shown on the

display or the ON indicator lamp will flash (on control

elements with no display). The heater can be additionally

checked with a personal computer (see operating

instructions for Webasto Thermo Test PC Diagnostics).

ATTENTION

Troubleshooting assumes detailed knowledge of the design

and functional principle of the individual heater components

and must only be carried out by specifically trained personnel.

If in doubt, refer to Section 2 and 3 for information on how

the functions interact.

NOTE

For ADR operation only

The control unit is in "fault lock-out" mode after an ADR

shutdown or the operating voltage has been applied by

switching on the main switch in the vehicle and setting the

control element to ON. Before restarting the heater, the

control element must be set to "OFF" or the Quick Heat

button on the combination timer pressed.

ATTENTION

Troubleshooting is generally restricted to locating faulty

components. The following potential sources of malfunction

are not taken into account as they should always be checked

to rule them out as the cause of fault:

• Corroded connectors

• Loose plug connectors

• Poor crimp contacts on connectors

• Corroded cables and fuses

• Corroded battery terminals

The electrical plug connections at the control unit must be

disconnected to check individual components.

Carry out a function check in the vehicle after rectifying after

each fault.

5.2 General fault symptoms

The following table (Fig. 501) lists the possible fault symptoms.

ault symptom Possible cause Corrective measures

F

Heater cuts out automatically No combustion after start

and restart

ON indicator lamp flashes

Flame goes out during operation

ON indicator lamp flashes

Heater overheating

ON indicator lamp flashes

Battery voltage too low

ON indicator lamp flashes

Heater emits black smoke Combustion air and/or exhaust system

blocked

Briefly switch heater off and on again

Briefly switch heater off and on again

Check heating air routing for free

passage, allow heater to cool,

briefly switch heater off and on again

Charge battery

Briefly switch heater off and on again

Check combustion-air and exhaust-gas

routing for free passage

Fig. 501 General fault symptoms

501

Page 22

5 Troubleshooting Air Top 2000 STC

5.3 Fault symptoms during operation

The following table (Fig. 502) lists the possible fault

symptoms during operation which should be checked first.

In the event of a malfunction, the fault is to be located and

rectified with the aid of this table. It is important to ensure

that the fault symptom is clearly identified.

Fault symptom Occurrence Possible cause

Heater will not start and LED on control

element not lit

Heater will not start, but LED lit Immediate The heater immediately assumes control pause mode

NOTE

A fault code can be shown as follows:

• MultiControl and SmartControl control element:

The malfunction is shown in the form of a fault code which begins with F and a hexadecimal combination of numbers

and/or letters (F HEX).

See “5.4 Fault code output (hexadecimal / Webasto Thermo Test)” on Page 503.

• Control elements with display (not MultiControl/SmartControl):

The malfunction is shown in the form of a fault code which begins with F and a two-number combination (FXX).

See “5.5 Fault code output (flashing or FXX output)” on Page 506.

• Control elements with indicator lamp:

the malfunction is indicated in the form of a flash code. After 5 fast flash pulses, the fault code is output by a sequence

of long flash pulses. The long flash pulses must be counted.

See “5.5 Fault code output (flashing or FXX output)” on Page 506.

Immediate Incorrect wiring, defective fuse

Fig. 502 Fault symptoms during operation

If the fault symptom is not included in this table, or if the

malfunction cannot be found under the specific fault

symptom, the fault can be determined by means of the fault

codes as described in the following tables (Section 5.4 and

5.5).

In an emergency you can contact our technicians on our

Service Hotline.

when switched on; the control pause speed for a boat

heater is 0 rpm.

502

Page 23

Air Top 2000 STC 5 Troubleshooting

5.4 Fault code output (hexadecimal / Webasto Thermo Test)

Fault code

output:

HEX

00 No error No error No action necessary

01 Defective control unit

02 No start

Fault message Fault details Recommended measures

Defective control unit, wrong end-

of-line programming or coolant

temperatur sensor (at water

heaters) failure

After start-up has been repeated,

combustion still fails to occur

1) Check for fault in air intake and

2) Check for fault in fuel system

3) Check fuel pump

4) Electrical check of glow plug

Replace control unit

exhaust systems

03 Flame failure

04 Supply Voltage too high

05

06 Heating unit overheated

07 Heater lock-out Heater interlocked

Flame was detected prior to

combustion

The flame went out during

operation and combustion.

