Page 1

For Commercial Applications

ES-WQ-PWM

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

Series PWM

Commercial Micro Z™ Filter

Systems

Connection Sizes: 1" to 3" (25 - 80 mm)

Flow Rates: Up to 106 gpm (401 lpm)

Watts Pure Water Series PWM Micro Z™ filters are highly

effective backwashing media filtration systems for the removal

of sediment and suspended solids from water.

They are suitable for commercial applications with flow rates up

to 106 gpm (401 lpm) with media bed sizes ranging from 1 to

20 cubic feet in size. If higher flow rates are required, multiple

units can be installed in parallel. The media bed is cleaned of

captured sediment by periodic backwashing and flushing. This

cleaning cycle is time clock demand initiated and can be programmed to occur at any time that is convenient for the user.

All steps of the cleaning cycle as well as returning to service

are fully automatic and do not require manual actuation.

Watts Pure Water Series PWM sediment filters are designed for

point of use or point of entry applications where filtered water

is required. Micro Z™ is a naturally occurring form of zeolite

that offers superior filtration characteristics over and above

sand, anthracite and garnet products currently in use today.

The key to Micro Z™’s performance is its hydrophilic properties combined with a jagged external surface texture. This

gives Micro Z™ a sediment holding capacity of 2.8 times that

of sand, which reduces backwash waste water volumes and

provides higher service flow rates which reduces over all system

size and cost. Micro Z™ has a 3-5 micron nominal particle size

removal rating versus 15-30 micron with other conventional

back-washable medias.

Reverse osmosis pretreatment, micro and ultra filtration system

pretreatment, cartridge filtration pretreatment, sediment reduction in city and rural water, municipal water filtration, as well as

general turbidity reduction are all common applications for the

Watts Pure Water Series PWM Micro Z™ filter systems.

Filtered water is a cleaner supply water for boilers, solenoid

valves, pumps, faucets, aerator screens, reverse osmosis

systems, micro and ultra filtration systems, pools, aquariums,

washing, and rinsing processes that reduces down time and

costly repairs.

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

PURE WATER

Series

PWM10

Features

• WQA Certified fully automatic time clock initiated control valve

• Sophisticated digital electronic controls that store operating

history that can be accessed by the user

• Fully adjustable backwash and flush cycles

• Durable brass bodied control valve for years of service

• Dry contact lock out switch for remote interface is standard

• NSF Certified high capacity Micro Z™ filter media

• Highly corrosion resistant NSF Certified fiberglass tanks

• Durable polypropylene lower distribution system

Standards

Control Valve- WQA Certified to NSF/ANSI Std. 61

Micro Z™ Filter Media- NSF Certified to ANSI Std. 61

Mineral Tank- NSF Certified to ANSI Std. 44 or 61

Series

PWM15

Series

PWM20

Series

PWM30

Note: Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before or after

the system.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

Specifications

E

D

Watts Pure Water Series PWM Micro Z™ filter system shall

be installed on the building’s main water line just after it enters

the building. The installation point shall be after any backflow

prevention or pressure regulating valves. Other installation

options are to install a system just before the plumbing equipment needing the protection of filtered water. In installations

where the dedicated cold water make up to a water heater is

the installation point, a backflow preventer and a thermal expansion tank must be installed as well. The system shall be installed

with a bypass valve to allow for the shut down and removal of

the unit without interrupting the water supply to the building.

The filter system shall be a backwashing granular media bed

type with digital programmable time clock initiated backwash,

high-capacity alumino-silicate filter media rated for 3-5 nominal

particle size removal, and all components necessary for proper

operation. Electrical requirements are 120 volt 60 hertz. A local

drain is required to accept drain water from the system. The

feed water pressure must not fall below 30psi (207 kPa) or

exceed 125psi (8.7 bar). Water temperature must not fall below

34°F or exceed 110°F (1 - 43°C).

The system shall provide water that has been filtered to a nominal micron rating of 3-5 micron.

