Page 1

Installation, Operation

and Maintenance Manual

Series PWBWIRONZ Filter Systems

PURE WATER

!

Warning

You are required to thoroughly read all installation instructions and product instructions and product safety information

before beginning the installation of this product. FAILURE TO

COMPLY WITH PROPER INSTALLATION AND MAINTENANCE

INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE,

PERSONAL INJURY AND/OR DEATH. Watts is not responsible

for damages resulting from improper installation and/or maintenance.

Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after

the system.

Local building or plumbing codes may require modifications to

the information provided. You are required to consult the local

building and plumbing codes prior to installation. If this information is not consistent with local building or plumbing codes, the

local codes should be followed.

Save manual for future reference

Refer to enclosed warranty for operating parameters to ensure

proper use with your water supply.

IOM-WQ-PWBWIRONZ

PWBWIRONZ

Table of Contents

Important Safety Information - Read All . . . . . . . . . . . . . . . . . . . . . . . 2

Instructions Before Using.................................. 2

Filter Anatomy ..........................................2

Specifications ..........................................3

Feed Water Parameters................................... 3

Power ................................................3

System Overview........................................ 3

Installation - Set Up ...................................... 4

Installation - Overview ....................................4

Control Valve Component Identification . . . . . . . . . . . . . . . . . . . . . . . 4

Deflector Installation .....................................4

Installation - Considerations................................ 5

Drain Requirements ......................................5

Installation .............................................5

Programming...........................................7

Controller Operation .....................................7

Troubleshooting.........................................8

Limited Warranty ........................................8

Page 2

I. Important Safety Information –

Read All

!

CAUTION: Read and follow the information in this manual

to minimize the risk of electric shock or personal injury.

Important: If you are unsure about installing your Watts water

filter, contact a Watts representative or consult a professional

plumber.

