For Residential and Commercial Applications

ES-WP-WPCCT-2

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

Model WPCCT-2

Manual CinchClamp™ Tool

Sizes: 3⁄8", 1⁄2", 5⁄8", 3⁄4" (10, 15, 18, 20mm)

The Watts Manual CinchClamp™ Tool is designed for use with

tubing and CinchClamp™ connections.

Specifications

Connections shall use Watts brass and poly-alloy crimp

fittings and Watts WaterPEX

Installation

All CinchClamps must be installed using a Watts CinchClamp

Tool and in accordance with all installation guidelines.

– Make sure the Watts WaterPEX

– Slide the CinchClamp over the Watts WaterPEX

– Insert fitting and position CinchClamp, allowing for

approximately

– Position the open jaws of the Manual CinchClamp Tool over

the tabs of the CinchClamp and squeeze. Tool will release

when cinch is complete.

1

⁄8" clearance between clamp and fitting.

®

cross-linked polyethylene pipe.

®

has a clean, square cut end.

®

.

Contractor

Approval

Contractor’s P.O. No.

Representative

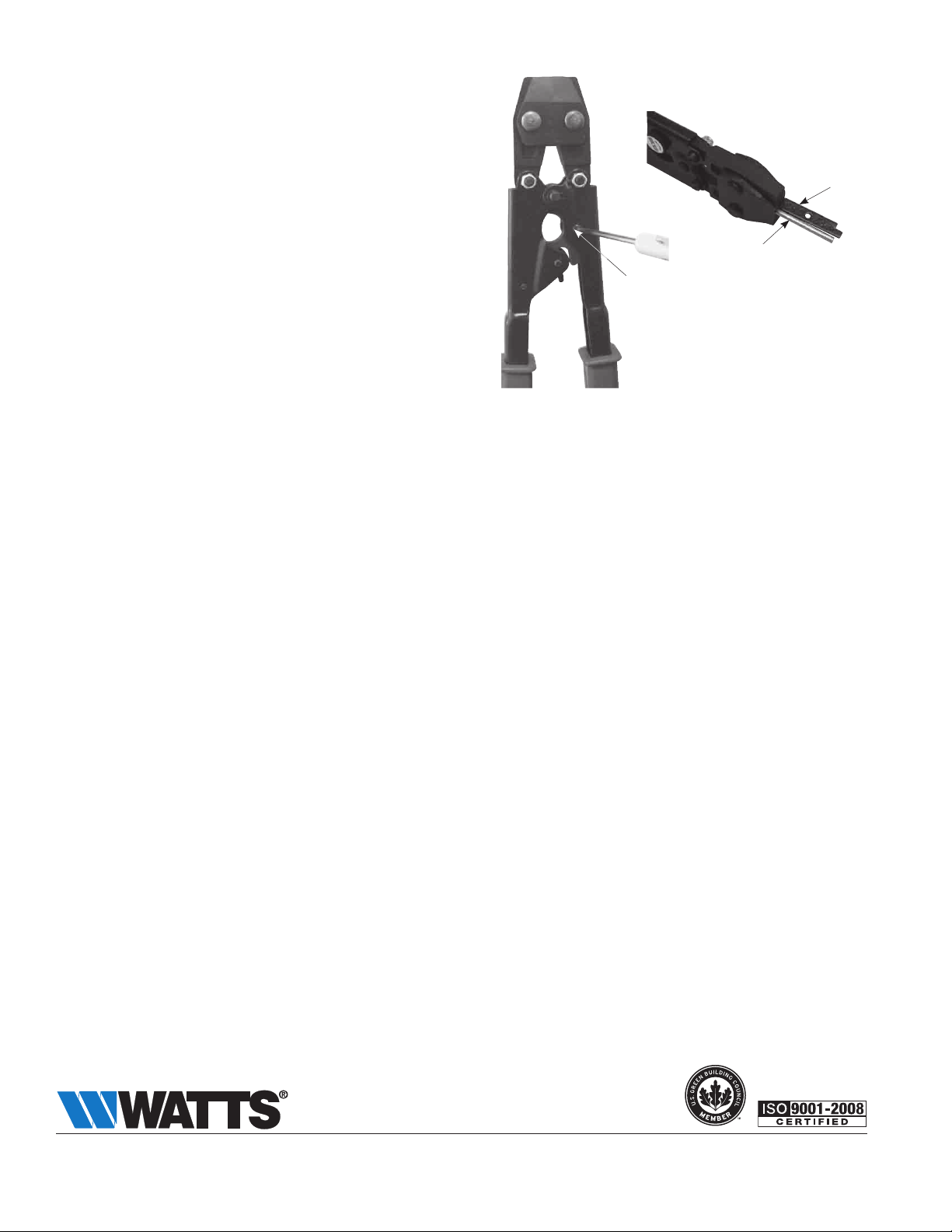

Manual CinchClamp™ Tool with work pouch and calibration gauge.

Calibration gauge and calibration bar are located in side pouch.

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

Holster

Gauge and

Calibration

Bar Pouch

Gauge

Standards

Manual

CinchClamp™ Tool

Calibration Bar

If connections are made in temperatures below 30°F,

caution must be taken to cinch slowly between ratchets,

allowing the Watts WaterPEX

against the barb.

Do not use the Manual CinchClamp Tool to remove

CinchClamps. This will cause damage to the tool, resulting in improper connections.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

®

to form a proper seal

– Watts WaterPEX® CinchClamps are manufactured in accor-

dance with American Society for Testing and Materials

(ASTM) F-2098.

– Watts WaterPEX

dance with American Society for Testing and Materials

(ASTM) F-1807, F-2159, and F-2434.

– Only for use with PEX manufactured to ASTM F-876/F-877

MODEL DESCRIPTION

WPCCT-2 Manual CinchClamp™ Tool

®

Fittings are to be manufactured in accor-

Calibration

Do not use the Manual CinchClamp Tool if it has been

damaged, as this may result in an improper cinch.

After repeated use of the Manual CinchClamp Tool, it

may require calibration. A calibration gauge and bar are

provided in the tool pouch. Follow these steps when calibrating a Watts Manual CinchClamp Tool.

1. Insert the Calibration Bar into the tool as shown and ratchet

the Manual CinchClamp™ Tool to the closed position and

hold. Use the calibration tool to gauge the jaw gap. Ideally,

the jaw gap should be between 1.5mm and 1.7mm. If the

1.7mm side of the gauge slides into the gap, then the jaw

space is too large. If the 1.5mm side of the gauge cannot

slide into the gap, then the jaw space is too narrow.

2. To adjust the jaw gap, turn the Manual CinchClamp™ Tool

on its side and locate the Phillips screw positioned on the

ratchet arm. Use a standard Phillips screwdriver to loosen

the screw and to adjust the ratchet arm position. Turning the

arm left or right will change the jaw gap. Tighten screw when

desired jaw gap is reached.

Gauge

Calibration Bar

Check Calibration

Adjustment Screw

Adjust Calibration

A Watts Water Technologies Company

ES-WP-WPCCT-2 1323 © 2013 Watts

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

Loading...

Loading...