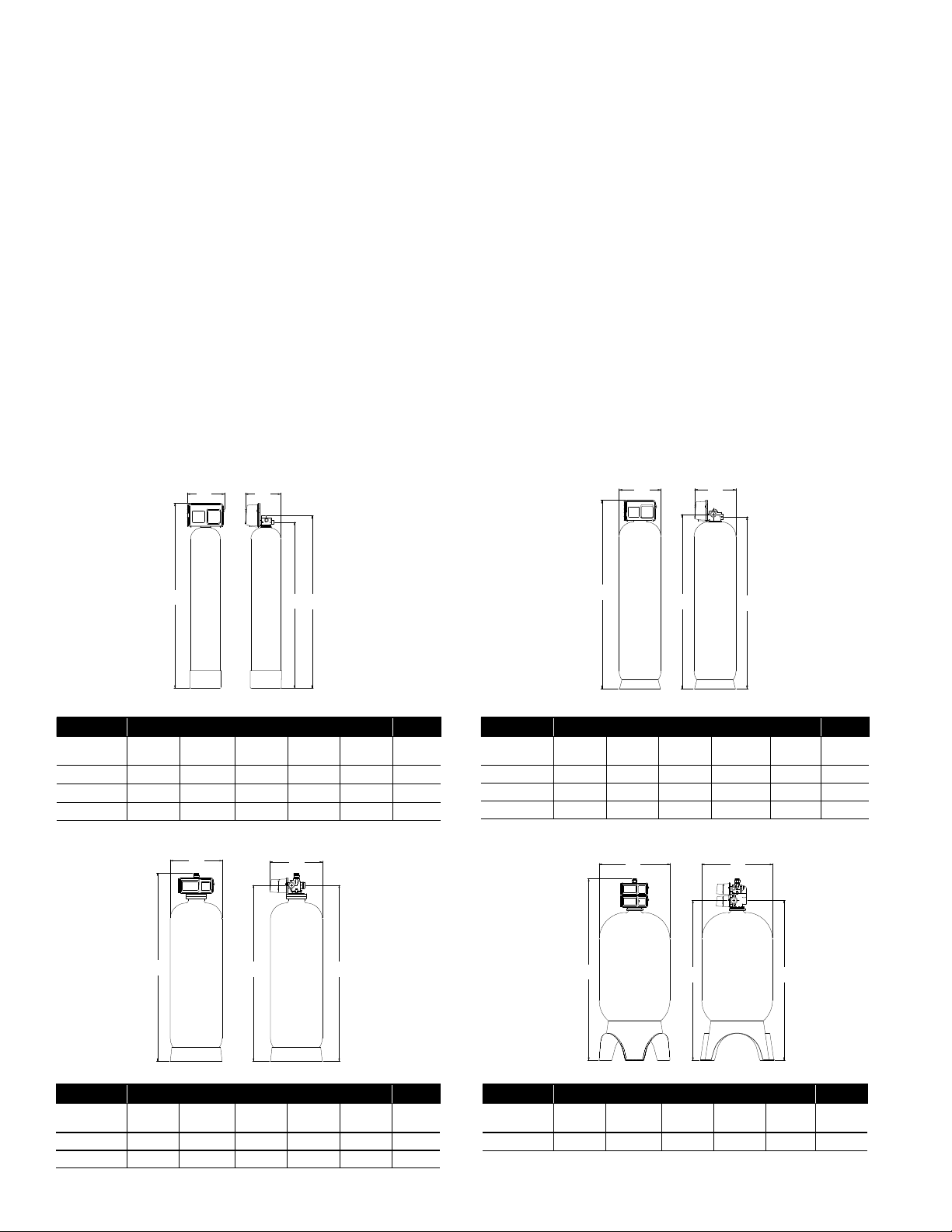

Dimensions - Weights

Feed Water Guidelines

pH .................... 6 to 8.5

Water Pressure .......... 30psi to 125psi

(207 kPa to 8.7 bar)

Temperature ............ 34 - 110°F (1 - 43°C)

Oil and H2S ............. None Allowed

* For all other guideline information please contact your Watts representative.