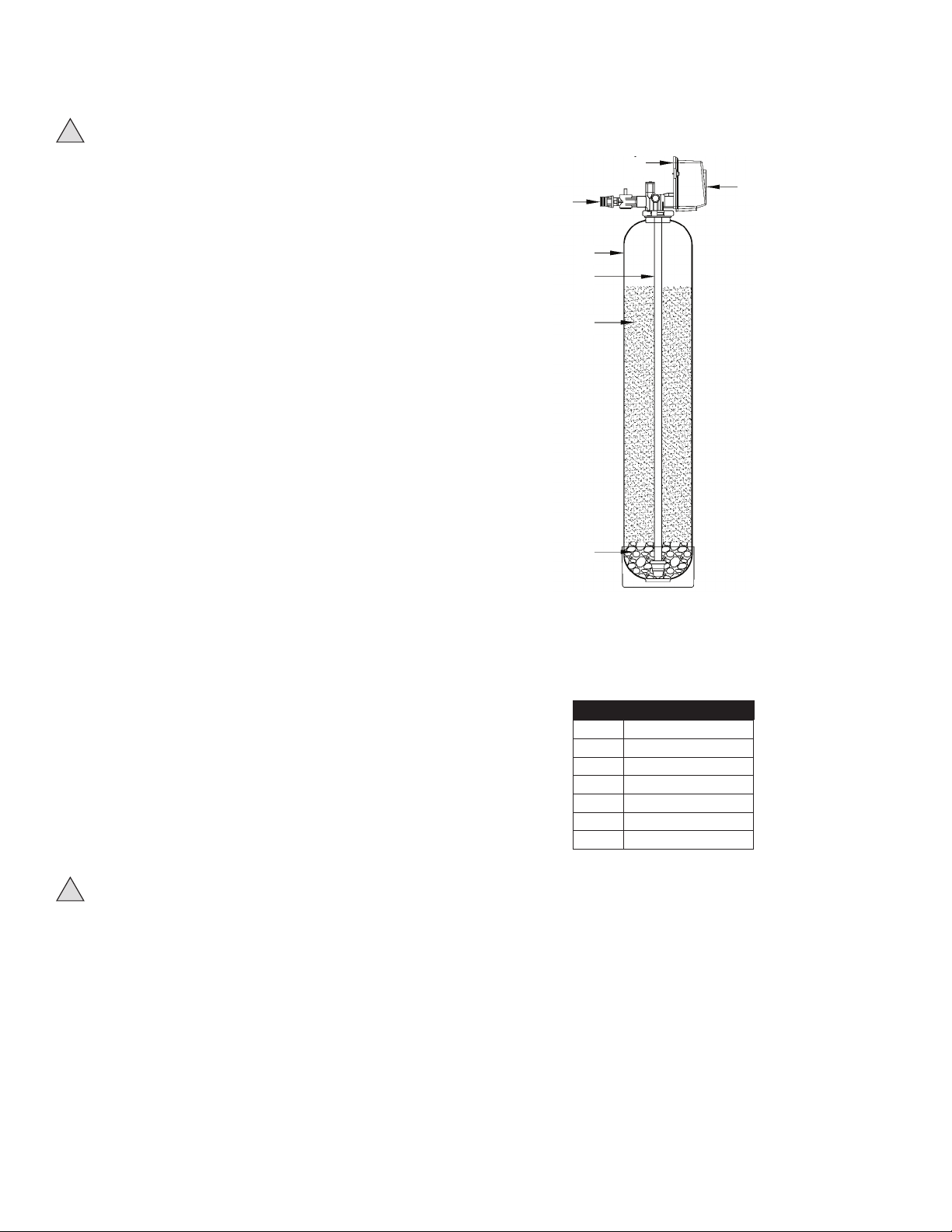

Filter Anatomy

1

6

2

A. READ Instructions Before Using

• After reading these instructions completely, obtain all the

materials and tools needed for installation.

NOTE: Failure to install the system correctly voids the warranty.

• Perform installation according to state, province and local

plumbing codes.

Use only lead-free solder and flux for sweat-solder

connections, as required by state, province and federal

codes.

• Handle all components of the system with care. Do not drop,

drag or turn components upside down.

• Be sure the oor under the water lter system is clean, level

and strong enough to support the unit.

• The system uses 24 volt-60Hz electrical power. Always use

the transformer supplied.

Plug transformer into an indoor 120 VAC, grounded outlet.

Properly ground the system to conform with all codes and

ordinances.

• Install the system in a protected area. Be sure electric outlet

and transformer do not come in contact with water. See

Installation Considerations, in the installation section of the

manual.

Do not attempt to treat water over 110°F (43°C) with the

system. Always connect the system to the main water

supply pipe before the water heater.

Do not expose the system to freezing temperatures. Wa-

ter freezing in the system causes equipment damage.

Do not install in direct sunlight. Ultraviolet rays from the

sun may cause damage.

• Minimum inlet water pressure is 30 psi. Maximum inlet water

pressure is 80 psi. Use a pressure reducing valve if neces-

sary.

3

4

5

7

Figure 1

ITEM DESCRIPTION

1 Control Valve

2 Bypass Valve

3 Mineral Tank

4 Distributor Tube

5 Filter Media

6 Faceplate/Control

7 Gravel Underbedding

!

CAUTION:

• Do not use with water that is microbiologically unsafe or of

unknown quality.

• Test the water periodically to verify that the system is performing satisfactorily.

• Discard small parts remaining after the installation.

