Page 1

Installation, Operation

and Maintenance Manual

Series PWBWGAC, PWBWMZ, PWBWCAL

Filter Systems

PURE WATER

!

Warning

You are required to thoroughly read all installation instructions and

product safety information before beginning the installation of this

product. FAILURE TO COMPLY WITH PROPER INSTALLATION

AND MAINTENTENANCE INSTRUCTIONS COULD RESULT IN

PROPERTY DAMAGE, PERSONAL INJURY AND/OR DEATH.

Watts is not responsible for damages resulting from improper installation and/or maintenance.

Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after

the system.

Local building or plumbing codes may require modifications to the

information provided. You are required to consult the local building

and plumbing codes prior to installation. If this information is not

consistent with local building or plumbing codes, the local codes

should be followed.

Save manual for future reference.

Refer to enclosed for operating parameters to ensure proper use

with your water supply.

IOM-WQ-PWBWGAC-PWBWMZ-PWBWCAL

PWBWGAC

PWBWMZ

PWBWCAL

Table of Contents Pages

Important Safety Information – Read All .......................2

Instructions Before Using.................................. 2

Filter Anatomy ..........................................3

Specifications ..........................................4

Feedwater Parameters ...................................4

Power ................................................4

Installation Considerations .................................4

Drain Flow Rates ........................................4

Setup ................................................5

Installation .............................................6

Controller..............................................7

Filter Operation .........................................7

Replenishing the Calcite Filter Media .........................7

Troubleshooting.........................................7

Limited Warranty ........................................8

Page 2

Important Safety Information –

Read All

Caution: Read and follow the information in this

manual to minimize the risk of electric shock or per-

!

sonal injury.

Important: If you are unsure about installing your Watts

water lter, contact a Watts representative or consult a

professional plumber.

Important: This system must be installed in compliance with applicable state province and local codes,

law, and regulations.

READ Instructions Before Using

• After reading these instructions completely, obtain all the

materials and tools needed for installation.

NOTE: Failure to install the system correctly voids the warranty.

• Perform installation according to state, province and local

plumbing codes.

Use only lead-free solder and flux for sweat-solder connec-

tions, as required by state, province and federal codes.

• Handle all components of the system with care. Do not drop,

drag or turn components upside down.

• Be sure the oor under the water lter system is clean, level

and strong enough to support the unit.

• The system uses 24 volt-60Hz electrical power. Always use

the transformer supplied.

Plug transformer into an indoor 120 VAC, grounded outlet.

Properly ground the system to conform with all codes and

ordinances.

• Install the system in a protected area. Be sure electric outlet

and transformer do not come in contact with water. For more

information on where to install the lter see the Installation

Considerations section of this manual.

Do not attempt to treat water over 110°F (43°C) with the

system. Always connect the system to the main water supply pipe before the water heater.

Do not expose the system to freezing temperatures. Water

freezing in the system causes equipment damage.

Do not install in direct sunlight. Ultraviolet rays from the sun

may cause damage.

• Minimum inlet water pressure is 30psi. Maximum inlet water

pressure is 125psi. Use a pressure reducing valve if necessary.

Caution:

• Do not use with water that is microbiologically

!

unsafe or of unknown quality.

• Test the water periodically to verify that the

system is performing satisfactorily.

• Discard small parts remaining after the installation.