Supply voltage was too long above

maximum threshold value

Flame detector signals flame

before combustion operation

Overheat protection has been

activated or the temperature at the

heat exchanger has exceeded the

upper limit

See error 02

Check system voltage

1) Check for fault in air intake,

exhaust systems

2) Check for fault in fuel system

3) Check fuel pump

4) Electrical check of glow plug

1) Check for fault in air intake/blow-

out side, exhaust systems

2) Check for fault in fuel system

1) Reset heater lock-out and attempt

restart

2) Read out further fault messages

and work through instructions

Reset heater lock-out: switch on

heater. Pull fuse F1 for at least 10 s.

Switch off heater. Reinsert fuse F1.

Switch on the heater.

NOTE

Following fault occurred several

imes:

t

Fault counter: > 10x

False start counter: > 7x

Overheating counter: > 20x

08 Fuel pump short circuit

09

11 Wrong fuel coding

Combustion air fan short

circuit

Fuel pump has short circuit to

ground

Combustion air fan has short

circuit to ground

Incorrect parameter block or

wrong heater (diesel/gasoline)

used

Electrical check of fuel system

Electrical check of combustion air fan

motor

Replace control unit

503

Page 24

5 Troubleshooting Air Top 2000 STC

Fault code

output:

HEX

12

Fault message Fault details Recommended measures

1) Check for fault in area of W-bus

W-bus communication

failure

W-Bus communication failure

communication/W-bus control

element/W-bus Telestart

2) Replace control unit

14

15 Combustion air fan blocked Combustion air fan is blocked

17

18

19

81 EOL checksum error Checksum of EOL dataset is wrong Replace control unit

82 No start during test-run No start during test-run See error 02

83 Flame failure

84 Operating voltage too low

Temperature sensor short

circuit (internal, external)

Gradient exceedance

overheat protection

Communication failure on

customer specific bus

Glow plug / flame monitor

short circuit

Temperature sensor has short

circuit to ground

The temperature rise at the heat

exchanger has exceeded the upper

limit.

Communication failure on

customer specific bus

Glow plug / electronic ignition unit

has short circuit to ground

Flame interruption during

combustion operation, more than

FAZ (EEPROM) times.

Supply voltage was too long below

maximum threshold value

Electrical check of external/internal

temperature sensor

1) Check for fault in fan motor

2) Heating air intake fan wheel

snagging or jammed

3) Combustion air intake fan wheel

snagging or jammed

Check for fault in air intake/blow-

out side, exhaust systems

-

Electrical check of glow plug

See error 02

Check system voltage

88 Fuel pump interruption

89

91 Wrong control unit coding

92 Command refresh failure Command refresh failure

94

97

99

0 A

1 A Flame sensor short circuit

Combustion air fan

interruption

Temperature sensor

interruption (internal,

external)

Gradient undershooting

during start

Glow plug / electronic

ignition unit interruption

Glow plug / flame monitor

short circuit

Fuel pump interrupted or short

circuit to supply voltage UB

Combustion air fan interrupted or

short circuit to supply voltage UB

Control unit locked or coded as

neutral

Temperature sensor interrupted or

short circuit to supply voltage UB

Overheat sensor position wrong

(temperatur gradient too low)

Glow plug / electronic ignition unit

interrupted or short circuit to

supply voltage UB

Glow plug/Flame monitor circuit

has short circuit to ground

Flame sensor has short circuit to

ground

Electrical check of fuel system

Electrical check of fan motor

Replace control unit

Check for fault in area of W-bus

communication/W-bus control

element/W-bus Telestart

Electrical check of external/internal

temperature sensor

1) Check position of overheating

sensor

2) Check fuel supply system

Electrical check of glow plug

Electrical check of glow plug

Electrical check of flame monitor

504

Page 25

Air Top 2000 STC 5 Troubleshooting

Fault code

output:

HEX

Fault message Fault details Recommended measures

1B

8 A

9 A Flame sensor interruption

9B

AB

Overheat sensor short

circuit

Glow plug / electronic

ignition unit interruption

Setpoint potentiometer

interruption

Overheat sensor

interruption

The overheat sensor has a short

circuit to ground

Glow plug/Flame monitor

interrupted or short circuit to

supply voltage UB

Flame sensor interrupted or short

circuit to supply voltage UB

Setpoint potentiometer

interrupted or short circuit to

supply voltage UB

Overheat sensor interrupted or

short circuit to supply voltage UB

Electrical check of overheating sensor

Electrical check of glow plug

Electrical check of flame monitor

Electrical check of setpoint sensor

Electrical check of overheating sensor

505

Page 26

5 Troubleshooting Air Top 2000 STC

5.5 Fault code output (flashing or FXX output)

Fault code

output:

Flashing / FXX

F00 Defective control unit

F01 No start

F02 Flame failure

F03 Supply Voltage too high

Fault message Fault details Recommended measures

1) Check for fault in area of W-bus

Control unit defective

EOL programming error

No flame formed even after

repeated start attempt

The flame goes out during

operation and no longer reformed

after a restart attempt.