2

Page 3

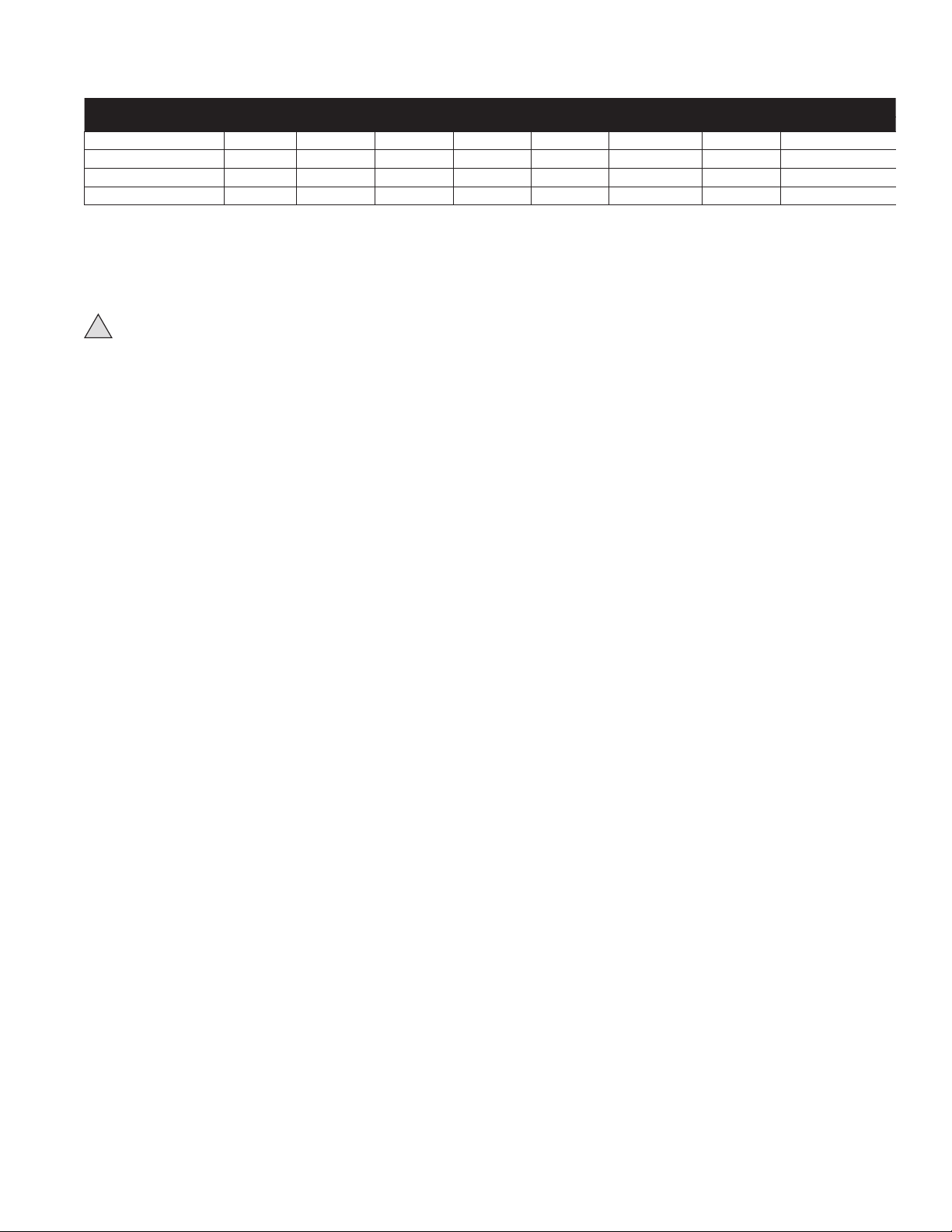

Specifications

MODEL VALVE MINERAL TANK MEDIA VOLUME GRAVEL PEAK SERVICE PRESSURE DROP BACK WASH FLOOR SPACE REQUIRED

TYPE SIZE (DXH) CUBIC FOOT (LBS) FLOW (GPM) @PEAK FLOW (PSI) FLOW (GPM) (L X W X H)

PWBWIRONZ1 Time Clock 9" x 48" 1 12 6 <15 7 16" x 15" x 55"

PWBWIRONZ1.5 Time Clock 10" x 54" 1.5 12 8 <15 8 16" x 15" x 62"

PWBWIRONZ2 Time Clock 12" x 52" 2 25 11 <25 12 17" x 15" x 60"

PWBWIRONZ3 Time Clock 13" x 65" 3 30 13 <25 15 18" x 15" x 74"

Note: Peak service flow rate is for intermittent use only and is not to be interpreted as continuous service flow rate capability. These

systems are designed to treat the domestic water used in a single family dwelling. For irrigation water treatment or higher volume

applications please contact your Watts representative.

