Page 1

List of Contents

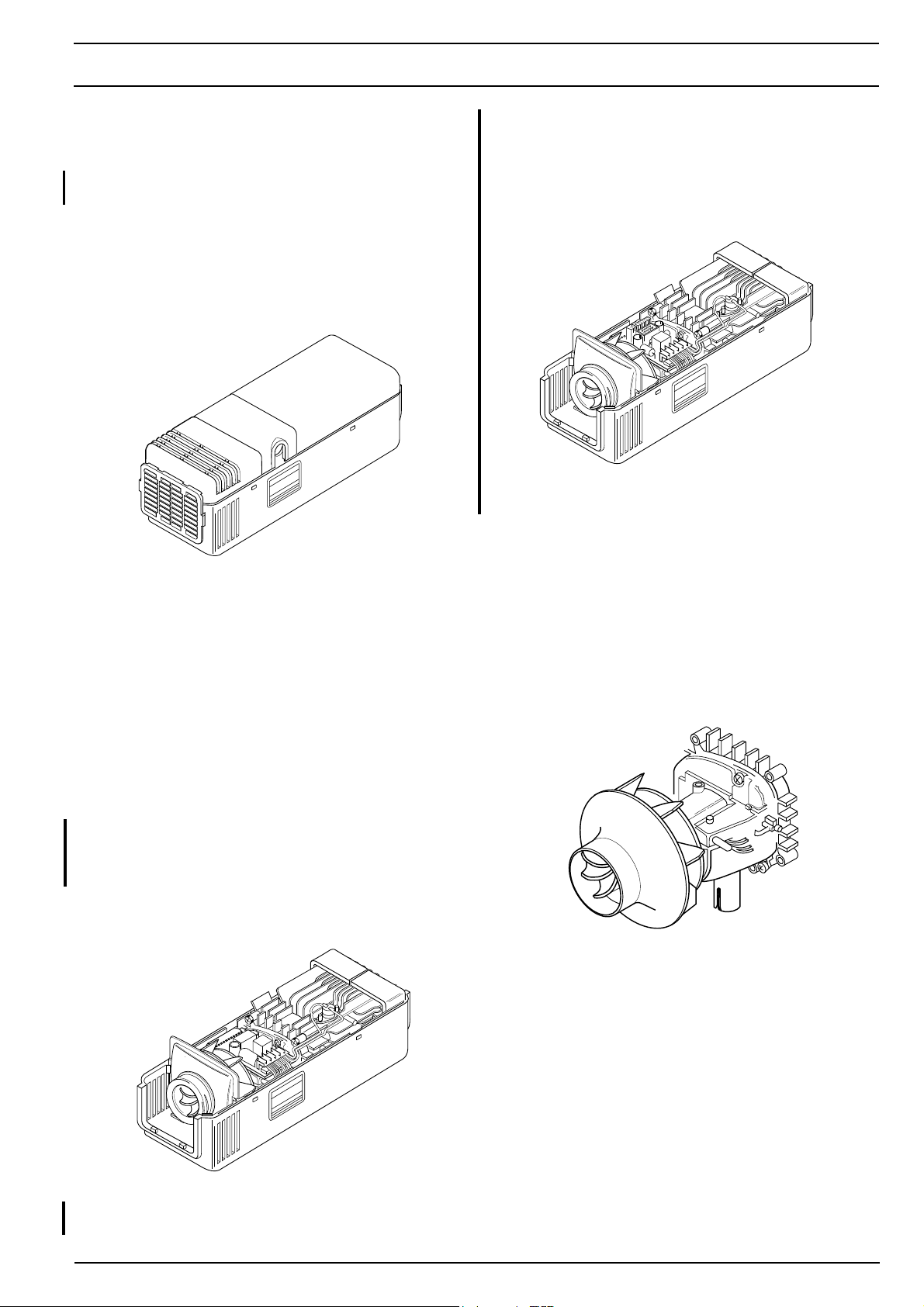

Air Top 2000

Air Heater

Air Top 2000 D (Diesel)

Air Top 2000 B (Gasoline)

Service and Repair Manual

NOTE

Technical changes in this issue of the

manual compared with its previous issue

are identified with a vertical change bar on

the lefthand side of columns.

– Improper installation or repair of Webasto heating and cooling systems can cause

fire or the leakage of deadly carbon monoxide leading to serious injury or death.

– Installation and repair of Webasto heating and cooling systems requires special

Webasto training, technical information, special tools and special equipment.

– NEVER attempt to install or repair a Webasto heating or cooling system unless you

have successfully completed the factory training course and have the technical skills,

technical information, tools and equipment required to properly complete the

necessary procedures.

– ALWAYS carefully follow Webasto installation and repair instructions and heed all

WARNINGS.

– Webasto rejects any liability for problems and damage caused by the system being

installed by untrained personnel.

Page 2

Air Top 2000

List of Con tents

List of Cont en ts

1. Introduction

1.1 Scope and Purpose.................................................................................................................................101

1.1.1 Use of Air Heaters...................... .......... ........ .......... .......... .......... .......... ........ .......... .......... .......... .101

1.2 Meaning of Warnings, Cautions, and Notes............................................................................................101

1.3 Additional Documentation to be used................................................................................................. .....101

1.4 Safety Information and Regulations........................................................................................................101

1.4.1 General Safety Notes......................................................................................... .........................101

1.5 Legal Provisions for Installation...................................................... ................ ................ ................ .........102

1.6 Corrections and Improvements.......... ................ ................ ................ ................ ................ ................ .....103

2. General Description

2.1 Combustion and Heating Air Fan ............................................................................................................201

2.2 Heat Exchanger.................................................................. ................ ................ ................ ................ .....202

2.3 Burner Insert with Com bustion Tube........................ .......... .......... ........ .......... .......... .......... .......... ........ ...202

2.4 Control Unit / Control Circuit Board.................. ................ ................ ................ ................ ................ .......202

2.5 Flame Sensor..........................................................................................................................................203

2.6 Glow Plug........................................................... ................................................ .....................................203

2.7 Temperature Limit er. ...... ........ .......... .......... .......... .......... ........ .......... .......... .......... .......... ........ .......... .......203

2.8 Dosing Pump...........................................................................................................................................20 3

3. Functional Description

3.1 Functional Description Air Top 2000 without Diagnosis (Fig. 301)..........................................................301

3.1.1 Control Element..........................................................................................................................301

3.1.2 Switch-On....................................................................................................................................301

3.1.3 Stabilization.................................................................................................................. .. .. .. .. .. .. .. .301

3.1.4 Heating Operation.......................................................................................................................301

3.1.5 Control Operation........................................................................................................................302

3.1.6 Control Idle..................................................................................................................................302

3.1.7 Switch-Off....................................................................................................................................302

3.1.8 Functions of the Air Heater in TRS Vehicles............................................ .......... .......... .......... .....302

3.1.9 Switch-Off upon Failure...............................................................................................................302

3.2 Functional Description Air Top 2000 Diagnosis................................................................................ .......304

3.2.1 Control Element..........................................................................................................................304

3.2.2 Switch-On....................................................................................................................................304

3.2.3 Stabilization.................................................................................................................. .. .. .. .. .. .. .. .304

3.2.4 Heating Operation.......................................................................................................................305

3.2.5 Control Operation........................................................................................................................305

3.2.6 Control Idle..................................................................................................................................305

3.2.7 Switch-Off....................................................................................................................................305

3.2.8 Functions of the Air Heater in TRS Vehicles............................................ .......... .......... .......... .....305

3.2.9 Switch-Off upon Failure...............................................................................................................306

4. Technical Data .... ........ ........ ........ ............ ........ ............ ........ ........ ............ ........ ............ ........ ........ ............ .......401

I

Page 3

List of Contents

5. Troubleshooting

5.1 General....................................................................................................................................................501

5.2 General Failure Symptoms.................................................................................................... ..................501

5.3 Failure Symptoms during Operation........................................................................................................502

5.4 Error Code Output (Air Top 2000 Diagnosis) ............................................................ ................ ..............503

6. Functional Test s

6.1 General....................................................................................................................................................601

6.2 Adjustments................................................................................................... ..........................................601

Air Top 2000

6.2.1 Adjustment of the CO

6.3 Components Testing .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .........602

6.3.1 Glow Plug Resistance Test.........................................................................................................602

6.3.2 Flame Sensor Resistance Test............................... ....................................................................602

7. Circuit Diagrams

7.1 General....................................................................................................................................................701

8. Servicing

8.1 General....................................................................................................................................................801

8.2 Work on the Air Heater.......................... .......... ........ .......... .......... .......... .......... ........ .......... .......... .......... ..801

8.3 Work on the Vehicle .................................................................................................. ..............................801

8.4 Air Heater Test Run.................................................................................................................................801

8.5 Servicing..................................................................................................................................................801

8.6 Visual Inspections and Installation Regulations ......................................................................................801

8.6.1 Heating Air System ........ .......... ........ .......... .......... .......... .......... ........ .......... .......... .......... .......... ....801

8.6.2 Fuel Supply............................................................................................................. ....................802

8.6.3 Dosing Pump...............................................................................................................................804

8.6.4 Fuel Filter.......................................... .......... .......... .......... .......... ........ .......... .......... .......... .......... ..804

8.6.5 Combustion Air Supply................................................................................................................805

8.6.6 Exhaust Line ...............................................................................................................................805

8.6.7 Combustion Air Intake and Exhaust Lines..................................................................................805

8.6.8 Electrical Connections.................................................................................................................806

Contents......................... .......................................................... ..............601

2

8.7 Removal and Installation.........................................................................................................................808

8.7.1 Air Heater, Removal and Installation................................................... ................ ................ ........808

8.7.2 Replacement of Control Unit.......................................................................................................808

8.7.3 Replacement of Temperature Limiter..........................................................................................808

8.8 Installation of new Control Units..............................................................................................................811

8.8.1 Replacement of Control Unit Air Top 2000 (12 Volt)

with External Temperat ure Sensor............................................................ ................ ................ ..811

8.8.2 Replacement of Control Unit Air Top 2000 (24 Volt) not TRS.....................................................811

8.8.3 Replacement of Control Unit Air Top 2000 (24 Volt) TRS......................................................... ..812

