Page 1

Wayne-Dalton Corp.

P.O. Box 67 Mt. Hope, OH 44660

www.wayne-dalton.com

WINDLOAD POST

WayneMark™8000, 8100

INSTALLATION INSTRUCTIONS

See garage door owner’s manual for warranty information.

Important Notice!

READ THE ENCLOSED INSTRUCTIONS MANUAL CAREFULLY BEFORE INSTALLING THIS WINDLOAD

POST. PAY CLOSE ATTENTION TO ALL WARNING LABELS AND NOTES. THIS MANUAL SHOULD BE

ATTACHED TO THE WALL IN CLOSE PROXIMITY TO THE WINDLOAD POST.

© Copyright 2007 Wayne-Dalton Corp. Rev3 6/26/2007

307330

Page 2

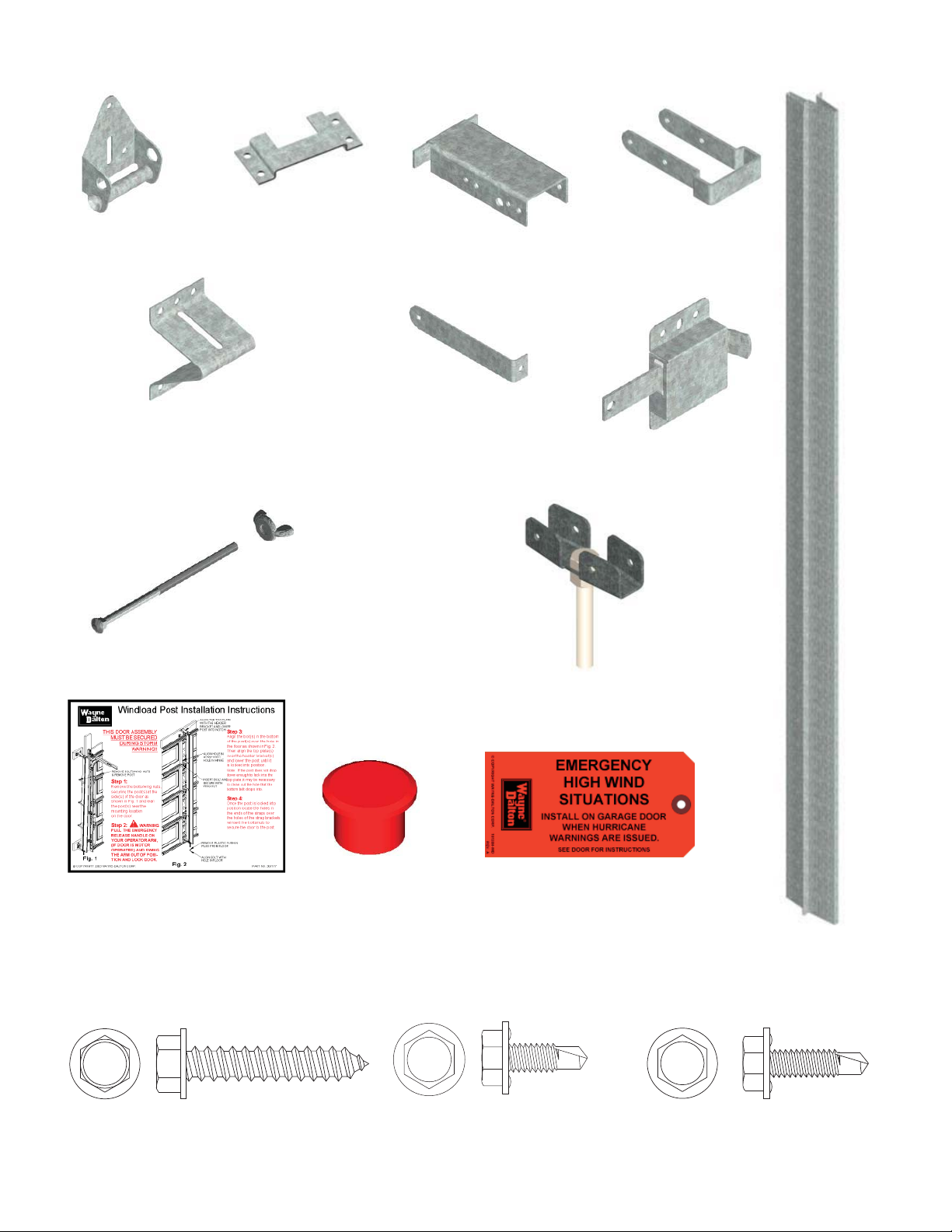

HEADER LOCK BRACKET

HALF HINGE

(2) # 130352

JR. UNIVERSAL “A” FRAME BRACKET

(5) # 270343 w/ 7’ kit

(6) # 270343 w/ 8’ kit

CARRIAGE BOLTS

(3) # 305210 w/ 7’ kit - (3” LG)

(4) # 305210 w/ 8’ kit- (3” LG)

(1) #307529 w/ 7’ & 8’ kit’s - (3-1/2” LG)

(2) # 141092

WING NUTS

(4) # 305211 w/ 7’ kit

(5) # 305211 w/ 8’ kit

TOP PLATE EXTENSION

(1) # 305205

STRAPS

(8) # 307397 w/ 7’ kit

(10) #307397 w/ 8’ kit

TOP STRAP BRACKET

(1) # 305206

(1) SIDE LOCK

# 292857

(1) POST INSTALLATION DECAL

# 307177

(8) 5/16” X 1-5/8” LAG SCREW

# 100292

(1) PLASTIC PLUG

# 305226

SELF-DRILLING SCREW

(1) BOTTOM BRACKET ASSEMBLY

# 305327

(1) POST TAG

# 161384

WINDLOAD POST ASSEMBLY

(34) 1/4-20 X 11/16”

# 300723

# 305207 - (7’)

# 305332 - (8’)

(6) 1/4-20 X 7/8”