Feed Water Parameters

!

Do not use this system on water that is microbiologically

unsafe or of unknown quality without adequate disinfection

before or after the system!

Minimum inlet pressure: 30 psig

Maximum operating pressure: 80 psig

Minimum water temperature: 34°F (1°C)

Maximum water temperature: 110°F (43°C)

Maximum iron content: 10 PPM

Maximum hydrogen sulfide content: 3 PPM

Effective pH range: 6.5-9

Location: Indoors (Protect from direct sunlight)

Minimum ambient temperature: 34°F (1°C)

Maximum ambient temperature: 122°F (50°C)

Power

Voltage: 120VAC

Frequency: 60Hz

Installation

Location: Indoors (Protect from direct sunlight)

PWBWIRONZ System Overview

PWBWIRONZ systems are selected for use when the concentration

of iron and hydrogen sulfide in water need to be reduced. They

use the model 2510 AIO Control Valve to reduce the contaminants

in the water without the use of chemicals. The 2510 AIO valve is

specially designed to capture a volume of air inside the system’s

mineral tank. Water passes through the AIO valve then passes

through the air head in the top of the mineral tank. Oxygen from

the captured air transfers into the water. The oxygen oxidizes these

contaminates in the water to oxides or solid precipitants. Then they

are mechanically filtered out of the water by the Micro Z® media

filter bed. After a preprogrammed number of days have passed, the

system will perform a regeneration cycle to clean the Micro Z® media

of the solids it has accumulated, draw in more air, rinse, then return

to service. Watts recommends a daily regeneration of the system. A

regeneration every other day may be possible if system inlet water

quality permits (please contact your Watts representative).

Regeneration is as follows:

Backwash (BW): The Backwash cycle washes oxidized contaminCycle Step #1 ates to drain and reclassifies the media bed.

Air Draw (BD): Air Draw empties water from the tank and replen-

Cycle Step #2 ishes the oxygen within the mineral tank.

Rapid Rinse (RR): Rapid Rinse purges excess atmosphere from the

Cycle Step #3 mineral tank and distributor.

Upon completion of Rapid Rinse the system returns to the service

position.

NOTE: Due to the presence of air in the media tank the maximum operating pressure of the system is 80 psi.

3

Page 4

II. Installation

A. Setup

Unpack and check the system components for damaged or missing parts. Make sure that the bypass valve and plumbing yoke are

properly connected to each other and to the control valve with the

mounting clips. Make certain that the drain line flow control fitting

is installed properly on the drain port of the control valve. Systems

that are 13" in diameter and larger are not loaded with media. These

systems must be loaded with media before placing into service. To

load a system follow the below steps.

1. Cap the top open end of the distributor tube with tape and plas-

tic sheeting to keep foreign debris from entering the distributor

tube. This cap must be secure and not come off during media

loading.

2. Place the distributor tube, screen end down, into the mineral

tank and center it in the bottom. The top of the distributor tube

should be flush with the top of the tank.

3. Make sure the plastic and tape cap is secure to the top of the

distributor tube, place a funnel on the top of the tank and load

first the gravel then the Micro Z® media into the tank. The cap

must not come off of the distributor tube during the loading of

the media.

4. Remove the plastic cap from the distributor tube. DO NOT PULL

UP ON THE DISTRIBUTOR TUBE when removing the cap. The

distributor tube top must remain flush with the top of the tank.

5. Clean any media from the threads and top of the mineral tank

and install the deflector disk. See D. Deflector Installation section

for more details.

6. Lubricate the O-rings on the bottom of the control valve (dis-

tributor pilot O-ring and top of tank O-ring). Use non-petroleum

based silicone lubricant only.