2

Page 3

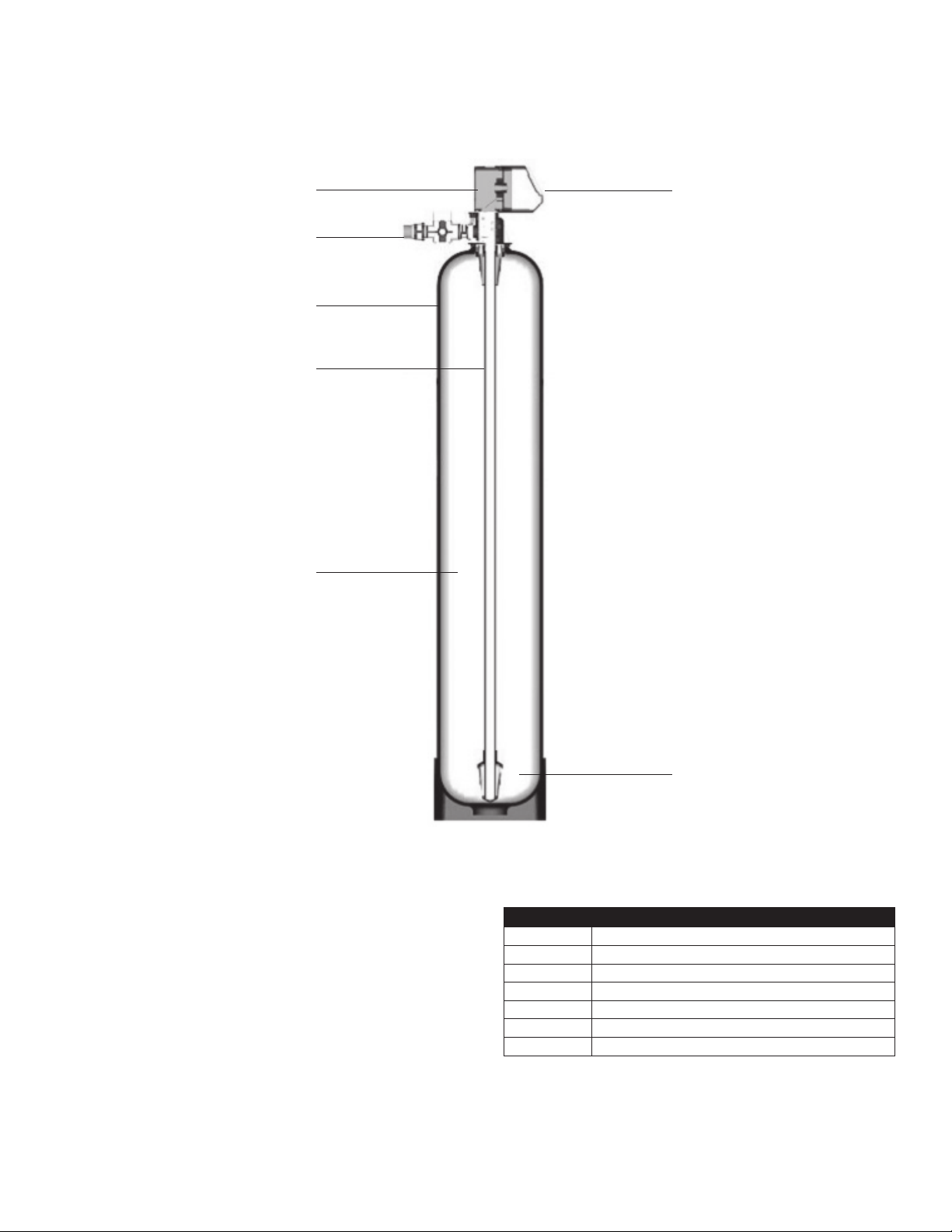

Filter Anatomy

1

6

2

3

4

5

7

ITEM # DESCRIPTION

1 Valve

2 Bypass

3 Tank

4 Distributor

5 Filter Media (Calcite, Carbon, or Micro Z™)

6 Faceplate/Controls

7 Gravel Underbed

3

Page 4

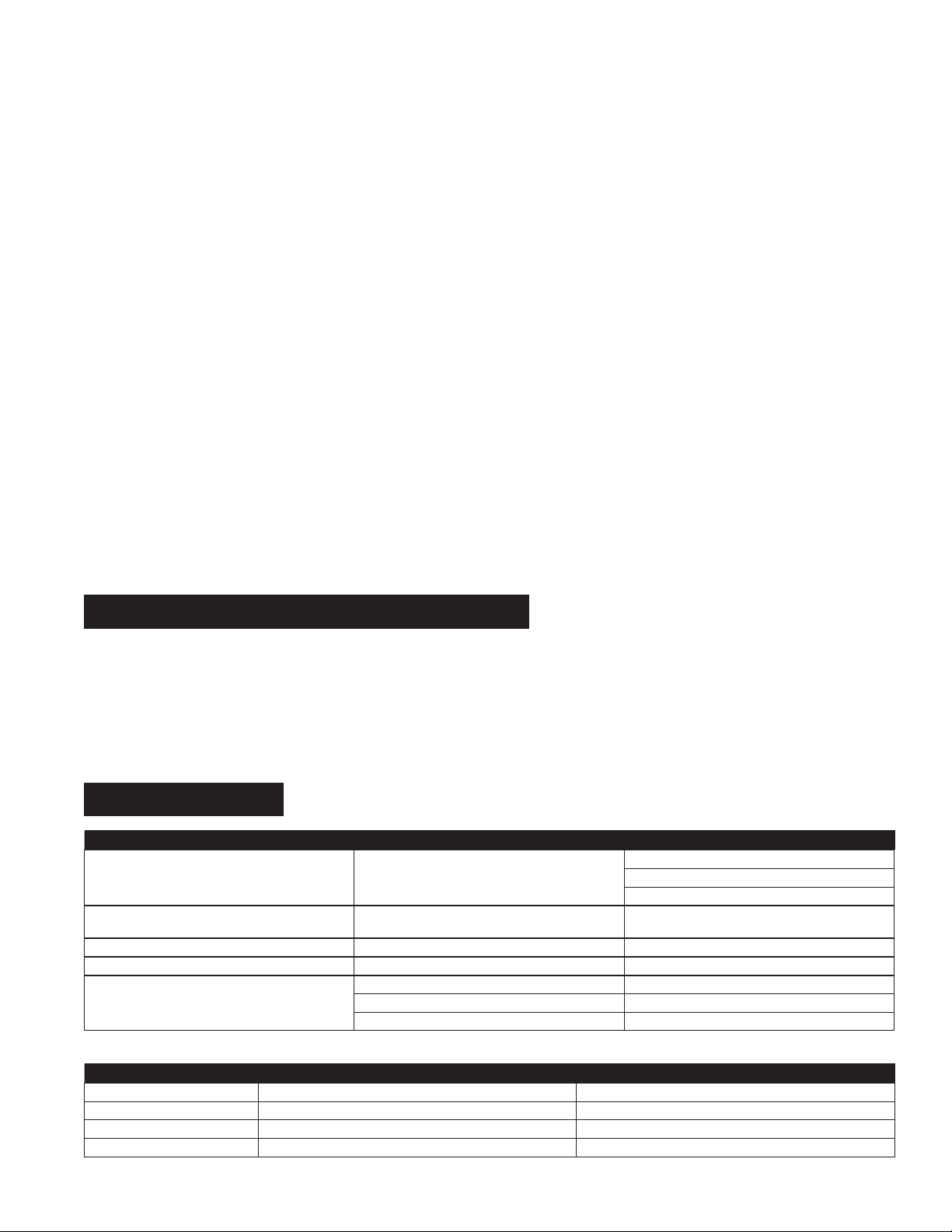

Specications

Feed Water Parameters

!

Do not use this system on water that is microbiologically

unsafe or of unknown quality without adequate disinfection

before or after the system !

Minimum inlet pressure: 30 psig

Maximum operating pressure: 125 psig

Minimum water temperature: 34°F (1°C)

Maximum water temperature: 110°F (43°C)

Power

Voltage: 120VAC

Frequency: 60Hz

Power consumption: 7 Watts Maximum

Installation

Location: Indoors (Protect from direct sunlight)

Minimum ambient temperature: 34°F (1°C)

Maximum ambient temperature: 122°F (50°C)

Drain Flow Rates - The drain system these lters

are plumbed to must be able to accept the listed drain

volumes for a period of 27 minutes.

