Page 1

For Commercial Applications

ES-WQ-PWR2511

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

Series PWR2511

Commercial Reverse Osmosis

Systems

Flow Rates: Up to 1,200 gpd (4,542 lpd)

Watts Pure Water Series PWR2511 reverse osmosis (RO)

systems are commercial grade high-pressure RO units for

the reduction of total dissolved solids from water. They are

designed to supply reverse osmosis quality water with production rates ranging from 150 to 1,200 gallons per day. The

standard units are designed for wall mounting. Where floor

mounting is preferred, the optional floor mounting kit Model

No. PWR2864 can be specified. Reverse osmosis is a process

where high-pressure feed water is fed into a semi-permeable

membrane. In the membrane, pure water is allowed to pass

through the membrane material and exit as purified permeate

water. Dissolved mineral salts are not allowed to pass through

the membrane and become a concentrated reject stream that

is sent to a drain. These RO systems use high-rejection membranes to achieve a minimum average NaCl ionic rejection of

95 percent.

Watts Pure Water Series PWR2511 RO systems are a well

designed, rugged line of purifiers. This series comes with a

pre-selected assortment of features for monitoring and operation. Stainless steel membrane housings, inlet and outlet prefilter pressure gauges, low-pressure switch with delayed auto

restart, permeate pressure switch, adjustable reject recycle,

permeate and reject water flow meters, permeate water check

valve, inlet solenoid valve, membrane feed water pressure

gauge, adjustable reject valve, and membrane auto flush are

all standard features. The standard systems are designed to

feed an atmospheric storage tank or a pressurized bladder

tank. Reverse osmosis water has a wide variety of applications including municipal water treatment, steam boiler and

steam sterilizer make up, laboratory use, spot free rinsing,

ice and beverage water, water for cooking, food processing,

metal plating and finishing, as well as water for humidification.

Reverse osmosis is also the pretreatment of choice for ion

exchange type de-ionization (DI) systems. Using RO water as

make up to a DI system reduces the exhaustion rate of the DI

resin by up to 95 percent saving time, money, and chemicals

associated with DI resin regeneration.

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

PURE WATER

Series PWR2511

Features

• 304 stainless steel wall mounted support frame

• 316L stainless steel 300psi high-pressure membrane

housings

• Pressure gauges for pre-filter inlet/outlet and membrane

feed pressure

• Low feed water pressure safety switch

• Microprocessor based controller with delayed auto restart

after low pressure shut down

• High-pressure/high-rejection membranes with 95% minimum

average salt rejection

• Permeate and reject water flow meters

• Adjustable reject and reject recycle valves

• Permeate pressure switch and check valve

• Automatic inlet solenoid valve

• Membrane Auto Flush

Standards

Note: Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before or after

the system.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

• Pre-filter Housing NSF/ANSI Certified 42

• Pre-filter Cartridge NSF/ANSI Certified 42

• Feed water must be pretreated for - Scale prevention

(Softened), dechlorinated (Carbon Filter), and free of

sediment.

Page 2

Specifications

Watts Pure Water Series PWR2511 reverse osmosis system

shall be installed to provide reverse osmosis quality water. The

RO system shall be installed after a Series PWS water softener

so that scale forming calcium and magnesium hardness cannot

scale the RO membrane(s). Series PWC backwashing carbon

filter shall be installed on the RO feed water line to remove

chlorine and prevent membrane degradation due to chlorine

attack. Series PWM backwashing sediment filter shall also be

installed on the RO feed water line to reduce the silt density

index of the water to prevent particulate fouling of the RO

membrane(s).

The RO system shall be a high-pressure/high-rejection type

unit complete with permeate and reject water flow meters, pre-

filter inlet/outlet and membrane feed water pressure gauges,

316L stainless steel membrane housings, automatic inlet sole-

noid valve, low feed water pressure switch, permeate water

pressure switch, reject and recycle valves, auto flush feature,

micro electronic controller, high-pressure pump, and all other

components necessary for proper operation. The system shall

be a wall mount design with an optional leg kit for floor mount

installations. The RO permeate water shall be collected in an

atmospheric storage tank or a pressurized bladder tank. A permeate water pressure switch is provided on the RO system for

automatic on/off operation when using a pressurized bladder

tank. Electrical requirements are 120 volt 60 hertz. A local drain

is required to accept drain water from the system. The feed

water pressure must not fall below 20psi. The feed water tem-

perature must not fall below 35°F or exceed 100°F (2 - 38°C).

The system shall produce reverse osmosis quality water with

95 percent minimum average ionic rejection of total dissolved

solids when operated within the manufacturer’s operational

specifications.