7. Place the control valve on top of the tank. When doing this step,

seat the top of the distributor tube inside the centered O-ring

sealed port on the bottom of the valve first then press the valve

down until the tank threads come in contact with the valve

threads. This ensures that the distributor tube is properly seated

into the bottom of the control valve. Thread the valve on to the

tank clockwise. Be careful not to cross thread the valve or over

tighten it. A hand tight snug fit is appropriate for the control valve

torque. A wrench is not necessary. Do not use thread sealant or

PTFE tape on the threads.

8. The system is now ready for installation.

B. Installation Overview

Install the system after the supply lines to the outside faucets. This

system should be installed before a water softener or any taste/odor

cartridges, if applicable.

Ensure the inlet check valve item #5 is connected as shown in

Figure 2 to the inlet side of the 2510 AIO valve. The drain should be

installed in accordance with plumbing codes. Due to the release of

air during regeneration, the drain line should be anchored throughout

the run, secured at the end of the drain line, and properly vented.

The drain line should be sized for the backwash rate listed under

Drain Requirements taking into account friction loss.

C. 2510 AIO Control Valve Component

Identification:

4

3

2

1

5

Drain

6

Figure 2

ITEM DESCRIPTION

1 2510 AIO CONTROL VALVE

2 VALVE COVER

3 CHECK VALVE, AIR DRAW VALVE

4 SCREEN, AIR CHECK ADAPTOR

5 INLET CHECK VALVE

6 SCREW, 8-32, SS, 2510AIO

7 DEFLECTOR DISK

D. Deflector Installation

Put a thin layer of silicone lubricant around inside diameter of the

deflector #7. Slowly slide the deflector over the distributor tube down

about 1". When threading the AIO valve to the tank, the bottom of

the threads will slide the deflector down. As shown in Figure 3.

7

Figure 3

4

Page 5

E. Installation Considerations

Consider the following points when determining where to install the

filter:

• Place the system as close as possible to a sewer drain.

• Do not install the lter where it would block access to the water

heater, or access to the main water shutoff, water meter, or electrical panels.

• Install the lter in a place where water damage is least likely to occur if a leak develops.

• A 120VAC electrical outlet is needed to plug in the transformer.

• Always connect the system to the main water supply pipe before

the water heater.

• Install the system where it will not be subject to temperatures

outside of the limits stated in the Specification Section or to direct

sunlight.

F. Drain Requirements

The drain systems these filters are plumbed into must be able to

accept the drain rates listed below. The well or water supply must

be capable of maintaining a 30 psi minimum feed water pressure,

continuously, at these drain flow rates.

MODEL TANK SIZE DRAIN RATE

PWBWIRONZ1 9" x 48", 1 cubic ft. 7 gpm

PWBWIRONZ1.5 10" x 54", 1.5 cubic ft. 8 gpm

PWBWIRONZ2 12" x 52", 2 cubic ft. 12 gpm

PWBWIRONZ3 13" x 65", 3 cubic ft. 15 gpm

III. Valve Installation

1. Turn off gas or electric supply to the water heater.

2. Close the feed water valve to the plumbing system. Then

relieve the pressure in the plumbing by opening the hot and

cold water faucets.

3. Cut the pipes at the installation point. Use a drain pan to catch

any spillage that results.

4. Move the filter system into installation position.

• Be sure the installation point is downstream of the bladder tank

and irrigation system if this system is being installed on a well.

• The installation surface must be strong enough to support the

weight of the system once it is placed into operation.

5. Plumb INLET and OUTLET connections to and from the filter.

• Be sure the incoming water supply is directed to the INLET port

of the valve.

• The valve body of the control is marked with arrows indicating

the proper flow direction.

• Connections are illustrated below in Figure 4 (shown without

bypass and yoke) and Figure 5 (bypass piping detail).