8.9 First Operation.........................................................................................................................................812

II

Page 4

Air Top 2000

9. Repair

9.1 General....................................................................................................................................................901

9.1.1 Work on Components after Disassembly....................................................................................901

9.1.2 Incorporation of Modifications.............................................................. .. .....................................901

9.2 Disassembly and Assembly.....................................................................................................................902

9.2.1 Removal of Housing Components/Covers..................................................................................902

9.2.2 Replacement of Control Unit.......................................................................................................904

9.2.3 Replacement of Temperature Limiter............................................................. ................ .............904

9.2.4 Replacement of Combustion Air Fan ..........................................................................................905

9.2.5 Replacement of Flame Sensor....................................................................................................906

9.2.6 Replacement of Glow Plug..........................................................................................................906

9.2.7 Replacement of Burner Insert, Combustion Tube, and Heat Exchanger....................................909

10. Packaging/Storage and Shipping

10.1 General..................................................................................................................................................1001

List of Con tents

III

Page 5

Lis t of Figu res

Air Top 2000

Lis t of Figu res

301 Functional Diagram (Air Top 2000 without Diagnosis)....................................................................................303

501 General Failure Symptoms.............................................................................................................................501

502 Failure Symptoms during Operation...............................................................................................................502

601 Adjustment of CO

701 Terminal Pin Assignment, Air Top 2000 Diagnosis.........................................................................................701

702 Terminal Pin Assignment, Air Top 2000 without Diagnosis............................................................................702

703 Circuit Diagram Automatic Control Air Top 2000 Diagnosis, 12V/24V with Control Element.........................703

704 Circuit Diagram Automatic Control Air Top 2000 Diagnosis, 12V/24V with Combination Tim er.....................704

705 Circuit Diagram Automatic Control Air Top 2000 Diagnosis,

12V/24V with Control Elem ent and Standard Tim er........................................... ................ ................ ............705

706 Circuit Diagram Automatic Control Air Top 2000 Diagnosis,

24V TRS Operation with Control Element................................................................ ................ ................ ......706

707 Circuit Diagram Automatic Control Air Top 2000 Diagnosis,

24V TRS Operation with Combination Tim er.................................................... ................ ................ ..............707

708 Circuit Diagram Automatic Control Air Top 2000 Diagnosis,

24V TRS Operation with Combination Tim er and 2 Auxiliary Drives..............................................................708

709 Circuit Diagram Automatic Control Air Top 2000 without Diagnosis, 12V with Control Element....................709

710 Circuit Diagram Automatic Control Air Top 2000 without Diagnosis,

12V with Control Element and Timer.................................................. ................ ................ ................ ............710

711 Circuit Diagram Automatic Control Air Top 2000 without Diagnosis, 24V with Control Element....................711

712 Circuit Diagram Automatic Control Air Top 2000 without Diagnosis,

24V with Control Element and Timer.................................................. ................ ................ ................ ............712

713 Circuit Diagram Automatic Control Air Top 2000 without Diagnosis,

24V with Control Element , TRS................................................ ................ ................ ................ ................ ......713

714 Circuit Diagram Automatic Control Air Top 2000 Diagnosis,

24V TRS Operation with Control Element in Vehicles without Auxiliary Drive................................................714

715 Connection Diagram, Air Top 2000 Diagnosis with Combination Timer (not TRS!).............................. ..........715

Contents ..........................................................................................................................601

2

801 Fuel Supply.....................................................................................................................................................802

802 Webasto Fuel Tank Tap ................................................................................................................................. 803

803 Fuel Tapping from Plastic Tank (tapping via fuel drain plug).................................................. ................ ........803

804 Fuel Tapping from Plastic Tank (tapping via fitting plate)......................................................................... ......803

805 Pipe/Hose Connection....................................................................................................................................804

806 Dosing Pumpe, Installation Position and Attachment....................................................................... ..............804

807 Fuel Filter................................................................ ................................................ .. ......................................804

808 Exhaust Muffler, Direction of Flow..................................................................................................................805

809 Exhaust Pipe Outlet, Installation Position..................................... ................ ................ ................ ................ ..805

810 Removal of Fuse Holder Attachment Plate.....................................................................................................806

811 Fuse Holder, Installation Position ........................................... ................ ................ ................ ................ ........806

812 Control Element..............................................................................................................................................806

813 Pulling the Plug...............................................................................................................................................806

814 Example of an Installation...............................................................................................................................807

815 Replacement of Control Unit and Temperature Limiter (Air Top 2000 without Diagnosis).............................809

816 Replacement of Control Unit and Temperature Limiter (Air Top 2000 Diagnosis)..........................................810

901 Removal of Housing Components/Covers......................................................................................................903

902 Replacement of Combustion Air Fan (Removal) ............................................................................................904

903 Replacement of Combustion Air Fan (Disassembly)......................................................................................905

904 Disassembly of Heat Exchanger........................................................................................................... ..........907

IV

Page 6

Air Top 2000

1 Introduction

1. Introduction

1.1 Scope and Purpose

This repair shop manual is intended to support familiarized personnel in the repair of air heaters Air Top

2000 of the fuel and Diesel type as well as of Air Top

2000 Diagnosis with serial no. 30.000 and up.

1.1.1 Use of Air Heaters

The air heaters Air Top 2000 and Air Top 2000 Diagnosis are used to

- heat the cabin

- defrost the windscreens.

They are not cleared for heating a transportation com-

partment for dangerous goods.

The heaters operate independent from the vehicle engine and are connected to the fuel tank and to the electrical system of the vehicle. Their use is possible in

vehicles with water- or air-cooled engines.

1.2 Meaning of Warnings, Cautions

and Notes

WARNINGS, CAUTIONS, and NOTES in this manual

have the following meaning:

WARNING

This heading is used to highlight that non-compliance

with instructions or procedures m ay cause injuries or

lethal accidents to personnel.

CAUTI ON

This heading is used to highlight that non-compliance

with instruct ions or procedures m ay cause dam age to

equipment.

NOTE

This heading is used to highlight and draw specific attention to information.

1.3 Additional Documentation to be used

This workshop manual contains all informat ion and procedures necessary for the repair of heaters Air Top 2000

and Air Top 2000 Diagnosis.

The use of additional documentation is normally not

necessary.

Operating instructions/ins tallat ion instruct ions and the

vehicle specific installation proposal may be used as

complementary inform ation as necessary .

1.4 Safety Information and Regulations

The general safety regulations for the prevention of accidents and the relevant operating safety instructions have

to be observed at all times."General Safety Regulations"

beyond the scope of these regulations are detailed in the

following.The specific safety regulations applicable to

this manual are highlight ed in the individual chapters by

Warnings, Cautions, and Notes.

1.4.1 General Safety Notes

Within the scope of the StVZO (Road Licensing Regulations of the Federal Republic of Germany) “Design

General Approvals”, laid down by the Federal Office for

Motor Traffic, exist for the Water Heater Air Top 2000

and Air Top 2000 Diagnosis with the following official

marks of conformity:

-S 270 (Diesel)

-S 277 (Fuel)

The installation of the heaters is to be performed in accordance with the installation instruct ions and must be

checked in case of

a) the vehicle type inspection in accordance with

§ 20 StVZO

b) the individual inspection in accordance with

§ 21 StVZO or

c) the examination in accordance with § 19 StVZO

performed by an officially authorised expert or examiner for road traffic, a vehicle inspector or a public

servant as per section 7.4 a of Annex VIII to the

StVZO.

In the event of c) the installation must be certified on the

acceptance certificate included in the copy of the

“General Operating License” giving details about

- manufacturer

- ty pe of vehicle , and

- vehicle identif ication num ber.

This validates the “Design General Approval”.

The acceptance certi ficate must be kept with the

vehicle.

The year of first operation must be permanently

marked on the identification label.

The heaters are cleared for heating the passenger and

driver cabins but not for heating compartments intended

for the transportation of dangerous goods.

The use of the heater in special vehicles (e.g. vehicles

for the transportation of dangerous goods TRS) or vehicles not subject to the StZVO (e.g. ships) are ruled by

partially regional regulations.

For the installation of the

the transportation of dangerous goods, in addition to the

StVZO, the requirements in TRS 002 and TRS 003

(Technical Guidelines for the Transportation of Dangerous Goods on Roads) must be met.

AT 2000 D in vehicles used for

101

Page 7

1 Introduction

Air Top 2000

The heater must not be installed in the passenger or

driver compartments of busses. Should the heater nevertheless be installed in such a compartment, the installation box must be sealed tight against the vehicle interior.

There must be sufficient ventilation of the installation box

from the exterior in order not to exceed a maximum temperature of 40 °C in the installation box.

At filling station s and fuel depots the heat er mu st be

switched off as there is a potenti al dan ger of exp losion.

Where flammable fumes or dust may build up (e.g.

in the vicini ty of fuel, coal , wood, cereal depots, or

similar installat ions) the heat er must be switched off

to prevent explosions.

Due to the danger of poisoning and suffocation the

heater must not be operated in enclosed areas such as

garages or workshops without exhaust venting, not even

if the start-up is activated by the timer or telest art device.

When removing the heater the gasket below must be replaced.

The heat exchanger of the air heater remains serviceable for a maximum of 10 years and must then be r eplaced with an original spare part by the manufacturer or by one of its authorized workshops.

The heater must then be provided with a label

marked with the sales date and with the words “Original Spare”.

Should exhaust pipes be rou ted through room s

accommodating person s, these pipes shal l also be

renewed after 10 years.

Heating Air System

Heating air intake openings must be arranged so that

under normal operating conditions exhaust fumes of the

vehicle engine or air heater are not likely to be expected.

Extracting combustion air from the vehicle interior is not

permissible.

Combustion A ir Line

The combustion air required must be taken from the

exterior.

Within rooms accommodat ing persons, the com busti on

air lines must not have more than four disconnects and a

splash-water protected ext erior w all feedthrough. The

disconnects must be sealed in a way not to exceed a

leak rate of 200 l/h at an overpressure of 0.5 mbar.

The line including feedthrough, disconnects, material

and specific type must be described in the installation

instructions.