Feed Water Guidelines

pH ......................... 6 to 9

Hardness (maximum) ........... Less than 1 grain per gallon as

CaCO3 (Softened) or anti scale

chemical injection if not softened

(contact your Watts representative)

Feed Water Pressure (minimum) ..20psi

Temperature .................35 - 100°F (2 - 38°C)

Free Chlorine (maximum) ........None Allowed

Iron (maximum) ................Less than .1mg/L

Oil and H2S ..................None Allowed

Turbidity ....................Less than 1.0 NTU

Silt Density Index ..............Less than 5.0 SDI

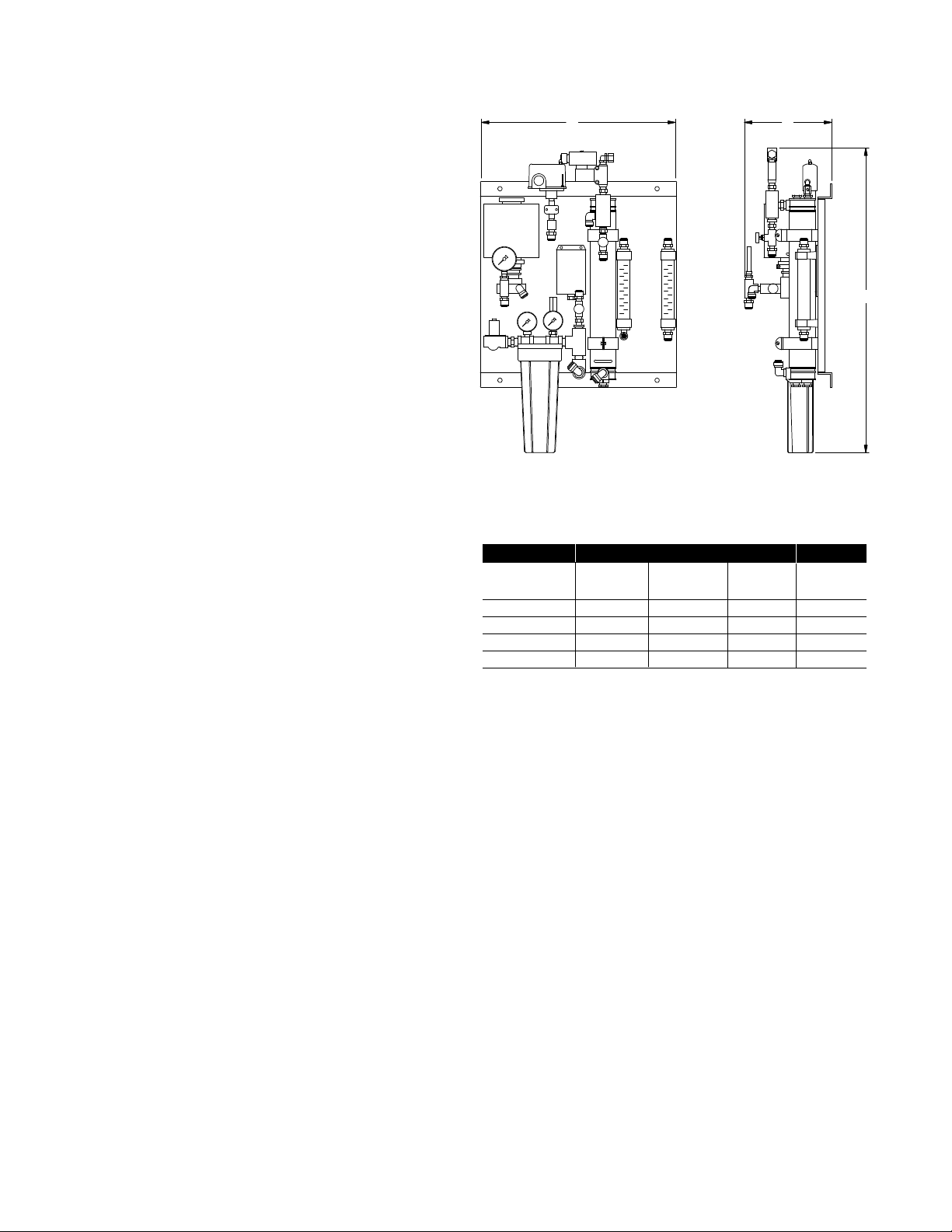

Dimensions - Weights

C

FRONT

MODEl NO. DIMENSIONS WEIghTS

A B C

in. mm in. mm in. mm lbs. kgs.

PWR25111011 9 229 30 762 21 533 50 23

PWR25112011 9 229 32 813 21 533 50 23

PWR25113011 9 229 51 1295 21 533 60 27

PWR25113021 9 229 51 1295 21 533 70 32

A

SIDE

B

Notes:

For all other guideline information please contact your Watts

representative.