Outlet

Outlet

Inlet

Inlet

rai

D

Drain

n

Figure 4

6. Connect and route the valve drain line using rigid piping or

hose. Use the same size plumbing for the drain line as the fitting provided for the drain connection. The smallest units have

a 1⁄2" connection, the medium sized units have a 3⁄4" connection, and the largest units have a 1" connection. It is important

to use the same size plumbing as the connection to ensure

proper backwash flow.

Note: Leave an air gap of at least 11⁄2" between the end of the

drain plumbing and the drain point.

CAUTION: If making a soldered copper installation, do all

sweat soldering before connecting pipes to the bypass valve.

Torch heat will damage plastic parts.

CAUTION: When turning threaded pipe fittings onto plastic

fittings, use care not to cross-thread or overtighten.

CAUTION: Use PTFE tape on all external pipe threads. Do not

use pipe joint compound.

CAUTION: Support inlet and outlet plumbing in some manner

(use pipe hangers) to keep the weight off of the control valve

drain, bypass, and plumbing yoke points of connection.

5

Page 6

III. Installation (cont.)

7. Place the bypass valves into the "bypass" position as shown

below in Figure 5 by rotating the bypass handles. The handles

will point to each other when they are placed into the bypass

position.

Outlet

Inlet

Figure 5

8. Fully open two (2) cold water faucets near the water filter.

9. Fully open the main feed water valve described in step 2.

Observe a steady flow from both faucets.

10. Close all faucets at this time.

11. Check plumbing work for leaks and fix immediately if any are

found.

12. Connect electrical power by plugging the transformer into a

(120 VAC) outlet.

16. Open the outlet bypass valve fully.

17. Open the inlet bypass valve slightly. Open the valve just until

you hear water flowing.

18. Observe the drain flow. It may take several minutes for the

filter vessel to fill up with water and begin to flow water to

drain.

19. After all the air is purged from the vessel and a steady drain

flow is observed, allow the unit to backwash for 10 minutes

with the inlet valve open slightly.

20. After the 10 minutes of backwashing is complete, fully open

the inlet bypass valve and allow the unit to backwash for 90

minutes.

21. After 90 minutes, observe the drain flow. If the drain flow is

clear proceed to the next step. If the drain flow is still cloudy,

allow the system to continue to backwash until it is clear. Do

not capture the drain water in a container to evaluate its clarity. Oxidized impurities in the water will give the drain water

a cloudy appearance if it is caught and viewed in volume.

Evaluate its clarity as it flows out of the open end of the drain

pipe or hose to avoid unnecessary backwashing time.

22. Plug the unit back in to the electrical outlet and allow it to finish backwash, draw, and rinse cycles. This will take approximately 60 minutes.

23. Set the time of day. Press and hold either the Up or Down

buttons until the programming icon replaces the service icon

and the parameter display reads TD. Adjust the displayed

time with the Up and Down buttons. When the desired

time is set, press the Extra Cycle button to resume normal

operation. The unit will also return to normal operation after 5

seconds if no buttons are pressed.

24. Turn on the gas or electric supply to the water heater after

all air has been purged from the house's plumbing system

and water heaters. Flush water heaters and plumbing system

with filtered water to help clear the lines of any residual iron

content.

The system is now ready to be programmed.

13. Open the valve cover to access the timer. Press and hold the

“Extra Cycle” button until the flashing “BW” symbol appears

in the Parameter Display.

14. Slowly, turn the bypass valve back to the "service" position.

In the service position both handles of the bypass valve will

point to the control valve. Then close the inlet bypass valve.

15. Unplug the valve when the “BW” symbol stops flashing and

the countdown timer appears. This keeps the valve in an

extended backwash for the initial startup.

6

Page 7

IV. Programming

Figure 6 shows the icons and display characters of the timer mechanism.

Figure 6

When the Master Programming Mode is entered, all available option/

setting/displays may be viewed and set as needed. Depending on

current option settings, some parameters cannot be viewed or set.