The operating voltage was higher

than the maximum permissible

value for too long

communication/W-bus control

element/W-bus Telestart

2) Replace control unit

1) Check for fault in air intake and

exhaust systems

2) Check for fault in fuel system

3) Check fuel pump

4) Electrical check of glow plug

See error 01

Check system voltage

F04

F05 Flame sensor interruption

F06

F07 Fuel pump interruption

F08

Flame was detected prior to

combustion

Temperature sensor

interruption (internal,

external)

Combustion air fan short

circuit

Combustion air fan blocked

The flame monitor detected a

flame before combustion started

There is a break or short to UB in

the electrical circuit of the flame

detector

There is a break or short to UB in

the temperature sensor

There is a break or short to UB in

the electrical circuit of the fuel

pump

The combustion air fan has a short

to ground or the fan motor is

overloaded

Combustion air fan blocking guard

has tripped

1) Check for fault in air intake,

exhaust systems

2) Check for fault in fuel system

3) Check fuel pump

4) Electrical check of glow plug

Electrical check of flame monitor

Electrical check of external/internal

temperature sensor

Electrical check of fuel system

Electrical check of combustion air fan

motor

1) Check for fault in fan motor

2) Heating air intake fan wheel

snagging or jammed

3) Combustion air intake fan wheel

snagging or jammed

F09

F10 Heating unit overheated

F11

506

Glow plug / electronic

ignition unit interruption

Overheat sensor

interruption

There is a break or short to UB in

the glow plug/ignition spark

generator

Overheating lock-out has tripped

(heater overheated)

There is a break or short to UB in

the electrical circuit of the

overheating sensor

Electrical check of glow plug

1) Check for fault in air intake/blow-

out side, exhaust systems

2) Check for fault in fuel system

Electrical check of overheating sensor

Page 27

Air Top 2000 STC 5 Troubleshooting

Fault code

output:

Flashing / FXX

F12 Heater lock-out Heater lock-out was activated

Fault message Fault details Recommended measures

1) Reset heater lock-out and attempt

restart

2) Read out further fault messages

and work through instructions

Reset heater lock-out: switch on

heater. Pull fuse F1 for at least 10 s.

Switch off heater. Reinsert fuse F1.

Switch on the heater.

NOTE

Following fault occurred several

imes:

t

Fault counter: > 10x

False start counter: > 7x

Overheating counter: > 20x

F14

F15

Gradient undershooting

during start

Setpoint potentiometer

interruption

Wrong position of overheating

sensor (overheating sensor

gradient too small)

There is a break or short to UB in

the electrical circuit of the setpoint

potentiometer

1) Check position of overheating

sensor

2) Check fuel supply system

Electrical check of setpoint sensor

507

Page 28

5 Troubleshooting Air Top 2000 STC

Page for notes

508

Page 29

Air Top 2000 STC 6 Function checks

Example of heater test bench

6 Function checks

6.1 General information

This section describes the checks conducted on the heater in

installed and uninstalled state to verify that it is in working

order.

CAUTION

The heater must not be operated in enclosed areas such as

garages and workshops without an emissions extraction

system.

ATTENTION

The complete testing of the heater and the control unit test

for "OEM" heaters are only possible together with the

vehicle.

6.2 Required test and measuring

quipment

e

The test and measuring equipment must be calibrated and

measuring equipment suitability must be certified.

Digital multimeter

For measuring electrical resistance [ohms], electrical

continuity

≤ 0.1 ohms

Test current < 5 mA

Heater test bench

For checking heater operation

Contact for Webasto heater test bench: International

Technical Support - International Hotline:

hotline.wt@webasto.com

Voltage source, adjustable

Supplies electrical voltage [Volt]

10 - 30 V

≥ 30 A

CO2 measuring device

or checking CO

F

Maximum ±0.3 vol%

PC (personal computer)

System requirements:

– See operating instructions for WTT Diagnostics

– Information can be found at dealers.webasto.com

Webasto diagnostics adapter including Webasto

Thermo Test software.