SELF-DRILLING SCREW

# 100507

2

Page 3

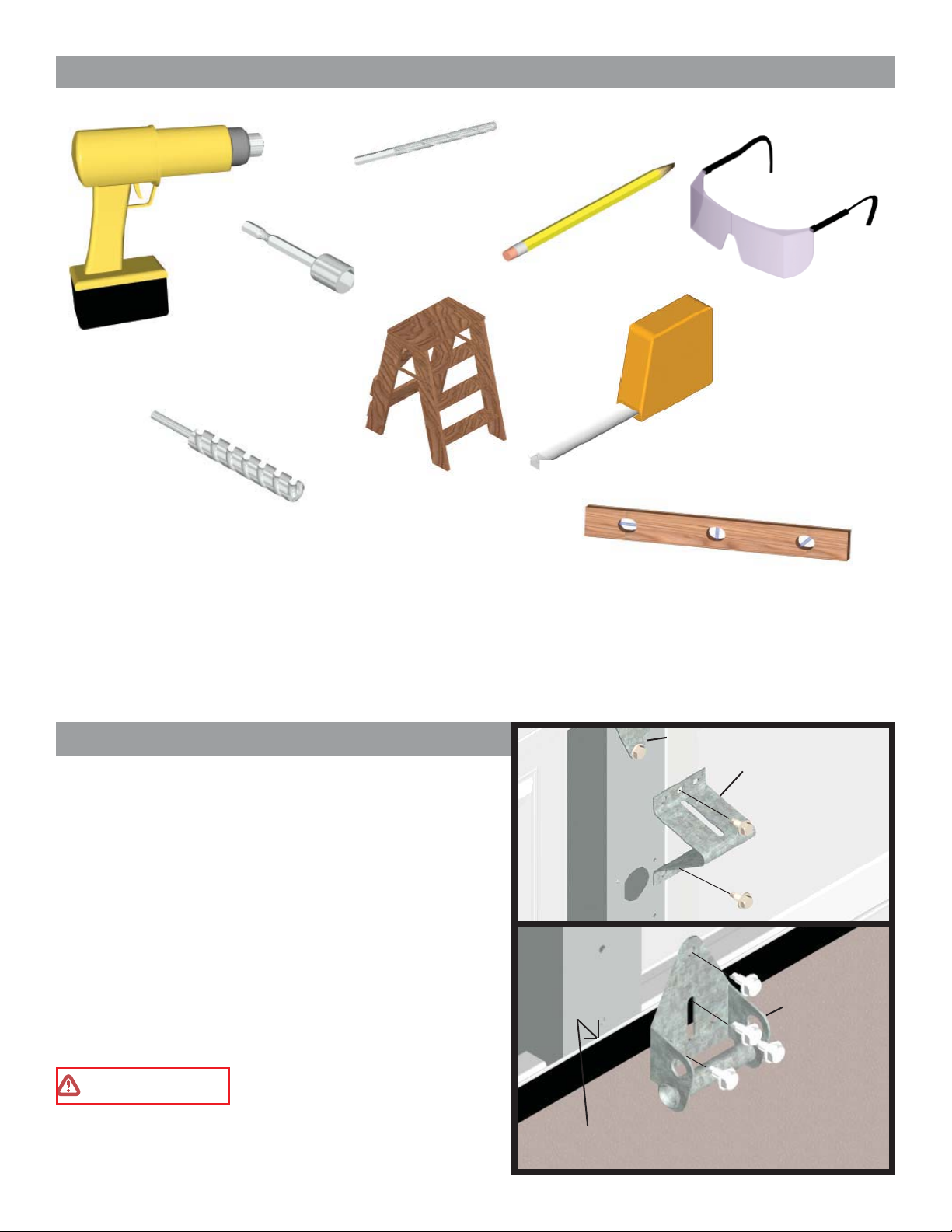

Required Tools

(1) 3/16” DRILL BIT

PENCIL

(1) 7/16” HEX

DRILL

(1) 5/8” X 4”

MASONRY DRILL BIT

HEAD DRIVER

STEP LADDER

Windload Post Installation

JR. “A” Frame Installation

IMPORTANT! Refer to the windload specifi cation draw-

ings (supplied) for windload post location(s).

FIG. 1

SAFETY GLASSES

TAPE MEASURE

LEVEL

CENTER HINGE

JR. “A” FRAME

Place the “A” frame brackets below the center hinges of

each intermediate section, fasten with (2) 1/4-20 x 11/16”

self drilling screws (see Fig.1). For the bottom section, align

half hinge with top edge of astragal retainer and center on

stile(s). Fasten half hinge with (4) 1/4-20 x 11/16” self-drilling screws (see Fig.1A). Center all brackets in the required

positions per the windload specifi cation drawings.

NOTE: Additional Jr. “A” frame brackets are required

for 10’ and 12’ wide doors.

WARNING

“A” FRAME BRACKETS MUST

BE INSTALLED ACCORDING TO THE WINDLOAD

SPECIFICATION DRAWINGS, OR DOOR FAILURE

WILL OCCUR UNDER WINDLOAD

.

3

(2) 1/4-20 X 11/16”

SELF-DRILLING SCREW

FIG. 1A

HALF HINGE

(4) 1/4-20 X 11/16”

SELF-DRILLING SCREW

EDGE OF

ASTRAGAL RETAINER

Page 4

Header Lock Bracket Installation

Mark a vertical line on the header, aligned with the

CENTER

LINE

HEADER

center of the Jr. “A” frame bracket. Measure up 1-1/2”

above the top of the door and mark a horizontal line.

1-1/2”

Center the header lock bracket with the vertical line

and align the bottom of the header lock bracket with

the horizontal line. Secure the header lock bracket to

HEADER LOCK

BRACKET

the header using (4) 5/16” x 1-5/8” lag screws.

(see Fig. 2)

(4) 5/16” X 1-5/8”

LAG SCREWS

FIG. 2

NOTE: It is recommended that lag screws be pilot

drilled using a 3/16” drill bit prior to fastening.