Micro Z™ Filters

9" X 48", 1 cubic ft. 7 gpm

10" X 54", 1.5 cubic ft. 7 gpm

12" X 52", 2 cubic ft. 10 gpm

13" X 65", 3 cubic ft. 15 gpm

Carbon Filters:

9" X 48", 1 cubic ft. 4 gpm

10" X 54", 1.5 cubic ft. 5 gpm

12" X 52", 2 cubic ft. 7 gpm

13" X 65", 3 cubic ft. 9 gpm

16" X 65", 4 cubic ft. 15 gpm

Calcite Filters:

9" X 48", 1 cubic ft. 7 gpm

10" X 54", 1.5 cubic ft. 7 gpm

12" X 52", 2 cubic ft. 10 gpm

13" X 65", 3 cubic ft. 15 gpm

MODEL NO. VALVE MINERAL TANK

SIZE

MEDIA CUBIC

FOOT

GRAVEL

(LBS)

SERVICE FLOW*

(GPM)

PRESSURE DROP

(PSI)

BACK WASH

(GPM)

FLOOR SPACE

LXWXH

PWBWMZ1 Time Clock 9" X 48" 1 10 9 15 7 16" X 10" X 55"

PWBWMZ15 Time Clock 10" X 54" 1.5 10 10 15 7 16" X 11" X 62"

PWBWMZ2 Time Clock 12" X 52" 2 30 10 15 10 17" X 13" X 60"

PWBWMZ3 Time Clock 13" X 65" 3 40 15 15 15 18" X 14" X 74"

MODEL NO. VALVE MINERAL TANK

SIZE

MEDIA CUBIC

FOOT

GRAVEL (LBS) SERVICE FLOW*

(GPM)

PRESSURE DROP

(PSI)

BACK WASH

(GPM)

FLOOR SPACE

LXWXH

PWBWGAC1 Time Clock 9" X 48" 1 10 3.7 <15 4 16" X 10" X 55"

PWBWGAC15 Time Clock 10" X 54" 1.5 10 5.5 <15 5 16" X 11" X 62"

PWBWGAC2 Time Clock 12" X 52" 2 30 7.4 <15 7 17" X 13" X 60"

PWBWGAC3 Time Clock 13" X 65" 3 40 11.1 <15 9 18" X 14" X 74"

PWBWGAC4 Time Clock 16" X 65" 4 60 14.8 <15 15 20" X 17" X 74"

MODEL NO. VALVE MINERAL TANK

SIZE

MEDIA CUBIC

FOOT

GRAVEL

(LBS)

PEAK SERVICE

FLOW (GPM)*

PRESSURE DROP BACK WASH

(GPM)

FLOOR SPACE

L X W X H

PWBWCAL1 Time Clock 9" X 48" 1 10 5 <15 7 16" X 10" X 55"

PWBWCAL15 Time Clock 10" X 54" 1.5 10 7 <15 7 16" X 11" X 62"

PWBWCAL2 Time Clock 12" X 52" 2 30 10 <15 10 17" X 13" X 60"

PWBWCAL3 Time Clock 13" X 65" 3 40 15 <15 15 18" X 14" X 74"

*Note: Peak service flow rate is for intermittent use only and is not to be interpreted as continuous service flow rate capability. These systems are designed to treat the domestic water used in a

single family dwelling. For irrigation water treatment or higher volume applications please contact your Watts representative.

4

Page 5

Setup

Unpack and check the system components for damage or missing

parts.

Make sure that the bypass valve and plumbing yoke are properly

connected to each other and to the control valve with the mounting

clips. Make certain that the drain line flow control fitting is installed

properly on the drain port of the control valve. Systems that are 13”

in diameter and larger are not loaded with media. These systems

must be loaded with media before placing into service. To load a

system follow the below steps.

1. Cap the top open end of the distributor tube with tape and plastic sheeting to keep foreign debris from entering the distributor

tube. This cap must be secure and not come off during media

loading.

2. Place the distributor tube, screen end down, into the mineral

tank and center it in the bottom. The top of the distributor tube

should be flush with the top of the tank.

3. Make sure the plastic and tape cap is secure to the top of the

distributor tube, place a funnel on the top of the tank and load

first the gravel then the filter media into the tank. The cap must

not come off of the distributor tube during the loading of the

media.

4. Remove the plastic cap from the distributor tube. DO NOT PULL

UP ON THE DISTRIBUTOR TUBE when removing the cap. The

distributor tube top must remain flush with the top of the tank.

5. Clean any media from the threads and top of the mineral tank.

6. Lubricate the O-rings on the bottom of the control valve (distributor pilot O-ring and top of tank O-ring). Use non-petroleum

based silicone lubricant only.