Diagnostic adapter Ident.-No. 9009064_ is available from

Webasto.

Display of fault code memory, operating data, control unit information.

Reference heater Air Top 2000 STC 24V diesel

The reference heater must be continually monitored.

value [vol%]

2

601

Page 30

6 Function checks Air Top 2000 STC

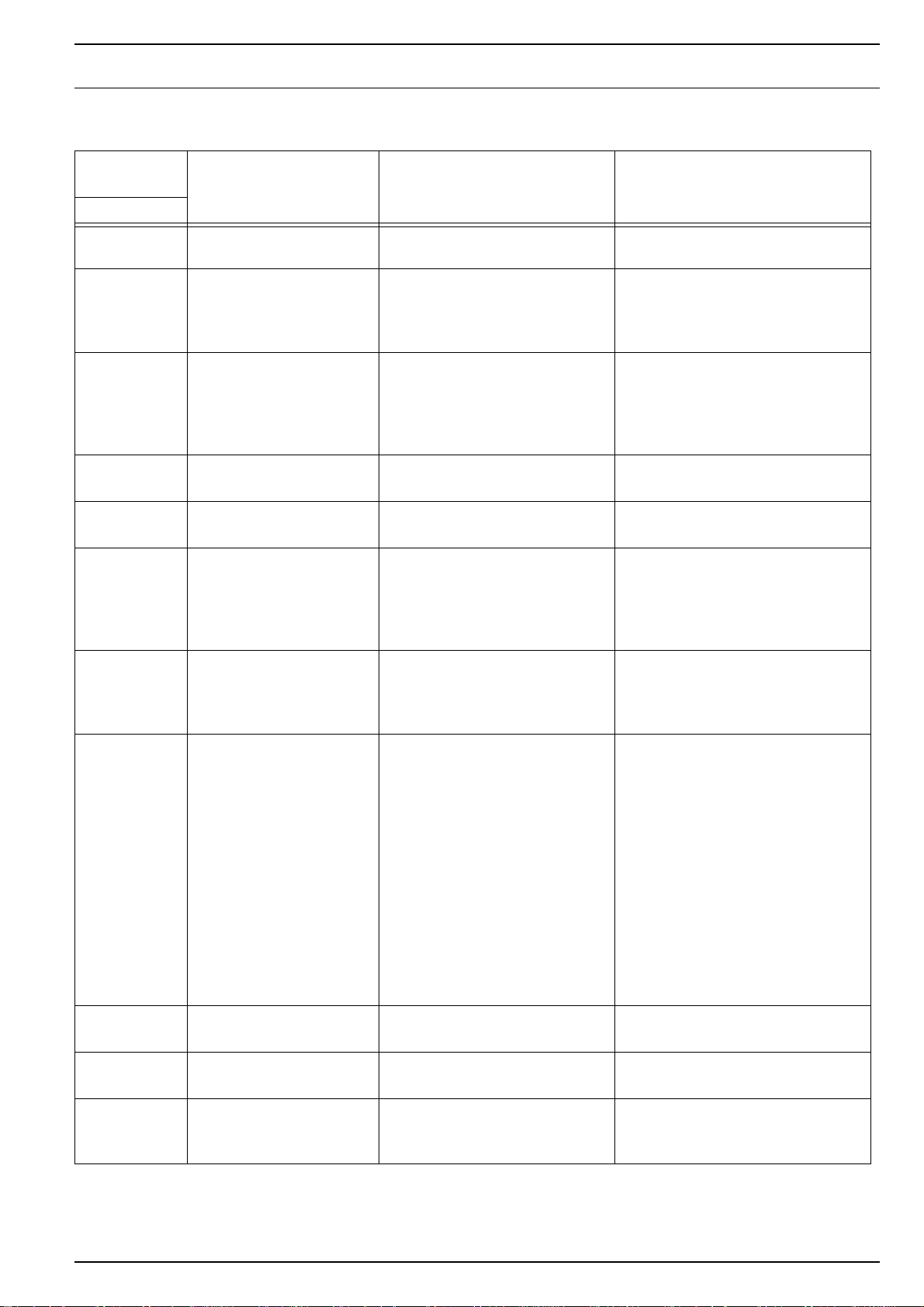

16

1 Rotary switch control element

2 Electrical vehicle interface

3 Heater fuse

4 Heating air outlet

5 Heating air outlet hose

6 Fuel pump

7 Fuel filter

8 Tank extracting device

9 Fuel tank

10 Fuel line

11 Exhaust pipe

12 Combustion air intake line

13 Heating air intake grille

14. Air Top Evo Multi Control (MC04) control element

15. Combination timer

16 MultiControl / SmartControl

A schematic diagram of the components necessary to operate a heater is shown below.