IMPORTANT! If there is drywall or other materials covering the header it is required that such materials be

removed from the header lock bracket location(s) and replaced with the same thickness of wood before installing

the header lock bracket(s). If this process is performed, the length of the lag screws MUST be increased by the

thickness of wood material, so that a minimum of 1-1/2” penetration into the existing header is obtained.

Bottom Bracket Installation

FIG. 3

Locate the bottom bracket assembly and align it to the

bottom of the post. Secure the bottom bracket to the

bottom of the windload post using (4) 1/4-20 x 11/16”

self-drilling screws. (see Fig. 3)

NOTE: The bottom of the windload post is fl ush

while the top is offset.

Post Hole Placement

At each windload post location, mark a center line on

(4) 1/4-20 X 11/16”

SELF-DRILLING

SCREWS

BOTTOM

BRACKET

ASSEMBLY

the fl oor that is aligned with the center of half hinge.

Measure out from the back of the door (see Fig. 4) 5-3/4”

and make a second mark as shown in Fig. 5. Using a masonry bit, drill (1) 5/8” x 4” deep hole into the concrete.

Clean out the hole.

IMPORTANT! For proper operation of the windload

post, it is important that the 5-3/4” dimension be held,

FIG. 5

to assure the post is installed plumb.

DIM. 5-3/4”

FIG. 4

4

DIM. 5-3/4”

DO NOT MEASURE

FROM BOTTOM SEAL

(SEE FIG.4)

CENTER LINE

OF HALF HINGE

5/8” X 4”

DEEP HOLE

Page 5

Top Plate Extension Installation

Locate the top plate extension and top strap bracket. Place the top strap bracket onto the top plate extension and

adjust so that the holes in the top strap bracket align with the corresponding door model holes in the top plate

extension. Hold in position and secure using (4) 1/4-20 x 7/8” self-drilling screws. (see Fig. 6)

Slide the top plate extension assembly into the header bracket. Now, install the windload post into the post hole

in the fl oor and align the top of the windload post with the top plate extension assembly. Ensure that the post is

level and plumb. Using (2) 1/4-20 x 7/8” self-drilling screws, secure the windload post to the top plate extension

assembly. (see Fig. 7)

NOTE: Doors without a 2” U-bar on the top section will require an extra Jr. “A” frame bracket, at the top

of the section. (see Fig. 7).

TOP PLATE

EXTENSION

(4) 1/4-20 X 7/8”

SELF-DRILLING

SCREWS

FIG. 6

TOP STRAP

BRACKET

TOP PLATE

EXTENSION

ASSEMBLY

(2) 1/4-20 X 7/8”

SELF-DRILLING

SCREWS

JR. “A”

FRAME

FIG. 7

5

Page 6

Strap Bracket Installation

Loosely attach (2) straps to each center hinge, with (1)

3” long carriage bolt and wing nut (see Fig. 8). Attach

(2) straps to the bottom half hinge, with (1) 3-1/2” long

carriage bolt and wing nut (see Fig. 9). Position the straps

at each center hinge, and bottom half hinge locations.

Ensure that the windload post is plumb while locked into

the header lock bracket and hole in fl oor. Now, secure

each strap to the windload post using (1) 1/4-20 x 11/16”

self-drilling screw.

CENTER

HINGE

WING

NUT

(2) STRAP

NOTE: Keep straps parallel and level. (see Fig. 10)

Finish hand tightening the carriage bolts and wing

FIG. 9

WING

NUT

HALF HINGE

(2)STRAPS

3-1/2” LG.

CARRIAGE BOLT

Side Lock Installation

3” LG.