This timer is used on other system configurations as well so it is

important that the user carefully programs the system in accordance

with the values shown on the Master Programming Chart.

A. Setting the Time of Day

1. Press and hold either the Up or Down buttons until the programming icon replaces the service icon and the parameter

display reads TD.

2. Adjust the displayed time with the Up and Down buttons.

3. When the desired time is set, press the Extra Cycle button to

resume normal operation. The unit will also return to normal

operation after 5 seconds if no buttons are pressed.

D. Master Programming Chart

PROGRAMMING

ABBREVIATION

DF Display Format GAL Gallons - 12 hour time

VT Valve Type DF 1b Downflow Single Backwash

CT Control Type tc

NT Number of Tanks 1 Single Tank

DO Day Override 1

RT

BW Backwash 14 See Page 3 for Definition

BD Air Draw 40 See Page 3 for Definition

RR Rapid Rinse 1 See Page 3 for Definition

BF Brine Fill Off Not Applicable

*Factory Default Values

PROGRAMMING

DEFINITION

Regeneration

Time

*OPTION

ABBREVIATION

12:30 AM

OPTION

DEFINITION

Time Clock - Regenerates based

on days

Days Between Regeneration –

DO NOT set the regeneration day

override for a longer period than

two days, as the filter media can

become fouled with contaminates,

rendering the system ineffective.

Regeneration Time – Time of day

regeneration is to occur. Make

sure this time does not overlap

with the regeneration process

of another piece of equipment

such as an existing softener or

media filter.

V. Controller Operation

The factory default program settings should be adequate for most

installations.

A. Queueing a Regeneration

1. Press the Extra Cycle button. The service icon will flash to

indicate that a regeneration is queued. Regeneration will occur

that day at the programmed Regeneration Time (RT).

2. To cancel a queued regeneration, press the Extra Cycle button.

B. Entering Master Programming Mode

The master level programming has been set at the factory however

you should check the program against the Master Programming

Chart. With the control valve in the service position set the Time

Of Day display to 12:01 P.M. Press the Extra Cycle button (to exit

Setting Time of Day mode). Then press and hold the Up and Down

buttons together until the programming icon replaces the service

icon and the Display Format "DF" screen appears. Once you are in

the master programming screen, pressing the extra cycle button

will advance the controller to the next parameter. Pressing the up or

down buttons allows the user adjust each parameter’s value up or

down respectively.

C. Exiting Master Programming Mode

Press the Extra Cycle button to accept the displayed settings and

advance to the next parameter. Press the Extra Cycle button at the

last parameter to save all settings and return to normal operation.

The control will automatically disregard any programming changes

and return to normal operation if it is left in Master Programming

mode for 5 minutes without any keypad input.

B. Regenerating Immediately

Press and hold the Extra Cycle button for five seconds.

Time Clock Delayed Control

A Time Clock Delayed Control regenerates the system on a timed

interval. The control will initiate a regeneration cycle at the programmed regeneration time when the number of days since the last

regeneration equals the regeneration day override value.

Control Operation During Regeneration

During regeneration, the control displays a special regeneration display. In this display, the control shows the current regeneration step

number, the valve it is advancing to, or has reached, and the time

remaining in that step. The step number that displays flashes until

the valve completes driving to this regeneration step position. Once

all regeneration steps are completed the valve returns to service and

resumes normal operation.

Pressing the Extra Cycle button during a regeneration cycle immediately advances the valve to the next cycle step position and resumes

normal step timing.

Control Operation During Programming

The control only enters the Program Mode with the valve in service. While in the Program Mode, the control continues to operate

normally monitoring water usage and keeping all displays up to date.

Control programming is stored in memory permanently, eliminating

the need for battery backup power.

7

Page 8

V. Controller Operation (cont.)

C. Control Operation During A Power Failure

The controller includes integral power backup. In the event of a

power failure, the control shifts into a power-saving mode. The display and motor shut down, but it continues to keep track of the time

and day for a minimum of 48 hours.