The line must require tools for installation and removal,

must be protected against damage, and must be shockproof.

Exhaust Line

Heaters must be designed to discharge the exhaust to

the exterior.

Exhaust pipes must be routed so that exhaust fumes are

unlikely to penetrate into the vehicle’s interior.

The function of any parts of the vehicle essential for its

operation must not be impaired. Condensate or water

penetrated must not be able to accumulate in the

exhaust line.

Drain holes are permissible; these must drain the fluid to

the exterior via lines sealed against the vehicle interior.

Installations not legally authorized will void the air

heater’s “Official Marks of Conformity” and thus the

vehicle’s permit of operation. The same applies for

repairs performed by unskilled personnel and repairs

with no original spare parts.

1.5 Legal Provisions for Installation

For testing the heater in accordance with 19, 20, or 21

of the StVZO the following regulations are to be observed in particular (§ 22 a StVZO):

Testing is performed upon presentation of the operating

and installation instructions of the manufacturer.

The year of the initial operation must be durably marked

on the heater identification plate by the installing person.

The exhaust line outlet is to be positioned to the top, to

the side, or in case of exhaust venting below the vehicle

floor, to the nearest possible location of the vehicle’s or

cockpit’s side or rear end. In compartments accommodating persons, exhaust lines must not have more th an

one disconnect and must have a splash-water protected

feedthrough in the exterior wall/floor . For water , that has

penetrated into the exhaust line, the connection of a

drain line with a metal-sealing joint is permissible. The

drain pipe must be routed sealed through the exterior

wall or the vehicle floor.The heat exchanger, the exhaus t

line connected, as well as the possible drain pipe must

be sealed so that with an overpressure of double the

overpressure of the exhaust having the maximum permissible exhaust line length - at least however at an overpressure of 0.5 bar - a total leak rate of 30 l/h is not

exceeded.

The line including feedthrough, disconnects, material

and specific type must be described in the installation

instructions.

The line must require tools for installation and removal,

must be protected against damage, and must be shockproof.

102

Page 8

Air Top 2000

1 Introduction

Metal lines must be used. These m ay not heat to m ore

than 110 °C should there be the possibility of contact

within the room interior. Protective devices against contact may be fitt ed.

Should exhaust pipes be routed through rooms accommodating persons, these pipes shall be renewed after 10

years using genuine spare parts.

Combustion Air Inlet and Exhaust Outlet

During installations these ports for combustion air entry

and exhaust fume exit must be of such type, that a ball

with a diameter of 16 mm cannot be inserted.Elec tric al

lines, switch gear and control gear of the heater must be

located in the vehicle so that their proper function cannot

be impaired under normal operating conditions.

For the routing of fuel lines and the installation of additional fuel tanks §§ 45 and 46 of the StVZO are to be

adhered to.

The most important regulations are: Fuel lines are to be

designed in such a way that they remain unaffected by

torsional stresses in the vehicle, engine movement and

the like. They must be protected against mechanical

damage.

Fuel-carrying parts are to be protected against excessive heat and are to be arranged so that any dripping

or evaporating fuel can neither accumulate nor be ignited by hot c omponents or electrical equipment.

In busses, fuel lines and fuel tanks may be located

neither in the passenger area nor in the driver’s compartment. In these type of vehicles the fuel tanks must be located such that they do not pose a direct hazard to the

exits in the event of a fire. Fuel supply must not be by

means of gravity or pressurization of the fuel tank.

1.6 Corrections and Improvements

Deficiencies, improvements , or proposals for correction

of this workshop manual are to be mailed to:

Webasto Thermosys tem e Gmb H

Abt. Technische Dokumentation

D-82131 Stockdorf

Telephone: 0 89 / 8 57 94 - 5 42

Telefax: 0 89 / 8 57 64 10

Installat ion Rules for Webasto Fuel Tanks for the

Fuel Supply of Heaters in Vehicles

In busses the installation is not permitted in the passenger or driver compartment.

The fuel fill neck must in no vehicle be located within any

of these compartments.

Fuel containers for carburettor fuel must not be located

immediately behind the front panelling of the vehicle.

They must be sparate from the engine so that even in

case of an accident the inflammation of fuel is unlikely to

be expected. This does not apply for towing vehicles

with an open cockpit.

The operational state of the heater, i.e. an indication “on”

or “off”, must be easily and clearly visible.

103

Page 9

Air Top 2000

2 General Description

2. General Description

The air heater Air Top 2000 and Air Top 2000 Diagnosis

with serial no. 30.000 and up operating to the evaporator

principle basically consist of:

- combustion and heating air fan

- heat exchanger

- burner insert with combustion tube

- control unit

A malfunction in air heaters Air Top 2000 Diagnosis outputs an error code to the display of the combination or

standard timer. When equipped with a control element

the operating indicator flashes. In addition a heater checkout may be performed using a personal computer (refer

to operating instructions PC air heater diagnosis).

Air Heater Air Top 2000 Diagnosis

(covers removed)

Air Heater Air Top 2000

For control and monitoring a

- control unit/control circuit board

- flame sensor

- glow plug

- temperature limiter

- temperature sensor

are located within the unit.

12 Volt heaters (Air Top 2000 without Diagnosis) may be

controlled by means of an external temperatur e sensor.

All heaters of air Top 2000 Diagnosis may be controlled

by means of an external temperature sensor.

Fuel supply is provided externally by a fuel dosing pump.

2.1 Combustion and Heating Air Fan

The combustion and heating air fan delivers the air required for combustion from the combustion air inlet to

the burner insert. By means of the fan the heating air is

also delivered to the air outlet.

Combustion and Heating Air Fan

Air Heater Air Top 2000 without Diagnosis

(covers removed)

201

Page 10

2 General Description

Air Top 2000

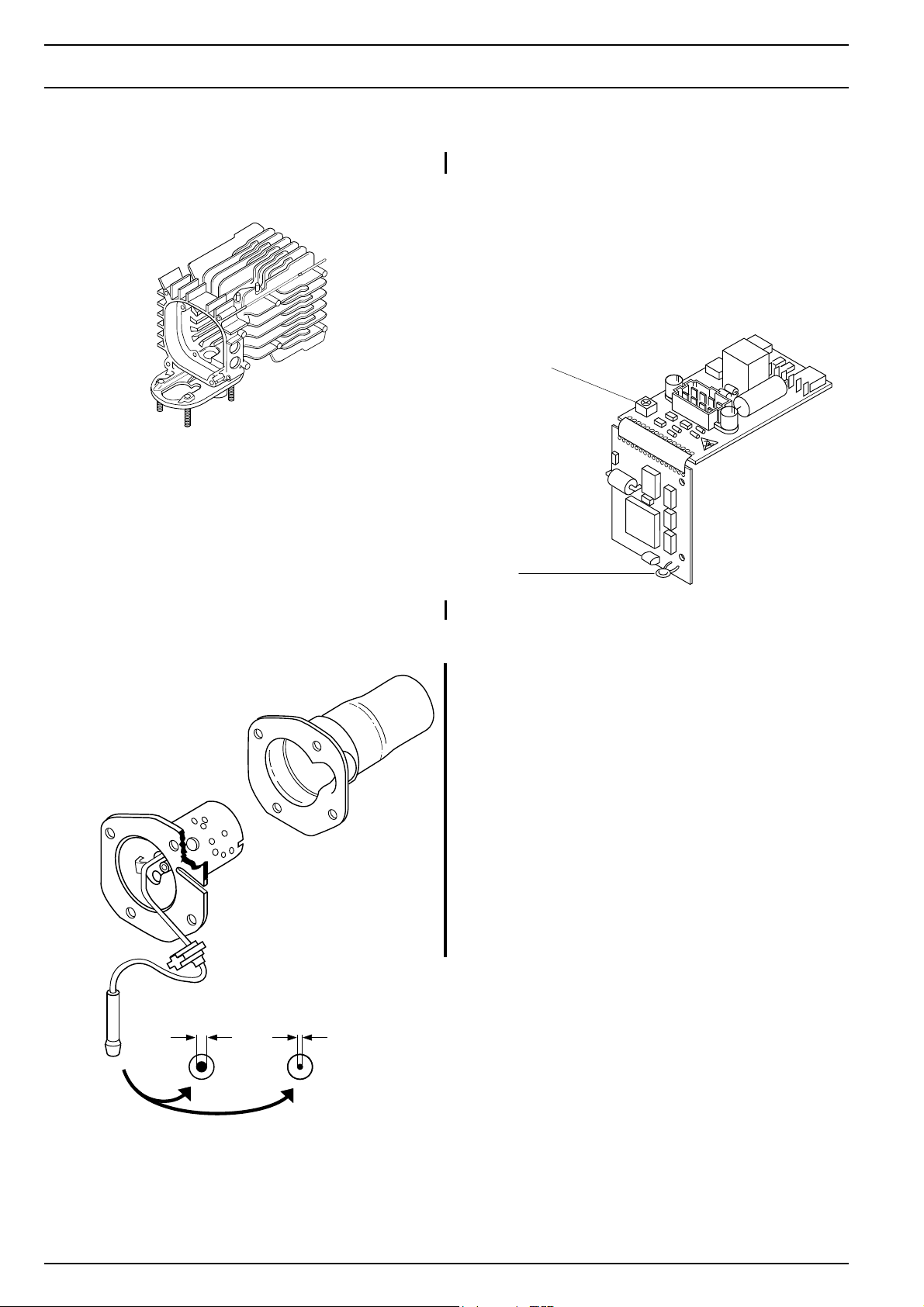

2.2 Heat Exchanger

The heat exchanger dissipates the heat provided by

combustion to the air delivered by the combustion and

heating air fan.

Heat Exchanger

2.3 Burner Insert with Combustion Tube

Within the burner insert fuel is distributed in the combustion tube across the burner cross-section. In the combu stion tube the combustion of the fuel/air mix ture tak es

place heating up the heat exchanger.