CARRIAGE BOLT

STRAP

JR. “A”

FRAME

FIG. 8

FIG. 10

WINDLOAD

POST

(2) 1/4-20 X 11/16”

SELF-DRILLING SCREWS

Install side lock on the second section from the bottom

of the door. Square side lock assembly with door section and hole in vertical track. The side lock should be

spaced approximately 1/8” from the section edge. Secure

the side lock to the section with (4) 1/4-20 x 11/16” self

drilling screws.(see Fig. 11)

IMPORTANT! Side locks and openers should not be

engaged at the same time. If an opener is installed on

the door and engaged, be sure side locks are disengaged,

otherwise damage could result to door and/or opener.

Only use side locks when opener is disengaged from

the garage door.

ALIGN WITH

HOLE IN

VERTICAL

TRACK

6

1/8”

FIG. 11

SIDE LOCK

(4) 1/4-20 X 11/16”

SELF DRILLING

SCREWS

Page 7

Securing Post for Storage

Locate a convenient place to store the windload post(s).

Measure and cut (2) 2” x 6” wood mounting blocks a

minimum of 10” long for each windload post. Locate

the mounting blocks horizontally on the wall as shown

in Fig. 12. Secure them adequately to the wall at the top

and bottom of the post storage location, with masonry

anchors for concrete construction, or 16 penny nails for

wood construction. Measure a distance of 6” greater than

door height as illustrated in Fig. 12, and mount the extra

header lock bracket(s) to the top mounting block(s) using

(2) 5/16” x 1-5/8” lag screws as shown in Fig. 12.

TOP OF WINDLOAD POST

JR. “A”

FRAME

MEASURE THE

DISTANCE FROM THE

TOP OF THE WINDLOAD

POST TO THE CENTER

OF THE BOTTOM STRAP

Measure the distance from the top of the windload post

to the center of the bottom strap (see Fig. 13). Use that

measurement for the dimension between the center of

the extra header lock bracket and half-hinge tube. Position the half-hinge on the bottom mounting block and

secure the half-hinge using (2) 5/16” x 1-5/8” lag screws.

Repeat this step for remaining windload posts if necessary. (see Fig. 12)

HEADER LOCK

BRACKET

6” MIN.

(2) 5/16” X 1-5/8”

LAG SCREWS

DISTANCE BETWEEN TOP

OF WINDLOAD POST AND

CENTER OF BOTTOM

STRAP

HALF

HINGE

BOTTOM

STRAP

FIG. 13

BOTTOM OF

WINDLOAD POST

HALF-HINGE

TUBE

(2) 5/16” X 1-5/8”

LAG SCREWS

FIG. 12

Slide the windload post(s) into storage header bracket(s)

and secure the bottom strap(s) to the half hinge(s) using

the 3-1/2” carriage bolt and wing nut. Place all remaining

wing nuts and carriage bolts into the remaining straps for

storage. Insert plastic plug into hole in fl oor.

7

Page 8

Attaching the Installation Decals

After the installation is complete, locate in a obviously visible location on the inside of the garage door and the

post(s) and place the provided installation labels and tag(s) onto the door and post(s) for future reference.

IMPORTANT! LABELS AND TAG(S) MUST BE ATTACHED TO BOTH DOOR AND POST(S).

Windload Label Locations

2

1

3

1 Applied by Installer - One (1) Emergency High Wind Situations Tags

(161384) per post -Tags are to be applied to post(s) when stored on

wall for constant reminder to consumer.

2

3

Applied by Installer - One (1) Windload PSF Label per post, based

on the required design PSF load. Label is to be applied to windload

post for reference.

Applied by Installer - One (1) Windload Post Installation Instructions

Label (307177) -Only on doors specifi ed with one or more posts. To be

applied to inside of door, next to endcap of second section on side of the

door where Post no. 1 is stored.

MAKE SURE LABELS AND TAG(S) LIKE THE ONES ABOVE ARE INSTALLED ON THE DOOR

AND POST(S)!

CONTACT WAYNE-DALTON CORP. FOR A FREE REPLACEMENT DECAL.

Please Do Not Return This Product To The Store.

Contact your local Wayne-Dalton dealer. To fi nd your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the Find a Dealer section online at www.wayne-dalton.com

8

Loading...

Loading...