Series PWM10

MODEL NO. DIMENSIONS WEIGHTS

A B C D E

in. mm in. mm in. mm in. mm in. mm lbs. kgs

C

C

FRONT

E D

E D

SIDE

B

A

B

A

PWM10111A10 501/8 1273 523/8 1330 561/2 1435 111/2 292 123/4 324 118 54

PWM10111B10 56

PWM10111C10 54

Series PWM20

1

/4 1429 587/16 1484 625/8 1591 12 305 123/4

5

/8 1387 5613/16 1443 61 1549 13 330 123/4 324 173 79

E

D

324 147 67

Series PWM15

MODEL NO. DIMENSIONS WEIGHTS

A B C D E

in. mm in. mm in. mm in. mm in. mm lbs. kgs

E

E

C

C

FRONT

FRONT SIDE

D

D

B

B

A

A

SIDE

PWM15121D10 6615/16 1699 677/8 1724 733/8 1864 1415/16 378 141/8 358 278 366

PWM15121E10 663/8 1686 671/4 1708 723/4 1848 1515/16 405 161/8 409 667 303

PWM15121G10 70 1778 71 1803 767/16 1941 211/8 536 211/8 536 1015 461

Series PWM30

E

E D

D

C

C

B A

AB

FRONT SIDE

MODEL NO. DIMENSIONS WEIGHTS

A B C D E

in. mm in. mm in. mm in. mm in. mm lbs. kgs

PWM20141H10 817/8 2079 817/8 2079 871/2 2222 247/16 620 241/8 612 1015 461

PWM20141I10

833/8 2118 833/8 2118 89 2260 301/8 765 301/8 765 1852 842

C

C

AB

AB

FRONT SIDE

MODEL NO. DIMENSIONS WEIGHTS

A B C D E

in. mm in. mm in. mm in. mm in. mm lbs. kgs

PWM30151J10 871/4 2216 871/4 2216 100 2540 361/8

917

361/8 917 2525 1148

Page 3

Specifications

MINERAL TANK FLOW RATES FOR SERVICE AND BACKWASH

TANK TANK SIZE MICRO Z™ SERVICE GPM BACKWASH GPM

MODEL NO. SIZE Ft

2

Ft3 10 GPM Ft

2

15 GPM Ft

2

20 GPM Ft2

PWM10111A10 9" x 48" .44 1.0 4.4 6.6 8.8 7.0 GPM

PWM10111B10 10" x 54" .54 1.5 5.4 8.1 10.8 7.0 GPM

PWM10111C10 12" x 52" .78 2.0 7.8 11.7 15.6 10 GPM

PWM15121D10 14" x 65" 1.07 3.0 10.7 16.0 21.4 20 GPM

PWM15121E10 16" x 65" 1.39 4.0 13.9 20.8 27.8 20 GPM

PWM15121G10 21" x 62" 2.41 7.0 24.1 36.1 48.2 40 GPM

PWM20141H10 24" x 72" 3.14 10 31.4 47.1 62.8 50 GPM

PWM20141I10 30" x 72" 4.91 15 49.1 73.6 98.2 85 GPM

PWM30151J10 36" x 72" 7.07 20 70.7 106.1 141.4 100 GPM

Ordering Information

SPACE

MODEL NO. DESCRIPTION PIPE SIZE REQUIRED WEIGHT

W x D x H LBS KGS

PWM10111A10 1 Cubic Foot Micro Z™ filter with Auto Backwash 1" 10" x 11" x 60" 118 54

PWM10111B10 1.5 Cubic Foot Micro Z™ filter with Auto Backwash 1" 11" x 12" x 65" 147 67

PWM10111C10 2 Cubic Foot Micro Z™ filter with Auto Backwash 1" 13" x 14" x 65" 173 79

PWM15121D10 3 Cubic Foot Micro Z™ filter with Auto Backwash 1

PWM15121E10 4 Cubic Foot Micro Z™ filter with Auto Backwash 1

PWM15121G10 7 Cubic Foot Micro Z™ filter with Auto Backwash 1

PWM20141H10 10 Cubic Foot Micro Z™ filter with Auto Backwash 2" 27" x 27" x 95" 1015 461

PWM20141I10 15 Cubic Foot Micro Z™ filter with Auto Backwash 2" 33" x 33" x 95" 1852 842

PWM30151J10 20 Cubic Foot Micro Z™ filter with Auto Backwash 3" 40" x 48" x 114" 2525 1148

1

⁄2" 15" x 16" x 75" 278 126

1

⁄2" 17" x 18" x 75" 366 166

1

⁄2" 23" x 24" x 84" 667 303

Notes: Flow rates, dimensions, and capacities are per tank. Pipe size, tank size, and space requirements are in inches. 20 gpm per square foot flow rates are for intermittent

peak flows only and should not be used as continuous flows.

A Watts Water Technologies Company

USA: North Andover, MA • Tel. (800) 224-1299 • www.watts.com

Canada: Burlington, ON • Tel. (888) 208-8927 • www.wattscanada.ca

ES-WQ-PWM 1122 © 2011 Watts

Loading...

Loading...