Page 3

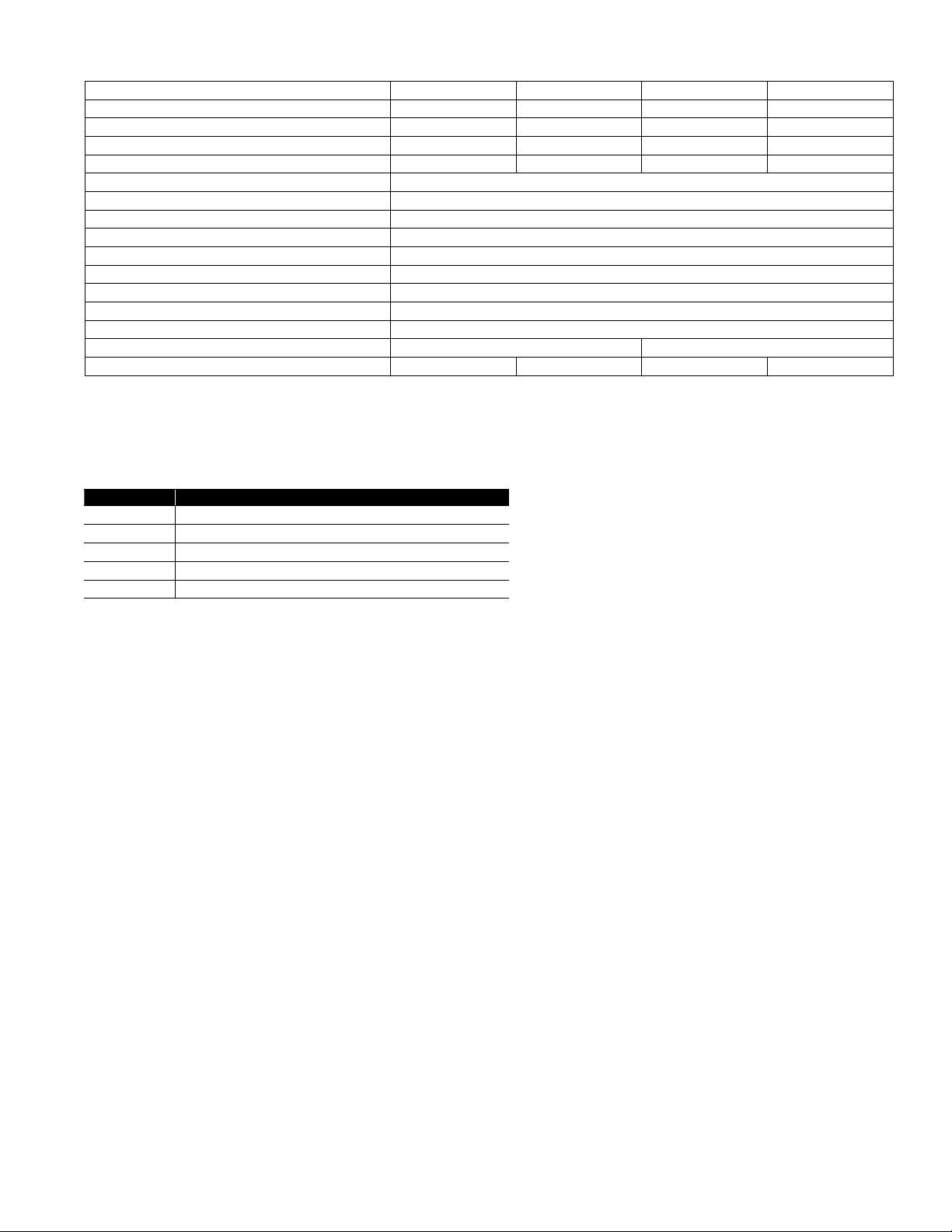

Performance

Maximum Productivity (gallons per day) 150 250 600 1200

Quality (average membrane rejection) 98 % 98 % 98 % 98 %

Recovery (user adjustable) 15 - 75 % 15 – 75% 15 - 75 % 25 - 75 %

Membrane Size 2.5” x 14” 2.5” x 21” 2.5” x 40” 2.5” x 40”

Number Of Membranes 1 1 1 2

Prefilter (system ships with one 5 micron cartridge) 10"

Feed Water Connection ½" NPT

Product Water Connection (tubing OD)

Reject Water Connection (tubing OD)

Feed Water Required (maximum) 2.4 gpm

Feed Water Pressure (minimum) 20psi

Drain Required (maximum) 2.4 gpm

Electrical Requirement 120 VAC 60 Hz 8 amps

Motor Horse Power ½

Dimensions W x H x D (approximate) 22" x 32" x 12" 22" x 52" x 12"

Shipping Weight (estimated pounds) 50 50 60 70

3

⁄8"

3

⁄8"

Ordering Information

MODEl NO. DESCRIpTION

PWR25111011 150 Gallon Per Day Reverse Osmosis System With Auto Flush

PWR25112011 250 Gallon Per Day Reverse Osmosis System With Auto Flush

PWR25113011 600 Gallon Per Day Reverse Osmosis System With Auto Flush

PWR25113021 1200 Gallon Per Day Reverse Osmosis System With Auto Flush

PWR2864 Optional Stainless Steel Leg Kit For All Models

Notes:

• Maximum production based on a feed water of 77°F, SDI < 3, 1000 ppm

TDS, and pH 8.

• Individual membrane productivity may vary (± 15%). May be operated on

other feed waters with reduced capacity.

• Percent Rejection is based on membrane manufacturer’s specifications;

overall system percent rejection may be less.

Page 4

A Watts Water Technologies Company

USA: North Andover, MA • Tel. (800) 224-1299 • www.watts.com

Canada: Burlington, ON • Tel. (888) 208-8927 • www.wattscanada.ca

ES-WQ-PWR2511 1122 © 2011 Watts

Loading...

Loading...