The system configuration settings are stored in a non-volatile

memory and are stored indefinitely with or without line power. The

Time of Day flashes when there has been a power failure. Press any

button to stop the Time of Day from flashing.

If power fails while the unit is in regeneration, the control will save the

current valve position before it shuts down. When power is restored,

the control will resume the regeneration cycle from the point where

power failed. Note that if power fails during a regeneration cycle,

the valve will remain in it’s current position until power is restored.

System installation should include all required safety components to

prevent overflows resulting from a power failure during regeneration.

The control will not start a new regeneration cycle without line power.

If the valve misses a scheduled regeneration due to a power failure,

it will queue a regeneration. Once power is restored, the control will

initiate a regeneration cycle the next time that the Time of Day equals

the programmed regeneration time. Typically, this means that the

valve will regenerate one day after it was originally scheduled.

Troubleshooting

PROBLEM CAUSE SOLUTION

1. Loss of Water Pressure Sediment buildup in filter bed A. Perform a manual backwash

2. Drain Flows Continuously Foreign material in control Remove piston assembly and inspect bore, remove foreign

3. Wrong time of day Power Outage Reset time of day, be sure power supply is uninterrupted

4. Controller Cycles Continuously Faulty timer board or microswitch A. Perform a manual regeneration to clear issue

5. Unfiltered water in house A. Bypass in bypass position

B. Valve stalled in backwash

C. No air in tank

D. Media is fouled

E. No power to valve

F. System is plumbed in backwards

G. System needs to be regenerated more frequently

6. System fails to regenerate A. Electrical service to unit has been interrupted

B. Timer is defective

C. Power failure

B. Make sure unit is plugged in

C. Replace media bed

material & check control in various ports

B. Check programming for accuracy

C. Make sure all wire connections are secure

A. Move bypass to service position

B. Have valve serviced

C. Have valve serviced

D. Have media replaced

E. Restore power to valve

F. Correct plumbing

G. Increase regeneration frequency

A. Ensure permanent electrical service (check fuse, plug, GFCI)

B. Replace timer

C. Reset time of day

Error Codes

Note: Error codes appear in the service display.

ERROR CODE CAUSE SOLUTION

(Err 0) Drive motor is stalled See above troubleshooting table, #5-B

(Err 1) Drive motor runs continuously See above troubleshooting table, #4

(Err 2) There has been more than 99 days since the last regeneration Initiate a manual regeneration. Verify that all master programming in the

(Err 3) Control Board memory failure Replace control board

timer matches the master programming chart.

!

CALIFORNIA PROPOSITION 65 WARNING

Warning: This product contains chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

(California law requires this warning to be given

to customers in the State of California).

For more information: www.watts.com/prop65

LIMITED WARRANTY: Certain Watts Pure Water products come with a limited warranty from Watts Regulator Co. Other products may have no warranty or are covered by the original manufacturer’s

warranty only. For specific product warranty information, please visit www.watts.com or the published literature that comes with your product. Any remedies stated in such warranties are exclusive and

are the only remedies for breach of warranty. EXCEPT FOR THE APPLICABLE PRODUCT WARRANTY, IF ANY, WATTS MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. TO THE FULLEST EXTENT

PERMITTED BY APPLICABLE LAW, WATTS HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, AND IN NO EVENT SHALL WATTS BE LIABLE, IN CONTRACT, TORT, STRICT LIABILITY OR UNDER ANY OTHER LEGAL THEORY, FOR

INCIDENTAL, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOST PROFITS OR PROPERTY DAMAGE, REGARDLESS OF WHETHER IT WAS INFORMED ABOUT

THE POSSIBILITY OF SUCH DAMAGES.

A Watts Water Technologies Company

IOM-WQ-PWBWIRONZ 1318 EDP# 2915999 © 2013 Watts

USA: Tel. (800) 224-1299 • www.watts.com

Canada: Tel. (888) 208-8927 • www.watts.ca

Loading...

Loading...