7. Place the control valve on top of the tank. When doing this step,

seat the top of the distributor tube inside the centered O-ring

sealed port on the bottom of the valve first then press the valve

down until the tank threads come in contact with the valve

threads. This ensures that the distributor tube is properly seated

into the bottom of the control valve. Thread the valve on to the

tank clockwise. Be careful not to cross thread the valve or over

tighten it. A hand tight snug fit is appropriate for the control valve

torque. A wrench is not necessary. Do not use thread sealant or

PTFE tape on the valve base threads.

8. The system is now ready for installation.

Installation Considerations

Consider the following points when determining where to install

the filter:

• Place the system as close as possible to a sewer drain.

• Do not install the lter where it would block access to the water

heater, or access to the main water shutoff, water meter, or electrical panels.

• Install the lter in a place where water damage is least likely to oc-

cur if a leak develops.

• A 120VAC electrical outlet is needed to plug in the transformer.

• Always connect the system to the main water supply pipe before

the water heater.

• Install the system where it will not be subject to temperatures

outside of the limits stated in the Specification section or to direct

sunlight.

• Make sure the installation surface is smooth, level, and sturdy

enough to support the weight of the wetted system.

5

Page 6

Installation

1. Turn off gas or electric supply to the water heater.

2. Turn off the main water supply to pipes to be cut and drain the

house water pipes.

3. Open both hot and cold faucets.

4. Move the filter assembly into installation position.

• Be sure the oor under the water lter system is clean, level and

strong enough to support the unit.

5. Plumb IN and OUT connections to and from filter.

• Be sure the incoming water supply is connected to the INLET

port of the valve.

• The valve body of the control is marked with arrows indicating

the proper flow direction.

• Connections are illustrated below.

Drain

8. Fully open two (2) cold water faucets near the water filter.

9. Fully open the house main water shutoff valve. Observe a steady

flow from both faucets.

10. Close the cold water faucets.

11. Check plumbing work for leaks and fix immediately if any are

found.

12. Connect electrical power by plugging the transformer into a

(120 VAC) outlet.

13. Remove the cover from the valve. Press and hold the “Extra

Cycle” button until the flashing “BW” symbol appears in the

Parameter Display.

6. Connect and route the valve drain line using rigid piping or hose.

Use the same size plumbing for the drain line as the fitting for

the drain connection. The smallest units have a

the larger sized units have a

use the same size plumbing as the connection to ensure proper

backwash flow. Properly secure the end of the drain line.

Note: Leave an air gap of at least 1

drain plumbing and the drain point.

CAUTION: If making a soldered copper installation, do all sweat

soldering before connecting pipes to the bypass valve. Torch

heat will damage plastic parts.

CAUTION: When turning threaded pipe ttings onto plastic t-

tings, use care not to cross-thread.

CAUTION: Use PTFE tape on all external pipe threads. Do not

use pipe joint compound.

CAUTION: Support inlet and outlet plumbing in some manner

(use pipe hangers) to keep the weight off of the valve ttings.

7. Place bypass valve in "bypass" position as shown below.

3

⁄4" connection. It is important to

1

⁄2" between the end of the

1

⁄2" connection,

14. Unplug the valve when the “BW” symbol stops flashing and the

countdown timer appears. This keeps the valve in an extended

backwash for the initial startup.

15. Open the outlet bypass valve fully.

16. Open the inlet bypass valve slightly. Open the valve just until you

hear water flowing.

17. Observe the drain flow. It may take several minutes for the filter

vessel to fill up with water and begin to flow to drain.

18. After all the air is purged from the vessel and a steady drain flow

is observed, allow the unit to backwash for 2 hours with the inlet

valve open slightly.

19. Fully open the inlet bypass valve and allow the unit to backwash

for 30 minutes.

20. After 30 minutes, observe the drain flow. If the drain flow is clear

proceed to the next step. If the drain flow is still cloudy, allow it

to continue to backwash until it is clear.

6

Page 7

Installation continued

22. Plug the unit back in to the electrical outlet and allow it to finish

the flush cycle. This will take approximately 20 minutes.