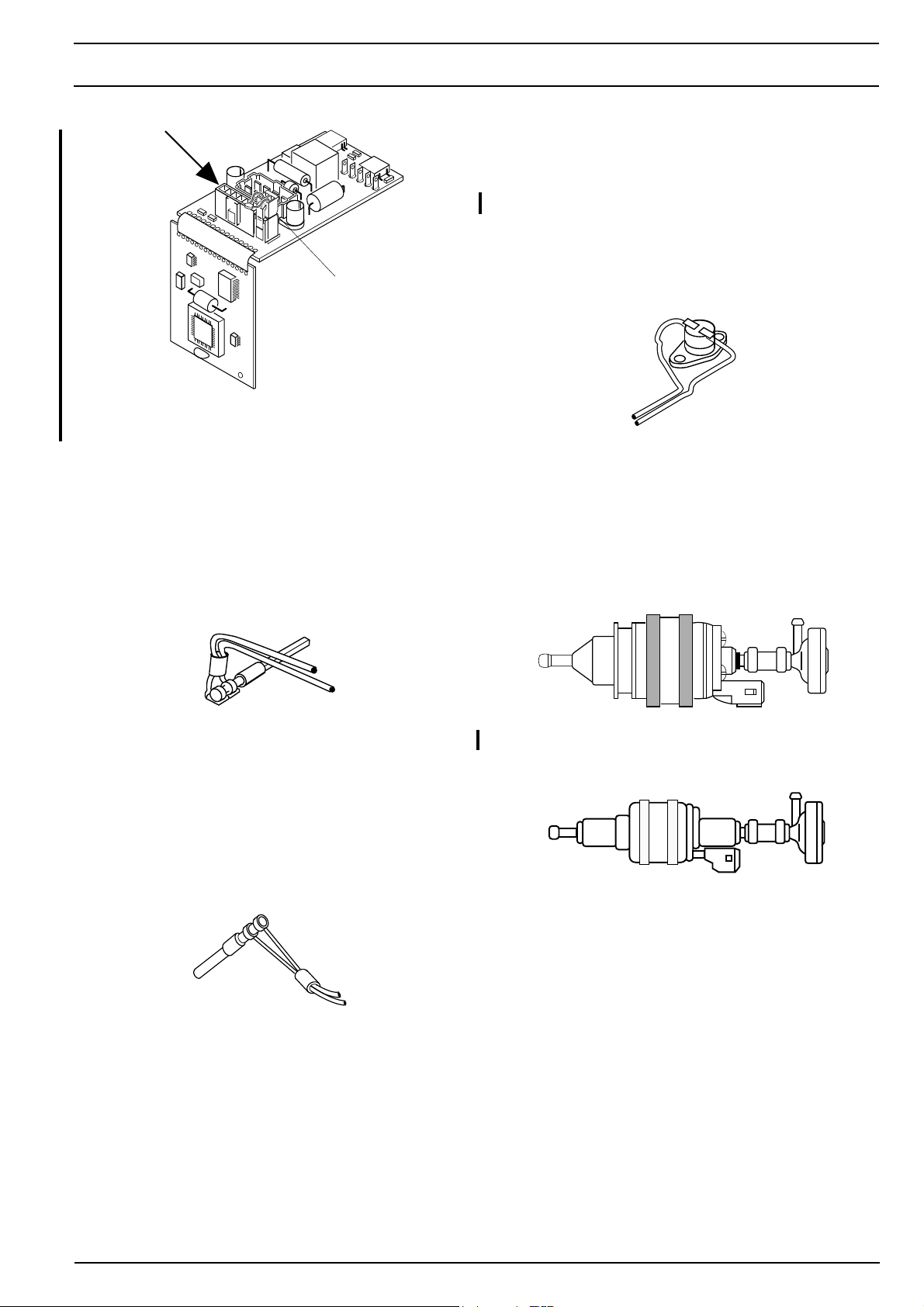

2.4 Control Unit / Control Circuit Board

Air Top 2000 without Diagnosis

The control unit /cont rol ci rc uit boar d is the central co nt rolling unit for functional sequen cing and m on itori ng of the

combustion oper ation . A tempera ture sens or locate d on

the side is used for temperatur e control . 12 Volt heate rs

may have the temperat ure sensor replaced agai nst an external temper at ure sensor . The com bust ion an d heat in g

air fan may be set by m eans of a po te nt iom eter .

Potentiometer

Temperature

Sensor

Control Unit Air Top 2000 without Diagnosis

Diesel

2 mm

Combustion

Tube

Burner

Insert

Air Top 2000 Diagnosis

The control unit/control circuit board is the central controlling unit for functional sequencing and monitoring of

the combustion operation. A temperature sensor located

on the control unit is used for temperature control. All

heaters may have the temperature sensor replaced

against an external temperature sensor. The combustion

and heating air fan may be set by means of a potentiometer.

A malfunction in air heaters Air Top 2000 Diagnosis outputs an error code to the display of the combination or

standard timer. When equipped with a control element

the operating indicator flashes. In addition a heater checkout may be performed using a personal computer (refe r

to operating instructions PC air heater diagnosis).

Fuel

1 mm

202

Page 11

Air Top 2000

2 General Description

Potentiometer

Temperature

Sensor

Control Unit Air Top 2000 Diagnosis

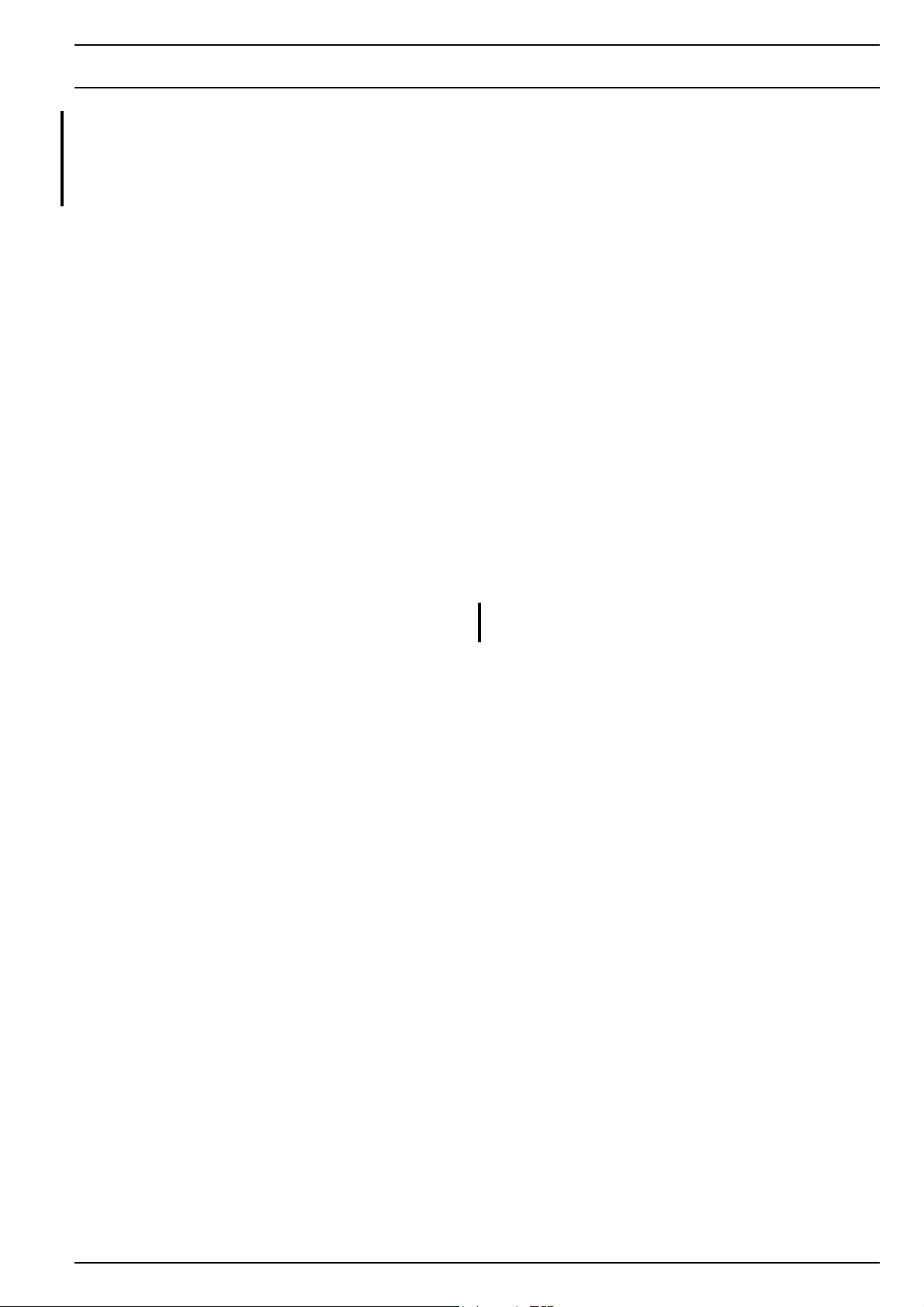

2.5 Flame Sensor

The flame sensor is a low-Ohm PTC resistor changing

its resistance dependent on its heating by the flame.

The signals are routed to the control unit for processing.

The flame sensor monitors the flame operating condition

over the complete duration of heater operation.

2.7 Temperature Limiter

The temperature limiter protec ts the air heater against

excessive operating temperatures . Overheat protec tion

is activated at temperature higher than 150 °C to interrupt the electrical circuit of the dosing pump and switch

off the heater with run-dow n operation.

After cooling down the electrical circuit is restored.

The air heater may be switched on again (see 3.9).

Temperature Limiter

2.8 Dosing Pump

The dosing pump is a combined supply, dosing and shutoff system for the fuel supply of the heater out of the

vehicle’s fuel tank.

Flame Sensor

2.6 Glow Plug

The glow plug ignites the fuel/air mixture at the start of

the air heater operation. The glow plug is acting as an

electrical resistor and is located in the burner insert

opposed to the flame side.

Glow Plug

Dosing Pump DP 2 for Fuel and Diesel operated Heaters

Dosing Pump DP 30 for Diesel operated Heaters

203

Page 12

Air Top 2000

3 Functional Description

3. Functional Description

3.1 Functional Description Air Top 2000

without Diagnosis (Fig. 301)

3.1.1 Control Element

The control element is used to switch the air heater on

and off, set the desired room temperat ure (air intake tem perature between 10 °C and 45 °C), and to unlock a

failure interrupt condition.