Application-specific interfaces must be taken into account. A calibrated fuel pump, which is continually monitored, must be

used for testing. The technical requirements are specified in the Webasto product documentation. Webasto components

should preferably be used. Pay particular attention to occupational health and safety.

602

Fig. 603 Component overview

Page 31

Air Top 2000 STC 6 Function checks

Geodetic altitude [m]

CO

2

value [vol.%]

CO2 [vol.%]

min. tolerance for operation [vol.%]

max. tolerance for operation [vol.%]

6.3 Settings

6.3.1 Setting the CO2 content

The CO2 content in the exhaust gas is set using the

adjustment knob on the control element. At a constant fan

speed, the volume of fuel is controlled by changing the fuel

pump cycle.

ATTENTION

The CO2 measuring instruments must be calibrated.

The heater must be switched off.

1. Connect the CO2 line to the negative terminal.

. Turn the adjustment knob on the control element to mid-

2

position. The heater starts up and automatically assumes

partial load mode.

NOTE

The operation indicator lamp flashes in the same way as for

a control unit fault when the heater is ready to be adjusted.

Diesel heaters:

3. Set the CO2 value by correspondingly turning the

adjustment knob. Turning the adjustment knob

anticlockwise reduces the CO2 value while turning the

knob clockwise will increase the value. The measured

CO2 content at partial load (1 kW) must be at 6.6 ±0.5%.

After adjustment, the CO2 content at full load should be

10.3 ±0.5 vol.%.

6.3.2 CO2 setting for reference heater

The reference heater is set at the factory to 10.3 vol.% CO2

a

t a geodetic altitude of 0 m. To subsequently reset the

heater, a CO2 value must be set as a function of the geodetic

altitude as shown in the diagram.

See Section 6.3.1.

Petrol heaters:

3. The CO2 content should only be measured with the

eater at operating temperature. For this purpose, the

h

heater should be operated for at least 8 minutes. The CO2

content is then set to 7.3 ±0.5 vol.% at partial load (1

kW). After adjustment, the CO2 content at full load

should be 10.3 ±0.5 vol.%.

Diesel and petrol heaters:

4. When the CO2 value is in the permissible range,

disconnect the CO2 line from the negative terminal. This

saves the setting.

NOTE

The heater will now run in normal mode again and can be

switched off at the control element.

The heater is set at the factory to match the fan motor.

603

Page 32

6 Function checks Air Top 2000 STC

6.4 Testing individual components

ATTENTION

When carrying out function tests, always disconnect the

connection between the control unit and the component to

be tested.

NOTE

If this procedure is not able to detect the fault, the heater/

component must be sent in to the Webasto Warranty

Department.

You will find the address for your Webasto dealer at

http://dealers.webasto.com.

NOTE

Damage caused by soiling will not be recognised by

Webasto!

Legend to flowchart:

1 Replace component. Within the warranty period, send

in the defective component (not the entire heater) to

Webasto.

2 Replace component and continue.

3 Replace heater. Within the warranty period, send in the

defective heater to Webasto.

4 Continue.

A (or B, C), see flowchart.

604

Page 33

Air Top 2000 STC 6 Function checks

2

1

1

2

1

1

Burner

Combustion chamber

mechanically damaged?

No

Yes

Starting air

hole open?

No

Check function on heater

test bench

Can CO2 value be set within

t

olerance?

No

Yes

Procedure Test and measuring

equipment

Visualisation

Visual inspection

Visual inspection

Visual inspection

Blow through

with mouth

Check function

with reference

heater.

After 5 minutes of

full load operation, set reference

heater to nominal

CO2 value as

shown in the

graphic, install the

burner to be

tested in the

reference heater

and measure the

CO2 value after 5

m

inutes of full

load operation

– Heater test bench

– CO2 measuring de-

v

ice

– Webasto diagnos-

tics adapter