23. Set the time of day. Press and hold either the Up or Down buttons until the programming icon replaces the service icon and

the parameter display reads TD. Adjust the displayed time with

the Up and Down buttons. When the desired time is set, press

the Extra Cycle button to resume normal operation. The unit will

also return to normal operation after 5 seconds if no buttons are

pressed.

24. Turn on the gas or electric supply to the water heater after all air

has been purged from the house's plumbing system and water

heaters.

Controller

The factory default program settings should be adequate for most

installations. See the ProFlo SXT Service Manual included with the

unit for advanced programming options.

Filter Operation

As water enters the filter, it passes through the filter media. Over

time, suspended solids accumulate in the filter media and need to be

rinsed out. This is accomplished by performing a backwash. During

backwash the filter is in automatic bypass allowing unfiltered water

to pass downstream. The automatic backwash is initiated based on

time and is normally set to occur in the middle of the night.

This System Has Three Positions:

1. Backwash Position

Backwash is a rapid upward flow of water that loosens the filter bed

and flushes dirt and sediment captured in the bed out to the drain.

2. Fast Rinse Position

Fast Rinse is a fast flow of water down through the filter bed that

follows a Backwash. This packs the filter bed for the next service

cycle.

3. Service Position

When the filter is In Service, water is flowing through the system and

sediment is being removed from your water if it’s a Micro Z™ filter.

If it’s a carbon filter, it removes chlorine, tastes, odors, and organics

from your water. If your system contains calcite media your water's

acidic pH will be raised closer to a value of 7.

Replenishing Calcite Filter Bed Media

As low pH water is neutralized by the calcite filter media a small

amount of calcite dissolves into the water. Over a period of time

calcite media will need to be added to the system so that it can

continue to perform properly. The need to add calcite media to the

system can be verified by performing a pH test on the treated water.

If the results of the pH test show a value below 6.5 pH units contact

your system installer or local water treatment professional to have

the media bed replenished.

Troubleshooting

PROBLEM CAUSE SOLUTION

1. Loss of Water Pressure Sediment buildup in filter bed

2. Drain Flows Continuously Foreign material in control

3. Wrong time of day Power Outage Reset time of day. Be sure power supply in uninterrupted

4. Controller Cycles Continuously Faulty timer board or microswitch Replace defective components

5. Unfiltered water in house

Note: Error codes appear in the service display.

ERROR CODE CAUSE SOLUTION

(Err 0) Drive motor is stalled See above troubleshooting table, #5-B

(Err 1) Drive water runs continuously See above troubleshooting table, #4

(Err 2) There has been more than 99 days since the last regeneration Initiate a manual regeneration

(Err 3) Control Board memory failure Replace control board

A. Bypass in Bypass position A. Move Bypass to service position

B. Valve stalled in backwash B. Have valve serviced

C. Media needs to be replaced C. Have system serviced

A. Perform a manual backwash

B. Make sure unit is plugged in

C. Replace media

Remove piston assembly and inspect bore, remove foreign

material & check control in various ports

7

Page 8

LIMITED WARRANTY: Certain Watts Pure Water products come with a limited warranty from Watts Regulator Co. Other products may have no warranty or are covered by the original manufacturer’s

warranty only. For specic product warranty information, please visit www.watts.com or the published literature that comes with your product. Any remedies stated in such warranties are exclusive and

are the only remedies for breach of warranty. EXCEPT FOR THE APPLICABLE PRODUCT WARRANTY, IF ANY, WATTS MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. TO THE FULLEST EXTENT

PERMITTED BY APPLICABLE LAW, WATTS HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, AND IN NO EVENT SHALL WATTS BE LIABLE, IN CONTRACT, TORT, STRICT LIABILITY OR UNDER ANY OTHER LEGAL THEORY, FOR

INCIDENTAL, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOST PROFITS OR PROPERTY DAMAGE, REGARDLESS OF WHETHER IT WAS INFORMED ABOUT

THE POSSIBILITY OF SUCH DAMAGES.

A Watts Water Technologies Company

USA: Tel. (800) 224-1299 • www.watts.com

Canada: Tel. (888) 208-8927 • www.watts.ca

IOM-WQ-PWBWGAC-PWBWMZ-PWBWCAL 1225 EDP# 2915893 © 2012 Watts

Loading...

Loading...