The green LED indication is used to indicate the operating condition (LED permanently on) and an overheat

condition (LED flashes).

NOTE

After application of power upon swit ch-on of the battery

switch and selecting the contr ol element “ON”, the c ontrol unit enters the “error lockout” condition. Prior to a reactivation the control element has to be placed to “OFF”.

3.1.2 Switch-On

The control element is set to the desired room temperature. When switching the air heater on, the operating indicator is illuminated and the glow plug is activated

(cycled). The motor of the combustion and heating air

fan starts high-speed operation for 1 second (breakaway mom ent) and is then under slow-dow n control.

NOTE

Should the temperature of the intake air be above the selected, rated temperature, only the mot or of the combustion and heating air fan will operate (control idle). Start

operation will be initiated with a heating air temperature

below the rated temperature.

After approx. 20 seconds (for fuel operated heaters after

approx. 15 seconds) the fuel dosing pump is activated.

After another 25 seconds the speed of the combustion

and heating air fan is continuously increased to a higher

rate and combustion begins. As soon as a flame is

detected, combustion w ill be stabilized (see 3.1.3) .

Should no normal combustion be achieved within 120

seconds (for fuel operated heaters after approx. 115

seconds), the speed of the combustion and heating air

fan is increased for approx. 30 sec and there will be an

automatic repeat start with the glow plug activated and

fuel dosing pump deactivated (no fuel supply).

Should the no-combustion-condition persist , after another 80 seconds (for fuel operated heaters after approx.

85 seconds) there will be a switch-off by error lockout

(see 3.1.9) with a run-down of the combustion and heating air fan lasting 120 seconds at 2/3 of its max. speed.

3.1.3 Stabili zation

Diesel Operated Heaters

With the glow plug activated the operating speed of the

combustion and heating air fan is increased. After another 20 seconds the speed of the combustion and heating air fan is continuously increased within 17

seconds to full load for full heat.

A flame-out during the speed rise control period causes

a repeat start.

Fuel Operated Heaters

With the glow plug activated the operating speed of the

combustion and heating air fan is continuously increased

within 4 seconds to full load for full heat. A flame-out during the speed rise control period causes a repeat start.

3.1.4 Heating Ope ra tion

During operation the combustion exhaust gasses flow

through the heat exchanger charging its walls w ith com bustion heat, which in turn is taken up by the heating air

delivered by the heating air fan to be routed to the

vehicle interior.

The temperature of the heating air sucked in is

measured by means of a temperature sensor fitt ed to

the air intake side of the air heater or in case of 12 Volt

heaters also by means of an externally located temperature sensor. A temperature below the one set with the

control element increases the heater performanc e up to

maximum heat.

In order to extend the burner idle period of Diesel operated heaters during permanent operation with a heating

performance in excess of 1.2 kW, the fuel dosing pump

delivery rate is reduced every 30 minutes for 20 seconds.

A heating performance less than 1.2 kW causes the fuel

delivery to the dosing pump to be interrupted every 30

minutes for 4 seconds. For both types of heaters (fuel

and Diesel) heating operation is shortly interrupted every

9 hours like in control idle.

After reaching the temperature set with the contr ol element, heating performance is controlled to decrease.

The speed of the combustion and heating air fan slows

down and the fuel delivery rate to the pump is reduced.

When exceeding the air intake temperature set with the

control element during minimum heating perform ance,

the dosing pump is deactivated after 5 seconds and combustion terminates.

NOTE

The control unit/air heater reacts to new sett ings of the

control element with a time delay.

301

Page 13

3 Functional Description

Air Top 2000

3.1.5 Control Operation

During control operation fan speed and dosing pum p

rate of delivery are subject to heating performance.

The glow plug is deactivated.

3.1.6 Control Idle

In case the air intake temperature set with the cont rol element is exceeded and the minimum heating performance had been achieved for longer than 5 seconds,

the fuel supply is cut off to terminate combustion.

The motor of the combustion and heating air fan continues operation for another 155 seconds at 2/3 of maximum speed to cool down the air heater (run-dow n). In

control idle the combustion and heating air fan runs at

minimum speed. The operation indication remains lit.

After reaching the air intake temperature set with the

control element a new start procedure is launched (without break-away) .

3.1.7 Switch-Off

Switching the heater off ext inguishes the operation indication of the control element.

If no fuel has been delivered (within 20 seconds for Diesel operated heaters or within 15 seconds for fuel operated heaters after swit ch-on) or if the air heater is in

control idle, the air heater is deactivated immediately

without run-down.

If fuel supply has commenced it will be immediately

stopped at switch-off. The fan speed decreases within

35

seconds to 2/3 of maximum.

Subsequently or if the flame sensor detects “no flame”

the fan speed is increased to maximum for 60 seconds

and run-down is initiated to last 120 seconds. Run-down

is automatically halted.

NOTE

Re-activation of the heater during run-down is permitted.

Run-down will be completed first with a subsequent restart.

3.1.8 Functions o f the A ir Hea ter in

TRS Vehicles

NOTE

Applicable only for Air Top 2000 D Air Heaters installed

in vehicles for the transportation of dangerous goods

(TRS).

If the heater is deact ivated using the control element,

run-down will not change.

A short run-down (max. 40 seconds) is automatically

activated if:

l

the vehicle engine is turned off

l

a conveyor facility is put into operation

The short run-down time depends on the operational

condition at which TRS swit ch-off occurs.

A 40 second run-down with maxim um speed is initiate d

(TRS switch-off) when:

l

air heater is s till in the start phase; stabilization

not yet achieved

l

air heater is in normal run-down

l

air heater is in control idle.

A 20 second run-down is switched on in normal combustion operation with the fuel delivery immediately halted

maintaining the fan speed for 5 seconds. Then the

speed is increased for 30 seconds within another 5 seconds.

For all heaters after July 1995 the short run-down

out of all operating conditions is a max. of 20 seconds.

After a TRS switch-off the control unit is in the “error

lockout” condition.

Prior to resuming operation the control element has to

be set to “OFF”.

3.1.9 Switch-off upon Failure

The control unit recognises failures of individual air

heater components and malfunctions in the start sequence and in normal operation.

The air heater is deactivated and enters the error lockout

mode under the following conditions:

l

flame sensor resistance out of tolerance

l

temperature sensor resistance out of tolerance

l

glow plug/glow plug trigger defective

l

fan speed too low , short circuit or open circuit

l

error in dosing pump electrical circuit or of

overheat protection (in start phase only)

l

low voltage below 10 Volt and in excess of 20

seconds for 12 Volt heaters

l

low voltage below 20 Volt and in excess of 20

seconds for 24 Volt heaters

l

control unit defective

In case of overheating there will be no fuel supply. A rundown like after manual switch-off will be performed.

After run-down the control unit is in the error lockout

mode. Overheating is indicated by the operation indication flashing. For error unlock the air heater has to be

switched off momentarily to be switched on again.

302

Page 14

Air Top 2000

3 Functional Description

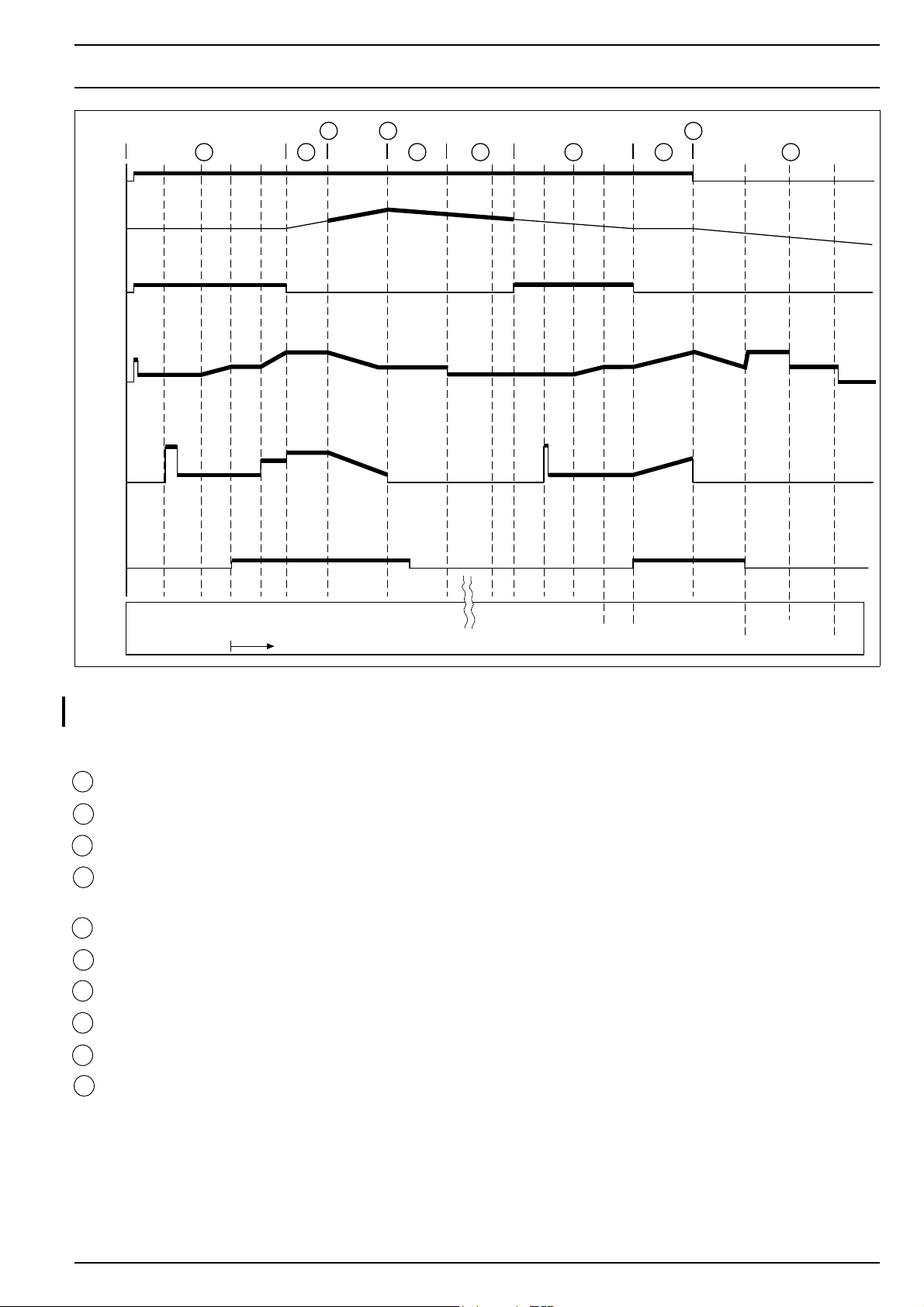

3 4

On

1

0

A

1 2

5 6 7 8

9

10

B

1

0

C

100%

90%

60%

30%

0

D

1,3 Hz

1,0 Hz

0,8 Hz

0,6 Hz

0

E

1

0

F

020

65 85 102

45

Fig. 301 Functional Diagram (Air Top 2000 without Diagnosis)

1 Start

2 Control Operation

3 Rated Value reached

4 Rated Value exceeded

(e.g. due to reduced heat sumption)

5 Run-down

6 Control Idle

7 Start

8 Control Operation (increased heat consumption)

9 Switch-off

(20) (60)

(120)

secondstypical

A = Control Element

B = Temperature Sensor

C = Glow Plug

D = Combustion and Heating Air Fan

E = Dosing Pump

F = Flame Sensor

10 Run-down

303

Page 15

3 Functional Description

Air Top 2000

3.2 Functional Description Air Top 2000

Diagnosis

3.2.1 Control Element

The control element is used to switch the air heater on

and off, set the desired room temperature (air intake temperature between 10 °C and 45 °C), and to unlock a

failure interrupt condition.

The green LED indication is used to indicate the operating condition (LED permanently on) and an overheat

condition (LED flashes).

NOTE

TRS Operation:

After application of power upon switch-on of the battery

switch and selecting the control element “ON” , the control unit enters the “error lockout” condition. Prior to a reactivation the control element has to be placed to “OFF”.

3.2.2 Switch-On

The control element is set to the desired room temperature. When switching the air heater on, the operating indicator is illuminated and the glow plug is activated

(cycled). The motor of the combustion and heating air

fan starts high-speed operation for 1 second (breakaway moment) and is then under slow-do wn control to

approx. 30% (Diesel) or 50% (fuel) of full speed.

NOTE

Should the temperature of the intake air be above the selected, rated temperature, only the mot or of the combustion and heating air fan will operate (control idle). Start

operation will be initiated with a heating air temperat ure

below the rated temperature.

The flame sensor function is checked. If the flame sensor at this time already signals “flame”, there will be a

120 second run-down and an error lockout of the control

unit. A malfunction of any other component monitored

causes an error lockout without run-down.

After approx. 20 seconds (for fuel operated heaters after

approx. 15 seconds) the fuel dosing pump is activated.

After another 25 seconds the speed of the combustion

and heating air fan is continuously increased to a higher

rate and combustion begins. As soon as a flame is

detected, combustion will be stabilized (see 3. 2.3).

Should no proper combustion develop within 120 seconds (for fuel-operated within 115 seconds) the combustion and heating air fan speed is increased to full load for

approx. 30 seconds (15 seconds for fuel-operated

heaters) with the glow plug on and the dosing pump off

(no fuel delivery) with a subsequent automatic restart.

Should the no-combustion-condition persist, after another 80 seconds (for fuel operated heaters after approx.

85 seconds) there will be a switch-off by error lockout

(see 3.2.9) with a run-do w n of the combustion and heating air fan lasting 120 seconds at 2/3 of its max. speed.

2. Start (automatic restart)

Fan speed is again reduced to approx. 30% (for fuel

operated heaters to approx. 50%) and fuel is delivered.

During the next 20 seconds fan speed is increased to approx. 60% (for fuel-operated heaters to approx. 75% ) of

full speed. As soon as a flame is detected within the next

55 seconds, combustion will be stabilized. Should there

be no flame condition after a total fuel delivery period of

180 seconds, fuel delivery will be stopped and the glow

plug deactivated. The combustion air fan continues full

load operation for another 120 seconds (run-dow n) and

the heater enters the error lockout condition.

3.2.3 Stabilization

Diesel Operated Heaters

With the glow plug activated the operating speed of the

combustion and heating air fan is increased. After another 20 seconds the speed of the combustion and heating air fan is continuously increased within 17 seconds

to full load for full heat.

NOTE

This operating condition is omitted if the set temperature

(control idle) has already been achieved once.

The glow plug is deactivated and heating operation commences. A flame-out during speed up control causes a

restart, 5 restarts an error lockout of the heater.

Fuel Operated Heaters

With the glow plug activated the operating speed of the

combustion and heating air fan is continuously increased

within 4 seconds to full load for full heat. This operating

condition will be omitted if the start occurs after a control

idle period.

The glow plug is deactivated and heating operation commences. A flame-out during speed up control causes a

restart, 5 restarts an error lockout of the heater.

Should no normal combustion be achieved within 120

seconds (for fuel operated heaters after approx. 115

seconds), the speed of the combustion and heating air

fan is increased for approx. 30 sec and there will be an

automatic repeat start w ith the glow plug activated a nd

fuel dosing pump deactivated (no fuel supply).

304

Page 16

Air Top 2000

3 Functional Description

3.2.4 Heating Operation

During operation the combustion exhaust gasses flow

through the heat exchanger charging its walls with com bustion heat, which in turn is taken up by the heating air

delivered by the heating air fan to be routed to the vehicle interior.

The temperature of the heating air sucked in is

measured by means of a temperature sensor fit ted to

the air intake side of the air heater or by means of an externally located temperature sensor.

A temperature below the one set with the control element increases the heater performance up to max imum

heat. In order to extend the burner idle period of Diesel

operated heaters during permanent operation w ith a

heating performance in excess of 1.1 kW, the fuel dosing pump delivery rate is reduced every 15 minutes for

20 seconds.

A heating performance less than 1.1 kW causes the fuel

delivery to the dosing pump to be interrupted every 30

minutes for 4 seconds. Additionaly heating operation is

briefly suspended every 9 hours like in control idle. For

Diesel-operated heaters this is only applicable, if at this

time heating performance is less than 1.1 kW.

3.2.7 Switch-Off

Switching the heater off ext inguishes the operation indication of the control element.

If no fuel has been delivered or if the air heater is in control idle, the air heater is deactivated immediately

without run-down.

If fuel supply has commenced it will be immediately

stopped at switch-off. Fan speed remains constant and

then decreases within 30 seconds to approx. 60% of full

speed. After this or with the flame sensor detect ing “no

flame”, fan speed rises to maximum speed for 60 seconds and run down for 120 seconds is initiated. Rundown is at approx. 60% of full speed and is deactivated

automatically.

NOTE

Re-activation of the heater during run-down is permitted.

Run-down will be completed first with a subsequent restart.

3.2.8 Functions o f the A ir Hea ter in

TRS Vehicles

3.2.5 Control Operation

During control operation fan speed and dosing pump

rate of delivery are subject to heating performance.

The glow plug is deactivated.

3.2.6 Control Idle

After reaching the temperature set w ith the cont rol element, heating performance is controlled to decrease.

The speed of the combustion and heating air fan slows

down and the fuel delivery rate to the dosing pump is reduced. When exceeding the air intake temperature set

with the control element during minimum heating perfor mance, the dosing pump is deactivated after 5 seconds

and combustion terminates.

Fan speed remains constant for 35 seconds and is then

increased to approx. 60% of full speed for cooling the

heater down. the fan then continues to operate at approx. 30% of full speed until temperature is below the

temperature set with the control element . If temperature

falls below the one set with the control element, the

heater will restart (wit hout break a w ay).

NOTE

New settings on the control element are executed by the

control unit/heater w ith a time delay.

NOTE

Applicable only for Air Top 2000 D Air Heaters installed

in vehicles for the transportation of dangerous goods

(TRS).

If the heater is deact ivated using the control element,

run-down will not change.

A short run-down (max . 20 seconds) is automatic ally

activated if:

l

the vehicle engine is turned off

l

a conveyor facility is put into operation

The short run-down time depends on the operational

condition at which TRS switch-off occurs.

A 15 second run-down with m aximum speed is initiated

(TRS switch-off) when:

l

air heater is still in the start phase; stabilization

not yet achieved

l

air heater is in normal run-down

l

air heater is in control idle.

A 20 second run-down is switched on in normal combustion operation and in stabilization with the fuel delivery

immediately halted maintaining the fan speed for 5 seconds. Then the speed is increased to maximum for 15

seconds within for a run-down.

After a TRS switch-off the contr ol unit is in the “error

lockout” condition.

Prior to resuming operation the control element has to

be set to “OFF”.

305

Page 17

3 Functional Description

3.2.9 Switch-off upon Failure

The control unit recognises failures of individual air

heater components and malfunctions in the start sequence and in normal operation.

The air heater is deactivated and enters the error lockout mode under the following conditions:

l

flame sensor open or short circuit

l

temperature sensor open or short circuit

l

glow plug open or short circuit

l

fan motor open or short circuit or fan speed wrong

l

dosing pump open or short circuit

l

overheating

l

low voltage below 10 Volt or high voltage above

15 Volt in excess of 20 seconds for 12 Volt heaters

l

low voltage below 20 Volt or high voltage above

30 Volt in excess of 20 seconds for 24 Volt heaters

A switch-off like in “sw itch- off” w ill be performed.

In case of overheating there will be no fuel supply. After

run-down the control unit is in the error lockout mode.

The operation indication outputs a flash code.

For error unlock the air heater has to be switched off

momentarily (at least 2 seconds) to be switched on

Air Top 2000

306

Page 18

Air Top 2000

4 Technical Data

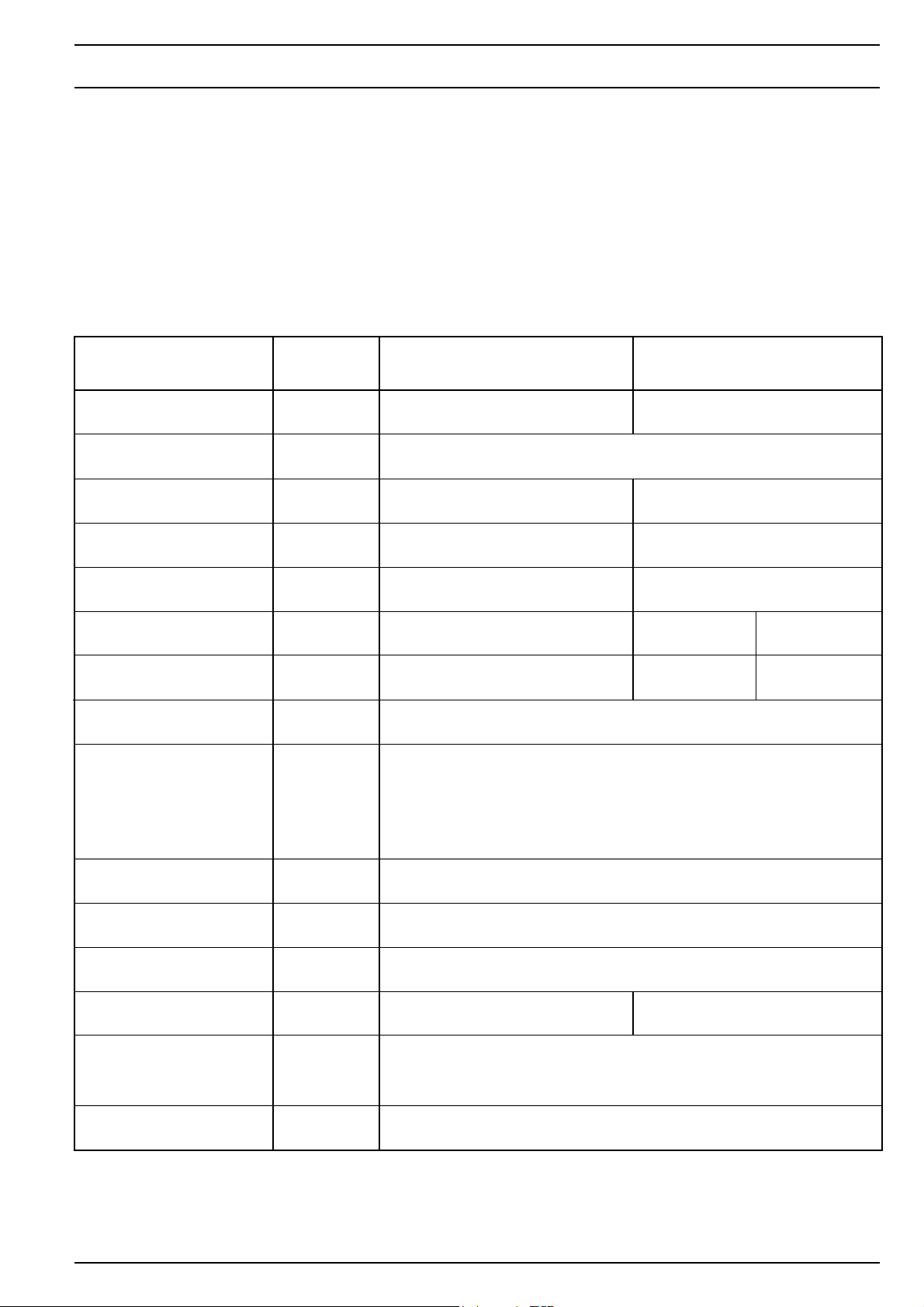

4. Technical Data

As long as no threshold values are given, the following

technical data are understood to include tolerances of

±10% usual for heaters at an ambient temperature of

+20 °C and at nominal voltage and conditions.

Air Heater Operation

Mark of conformity

Heater type

Heat flow

Type of fuel

Control range

Electrical Components:

Control unit, combustion air fan, dosing pump, timer*,

glow plug and control element are for 12 or 24 Volts

operation.

The components temperature limiter and flame detec tor

are independent of voltage.

*not for TRS

AT 2000 B

~ S 277

Air heater with

evaporator burner

1.1 – 2.0 kW

Fuel

AT 2000 D

~ S 270

0.9 – 2.0 kW

Diesel/Fuel oil (EL)

Fuel consumption

Nominal voltage

Operation voltage

Rated power consumption

Permitted ambient temp.:

Heater:

Dosing pump:

Control element:

- operation

- storage

- operation

- storage

- operation

- storage

Permitted combustion air

intake temperature

Setting range for

indoor temperature

Volume flow of heating air

against 0.5 bar

CO

in exhaust

2

(perm. functional range)

Control range

Control range

Control range

Max.

Max.

0.1 .. 0.2 kg/h (0.16..0.27 l/h)

12 Volt

10 … 15 Volt

-40 ° … +40 °C

-40 ° … +85 °C

-40 ° … +20 °C

-40 ° … +85 °C

-40 ° … +75 °C

-40 ° … +85 °C

-40 ... +20 °C

+10 ... +45 °C

9.5 … 10.5

0.1 .. 0.21 kg/h (0.12 .. 0.24 l/h)

12 Volt

10 … 15 Volt

9 ...22 W

3

70 m

/h

9.5 … 12.0

24 Volt

20 … 30 Volt

Dimensions air heater

Weight, heater

Length 322 ± 2 mm

Width 130 ± 1 mm

Height 122 ± 1 mm

2.6 kg

401

Page 19

Air Top 2000

5 Troubleshooting

5. Troubleshooting

5.1 General

This section describes troubleshooting procedures for

the Air Heater Air Top 2000 and Air Top 2000 Diagnosis.

A malfunction in air heaters Air Top 2000 Diagnosis outputs an error code to the display of the combination or

standard timer. When equipped with a control element

the operating indicator flashes. In addition a heater checkout may be performed using a personal computer (refer

to operating instructions PC air heater diagnosis).

CAUTI ON

Troubleshooting requires pr ofound knowledge about

structure and theory of operation of heater components

and may only be performed by skilled personnel.

In cases of doubt refer to Sections 2 or 3 for functional

interrelations.

NOTE

Only for TRS operation

After a TRS switch-off or po w er application by vehicle

main power switch operation and the control elem ent to

“ON”, the control unit will be in “error lockout”.

Prior to reactivation the control element m ust be set to

“OFF” or the instant heat switch on the combinat ion or

standard timer be operated.

CA UTI ON

Troubleshooting is normally limited to the isolation of

defective components.

The following causes for trouble are not considered and

should always be checked for to exclude them as cause

for trouble:

corrosion on connector

loose contact on connector

wrong crimping on connector

corrosion on electrical wiring and fuses

corrosion on battery terminals

If individual components are checked, the control unit

electrical connections must be disconnected.

After any correction of a failure a functional test has to

be performed in the vehicle.

5.2 General Failure Symptoms

The following table (Fig. 501) lists the possible failure

symptoms.

Failure Symptom Probable Cause Remedy

Air heater switches No combustion after start or repeat Switch off heater momentarily and

off automatically start switch on

Flame extinguishes during Switch off heater momentarily an d

operation switch on

Heater overheats Check heat air ducting for

Operation indication flashes obstructions, allow heater to cool

down, switc h off heater mom entar ily

and switch on

Vehicle electrical Charge battery

system voltage too low Switch off heater momentarily and

switch on

Heater expels black fumes Combustion air and/or Check combustion and exhaust

exhaust ducting blocked ducting for obstructions

Fig. 501 General Failure Symptoms

once again

once again

once again

once again

501

Page 20

5 Troubleshooting

Air Top 2000

5.3 Failure Sympt oms during Opera tion

The following table (Fig. 502) lists the possible failure

symptoms as they might occur during the functional

sequence of operation.

In case of malfunction the failure is to be isolated and

removed using this table. It is important to accurately

identify the failure symptom .

Should the failure symptom not be contained in this

table or the trouble not be detected under the specific

Failure Sym pto m shows after

....s

No start and no illumination immediately

of LED on control element

No start but LED illuminates immediately

Very low speed with no start immediately

failure symptom listed, in emergenc ies assist ance by our

service technicians may be requested

(Tel. 089 / 8 57 94 - 512).

NOTE

Overheating and dosing pump failure are alway s indicated additionally after run-down by the flashing LED of

the control element.

In all cases of trouble also a defective control unit may

be the cause should all other components turn out to be

serviceable.

Possible Causes

Wrong cabling, defective fuse

Fan or control unit defective or fan blocked

Control idle operation: wrong manual control (selected

temperature is below air intake temperat ure) or wro ng

integration (excessive air intake temperat ure)

Motor operates mom entarily 1

and then stops

Stoppage without run-dow n 5

Run-down after 1

Run-down after 20

Run-down after 120

and dosing pump does not cycle

Run-down after 40 to 120

Run-down after 230

Run-down during combustion

operation

Glow plug or flame sensor short or open circuit or

control unit defective

Fan motor obstructed, binding

Flame detection erroneous

Voltage to control unit too low

Cabling to dosing pump, pump itself or overheat

protection defective

Intermittent disconnect of connection to dosing pump

or to overheat protection

No flame: wrong fuel supply quantity, defective or slow

fan, coked burner (in particular pilot flame outlet bore),

combustion air/exhaust ducting obst ructed or heat

exchanger coked, dosing pump seized

Overheating or

voltage too low o r

component error (flame sensor, glow plug,

overheat sensor, dosing pump, burner) or

no fuel supply or obstructed combustion air/exhaust

ducting

Stoppage without run-dow n dur ing combust io n

operation

Interruption of dosing pump during combustion

cycling and max. speed for operation

30 sec with subsequent re-start

Fig. 502 Failure Symptoms during Operati on

502

Fan motor failure or seizure

Flame-out by gas bubbles in fuel delivery or strong

wind against exhaust outlet or defective no-flam e

detection

Page 21

Air Top 2000

5.4 Error Code Output

(Air Top 2000 Diagnosis)

When equipped with a combination or standard timer a

malfunction will cause an error code output to the display of the timer for indication.

NOTE

When equipped with a control element the error code

output is indicated by flashing of the operating indicator/error code indication. The number of flash pulses

corresponds to the number indicated in the table below.

After a quick pulse train there will always be an error

code output.

Error code output on display of comb inatio n or

standard timer

F 01 No start (after 2 attempts)

5 Troubleshooting

F 02 Flame out (at least >5)

F 03 Voltage too low or too high

F 04 Premature flame detection

F 05 Flame sensor open or short circuit

F 06 Temperature sensor open or short circuit

F 07 Dosing pump open or short circuit

F 08 Fan motor open or short circuit or

wrong speed

F 09 Glow plug open or short circuit

F 10 Overheating

503

Page 22

Air Top 2000

6 Functional Tests

6. F unc tion al Tests

6.1 General

This section describes the on-vehicle and off-vehicle

testing of the air heater to check its proper operation.

WARNING

The air heater shall not be operated in enclosed areas

like garages or workshops not provided with exhaust

venting facilities.

6.2 Adjustments

6.2.1 Adjustment of the CO2 Contents

6.2.1.1 General

The CO

potentiometer on the control circuit board. The air heater

is preset by the manufacturer wit h respect to the combustion and heating air fan fitted. After adjustment by the

manufacturer the potenti om eter is in center position

(Fig. 601). After an inadvertent loss of this position it is

sufficient to restore its original position.

The manufacturer setting may be correct ed by rotati ng

the potentiometer. A suitable tool like a small screw

driver (2.5 mm tip) is to be used.

contents of the exhaust is adjusted with the

2

CA UTI ON

Set potentiometer slowly; observe end positions.

Adjustment may be perform ed at any electrical sys tem

voltage.

Clockwise rotation increases the fan speed and de-

creases the CO

creases the fan speed and increases the CO

If the setting range is not sufficient (e.g. after replacement of the combustion and heating air fan) the manufacturer’s setting may be cancelled according to the

procedure described in the following.

6.2.1.2 New Basic Setting

The manufacturer’s setting cannot be restor ed.

1. Withdraw cover from upper shell according to 9.2.1.1.

2. Switch on air heater.

3. Rotate potentiomet er tw o tim es and with no interrupt

through its complete setting range (e.g. m ax. - min.max.).

4. Adjust desired CO

5. Switch off air heater.

6. Plug on cover and secure.

contents. Counterclockwise rotation d e-

2

contents.

2

CAUTION

contents (Fig. 601).

2

CO

2

CO

+–

2

+–

Air Top 2000 Diagnosis Air Top 2000 without Diagnosis

Fig. 601 Adjustment of CO2 Contents

601

Page 23

6 Functional Tests

6.3 Components Testing

CAUTION

During electrical testing always ensure that the control

unit and the component under test are electrically disconnected from each other.

6.3.1 Glow Plug Resistance Test

During electrical testing of the glow plug using a digital

multimeter, the following readings should be obtained:

Glow plug 12 Volt (red) 24 Volt (green)

Resistance at 25 °C: 0. 324 ... 0.360 Ω 1.3 ... 1.44 Ω

Test current: < 5 mA < 5 mA

6.3.2 Flame Sensor Resistance Test

During electrical testing of the flame sensor using a digital multimeter, the following readings should be obtained:

Air Top 2000

Cold test:

Resistance at 25 °C: 2.6 ... 3.4 Ω

Test current: < 5 mA

Hot test:

Resistance at 800 - 1000 °C: 12 ... 15 Ω

(ceramic rod red hot over a length of approx. 20 mm)

Test current: < 5 mA

602

Page 24

Air Top 2000

7 Circuit Diagrams

7. Circuit Diagrams

7.1 General

The air heater Air Top 2000 Diagnosis may be operated

using the control element (rated value transmit ter/ sw it ch)

or with the control element and a combination or

standard timer. The circuit diagrams (Figs. 703 to 708

and 714) show the possible circuits 12 or 24 Volt with

l

control element

l

combination timer

l

control element and standard timer

l

control element for TRS

l

combination timer for TRS

l

TRS operation for vehicles without auxiliary driv e

Fig. 701 shows the terminal pin assignment.

The air heater Air Top 2000 without Diagnosis may be

operated using the control element (rated value transmit ter/switch) or w ith the control elem ent and a timer. The

circuit diagrams (Figs. 709 to 713) show the possible circuits 12 or 24 Volt with

l

control element

l

control element and timer

l

control element for TRS

Fig. 702 shows the terminal pin assignment.

X1 X4X3X2 X5

violet yellowbrownblack blue

X1 = Connection, Combustion and Heating Air Fan

X2 = Connection, Dosing Pump

X3 = Connection, Flame Sensor

X4 = Connection, Glow Plug

X5 = Connection, Temperature Limiter

Fig. 701 Terminal Pin Assignment, Air Top 2000 Diagnosis

701

Page 25

7 Circuit Diagrams

Air Top 2000

X1 X4X3X2 X5

violet yellowbrownblack blue

X1 = Connection, Combustion and Heating Air Fan

X2 = Connection, Dosing Pump

X3 = Connection, Flame Sensor

X4 = Connection, Glow Plug

X5 = Connection, Temperature Limiter

702

Fig. 702 Terminal Pin Assignment, Air Top 2000 without Diagnosis

Page 26

Connection X11/2 and X11/3

for TRS function only

2

Air Top 2000

7 Circuit Diagrams

ϑ ϑ

ϑ

Item Nomenclature Remark

A1 Air Heater Air Top 2000

A2 Control Unit

B1 Flame Sensor

B2 Te mperatu re Sensor

B3 Temper atu re Limiter

E Glow Plug

F2 Fuse 24V 10A/12V 15A Flat Fuse SAE J 1284

H1 LED green (in item S1) Operation indication

M Motor

S1 Control Element Rated Value Setting Switch

X1-X5 Connection 2-pole of item A2

X6 Connection 8-pole of item A2

X7 Connection 4-pole of item S

X8 Connection 2-pole

X9 Connection 2-pole of item A2

X11 Connection 6- pole of item A2

X12 Connection 1-pole Diagnosis (K-wire)

Y1 Dosing Pump

Wire Colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

2

Wire Gauges

< 7.5 m 7.5 - 15 m

2

0.75 mm

2

1.0 mm

2

1.5 mm

2

2.5 mm

2

4.0 mm

blue

brown

yellow

green

grey

orange

red

black

violet

white

1.5 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

2

2

2

2

2

Fig. 703 Circuit Diagram Automatic Control Air Top 2000 Diagnosis, 12V/24V wit h Control Element

703

Page 27

112

7 Circuit Diagrams

Air Top 2000

2

ϑ ϑ

ϑ

Item Nomencl at ure Remark

A1 Air Heater Air Top 2000

A2 Control Unit

B1 Flame Sensor

B2 Temperature Sensor

B3 Tempera ture Limiter

E Glow Plug

F2 Fuse 24V 10A/12V 15A Flat Fuse SAE J 1284

H7 LED red (in item P) Instan t heat swit ch illumination,

standy indication,

operating indicator light

H8 Hea ting sy m bol in display (in item P) Operating indicator light,

overheat indication

H9 Ligh t (in item P) Symbol illumin ation

M Motor

P1 Combination Timer (1531)

S3 Switch Instant heating remo te con trol

X1-X5 Connection 2-p ole of item A2

X6 Connection 8-p o le of item A2

X8 Connection 2-p o le

X9 Connection 2-p o le of item A2

X11 Connect ion 6-p ole of item A2

X12 Connect ion 1-p ole Diagnosis (K-wire)

X13 Connection 12- pole of item P

Y1 Dosing Pump

Wire Gauges

< 7.5 m 7.5 - 15 m

2

0.75 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

Wire Colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

blue

brown

yellow

green

grey

orange

red

black

violet

white

with plus from terminal (15/75)

to connection 10:

permanent operation during

instant heating as long as

ignition on

without plus to connection 10:

heating time programmable as

required (10 min to 120 min),

default setting 120 min.

Connection X11/2 and X11/3

for TRS function only

1.5 mm

2

1.5 mm

2

2.5 mm

2

4.0 mm

2

6.0 mm

2

2

2

2

2

Fig. 704 Circuit Diagram Automatic Control Air Top 2000 Diagnosis, 12V/24V with Com bination Tim er

704

Page 28

Air Top 2000

1

7 Circuit Diagrams

2

ϑ ϑ

ϑ

Item Nomenclature Remark

A1 Air Heater Air Top 2000

A2 Control Unit

B1 Flame Sensor

B2 Temperature Sensor

B3 Temper atu re Limiter

E Glow Plug

F2 Fuse 24V 10A/12V 15A Flat Fuse SAE J 1284

H7 L ED red (in item P) Instant hea t swit ch illum ination,

standy indicatio n,

operating indicator light

H8 Heating symbol in display (in item P) Operating indicator light,

overheat indication

H9 L ight (in item P) Sym bol illuminat io n

M M oto r

P2 Standard timer

S1 Control Element Rated Value Setting Switch

S3 Switc h Instant heating re m ote contr ol

X1-X5 Connection 2-pole of item A2

X6 Connection 8-pole of item A2

X7 Connection 4-pole of item S1

X8 Connection 2-pole

X11 Connection 6- pole of item A2

X12 Connection 1-pole Diagnosis (K-wire)

X13 Connection 12- pole of item P

Y1 Dosing Pump

Wire Gauges

< 7.5 m 7.5 - 15 m

2

0.75 mm

2

1.0 mm

2

1.5 mm

2

2.5 mm

2

4.0 mm

Wire Colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

1

2

blue

brown

yellow

green

grey

orange

red

black

violet

white

with plus from terminal (15/75)

to connection 10:

permanent operation during

instant heating as long as

ignition on

without plus to connection 10:

heating time programmable as

required (10 min to 120 min),

default setting 120 min.

Connection X11/2 and X11/3

for TRS function only

1.5 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

2

2

2

2

2

Fig. 705 Circuit Diagram Automatic Control Air Top 2000 Diagnosis,

12V/24V with Contr ol Element and Standard Timer

705

Page 29

7 Circuit Diagrams

Air Top 2000

ϑ ϑ

ϑ

Item Nomencl at ure Remark